Page 1

SERVICE MANUAL

■ CONTENTS

PANEL LAYOUT .......................................................................................... 3

CIRCUIT BOARD LAYOUT ......................................................................... 4

SERVICE PRECAUTIONS ........................................................................... 5

OVERALL ASSEMBLY WIRING .................................................................. 7

DISASSEMBLY PROCEDURES ................................................................ 17

LSI PIN DESCRIPTION .............................................................................. 26

IC BLOCK DIAGRAM ................................................................................ 27

CIRCUIT BOARDS ..................................................................................... 33

TEST PROGRAM ....................................................................................... 52

INSPECTIONS ...........................................................................................59

UPDATING THE FIRMWARE .................................................................... 64

PARTS LIST

IC & DIODE FIGURES

BLOCK DIAGRAM

CIRCUIT DIAGRAM

Copyright (c) NEXO S.A. All rights reserved. PDF ’ 08.01

Page 2

NXAMP4x1

WARNING: This product contains chemicals known to the State of California to cause cancer, or birth defects or other reproductive harm.

DO NOT PLACE SOLDER, ELECTRICAL/ELECTRONIC OR PLASTIC COMPONENTS IN YOUR MOUTH FOR ANY REASON WHAT SO

EVER!

Avoid prolonged, unprotected contact between solder and your skin! When soldering, do not inhale solder fumes or expose eyes to solder/flux

vapor!

If you come in contact with solder or components located inside the enclosure of this product, wash your hands before handling food.

IMPORTANT NOTICE FOR THE UNITED KINGDOM

Connecting the Plug and Cord

WARNING: THIS APPARATUS MUST BE EARTHED

IMPORTANT. The wires in this mains lead are coloured in accordance with the following code:

As the colours of the wires in the mains lead of this apparatus may not correspond with the coloured markings identifying the terminals in your

plug, proceed as follows:

The wire which is coloured GREEN and YELLOW must be connected to the terminal in the plug which is marked by the letter E or by the safety

earth symbol or colored GREEN or colored GREEN and YELLOW.

The wire which is coloured BLUE must be connected to the terminal which is marked with the letter N or coloured BLACK.

The wire which is coloured BROWN must be connected to the terminal which is marked with the letter L or coloured RED.

GREEN-AND-YELLOW: EARTH

BLUE: NEUTRAL

BROWN: LIVE

■ WARNING

Components having special characteristics are marked and must be replaced with parts having specification equal to those originally

installed.

