Yamaha TZ125 M1 (M) 2000 Owner's manual

4JT-28199-16LIT-11626-13-42

OWNER’S SERVICE MANUAL

TZ125M1/(M)

TZ125M1/(M)

OWNER’S SERVICE MANUAL

©1999 by Yamaha Motor Corporation, U.S.A.

1st Edition, August 1999

All rights reserved. Any reprinting or

unauthorized use without the written

permission of Yamaha Motor Corporation

U.S.A. is expressly prohibited.

Printed in Japan

P/N. LIT-11626-13-42

EC010000

EC020000

INTRODUCTION

Congratulations on your purchase of a Y amaha

TZ series. This model is the culmination of

Yamaha’s vast experience in the production of

pacesetting racing machines. It represents the

highest grade of craftsmanship and reliability

that have made Yamaha a leader.

This manual explains operation, inspection,

basic maintenance and tuning of your

machine. If you have any questions about this

manual or your machine, please contact your

Yamaha dealer.

NOTE:

As improvements are made on this model,

some data in this manual may become outdated. If you have any questions, please consult

your Yamaha dealer.

W

PLEASE READ THIS MANUAL CAREFULLY

AND COMPLETELY BEFORE OPERATING

THIS MACHINE. DO NOT ATTEMPT TO

OPERATE THIS MACHINE UNTIL YOU

HAVE ATTAINED A SATISFACTORY

KNOWLEDGE OF ITS CONTROLS AND

OPERATING FEATURES AND UNTIL YOU

HAVE BEEN TRAINED IN SAFE AND PROPER RIDING TECHNIQUES. REGULAR

INSPECTIONS AND CAREFUL MAINTENANCE, ALONG WITH GOOD RIDING

SKILLS, WILL ENSURE THAT YOU SAFELY

ENJOY THE CAPABILITIES AND THE

RELIABILITY OF THIS MACHINE.

EC030010

WARRANTY INFORMATION

This model is sold AS IS, WITHOUT ANY WARRANTIES EXPRESSED OR IMPLIED REGARDLESS OF THE INTENDED USE.

THE PURCHASER OF THIS MACHINE, which is intended for competition purposes, IS RESPONSIBLE FOR ALL COSTS, SERVICE AND/OR REPAIR.

EC040001

IMPORTANT NOTICE

THIS MACHINE IS DESIGNED STRICTLY

FOR COMPETITION USE, ONLY ON A

CLOSED COURSE. It is illegal for this

machine to be operated on any public street,

road, or highway. Off-road use on public lands

may also be illegal. Please check local regulations before riding.

1. THIS MACHINE IS TO BE OPERATED

BY AN EXPERIENCED RIDER ONLY.

Do not attempt to operate this

machine at maximum power until you

are totally familiar with its characteristics.

2. THIS MACHINE IS DESIGNED TO BE

RIDDEN BY THE OPERATOR ONLY.

Do not carry passengers on this

machine.

3. ALWA YS WEAR PROTECTIVE APPAREL.

When operating this machine, always

wear an approved helmet with goggles or a face shield. Also wear heavy

boots, gloves, and protective clothing. Always wear proper fitting clothing that will not be caught in any of

the moving parts or controls of the

machine.

4. ALWAYS MAINTAIN YOUR MACHINE

IN PROPER WORKING ORDER.

For safety and reliability, the machine

must be properly maintained. Always

perform the pre-operation checks

indicated in this manual. Correcting a

mechanical problem before you ride

may prevent an accident.

5. GASOLINE IS HIGHLY FLAMMABLE.

Always turn off the engine while refueling. Take care to not spill any gasoline on the engine or exhaust system.

Never refuel in the vicinity of an open

flame, or while smoking.

&SAFETY INFORMATION

6. GASOLINE CAN CAUSE INJURY.

If you should swallow some gasoline,

inhale excess gasoline vapors, or

allow any gasoline to get into your

eyes, contact a doctor immediately. If

any gasoline spills onto your skin or

clothing, immediately wash skin

areas with soap and water, and

change your clothes.

7. ONLY OPERATE THE MACHINE IN AN

AREA WITH ADEQUATE VENTILATION.

Never start the engine or let it run for

any length of time in an enclosed

area. Exhaust fumes are poisonous.

These fumes contain carbon monoxide, which by itself is odorless and

colorless. Carbon monoxide is a dangerous gas which can cause unconsciousness or can be lethal.

8. PARK THE MACHINE CAREFULLY;

TURN OFF THE ENGINE.

Always turn off the engine if you are

going to leave the machine. Do not

park the machine on a slope or soft

ground as it may fall over.

9. PROPERLY SECURE THE MACHINE

BEFORE TRANSPORTING IT.

When transporting the machine in

another vehicle, always be sure it is

properly secured and in an upright

position and that the fuel cock is in

the “OFF” position. Otherwise, fuel

may leak out of the carburetor or fuel

tank.

EC050000

TO THE NEW OWNER

This manual will provide you with a good basic

understanding of features, operation, and

basic maintenance and inspection items of this

machine. Please read this manual carefully

and completely before operating your new

machine. If you have any questions regarding

the operation or maintenance of your machine,

please consult your Yamaha dealer.

NOTE:

This manual should be considered a permanent part of this machine and should remain

with it even if the machine is subsequently

sold.

EC060000

NOTICE

Some data in this manual may become outdated due to improvements made to this model in

the future. If there is any question you have

regarding this manual or your machine, please

consult your Yamaha dealer.

Weights of machines without fuel

The minimum weights for road race

machines are:

for the class 125 cc . . . . . . . . . . .minimum

70 kg (154 lb)

for the class 250 cc . . . . . . . . . . .minimum

95 kg (209 lb)

for the class 500 cc . . . . . . . . . . .minimum

131 kg (289 lb)

In modifying your machine (e.g., for weight

reduction), take note of the above limits of

weight.

EC070011

F.I.M. MACHINE WEIGHTS:

EC080000

HOW TO USE

THIS MANUAL

EC081000

P ARTICULARLY IMPORTANT INFORMA TION

!!

The Safety Alert Symbol means ATTENTION!

BECOME ALERT! YOUR SAFETY IS

INVOLVED!

W

Failure to follow WARNING instructions could

result in severe injury or death to the machine

operator, a bystander, or a person inspecting

or repairing the machine.

CC

CAUTION:

A CAUTION indicates special precautions that

must be taken to avoid damage to the

machine.

NOTE:

A NOTE provides key information to make procedures easier or clearer.

EC082000

FINDING THE REQUIRED PAGE

1. This manual consists of seven chapters;

“General Information”, “Specifications”,

“Regular inspection and adjustments”,

“Engine”, “Chassis”, “Electrical” and

“Tuning”.

2. The table of contents is at the beginning of

the manual. Look over the general layout of

the book before finding then required chapter and item.

Bend the book at its edge, as shown, to find

the required fore edge symbol mark and go

to a page for required item and description.

EC083000

MANUAL FORMAT

All of the procedures in this manual are organized in a sequential, step-by-step format. The information has been complied to provide the mechanic with an easy to read, handy reference that contains comprehensive explanations of all disassembly, repair, assembly, and inspection operations.

In this revised format, the condition of a faulty component will precede an arrow symbol and the

course of action required will follow the symbol, e.g.,

•Bearings

Pitting/Damage ≥ Replace.

EC084002

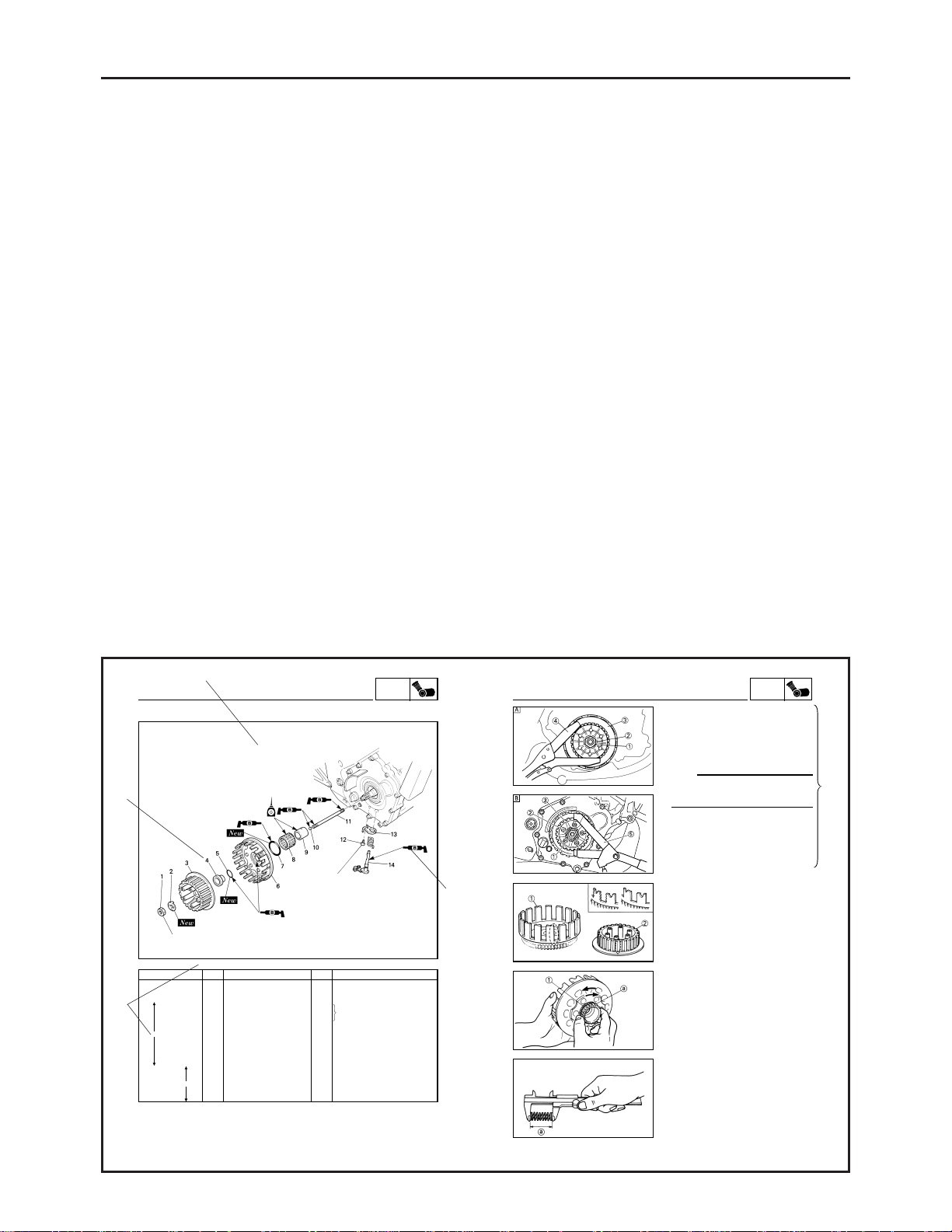

HOW TO READ DESCRIPTIONS

To help identify parts and clarify procedure steps, there are exploded diagrams at the start of each

removal and disassembly section.

1. An easy-to-see exploded diagram 1 is provided for removal and disassembly jobs.

2. Numbers 2 are given in the order of the jobs in the exploded diagram. Anumber that is enclosed

by a circle indicates a disassembly step.

3. An explanation of jobs and notes is presented in an easy-to-read way by the use of symbol marks

3. The meanings of the symbol marks are given on the next page.

4. Ajob instruction chart 4 accompanies the exploded diagram, providing the order of jobs, names

of parts, notes in jobs, etc.

5. Extent of removal 5 is provided in the job instruction chart to save the trouble of an unneces-

sary removal job.

