Page 1

OWNER’S MANUAL

SX225A

LX225A

SX250A

LX250A

U.S.A.Edition

LIT-18626-04-64

Page 2

Page 3

EMU01449

TO THE OWNER

Thank you for choosing a Yamaha outboard motor. This Owner’s manual contains information needed for proper operation, maintenance and care. A thorough

understanding of these simple instructions will help you obtain maximum

enjoyment from your new Yamaha. If you

have any question about the operation or

maintenance of your outboard motor,

please consult a Yamaha dealer.

In this Owner’s Manual particularly

important information is distinguished in

the following ways.

The Safety Alert Symbol means

ATTENTION! BECOME ALERT!

Q

YOUR SAFETY IS INVOLVED!

E

cC

A CAUTION indicates special precautions

that must be taken to avoid damage to

the outboard motor.

NOTE:

A NOTE provides key information to make

procedures easier or clearer.

* Yamaha continually seeks advance-

ments in product design and quality.

Therefore, while this manual contains

the most current product information

available at the time of printing, there

may be minor discrepancies between

your machine and this manual. If there

is any question concerning this manual,

please consult your Yamaha dealer.

w

Failure to follow WARNING instructions

could result in severe injury or death to

the machine operator, a bystander, or a

person inspecting or repairing the outboard motor.

EMU01446

SX225A/LX225A/SX250A/LX250A

OWNER'S MANUAL

©2001 by Yamaha Motor Corporation, USA

1st Edition, March 2001

All rights reserved.

Any reprinting or unauthorized use

without the written permission of

Yamaha Motor Corporation, USA

is expressly prohibited.

Printed in Japan

P/N LIT-18626-04-64

NOTE:

The SX225TR, LX225TR and their standard accessories are used as a base for

the explanations and illustrations in this

manual. Therefore, some items may not

apply to every model.

Page 4

EMA20010

CONTENTS

E

GENERAL INFORMATION

BASIC COMPONENTS

OPERATION

MAINTENANCE

1

2

3

4

TROUBLE RECOVERY

INDEX

READ THIS OWNER’S MANUAL CAREFULLY

BEFORE OPERATING YOUR OUTBOARD MOTOR.

5

6

Page 5

E

EMB00010

Chapter 1

GENERAL

INFORMATION

IDENTIFICATION NUMBERS RECORD ..1-1

Outboard motor serial number...........1-1

Key number...........................................1-1

EMISSION CONTROL INFORMATION...1-2

SAFETY INFORMATION..........................1-3

1

2

IMPORTANT LABELS ..............................1-5

BASIC BOATING RULES .........................1-6

FUELING INSTRUCTIONS.....................1-10

Gasoline (petrol).................................1-10

Engine oil ............................................1-11

BATTERY REQUIREMENT ....................1-12

PROPELLER SELECTION .......................1-12

START-IN-GEAR PROTECTION ............1-14

3

4

5

6

Page 6

1

904011*

123

YAMAHA

q

401012

E

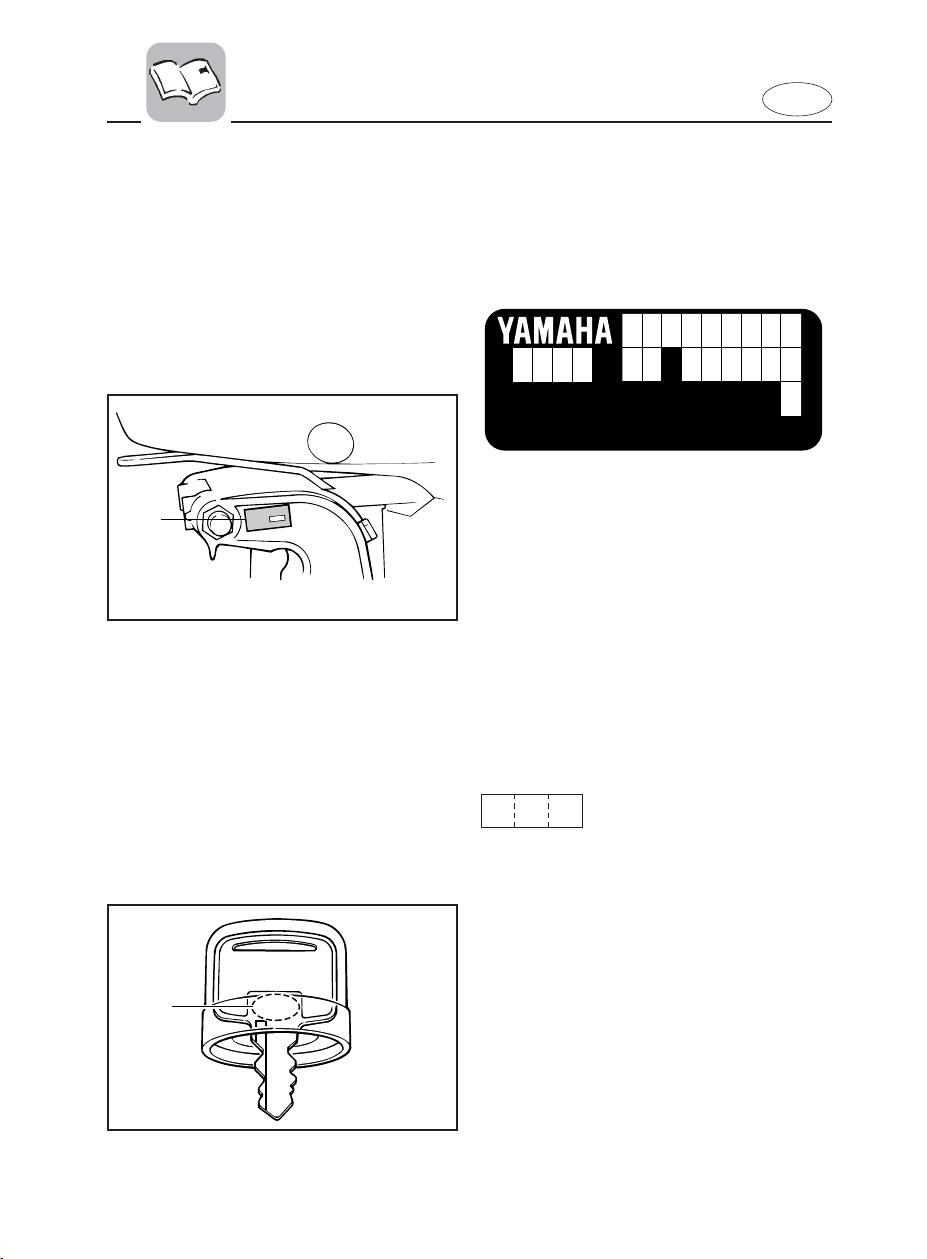

EMU00005

IDENTIFICATION NUMBERS

RECORD

EMU00007

OUTBOARD MOTOR SERIAL NUMBER

YAMAHA MOTOR CO., LTD.

MADE IN JAPAN

PAYS D'ORIGINE JAPON

The outboard motor serial number is

stamped on the label attached to the port

side of the clamp-bracket.

Record your outboard motor serial number in the spaces provided to assist you in

ordering spare parts from your Yamaha

dealer or for reference in case your outboard motor is stolen.

1 Outboard motor serial number

EMU00008

KEY NUMBER

If a main key switch is equipped with the

motor, the key identification number is

stamped on your key as shown in the

illustration. Record this number in the

space provided for reference in case you

need a new key.

1 Key number

1-1

Page 7

E

q

w

EMISSION CONTROL INFORMATION

ENGINE FAMILY :

THIS ENGINE CONFORMS TO 2001 U.S. EPA REGULATIONS FOR MARINE SI ENGINES.

THIS ENGINE CONFORMS TO 2001 CALIFORNIA EMISSION REGULATIONS FOR SI MARINE ENGINES AND

IS CERTIFIED TO g/kw-hr HC

+

NOx ENGINE FAMILY EXHAUST EMISSION STANDARD IN CALIFORNIA.

REFER TO THE OWNERS MANUAL FOR MAINTENANCE SPECIFICATIONS AND ADJUSTMENTS.

FELs :

SPARK PLUG :

DISPLACEMENT :

ADVERTISED POWER :

IDLE SPEED :

SPARK PLUG GAP (mm) :

FUEL : GASOLINE

VALVE LASH (mm) :

IN EX

cm

kw

g/kw-hr

rpm IN NEUTRAL

3

Manufactured:

EMISSION CONTROL INFORMATION

ENGINE FAMILY :

THIS ENGINE CONFORMS TO 2001 U.S. EPA REGULATIONS FOR MARINE SI ENGINES.

FELs :

SPARK PLUG :

IDLE SPEED :

rpm IN NEUTRAL

SPARK PLUG GAP (mm) :

g/kw-hr

EMU01385

EMISSION CONTROL

INFORMATION

EMU01388*

CALIFORNIA AND OTHER STATES

This engine conforms to U.S.

Environmental Protection Agency (EPA)

and/or California Air Resources Board

(CARB) regulations for marine SI engines.

See the label affixed to your engine for

details.

Approval label of Emission control

certificate

This label is attached to the bottom cowling.

1

Emission control information label (California)

1

Emission control information label (other states)

Existing Technology ; N/A

Manufactured date label

This label is attached to the clamp bracket

or the swivel bracket.

2 Manufactured date label

1-2

Page 8

E

EMU00917

SAFETY

Q

8 Before mounting or operating the out-

board motor, read this entire manual.

Reading it should give you an understanding of the motor and its operation.

8 Before operating the boat, read any

owner’s or operator’s manuals supplied

with it and all labels. Be sure you understand each item before operating.

8 Do not overpower the boat with this

outboard motor. Overpowering the

boat could result in loss of control. The

rated power of the outboard should be

equal to or less than the rated horsepower capacity of the boat. If the rated

horsepower capacity of the boat is

unknown, consult the dealer or boat

manufacturer.

8 Do not modify the outboard.

Modifications could make the motor

unfit or unsafe to use.

8 Never operate after drinking alcohol or

taking drugs. About 50% of all boating

fatalities involve intoxication.

8 Have an approved personal flotation

device (PFD) on board for every occupant. It is a good idea to wear a PFD

whenever boating. At a minimum, children and non-swimmers should always

wear PFDs, and everyone should wear

PFDs when there are potentially hazardous boating conditions.

8 Gasoline is highly flammable, and its

vapors are flammable and explosive.

Handle and store gasoline carefully.

Make sure there are no gas fumes or

leaking fuel before starting the engine.

INFORMATION

8 This product emits exhaust gases which

contain carbon monoxide, a colorless,

odorless gas which may cause brain

damage or death when inhaled.

Symptoms include nausea, dizziness,

and drowsiness. Keep cockpit and cabin

areas well ventilated. Avoid blocking

exhaust outlets.

8 Check throttle, shift, and steering for

proper operation before starting the

engine.

8 Attach the engine stop switch lanyard

to a secure place on your clothing, or

your arm or leg while operating. If you

accidentally leave the helm, the lanyard

will pull from the switch, stopping the

engine.

8 Know the marine laws and regulations

where you will be boating - and obey

them. Refer to the “RULES OF THE

ROAD” section for basic boating rules.

8 Stay informed about the weather.

Check weather forecasts before boating.

Avoid boating in hazardous weather.

8 Tell someone where you are going:

leave a Float Plan with a responsible

person. Be sure to cancel the Float Plan

when you return.

8 Use common sense and good judgment

when boating. Know your abilities, and

be sure you understand how your boat

handles under the different boating

conditions you may encounter. Operate

within your limits, and the limits of your

boat. Always operate at safe speeds,

and keep a careful watch for obstacles

and other traffic.

8 Always watch carefully for swimmers

during the engine operation.

8 Stay away from swimming areas.

1-3

Page 9

8 When a swimmer is in the water near

you shift into neutral and shut off the

engine.

8 Be informed about boating safety.

Additional publications and information

can be obtained from many organizations, including the following:

United States Coast Guard

Consumer Affairs Staff (G-BC)

Office of Boating, Public, and Consumer

Affairs

U.S. Coast Guard Headquarters

Washington, D.C. 20593-0001

Boating Safety Hotline: 1-800-368-5647

National Marine Manufacturers

Association (NMMA)

