Page 1

SERVICE MANUAL

PA

011947

■ CONTENTS

PANEL LAYOUT

CIRCUIT BOARD LAYOUT

SERVICE PRECAUTIONS

OVERALL ASSEMBLY WIRING

DISASSEMBLY PROCEDURES

LSI PIN DESCRIPTION

IC BLOCK DIAGRAM

CIRCUIT BOARDS

TEST PROGRAM .......................................................................................64

テストプログラム

INSPECTIONS ...........................................................................................78

.............................................................................................................83

検査

UPDATING THE FIRMWARE .....................................................................88

ファームウェアのアップデート

PARTS LIST

BLOCK DIAGRAM

IC & DIODE FIGURES

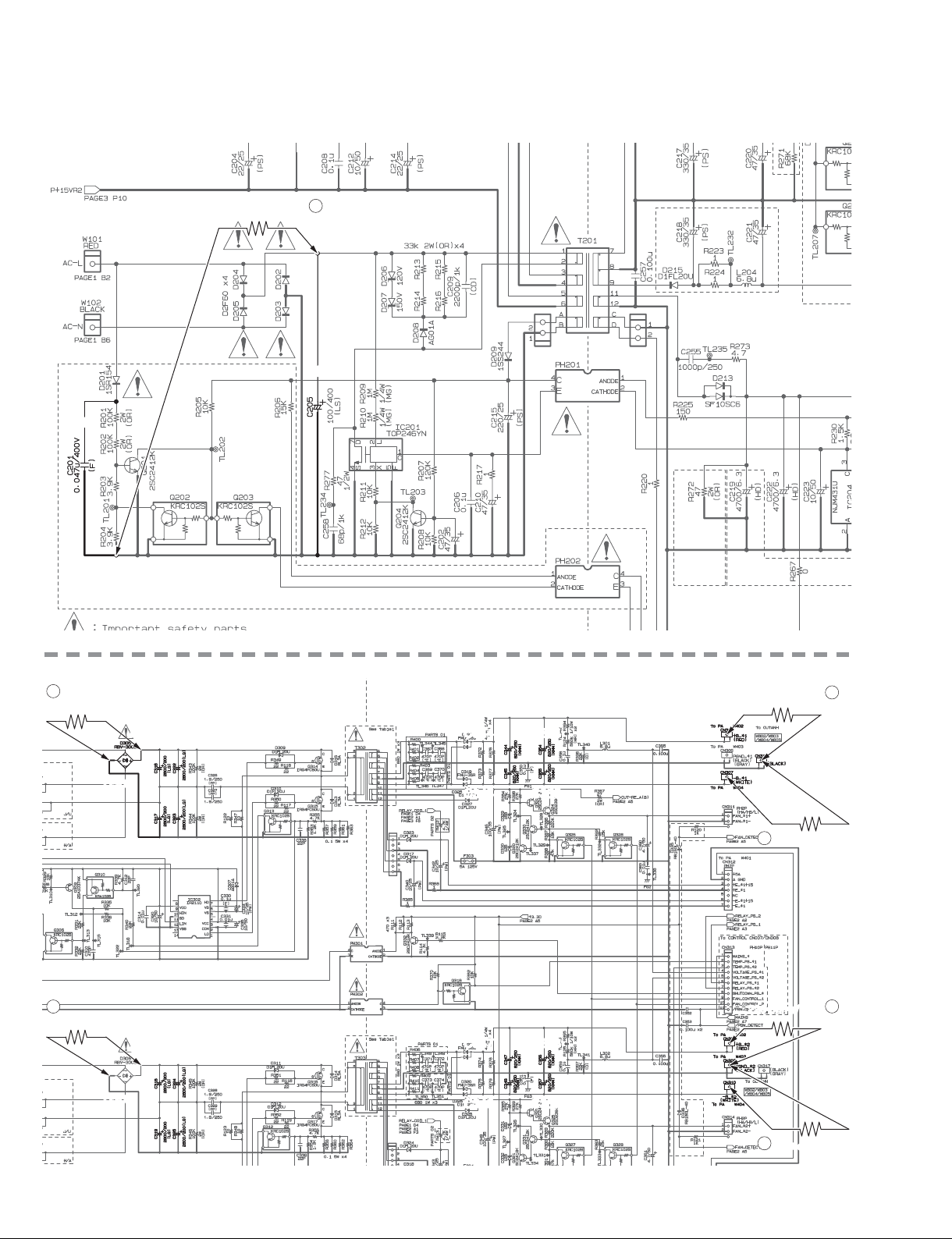

CIRCUIT DIAGRAM

(目次)

(パネルレイアウト)

(ユニットレイアウト)

(サービス時の注意)

(LSI 端子機能表)

(IC ブロック図)

(シート基板図)

........................................................................................71

...........................................................3

........................................4

............................................5

(総組立配線図)

(分解手順)

.......................................................38

.............................................................44

....................................................................90

Copyright (c) NEXO S.A. All rights reserved. PDF ´09.10

.......................................... 7

...............................................25

...................................................37

Page 2

NXAMP4x4

WARNING: This product contains chemicals known to the State of California to cause cancer, or birth defects or other reproductive harm.

DO NOT PLACE SOLDER, ELECTRICAL/ELECTRONIC OR PLASTIC COMPONENTS IN YOUR MOUTH FOR ANY REASON WHAT SO

EVER!

Avoid prolonged, unprotected contact between solder and your skin! When soldering, do not inhale solder fumes or expose eyes to solder/flux

vapor!

If you come in contact with solder or components located inside the enclosure of this product, wash your hands before handling food.

IMPORTANT NOTICE FOR THE UNITED KINGDOM

Connecting the Plug and Cord

WARNING: THIS APPARATUS MUST BE EARTHED

IMPORTANT. The wires in this mains lead are coloured in accordance with the following code:

GREEN-AND-YELLOW: EARTH

BLUE: NEUTRAL

BROWN: LIVE

As the colours of the wires in the mains lead of this apparatus may not correspond with the coloured markings identifying the terminals in your

plug, proceed as follows:

The wire which is coloured GREEN and YELLOW must be connected to the terminal in the plug which is marked by the letter E or by the safety

earth symbol

The wire which is coloured BLUE must be connected to the terminal which is marked with the letter N or coloured BLACK.

The wire which is coloured BROWN must be connected to the terminal which is marked with the letter L or coloured RED.

or colored GREEN or colored GREEN and YELLOW.

WARNING

■

Components having special characteristics are marked and must be replaced with parts having specification equal to those originally

installed.

印の商品は、安全を維持するために重要な部品です。交換する場合は、安全のために必ず指定の部品をご使用ください。

(注意)

2

Page 3

NXAMP4x4

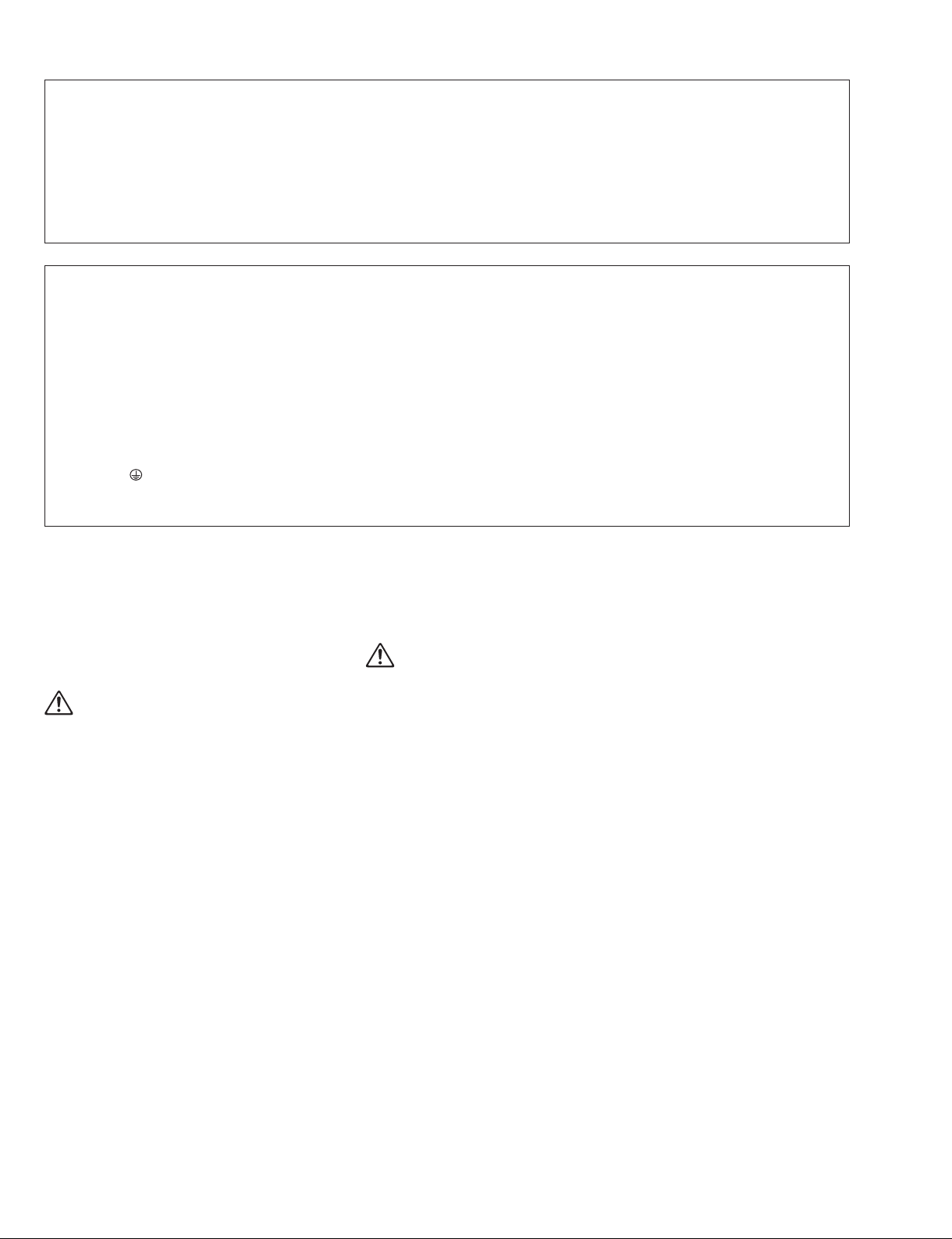

PANEL LAYOUT

■

• Front Panel

Power switch

❶

Amplifier indicators

❷

LCD display

❸

Encoder

❹

Navigation buttons (A & B)

❺

Volume indicators

❻

(フロントパネル)

(パネルレイアウト)

Mute buttons

❼

Select buttons

❽

Channel indicators

❾

Air intakes

❿

Screw holes for handles

⓫

❶ 電源スイッチ

❷ アンプディスプレイ

❸ LCD ディスプレイ

❹ エンコーダー

❺

❶❷❼❸❿ ⓫❻❾❽❺❹

ナビゲーションボタン

(A&B)

❻ ボリュームディスプレイ

❼ ミュートボタン

❽ セレクトボタン

❾ チャンネルディスプレイ

❿ 吸気口

⓫ ハンドル用ネジ穴

• Rear Panel

Mains connectors

❶

Balanced audio inputs with link

❷

Expansion slot

❸

Power outputs

❹

RS-232 Firmware update port

❺

GPIO port

❻

Rear end mounting holes

❼

(リアパネル)

❸❹ ❻❷❶❺❼

❶ 電源端子

❷ バランスオーディオ入力(リンク付き)

❸ 拡張スロット

❹ パワー出力

❺ RS-232C ファームウェアアップデート用ポート

❻ GPIO ポート

❼ リアエンド取り付け穴

3

Page 4

NXAMP4x4

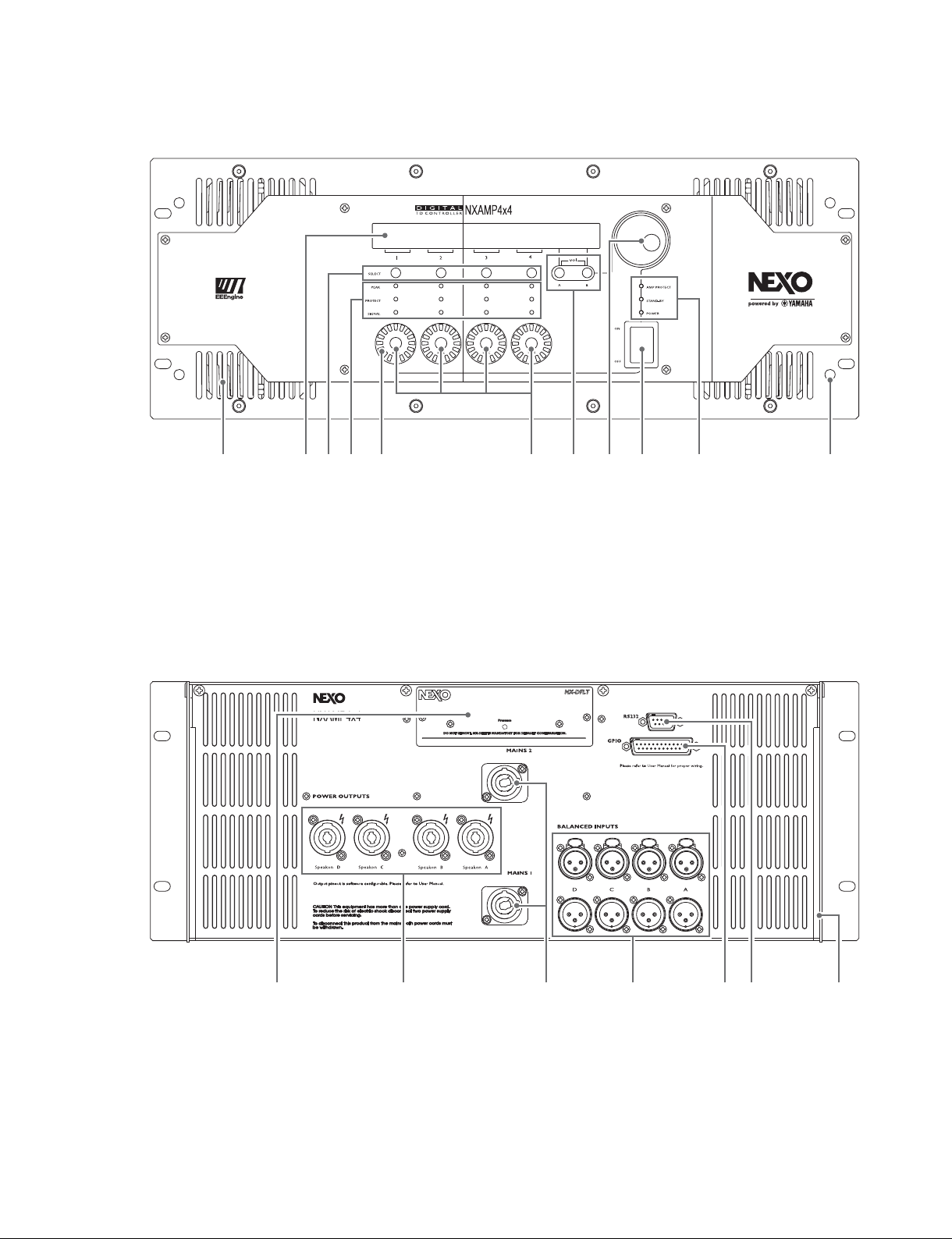

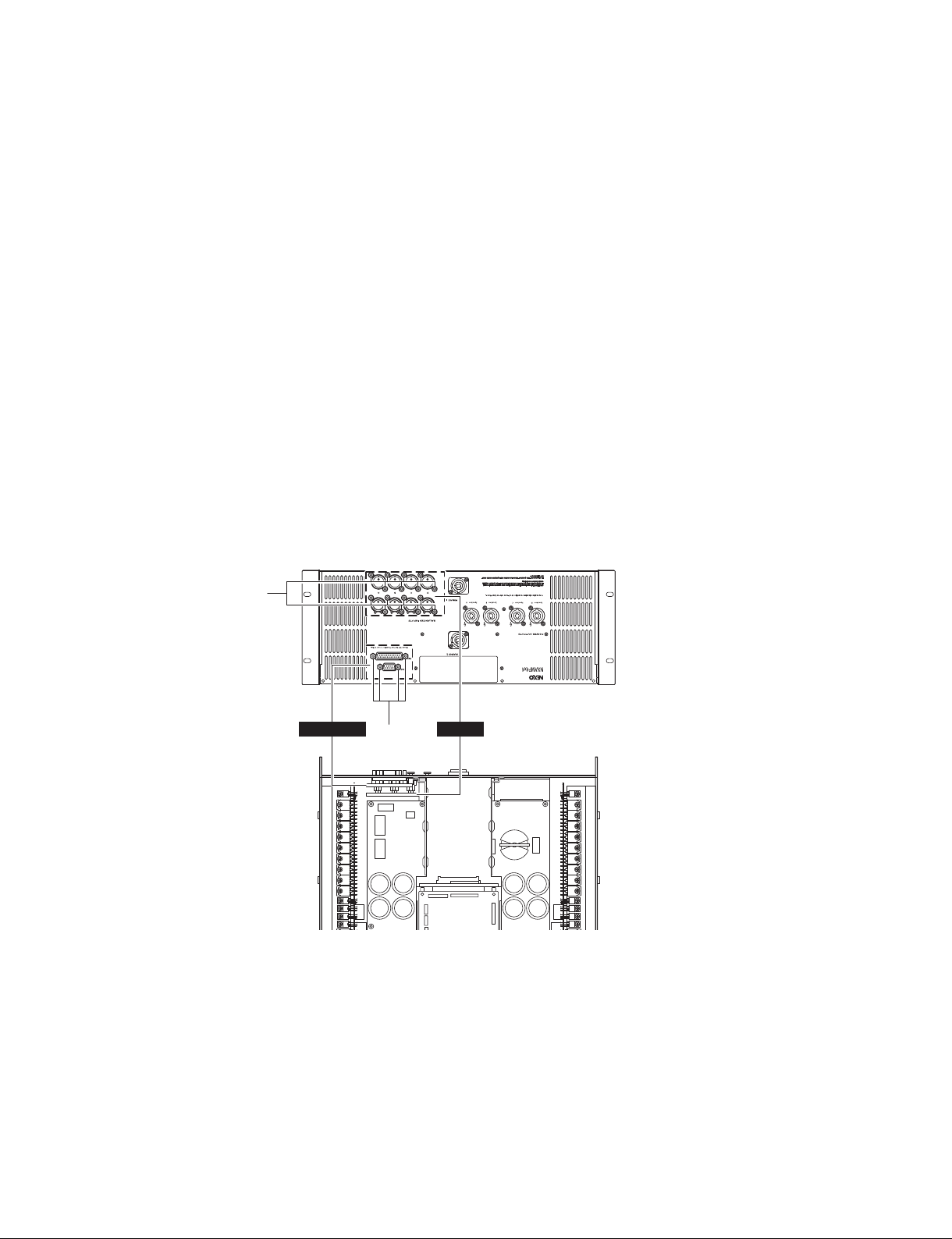

CIRCUIT BOARD LAYOUT

■

RS232-GPI NX-DFLT

INANH

(PA unit)

(PA ユニット)

(ユニットレイアウト)

PSANHA

CONTROL

OPT-AN

PAANHPAANH

(PA unit)

(PA ユニット)

Rear Panel (リアパネル)

NX-DFLT

Front Panel (フロントパネル)

PAANH

(PA unit)

(PA ユニット)

PSANHBOUTANH

PN-AN

OPT-AN

RS232-GPI

INANH

PSANHA

PAANH

(PA unit)

(PA ユニット)