2

Page 3

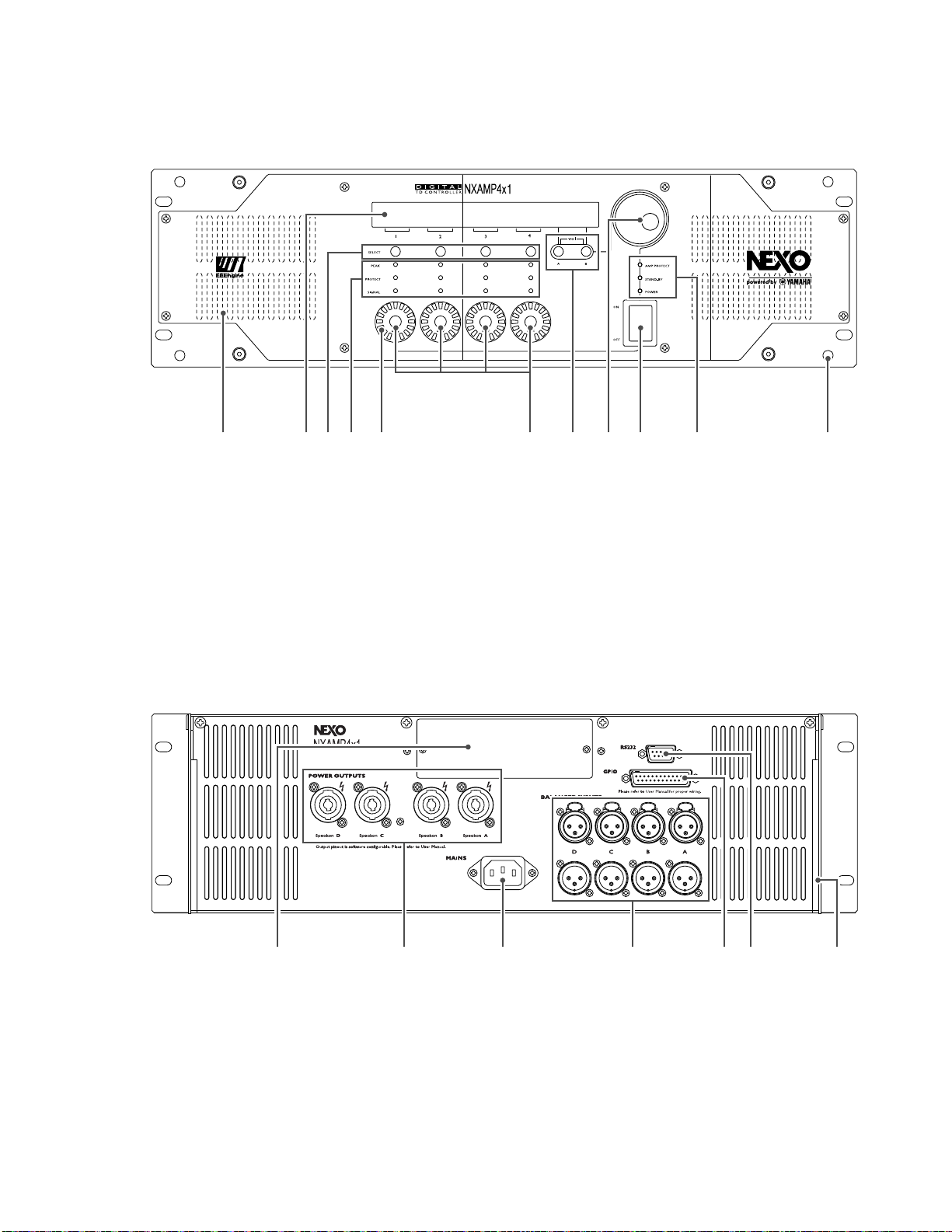

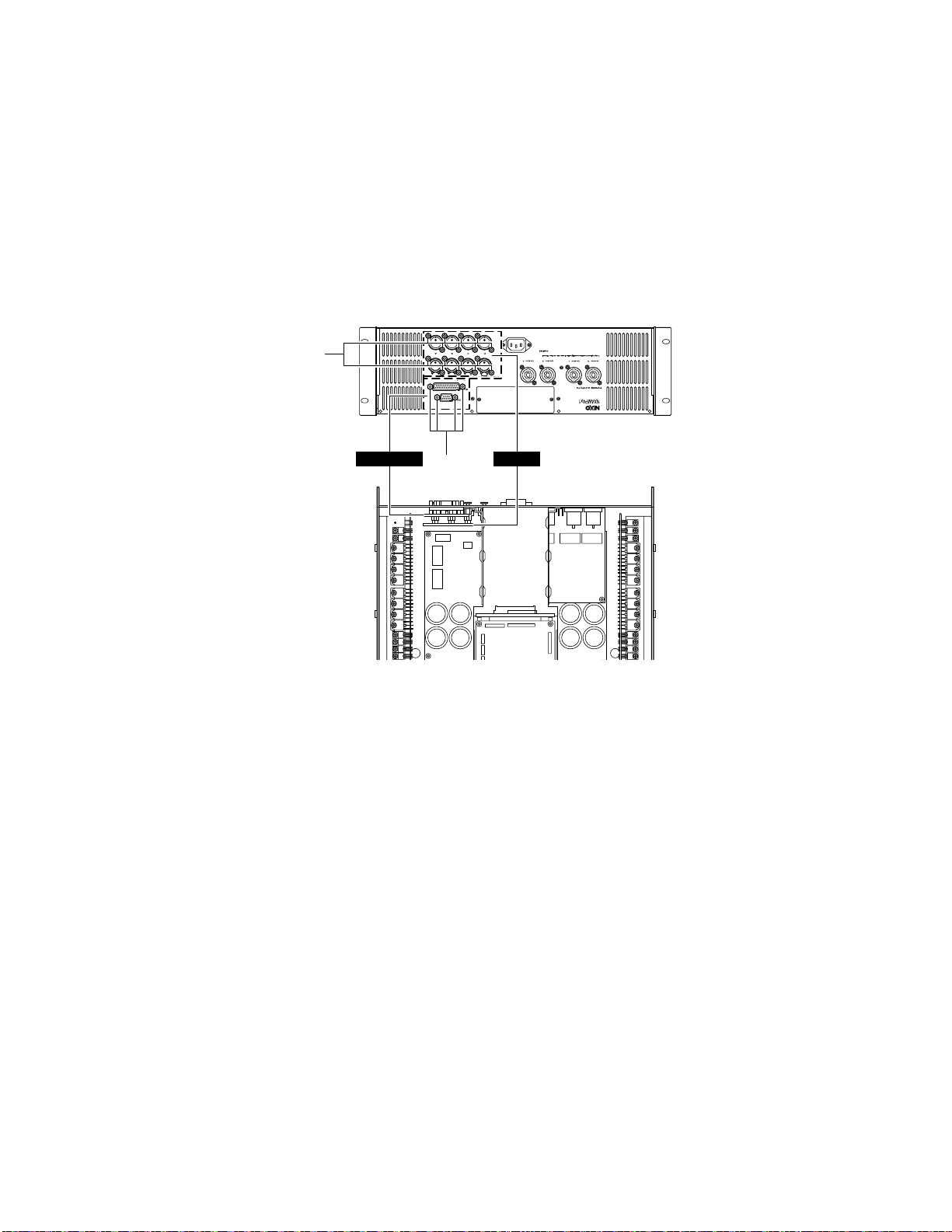

■ PANEL LAYOUT

A0 216 7 53 48 9

• Front Panel

NXAMP4x1

• Rear Panel

1 Power switch

2 Amplifier indicators

3 LCD display

4 Encoder

5 Navigation buttons (A & B)

6 Volume indicators

7 Mute buttons

8 Select buttons

9 Channel indicators

0 Air intakes

A Screw holes for handles

1 Mains connectors

2 Balanced audio inputs with link

3 Expansion slot

4 Power outputs

6 5 73 24 1

5 RS-232 Firmware update port

6 GPIO port

7 Rear end mounting holes

3

Page 4

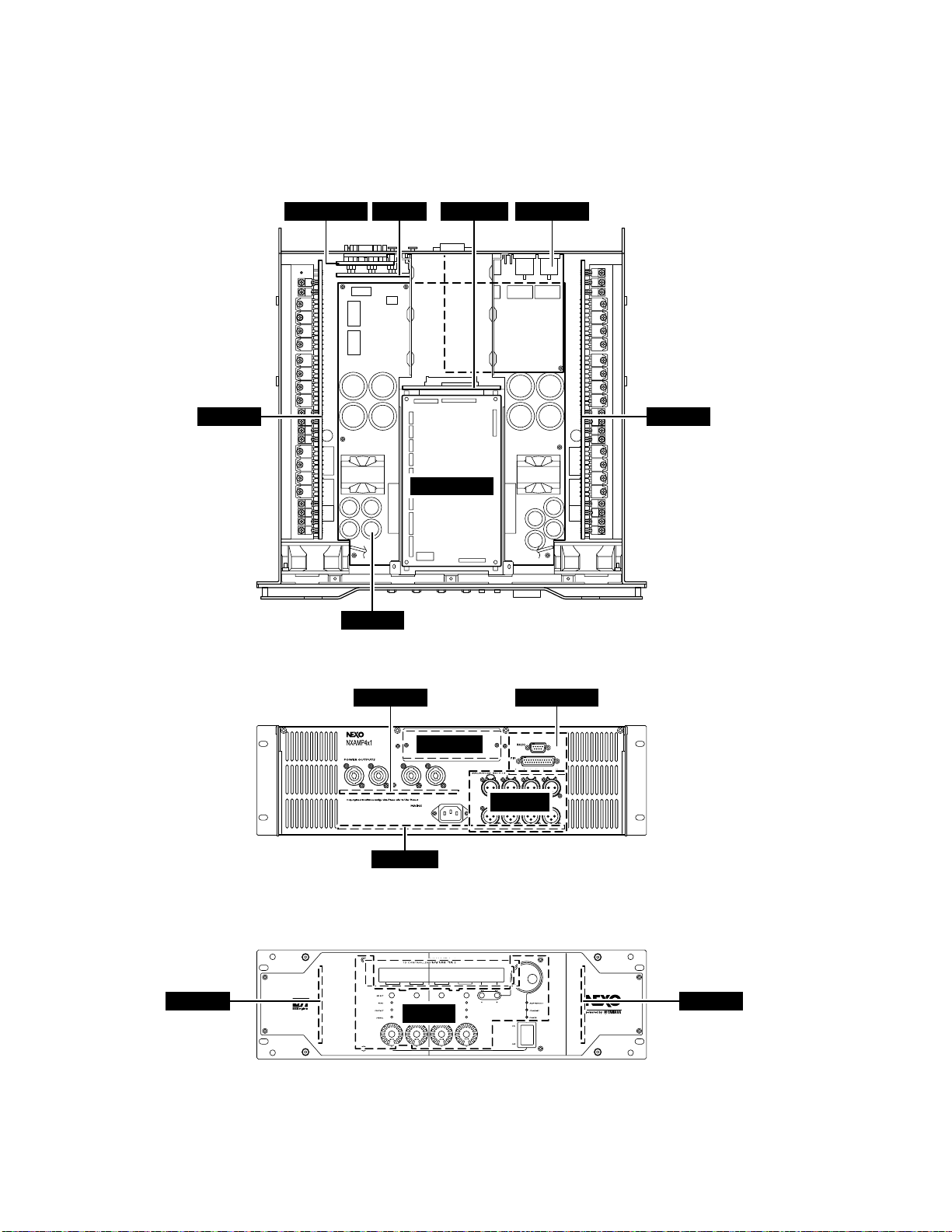

NXAMP4x1

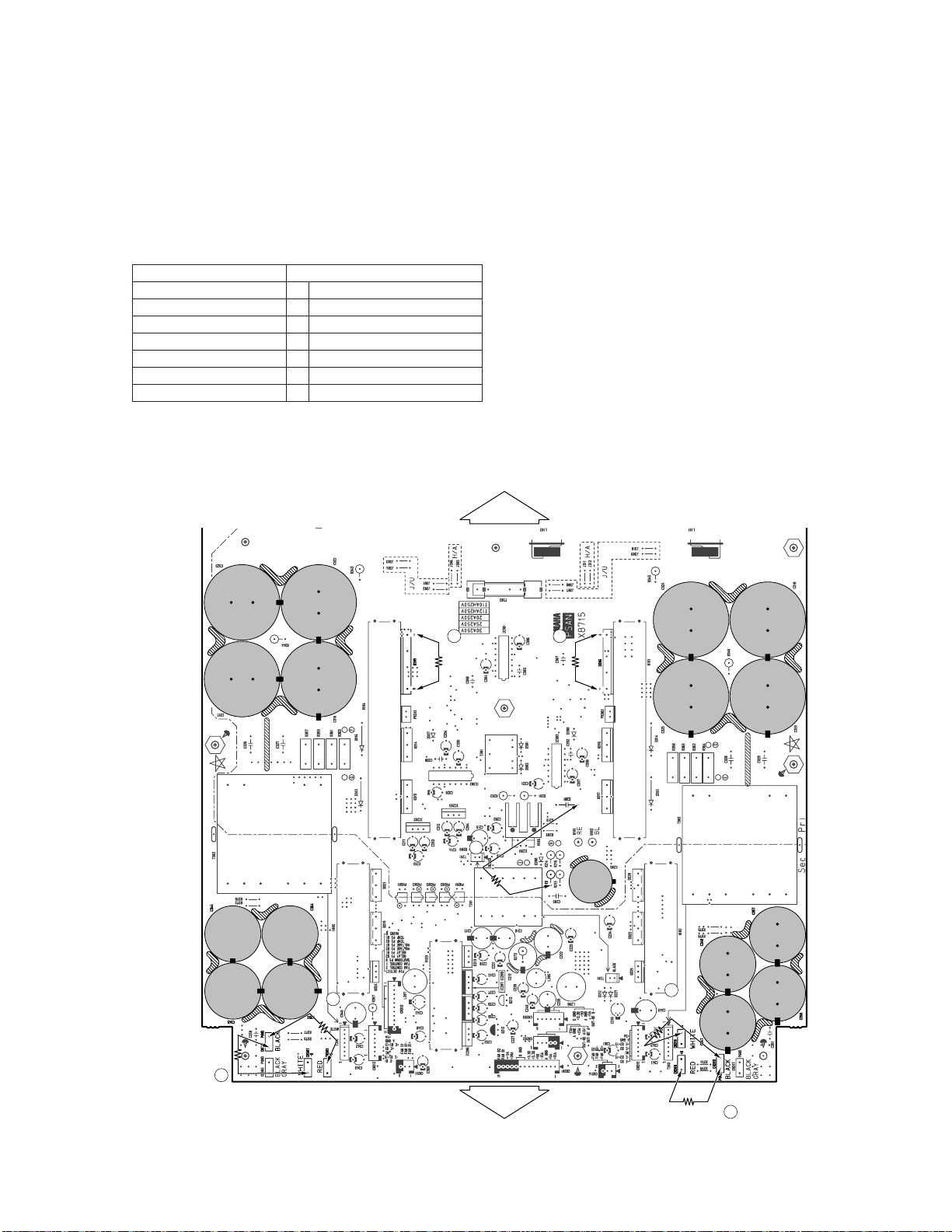

■ CIRCUIT BOARD LAYOUT

PAANL

(PA unit)

RS232-GPI

PSANL

INANL

OPT-AN

CONTROL

OUTANL

PAANL

(PA unit)

Rear Panel

OUTANL

RS232-GPI

OPT-AN

INANL

PSANL

Front Panel

(PA unit) (PA unit)

PN-AN

PAANLPAANL

4

Page 5

C323 C322

C317 C316

C324 C318

C325

C205

C344 C354

C345 C355

C357

C356

C348

C347

C319

C323 C322

REAR

FRONT

C317 C316

C324 C318

C325

C205

C201C201

R213R213

C344 C354

C345 C355

C357

C356

C348

C347

C319

D305

220 ohms/

10W

220 ohms/

10W

220 ohms/

10W

220 ohms/

10W

220 ohms/10W220 ohms/10W

220 ohms/10W

220 ohms/10W220 ohms/10W

220 ohms/10W220 ohms/10W

220 ohms/10W

D306D306

1

3

4

2

CN316CN316

CN307 CN305CN307 CN305 CN308 CN309CN308

CN310CN310

CN309

6

7

5

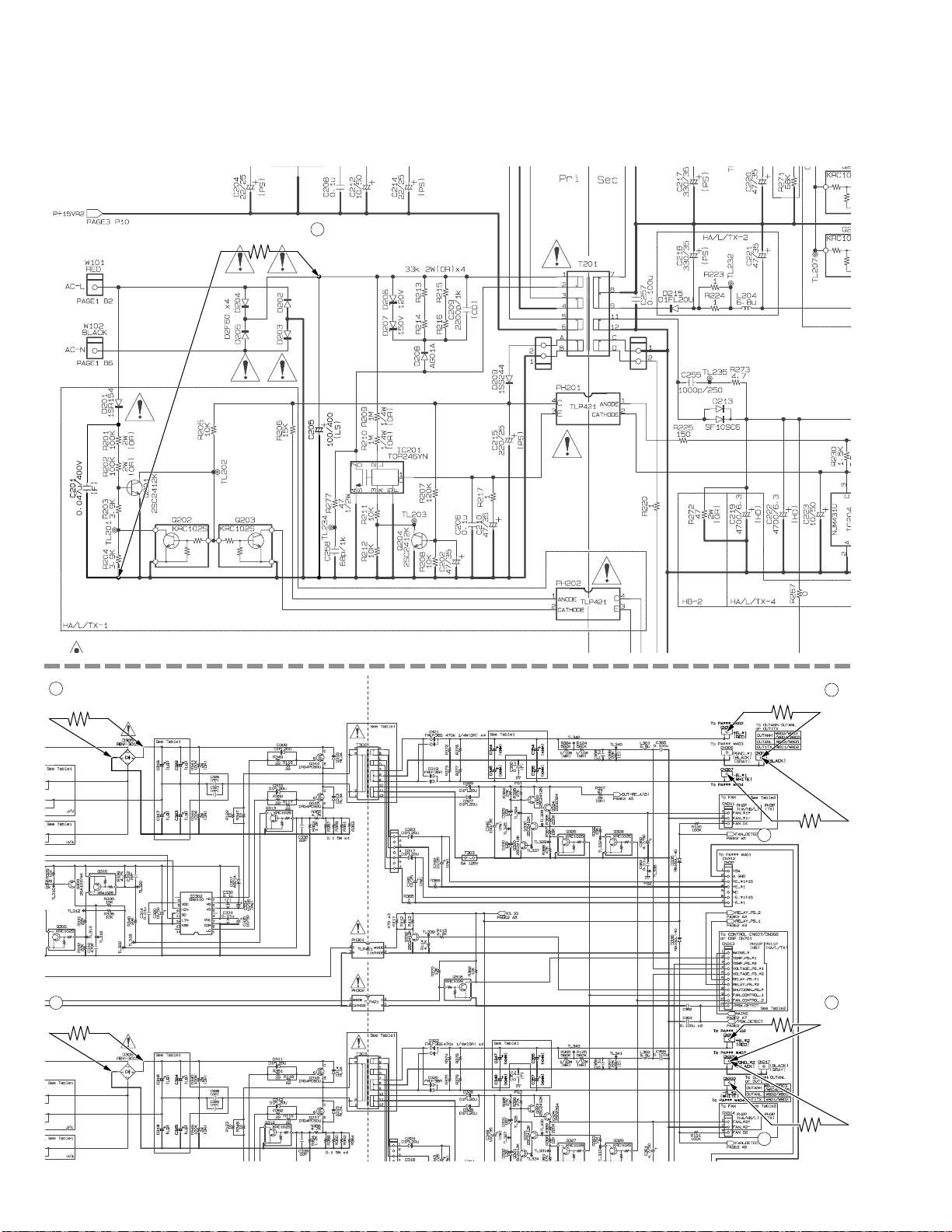

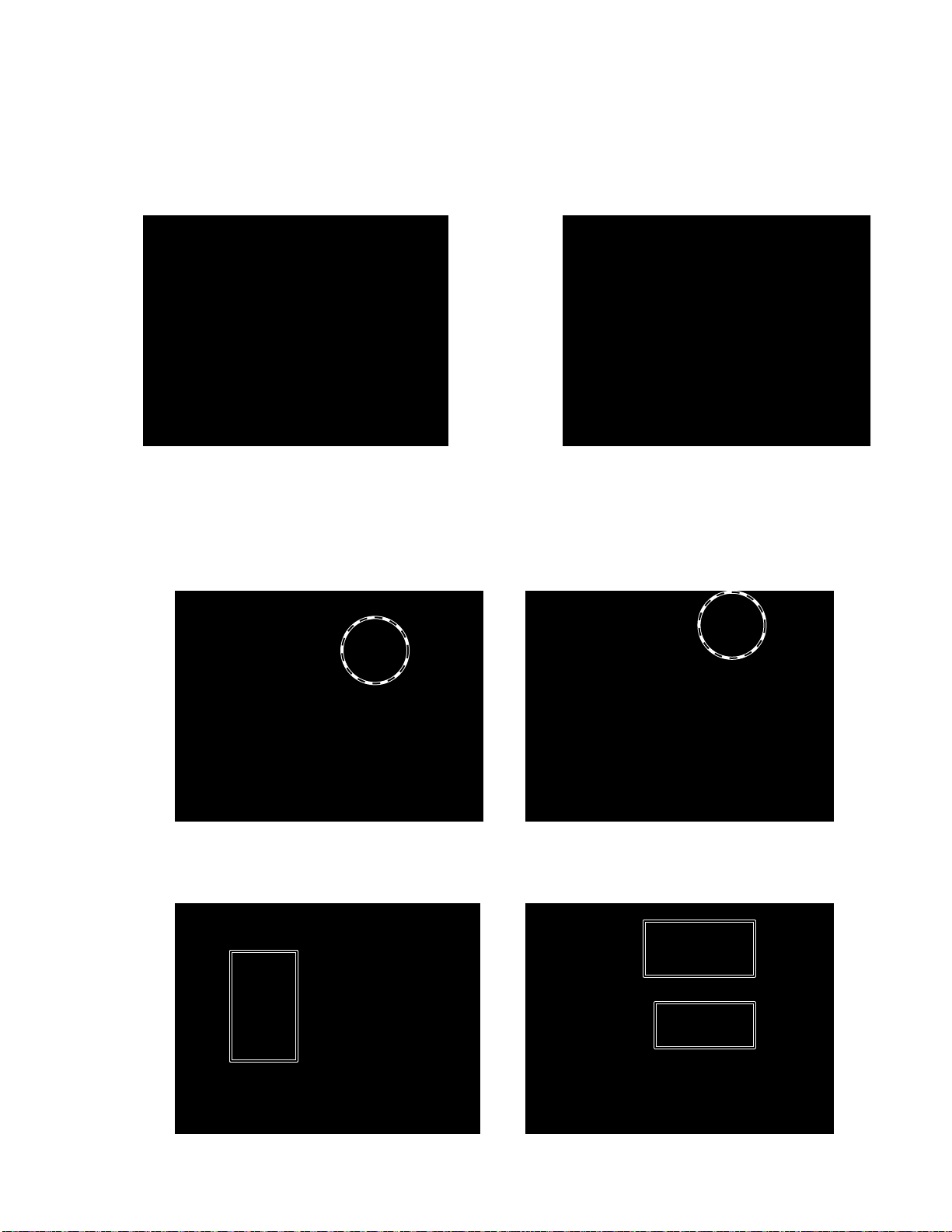

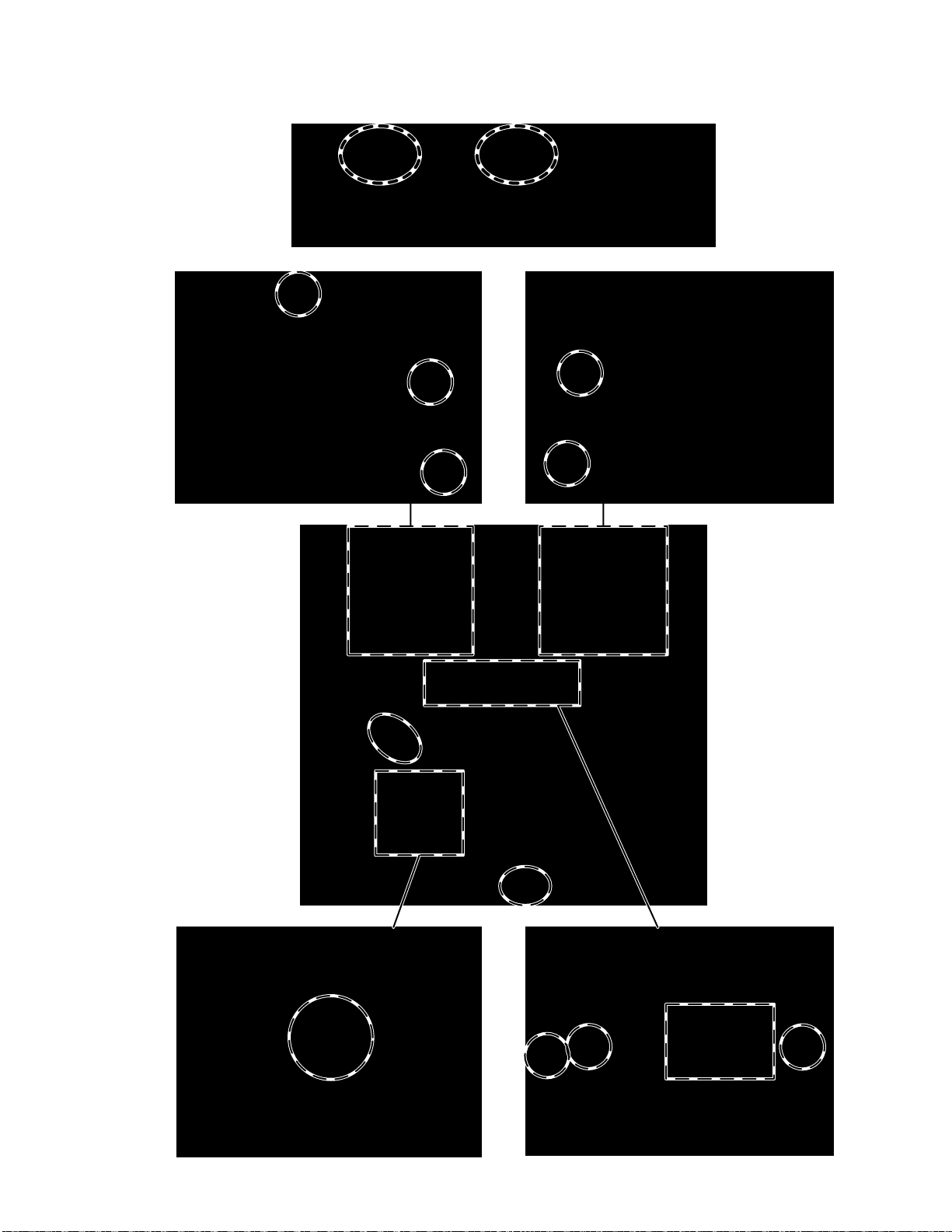

■ SERVICE PRECAUTIONS

Safety measures

• Some component parts on the PSANH circuit board maintain a high voltage even when the power is switched off.

For this reason to av oid an electrical shock, do not touch

the upper metallic part of the following capacitors until

the remaining voltage has discharged.