401 N. Michigan Ave.

Chicago, Il 60611

Marine Retailers Association of America

155 N. Michigan Ave.

Chicago, Il 60601

E

1-4

Page 10

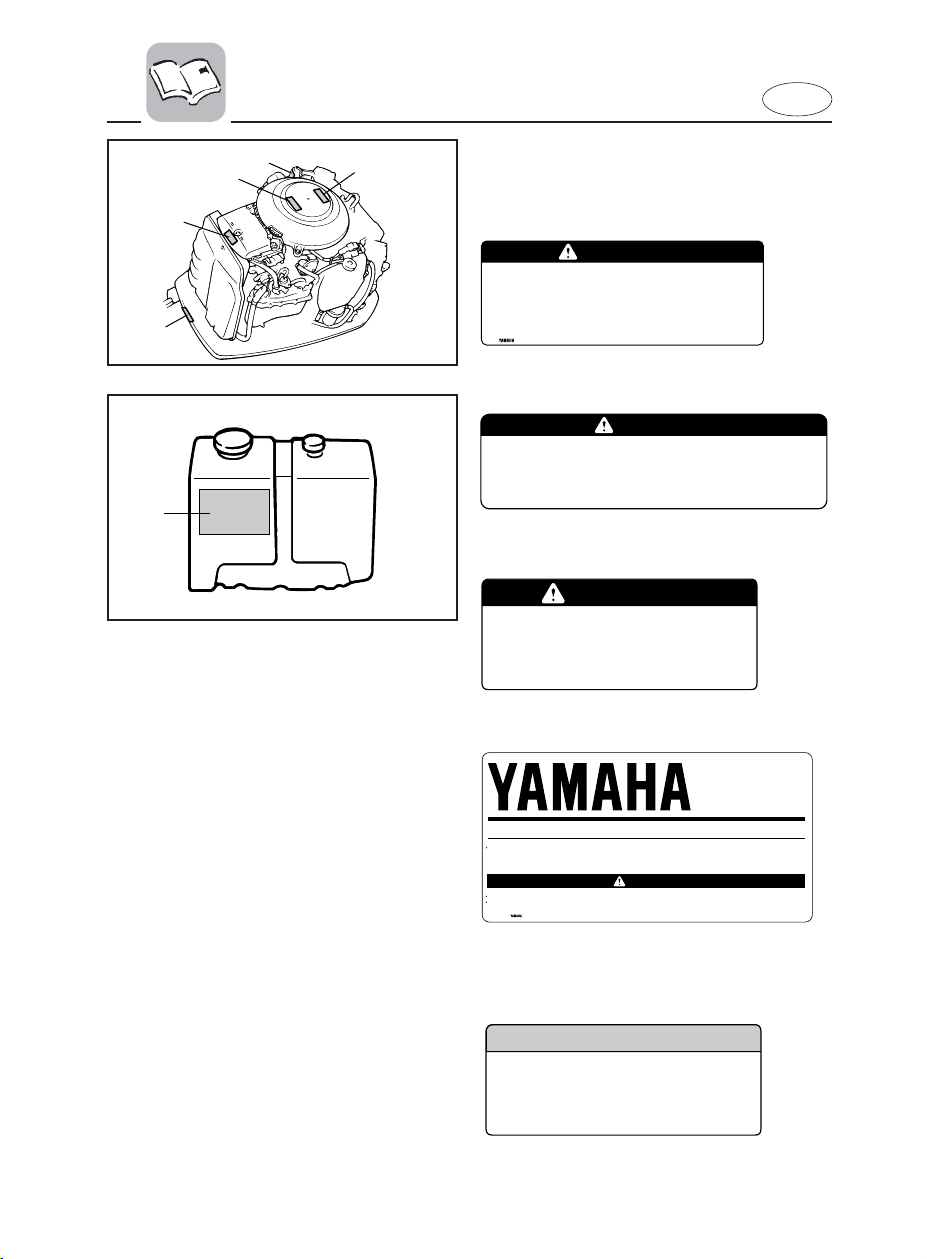

e

WARNING

6K1-83623-41

YAMAHA

Use only a counterclockwise rotation propeller with this engine.

Counterclockwise propellers are marked with a letter "L"

after the size indication.

The wrong type of propeller could cause the boat to go

in an unexpected direction, which could lead to an accident.

WARNING

6

Be sure shift control is in neutral

6

before starting engine. (except 2HP)

6

Do not touch or remove electrical parts

6

when starting or during operation.

6

Keep hands,hair,and clothes away from flywheel

6

and other rotating parts while engine is running.

6A1-83625-41

WARNING

Hot surface under this cover

during and after operation.

To avoid burns, do not touch

finned resistor with bare hands.

65L-83625-40

YAMAHA

ENGINE OIL ONLY

WARNING

6E5-13437-43

Pour the engine oil into this oil tank, not gasoline.

RECOMMENDED OIL:

YAMALUBE 2 STROKE OUTBOARD OIL or an equivalent TC-W3 certified outborad oil.

Do not add gasoline to the oil tank.

Fire or explosion could result.

OIL TANK

CAPACITY:10.5 LITERS

11.1 U.S. qt.

9.2 IMP. qt.

CAUTION

UNLEADED GASOLINE ONLY.

Gasoline containing lead can cause

performance loss and engine damage.

Refer t o Owne r’s Manual.

65L-2415E-40

YAMAHA

w

e

q

E

EMB30010

IMPORTANT LABELS

WARNING LABELS

1

t

r

202014*

2

3

905011

4

CAUTION LABELS

5

1-5

Page 11

E

EMB40010

BASIC BOATING RULES

(Rules of the road)

Just as there are rules which apply when

you are driving on streets and high ways,

there are waterway rules which apply

when you are driving your boat. These

rules are used internationally, and are

also enforced by the United States Coast

Guard and local agencies. You should be

aware of these rules, and follow them

whenever you encounter another vessel

on the water.

Several sets of rules prevail according to

geographic location, but are all basically

the same as the International Rules of the

Road. The rules presented here in your

Owner’s Manual are condensed, and have

been provided for your convenience only.

Consult your local U.S. Coast Guard

Auxiliary or Department of Motor

Vehicles for a complete set of rules governing the waters in which you will be

using your boat.

STEERING AND SAILING RULES AND

SOUND SIGNALS

Whenever two vessels on the water meet

one another, one vessel has the right-ofway; it is called the “stand-on” vessel.

The vessel which does not have the rightof-way is called the “give-way” or “burdened” vessel. These rules determine

which vessel has the right-of-way, and

what each vessel should do.

Stand-on Vessel

The vessel with the right-of-way has the

duty to continue its course and speed,

except to avoid an immediate collision.

When you maintain your direction and

speed, the other vessel will be able to

determine how best to avoid you.

Give-way Vessel

The vessel which does not have the rightof-way has the duty to take positive and

timely action to stay out of the way of the

Stand-On vessel. Normally, you should

not cross in front of the vessel with the

right-of-way. You should slow down or

change directions briefly and pass behind

the other vessel. You should always move

in such a way that the operator of the

other vessel can see what you are doing.

“The general prudential rule”

This rule is called Rule 2 in the International Rules and says,

‘In obeying and construing these rules

due regard shall be had to all dangers

of navigation and collision, and to any

special circumstances, which may render a departure from the above rules

necessary in order to avoid immediate

danger.’

In other words, follow the standard rules

except when a collision will occur unless

both vessels try to avoid each other. If

that is the case, both vessels become

“Give-Way” vessels.

1-6

Page 12

E

102045

102046

RULES WHEN ENCOUNTERING

VESSELS

There are three main situations which you

may encounter with other vessels which

could lead to a collision unless the

Steering Rules are followed:

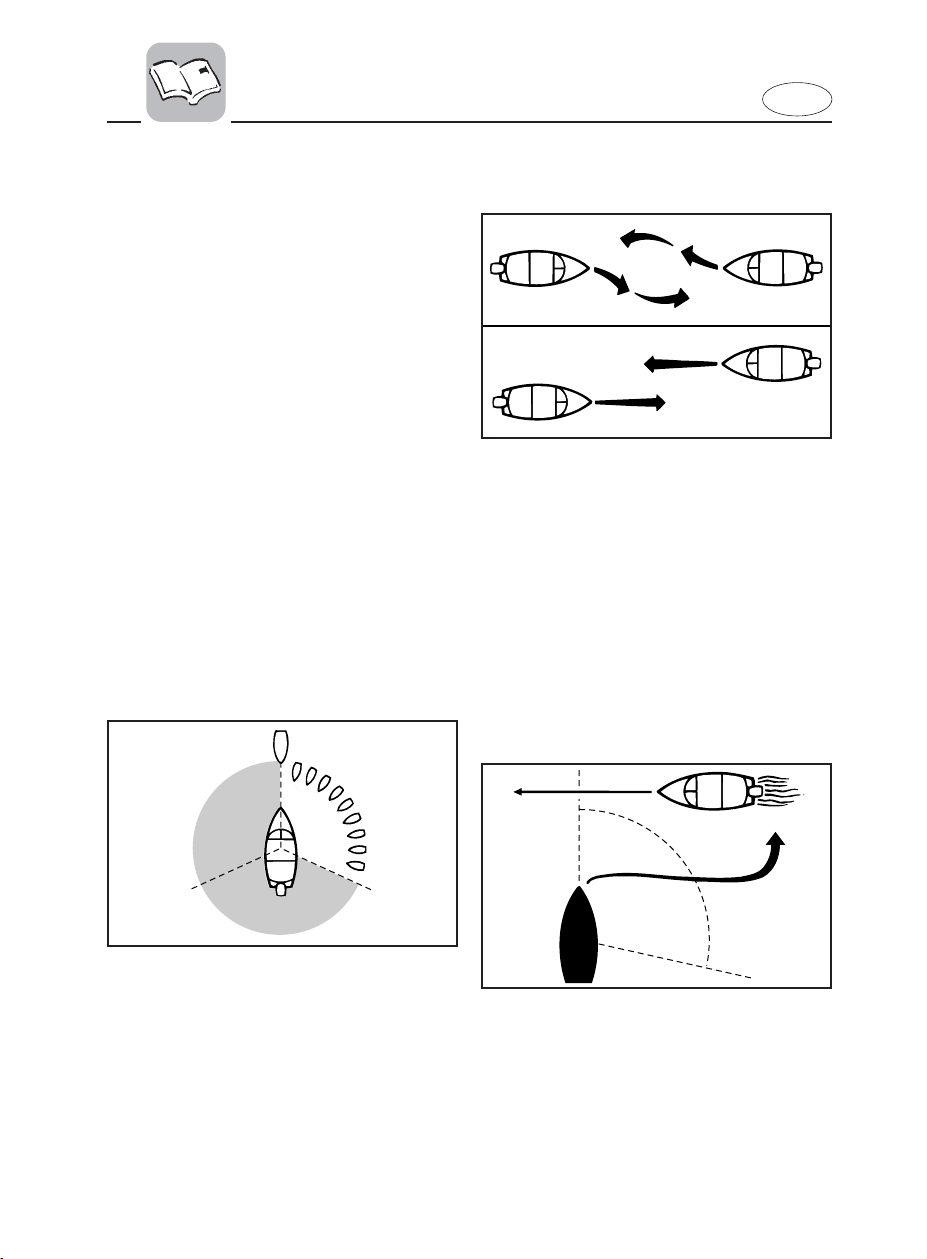

Meeting

(you are approaching another vessel

head-on)

Crossing

(you are travelling across the other vessel’s path)

Overtaking

(you are passing or being passed by

another vessel)

In the following illustration, your boat is

in the center. You should give the right-ofway to any vessels shown in white area

(you are the Give-Way vessel). Any vessels in the shaded area must yield to you

(they are the Give-Way vessels). Both you

and the meeting vessel must alter course

to avoid each other.

side. This rule doesn’t apply if both of you

will clear one another if you continue on

your set course and speed.

102044

Crossing

When two power driven vessels are

crossing each other’s path close enough

to run the risk of collision, the vessel

which has the other on the starboard

(right) side must keep out of the way of

the other. If the other vessel is on your

right, you must keep out of its way; you

are the Give-Way vessel. If the other vessel is on your port (left) side, remember

that you should maintain course and

direction, provided the other vessel gives

you the right-of-way as it should.

Meeting

If you are meeting another power vessel

head on, and are close enough to run the

risk of collision, neither of you has the

right-of-way! Both of you should alter

course to avoid an accident. You should

keep the other vessel on your port (left)

Overtaking

If you are passing another vessel, you are

the “Give-Way” vessel. This means that

the other vessel is expected to maintain

its course and speed. You must stay out

1-7

Page 13

E

of its way until you are clear of it.

Likewise, if another vessel is passing you,

you should maintain your speed and

direction so that the other vessel can steer

itself around you.

OTHER SPECIAL SITUATIONS

There are three other rules you should be

aware of when driving your boat around

other vessels.

Narrow Channels and Bends

When navigating in narrow channels, you

should keep to the right when it is safe

and practical to do so. If the operator of a

power-driven vessel is preparing to go

around a bend that may obstruct the view

of other water vessels, the operator

should sound a prolonged blast on the

whistle (4 to 6 seconds). If another vessel

is around the bend, it too should sound

the whistle. Even if no reply is heard,

however, the vessel should still proceed

around the bend with caution. If you navigate such waters with your boat, you will

need to carry a portable air horn, available from local marine supply stores.

Fishing Vessel Right-of-way

All vessels which are fishing with nets,

lines or trawls are considered to be“fishing vessels” under the International

Rules. Vessels with trolling lines are not

considered fishing vessels. Fishing vessels have the right-of-way regardless of

position. Fishing vessels cannot, however, impede the passage of other vessels in

narrow channels.

Sailing Vessel Right-of-way

Sailing vessels should normally be given

the right-of-way. The exceptions to this

are:

1. When the sailing vessel is overtaking

the power-driven vessel, the powerdriven vessel has the right-of-way.

2. Sailing vessels should keep clear of

any fishing vessel.

3. In a narrow channel, a sailing vessel

should not hamper the safe passage

of a power-driven vessel which can

navigate only in such a channel.

