XQ125

2001

XQ150

5HT1-AE2

SERVICE MANUAL

EASM0000

XQ125 / XQ150

SERVICE MANUAL

© 2001 by MBK Industrie

2nd edition, April 2001

All rights reserved.

Any reproduction or unauthorized

use without the written

permission of MBK Industrie

is expressly prohibited.

EAS00005

IMPORTANT MANUAL INFORMATION

Particularly important information is distinguished in this manual by the following.

The Safety Alert Symbol means ATTENTION! BECOME ALERT! YOUR SAFETY

IS INVOLVED!

Failure to follow WARNING instructions

could result in severe injury or death to

the scooter operator, a bystander or a person checking or repairing the scooter.

A CAUTION indicates special precautions that must be taken to avoid damage

to the scooter.

A NOTE provides key information to make procedures easier or clearer.

NOTE:

WARNING

CAUTION:

EASM0001

NOTICE

This manual was produced by the MBK Industrie primarily for use by Yamaha and MBK dealers and

their qualified mechanics. It is not possible to include all the knowledge of a mechanic in one manual.

Therefore, anyone who uses this book to perform maintenance and repairs on Yamaha and MBK

vehicles should have a basic understanding of mechanics and the techniques to repair these types

of vehicles. Repair and maintenance work attempted by anyone without this knowledge is likely to

render the vehicle unsafe and unfit for use.

MBK Industrie is continually striving to improve all of its models. Modifications and significant changes in specifications or procedures will be forwarded to all authorized Yamaha and MBK dealers and

will appear in future editions of this manual where applicable.

NOTE:

Designs and specifications are subject to change without notice.

TECHNICAL DOCUMENTATION

MBK INDUSTRIE

EAS00007

HOW TO USE THIS MANUAL

This manual is intended as a handy, easy-to-read reference book for the mechanic. Comprehensive

explanations of all installation, removal, disassembly, assembly, repair and check procedures are

laid out with the individual steps in sequential order.

햲 The manual is divided into chapters. An abbreviation and symbol in the upper right corner of each

page indicate the current chapter. Refer to "SYMBOLS".

햳 Each chapter is divided into sections. The current section title is shown at the top of each page,

except in Chapter 3 ("PERIODIC CHECKS AND ADJUSTMENTS"), where the sub-section title(s)

appears.

햴 Sub-section titles appear in smaller print than the section title.

햵 To help identify parts and clarify procedure steps, there are exploded diagrams at the start of each

removal and disassembly section.

햶 Numbers are given in the order of the jobs in the exploded diagram. A circled number indicates

a disassembly step.

햷 Symbols indicate parts to be lubricated or replaced. Refer to "SYMBOLS".

햸 A job instruction chart accompanies the exploded diagram, providing the order of jobs, names of

parts, notes in jobs, etc.

햹 Jobs requiring more information (such as special tools and technical data) are described

sequentially.

ENG

ENG

EASM0025

CYLINDER AND PISTON

Removing the cylinder and piston

Remove the parts in the order listed.

Cylinder head

Refer to “CYLINDER HEAD” section.

1 Cylinder bolt

2

2 Timing chain guide (exhaust side)

1

3 Cylinder

1

4 Dowel pin

2

5 Cylinder gasket

1

6 Piston pin clip

2

7 Piston pin

1

8 Piston

1

9 Piston ring (top)

1

10 Piston ring (2nd)

1

11 Oil ring

1

For installation, reverse the removal

procedure.

EAS00253

REMOVING THE CYLINDER AND PISTON

1. Remove:

•piston pin clip 햲

•piston pin 햳

•piston 햴

CAUTION:

Do not use a hammer to drive the piston pin

out.

NOTE:

•Before removing the piston pin clip, cover the

crankcase opening with a clean rag to prevent

the piston pin clip from falling into the crankcase.

• Before removing the piston pin, deburr the

piston pin clip’s groove and the piston’s pin

bore area. If both areas are deburred and the

piston pin is still difficult to remove, remove it

with the piston pin puller.

Piston pin puller

90890-01304

2. Remove:

•top ring

•2nd ring

•oil ring

NOTE:

When removing a piston ring, open the end gap

with your fingers and lift the other side of the ring

over the piston crown.