4

Page 5

NXAMP4x4

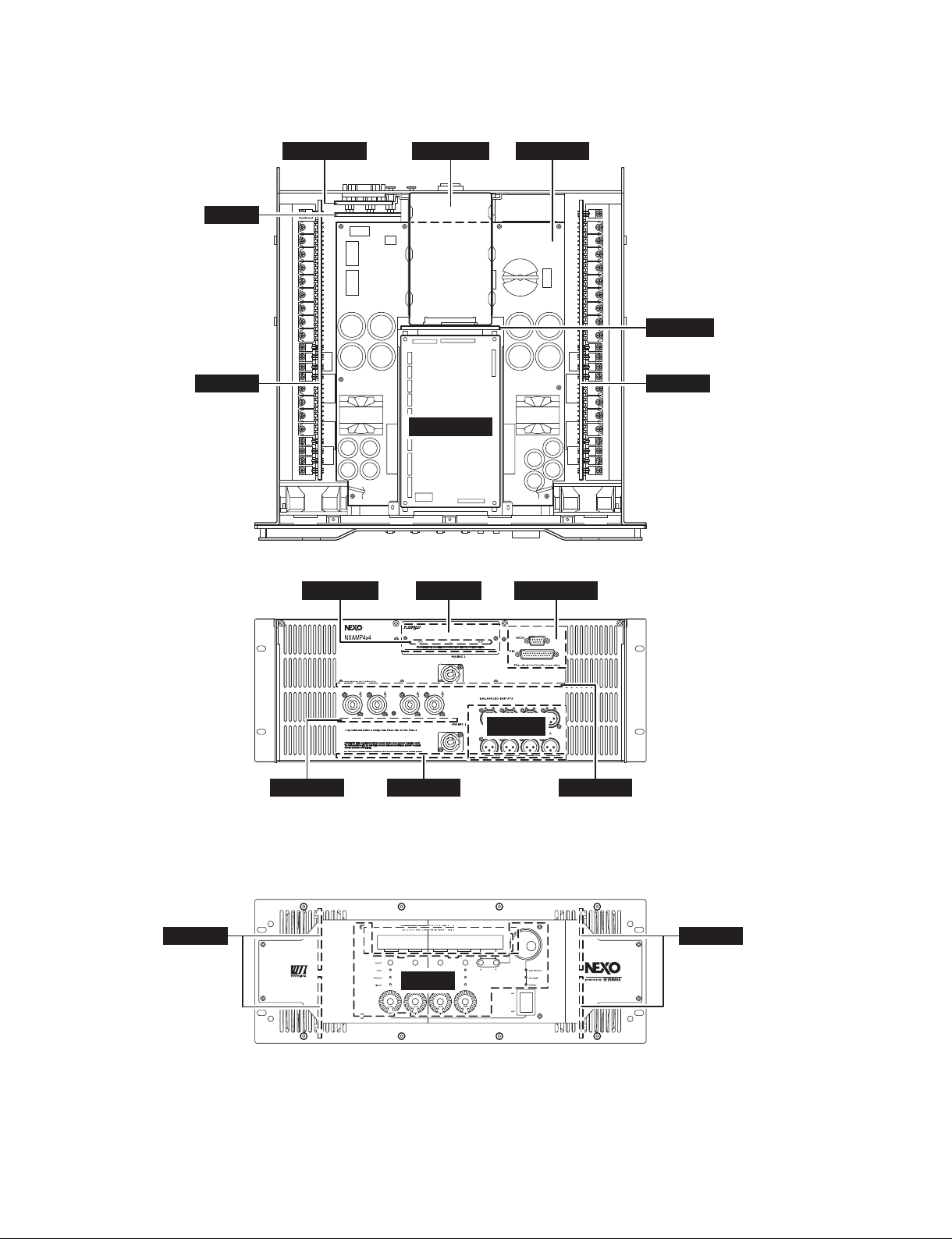

SERVICE PRECAUTIONS

■

(サービス時の注意)

Safety measures

• Some component parts on the PSANH circuit board

maintain a high voltage even when the power is switched

off. For this reason to avoid an electrical shock, do not

touch the upper metallic part of the following capacitors

until the remaining voltage has discharged.

Capacitors /

C316, C317, C322, C323

C318, C319, C324, C325

C344, C354

C345, C355

C347, C356

C348, C357

C205

[Discharging Method]

Before starting the service work, connect discharging

resistors (220 Ω 10W) to the terminals indicated in the

figure below to discharge electricity. (7 points)

The required discharging time is about 10 seconds.

Check that the DC voltage between the terminals

measures close to 0 (zero) volts using a multi-meter to

make sure that the discharge is completed.

Note:

Do not touch the IC201 and its heat sink before

discharging the C205.

コンデンサ

安全対策

・ PSANH シートの部品の一部には電源 OFF 状態でも高

電圧が残ります。感電防止のため、残った電圧を放電

するまで下記のコンデンサの上部の金属部分に触らな

いでください。

Discharging point /

D305: + pin <=> D305: - pin

①

D306: + pin <=> D306: - pin

②

CN305 <=> CN316

③

CN307 <=> CN316

④

CN308 <=> CN309

⑤

CN310 <=> CN309

⑥

R213: lead <=> C201

⑦

[放電方法]

修理作業を始める前に、放電抵抗(220 Ω、10W)を

下図に示す放電用の端子間に接続します。(7 箇所)

放電に必要な時間は約 10 秒です。放電完了確認のため、

端子間電圧がほぼ 0(ゼロ)V であることをテスターで

チェックします。

注意:

C205 の放電完了まで IC201 とそれを固定しているヒー

トシンクには触らないでください。

放電箇所

PSANH circuit board

220 ohms/10W

C323 C322

C317 C316

C344 C354

C345 C355

CN316

4

CN307 CN305 CN308

3

220 ohms/10W

D305

1

220 ohms/

10W

220 ohms/10W

REAR

7

FRONT

220 ohms/

10W

C201

R213

D306

2

C205

220 ohms/10W

C324 C318

C325

6

CN310

220 ohms/10W

C319

C357

C348

C356

C347

CN309

5

5

Page 6

NXAMP4x4

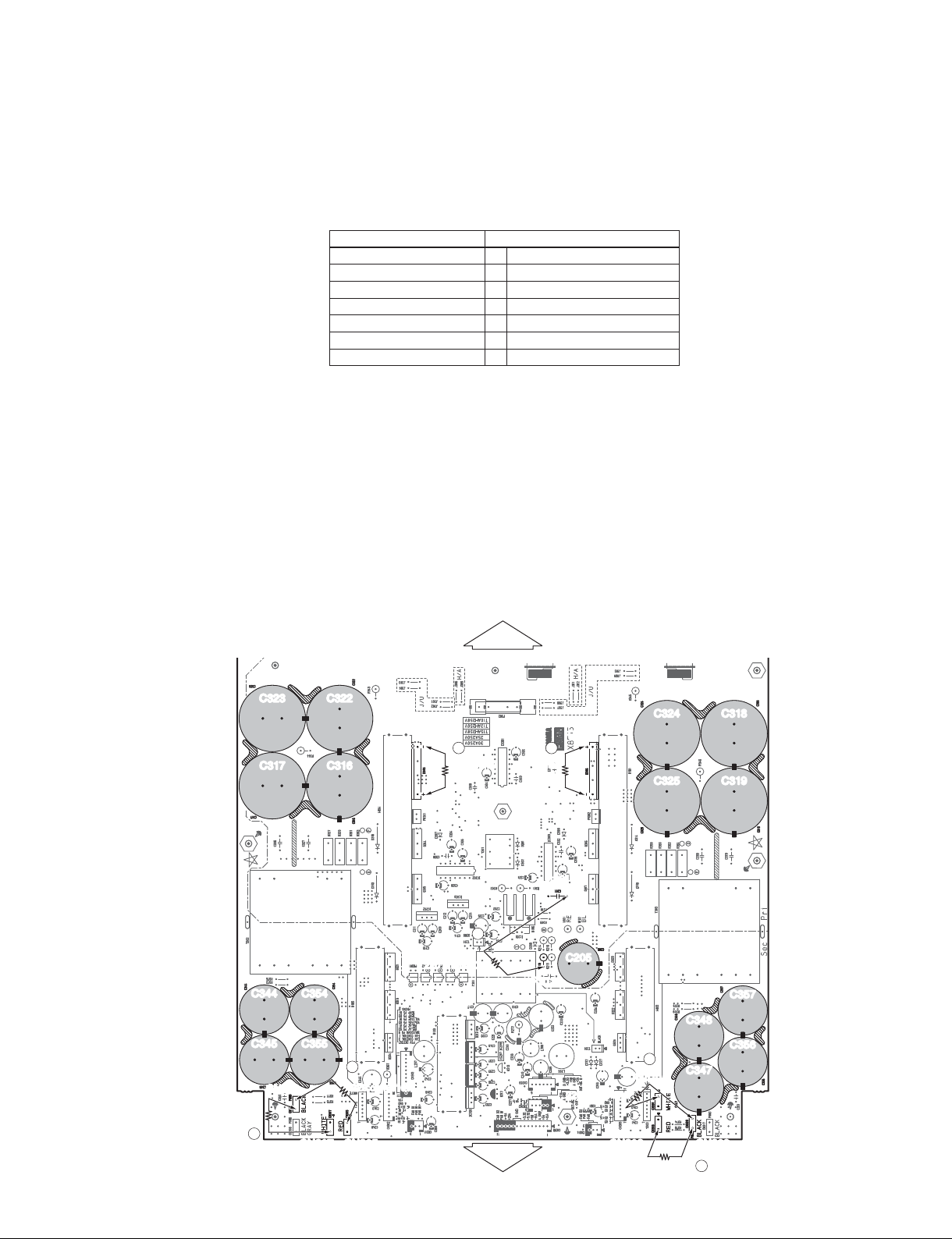

PSANH circuit diagram

1

2

C201

PSANHA only

220 ohms/10W

7

C205

PSANHA only

PSANHB only

PSANHA only

1

220 ohms/10W

D305

2

220 ohms/10W

D306

C316

C322

C317 C323

C318

C324

Primary

Secondary

220 ohms/10W

C305

ANH

C354C344

ANH

ANH

3

C316

ANH

C355C345

C356C347

C357C348

C307

ANH

To FAN

ANH

PSANHB

220 ohms/10W

ANH

ANH

ANH

ANH

ANH

ANH

To FAN

4

220 ohms/10W

PSANHA

5

6

XX

220 ohms/10W

C319 C325

6

Page 7

NXAMP4x4

OVERALL ASSEMBLY WIRING

■

This product has various cables (wires and connector

assemblies) inside. To prevent touching component to

the cables and/or connection mistake, perform the cable

connection and fixing cables according to the following

instructions referring the wiring diagram, P3 of the circuit

diagram.

Notice: Since the following pictures are taken of the

preproduction product, they may differ from the

commodity products in detail. However, the wiring

and so on is not so differ between them. So, refer

only to wiring and so on.

(総組立配線図)

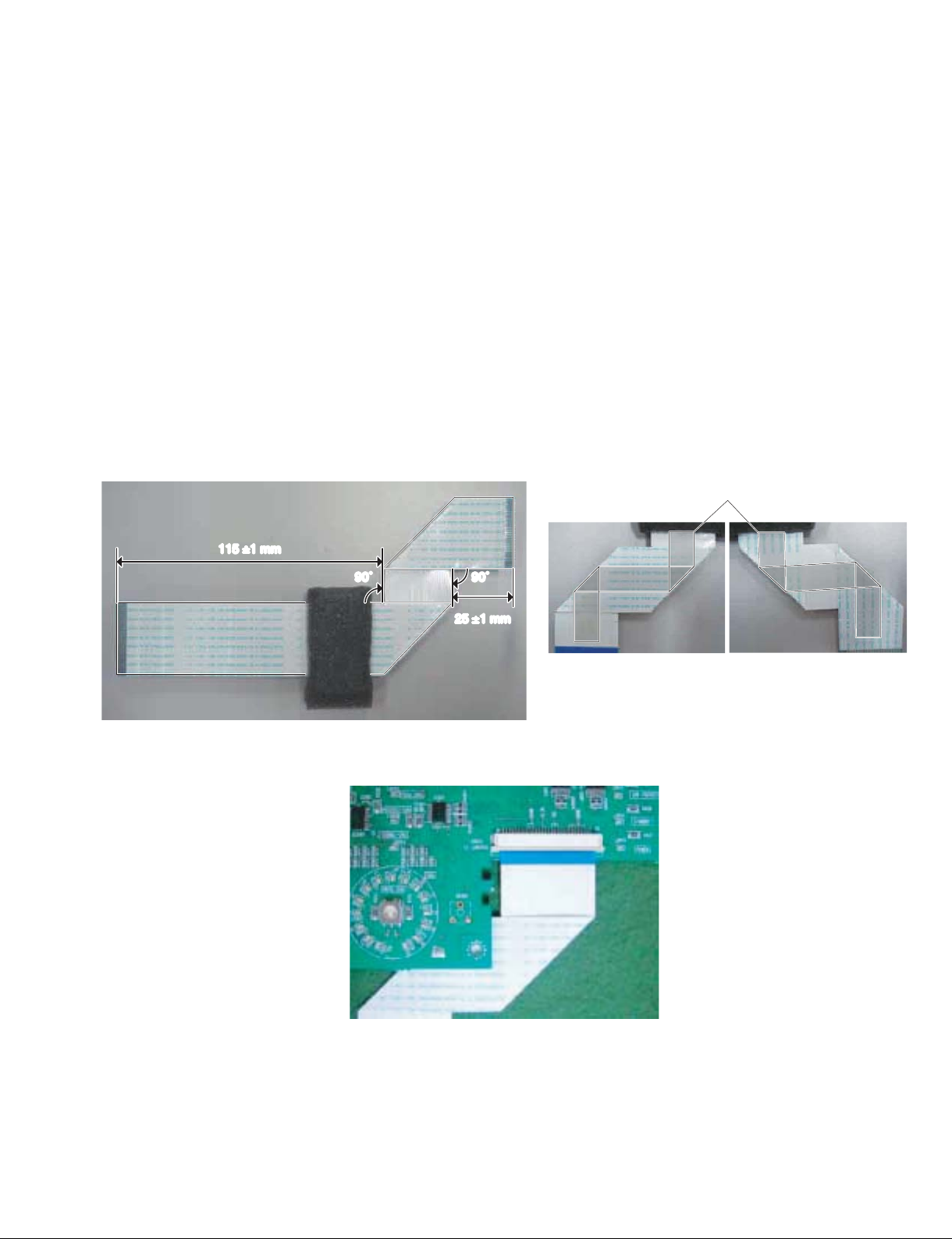

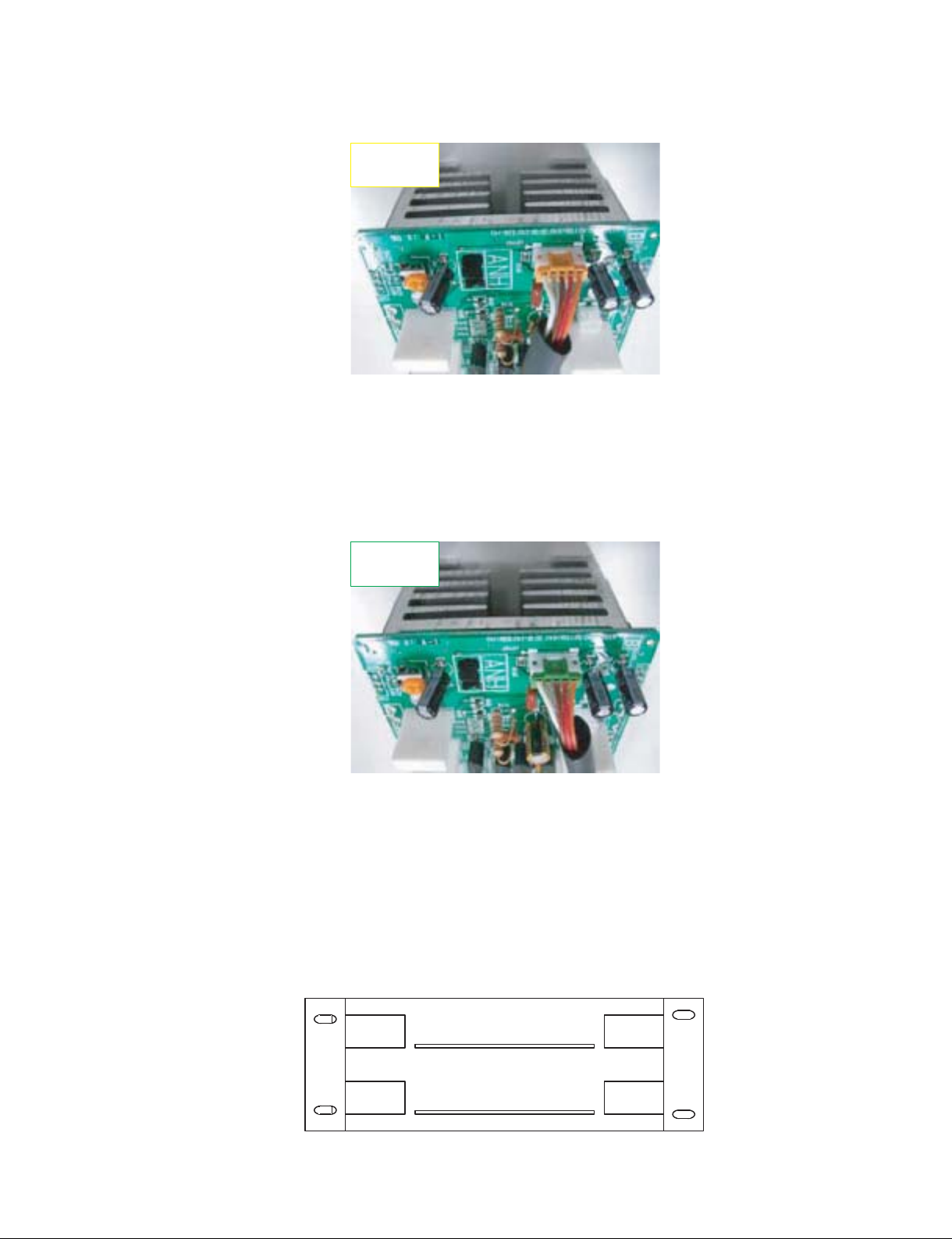

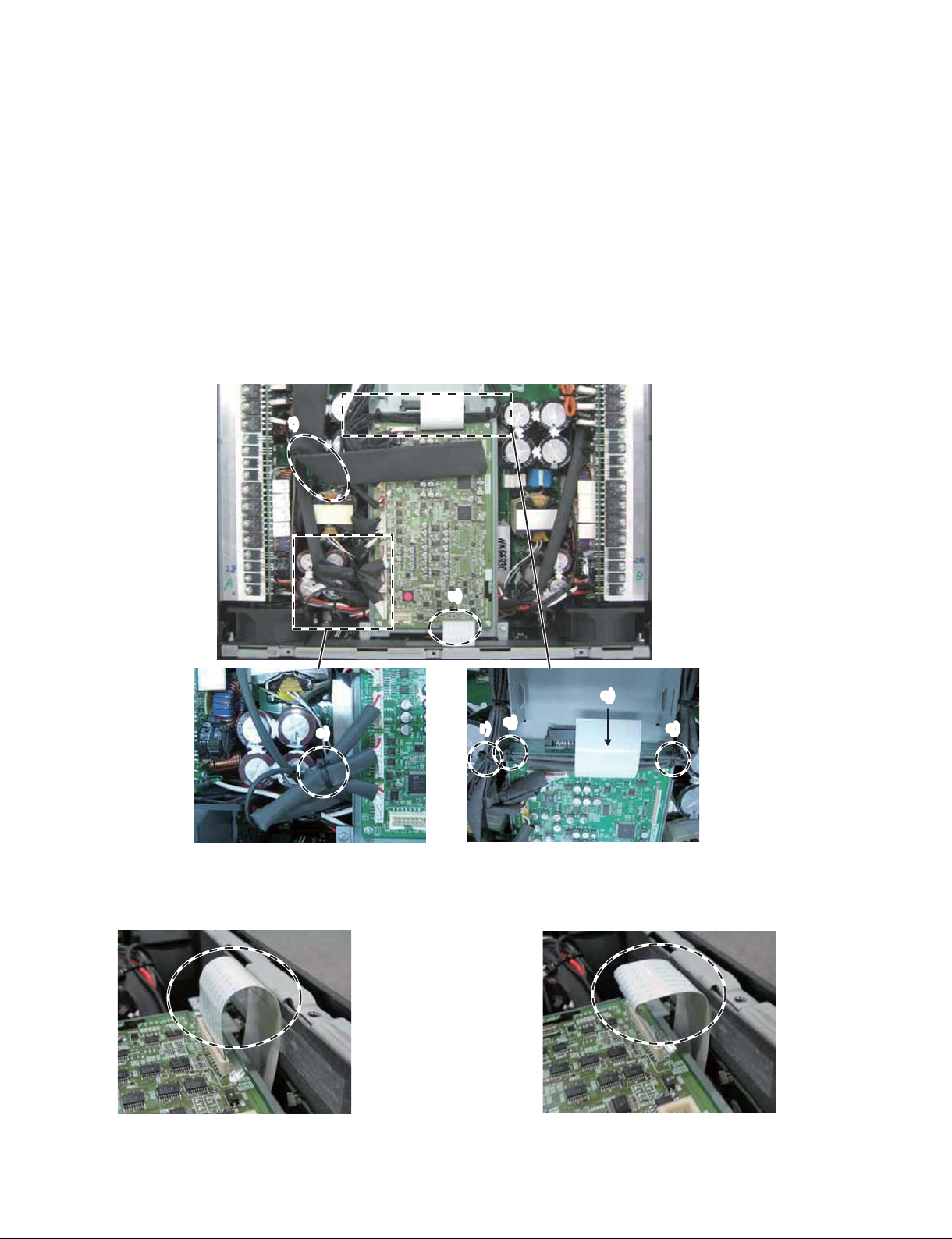

1. Wiring of the PN-AN circuit board

1) Process the PN FFC assembly (WR37010). (Fig. 1, 2)

2) Connect the PN FFC assembly (WR37010) to the PNAN circuit board. (Fig. 3)

3) Install the PN-AN circuit board to the front panel.