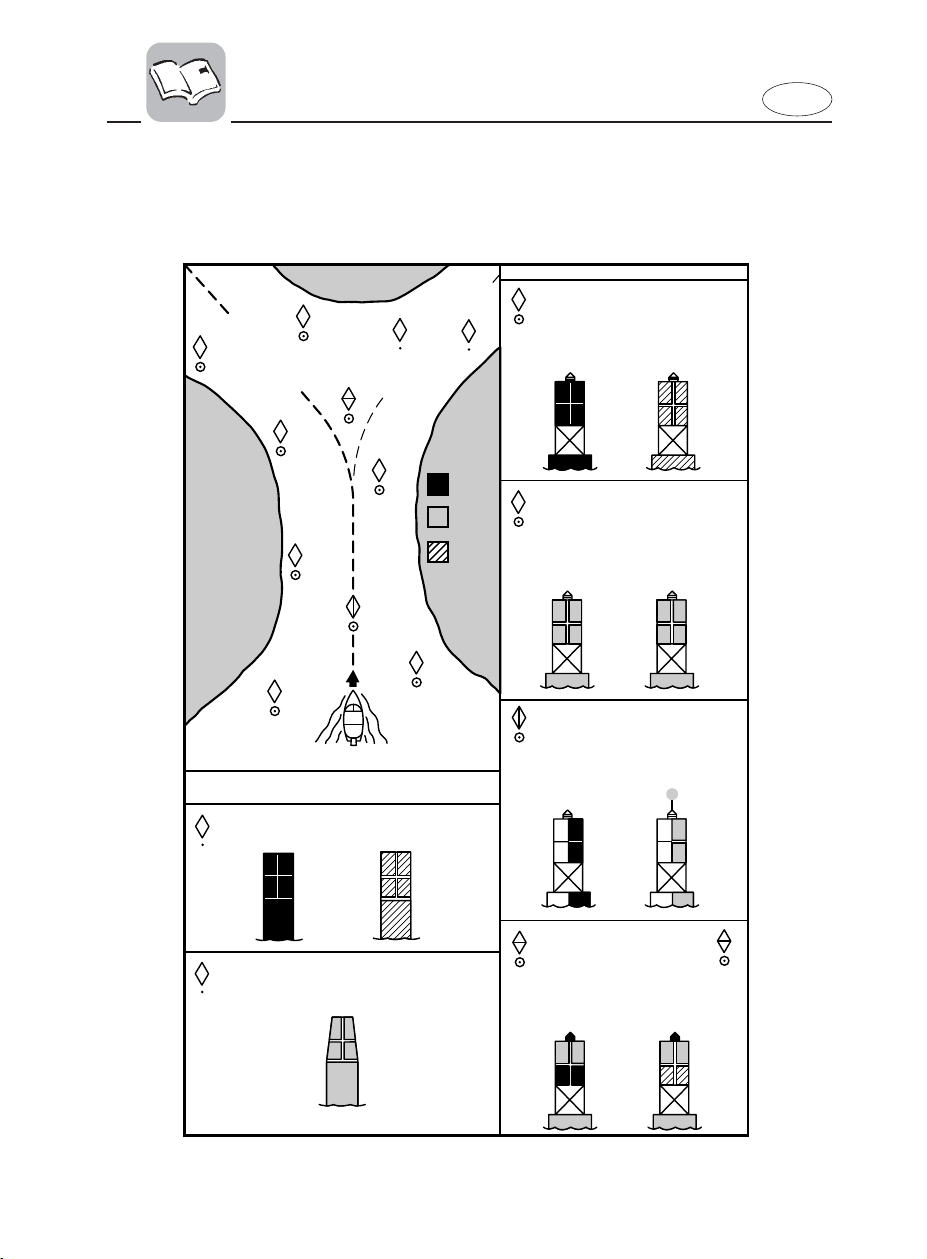

Reading Buoys and Other Markers

The waters of the United states are

marked for safe navigation by the lateral

system of buoyage. Simply put, buoys

and markers have an arrangement of

shapes, colors, numbers and lights to

show which side of the buoy a boater

should pass on when navigating in a particular direction. The markings on these

buoys are oriented from the perspective

of being entered from seaward (the

boater is going towards the port). This

means that red buoys are passed on the

starboard (right) side when proceeding

from open water into port, and black

buoys are to port (left) side. When navigating out of port, your position with

respect to the buoys should be reversed;

red buoys should be to port and black

buoys to starboard.

Many bodies of water used by boaters are

entirely within the boundaries of a particular state. The Uniform State Waterway

Marking System has been devised for

these waters. This system uses buoys and

signs with distinctive shapes and colors

to show regulatory or advisory information. These markers are white with black

letters and orange boarders. They signify

speed zones, restricted areas, danger

areas, and general information.

1-8

Page 14

1

1

A

1

1

Proceeding toward head

of navigation from seaward

CAN BUOY

Odd number. Leave to port.

OR

SECONDARY CHANNEL BUOYS

STARTS NEW NUMBERING SYSTEM

old new

C"1

"

NUN BUOY

Even number. Leave to starboard

N

"2"

No change

BUOY

COLOR CODE

BLACK

RED

GREEN

"A"

"2"

"

1

"

"

3

"

"

4

"

"

5

"

"

7

"

N"2

"

"

6

"

C"1

"

RB"L

"

RG"L

"

or

SECONDARY CHA

NNEL

MAIN CHAN

NEL

old

new

2

2

2

A

L

L

Odd number. increasing toward head of naviga-

MAIN CHANNEL BUOYS

"1""3""5""7"

tion.Leave to port (left) proceeding upstream.

LIGHTED BUOY (Port Hand)`

White Light

Green Light

old

new

old

new

old

new

LIGHTED BUOY (Starboard Hand)`

"2""4""6"

Even number,increasing toward head of navigation. Leave to starboard (right)proceeding upstream.

White Light Red Light

"A"

LIGHTED SAFE WATER BUOY

No number. Marks midchannel, pass on either

side. Letter has no lateral significance, used for

No number. Topmost band red

-

preferred

Top Mark

White Light

White Light

OR

OR

LIGHTED PREFERRED CHANNEL TO

RB

"L"

RG"L

"

PORT BUOY

identification and location purposes.

channel is to left of buoy. Letter has no lateral

significance, used for identification and location

purposes.

Red Light

Red or

White Light

OR

102052

Remember, markings may vary by geographic location. Always consult local

boating authorities before driving your

boat in unfamiliar waters.

E

1-9

Page 15

E

EMB50510

FUELING INSTRUCTIONS

w

GASOLINE AND ITS VAPORS ARE HIGHLY FLAMMABLE AND EXPLOSIVE!

8 Do not smoke when refueling, and

keep away from sparks, flames, or

other sources of ignition.

8 Stop engine before refueling.

8 Refuel in a well-ventilated area. Refuel

portable fuel tanks off the boat.

8 Take care not to spill gasoline. If gaso-

line spills, wipe it up immediately with

dry rags.

8 Do not overfill the fuel tank.

8 Tighten the filler cap securely after

refueling.

8 If you should swallow some gasoline

inhale a lot of gasoline vapor, or get

gasoline in your eyes, get immediate

medical attention.

8 If any gasoline spills onto your skin,

immediately wash with soap and

water. Change clothing if gasoline spills

on it.

8 Touch the fuel nozzle to the filler open-

ing or funnel to help prevent electrostatic sparks.

GASOLINE (PETROL)

Recommended gasoline:

Regular unleaded gasoline with a

minimum octane rating of 86

(Pump octane number): (R+M)/2

If knocking or pinging occurs, use a different brand of gasoline or premium unleaded fuel.

1-10

Page 16

E

Gasohol

There are two types of gasohol: gasohol

containing ethanol and that containing

methanol. Gasohol containing ethanol

can be used if ethanol content does not

exceed 10% and the fuel meets minimum

octane ratings. Gasohol containing

methanol is not recommended by

Yamaha because it can cause fuel system

damage or engine performance problems.

cC

8 Use only new clean gasoline which has

been stored in clean containers and is

not contaminated with water or foreign

matter.

8 Do not use leaded gasoline(petrol).

Leaded gasoline will cause damage to

the oxygen sensor for Electronic Fuel

Injection system.

EMU00858

ENGINE OIL

Recommended engine oil:

YAMALUBE 2 STROKE OUTBOARD OIL

If the recommended engine oil is not

available, another 2-stroke engine oil with

a NMMA-certified TC-W3 rating may be

used.

1-11

Page 17

E

EMB70210

BATTERY REQUIREMENT

(for Electric start model)

Choose battery which meets the following

specifications.

Minimum cold crank performance

512 Amps at -17.8°C (0°F)

Minimum reserve capacity

182 Minutes at 26.7°C (80°F)

If any electrical accessories are used, use

a second battery to power them. Choose

a battery with the same capacity as the

one for the engine. If the engine’s battery

voltage drops approximately 9 volts or

below during operation or while starting,

the electric fuel pump for Electronic Fuel

Injection system will not operate. The

engine can not be started if battery voltage is too low.

cC

Do not use the battery that does not

meet the specified capacity. If different

battery from the specification is used, the

electric system may perform poorly or be

overloaded, causing electrical system

damage.

EMU01395

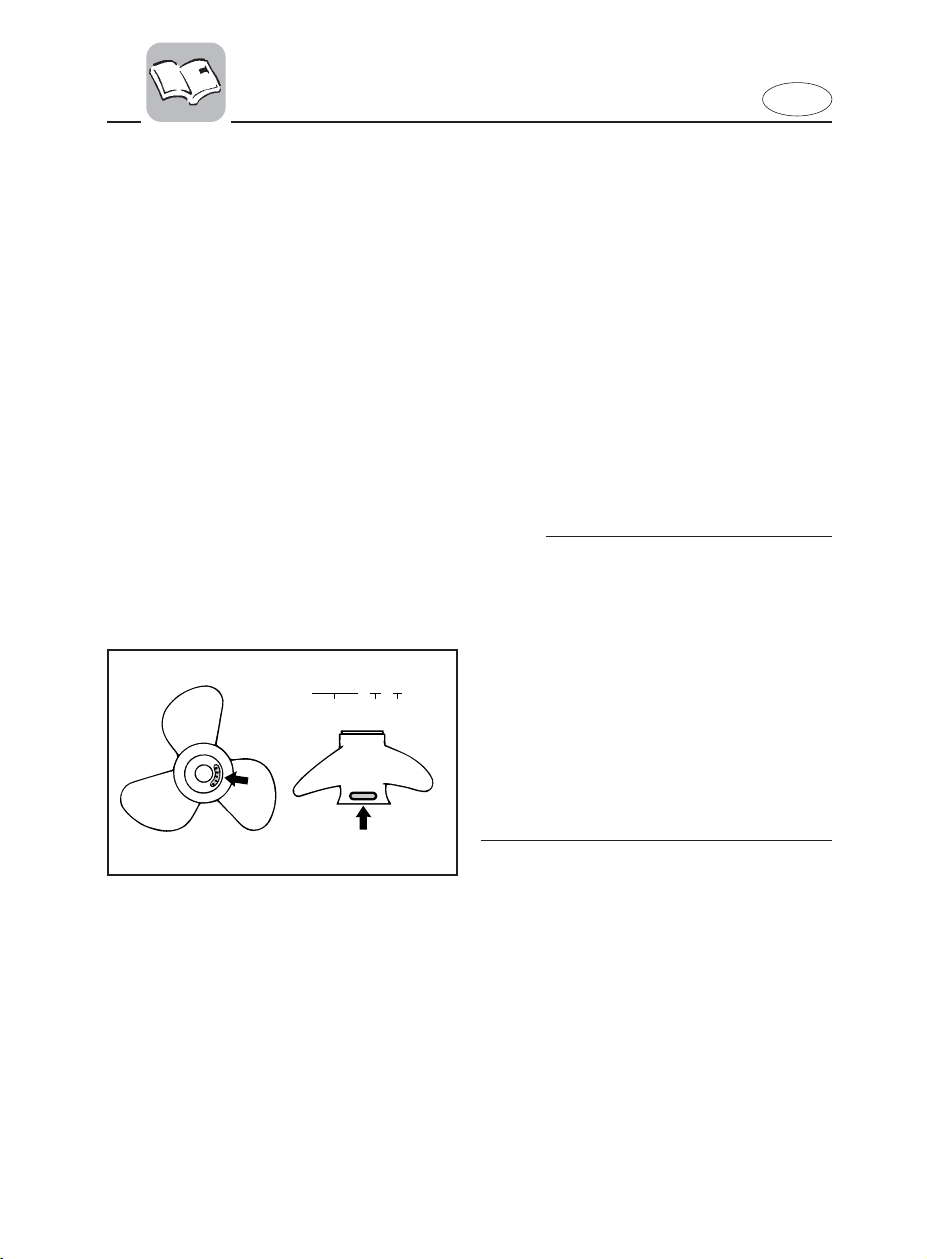

PROPELLER SELECTION

The performance of your outboard motor

will be critically affected by your choice of

propeller, as an incorrect choice could

adversely affect performance and could

also seriously damage the motor. Engine

speed depends on the propeller size and

boat load. If engine speed is too high or

too low for good engine performance,

this will have an adverse effect on the

engine.

1-12

Page 18

14-1/2x17-M

123

E

Yamaha outboard motors are fitted with

propellers chosen to perform well over a

range of applications, but there may be

uses where a propeller with a different

pitch would be more appropriate. For a

greater operating load, a smaller-pitch

propeller is more suitable as it enables

the correct engine speed to be maintained. Conversely, a larger-pitch propeller is more suitable for a smaller operating load.

Yamaha dealers stock a range of propellers, and can advise you and install a

propeller on your outboard that is best

suited to your application.

NOTE:

At full throttle and under a maximum

boat load, the engine’s rpm should be

within the upper half of the full throttle

operating range, as listed in “SPECIFICATIONS” on page 4-1. Select a propeller

which fulfills this requirement.

If operating under conditions which allow

the engine’s rpm to rise above the maximum recommended range (such as light

boat loads), reduce the throttle setting to

maintain the rpm in the proper operating

range.

602022

1 Propeller diameter (in inches)

2 Propeller pitch (in inches)

3 Type of propeller (propeller mark)

Refer to the section “CHECKING PROPELLER” for instructions on propeller

removal and installation.

1-13

Page 19

E

EMU01209

START-IN-GEAR PROTECTION

Yamaha outboard motors or Yamaha

approved remote control units are

equipped with start-in-gear protection

device(s). This feature permits the engine

to be started only when it is Neutral.

Always select Neutral before starting the

engine.

