Yamaha XS750-2D Service Manual

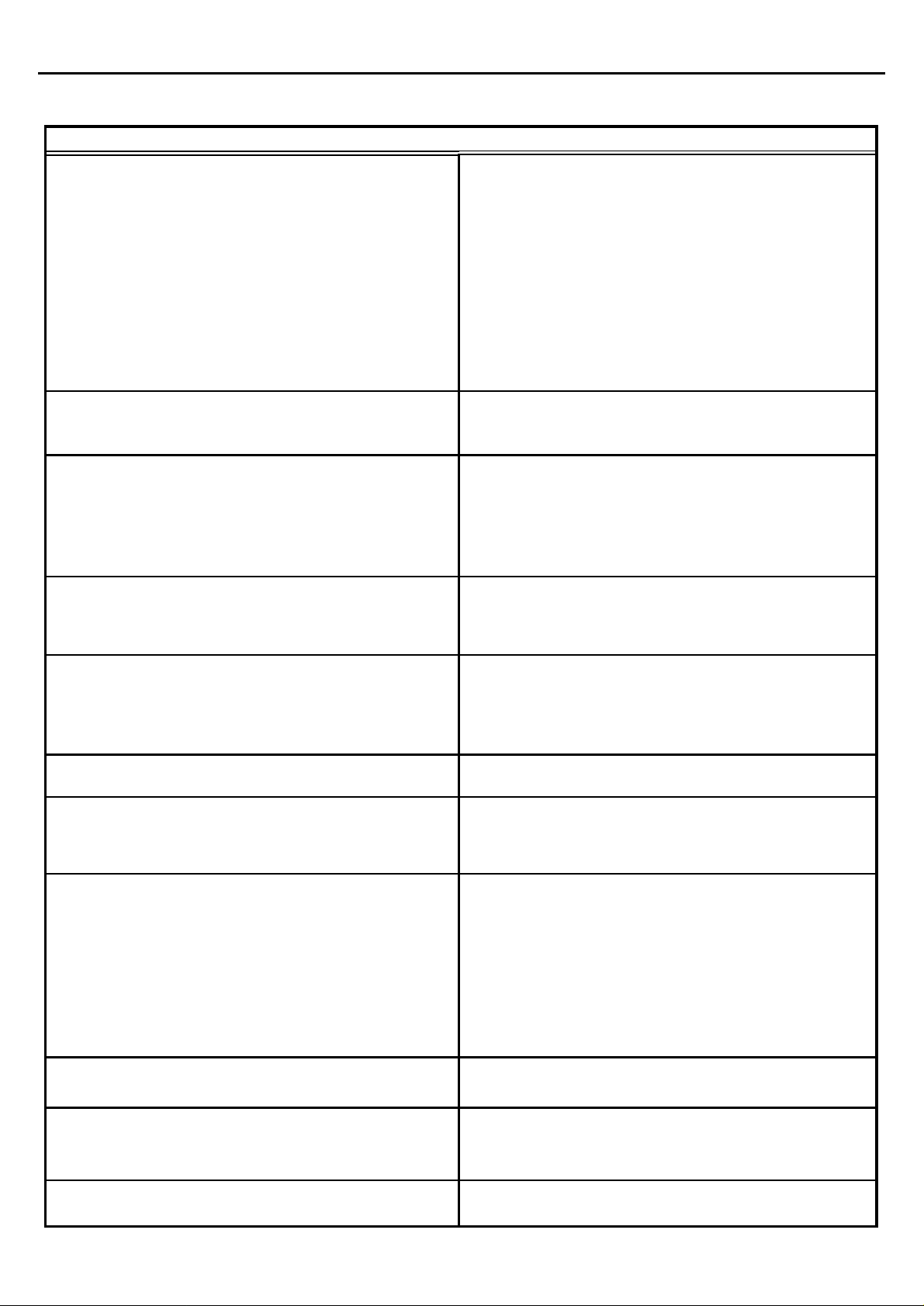

SPECIFICAT IONS

A.GENERALSPECIFICATIONS

Basiccolor

Dimensions:

Overall length

OveralI width

Overall height

Seat

height

Wheelbase

Minimumgroundclearance

Caster

(steeringheadangle)

TraiI

Weight:

Net

Engine:

Type

Borexstrokexcylinders

Displacement

Compressionratio

Compressionpressure(warmengine)

Lu b r ication

:

Lubricationsystem

Deliverypump type

CrystalSilver

2180mm(85.8in.)

835mm(32.9 in.)

1150mm(45.3 in.)

810mm(31.9in.)

1465mm(57.7in.)

145mm(5.7in.)

27°

110mm(4.3 in.)

229kg(505Ibs.)

________~~

D.O.H.C., air-coo led, triple

68mmx68.6mmx3

747cc

8.5:1

142Ibsin²(±14Ibsin²)

Pressurelubricated, wet sump

Trocoid

Carburetion:

Manufacture

Type,I.D.No.,Quantity

Ratedventuri

size

Airfilter

Ignition:

Type

Sparkplug

Charging

Type

Manufacture,I.D.No.

Maximumoutput

Batterytype

Batterydimensions

Regulator

Rectifier

Starting

Mikuni

BS34,constantvelocity,1J701,3pcs.

34mm

Dryfoamrubber

Battery/coi

I

NGKBP-7ES,ChampionN-7Y

Three-phase,regulatedalternator

HitachiLD120-02

14.5Volt/l8amp

12volt14amp-hour

134x166x89mm

Hitachi TL1Z-80

Stanley DE-4404,Silicon,fullwave

Transmissioncoupledkick

MitsubaElectricSM-224C

Primarydrive

Type

Teeth,ratio

Clutch

Hy-Vo silentchain

45/271.666

Wet,

multipledisc.

Transmission:

Teeth,ratio,overall1st

SecondaryDrive:

Transmission0utput

Type,teeth,ratio

Middlegear

case

Type, teeth, ratio

Finalgearcase

Type, teeth, ratio

Chassis:

Frame

Suspension:

Front

Rear

(type,

(type,

travel)

travel)

Tires:

Front

Rear

Brakes:

Front

Rear

Fueltank

Wheels:

Front

Rear

:

2nd

3rd

4th

5th

Constantmesh,5-speed,drumshifter

32/132.46113.285

27/171.5888.636

26/20 1.300 7.069

11.0955.955

22/23 0.956 5.201

Shaftdrive

Spurgear,34/32,1.063

Bevelgear,19/18,1.056

Bevelgear,32/11,2.909

Tubularsteeldoublecradle

Telescopicfork,175mm (6.9 in.)

Swingarm,75mm(3.0in.)

3.25 H 19Bridgestone

4.00H18Bridgestone

Dualhydraulicdisc

Singlehydraulicdisc

USgal.)Regularleadedorunleaded

1.85x19

2.15x18

Cast

Cast

Aluminum

Aluminum

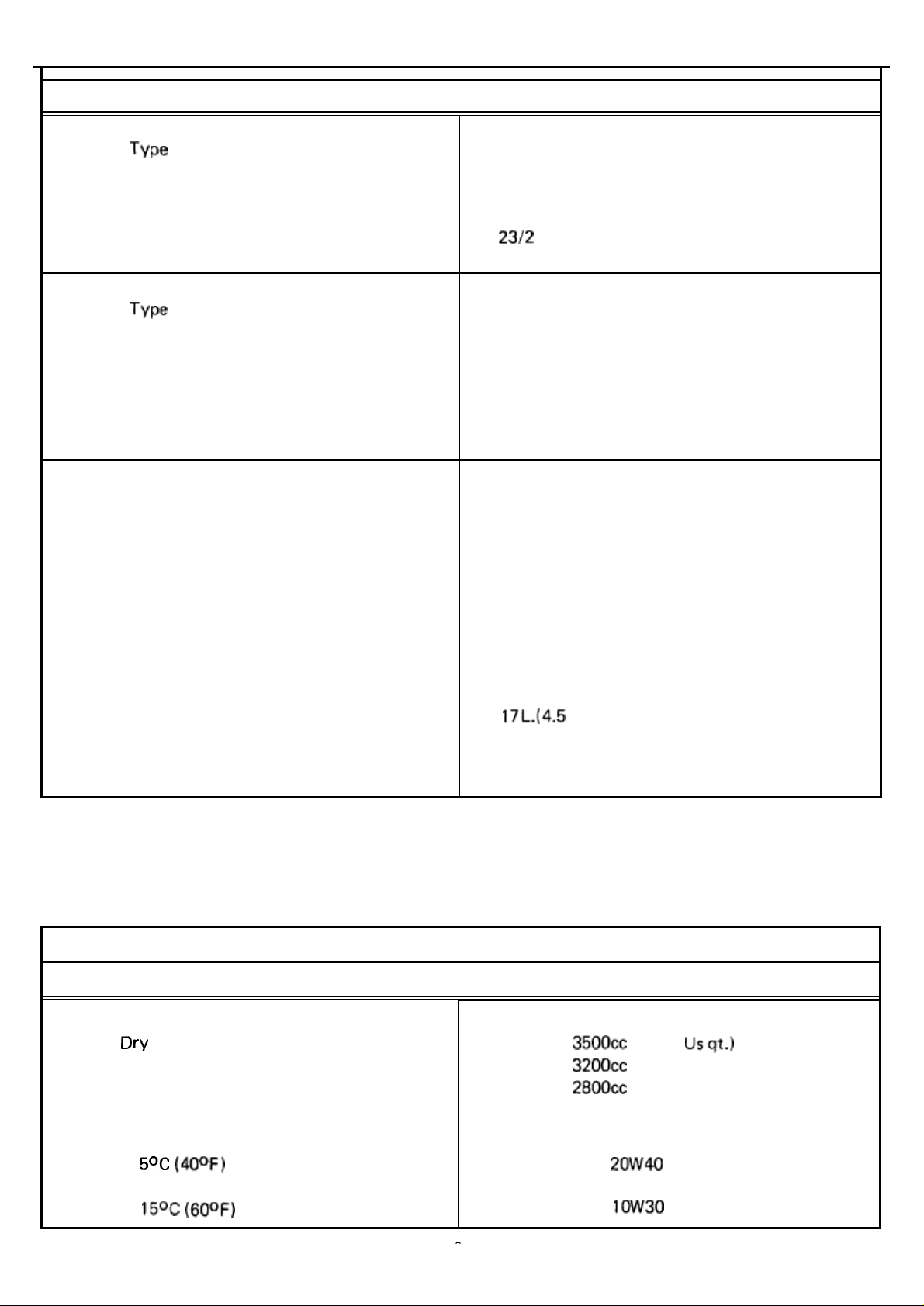

B.

MAINTENANCESPECIFICATIONS

1.

Engine

EngineOilCapacity

Oil

andfilterchange

Oilchange

R

ecommended Iubrican

If

temperaturedoesnotgobelow

t

:

Iftemperaturedoesnotgoabove

SAE

SAE

(3.7

(3.4USqt.)

(3.0USqt.)

SE

motoroil

SE

motoroil

Middlegear

case

capacity:

FinalGearcasecapacity

Recommended Iu b r ican

t

Iftemperaturedoesnotgobelow

5°C (40°F)

Iftemperaturedoesnotgoabove

15°C(60°F)

A

I I

weather

375cc(13 oz.)

300cc

SAE90Hypoid

SAE80Hypoidgearoil,

(1

00

oz.)