115 ±1 mm

本製品内部には色々な種類のケーブル(線材、束線)があり

ます。ケーブルの部品への接触やケーブルの接続ミスを防止

するために、回路図 3 ページのシート配線図を参照の上で下

記の指示にしたがってケーブルの接続と固定を行ってくださ

い。

注意: 掲載した写真は量産試作品を撮影したものですので

生産品とは細かい部分で異なりますが、配線周辺に

ついて違いはありません。配線作業用に限定して参

考にしてください。

1. PN-AN シートの配線

1) PNFFCAss'y(WR37010)を加工します。(図 1、2)

2) PNFFCAss'y(WR37010)を PN-AN シートへ接続し

ます。(図3)

3) PN-AN シートをフロントパネルへ取り付けます。

[635]

Fig. 1

(図 1)

90˚ 90˚

25 ±1 mm

Fix the bent part with adhesive tape [635].

(Attach it through the center of FFC.)

(折り曲げた部分をフィラメントテープ[635]で固定します。

(FFC の中心を通るように貼ります。))

Fig. 2

(図 2)

Fig. 3

* For details of wiring in the enclosure, refer to step “13.

Method of Fixing PN FFC Assembly”.

(図 3)

※ 筐体内部での配線についての詳細は「13. PNFFC

Ass'y の固定方法」を参照してください。

7

Page 8

NXAMP4x4

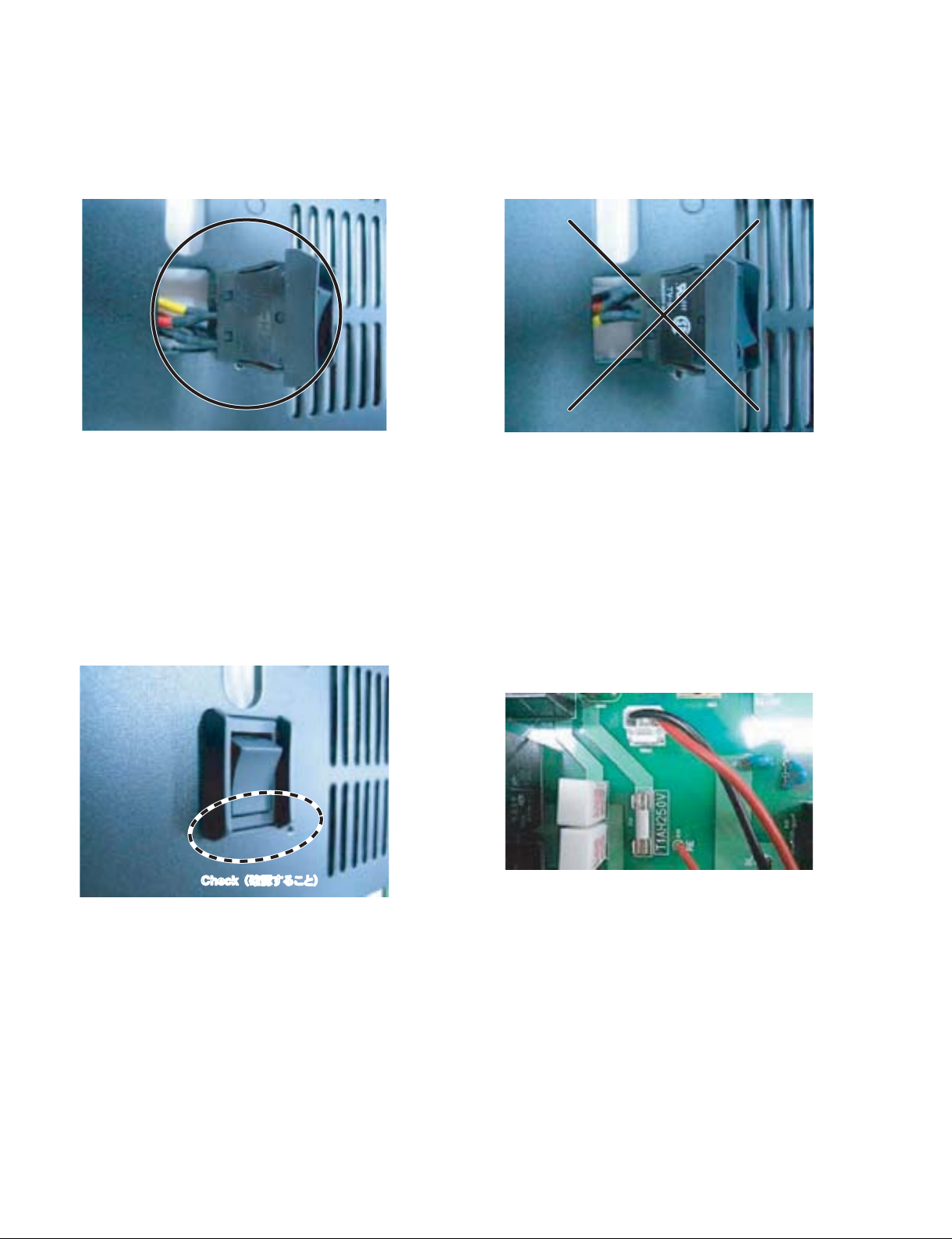

2. Wiring of the power switch

1) Install the power switch to the front panel with its

terminals set downward. (Fig. 4, 5)

Fig. 4

(図 4)

2) Confirm that the power switch is set to the off position as

shown in the figure. (Fig. 6)

3) Twist the wires of the power switch assembly more than

three times.

4) Connect the power switch connector assembly to the

connector (CN103) of the PSANHB circuit board. (Fig. 7)

2. 電源スイッチの配線

1) 端子の位置を下側にセットして、電源スイッチをフロ

ントパネルへ取り付けます。(図 4、5)

Fig. 5

(図 5)

2) 電源スイッチが図のように OFF ポジションにセットさ

れていることを確認します。(図 6)

3) 電源スイッチの線材を 3 回以上捻ります。

4) 電源スイッチの線材を PSANHB シートのコネクター

(CN103)へ接続します。(図 7)

Check (確認すること)

Fig. 6

(図 6)

Fig. 7

(図 7)

8

Page 9

NXAMP4x4

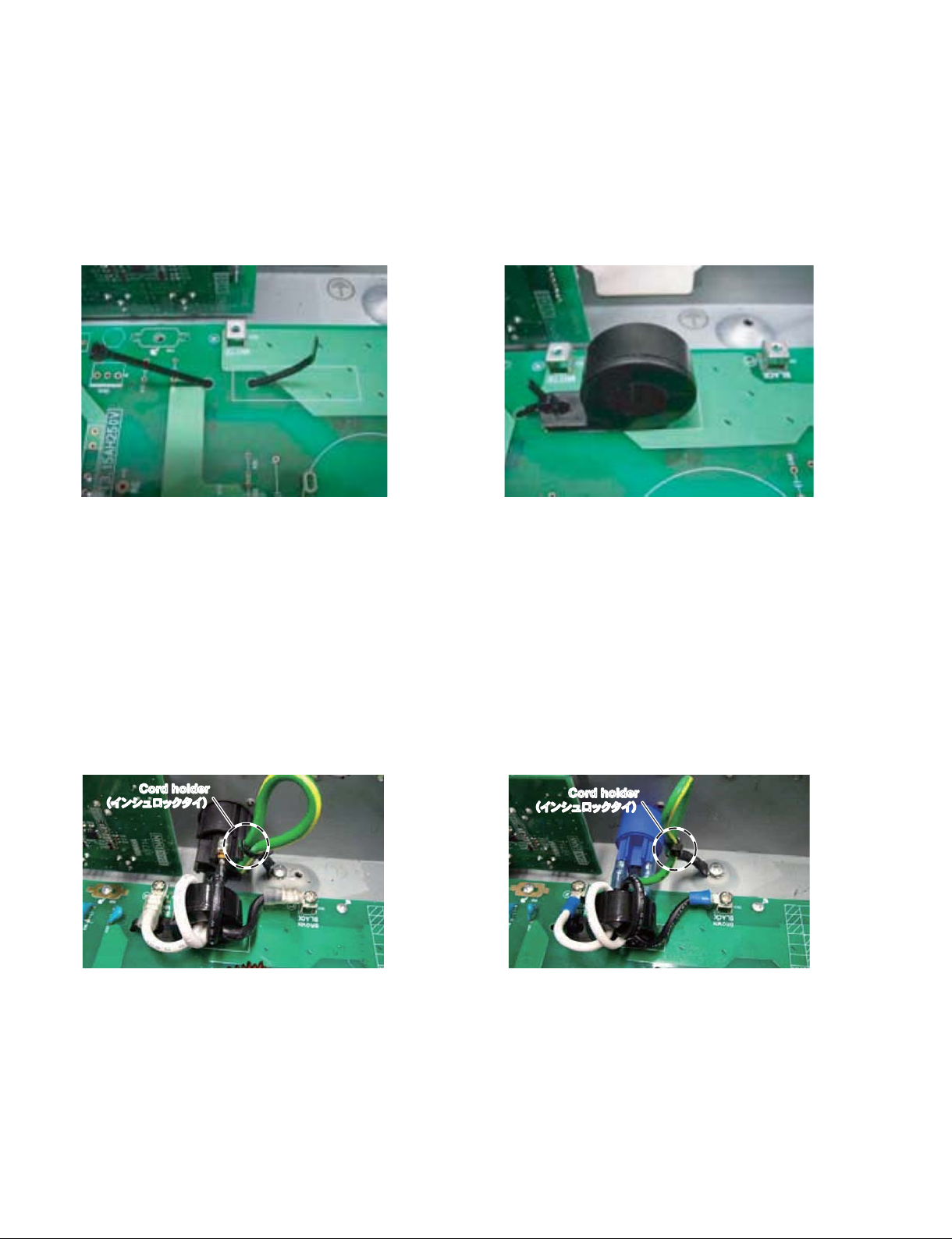

3. Wiring of the FAN

Connect the wire of the FAN to each connector. (Fig. 8)

4. Attaching of the support cushion

Attach the support cushion (WN15950) at the specified

area on the pattern side of the CONTROL circuit board.

(Fig. 9)

Note: Be sure to remove the oil and the dust, etc. on

the attaching surface before attaching the support

cushion.

Fig. 8

3. ファンの配線

ファンの線材を各コネクターへ接続します。(図8)

(図 8)

4. サポートクッションの取り付け

CONTROL シートパターン面の所定の位置にサポート

クッション(WN15950)を取り付けます。(図 9)

注意: サポートクッションを取り付ける前に、取り付

け面の油、埃などはきれいに取り除いてくださ

い。

Fig. 9

(図 9)

9

Page 10

NXAMP4x4

5. Wiring of the AC-INLET

a) Set a cord holder before installing the PSANHB circuit

board to the enclosure. (Fig. 10)

b) Set a ferrite-core at the specified area on the PSANHB

circuit board, and fasten the ferrite-core with a cord

holder. (Fig. 11)

Fig. 10

(図 10)

c) Pass the live and neutral wires of the AC-INLET through

the ferrite core’s hole twice and wind them to the ferrite

core.

Screw each screw terminal to the specified terminal.

(Fig. 12, 13)

Fasten the GND wire with a cord holder. (Fig. 12, 13)

Screwing torque: GND LINE 1.8N • m /

L, N LINE 0.78 • m

5. AC インレットの配線

a) PSANHB シートを取り付ける前に、インシュロックタ

イをセットします。(図 10)

b) PSANHB シートの所定の位置にフェライトコアをセッ

トし、インシュロックタイで固定します。(図 11)

Fig. 11

(図 11)

c) AC インレットの L、N の線をフェライトコアの穴に 2

回通して、フェライトコアに巻きつけます。

各端子を図のように固定します。(図 12、13)

GND 線をインシュロックタイで図のように固定しま

す。(図 12、13)

ネジ締め付けトルク: GNDLINE1.8 N・m /

L、NLINE0.78・m

10

U/J destination

Cord holder

(イン シュロックタイ)

Fig. 12

(U / J 仕向)

(図 12)

CHN destination

Cord holder

(イン シュロックタイ)

Fig. 13

(CHN 仕向)

(図 13)

Page 11

NXAMP4x4

d, e) Fix the wires to the terminal with the screws, and refer to

the fig. 14 and fig. 15 for the direction of each terminal.

Screw the GND wire’s screw terminal of the upper ACINLET as shown in the figure, and don’t fasten it with a

cord holder. (Fig. 14, 15)

Fig. 14

(図 14)

d

、

e)端子をネジで固定します。このとき端子の向きは図に

従ってください。

上側の AC インレットの GND 線を図のようにネジで固

定します。ただし、このときインシュロックタイで固

定しないでください。(図 14、15)

Fig. 15

(図 15)

11

Page 12

NXAMP4x4

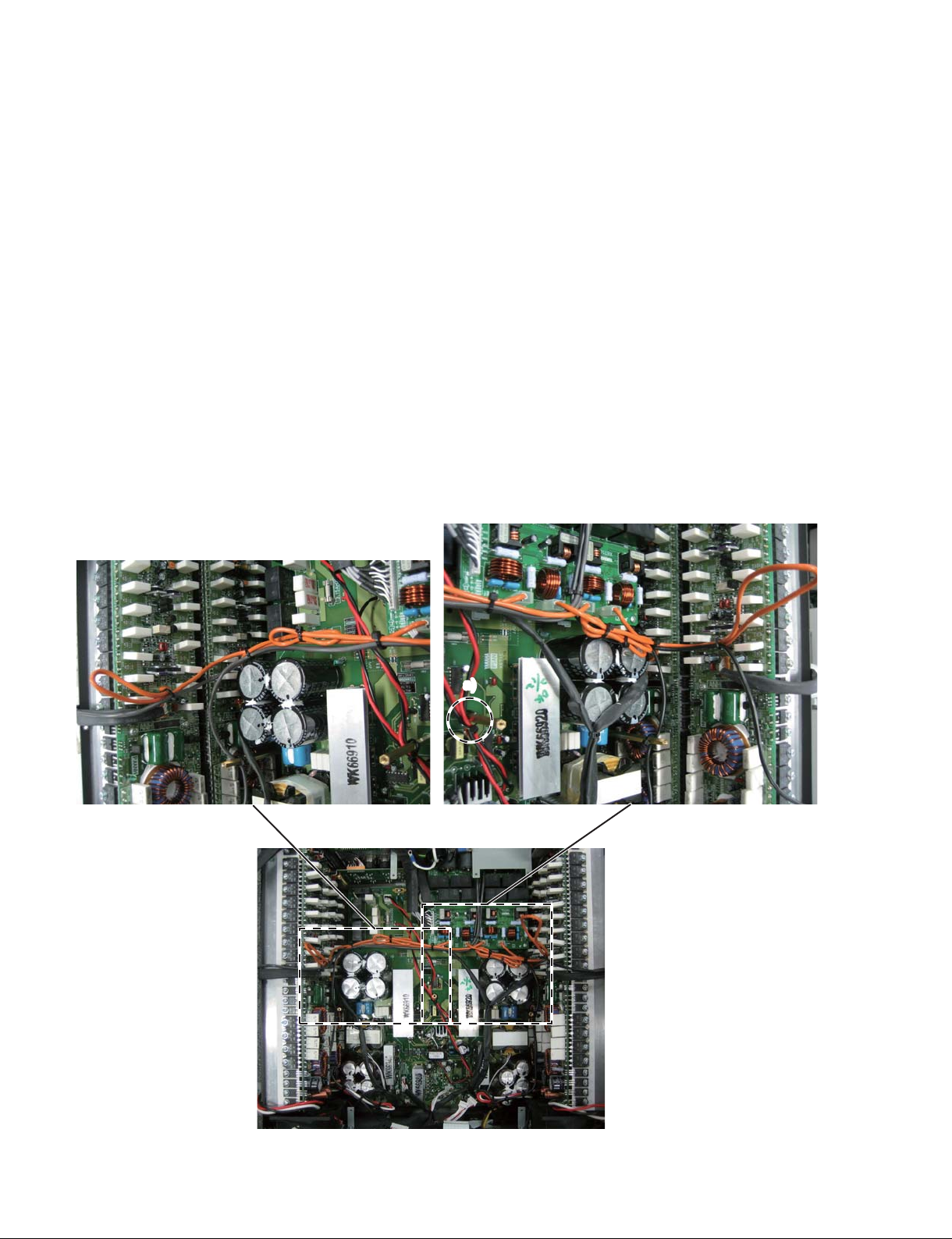

6. Wiring of the PA unit

Connect the wire to the CN401. (Fig. 18, 19, 20 and 21)

CN401

RED (赤)

NOTE: The wire to be connected is WK02080.

Install this PA unit on the upper left side of

enclosure.

Hereafter, this unit is called PA unit of CH1.

Fig. 18

6. PA ユニットの配線

下図のように CN401 へ線材を接続します。(図 18、

19、20、21)

(図 18)

注意: 線材(WK02080)を接続します。

この PA ユニットを筐体の上左側へ取り付け

ます。

これ以後、このユニットを CH1 の PA ユニッ

トと呼びます。

CN401

BLUE (青)

NOTE: The wire to be connected is WK17090.

Install this PA unit on the upper right side of

enclosure.

Hereafter, this unit is called PA unit of CH2.

Fig. 19

(図 19)

注意: 線材(WK17090)を接続します。

この PA ユニットを筐体の上右側へ取り付け

ます。

これ以後、このユニットを CH2 の PA ユニッ

トと呼びます。

12

Page 13

CN401

YELLOW (黄)

Fig. 20

NXAMP4x4

(図 20)

NOTE: The wire to be connected is WK17100.

Install this PA unit on the lower left side of

enclosure.

Hereafter, this unit is called PA unit of CH3.

CN401

GREEN (緑)

NOTE: The wire to be connected is WK17110.

Install this PA unit on the lower right side of

enclosure.

Hereafter, this unit is called PA-UNIT of CH4.