1-14

Page 20

-MEMO-

E

Page 21

E

EMC00010

Chapter 2

BASIC COMPONENTS

MAIN COMPONENTS..............................2-1

OPERATIONS OF CONTROLS AND

OTHER FUNCTIONS ................................2-2

Remote control .....................................2-2

Trim tab .................................................2-7

Power trim / tilt switch .........................2-8

Tilt support lever ..................................2-8

Digital tachometer................................2-9

Digital speedometer...........................2-12

Fuel management meter ...................2-15

Top cowling release lever .................2-19

Flushing device...................................2-20

WARNING SYSTEM ..............................2-21

Overheat warning...............................2-21

Oil level warning / Oil filter clogging

warning ...............................................2-22

1

2

3

4

5

6

Page 22

EMU01206

TRIP TIME BATT

Km/h

knot

mph

km

mile

SPEED

YAMAHA

set

mode

!6

!9

@0

!7

!5

!3

!4

YAMAHA

set

mode

P S

mpg

Km/L

gph

I/h

ECON SYNCTTL

FUEL MANAGEMENT

!8

000905

q

e

r

t

y

u

i

o

!0

!1

!2

w

E

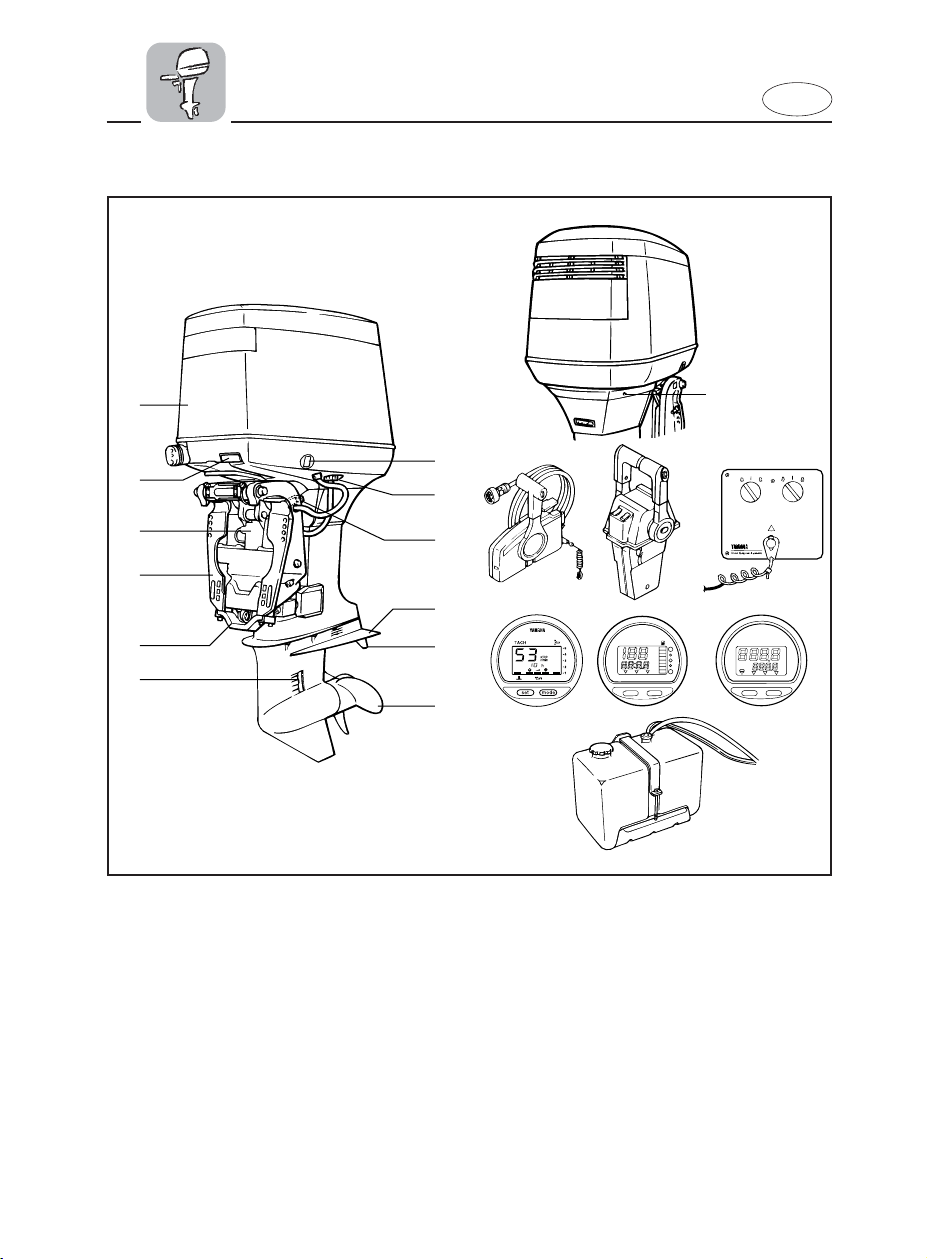

MAIN COMPONENTS

1 Power trim and tilt switch

2 Flushing device

3 Tilt support lever

4 Anti-cavitation plate

5 Trim tab (Anode)

6 Propeller

7 Cooling water inlet

8 Anode

9 Clamp bracket

0 Power trim and tilt unit

q Cowling release lever

w Top cowling

e Cooling water pilot hole

* r Remote control box (Side mount type)

* t Remote control box (Binnacle mount type)

* y Switch panel (For use with t)

u Digital tachometer

i Digital speedometer

* o Fuel management meter

p Remote oil tank

* May not be exactly as shown; also may not

be included as standard equipment on all

models.

2-1

Page 23

E

701011*

w

q

e

t

y

u

i

A

EMC20010

OPERATIONS OF CONTROLS

AND OTHER FUNCTIONS

EMU01273

REMOTE CONTROL

Both the shifter and the throttle are actuated by the remote control lever. In addition, the electrical switches are mounted

on the remote control box.

B

q

u

i

u

r

C

ON

STARTOFF

ON

STARTOFF

å Side mount remote control box

∫ Binnacle mount remote control box

ç Switch panel (for use with ∫)

1 Remote control lever

2 Neutral interlock trigger

3 Neutral throttle lever

4 Free accelerator

5 Main switch

6 Engine stop lanyard switch

7 Power trim/tilt switch

8 Throttle friction adjusting screw

t

y

2-2

Page 24

R

N

F

q

w

e

r

t

y

u

u

t

r

y

701031

u

w

E

EMC50010

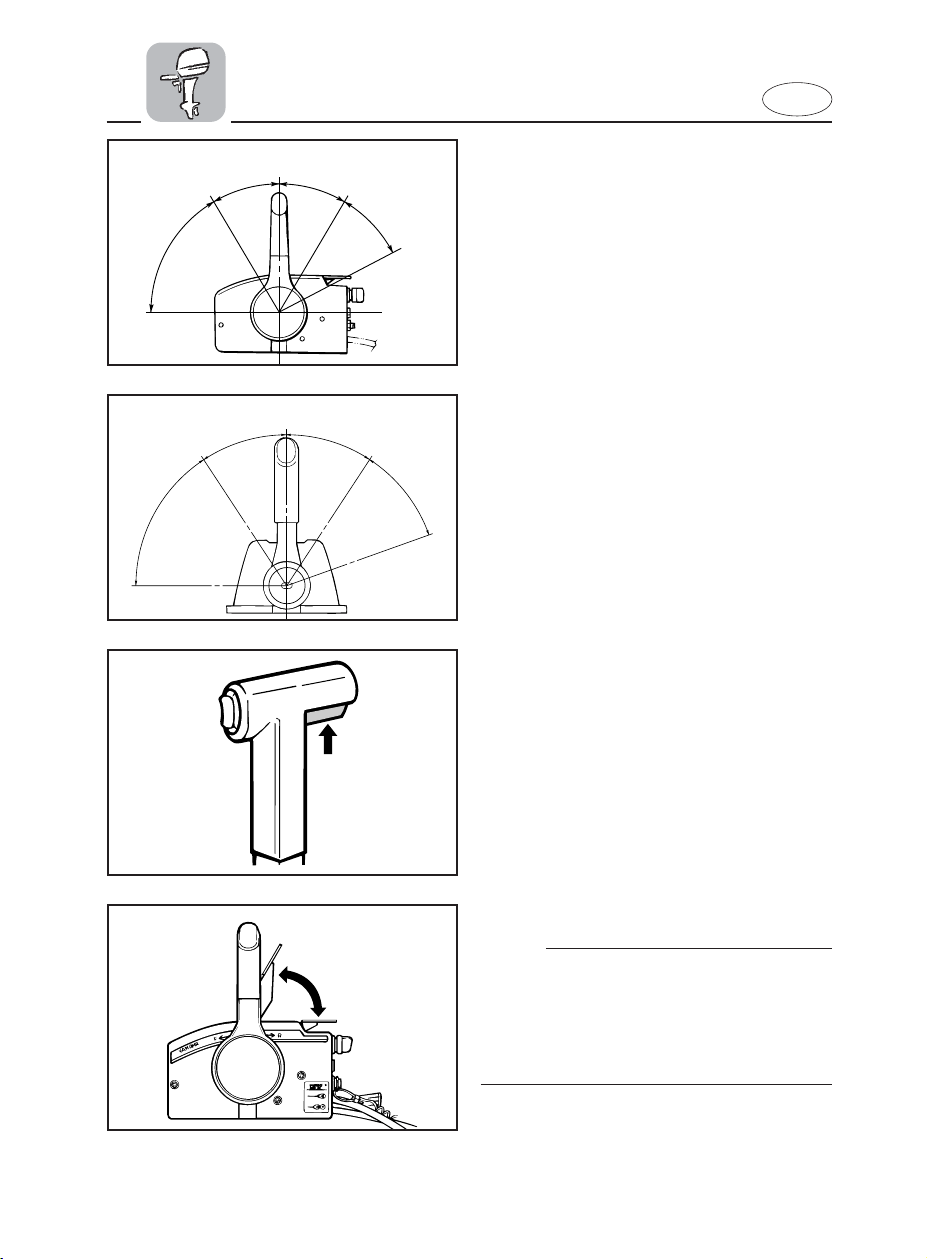

Remote control lever

Moving the lever forward from the

Neutral position engages Forward gear.

Pulling the lever back from Neutral

engages Reverse. The engine will continue to run at idle until the lever is moved

about 35° (a detent can be felt). Moving

the lever farther opens the throttle, and

the engine will begin to accelerate.

1 Neutral

q

rr

e

tty

y

u

702032

2 Forward

3 Reverse

4 Shift

5 Fully closed

6 Throttle

7 Fully open

EMC50110

Neutral interlock trigger

To shift out of Neutral, the neutral interlock trigger of the remote control lever

must first be pulled up.

EMC50210

Neutral throttle lever

701034*

N

q

w

701033

To open the throttle without shifting into

either Forward or Reverse, place the

remote control lever in the Neutral position and lift the neutral throttle lever.

NOTE:

The neutral throttle lever will operate only

when the remote control lever is in

Neutral. The remote control lever will

operate only when the neutral throttle

lever is in the closed position.

1 Fully open

2 Fully closed

2-3

Page 25

UP

DN

UP

ON

UP

DN

DOWN

E

EMC48110

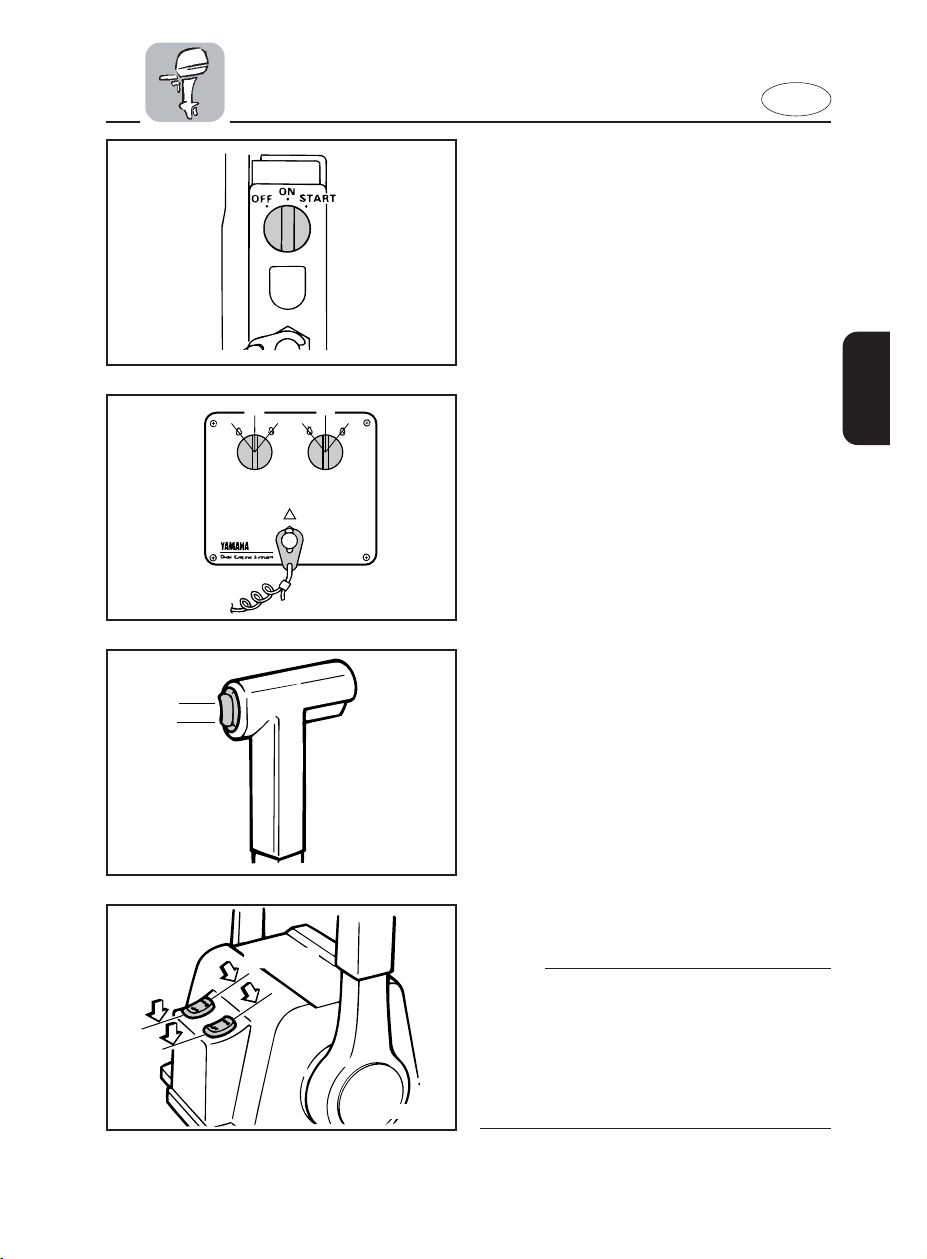

Main switch

The main switch controls the ignition system; its operation is described below.