6. For jobs requiring more information, the step-by-step format supplements 6 are given in addi-

tion to the exploded diagram and job instruction chart.

CLUTCH

4-25

ENG

EC4A8100

CLUTCH HOUSING AND PUSH LEVER AXLE

Extend of removal: 1 Clutch housing removal 2 Push lever axle removal

Extend of removal Order Part name Q’ty Remarks

CLUTCH HOUSING AND

PUSH LEVER AXLE

REMOVAL

1 Nut (clutch boss) 1

2 Lock washer 1

Use special tool.

3 Clutch boss 1

Refer to “REMOVAL POINTS”.

4 Spacer 2 1

5 O-ring (small) 1

6 Clutch housing 1

7 O-ring (large) 1

8 Bearing 1

9 Spacer 1 1

10 Ball 1

11 Push rod 1

12 Bolt (seat plate) 1

13 Seat plate 1

14 Push lever axle 1

T

50 Nm (5.0 mdkg, 36 ftdlb)

T

11 Nm (1.1 mdkg, 8.0 ftdlb)

2

1

CLUTCH

4-26

EC4A3000

REMOVAL POINTS

EC483211

Clutch boss

1. Remove:

•Nut 1

•Lock washer 2

•Clutch boss 3

NOTE:

Straighten the lock washer tab and use the

clutch holding tool 4, 5 to hold the clutch

boss.

Clutch holding tool:

YM-91042 . . . . . . . . . . . . . . . .

44

90890-04086 . . . . . . . . . . . . .

55

B

A For USA and CDN

B Except for USA and CDN

EC4A4000

INSPECTION

EC484100

Clutch housing and boss

1. Inspect:

•Clutch housing 1

Cracks/Wear/Damage ≥ Replace.

•Clutch boss 2

Scoring/Wear/Damage ≥ Replace.

EC4A4100

Clutch housing

1. Check:

•Circumferential play

Free play exists ≥ Replace.

•Gear teeth a

Wear/Damage ≥ Replace.

•O-ring 1

Damage ≥ Replace.

EC484400

Clutch spring

1. Measure:

•Clutch spring free length a

Out of specification ≥ Replace springs as

a set.

Clutch spring free length:

Standard <Limit>

36.0 mm (1.417 in) 35.0 mm (1.378 in)

{

ENG

1

6

2

4

5

3

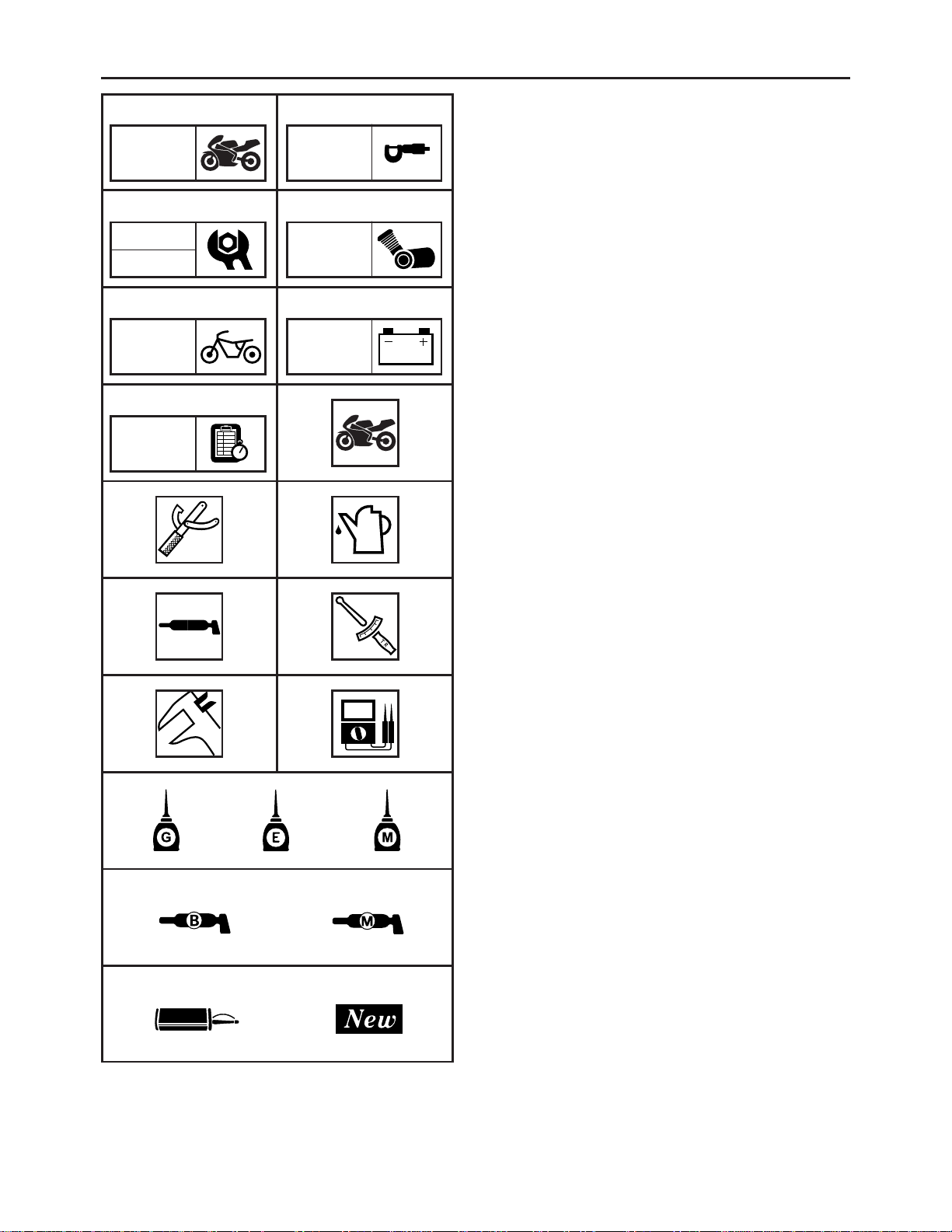

EC085002

ILLUSTRATED SYMBOLS

(Refer to the illustration)

Illustrated symbols 1 to 7 are designed as

thumb tabs to indicate the chapter’s number

and content.

1 General information

2 Specifications

3 Regular inspection and adjustments

4 Engine

5 Chassis

6 Electrical

7 Tuning

Illustrated symbols 8 to ¢ are used to identify the specifications appearing in the text.

8 With engine mounted

9 Special tool

0 Filling fluid

¡ Lubricant

™ Tightening

£ Specified value, Service limit

¢ Resistance ( Ω ), Voltage ( V ), Electric cur-

rent ( A)

Illustrated symbols ∞ to ª in the exploded dia-

grams indicate grade of lubricant and location

of lubrication point.

∞ Apply transmission oil

§ Apply engine mixing oil

¶ Apply molybdenum disulfide oil

• Apply lightweight lithium-soap base grease

ª Apply molybdenum disulfide grease

Illustrated symbols º to ! in the exploded dia-

grams indicate where to apply a locking agent

and where to install new parts.

º Apply locking agent (LOCTITE

®

)

! Use new one

1

GEN

INFO

3

INSP

ADJ

5

CHAS

7

TUN

8

6

ELEC

4

ENG

2

SPEC

9

¡

£

∞

º!

