Yamaha TR-SMS-02 Service Manual

Tyros3

MONITOR SPEAKER

/ TRS-MS02

SERVICE MANUAL

SERVICE MANUAL

CONTENTS

SPECIFICATIONS (Tyros3) ........................................3

SPECIFICATIONS (TRS-MS02) ................................. 5

PANEL LAYOUT (Tyros3) ...........................................6

PANEL LAYOUT (TRS-MS02) ....................................8

CIRCUIT BOARD LAYOUT .........................................9

DISASSEMBLY PROCEDURE (Tyros3) ...................11

DISASSEMBLY PROCEDURE (TRS-MS02) ........... 24

INSTALLING THE OPTIONAL DIMMS .....................26

REPLACING THE INTERNAL HARD DISK ............. 28

LSI PIN DESCRIPTION ............................................ 30

IC BLOCK DIAGRAM ...............................................44

CIRCUIT BOARDS ...................................................47

TEST PROGRAM .....................................................78

INITIAL SETTING ....................................................111

001811

PK

TRS-MS02

FORMATTING HDD ................................................113

SYSTEM RESET .....................................................114

OS UPDATE ............................................................116

INITIALIZING INTERNET SETTINGS .....................118

DATA BACKUP ........................................................119

DISPLAY MESSAGES ...........................................120

SYSTEM BOOTING FLOWCHART .......................123

MIDI IMPLEMENTAION CHART ............................ 125

MIDI DATA FORMAT .............................................. 126

PARTS LIST

BLOCK DIAGRAM

WIRING

OVERALL CIRCUIT DIAGRAM

HAMAMATSU, JAPAN

Copyright (c) Yamaha Corporation. All rights reserved. PDF ’08.09

Tyros3

IMPORTANT NOTICE

This manual has been provided for the use of authorized Yamaha Retailers and their service personnel. It has been assumed that basic

service procedures inherent to the industry, and more specifically Yamaha Products, are already known and understood by the users,

and have therefore not been restated.

WARNING : Failure to follow appropriate service and safety procedures when servicing this product may result in personal injury,

IMPORTANT : This presentation or sale of this manual to any individual or firm does not constitute authorization certification,

The data provided is belived to be accurate and applicable to the unit(s) indicated on the cover. The research engineering, and service

departments of Yamaha are continually striving to improve Yamaha products. Modifications are, therefore, inevitable and changes in

specification are subject to change without notice or obligation to retrofit. Should any discrepancy appear to exist, please contact the

distributor’s Service Division.

WARNING : Static discharges can destroy expensive components. Discharge any static electricity your body may have accumulated

destruction of expensive components and failure of the product to perform as specified. For these reasons, we advise

all Yamaha product owners that all service required should be performed by an authorized Yamaha Retailer or the

appointed service representative.

recognition of any applicable technical capabilities, or establish a principal-agent relationship of any form.

by grounding yourself to the ground bus in the unit (heavy gauge black wires connect to this bus.)

IMPORTANT : Turn the unit OFF during disassembly and parts replacement. Recheck all work before you apply power to the unit.

WARNING: This product contains chemicals known to the State of California to cause cancer, or birth defects or other reproductive harm.

DO NOT PLACE SOLDER, ELECTRICAL/ELECTRONIC OR PLASTIC COMPONENTS IN YOUR MOUTH FOR ANY REASON WHAT SO EVER!

Avoid prolonged, unprotected contact between solder and your skin! When soldering, do not inhale solder fumes or expose eyes to solder/

flux vapor!

If you come in contact with solder or components located inside the enclosure of this product, wash your hands before handling food.

IMPORTANT NOTICE FOR THE UNITED KINGDOM

Connecting the Plug and Cord

WARNING: THIS APPARATUS MUST BE EARTHED

IMPORTANT. The wires in this mains lead are coloured in accordance

with the following code:

GREEN-AND-YELLOW : EARTH

BLUE : NEUTRAL

BROWN : LIVE

As the colours of the wires in the mains lead of this apparatus may not

correspond with the coloured markings identifying the terminals in your

plug proceed as follows:

The wire which is coloured GREEN-and-YELLOW must be connected to

the terminal in the plug which is marked by the letter E or by the safety

earth symbol

The wire which is coloured BLUE must be connected to the terminal

which is marked with the letter N or coloured BLACK.

The wire which is coloured BROWN must be connected to the terminal

which is marked with the letter L or coloured RED.

or colored GREEN or GREEN-and-YELLOW.

W ARNING

Components having special characteristics are marked

and must be replaced with parts having specifi ca-

tion equal to those

originally installed.

• This applies only to products distributed by Yamaha-Kemble Music (U.K.) Ltd. (3 wires)

SAVING DATA

Saving and backing up your data

• The data of the types listed below are lost when you turn off the power to the instrument. Save the data to the User drive

or appropriate external media.

• Created/Edited Voices

Be sure to

• Created/Edited Styles

perform it

• Memorized One Touch Settings

• Recorded/Edited Songs

• Created Multi Pads

• Edited MIDI Settings

Data in the User drive may be lost due to malfunction or incorrect operation. Save important data to an external media.

Data in the internal hard disk drive may be lost due to malfunction or incorrect operation. We recommend that you backup

any necessary data to computer by using the USB Storage Mode.

Backing up the USB storage device/external media

• To protect against data loss through media damage, we recommend that you save your important data onto two USB

storage devices/external media.

2

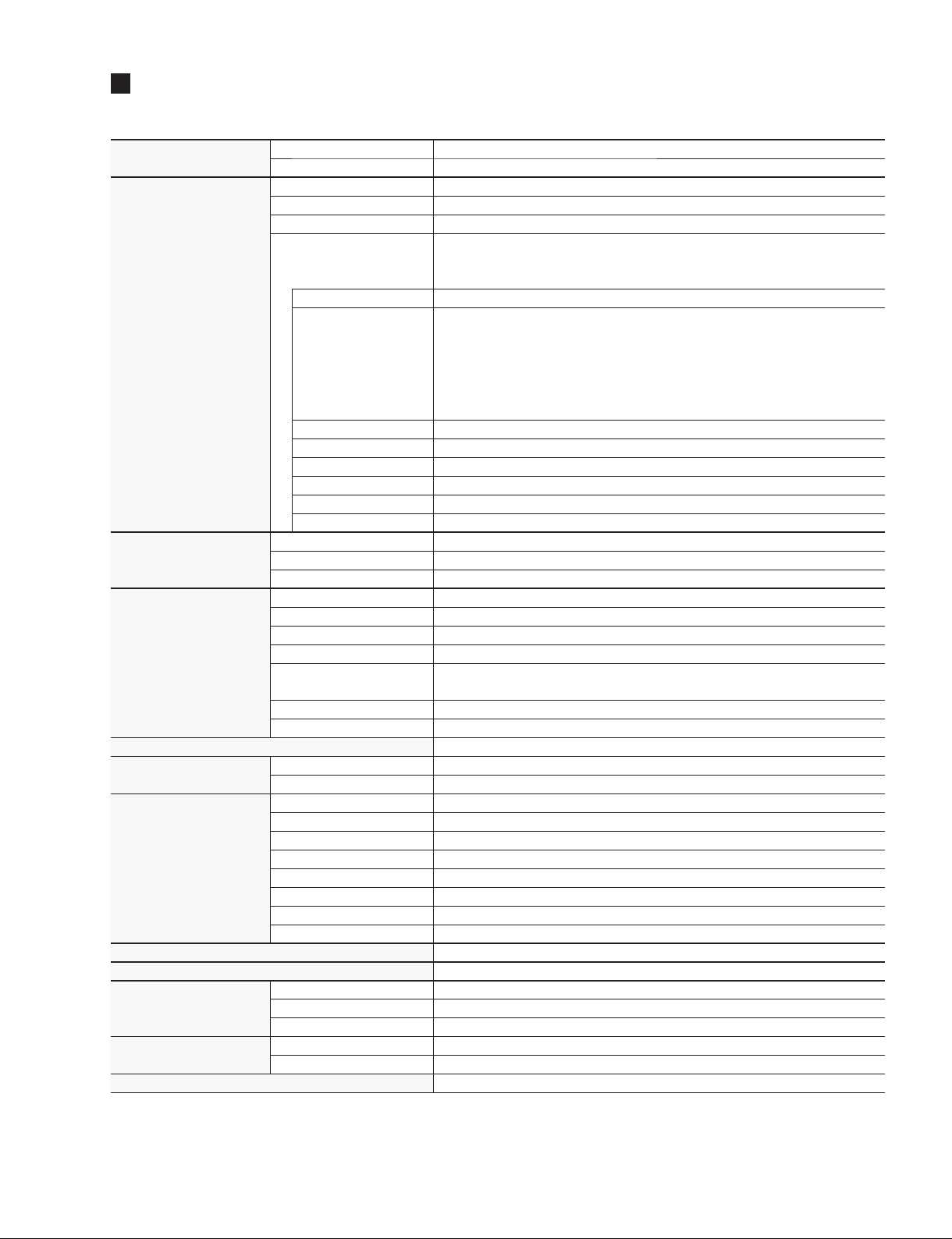

SPECIFICATIONS (Tyros3)

Tyros3

Keyboard

Voice

Voice Expandability

Style

OTS (One Touch Setting)

Music Finder

Song

Style/Song Control

Data Compatibility

Hard Disk Recorder

MultiPad

Vocal Harmony

Keys 61 keys (C1–C6) Initial Touch/Aftertouch

Type

Polyphony (max) 128

Layer R1/R2/R3/L

Split Style (default point: F#2), Left (default point: F#2), Right 3 (default point: G2)

Voices 749 Voices + 20 Organ Flutes + 480 XG Voices + 256 GM2 Voice +

MegaVoice 23

S.Articulation2!

(AEM technology)

S.Articulation! 53

Sweet! 26

Cool! 58

Live! 70

Live! Drums 12 (Included Live! SFX)

Organ Flutes! 20 Presets

Custom Voices Yes (Wave Addition: Normal Voices, Drum Voices)

Premium Voices Yes (optional DIMM memory is necessary)

Voice Set Yes

Styles 450

Format SFF GE

Control SYNC STOP, SYNC START, START/STOP, AUTO FILL IN

Section Intro x 3, Ending x 3, Main x 4, Fill In x 4, Break

Fingering Single Finger, Fingered, Fingered On Bass, Multi Finger, AI Fingered, Full

Style Creator Yes

RAM Capacity per a Style approx. 120 KB

Preset Records 1850

Music Finder Plus Yes

Preset Songs 5 Sample Songs

Control REC, STOP, PLAY/PAUSE, REW, FF, METRONOME

Recording Quick Recording, Multi Recording, Step Recording

Tracks 16

RAM Capacity per a Song approx. 300 KB

Lyric Display Yes

Score Display Yes

Song Position Jump 4 point / Loop

Tracks Play: 2 Stereo Track REC: 1 Stereo Track

Control REC, STOP, PLAY/PAUSE, PREV, NEXT, SELECT, SETTING

File Format Wave (16-bit, 44.1 kHz, stereo)

Preset 123 banks x 4 Pads

Control Pad 1–4, SELECT, STOP, SYNC START

Organ (FSX)

35 Drum/SFX kits

(And GS Voices for GS Song playback)

11

[TRUMPET] JazzTrumpet / ClassicTrumpet

[SAXOPHONE] JazzSax / BreathySax

[FLUTE/CLARINET] Clarinet / BalladClarinet / RomanceClarinet /

IrishPipeAir / IrishPipeDance

[ACCORDION] Harmonica / BluesHarp

Keyboard, AI Full Keyboard

4 for each Style

FADE IN/OUT, TAP TEMPO, TEMPO (5–500)

GM, XG, XF, SFF, SFF GE, GM2/GS (for Song Playback)

60 Preset + 10 user

3

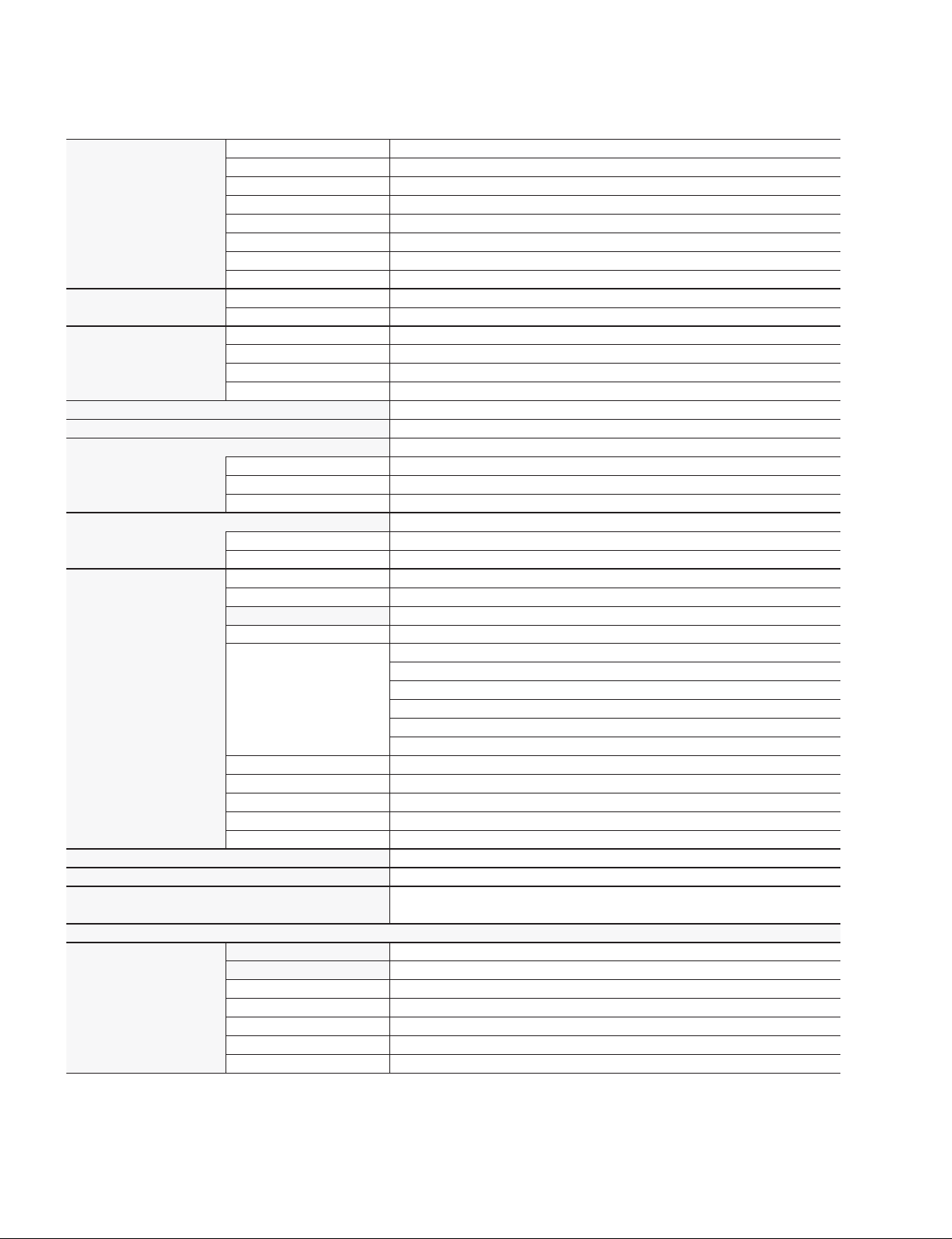

Tyros3

Effects

Registration Memory

Control

Transpose

Tuning

Display

Storage

Terminals

Dimensions [W x D x H] (without Music Rest)

Weight (without Music Rest)

Included Accessories

Reverb 42

Chorus 106

DSP1–DSP7 272

DSP8–DSP9 272 (for Style)

Master Compressor 5 presets + 5 user settings

Master Equalizer 5 presets + 2 user settings

Harmony/Echo Yes

Sustain Button Yes

Buttons 1–8

Control Bank select, Memory, Freeze, Registration Sequence

Pitch Bend Wheel Yes

Modulation Wheel Yes

Articulation Switch ART. 1, ART. 2

Sliders 9 (including 1 assignable)

Language 5 languages (English, German, French, Spanish, Italian)

Text Viewer Yes

Wallpaper Customize Yes

Internal Flash 3.2MB

Hard Disk (installable) Yes

USB TO HOST USB 2.0 HighSpeed x 1

USB TO DEVICE USB 2.0 HighSpeed x 2 (Front/Back)

MIDI MIDI A (IN/OUT), MIDI B (IN/OUT)

FOOT PEDAL 1 (SUSTAIN), 2 (ARTICULATION 1), 3 (VOLUME), Function Assignable

Audio LINE OUT MAIN (L/L+R, R)

RGB OUT Yes

VIDEO OUT NTSC / PAL Composit

LAN Yes (Internet Direct Connection)

For Option Speaker To Satellite Speaker (L/R), To Sub Woofer (L/R)

Power Supply AC IN

-12–0–12 (Keyboard/Song/Master)

414.8–440–466.8 Hz

640 x 480 dots TFT VGA color 7.5 inch LCD

USB to Device

LINE OUT SUB (1, 2)

LOOP SEND (L/L+R, R) / AUX OUT (Level Fixed): Selectable

LOOP RETURN (L/L+R, R) / AUX IN (with TRIM control)

MIC/LINE IN (with TRIM control)

PHONES

1140 x 450 x 143 mm

15 kg

AC power cord, Music rest and brackets, CD-ROM, Owner’s Manual,

Installation Guide, User Registration Card

Optional Accessories

4

Speaker TRS-MS02

Headphones HPE-150

Footswitch FC4/FC5

Foot Controller FC7

MIDI Foot Controller MFC10

Floppy Disk Drive UD-FD01

Keyboard Stand L-7S

SPECIFICATIONS (TRS-MS02)

Type AdvancedActive Servo Technology

Output power Satellitespeakers....... 20W + 20W (1 kHz, 4Ω

Subwoofer.................. 40 W(100 Hz, 5 Ω

Frequency response 32 Hzto 20 kHz

Speaker unit Satellitespeakers

Tweeter.......................1.9 cm(3/4")dome, magnetic shielding

Midrange.................... 8 cm (3")cone,magnetic shielding

Subwoofer...................16 cm (6.5") cone,magneticshielding

Power consumption 65W

Power supply U.S.A.and Canada models..........AC120V, 60 Hz

Australia model............................AC 240V, 50 Hz

U.K. andEurope models..............AC 230 V, 50Hz

Dimensions (WxHxD) Satellite speakers........97 (3.8") x174(6.9") x 178 (7")mm

Subwoofer...................350 (13.8") x 210(8.3")x 321 (12.6")mm

Weight Satellite speakers........0.7 kg(1lb. 9 oz.) x2

Subwoofer...................8.0 kg (17 lbs.10oz.)

