Yamaha SW-500 Service manual

SUBWOOFER

SW500

SERVICE MANUAL

This document is printed on chlorine free (ECF) paper with soy ink.

011610

PA

20020110-110000

CONTENTS

SPECIFICATIONS ................................................. 3

PERFORMANCE GRAPH .......................................... 4

PANEL LAYOUT ...................................... 4

CIRCUIT BOARD LAYOUT ................. 5

DIMENSIONS ............................................................ 5

WIRING ............................................................... 6

BLOCK DIAGRAM ........................... 7

DISASSEMBLY PROCEDURE .............................. 8

IC BLOCK DIAGRAM ................................... 11

CIRCUIT BOARDS ......................................... 11

INSPECTIONS ....................................................... 14/15

OVERALL CIRCUIT DIAGRAM

PARTS LIST

HAMAMATSU, JAPAN

1.396K-295 Printed in Japan ’02.01

SW500

IMPOR TANT NOTICE

This manual has been provided for the use of authorized Yamaha Retailers and their service personnel. It has been assumed

that basic service procedures inherent to the industry, and more specifically Yamaha Products, are already known and understood by the users, and have therefore not been restated.

WARNING : Failure to follow appropriate service and safety procedures when servicing this product may result in per-

IMPORTANT : This presentation or sale of this manual to any individual or firm does not constitute authorization certifi-

The data provided is belived to be accurate and applicable to the unit(s) indicated on the cover. The research engineering, and

service departments of Yamaha are continually striving to improve Yamaha products. Modifications are, therefore, inevitable

and changes in specification are subject to change without notice or obligation to retrofit. Should any discrepancy appear to

exist, please contact the distributor’s Service Division.

WARNING : Static discharges can destroy expensive components. Discharge any static electricity your body may have

IMPORTANT : Turn the unit OFF during disassembly and parts replacement. Recheck all work before you apply power

sonal injury, destruction of expensive components and failure of the product to perform as specified. For

these reasons, we advise all Yamaha product owners that all service required should be performed by an

authorized Yamaha Retailer or the appointed service representative.

cation, recognition of any applicable technical capabilities, or establish a principal-agent relationship of

any form.

accumulated by grounding yourself to the ground bus in the unit (heavy gauge black wires connect to

this bus.)

to the unit.

WARNING: CHEMICAL CONTENT NOTICE!

The solder used in the production of this product contains LEAD. In addition, other electrical/electronic and/or plastic (Where

applicable) components may also contain traces of chemicals found by the California Health and Welfare Agency (and possibly

other entities) to cause cancer and/or birth defects or other reproductive harm.

DO NOT PLACE SOLDER, ELECTRICAL/ELECTRONIC OR PLASTIC COMPONENTS IN YOUR MOUTH FOR ANY REASON WHAT

SO EVER!

Avoid prolonged, unprotected contact between solder and your skin! When soldering, do not inhale solder fumes or expose

eyes to solder/flux vapor!

If you come in contact with solder or components located inside the enclosure of this product, wash your hands before handling

food.

IMPOR TANT NOTICE FOR THE UNITED KINGDOM

Connecting the Plug and CoConnecting the Plug and Co

Connecting the Plug and Co

Connecting the Plug and CoConnecting the Plug and Co

IMPORTANT. The wires in this main lead are coloured in

As the colours of the wires in the main lead of this apparatus may not

correspond with the coloured markings identifying the terminals in

your plug, proceed as follows:

The BLUE wire must be connected to the terminal that is marked with

the letter N (or coloured BLACK).

The BROWN wire must be connected to the terminal that is marked

with the letter L (or coloured RED).

Be certain that neither core is connected to the earth terminal of the

three pin plug.

accordance with the following code:

BLUE: NEUTRAL

BROWN: LIVE

rr

dd

r

d

rr

dd

WARNING

Components having special characteristics are marked and must be replaced with parts having specification equal to those

originally installed.