EAS00255

CHECKING THE CYLINDER AND PISTON

1. Check:

•piston wall

•cylinder wall

Vertical scratches → Rebore or replace the

cylinder, and replace the piston and piston

rings as a set.

4 - 23 4 - 24

CYLINDER AND PISTON CYLINDER AND PISTON

Order Job/Part

Q’ty Remarks

햲

햳

햴

FWD

1

2

3

4

5

6

7

8

9

10

11

T

.R

12 Nm (1.2 m•kg)

햲

햹

햳햴햵

햶

햷

햸

COOL

GEN

INFO

ENG

SPEC

햲햳

햵햴

햶

햷

햸햹

햺햻

햽

햾

햿헀

헁헂

헅

쎻

22

쎻

23

헄헆

쎻

21

쎻

24

쎻

25

EAS00008

SYMBOLS

The following symbols are not relevant to every

vehicle.

Symbols

햲 to 햺 indicate the subject of each

chapter.

햲 General information

햳 Specifications

햴 Periodic checks and adjustments

햵 Engine

햶 Cooling system

햷 Carburetor

햸 Chassis

햹 Electrical system

햺 Troubleshooting

Symbols

햻 to 헃 indicate the following.

햻 Serviceable with engine mounted

햽 Filling fluid

햾 Lubricant

햿 Special tool

헀 Tightening torque

헁 Wear limit, clearance

헂 Engine speed

헃 Electrical data

Symbols

헄 to 쎻

23

in the exploded diagrams indicate

the types of lubricants and lubrication points.

헄 Engine oil

헅 Gear oil

헆 Molybdenum disulfide oil

쎻

21

Wheel bearing grease

쎻

22

Lithium soap base grease

쎻

23

Molybdenum disulfide grease

Symbols

쎻

24

to 쎻25 in the exploded diagrams

indicate the following.

쎻

24

Apply locking agent (LOCTITE®)

쎻

25

Use a new one

T.R

TRBL

SHTG

ELEC

CHAS

CARB

CHK

ADJ

헃

GENERAL INFORMATION

SPECIFICATIONS

PERIODIC CHECKS AND

ADJUSTMENTS

ENGINE OVERHAUL

COOLING SYSTEM

CARBURETOR

CHASSIS

ELECTRICAL SYSTEM

TROUBLESHOOTING

1

2

3

4

6

7

8

9

TRBL

SHTG

GEN

INFO

SPEC

CHK

ADJ

ENG

CARB

ELEC

CHAS

5

COOL

EAS00010

TABLE OF CONTENTS

1

GEN

INFO

GEN

INFO

CHAPTER 1.