Fig. 21

注意: 線材(WK17100)を接続します。

この PA ユニットを筐体の下左側へ取り付け

ます。

これ以後、このユニットを CH3 の PA ユニッ

トと呼びます。

(図 21)

注意: 線材(WK17110)を接続します。

この PA ユニットを筐体の下右側へ取り付け

ます。

これ以後、このユニットを CH4 の PA ユニッ

トと呼びます。

* The following figure describes a layout drawing of

the PA units seen from the front panel. (Fig. 22)

CH1

RED

(赤)

CH3

YELLOW

(黄)

Fig. 22

PSANHA

PSANHB

(図 22)

※ 次の図は、フロントパネル側から見た PA ユニッ

トのレイアウト図です。(図 22)

CH2

BLUE

(青)

CH4

GREEN

(緑)

13

Page 14

NXAMP4x4

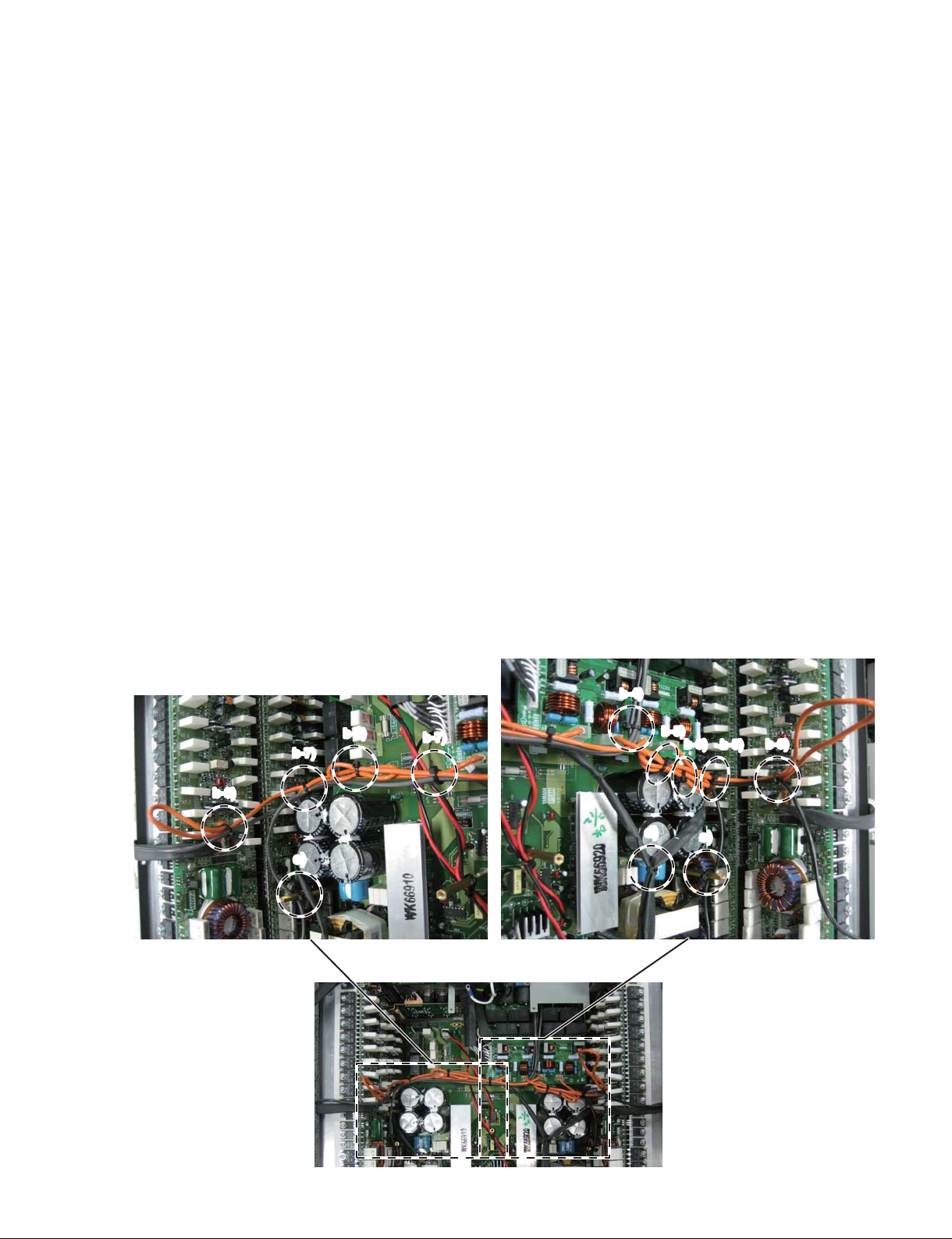

7. Wiring and fastening

Connect the following wires at first.

CN313: WK68740

CN203: WK66350

a) Fasten these wires (WK17900, WK17910 and WK94690)

with a cord holder to the hexagonal spacer. (Fig. 23)

Note: Do not fasten the wires (brown and yellow) of

WK94690 because they must be connected to

the PSANHA (upper PSANHA) circuit board

later.

b) Connect the wire (WN52520) of each PA unit (CH1–CH4)

to CH1–CH4 connectors of the OUTANH circuit board

referring the component location printed on the board.

(Fig. 23)

Way of fastening wire

b-1) Fold the wires of the lower PA unit at the center of

them.

b-2) Pull the wires of the upper PA unit toward the PA

unit. (Do not fold these wires.)

7. 配線と固定

初めに下記の線材を接続します。

CN313:WK68740

CN203:WK66350

a) 線材(WK17900、WK17910、WK94690)をインシュ

ロックタイで六角スペーサーへ固定します。(図 23)

注意: 束線(WK94690)の線材(茶色、黄色)は、

後で上側にある PSANHA シートへ接続するの

で、ここでは固定しません。

b) 各 PA ユ ニ ッ ト(CH1 〜 CH4)の線材(WN52520)

を、OUTANH シートに印刷された表示にしたがって

OUTANH シートのファストン端子へ接続します。

(図 23)

線材の固定方法

b-1)下側の PA ユニットの線材を図のように中央で折

りたたみます。

b-2)上側の PA ユニットの線材を PA ユニット側に引っ

張ります。

(この線材は折りたたまないでください。)

a)

14

Fig. 23

(図 23)

Page 15

NXAMP4x4

b-3) Then

fasten these wires with a cord holder as

shown in the figure.

b-4) Fasten these wires (WM04880 x 2, WK16820 x 2)

with a cord holder.

b-5) Fasten these wires (WN52520 x 2, WK16820 x 2)

with a cord holder (2 places).

b-6) Fasten these wires (WN52520, WK16820) with a

cord holder (1 place).

* Bend wire (WN52520) once.

b-7) Fasten these wires (WN52520 x 2, WM04880 x 2)

with a cord holder (2 places).

b-8) Fasten these wires (WN52520, WM04880) by wire

harness Tie (1 place).

* Bend wire (WN52520) once.

c) Connect the wire (WM04880) to connector (CN306) of

the PSANHA circuit board. Connect the wire (WK16820)

to the connector (CN317) of the PSANHB circuit board.

Fasten these wires (WM04880, WK16820) with a cord

holder to the hexagonal spacer as shown in the figure.

(Pass the wires to the PA unit side of a hexagonal

spacer)

d) Connect the wire (WK14210) of the PA unit (CH4) to the

connector (CN315) of the PSANHB circuit board. (Draw

the Black tube to the PA unit side.)

Pull the wire (WK14210) from PA unit to the direction of

T301 and fasten these wires (WK14200, WK14210) with

a cord holder. Before fastening, pull the wire (WK14200)

toward the front panel side in advance.

b-3)その後、これらの線材を図のようにインシュロッ

クタイで固定します。

b-4)線材(WM04880x2、WK16820x2)をインシュ

ロックタイで固定します。

b-5)線材(WN52520x2、WK16820x2)をインシュ

ロックタイで固定します。(2 箇所)

b-6)線材(WN52520、WK16820)をインシュロック

タイで固定します。(1 箇所)

※ WN52520 は一度折り返します。

b-7)線材(WN52520x2、WM04880x2)をインシュ

ロックタイで固定します。(2 箇所)

b-8)線材(WN52520、WM04880)をインシュロック

タイで固定します。(1 箇所)

※ WN52520 は一度折り返します。

c) 線材(WM04880)を PSANHA シートのコネクター

(CN306)へ、線材(WK16820)を PSANHB シート

のコネクター(CN317)へ接続します。

線材(WM04880、WK16820)を図のようにインシュロッ

クタイで六角スペーサーへ固定します。

(線材を六角スペーサーの PA ユニット側を通します)

d) PA ユニット(CH4)の線材(WK14210)を PSANHB シー

トの CN315 へ接続します。(スミチューブを PA ユニッ

ト側に寄せます。)

線材(WK14210)を PA ユニットから T301 の方向に

引っ張り、線材(WK14200、WK14210)をインシュロッ

クタイで固定します。このとき線材(WK14200)をフ

ロント側へ引っ張っておきます。

b-8)

b-7)

c)

b-3)

b-7)

b-4)

d)

b-5)

b-3)

c)

b-5)

b-6)

Fig. 24

(図 24)

15

Page 16

NXAMP4x4

e) Connect the wire (WK14210) of the PA unit (CH3) to the

connector (CN312) of the PSANHB circuit board. (Draw

the black tube to the PA unit side.)

Fasten the wire (WK14210) and the wire of the FAN with

a cord holder. (Fig. 22)

f) Twist the wires (white, red, black) of the PA unit more

than two times, and connect them to the terminals

according to the wire color displayed on the PSAN circuit

board. Fasten these wires (white, red, black) and wire

(WM04880) with a cord holder. (2 places)

Then bend the wires (white, red, black), and fasten them

with a cord holder. (Fig. 22)

g) Connect the wires (white, red, black) of PA unit to the

terminals in the same manner as step f).

Fasten these wires (white, red, black) and wire

(WK16820) with a cord holder (2 places). And then,

bend these wires (white, red, black) and fasten them

with a cord holder.

Fasten the wires (WK14210, WK14200) and the wire of

FAN with a cord holder.

h)

h-1) Fasten the wires (WK68740, WK14200, WK66350)

with a cord holder.

e) PA ユニット(CH3)の線材(WK14210)を PSANHB シー

トの CN312 へ接続します。(スミチューブを PA ユニッ

ト側に寄せます。)

線材(WK14210)と FAN の線材を図のようにインシュ

ロックタイで固定します。

f) PA ユニットの線材(白、赤、黒)を 2 回以上捻った後、

PSAN シートに表示された線材の色にしたがって各線

材をファストン端子へ接続します。そのとき、それら

の線材(白、赤、黒)と線材(WM04880)をインシュ

ロックタイで固定します。(2 箇所)

またそれら(白、赤、黒)の線材を折り曲げた後インシュ

ロックタイで固定します。

g) f)と同じ方法で、PA ユニットの線材(白、赤、黒)を

端子へ接続します。

それら(白、赤、黒)の線材を、線材(WK16820)と

一緒にインシュロックタイで固定します。(2 箇所)

またそれら(白、赤、黒)の線材を折り曲げた後、インシュ

ロックタイで固定します。

線材(WK14210、WK14200)と FAN の線材をまとめ

てインシュロックタイで固定します。

h)

h-1)線材(WK68740、WK14200、WK66350)をイン

シュロックタイで固定します。

16

e)

g)

g)

f)

f)

f)

h-1)

Fig. 25

(図 25)

g)

g)

Page 17

NXAMP4x4

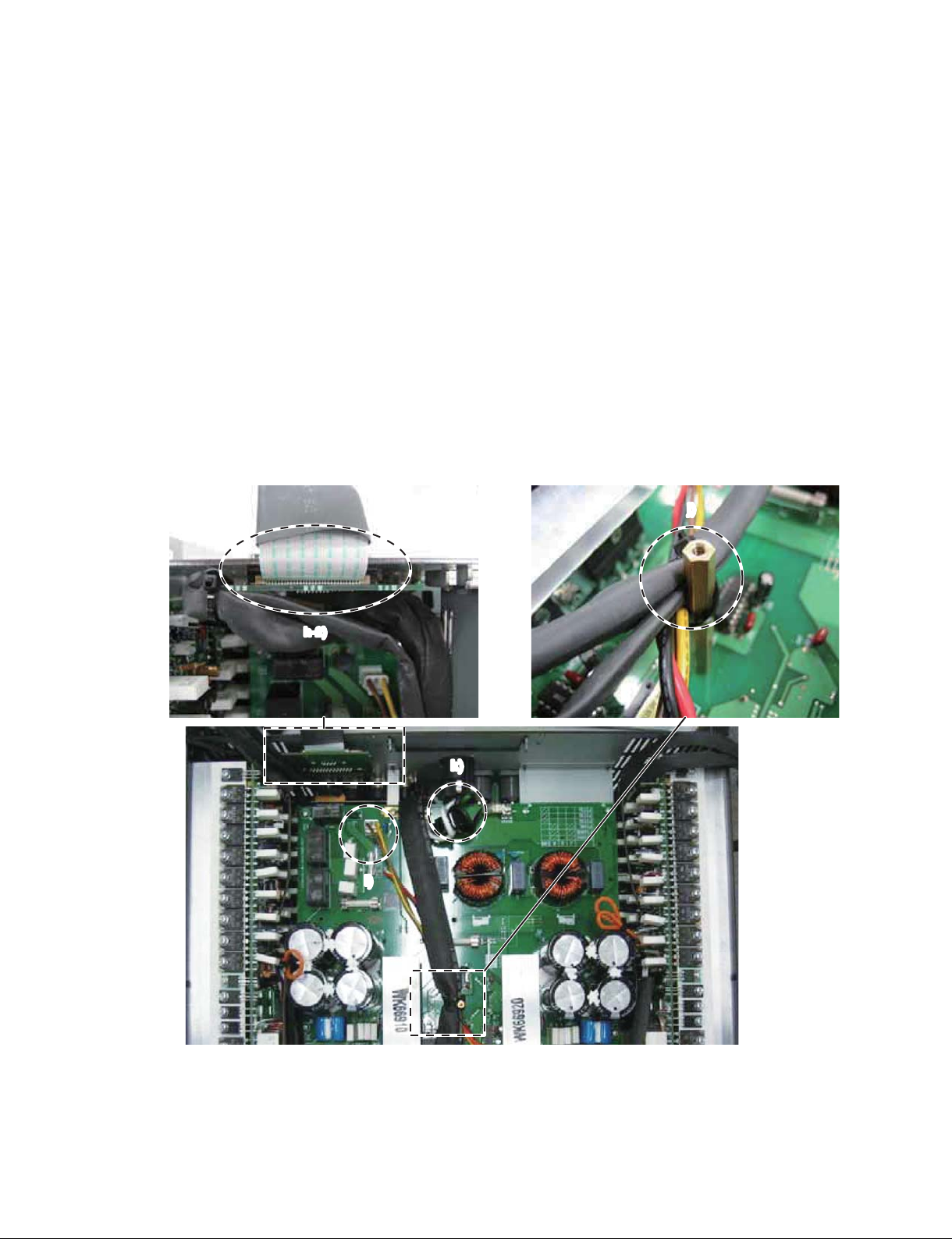

At the stage as shown in Fig. 26, connect the

following wires.

CN313: WK68760

CN201: WK68770

CN202: WK14200 from OUTANH board

CN203: WK66350 from PSANHB board

h-2) After connecting the wire (WM15830) to it, install

the RS232-GPI circuit board to the enclosure.

i) Twist the wires (yellow, brown) of the power switch

assembly more than three times, and connect it to the

connector (CN103) of the PSANHA circuit board.

j) Fasten these wires (WK17900, WK17910, WK94690 and

WK02090) with a cord holder to the hexagonal spacer.

k) Connect the wire of the AC-INLET according to the step

“5. Wiring of the AC-INLET”.

Note: Do not fasten the GND wire with a cord holder.

図 26 の段階で下記の線材を接続しておきます。

CN313:WK68760

CN201:WK68770

CN202:WK14200OUTANHシートから

CN203:WK66350PSANHBシートから

h-2)RS232-GPI シートに線材(WM15830)を接続し

た後、RS232-GPI シートを筐体へ取り付けます。

i) 電源 SW の線材(黄色、茶色)を 3 回以上捻った後、

PSANHA シートのコネクター(CN103)へ接続します。

j) 線材(WK17900、WK17910、WK94690、WK02090)

をインシュロックタイで六角スペーサーへ固定します。

k) 「5. AC インレットの配線」にしたがって AC インレッ

トの線材を接続します。

注意: GND 線材はインシュロックタイで固定しない

でください。

j)

h-2)

k)

i)

Fig. 26

(図 26)

17

Page 18

NXAMP4x4

l) Connect the wire (WK14210) of PA unit (CH1) to the

connect

(Draw a black tube to the PA unit side.)

Connect the wire (WK14210) of PA unit (CH2) to the

connector (CN315) of the PSANHA circuit board.

(Draw a black tube to the PA unit side.)

Fasten the wire (WK14210) and the wire of FAN with a

cord holder as shown in the figure. (Fig. 24)

m) Twist the wires (white, red, black) of the PA unit more

than two times, and connect them to the FASTON

terminals according to the wire color displayed on the

PSANHA circuit board.

m-1, 2) Fasten these wires (white, red, black) together

m-3) Bend these wires (white, red, black) and fasten

n) Fasten the wire (WN52520) with a cord holder.

(Fig. 25, 26)

Note: When connecting the connector assembly to

or (CN312) of the PSANHA circuit board.

with wires (WM04880, WK16820) with a cord

holder as shown in the figure.

them with a cord holder as shown in the figure.

the CONTROL circuit board、 confirm that the

connector housing pin number of the connector

assembly is the same as the connector pin

number of the circuit board.

l) PA ユニット(CH1)の線材(WK14210)を PSANHA シー

トのコネクター(CN312)へ接続します。(スミチュー

ブを PA-UNIT 側に寄せます。)

PA ユニット(CH2)の線材(WK14210)を PSANHA シー

トのコネクター(CN315)へ接続します。(スミチュー

ブを PA-UNIT 側に寄せます。)

線材(WK14210)と FAN の線材をインシュロックタ

イで図のように固定します。

m) PA ユニットの線材(白、赤、黒)を 2 回以上捻った

後、PSANHA シートに表示された線材の色にしたがっ

てファストン端子に接続します。

m-1、2)これらの線材(白、赤、黒)を線材(WM04880)、

(WK16820)と一緒にインシュロックタイで

固定します。

m-3) それら(白、赤、黒)の線材を折り曲げた後、

インシュロックタイで固定します。

n) 線材(WN52520)を図のようにインシュロックタイで

固定します。

注意: CONTROL シートに束線を接続するとき、

線材側のコネクターハウジングのピン数が

CONTROL シート側のコネクターのピン数と

同じであることを確認してください。

m-1)

l)

m-2)

m-3)

m-3)

n)

l)

m-1)

m-2)

18

Fig. 27

(図 27)

Page 19

NXAMP4x4

o) Fasten the wires (WK02080, WK17100) with a cord

holder to the hole of the RS232-GPI circuit board.