gear

oil,GL-4

GL-4

SAE80W90Hypoidgearoil,GL-4

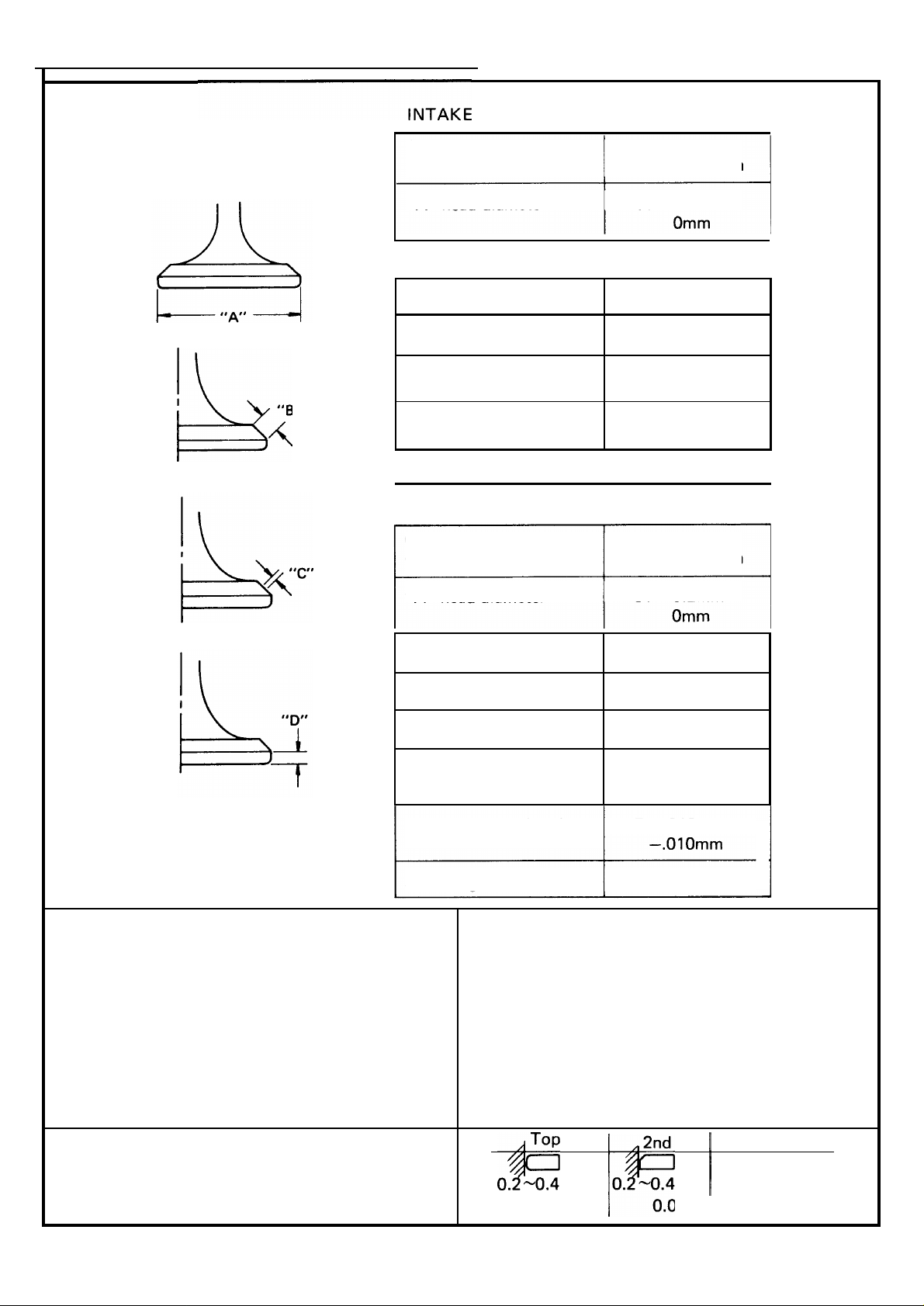

Crankingpressure

(at

sea

Maximum difference betweencylinders

Camshafts

I

Camshaftbearingsurfacediameter 24.97~24.98mm (0.9830~0.9835 in.)

Camshaft-to-capclearance

Standard

Maximum

Camshaftrunoutlimit

Valves

level)

:

10 ± 1kg/cm²(142 ±14psi)

1.0kg/cm²(14psi)

8.018mmm

A

Exhaust

B

28.285 ±0.05mm28.13mm

C

36.303 ± 0.05mm36.15mm

.020~.054mm(.0008~.002in.)

.160mm(.006in.)

0.1mm(.004in)

I

INNER

Wear

-------------

OUTER

Iim

it

I

ALLOWABLETILT

FROMVERTICAL

I

OUTER

INTAKE EXHAUST

DIRECTIONOFWINDINGS

(TOPTOBOTTOM)

I

Valvestemrun-outmaximum

Valve

seat

Freelength

Springrate(kg/mm)

Installedlength

(valve closed)

Installedpressure

(valve closed)

OUTER

Compressedlength

(valveopen)23.0mm

Wire diameter

Numberofwindings

Winding

widthstandard/maximum

O.D.

INTAKE/EXHAUST

35.6mm

K11.84

K22.36

INTAKE/EXHAUST

39.9mm

K13.32

K24.18

34.5mm31.5mm

1

7.5 ± 0.75kg 17.5 ± 1.2kg

26.0mm

2.8mm

7.75

15+0.3mm

0

I

~

3.9mm

6.4

21.6

1

0

-

0.3mm

.03mm(.0012in.)

1.3mm(.050in.)/2.0mm(.080in.)

C

I

ea

rance

(Coldengine)

0.1

6~0.20mm

"B"

"A"

headdiameter

I

"B"

facewidth2.26 ± 0.57mm

"C"

seat

width

"D" marginthickness

Stemdiameter

Guide diameter (I.D.)

I

Stem-to-guideclearance

EXHAUST

CIearance

(Coldengine)0.21 ~0.25mm

"A"

headdiameter

(O.D.)

36+0.2

1.3 ±0.15mm

1.2±0.2mm

7+.010mm

-.025mm

7+.019mm

-.010mm

I

0.020~0.041mm

31+0.2mm

I

CylinderandPiston

Cylinder material

Cylinder liner

Standardboresizehtandard

maximum

Cylindertaperlimit

Cylinderout-of-roundlimit

Pistonclearancehtandard

maximum

"B"

facewidth

"C"

seat

width

"D" margin thickness

Stemdiameter (O.D.)

Guide diameter (I.D.)

St

em

-t

o

-g

uid

e

clearance

Aluminum

Pressed

68.00~68.02mm/(2.677~2.678in.)

68.10mm(2.681)

0.05mm(.002in.)

0.01mm(.0004in.)

0.050~0.055mm/(.0020~.0022 in.)

0.1mm(.004in.)

in;

special

2.26 ± 0.57mm

1.3 ± 0.15mm

1.2± 0.2mm

7+.025mm

-.040m m

7+.019mm

0.035~0.059mm

castiron

PistonRings

Design

Endgap(installed)

Side clearance

Oil

-0.4mm-0.4mm0.2~0.9mm

0.04-0.08mm0.03-0.07mm

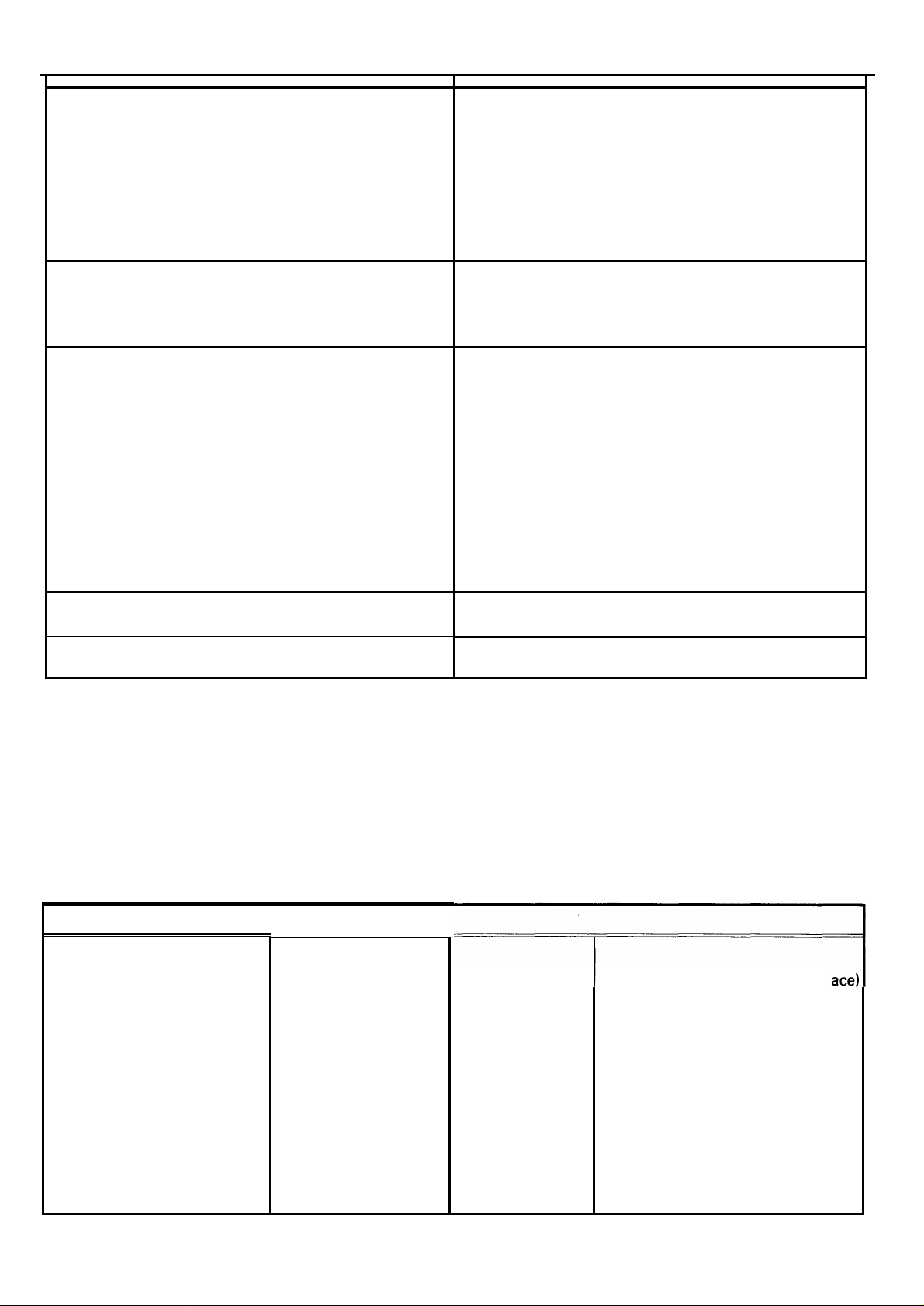

CrankshaftandConnectingRods:

Mainbearingoilclearance

Rod bearing oilclearance

Mainjournalrun-out(maximun)

Oil

Pump

Housing-to-outerrotorclearance

Outerrotor-to-inner rotor clearance

Clutch

Frictionplatethicknessstandard

minimum

Clutchplatewarpmaximum

0.022~0.044mm(.0009~.0017in.)

0.032~0.054mm(.0013~.0021in.)

0.03mm(.0012in.)

,090~.015mm(.0035~.0059in.)

.03 ~.09mm(.0011~.0035in.)

3.0mm(0.12in.)

2.8mm(0.11in.)

0.05mm(.002in)

Clutchspring length standard

minimum

Clutchpushrodrun-outmaximum

Clutchleverfreeplay(endoflever)

Transmissionshaftrun-outmaximum

Middle gear

2.

Carburetion

case

lash

I

42.8mm(1.685in.)

41.5mm(1.634in.)

0.4mm(.016in.)

13~26mm(0.5~1.0in)

.08mm(.001in.)

0.1 ~0.2mm(.004~.008in.)

Manufacturer

Model,

I.D.No.

Mainjet

Needlejet

Pilot jet

Starterjet

Jetneedles/Clip position

Mikuni

BS34,1J701

No.

145

Y-2

No.

17.5

No.

45

4H11/3

Floatlevel

Pilotscrew

Airjet,Main

Airjet, Pilot

Throttlevalve

Inletvalve

size

Engineidlespeed

26.5 ±2.5mm(fromgasketsurf

2¼turns

1

.0mm

1.6mm

No. 140

2.0mm

1050 ~ 1150r.p.m.

3.

Chassis

WheelsandTires

Rimrun-out,vertical

Rim run-out, horizontal

Tirepressure,front,normalriding

Highspeedorwithpassenger

Tirepressure,rear,normalriding

Highspeedorwithpassenger

Brakes

Recommendedfluid

Minimum boiling point

Padthicknesswearlimit

Brakediscmaximum deflection

Brakediscminimumthickness

Frontbrake freeplay (endoflever)

Rearbrake freeplay (endofpedal)

Frontforks

Spring(upper)free length

Spring(lower)freelength

Springrate

Forkoilcapacity(each side)

preload length

preload length

(0 ~100

(100~175mmtravel)

mmtravel)

2.0mm(.080in.)

l.0mm(.040in.)

1.8(26p.s.i.)

2.0kg/cm2(28p.s.i.)

2.0kg/cm2(28p.s.i.)

2.3kg/cm2(33p.s.i.)

DOTNo.3

240°C(464°F)

5.5mm(0.18in.)

0.15mm(.006in.)

6.5mm(0.26in.)

5.0~10.0mm(0.2~0.4in.)

5.0~10.0mm(0.2~0.4in.)

55.8mm(2.2in.)

50.8mm(2.0in.)

448.3mm(17.65in.)

423.3mm(16.67in.)

0.5kg/mm(28Ibs/in.)

0.6kg/mm(33.6Ibs./in.)

170cc(5.75USfl. oz.)

~~

Rearshock absorbers

Spring free length

Spring preload length

Springrate(0~45mmtravel)

(45~75mmtravel)

Ignition timing retarded

advanced

advancestarts

Sparkplug

Electrodegap

Sparkplugcapresistance

Contactpointgap

Spring tension

Condensercapacity

Insulationresistance

253mm(9.95in.)

228mm(9.0 in.)

1.9kg/mm(106Ibs./in.)

2.6kg/mm(145Ibs./in.)