Capacitors Discharging point

C316, C317, C322, C323

C318, C319, C324, C325

C344, C354

C345, C355

C347, C356

C348, C357

C205

PSANL circuit board

1

D305: + pin <=> D305: - pin

2

D306: + pin <=> D306: - pin

3

CN305 <=> CN316

4

CN307 <=> CN316

5

CN308 <=> CN309

6

CN310 <=> CN309

7

R213: lead <=> C201

NXAMP4x1

[Discharging Method]

Before starting the service work, connect discharging

resistors (220 ohms 10W) to the terminals indicated in

the figure below to discharge electricity. (7 points)

The required discharging time is about 10 seconds. Check

that the DC voltage between the terminals measures close

to 0 (zero) volts using a multi-meter to mak e sure that the

discharge is completed.

Note:

Do not touch the IC201 and its heat sink before discharging the C205.

5

Page 6

NXAMP4x1

C205

C201

C316

D305

C354C344

C355C345

C356C347

C357C348

C318

C319

D306

C305

C307

C316

220 ohms/10W

220 ohms/10W

PSANL circuit diagram

C201

220 ohms/10W

7

C205

1

220 ohms/10W

2

220 ohms/10W

6

D305

D306

C316

C322

C317 C323

C318

C324

C319 C325

220 ohms/10W

3

C305

C354C344

C316

C355C345

C307

4

220 ohms/10W

220 ohms/10W

5

C356C347

C357C348

6

220 ohms/10W

Page 7

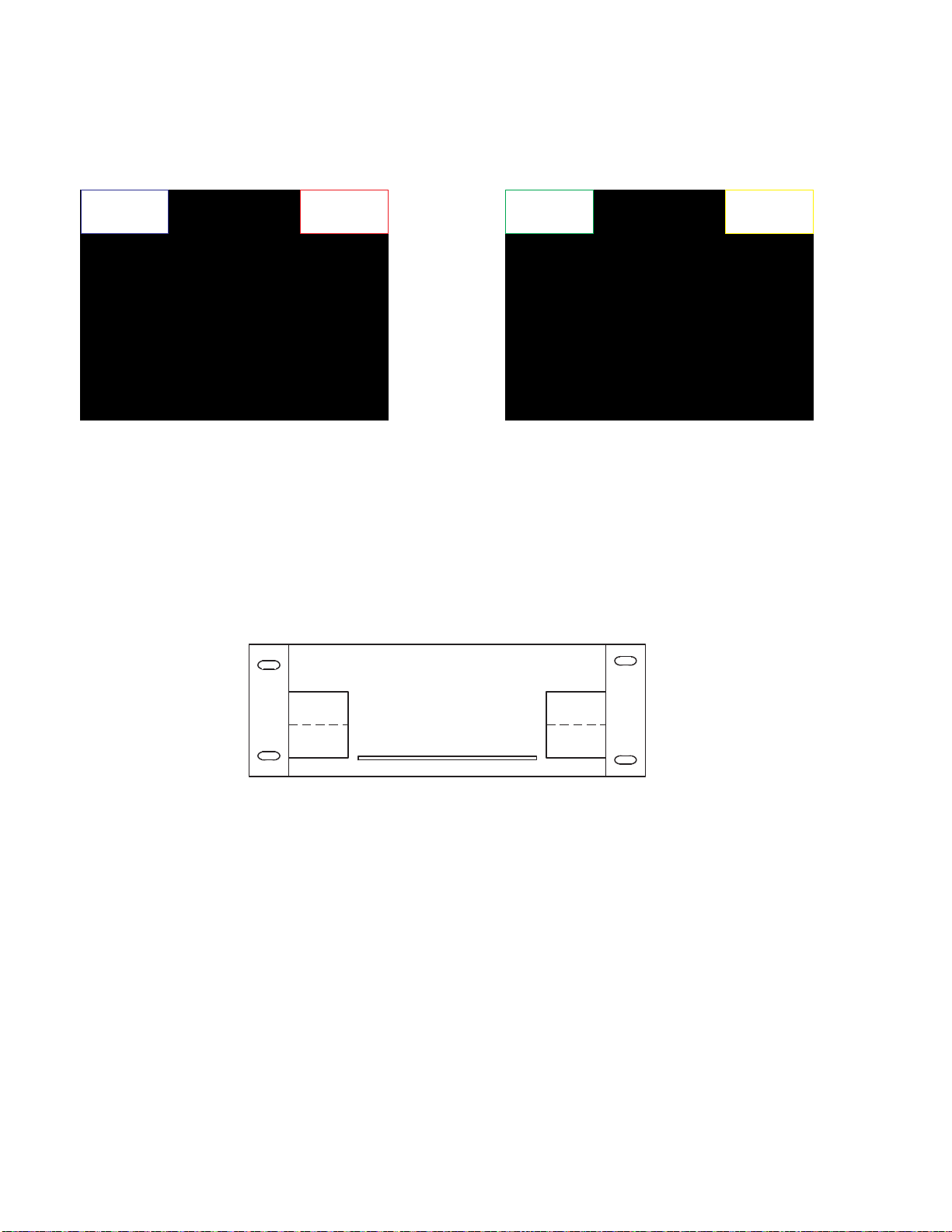

■ OVERALL ASSEMBLY WIRING

115 ± 1 mm

25 ± 1 mm

90˚

90˚

This product has various cables (wires and connector assemblies) inside. To prevent touching component to the cables and/

or connection mistake, perform the cable connection and fixing cables according to the following instructions referring the

wiring diagram, P3 of the circuit diagram.

Notice: Since the following pictures are taken of the preproduction product, they may differ from the commodity products in

detail. However, the wiring and so on is not so differ between them. So, refer only to wiring and so on.

1. Wiring of the PN-AN circuit board

1) Process the flat cable (WK02100). (Fig. 1)

2) Connect the flat cable (WK02100) to the PN-AN circuit board. (Fig. 2)

3) Install the PN-AN circuit board to the front panel. (Fig. 3)

NXAMP4x1

115 ± 1 mm

90˚

Fig. 1

Fig. 2 Fig. 3

90˚

25 ± 1 mm

2. Wiring of the power switch

1) Install the power switch to the front panel with its terminals set downward. (Fig. 4, 5)

Fig. 4 Fig. 5

7

Page 8

NXAMP4x1

Check

2) Confirm that the power switch is set to the off position as shown in the figure 6. (Fig. 6)

3) Twist the wires of the power switch assembly more than three times.

4) Connect the connector of the power switch assembly to the connector (CN103). (Fig. 7)

Check

Fig. 6

3. Wiring of the FAN

Connect the connector of the FAN to the each ter minal. (Fig. 8)

4. Attaching of the support cushion

Attach the support cushion (WN15950) at the specified

area on the pattern side of the CONTROL circuit board.

(Fig. 9)

Note: Be sure to remove the oil and the dust, etc. on the

attaching surface before attaching the support

cushion.

Fig. 7

Fig. 8

Fig. 9

8

Page 9

5. Wiring of the AC-INLET

Cord holder

Cord holder

a) Set a cord holder before installing the PSAN circuit board

on the enclosure. (Fig. 10)

NXAMP4x1

b) Set a ferrite-core at the specified area on the PSAN cir-

cuit board, and fasten the ferrite-core with the cord holder .

(Fig. 11)

Fig. 10

Fig. 11

c) Pass the live and neutral wires of the AC-INLET through the ferrite core’s hole twice and wind them to the ferrite core.

Screw an each screw terminal to the specified terminal. (Fig. 12, 13)

Fasten the GND wire with a cord holder. (U destination) (Fig. 12)

Screwing torque: GND LINE 1.8N • m / L, N LINE 0.78 • m

Cord holder

Cord holder

Fig. 12 Fig. 13

(U.S.A. model) (Chinese model)

d, e)Fix the wires to the terminal using the screws, and refer to the fig. 14 and fig. 15 for the direction of each terminal.

Fig. 14 Fig. 15

9

Page 10

NXAMP4x1

6. Wiring of the PA-UNIT

Connect the wires to the connectors (CN401, CN403). (Fig. 16, 17)

CN403

BLUE

CN401

RED

CN403

GREEN

Fig. 16 Fig. 17

NOTE: The followings are wires to be connected.

CN401: WK02080

CN403: WK90770

Install this PA-UNIT on the left side of enclosure.

Hereafter, this unit is called PA-UNIT of CH1,

CH2.

The following figure describes a layout drawing of the PA-UNITs seen from the front panel. (Fig. 18)

*

NOTE: The followings are wires to be connected.

CN401: WK90790

CN403: WK17110

Install this PA-UNIT on the right side of enclosure.

Hereafter, this unit is called PA-UNIT of CH3,

CH4.

CN401

YELLOW

CH2

BLUE

CH1

RED

PSANHL

CH3

YELLOW

CH4

GREEN

Fig. 18

7. Wiring of the flat cable and fastening wires

Connect the following wires at first.

CN313: WK68760

CN201: WK68770

a) Install the RS232-GPI circuit board on the enclosure after connecting the wire (WM15830) to it.

b) Connect the wires (WK16830, WN52530) from each PA UNIT to the FASTON terminals of the OUTANL circuit board.

PA-UNIT (CH1, CH2) : WN52530 (ORANGE) –> CN805

WK16830 (YELLOW) –> CN806

PA-UNIT (CH3, CH4) : WN52530 (ORANGE) –> CN807

WK16830 (YELLOW) –> CN808

Then fold the wires (WK16830, WF44430) at the center of them, and fasten them with a cord holder. (Fig. 19)

c) Connect the wires (WK16820 x2) to the connectors (CN306, CN317) of the PSAN circuit board.

Connect the wire (WK14200) to the connector (CN202) of the PSAN circuit board.

Fasten these wires with a cord holder at the position as shown in the figure. (Fig. 19)

d) Connect the wire (WK14210) of PA-UNIT (CH3, CH4) to the connector (CN315).

Fasten the wire (WK14210) and the wires (WK16820 x2, WK14200) with a cord holder at the position where the wire (WK14210)

is vertically pulled from PA-UNIT. Before fastening, pull the wires (WK16820 x2, WK14200) toward the front panel side in

advance.

10

Page 11

NXAMP4x1

a)

c)

b)

b)

e) d)

f)

f)

e) Connect the wire (WK14210) of PA-UNIT (CH1, CH2) to the connector (CN312).

Fasten the wire (WK14210) and the wire (WK02090) with a cord holder at the position where the wire (WK14210) is vertically

pulled from PA-UNIT. Before fastening, pull the wire (WK02090) toward the front panel side in advance.

f) Twist the wires (white, red and blac k) of PA-UNIT more than two times, and connect them to the FASTON terminals according

to the wire color displayed on the PSANL circuit board.

Then bend these wires, and fasten them with a cord holder. (Fig. 20)

a)

b)

c)

b)

e)

f)

d)

f)

Fig. 19

Fig. 20

11

Page 12

NXAMP4x1

g)

h)

g) Fasten these wires (WK17900, WK17910 and WK94710) with a cord holder to the hexagonal spacer. (Fig. 21)

h) Bend the wire (WK14200) and wire (WK16820) connected to the connector (CN317), and fasten the wires (WK14210, WK16820

x 2 and WK14200) with a cord holder. (Fig. 21)

h)

g)

Fig. 21

Note: When connecting the connector assembly to the CONTROL circuit board, confirm that the connector housing pin

number of the connector assembly is the same as the connector pin number of the circuit board.

i) Fasten the wires (WK02080, WK90770) with a cord holder at the hole of the RS232-GPI circuit board. (Fig. 22)

j) Fasten the wires (WK02080, WK90770 and WK02070) with a cord holder at the hole of the enclosure.

Fasten the wires (WK90790, WK17110) with a cord holder at the hole of the enclosure. (Fig. 22)

k) Fasten the wires (WK90790, WK17110) with a cord holder at the hole of the OPT-AN circuit board. Then connect the flat cable

(WK02120). (Fig. 22)

l) Fasten the wires (WK02080, WK90770, WK90790, WK17110 and WK02070) with a cord holder at the position close to the

OPT-AN circuit board. (Fig. 22)

m) Bend the wire (WK02090), and fasten the wires (WK02090, WK68760 and WK68770) with a cord holder. (Fig. 22).

n) Bend the flat cable as shown in the figure. (Fig. 22)

12

Page 13

i)

j)

*

1

j)

*

2

j)

*

2

j)

*

1

m)

o)

n)

l)

k)

k)

k)

The hole of the enclosure

NXAMP4x1

The hole of the enclosure

i)

j)

1

*

1

j)

*

n)

j)

2

*

j)

2

*

m)

o)

k)

k)

l)

Fig. 22

k)

13

Page 14

NXAMP4x1

Switch knob Switch knob

o) Bend the flat cable to avoid touching the top cover. (Fig. 23, 24)

Fig. 23 Fig. 24

8. Color of the connectors connected to the connector CN012-CN015

Connect the connector assembly from the PA unit to the CONTROL circuit board as shown in the figure below. (Fig. 25)

CN012

RED

CN013

BLUE

CN014

YELLOW

CN015

GREEN

Fig. 25

9. Change of the destination

Set the knob position of the switch SW001 on the CONTROL circuit board as shown in the figure below. (Fig. 26, 27)

U destination CHN destination

Switch knob Switch knob

14

Fig. 26 Fig. 27

Page 15

10. Insulation distance between WK17110 and primary side capacitor

Perform wiring the connector assembly WK17110 with care so that its uncovered portion with the SUMI tube does not touch

the capacitor C316 on primary side of the PSANL circuit board. (Fig. 28, 29)

Fig. 28 Fig. 29

NXAMP4x1

11. Insulation distance between WK14210 and primary side capacitor

Perform wiring the connector assembly WK14210 with care so that its uncovered portion with the SUMI tube does not touch

the capacitors C317 and C319 on primary side of the PSANL circuit board. (Fig. 30, 31)

C324 C318

C325 C319

Fig. 30

C323 C322

C317 C316

C324 C318

C325 C319

C323 C322

C317 C316

Fig. 31

15

Page 16

NXAMP4x1

12. Prevention of touching WK02070 to connector terminal

Perform wiring the connector assembly WK02070 with care so that its uncovered portion with the SUMI tube does not touch

the bare terminal of the connector CN203 of the RS232-GPI circuit board. (Fig. 32)

GPI circuit board

IOAN circuit board

Fig. 32

GPI circuit board

IOAN circuit board

13. Adhesive cloth tape

Cover the two scre ws near R587 and R588 in each PA unit (190 and 230) with adhesive cloth tape (185 and 225) as shown in

the figure below. (Fig. 33)