(Fig. 28)

p) 1) Fasten the wires (WK02080, WK17100 and

WK02070) with a cord holder to the hole of the

enclosure. (Fig. 28 *1, 29)

2) Fasten the wires (WK17090, WK17110) with a cord

holder to the hole of the enclosure. (Fig. 28 *2, 29)

o)

p)

p)

*1

*1

o) 線材(WK02080、WK17100)をインシュロックタイ

で RS232-GPI シートの穴へ固定します。(図 28)

p)1) 線材(WK02080、WK17100、WK02070)をイン

シュロックタイで筐体の穴へ固定します。

(図 28*1、29)

2) 線材(WK17090、WK17110)をインシュロック

タイで筐体の穴へ固定します。(図 28*2、29)

*2

p)

*2

p)

Fig. 28

(図 28)

The hole of the enclosure

(筐体の穴)

Fig. 29

(図 29)

19

Page 20

NXAMP4x4

q) Fasten the wires (WK17090 and WK17110) with a cord

holder at the hole of the OPT-AN board. Then connect

the flat cable (WK02120). (Fig. 30)

r) Fasten the wires (WK02080, WK17090, WK17100,

WK17110 and WK02070) with a cord holder at the close

area to the OPT-AN circuit board. (Fig. 30)

s) Fasten the wires (WK68740, WK68760 and WK68770)

with a cord holder. (Fig. 30)

t) Bend the flat cable as shown in the figure. (Fig. 30)

u) Bend the flat cable to prevent it from touching the top

cover. (Fig. 31, 32)

t)

q) 線材(WK17090、WK17110)をインシュロックタイ

で OPT-AN シートの穴へ固定します。その後、フラッ

トケーブル(WK02120)を接続します。(図 30)

r) OPT-AN シートの横で線材(WK02080、WK17090、

WK17100、WK17110、WK02070)をインシュロック

タイで固定します。(図 30)

s) 線材(WK68740、WK68760、WK68770)を図のよう

にインシュロックタイで固定します。(図 30)

t) フラットケーブルを図のように折り曲げます。(図 30)

u) トップカバーとの接触を避けるためにフラットケーブ

ルを折り曲げます。(図 31、32)

u)

Fig. 31

(図 31)

s)

Fig. 30

r)

(図 30)

q)

q)

Fig. 32

q)

(図 32)

20

Page 21

NXAMP4x4

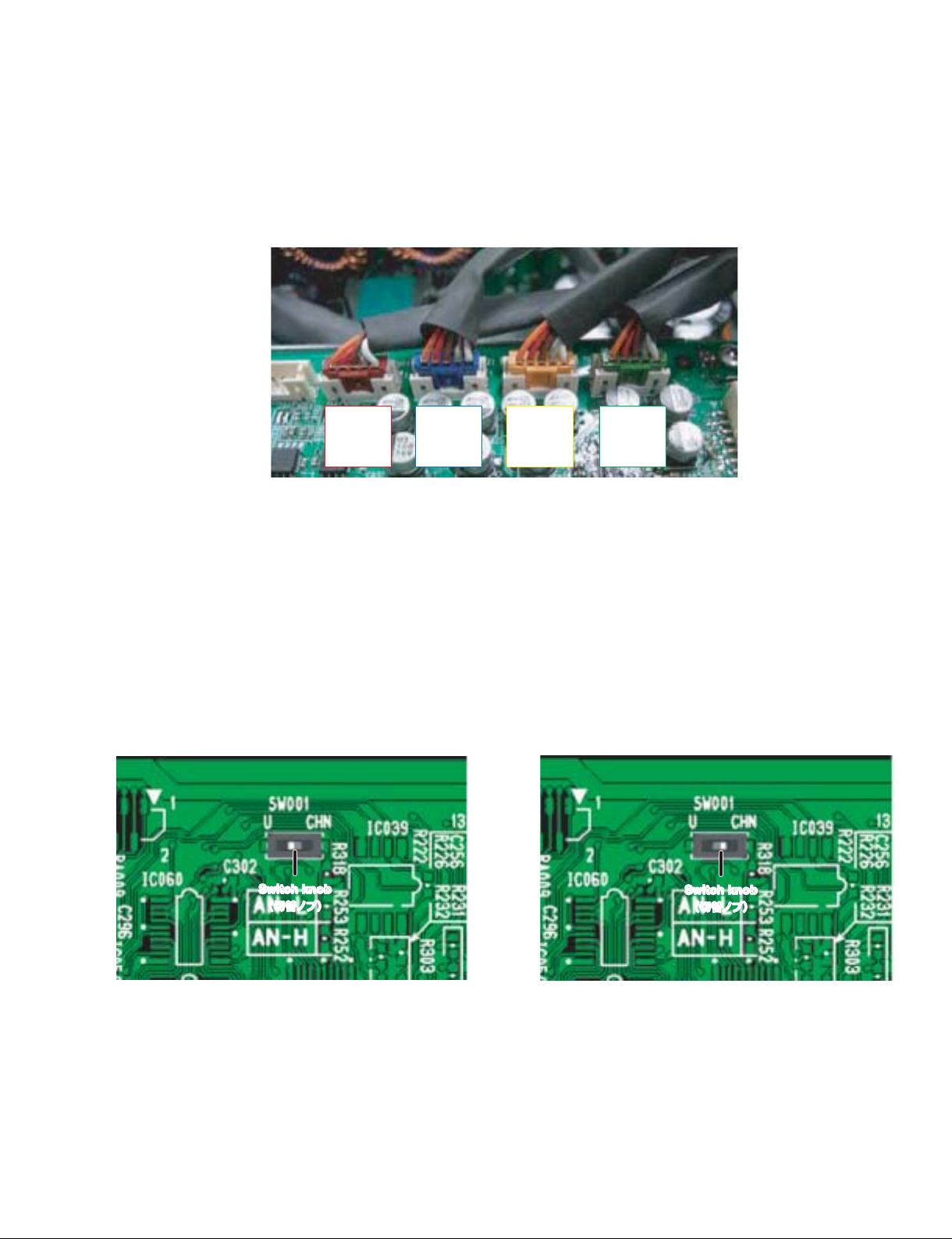

8. Color of the connectors connected to the connector CN012–CN015

Connect the connector assembly from the PA unit to the

CONTROL circuit board as shown in the figure below.

(Fig. 33)

CN012

RED

(赤)

CN013

BLUE

(青)

Fig. 33

8. CN012 − CN015 へ接続するコネクターの色

PAユニットからの束線を下図のようにCONTROLシー

トへ接続します。(図 33)

CN014

YELLOW

(黄)

(図 33)

CN015

GREEN

(緑)

9. Change of the destination

Set the knob position of the switch SW001 on the

CONTROL circuit board as shown in the figure below.

(Fig. 34, 35)

U/J destination

Fig. 34

(U / J 仕向)

Switch knob

(切替ノブ)

(図 34)

9. 仕向け先の切り替え

CONTROL シートのスイッチ(SW001)を下図のよう

に切り替えます。(図 34、35)

CHN destination

Fig. 35

(CHN 仕向)

Switch knob

(切替ノブ)

(図 35)

21

Page 22

NXAMP4x4

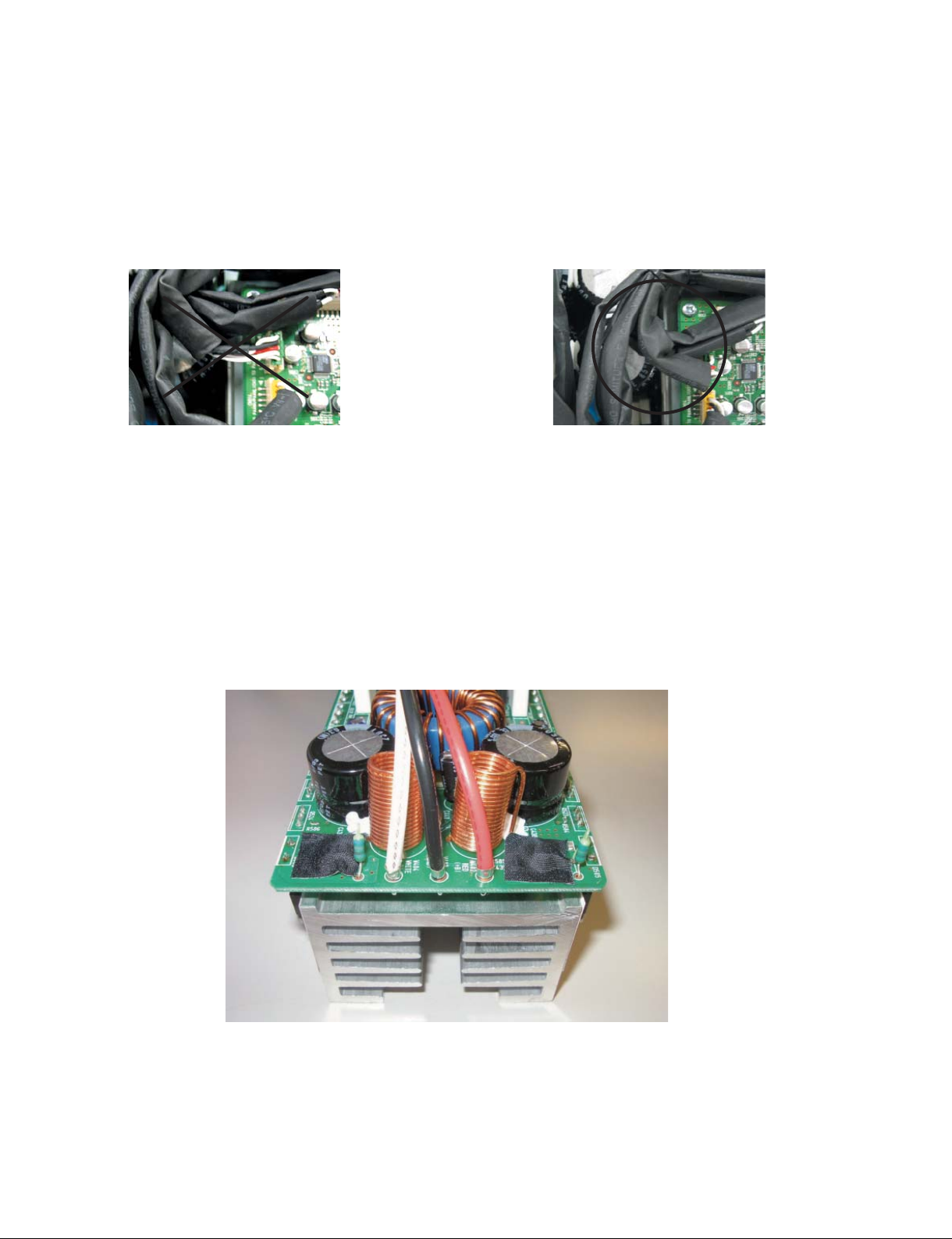

10. Insulation distance between wire (WK17110) and primary side capacitor

Perform wiring of the connector assembly (WK17110)

with care so that its uncovered portion with the SUMI

tube does not touch the capacitor (C316) on primary

side of the PSANHA circuit board. (Fig. 36, 37)

Fig. 36

(図 36)

11. Adhesive cloth tape

Cover the two screws near R587 and R588 in each PA

unit [190, 220, 250 and 280] with adhesive cloth tape

[185, 215, 245 and 275] as shown in the figure below.

(Fig. 38)

10.束線 WK17110 と 1 次側ケミコンの絶縁距離

束線(WK17110)を配線するとき、スミチューブに覆

われていない部分が PSANHA シートの 1 次側にあるコ

ンデンサ(C316)に接触しないように注意してくださ

い。(図 36、37)

Fig. 37

(図 37)

11.アセテートクロス粘着テープ

各 PA ユ ニ ッ ト[190、220、250、280] の R587、

R588 の直近にある 2 つのネジを下図のようにアセテー

トクロステープ[185、215、245、275]で覆います。

(図 38)

22

Fig. 38

(図 38)

Page 23

NXAMP4x4

12. Confirmation of Switch LED lighting

With the front panel 2 uninstalled, confirm that the LEDs

of switches (SW003–SW006) light. (Fig. 39)

Procedure

1. Press the power switch of this unit to turn on the

power.

2. Press the switches (SW003–SW006) on the PN-AN

circuit board, and confirm that both LEDs of each

switch light.

SW003 SW004 SW005 SW006

OK NG

12.スイッチ LED 点灯確認

フロントパネル2を取り外した状態で、スイッチ

(SW003 〜 SW006)の LED が点灯することを確認し

ます。(図 39)

手順

1. 本機の電源スイッチを ON にします。

2. PN-AN シートのスイッチ(SW003 〜 SW006)

を押し、各スイッチの両方の LED が点灯すること

を確認します。

Lighting of both

(両方とも点灯)

Left is turned off

(左が消灯)

Fig. 39

Right is turned off

(右が消灯)

(図 39)

Turning off of both

(両方とも消灯)

23

Page 24

NXAMP4x4

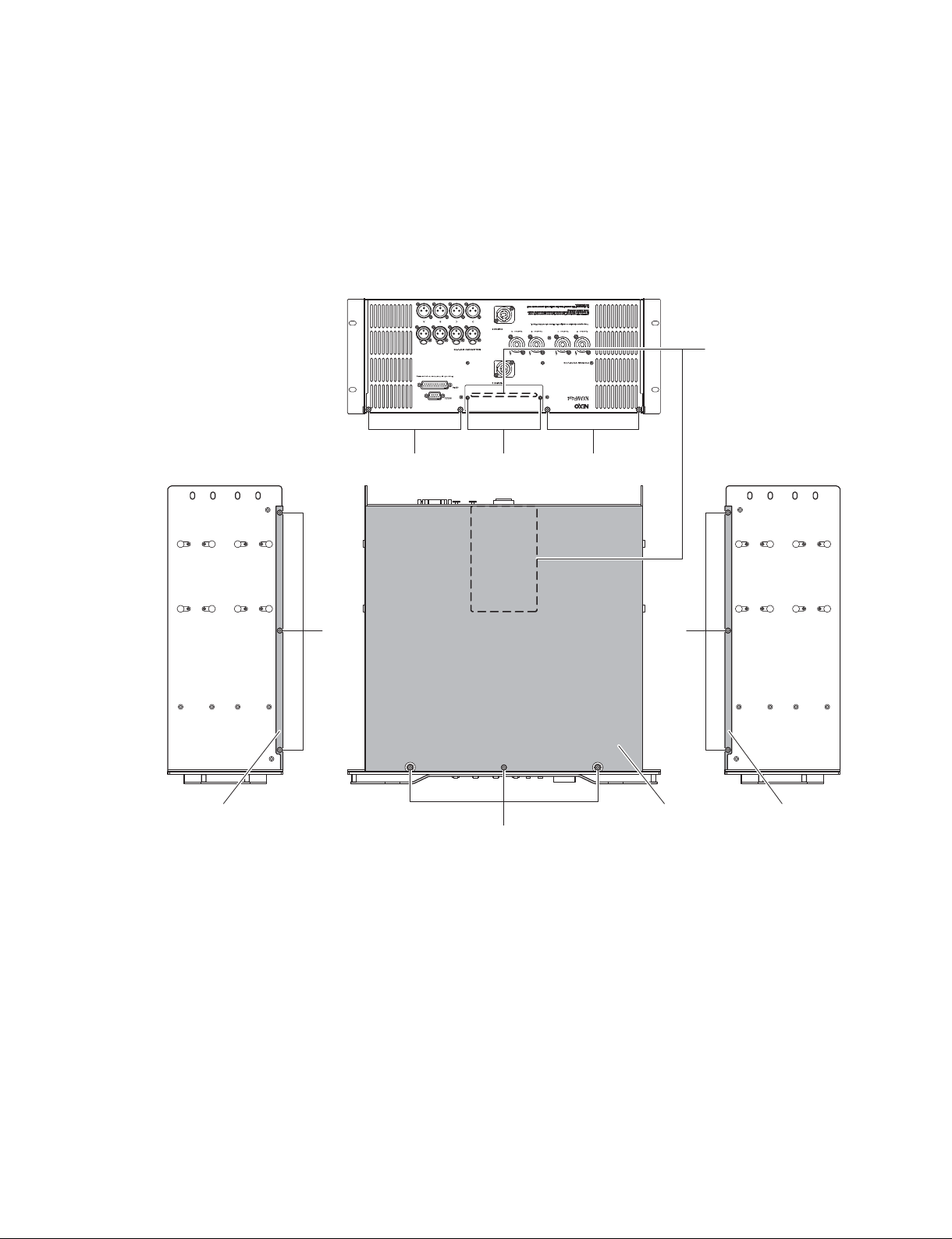

13. Method of Fixing PN FFC Assembly

Fix the PN FFC assembly with the adhesive tape [635]

as shown in the figure (2 places). (Fig. 40)

43 mm

Adhesive tape [635]

(粘着テープ[635])

Attach the ferrite support 1 [636] to the position as

shown in the figure below left. (Fig. 41)

(The figure below right shows the attached state.)

Fig. 40

13.PNFFCAss'y の固定方法

PNFFCAss'y を図のように粘着テープ[635]で固定

します(2 箇所)。(図 40)

Match the edge of FFC as shown in the figure.

(FFC の端を図のように合わせる。)

(図 40)

下左図に示す位置にフェライトサポート 1[636]を貼

り付けます。(図 41)

(下右図は貼り付けた状態を示します。)

24

It is based on this position.

(この位置を基準とする。)

Fig. 41

Ferrite support [636]

(フェライトサポート[636])

(図 41)

Page 25

NXAMP4x4

DISASSEMBLY PROCEDURES

■

(分解手順)

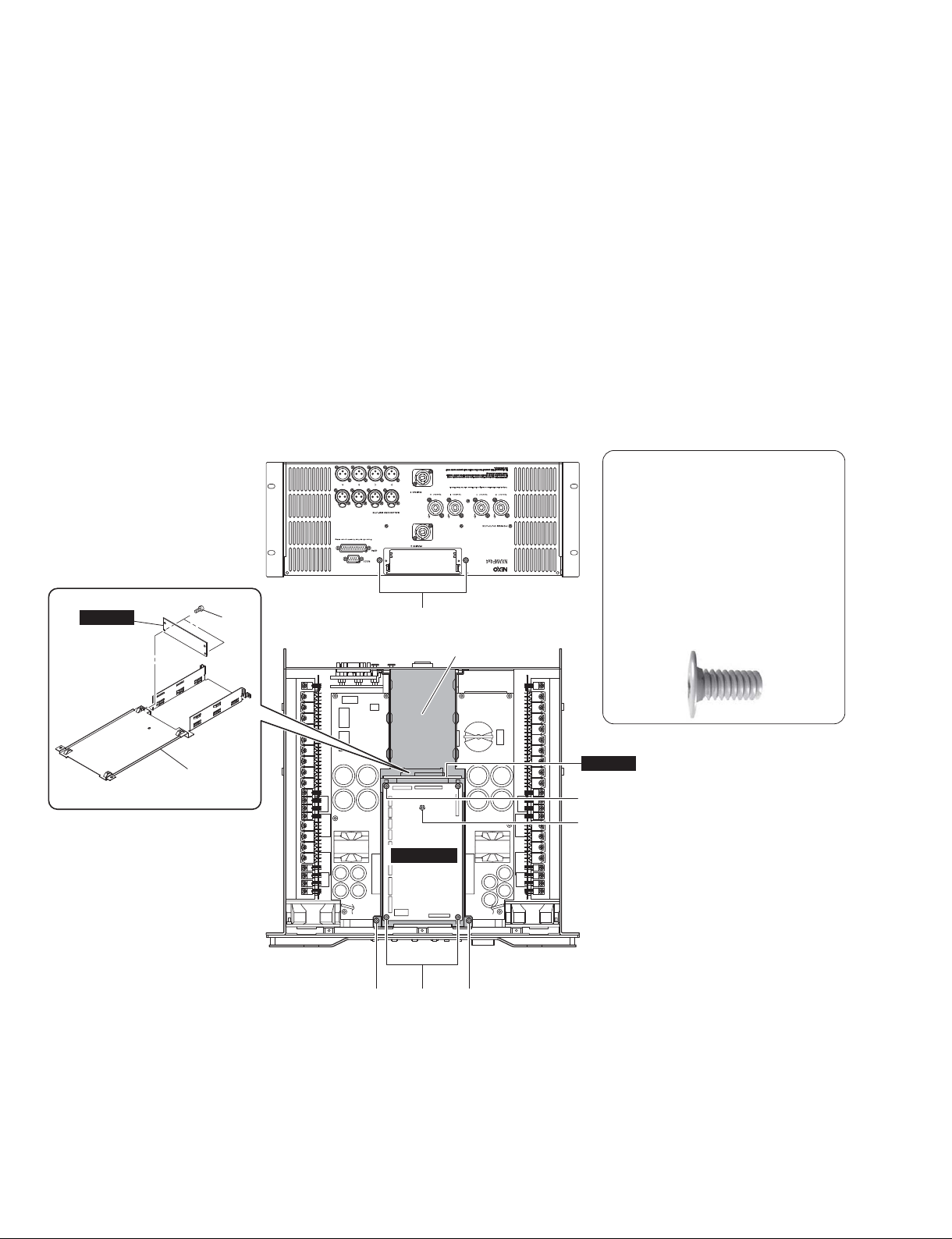

1. Top Cover and NX-DFLT Card (Time required: about 3 minutes)

1-1. Remove the thirteen (13) screws marked [800]. The

top cover can then be removed. (Fig.1)

1-2. Remove the two (2) screws marked [770]. The NX-

DFLT card can then be removed. (Fig. 1)

[800] [800][770]

1. トップカバー、NX-DFLT カード

(所要時間:約 3 分)

1-1. [800]のネジ 13 本を外し、トップカバーを外します。

(図 1)

1-2. [770]のネジ 2 本を外し、NX-DFLT カードを外しま

す。(図 1)

NX-DFLT card

(NX-DFLT カード)

Top cover

(トップカバ ー )

[800] [800]

[800]

[770]: BIND HEAD TAPPING SCREW-S 3x6 MFZN2B3 (--)

[800]: BIND HEAD TAPPING SCREW-B 4x8 MFZN2B3 (--)

Fig. 1

(図 1)

Top cover

(トップカバ ー )

S タイト+ BIND

B タイト+ BIND

Top cover

(トップカバ ー )