2

SPECIFICATIONS

General specifications

Type

Bass Reflex powered subwoofer

Frequency Range

40–120 Hz (–10 dB)

Maximum Output Level

122 dB (1 m on Axis)

Dimensions (W x H x D)

480 x 619 x 590 mm

Weight

42.5 kg

Installation pole diameter

35 mm (1.375”)

Accessories

Power cable 2.5 m (AC inlet type)

SW500

Speaker unit

Speaker Unit

38 cm cone (8Ω)

Enclosure

Type: Bass Reflex

Amp. unit

Maximum Output Power

500 W at 100 Hz, THD=1%, RL=8Ω

650 W at 100 Hz, 20 ms nonclip RL=8Ω

Input Sensitivity/Impedance

+4 dB/30 kΩ (channels A and B)

Controls

LEVEL Control

CUTOFF FREQ. Control: 80–100 Hz (Variable)

PHASE Switch: (REV/NORM)

POWER Switch: ON/OFF

Connectors

INPUT A ,B (XLR-3-31), OUTPUT THRU A, B (XLR-3-32)

OUTPUT HIGH PASS A ,B (XLR-3-32): Impedance 150Ω

Power Indicator

Green LED

Clip Indicator

Red LED

Power Requirement

USA and Canada: AC 120 V, 60 Hz

Europe: AC 230 V, 50 Hz

Others: AC 240 V, 50 Hz

Power Consumption

200 W

0 db=0.775 *V

3

SW500

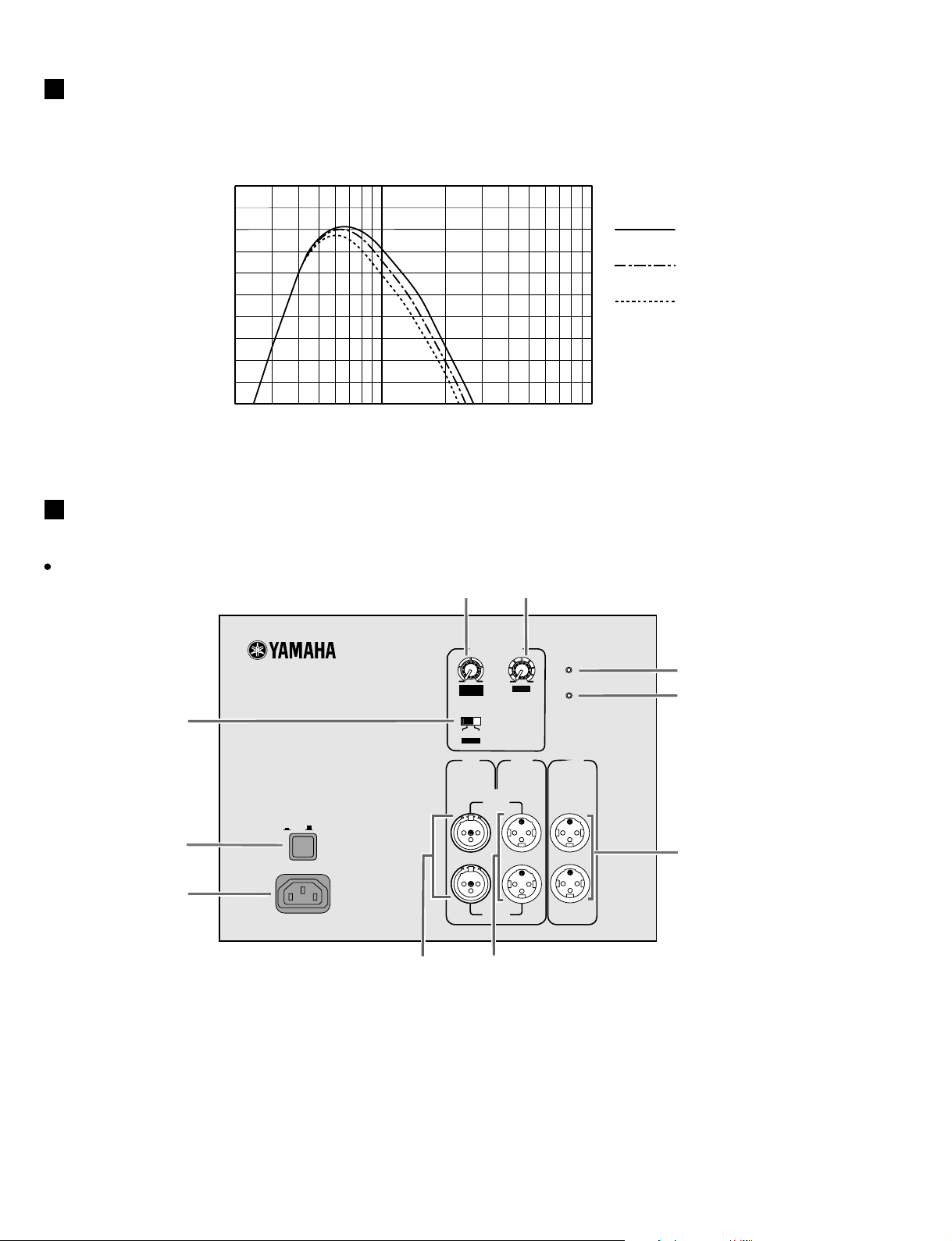

PERFORMANCE GRAPH

Standard frequency response

RESPONSE (dB)