Accessories Speaker bracketsx2, RCA pin cablesx 2, RCA pin/8-pincombinationcable x 1

at

T.H.D.=10%)

at

T.H.D.=10%)

Tyros3

5

Tyros3

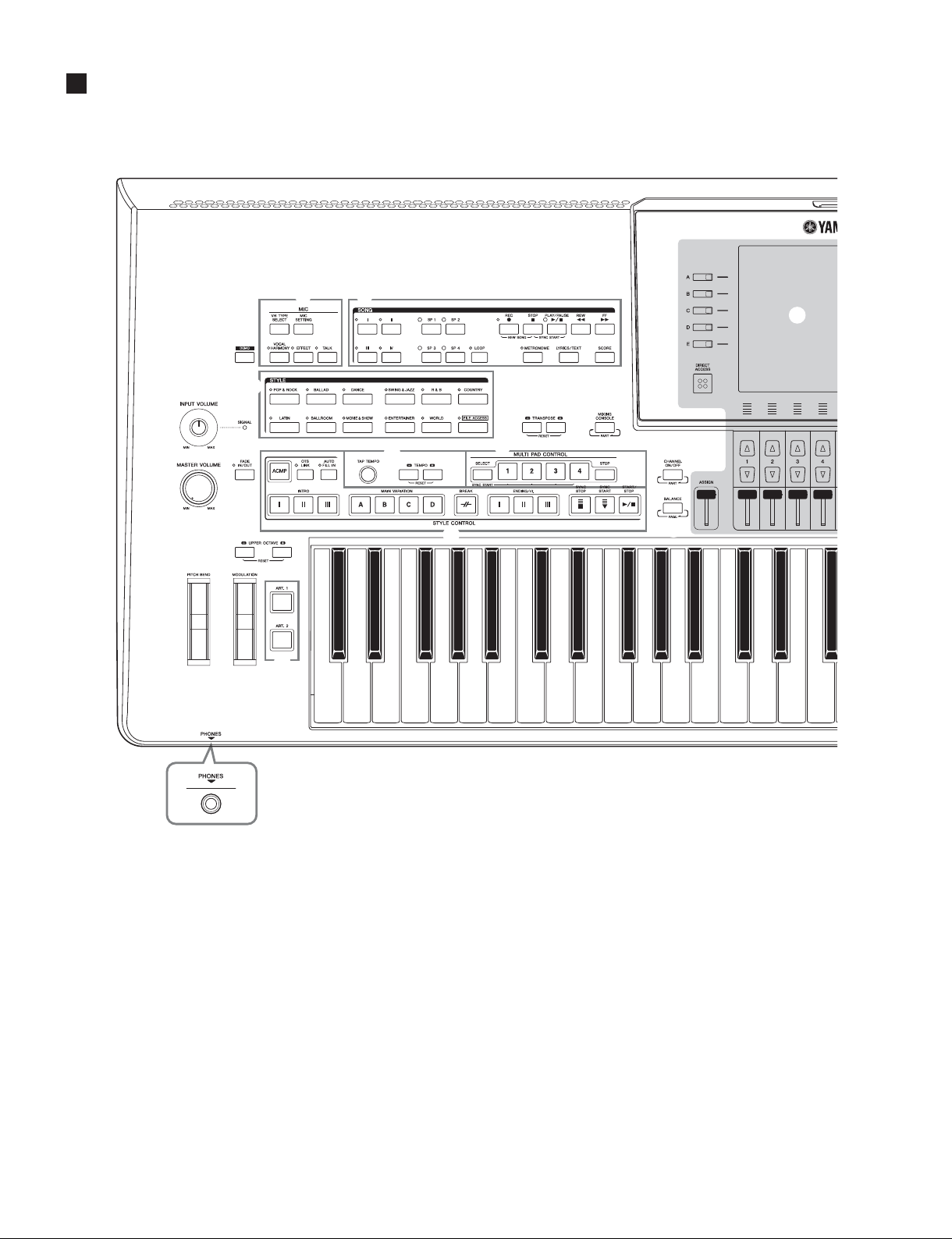

PANEL LAYOUT (Tyros3)

• T op Panel

)

/

4

6

-

1

0

2

*

C1 D1 E1 F1 G1 A1 B1 C2 D2 E2 F2 G2 A2 B2 C3 D3 E3 F3

q [INPUT VOLUME] control

w [MASTER VOLUME] control

e [DEMO] button

r [FADE IN/OUT] button

t [UPPER OCTAVE] buttons

y [PITCH BEND] wheel

u [MODULATION] wheel

i [ART. 1/ART. 2] buttons

o [PHONES] jack

!0 [MIC] buttons

6

!1 [SONG] buttons

!2 [STYLE] category selection buttons

!3 [STYLE CONTROL] buttons

!4 [TEMPO] buttons

!5 [MULTI PAD CONTROL] buttons

!6 [TRANSPOSE] buttons

!7 [MIXING CONSOLE] button

!8 [CHANNEL ON/OFF] button

!9 [BALANCE] button

@0 LCD and related controls

Tyros3

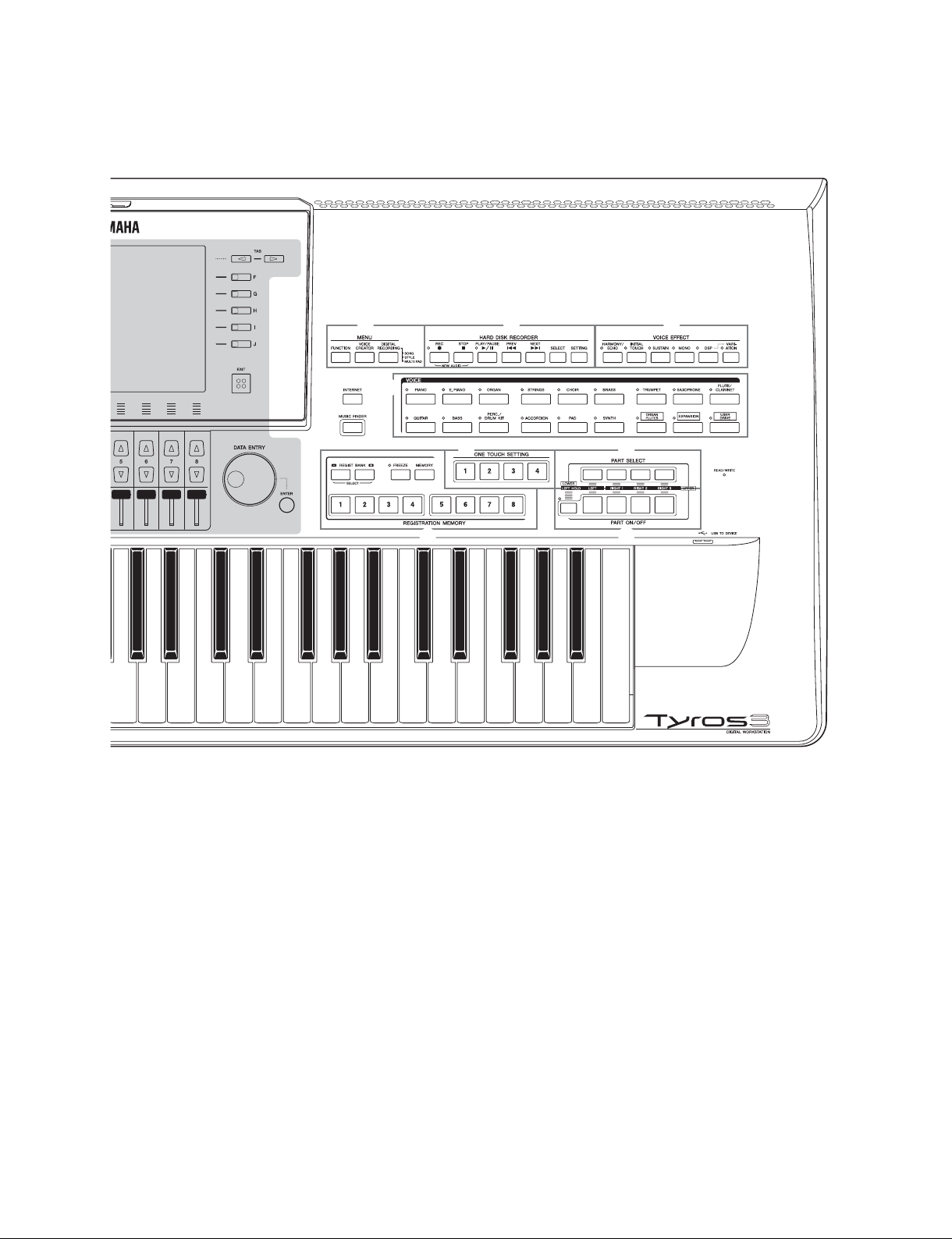

G3 A3 B3 C4 D4 E4 F4 G4 A4 B4 C5 D5 E5 F5 G5 A5 B5 C6

@1 [MENU] buttons

@2 [HARD DISK RECORDER] buttons

@3 [VOICE EFFECT] buttons

@4 [INTERNET] button

@5 [MUSIC FINDER] button

@6 [VOICE] category selection buttons

@7 [REGISTRATION MEMORY] buttons

@8 [ONE TOUCH SETTING] buttons

@9 [PART SELECT] buttons

#0 [PART ON/OFF] buttons

#1 [USB TO DEVICE] terminal

7

Tyros3

• Rear Panel

4 )

/

-

q [TO RIGHT SPEAKER] jack

w [LAN] terminal

e [USB TO HOST] terminal

r [USB TO DEVICE] terminal

t [ASSIGNABLE FOOT PEDAL] jacks

y [MIDI] terminals

u [RGB OUT] terminal

i [VIDEO OUT] terminal

0

1 6 2 *

o [LINE OUT] jacks

!0 [AUX IN/LOOP RETURN] jacks

!1 [AUX OUT/LOOP SEND] jacks

!2 [LINE IN/MIC] jacks

!3 [TO SUB WOOFER] jacks

!4 [POWER ON/OFF] switch

!5 [AC IN] terminal

!6 [TO LEFT SPEAKER] jack

PANEL LAYOUT (TRS-MS02)

BASS

/

100

/ [BASS] control knob

4 Main [POWER] switch

) [TO KEYBOARD L,R] jacks (WOOFER)

0 [TO KEYBOARD] jack (Satellite)

8

4

)

SPEAKER REAR

ETILLETASRAERREFOOWBUSTNORFREFOOWBUS

0

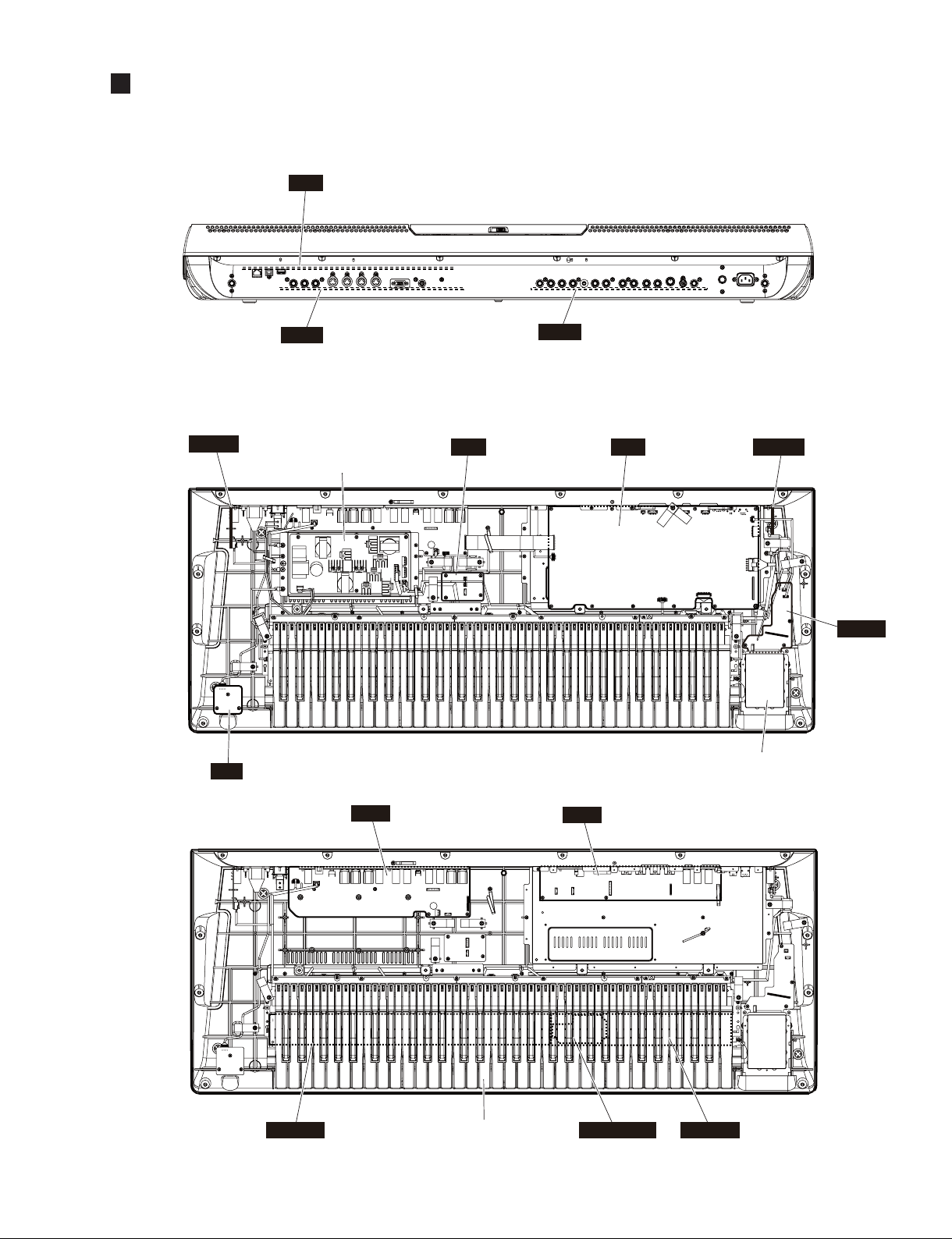

CIRCUIT BOARD LAYOUT

• Rear Side

DM

Tyros3

• Lower Case Side

SPOL

HP

DJK

POWER SUPPLY UNIT

AJK

DMCK

SPOR

HDSB

HARD DISK DRIVE UNIT

AJK

MK61L MKH-DEMKS-FD

KEYBOARD ASSEMBLY

DJK

(E-BUS)