16

Fig. 33

Page 17

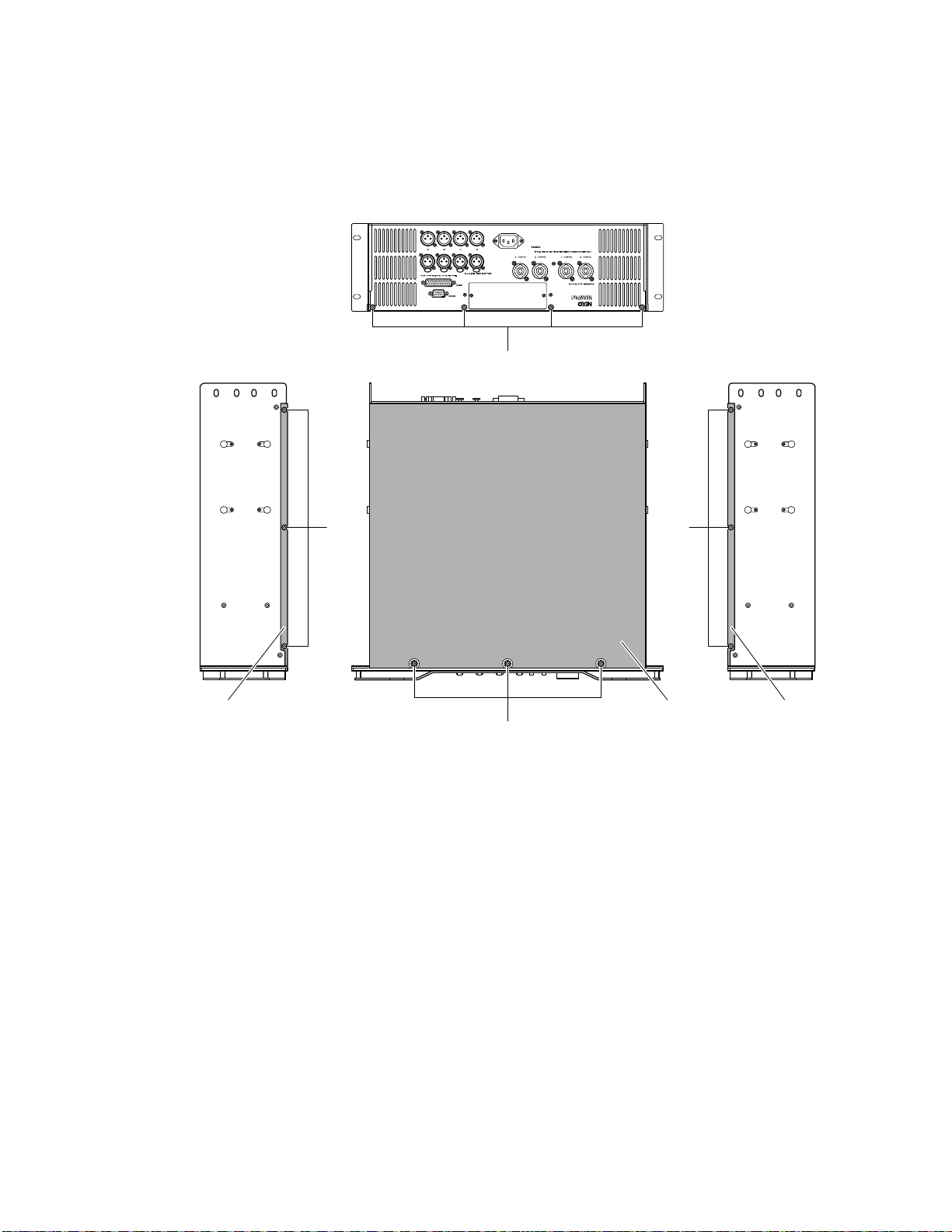

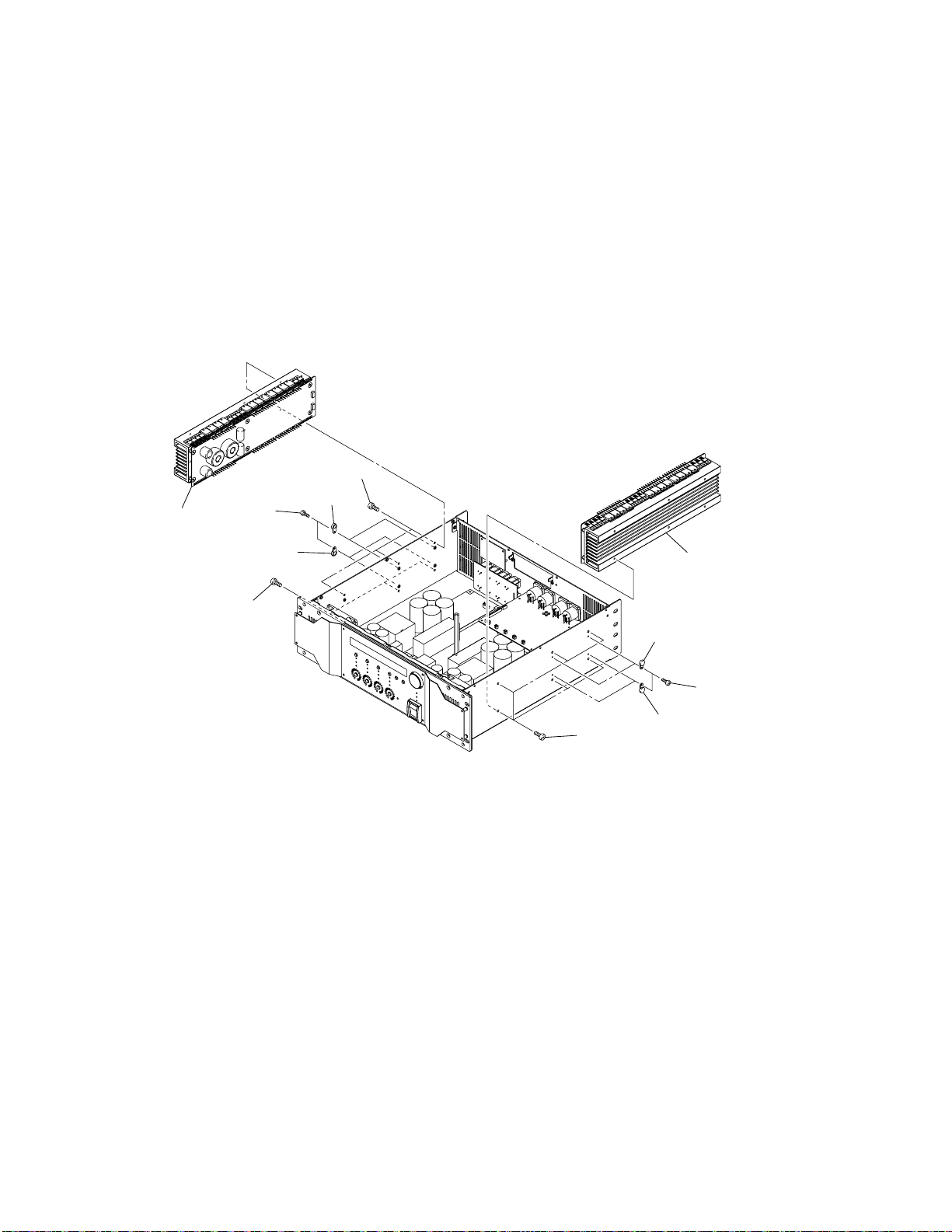

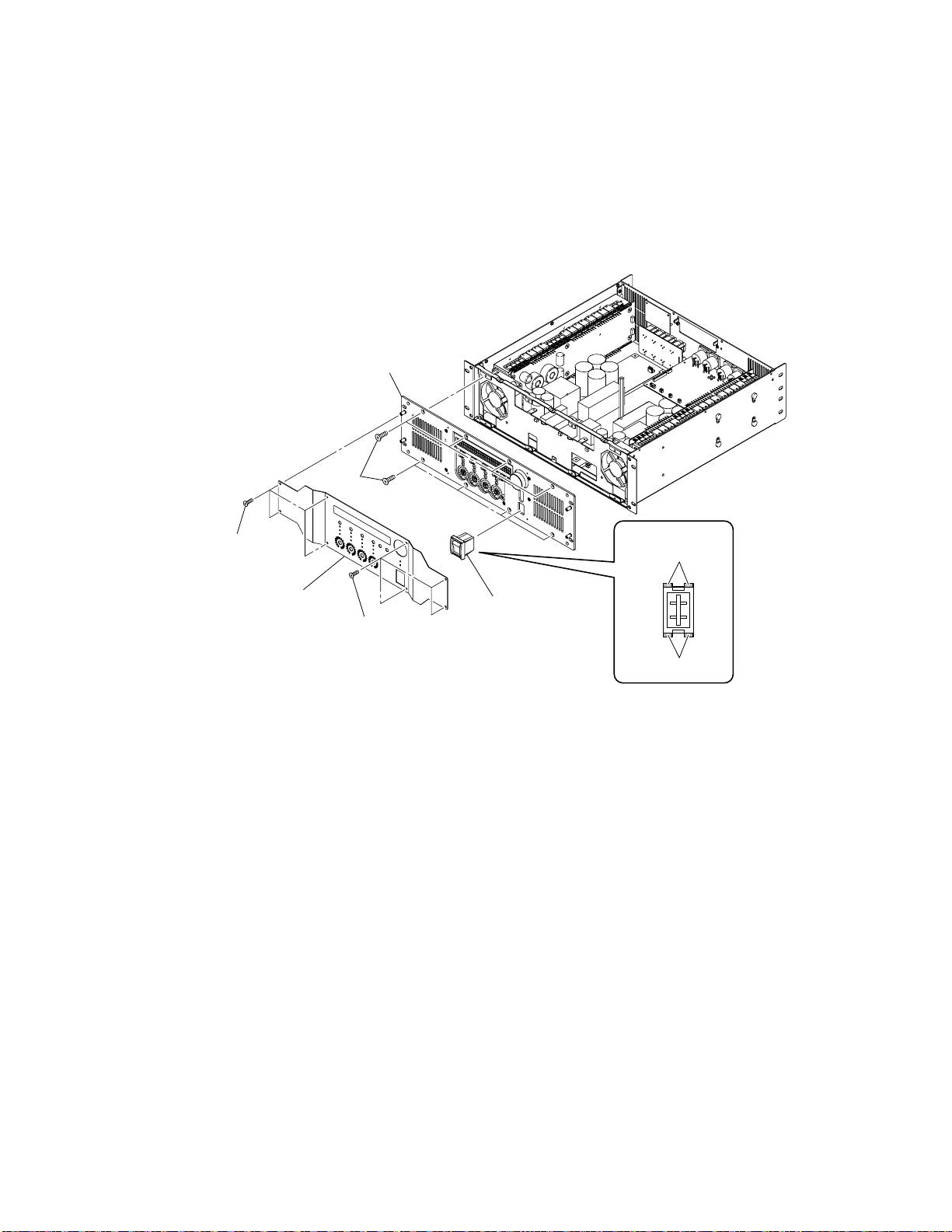

■ DISASSEMBLY PROCEDURES

1. Top Cover (Time required: about 3 minutes)

1-1. Remove the thirteen (13) screws marked [650]. (Fig. 1)

1-2. The top cover can then be removed. (Fig. 1)

NXAMP4x1

[650]

[650] [650]

[650]: Bind Head Screw 4x8 MFZN2B3 (--)

(Fig. 1)

Top cover Top coverTop cover

[650]

17

Page 18

NXAMP4x1

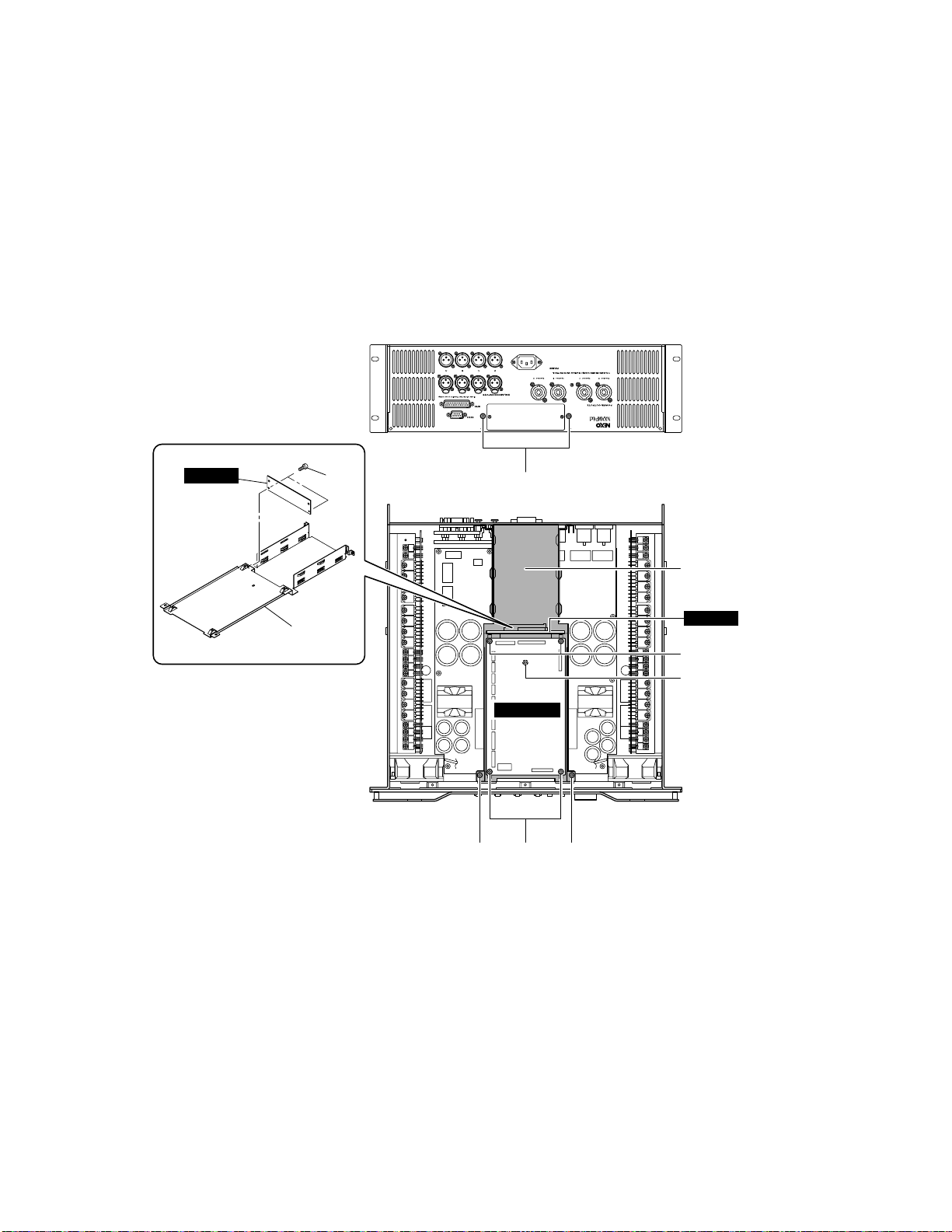

2. CONTROL Circuit Board, OPT angle and OPT-AN Circuit Board

(Time required: about 10 minutes)

2-1. Remove the top cover. (See procedure 1.)

