Yamaha WaveRunner XLT1200 Service Manual

YAMAHA

WaveRunner

LT1200

'Y

^SERVICE MANUAL

<pMANUEM)™RETIEN

<S)WARTUNGSHANDBUCH

^MANUAL

DE

SERVICIO

^=-

460068

FOV-28197-2D-C1

"^'

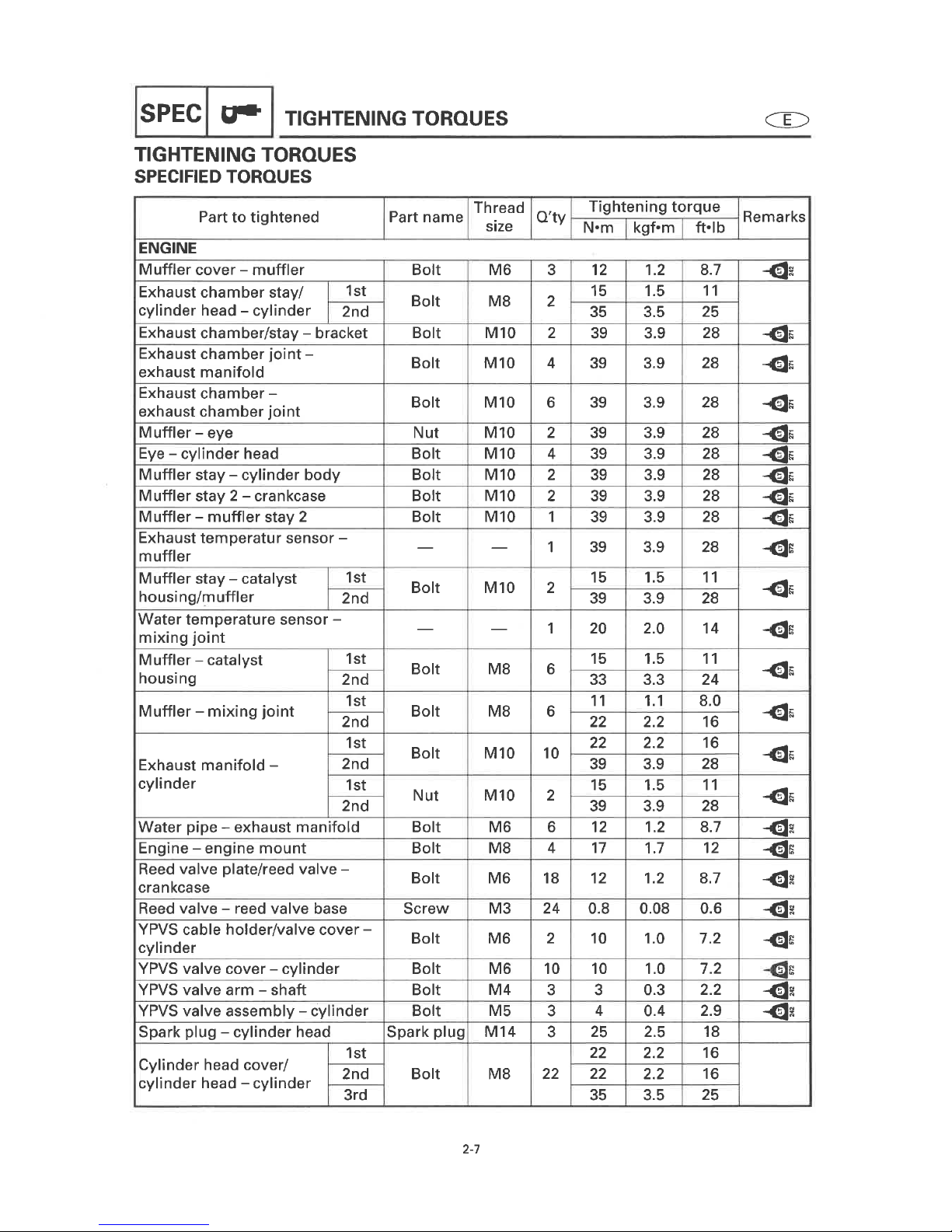

SPEC

TIGHTENING

TORQUES

TIGHTENING

TORQUES

SPECIFIED

TORQUES

Part

to

tightened

ENGINE

Muffter

cover - muffler

Exhaust

chamber

stay/

1st

cylinder

head-cylinder

2nd

Exhaust

chamber/stay - bracket

Exhaust

chamber

joint -

exhaust

manifold

Exhaust

chamber -

exhaust

chamber

joint

Muffler-eye

Eye-cylinder

head

Muffler

stay - cylinder

body

Muffler

stay 2 -crankcase

Muffler - muffler

stay 2

Exhaust

temperatur

sensor -

muffler

Muffler

stay-catalyst

1st

housing/muffler

2nd

Water

temperature

sensor -

mixing

Joint

Muffler-catalyst

housing

Muffler-mixing

joint

Exhaust

manifold -

cylinder

1st

2nd

1st

2nd

1st

2nd

1st

2nd

Water

pipe - exhaust

manifold

Engine-engine mount

Reed

valve

plate/reed

valve -

crankcase

Reed

valve - reed

valve

base

YPVS

cable

holder/valve

cover -

cylinder

YPVS

valve

cover - cylinder

YPVS

valve

arm - shaft

YPVS

valve

assembly - cylinder

Spark

plug - cylinder

head

1st

Cylinder

head

cover/

cylinder

head - cylinder

Part

name

Thjead

Q'ty ,

TightemngJ°rque,

size

~''

N'm

kgf'm

ft'lb

Bolt

Bolt

Bolt

Bolt

Bolt

Nut

Bolt

Bolt

Bolt

Bolt

Bolt

Bolt

Bolt

Bolt

Nut

Bolt

Bolt

Bolt

Screw

Bolt

Bolt

Bolt

Bolt

M6

M8

M10

M10

M10

M10

M10

M10

M10

M10

M10

M8

M8

M10

M6

M8

M6

M3

M6

M6

M4

M5

Spark

plug

M14

3

2

2

4

2

4

2

2

1

1

2

1

6

M10

10

Bolt

MS

6

4

18

24

2

10

3

3

3

22

12

15

35

39

39

39

39

39

39

39

39

39

15

39

20

15

33

11

22

22

39

15

39

12

17

12

10

10

3

4

25

22

22

35

1.2

1.5

3.5

3.9

3.9

3.9

3.9

3.9

3.9

3.9

3.9

3.9

1.5

3.9

2.0

1.5

3.3

1.1

2.2

2.2

3.9

1.5

3.9

1.2

1.7

1.2

0.

8

0.

08

1.0

1.0

0.3

0.4

2.5

2.2

2.2

3.5

8.7

11

25

28

28

28

28

28

28

28

28

28

11

28

14

11

24

8.0

16

16

28

11

28

8.7

12

8.7

0.6

7.2

7.2

2.2

2.9

18

16

16

25

Remarks

I

3.

3.

3.

3.

a.

^

^

^

^

<a.

^

<a.

^

-<3E

^

-<UE

^

^

<a.

