Yamaha WR 250f Assembly Manual

WR250FR

5UM-28107-10

ASSEMBLY MANUAL

LIT-11666-16-48

WR250FR

ASSEMBLY MANUAL

©2002 by Yamaha Motor Corporation, U.S.A.

First Edition, December 2002

All rights reserved.

Any reproduction or unauthorized use

without the written permission of

Yamaha Motor Corporation, U.S.A.

is expressly prohibited.

Printed in U.S.A.

LIT-11666-16-48

EAA00002

FOREWORD

This Assembly Manual contains the information required for the correct reassembly of this Yamaha

machine prior to delivery to the customer. Since some external parts of the machine have been

removed at the Yamaha factory for the convenience of packing, assembly by the Yamaha dealer is

required. It should be noted that the assembled machine should be thoroughly cleaned, inspected,

and adjusted prior to delivery to the customer.

EAA00005

NOTICE

The service specifications given in this assembly manual are based on the model as manufactured.

Yamaha Motor Company, Ltd. is continually striving to improve all of its model. Modifications and significant changes in specifications or procedures will be forwarded to all authorized Yamaha dealers and will

appear in future editions of this manual where applicable.

The procedures below are described in the order that the procedures are carried out correctly and completely. Failure to do so can result in poor performance and possible harm to the machine and/or rider.

w

Failure to follow WARNING instructions could result in se

vere injury or death to

the machine operator, a bystander, or a person inspecting or repairing the

machine.

A CAUTION indicates special precautions that must be taken to avoid damage to

the machine.

CAUTION:

A NOTE provides key information to make procedures easier or clearer.

NOTE:

CONCERNING CRATE DAMAGE:

Follow the instructions in the Dealer Warranty Handbook, Procedure Section.

The Safety Alert Symbol means ATTENTION! BECOME ALERT! YOUR SAFETY

IS INVOLVED!

!!

Particularly important information is distinguished in this manual by the following notations.