9

Tyros3

• Upper Case Side

WHEEL ASSEMBL Y

PITCH BEND

MODULATION

USBPNCPNLS EN

• LCD Unit

MICVR PNL PNR

LCR

LCD UNIT

CRYSTAL DISPLAY

LCL

10

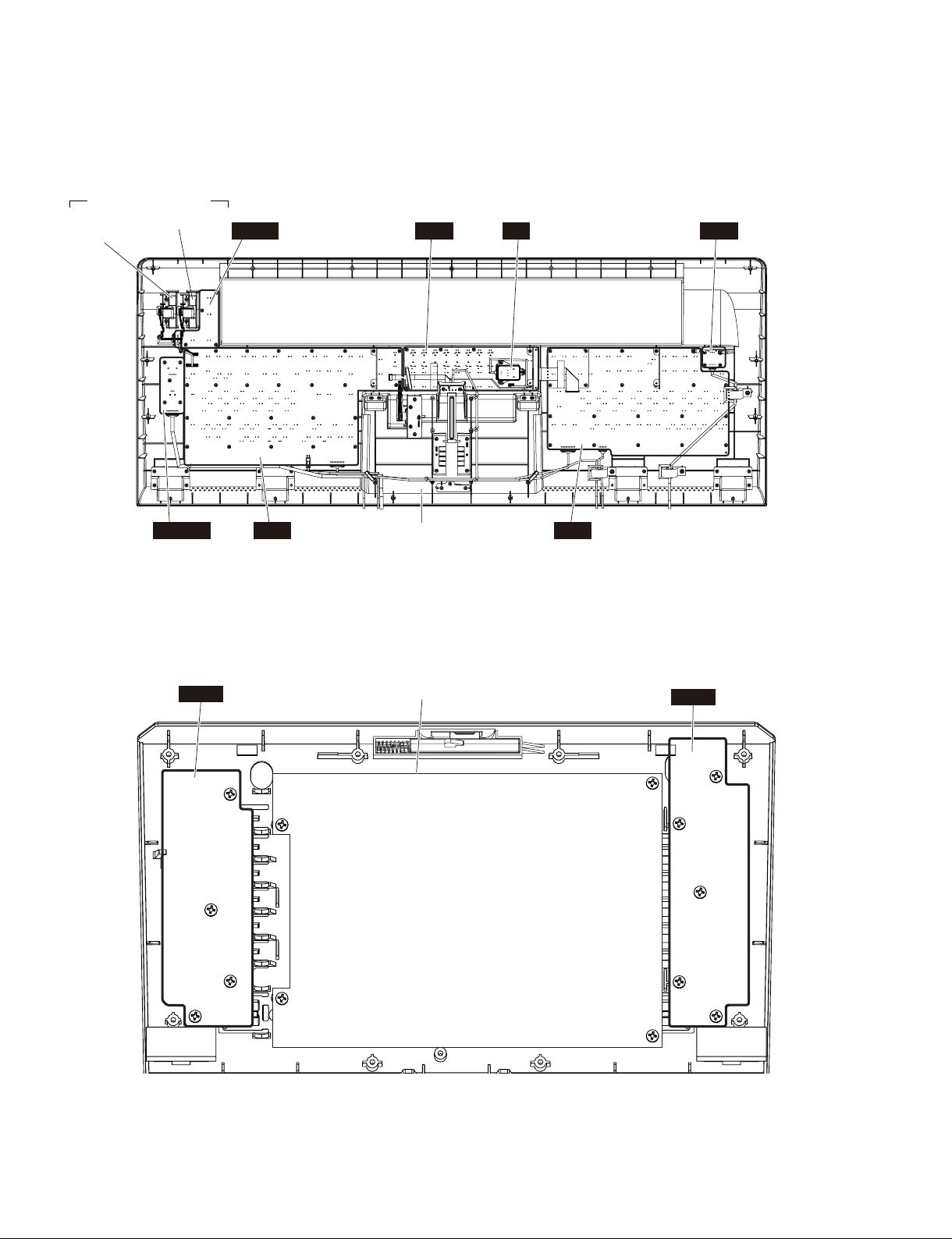

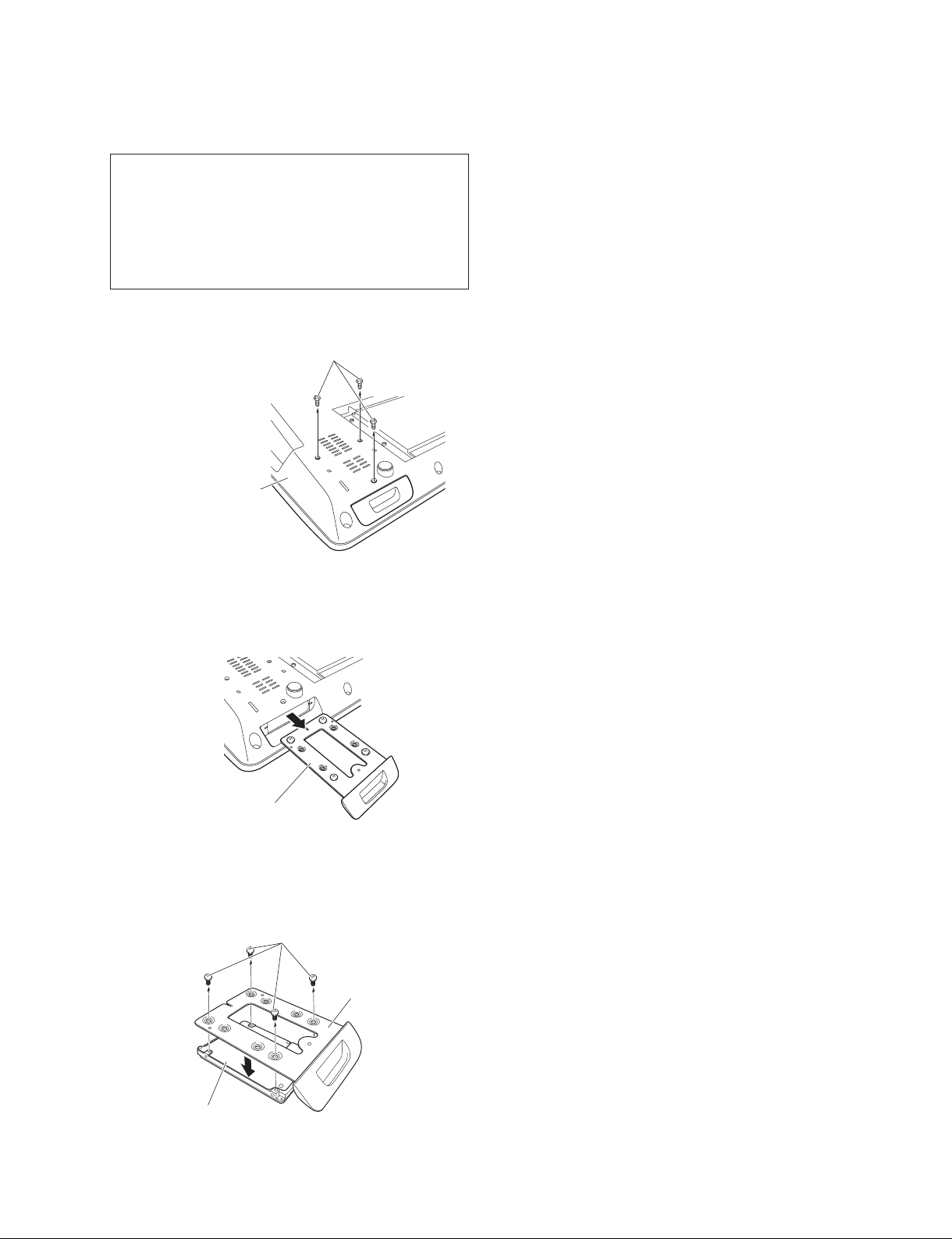

DISASSEMBLY PROCEDURE (Tyros3)

Precautions

Tyros3

•

If you want to turn the instrument or upper case

unit upside down, prepare supporting materials

and put the both end portions of the instrument

or upper case unit on the supporting materials.

(Fig. A)

•

During reassembly, reinstall the adhesive tape,

cord holder, GND wire and ferrite core that were

removed during disassembly as they were before

removal.

Fig. A

1. Separation of Upper Case Unit and Lower Case Unit.......................................................................12

2. DM Circuit Board ..................................................................................................................................13

3. DJK Circuit Board ................................................................................................................................14

4. AC Upper Frame Assembly .................................................................................................................14

5. Power Supply Unit ...............................................................................................................................14

6. AC Lower Frame Assembly .................................................................................................................14

7. AJK Circuit Board ................................................................................................................................15

8. ACIN Wiring Assembly .........................................................................................................................15

9. SPOL Circuit Board, SPOR Circuit Board ..........................................................................................15

10. CK Circuit Board ..................................................................................................................................15

11. HP Circuit Board ..................................................................................................................................15

12. HDSB Circuit Board .............................................................................................................................15

13. PNL Circuit Board ................................................................................................................................16

14. EN Circuit Board ..................................................................................................................................16

15. PNC Circuit Board ................................................................................................................................16

16. PNR Circuit Board ................................................................................................................................16

17. PNLS Circuit Board ..............................................................................................................................17

18. MICVR Circuit Board ............................................................................................................................17

19. USB Circuit Board ................................................................................................................................17

20. Wheel Assembly (PITCH BEND, MODULATION) ...............................................................................17

21. LCD Unit ................................................................................................................................................17

22. LCD Lower Assembly and Gear ..........................................................................................................18

23. LCL Circuit Board ................................................................................................................................18

24. LCR Circuit Board ................................................................................................................................18

25. Crystal Display .....................................................................................................................................19

26. Keyboard Assembly .............................................................................................................................19

27. Keys (White and Black Keys) ..............................................................................................................20

28. Installing Keys (Black and White Keys) .............................................................................................21

29. Disassembling Keyboard Assembly .................................................................................................21

29-1 Rubber Contact ....................................................................................................................................21

29-2 MK61L Circuit Board ............................................................................................................................22

29-3 MKH-D Circuit Board, EMKS-FD Circuit Board..................................................................................22

30. Hard Disk Drive Unit ............................................................................................................................23

•

Notes on Flat Cable

When connecting to the connector, pay attention

not to insert the cable inversely. (Photo A)

Front Side

Photo A

Back Side

11

Tyros3

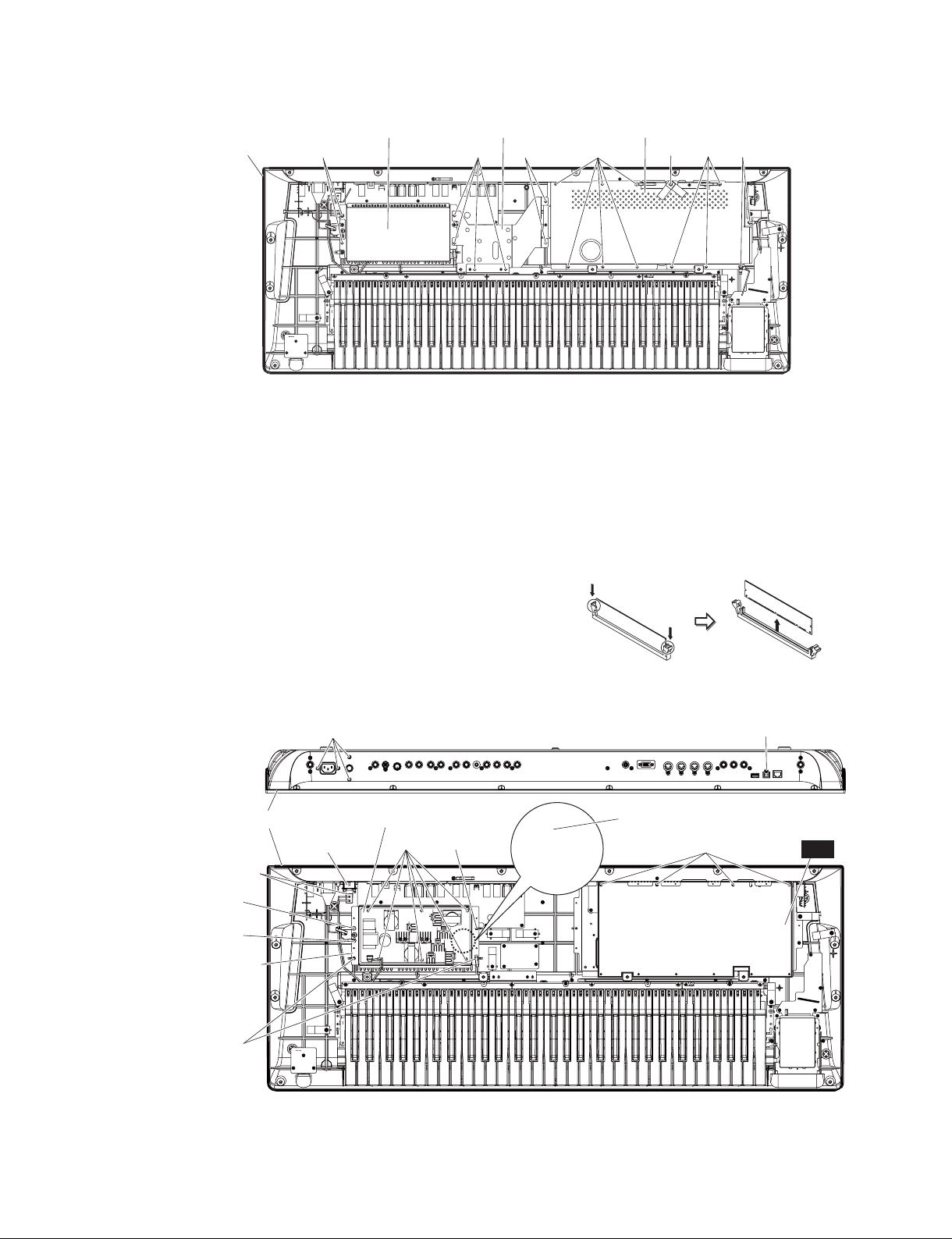

1. Separation of Upper Case Unit and Lower Case Unit

(The required: About 5 minutes).

1-1 Remove the four (4) screws marked [S12] and

seventeen (17) screws marked [S14A], lift the rear side

of the upper case unit a little, pull it toward you a little

paying attention not to damage connector assemblies,

and lift the upper case unit carefully. (Fig. 1, Photo 1)

1-2 Remove the six (6) screws marked [S03A]. The ACDM

earth angle can then be removed. (Fig. 2)

1-3 Remove the screw marked [S09]. (Fig. 2)

1-4 Disconnect all the connector assemblies connecting the

upper case unit and lower case unit. The upper case unit

and lower case unit can then be separated.