8 OFF

Electrical circuits switched off.

(The key can be removed.)

8 ON

Electrical circuits switched on.

(The key cannot be removed.)

8 START

STARTOFF

ON

STARTOFF

701034

702042

Starter-motor will turn and start engine.

(When the key is released, it returns automatically to “ON”.)

EMU01112

Power Trim/Tilt Switches

The power trim/tilt adjusts the motor

angle in relation to the transom. The

power trim/tilt switch is located on the

remote control lever grip. Individualengine switches are also on the control

cover. Pushing the switch “UP” trims the

motor up, then tilts the motor up.

Pressing the switch “DN” tilts the motor

down and trims the motor down. When

the switch button is released, the motor

will stop in its current position.

NOTE:

8 On the dual engine control, the switch

on the remote control grip controls both

engines at the same time.

8 Refer to the sections “Adjusting Trim

Angle” and “Tilting Up/Down” in

Chapter 3 for instructions on usage.

2-4

Page 26

E

000569

q

w

EMC28210

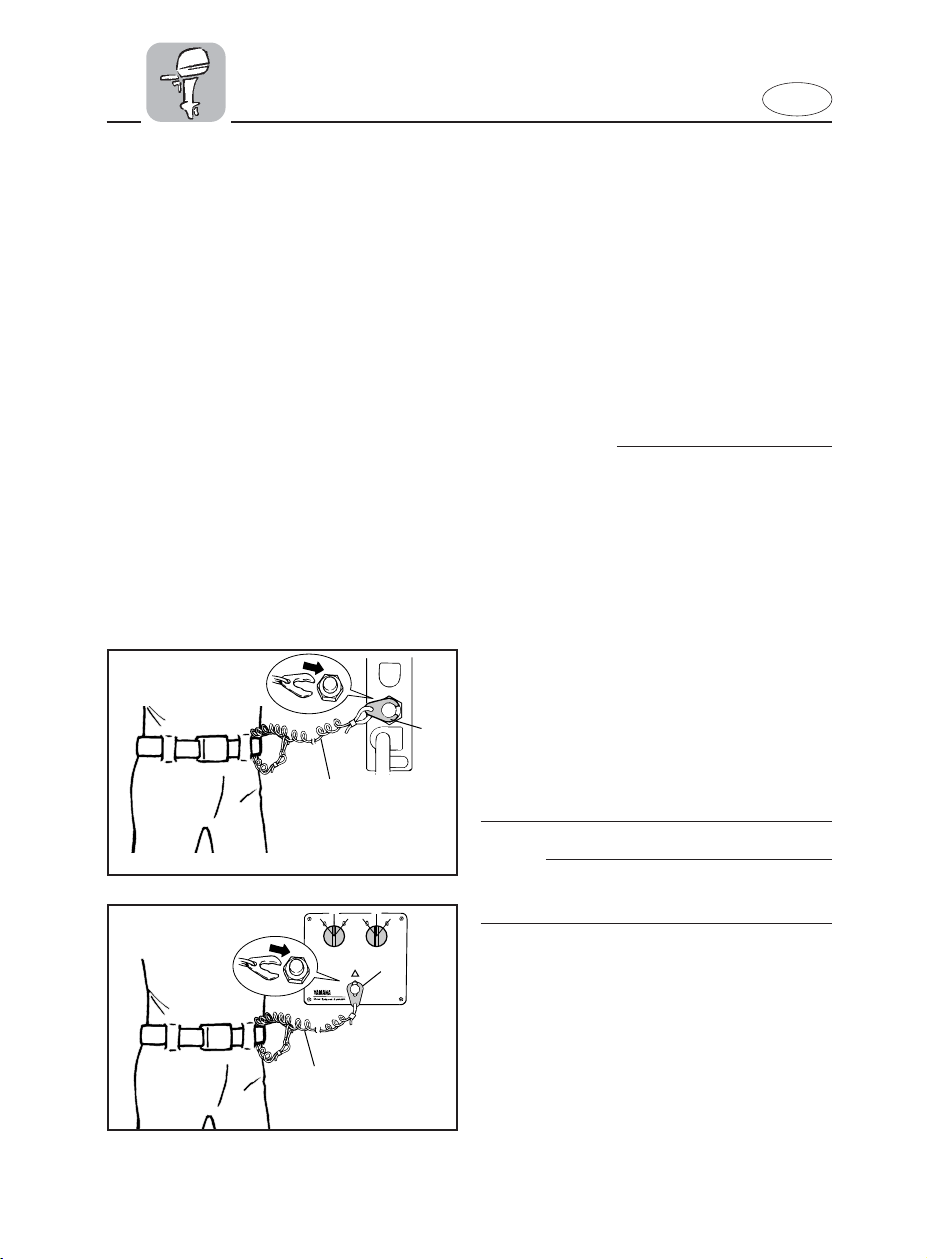

Engine stop lanyard switch

The lock-plate on the end of the lanyard

must be attached to the engine stop

switch for the engine to run. The lanyard

should be attached to a secure place on

the operator’s clothing, or arm or leg.

Should the operator fall overboard or

leave the helm, the lanyard will pull out

the lock plate, stopping ignition to the

engine. This will prevent the boat from

running away under power.

w

8 Attach the engine stop switch lanyard

to a secure place on your clothing, your

arm or leg while operating.

8 Do not attach the lanyard to clothing

that could tear loose. Do not route the

lanyard in such a way that it could

become entangled, preventing it from

functioning.

8 Avoid accidentally pulling the lanyard

during normal operation. Loss of

engine power means the loss of most

steering control. Also, without engine

power, the boat could slow rapidly.

This could cause people and objects in

the boat to be thrown forward.

w

NOTE:

The engine cannot be started with the

ON

ON

STARTOFF

STARTOFF

q

000715

lock-plate removed.

1 Lock-plate

2 Lanyard

2-5

Page 27

702043

35°

q

w

e

1 Fully-open

2 Fully-closed

3 Free accelerator

E

EMC81110

Free accelerator

To open the throttle without shifting into

either Forward or Reverse, push the free

accelerator button and turn the remote

control lever.

NOTE:

8 The free accelerator button can be oper-

ated only when the remote control lever

is in the Neutral position.

8 After the button is pushed, the remote

control lever must be moved at least

35° to begin opening the throttle.

8 After operating the free accelerator,

return the remote control lever to the

Neutral position. The free accelerator

button will return automatically to its

set position. The remote control will

then engage Forward and Reverse normally.

EMC87011

Throttle friction adjusting screw

A friction device in the remote control box

provides resistance to movement of the

remote control lever.

This is adjustable for operator preference.

An adjusting screw is located at the front

of the remote control box.

701035

702035

Resistance Screw

Increase Turn clockwise

Decrease Turn counterclockwise

w

Do not overtighten the friction adjusting

screw.

If there is too much resistance, it may be

difficult to move the lever, which could

result in an accident.

2-6

Page 28

A

B

e

w

q

E

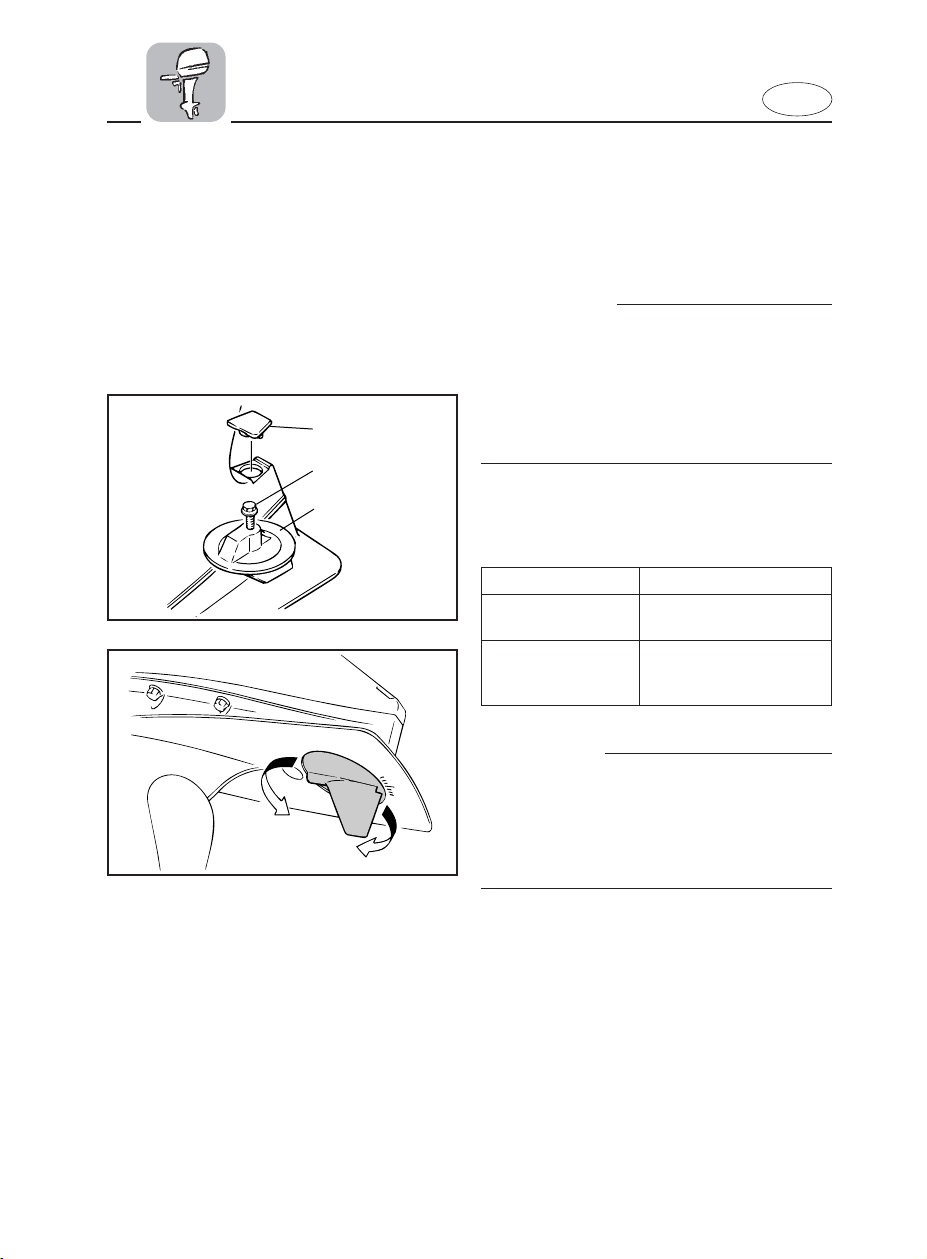

EMD04011

TRIM TAB

The trim tab should be adjusted so that

the steering control can be turned to

either the right or left by

applying the same amount of force.

w

An improperly adjusted trim tab may

cause difficult steering. Always test run

after the trim tab has been installed or

replaced to be sure steering is correct. Be

sure you have tightened the bolt after

adjusting the trim tab.

1 Trim tab

2 Bolt

3 Cap

603014

Boat tends to veer

To the left

(port side)

To the right

(starboard side)

The rear end of trim tab

Turn the left(port side),

“A” in the figure

Turn the right

(starboard side),

“B” in the figure

cC

The trim tab also serves as an anode to

protect the engine from electroche mical

corrosion.

Never paint the trim tab as it will become

ineffective as an anode.

2-7

Page 29

E

302012

UP

DOWN

EMU01125

POWER TRIM/TILT SWITCH

The power trim/tilt adjusts the motor

angle in relation to the transom. The

power trim/tilt switch is located on the

side of the bottom engine cowling.

Pushing the switch “UP” trims the motor

up, then tilts the motor up. Pressing the

switch “DN” tilts the motor down and

trims the motor down. When the switch

button is released, the motor will stop in

its current position.

w

Use the power trim/tilt switch located on

the bottom engine cowling only when

the boat is at a complete stop with the

engine off. Attempting to use the cowling-mounted power trim/tilt switch while

the boat is moving could increase the risk

of falling overboard and could distract

the operator, increasing the risk of collision with another boat or an obstacle.

NOTE:

Refer to the section “Adjusting Trim

Angle” and “Tilting Up/Down” for instructions on usage.