2-2. Remove the four (4) screws marked [430]. (Fig. 2)

2-3. Disconnect the connector assemblies from other units connected to the CONTROL circuit board. (Fig. 2)

2-4. The CONTROL circuit board can then be removed. (Fig. 2)

2-5. Remove the three (3) screws marked [400] and the two (2) screws marked [410]. (Fig. 2)

2-6. Remove the OPT angle with the OPT-AN circuit board. (Fig. 2)

2-7. Remove the two (2) screws marked [380]. (Fig. 2)

2-8. The OPT-AN circuit board can then be removed. (Fig. 2)

OPT-AN

OPT angle

[380]: Bind Head Tapping Screw-S 3x6 MFZN2W3 (--)

[400]: Bind Head Tapping Screw-S 3x6 MFZN2W3 (--)

[410]: Bind Head Tapping Screw-S 3x6 MFZN2B3 (--)

[430]: Bind Head Tapping Screw-S 3x6 MFZN2W3 (--)

[380]

[410]

OPT angle

OPT-AN

[430]

[400]

CONTROL

[430][400] [400]

18

(Fig. 2)

Page 19

NXAMP4x1

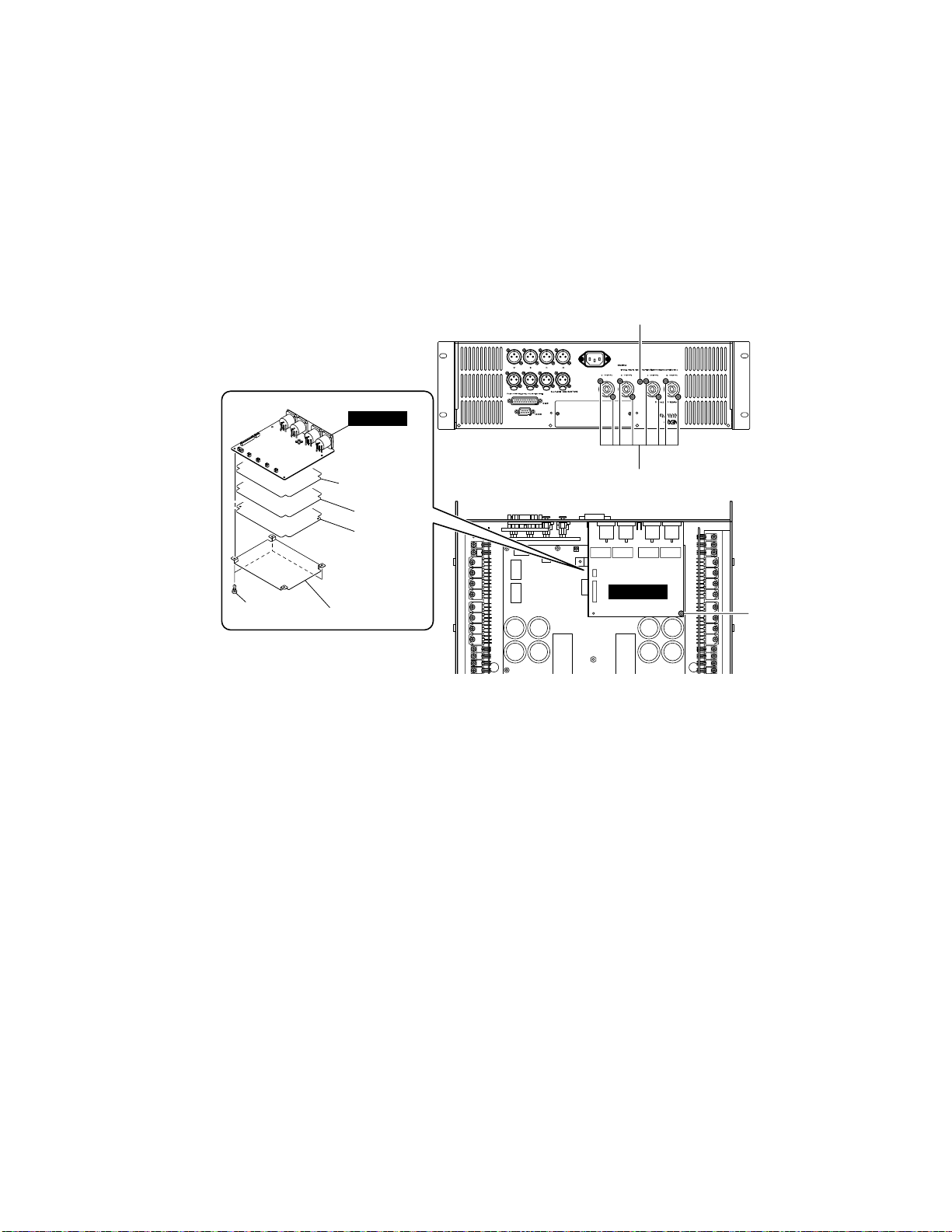

3. OUTANL Circuit Board (Time required: about 15 minutes)

3-1. Remove the top cover. (See procedure 1.)

3-2. Remove the CONTROL circuit board and the OPT angle. (See procedure 2.)

3-3. Remove the eight (8) screws marked [280], the one (1) screw marked [290] and the one (1) screw marked [285]. (Fig. 3)

3-4. Disconnect the connector assemblies from other units connected to the OUTANL circuit board. (Fig. 3)

3-5. The OUTANL circuit board with the two (2) insulation sheets and the two (2) shields can then be removed. (Fig. 3)

3-6. Remove the three (3) plastic rivets marked [277]. (Fig. 3)

3-7. Remove the insulation sheet 1, the shield 1, the shield 2 and the insulation sheet 2 from the OUTANL circuit board. (Fig. 3)

[290]

OUTANL

Insulation

sheet 2

Shield 2

Shield 1

[277]

[277]: Plastic Rivet NRP-345 (--)

[280]: Flat Head Tapping Screw-B 3x8 MFZN2B3 (--)

[285]: Bind Head Tapping Screw-S 3x6 MFZN2W3 (--)

[290]: Bind Head Tapping Screw-B 3x8 MFZN2B3 (--)

Insulation sheet 1

(Fig. 3)

[280]

OUTANL

[285]

19

Page 20

NXAMP4x1

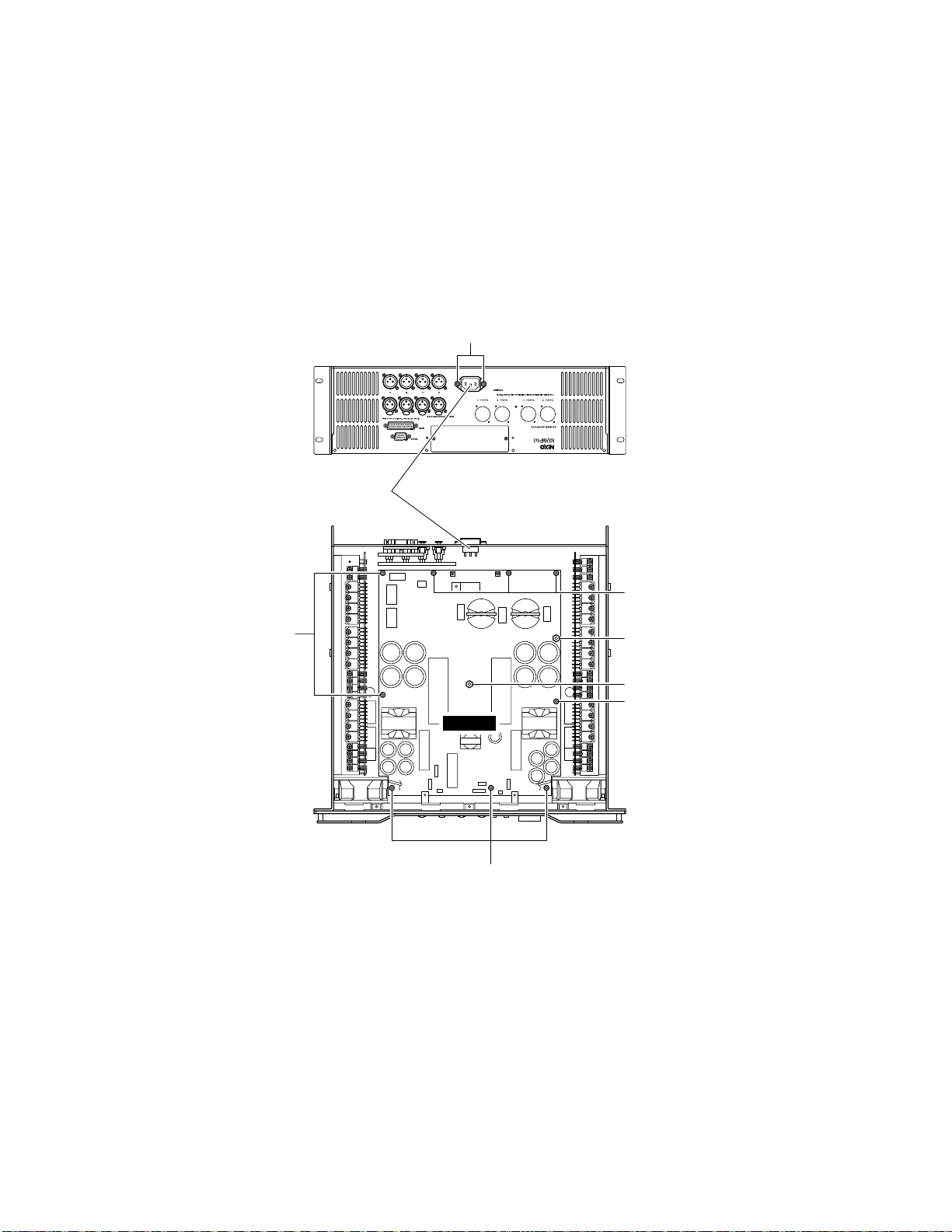

4. PSANL Circuit Board (Time required: about 20 minutes)

4-1. Remove the top cover. (See procedure 1.)

4-2. Remove the CONTROL circuit Board and the OPT angle. (See procedure 2.)

4-3. Remove the OUTANL Circuit Board. (See procedure 3.)

4-5. Remove the two (2) screws marked [150], and remove the ACPS connector assembly. (Fig. 4)

4-6. Remove the nine (9) screws marked [100], the one (1) hexagonal spacers marked [90] and the one (1) hexagonal spacer

marked [95]. (Fig. 4)

4-7. Disconnect the connector assemblies from other units connected to the PSANL circuit board. (Fig. 4)

4-8. The PSANL circuit board can then be removed. (Fig. 4)

[150]

ACPS connector assembly

[100]

PSANL

[100]

[90]: Hexagonal Spacer H=89 B=5.5 (--)

[95]: Hexagonal Spacer H=41 B=5.5 (--)

[100]: Bind Head Tapping Screw-S 3x6 MFZN2W3 (--)

[150]: Flat Head Tapping Screw-B 3x8 MFZN2B3 (--) (U destination)

[150]: Bind Head Tapping Screw-B 3x8 MFZN2B3 (--) (O destination)

[100]

[95]

[90]

[100]

20

(Fig. 4)

Page 21

NXAMP4x1

5. INANL Circuit Board (Time required: about 7 minutes)

5-1. Remove the top cover. (See procedure 1.)

5-2. Remove the sixteen (16) screws marked [70]. (Fig. 5)

5-3. Disconnect the connector assembly from other unit con-

nected to the INANL circuit board. (Fig. 5)

5-4. The INANL circuit board can then be removed. (Fig. 5)

[70]

RS232-GPI

[330]

6. RS232-GPI Circuit Board (Time required: about 7 minutes)

6-1. Remove the top cover. (See procedure 1.)

6-2. Remove the four (4) hexagonal lock screws marked

[330]. (Fig. 5)

6-3. Disconnect the flat cable from other unit connected to

the RS232-GPI circuit board. (Fig. 5)

6-4. The RS232-GPI circuit board can then be removed.

(Fig. 5)

INANL

[70]: Bind Head Tapping Screw-B 2.6x8 MFZN2B3 (--)

[330]: Hexagonal Lock Screw (--)

(Fig. 5)

21

Page 22

NXAMP4x1

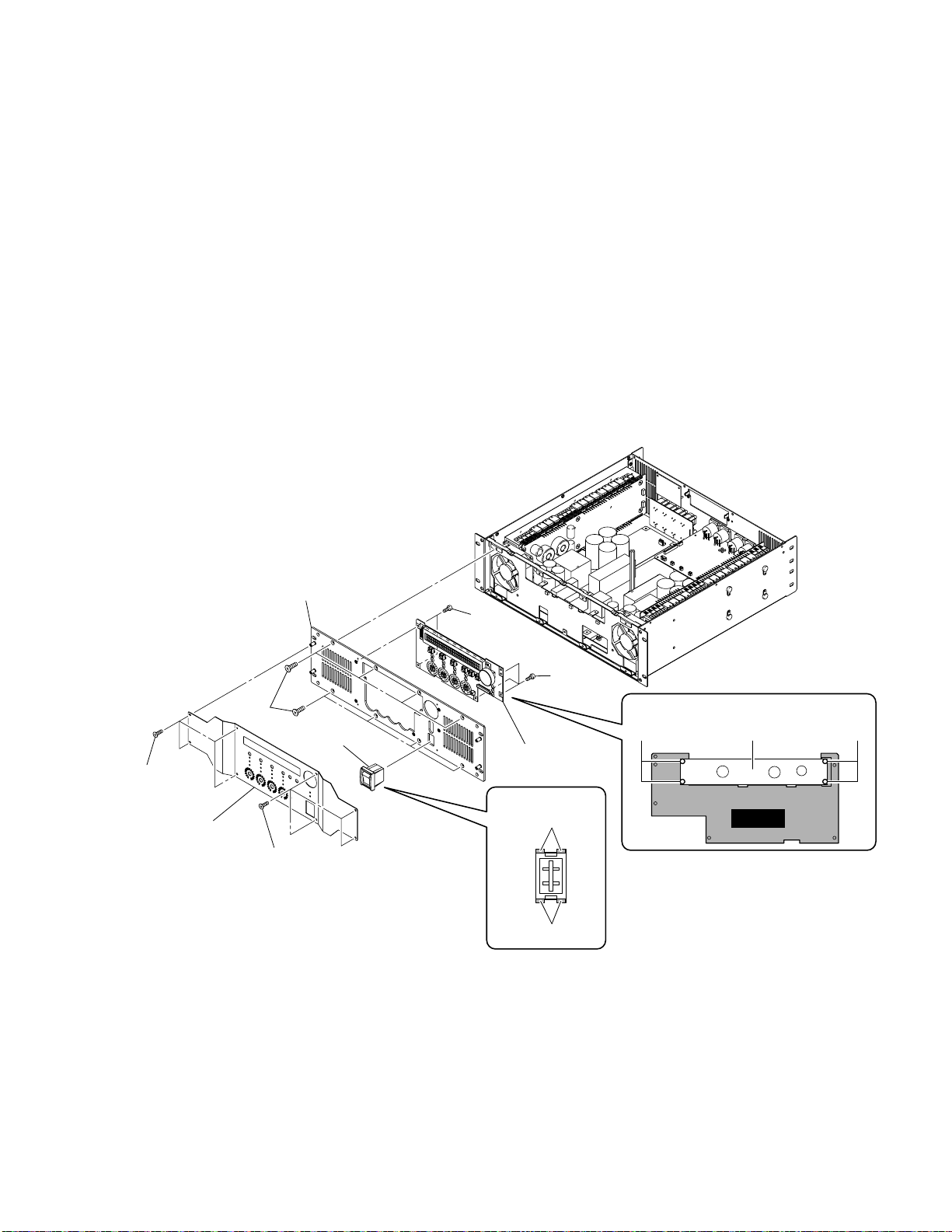

7. Left (CH1, CH2) PA unit (Time required: about 15 minutes)

7-1. Remove the top cover. (See procedure 1.)