^

^

-<3s

-<3a

-<3S

^

5 S

-^

-<3s

2-7

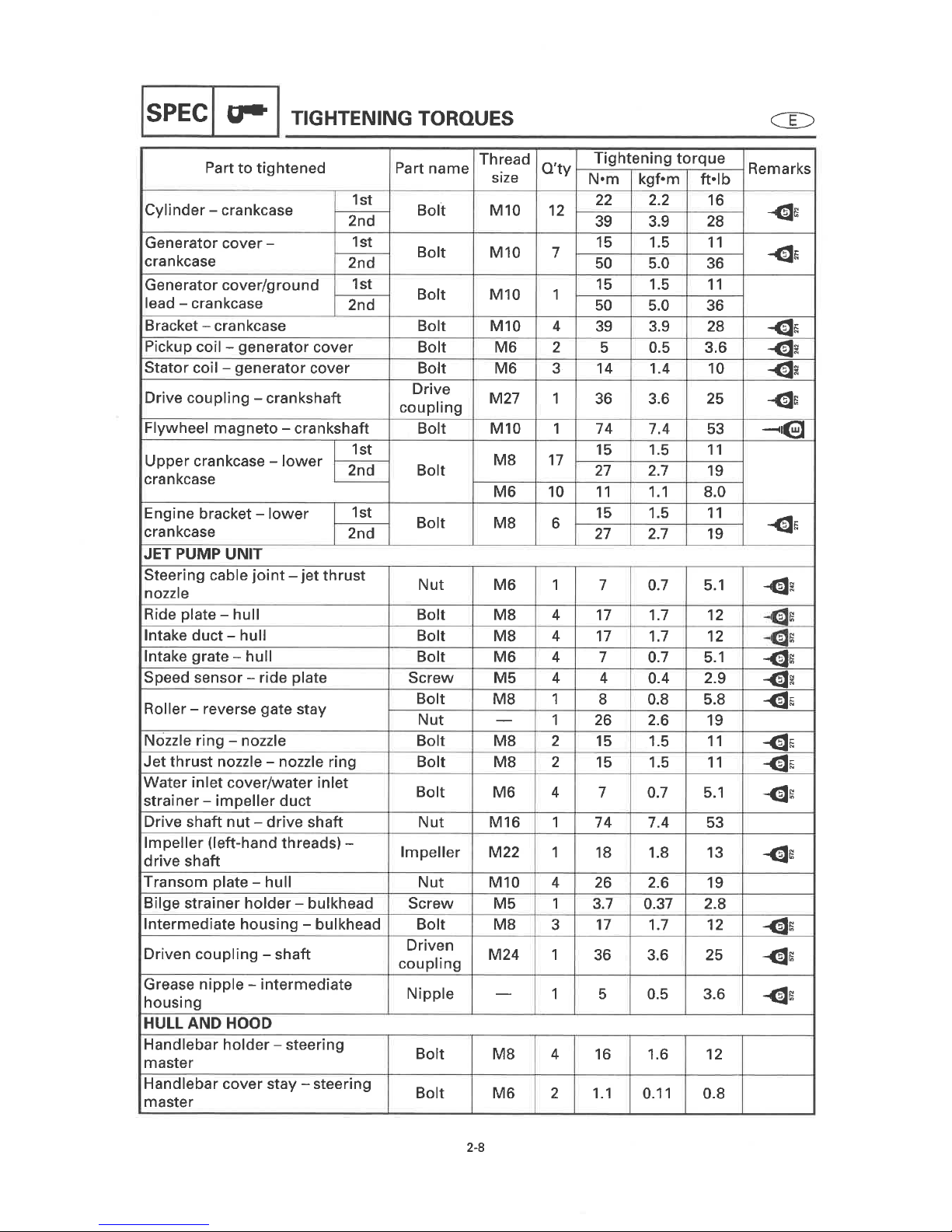

SPEC

TIGHTENING

TORQUES

Part

to

tightened

Cylinder - crankcase

Generator

cover -

crankcase

Generator cover/ground

lead - crankcase

Bracket - crankcase

Pickup

coil - generator

cover

Stator

coil - generator

cover

Drive

coupling - crankshaft

1st

2nd

1st

2nd

1st

2nd

Flywheel

magneto-crankshaft

1st

2nd

Upper

crankcase - lower

crankcase

Engine

bracket - lower

1st

crankcase

2nd

JET

PUMP

UNIT

Steering

cable

joint - jet

thrust

nozzle

Ride

plate-

hull

Intake

duct-

hull

Intake

grate-

hull

Speed

sensor - ride

plate

Roller - reverse

gate

stay

Nozzle

ring - nozzle

Jet

thrust

nozzle - nozzle

ring

Water

inlet

cover/water

inlet

strainer - impeller

duct

Drive

shaft

nut - drive

shaft

Impeller

(left-hand

threads) -

drive

shaft

Transom

plate - hull

Bilge

strainer

holder-

bulkhead

Intermediate

housing - bulkhead

Driven

coupling - shaft

Grease

nipple - intermediate

housing

HULL

AND

HOOD

Handlebar

holder - steering

master

Handlebar

cover

stay - steering

master

Part

name

Thread

Q'ty

Bolt

Bolt

Bolt

Bolt

Bolt

Bolt

Drive

coupling

Bolt

Bolt

Bolt

Nut

Bolt

Bolt

Bolt

Screw

Bolt

Nut

Bolt

Bolt

Bolt

Nut

Impeller

Nut

Screw

Bolt

Driven

coupling

M10

12

M10

M10

M10

M6

M6

M

27

M10

MS

M6

MS

M6

M8

M8

M6

M5

M8

MS

M8

M6

M16

M22

M10

M5

M8

M24

Nipple —

4

2

3

1

1

17

10

6

4

4

4

4

1

1

2

2

4

1

1

4

1

3

Tightening

torque

N'm

kgf'm

ft'lb

22

2.

2

16

39

3.

9

28

15

1.

5

11

50

5.

0

36

15

1.

5

11

50

5.

0

36

39

3.

9

28

5

0.

5

3.6

14

1.

4

10

36

74

15

27

11

15

27

17

17

7

4

8

26

15

15

7

74

18

26

3.7

17

36

3.6

7.4

1.5

2.7

1.1

1.5

2.7

0.7

1.7

1.7

0.7

0.4

0.8

2.6

1.5

1.5

0.7

7.4

1.8

2.6

0.

37

1.7

3.6

0.5

25

53

11

19

8.0

11

19

5.1

12

12

5.1

2.9

5.8

19

11

11

5.1

53

13

19

2.8

12

25

3.6

Remarks

^

-<3a

<a.

^

-Og

E2s

^

-<3S

a

ES

a S

-<3e

-<3?i

-d.

<a.

^

-<3s

-0s,

-<UE

-<3s

-<3s

Bolt

Bolt

MS

M6

4

2

16

1.

6

12

1.

1

0.

11

0.8

2-8

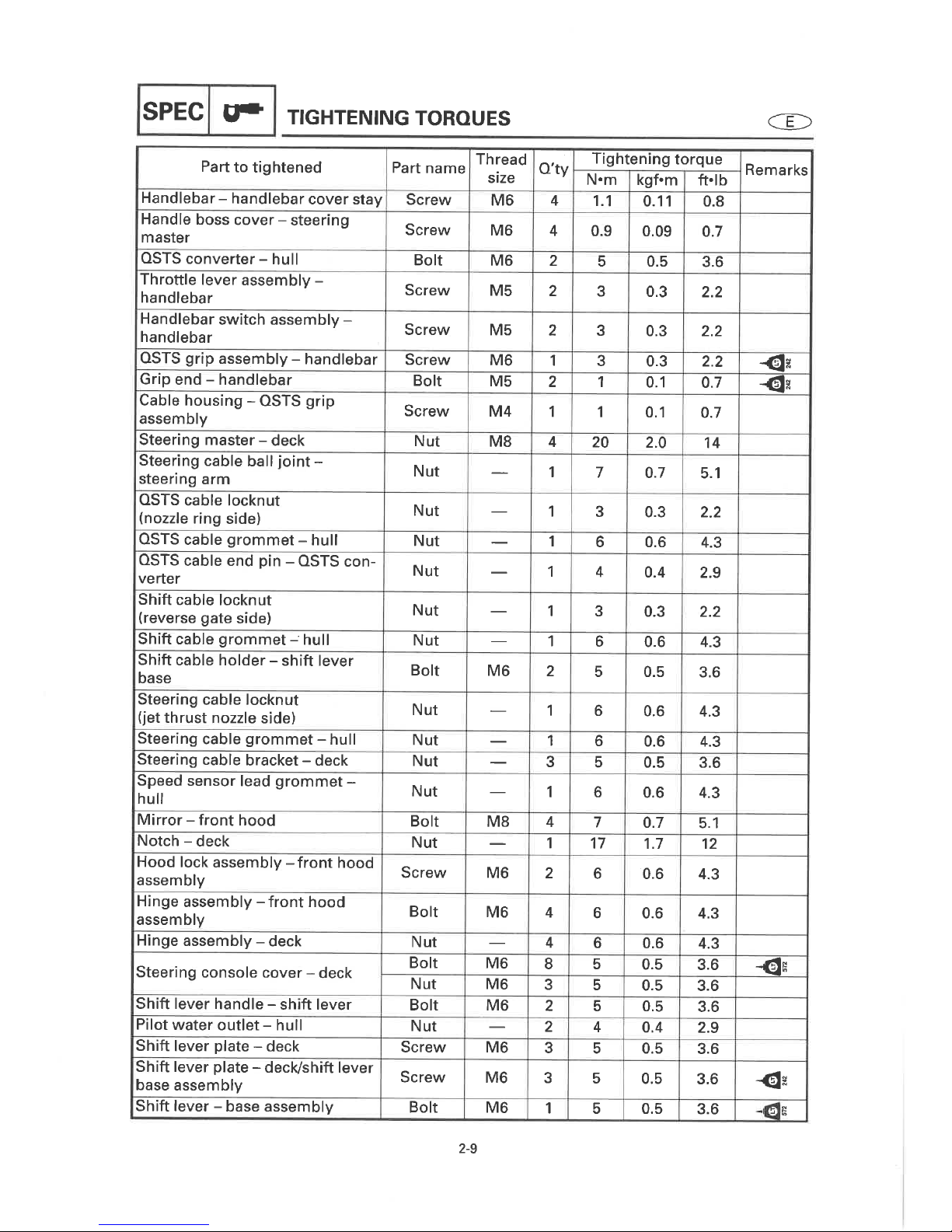

SPEC

TIGHTENING

TORQUES

Part

to

tightened

Handlebar - handlebar

cover

stay

Handle

boss

cover - steering

master

QSTS

converter-hull

Throttle

lever

assembly -

handlebar

Handlebar

switch

assembly -

handlebar

QSTS

grip

assembly-

handlebar

Grip

end-

handlebar

Cable

housing - QSTS

grip

assembly

Steering

master-deck

Steering

cable

ball

joint -

steering

arm

QSTS

cable

locknut

(nozzle

ring

side)

QSTS

cable

grommet - hull

QSTS

cable

end

pin - QSTS

con-

verter

Shift

cable

locknut

(reverse

gate

side)

Shift

cable

grommet - hull

Shift

cable

holder - shift

lever

base

Steering

cable

locknut

(jet

thrust

nozzle

side)

Steering

cable

grommet - hull

Steering

cable

bracket-deck

Speed

sensor

lead

grommet-

hull

Mirror-front

hood

Notch - deck

Hood

lock

assembly - front

hood

assembly

Hinge

assembly - front

hood

assembly

Hinge

assembly - deck

Steering

console

cover - deck

Shift

lever

handle - shift

lever

Pi

lot

water

outlet-

hull

Shift

lever

plate - deck

Shift

lever

plate - deck/shift

lever

base

assembly

Shift

lever - base

assembly

Part

name

Thread

Q'ty

Screw

Screw

Bolt

Screw

Screw

Screw

Bolt

Screw

Nut

Nut

Nut

Nut

Nut

Nut

Nut

Bolt

Nut

Nut

Nut

Nut

Bolt

Nut

Screw

Bolt

Nut

Bolt

Nut

Bolt

Nut

Screw

Screw

Bolt

M6 4

M6 4

M6 2

M5 2

M5

M6

M5

M4

MS

M6

MS

M6

M6

M6

M6

M6

M6

M6

M6

1

2

1

4

1

1

1

1

1

1

2

1

1

3

1

4

1

4

8

3

2

2

3

3

1

Tightening

torque

N'm

kgf'm

ft'lb

1.

1

0.

11

0.8

0.

9

0.