10° @1100rpm

38.5° ± 1.5°@ 2,900 rpm

1550 + 200rpm

0

NGKBP-7ESorChampionN-7Y

0.7~0.8mm(.028~.032in)

I

5.0 K ohms

0.3~0.4mm(.012 ~.016in)

750 ±1 00g(26.5 ± 3.5oz)

0.22µF ± 10%

10 M ohms ormore

Ignitioncoiltype

Sparkgap6V

12V

Primaryresistance(20°C)

Secondaryresistance

(20°C)

H

itachiCM11-

6mm @

7mm@ 5,000 rpm

4.0 ± 0.4 ohms

11.0 ± 1.1K ohms

52A

100 rpm

~~~

Startermotor type

Armaturecoilresistance(2O°C)

Fieldcoilresistance(2O°C)

Brushlengthstandard

minimum

Brush spring pressure

Armaturemicaundercut

Batterytype

Chargingrate

Generator

type

Noloadvoltage

Field(inner) coil resistance(20°C)

Stator (outer) coil resistance (20°C)

Regulatortype

Reg

ulatedvo

I

t

age

Core gap

Yokegap

Point

gap

Mitsuba SM-224C

0.007 ohms

0.01 ohms

12.5mm(0.5in)

5.5mm(0.22in)

620 ± 60g (22.0 ± 2.0 oz)

0.5 ~ 0.8mm(0.02 ~ 0.03in)

YuasaYB14L

1.4ampsfor10hours

HitachiLd120-02

14.5 ± 0.5V

4.04 ±0.4 ohms

0.48 ±0.05 ohms

HitachiTLIZ-80

14.5 ±0.5V

0.6 ~ 1.0mm (.024 ~.040 in)

0.9mm(.035in)

0.3 ~ 0.4mm(.012 ~.016in)

Starterrelayswitch

Cut-involtage

Windingresistance(20°C)

Lighting

Headlight

Ta

i

IIigh t/stopIight

Licenselight

FlasherIight

Flasherpilotlight

Meter Iights

Highbeamindicator light

Oilpressurewarninglight

Neutrallight

HitachiA104-70

6.5 V

3.5 ohms

Sealed beam 12V50/40W

12V8/27W(twobulbs)

12v 8W

12V27W(fourbulbs)

12V3.4W(twobulbs)

12V3.4W(twobulbs)

12v3.4w

12v3.4w

12v3.4w

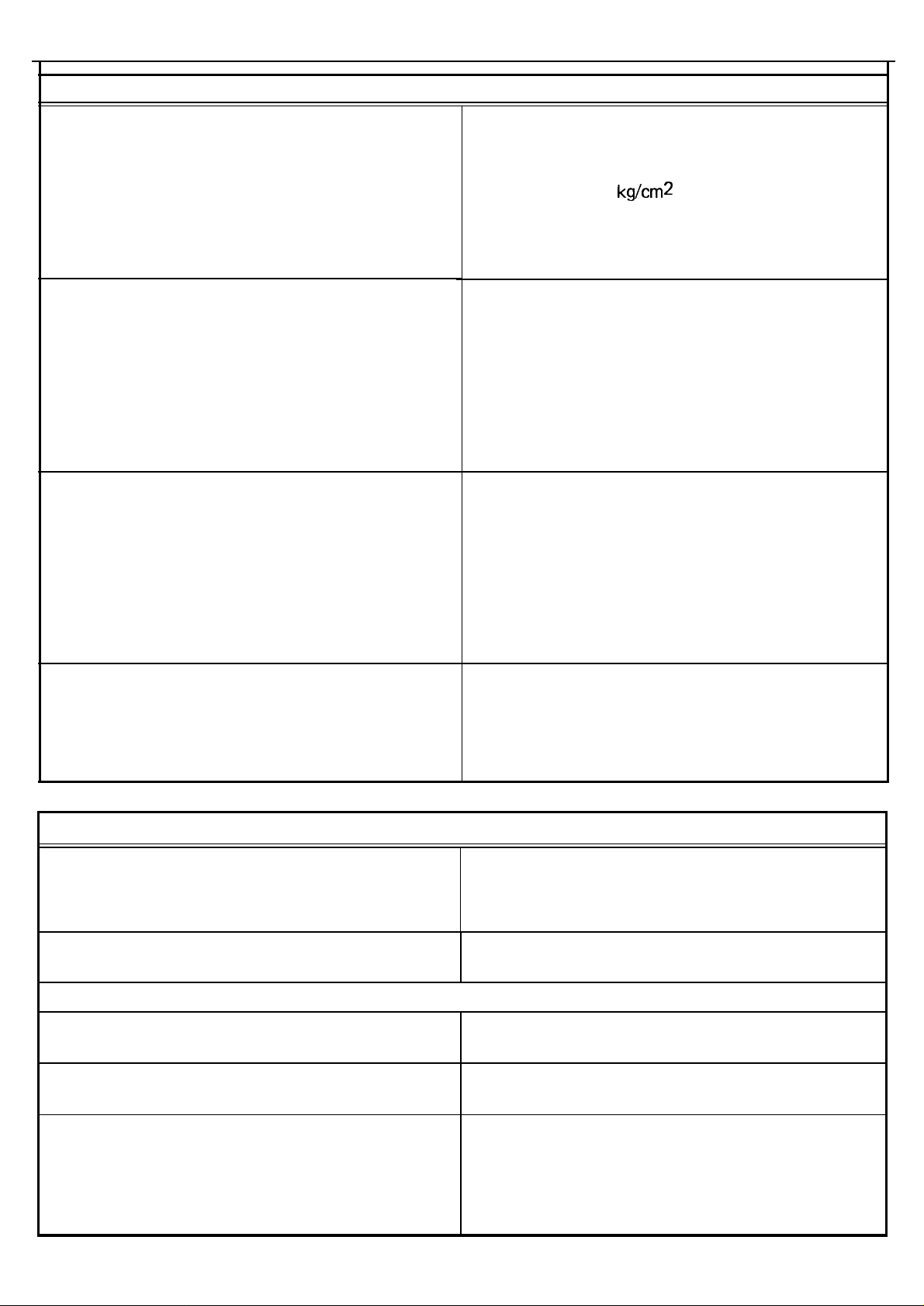

C.

I

I

Torque

Engine

Sparkplug

Camcapnut

Starterclutchbolt

Shiftcamlocatingbolt

Detentassembly

Transmission bearing caps

Crankcasebolts8mm

Clutch holding nut

Clutchspringscrews

Middle gear case mounting screws

Rotorholdingbolt

Bearinghousingbolt

Oil

Oil pump drive gear nut

Crankshaftturningnut

Cylinderhead8mm

Cylinderholdingnuts

Camshaftcapnuts

Enginemountingbolts10mm

Specifications

Rodcap

pipe

1 0mm

unionbolt

1 0mm

12mm

Engineoildrain plug

Oil

filtermountingbolt

Middlegeardrain plug

Chassis

Frontaxlenut

Frontaxleholdernuts

Rearaxlenut

Rearaxlepinchbolt

Brakes

Calipersupportbolt

Calipermountingbolt

Brakehoseunionbolt

Discmountingbolt

Frontforkpinchbolt

Steeringstemtopbolt

Swing arm pivotlocknut

Rearshock absorber nut

1.5 ~ 2.5m-kg(11.0 ~18.0ft-lbs.)

0.8 ~ 1.Om-kg(6.0 ~ 7.0ft-lbs.)

3.8m-kg(27ft-lbs.)

2.8 ~ 3.2m-kg(20 ~ 23ft-lbs.)

1.3 ~ 2.1m-kg(9 ~ 15ft-lbs.)

4.0 ~ 4.5m-kg(29 ~ 32ft-lbs.)

1.8 ~ 2.2m-kg(13 ~ 16ft-lbs.)

2.0rn-kg(14 ft-lbs.)

3.7m-kg(27 ft-lbs.)

8 m-kg (58ft-lbs)

0.8 ~ 1.Om-kg(6.0 ~ 7.0ft-lbs.)

2.0 ~ 2.5m-kg(14 ~ 18ft-lbs.)

3.0 ~

2.0 ~

2.0 ~ 2.2m-kg(14 ~ 16ft-lbs.)

8.0~12.0m-kg(58 ~ 87ft-lbs.)

1.5 ~ 2.9m-kg(11 ~ 21ft-lbs.)

2.0m-kg(14ft-lbs.)

3.5m-kg(25ft-lbs.)

2.0m-kg(14ft-lbs.)

1.Om-kg(7ft-lbs.)

5.0 ~ 6.0m-kg(36 ~ 43ft-lbs.)

I

1

8.0 ~ 11.0m-kg(58 ~ 80ft-lbs.)

3.9 ~ 4.7m-kg(28 ~ 34ft-lbs.)

3.0 ~ 3.4m-kg(22 ~ 25ft-lbs.)

3.9 ~ 4.7m-kg(28 ~ 34ft-lbs.)

7.0 ~ 10.0m-kg(50 ~ 72ft-lbs.)

1.3 ~ 2.3m-kg(9 ~ 17ft-lbs.)

12.0 ~ 18.0m-kg(87 ~ 130ft-lbs.)

0.45 ~ 0.75m-kg(3.0 ~ 5.0ft-lbs.)

1.5 ~ 2.0m-kg(11 ~ 15ft-lbs.)

4.5 ~ 5.0m-kg(28 ~ 35ft-lbs.)

2.3 ~ 2.8m-kg(16 ~ 20ft-lbs.)

1.7 ~ 2.2m-kg(12 ~ 16ft-lbs.)

1.3 ~ 2.3m-kg(9 ~ 17ft-lbs.)

6.6 ~ 10.5m-kg(48 ~ 76ft-lbs.)

8.0 ~ 10.0m-kg(58 ~ 72ft-lbs.)

2.3 ~ 3.7m-kg(20 ~ 27ft-lbs.)

4.0m-kg(22 ~ 29ft-lbs.)

2.4m-kg(14 ~ 17ft-lbs.)

500 - 600

Componentsshould be room temperature.

SPECIAL

tool

TOOLS

ValveguideremoverClutchholdingtool

Valve guide installer

Valvespringcompressor

Clutch plate installation tool

Clutch lock

nut

Final drive gearholdingtool

Middle

wrenchDamperspecial

and

finalgearholding

tool

Valveseatcutterset

Tappetadjustingtool

Vacuumgauge

Camchain cutter

Slide hammer

Gear lash measurementtool

(middlegear)

Rotorpuller

Rotor holding tool

Gear

lash

measurementtool

(finalgear)

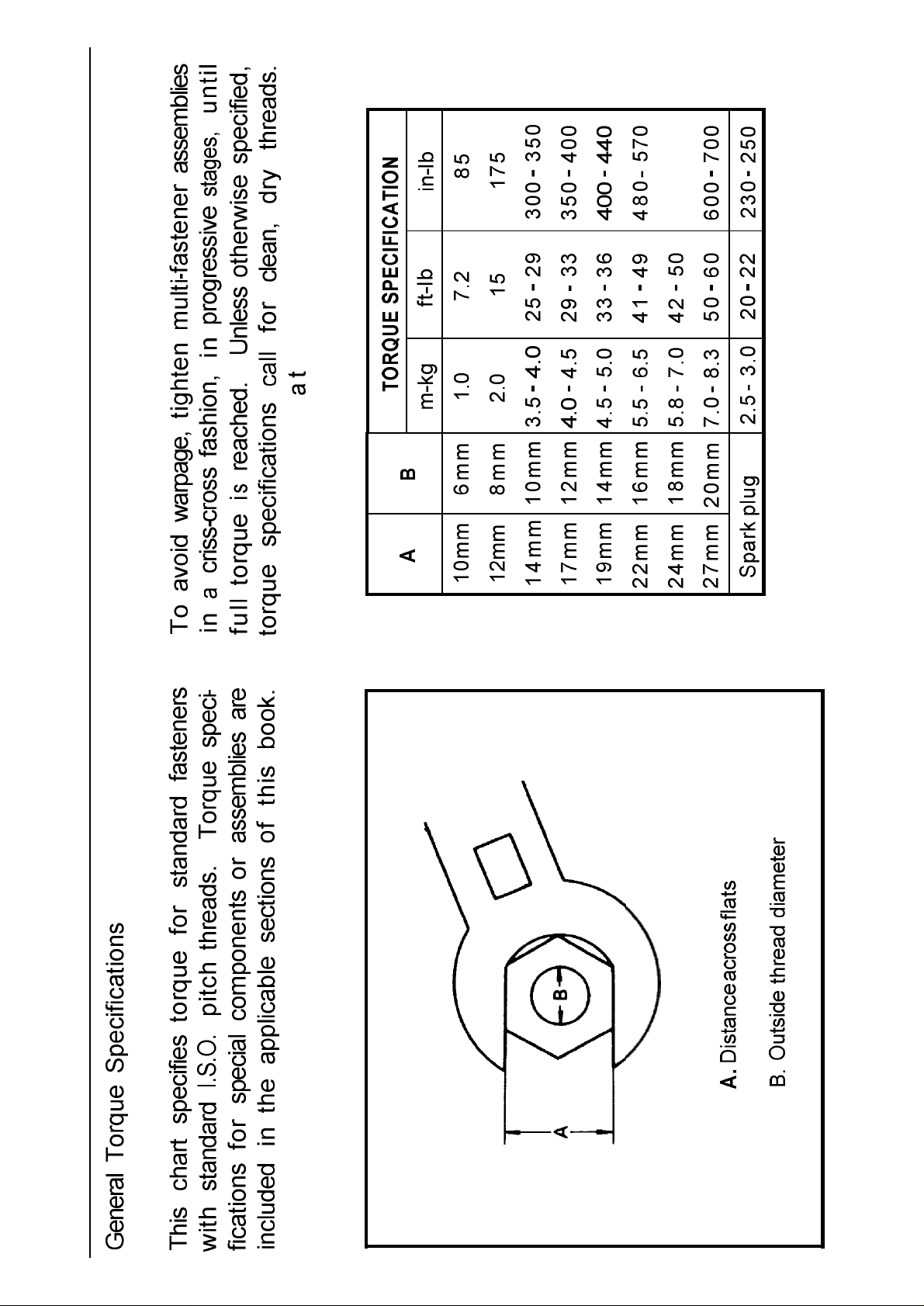

d.Turnpetcocksto"prime"position.

or out

e.

Start

motorcycleandallowittowarmupfor

2-3

minutes.The warm-upiscompletewhen

enginerespondsnormallytothrettleopening.

f.

Adjustdampingvalveoneachvacuumgauge

untiltheneedleflutters only slightly. The

gaugeneedlesmust respond quicklytorapid

openingofthe throttle.

g.Eachgaugewillindicatethesamereadingif

thecarburetorsaresynchronized.Theleftand

rightcarburetors

centercarburetor,which

screw.Turnthe

screwuntilthegaugereadingisthesame

forthecentercarburetor.Repeatfortheright

carburetor.

are

tobe synchronized tothe

has

nosynchronizing

left

carburetorsynchronizing

as

a.

Theenginemustbewarmedupbeforesetting

idlespeed.

b.Set engine idlespeedbyturningthethrottle

stopscrewin(toincreaseenginespeed)

(todecreasespeed).

StandardIdle

1,050

-

1,1

RPM

50rpm

SYNCHRONIZING

3.

-_-

Idle

speed

NOTE:

beforesetting

adjustment

throttlestopscrew.

Carburetorsmustbesynchronized

SCREWS

adjustment.

final

idlespeed.Theidlespeed

is

madebyturning only one

B.

AirFilter

1.

Removal

a.

Lifttheseatandremovethe

byremovingthepanheadscrews

air

filtercasecap

(2).

b.

the two.