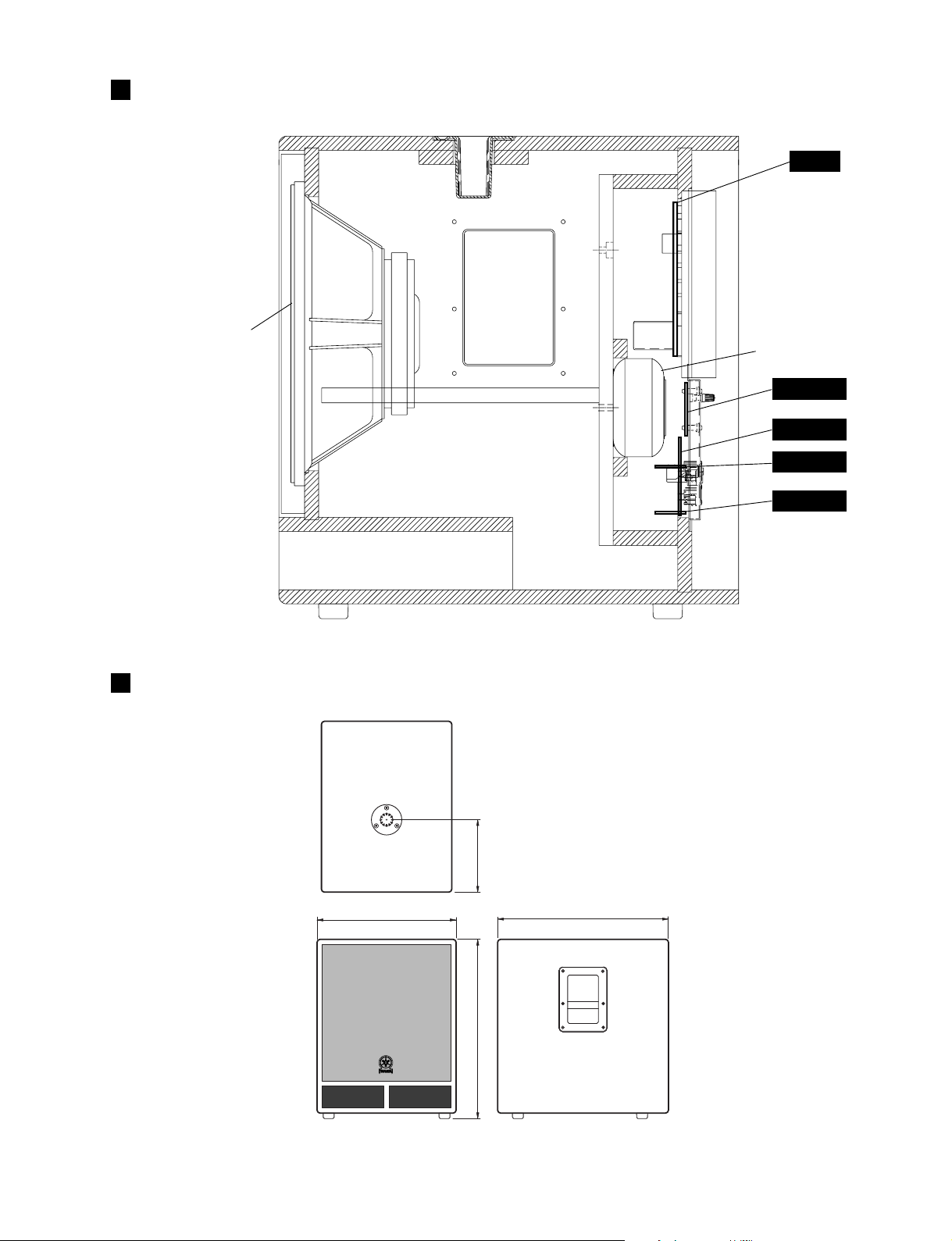

PANEL LAYOUT

Rear Panel

+10

-10

-20

-30

-40

Cutoff Frequency

0

100Hz

90Hz

80Hz

20

1k100

FREQUENCY (Hz)

e

r

SUBWOOFER

MODEL SW500

t

POWER

ON /

OFF

q

w

AC IN

q [POWER] switch

w [AC IN] connector

e [CUTOFF FREQ.] control

r [LEVEL] control

t [PHASE] switch

y [INPUT] jacks A and B

u [OUTPUT THRU] jacks A and B

i [OUTPUT HIGH PASS] jacks A and B

o [POWER] indicator

!0 [CLIP] indicator

y

A

B

SUBWOOFER CONTROL

80

CUTOFF

FREQ.

NORM

PHASE

INPUT

(+4dB)

REV

100

PARALLEL

PARALLEL

u

POWER

0

10

LEVEL

OUTPUT

THRU

CLIP

OU TPUT

HIGH PASS

100Hz

(+4dB)