25

Page 26

NXAMP4x4

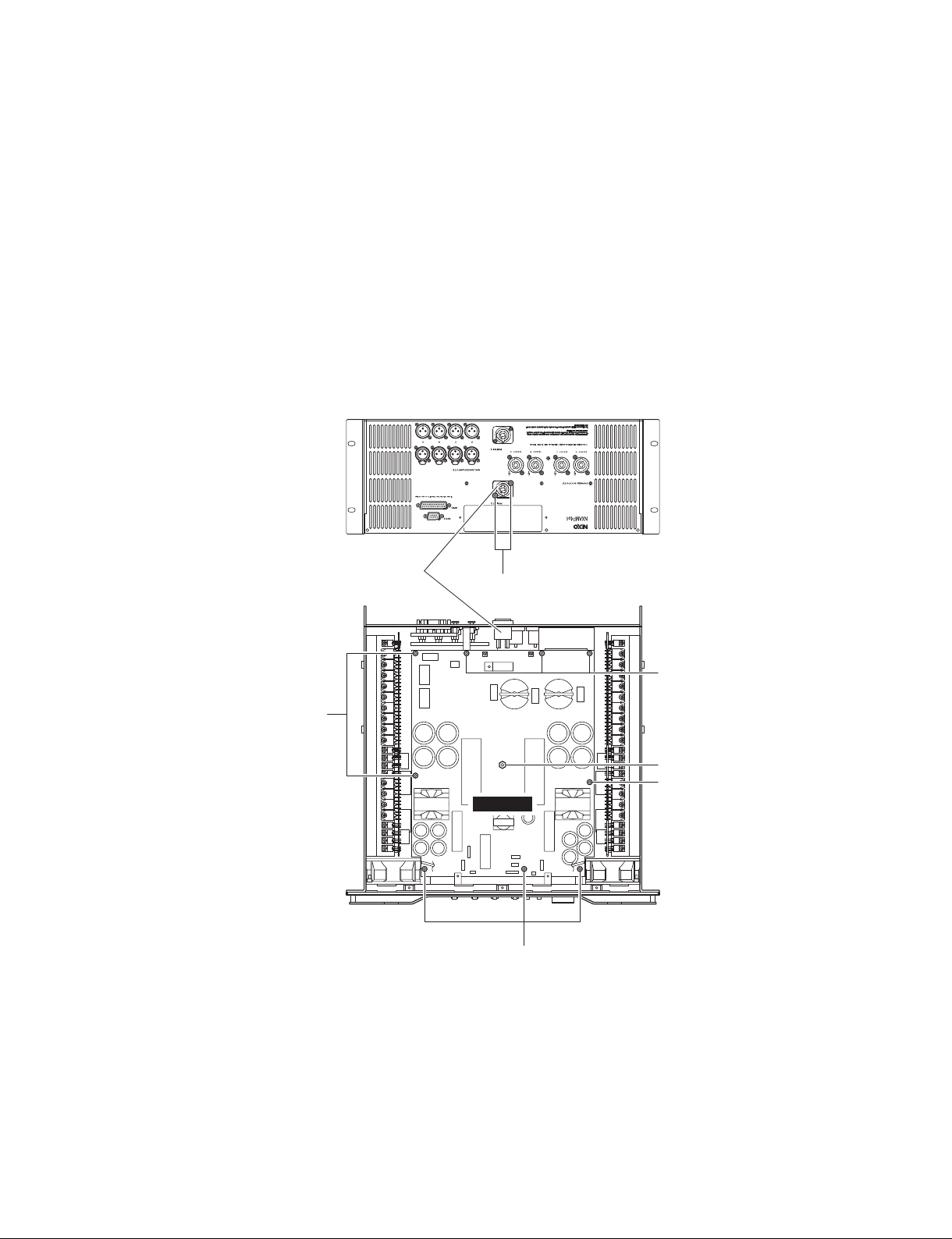

2. CONTROL Circuit Board, OPT angle and OPTAN Circuit Board

(Time required: about 10 minutes)

2-1. Remove the top cover and the NX-DFLT card.

(See procedure 1.)

2-2. Disconnect the connector assemblies from the

CONTROL circuit board. (Fig. 2)

2-3. Re move the fo ur (4) sc rews ma rked [580]. The

CONTROL circuit board can then be removed. (Fig. 2)

2-4. Remove the two (2) screws marked [550], one (1)

screw marked [555] and the two (2) screws marked

[560]. The OPT angle can then be removed together

with the OPT-AN circuit board. (Fig. 2)

2-5. Remove the two (2) screws marked [530]. The OPT-

AN circuit board and the OPT angle can then be

separated. (Fig. 2)

OPT-AN

[530]

[560]

2. CONTROL シート、OPT アングル、OPT-AN シー

ト(所要時間:約 10 分)

2-1. トップカバー、NX-DFLT カードを外します。

(1 項参照)

2-2. CONTROL シートから束線を外します。(図 2)

2-3. [580]のネジ 4 本を外し、CONTROL シートを外し

ます。(図 2)

2-4. [550]のネジ 2 本、[555]のネジ 1 本、[560]のネ

ジ 2 本を外し、OPT アングルを OPT-AN シートと共

に外します。(図 2)

2-5. [530]のネジ 2 本を外し、OPT-AN シートと OPT

アングルを別けます。(図 2)

CAUTION

The figure below shows the screw

marked [555] head shape.

To avoid the unit malfunction, make sure

the screw marked [555] head shape is

same as shown below before

assembling the OPT angle.

[555]のネジ頭形状を下図に示します。

動作不良防止のため、OPT アングルを取り

OPT angle

(OPT アングル)

付ける前に、[555]のネジ頭形状が下図のと

おりであることを確認してください。

26

OPT angle

(OPT アングル)

CONTROL

[580][550] [550]

[530]: BIND HEAD TAPPING SCREW-S 3x6 MFZN2W3 (--)

[550]: BIND HEAD TAPPING SCREW-S 3x6 MFZN2W3 (--)

[555]: BIND HEAD TAPPING SCREW-S 3x6 MFZN2B3 (--)

[560]: BIND HEAD TAPPING SCREW-S 3x6 MFZN2B3 (--)

[580]: BIND HEAD TAPPING SCREW-S 3x6 MFZN2W3 (--)

Fig. 2

(図 2)

OPT-AN

[580]

[555]

S タイト+ BIND

S タイト+ BIND

S タイト+ BIND

S タイト+ BIND

S タイト+ BIND

Page 27

NXAMP4x4

3. PSANHA Circuit Board (Time required: about 15 minutes)

3-1. Remove the top cover and the NX-DFLT card.

(See procedure 1.)

3-2. Remove the CONTROL circuit board and the OPT

angle. (See procedure 2.)

3-3. Remove the two (2) screws marked [150A], and remove

the upper ACPS connector assembly. (Fig. 3)

3-4. Disconnect the connector assemblies from the

PSANHA circuit board. (Fig. 3)

3-5. Remove the nine (9) screws marked [450] and the

one (1) hexagonal spacer marked [440]. The PSANHA

circuit board can then be removed. (Fig. 3)

Upper ACPS connector assembly

(上側の ACPS 束線)

3. PSANHA シート(所要時間:約 15 分)

3-1. トップカバー、NX-DFLT カードを外します。

(1 項参照)

3-2. CONTROL シート、OPT アングルを外します。

(2 項参照)

3-3. [150A]のネジ 2 本を外し、上側の ACPS 束線を外

します。(図 3)

3-4. PSANHA シートから束線を外します。(図 3)

3-5. [450]のネジ 9 本、[440]の六角スペーサー 1 個を

外し、PSANHA シートを外します。(図 3)

[150A]

[450]

PSANHA

[450]

[150A]: FLAT HEAD TAPPING SCREW-B 3x8 MFZN2B3 (--)

[440]: HEXAGONAL SPACER H=50 B=5.5 (--)

[450]: BIND HEAD TAPPING SCREW-S 3x6 MFZN2W3 (--)

Fig. 3

六角スペーサー

(図 3)

[450]

[440]

[450]

B タイト+ FLAT

S タイト+ BIND

27

Page 28

NXAMP4x4

4. OUTANH Circuit Board (Time required: about 20 minutes)

4-1. Remove the top cover and the NX-DFLT card.

(See procedure 1.)

4-2. Remove the CONTROL circuit board and the OPT

angle. (See procedure 2.)

4-3. Remove the PSANHA circuit board. (See procedure 3.)

4-4. Disconnect the connector assemblies from the

OUTANH circuit board. (Fig. 4)

4-5. Remove the eight (8) screws marked [320], the one

(1) screw marked [330] and the one (1) screw marked

[325]. The OUTANH circuit board can then be removed

together with the two (2) insulation sheets and the two

(2) shields. (Fig. 4)

4-6. Remove the three (3) plastic rivets marked [317]. The

OUTANH circuit board can be separated from the two

(2) insulation sheets and the two (2) shields attached

to them. (Fig. 4)

Note: The two (2) insulation sheets and the two (2)

shields can not be separated because they are

attached each other with both side adhesive

tapes.

4. OUTANH シート(所要時間:約 20 分)

4-1. トップカバー、NX-DFLT カードを外します。

(1 項参照)

4-2. CONTROL シート、OPT アングルを外します。

(2 項参照)

4-3. PSANHA シートを外します。(3 項参照)

4-4. OUTANH シートから束線を外します。(図 4)

4-5. [320]のネジ 8 本、[330]のネジ 1 本、[325]のネ

ジ 1 本を外し、OUTANH シートを絶縁シート 2 枚、

シールド 2 枚と共に外します。(図 4)

4-6. [317]のプラスチックリベット3個を外し、

OUTANH シートを絶縁シート 2 枚とこれらのシート

に貼付されたシールド 2 枚から別けます。(図 4)

注: 絶縁シート 2 枚とシールド 2 枚は、両面テー

プで互いに貼り付けられているために分離す

ることはできません。

[330]

[317]

OUTANH

Insulation sheet 2

(絶縁シート 2)

Shield 2

(シールド 2)

Shield 1

(シールド 1)

Insulation sheet 1

(絶縁シート 1)

[317]: PLASTIC RIVET NRP-345 (--)

[320]: FLAT HEAD TAPPING SCREW-B 3x8 MFZN2B3 (--)

[325]: BIND HEAD TAPPING SCREW-S 3x6 MFZN2W3 (--)

[330]: BIND HEAD TAPPING SCREW-B 3x8 MFZN2B3 (--)

[320]

OUTANH

プラスチックリベット

Fig. 4

(図 4)

[325]

B タイト+ FLAT

S タイト+ BIND

B タイト+ BIND

28

Page 29

NXAMP4x4

5. PSANHB Circuit Board (Time required: about 25 minutes)

5-1. Remove the top cover and the NX-DFLT card.

(See procedure 1.)

5-2. Remove the CONTROL circuit Board and the OPT

angle. (See procedure 2.)

5-3. Remove the PSANHA circuit Board. (See procedure 3.)

5-4. Remove the OUTANH circuit Board. (See procedure 4.)

5-5. Remove the two (2) screws marked [150B], and remove

the lower ACPS connector assembly. (Fig. 5)

5-6. Remove the two (2) screws marked [390], and remove

the PS Angle 1. (Fig. 5)

5-7. Remove the one (1) screw marked [396], and remove

the GND Angle. (Fig. 5)

5-8. Remove the two (2) screws marked [410], and remove

the two (2) pieces of PS Angle 2. (Fig. 5)

5-9. Disconnect the connector assemblies from the

PSANHB circuit board. (Fig. 5)

5-10. Remove the five (5) screws marked [100], the five

(5) hexagonal spacers marked [90] and the one (1)

hexagonal spacer marked [95]. The PSANHB circuit

board can then be removed. (Fig. 5)

[90]: HEXAGONAL SPACER H=81.4 B=5.5 (--)

[95]: HEXAGONAL SPACER H=41 B=5.5 (--)

[100]: BIND HEAD TAPPING SCREW-S 3x6 MFZN2W3 (--)

S タイト+ BIND

[150]: FLAT HEAD TAPPING SCREW-B 3x8 MFZN2B3 (--)

B タイト+ FLAT

[390]: BIND HEAD TAPPING SCREW-S 3x6 MFZN2B3 (--)

S タイト+ BIND

[396]: BIND HEAD TAPPING SCREW-S 3x6 MFZN2B3 (--)

S タイト+ BIND

[410]: BIND HEAD TAPPING SCREW-S 3x6 MFZN2W3 (--)

S タイト+ BIND

GND angle

PS angle 2

(PS アングル 2)

(GND アングル)

[410]

六角スペーサー

六角スペーサー

PS angle 1

(PS アングル 1)

[396]

[390]

5. PSANHB シート(所要時間:約 25 分)

5-1. トップカバー、NX-DFLT カードを外します。

(1 項参照)

5-2. CONTROL シート、OPT アングルを外します。

(2 項参照)

5-3. PSANHA シートを外します。(3 項参照)

5-4. OUTANH シートを外します。(4 項参照)

5-5. [150B]のネジ 2 本を外し、下側の ACPS 束線を外

します。(図 5)

5-6. [390]のネジ 2 本を外し、PS アングル 1 を外します。

(図 5)

5-7. [396]のネジ 1 本を外し、GND アングルを外します。

(図 5)

5-8. [410]のネジ 2 本を外し、2 つの PS アングル 2 を

外します。(図 5)

5-9. PSANHB シートから束線を外します。(図 5)

5-10.[100]のネジ 5 本、[90]の六角スペーサー 5 個、[95]

の六角スペーサー 1 個を外し、PSANHB シートを外

します。(図 5)

[150B]

Lower ACPS connector assembly

(下側の ACPS 束線)

[100]

[90]

Fig. 5

(図 5)

PSANHB

[90] [100][100]

[90]

[95]

[90]

29

Page 30

NXAMP4x4

6. INANH Circuit Board (Time required: about 7minutes)

6-1. Remove the top cover and the NX-DFLT card.

(See procedure 1.)

6-2. Disconnect the connector assembly from the INANH

circuit board. (Fig. 6)

6-3. Remove the sixteen (16) screws marked [70]. The

INANH circuit board can then be removed. (Fig. 6)

7. RS232-GPI Circuit Board (Time required: about 7 minutes)

7-1. Remove the top cover and the NX-DFLT card.

(See procedure 1.)

7-2. Disconnect the flat cable from the RS232-GPI circuit

board. (Fig. 6)

7-3. Remove the four (4) hexagonal lock screws marked

[370]. The RS232-GPI circuit board can then be

removed. (Fig. 6)

6. INANH シート(所要時間:約 7 分)

6-1. トップカバー、NX-DFLT カードを外します。

(1 項参照)

6-2. INANH シートから束線を外します。(図 6)

6-3. [70]のネジ 16 本を外し、INANH シートを外します。

(図 6)

7. RS232-GPI シート(所要時間:約 7 分)

7-1. トップカバー、NX-DFLT カードを外します。

(1 項参照)

7-2. RS232-GPI シートからフラットケーブルを外します。

(図 6)

7-3. [370]の六角ロックネジ 4 本を外し、RS232-GPI シー

トを外します。(図 6)

[70]

RS232-GPI

[70]: BIND HEAD TAPPING SCREW-B 2.6x8 MFZN2B3 (--)

[370]: HEXAGONAL LOCK SCREW (--)

[370]

INANH

6 角ロックネジ

B タイト+ BIND

30

Fig. 6

(図 6)

Page 31

NXAMP4x4

8. Upper left (CH1) PA unit (Time required: about 15 minutes)

8-1. Remove the top cover and the NX-DFLT card.

(See procedure 1.)

8-2. Remove the CONTROL circuit board and the OPT

angle. (See procedure 2.)

8-3. Disconnect the connector assemblies which connects

the upper left PA unit and other units. (Fig. 7)

8-4. Remove the four (4) screws mar ked [820A], and

remove the four (4) screw covers marked [810A].

(Fig. 7)

8-5. Remove the six (6) screws marked [270]. The upper

left PA unit can then be removed. (Fig. 7)

9. Upper right (CH2) PA unit (Time required: about 15 minutes)

9-1. Remove the top cover and the NX-DFLT card.

(See procedure 1.)

9-2. Remove the CONTROL circuit board and the OPT

angle. (See procedure 2.)

9-3. Disconnect the connector assemblies which connects

the upper right PA unit and other units. (Fig. 7)

9-4. Remove the four (4) screws mar ked [820B], and

remove the four (4) screw covers marked [810B].

(Fig. 7)

9-5. Remove the six (6) screws marked [300]. The upper

right PA unit can then be removed. (Fig. 7)

8. 上左側(CH1)PA ユニット(所要時間:約 15 分)

8-1. トップカバー、NX-DFLT カードを外します。

(1 項参照)

8-2. CONTROL シート、OPT アングルを外します。

(2 項参照)

8-3. 上左側の PA ユニットと他のユニットを接続している

束線を外します。(図 7)

8-4. [820A]のネジ 4 本を外し、[810A]のネジカバー 4

個を外します。(図 7)

8-5. [270]のネジ 6 本を外し、上左側の PA ユニットを

外します。(図 7)

9. 上右側(CH2)PA ユニット(所要時間:約 15 分)

9-1. トップカバー、NX-DFLT カードを外します。

(1 項参照)

9-2. CONTROL シート、OPT アングルを外します。

(2 項参照)

9-3. 上右側の PA ユニットと他のユニットを接続している

束線を外します。(図 7)

9-4. [820B]のネジ 4 本を外し、[810B]のネジカバー 4

個を外します。(図 7)

9-5. [300]のネジ 6 本を外し、上右側の PA ユニットを

外します。(図 7)

PA unit

(PA ユニット)

[820A]

[810A]

[810A]

[270]

[270]: BIND HEAD TAPPING SCREW-B 4x8 MFZN2B3 (--)

[300]: BIND HEAD TAPPING SCREW-B 4x8 MFZN2B3 (--)

[810A]: SCREW COVER T5N (--)

[810B]: SCREW COVER T5N (--)

[820A]: BIND HEAD TAPPING SCREW-B 3x8 MFZN2B3 (--)

[820B]: BIND HEAD TAPPING SCREW-B 3x8 MFZN2B3 (--)

ネジカバー

ネジカバー

PA unit

(PA ユニット)

[810B]

[820B]

[810B]

[300]

B タイト+ BIND

B タイト+ BIND

B タイト+ BIND

B タイト+ BIND

Fig. 7

(図 7)

31

Page 32

NXAMP4x4

10. Lower left (CH3) PA unit (Time required: about 25 minutes)

10-1. Remove the top cover and the NX-DFLT card.

(See procedure 1.)

10-2. Remove the CONTROL circuit board and the OPT

angle. (See procedure 2.)

10-3. Remove the PSANHA circuit board. (See procedure 3.)

10-4. Remove the upper left PA unit. (See procedure 8.)

10-5. Disconnect the connector assemblies which connects

the lower left PA unit and other units. (Fig. 8)

10-6. Remove the four (4) screws m ar ked [820C], and

remove the four (4) screw covers marked [810C].

(Fig. 8)

10-7. Remove the six (6) screws marked [210]. The lower

left PA unit can then be removed. (Fig. 8)

11. Lower right (CH4) PA unit (Time required: about 25 minutes)

11-1. Remove the top cover and the NX-DFLT card.

(See procedure 1.)

11-2. Remove the CONTROL circuit board and the OPT

angle. (See procedure 2.)

11-3. Remove the PSANHA circuit board. (See procedure 3.)

11-4. Remove the upper right PA unit. (See procedure 9.)

11-5. Disconnect the connector assemblies which connects

the lower right PA unit and other units. (Fig. 8)

11-6. Remove the four (4) screws marked [820D], and

remove the four (4) screw covers marked [810D].