Pullouttheelement.

2.

Cleaningmethod

a.

Tapthe element lightlytoremovemostofthe

dustanddirt;thenblowouttheremainingdirt

withcompressed

ofthe element. Ifelementisdamaged,replace.

air

through the innersurface

C.

Engine/TransmissionOil

1.

Oillevel measurement

a.

Tocheckthe

severalminutes.Stoptheengine.Withthe

enginestopped,screwthedipstickcompletely

outandthen

NOTE:

thedipstick,

onthecasethreads.

stopped and themachineispositionedstraight

upandonbothwheels.

Whencheckingengineoillevelwith

level,

warmtheengineupfor

rest

thestickinthehole.

let

theunscreweddipstick

Be

suretheengine

rest

is

b.Reassemblebyreversingtheremovalpro

cedure.Checkwhethertheelementisseated

completelyagainstthecase.

c.

The

air

filterelement should becleanedonce

a

monthorevery1,600km

shouldbecleanedmoreoftenifthemachine

is

operatedinextremely dusty areas.

(1,000

miles).

b.ThedipstickhasaMinimumandaMaximum

mark.Theoil

If

the

levelislow,

totheproperlevel.

2.

Engine/Transmissionoilandoilfilterreplace

ment

a.

Start

theengine.Allowittowarmupfor

minutes.Stop the engine.

b.

Placeanoil

theoil

c.Removethedrainpluganddraintheoil.

-

filler

level

should be between

add

sufficientoilto

pan under theengineandremove

cap.

raise

it

-

It

without

cessiveoilcontamination

may

theaircleanerelement

result.

installed.

and

enginewear

Ex

-

d.Removetheoil filter boltand

level

end marked

case.

e.

Reinstall

e.

Reinstall

f.Installtheoilfilterelement andcover. Tighten

theoil filter bolt.

thedrain plug (makesureitistight).

thedrain plug (makesureitistight).

4.0 ~4.5m-kg(28.9-32.5ft-lb)

filter

element.

h.Afterreplacementofengineoil, and/or oil

filter,

leakage.Theoilpressureindicatorlightshould

gooff

CAUTION:

remains on, immediatelystop

Refertolubrication information inSec.

D.

MiddleGear/FinalGear

be sure tochecktheoilpressureandoil

after

theengineisstarted.

If

the"Oil"indicatorlight

the

Oil

engine.

3-5

NOTE: Make surethe

properly.

g.

Add oil through the dipstickhole.

"

0'

ringispositioned

1.

Oillevel measurement

a.Placethemachineonalevelsurfaceandplace

it

onthecenterstand.Theengineshouldbe

cool

(at

atmospherictemperature).Allow

minutesfor oil todraintobottomofcases.

b. Remove theoil

withlevelgauge(fromtoolkit)

The correct oillevelisbetweenthetwomarks

oneachendof

gaugemarked"REAR"formeasuringthe

rear

(final)gearcase.

NOTE:Middlegearandfinalgearoilcanbe

checkedwithsamelevelgauge,whichisin

theownerstool kit.

filler

cap.Checktheoil

as

shown.

the

level

gauge.

Use

measuringthemiddlegear

Use

the

endof

2

Oilquantity:PeriodicOilChange

2.8

liter

(3USqt)

Withoilfilterchange:

3.2

liter

(3.4USqt)

Recommendedoil:exceptincoldweather

Yamalube4-cycleorSAE20W40

(see

page

8)

"SE"

d.Fillthe

gear

case(s)uptospecifiedlevel.

CAUTION:

Takecarenottoallowforeign

materialtoenterthemiddleand/orfinal

aear case.

2.

Gear

oilreplacement

a.

Placeanoilpan under

themiddle

b.

Removethe middle and/orfinal

gear

and under the final

the

transmissionfor

gear

gear

oil

case.

filler

cap(s)andthedrainplug(s),anddrainthe

nottoallowforeignmaterialtoenterthe

middleandlor

the

gearoiltocontactthetire

final

gear case.

Do

and

notallow

wheel.

c.Reinstallthe middle and/orfinaldrainplug(s).

oil.

OilCapacity:

Middlegear case:

Final

gear

Recommendedoil:

e.

Reinstallthe filler cap(s)securely.

NOTE:

is

normallynotnecessarytochangemiddle

andfinal

indicatedserviceintervalof

E.

Clutch Adjustment

375cc(12.7

case:

300cc

(see

Afterinitial

gear

oilmorefrequently than the

page

250

US.

fl

(10.0

U.S.

fl

8)

mileoilchange,

6,000

02)

02)

it

miles.

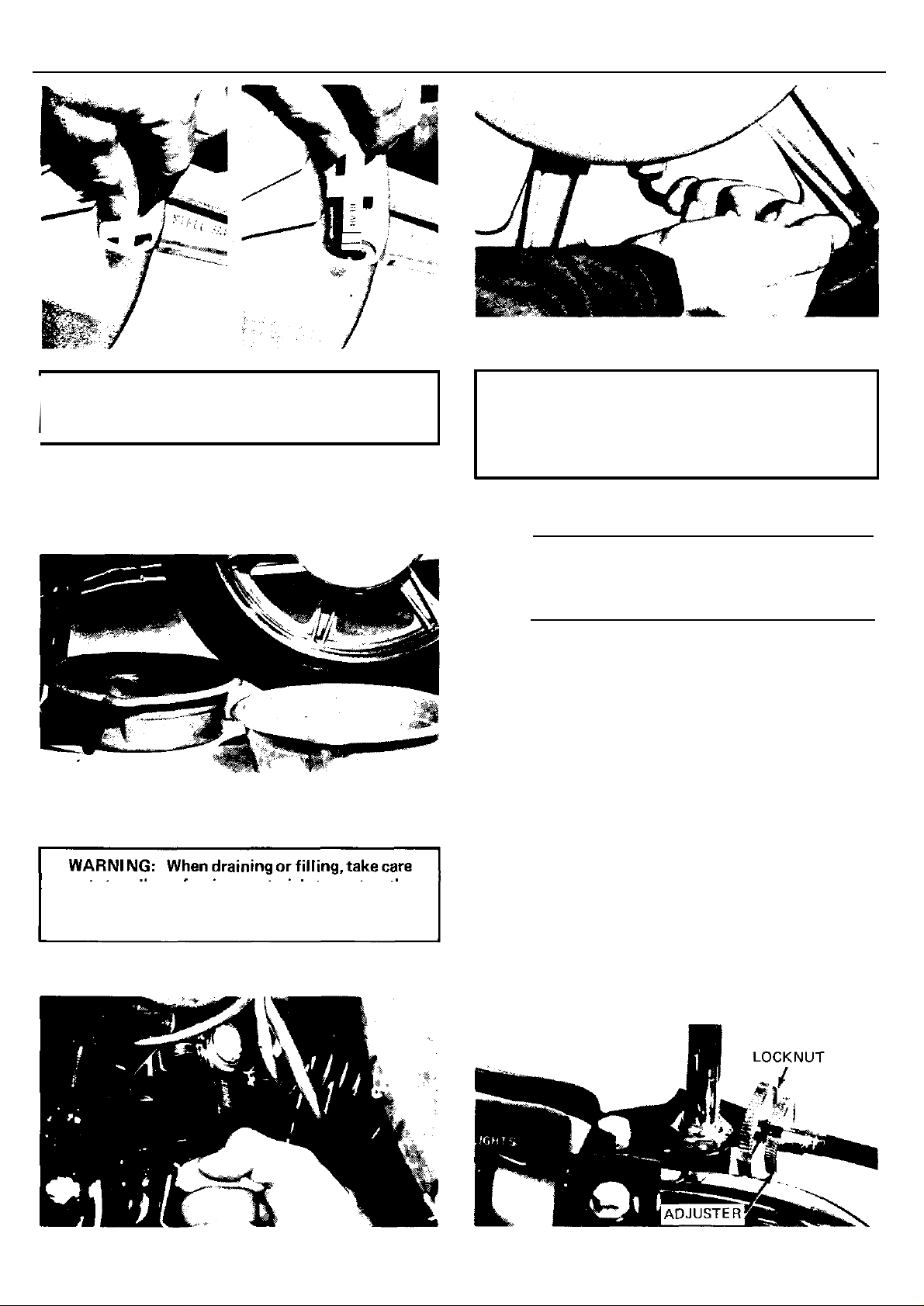

Thismodelhasaclutchcablelength adjustor and

clutchmechanismadjustor.Thecablelengthadjustor5

are

usedto

take

upslackfromcablestretchandto

providesufficientfreeplayforproperclutchoperation

under various operating conditions. The clutchmech

anismadjustorisusedtoprovidethecorrect amount

ofclutch"throw"forproperdisengagement.Normal

ly,oncethemechanismisproperlyadjusted,theonly

adjustment required ismaintenanceoffreeplay

the clutch handle

1.

Freeplayadjustment

lever.

at

Looseneither the handle leveradjustorlock

nutor the cablelength adjustor locknut.

Next,turnthe length adjustor eitherinorout

untilproper

lever

freeplayisachieved.

a

-

-

cover.

2.

nut

Mechanismadjustment

Thesecondadjustmentislocatedbehindthe

adjusting cover. Removing thecoverwill

exposethe adjusting

Loosenthelocknutandrotatethe

in until itlightly

rodthatworkswiththe

theclutch.Backthesetscrewout ¼ turnand

tightenthelocknut. This adjustmentmustbe

checkedbecauseheatandclutchwearwill

affectthis

causeimproperclutchoperation.Recheck

clutchcableadjustment

adjusting.

free

set

screwandlocknut.

set

seats

againstaclutchpush

set

screwtooperate

play,possibly enough to

at

handlebarafter

screw

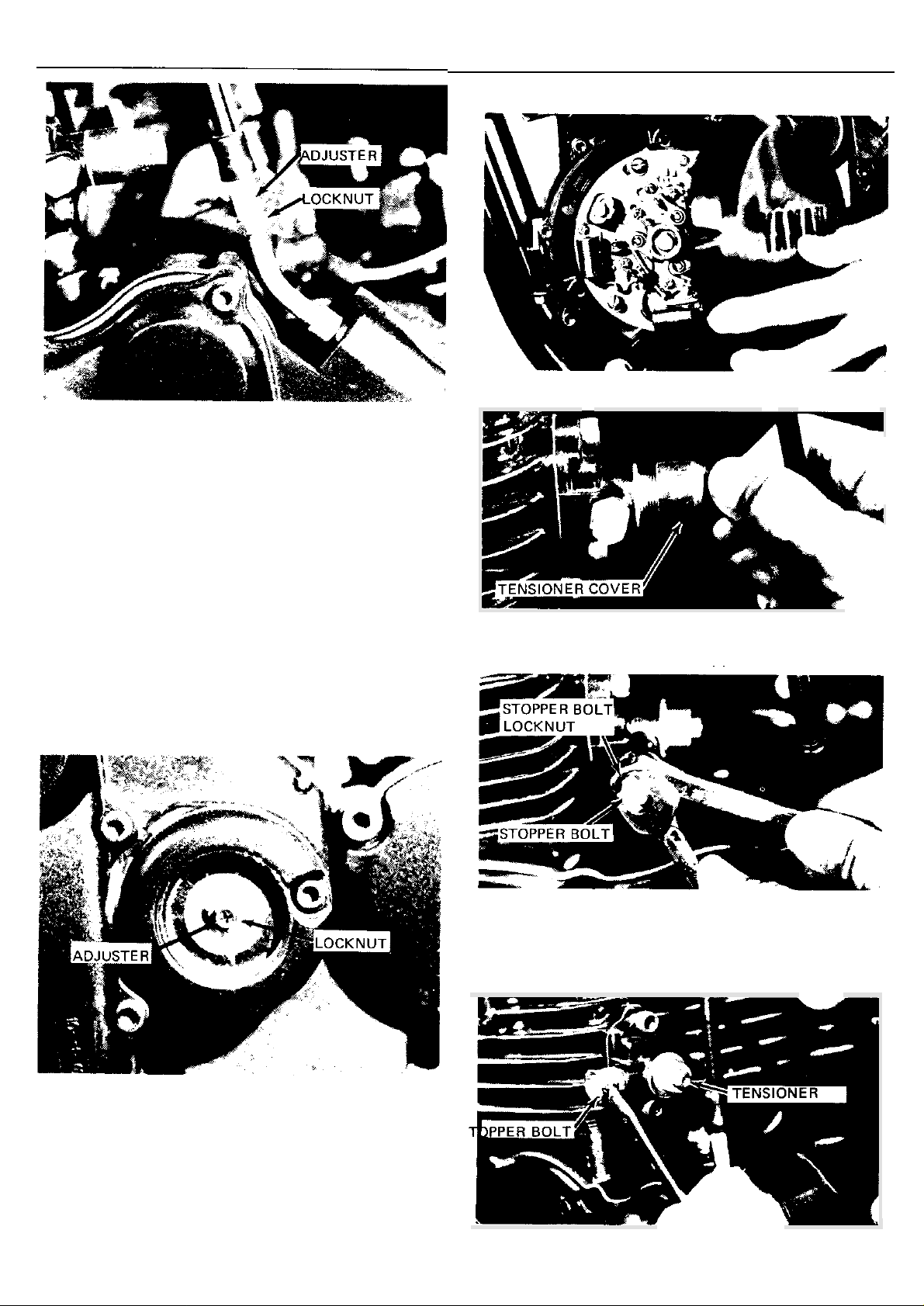

1.

Removethebreakercover

2.

Removethecamchain tensioner