7-2. Remove the CONTROL circuit board and the OPT

angle. (See procedure 2.)

7-3. Remove the four (4) screws marked [670A], and re-

move the four (4) screw covers marked [660A]. (Fig. 6)

7-4. Remove the six (6) screws marked [220]. (Fig. 6)

7-5. Disconnect the connector assemblies that connects the

left PA unit and other units. (Fig. 6)

7-6. The left PA unit can then be removed. (Fig. 6)

[220]

[660A]

PA unit

[670A]

[660A]

8. Right (CH3, CH4) PA unit (Time required: about 15 minutes)

8-1. Remove the top cover. (See procedure 1.)

8-2. Remove the CONTROL circuit board and the OPT

angle. (See procedure 2.)

8-3. Remove the four (4) screws marked [670B], and re-

move the four (4) screw covers marked [660B]. (Fig. 6)

8-4. Remove the six (6) screws marked [260]. (Fig. 6)

8-5. Disconnect the connector assemblies that connects the

right PA unit and other units. (Fig. 6)

8-6. The right PA unit can then be removed. (Fig. 6)

PA unit

[220]

[220]: Bind Head Screw 4x8 MFZN2B3 (--)

[260]: Bind Head Screw 4x8 MFZN2B3 (--)

[660A]: Screw Cover T5N (--)

[660B]: Screw Cover T5N (--)

[670A]: Bind Head Tapping Screw-B 3x8 MFZN2B3 (--)

[670B]: Bind Head Tapping Screw-B 3x8 MFZN2B3 (--)

(Fig. 6)

[660B]

[670B]

[660B]

[260]

22

Page 23

NXAMP4x1

[500]

[500]

[40]

[510]

[590]

[590]

Front panel assembly

Front panel 2

Power switch

Power switch

HookHookHook

Hook

LCD assembly

LCD assembly

LCD unit

PN-AN

[40]

9. Front Panel Assembly

(Time required: about 6 minutes)

9-1. Remove the top cover. (See procedure 1.)

9-2. Remove the CONTROL circuit Board and the OPT

angle. (See procedure 2.)

9-3. Remove the eight (8) screws marked [590]. (Fig. 7)

9-4. Remove the front panel 2. (Fig. 7)

9-5. Disconnect the connector of the power switch assem-

bly connected to the PSANL circuit board. (Fig. 7)

9-6. Remove the eight (8) screws marked [510]. (Fig. 7)

9-7. Disconnect the flat cable from other unit connected to

the PN-AN circuit board. (Fig. 7)

9-8. The front panel assembly can the be removed. (Fig. 7)

10. PN-AN Circuit Board (Time required: about 10 minutes)

10-1. Remove the top cover. (See procedure 1.)

10-2. Remove the front panel assembly. (See procedure 9.)

10-3. Remove the five (5) screws marked [500]. (Fig. 7)

10-4. Remove the LCD assembly. (Fig. 7)

10-5. Remove the four (4) nylon rivets [40]. (Fig. 7)

10-6. The PN-AN circuit board and the LCD unit can then be

separated. (Fig. 7)

[40]: Nylon Rivet (--)

[500]: Bind Head Screw 3x4 MFZN2B3 (--)

[510]: Flat Head Screw 4x8 MFZN2B3 (--)

[590]: Bind Head Tapping Screw-S 3x6 MFZN2B3 (--)

(Fig. 7)

23

Page 24

NXAMP4x1

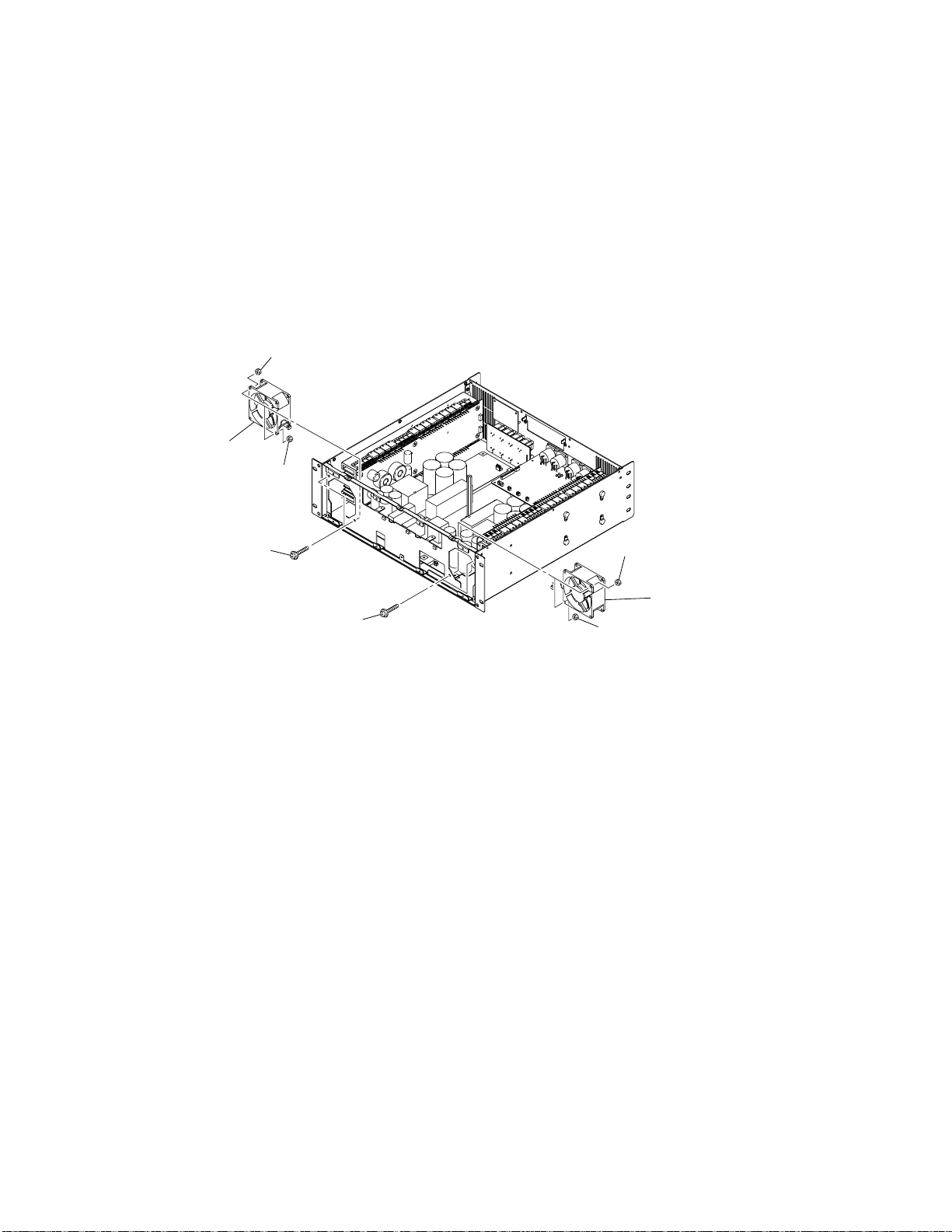

11. Left DC Fan (Time required: about 15 minutes)

11-1. Remove the top cover. (See procedure 1.)

11-2. Remove the CONTROL circuit board and the OPT

angle. (See procedure 2.)

11-3. Remove the front panel assembly. (See procedure 9.)

11-4. Remove the two (2) screws marked [40A] and the two

(2) hexagonal nuts marked [50A]. (Fig. 8)

11-5. Disconnect the connector of the left DC fan connected

to the PSANL circuit board. (Fig. 8)

11-6. The left DC fan can then be removed. (Fig. 8)

[50A]

DC fan

[50A]

[40A]

12. Right DC fan (Time required: about 15 min utes)

12-1. Remove the top cover. (See procedure 1.)

12-2. Remove the CONTROL circuit board and the OPT

angle. (See procedure 2.)

12-3. Remove the front panel assembly. (See procedure 9.)

12-4. Remove the two (2) screws marked [40B] and the two

(2) hexagonal nuts marked [50B]. (Fig. 8)

12-5. Disconnect the connector of the right DC fan connected

to the PSANL circuit board. (Fig. 8)

12-6. The right DC fan can then be removed. (Fig. 8)

[50B]

[40B]

[40A]: Bind Head Screw 4x35 MFZN2W3 SP (--)

[40B]: Bind Head Screw 4x35 MFZN2W3 SP (--)

[50A]: Hexagonal Nut M4 #1 (--)

[50B]: Hexagonal Nut M4 #1 (--)

(Fig. 8)

DC fan

[50B]

24

Page 25

NXAMP4x1

Hook

13. Power switch (Time required: about 15 minutes)

13-1. Remove the top cover. (See procedure 1.)

13-2. Remove the CONTROL circuit Board and the OPT angle. (See procedure 2.)

13-3. Disconnect the connector of the power switch assembly connected to the PSANL circuit board. (Fig. 9)

13-4. Remove the front panel assembly. (See procedure 9.)

13-5. Release the four (4) hooks of the power switch, and remove the power switch from the front panel assembly. (Fig. 9)

Front panel assembly

[510]

[590]

Front panel 2

[590]

[510]: Flat Head Screw 4x8 MFZN2B3 (--)

[590]: Bind Head Tapping Screw-S 3x6 MFZN2B3 (--)

Power switch

(Fig. 9)

Power switch

Hook

Hook

Hook

25

Page 26

NXAMP4x1

■ LSI PIN DESCRIPTION

• PCM1803ADBR (X7357B0) A/D CONVERTER CONTROL: IC035, IC036, IC037, IC038

PIN

NO.

10

11

12

13

14

15

16

17

18

19

20

(1) Schmitt trigger input

(2) Schmitt trigger input with internal pulldown (50 kΩ, typically), 5 V tolerant

(3) Schmitt trigger input, 5 V tolerant

NAME

1

2

3

4

5

6

7

8

9

VINL

V

INR

REF1

V

V

REF2

VCC

AGND

PDWN

BYPAS

TEST

LRCK

BCK

DOUT

DGND

V

DD

SCKI

OSR

FMT0

FMT1

MODE0

MODE1

I/O FUNCTION

I

Analog input, L-channel

Analog input, R-channel

I

–

Reference voltage 1 decoupling capacitor

–

Reference voltage 2 decoupling capacitor

Analog power supply, 5 V

–

–

Analog GND

I

Power-down control, active-low

I

HPF bypass control / LOW: Normal mode (dc reject); HIGH: Bypass mode (through)

I

Test, must be connected to DGND

I/O

Audio data latch enable input/output

I/O

Audio data bit clock input/output

O

Audio data digital output

–

Digital GND

–

Digital power supply, 3.3 V

I

System clock input: 256 fs, 384 fs, 512 fs or 768 fs

I

Oversampling ratio select input / LOW: x 64 fs, HIGH: x 128 fs

I

Audio data format select input 0 / See data format section

I

Audio data format select input 1 / See data format section

I

Mode select input 0 / See data format section

I

Mode select input 1 / See data format section

(2)

(2)

(1)

(1)

(3)

(2)

(2)

(2)

(2)

(2)

(2)