• Bottom View

[S14A]

[S12]

LOWER CASE UNIT

[S14A]

③

②

[S12]

[S14B]

Photo1

[S14A]

UPPER CASE UNIT

①

HDD ASSEMBLY

[S14A]

[S02C]

12

• Top View

[S14B]

KNOB VR (INPUT VOLUME)

KNOB MASTER VOLUME

[S02]: BIND HEAD SCREW 3.0X8 MFZN2B3 (WE983600)

[S12]:

[S14]: BIND HEAD TAPPING SCREW-B 4.0X16 MFZN2W3 (WF15410R)

[S14A]

SLIDER KNOB (ASSIGN)

BIND HEAD SCREW 4.0X10 MFZN2W3 (WE96650R)

DIMM COVER

LCD UNIT

[S14A]

UPPER CASE UNIT

SLIDER KNOB [1]-[8]

Fig.1

[S02A]

[S02A]

[S14B]

ENCODER KNOB

[S14A]

Tyros3

• Top View

LOWER CASE UNIT

AC UPPER FRAME ASSEMBLY

[S01]: BIND HEAD SCREW 3.0X6 MFZN2W3 (WE774000)

[S03]: BIND HEAD TAPPING SCREW-B 3.0X8 MFZN2W3 (WE774301)

[S09]: PW HEAD MACHINE SCREW 3.0 X 12 MFZN2W3 (WP817100)

ACDM EARTH ANGLE

[S03A][S03C] [S03A]

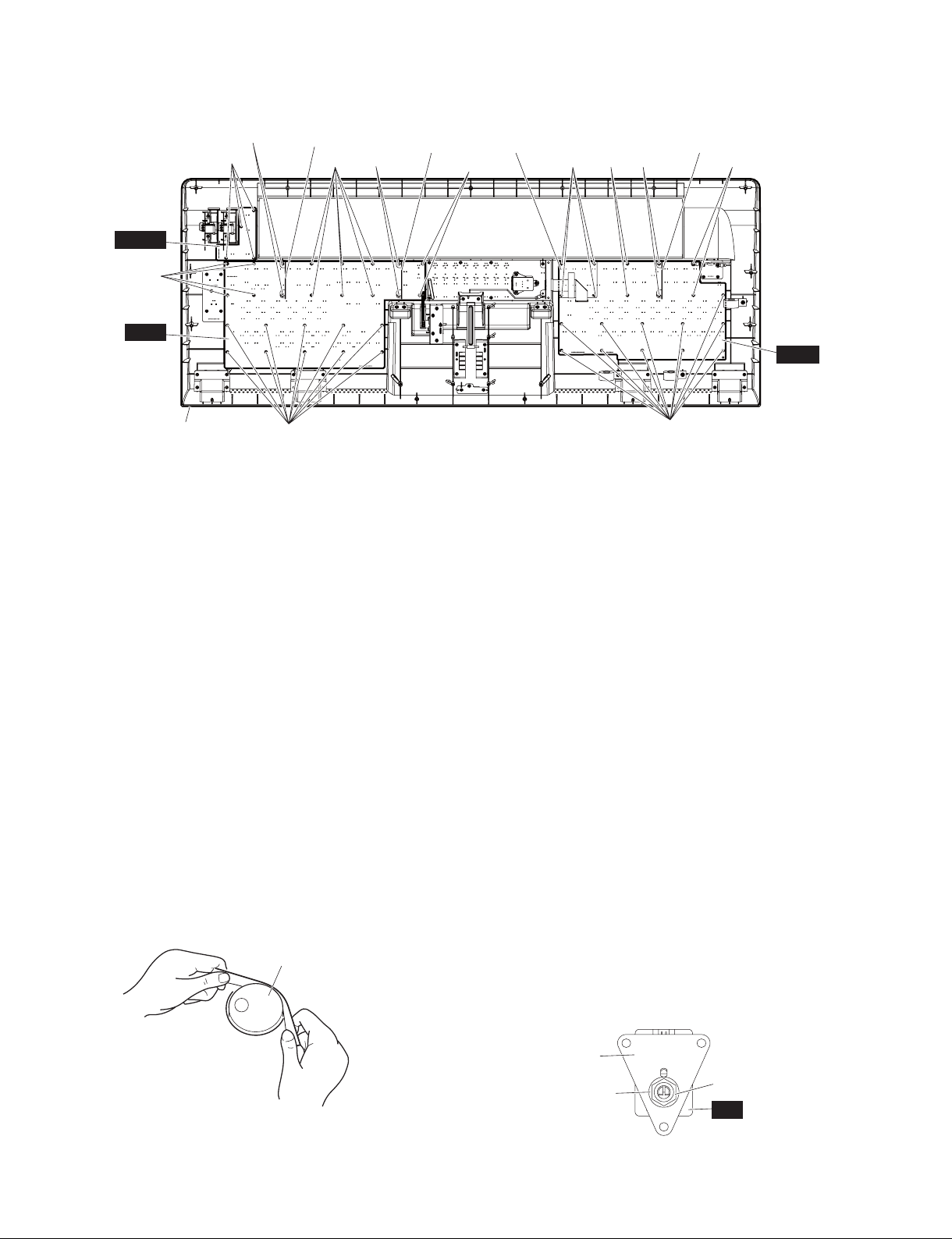

2. DM Circuit Board

(Time Required: About 8 minutes)

*

If there is a DIMM inserted into the DIMM socket, remove

the four (4) screws marked [S02A], DIMM cover and the

DIMM before going to the procedures below. (Fig1, Fig. 3)

2-1 Separate the upper case unit and lower case unit.

(See procedure 1.)

2-2 Remove the sine (9) screws marked [S01A] and two

(2) screws marked [S01B]. The DM cover can then be

removed. (Fig. 2)

2-3 Remove the four (4) screws marked [S01C] and the

screw marked [S02B]. The DM circuit board can then

be removed. (Fig. 4)

DM COVER

[S09]

[S01A]

Fig.2

* MAC (Media Access Control) address is stored in the

DM circuit board. If the DM circuit board is replaced,

MAC address will be changed.

[S01A] [S01B]

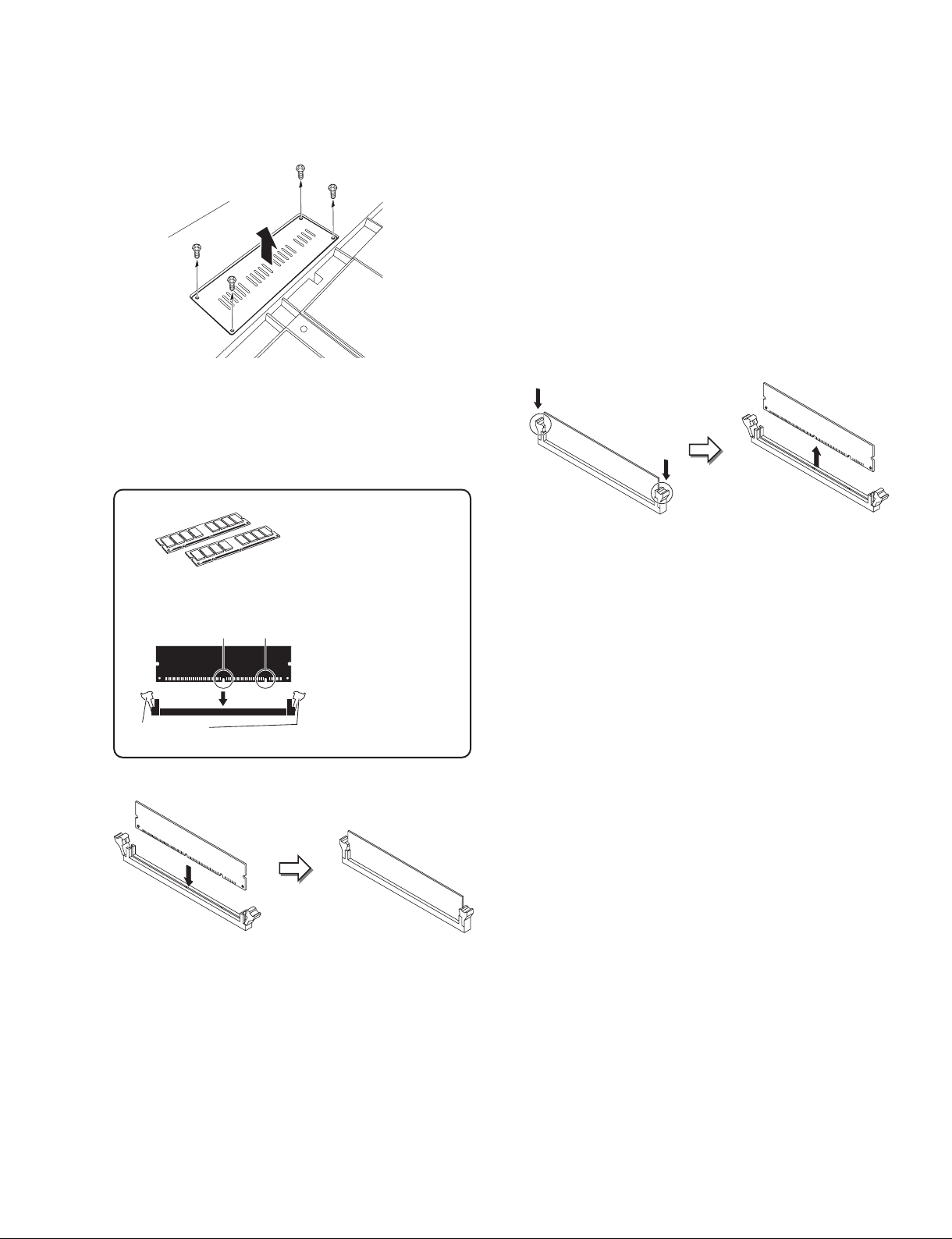

• Removing DIMMs

Press the ejector levers

until the DIMM unlocks.

Fig.3

Pull the DIMM vertically

out of the socket.

• Rear View

LOWER CASE UNIT

• Top View

WIRING ASSEMBLY

ACIN

[S03E]

[S11]

AC LOWER FRAME

ASSEMBLY

[S03E]

[S04C]

POWER SWITCH

ANGLE

[S01B]: BIND HEAD SCREW 3.0X6 MFZN2W3 (WE774000)

[S02B]: BIND HEAD SCREW 3.0X8 MFZN2B3 (WE983600)

[S03]: BIND HEAD TAPPING SCREW-B 3.0X8 MFZN2W3 (WE774301)

[S04C]: BIND HEAD TAPPING SCREW-B 3.0X10 MFZN2B3 (WE972200)

[S11]: BIND HEAD SCREW 4.0X8 MFZN2W3 (WE968500)

POWER SUPPLY UNIT

[S03D]

[S03E]

Fig.4

CN4

[S01C]

[S02B]

DM

13

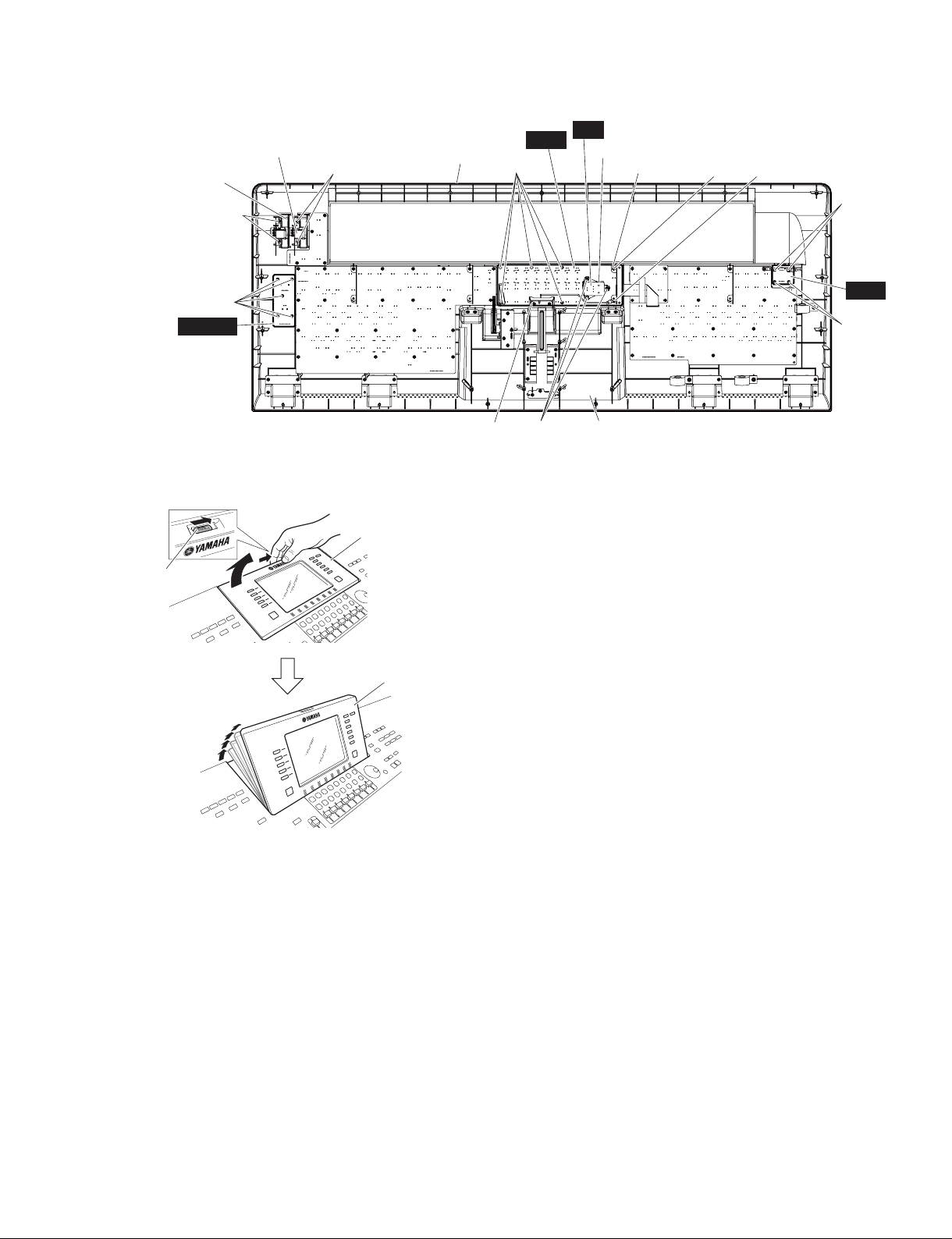

Tyros3

• Rear View

• Top View

LOWER CASE UNIT

SPOL

[S04D]

KNOB VR (LINE IN/MIC [TRIM])

[S04B][S04B]

[S03F]

AJK

CK

[S21]

[S03B]

[S04A][S04A]

[S04D]

DJK

SPOR

HDSB

[S03I]

HP

[S03G][S03H]

[S03]: BIND HEAD TAPPING SCREW-B 3.0X8 MFZN2W3 (WE774301)

[S04]: BIND HEAD TAPPING SCREW-B 3.0X10 MFZN2B3 (WE972200)

[S21]: HEXAGONAL LOCK SCREW HFS-4S-B1WM (V7569300)

3. DJK Circuit Board

(Time Required: About 10 minutes)

3-1 Separate the upper case unit and lower case unit.

(See procedure 1.)

3-2 Remove the DM circuit board. (See procedure 2.)

3-3 Remove the three (3) screws marked [S03B], eight (8)

screws marked [S04A] and two (2) hexagonal lock

screws marked [S21]. The DJK circuit board can then

be removed. (Fig. 5)

4. AC Upper Frame Assembly

(Time Required: about 6 minutes)

4-1 Separate the upper case unit and lower case unit. (See

procedure 1.)

4-2 Remove the two (2) screws marked [S03C]. The AC

upper frame assembly can then be removed. (Fig. 2)

HARD DISK DRIVE UNIT

Fig.5

5. Power Supply Unit

(Time Required: About 7 minutes)

5-1 Separate the upper case unit and lower case unit.

(See procedure 1.)

5-2

Remove the AC upper frame assembly. (See procedure 4.)

5-3 Remove the six (6) screws marked [S03D]. The power

supply unit can then be removed. (Fig. 4)

* No cord should be connected to the CN4 of the

power supply unit. Pay attention to connection

during installment. (Fig. 4)

6. AC Lower Frame Assembly

(Time Required: about 7 minutes)

6-1 Separate the upper case unit and lower case unit. (See

procedure 1.)

Remove the AC upper frame assembly. (See procedure 4.)

6-2

6-3

Remove the two (4) screws marked [S03E] and the

screw marked [S11]. The AC lower frame assembly can

then be removed with the power supply unit on it. (Fig. 4)

* No cord should be connected to the CN4 of the

power supply unit. Pay attention to connection

during installment. (Fig. 4)

14

Tyros3

7. AJK Circuit Board

(Time Required: About 8 minutes)

7-1 Separate the upper case unit and lower case unit.

(See procedure 1.)

7-2

Remove the AC upper frame assembly. (See procedure 4.)

7-3 Remove the AC lower frame assembly with the power

supply unit on it (See procedure 6.)

7-4 Remove the VR knob (LINE IN/MIC [TRIM]). (Fig. 5)

7-5 Remove the four (4) screws marked [S03F] and six (6)

screws marked [S04B]. The AJK circuit board can then

be removed. (Fig. 5)

8. ACIN Wiring Assembly

(Time Required: About 7 minutes)

8-1 Separate the upper case unit and lower case unit.

(See procedure 1.)

8-2

Remove the AC upper frame assembly. (See procedure 4.)