09

5

0.5

3

0.3

3

1

1

20

7

3

6

4

3

6

5

6

5

7

17

6

5

5

5

4

5

0.3

0.3

0.1

0.1

2.0

0.7

0.3

0.6

0.4

0.3

0.6

0.5

0.6

0.6

0.5

0.6

0.7

1.7

0.6

0.6

0.6

0.5

0.5

0.5

0.4

0.5

0.5

0.5

0.7

3.6

2.2

2.2

2.2

0.7

0.7

14

5.1

2.2

4.3

2.9

2.2

4.3

3.6

4.3

4.3

3.6

4.3

5.1

12

4.3

4.3

4.3

3.6

3.6

3.6

2.9

3.6

3.6

3.6

co

Remarks

-<3S

-<3r

-^s,

-<3s

2-9

SPEC

TIGHTENING

TORQUES

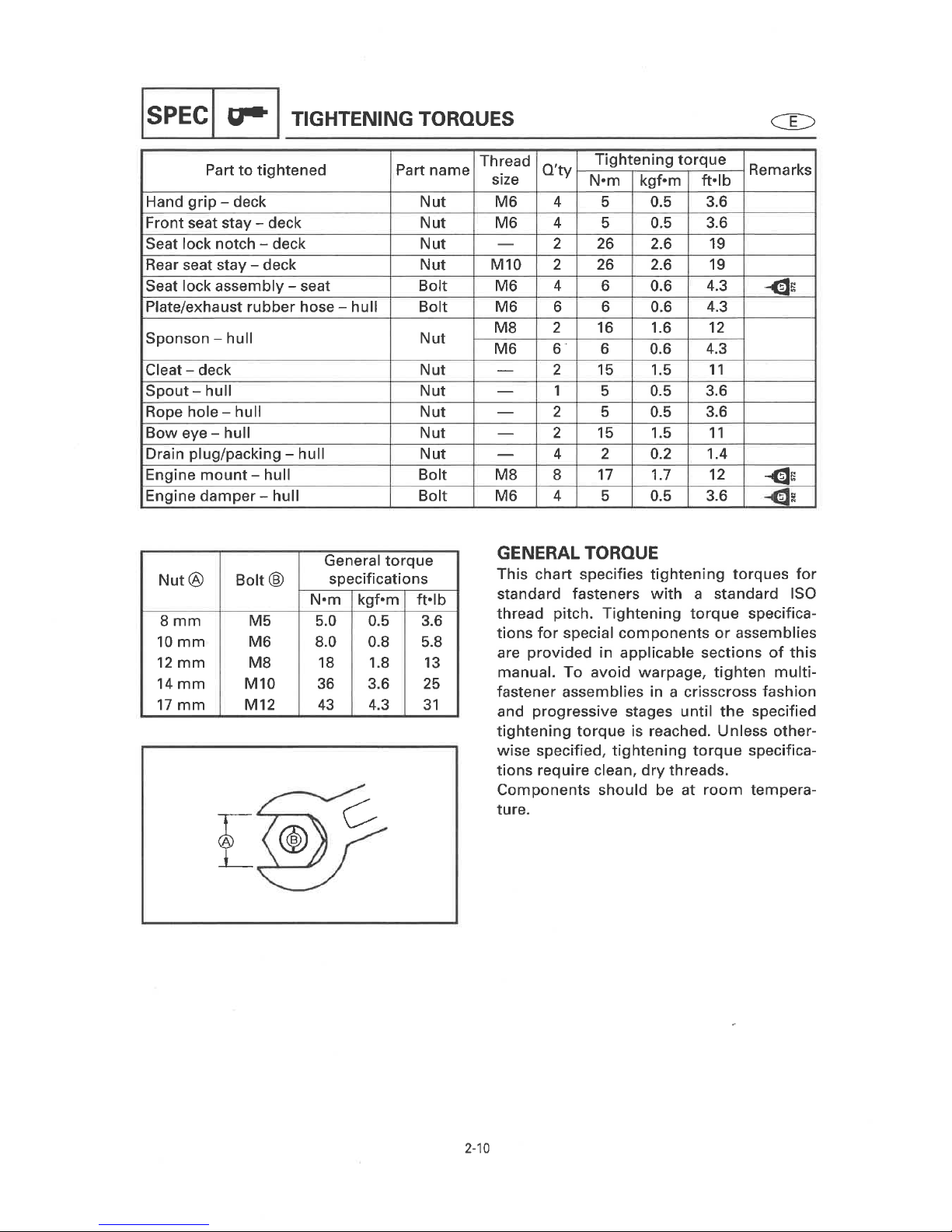

Part to

tightened

Part

name

Hand

grip-deck

Nut

Front

seat

stay - deck

Nut

Seat

lock

notch - deck

Nut

Rear

seat

stay - deck

Nut

Seat

lock

assembly-seat

Bolt

Plate/exhaust

rubber

hose - hull

Bolt

Sponson-hull

Nut

Cleat-deck

Nut

Spout-hull

Nut

Rope

hole-hull

Nut

Bow

eye-hull

Nut

Drain

plug/packing - hull

Nut

Engine

mount-hull

Bolt

Engine

damper-hull

Bolt

Thread

size

M6

M6

M10

M6

M6

M8

M6

MS

M6

.

>...

Tightening

torque

y

N-m

kgf-m

ft-lb

4

5

0.

5

3.6

4

5

0.

5

3.6

2

26

2.

6

19

2

26

2.

6

19

4

6

0.

6

4.3

6

6

0.

6

4.3

2

16

1.

6

12

6 6

0.

6

4.3

2

15

1.

5

11

1

5

0.

5

3.6

2

5

0.

5

3.6

2

15

1.

5

11

4

2

0.

2

1.4

8

17

1.

7

12

4

5

0.

5

3.6

Remarks

IS

^

Nut

8

mm

10

mm

12

mm

14

mm

17

mm

Bolt i

M5

M6

M8

M10

M12

General

torque

specifications

N'm

kgf'm

ft'lb

5.

0

0.

5

3.6

8.

0

0.

8

5.8

18

1.

8

13

36

3.

6

25

43

4.

3

31

c-

GENERAL

TORQUE

This

chart

specifies

tightening

torques

for

standard

fasteners

with a standard

ISO

thread

pitch.

Tightening

torque

specifica-

tions

for

special

components

or

assemblies

are

provided

in

applicable

sections

of

this

manual.

To

avoid

warpage,

tighten

multi-

fastener

assemblies

in a crisscross

fashion

and

progressive

stages

until

the

specified

tightening

torque

is

reached.

Unless

other-

wise

specified,

tightening

torque

specifica-

tions

require

clean,

dry

threads.

Components

should

be

at

room

tempera-

ture.

2-10

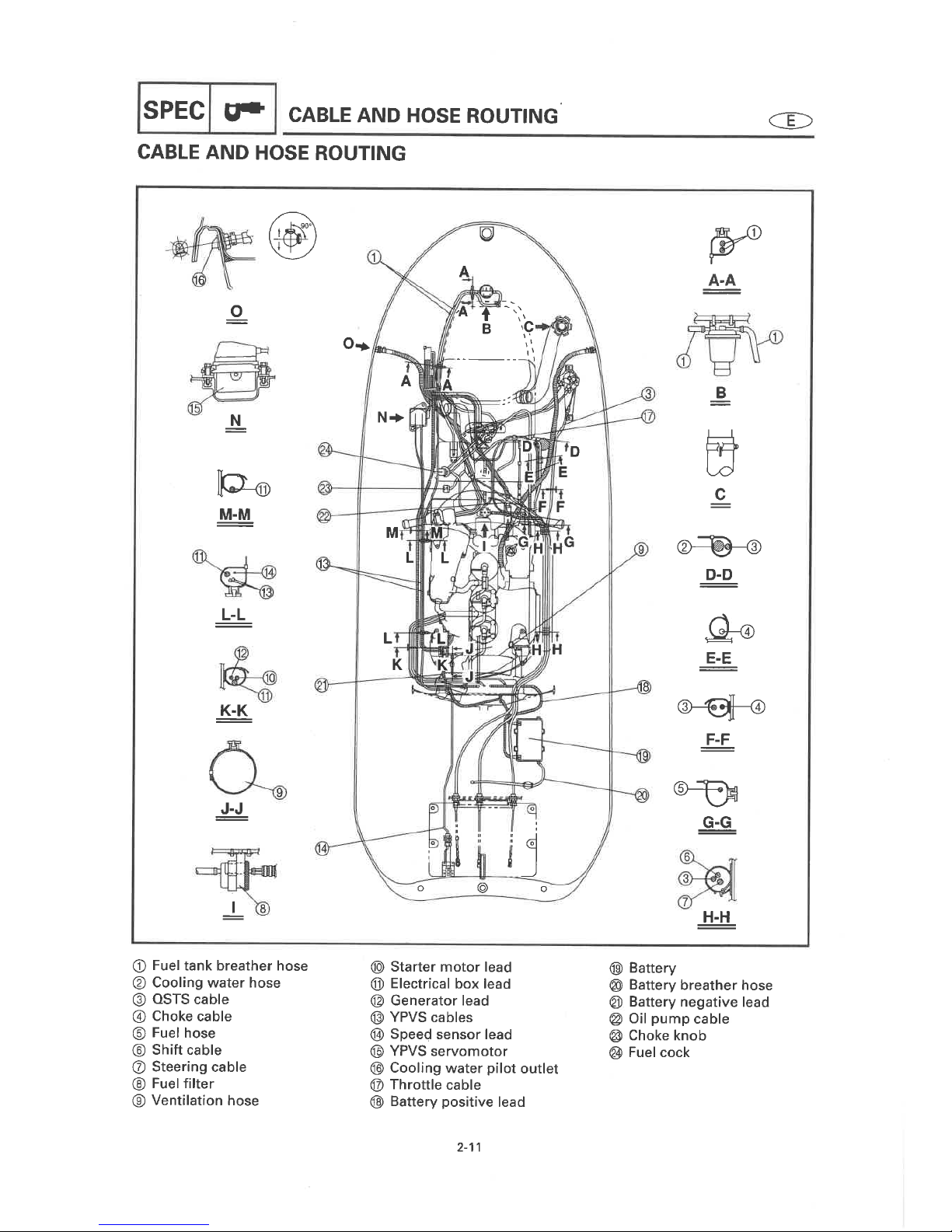

SPEC

O*

CABLE

AND

HOSE

ROUTING

CABLE

AND

HOSE

ROUTING

CE^

16

N

IO^D

M-M

14

13

L-L

K-K

10

11

0^

13

N-».