o

!0

i

4

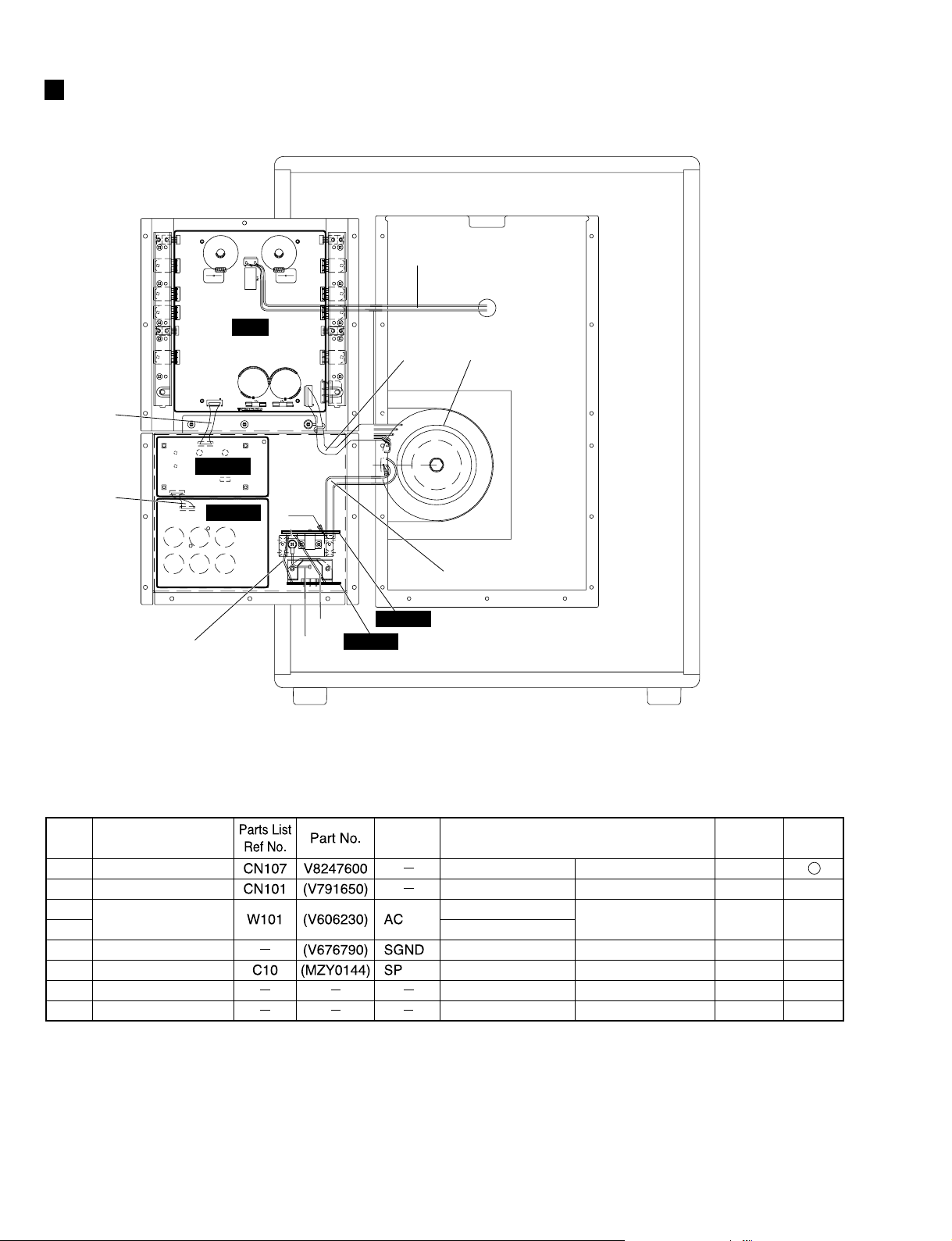

CIRCUIT BOARD LAYOUT

SW500

AMP

Power TransformerSpeaker <Woofer>

MIX 1/4

MIX 2/4

MIX 3/4

DIMENSIONS

480

MIX 4/4

250

590

619

Units: mm

5

SW500

WIRING

q

w

CN102

CN101

CN201

MIX 1/4

MIX 2/4

e-2

CN107

CN203

AMP

CN202

CN106

CN105

W101BW101BW101B W101AW101AW101A

e-1

r

BL

YE

MIX 3/4

MIX 4/4

y

t

Power Transformer

u

Location

q

w

e-1

e-2

r

t

y

u

6

Unit Name

MIX 1/4 Circuit Board

MIX 2/4 Circuit Board

MIX 4/4 Circuit Board

MIX 4/4 Circuit Board

Cabinet Assembly

Power Transformer

Power Transformer

Connector

Assembly

Destination

MIX 1/4-CN107 AMP-CN201

MIX 2/4-CN101 MIX 1/4-CN102

MIX 4/4-W101A

MIX 4/4-W101B

MIX 3/4-CN105

MIX 4/4-JK107 Rear Panel (GND)