EAA00001

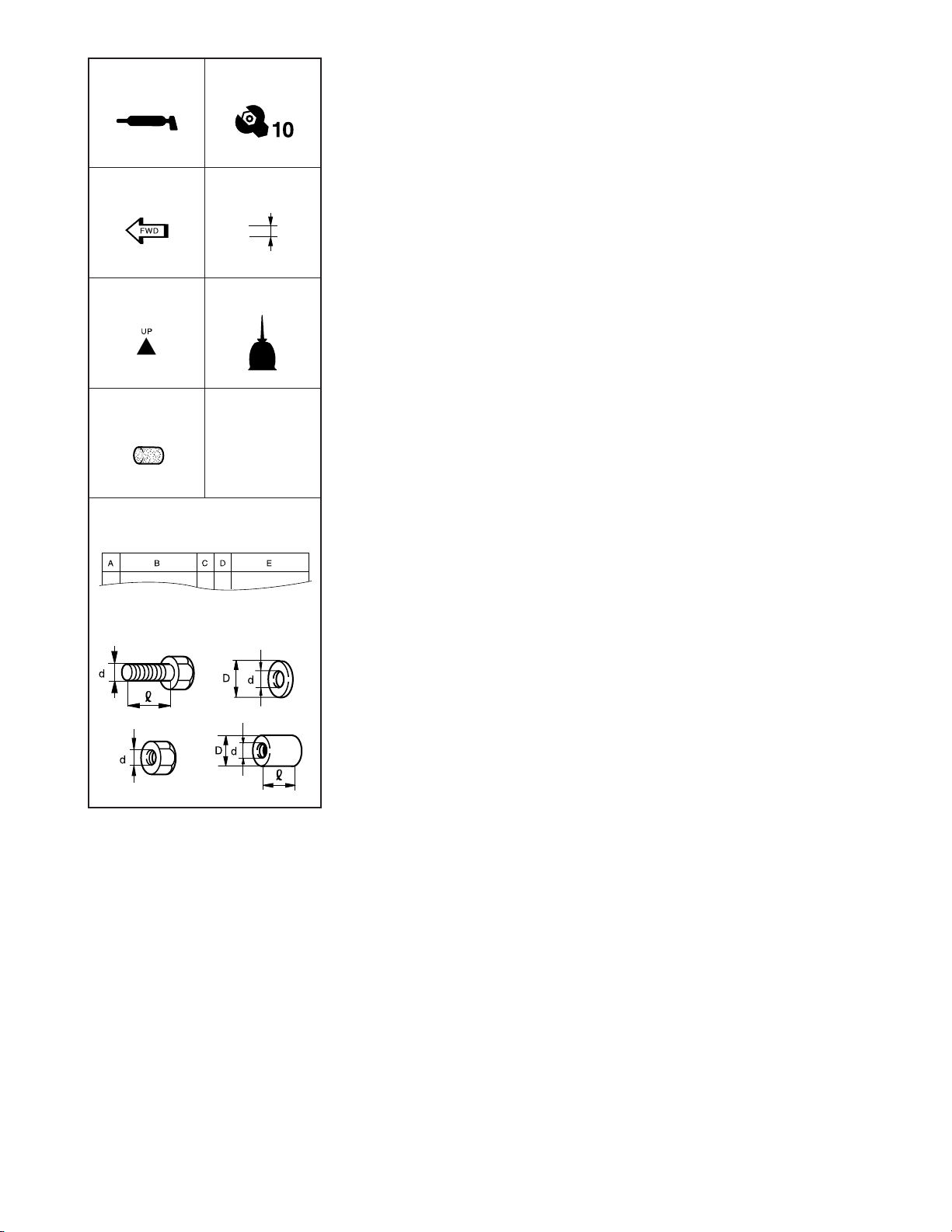

EAA00008

SYMBOLS USED IN

ASSEMBLY MANUAL

In order to simplify descriptions in this

assembly manuals, the following symbols

are used:

(1) Coat with lithium-soap-based-grease.

(2) Tighten to 10 Nm.

(10 Nm = 1.0 mdkg = 7.2 ftdlb)

(3) Towards the front of the machine.

(4) Clearance required.

(5) Install so that the arrow mark faces

upward.

(6) Apply a motor oil.

(7) Made of rubber or plastics.

(8)

A: Ref No. (indicating the order of

operations.)

B: Part name

C: Quantity of parts per machine.

D: Place where parts are held.

V: Stored in vinyl bag.

C: Stored in carton box.

S: Fixed inside the steel frame,

and/or contained in the styrofoam tray (upper or lower).

*: Temporarily installed or secured.

E: Size or material of parts.

d/D: Diameter of part.

l: Length of part.

ex, D = 5 (0.2) = 5 mm (0.2 in)

(1) (2)

(3) (4)

(5) (6)

(7)

(8)

(1) (2)

(3)

(4)

EAA00040

PREPARATION

To assemble the machine correctly, supplies (e.g. oils, greases, and shop rags)

and sufficient working space are required.

Workshop

The workshop where the machine is assembled, should be clean, specious, and have a

level floor.

Self-protection

Protect your eyes with suitable safety

glasses or goggles when using compressed air, when grinding or when doing

any operation which may cause particles

to fly off.

Protect hands and feet by wearing safety

gloves and shoes.