Loosenthetensioner stopper boltlock

andthenloosenthestopperbolt.

F.

CamChainAdjustment

Thecamchain becomesstretched with

improper

thecamchain tensioner must be adjusted regularly.

valve

timingandenginenoise.Topreventthis

use,

resultingin

4.

Slowlyrotate the crankshaftcounterclockwise

severalturns.Whenthetensionergetsdeepest

intothe tensioner holder,tighten the stopper

boltandsecureitwiththelocknut.

S

5.

Adjustment

appropriate chart

Reinstall the chain tensionercapandthecon

tactbreakercover.

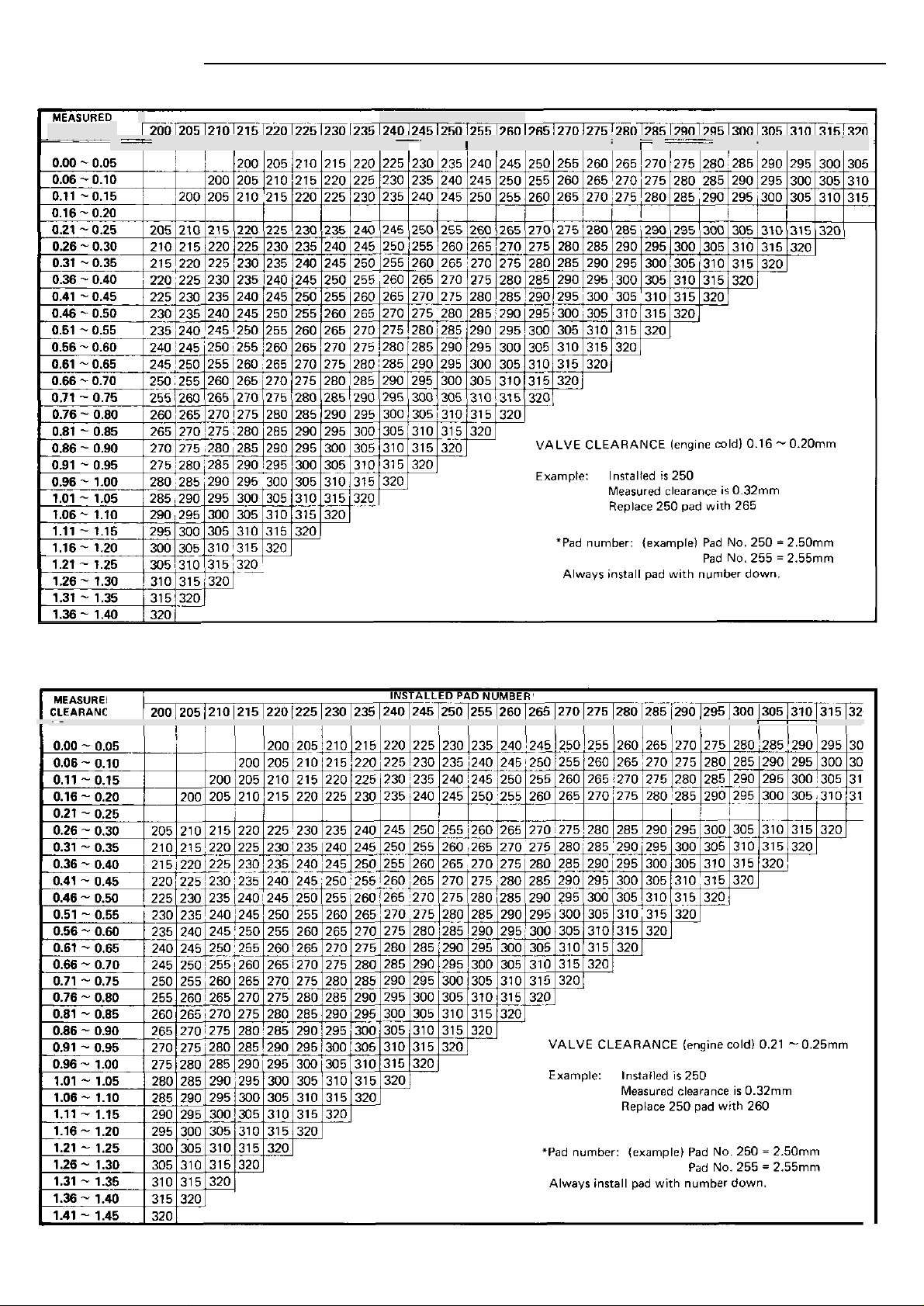

G.

ValveClearanceAdjustment

-

Exhaustvalve clearance (cold)

0.21-0.25mm(.008 -.010")

Intakevalve clearance (cold)

0.16-0.20mm(.006-,008")

NOTE:

Valveclearancemustbemeasuredwith

theengineatroomtemperature.

1.

Remove

gas

tank.

2.Removeairscooponcylinderhead

3.

Removecylinderheadcoverandbreakerpoint

cover.Careshouldbetaken

to

notscratchor

damagegasketsealing surfaces.

4.

Turncrankshaftwith nut on

left

endofcrankshafttoturncams.The proper positionofthe

camwhenmeasuring

valve

clearanceiswith

thecamlobedirectlyoppositethevalvelifter.

Adjustment

Valveclearanceisadjustedbyreplacingtheadjusting

padonthetopofthevalvelifter.Adjustingpadsare

availablein25thicknessesrangingfrom

No.

200

(2.00mm)toNo.320(3.20mm)instepsof0.05mm.

Thethicknessofeachpadismarkedonthepadface

thatcontactsthe valve lifter(notthe cam).

ofvalve clearance isaccomplishedasfollows:

1.Determinevalve clearance

(feeler

gauge

measurement.

2.

Removeadjustingpadandnotenumber.

3. Select properpadfrom

(intakeorexhaustchart).

4.

Installnewpadandcheckinstalledclearance.

Procedure

5.

Insertafeelergaugebetweenthevalvelifter

andthecamheel.

1.

Measurevalveclearance.Ifclearanceisin

correct,recordthemeasuredamountof

clearance.This must bemeasuredcarefully.

2.

Thereisa

slotinthevalve lifter. This slot must

bepositionedoppositethebladeofthetappet

adjustingtoolbeforethetool

3.

Turnthecamuntilthelobefullydepresses

is

installed.

thevalvelifterand opens thevalve.Install the

tappetadjustingtool

as

showntoholdthe

lifterinthisdepressedposition.

AD

JUST

I

NG

TOOL,

CYLINDER

-

PADREMOVAL

SLOT

NOTE:The tappet adjustingtoolisfastened

to

thecylinderheadusingone

suchasoneusedto

install

(1)

allenscrew

thecylinderhead

cover.Makesurethat the tool contactsthe

lifteronly,

and

not

the

pad.

EXAMPLE:Exhaustvalve,installed

No. 250

(readdown)

Measuredclearance:0.32mm

(readacross)

Newpad number: No.

(intersectionofdown&across)

pad:

260

CAUTION:Ifthecamlobetouchesthetappet

adjusting

cylinderhead.

tool,

thestressmayfracturethe

DO

NOTALLOW THE CAM

TOCONTACTTHETAPPETADJUSTING

TOOL.

4.

Carefullyrotatethecamsothat the padcan

be removed. Toavoid cam touchingadjusting

tool,turncamsasfollows: (view fromleft

sideofmachine)

Intake: Carefully rotate CLOCKWISE.

Exhaust: Carefully rotateCOUNTERCLOCK

WISE.

5.

Removethepadfromthe lifter. Thereisa

slotinthelifter.Useasmallscrewdriveror

otherblade

pad.

Notethe number

and

a

magneticrodtoremovethe

on

the

pad.

NOTE:Thenewpad number

is

to

aguideonly.Verifythecorrectnessofthis

choiceinthefollowingsteps).

7.

Installthenew

pad

withthenumberdown.

8.

Removetappetadjustingtool.

9.

Turncrankshaft

tions.

10.

Checkvalve clearance (step3).Ifclearance

This

incorrect,repeatpreceding

-

clearanceisobtained.

11.

Inspectheadcovergasket.

pad

in

to

rotatecamseveralrota

willsetthe

thelifter.Installthe

pad

in

steps

until

If

bentortorn,

replacegasket.

12.

Reinstallremovedpartsinreverseorder.

H.

CompressionPressureMeasurement

Insufficientcompressionpressurewillresultinper

formance

loss

and may indicate leaking valvesorworn

ordamaged rings.

be usedas

the

lifter.

proper

-

is

-

6.

Proper

pad

selectionismadeasfollows:

(Useappropriate chart forexhaustorintake

valves.)

a.Findnumberoforiginal (installed)

pad

num

beronchart.Readdownonchart.

b.

Findmeasured valve clearance (fromstep

onchart.Readacross.

c.Attheintersectionofinstalledpadnumber

(down)andmeasuredclearance(across)isa

new

pad

number.

1)

-

Procedure

1.

Makesurevalveclearanceiscorrect.

2.

Warmupengine 2-3 minutes.Stopengine.

3.

Removespark plugs.

4.

Installcompression check gauge.

Intake

CLEARANCE

...

,

.............. .

.....

.

,

.

i..

:

.

I

...........

Exhaust

5.

Turnoverenginewithkickorelectric

(makesurebattery

throttlewide open untilpressureindicatedon

thegaugedoesnotincreasefurther.

Standard:I0kg/cm²(142psi)

Minimum:9kg/cm²(128psi)

Maximum: 11kg/cm²(156psi)

.

Ifpressureistoolow,squirtafew drops ofoil

intothe cylinder beingmeasured.Measure

compressionagain.Ifthereisa

thanbefore(withoutoil),thepistonrings

maybewornordamaged.Ifthepressure

mains

eitherorboththe

the

Checkeachcylinder.

shouldnotvarymorethan1kg/cm²(14psi)

fromonecylindertoanyothercylinder.

the

cause.

same

is

fullycharged)withsolvent.

after

measuringwith

ringsand

Compression pressure

higherreading

valves

starter

re

the

oil,

maybe

2.Removethedraincoverandclean