A 1 ~-^

B

\C

M

|M

L L

E E

F F

I

GH

HG

K K

H H

18

19

A-A

B

J_[

m

L^O

c

E-E

F-F

J-J

I 8

14

G-G

6

3

7

H-H

Fuel

tank

breather

hose

@

Cooling

water

hose

QSTS

cable

Choke

cable

Fuel

hose

Shift

cable

Steering

cable

Fuel

filter

Ventilation

hose

Starter

motor

lead

@

Electrical

box

lead

Generator

lead

YPVS

cables

Speed

sensor

lead

©

YPVS

servomotor

®

Cooling

water

pilot

outlet

Throttle

cable

Battery

positive

lead

®

Battery

Battery

breather

hose

®

Battery

negative

lead

®

Oil

pump

cable

©

Choke

knob

Fuel

cock

2-11

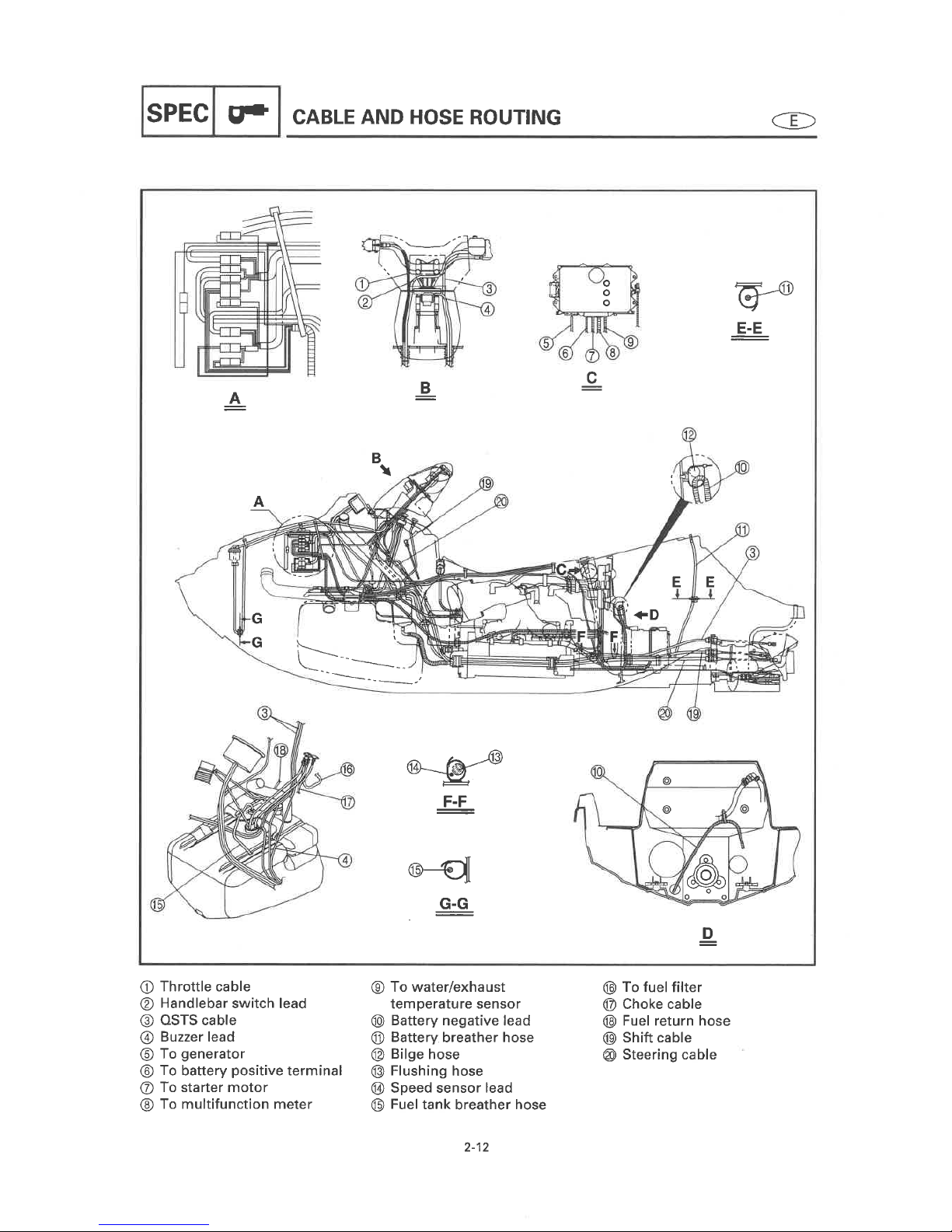

SPEC

CABLE

AND

HOSE

ROUTING

d^

3

4

B

0

0

0

E-E

7 8

c

B

10

19

E E

G

G

<<-D

F F

19

18

16

1

10

G-G

Throttle

cable

@

Handlebar

switch

lead

®

QSTS

cable

Buzzerlead

(5)

To

generator

To

battery

positive

terminal

To

starter

motor

To

muttifunction

meter

®

To

water/exhaust

temperature

sensor

®

Battery

negative

lead

Battery

breather

hose

Bilge

hose

Flushing

hose

Speed

sensor

lead

Fuel

tank

breather

hose

®

To

fuel

filter

@

Choke

cable

®

Fuel

return

hose

®

Shift

cable

®

Steering

cable

2-12

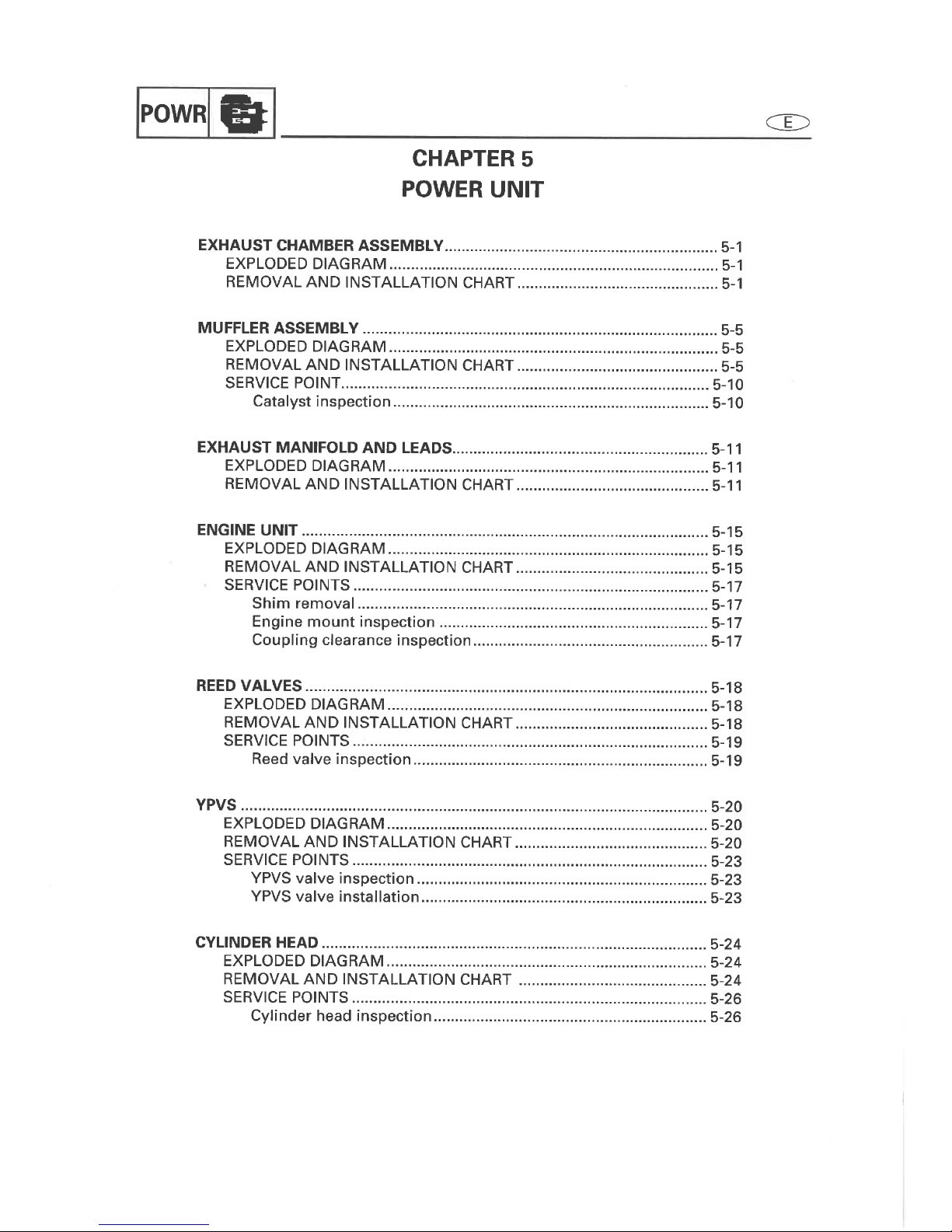

POWR

co

CHAPTER 5

POWER

UNIT

EXHAUST

CHAMBER

ASSEMBLY................................................................

5-1

EXPLODED

DIAGRAM.............................................................................

5-1

REMOVAL

AND

INSTALLATION

CHART...............................................

5-1

MUFFLER

ASSEMBLY...................................................................................

5-5

EXPLODED

DIAGRAM.............................................................................

5-5

REMOVAL

AND

INSTALLATION

CHART...............................................

5-5

SERVICE

POINT......................................................................................

5-10

Catalyst

inspection..........................................................................

5-10

EXHAUST

MANIFOLD

AND

LEADS............................................................

5-1 1

EXPLODED

DIAGRAM...........................................................................

5-11

REMOVAL

AND

INSTALLATION

CHART.............................................

5-11

ENGINE

UNIT ...............................................................................................

5-15

EXPLODED

DIAGRAM...........................................................................

5-15

REMOVAL

AND

INSTALLATION

CHART.............................................

5-15

SERVICE

POINTS...................................................................................

5-17

Shim

removal..................................................................................

5-17

Engine

mount

inspection ...............................................................

5-17

Coupling

clearance

inspection.......................................................

5-17

REED

VALVES..............................................................................................

5-18

EXPLODED

DIAGRAM...........................................................................

5-18

REMOVAL

AND

INSTALLATION

CHART.............................................

5-18

SERVICE

POINTS...................................................................................

5-19

Reed

valve

inspection.....................................................................

5-19

YPVS.............................................................................................................

5-20

EXPLODED

DIAGRAM...........................................................................

5-20

REMOVAL

AND

INSTALLATION

CHART.............................................

5-20

SERVICE

POINTS...................................................................................

5-23

YPVS

valve

inspection....................................................................

5-23

YPVS

valve

installation...................................................................

5-23

CYLINDER

HEAD..........................................................................................

5-24

EXPLODED

DIAGRAM...........................................................................

5-24

REMOVAL

AND

INSTALLATION

CHART ............................................

5-24

SERVICE

POINTS...................................................................................

5-26

Cylinder

head

inspection................................................................

5-26

POWR

CE^

CYLINDERS...................................................................................................

5-27

EXPLODED

DIAGRAM...........................................................................

5-27

REMOVAL

AND

INSTALLATION

CHART.............................................

5-27

SERVICE

POINTS...................................................................................

5-28

Cylinder

inspection.........................................................................

5-28

PISTONS.......................................................................................................

5-29

EXPLODED

DIAGRAM...........................................................................

5-29

REMOVAL

AND

INSTALLATION

CHART.............................................

5-29

SERVICE

POINTS...................................................................................

5-31

Piston

pin

clip

removal

and

installation........................................

5-31

Piston

inspection.............................................................................

5-31

Cylinder

and

piston

combination ..................................................

5-32

Piston

ring

inspection.....................................................................

5-32

Piston

pin

and

bearing

inspection .................................................

5-33

GENERATOR

AND

STARTER

MOTOR........................................................

5-35

EXPLODED

DIAGRAM...........................................................................

5-35

REMOVAL

AND

INSTALLATION

CHART ............................................

5-35

SERVICE

POINTS...................................................................................

5-41

Drive

coupling

removal

and

installation .......................................

5-41

Flywheel

magneto

removal

and

installation ................................

5-41

Drive

coupling

inspection...............................................................

5-42

Flywheel

magneto

inspection........................................................

5-42

Starter

clutch

assembly

inspection ...............................................

5-42

CRANKCASE.................................................................................................

5-43

EXPLODED

DIAGRAM...........................................................................

5-43

REMOVAL

AND

INSTALLATION

CHART.............................................

5-43

SERVICE

POINTS...................................................................................

5-45

Crankcase

inspection......................................................................

5-45

Crankcase

installation.....................................................................

5-45

CRANKSHAFT...............................................................................................

5-46

EXPLODED

DIAGRAM...........................................................................

5-46

REMOVAL

AND

INSTALLATION

CHART.............................................

5-46

SERVICE

POINTS...................................................................................

5-47

Crankshaft

inspection.....................................................................