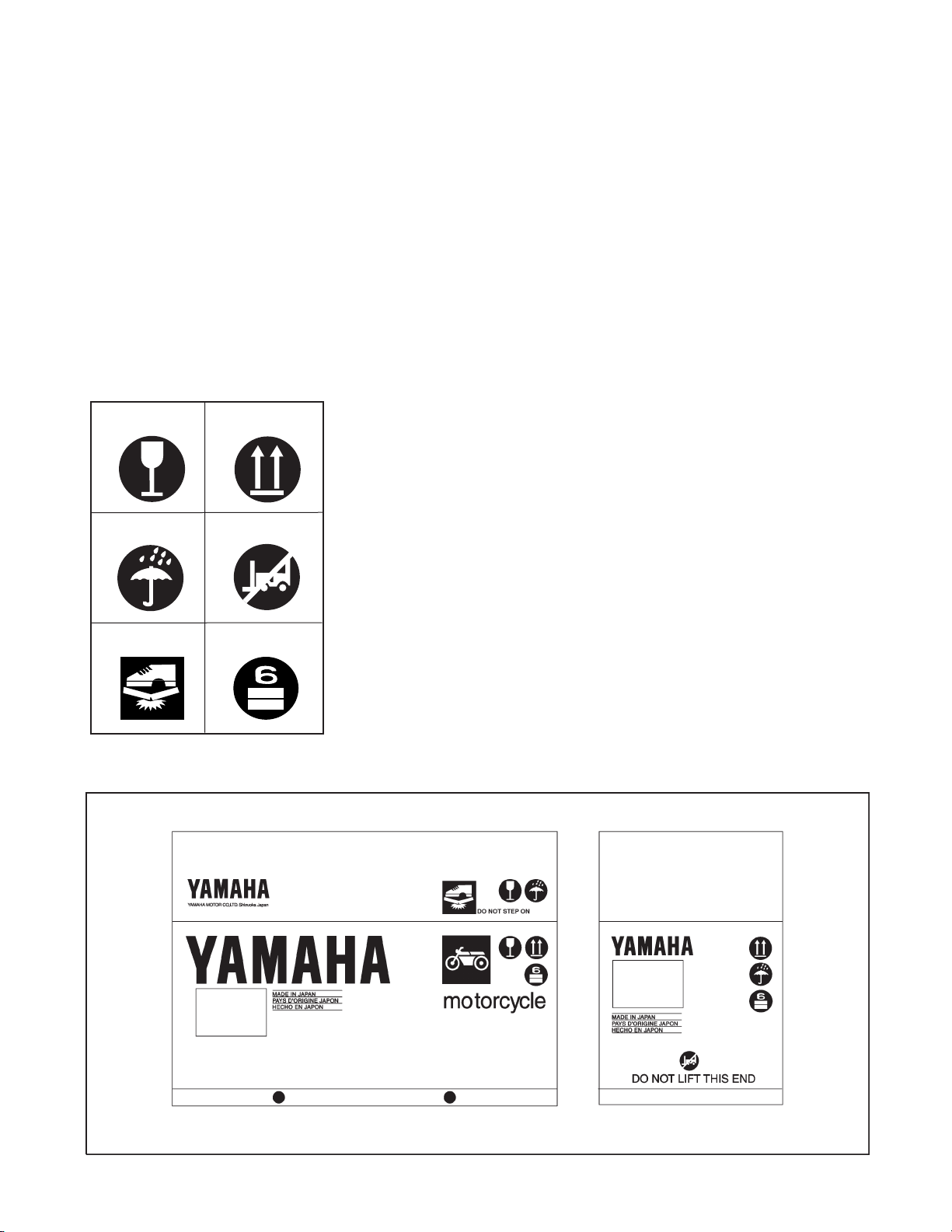

EAA00050

SYMBOLS USED ON

CRATE CARTON

(1) Contents of the transport package are

fragile, therefore the package must be

handled with care.

(2) Indicates correct upright position of

the transport package.

(3) Transport package must be kept away

from rain.

(4) Insertion of the forklift arm from this

side will cause damage.

(5) Do not step anywhere on the transport

package.

(6) Up to 6 of the transport packages can

be piled up.

(7)

(7)

(7) Yellow label

Lift arm insertion position

If the forklift arms cannot be inserted

under the transport package in alignment with the two yellow labels, adjust

the arms so that they are positioned

evenly in relation to these marks while

taking care not to damage the package

contents.

(5)

(6)