•

ª

¶§

¢

™

0

MEMO

EC090000

INDEX

GENERAL INFORMATION

GEN

INFO

1

TUNING

TUN

7

CHASSIS

CHAS

5

ELECTRICAL

ELEC

6

ENGINE

ENG

4

REGULAR INSPECTION AND ADJUSTMENTS

INSP

ADJ

3

SPECIFICATION

SPEC

2

EC0A0000

CONTENTS

CHAPTER 1

GENERAL INFORMATION

DESCRIPTION . . . . . . . . . . . . . . . . . . . . . 1-1

MACHINE IDENTIFICATION . . . . . . . . . . 1-2

IMPORTANT INFOMATION . . . . . . . . . . . 1-3

CHECKING OF CONNECTION . . . . . . . . 1-5

SPECIAL TOOLS. . . . . . . . . . . . . . . . . . . 1-6

CONTROL FUNCTIONS . . . . . . . . . . . . . 1-9

FUEL AND ENGINE MIXING OIL. . . . . . 1-14

INFORMATION BEFORE

PRE-OPERATION . . . . . . . . . . . . . . . . . 1-15

STARTING AND BREAK-IN . . . . . . . . . . 1-16

TORQUE-CHECK POINTS. . . . . . . . . . . 1-19

CLEANING AND STORAGE . . . . . . . . . 1-20

CHAPTER 2

SPECIFICATIONS

GENERAL SPECIFICATIONS . . . . . . . . . 2-1

MAINTENANCE SPECIFICATIONS . . . . . 2-3

GENERAL TORQUE SPECIFICATIONS . 2-11

DEFINITION OF UNITS . . . . . . . . . . . . . 2-11

CABLE ROUTING DIAGRAM . . . . . . . . 2-12

CHAPTER 3

REGULAR INSPECTION

AND ADJUSTMENTS

MAINTENANCE INTERVALS. . . . . . . . . . 3-1

PRE-OPERATION INSPECTION AND

MAINTENANCE. . . . . . . . . . . . . . . . . . . . 3-4

LOCKING WIRE INSTALLATION GUIDE. 3-5

ENGINE. . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

CHASSIS. . . . . . . . . . . . . . . . . . . . . . . . 3-13

ELECTRICAL. . . . . . . . . . . . . . . . . . . . . 3-37

CHAPTER 4

ENGINE

COWLING, SEAT AND FUEL TANK . . . . 4-1

EXHAUST PIPE AND SILENCER . . . . . . 4-3

RADIATOR . . . . . . . . . . . . . . . . . . . . . . . 4-4

CARBURETOR AND REED VALVE. . . . . 4-7

CYLINDER HEAD,CYLINDER AND

PISTON . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

CLUTCH . . . . . . . . . . . . . . . . . . . . . . . . 4-27

PRIMARY DRIVEN GEAR, PRIMARY

DRIVE GEAR AND BALANCER

SHAFT. . . . . . . . . . . . . . . . . . . . . . . . . . 4-35

SHIFT SHAFT AND OIL PUMP . . . . . . . 4-42

TRANSMISSION, SHIFT CAM AND

SHIFT FORK . . . . . . . . . . . . . . . . . . . . . 4-48

CDI MAGNETO . . . . . . . . . . . . . . . . . . . 4-58

ENGINE REMOVAL . . . . . . . . . . . . . . . . 4-61

CRANKCASE, CRANKSHAFT AND

WATER PUMP . . . . . . . . . . . . . . . . . . . . 4-65

CHAPTER 5

CHASSIS

FRONT WHEEL AND REAR WHEEL. . . . 5-1

FRONT BRAKE AND REAR BRAKE . . . . 5-9

FRONT FORK . . . . . . . . . . . . . . . . . . . . 5-25

HANDLEBAR. . . . . . . . . . . . . . . . . . . . . 5-39

STEERING . . . . . . . . . . . . . . . . . . . . . . . 5-44

SWINGARM. . . . . . . . . . . . . . . . . . . . . . 5-51

REAR SHOCK ABSORBER. . . . . . . . . . 5-58

CHAPTER 6

ELECTRICAL

ELECTRICAL COMPONENTS AND

WIRING DIAGRAM . . . . . . . . . . . . . . . . . 6-1

IGNITION SYSTEM . . . . . . . . . . . . . . . . . 6-2

SOLENOID VALVE SYSTEM . . . . . . . . . . 6-6

THERMO UNIT SYSTEM. . . . . . . . . . . . . 6-9

CHAPTER 7

TUNING

ENGINE. . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

CHASSIS. . . . . . . . . . . . . . . . . . . . . . . . 7-14

DESCRIPTION

1-1

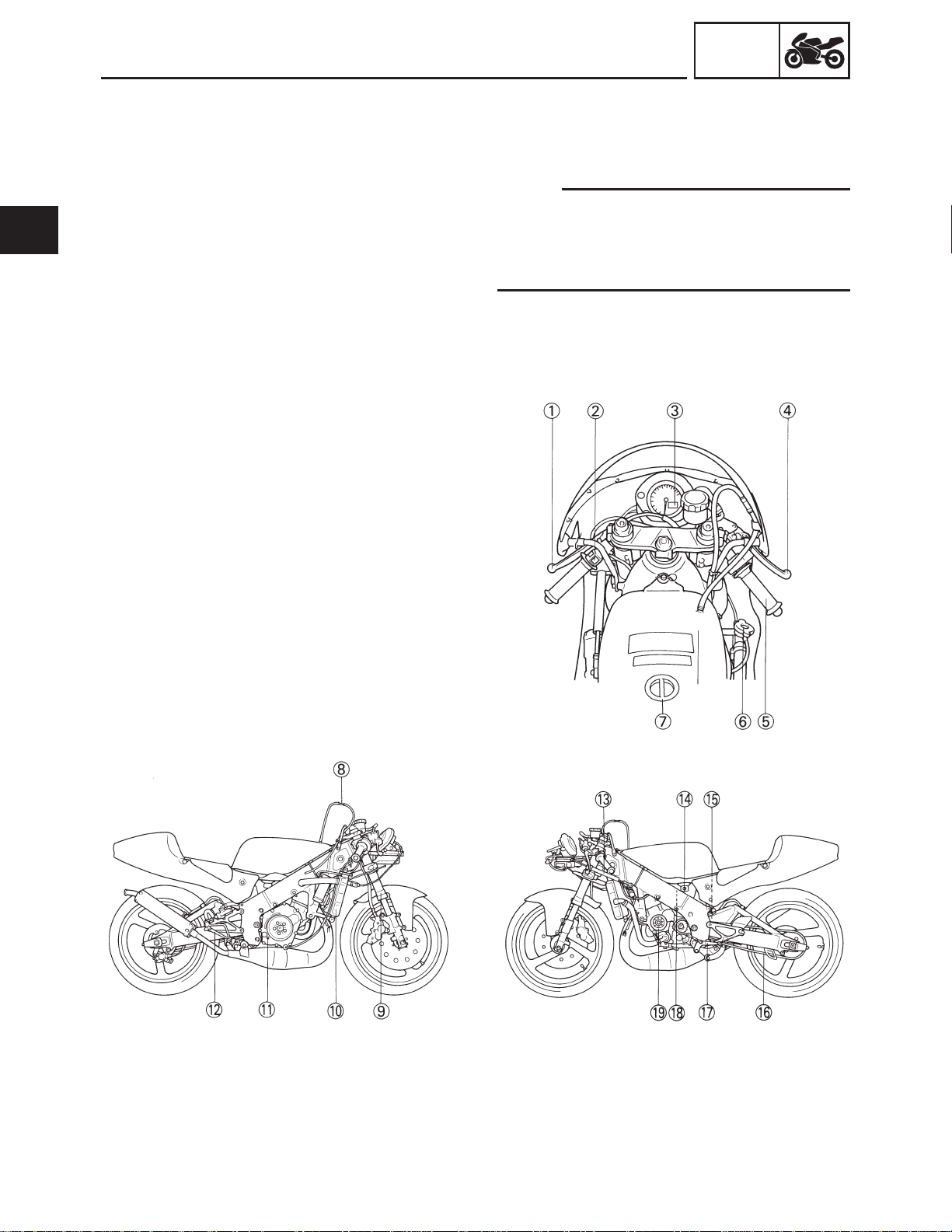

NOTE:

•The machine you have purchased may differ

slightly from those shown in the following.

•Designs and specifications are subject to

change without notice.

GEN

INFO

EC100000

GENERAL INFORMATION

EC110000

DESCRIPTION

1 Clutch lever

2 “ENGINE STOP” button

3 Water temperature gauge

4 Front brake lever

5 Throttle grip

6 Radiator cap

7 Fuel tank cap

8 Valve joint

9 Front fork

0 Radiator

¡ Check bolt (Transmission oil level)

™ Rear brake pedal

£ Steering damper

¢ Fuel cock

∞ Rear shock absorber

§ Drive chain

¶ Shift pedal

• Starter knob

ª CDI magneto

1

MACHINE IDENTIFICATION

1-2

EC120001

MACHINE IDENTIFICATION

There are two significant reasons for knowing

the serial number of your machine:

1. When ordering parts, you can give the num-

ber to your Yamaha dealer for positive identification of the model you own.

2. If your machine is stolen, the authorities will

need the number to search for and identify

your machine.

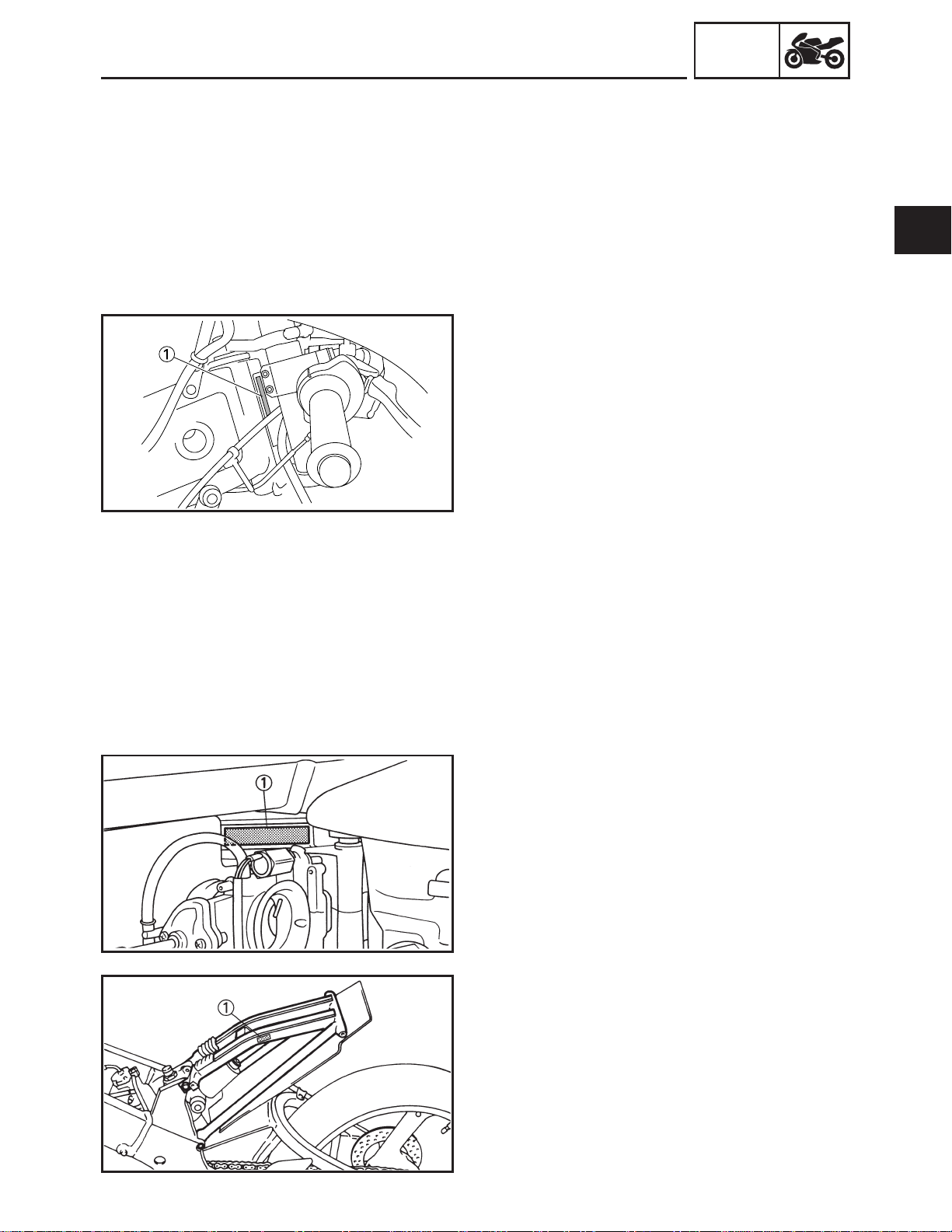

EC121001

VEHICLE IDENTIFICATION NUMBER

(For USA, CDN, AUS, NZ and E)

The vehicle identification number 1 is

stamped on the right of the steering head pipe.

EC122001

FRAME SERIAL NUMBER

(Except for USA, CDN, AUS, NZ and E)

The frame serial number 1 is stamped on the

right of the steering head pipe.

EC123001

ENGINE SERIAL NUMBER

The engine serial number 1 is stamped into

the elevated part of the right-side of the

engine.

EC124000

MODEL LABEL

The model label 1 is affixed to the frame

under the rider’s seat. This information will be

needed to order spare parts.

GEN

INFO

1

IMPORTANT INFORMATION

1-3

EC130000

IMPORTANT INFORMATION

EC131002

PREP ARATION FOR REMOVALAND DISASSEMBL Y

1. Remove all dirt, mud, dust, and foreign

material before removal and disassembly.

2. Use proper tools and cleaning equipment.

Refer to “SPECIAL TOOLS” section.

3. When disassembling the machine, keep

mated parts together. They include gears,

cylinders, pistons, and other mated parts

that have been “mated” through normal

wear. Mated parts must be reused as an

assembly or replaced.

4. During the machine disassembly, clean all

parts and place them in trays in the order of

disassembly. This will speed up assembly

time and help assure that all parts are correctly reinstalled.

5. Keep away from fire.

GEN

INFO

IMPORTANT INFORMATION

1-4

EC132000

ALL REPLACEMENT PARTS

1. We recommend to use Yamaha genuine

parts for all replacements. Use oil and/or

grease recommended by Yamaha for

assembly and adjustment.

EC133000

GASKETS, OIL SEALS AND O-RINGS

1. All gaskets, oil seals, and O-rings should be

replaced when an engine is overhauled. All

gasket surfaces, oil seal lips, and O-rings

must be cleaned.

2. Properly oil all mating parts and bearings

during reassembly. Apply grease to the oil

seal lips.