Speaker AMP-CN203

Power Transformer AMP-CN202

Power Transformer MIX 3/4-CN106

Remarks

6P-100L

4P-60L

2P

1P

2P

6P

2P

Availability

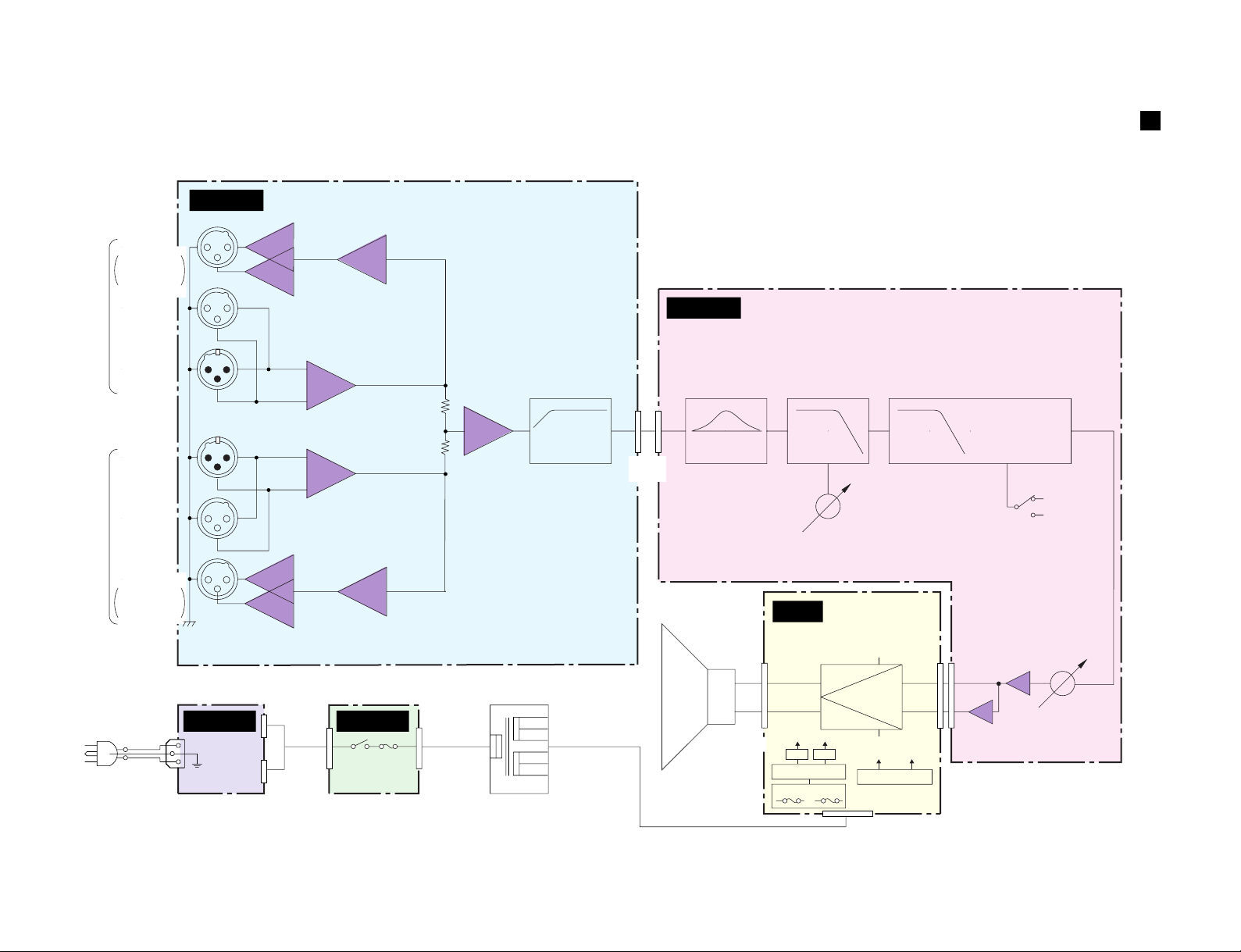

HPF

HPF

BOOST

LOW

CUT

LOW

LPF LPF

SUM

OUTPUT

(THRU)

OUTPUT

(+4dB)

INPUT

(+4dB)

INPUT

(THRU)

OUTPUT

100Hz

100Hz

PHASE

NORMAL

REVERSE

(80Hz to 100Hz)

CUTOFF FREQ.

ch A

ch B

SPEAKER

Secondary

(Woofer)

LEVEL

BTL

MIX 2/4

MIX 1/4

AMP

MIX 3/4

+

-

RECTIFIER

RECTIFIER

OUTPUT

HIGH PASS

100Hz

+4dB

Power Transformer

Primary

AC IN

MIX 4/4

HIGH PASS

100Hz

+4dB

F201 F202

JK101

JK102

JK103JK103

JK105

JK106JK106

GND

7

51 3

2

1

JK104JK104

IC104

(8P)