EAA00060

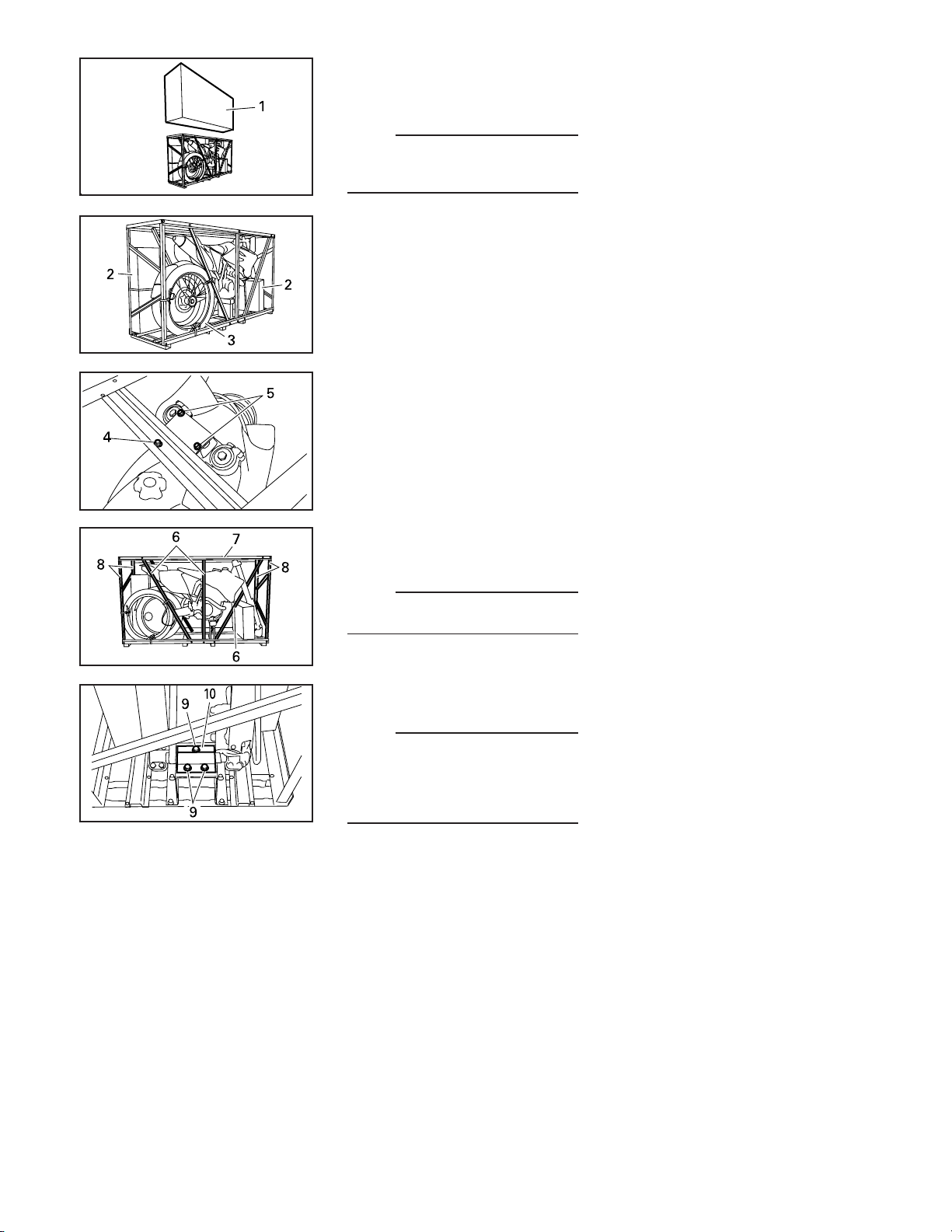

UNPACKING

1. Remove the frame cover (1).

NOTE:

To remove the frame cover, cut the vinyl

bands around the cover using a cutter or

scissors.

2. Remove the carton boxes (2), front tire

(3).

3. Remove the packing frame bolt (4),

and handlebar holder bolts (5).

4. Remove the packing frames (in order

of sideways (6), upward (7), and

front/back (8)).

NOTE:

Hold the frame while removing the frame

bolts.

5. Remove the bolts (9). (front axle fixed

plate (10)).

NOTE:

Before starting the assembly, check for

damaged or missing parts. Check the

parts contained in the carton boxes and

on the machine for damage, scratches

and other defects.