EC134000

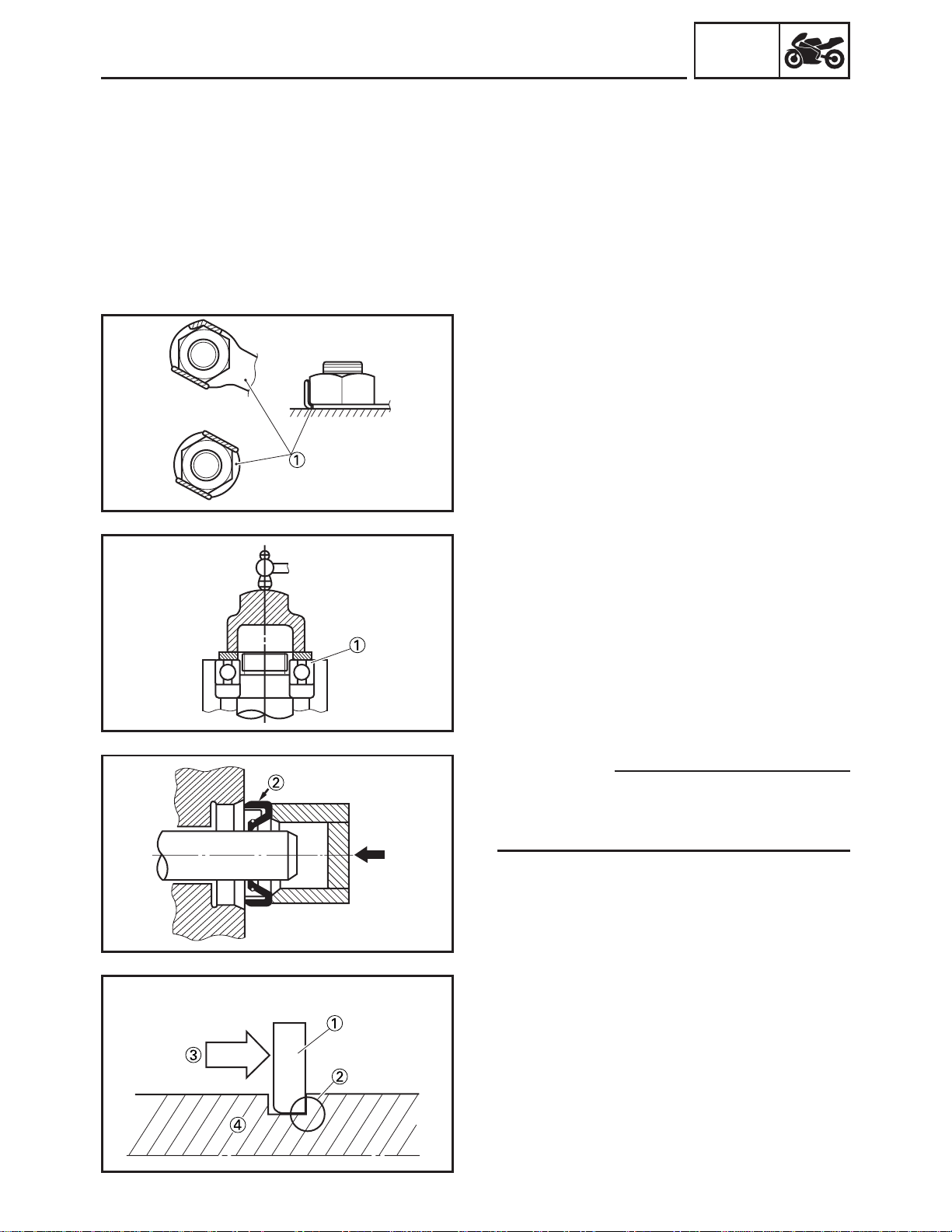

LOCK WASHERS/PLATES AND COTTER

PINS

1. All lock washers/plates 1 and cotter pins

must be replaced when they are removed.

Lock tab(s) should be bent along the bolt or

nut flat(s) after the bolt or nut has been

properly tightened.

EC135001

BEARINGS AND OIL SEALS

1. Install the bearing(s) 1 and oil seal(s) 2

with their manufacturer’s marks or numbers

facing outward. (In other words, the

stamped letters must be on the side

exposed to view.) When installing oil

seal(s), apply a light coating of light-weight

lithium base grease to the seal lip(s). Oil the

bearings liberally when installing.

CC

CAUTION:

Do not use compressed air to spin the bearings dry. This causes damage to the bearing surfaces.

EC136000

CIRCLIPS

1. All circlips should be inspected carefully

before reassembly. Always replace piston

pin clips after one use. Replace distorted

circlips. When installing a circlip 1, make

sure that the sharp-edged corner 2 is positioned opposite to the thrust 3 it receives.

See the sectional view.

4 Shaft

GEN

INFO

CHECKING OF CONNECTION

1-5

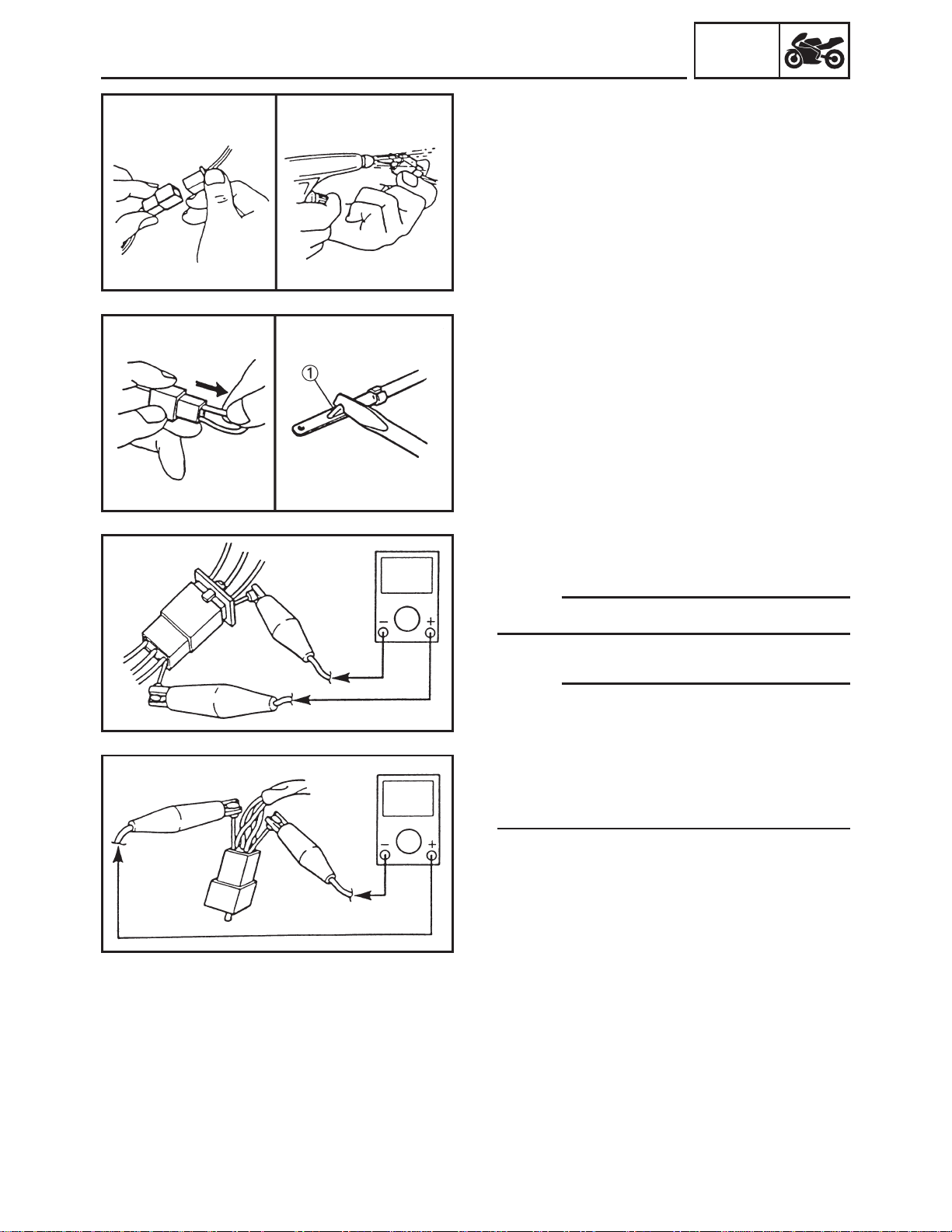

EC1C0001

CHECKING OF CONNECTION

Dealing with stains, rust, moisture, etc. on the

connector.

1. Disconnect:

•Connector

2. Dry each terminal with an air blower.

3. Connect and disconnect the connector two

or three times.

4. Pull the lead to check that it will not come

off.

5. If the terminal comes off, bend up the pin 1

and reinsert the terminal into the connector.

6. Connect:

•Connector

NOTE:

The two connectors “click” together.

7. Check for continuity with a tester.

NOTE:

•If there in no continuity, clean the terminals.

• Be sure to perform the steps 1 to 7 listed

above when checking the wireharness.

• For a field remedy, use a contact revitalizer

available on the market.

•Use the tester on the connector as shown.

GEN

INFO

SPECIAL TOOLS

1-6

GEN

INFO

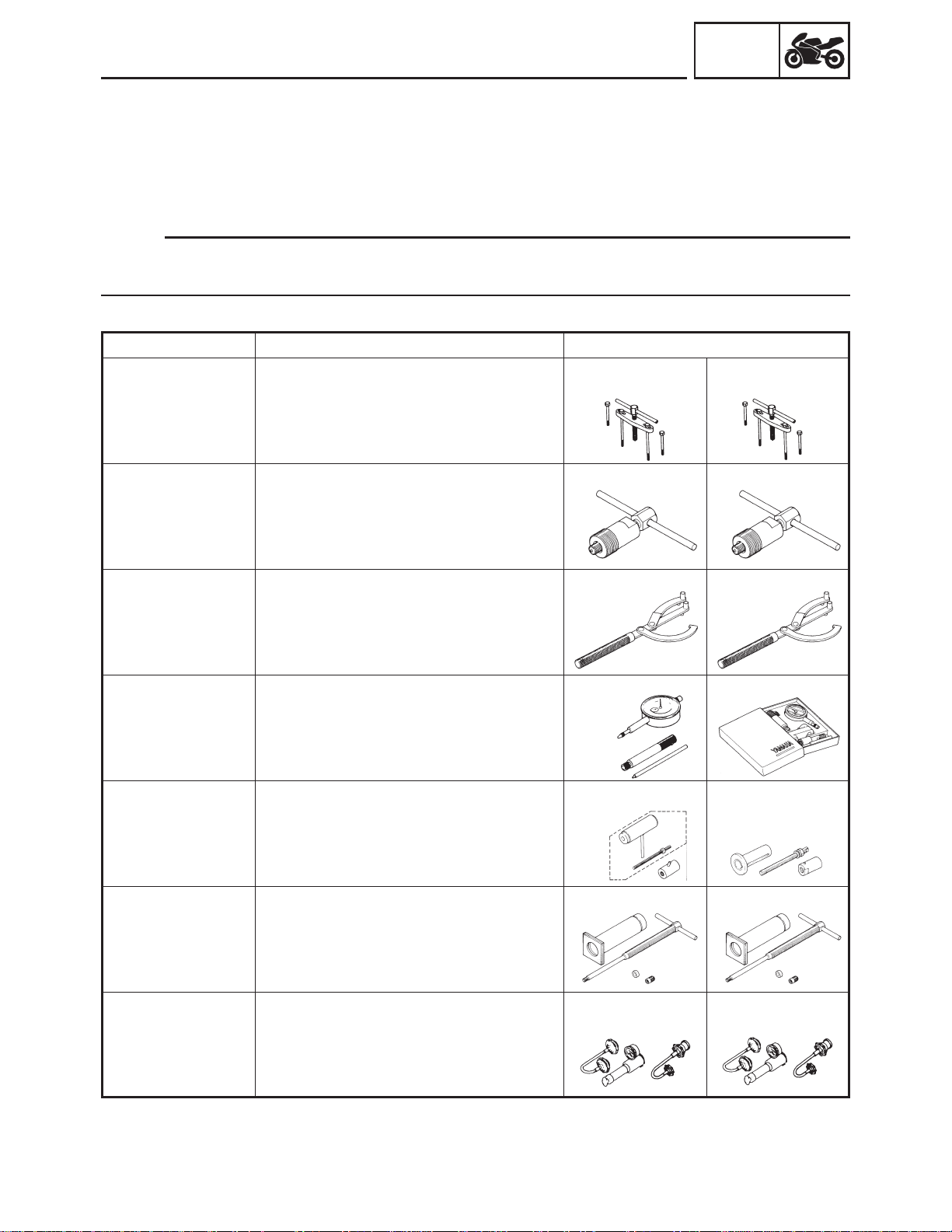

EC140001

SPECIAL TOOLS

The proper special tools are necessary for complete and accurate tune-up and assembly. Using the

correct special tool will help prevent damage caused by the use of improper tools or improvised

techniques. The shape and part number used for the special tool differ by country, so two types are

provided. Refer to the list provided to avoid errors when placing an order.