5-47

POWR

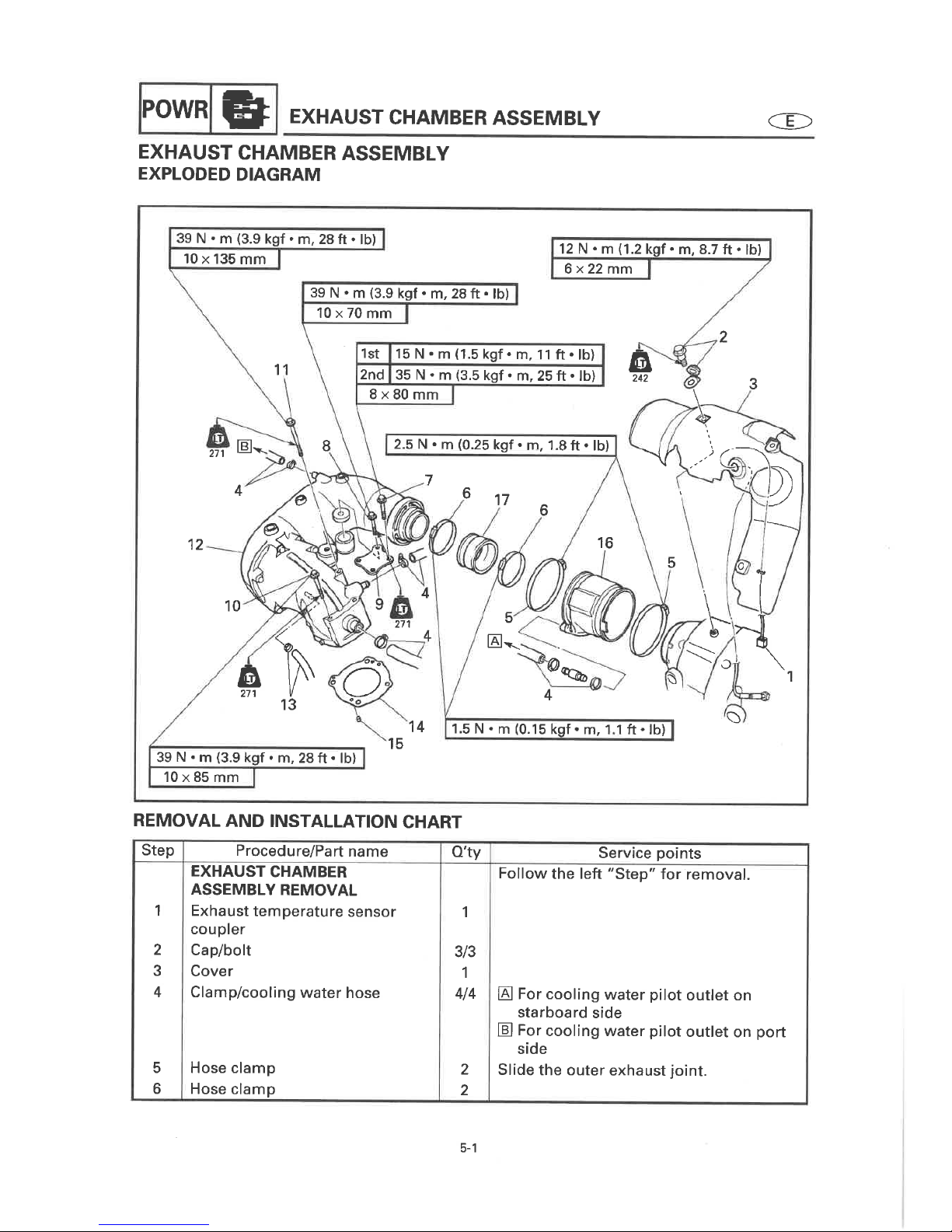

EXHAUST

CHAMBER

ASSEMBLY

EXHAUST

CHAMBER

ASSEMBLY

EXPLODED

DIAGRAM

39 N • m

(3.9 kgf

• m,

28

ft

• Ib)

10x135

mm

39 N • m

(3.9 kgf

• m,

28

ft

• Ib)

10x70

mm

12 N.m

(1.2 kgf-m, 8.7

ft

• Ib)

6x22

mm

11

271

8

0

12

1st

15

N •md.

5kgf.

rn,

11

ft

• Ib)

2nd

35 N «m

(3.5 kgf'm,

25ft*

Ib)

~^

8 x 80

mm

2.5 N.m (0.

25

kgf'm, 1.8

ft.

lb)

17

16

^

•'c:

10

271

271

'0

0

39 N • m

(3.9 kgf

• m,

28

ft

• Ib)

10x85

mm

15

14 1.5 N.m

(0.

15

kgf.m,1

1ft-Ib)

rA

Q

REMOVAL

AND

INSTALLATION

CHART

Q'ty

Step

Procedure/Part

name

EXHAUST

CHAMBER

ASSEMBLY

REMOVAL

1

Exhaust

temperature

sensor

coupler

2

Cap/bolt

3

Cover

4

Clamp/cooling

water

hose

5

Hose

clamp

6

Hose

clamp

Service

points

Follow

the

left

"Step"

for

removal.

1

3/3

1

4/4

For

cooling

water

pilot

outlet

on

starboard

side

For

cooling

water

pilot

outlet

on

port

side

2

Slide

the

outer

exhaust

joint.

2

5-1

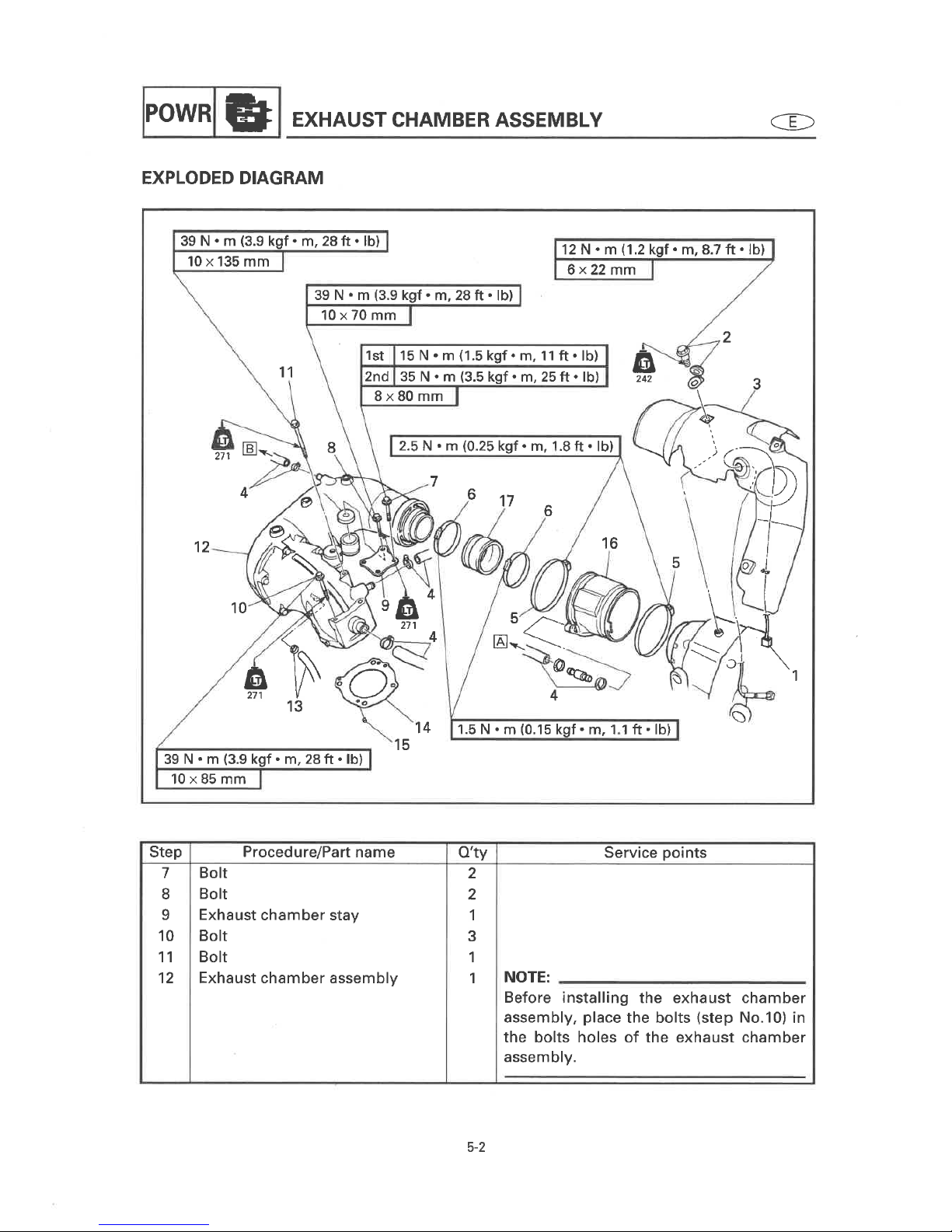

POWR

g|

EXHAUST

CHAMBER

ASSEMBLY

EXPLODED

DIAGRAM

39 N • m

(3.9 kgf

• m,

28

ft

• Ib)

10x135

mm

12N«m(1.

2kgfTn,8.7ft-lb)

6x22

mm

39 N • m

(3.9 kgf

• m,

28

ft

• Ib)

10x70

mm

11

271

8

12

0.

0

^

10

271

1st

15

N*m

(1.

5kgf«

m,

11

ft*

Ib)

2nd

35

N«m

(3.5 kgf'm,

25ft*

Ib)

'3Z7 „

8 x 80

mm

2.5 N-m

(0.

25

kgf.

m, 1.8ft'Ib)

"<r

17

16

271

13

•«

0

39 N • m

(3.9 kgf

• m,

28

ft

• Ib)

10x85

mm

15

14 1.5N •m(0.

15kgf-m, 1 1

ft-lb)

0

Step

Procedure/Part

name

7

Bolt

8

Bolt

9

Exhaust

chamber

stay

10

Bolt

11

Bolt

12

Exhaust

chamber

assembly

Q'ty

Service

points

2

2

1

3

1

1

NOTE:

Before

installing

the

exhaust

chamber

assembly,

place

the

bolts

(step

No.

10)

in

the

bolts

holes

of

the

exhaust

chamber

assembly.