-1-

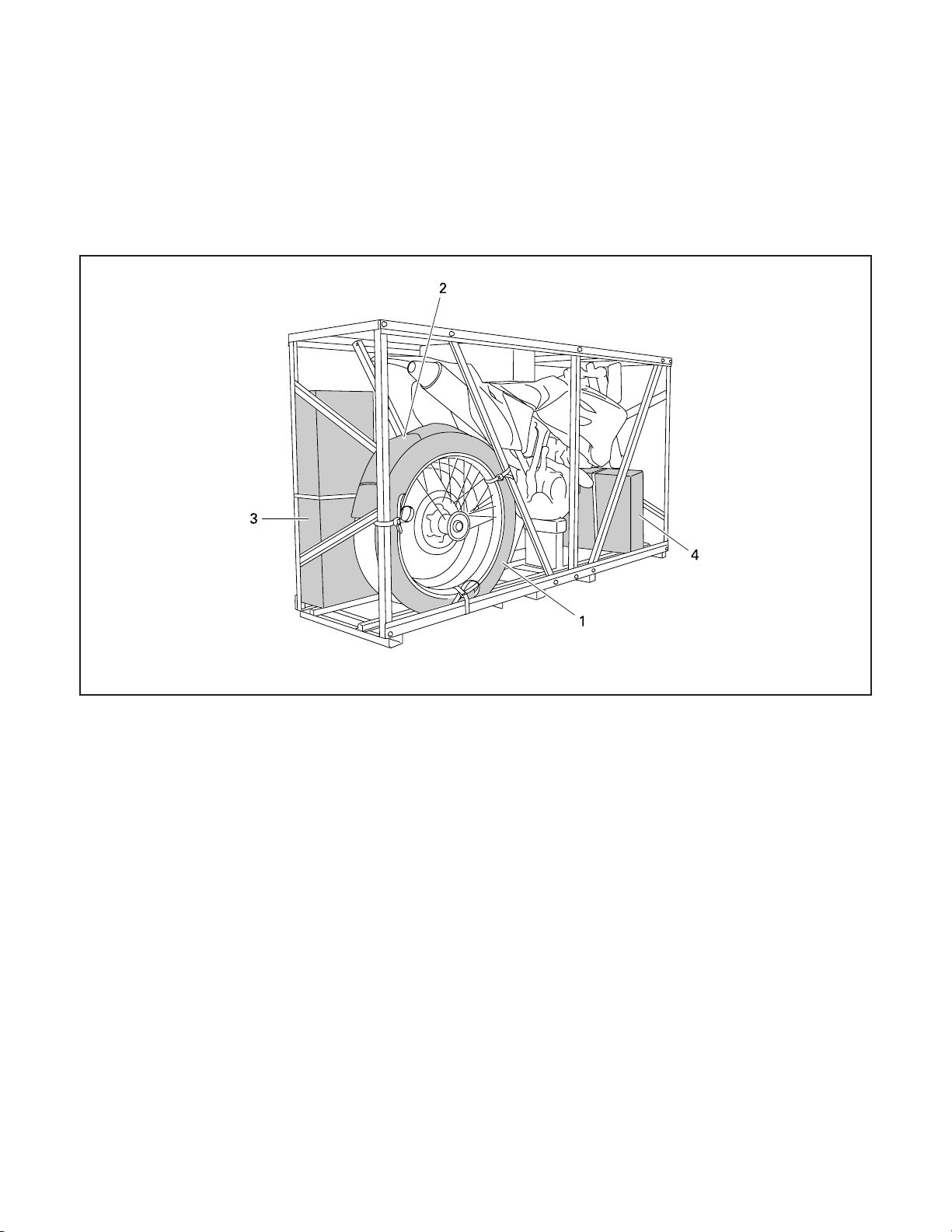

EAA00070

PARTS LOCATION

1. Front wheel

2. Front fender

3. Carton Box 1

4. Carton Box 2

-2-

Packing frame

1. Front wheel

2. Front fender

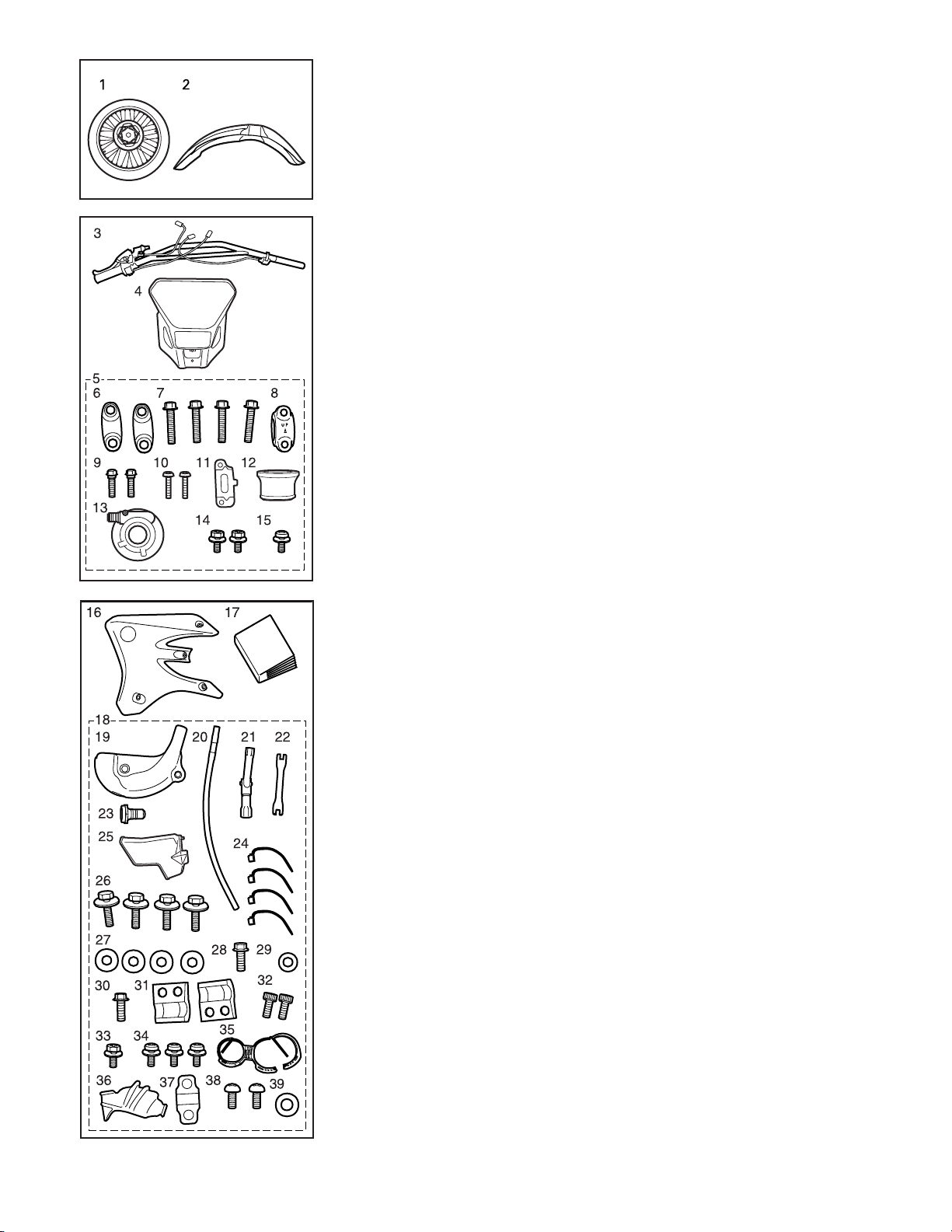

EAA00080

Carton Box 1

3. Handlebar

4. Headlight

5. Plastic bag

6. Handlebar upper holder

7. Flange bolt [d=8 (0.31), l=35 (1.38)]

8. Master cylinder bracket

9. Flange bolt [d=6 (0.24), l=22 (0.87)]

10.Panhead screw (light switch) [d=4

(0.16), l=14 (0.55)]

11.Bracket (light switch)

12.Collar (front wheel axle)

13.Trip meter gear unit

14.Flange bolt (headlight) [d=6 (0.24),

l=10 (0.39)]

15.Panhead screw with plain washer

(headlight) [d=6 (0.24), l=12 (0.47)]

Carton Box 2

16.Air scoop (left)

17.Owner’s service manual

18.Plastic bag

19.Brake hose cover

20.Fuel tank breather hose

21.Spark plug wrench

22.Nipple wrench

23.Boot (adjust nut)

24.Handlebar clamp

25.Boot (clutch lever)

26.Hexagon bolt with plain washer (front fender)

[d=6 (0.24), l=20 (0.79)]

27.Collar (front fender) [d=6 (0.24)]

28.Flange bolt (brake hose cover)

[d=6 (0.24), l=12 (0.47)]

29.Plain washer (brake hose cover)

[d=8 (0.31)]

30.Flange bolt (brake hose cover)

[d=8 (0.31), l=20 (0.79)]

31.Brake hose holder

32.Hexagon socket bolt (brake hose holder)

[d=6 (0.24), l=14 (0.55)]

33.Hexagon bolt with plain washer (air scoop)

[d=6 (0.24), l=16 (0.63)]

34.Panhead screw with plain washer (air scoop)

[d=6 (0.24), l=11 (0.43)]

35.Cable clamp (handlebar)

36.Boot [hot starter (choke) lever]

37.Bracket (trip meter cable)

38.Button head bolt (trip meter cable)

[d=5 (0.20), l=8 (0.31)]