IC102

(8P)

5

3

1

215 373113

2

CH1

CH2

W+

W-

+B

-B

IC202IC201

+15

+15V

-15

-15V

T101

+B -B

57

21

1/7

2

6

7

IC103

(8P)

IC103

(8P)

IC105

(8P)

CN101

(4P)

CN102

(4P)

IC105

(8P)

IC106

(8P)

IC107

(8P)

IC108

(8P)

IC109

(8P)

IC109

(8P)

CN107

(6P)

CN201

(6P)

CN202

(6P)

CN203

(4P)

CN106

(3P)

CN105

(3P)

W101B

(1P)

W101A

(1P)

FG

SW101 F101

IC104

(8P)

IC101

(8P)

7

57 5

2

1

VR101

VR102

SW102

BLOCK DIAGRAM

7

SW500

SW500

DISASSEMBLY PROCEDURE

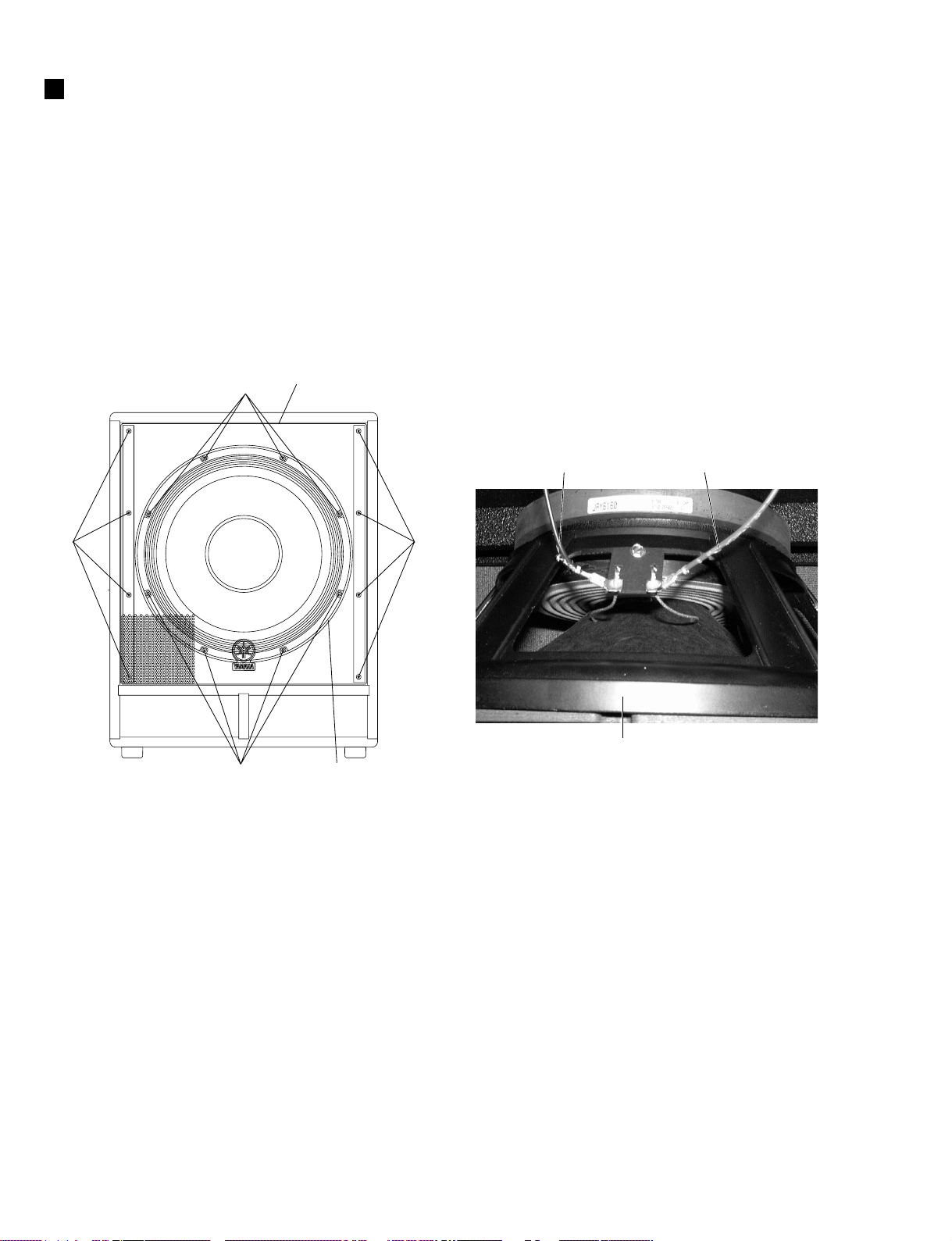

1. Speaker (Woofer) (Time required: About 10 minutes)

1-1 Remove the eight (8) screws marked [60]. The front grille

assembly can then be removed. (Fig.1)

1-2 Remove the eight (8) cap screws marked [C90]. The speaker

(woofer) can then be removed. (Fig.1)

1-3 Remove the SP connector assembly (red/black) installed to the

speaker (woofer). (Photo.1)

<Front View>

[C90]

[60] [60]

[C90]

Front Grille Assembly

Speaker (Woofer)

SP Connector

Assembly (Black)

Speaker (Woofer)

SP Connector

Assembly (Red)

Photo.1

[60]: Cup Head Tapping Screw-1

4.0X16 MFZN2BL (V8889600)

[C90]: Cap Screw

#10X1-1/2 BL Z (EKY01010)

Fig.1

8

2. Amplifier Assembly (Time required: About 5 minutes)

2-1 Remove the sixteen (16) screws marked [30]. The amplifier

assembly can then be removed. (Fig.2)

3. Power Transformer (Time required: About 10 minutes)

3-1 Remove the amplifier assembly. (See procedure 2.)

3-2 Remove the hexagonal bolt marked [A]. The power transformer

can then be removed. (Fig.3, 4)

SW500

4. AMP Circuit Board

(Time required: About 15 minutes)