8-3

Remove the four (4) screws marked [S04C] and the

screw marked [S11]. The ACIN wiring assembly can

then be removed together with the power switch angle.

(Fig. 4)

8-4 Remove the two (2) screws marked [S01D]. The power

switch angle can then be removed. (Photo 2)

* The push button is not part of the ACIN wiring

assembly. When replacing the ACIN wiring assembly

(push switch), remove the push button from the

push switch of the ACIN wiring assembly and install

it on the new ACIN wiring assembly. (Photo 2)

[S01D]

9. SPOL Circuit Board, SPOR Circuit Board

(Time Required: About 6 minutes)

9-1 Separate the upper case unit and lower case unit.

(See procedure 1.)

9-2 Remove the two (2) screws marked [S04D]. The SPOL

circuit board can then be removed. (Fig. 5)

* The SPOR circuit board can be removed in the same

way.

10. CK Circuit Board

(Time Required: About 6 minutes)

10-1 Separate the upper case unit and lower case unit.

(See procedure 1.)

10-2 Remove the four (4) screws marked [S03G]. The CK

circuit board can then be removed. (Fig. 5)

11. HP Circuit Board

(Time Required: About 6 minutes)

11-1 Separate the upper case unit and lower case unit. (See

procedure 1.)

11-2 Remove the three (3) screws marked [S03H]. The HP

circuit board can then be removed. (Fig. 5)

12. HDSB Circuit Board

(Time Required: About 6 minutes)

12-1 Separate the upper case unit and lower case unit.

(See procedure 1.)

12-2 Remove the two (2) screws marked [S01B] and four (4)

screws marked [S03I]. (Fig. 2, Fig. 5)

12-3 Pull off the HDSB circuit board from the HDD

terminal. (Photo 3)

PUSH BUTTON

POWER SWITCH ANGLEPOWER SWITCH ANGLE

[S01]: BIND HEAD SCREW 3.0X6 MFZN2W3 (WE774000)

Photo2

PUSH SWITCH

PUSH SWITCH

PUSH BUTTON

HDSB

HARD DISK DRIVE UNIT

Photo3

15

Tyros3

• Bottom View

[S05A]

[S05K]

PANEL STAY A

[S05B] [S05A]

PANEL STAY A PANEL STAY CPROTECT SHEET

PNLS

[S05B]

PNL

UPPER CASE UNIT

[S05B]

[S05]: BIND HEAD TAPPING SCREW-B 3.0X10 MFZN2W3 (WE774200)

13. PNL Circuit Board

(Time Required: About 10 minutes)

13-1 Remove the slider knob (ASSIGN) from the control

panel. (Fig. 1)

13-2 Separate the upper case unit and lower case unit.

(See procedure 1.)

13-3 Remove the four (4) screws marked [S05A]. The two (2)

panel stays A can then be removed. (Fig. 6)

13-4 Remove the twenty-two (22) screws marked [S05B].

The PNL circuit board can then be removed. (Fig. 6)

14. EN Circuit Board

(Time Required: About 6 minutes)

14-1 Remove the encoder knob from the control panel

(Fig. 1, Fig. 7).

14-2 Separate the upper case unit and lower case unit.

(See procedure 1.)

14-3 Remove the three (3) screws marked [S05C]. The ENC

assembly can then be removed. (Fig. 9)

14-4 Remove the hexagonal nut marked [A] and the washer

marked [B]. The ENC stay can then be removed. (Fig. 8)

ENCODER KNOB

Fig.6

[S05B]

[S05H][S05J]

[S05J]

[S05J][S05I]

15. PNC Circuit Board

(Time Required: About 8 minutes)

15-1 Remove the eight (8) slider knobs (ASSIGN) and the

encoder knob from the control panel. (Fig. 1)

15-2 Separate the upper case unit and lower case unit.

(See procedure 1.)

15-3 Remove the ENC assembly. (See procedure 14-3)

15-4 Release the lock at the back of the LCD unit, open the

LCD unit and remove the screw marked [S05D] which

has been hidden. (Fig. 9, 10)

15-5 Remove the fi ve (5) screws marked [S05E], the screw

marked [S05F], the screw marked [S05G] and the panel

stay B. The PNC circuit board can then be removed.

(Fig. 9)

16. PNR Circuit Board

(Time Required: About 9 minutes)

16-1 Separate the upper case unit and lower case unit.

(See procedure 1.)

16-2 Remove the four (4) screws marked [S05H] and the

protect sheet. (Fig. 6)

16-3 Remove the two (2) screws marked [S05I]. The panel

stay C can then be removed. (Fig. 6)

16-4 Remove the fifteen (15) screws marked [S05J]. The

PNR circuit board can then be removed. (Fig. 6)

PNR

16

Fig.7

• ENC Ass’y

ENC STAY

[B] Washer

[A] Hexagon Nut

EN

Fig.8

Tyros3

• Bottom View

WHEEL ASSEMBLY

(PITCH BEND)

[S05N]

[S05L]

MICVR

LCD Hook

WHEEL ASSEMBLY

(MODULATION)

[S05N]

[S05]: BIND HEAD TAPPING SCREW-B 3.0X10 MFZN2W3 (WE774200)

UPPER CASE UNIT

LCD UNIT

[S05D]

Fig.9

EN

PNC

[S05E]

[S05C]

ENC ASSEMBLY

PANEL STAY B

LCD UNIT

[S05F]

[S05G]

19. USB Circuit Board

(Time Required: About 6 minutes)

19-1 Separate the upper case unit and lower case unit.

(See procedure 1.)

19-2 Remove the four (4) screws marked [S05M]. The USB

circuit board can then be removed. (Fig. 9)

[S05M]

USB

[S05M]

LCD UNIT

Fig.10

17. PNLS Circuit Board

(Time Required: About 6 minutes)

17-1 Separate the upper case unit and lower case unit.

(See procedure 1.)

17-2 Remove the four (4) screws marked [S05K]. The PNLS

circuit board can then be removed. (Fig. 6)

18. MICVR Circuit Board

(Time Required: About 6 minutes)

18-1

Remove the VR knob (INPUT VOLUME) and the

MASTER VOLUME knob from the control panel. (Fig. 1)

18-2 Separate the upper case unit and lower case unit.

(See procedure 1.)

18-3 Remove the five (5) screws marked [S05L]. The

MICVR circuit board can then be removed. (Fig. 9)

20.

Wheel Assembly (PITCH BEND, MODULATION)

(Time Required: About 6 minutes)

20-1 Separate the upper case unit and lower case unit

(See procedure 1).

20-2 Remove the two (2) screws marked [S05N]. The wheel

assembly (PITCH BEND) can then be removed. (Fig. 9)

* The wheel assembly (MODULATION) can be removed

in the same way.

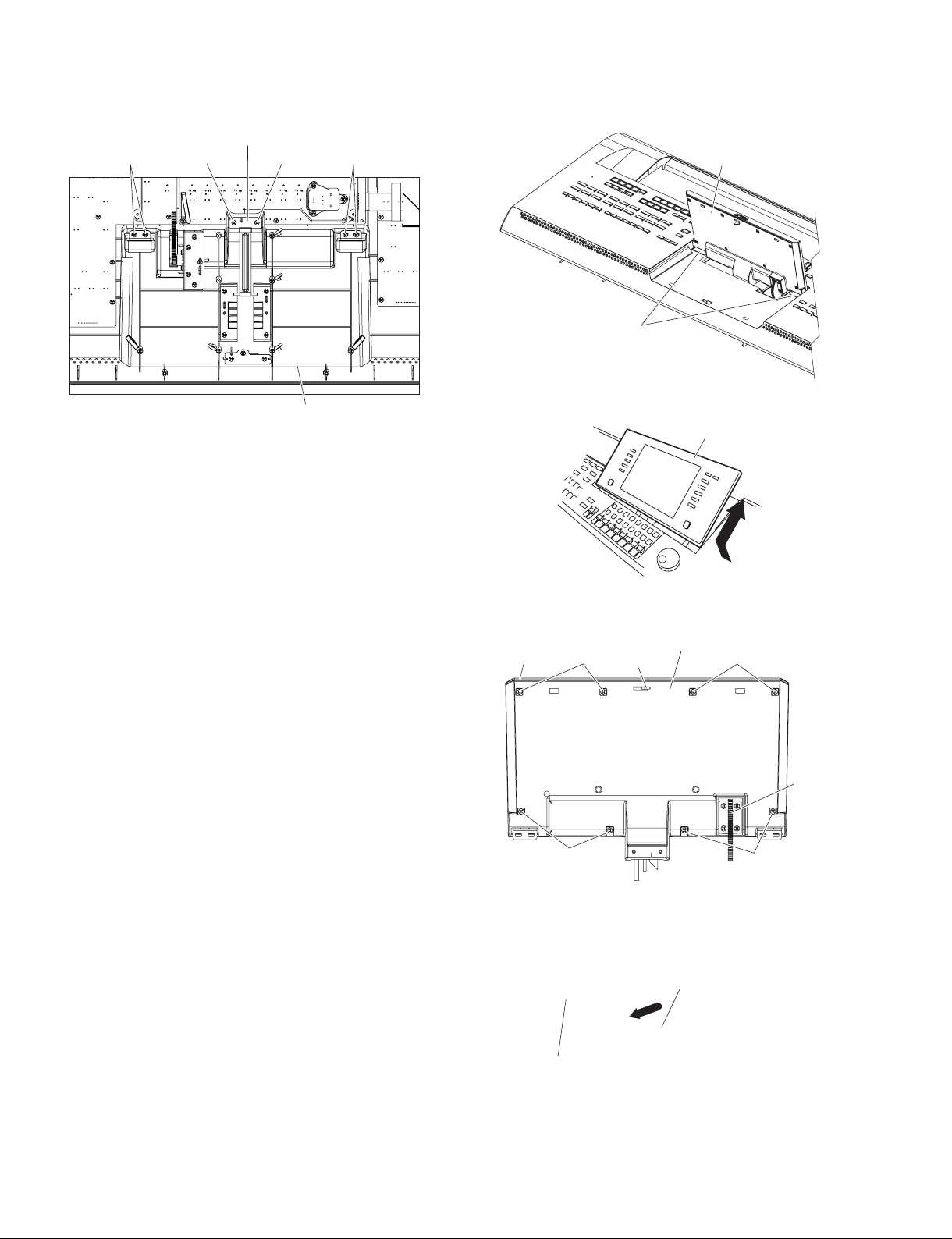

21. LCD Unit (Time Required: About 7 minutes)

21-1 Separate the upper case unit and lower case unit.

(See procedure 1.)

21-2 Remov e the two (2) screws mark ed [S05O]. The s tay

hinge assembly can then be removed. (Fig. 11)

21-3 Remove the four (4) screws marked [S05P] and the

screw marked [S05G]. (Fig. 9, 11)

21-4 Turn the front side of the upper case unit upward.

* Disconnect the connector assemblies of the LCD

unit in advance.

21-5 Release the lock at the back of the LCD unit, raise the

LCD unit and remove the two (2) dust proof cloths.

(Fig. 10, 12)

Tip the LCD unit until it is at an angle shown in Fig. 13,

21-6

lift it a little and then pull it out obliquely upward. (Fig. 13)

17

Tyros3

STAY HINGE ASSEMBLY

[S05O][S05O][S05P] [S05P]

LCD UNIT

[S05]: BIND HEAD TAPPING SCREW-B

3.0X10 MFZN2W3 (WE774200)

Fig.11

LCD UNIT

DUST PROOF FOAM

Fig.12

LCD UNIT

22. LCD Lower Assembly and Gear

(Time Required: About 7 minutes)

22-1 Separate the upper case unit and lower case unit.

(See procedure 1.)

22-2 Remove the LCD unit. (See procedure 21.)

22-3 Remove the eight (8) screws marked [S04E], slide the

LCD hook and remove the LCD lower assembly and

gear while shifting the hook at the back of the LCD unit

as shown in Photo 4. (Fig. 14, Photo 4)

23. LCL Circuit Board

(Time Required: About 7 minutes)

23-1 Separate the upper case unit and lower case unit.

(See procedure 1.)

23-2 Remove the LCD unit. (See procedure 21.)

23-3 Remove the LCD lower case assembly and gear.

(See procedure 22.)

Lift the stopper of the CN2 connector as shown in Fig. 15

23-4

and then remove the fl at cable and ferrite core. (Fig. 15)

23-5 Remove the five (5) screws marked [S03J]. The LCL

circuit board can then be removed. (Fig. 15)

24. LCR Circuit Board

(Time Required: About 7 minutes)

24-1 Separate the upper case unit and lower case unit.

(See procedure 1.)

24-2 Remove the LCD unit. (See procedure 21.)

24-3 Remove the LCD lower case assembly and gear.

(See procedure 22.)

24-4 Remove the four (4) screws marked [S03K]. The LCR

circuit board can then be removed. (Fig. 15)

Fig.13

LCD UNIT

LCD LOWER ASSEMBLY

[S04E] [S04E]

[S04E]

[S04E]: BIND HEAD TAPPING SCREW-B

3.0X10 MFZN2B3 (WE972200)

LCD LOWER ASSEMBLY

Hook

Fig.14

Hook

GEAR

[S04E]

18

Photo4

Tyros3

[S03K]

LCD UPPER CASE

LCR

[S03]: BIND HEAD TAPPING SCREW-B

3.0X8 MFZN2W3 (WE774301)

Fig.15

LCD UPPER CASE CRYSTAL DISPLAY

[S03L]

A

[S03J]

LCL

25. Crystal Display

(Time Required: About 7 minutes)

25-1 Separate the upper case unit and lower case unit.

(See procedure 1.)

25-2 Remove the LCD unit. (See procedure 21.)

25-3 Remove the LCD lower case assembly and gear.

(See procedure 22.)

25-4 Lift the stopper of the connector at the portion [A] as

CN2

shown in Fig. 16 and then remove the flat cable and

ferrite core. (Fig. 16)

25-5 Remove the four (4) screws marked [S03L]. The crystal

display can then be removed. (Fig. 16)

CN2CN2

When connecting to the connector, pay attention

not to insert the cable inversely.

26. Keyboard Assembly

(Time Required: About 9 minutes)

26-1 Separate the upper case unit and lower case unit.

(See procedure 1.)

26-2 Remove the two (2) screws marked [S07A]. The two (2)

data line fi lters can then be removed. (Fig. 17)

26-3 Remove the eight (8) screws marked [S14B] and fi ve (5)

screws marked [S05P]. (Fig. 1、Fig. 17)

* Be sure to loosen the cord holder marked [18] and

release the flat cable (PC sensor) from the cord

holder before lifting the keyboard. (Fig.17)

A

If the keyboard is lifted without releasing the flat

cable from the cord holder, the flat cable or the

sensor may be damaged.

26-4 Raise the MK unit from front side so that the front

side will face upward while paying attention to the

connector assemblies. (Photo 5)

26-5 Remove the screw marked [MS13] and two (2) screws

marked [MS03]. The keyboard assembly can then be

removed. (Fig. 18)

• Top View

LOWER CASE UNIT

DATA LINE FILTER

[S07A]

[S03L]: BIND HEAD TAPPING SCREW-B

3.0X8 MFZN2W3 (WE774301)

Fig.16

[S05P]

DATA LINE FILTER

[S05P]: BIND HEAD TAPPING SCREW-B 3.0X10 MFZN2W3 (WE774200)

[S07A]: PW HEAD TAPPING SCREW-B 3.0X12 MFZN2W3 (WF00210R)

[S07A]

[S05P]

MK UNIT

[S05P]

FLAT CABLE

Fig.17

[S05P]

[18]

19

Tyros3

MK UNIT

LOWER CASE UNIT

Photo5

• Bottom View

[MS03]: BIND HEAD TAPPING SCREW-B 3.0X8 MFZN2W3 (WE774301)

[MS13]: BIND HEAD TAPPING SCREW-B 4.0X12 MFZN2W3 (WE98120R)

27. Keys (White and Black Keys)

27-1 Remove the keyboard assembly.

(See procedure 26.)

27-2 Remove the key stoppers corresponding to the keys to

be replaced. (Table 1, Fig. 19)

27-3 White key

27-3-1 Place the white key in the horizontal position and

remove it, lifting while pushing rearward. (Photo 6)

* At this time, a key guide cap may come off together.