39.Steering shaft cap

-3-

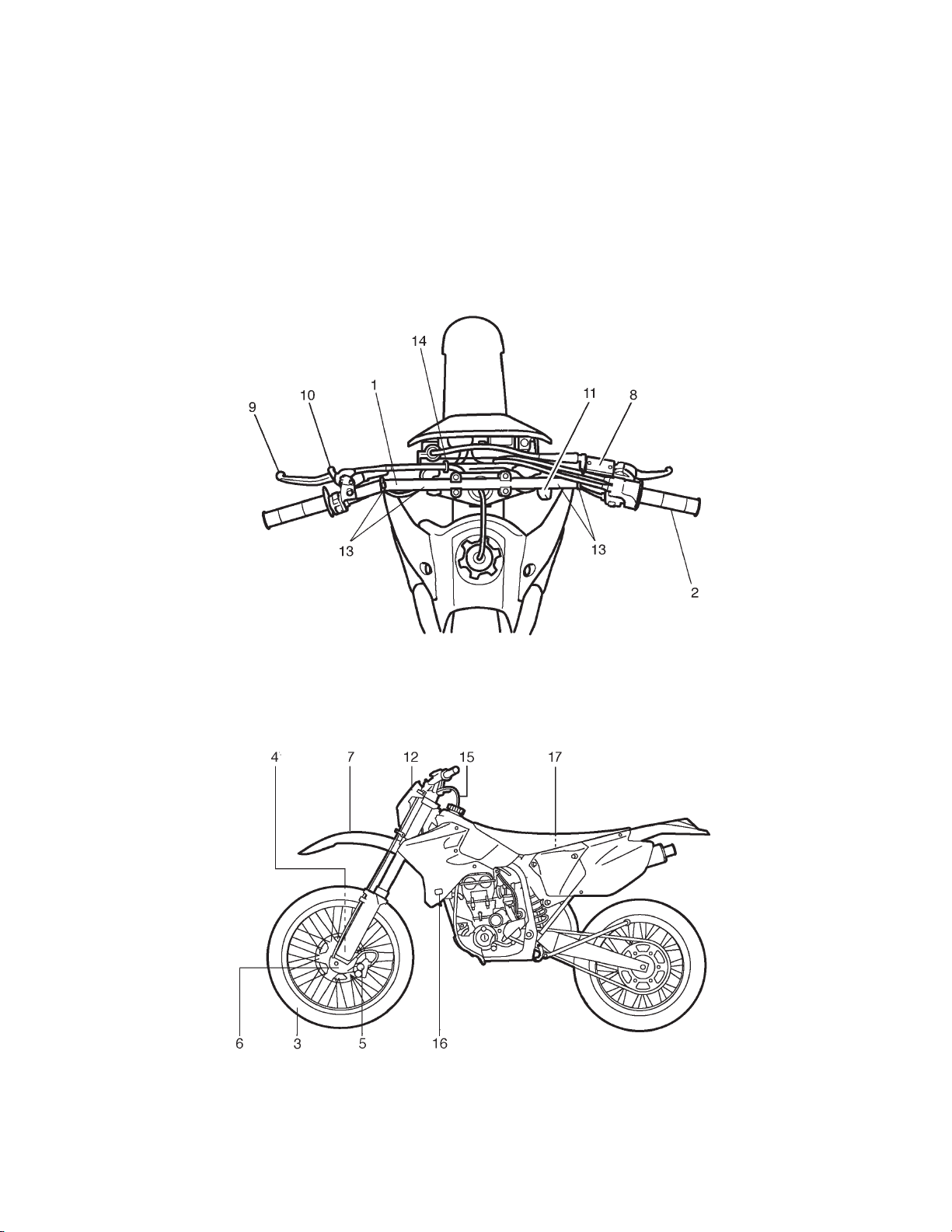

EAA00100

SETUP PROCEDURES

Perform the setup procedures in the order indicated by the numbers.

Always follow the order as shown.