GENERAL INFORMATION

SCOOTER IDENTIFICATION ........................................................................1-1

VEHICLE IDENTIFICATION NUMBER .................................................... 1-1

MODEL LABEL ........................................................................................ 1-1

FEATURES ................................................................................................... 1-2

OIL INDICATOR LIGHT ...........................................................................1-2

ODOMETER/TRIPMETER READING MODE .........................................1-2

BATTERY VOLTAGE/FUEL GAUGE ......................................................1-2

THE CLOCK .............................................................................................1-3

AUTO-CHOKE SYSTEM .........................................................................1-3

IMPORTANT INFORMATION ...................................................................... 1-4

PREPARATION FOR REMOVAL AND DISASSEMBLY ........................ 1-4

REPLACEMENT PARTS ........................................................................ 1-4

GASKETS, OIL SEALS AND O-RINGS .................................................. 1-4

LOCK WASHERS/PLATES AND COTTER PINS................................... 1-5

BEARINGS AND OIL SEALS.................................................................. 1-5

CIRCLIPS................................................................................................ 1-5

CHECKING THE CONNECTIONS ............................................................... 1-6

SPECIAL TOOLS ..........................................................................................1-7

GEN

INFO

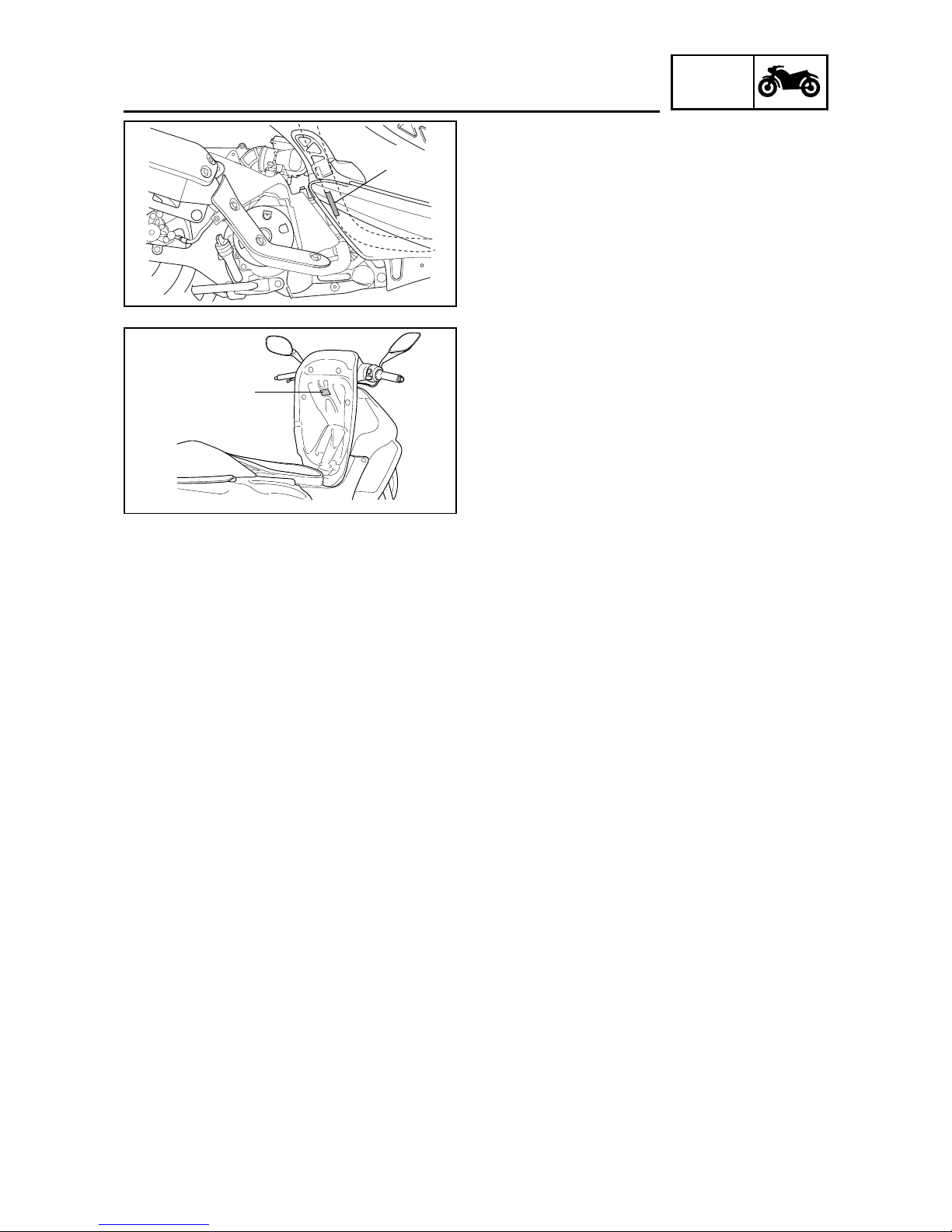

SCOOTER IDENTIFICATION

EAS00015

GENERAL INFORMATION

SCOOTER IDENTIFICATION

EASM0002

VEHICLE IDENTIFICATION NUMBER

The vehicle identification number 햲 is stamped

into the frame.

EASM0003

MODEL LABEL

The model label 햲 is affixed under the seat.

This information will be needed to order spare

parts.