5-2

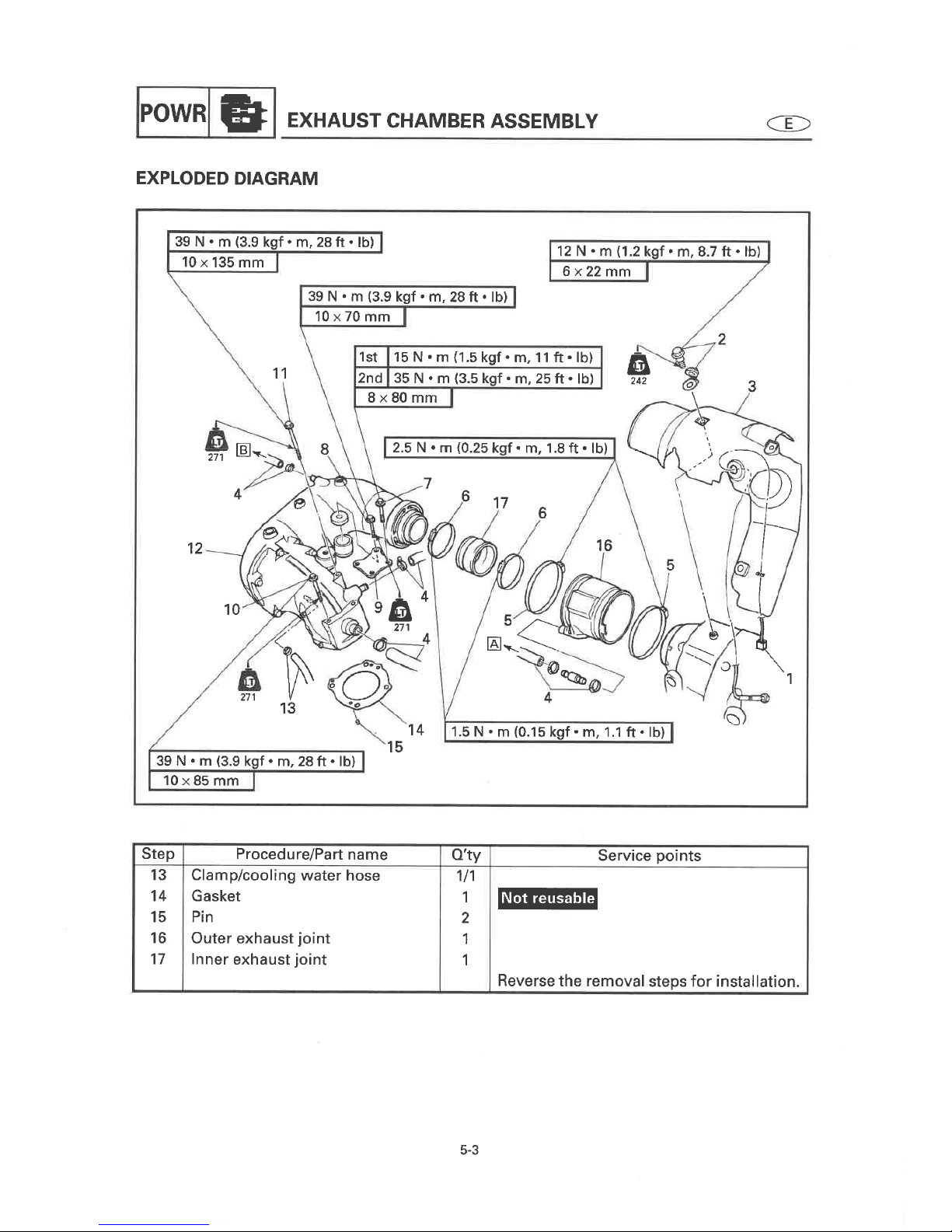

POWR

EXHAUST

CHAMBER

ASSEMBLY

EXPLODED

DIAGRAM

39 N • m

(3.9 kgf«

m,

28

ft

• Ib)

10x135

mm

12

N-md.

2kgf.

rn, 8.7ft

• tb)

6x22

mm

39 N • m

(3.9 kgf

• m,

28

ft

• Ib)

10x70

mm

11

271

8

0

12

1st

15N'm

(1.

5kgf«m,

11

ft-lb)

|R|

2nd

35 N • m

(3.5 kgf*

m,

25ft*

Ib)

~^

8 x 80

mm

2.

5NTn(0.

25kgfTn,1.8fflb)

7

17

^ ..

-;G-

16

10

271

13

° 9

"0

0

271

39N.

m(3.

9kgf.m,28ft.

lb)

10x85

mm

15

^

14 1.5 N 'm

(0.

15

kgf-m,

1. 1

ft'lb)

0

Q

Step

Procedure/Part

name

13

Clamp/cooling

water

hose

14

Gasket

15

Pin

16

Outer

exhaust

joint

17

Inner

exhaust

joint

Q'ty

1/1

1

2

1

1

Service

points

Not

reusable

Reverse

the

removal

steps

for

installation.

5-3

POWR

EXHAUST

CHAMBER

ASSEMBLY

co

EXPLODED

DIAGRAM

39 N • m

(3.9 kgf

• m,

28

ft

• Ib)

10x85

mm

271

9

.€>

271

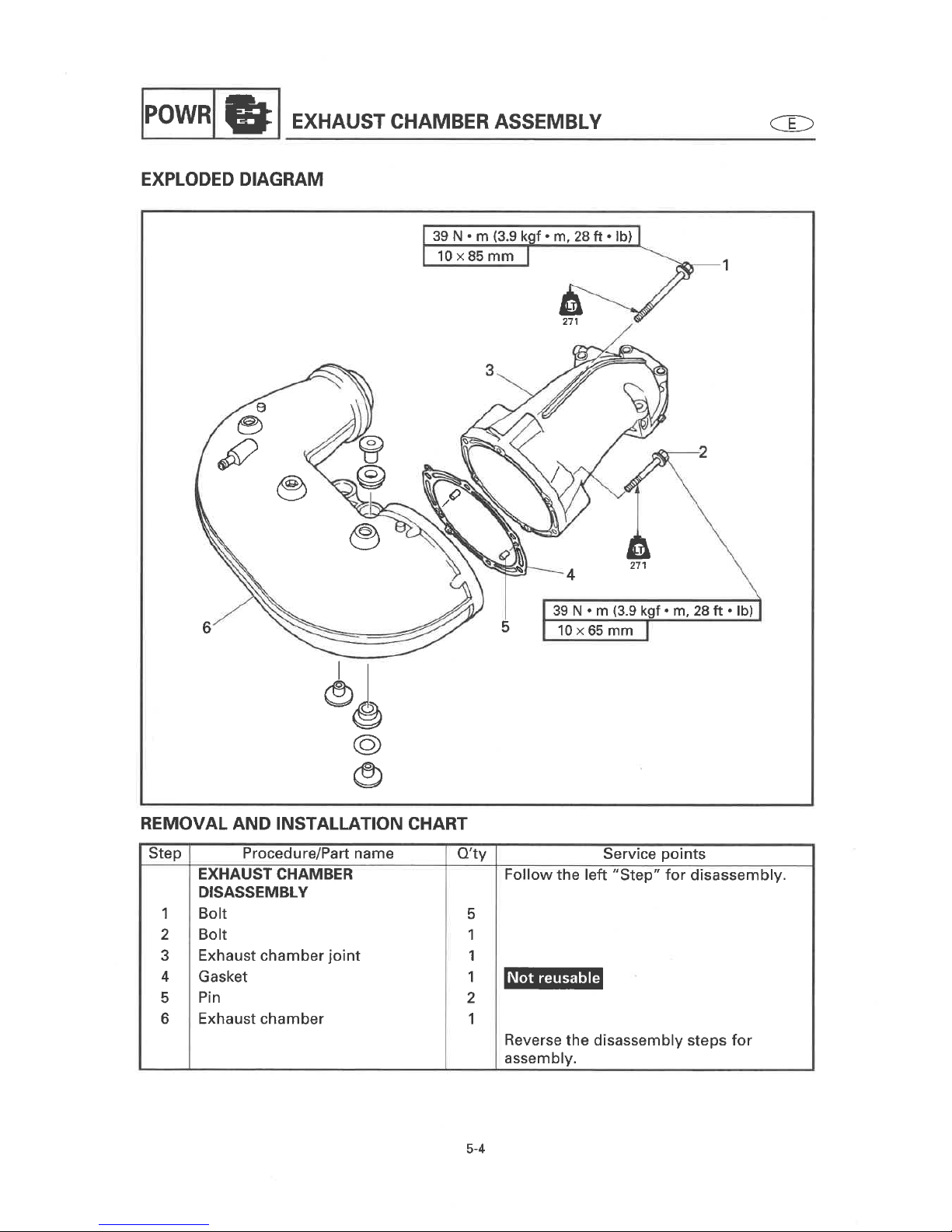

REMOVAL

AND

INSTALLATION

CHART

Step

P

raced

ure/Part

name

EXHAUST

CHAMBER

DISASSEMBLY

1

Bolt

2

Bolt

3

Exhaust

chamber

joint

4

Gasket

5

Pin

6

Exhaust

chamber

39 N • m

(3.9 kgf

• m,

28

ft

• Ib)

10x65

mm

Q'ty

Service

points

Follow

the

left

"Step"

for

disassembly.

5

1

1

1

2

1

Not

reusable

Reverse

the

disassembly

steps

for

assembly.