-

B.

Fuel Petcock

Ifthefuel petcock isleakingorexcessivelycontami

nated,itshouldberemovedfrom the fuel tank

inspected.

1.Removefueltankandpositionitso

will not spillwhenthepetcockisremoved.

Disassembly

it

with

and

thatfuel

-

2-4

CHASSIS 4.

A. FuelPetcockCleaning

1.

Turn the petcocklevertothe

"

RES

"

position.Removethe fuel pipe.

"ON"

or

2. Remove petcockandinspectfilterscreen.

Replacefilterifseriously contaminated.

3. Remove4screwsonfrontandrear

andremoveplate,gaskets,leveranddiaphragm.

Inspect

are

damaged,or the petcockbodygasketsurfaces

scratchedorcorroded,thepetcockassembly

mustbereplaced.Ifthere

toany component, the

drainedandflushed.

5.

Reassemblepetcockand

C.FrontAndRearBrake

See

pages158-159foradjustments

1.Brake adjustment

Thebrakescanbeadjustedbysimplyadjusting

the

pistoninthe caliper movesforward

brakepadwearsout,automaticallyadjusting

theclearancebetweenthebrakepadandthe

brake disc.)

all

componentsandreplaceanythat

damaged.Ifthediaphragmisinany way

free

playof

the

brake

is

fuel

install

lever

of

abrasive

tank must be

on

fuel

andpedal.

petcock

damage

tank.

as

the

a.

Frontbrakeleverfreeplay

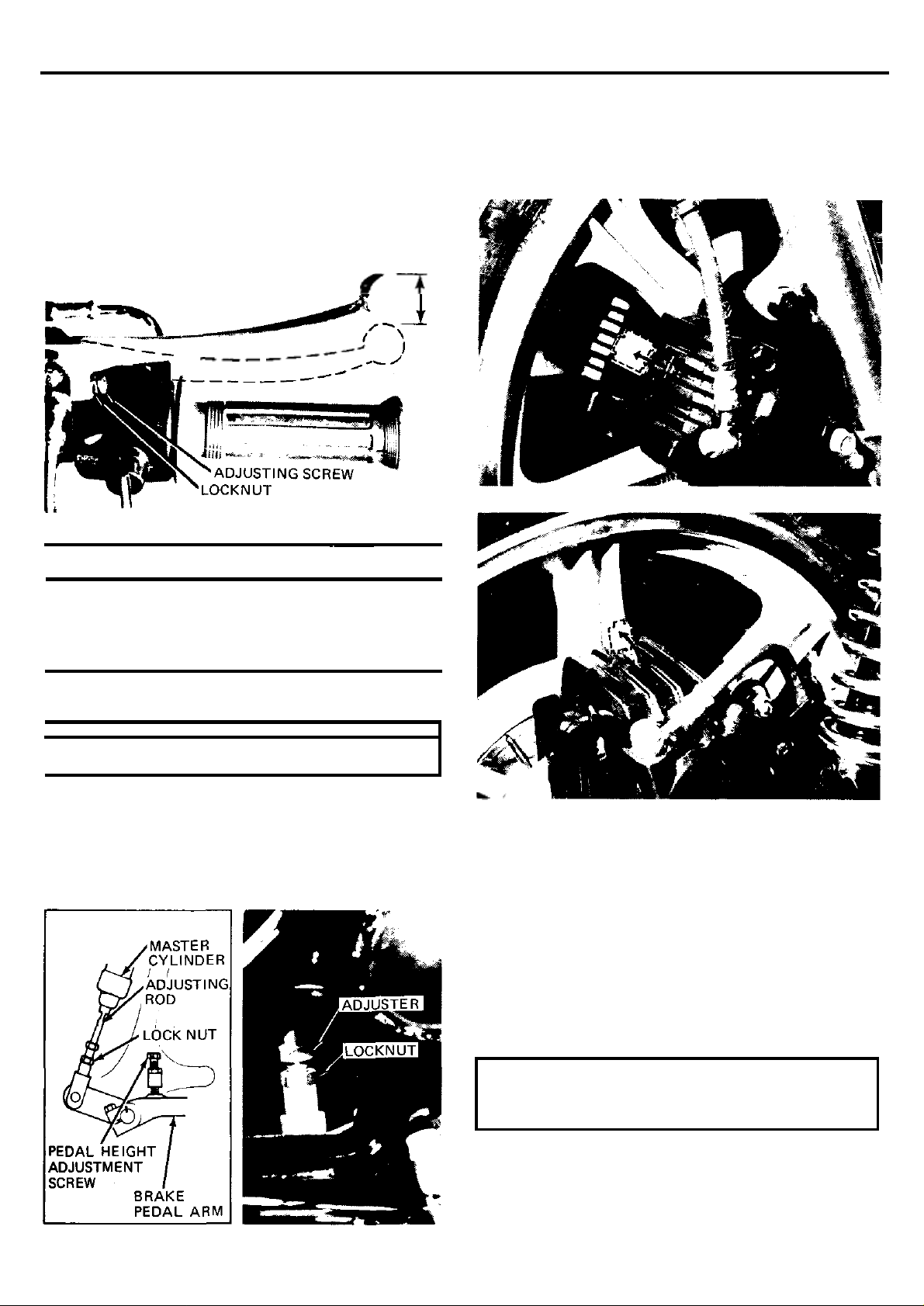

CAUTION:

toavoidexcessivebrakedrag.

Proper lever freeplayisessential

1)

Loosenthe adjusting screwlocknut.

2)

Byturning the adjustingscrewinorout,

adjusttheplayofthebrake

tighten the locknut.Measurefreeplay

endoflever.

lever

andthen

FREEPLAY

-

at

2.

Brake pad check

To

checkpadwear,openthewearindicator

cap.Ifany pad isworntotheredline,replace

bothpadsinthecaliper.

I

I

FREE PLAY:10mm(0.437in.)

Freeplay:5~8mm(0.2~0.3in.)

b.

Rear

brakepedal free play

CAUTION:

to

avoid

1)

Loosentheadjusterlocknutatthepushrod.

2)

Byturningthe adjuster inorout,adjust

theplayofthebrakepedalandthen tighten

thelock nut.

Properpedalfree

excessive

brakedrag.

playisessential

1

I

3

Checkthebrakefluid

Insufficientbrakefluidrnayallow

thebrakesystem,possiblycausingthebrake

tobecomeineffective.Checkthebrakefluid

level

and replenish when necessaryandobserve

theseprecautions:

a.

Use

onlythedesignatedqualitybrakefluid;

otherwise, the rubber

causingleakageandpoorbrake performance.

level

seals

air

rnaydeteriorate,

toenter

Recommendedbrakefluids:

DOT

No. 3

with

240° C (464°F)

boilingpoint

b.Refillwiththesametypeandbrandofbrake

fluid;mixingfluidsmay result inaharmful

chemical reaction and lead topoor perfor

mance.

-

c.

Be

carefulthatwaterorother contamination

doesnotenterthemastercylinderwhen re

filling.Waterwillsignificantlylower the

boilingpointandmayresultinvaporlock.

2.Frontaxle

-

a.

Checkaxle nuts.

Frontaxlenuttorque:

7.0~10.0m-kg

(50~72ft-lb)

Rearaxlenuttorque:

12~18m-kg

(87~130ft-lb)

b.Checkaxleholdernuts(rightside).

Frontaxleholdernuts:

I

CAUTION: First tighten the nutonthefront

end

of

nutonthe

1.3-2.3m-kg(9-17ft-lbs)

the

axle holder, and thentighten

rear

end.

1

the

D.

WheelsAndTires

1.

Checkingthealuminumwheels.

a.Checkforcracks,bendsorwarpageofthe

wheels.Ifawheelisdeformedorcracked,

mustbereplaced.

NOTE:ThesealuminumwheelsareNOTde

signedforusewithtubelesstires.

b.

Raise

thewheelofftheground. Spin.

Rimrunoutlimits:

Vertical

Lateral

-

2mm

-1

mm(

(0.08

0.04

in.)

in.)

Rearaxlepinchbolt:

0.45-0.75

m-kg(3-5ft-lbs)

I

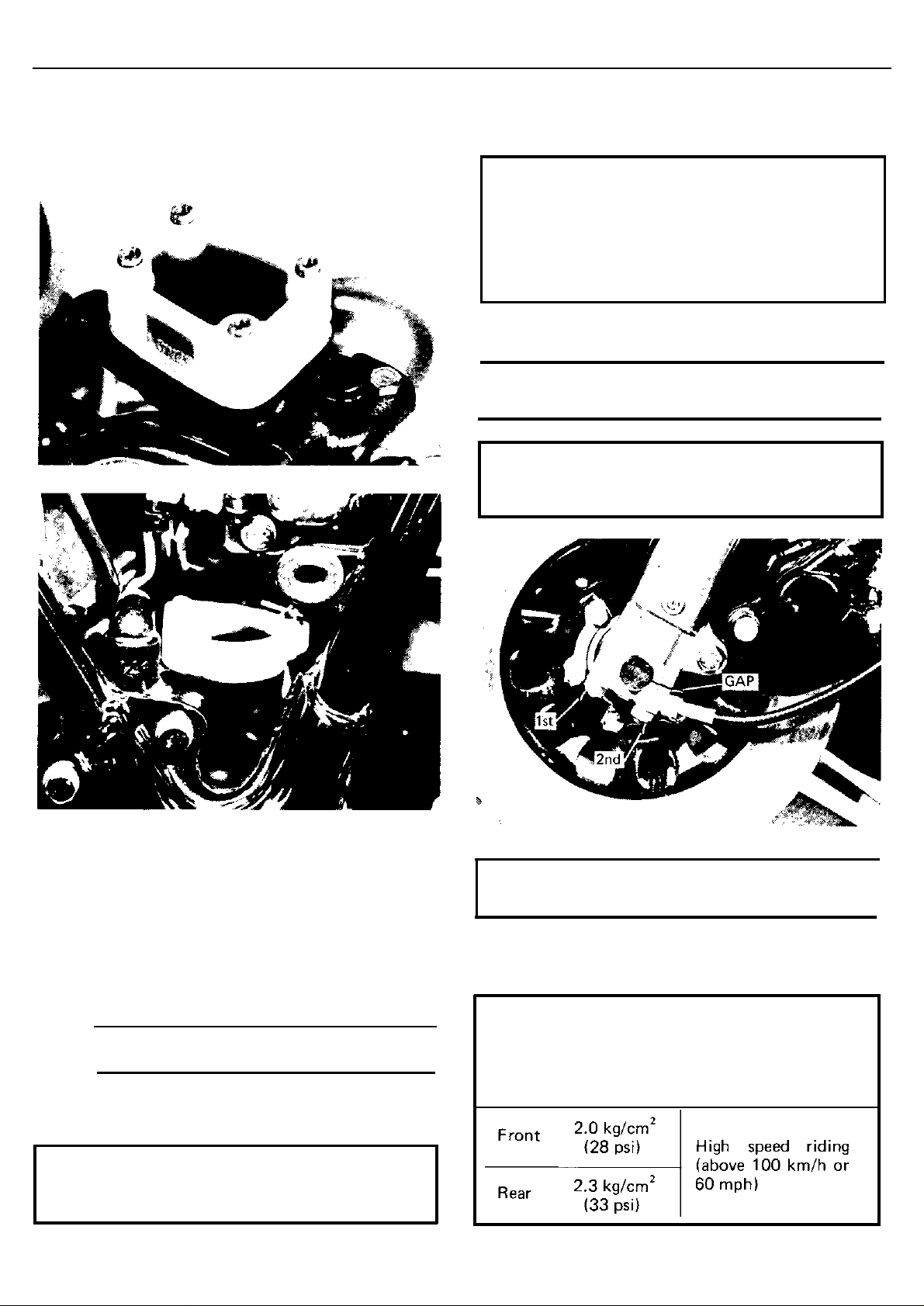

3.Tires

it

Tirepressure

1.8

Front

-

,,I

Rear 2.0 kg/cm² | Normal riding

kg/cm²

(26

psi)

(28 psi)

I

b.Checkthetirewear

If

a

tire

treadshowscrosswiselines,itmeans

thatthe

tire.

tireiswornto

its

limit.Replacethe

9. Inspect the O

O-ringifdamaged.

10.

Reinstalltopspring,O-ring,spring

stopperringandrubbercap.

-

ring on the spring

seat.

Replace

seat,

E.FrontForkOil Change

1.

Raise

themachineorremovethefrontwheel

so

thatthereisnoweightonthefrontendof

themachine.

2.

Removethe rubber capfromthetopofeach

fork.

3.

The spring

stopperring(springwire circlip). Itisnecessary

todepressthespring

removethe stopper ring. Removethestopper

ringby carefully pryingoutoneendwith

smallscrewdriver.

4.

Placeopencontainer under eachdrainhole.

Removedrainscrewfromeachouter tube.

seat

and springs

are

retainedbya

seat

andforksprings to

CAUTION:

(wirecirclip).

F.

SteeringHeadAdjustment

a

The

XS750D

bearings.

periodicallyforlooseness.

Procedure

The

STOPPER

steeringheadisfitted with taperedroller

steeringassemblyshould be checked

RING

Alwaysuseanewstopperring

CAUTION:Donotallowoiltocontactdisc

brakecomponents.

5.

Whenmostofthe

raise

andlower the outertubestopump

theremainingoil.Itmaybenecessaryto

removethe spring

themfromfallingoutwhen raising forktubes.

6.

Inspectdrainscrewgasket.Replaceifdamaged.

Reinstalldrainscrew.

7.

Pourspecifiedamountofoilintothefork

innertube.

Frontforkoil(eachfork):170cc

2OW

YamahaForkOil

8.

Afterfilling, slowly pump the outertubesup

anddowntodistribute the oil.

oil

hasdrained,slowly

seat

andtopspringtokeep

1.

Raise

frontendofmachinesothatthereisno