ZAUM0113

햲

ZAUM0114

햲

1-1

GEN

INFO

1-2

FEATURES

EASM0004

FEATURES

OIL INDICATOR LIGHT

• FUNCTION

Pulses (travel distance signals) from the speedometer are counted and cause the oil indicator light

to come on at 500 km for the first time and thereafter every 3,000 km. In this way, the light indicates

the time for oil change.

• RESETTING PROCEDURE

To reset the oil change indicator light

1) Press the “TRIP” button while turning the key to “ON”.

2) Release the button and the oil change indicator light will go off.

NOTE:

To reset the oil change indicator light before the periodic oil change interval has been reached, follow

the above procedure.

ODOMETER/TRIPMETER READING MODE

The odometer and tripmeter can be set to count in either miles or kilometers according to the following

procedure.

1) Turn the key to “ON”.

2) Press the “TRIP” button until the current mode appears in the dispaly:

“CONT” (continental) for kilometer mode and “EnGL” (English) for the mile mode.

3) Press the “TRIP” button to switch mode.

4) Press the “TRIP” button for two seconds to confirm the setting.

NOTE:

• The odometer/tripmeter reading mode can be changed any number of times while the odometer

reading is below 10, but it cannot changed anymore after the reading has reached 10.

• Switching between the mile and the kilometer mode does not change or convert the current odometer/

tripmeter reading.

BATTERY VOLTAGE/FUEL GAUGE

When the key is turned to “OFF”, the voltage/fuel gauge indicates the battery voltage.

NOTE:

If the battery voltage drops to 10V, refer to “CHECKING THE BATTERY” section in chapter 3.

When the key is turned to “ON”, the voltage/fuel gauge indicates the amount of fuel in the fuel tank

after indicating the battery voltage for two seconds.

GEN

INFO

THE CLOCK

• Setting the clock

To set the clock:

1) Make sure that the key is turned to “OFF”.

2) Press the “TRIP” button for two seconds and the hour display will flash.

3) Press the “TRIP” button to set the hours.

4) Press the “TRIP” button for two seconds, and the first minute digit will flash.

5) Press the “TRIP” button to set the first minute digit.

6) Press the “TRIP” button for two more seconds, and the second minute digit will flash.

7) Press the “TRIP” button to set the second minute digit.

8) Press the “TRIP” button for two seconds to set the clock.

AUTO-CHOKE SYSTEM

This system is the parallel connection of the ignitor unit circuit and the thermo switch as shown,

detecting the engine temperature, and facilitates the restarting with the warm engine.

• Circuit diagram

• Auto-choke operation

FEATURES

Main switch

Fuse

Battery

Thermo

switch

Auto-choke

Ignitor unit

C.P.U

Ignition

Engine condition

Start with the Crank with the Crank with the Restart with the

cold engine cold engine warm engine warm engine

Thermo switch OFF OFF ON ON

Ignitor unit circuit OFF ON ON OFF

Auto-choke Activates Activates Not activate Not activate

1-3

GEN

INFO

EAS00020

IMPORTANT INFORMATION

PREPARATION FOR REMOVAL AND

DISASSEMBLY

1.Before removal and disassembly, remove all

dirt, mud, dust and foreign material.

2.Use only the proper tools and cleaning equipment.

Refer to the “SPECIAL TOOLS”.

3. When disassembling, always keep mated parts

together. This includes gears, cylinders, pistons and other parts that have been “mated”

through normal wear. Mated parts must always be reused or replaced as an assembly.

4.During disassembly, clean all of the parts and

place them in trays in the order of disassembly. This will speed up assembly and allow for

the correct installation of all parts.

5.Keep all parts away from any source of fire.

EAS00021

REPLACEMENT PARTS

1.Use only genuine Yamaha and MBK parts for

all replacements. Use oil and grease recommended by Yamaha or MBK for all lubrication

jobs. Other brands may be similar in function

and appearance, but inferior in quality.

EAS00022

GASKETS, OIL SEALS AND O-RINGS

1.When overhauling the engine, replace all gaskets, seals and O-rings. All gasket surfaces,

oil seal lips and O-rings must be cleaned.

2.During reassembly, properly oil all mating

parts and bearings and lubricate the oil seal

lips with grease.

IMPORTANT INFORMATION

1-4

Loading...

Loading...