-4-

1 Handlebar 1 C

2 Handlebar upper holder 2 V

3 Flange bolt 4 V d=8 (0.31), l=35 (1.38)

-5-

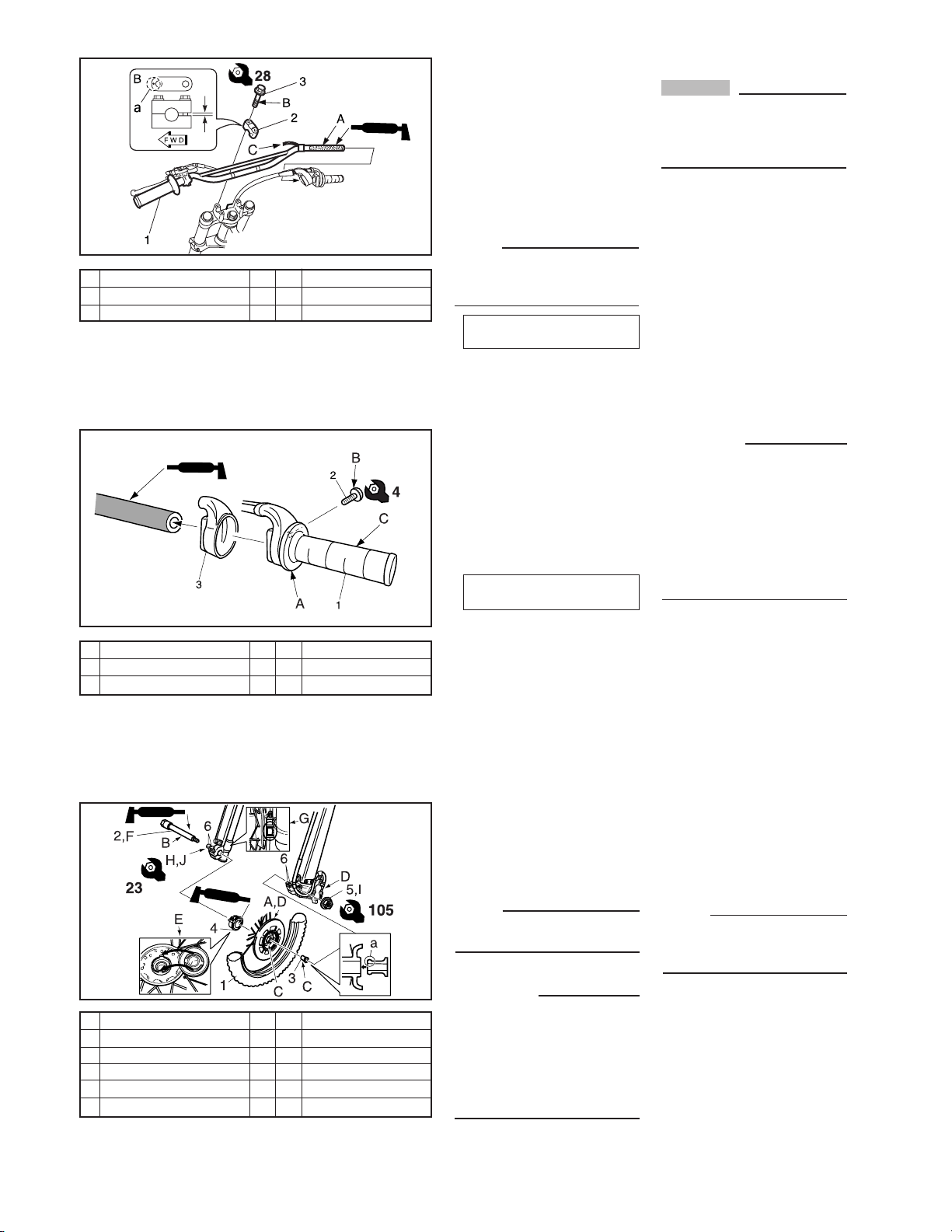

EAA00200*

1. HANDLEBAR

A: Clean the right handlebar end.

Apply light coat grease.

B: First tighten the bolts on the

front side of the handlebar

holder, and then tighten the

bolts on the rear side to specification.

NOTE:

The upper handlebar holder

should be installed with the

punched mark (a) forward.

Bolt:

28 Nm (2.8 mdkg, 20 ftdlb)

EAA00018

2. THROTTLE GRIP

A: Slip the throttle grip over the

right handlebar completely

and then slide it back about 2

mm (0.08 in).

B: Tighten the screws to specifi-

cation.

Screw:

4 Nm (0.4 mdkg, 2.9 ftdlb)

C: Check the throttle grip for

smooth action.

W

D The throttle cables should

not be twisted, and make

sure that the throttle grip

rotates on the handlebar

freely, without binding.

D Proper cable routing is

essential to assure safe

machine operation.

Refer to "CABLE ROUTING".

C: Connect the couplers.

CAUTION:

Proper cable and lead routing

is essential to assure safe

machine operation. Refer to

"CABLE ROUTING".

EAA000205*

3. FRONT WHEEL

A: Clean the brake disc.

B: Clean the front wheel axle.

C: Clean the collars.

NOTE:

Install the collars with its position

(a) facing the wheel.

D:

W

Take care not to get grease on

the brake disc or inner surface

of the brake pads. If you do so,

clean using a rag dampened

with a solvent. Foreign material on the braking surface can

cause impaired braking action.

E: Make sure the two projections

in the wheel hub are meshed

with the two slots in the trip

meter gear unit.

F: Lift the front wheel and install

the front wheel axle.

NOTE:

Do not depress the brake lever

when the caliper is off the brake

disc.

G: Before tightening the front

wheel axle, make sure the

projection (torque stopper) on

the front fork end is placed in

the slot in the trip meter gear

unit as shown.

H: Tighten the front axle bolts

temporarily before tightening

the axle.

1 Throttle grip 1 *

2 Panhead screw 2 * d=5 (0.2), l=20 (0.79)

3 Grip cap cover 1 *

1 Front wheel 1 S

2 Front wheel axle 1 *

3 Collar (front wheel axle) 1 V d=20 (0.79)

4 Trip meter gear unit 1 V

5 Axle nut 1 * d=16 (0.63)

6 Flange bolt 4 * d=8 (0.31), l=40 (1.57)

Loading...

Loading...