(Photo 8)

27-4 Black key

27-4-1 Remove the white keys on the right and left sides of the

black key to be removed. (Photo 6)

27-4-2 Place the black key in the horizontal position and

remove it, lifting while pushing rearward. (Photo 7)

KEYBOARD ASSEMBLY

Fig.18

Photo6

[MS13]

[MS03]

20

Photo7

KEY SPRING

KEY GUIDE CAP

Photo8

Table 1

REMOVE SCREW

Tyros3

KEY STOPPER L KEY STOPPER H KEY STOPPER 61

[240A] X 2, [240B] X 1 [240B] X 1, [240C] X 2 [240D] X 2

[240A]

C1 C2 C3 C4 C5 C6

RUBBER CONTACT 13 KEY

(C1-C2)

KEY STOPPER L

MK61L

C#2 C#3 C#4 C#5

RUBBER CONTACT 12 KEY A

(C2-C3)

[240]:BINDHEADTAPPINGSCREW-P3.0X16MFZN2B3(WE983200)

KEY STOPPER H

[240B]

RUBBER CONTACT 12 KEY B

(C3-C4)

[240C]

EMKS-FD

RUBBER CONTACT 12 KEY C

[240C]

RUBBER CONTACT 12 KEY D

(C4-C5)

KEY STOPPER 61

[240D]

MKH-D

(C5-C6)

Fig.19

28. Installing Keys (White and Black Keys)

28-1 Black key

28-1-1 With the white keys to the right and left sides removed,

lower the front end of the horizontal black key and fi t it

into the frame while pushing it rearward.

* At this time, pay attention not to bend the key guide

cap by lowering the front portion of the key too

much. (Photo 8)

28-2 White key

28-2-1 After installing the black keys, install the white keys in

the same way as the black keys.

(See procedure 28-1.)

28-3 Install the removed key stoppers.

29. Disassembling Keyboard Assembly

29-1 Rubber Contact

29-1-1 Remove the keyboard assembly.

(See procedure 26.)

29-1-2 Remove the key stoppers and keys listed in the table

2, corresponding to the rubber contacts to be removed.

(Table 2, fi g. 19) (See procedure 27.)

29-1-3 Pull out the rubber contact. (Fig. 19)

* The orientation of rubber contacts on the keyboard

is previously designated. Pay attention not to install

the rubber contacts inversely. (Fig. 20)

* When installing the rubber contact, push it with the

end of a clip. (Photo 9)

(Table 1, Fig. 19)

[240D]

RUBBER CONTACT

Photo9

CONTACT (LONG)

RUBBER CONTACT

CONTACT (SHORT)

Fig.20

21

Tyros3

Table 2

APPLICATION CIRCUIT BOARD

REMOVE KEY STOPPER

REMOVE KEY

RUBBER CONTACT

13KEY

MK61L MK61L MK61L MKH-D MKH-D

L L, H L, H H 61

C1-C2 C2-C3 C3-C4 C4-C5 C5-C6

[250A] [250B]

RUBBER CONTACT

12KEY A

RUBBER CONTACT

12KEY B

RUBBER CONTACT

12KEY C

RUBBER CONTACT

12KEY D

MK61L

[250]:BINDHEADTAPPINGSCREW-P3.0X8MFZN2B3(WF266600)

29-2 MK61L Circuit Board (Time required: About 8 minutes)

29-2-1 Remove the keyboard assembly.

(See procedure 26.)

29-2-2 Remove the key stopper L and key stopper H. (Table 1,

Fig. 19)

29-2-3 Remove the keys and the key springs from C1 to C4.

(See procedure 27.)

29-2-4 Remove the thirteen (13) screws marked [250A] and

disconnect the connector from the underside of the

keyboard unit. The MK61L circuit board can then be

removed. (Fig. 21, Photo 10)

* The rubber contacts are not parts of the MK61L

circuit board. When replacing the MK61L circuit

board, remove the rubber contacts from the circuit

board and install them to new circuit board.

Fig.21

MKH-D

[250B][250A]

EMKS-F

29-3 MKH-D Circuit Board, EMKS-FD Circuit Board (Time required: About 8 minutes)

29-3-1 Remove the keyboard assembly.

(See procedure 26.)

29-3-2 Remove the key stopper H and key stopper 61. (Table 1,

Fig. 19)

29-3-3 Remove the keys and key springs from C4 to C6.

(See procedure 27.)

29-3-4 Remove the nine (9) screws marked [250B] and

disconnect the connectors from the underside of the

keyboard. The MKH-D circuit board can then be

removed. (Fig. 21, Photo 10)

* The EMKS-FD circuit board is a part of the MKH-D

circuit board and is soldered to the MKH-D circuit

board at connectors. (Photo 11)

* The rubber contacts are not parts of the MKC circuit

board. When replacing the MKC circuit board,

remove the rubber contacts from the circuit board

and install them to new circuit board.

22

MKH-D

MK61L

MKH-D EMKS-FD

Connector

Soldered

Photo10 Photo11

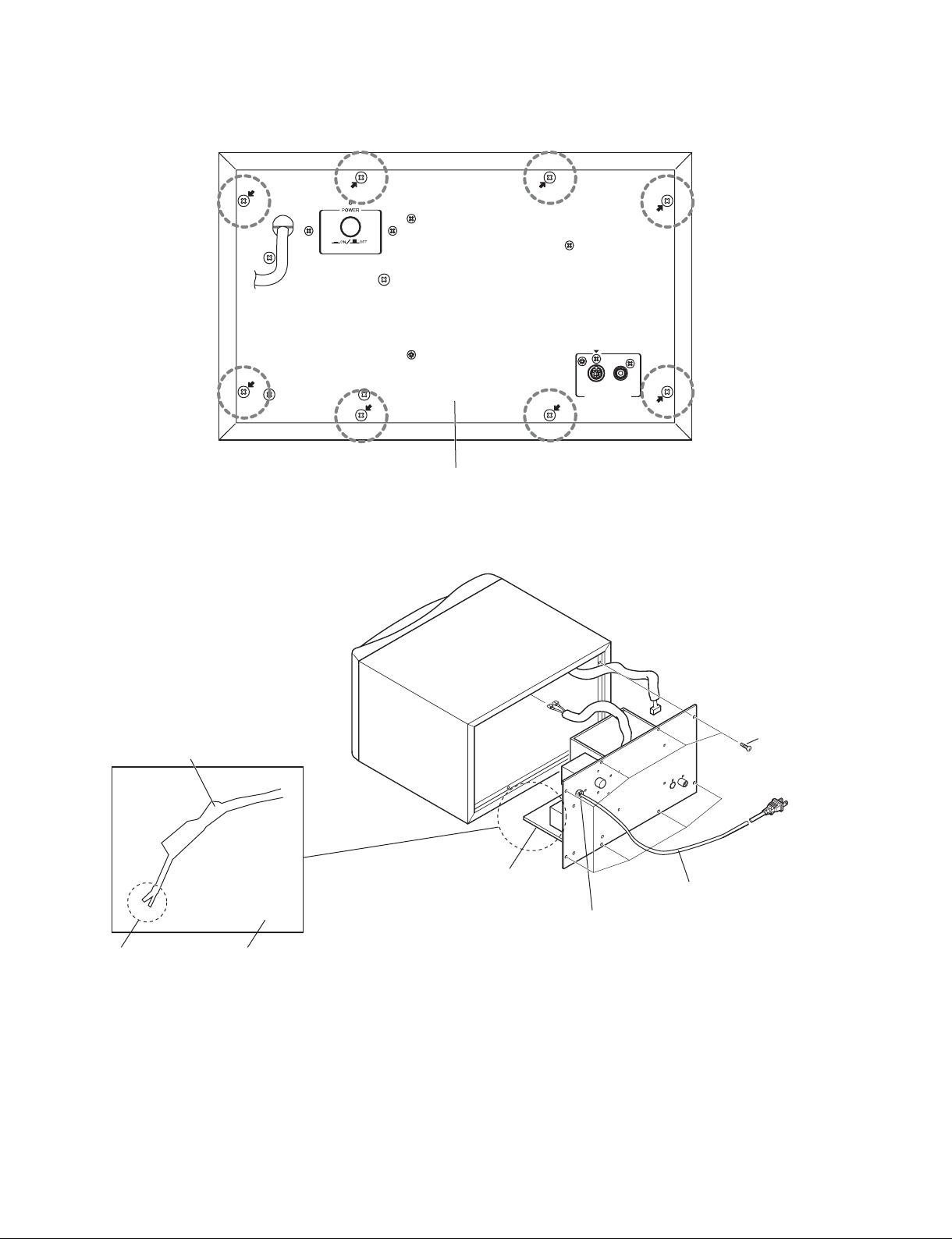

30. Hard Disk Drive Unit

Turn the Tyros3’s power off, disconnect any cables including

AC power cord from the keyboard.

Also make sure to close the LCD panel and disconnect a

USB device from the USB TO DEVICE terminal.

Turn the Tyros3 face down on a blanket or some soft surface,

giving you direct access to the bottom of the instrument.

30-1 Remove the three (3) screws marked [S02C].

(Fig. 1, Fig. 22)

[S02C]

Tyros3

LOWER CASE UNIT

[S02C]: BIND HEAD SCREW 3.0X8 MFZN2B3 (WE983600)

Fig.22

30-2 Pull out the HDD bracket. (Fig. 23)

HDD BRACKET

Fig.23

30-3 Remove the four (4) screws marked [S08]. The hard

disk drive unit can then be removed. (Fig. 24)

[S08]

HDD BRACKET

HARD DISK DRIVE UNIT

[S08]: BIND HEAD SCREW 3.0X4 MFNI33 (VG048000)

Fig.24

23

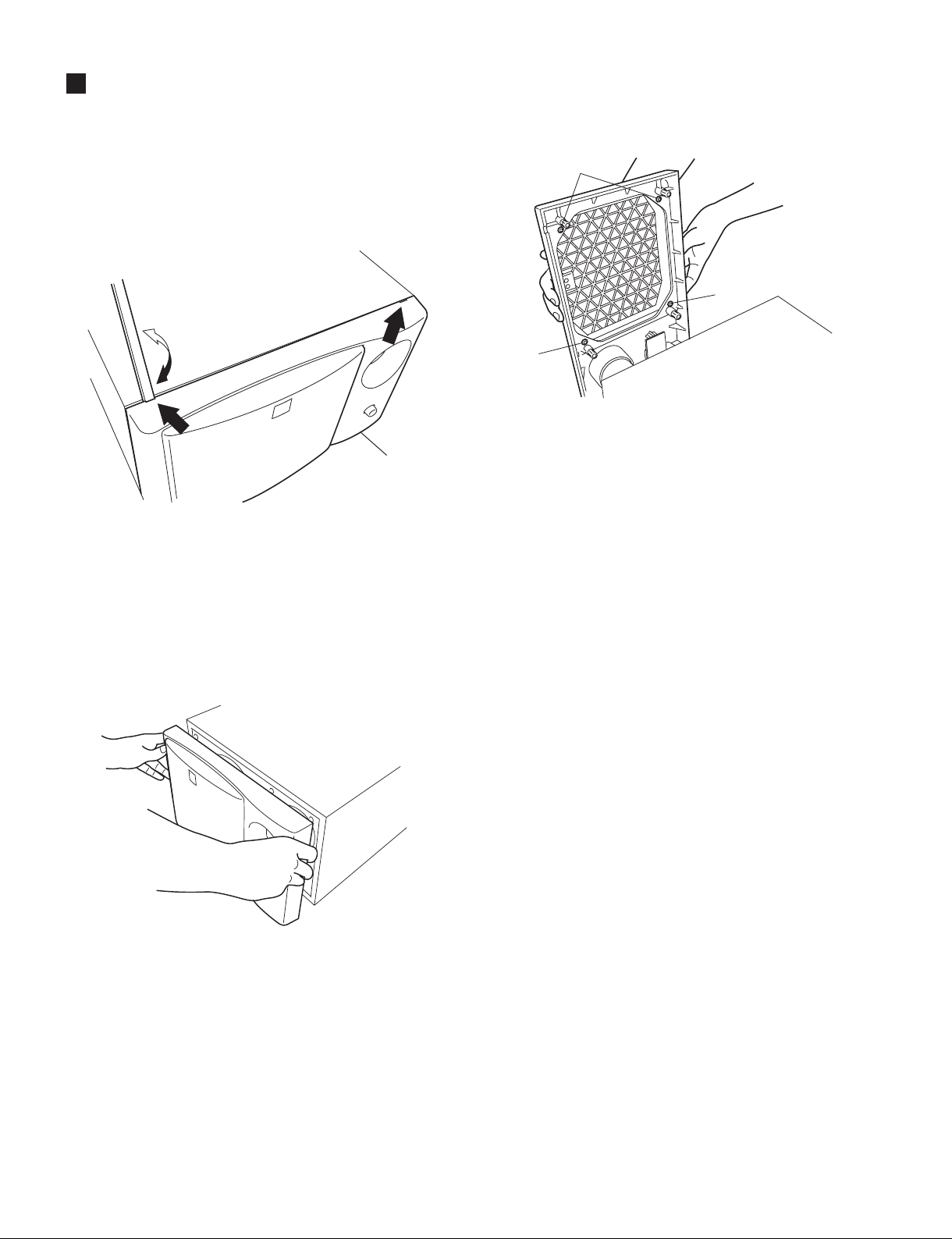

TRS-MS02

T

M

DISASSEMBLY PROCEDURE (TRS-MS02)

1. Grille Assembly

(Time required: About 2 minutes)

1-1 Lay the unit upside down, insert a thin plate such as a

ruler into the two slits on the bottom, then unclench

slightly the front panel. (Fig.1)

Cabinet Bottom Side

(Fig.1)

* Take great care not to damage the cabinet. Stop

unclenching when a small clearance is formed.

1-2 Pull the front panel forward to remove. (Fig.2)

Front Panel

[A]

[A]

[A]

(Fig.3)

2. AC Power Cord

(Time required: About 3 minutes)

2-1 Remove the eight (8) screws marked [B]. The rear panel

can then be removed.

(The screws to be removed are indicated by arrows ‘->’

on the rear panel.) (Fig.4)

* When reinstalling the rear panel, confirm that the packing

is not damaged to avoid air leakage. (Fig.5)

2-2 Remove the soldering portions of the AC power cord

from the AMP assembly. (Fig.5)

2-3 Remove the cord bushing from the rear panel. The AC

power cord can then be removed. (Fig.5)

* When reinstalling the rear panel, confirm that the

packing is not damaged to avoid air leakage. (Fig.5)

NI

R’S

NUN

D’E

(Fig.2)

* The front panel is fixed on the cabinet by six dowels, so

take care not to force diagonally too much.