NOTE:

•For U.S.A. and Canada, use part number starting with “YM-” or “YU-”.

•For others, use part number starting with “90890-”.

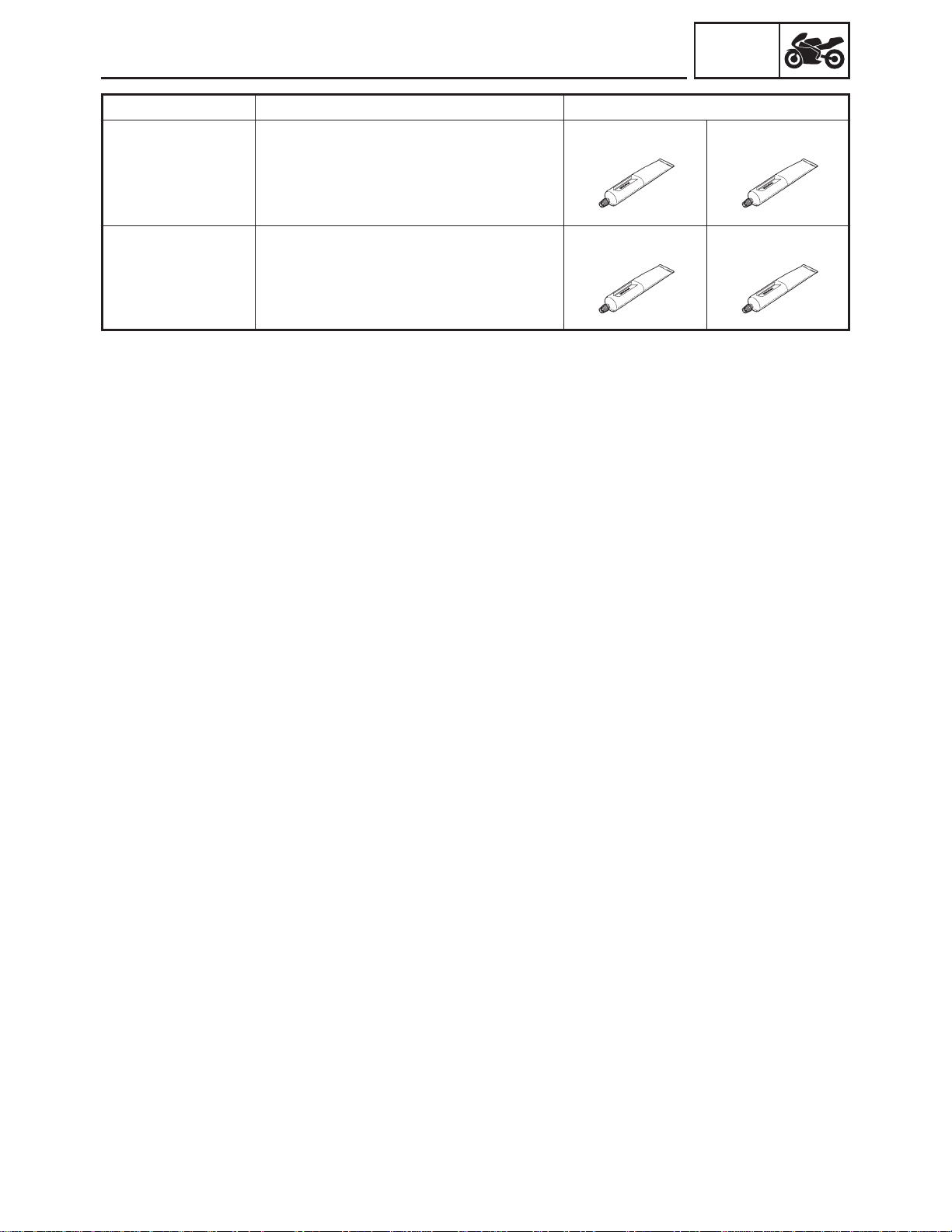

Part number Tool name / How to use Illustration

YU-01135-A, 90890-01135 Crankcase separating tool YU-01135-A 90890-01135

YM-01305, 90890-01305 Crankcase separating bolt YM-01305 90890-01305

These tools are used to split the crankcase as well

as remove the crankshaft from either case.

YM-01189, 90890-01189 Flywheel puller YM-01189 90890-01189

This tool is used to remove the flywheel magneto.

YU-01235, 90890-01235 Rotor holding tool YU-01235 90890-01235

This tool is used when loosening or tightening the

flywheel magneto securing nut.

YU-03097, 90890-01252 Dial gauge and stand YU-03097 90890-01252

YU-01256 Stand YU-01256

These tools are used to set the ignition timing.

Crankcase installing tool YU-90050 90890-01274

YU-90050, 90890-01274 Pot YU-90063 90890-01275

YU-90050, 90890-01275 Bolt 90890-01278

YU-90063, 90890-01278 Adapter

These tools are used to install the crankshaft.

YU-01304, 90890-01304 Piston pin puller YU-01304 90890-01304

This tool is used to remove the piston pin.

YU-24460-1, 90890-01325 Radiator cap tester YU-24460-1 90890-01325

YU-33984, 90890-01352 Adapter YU-33984 90890-01352

These tools are used for checking the cooling system.

SPECIAL TOOLS

1-7

GEN

INFO

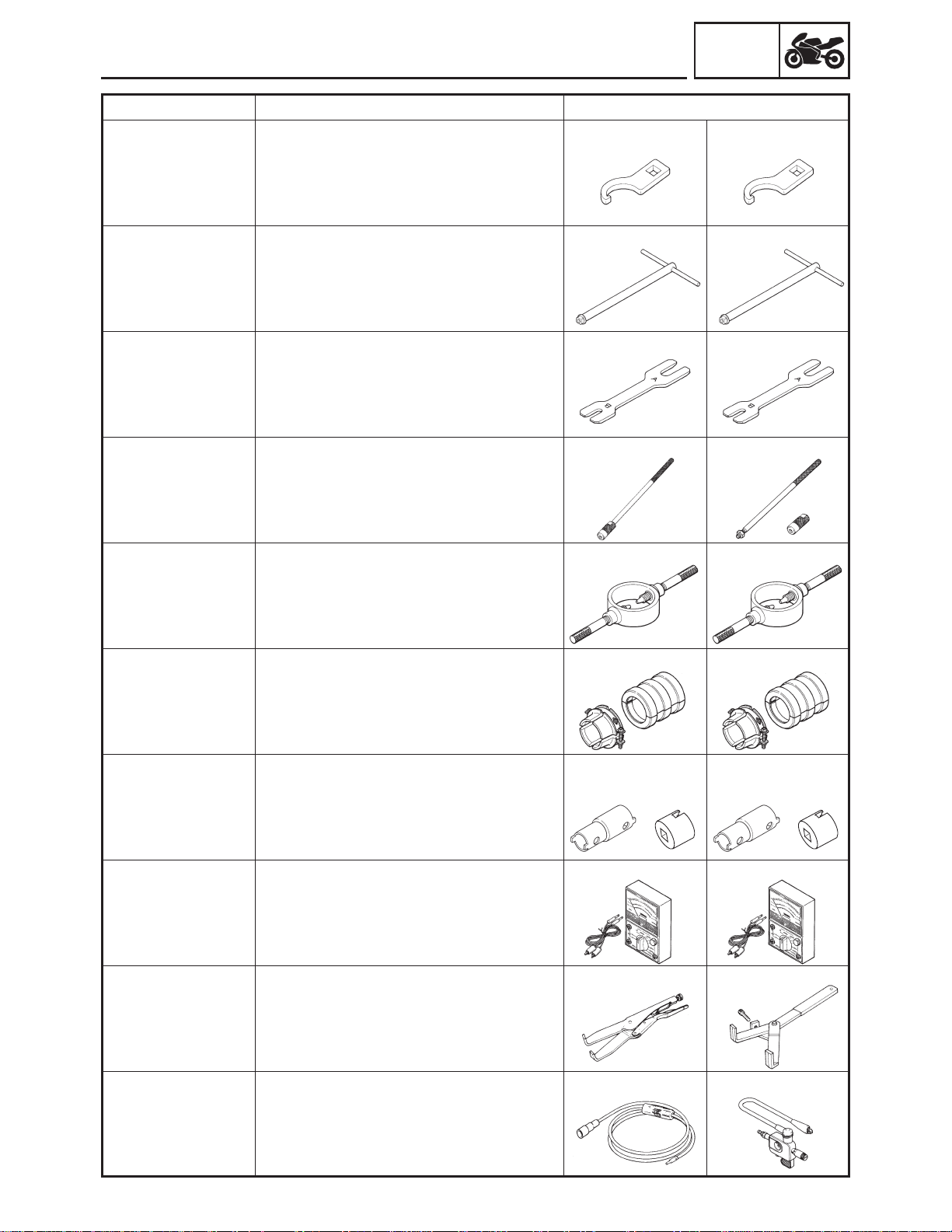

Part number Tool name / How to use Illustration

YM-33975, 90890-01403 Ring nut wrench YM-33975 90890-01403

This tool is used when tighten the steering ring nut

to specification.

YM-01425, 90890-01425 Damper rod holder YM-01425 90890-01425

Use this tool to remove and install the damper rod.

YM-01434, 90890-01434 Rod holder YM-01434 90890-01434

This tool is used to hold the fork spring.

90890-01436 Rod puller attachment YM-01437 90890-01436

YM-01437, 90890-01437 Rod puller 90890-01437

These tools are used to pull up the fork damper rod.

YM-01441, 90890-01441 Fork spring compressor YM-01441 90890-01441

This tool is used to compress the fork spring.

YM-01442, 90890-01442 Fork seal driver YM-01442 90890-01442

This tool is used when install the fork oil seal.

YM-01455, 90890-01455 Pivot shaft wrench YM-01455 90890-01455

YM-01476, 90890-01476 Pivot shaft wrench adapter YM-01476 90890-01476

These tools are used to loosen or tighten the pivot

adjust bolt.

YU-03112, 90890-03112 Yamaha pocket tester YU-03112 90890-03112

Use this tool to inspect the coil resistance, output

voltage and amperage.

YM-91042, 90890-04086 Clutch holding tool YM-91042 90890-04086

This tool is used to hold the clutch when removing or

installing the clutch boss securing nut.

YM-34487 Dynamic spark tester YM-34487 90890-06754

90890-06754 Ignition checker

This instrument is necessary for checking the ignition

system components.

SPECIAL TOOLS

1-8

GEN

INFO

Part number Tool name / How to use Illustration

ACC-11001-05-01 Quick gasket

®

ACC-11001-05-01 90890-85505

90890-85505 YAMAHABond No. 1215

This sealant (Bond) is used for crankcase mating

surface, etc.

ACC-11001-30-00 Quick gasket

®

ACC-11001-30-00 90890-05143

90890-05143 YAMAHABond No.4

This sealant (Bond) is used for crankcase mating

surface, etc.