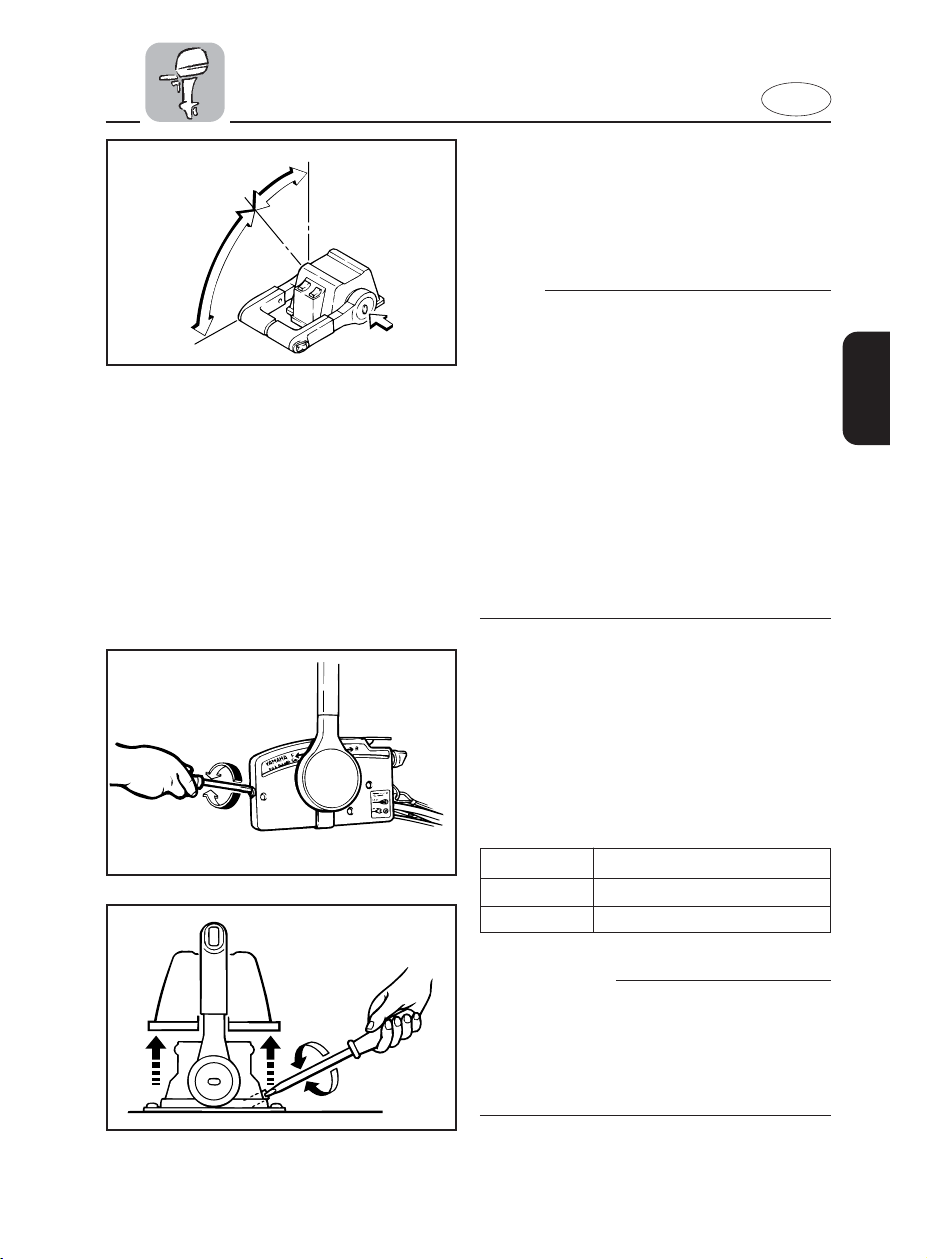

EMD60010

TILT SUPPORT LEVER

To keep the outboard motor in the tiltedup position, lock the tilt support lever to

the clamp bracket.

403033

2-8

Page 30

q

t

w

u

y

e

r

001078

001082

E

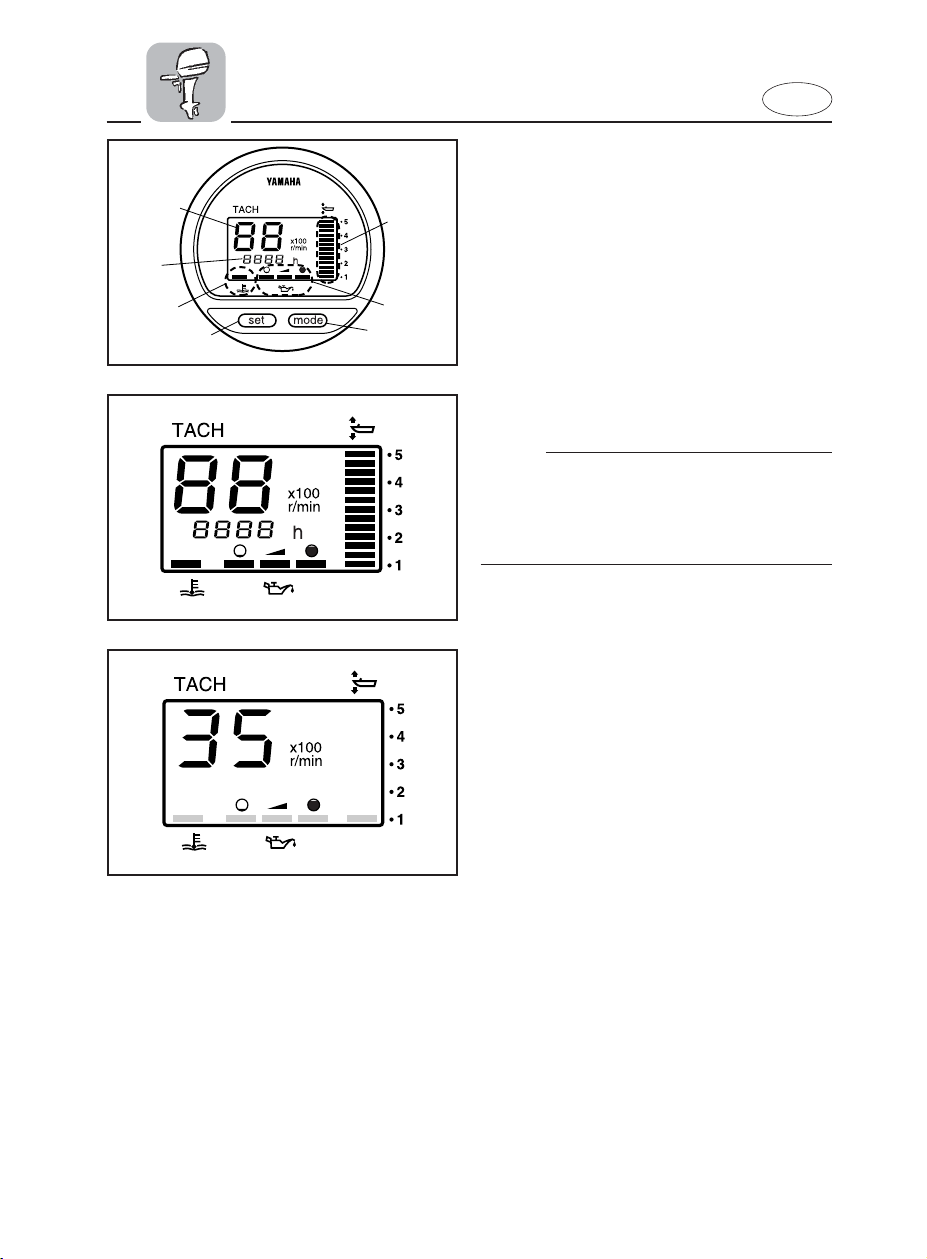

EMU01614

DIGITAL TACHOMETER

This gauge contains the tachometer, trim

meter, hour meter, oil level indicator, and

the overheat warning indicator.

1 Tachometer

2 Trim meter

3 Hour meter

4 Oil level indicator

5 Overheat warning indicator

6 Set button

7 Mode button

NOTE:

All segments of the display will light

momentarily after the main switch is

turned on and will return to normal thereafter.

EMU00136

Tachometer

This meter shows the engine speed.

001049

2-9

Page 31

E

001050

001087

EMU01109

Trim Meter

This meter shows the trim angle of your

outboard motor.

NOTE:

8 Memorize the trim angles that work

best for your boat under different conditions. Adjust the trim angle to the

desired setting by operating the power

trim and tilt switch.

8 If the trim angle of your motor exceeds

the trim operating range, the top segment on the trim meter display will start

to blink.

EMU01620

Hour Meter

This meter shows the number of hours

the engine has been run. It can be set to

show the total number of hours or the

number of hours for the current trip. The

display can also be turned on and off.

8 Changing the display format

Pressing the MODE button changes the

display format in the following circular

pattern:

Total hours - Trip hours - Display off

8 Resetting the trip hours

Simultaneously pressing the SET and

MODE buttons for more than 1 second

while the trip hours are displayed resets

the trip counter to 0 (zero).

NOTE:

8 The total number of hours the engine

has been run cannot be reset.

2-10

Page 32

001051

q

q

E

EMU00138

Oil-Level Indicator

This indicator shows the engine oil level.

If the oil level falls below the lower limit,

the warning indicator will start to blink.

Refer to the sections “FILLING OIL” and

“OIL LEVEL WARNING” for details.

1 Oil-level indicator

cC

Do not operate the engine without oil.

Serious engine damage will occur.

EMU01553

Overheat Warning Indicator

If the engine temperature rises too high,

the warning indicator will start to blink.

Refer to “OVERHEAT WARNING” for

details.

001052

1 Overheat warning indicator

cC

Do not continue to operate the engine if a

warning device has activated. If necessary, refer to the “TROUBLESHOOTING”

section in this manual. Consult your dealer if the problem cannot be located and

corrected.

2-11

Page 33

q

w

e

802023*

YAMAHA

802016*

TRIP TIME BATT

Km/h

knot

mph

km

mile

SPEED

YAMAHA

set

mode

q

w

e

r

SPEED

TRIP TIME BATT

set

Km/h

knot

mph

km

mile

mode

802034

E

EMD40012

DIGITAL SPEEDOMETER

This meter contains the speedometer, fuel

meter with warning, trip meter, clock and

voltmeter with warning.

1 Speedometer

2 Fuel meter

3 Trip meter/clock/voltmeter

4 Warning indicator

NOTE:

After the main switch is first turned on, all

portions of the meter come on as a check.

After a few seconds, the meters will

change to normal operation. Watch the

meter when turning on the main switch to

make sure all segments come on.

EMD25110

Speedometer

The meter will show the boat speed.

NOTE:

The speedometer displays km/h, mph, or

knots, depending upon operator preference. Select the desired unit of measurement by setting the selector switch on the

back of the meter. See the illustration for

setting.

1 Cap

2 Selector switch (For speed unit)

3 Selector switch (For fuel sender)

2-12

Page 34

802025*

TRIP TIME BATT

Km/h

knot

mph

km

mile

SPEED

YAMAHA

set

mode

802024*

TRIP TIME BATT

Km/h

knot

mph

km

mile

SPEED

YAMAHA

set

mode

E

EMU01274

Trip Meter

This meter displays the distance the boat

has traveled since the meter was last

reset.

Repeatedly push and release the “mode”

button until the indicator on the face of

the meter points to “TRIP”. To reset the

trip meter to “0”, press the “set” and

“mode” button together.

NOTE:

8 The trip distance is shown in kilometers

or miles depending upon the unit of

measurement selected for the

speedometer.

8 The trip distance is kept in memory by

battery power. The stored data will be

lost if the battery is disconnected.

EMU01275

Clock

This meter shows the current time.

Repeatedly push and release the “mode”

button until the indicator on the face of

the meter points to “TIME.” To set the

clock, be sure the meter is in the “TIME”

mode. Press the “set” button; the hour

display will begin blinking. Press the

“mode” button until the desired hour is

displayed. Press the “set” button again,

the minute display will begin blinking.

Press the “mode” button until the desired

minute is displayed. Press the “set” button again to start the clock.

NOTE:

The clock operates on battery power.

Disconnecting the battery will stop the

clock. Reset the clock after connecting the

battery.

2-13

Page 35

E

802031

TRIP TIME BATT

Km/h

knot

mph

km

mile

SPEED

YAMAHA

set

mode

q

w

802032TRIP TIME BATT

Km/h

knot

mph

km

mile

SPEED

EMD40310

Fuel meter

The fuel level is displayed by eight segments. When all segments are showing,

the fuel is full.

cC

The Yamaha fuel tank sensor is different

from a conventional-type sensor. A

wrong setting of the selector switch on

the meter will give incorrect readings.

Consult Yamaha dealer for correct setting.

NOTE:

The fuel reading can be affected by the

position of the sensor in the fuel tank and

the attitude of the boat in the water.

Operation with bow-up trim or continuous turning can give false readings.

EMD40410

Warning indicator

8 Fuel warning

If the fuel level decreases to one segment

the fuel level warning segment 1 begins

blinking.

8 Low battery voltage warning

If battery voltage drops, the display 2 will

be automatically turned on and it begins

blinking.

cC

Do not continue to operate the engine if a

warning device has activated. Refer to

the TROUBLESHOOTING section in this

manual. Consult a Yamaha dealer if the

problem cannot be located and corrected.

2-14

Page 36

YAMAHA

set

mode

PS

mpg

Km/L

gph

I/h

ECON SYNCTTL

FUEL MANAGEMENT

q

w

e

FUEL MANAGEMENT

E

EMD42012

FUEL MANAGEMENT METER

Optional equipment

The meter contains the fuel flow meter,

fuel consumption meter, fuel economy

meter, twin engine speed synchronizer,

water separator warning indicator.

1 Fuel flow meter

2 Fuel consumption/Fuel economy

meter/Twin engine speed synchronizer

3 Water separator warning indicator

(Operates only if the sensor has been

installed.)

PS

I/h

gph

Km/L

mpg

NOTE:

After the main switch is first turned on, all

portions of the meter come on as a check.

After a few seconds, the meters will

change to normal operation. Watch the

ECON SYNCTTL

meter when turning on the main switch to

make sure all segments come on.

2-15

Page 37

E

YAMAHA

PS

gph

I/h

ECON SYNCTTL

FUEL MANAGEMENT

set

mode

PS

mp

Km

gph

I/h

EMD32010

Fuel flow meter

The meter displays fuel flow within one

hour, at the rate of current engine operation.

If twin engines are installed on your boat,

the meter will display total fuel flow of

Port and Starboard side engine. It also

displays PS indication at the same time.

By pressing “set” button, the meter will

display fuel flow of starboard side engine

ON

2 65431

q

l/h

(liter)

gph

(gallon)

and S indication.

By pressing “set” button again, the meter

will display fuel flow of port side engine

and P indication.

By pressing “set” button again, the meter

will display total fuel flow.

NOTE:

8 The meter displays gallon/hour and liter

depending upon operator preference.

Select the desired unit of measurement

by setting the selector switch 1 on the

back of the meter during installation.

8 Fuel consumption meter and Fuel econ-

omy meter will indicate same unit of

measurement.