1-3 Remove the four (4) screws marked [A]. The grille

assembly can then be removed. (Fig.3)

24

OR SPEAKER

MANUAL

GSANLEITUNG

PLOI

Rear Panel

R

TO KEYBOARD

TRS-MS02

L

Soldering part

Power Cord

Packing sheet

(Fig.4)

AMP Assembly

[B]

Power Cord

Cord Bushing

(Fig.5)

Fig.1

25

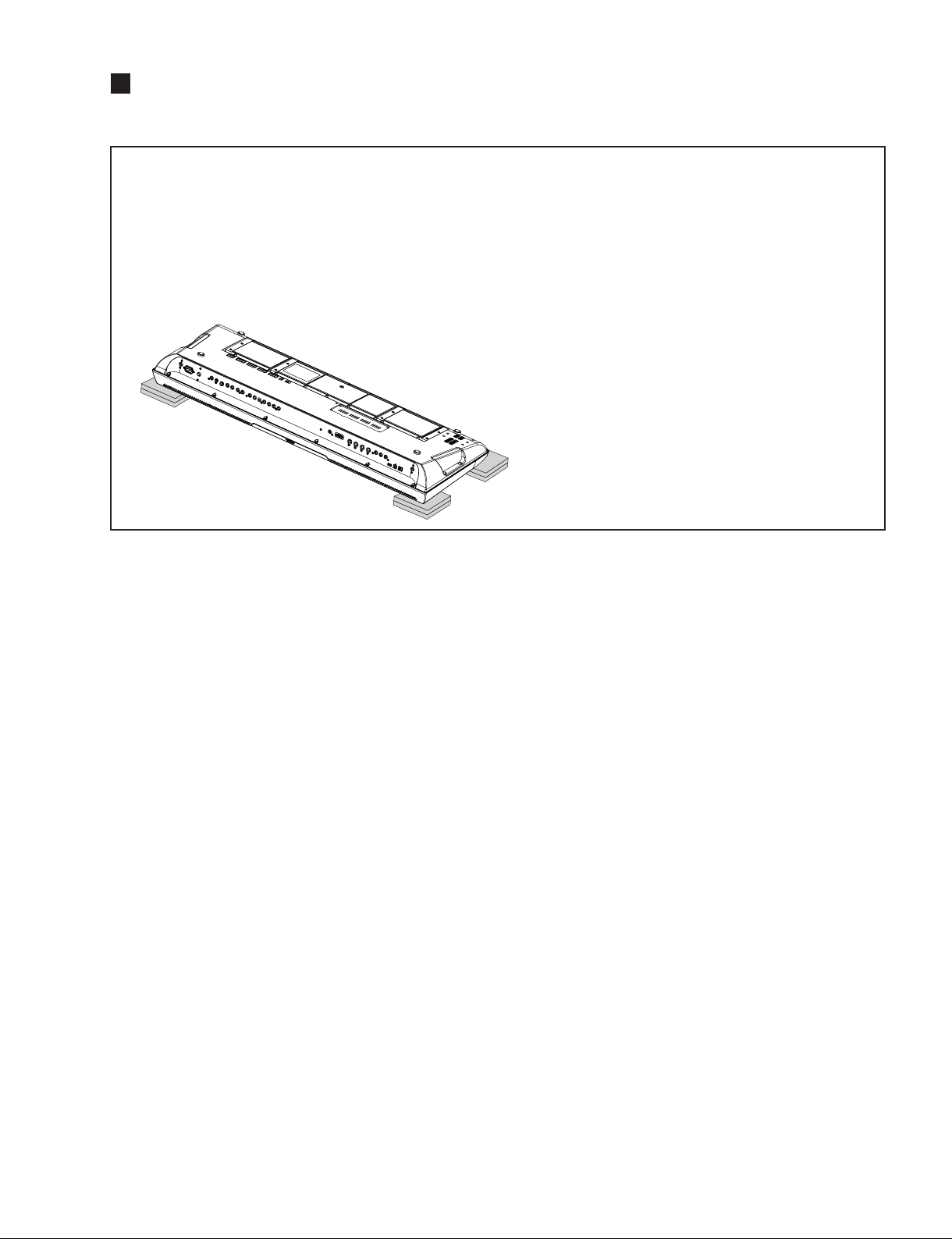

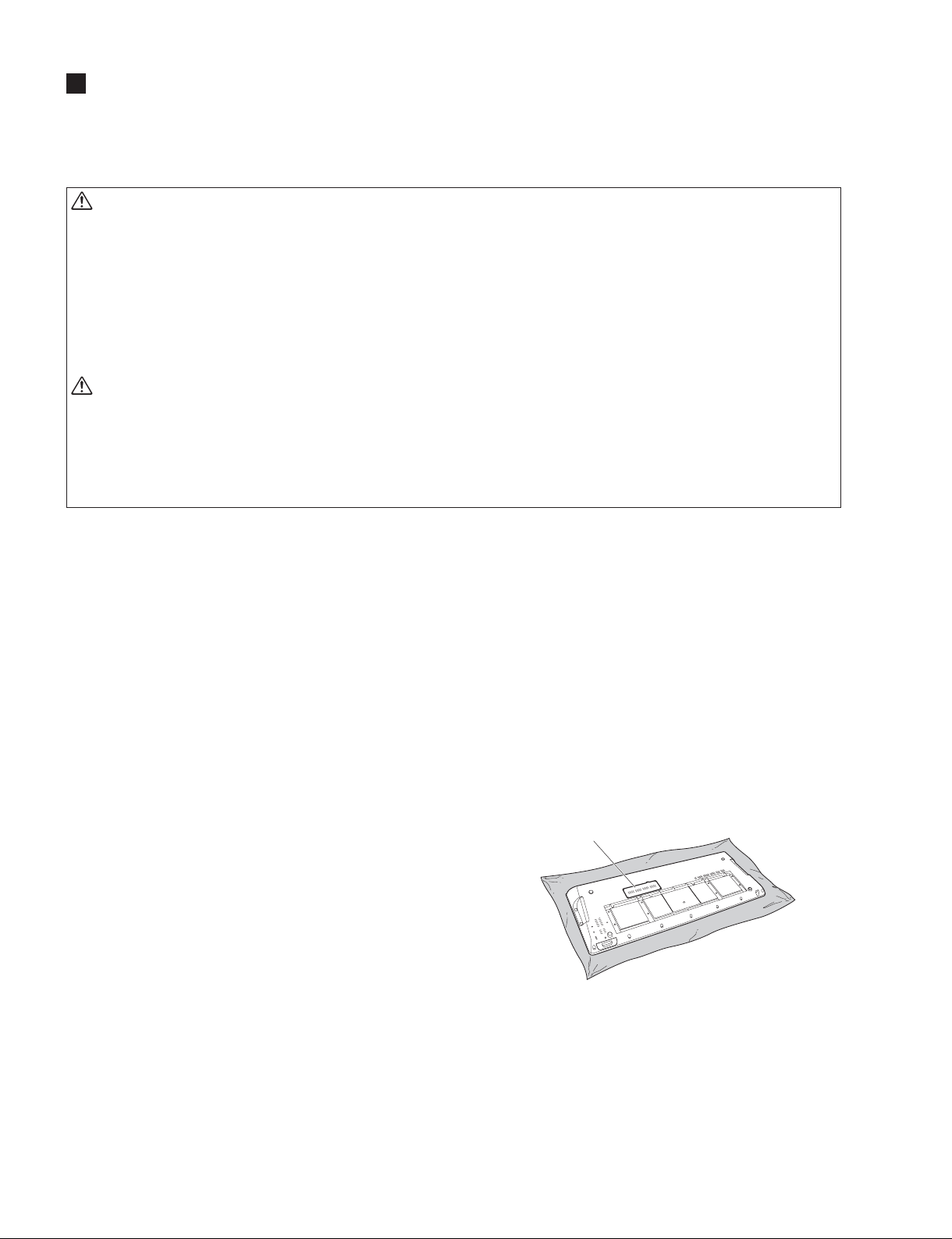

Tyros3

INSTALLING THE OPTIONAL DIMMS

Installing optional DIMMs to the Tyros3 allows you to save large amounts of Voice data created by the Voice Creator function. This section explains how to install DIMM memory modules to the Tyros3.

WARNING

• Before beginning installation, switch off the power to the Tyros3 and connected peripherals, and unplug them from the

power outlet. Then remove all cables connecting the Tyros3 to other devices. (Leaving the power cord connected while

working can result in electric shock. Leaving other cables connected can interfere with work.)

• Be careful not to drop any screws inside the instrument during installation (this can be prevented by keeping the optional

units and cover away from the instrument while attaching). If this does happen, be sure to remove the screw(s) from

inside the unit before turning the power on. Loose screws inside the instrument can cause improper operation or serious

damage.

• Install the optional units carefully as described in the procedure below. Improper installation can cause shorts which may

result in irreparable damage and pose a fi re hazard.

CAUTION

• Do not touch the exposed metal parts in the circuit board. Touching these parts may result in a faulty contact.

• Be careful not to misplace any of the screws since all of them are used.

• Be careful of static electricity. Static electricity discharge can damage the DIMMs or the instrument. Before you handle

the DIMMs, to reduce the possibility of static electricity, touch some unpainted metal surface or a ground wire on a

device that is grounded.

• Do not use any screws other than what are installed on the instrument.

Compatible DIMMs

The Tyros3 does not necessarily support all commercially

available DIMMs. Yamaha cannot guarantee operation of

DIMMs that you purchase. Before purchasing DIMMs, see the

following page:

http://music-tyros.com/

DIMM Type and DIMM Confi guration

• Yamaha recommends that you purchase DIMMs that

conform to the JEDEC* standard. Please be aware, however,

that conformance to this standard does not constitute a

guarantee that the DIMMs will operate correctly on the

Tyros3.

* JEDEC (Joint Electron Device Engineering Council)

sets standards for terminal configurations within

electronic devices.

• Use only 168-pin DIMMs of 64, 128, 256 or 512 MB

capacity (synchronized DRAM; PC100 or PC133).

• Use only DIMMs that have a height of 38.2 mm or less.

• When installing DIMMs, make sure to install them in a

matched pair of the same capacity. You cannot install only

one module and leave the second memory socket open.

Also make sure each DIMM in the pair is of the same

manufacturer and the same type. DIMMs of different makers

and confi gurations may not work together.

• When purchasing DIMMs, make sure that the DIMM design

does not utilize more than 18 memory chips per module.

(DIMMs comprised of more than 18 chips do not operate

correctly on the Tyros3.)

appropriate DIMMs and a Phillips screwdriver.

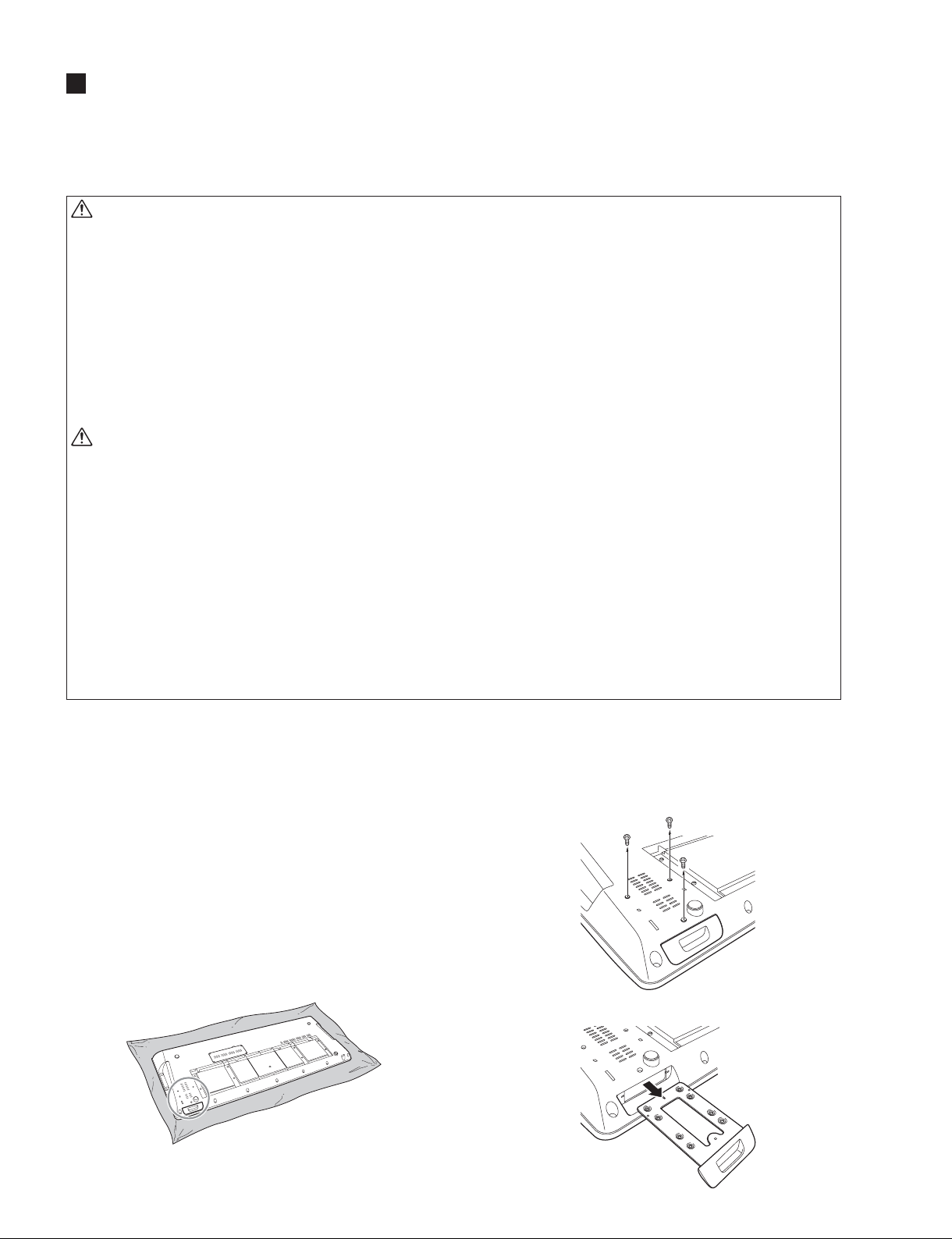

1 Turn the Tyros3’s power off, and disconnect

any cables including AC power cord from the

keyboard.

Also make sure to close the LCD panel and disconnect a

USB device from the USB TO DEVICE terminal.

2 Turn the Tyros3 face down on a blanket or some

soft surface, giving you direct access to the

bottom of the instrument.

3 Remove the four screws from the cover.

Cover

DIMM Installation

Before following the steps below, make sure you have

26

Tyros3

4 Insert the two DIMMs into the DIMM sockets.

Open the ejector levers, then insert the DIMM vertically

in the socket.

5 Re-install the cover you removed in step 3, in

reverse order.

168-pin DIMMs

6 Check that the installed DIMMs are functioning

properly.

Set the Tyros3 right-side up, turn the power on and check

the WAVE RAM by accessing [VOICE CREATOR] →

[B] LIBRARY EDIT → [8 ▼ ] PROPERTY.

If the DIMMs have been installed properly, the

appropriate available memory size is indicated in the

display.

Removing DIMMs

Press the ejector levers

until the DIMM unlocks.

Pull the DIMM vertically

out of the socket.

Notch for alignment

Ejector levers

Insert the DIMM vertically in the

socket, aligning the notches to the

corresponding protrusions.

Make sure that the DIMM

module is aligned correctly

before you install it.

Press it in firmly until it

“snaps” or locks in place.

27

Tyros3

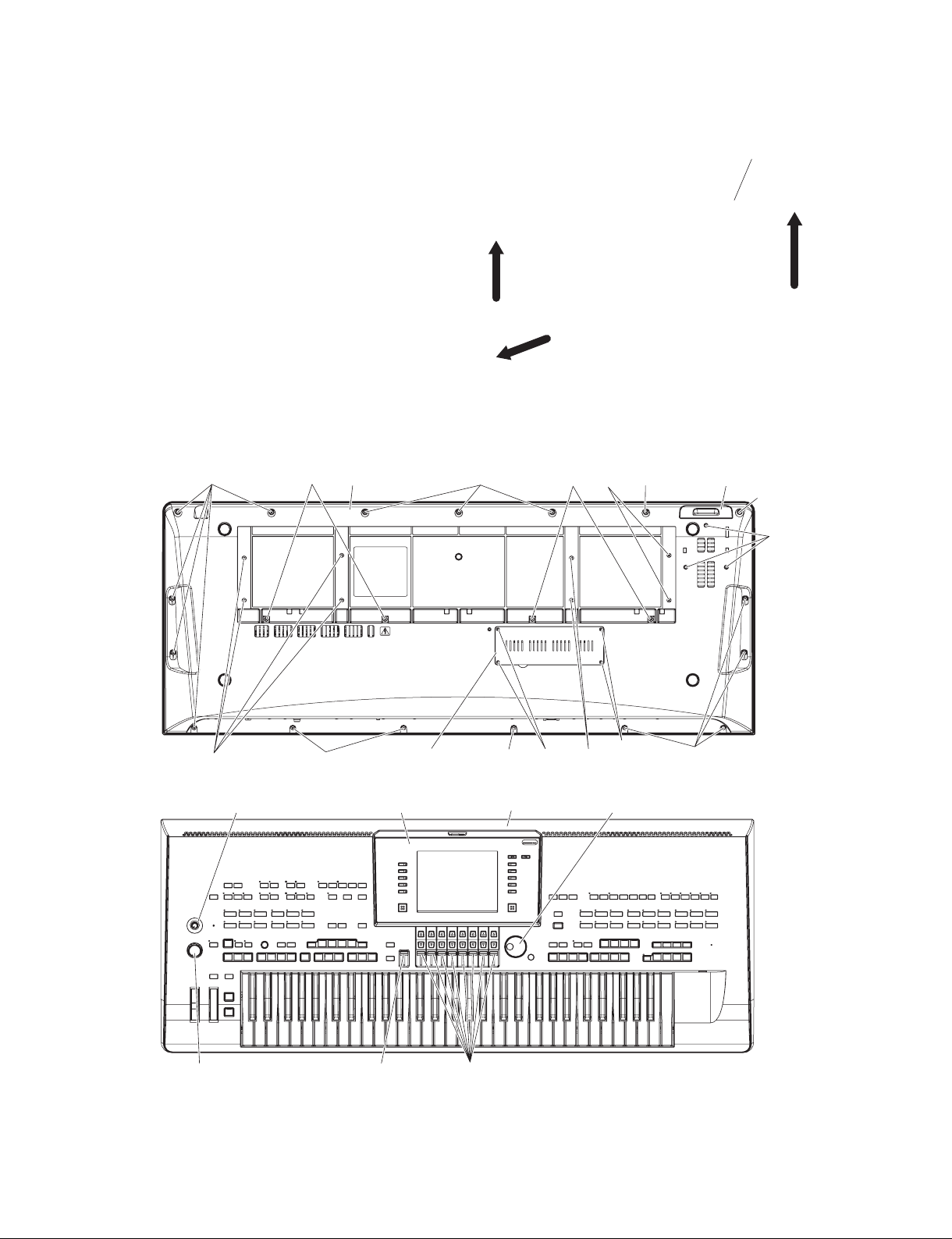

REPLACING THE INTERNAL HARD DISK

If the factory-installed hard disk crashes or when you want to replace it with another one (for example, one you have used on the Tyros/

Tyros2), you can remove the current one and install the new one by following the procedure below. The hard disk used must be a 2.5-inch

P-ATA (parallel ATA) compatible; however, not all such drives may be installable.