(Fig. 8)

11-7. Remove the six (6) screws marked [240]. The lower

right PA unit can then be removed. (Fig. 8)

10. 下左側(CH3)PA ユニット(所要時間:約 25 分)

10-1. トップカバー、NX-DFLT カードを外します。

(1 項参照)

10-2. CONTROL シート、OPT アングルを外します。

(2 項参照)

10-3. PSANHA シートを外します。(3 項参照)

10-4. 上左側の PA ユニットを外します。(8 項参照)

10-5. 下左側の PA ユニットと他のユニットを接続している

束線を外します。(図 8)

10-6.[820C]のネジ 4 本を外し、[810C]のネジカバー 4

個を外します。(図 8)

10-7.[210]のネジ 6 本を外し、下左側の PA ユニットを

外します。(図 8)

11. 下右側(CH4)PA ユニット(所要時間:約 25 分)

11-1. トップカバー、NX-DFLT カードを外します。

(1 項参照)

11-2. CONTROL シート、OPT アングルを外します。

(2 項参照)

11-3. PSANHA シートを外します。(3 項参照)

11-4. 上右側の PA ユニットを外します。(9 項参照)

11-5. 下右側の PA ユニットと他のユニットを接続している

束線を外します。(図 8)

11-6.[820D]のネジ 4 本を外し、[810D]のネジカバー 4

個を外します。(図 8)

11-7.[240]のネジ 6 本を外し、下右側の PA ユニットを

外します。(図 8)

32

PA unit

(PA ユニット)

[210]: BIND HEAD TAPPING SCREW-B 4x8 MFZN2B3 (--)

[240]: BIND HEAD TAPPING SCREW-B 4x8 MFZN2B3 (--)

[810C]: SCREW COVER T5N (--)

[810D]: SCREW COVER T5N (--)

[820C]: BIND HEAD TAPPING SCREW-B 3x8 MFZN2B3 (--)

[820D]: BIND HEAD TAPPING SCREW-B 3x8 MFZN2B3 (--)

[820C]

[810C]

[810C]

[210]

ネジカバー

ネジカバー

Fig. 8

PA unit

(PA ユニット)

[810D]

[820D]

[810D]

[240]

B タイト+ BIND

B タイト+ BIND

B タイト+ BIND

B タイト+ BIND

(図 8)

Page 33

NXAMP4x4

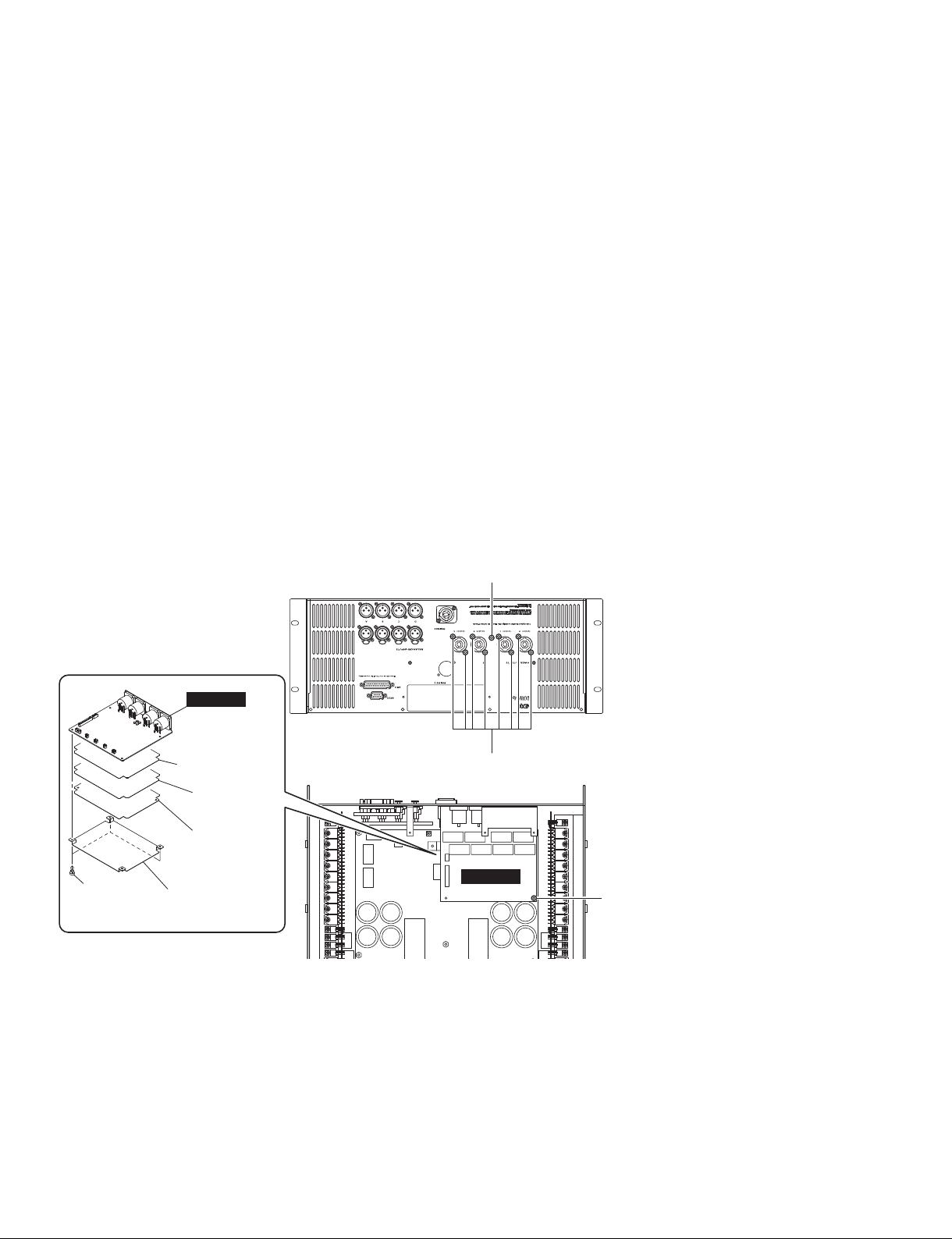

12. Front Panel Assembly

(Time required: about 20 minutes)

12-1. Remove the top cover and the NX-DFLT card.

(See procedure 1.)

12-2. Remove the CONTROL circuit Board and the OPT

angle. (See procedure 2.)

12-3. Disconnect the power switch connector assembly from

the PSANHA circuit board. (Fig. 9)

12-4. Remove the PSANHA Circuit Board.

(See procedure 3.)

12-5. Disconnect the power switch connector assembly from

the PSANHB circuit board. (Fig. 9)

12-6. Disconnect the flat cable from the PN-AN circuit board.

(Fig. 9)

12-7. Remove the eight (8) screws marked [660]. The front

panel assembly can then be removed. (Fig. 9)

13. PN-AN Circuit Board (Time required: about 25 minutes)

13-1. Remove the top cover and the NX-DFLT card.

(See procedure 1.)

13-2. Remove the front panel assembly. (See procedure 12.)

13-3. Remove the five (5) screws marked [650]. The LCD

assembly can then be removed. (Fig. 9)

13-4. Remove the four (4) nylon rivets marked [40]. The

PN-AN circuit board and the LCD unit can then be

separated. (Fig. 9)

12. フロントパネル Ass'y(所要時間:約 20 分)

12-1. トップカバー、NX-DFLT カードを外します。

(1 項参照)

12-2. CONTROL シート、OPT アングルを外します。

(2 項参照)

12-3. PSANHA シートから電源スイッチ Ass'y の線材を外

します。(図 9)

12-4. PSANHA シートを外します。(3 項参照)

12-5. PSANHB シートから電源スイッチ Ass'y の線材を外

します。(図 9)

12-6. PN-AN シートからフラットケーブルを外します。

(図 9)

12-7.[660]のネジ 8 本を外し、フロントパネル Ass'y を

外します。(図 9)

13. PN-AN シート(所要時間:約 25 分)

13-1. トップカバー、NX-DFLT カードを外します。

(1 項参照)

13-2. フロントパネル Ass'y を外します。(12 項参照)

13-3.[650]のネジ 5 本を外し、LCDAss'y を外します。

(図 9)

13-4.[40]のナイロンリベット 4 個を外し、PN-AN シー

トと LCD ユニットを別けます。(図 9)

Front panel assembly

(フロントパネルAss'y)

[660]

[40]: NYLON RIVET P3570-W/BW (--)

[650]: BIND HEAD SCREW 3x4 MFZN2B3 (--)

[660]: FLAT HEAD SCREW 4x8 MFZN2B3 (--)

[660]

[650]

LCD assembly

(LCDAss'y)

Fig. 9

[650]

ナイロンリベット

小ネジ+ BIND

小ネジ+ FLAT

(図 9)

[40]

LCD assembly

(LCDAss'y)

LCD unit

(LCDユニット)

PN-AN

[40]

33

Page 34

NXAMP4x4

14. Upper left DC Fan

(Time required: about 15 minutes)

14-1. Remove the top cover and the NX-DFLT card.

(See procedure 1.)

14-2. Remove the CONTROL circuit board and the OPT

angle. (See procedure 2.)

14-3. Remove the front panel assembly. (See procedure 12.)

14-4. Disconnect the upper left DC fan connector assembly

from the PSANHA circuit board. (Fig. 10)

14-5. Remove the two (2) screws marked [40A] and the two

(2) hexagonal nuts marked [50A]. The upper left DC

fan can then be removed. (Fig. 10)

15. Upper right DC fan (Time required: about 15 minutes)

15-1. Remove the top cover and the NX-DFLT card.

(See procedure 1.)

15-2. Remove the CONTROL circuit board and the OPT

angle. (See procedure 2.)

15-3. Remove the front panel assembly. (See procedure 12.)

15-4. Disconnect the upper right DC fan connector

assembly from the PSANHA circuit board. (Fig. 10)

15-5. Remove the two (2) screws marked [40B] and the two

(2) hexagonal nuts marked [50B]. The upper right DC

fan can then be removed. (Fig. 10)

14. 上左側の DC ファン(所要時間:約 15 分)

14-1. トップカバー、NX-DFLT カードを外します。

(1 項参照)

14-2. CONTROL シート、OPT アングルを外します。

(2 項参照)

14-3. フロントパネル Ass'y を外します。(12 項参照)

14-4. PSANHA シートから上左側の DC ファンの線材を外

します。(図 10)

14-5.[40A]のネジ 2 本、[50A]の六角ナット 2 個を外し、

上左側の DC ファンを外します。(図 10)

15. 上右側の DC ファン(所要時間:約 15 分)

15-1. トップカバー、NX-DFLT カードを外します。

(1 項参照)

15-2. CONTROL シート、OPT アングルを外します。

(2 項参照)

15-3. フロントパネル Ass'y を外します。(12 項参照)

15-4. PSANHA シートから上右側の DC ファンの線材を外

します。(図 10)

15-5.[40B]のネジ 2 本、[50B]の六角ナット 2 個を外、

上右側の DC ファンを外します。(図 10)

[50A]

DC fan

(DC ファン)

[40A]: BIND HEAD SCREW 4x16 MFZN2W3 SP (--)

[40B]: BIND HEAD SCREW 4x16 MFZN2W3 SP (--)

[50A]: HEXAGONAL NUT M4 #1 (--)

[50B]: HEXAGONAL NUT M4 #1 (--)

[50A]

[40A]

[40B]

6 角ナット

6 角ナット

[50B]

DC fan

(DC ファン)

[50B]

小ネジ+ BIND

小ネジ+ BIND

34

Fig. 10

(図 10)

Page 35

NXAMP4x4

16. Lower left DC Fan (Time required: about 23 minutes)

16-1. Remove the top cover and the NX-DFLT card.

(See procedure 1.)

16-2. Remove the CONTROL circuit board and the OPT

angle. (See procedure 2.)

16-3. Remove the PSANHA circuit board. (See procedure 3.)

16-4. Remove the front panel assembly. (See procedure 12.)

16-5. Remove the upper left DC fan. (See procedure 14.)

16-6. Disconnect the lower left DC fan connector assembly

from the PSANHB circuit board. (Fig. 11)

16-7. Remove the two (2) screws marked [40C] and the two

(2) hexagonal nuts marked [50C]. The lower left DC

fan can then be removed. (Fig. 11)

17. Lower right DC Fan (Time required: about 23 minutes)

17-1. Remove the top cover and the NX-DFLT card.

(See procedure 1.)

17-2. Remove the CONTROL circuit board and the OPT

angle. (See procedure 2.)

17-3. Remove the PSANHA circuit board. (See procedure 3.)

17-4. Remove the front panel assembly. (See procedure 12.)

17-5. Remove the upper right DC fan. (See procedure 15.)

17-6. Disconnect the lower right DC fan connector assembly

from the PSANHB circuit board. (Fig. 11)

17-7. Remove the two (2) screws marked [40D] and the two

(2) hexagonal nuts marked [50D]. The lower right DC

fan can then be removed. (Fig. 11)

16. 下左側の DC ファン(所要時間:約 23 分)

16-1. トップカバー、NX-DFLT カードを外します。

(1 項参照)

16-2. CONTROL シート、OPT アングルを外します。

(2 項参照)

16-3. PSANHA シートを外します。(3 項参照)

16-4. フロントパネル Ass'y を外します。(12 項参照)

16-5. 上左側の DC ファンを外します。(14 項参照)

16-6. PSANHB シートから下左側の DC ファンの線材を外

します。(図 11)

16-7.[40C]のネジ 2 本、[50C]の六角ナット 2 個を外し、

下左側の DC ファンを外します。(図 11)

17. 下右側の DC ファン(所要時間:約 23 分)

17-1. トップカバー、NX-DFLT カードを外します。

(1 項参照)

17-2. CONTROL シート、OPT アングルを外します。

(2 項参照)

17-3. PSANHA シートを外します。(3 項参照)

17-4. フロントパネル Aass'y を外します。(12 項参照)

17-5. 上右側の DC ファンを外します。(15 項参照)

17-6. PSANHB シートから下右側の DC ファンの線材を外

します。(図 11)

17-7.[40D]のネジ 2 本、[50D]の六角ナット 2 個を外し、

下右側の DC ファンを外します。(図 11)

[50C]

DC fan

(DC ファン)

[40C]: BIND HEAD SCREW 4x16 MFZN2W3 SP (--)

[40D]: BIND HEAD SCREW 4x16 MFZN2W3 SP (--)

[50C]: HEXAGONAL NUT M4 #1 (--)

[50D]: HEXAGONAL NUT M4 #1 (--)

[50C]

[40C]

[40D]

6 角ナット

6 角ナット

Fig. 11

[50D]

DC fan

(DC ファン)

[50D]

小ネジ+ BIND

小ネジ+ BIND

(図 11)

35

Page 36

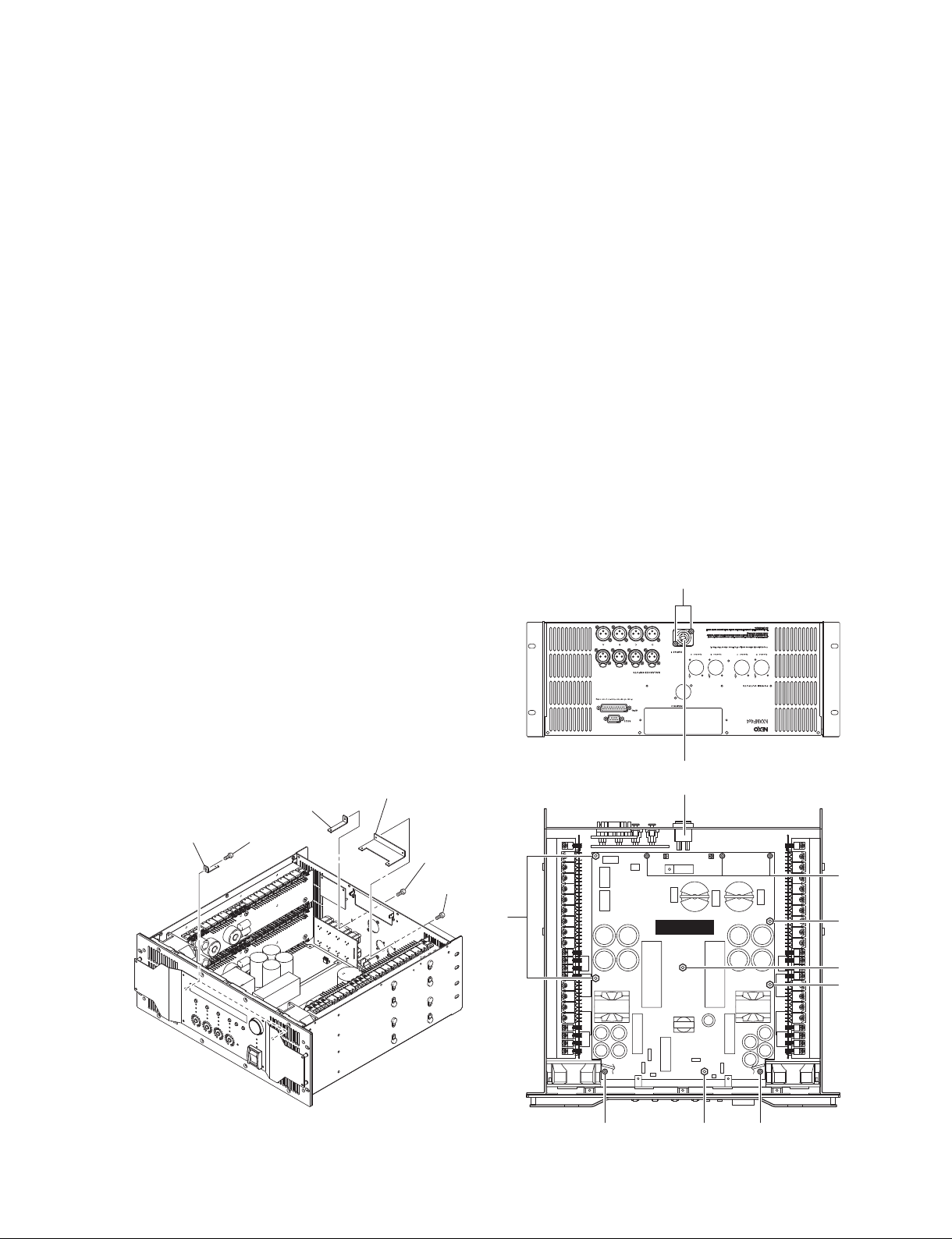

NXAMP4x4

18. Power switch

(Time required: about 25 minutes)

18-1. Remove the top cover and the NX-DFLT card.

(See procedure 1.)

18-2. Remove the CONTROL circuit Board and the OPT

angle. (See procedure 2.)

18-3. Disconnect the power switch connector assembly from

to the PSANHA circuit board.

18-4. Remove the PSANHA circuit Board. (See procedure 3.)

18-5. Disconnect the power switch connector assembly from

the PSANHB circuit board. (Fig. 12)

18-6. Remove the front panel assembly. (See procedure 12.)

18-7. Release the four (4) hooks of the power switch. The

power switch can be removed from the front panel

assembly. (Fig. 12)

Front panel assembly

(フロントパネルAss'y)

18. 電源スイッチ(所要時間:約 25 分)

18-1. トップカバー、NX-DFLT カードを外します。

(1 項参照)

18-2. CONTROL シート、OPT アングルを外します。

(2 項参照)

18-3. PSANHA シートから電源スイッチ Ass'y の線材を外

します。(図 12)

18-4. PSANHA シートを外します。(3 項参照)

18-5. PSANHB シートから電源スイッチ Ass'y の線材を外

します。(図 12)

18-6. フロントパネル Ass'y を外します。(12 項参照)

18-7. 4 箇所のフックを解除し、フロントパネル Ass'y から

電源スイッチを外します。(図 12)

[660]

Power switch

(電源スイッチ)

Hook

(フック)

HookHook

(フック)

[660]: FLAT HEAD SCREW 4x8 MFZN2B3 (--)

Power switch

(電源スイッチ)

Fig. 12

[660]

小ネジ+ FLAT

(図 12)

36

Page 37

NXAMP4x4

LSI PIN DESCRIPTION

■

PCM1803ADBR (X7357B0) A/D CONVERTER

•

PIN

NO.