26

Page 27

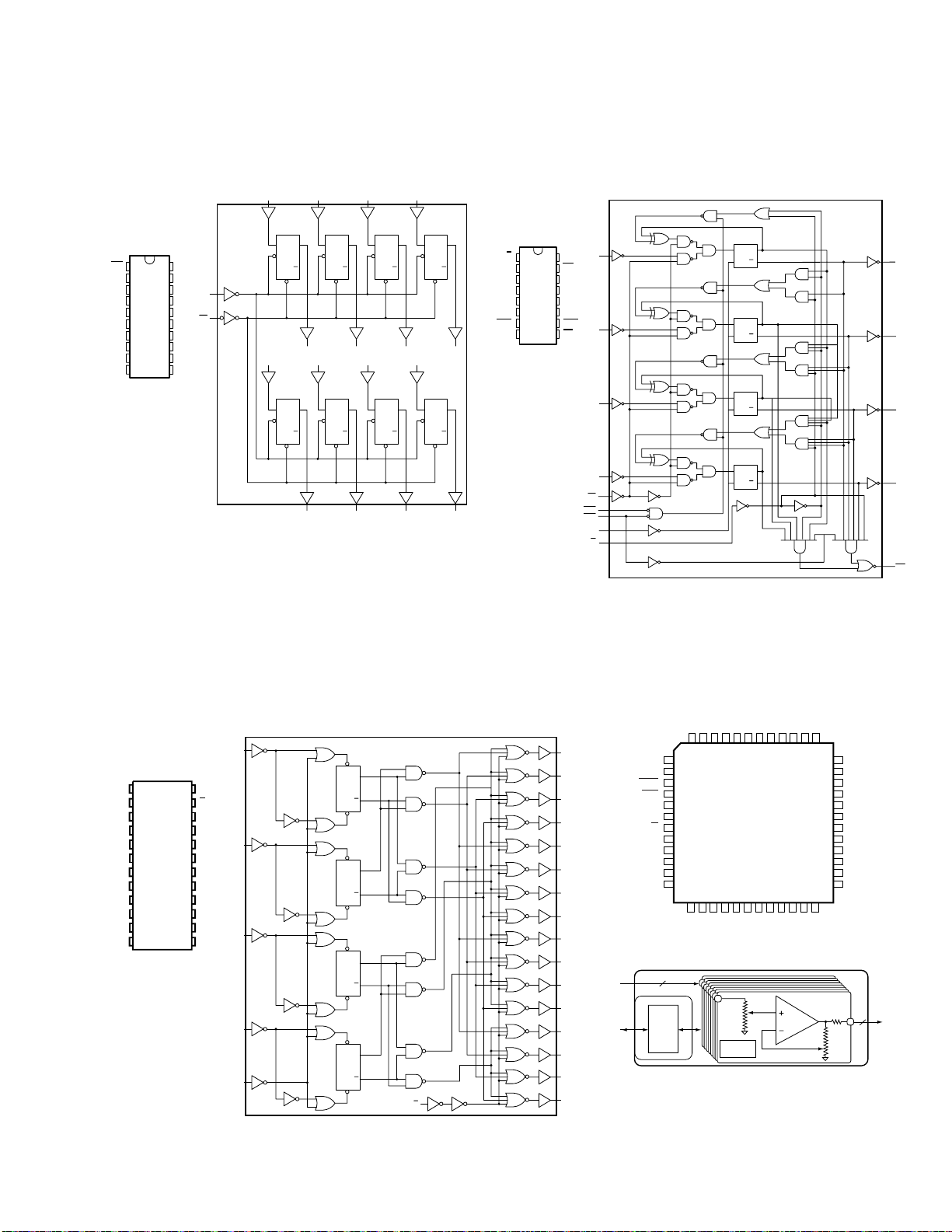

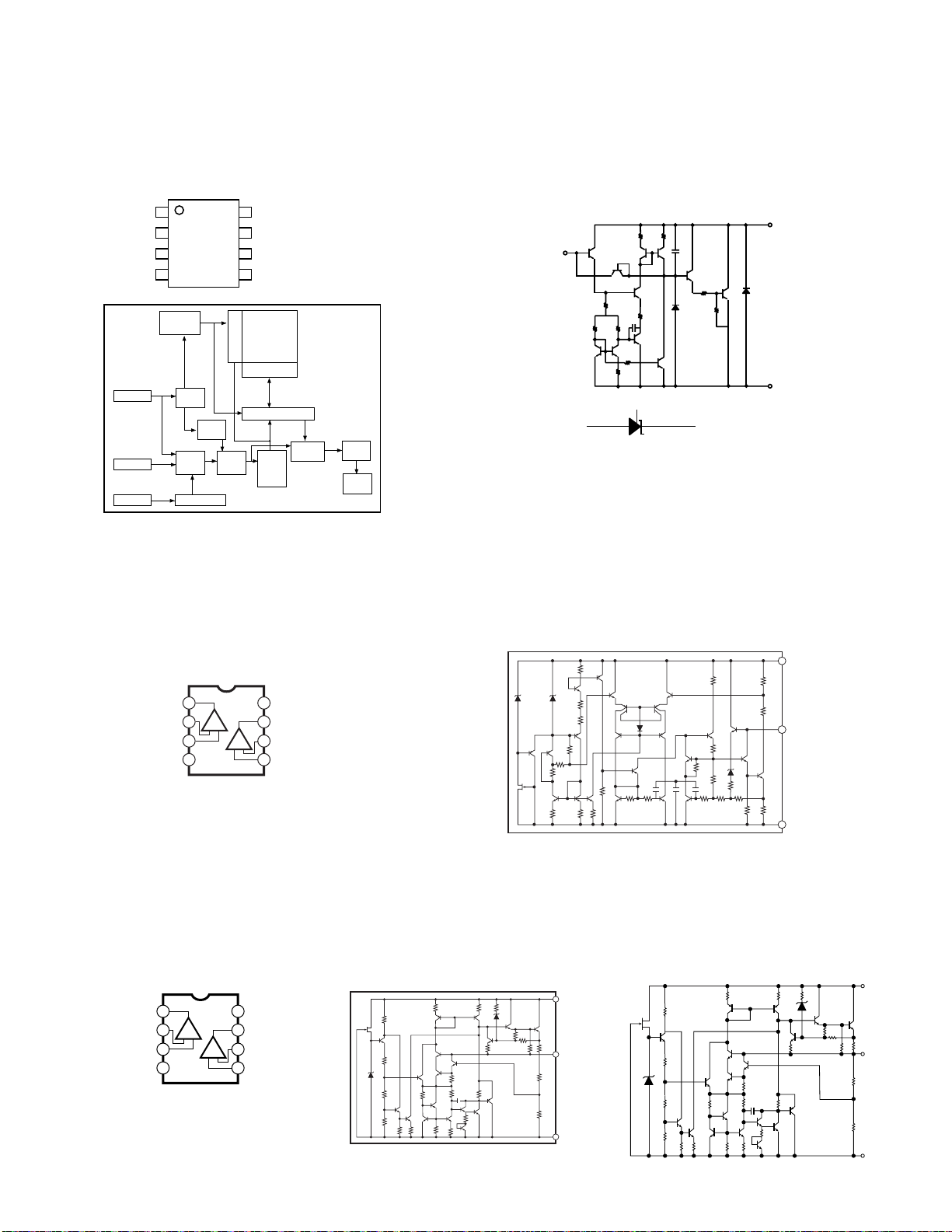

■ IC BLOCK DIAGRAM

NXAMP4x1

• 74HCT273PW,118 (X8681A0)

D-type Flip Flop

PN-AN: IC002, 003

D0

CP

MR

GND

1

20

V

2

Q0

3

D0

4

D1

5

Q1

6

Q2

7

D2

8

D3

9

Q3

10

CC

19

Q7

18

D7

CP

17

D6

16

Q6

MR

15

Q5

14

D5

13

D4

12

Q4

11

CP

FF1

R

D

D4

CP

FF5

R

D

• 74LVC169PW,118 (X8482A0)

Binaly Counter

CONTROL: IC044, 045

D1

QD

Q

Q0

D5

QD

Q

Q4

D2

QD

CP

FF2

Q

R

D

Q1

D6

QD

CP

FF6

Q

R

D

Q5

D3

QD

CP

FF3

Q

R

D

QD

CP

FF7

Q

R

D

QD

CP

FF4

Q

R

D

Q2

Q6

Q3

D7

QD

CP

FF8

Q

R

D

Q7

U/D

CEP

GND

1

16

CP

2

15

D0

3

14

D1

4

13

5

12

D2

6

11

D3

7

10

8

9

V

TC

Q0

Q1

Q2

Q3

CET

PE

3

DC

CC

4

D1

5

D2

6

D3

9

PE

7

CEP

10

CET

2

CP

1

U/D

Q

D

CP

Q

Q

D

CP

Q

Q

D

CP

Q

Q

D

CP

Q

14

Q0

13

Q1

12

Q2

11

Q3

15

TC

• 74HCT4514PW,118 (X8630A0)

Decoder

PN-AN: IC004-007

A

0

V

24

Q

Q

Q

Q

Q

Q

Q

Q

GND

1

LE

A

2

0

A

3

1

4

7

5

8

6

5

7

4

8

3

9

1

10

2

11

0

12

CC

23

E

A

22

3

21

A

2

20

19

18

17

16

15

14

13

A

Q

1

10

Q

11

Q

8

Q

9

Q

14

Q

15

Q

A

12

2

Q

13

A

3

LE

latch

latch

latch

latch

• CS3318-CQZ (X8486A0)

Volume Controller

CONTROL: IC001

REFO1

OUT1

OUT2

REFO2

IN2

VA-

VA+

Q

0

S

D

Q

1

Q

R

D

S

D

Q

2

Q

R

D

S

D

Q

3

Q

R

D

S

D

Q

4

Q

R

D

E

Q

1

Q

2

Q

3

Q

4

Q

5

Q

6

Q

7

Q

8

Q

9

Q

10

Q

11

Q

12

Q

13

Q

14

Q

15

8-channel

Analog

Inputs

I2C/SPI

Serial

Control

REFI1

RESET

MUTE

SCL/CCLK

SDA/MOSI

AD0/CS

ENOut

DGND

REFI8

±8V to ±9V

+3.3V

4847464544434241403938

1

IN1

2

3

4

5

6

7

8

9

VD

10

11

IN8

12

1314151617181920212223

OUT8

REFO8

5

I2C/SPI

Control

Port

VA+

VA-

OUT7

Zero Crossing

Detector

REFO7

IN7

REFI2

REFI7

REFI3

REFI8

OUT3

REFO3

IN3

37

36

VA-

35

VA+

34

OUT5

33

REFO4

32

IN4

31

REFI4

30

REFI5

29

IN5

REFO5

28

OUT5

27

VA-

26

VA+

25

24

IN6

OUT6

REFO6

8-channel

3

Analog

Outputs

27

Page 28

NXAMP4x1

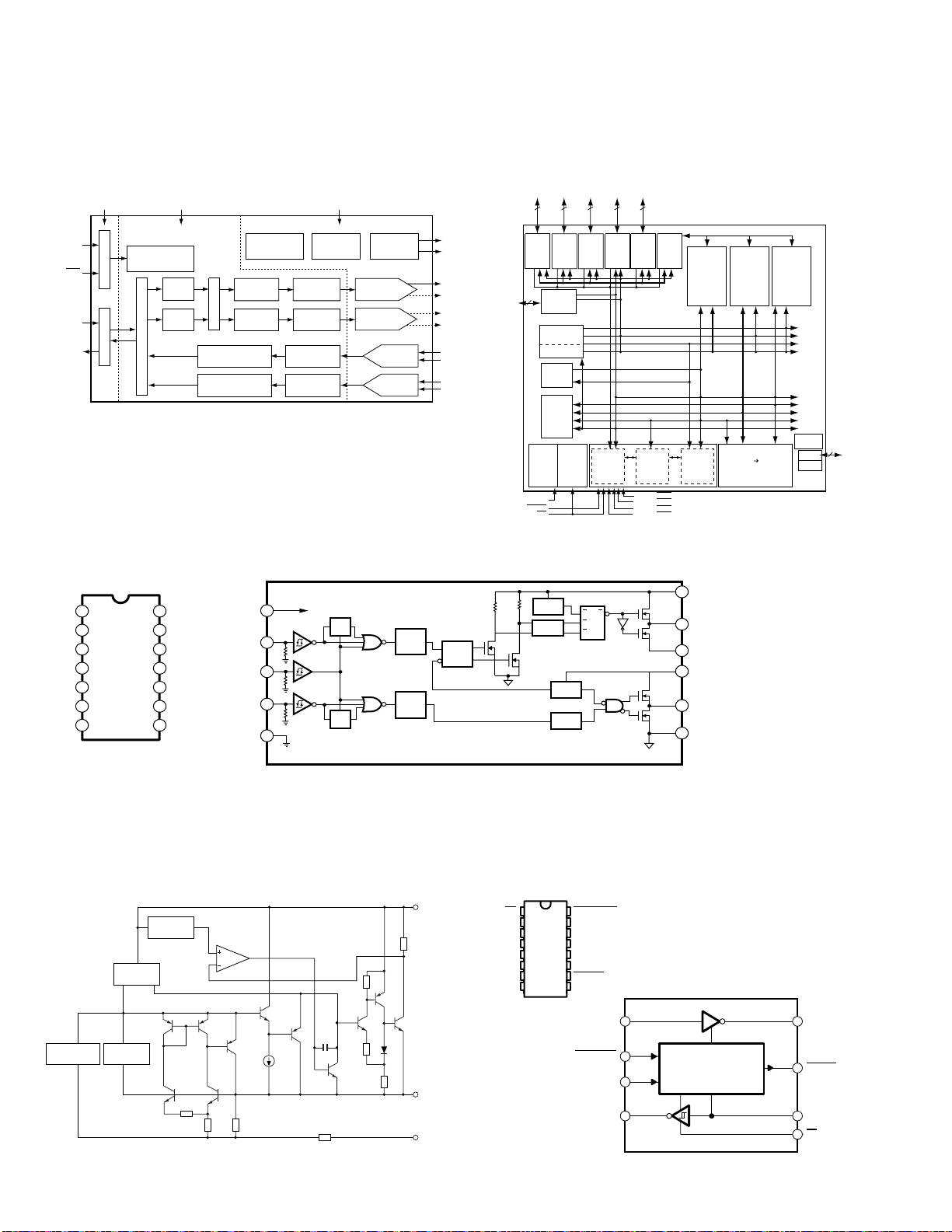

• CS4272-CZZR (X8487A0)

CODEC

CONTROL: IC012, 013

3.3V to 5V2.5V to 5V

Hardware or

I2C/SPI

Control Data

Reset

Serial

Audio

Intput

Serial

Audio

Output

Registor/Hardware

Level Translator Level Translator

Configuration

Volume

Control

Volume

Control

PCM Serial Interface/Loopback

• IR2110 (X2382A02)

Driver

PSANL: IC302, 303

Selectable

Interpolation

Filter

Mixer

Selectable

Interpolation

Filter

High Pass Filter and

DC Offset Calibration

High Pass Filter and

DC Offset Calibration

Internal Voltage

Reference

∆∑ Modulator

∆∑ Modulator

LOW-Latency

Anti-Alias Filter

LOW-Latency

Anti-Alias Filter

Internal

Oscilator

5V

External

Mute Control

Switched Capasito

DAC and Filterr

Switched Capasito

DAC and Filterr

Multibit

Oversampling

ADC

Multibit

Oversampling

ADC

Left and

Right Mute

Controls

Left

Differential

Output

Right

Differential

Output

Left

Differential

Input

Right

Differential

Input

• DSPB56371AF180 (X8489A0)

DSP

CONTROL: IC022, 023

5

SHI

Interface

2

EXTAL

RESET

PINIT/NMI

212

Triple

Timer

DAX

Address

Generation

Unit

Six Channel

DAM Unit

Bootstrap

ROM

Internal

Data

Bus

Switch

Clock

Gen-

erator

PLL

ESAI

Interface

12

ESAI_1

Interface

Program

Interruput

Controller

Expansion Area

PIO_EB

11

GPIO

Peripheral

Program

Decode

Controller

MODA/IRQA

MODB/IRQB

MODC/IRQC

MODD/IRQD

EFCOP

Program

Address

Controller

Program

RAM

4K x 24

ROM

64K x 24

YAB

PM_EB

XAB

PAB

DAB

24-Bit

DSP56300

Core

DDB

YDB

XDB

PDB

GDB

24 x 24+56 56-bit MAC

Two 56-bit Accumulators

Memory Expansion Area

X Data

RAM

36K x 24

ROM

32K x 24

XM_EB

Data ALU

56-it barrel Shifter

Y Data

RAM

48K x 24

ROM

32K x 24

YM_EB

Power

Mngmnt.

JTAG

OnCE

4

TM

COM

VCC

1

LO

2

3

4

5

VS

6

VB

HO

7

14

13

VSS

12

LIN

11

SD

10

HIN

9

VDD

8

• LD1117STR (X8495A0)

Regulator

CONTROL: IC024

VOLTAGE

GENERATOR

CURRENT

GENERATOR

V

B

HV

UV

9

V

DD

10

HIN

11

SD

LIN

12

V

SS

13

Q

R

S

S

Q

R

VDD/V

LEVEL

SHIFT

VDD/V

LEVEL

SHIFT

CC

PULSE

PULSE

GEN

GEN

CC

LEVEL

SHIFT

DETECT

PULSE

FILTER

UV

DETECT

DELAY

R

Q

R

S

6

7

HO

5

V

S

3

CC

V

LO

1

2

COM

• MAX3221CPWR (X2757A0)