weightonthefrontwheel.

2.

Graspbottomofforksandgentlyrockfork

assemblybackward and forward,checkingfor

loosenessinthesteeringassembly bearings.

3.

adjustable contact

Repeat

NOTE: Point gap must beset before setting timing.

If

thereisloosenessinthesteeringhead,loosen

the crown pinchboltandsteeringfittingbolt.

4.Use steering nut wrench to loosen top steering

fittingnut.Thetop nut

5.

Tightenthelowersteeringfittingnutuntilthe

steeringheadistight,butdoesnotbindwhen

forksareturned.

6.

Retightenthetopsteeringfittingnut,steering

fittingboltandcrownpinchbolt,inthatorder.

7.

Rechecksteeringadjustmenttomakesure

thereisno binding whenthe forks aremoved

fromlocktolock.Ifnecessary,repeatadjust

mentprocedure.

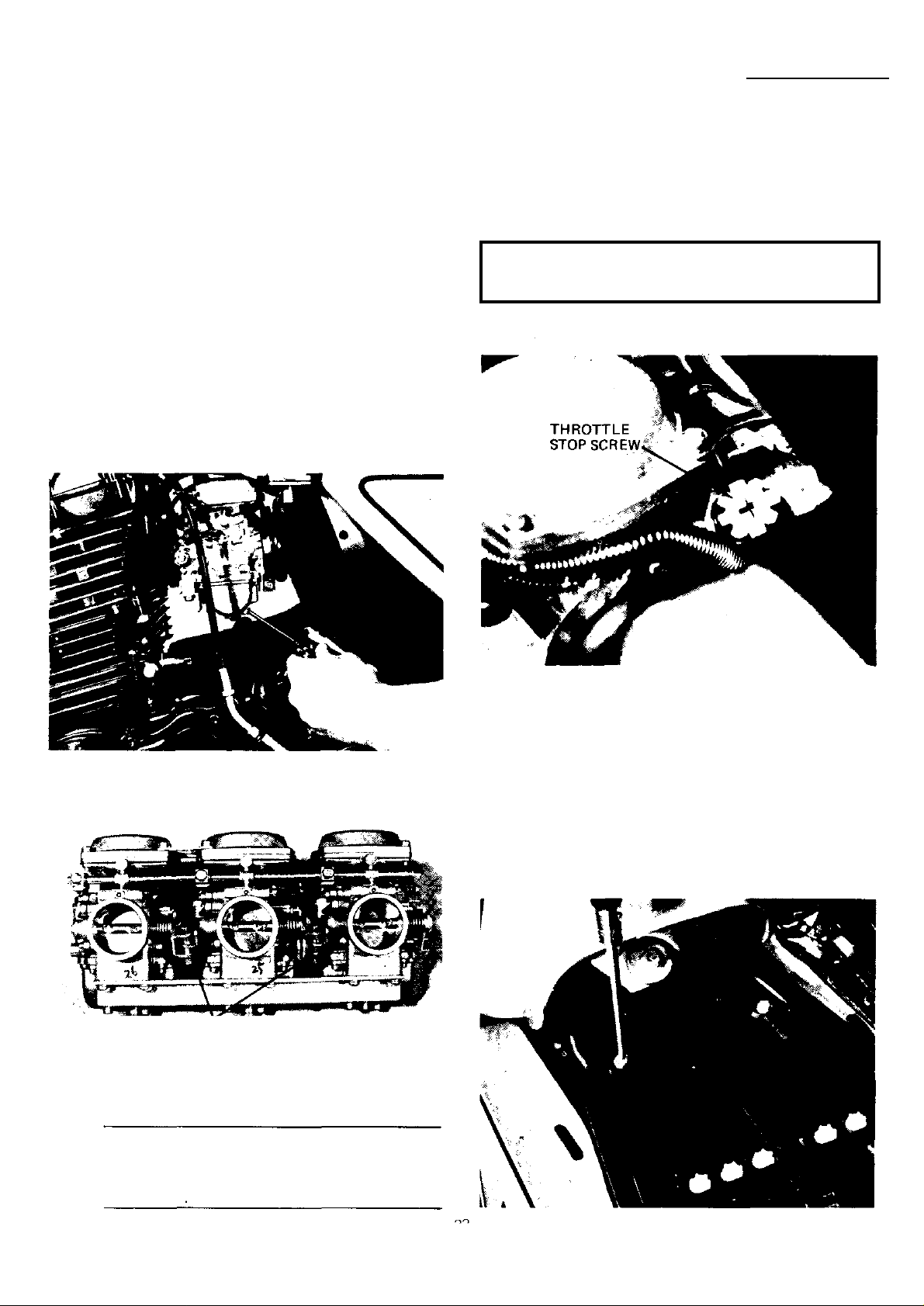

G.ThrottleCableAndGrip Lubrication

serves

asalock nut.

ContactBreaker Gap:

0.3

-

0.4mm (.012~.016 in.)

-

Thethrottletwistgripassemblyshouldbegreased

thetimethatthecableislubricatedsincethegrip

mustberemovedto

cable.Twoscrewsclampthethrottlehousingtothe

handlebar.Oncethesetwo

thecablecanbeheidhightopourinseveraldropsof

lubricant.With the throttlegripdisassembled,coat

theinsidesurfaceof the throttlegripguidetubewith

a

suitable all-purposegreasetocutdownfriction.

H.

LubricationOfLevers,Pedals,Etc.

1.

Lubricatethepivotingpartsofthebrake and

clutchleverswithmotor oil (10W30).

2.Lubricatethe shaft of the brakepedalwith

lithiumsoap

2-5

ELECTRICAL

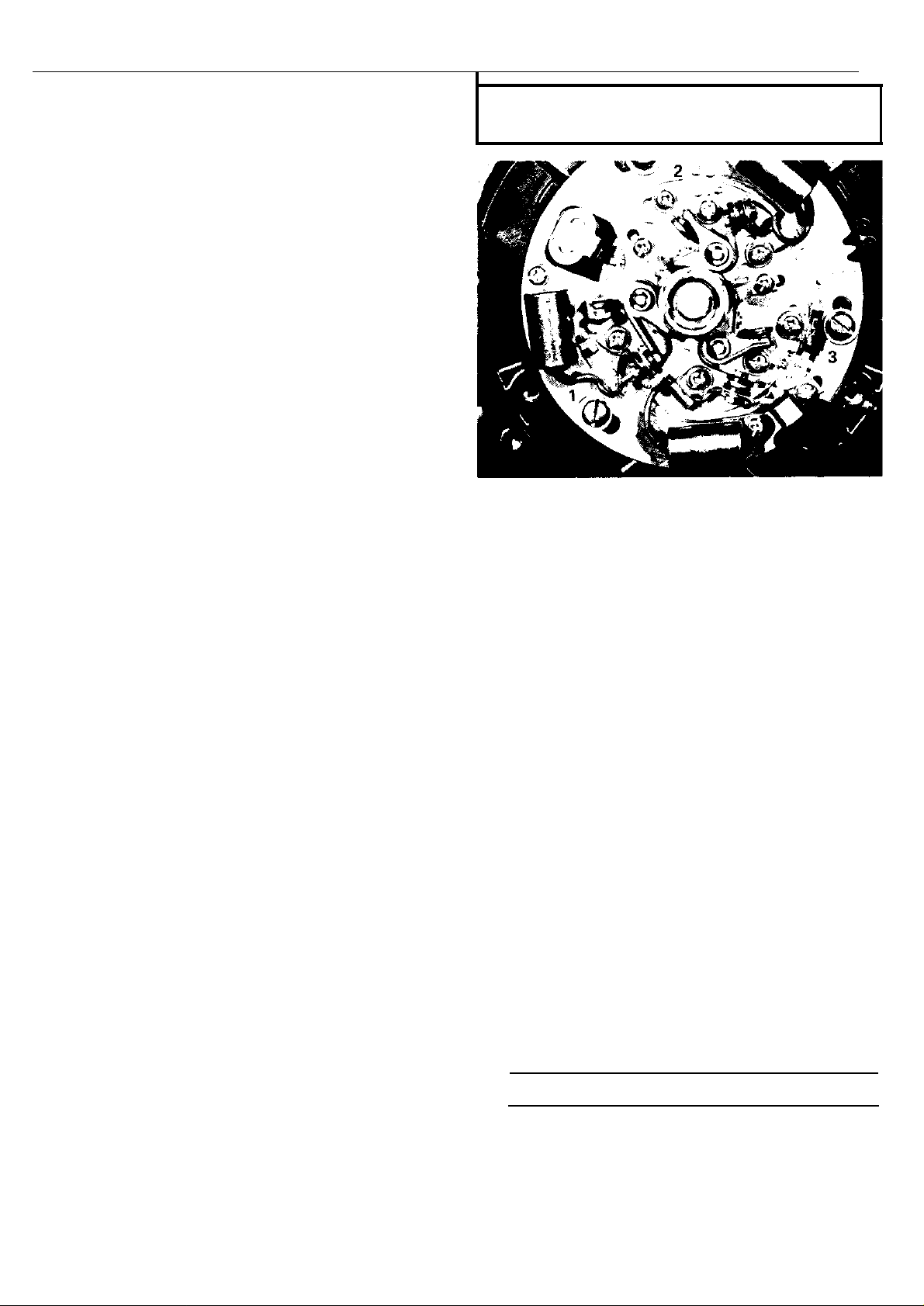

A.ContactBreakerPoint Adjustment

1.Removebreakerpointcover.

2.

Eachcylinderhas

No. 1(left)cylinder

onthebacking plate. The

cylinder

No.3cylinder

plugwires

3.

Checkcontactbreakerpointgap

gap)withfeelergauge.

get

at

theendofthethrottle

are

removed,theendof

grease.

a set

ofbreakerpoints. The

set

is

markedwith

No.

2 (center)

setismarkedwitha"2",andthe

set

is

marked"3".Thespark

are

alsonumbered.

(at

at

a

"1"

largest

Ifnecessary,adjustbylooseningsecuring

screwsandmovingthe

point.

4.Tightenadjustingscrewsandrecheckbreaker

pointgap.

B.

ContactBreakerPointMaintenance

1.Applyafew drops oflightweightlubricantto

thepointcamlubricators.

2.

Thepointscanbelightlysandedwithfine

emerypapertoremovecorrosion. Then place

a

pieceofcleanpaperbetweenthepointsand

let

themclose. Remove thepaper.

untilnoresidueshows.Thepapermaybe

dippedinlacquerthinner or contactpoint

cleaningfluidtoremoveoilorsandingresidue

fromthepointsurface.

3.

Pointreplacement should benecessaryonly

whenpointgapexceedsmaximumtolerance,

whenthe points becomeseverelypitted,orif

the points becomeshortedorshowfaulty

operation.Newpointsmustbecleanedand

adjusted when installed.

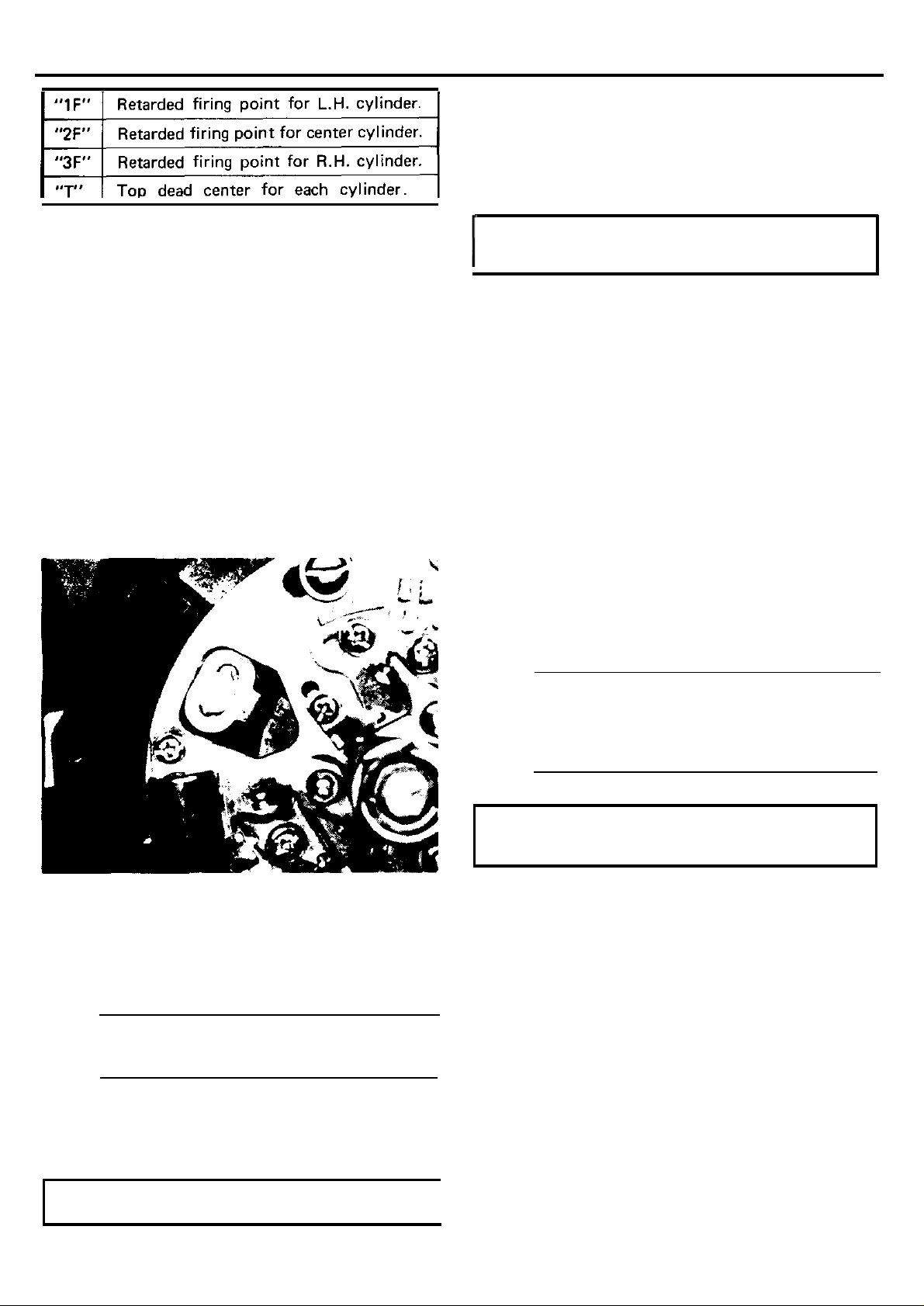

C. IgnitionTiming

1.

Ignition timing ischeckedwithatiminglight

byobservingthe position ofthestationary

pointerandthemarksstampedonthegov

ernorassembly.Thegovernorassembly

markedasfollows:

-

is

8.

upper and

Theaboveprocedureisrecommendedfor

ting ignition timing.However,thefollowing

informationisprovidedsothat the positionof

the

staticpointercanbeverifiedusingadegree

wheel.

set

-

There

lines.TheyindicatetheFullAdvancefiring

rangeforeachcylinder.

ConnecttiminglighttoNo.

2.

IgnitiontimingofNo.1cylindermustbe

first.Connecttiminglightto No.1sparkplug

leadwire.

3.

Startengine

4.

Thestationarypointershouldlineup with the

"1F"

notalign,loosen

screwsandmovethecompletebacking plate

until"1F"andthepointermarksalign.

are

alsothree

timingmarkonthegovernor.Ifitdoes

(3)

pairofunmarked

1

(left)

cylinder.

3

breakerbackingplate

set

Retardedignition:

FullyAdvancedIgnition:

D.

Battery

Apoorlymaintainedbatterywilldeterioratequickly.

Thebatteryfluidshouldbechecked

month.

1.

The

level

lowerlevelmarks.

refilling.Normaltap water containsminerals

which

fillonlywithdistilledwater.

2.Alwaysmakesuretheconnectionsarecorrect

wheninstalling

the

(-)

properlyconnected,properlyrouted,and

notdamagedorobstructed.

are

(+)

terminalandtheblackleadisforthe

terminal.Makesurethebreatherpipe

10°

BTDC

38.5±1.5°

shouldbebetweenthe

Use

only distilled waterfor

harmfultoabattery;therefore,

the

battery. The red lead isfor

at

BTDC

least

once

re

a

-

is

is

5.

Retightenscrew.Checktimingagainforthe

No.

1

cylinder.

6.

Rev

theenginetoabove

shouldindicatetheareaofthe

vance"marksonthegovernor.

NOTE:Retardedignition:

Advancebegins:

FullAdvanceachieved:2,900

7.Repeatprocedure(steps2-7)forremaining

cylinders.Looseneachindividualpoint

semblyplate before adjusting. Retighten

screwsandrechecktiming for eachcylinder.

CAUTION:Neverbend adjusting pointer.

3,000

rpm.Thepointer

1,600'

two

"

fullad

1,100~1,550

as

NOTE: The batterymustbechargedbefore

usingtoinsuremaximumperformance.Failure

toproperlychargethe battery beforefirstuse,

oralow electrolyte

failureofthe battery.

Chargingcurrent:

Charginghours:

E.

Spark

Thesparkplugindicateshow the engineisoperating.

-

If

theengineisoperatingcorrectly.andthemachine

is

beingridden properly, thetipofthe white insulator