1V

2V

3V

4V

5V

NAME I/O FUNCTION

IN

L I Analog input, L-channel

IN

R I Analog input, R-channel

REF

1 – Reference voltage 1 decoupling capacitor

REF

2 – Reference voltage 2 decoupling capacitor

CC

– Analog power supply, 5 V

(LSI 端子機能表)

CONTROL: IC035, IC036, IC037, IC038

6 AGND – Analog GND

7

PDWN I Power-down control, active-low

(2)

8 BYPAS I HPF bypass control / LOW: Normal mode (dc reject); HIGH: Bypass mode (through)

9 TEST I Test, must be connected to DGND

10 LRCK I/O Audio data latch enable input/output

11 BCK I/O Audio data bit clock input/output

(2)

(1)

(1)

12 DOUT O Audio data digital output

13 DGND – Digital GND

14 V

DD

15 SCKI I System clock input: 256 fs, 384 fs, 512 fs or 768 fs

16 OSR I Oversampling ratio select input / LOW: x 64 fs, HIGH: x 128 fs

17 FMT0 I Audio data format select input 0 / See data format section

18 FMT1 I Audio data format select input 1 / See data format section

19 MODE0 I Mode select input 0 / See data format section

20 MODE1 I Mode select input 1 / See data format section

– Digital power supply, 3.3 V

(3)

(2)

(2)

(2)

(2)

(2)

(2)

(1) Schmitt trigger input

(2) Schmitt trigger input with internal pulldown (50 kΩ, typically), 5 V tolerant

(3) Schmitt trigger input, 5 V tolerant

37

Page 38

NXAMP4x4

IC BLOCK DIAGRAM

■

r74HCT273PW,118 (X8681A0)

D-type Flip Flop

PN-AN: IC002, 003

D0

QD

CP

MR

GND

1

20

V

2

Q0

3

D0

4

D1

5

Q1

6

Q2

7

D2

8

D3

9

Q3

10

CC

19

Q7

18

D7

CP

17

D6

16

Q6

MR

15

Q5

14

D5

13

D4

12

Q4

11

CP

FF1

Q

R

D

Q0

D4

QD

CP

FF5

Q

R

D

Q4

(IC ブロック図)

D1

D5

D2

QD

CP

FF2

Q

R

D

Q1

D6

QD

CP

FF6

Q

R

D

Q5

D3

QD

CP

FF3

Q

R

D

QD

CP

FF7

Q

R

D

QD

CP

FF4

Q

R

D

Q2

Q6

Q3

D7

QD

CP

FF8

Q

R

D

Q7

r74LVC169PW,118 (X8482A0)

Binaly Counter

CONTROL: IC044, 045

3

DC

U/D

CEP

GND

CP

D0

D1

D2

D3

V

1

16

CC

TC

2

15

Q0

3

14

Q1

4

13

5

12

Q2

6

11

Q3

7

10

CET

4

8

D1

9

PE

5

D2

6

D3

9

PE

7

CEP

10

CET

2

CP

1

U/D

Q

D

CP

Q

Q

D

CP

Q

Q

D

CP

Q

Q

D

CP

Q

14

Q0

13

Q1

12

Q2

11

Q3

15

TC

r74HCT4514PW,118 (X8630A0)

Decoder

PN-AN: IC004-007

A

0

V

24

CC

23

E

A

22

3

21

A

2

20

19

18

17

16

15

14

13

A

Q

1

10

Q

11

Q

8

Q

9

Q

14

Q

15

Q

A

12

2

Q

13

A

3

LE

GND

1

LE

A

2

0

A

3

1

Q

4

7

Q

5

8

Q

6

5

Q

7

4

Q

8

3

Q

9

1

Q

10

2

Q

11

0

12

latch

latch

latch

latch

rCS3318-CQZ (X8486A0)

Volume Controller

CONTROL: IC001

REFO1

OUT1

OUT2

REFO2

IN2

VA-

VA+

Q

0

S

D

Q

1

Q

R

D

S

D

Q

2

Q

R

D

S

D

Q

3

Q

R

D

S

D

Q

4

Q

R

D

E

Q

1

Q

2

Q

3

Q

4

Q

5

Q

6

Q

7

Q

8

Q

9

Q

10

Q

11

Q

12

Q

13

Q

14

Q

15

8-channel

Analog

Inputs

I2C/SPI

Serial

Control

REFI1

RESET

MUTE

SCL/CCLK

SDA/MOSI

AD0/CS

ENOut

DGND

REFI8

8V to 9V

+3.3V

4847464544434241403938

1

IN1

2

3

4

5

6

7

8

9

VD

10

11

IN8

12

1314151617181920212223

OUT8

REFO8

5

I2C/SPI

Control

Port

VA+

VA-

OUT7

Zero Crossing

Detector

REFO7

IN7

REFI2

REFI7

REFI3

REFI8

OUT3

REFO3

IN3

37

36

VA-

35

VA+

34

OUT5

33

REFO4

32

IN4

31

REFI4

30

REFI5

29

IN5

REFO5

28

OUT5

27

VA-

26

VA+

25

24

IN6

OUT6

REFO6

8-channel

3

Analog

Outputs

38

Page 39

NXAMP4x4

rCS4272-CZZR (X8487A0)

CODEC

CONTROL: IC012, 013

3.3V to 5V2.5V to 5V

Hardware or

I2C/SPI

Control Data

Reset

Serial

Audio

Intput

Serial

Audio

Output

Registor/Hardware

Level Translator Level Translator

Configuration

Volume

Control

Volume

Control

PCM Serial Interface/Loopback

rIR2110 (X2382A04)

Driver

PSANH: IC302, 303

Selectable

Interpolation

Filter

Mixer

Selectable

Interpolation

Filter

High Pass Filter and

DC Offset Calibration

High Pass Filter and

DC Offset Calibration

Internal Voltage

Reference

Modulator

Modulator

LOW-Latency

Anti-Alias Filter

LOW-Latency

Anti-Alias Filter

5V

Internal

Oscilator

External

Mute Control

Switched Capasito

DAC and Filterr

Switched Capasito

DAC and Filterr

Multibit

Oversampling

ADC

Multibit

Oversampling

ADC

Left and

Right Mute

Controls

Left

Differential

Output

Right

Differential

Output

Left

Differential

Input

Right

Differential

Input

rDSPB56371AF180 (X8489A0)

DSP

CONTROL: IC022, 023

5

SHI

Interface

2

EXTAL

RESET

PINIT/NMI

212

DAX

Address

Generation

Unit

Six Channel

DAM Unit

Bootstrap

ROM

Internal

Data

Bus

Switch

Clock

Gen-

erator

Triple

Timer

PLL

ESAI

Interface

12

ESAI_1

Interface

PIO_EB

Program

Interruput

Controller

11

GPIO

Peripheral

Expansion Area

Program

Decode

Controller

MODA/IRQA

MODB/IRQB

MODC/IRQC

MODD/IRQD

EFCOP

Program

Address

Controller

Memory Expansion Area

Program

RAM

4K x 24

ROM

64K x 24

YAB

PM_EB

XAB

PAB

DAB

24-Bit

DSP56300

Core

DDB

YDB

XDB

PDB

GDB

24 x 24+56 56-bit MAC

Two 56-bit Accumulators

X Data

RAM

36K x 24

ROM

32K x 24

XM_EB

Data ALU

56-it barrel Shifter

Y Data

RAM

48K x 24

ROM

32K x 24

YM_EB

Power

Mngmnt.

JTAG

OnCE

4

TM

COM

VCC

1

LO

2

3

4

5

VS

6

VB

HO

7

14

13

VSS

12

LIN

11

SD

10

HIN

9

VDD

8

rLD1117STR (X8495A0)

Regulator

CONTROL: IC024

VOLTAGE

GENERATOR

CURRENT

GENERATOR

VB

HV

UV

9

VDD

10

HIN

11

SD

LIN

12

VSS

13

Q

R

S

S

Q

R

VDD/VCC

LEVEL

SHIFT

VDD/VCC

LEVEL

SHIFT

PULSE

PULSE

GEN

GEN

LEVEL

SHIFT

DETECT

PULSE

FILTER

UV

DETECT

DELAY

R

Q

R

S

6

7

HO

5

VS

3

CC

V

LO

1

2

COM

rMAX3221CPWR (X2757A0)

RS-232C Driver

CONTROL: IC041

V

IN

C1+

C1–

C2+

C2–

RIN

EN

1

2

3

V+

4

5

6

7

V–

8

16

15

14

13

12

11

10

9

FORCEOFF

V

CC

GND

DOUT

FORCEON

DIN

INVALID

ROUT

DIN

11

13

DOUT

THERMAL

COMPENSATION

THERMAL

PROTECTION

FORCEOFF

16

12

V

OUT

FORCEON

ROUT

GND

Auto-powerdown

9 8

10

1

INVALID

RIN

EN

39

Page 40

NXAMP4x4

rMX25L1605AM2C-12G (X8718A0) (X8718B0)

Flash Memory

CONTROL: IC039

1

CS#

SCLK

CS#

2

SO

WP#

3

4

GND

Address

Generator

SI

Data

Register

SRAM

Buffer

Mode

Logic

Clock Generator

State

Machine

8

7

6

5

X-Decoder

Memory Array

VCC

HOLD#

SCLK

SI

Page Buffer

Y-Decoder

HV

Generator

Sense

Amplifire

Output

Buffer

SO

REFERENCE

r/+.65&(X6770A0)

SHUNT Regulator

PAANH: IC401

PSANH: IC204

REFERENCE (R)

ANODE

(A)

CATHODE

(K)

CATHOD

ANODE

rNJM2068M-D (X3505A0)

Operational Amplifier

CONTROL: IC002-005, 008-011, 018-021, 028-034

INANH: IC701, 702

OUTANH: IC801, 802

+-

8

7

6

5

+DC Voltage

8

+V

Supply

7

Output B

Inverting

6

Input B

Non-Inverting

5

Input B

+DC Voltage

Supply

Output B

Inverting

Input B

Non-Inverting

Input B

r/+.'"(XD853A0)

Regulator +15V

PSANH: IC202, 203

1

Output A

Inverting

2

Input A

Non-Inverting

Input A

-DC Voltage Supply

+-

3

4

-V

r/+.75&(XR532A0)

Operational Amplifier

CONTROL: IC047, 048, 050, 052

1

Output A

Inverting

Input A

Non-Inverting

Input A

Ground

2

3

4-V

+V

+-

+-

rNJM79M09DL1A (X5366A0)

Regulator

CONTROL: IC007

R1

Q3

Q4

Q10

R2

D2D1

Q6

Q2

R6

Q1

Q7

Q12

R3

Q5

R4

R5

Q17

Q9

Q8

R7

R9R8

Q11

Q13

Q14

Q15

R10

Q16

Q23

Q19

C1 C2

Q18

r/+..%-"(XZ940A0)

Regulator

CONTROL: IC006

INPUT

OUTPUT

COMMON

R22

R20

C3

Q24

R23

R24

Q25

Q20

R13

D3

R14

R17

R16R15R21R12R11

OUTPUT

Q21

Q22

R18

R19

INPUT

INPUT

OUTPUT

40

GND

GND

Page 41

NXAMP4x4

rNJU7630-M (X8682A0)

Regulator

PSANH: IC205

V+

1V

Vref

Soft Start

2

ER.AMP

UVLO

Latch

2A

SCP

2k

0.5

A

R

T

1V

1V

67 8

DTC

FB

IN-

SCP

3

4

5

rPQ1CX12H2ZP (X6188A0)

Regulator

PSANH: IC208

1 8

V

IN

Drive

2

V

B

Circuit

Comparator

Over

current

Detection

circuit

Over

Heat

Detection

circuit

Q

R

F/F

S

6, 7

COM

Oscill

ator

fo Conversion

circuit

Voltage

regulator

ON/OFF

circuit

+

-

AMP

Soft

Start

rPCM1803ADBR (X7357B0)

A/D Converter

CONTROL: IC035-038

Delta-Sigma

Modulator

Delta-Sigma

Modulator

DGND

20

MODE1

19

MODE0

18

FMT1

17

FMT0

16

OSR

15

SCKI

14

V

DD

13

DGND

12

DOUT

11

BCK

BCK

LRCK

x 1/64, x 1/128

Decimation

Filter

With

High-Pass Filter

Clock and Timing Control

V

DD

Serial

Interface

Mode/

Format

Control

DOUT

FMT0

FMT1

MODE0

MODE1

BYPAS

TEST

OSR

PDWN

SCKI

1

VINL

2

R

V

IN

3

V

1

REF

4

2

V

0.8V

0.2V

PWM

Buffer

OUT

1

OSC

0.5V

RT

GND

R

T

L

V

IN

1

V

REF

V

2

REF

V

R

IN

REF

V

AGND

PDWN

BYPAS

TEST

LRCK

Reference

5

CC

6

7

8

9

10

Power Supply

AGNDV

CC

rSG2525AN (X8960A0)

PW Modulator

PSANH: IC301

V

REF

OSC.

REF.

REG.

5k

COMP.

TO INTRENAL

CIRCUITRY

OSCILLATOR

V

REF

50A

16

OUTPUT

V

13

U.V.

LOCK

OUT

4

FLIP

FLOP

R

S

PWM

LATCH

S

NOR

NOR

OR

OR

C

OUTPUT A

11

OUTPUT B

14

SG1525A OUTPUT STAGE

V

13

C

OUTPUT A

11

OUTPUT B

14

Vo

V

15

i

12

GROUND

4

ON/OFF

5

+

V

ref

VNCadj

3

SYNC.

DISCHARGE

COMP.

INV.INPUT

N.I.INPUT

SOFT-START

SHUTDOWN

3

R

6

T

C

5

T

7

9

1

ERROR

AMP.

2

8

5k

10

SG1527A OUTPUT STAGE

41

Page 42

NXAMP4x4

rSN74ABT245BNSR (XU009A0)

BUS Transceiver

CONTROL: IC062

GND

1

DIR

2

A1

3

A2

4

A3

5

A4

6

A5

7

A6

8

A7

9

A8

10

20

Vcc

19

OE

18

B1

17

B2

16

B3

15

B4

14

B5

13

B6

12

B7

11

B8

rSN74LV273APWR (X5074A0)

D-type Flip Flop

CONTROL: IC057-061

1

20

CLR

1Q

2Q

3Q

4Q

GND

1D

2D

3D

4D

V

2

3

4

5

6

7

8

9

10

CC

19

8Q

18

8D

7D

7Q

6Q

6D

5D

5Q

CLK

CLK

CLR

17

16

15

14

13

12

11

1D

3

11

1D

C1

R

1

1Q

rSN74LV14APWR (X6688A0)

Inverter

CONTROL: IC063

VCC

14

A6

13

12

Y6

A5

11

10

Y5

9

A4

8

Y4

GND

A1

1

Y1

2

A2

3

Y2

4

A3

5

Y3

6

7

r4/-7"183#64# (X5966A0)

Buffer/Driver

CONTROL: IC055, 056

PN-AN: IC001

1

GND

G1

2

A1

A2

3

4

A3

5

A4

6

A5

A6

7

A7

8

A8

9

10

2D

3D

4D

5D

6D

7D

4

7

8

13

14

1D

1D

1D

1D

C1

C1

R

2

5

2Q

C1

R

R

6

3Q

9

4Q

1D

C1

R

C1

R

12

5Q

6Q

8D

17

18

1D

1D

C1

16 19

7Q

C1

R

8Q

R

15

20

Vcc

19

G2

18

Y1

17

Y2

16

Y3

15

Y4

Y5

14

13

Y6

12

Y7

11

Y8

rSN74LV4052APWR (X6976A0)

Demultiplexer

CONTROL: IC049

10

2Y0

2Y2

2-COM

2Y3

2Y1

INH

GND

GND

V

16

1

CC

1Y2

15

2

1Y1

14

3

1-COM

13

4

5

12

1Y0

6

11

1Y3

7

10

A

8

9

B

A

9

B

6

INH

42

rSN74LVC00APWR (X5406A0)

NAND

13

1-COM

12

1Y0

14

1Y1

15

1Y2

11

1Y3

1

2Y0

5

2Y1

2

2Y2

4

2Y3

3

2-COM

CONTROL: IC040

1B 2

1Y 3

2A 4

2B 5

2Y 6

GND 7

Vcc141A 1

4B13

4A12

4Y11

3B10

3A9

3Y8

Page 43

NXAMP4x4

rSN74LVC157APWR (X6786A0)

Data Selector

CONTROL: IC046, 051

1A

2

1B

3

CC

2A

5

2B

6

3A

11

3B

10

4A

14

4B

13

G

15

A/B

1

GND

A/B

1A

1B

1Y

2A

2B

2Y

G

15

2

4A

14

3

4B

13

4

5

12

4Y

6

11

3A

7

10

3B

8

9

3Y

V

16

1

rSN74LVC2G74DCTR (X8709A0)

Flip Flop

CONTROL: IC042

PRE

7

CLK

1

D

2

CLR

6

C

C

C

TG

C

C

TG

C

C

TG

C

rSN74LVC245APWR (XZ287A0)

Bas Transceiver

CONTROL: IC054

1

DIR

1Y

4

7

2Y

3Y

9

4Y

12

Q

5

C

TG

Q

C

3

GND

2

A1

3

A2

4

A3

5

A4

6

A5

7

A6

8

A7

9

A8

10

20

Vcc

19

OE

18

B1

17

B2

16

B3

15

B4

14

B5

13

B6

12

B7

11

B8

rTC74LCX04FT (X8415A0)

Inverter

CONTROL: IC064

VCC

14

6A

13

12

6Y

5A

11

10

5Y

9

4A

8

4Y

GND

1A

1

1Y

2

2A

3

2Y

4

3A

5

3Y

6

7

r501:/1% (X8576A0)

Regulator

PSANH: IC201

CONTROL (1C)

EXTERNAL

CURRENT LIMIT (3X)

LINE-SENSEL (2L)

FREQUENCY (5F)

Z

C

SHUNT REGULATOR/

ERROR AMPLIFIER

I

FB

CURRENT

LIMIT

ADJUST

LINE

SENSE

R

E

V

BG+VT

V

BG

V

C

V

ON/OFF

1 V

5.0V

I(LIMIT)

SOFT

START

OVAIV

DC

MAX

6.8V

4.6V

INTERNAL UV

COMPARATOR

STOP LOGIC

STOP

DC

MAX

HALF

FREQ

OSCILLATOR WITH JITTER

SOFTSTART

D

CLOCK

MAX

SAW

SOFT START

LIQHT LOAD

FREQUENCY

REDUCTION

+8

SHUTDOWN

AUTO-RESTART

HYSTERETIC

THERMAL

SHUTDOWN

PWM

COMPARATOR

0

1

INTERNAL

SUPPLY

DRAIN (7D)

Tab internally

connected to

SOURCE pin

CURRENT LIMIT

COMPARATOR

CONTROLLED

TURN-ON

GATE DRIVER

Q

S

R

LEADING

EDGE

BLANKING

2L

5F

3X

4S

1C

7D

SOURCE (4S)

43

Page 44

NXAMP4x4

■ CIRCUIT BOARDS

(シート基板図)

CONTENTS

• CONTROL Circuit Board (X8710D0) ............................ 46

• INANH Circuit Board (X8714C0) ............................ 45

• LCD SPACER Circuit Board (X8711E0) ............................62

• NX-DFLT Circuit Board (YC233A0) ............................63

• OPT-AN Circuit Board (X8711E0) ............................62

• OUTANH Circuit Board (X8714C0) ............................ 50

• PAANH Circuit Board (X8712G0) ............................56

• PN-AN Circuit Board (X8711E0) ............................52

• PSANHA, PSANHB Circuit Board (X8715G0) ............................58

• RS232-GPI Circuit Board (X8711E0) ............................62

Note: See parts list for details of circuit board component parts.

注: シートの部品詳細はパーツリストをご参照ください。

(目次)

44

Page 45

• INANH Circuit Board

NXAMP4x4

to CONTROL

CN006

DCBA

BALANCED INPUTS

Component side

(部品側)

2NA-WJ97320-10

Pattern side

0

(パターン側)

45

Page 46

NXAMP4x4

• CONTROL Circuit Board

A

to PN-AN

CN001

to PSANHB

CN313

to PSANHA

CN313

to PSANHA

CN201

to OUTANH

CN809, CN810

46

Component side

(部品側)

A'

2NA-WR77020-10

0

Page 47

A

• CONTROL Circuit Board

A

NXAMP4x4

to OUTANH

CN809, CN810

to PAANH

(CH1)

CN401

to PAANH

(CH2)

CN401

to PAANH

(CH3)

CN401

to PAANH

(CH4)

CN401

to INANH

W701

to OPT-AN

CN301

A'

2NA-WR77020-10

to RS232-GPI

CN201

Component side

0

(部品側)

47

Page 48

NXAMP4x4

• CONTROL Circuit Board

B

48

Pattern side

(パターン側)

B'

2NA-WR77020-10

0

Page 49

• CONTROL Circuit Board

B

NXAMP4x4

B'

2NA-WR77020-10