CONTROL FUNCTIONS

1-9

EC150000

CONTROL FUNCTIONS

EC151000

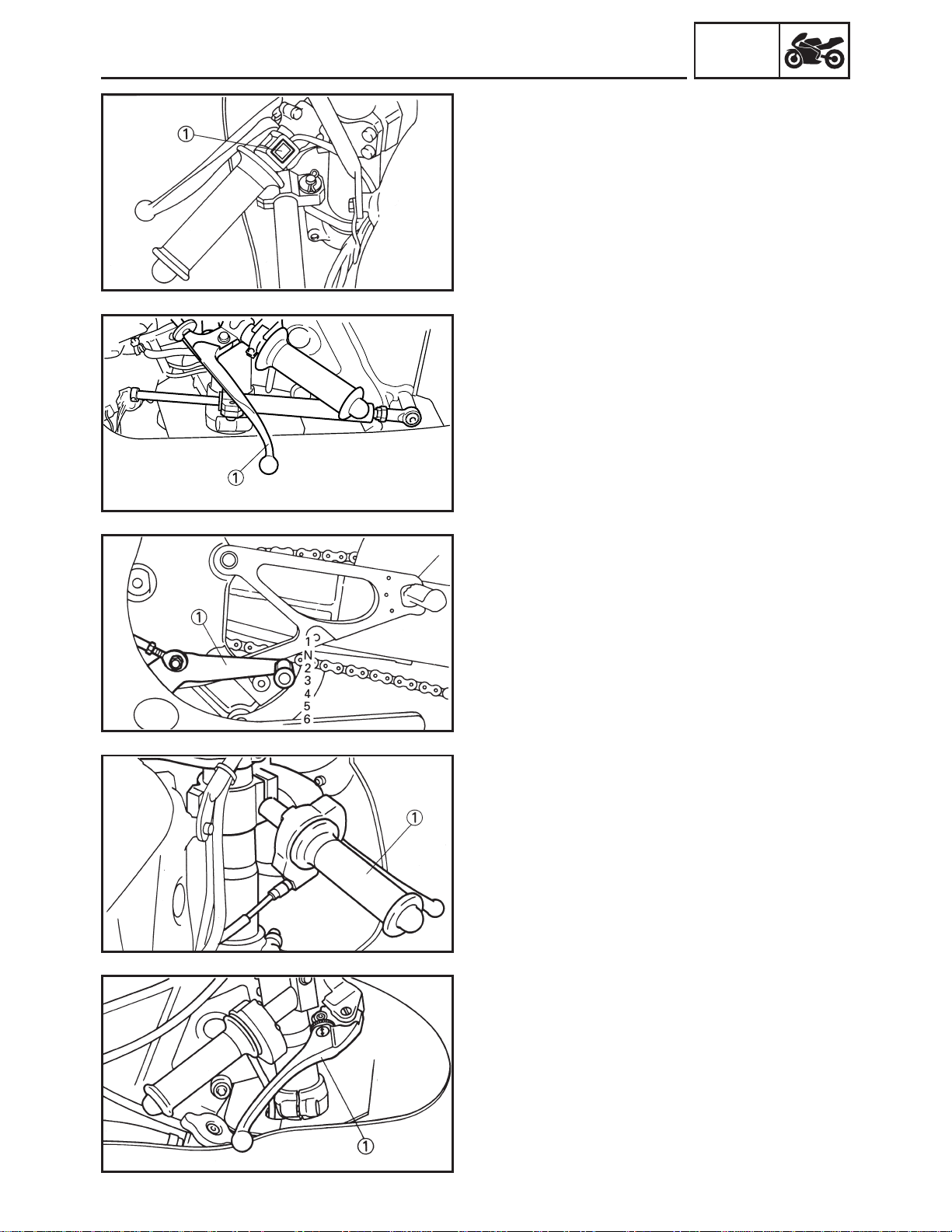

“ENGINE STOP” BUTTON

The “ENGINE STOP” button 1 is located on

the left handlebar. Continue pushing the

“ENGINE STOP” button till the engine comes

to a stop.

EC152000

CLUTCH LEVER

The clutch lever 1 is located on the left handlebar; it disengages or engages the clutch.

Pull the clutch lever to the handlebar to disengage the clutch, and release the lever to

engage the clutch. The lever should be pulled

rapidly and released slowly for smooth starts.

EC153000

SHIFT PEDAL

The gear ratios of the constant-mesh 6 speed

transmission are ideally spaced. The gears

can be shifted by using the shift pedal 1 on

the left side of the engine.

EC155001

THROTTLE GRIP

The throttle grip 1 is located on the right handlebar; it accelerates or decelerates the

engine. For acceleration, turn the grip toward

you; for deceleration, turn it away from you.

EC156000

FRONT BRAKE LEVER

The front brake lever 1 is located on the right

handlebar. Pull it toward the handlebar to activate the front brake.

GEN

INFO

CONTROL FUNCTIONS

1-10

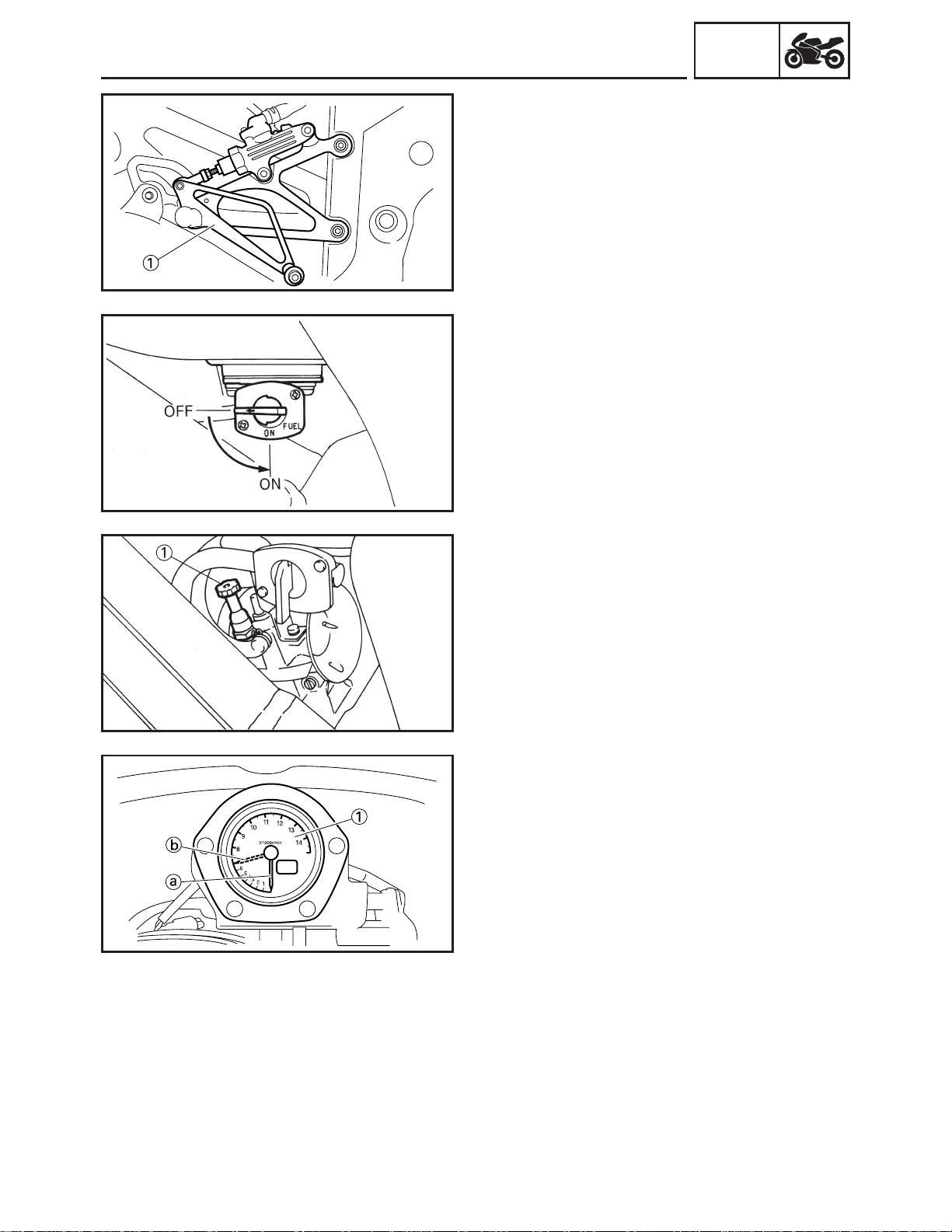

EC157000

REAR BRAKE PEDAL

The rear brake pedal 1 is located on the right

side of the machine. Press down on the brake

pedal to activate the rear brake.

EC158001

FUEL COCK

The fuel cock supplies fuel from the tank to

carburetor while filtering the fuel. The fuel cock

has the two positions:

OFF: With the lever in this position, fuel will

not flow. Always return the lever to this

position when the engine is not running.

ON: With the lever in this position, fuel flows

to the carburetor. Normal riding is done

with the lever in this position.

EC159000

STARTER KNOB (CHOKE)

When cold, the engine requires a richer air-fuel

mixture for starting. A separate starter circuit,

which is controlled by the starter knob 1, supplies this mixture. Pull the starter knob out to

open the circuit for starting. When the engine

has warmed up, push it in to close the circuit.

EC15V000

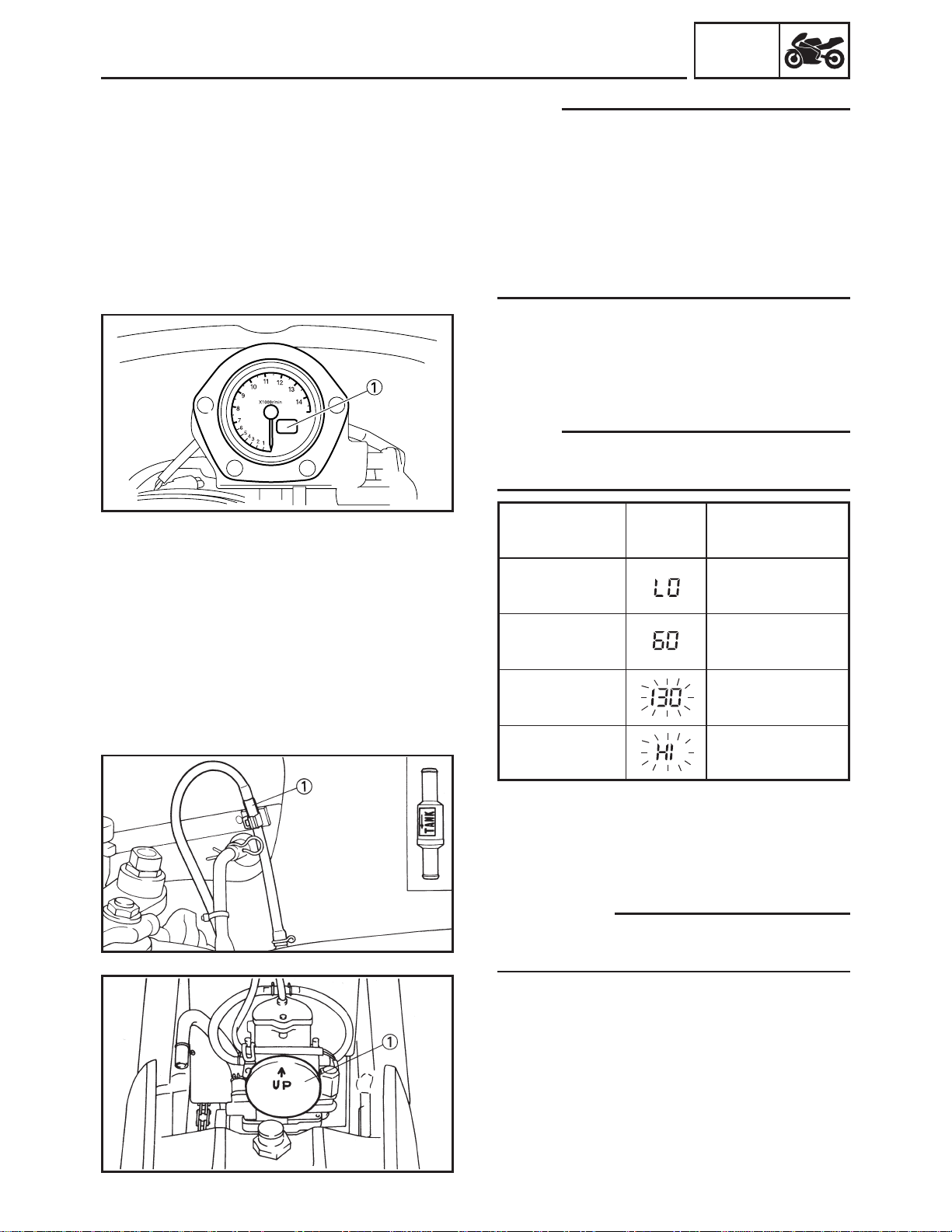

TACHOMETER

A stepping motor type tachometer is provided

for greater accuracy of the tachometer 1. This

tachometer features the following:

Sweeping:

After the engine is started, the tachometer

hand sweeps widely once over the tachometer

face and then returns to the zero position, as

initial operation. This is called “sweeping”. After

that, the tachometer indicates the correct revolutions.