WARNING

• Before beginning, switch off the power to the Tyros3 and connected peripherals, and unplug them from the power outlet.

Then remove all cables connecting the Tyros3 to other devices. (Leaving the power cord connected while working can

result in electric shock. Leaving other cables connected can interfere with work.)

• Be careful not to drop any screws inside the instrument. If this does happen, be sure to remove the screw(s) from inside

the unit before turning the power on. Loose screws inside the instrument can cause improper operation or serious

damage. If you are unable to retrieve a dropped screw, consult your Yamaha dealer for advice.

• Install the hard disk units carefully as described in the procedure below. Improper installation can cause shorts which

may result in irreparable damage and pose a fi re hazard.

• Do not disassemble, modify, or apply excessive force to board areas and connectors on hard disk units. Bending or

tampering with boards and connectors may lead to electric shock, fi re, or equipment failures.

CAUTION

• Before removing the installed hard disk unit, make sure to backup any necessary data on the disk to computer by using

the USB Storage Mode. This will prevent loss of important data and enable you to use the data on the new hard disk. (If

you need to backup the recorded audio fi les, save the hidden folder “HDR.ROOT” to the computer.)

• It is recommended that you wear gloves to protect your hands from metallic projections on hard disk units and other

components. Touching leads or connectors with bare hands may cause fi nger cuts, and may also result in poor electrical

contact or electrostatic damage.

• Handle the hard disk unit with care. Dropping or subjecting them to any kind of shock may cause damage or result in a

malfunction.

• Be careful of static electricity. Static electricity discharge can damage the IC chips on the hard disk or the instrument.

Before you handle the hard disk, to reduce the possibility of static electricity, touch the metal parts other than the painted

area or a ground wire on the devices that are grounded.

• Do not touch the exposed metal parts in the circuit board. Touching these parts may result in a faulty contact.

• Be careful not to misplace any of the screws since all of them are used.

• Do not use any screws other than what are installed on the instrument.

NOTE

• Hard disk drives thicker than 12.7 mm cannot be installed to the Tyros3.

• S-ATA compatible hard disks cannot be used.

Before following the steps below, make sure you have an appropriate hard disk drive and a Phillips screwdriver.

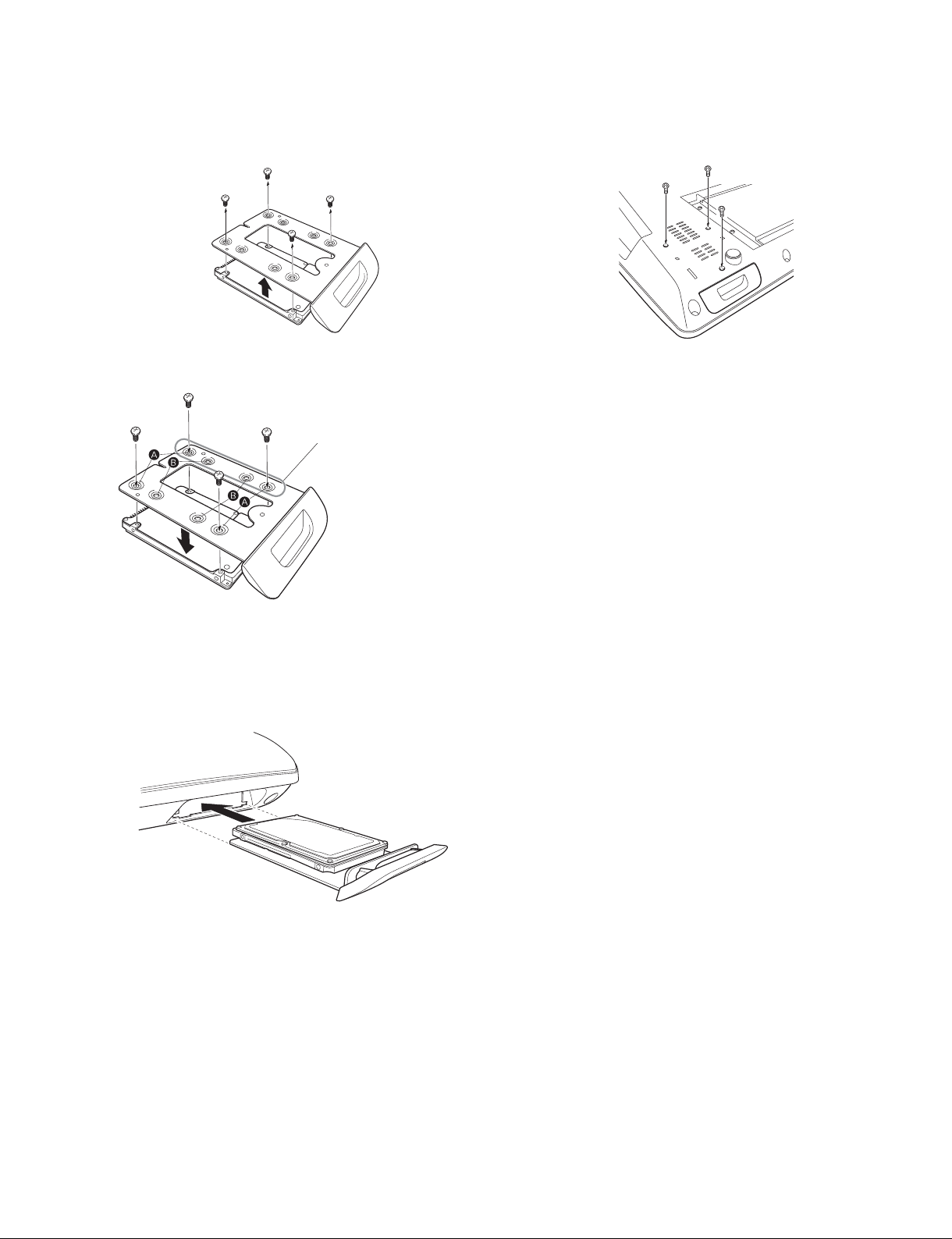

3 Remove the three screws.

1 Turn the Tyros3’s power off, disconnect any

cables including AC power cord from the

keyboard.

Also make sure to close the LCD panel and disconnect a

USB device from the USB TO DEVICE terminal.

2 Turn the Tyros3 face down on a blanket or some

soft surface, giving you direct access to the

bottom of the instrument.

4 Pull out the hard disk bracket.

28

Tyros3

5 Remove the four screws to remove the installed

hard disk unit from the bracket.

6 Attach the new hard disk unit to the bracket

using the four screws removed in step 5.

You should tighten these two

screws first.

9 Turn the Tyros3 face down again and fasten the

three screws removed in step 3.

10 Check that the installed hard disk is functioning

properly.

Set the Tyros3 right-side up, and turn the power on. If the

HD tab appears on the File Selection display, the hard

disk is OK.

Make sure the bottom of the hard disk is facing up.

Depending on the type of hard disk drive you plan to

install, select holes or holes to attach the hard disk

drive.

* Holes are used in this illustration.

7 Set the Tyros3 right-side up.

8 Insert the hard disk bracket into the slot.

NOTE

If you have installed the hard disk that was once used for the Tyros/Tyros2 and turn the Tyros3’s power on, you can

immediately view the fi les on the hard disk and use the Song fi les from the Tyros/Tyros2. However, to properly use the Style,

Multi Pad, and Registration Memory fi les from the Tyros/Tyros2, you will need to convert the data using a computer and the

File Converter software (available for free download on the Tyros3 website).

29

Tyros3

LSI PIN DESCRIPTION

AK4396VF-E2 (X8324A00) DAC (Digital to Analog Converter) ...........................................................42

AK5381VT-E2 (X5219A0R) ADC (Analog to Digital Converter) ...........................................................41

DM9000AEP (X7029A00) LAN CONTROLLER ..................................................................................41

DS99R103TSQX/NOPB (X9323A00) LVDS ........................................................................................42

DS99R104TSQX/NOPB (X9324A00) LVDS ........................................................................................43

HD6417727F160CV (X2890B00) CPU ................................................................................................31

HD6433693B14HV (X480120R) E-VKS ..............................................................................................30

ISP1761BE (X9073A00) HI-SPEED USB OTG CONTROLLER .........................................................38

LC4256V-75TN100 (X6046B0R) CPLD (MAT) ....................................................................................36

M34519M6-521FP (X5646200) CPLD (Complex Programmable Logic Device) .................................41

MB3516APF-G-BND-EF (X2314A00) RGB ENCODER .....................................................................40

R5S72060W200FPV (X8924A00) CPU ......................................................................................32

S1L50553F21Y000 (X4195A0R) MCI (Gate Array) ............................................................................40

S1L52502F24J200 (X2688A0R) GATE ARRAY .................................................................................39

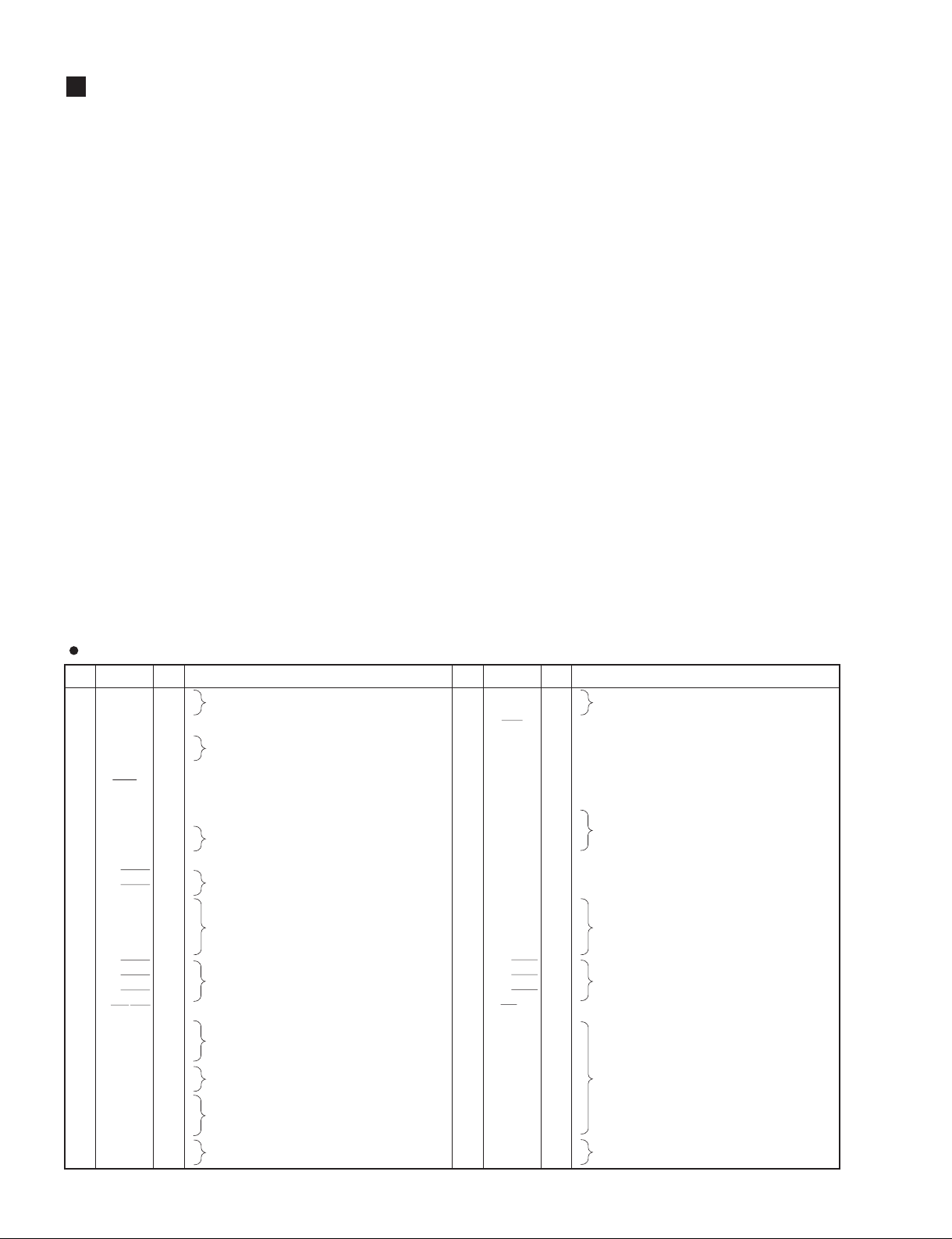

T6TZ2XBG-0002 (X7376B00) SWP51 (Tone Generator) ...........................................................34

YGV628B-VZ (X6356B00) RGB CONTROLLER AVDP7 ...................................................................37

µPD780031AYGK-N09 (XZ916300) E-PNS2a LED/SWITCH DRIVER ..............................................43

―

―

33

35

HD6433693B14HV (X480120R) E-VKS

PIN

NAME

NO.

1

2

3

AV

4

5

6

7

RES

8

TEST

9

10

OSC2

11

OSC1

12

VCC

13

P50/WKP0

14

P51/WKP1

15

16

17

18

19

P52/WKP2

20

P53/WKP3

21

P54/WKP4

22

P55/WKP5/ADTRG

23

P10/TMOW

24

P11

25

P12

26

SDA

27

SCL

28

P74/TMRIV

29

P75/TMCIV

30

P76/TMOV

31

32

NC

NC

X2

X1

V

V

NC

NC

NC

NC

NC

NC

SS

I/O

Not used

CC

-

O

I

CL

I

I

-

O

I

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

Power supply

Crystal resonator

Power supply

Reset pin

Test pin

Ground

Crystal or ceramic resonator

Power supply

8-bit I/O port / Interrupt request

Not used

8-bit I/O port / Interrupt request

8-bit I/O port / Interrupt request / A/D converter trigger

7-bit I/O port

IIC data I/O pin

3-bit I/O port / Timer

Not used

FUNCTION

PIN

NO.

33

NC

34

NC

35

NMI

36

P80/FTCI

37

P81/FTIOA

38

P82/FTIOB

P83/FTIOC

39

P84/FTIOD

40

41

P85

42

P86

43

P87

44

P20/SCK3

P21/RXD

45

P22/TXD

46

NC

47

NC

48

NC

49

NC

50

51

P14/IRQ0

52

P15/IRQ1

53

P16/IRQ2

54

P17/IRQ3/TRGV

PB4/AN4

55

PB5/AN5

56

PB6/AN6

57

PB7/AN7

58

PB3/AN3

59

PB2/AN2

60

PB1/AN1

61

PB0/AN0

62

NC

63

NC

64

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

EMKS-FD: IC005

FUNCTIONNAME

Not used

I

Non maskable interrupt

8-bit I/O port / External event input

8-bit I/O port / Output compare

8-bit I/O port / Output / input capture

8-bit I/O port / Input PWM

8-bit I/O port / Output

8-bit I/O port

3-bit I/O port / Clock

3-bit I/O port / Receive data input

3-bit I/O port / Transmit data output

Not used

7-bit I/O port / Interrput request

7-bit I/O port / Interrput request / Trigger input

8-bit I/O port / Analog input

Not used

30

Loading...

Loading...