aroundthepositiveelectrodeofthesparkplugwillbe

a

mediumtancolor.Iftheinsulator is very darkbrown

orblackcolor, then aplugwithahotterheatrange

might

during the enginebreak-inperiod.Iftheinsulatortip

showsaverylighttanorwhitecolor or isactually

-

purewhiteandglazed,orifelectrodes show signsof

melting,thenasparkplugwithacolderheatrange

required.Remember,the insulator

thepositiveelectrodeofthesparkplugmustbe

medium tan color.Ifitis

timingandignitionadjustments.

Plug

be

required.This situation isquitecommon

level,

willcausepremature

1.4

Amps

10

hrs.

area

not,checkcarburetion,

is

surrounding

a

Thesparkplug must beremovedandchecked.Check

under headlight

springs.

electrodewear,insulatorcolor, and electrode gap.

Sparkpluggap:

0.6~0.7mm(0.02~0.03in.)

Engineheat and combustionchamberdepositswill

causeany spark plugtoslowlybreakdownand erode.

Iftheelectrodesfinallybecometooworn,oriffor

anyreasonyoubelievethesparkplugisnotfunction

ingcorrectly,replace

wayscleanthegasketsurface,useanewgasket,wipe

offany grime thatmightbepresentonthesurfaceof

thesparkplug,andtorque the sparkplug properly.

TighteningTorque:1.5~2.5m-kg

F.

Headlight

1.Headlightbeamadjustment.

it.

Wheninstallingtheplug,al-

ChampionN-7Y

(10.8~18.1ft-lb)

b.Adjustverticallyasfollows:

1) Loosen adjustingscrew

body.

-

Adjustverticallybymovingtheheadlight

body.Whenproper adjustment isdeter

mined,retightenadjustingscrew.

2.Replacingtheheadlightbulb.

-

Whennecessary,adjusttheheadlightbeamas

follows:

a.

Adjusthorizontallybytighteningorloosening

theadjustscrew.

a.

Unhookspringsandpullthedefectiveunitout

of

theshell.

b.

Slipa

c.Adjustheadlightbeam.

newunit into positionandinstall

Toadjusttothe right: Tightenthescrew

Toadjusttothe

left:

Loosenthescrew

NOTE:

It

is

veryfragile.

Takecarenottodamagetheheadlight.

ENGINE OVERHAUL

the"on"position

ating).Disconnectfuelpipes and vacuumpipes

frompetcock.

unless

theengineisoper

-

3-1

ENGINEREMOVAL

NOTE:

toremove

A.

PreparationForRemoval

1.

2.

It

is

notnecessarytoremovetheengine

the

cylinderhead,cylinder, or pistons.

Alldirt,mud,dust

bethoroughlyremovedfrom

theenginebeforeremoval

Thiswill

materialfromenteringtheengine.

Beforeengineremoval

that

equipment so thatyoucanperformaclean

andefficient

helppreventanyharmfulforeign

you

havethe proper tools and cleaning

job.

and

foreign material should

the

exteriorof

and

disassembly.

and

disassembly,besure

3. Duringdisassemblyoftheengine,cleanand

place

all

parts

in

traysinorderofdisassembly.

Thiswillspeedassemblytimeandhelpinsure

correctreinstallationof

all

engine parts.

Liftseatand remove fuel

2.

Removefueltank.

tank

holdingbolt.

4.

Placemachineoncenterstand.Startengine

andallowittowarm up. Stopengineand

drainengine/transmissionoil.

5.

Removeoil filter elementtodrainoilfilter.

6.

If

middlegearcaseistoberemoved,drain

middlegearoil.

7.

Removeairscoopfromcylinderheadcover.

C.

Muffler,Footrest,BrakePedal

Removerearbrakepedalandpassengerright

footrest.

2.

Remove exhaust pipeholdingscrewsfromcy

linderhead.

-

B.

Fuel

TankRemoval

1.

Turnfuelpetcocksto"on"(thereisno"off

position-fuelwillnotflow from apetcockon

"

3. Removeexhaust pipes

assembly.

and

muffler

as

an

D.

to

left

Remove clutch

-

left.

at

SideCover,

1.

2.

Air

CleanerCase

Removeleftandrightside covers.

DOHC

Removescrewsholding intake silencers(left

andright).Removeintakesilencers.

4.

Remove

frame.Notegroundwireconnection

frame bracket.

5.

Pull

cablefromholder attached tothe left carbu

retor.Liftcarburetorsbackand

Removethrottlecablefromcarburetors.

bolts

aircleanercasetotherear.

holdingaircleanercase

to

on

the

3.

Loosen clamps

ercaseandintakemanifolds.Loosenbreather

hoseclamp

holding

at

air

carburetorstoairclean

cleanercasejunction.

6. Removeaircleanercase,

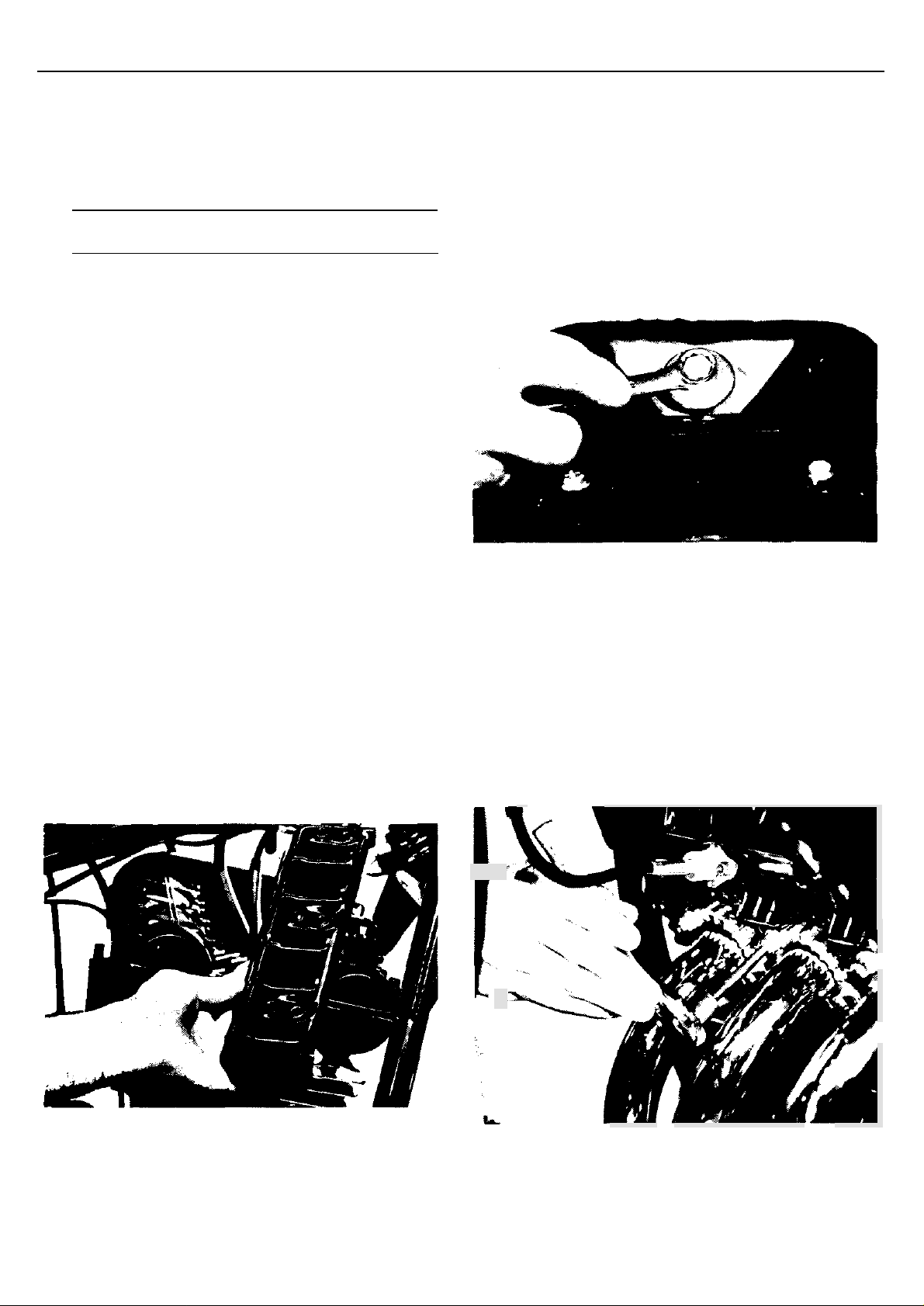

E.

WiringandCables

-

1. Pull

backrubbercoveronclutchadjustor

engine.Disconnectclutchcable.

2.

shaft coupling.

Removesparkplugwiresandtachometercable.

3.

Removetwo

cover.Removestartermotorcover.Disconnect

electricstartercable.

(2)

screwsholdingstartermotor

F.DriveShaftJoint

1.

Pull

rubberboot from driveshaftcouplingto

exposefour

(4)

bolts.

4.

Disconnectgroundwirefrom

case.

5.

Disconnectwiringharnesscouplersonleftside

ofmachine.Removeignition wiring (orange,

yellow, grey, bluewires),generatorwiring

(whitewires),andfieldwiring(green,black

wires).Positionwires

ly

removed.

so that

top

ofengine

theycanbesafe

G.Removal

-

Removefour

2.

Removethree

1.

frame.Removefootrestswiththetwo

enginemountingbolts.

(4)

bolts

ondrive

(3)

enginemountingboltsfrom

(2)

rear

2.

Slideengineforward.Remove engine tothe

right.Positionaboxor other support tothe

rightofthemachineforassistancewhenre

movingtheengine.

3-2

ENGINE

A.

CylinderHeadandCylinderRemoval

NOTE:

movedwithoutremovingengine.

1.

DISASSEMBLY

Cylinderheadandcylindercanbere

Removecylinderheadcover.

-

-

Loading...

Loading...