Out-of-step indication:

If this tachometer is subjected to impact, etc, it

may allow its hand to point to the position b

stepping out of the position a where the hand

should be for correct indication. This is called

an “out-of-step” indication. Asimilar phenomenon may take place when the engine is

stopped during sweeping or at high rpm (as in

a plug chop) or while the machine is transported, though it never happens in normal riding.

GEN

INFO

CONTROL FUNCTIONS

1-11

GEN

INFO

NOTE:

•If an out-of-step indication takes place,

restarting the engine brings the tachometer

back to a normal indication through its corrective action.

•There is no functional problem involved with

the out-of-step indication, which can be

brought back to a normal indication through

the corrective action of the tachometer.

EC15B010

WATER TEMPERATURE GAUGE

The water temperature gauge 1 displays different indications according to the change in

the water temperature.

NOTE:

Water temperature may be 60 ˚C (140 ˚F)

when engine is operated in good conditions.

Cooling water

Display Conditions

temp.

~19 ˚C

“LO” is display.

(~66 ˚F)

20~119 ˚C Temperature is

(68~247 ˚F) displayed.

120~140 ˚C Temperature

(248~284 ˚F) flash.

141 ˚C~ Message “HI”

(285 ˚F~) flash.

EC15F000

VALVE JOINT

This valve joint 1 prevents fuel from flowing

out and is installed to the fuel tank breather

hose.

CC

CAUTION:

In this installation, make sure the arrow

faces the fuel tank and also downward.

EC15G000

MIXING COVER

The mixing cover 1 is installed to prevent

dust, etc. from entering the carburetor.

Remove this cover before starting the engine.

CONTROL FUNCTIONS

1-12

EC15H000

CARBURETOR COVER

The carburetor cover 1 is provided for carburetor space.

CC

CAUTION:

If the machine is run without this cover, the

carburetor settings will become faulty.

EC15L000

LOWER COWL

Make sure that the lower cowl 1 is installed

before riding the machine.

CC

CAUTION:

If the machine is run without lower cowl,

the carburetor settings will become faulty.

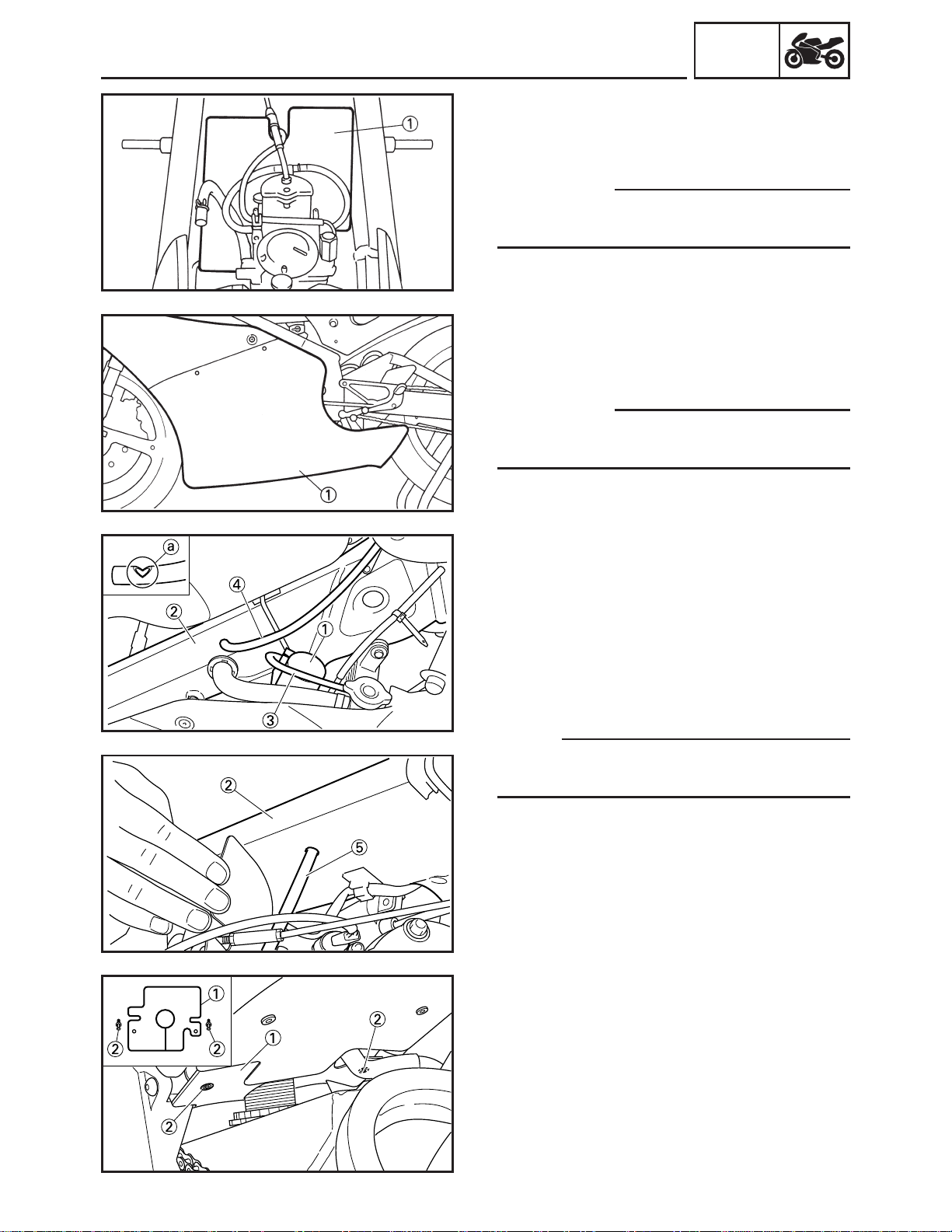

EC15M001

CATCH TANK

Put the tip of the breather hose into the catch

tank 1 and frame 2. Take care not to allow

the fuel, oil and cooling water to spill on the

course.

3 Radiator breather hose

4 Fuel tank breather hose

5 Transmission oil breather hose

NOTE:

When putting in the fuel tank breather hose, its

tip having a cut a should be on the frame side.

EC15N000

FLAP

When running in rainy weather, fit this flap 1 to

the rear frame with the screw 2 to prevent

water from entering the carburetor.

GEN

INFO

CONTROL FUNCTIONS

1-13

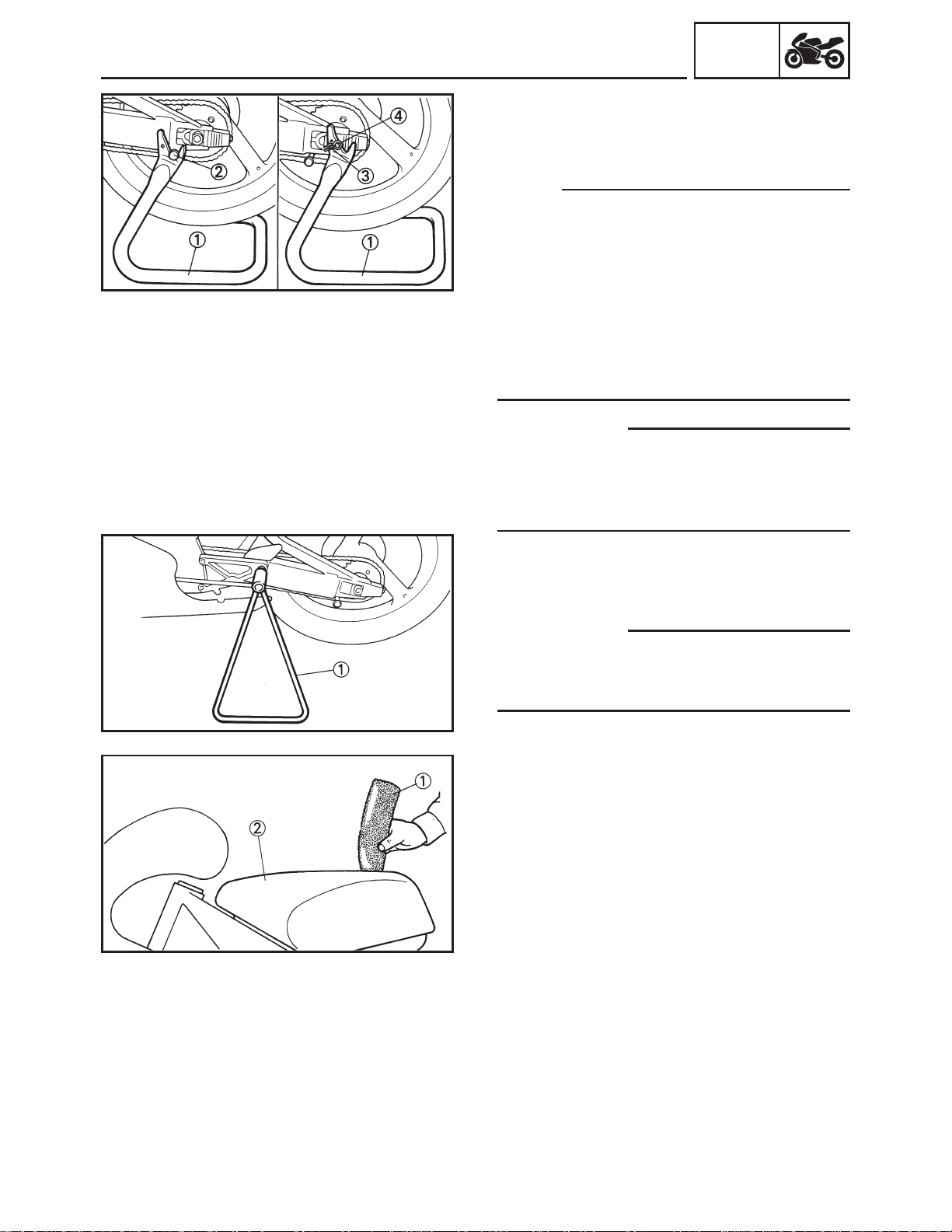

EC15Q001

DETACHABLE MAINSTAND

This mainstand 1 is used to support only the

machine when standing or transporting it.

NOTE:

The mainstand can be used to support the

machine two ways.