FUEL MANAGEMENT

ECON SYNCTTL

EMU01276

Fuel Consumption Meter

This meter displays the total amount of

fuel consumed since the meter was last

reset.

Repeatedly push and release the “mode”

/L

g

button until the indicator on the face of

the meter points to total (“TTL”). To reset

the total fuel consumption to “0”, press

the “set” and “mode” buttons together.

2-16

Page 38

PS

mpg

Km/L

gph

I/h

ECON SYNCTTL

FUEL MANAGEMENT

E

EMU01277

Fuel Economy

This meter displays the distance per liter

or gallon when cruising for reference use

by the operator.

Repeatedly push and release the “mode”

button until the indicator on the face of

the meter points to “ECON.”

NOTE:

If twin engines are installed on your boat,

the meter will display only the total fuel

economy of both engines.

NOTE:

8 Fuel consumption varies greatly with

boat design, weight, propeller used,

engine trim angle, sea conditions

(including wind), and throttle position.

Fuel consumption also varies slightly

with the type of water (salt, fresh, and

contaminate levels), air temperature

and humidity, cleanliness of the boat

bottom, engine mounting height, skill of

the operator, and individual gasoline

formulation (winter or summer fuel and

amount of additives).

8 The Yamaha digital speedometer and

fuel management meter calculates

speed, miles traveled, and fuel economy by water movement at the stern of

the boat. This distance can vary greatly

from the actual distance traveled

because of water currents, sea swells,

and the condition of the water speed

sensor (partially plugged or damaged).

8 Individual engines may slightly vary in

their fuel consumption due to manufacturing variations. These variations can

be even greater if the engines are of different year models. In addition, variations in propellers, even of the same

basic dimensions of the same design,

can also cause a slight variation in fuel

consumption.

2-17

Page 39

PS

mpg

Km/L

gph

I/h

ECON SYNCTTL

FUEL MANAGEMENT

q

w

e

r

t

PS

mpg

Km/L

gph

I/h

FUEL MANAGEMENT

PS

mpg

Km/L

gph

I/h

ECON SYNCTTL

FUEL MANAGEMENT

E

EMU01278

Twin Engine Speed Synchronizer

This meter displays the difference in

engine speed (r/min) between the Port

and Starboard engines for reference purposes when synchronizing the two

engines’ speeds.

Repeatedly push and release the “mode”

button until the indicator on the face of

the meter points to “SYNC”.

1 Port side engine speed is higher

2 Port side engine speed is slightly higher

3 Engine speed is synchronized evenly

between Port and Starboard side engines

4 Starboard side engine speed is slightly

higher

5 Starboard side engine speed is higher

NOTE:

If the two engines’ speeds are not synchronized while cruising, they can be synchronized by adjusting trim angle or

throttle.

EMU01207

Water Separator Warning Indicator

If the water which has been separated

ECON SYNCTTL

000341

from fuel in the water trap exceeds a specific volume, the indicator will blink showing the need for water to be drained.

NOTE:

This indicator only operates when a water

separator sensor is equipped.

2-18

Page 40

301023

211013

E

EMD64011

TOP COWLING RELEASE LEVER

The top cowling can be removed by operating the cowling release lever. Pulling

the front lever unlocks the top cowling for

removal.

When refitting the top cowling:

1) Set the top cowling straight down

onto the engine, being careful to

avoid catching spark plug leads or

other wires.

2) Align the three cowling hooks with

the locks on the bottom cowling.

3) Press down on the top of the cowling

at the front and both sides of the back

until the three locks click.

4) To make sure the cowling is locked

properly push the cowling from each

side. If it lifts, repeat step 3.

cC

Make sure the cowling lock connection

cable is operating correctly before reinstalling the top cowling.

8 When the release lever is operated,

both front and rear cowling hooks

should be released at the same time. If

not, adjust the cable adjuster for the

rear clamps.

8 Make sure the cable operates smoothly

and is free of corrosion.

8 Check that the cable is properly

secured in the holder.

8 When reinstalling the cowling, insure

that both the front and rear locks have

operated properly. If the cowling has

not been locked properly some parts

may be damaged by the top cowling

shaking during operation.

2-19

Page 41

E

q

000825

EMU01146

FLUSHING DEVICE

This device 1 is used to clean the cooling

water passages of the motor using a garden hose and tap water.

NOTE:

Refer to “Cleaning Cooling-water

Passages” in Chapter 4 for instructions on

usage.

2-20

Page 42

701054

ON ON

OFF START OFF START

001053

E

EMD80010

WARNING SYSTEM

cC

Do not continue to operate the engine if

the warning device has activated. Consult

your Yamaha dealer if the problem cannot be located and corrected.

EMD82312*

OVERHEAT WARNING

This engine has an overheat warning

device.

If the engine temperature rises too high,

the warning device will activate.

(1); Included (—); N/A

Warning device Tiller Remote

activation control control

model model

The engine speed

will automatically

decrease to about

2,000 r/min.

The overheat warning

indicator will come on.

The buzzer will sound

1

1

1

703026

605015

If the warning system has been activated,

stop the engine and check the water inlet

for clogging.

NOTE:

In case of dual engine drive;

Should the overheat warning system of

one engine operate, it slows down and

the buzzer sounds.

This will cause the other engine to slow

down and the buzzer to sound.

For the other engine, the warning system

can be released by shifting the remote

control lever into the neutral.

2-21

Page 43

001054

ON ON

OFF START OFF START

E

EMD84012

OIL LEVEL WARNING / OIL FILTER

CLOGGING WARNING

This engine has an oil level warning system.

If oil level falls below lower limit, the

warning device will activate.

(1); Included (—); N/A

Warning device Tiller Remote

activation control control

model model

The engine speed

will automatically

decrease to about

2,000 r/min.

The oil level warning

indicator will come on.

The buzzer will sound.

If the warning system has been activated,

stop the engine and check for the cause.

1

1

1

q

q

213022

905012

NOTE:

The warning for oil filter clogging is similar to the warnings for low oil level and

overheating.

For easy troubleshooting, it is advisable

to check for engine overheating first, then

oil level and finally oil filter clogging.

1 Oil filter

2-22

Page 44

-MEMO-

E

Page 45

E

EMF00010

Chapter 3

OPERATION

INSTALLATION ........................................3-1

Mounting the outboard motor............3-2

FILLING FUEL AND ENGINE OIL ............3-4

Filling fuel..............................................3-4

Filling oil ................................................3-5

PRE-OPERATION CHECKS......................3-8

Operation after a long period of

storage...................................................3-9

BREAKING IN (RUNNING IN) ENGINE 3-10

STARTING ENGINE ...............................3-12

WARMING UP ENGINE .........................3-15

1

2

3

SHIFTING ................................................3-16

Forward ...............................................3-16

Reverse................................................3-16

STOPPING ENGINE ...............................3-17

TRIMMING OUTBOARD MOTOR.........3-18

Adjusting trim angle ..........................3-19

TILTING UP/DOWN ...............................3-21

CRUISING IN OTHER CONDITIONS.....3-23

Cruising in salt water .........................3-23

Cruising in turbid water.....................3-23

4

5

6

Page 46

E

EMF10010

INSTALLATION

cC

Incorrect engine height or obstructions to

smooth water flow (such as the design or

condition of the boat or acce- ssories

such as transom ladders/depth finder

transducers) can create airborne water

spray while the boat is cruising.

Severe engine damage may result if the

motor is operated continuously in the

presence of airborne water spray.

NOTE:

During water testing check the buoyancy

of the boat, at rest, with its maximum

load. Check that the static water level on

the exhaust housing is low enough to prevent water entry into the powerhead,

when water rises due to waves when the

outboard is not running.

3-1

Page 47

E

q

EMU00176

MOUNTING THE OUTBOARD

MOTOR

w

Improper mounting of the outboard

motor could result in hazardous conditions such as poor handling, loss of control, or fire hazards. Observe the following:

8 The information presented in this sec-

tion is intended as reference only. It is

not possible to provide complete

instructions for every possible

boat/motor combination. Proper

mounting depends in part on experience and the specific boat/motor combination.

8 Your dealer or other person experi-

enced in proper rigging should mount

the motor. If you are mounting the

motor yourself, you should be trained

by an experienced person. [permanent

mounted type]

8 Your dealer or other person experi-

enced in proper outboard motor

mounting should show you how to

mount your motor. [portable type]

Mount the outboard motor on the center

line (keel line) of the boat, and ensure that

the boat itself is well balanced. Otherwise,

the boat will be hard to steer. For boats

without a keel or which are asymmetrical,

consult your dealer.

1 Center line (keel line)

3-2

Page 48

E

104014

w

Overpowering a boat may cause severe

instability. Do not install an outboard

motor with more horsepower than the

maximum rating on the capacity plate of

the boat. If the boat does not have a

capacity plate, consult the boat manufacturer.

EMU01299

Mounting Height

To run your boat at optimum efficiency,

the water-resistance (drag) of the boat

and outboard motor must be made as little as possible. The mounting-height of

the outboard motor greatly affects the

water-resistance. If the mounting-height

is too high, cavitation tends to occur, thus

reducing the propulsion; and if the propeller tips cut the air, the engine speed

will rise abnormally and cause the engine

to overheat. If the mounting-height is too

low, the water-resistance will increase

and thereby reduce engine efficiency.

Mount the engine so that the anti-cavitation plate is in alignment with the bottom

of the boat .

NOTE:

8 The optimum mounting height of the

outboard motor is affected by the

boat/motor combination. Test runs at

different heights can help determine the

optimum mounting height.

8 Refer to the section “TRIMMING OUT-

BOARD MOTOR” for instructions on

setting the trim angle of the outboard.

3-3

Page 49

E

EMU00186

FILLING FUEL

AND ENGINE OIL

EMU01031

FILLING FUEL

1) Remove the fuel tank cap.

2) Fill the fuel tank carefully.

3) Close the cap securely after refueling.

Wipe up any spilled fuel.

EMU01019

Ring Free Fuel Additive

Gasoline is a precise blend of many different substances, each chosen to give certain characteristics. Gasoline blends have

been changing in recent years in

response to concerns about pollution and

resulting emissions regulations. One of

the most obvious changes has been the

elimination of lead from most fuels.

As gasoline has changed, the amount of

additives such as aromatics and oxygenates has increased. These additives

are important for the engines in passenger cars, but they can have detrimental

effects in marine engines, because of

increased deposits in the combustion

chamber. When enough deposits collect,

piston rings begin sticking. Performance

drops and engine wear increases dramatically.

While many additives available may

reduce deposits, Yamaha recommends

the use of Ring Free Fuel Additive, available from your Yamaha dealer. Ring Free

has repeatedly proven its ability to clean

combustion deposits from inside the

engine, notably the critical piston-ringland area, and fuel system components.

Follow product labeling for use instructions.

3-4

Page 50

E

ON STARTOFF

701024

EMF32011

FILLING OIL (for Precision blend system model)

This engine uses the YAMAHA PRECISION BLEND SYSTEM, which provides

superior lubrication by ensuring the proper oil ratio for all operating conditions. No

fuel premixing is needed (except during

break-in/running-ins). Simply pour gasoline into the fuel tank and oil into the oil

tank.

Convenient indicator segments indicate

condition of the oil supply. Refer to oil

warning system.

To fill the engine oil into the engine oil

tank, proceed as follows:

w

Do not add gasoline (Petrol) into the oil

tank. Fire or explosion could result.

Engine oil tank capacity:

Refer to “SPECIFICATION”, page 4-1.

EMF34210

Procedure

When remote oil tank is used

Pour oil into the remote oil tank and turn

the main switch to “ON”, and the YAMAHA PRECISION BLEND SYSTEM automat-

ON STARTOFF

ically feeds the oil from the remote oil

tank to the engine oil tank in the top cowling.

After refilling, turn the main switch to

“OFF”. Then, proceed to start the engine.

701052

Otherwise, the oil-level warning system

may prevent the engine from revving up.

3-5

Page 51

E

cC

When the engine is operated for the first

time or stored for a period of time, a minimum of 5 liters (5.3 US qt, 4.4 Imp qt) of

oil should be kept in the remote oil tank.

Otherwise, the oil-feed pump chamber

will not be filled with oil, and no oil will

be supplied.

3-6

Page 52

EMU00200*

Oil Level Indicator

The various oil level system functions are as follows:

E

Oil level indi-

cator (Digital

tachometer)

Oil level indi-

cator (Analog

tachometer)

Green

Yellow

Red Green

Engine oil

tank

More than

3

300 cm

(0.32 US qt,

0.26 Imp qt)

More than

3

300 cm

(0.32 US qt,

0.26 Imp qt)

3

300 cm

(0.32 US qt,

0.26 Imp

qt) or less

Remote oil

tank

More than

1,500 cm

3

(1.6 US qt,

1.31 Imp qt)

1,500 cm

3

(1.6 US qt,

1.31 Imp

qt) or less

More than

1,500 cm

3

(1.6 US qt,

1.31 Imp qt)

Remarks

• No refilling necessary.

• Add oil, refer to oil

filling.

• Check oil filter for clogging.

• Check battery cable

connection.

• Buzzer will sound.

• Engine speed is automatically reduced to

about 2,000 r/min.

Red

3

300 cm

(0.32 US qt,

0.26 Imp

qt) or less

3-7

1,500 cm

(1.6 US qt,

1.31 Imp

qt) or less

3

• Oil has not been added.

• Buzzer will sound.

• Engine speed is automatically reduced to

about 2,000 r/min.

• Refer to Chapter 5.

Page 53

E

EMF40310

PRE-OPERATION CHECKS

w

If any item in the pre-operation check is

not working properly, have it inspected

and repaired before operating the outboard motor. Otherwise, an accident

could occur.

Fuel

8 Check to be sure you have plenty of fuel

for your trip.

8 Make sure there are no fuel leaks or

gasoline fumes.

8

Be sure the fuel hose is not being flattened or kinked by objects in the boat, and

that there are no sharp objects near it.