5-4

POWR

g|

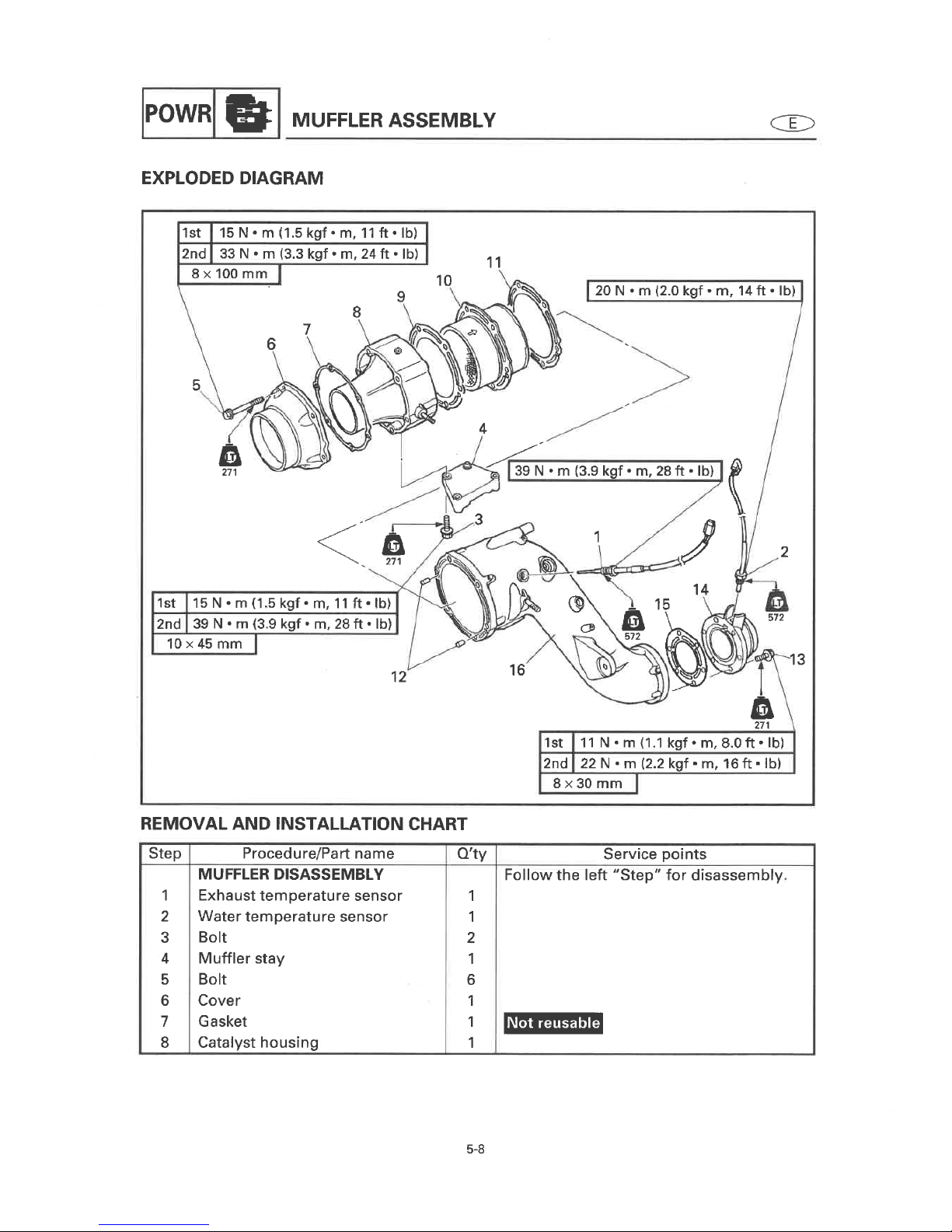

MUFFLER

ASSEMBLY

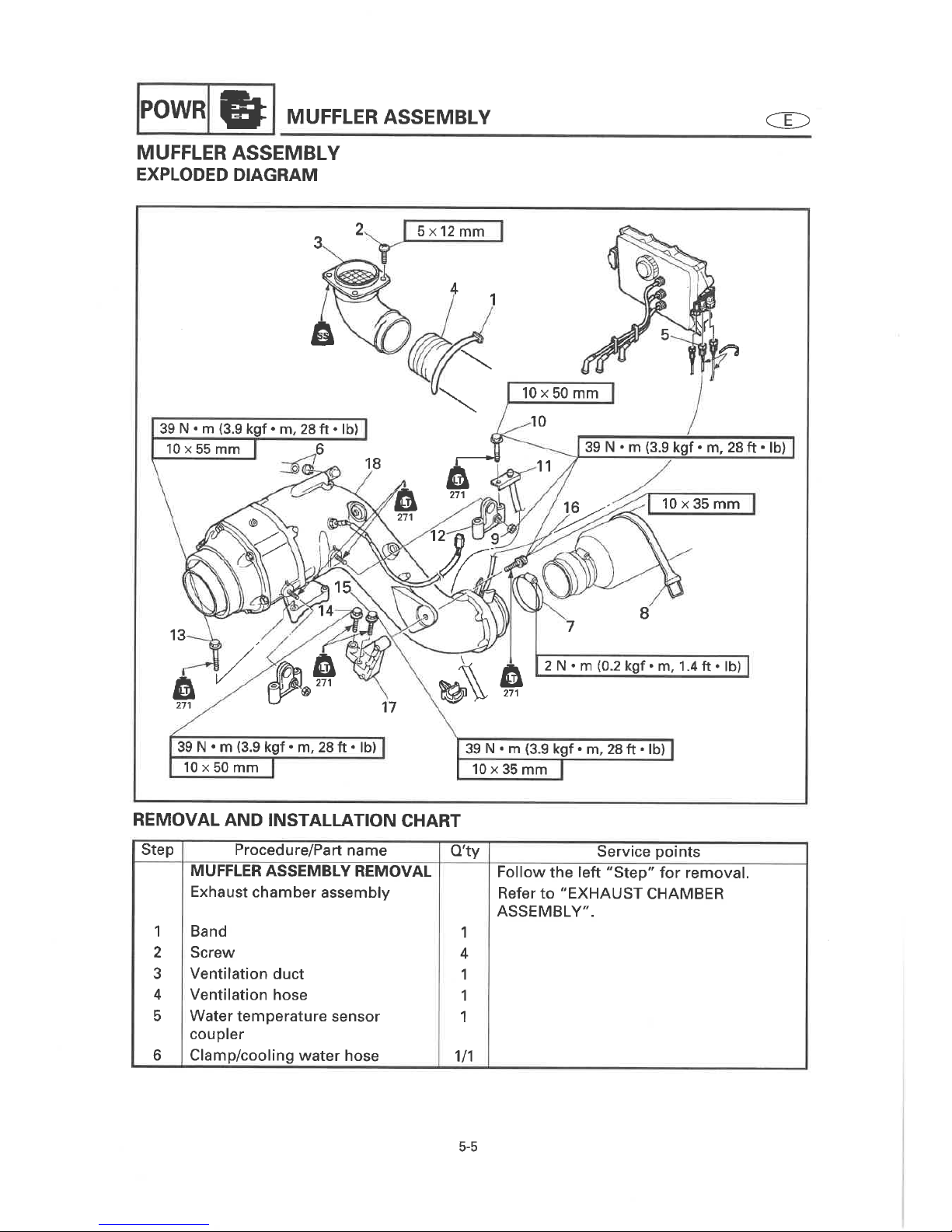

MUFFLER

ASSEMBLY

EXPLODED

DIAGRAM

5

x12

mm

39N.

m(3.

9kgf*m,

28fflb)

10x55

mm 6

o ,

18

^

13

271

^

271

271

15

14

271

17

12

10x50

mm

10

39 N • m

(3.9 kgf

• m,

28 ^ • Ib)

11

16

10 x 35

mm

2N-m

f0.

2kgf.

rn, 1.4ft*

Ib)

271

39 N • m

(3.9 kgf

• m,

28

ft

• Ib)

10x50

mm

39 N • m

(3.9 kgf

• m,

28

ft

• Ib)

10x35

mm

REMOVAL

AND

INSTALLATION

CHART

Step

Procedure/Part

name

Q'ty

Service

points

MUFFLER

ASSEMBLY

REMOVAL

Follow

the

left

"Step"

for

removal.

Exhaust

chamber

assembly

1

Band

2

Screw

3

Ventilation

duct

4

Ventilation

hose

5

Water

temperature

sensor

coupler

6

Clamp/cooling

water

hose

Refer

to

"EXHAUST

CHAMBER

ASSEMBLY".

1

4

1

1

1

1/1

5-5

POWR

g|

MUFFLER

ASSEMBLY

CI^

EXPLODED

DIAGRAM

5x12

mm

39 N • m

(3.9 kgf

• m,

28

ft

• Ib)

10x55

mm 6

o ,

18

5

^1

^

13

271

^

10x50

mm

10

39 N • m

(3.9 kgf

• m,

28

ft

• Ib)

11

271

271

16

10x35

mm

J

15

14

271

17

12

2 N < m (0.2 kgf*

m, 1.4ft*

Ib)

271

39 N • m

(3.9 kgf

• m,

28

ft

• Ib)

10x50

mm

39 N • m

(3.9 kgf

• m,

28

ft

• Ib)

10x35

mm

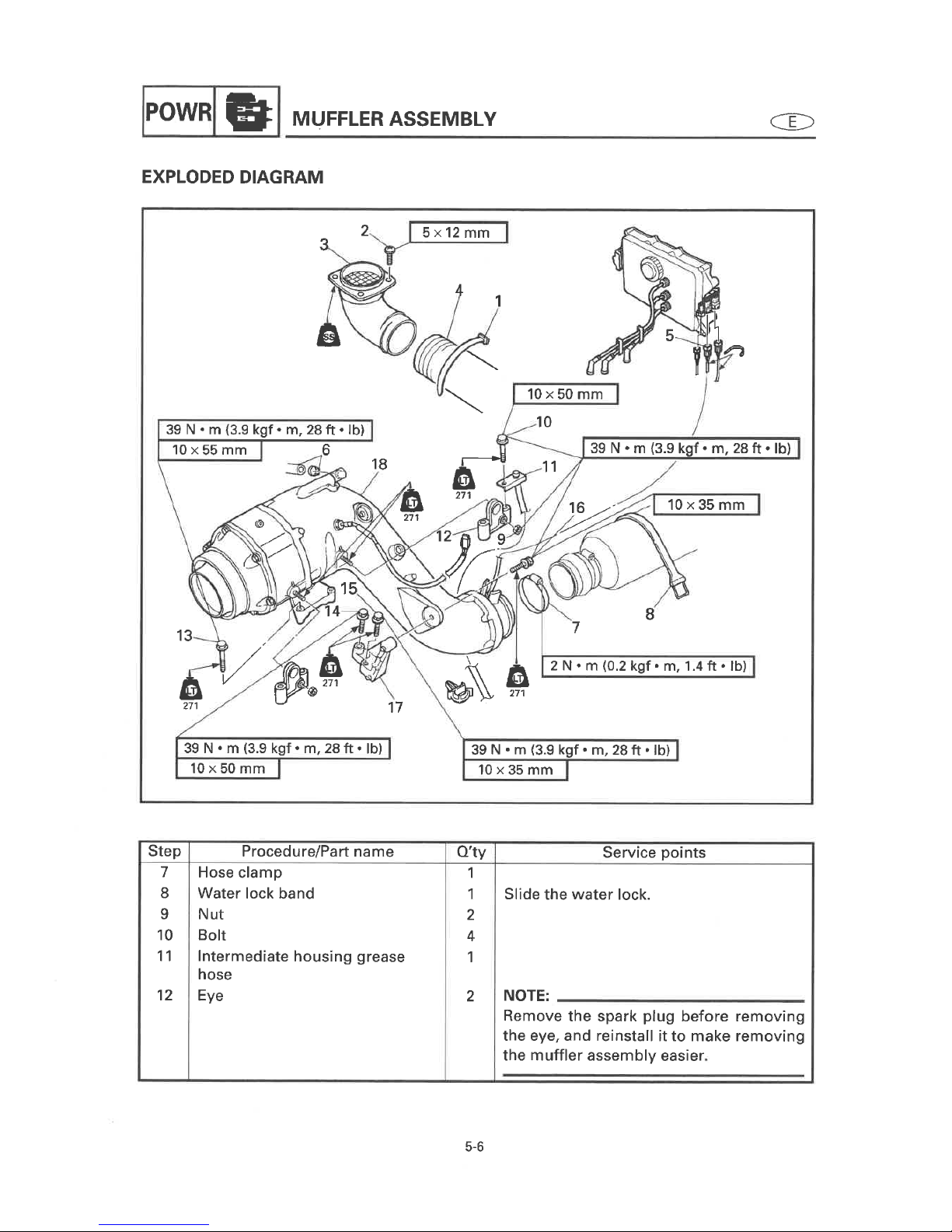

Step

Procedure/Part

name

7

Hose

clamp

8

Water

lock

band

9

Nut

10

Bolt

11

Intermediate

housing

grease

hose

12

Eye

Q'ty

Service

points

1

1

Slide

the

water

lock.