4-1 Remove the amplifier assembly. (See procedure 2.)

4-2 Remove the five (5) screws marked [A80A] in right and left

each. The right and left transistor holders can then be removed.

(Fig.3)

4-3 Remove the four (4) screws marked [A90]. The AMP circuit

board can then be removed. (Fig.3)

5. MIX 1/4 Circuit Board

(Time required: About 10 minutes)

5-1 Remove the knobs marked [A150] and [A160] from the rear

panel side. (Fig.2)

5-2 Remove the amplifier assembly. (See procedure 2.)

5-3 Remove the four (4) screws marked [A190]. The MIX 1/4 circuit

board can then be removed with the four (4) PCB supports.

(Fig.2, 3)

5-4 Remove the four (4) PCB supports from the MIX 1/4 circuit

board. (Fig.3)

6. MIX 2/4 Circuit Board

(Time required: About 15 minutes)

6-1 Remove the amplifier assembly. (See procedure 2.)

6-2 Remove the twelve (12) screws marked [A100A]. The MIX 2/4

circuit board can then be removed. (Fig.2, 3)

6-3 Remove the MIX 1/4 circuit board. (See procedure 5.)

And then disconnect the connector (CN102) from the MIX 1/4

circuit board.

7. MIX 3/4 Circuit Board

(Time required: About 10 minutes)

7-1 Remove the amplifier assembly. (See procedure 2.)

7-2 Remove the two (2) screws marked [A100B]. The MIX 3/4 circuit

board and the power switch knob can then be removed.

(Fig.2, 3)

8. MIX 4/4 Circuit Board

(Time required: About 10 minutes)

8-1 Remove the amplifier assembly. (See procedure 2.)

8-2 Remove the two (2) screws marked [A80B] and the screw marked

[A130]. The MIX 4/4 circuit board and the AC inlet angle bracket

can then be removed. (Fig.2, 3)

9

Loading...

Loading...