Oil

8 Check to be sure you have plenty of oil

for your trip.

Controls

8

Check throttle, shift, and steering for proper operation before starting the engine.

8 The controls should work smoothly,

without binding or unusual free play.

8 Look for loose or damaged connec-

tions.

8 Check operation of the starter and stop

switches when the outboard moter is in

the water.

Engine

8 Check the engine and engine mounting.

8 Look for loose or damaged fasteners.

8 Check the propeller for damage.

8 Check that the battery is in good condi-

tion and battery connections are secure.

cC

Do not start the engine out of water.

Overheating and serious engine damage

can occur.

3-8

Page 54

E

212022

EMF44110

OPERATION AFTER A LONG PERIOD

OF STORAGE

(for Precision blend system model)

When operating the engine after a long

period (12 months) of storage, proceed as

follows:

1) Use a 50 : 1 gasoline-oil mixture to

start the engine.

2) Start the engine. Leave it idling.

w

8 Do not touch or remove electrical parts

when starting or during operation.

8 Keep hands, hair, and clothes away

from flywheel and other rotating parts

while engine is running.

3) Watch for oil flowing through the oil

feed pipes. After any air in the oil

lines has been expelled, YAMAHA

PRECISION BLEND SYSTEM should

supply oil normally. If no oil has

begun flowing after 10 minutes of

idling, consult your Yamaha dealer.

cC

8 When operating the engine after a long

period of storage, be sure to take the

above steps; otherwise, engine seizure

may occur.

8 After completing the above steps, use

gasoline (petrol) only. If premix fuel is

used continually, the oxygen sensor for

Electronic Fuel Injection system could

be damaged.

3-9

Page 55

E

EMF50410

BREAKING IN (RUNNING IN)

ENGINE

Your new engine requires a period of

break-in (running-in) to allow mating surfaces of moving parts to wear-in evenly.

Correct break-in (running-in) will help

ensure proper performance and longer

engine life.

cC

8

Failure to follow the break-in (running-in)

procedure may result in reduced engine

life or even severe engine damage.

8 Premix fuel must be used during break-

in (running-in) in addition to oil in the

Precision Blend System.

8 After break-in (running-in), use gaso-

line(petrol) only. If premix fuel is used

continually, the oxygen sensor for

Electronic Fuel Injection system could

be damaged.

Break-in (running-in) time: 10 hours

Break-in (running-in) premix ratio

Gasoline (petrol) : Engine oil=50 : 1

Mixing

ratio

Gasoline

(Petrol)

Engine oil

1 L

(0.26 US gal,

0.22 Imp gal)

0.02 L

(0.02 US qt,

0.02 Imp ql)

12 L

(3.2 US gal,

2.6 Imp gal)

0.24 L

(0.25 US qt,

0.21 Imp qt)

50 : 1

14 L

(3.7 US gal,

3.1 Imp gal)

0.28 L

(0.30 US qt,

0.25 Imp qt)

cC

Make sure to mix gasoline (petrol) and oil

completely, otherwise your outboard

motor may be damaged.

3-10

24 L

(6.3 US gal,

5.3 Imp gal)

0.48 L

(0.51 US qt,

0.42 Imp qt)

Page 56

E

EMU00227

Run the engine under load (in gear with a

propeller installed) as follows.

1) First 10 minutes:

Run the engine at the lowest possible-speed. A fast idle in neutral is

best.

2) Next 50 minutes:

Do not exceed half throttle (approximately 3,000 r/min). Vary engine

speed occasionally. If you have an

easy-planing boat, accelerate at full

throttle onto plane, then immediately

reduce the throttle to 3,000 r/min or

less.

3) Second hour:

Accelerate at full throttle onto plane,

then reduce engine speed to threequarter throttle (approximately 4,000

r/min). Vary engine speed occasionally. Run at full throttle for one minute,

then allow about 10 minutes of operation at three-quarter throttle or less to

let the engine cool.

4) Third through tenth hours:

Avoid operating at full throttle for

more than 5 minutes at a time. Let the

engine cool between full-throttle runs.

Vary engine speed occasionally.

5) After the first 10 hours:

Operate the engine normally. Use

straight gasoline (petrol) in the fuel

tank; YAMAHA PRECISION BLEND

SYSTEM provides proper lubrication

for normal operation.

3-11

Page 57

E

902023*

EMU01197

STARTING ENGINE

w

8 Before starting the engine, make sure

that the boat is tightly moored and that

you can steer clear of any obstructions.

Be sure there are no swimmers in the

water near you.

8 When the air vent screw is loosened,

gasoline (petrol) vapor will be released.

Gasoline (petrol) is highly flammable,

and its vapors are flammable and

explosive. Refrain from smoking, and

keep away from open flames and

sparks while loosening the air vent

screw.

8 This product emits exhaust gases

which contain carbon monoxide, a colorless, odorless gas which may cause

brain damage or death when inhaled.

Symptoms include nausea, dizziness,

and drowsiness. Keep cockpit and

cabin areas well ventilated. Avoid

blocking exhaust outlets.

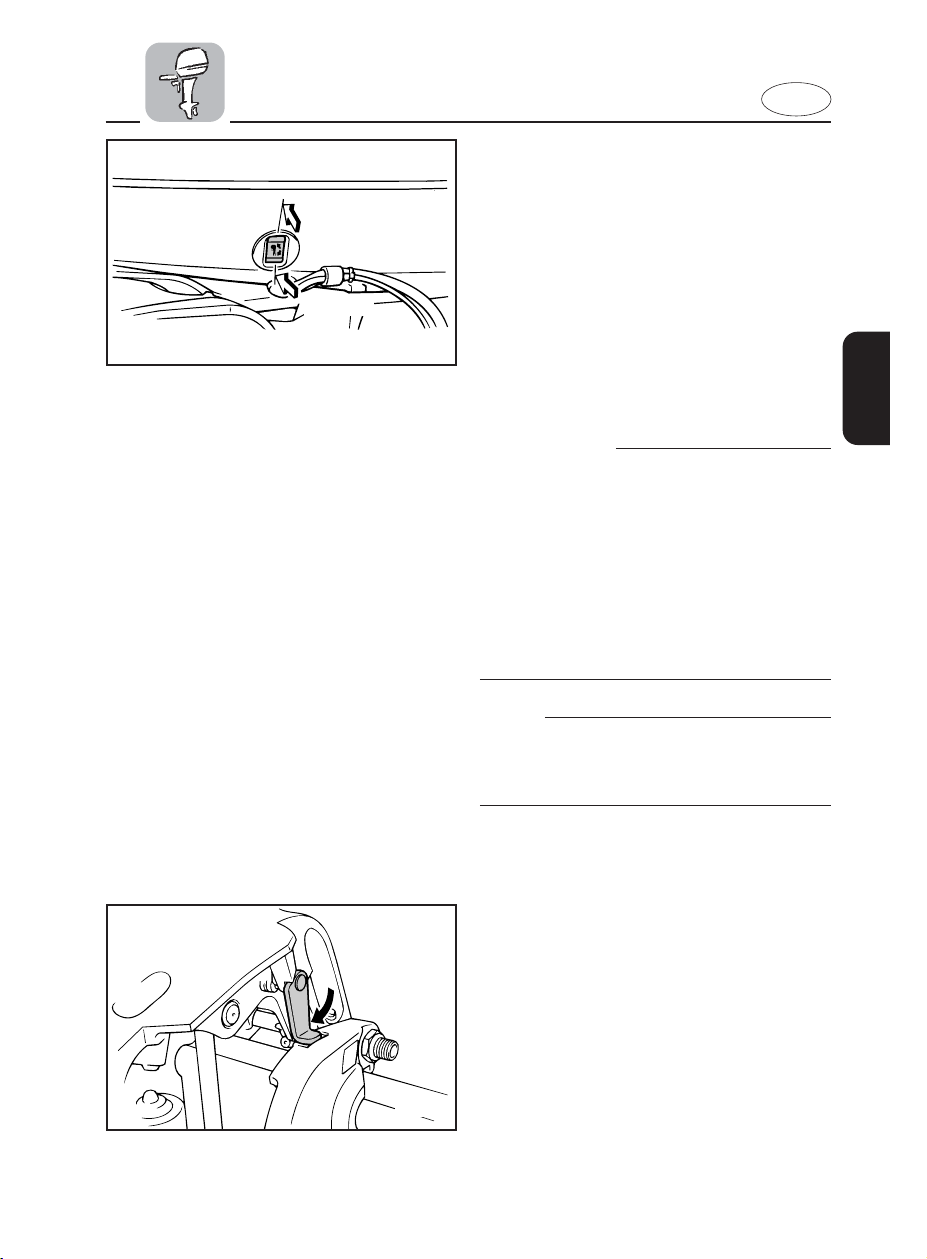

1) If there is an air vent screw on the fuel

tank cap, loosen it 2 or 3 turns.

2) If there is a fuel joint or a fuel cock on

the boat, firmly connect the fuel line

to the joint or open the fuel cock.

3) Squeeze the primer bulb with the out-

let end up until you feel it become

firm.

902025

3-12

Page 58

E

N

702025

EMU00248

N

PROCEDURE FOR REMOTE

CONTROL MODEL

4) Place the remote control lever in the

Neutral position.

NOTE:

The start-in-gear protection device permits the engine to be started only when it

701015

is in Neutral.

5) Attach the engine stop switch lanyard

to a secure place on your clothing, or

your arm or leg. Then, install the lock

plate on the other end of the lanyard

in the engine stop switch.

w

8 Attach the engine stop switch lanyard

to a secure place on your clothing, your

000293

ON

ON

STARTOFF

STARTOFF

000714

arm or leg while operating.

8 Do not attach the lanyard to clothing

that could tear loose. Do not route the

lanyard where it could become entangled, preventing it from functioning.

8 Avoid accidentally pulling the lanyard

during normal operation. Loss of

engine power means the loss of most

steering control. Also, without engine

power, the boat could slow rapidly.

This could cause people and objects in

the boat to be thrown forward.

3-13

Page 59

ON

STARTOFF

701056*

ON

OFF START

703045

E

6) Turn the main switch to “ON”.

NOTE:

In case of dual-engine operation, when

the main switch is turned on, the buzzer

operates for a few seconds and stops

automatically. Should either of the dual

engines stall, the buzzer operates.

EMU00949

Electric Start Model

7) Turn the main switch to “START”,

and hold it for a maximum of 5 seconds.

8) Immediately after the engine starts,

release the main switch to return it to

“ON”.

cC

8 Do not turn the main switch to

“START” when the engine is running.

8 Do not keep the starter-motor turning

for more than 5 seconds. The battery

will rapidly become exhausted and it

will be impossible for it to start the

engine. If the engine does not start

within 5 seconds, return the main

switch to “ON”, wait 10 seconds, and

then crank the engine again.

3-14

Page 60

E

309013

EMU01198

WARMING UP ENGINE

1) Before beginning operation, allow the

engine to warm up at idling speed for

3 minutes. (Failure to do this will

shorten engine life.)

2) Check for a steady flow of water from

the cooling-water pilot hole.

cC

A continuous flow of water from the pilot

hole shows that the water pump is

pumping water through the cooling passages. If water is not flowing out of the

pilot hole at all times while the engine is

running, do not continue to run the

engine. Overheating and serious damage

could occur. Stop the engine and check

to see if the water inlet on the lower casing is blocked. If the problem cannot be

found and corrected, consult your

Yamaha dealer.

3-15

Page 61

E

701043

N

F

EMG20310

SHIFTING

w

Before shifting, make sure there are no

swimmers or obstacles in the water near

you.

cC

F

N

702015

To change the shifting position from forward to reverse or vice-versa, close the

throttle first so that the engine idles (or

runs at low speeds).

FORWARD

Pull up the neutral interlock trigger (If

equipped) and move the remote control

lever quickly and firmly from Neutral to

Forward.

N

R

REVERSE

Pull up the neutral interlock trigger (If

equipped) and move the remote control

lever quickly and firmly from Neutral to

Reverse.

w

701044

N

R

702016

When operating in Reverse, go slowly. Do

not open the throttle more than half.

Otherwise, the boat may become unstable, which could result in loss of control

and an accident.

3-16

Page 62

E

OFF

OFF

ON

ON

703046

EMG38010

STOPPING ENGINE

Let it cool off for a few minutes at idle or

low speed first. Stopping the engine

immediately after operating at high speed

is not recommended.

EMG41511

1) Turn the main switch to “OFF”.

OFF

ON

START

701023

NOTE:

The engine can also be stopped by

pulling the lanyard from the engine stop

switch (then turning the main switch to

“OFF”).

2) Tighten the air vent screw on the fuel

tank cap after stopping the engine, if

it is equipped.

3) Remove the key if the boat will be left

unattended.

3-17

Page 63

E

q

000861

EMU01412

TRIMMING OUTBOARD

MOTOR

The trim angle of the outboard motor

helps determine the position of the bow

of the boat in the water. The correct trim

angle will help improve performance and

fuel economy while reducing strain on the

engine. The correct trim angle depends

upon the combination of boat, engine,

and propeller. Correct trim is also affected

by variables such as the load in the boat,

sea conditions, and running speed.

w

Excessive trim for the operating conditions (either trim up or trim down) can

cause boat instability and can make

steering the boat more difficult. This

increases the possibility of an accident. If

the boat begins to feel unstable or is hard

to steer, slow down and/or readjust the

trim angle.

NOTE:

Refer to the section “ADJUSTING TRIM

ANGLE” for instructions on usage.

1 Trim operating angle

3-18

Page 64

UP

DN

702014

q

UP

q

DOWN

E

ADJUSTING TRIM ANGLE

EMU01401

Power Trim/Tilt Model

w

8 Be sure all people are clear of the out-

board motor when adjusting the

trim/tilt angle, also be careful not to

pinch any body parts between the drive

unit and clamp bracket.

8 Use caution when trying a trim position