1. Hook the bracket of the mainstand onto the

swingarm hooks 2.

2. Stand shaft (with supplying parts):

Insert the stand shaft 3 through the hole of

the mainstand and rear wheel axle. Be sure

to install the clip 4 in the end of the stand

shaft.

W

•Never apply additional force to the mainstand.

•Remove this mainstand before starting

out.

EC15R001

DETACHABLE SIDESTAND

This sidestand 1 is used to support only the

machine when standing or transporting it.

W

• Never apply additional force to the sidestand.

•Remove this sidestand before starting out.

GEN

INFO

EC15T003

FIRE RETARDANT MATERIAL

For racing, be sure to fill the fuel tank 2 com-

pletely with fire retardant material (with supplying parts) 1.

FUEL AND ENGINE MIXING OIL

1-14

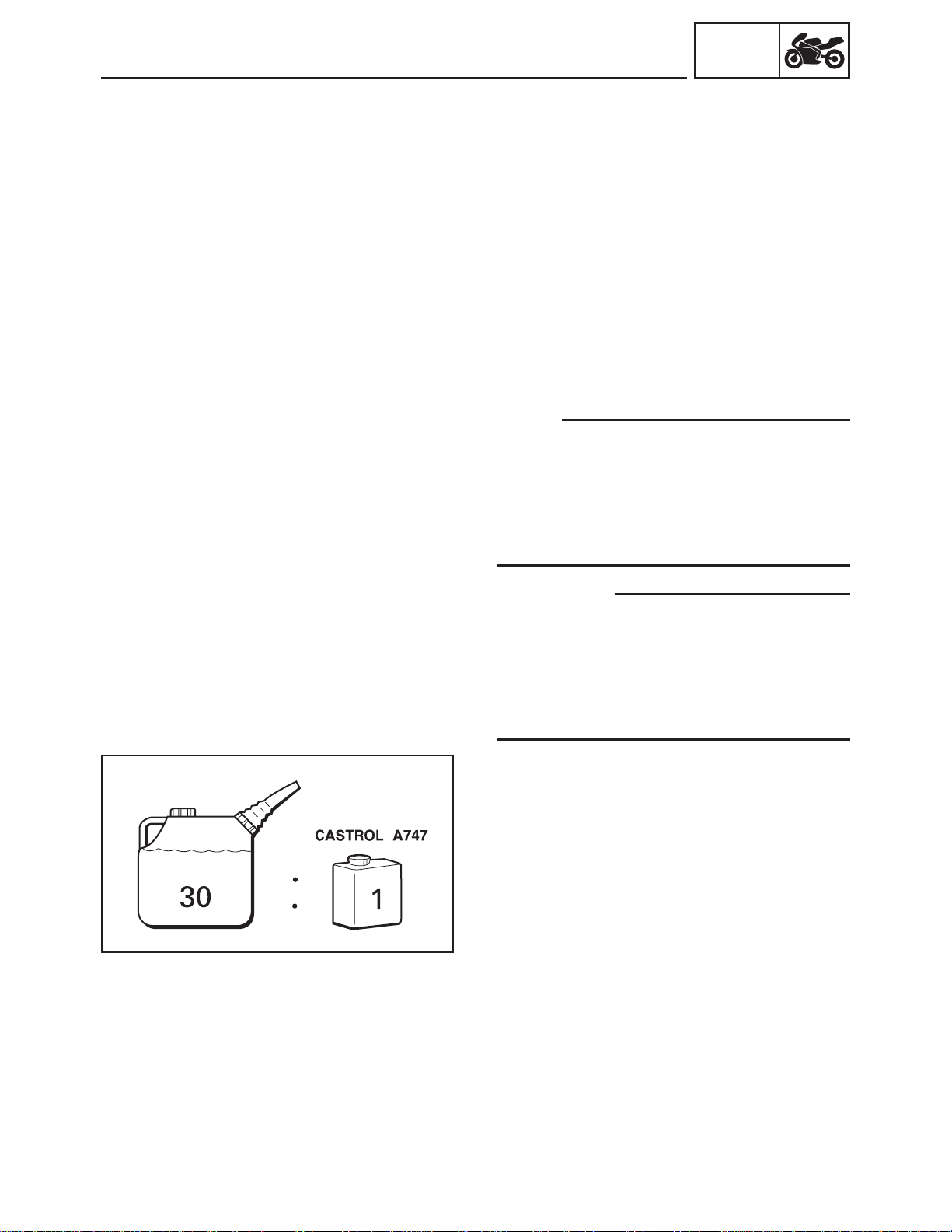

EC160040

FUEL AND ENGINE MIXING OIL

Mix oil with the gas at the ratio specified below.

Always use fresh, name-brand gasoline, and

mix the oil and gas the day of the race. Do not

use premix that is more than a few hours old.

Recommended fuel:

Except for AUS:

Premium unleaded fuel with

a research octane number of

95 or higher.

For AUS:

Unleaded fuel only

5

NOTE:

Except for AUS:

1. If knocking or pinging occurs, use a differ-

ent brand of gasoline or higher octane

grade.

2. If unleaded gasoline is not available, then

leaded gasoline can be used.

CC

CAUTION:

Never mix two types of oil in the same

batch; clotting of the oil could result. If you

wish to change oil types, be sure to drain

the fuel tank and the carburetor float bowl

of old premix prior to filling with the new

type.

Fuel tank capacity:

13.0 L (2.86 Imp gal, 3.43 US gal)

0

Mixing oil

Recommended oil:

Castrol A747

Mixing ratio: 30 : 1

2

GEN

INFO

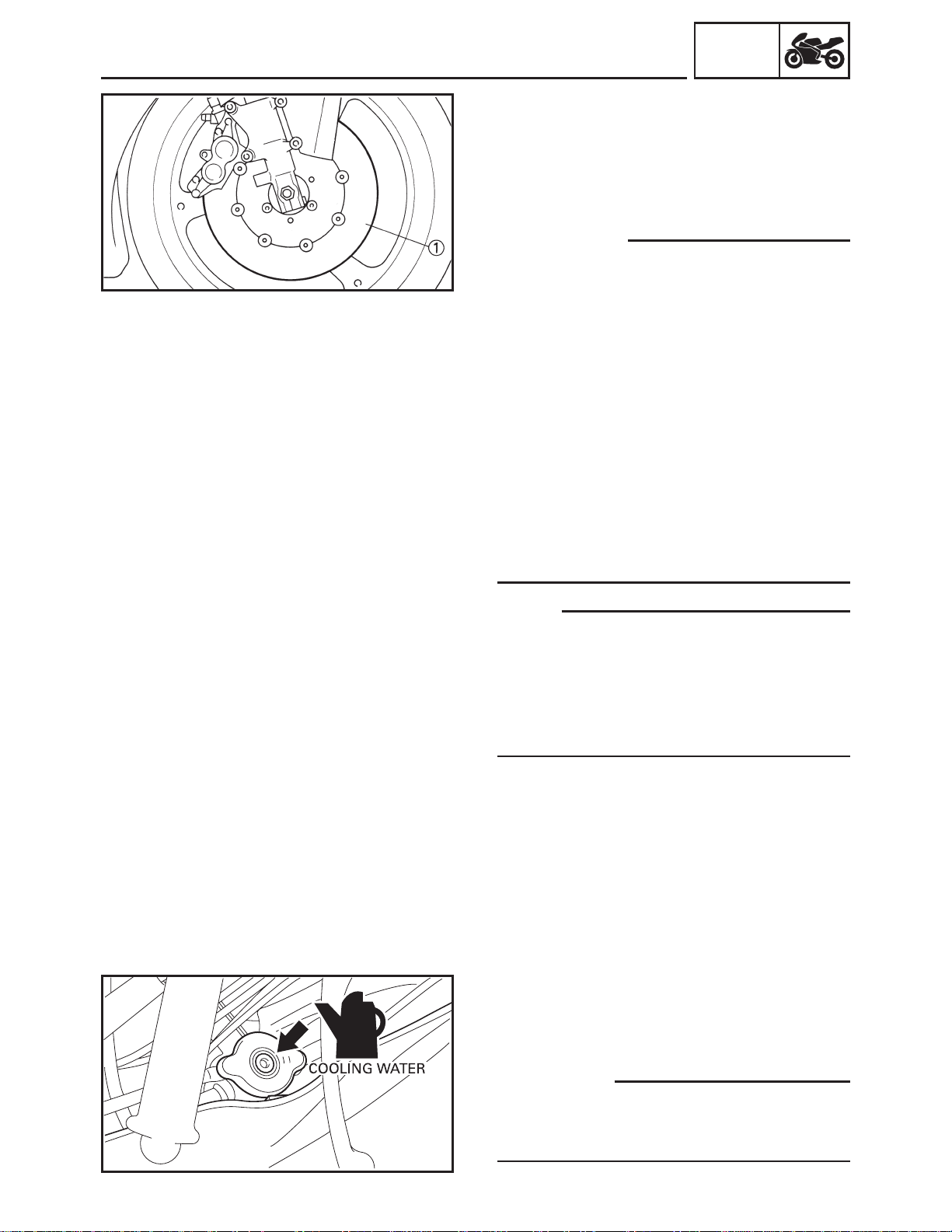

INFORMATION BEFORE PRE-OPERATION

1-15

EC170011

INFORMATION BEFORE PREOPERATION

1. The brake disc 1 is coated with a rust

inhibitor. Before riding the machine, thoroughly remove it using a lacquer thinner.

W

•LACQUER THINNER IS HIGHLY FLAMMABLE.

Always turn off the engine while using

lacquer thinner. Take care not to spill any

lacquer thinner on the engine or exhaust

system.

Never use it in the vicinity of an open

flame, or while smoking.

•LACQUER THINNER CAN CAUSE INJURY.

Always use lacquer thinner in a well ventilated area. If you should swallow some

lacquer thinner, inhale excess lacquer

thinner vapors, or allow any lacquer thinner to get into your eyes, contact a doctor

immediately.

NOTE:

• When the machine is not in use for a long

time, apply a rust inhibitor to the brake disc.

•After riding in the rainy weather, wipe the

moisture completely off the disc.

• If rust appears on the brake disc, carefully

remove it using #400 sand paper.

2. The cooling system is filled with coolant at

the factory to prevent rusting. Be sure to

replace coolant with soft water before riding.

CC

CAUTION:

Hard water or salt water is harmful to the

engine parts. You may use distilled water, if

you can’t get soft water.

GEN

INFO

STARTING AND BREAK-IN

1-16

EC190000

STARTING AND BREAK-IN

CC

CAUTION:

Before starting the machine, perform the

checks in the pre-operation check list.

W

Never start or run the engine in a closed

area. The exhaust fumes are poisonous;

they can cause loss of consciousness and

death in a very short time. Always operate

the machine in a well-ventilated area.

EC191020

STARTING A COLD ENGINE

1. Turn the fuel cock to “ON” and pull the

starter knob (CHOKE).

2. Shift the transmission into “1st” gear.

3. Apply the clutch lever and push the

machine.

4. After gaining some momentum, release the

clutch lever.

5. As soon as the engine starts, quickly apply

the clutch lever again and open the throttle

grip slightly at the same time so as to sustain idling of the engine. Then, shift the

transmission into neutral.

6. After applying full-throttle a few times, push

the starter knob (CHOKE) to the original

position. Take some time to allow the

engine to warm up.

EC192000

WARMING UP

Run the engine at varying speeds 5,000~6,000

r/min for 1~2 minutes. Fully warm up until the

water temperature gauge reads 60 ˚C (140 ˚F)

or so.

CC

CAUTION:

Do not warm up the engine for extended

periods.

GEN

INFO

Loading...

Loading...