2

4

1

2

NOTE:

Remove

the

spark

plug

before

removing

the

eye,

and

reinstall

it

to

make

removing

the

muffler

assembly

easier

5-6

POWR

MUFFLER

ASSEMBLY

d^

EXPLODED

DIAGRAM

5x12

mm

39 N • m

(3.9 kgf«

m,

28

ft

• Ib)

10x55

mm 6

o ,

18

10x50

mm

10

39N.

m(3.

9kgf«m,

28fflb)

^" "

271

271

16

10x35

mm

r

15

13

271

14

271

17

39 N • m

(3.9 kgf

• m,

28

ft

• Ib)

10x50

mm

12

8

2N

«m

(0.

2kgfTn, 1.4ft

Ib)

271

39N.

m(3.

9kgf.m,28fflb)

10x35

mm

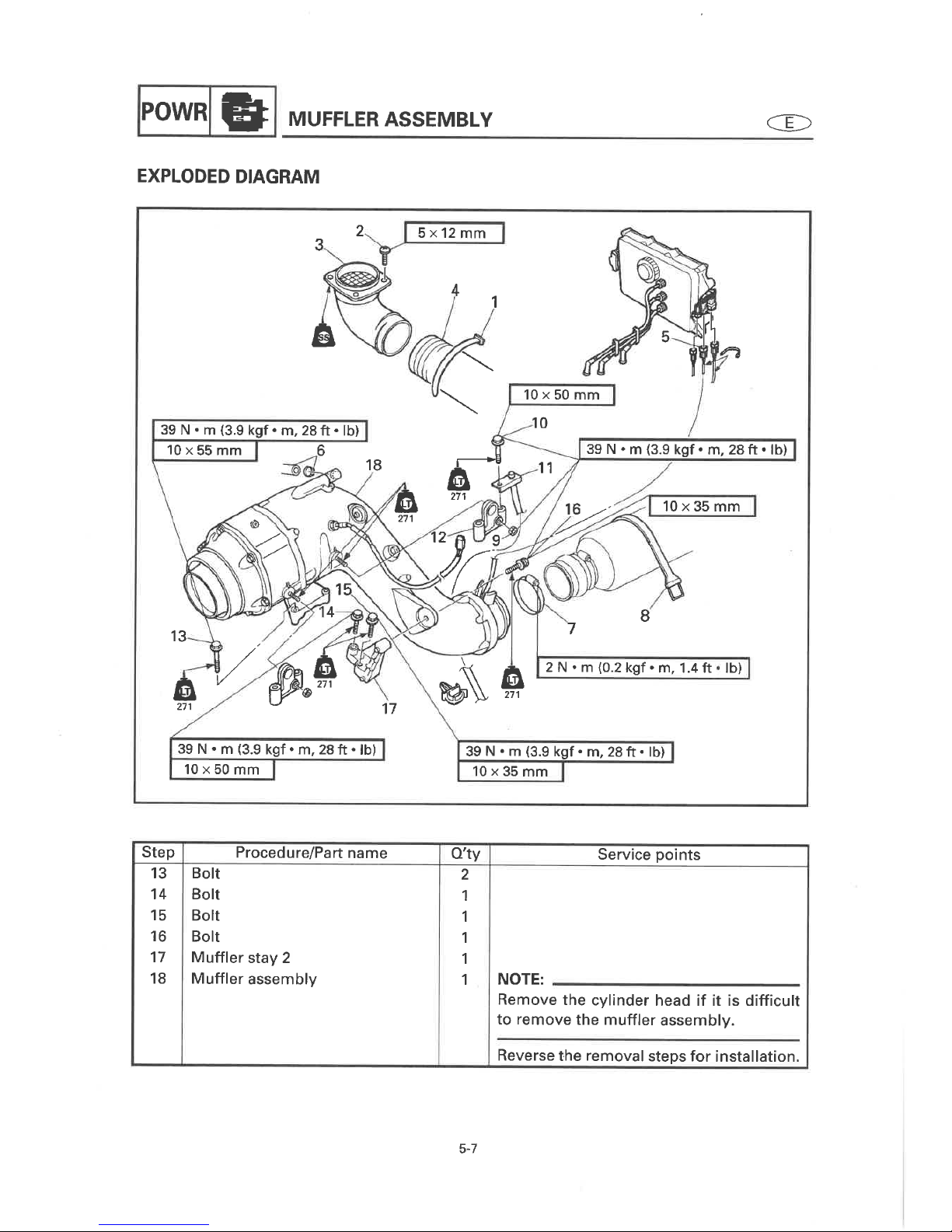

Step

Procedure/Part

name

13

Bolt

14

Bolt

15

Bolt

16

Bolt

17

Mufflerstay2

18

Muffler

assembly

Q'ty

Service

points

2

1

1

1

1

1

NOTE:

Remove

the

cylinder

head

if

it

is

difficult

to

remove

the

muffler

assembly.

Reverse

the

removal

steps

for

installation.

5-7

POWR

§|

MUFFLER

ASSEMBLY

EXPLODED

DIAGRAM

1st

15N'm(1.

5kgf-m,

nft.

lb)

2nd

33 N • m

(3.3 kgf.

m, 24

ft

• Ib)

8x

100

mm

8

20

N •m(2.

0kgf.

m,

14ft*

Ib)

D

271

271

1st

15N'm(1.

5kgf'm,

nft-tb>

2nd

39 N • m

(3.9 kgf

• m,

28

ft

• Ib)

10x

45

mm

12

39 N • m

(3.9 kgf

• m,

28

ft

• Ib)

16

572

13

1st

11

N-md.1 kgfTn, 8.0ft •lb)

2nd

22 N - m (2.2 kgf-m,

16

ft-Ib)

8x30

mm

REMOVAL

AND

INSTALLATION

CHART

Step

Procedure/Part

name

MUFFLER

DISASSEMBLY

1

Exhaust

temperature

sensor

2

Water

temperature

sensor

3

Bolt

4

Muffler

stay

5

Bolt

6

Cover

7

Gasket

8

Catalyst

housing

Q'ty

Service

points

Follow

the

left

"Step"

for

disassembly

1

1

2

1

6

1

1

1

Not

reusable

5-8

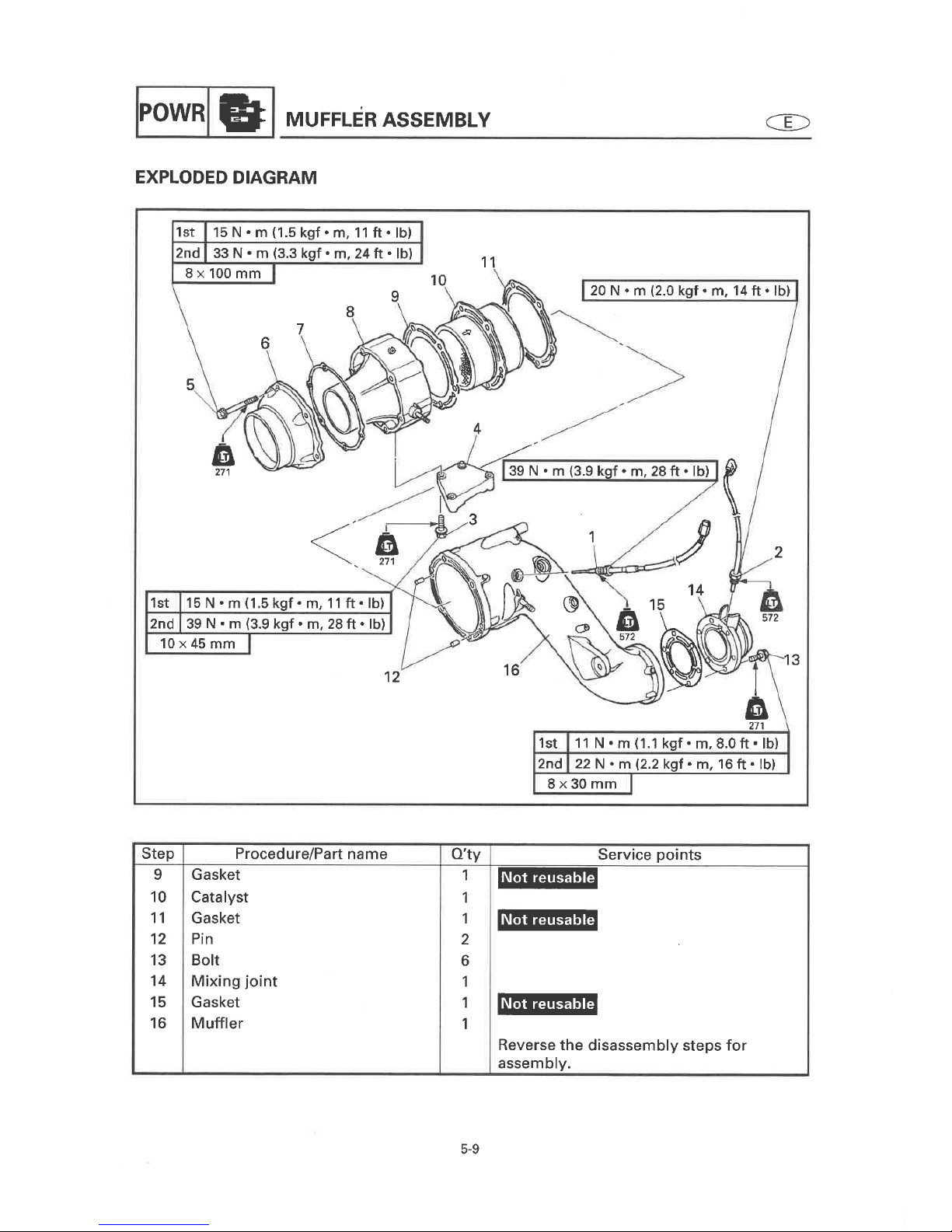

POWR

g|

MUFFLER

ASSEMBLY

EXPLODED

DIAGRAM

1st

15N*m(1.

5kgfTn,

11fflb)

2nd

33 N • m

(3.3 kgf

• m,

24

ft

• Ib)

8x

100

mm

9

8

7

6

20N

• m

(2.0 kgf-m,

Uft*

Ib)

271

39 N • m

(3.9 kgf

• m,

28

ft

• Ib)

271

1st

15

N •md.

5kgf.

rn,

11

ft.

lb)

2nd

39N-m(3.

9kgf'm,

28fflb)

10x45

mm

12

Step

Procedure/Part

name

9

Gasket

10

Catalyst

11

Gasket

12

Pin

13

Bolt

14

Mixing

joint

15

Gasket

16

Muffler

Q'ty

1

1

1

2

6

1

1

1

\y

16

1st

11

N-m

(1.1 kgf'm, 8.0ft-Ib)

2nd

22N.

m(2.

2kgf.m,16fflb)

8x30

mm

Service

points

Not

reusable

Not

reusable

Not

reusable

Reverse

the

disassembly

steps

for

assembly.

5-9

Loading...

Loading...