RS-232C Driver

CONTROL: IC041

V

IN

C1+

C1–

C2+

C2–

RIN

EN

1

2

3

V+

4

5

6

7

V–

8

16

15

14

13

12

11

10

9

FORCEOFF

V

CC

GND

DOUT

FORCEON

DIN

INVALID

ROUT

DIN

11

13

DOUT

THERMAL

COMPENSATION

28

THERMAL

PROTECTION

FORCEOFF

V

OUT

GND

16

12

FORCEON

9 8

ROUT

Auto-powerdown

10

1

INVALID

RIN

EN

Page 29

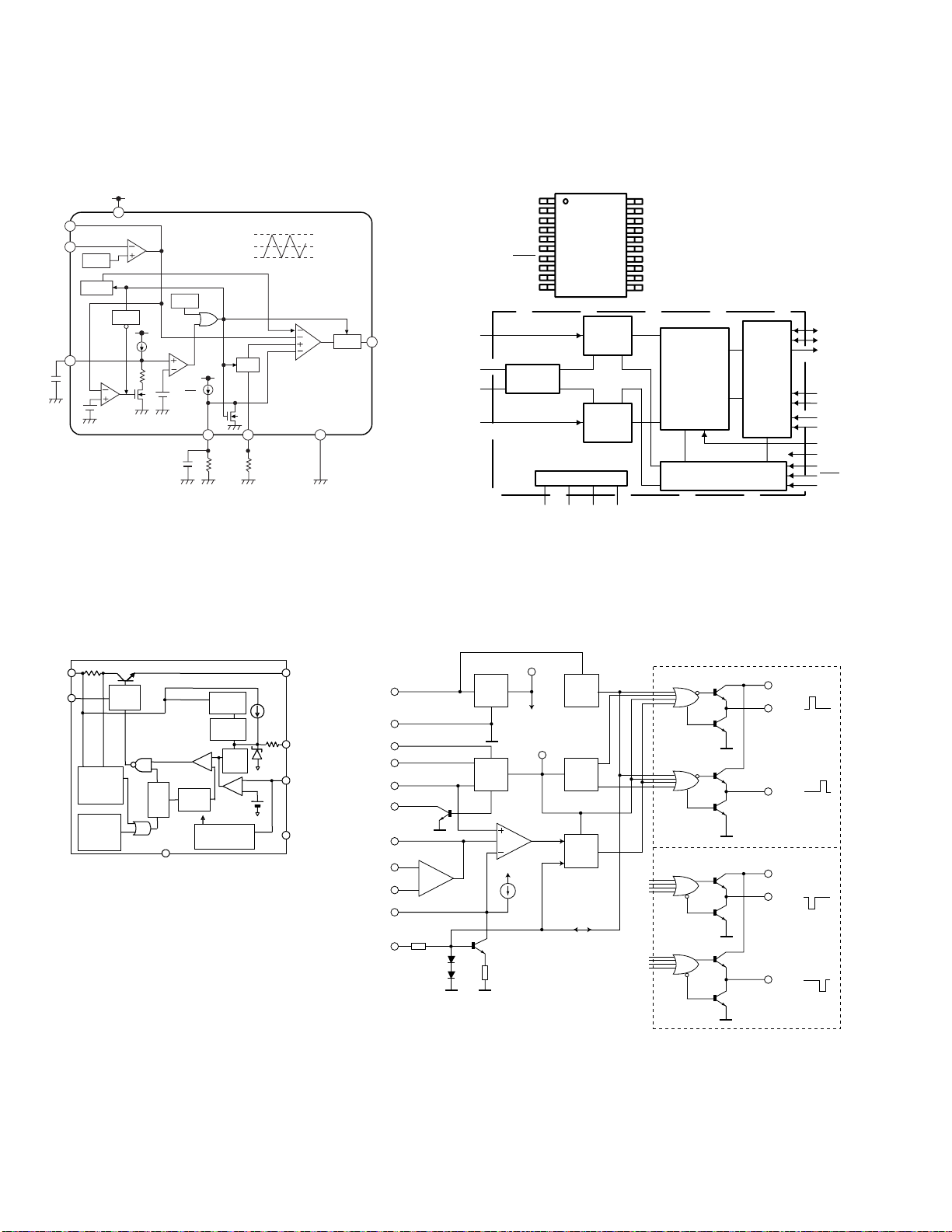

NXAMP4x1

CATHOD

REFERENCE

ANODE

(A)

CATHODE

(K)

REFERENCE (R)

ANODE

CS#

SO

GND

VCC

HOLD#

1

2

3

4

5

6

7

8

SI

WP#

SCLK

Data

Register

SRAM

Buffer

Output

Buffer

Sense

Amplifire

HV

Generator

Mode

Logic

SO

State

Machine

SI

Y-Decoder

Memory Array

Page Buffer

X-Decoder

CS#

Address

Generator

SCLK

Clock Generator

1

2

3

4

-V

8

7

6

5

Output A

+V

Non-Inverting

Input A

-DC Voltage Supply

+DC Voltage

Supply

Output B

Inverting

Input B

Non-Inverting

Input B

Inverting

Input A

+-

+-

1

2

3

4-V

8

7

6

5

Output A

+V

Non-Inverting

Input A

Ground

+DC Voltage

Supply

Output B

Inverting

Input B

Non-Inverting

Input B

Inverting

Input A

+-

+-

COMMON

OUTPUT

R23

R24

R13

R14

R20

R17

D3

Q22

Q21

Q25

Q20

Q24

Q18

Q9

R18

R19

R16R15R21R12R11

R10

Q17

R9R8

R7

R5

R4

D2D1

R6

C1 C2

C3

R22

Q11

Q13

Q14

Q15

Q19

Q16

Q23

Q8

Q7

Q2

Q1

Q6

Q5

Q3

Q10

Q12

Q4

R1

R2

R3

INPUT

INPUT

OUTPUT

GND

INPUT

OUTPUT

GND

• MX25L1605AM2C-12G (X8718A0)

Flash Memory

CONTROL: IC039

• NJM431U (TE1) (X6770A0)

SHUNT Regulator

PSANL: IC204

• NJM2068M-D (X3505A0)

Operational Amplifier

CONTROL: IC002-005, 008-011, 018-021, 028-034

INANL: IC701, 702

OUTANL: IC801, 802

• NJM79M09DL1A (X5366A0)

Regulator

CONTROL: IC007

• NJM7815FA (XD853A0)

Regulator +15V

PSANL: IC202, 203

• NJM78M09DL1A (XZ940A0)

Regulator

CONTROL: IC006

• NJM2904V (TE1) (XR532A0)

Operational Amplifier

CONTROL: IC047, 048, 050, 052

29

Page 30

NXAMP4x1

• NJU7630-M (X8682A0)

Regulator

PSANL: IC205

V+

1V

Vref

Soft Start

2

ER.AMP

UVLO

Latch

2µA

SCP

2kΩ

0.5

R

1V

1V

FB

IN-

SCP

3

4

5

PWM

OSC

0.5V

67 8

RT

GND

R

T

DTC

A

T

0.8V

0.2V

Buffer

• PCM1803ADBR (X7357B0)

A/D Converter

CONTROL: IC035-038

Delta-Sigma

Modulator

Delta-Sigma

Modulator

DGND

20

MODE1

19

MODE0

18

FMT1

17

FMT0

16

OSR

15

SCKI

14

V

DD

13

DGND

12

DOUT

11

BCK

BCK

LRCK

x 1/64, x 1/128

Decimation

Filter

With

High-Pass Filter

Clock and Timing Control

V

DD

Serial

Interface

Mode/

Format

Control

DOUT

FMT0

FMT1

MODE0

MODE1

BYPAS

TEST

OSR

PDWN

SCKI

1

VINL

2

R

V

IN

3

V

1

REF

4

2

V

REF

5

V

CC

6

AGND

7

PDWN

TEST

LRCK

Reference

CC

8

9

10

Power Supply

AGNDV

BYPAS

V

L

OUT

1

IN

1

V

REF

V

2

REF

V

R

IN

• PQ1CX12H2ZP (X6188A0)

Regulator

PSANL: IC208

1 8

V

IN

Drive

2

V

B

Circuit

Comparator

Over

current

Detection

circuit

Over

Heat

Detection

circuit

Q

R

F/F

S

6, 7

COM

Oscill

ator

fo Conversion

circuit

Voltage

regulator

ON/OFF

circuit

+

-

AMP

Soft

Start

• SG2525AN (X8960A0)

PW Modulator

PSANL: IC301

V

REF

OSC.

REF.

REG.

16

U.V.

LOCK

OUT

TO INTRENAL

CIRCUITRY

OSCILLATOR

OUTPUT

4

FLIP

FLOP

R

COMP.

V

5kΩ

S

PWM

LATCH

S

REF

50µA

NOR

NOR

OR

OR

V

13

C

OUTPUT A

11

OUTPUT B

14

SG1525A OUTPUT STAGE

V

13

C

OUTPUT A

11

OUTPUT B

14

SG1527A OUTPUT STAGE

Vo

V

15

i

12

GROUND

4

ON/OFF

5

+

V

ref

VNCadj

3

SYNC.

DISCHARGE

COMP.

INV.INPUT

N.I.INPUT

SOFT-START

SHUTDOWN

3

R

6

T

C

5

T

7

9

1

ERROR

AMP.

2

8

5kΩ

10

30

Page 31

NXAMP4x1

1

2

3

4

5

6

7

8

9

10

20

19

18

17

16

15

14

13

12

11

CLR

1Q

1D

2D

2Q

3Q

3D

4D

4Q

GND

V

CC

8Q

8D

7D

7Q

6Q

6D

5D

5Q

CLK

CLK

CLR

1D

1D

3

1Q

1

11

R

C1

1D

2D

4

2Q

2

R

C1

1D

3D

7

3Q

5

R

C1

1D

4D

8

4Q

6

R

C1

1D

5D

13

5Q

9

R

C1

1D

6D

14

6Q

12

R

C1

1D

7D

17

7Q

15

R

C1

1D

8D

18

8Q

16 19

R

C1

1Y0

1Y1

1Y2

1Y3

2Y0

2Y1

2Y2

2Y3

2-COM

1-COM

13

12

14

15

11

1

5

2

4

3

INH

B

A

10

9

6

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

2Y2

2Y0

2-COM

2Y3

2Y1

INH

GND

GND

V

CC

1Y2

1Y1

1-COM

1Y0

1Y3

A

B

1

2

3

4

5

6

7

20

19

18

17

16

15

14

Vcc

G2

Y1

Y2

Y3

Y4

Y5

Y6

Y7

Y8

8

9

10

12

11

GND

A8

A7

A6

A5

A4

A3

A2

A1

G1

13

4B13

4A12

4Y11

3B10

3A9

3Y8

1B 2

1Y 3

2A 4

2B 5

2Y 6

GND 7

Vcc141A 1

1

DIR

A1

A2

A3

A4

A5

A6

A7

A8

GND

Vcc

OE

B1

B2

B3

B4

B5

B6

B7

B8

2

3

4

5

6

7

8

9

10

20

19

18

17

16

15

14

13

12

11

GND

Y3

A3

A2

A1

VCC

A6

A5

A4

Y6

Y5

Y4

Y2

Y1

1

2

3

4

5

6

7

14

13

12

11

10

9

8

• SN74LV273APWR (X5074A0)

D-type Flip Flop

CONTROL: IC057-061

• SN74LV4052APWR (X6976A0)

Demultiplexer

CONTROL: IC049

• SN74LVC00APWR (X5406A0)

NAND

CONTROL: IC040

• SN74LV541APWRBUS B (X5966A0)

Buffer/Driver

CONTROL: IC055, 056

PN-AN: IC001

• SN74ABT245BNSR (XU009A0)

BUS Transceiver

CONTROL: IC062

• SN74LV14APWR (X6688A0)

Inverter

CONTROL: IC063

31

Page 32

NXAMP4x1

• SN74LVC157APWR (X6786A0)

Data Selector

CONTROL: IC046, 051

1A

2

1B

A/B

GND

1A

1B

1Y

2A

2B

2Y

G

15

2

4A

14

3

4B

13

4

5

12

4Y

6

11

3A

7

10

3B

8

9

3Y

V

16

1

3

CC

2A

5

2B

6

3A

11

3B

10

4A

14

4B

13

G

15

A/B

1

• SN74LVC245APWR (XZ287A0)

Bas T r ansceiver

CONTROL: IC054

GND

1

DIR

2

A1

3

A2

4

A3

5

A4

6

A5

7

A6

8

A7

9

A8

10

20

Vcc

19

OE

18

B1

17

B2

16

B3

15

B4

14

B5

13

B6

12

B7

11

B8

• SN74LVC2G74DCTR (X8709A0)

Flip Flop

CONTROL: IC042

PRE

7

CLK

1Y

4

7

2Y

3Y

9

4Y

12

1

D

2

CLR

6

C

C

C

TG

C

C

TG

C

C

Q

TG

C

C

TG

C

5

Q

3

• TC74LCX04FT (X8415A0)

Inverter

CONTROL: IC064

VCC

14

6A

13

12

6Y

5A

11

10

5Y

9

4A

8

4Y

GND

1A

1

1Y

2

2A

3

2Y

4

3A

5

3Y

6

7

• TOP246YN 1PD (X8576A0)

Regulator

PSANL: IC201

CONTROL (1C)

EXTERNAL

CURRENT LIMIT (3X)

LINE-SENSEL (2L)

FREQUENCY (5F)

Z

C

SHUNT REGULATOR/

ERROR AMPLIFIER

I

FB

CURRENT

LIMIT

ADJUST

LINE

SENSE

R

E

V

V

V

BG+VT

BG

C

5.0V

V

I(LIMIT)

SOFT

START

ON/OFF

1 V

OVAIV

DC

MAX

6.8V

4.6V

INTERNAL UV

COMPARATOR

STOP LOGIC

STOP

DC

MAX

HALF

FREQ

OSCILLAT OR WITH JITTER

SOFTSTART

D

CLOCK

MAX

SAW

SOFT START

LIQHT LOAD

FREQUENCY

REDUCTION

+8

SHUTDOWN

AUTO-RESTART

HYSTERETIC

THERMAL

SHUTDOWN

PWM

COMPARATOR

0

1

INTERNAL

SUPPLY

DRAIN (7D)

Tab internally

connected to

SOURCE pin

CURRENT LIMIT

COMPARATOR

CONTROLLED

TURN-ON

GATE DRIVER

Q

S

R

LEADING

EDGE

BLANKING

2L

5F

3X

4S

1C

7D

32

SOURCE (4S)

Page 33

■ CIRCUIT BOARDS

CONTENTS

• CONTROL Circuit Board (X8710C0) ..........................34

• INANL Circuit Board (X8714C0) ..........................38

• LCD SPACER Circuit Board (X8711C0) ..........................41

• OPT-AN Circuit Board (X8711C0) ..........................41

• OUTANL Circuit Board (X8714C0) ..........................39

• PAANL Circuit Board (X8713D0) ..........................46

• PN-AN Circuit Board (X8711C0) ..........................42

• PSANL Circuit Board (X8715D0) ..........................47

• RS232-GPI Circuit Board (X8711C0) ..........................41

Note: See parts list for details of circuit board component parts.

NXAMP4x1

33

Page 34

NXAMP4x1

• CONTROL Circuit Board

A

to PN-AN

CN001

N.C.

to PSANL

CN313

to PSANL

CN201

to OUTANL

CN809, CN810

34

Component side

A'

2NA-WJ97120-10

2

Page 35

NXAMP4x1

A

to OUTANL

CN809, CN810

to PAANL

(CH1)

CN401

to PAANL

(CH2)

CN403

to PAANL

(CH3)

CN401

to PAANL

(CH4)

CN403

to INANL

W701

to OPT-AN

CN301

A'

2NA-WJ97120-10

to RS232-GPI

CN201

Component side

2

35

Page 36

NXAMP4x1

• CONTROL Circuit Board

B

36

Pattern side

B'

2NA-WJ97120-10

2

Page 37

NXAMP4x1

B

B'

2NA-WJ97120-10

Pattern side

2

37

Page 38

NXAMP4x1

• INANL Circuit Board

to CONTROL

CN006

DCBA

BALANCED INPUTS

Component side

38

Pattern side

2NA-WJ97320-10

Page 39

• OUTANL Circuit Board

NXAMP4x1

to PAANL (CH4)

W406 (

YELLOW

to PAANL (CH3)

W405 (

)

ORANGE

to PAANL (CH2)

W406 (

)

YELLOW

to PAANL (CH1)

W405 (

)

ORANGE

)

to PSANL

CN202

to CONTROL

to CONTROL

CN016

CN016

CN317

to PSANL

2NA-WJ97320-10

CN306

to PSANL

Speakon D Speakon C Speakon B Speakon A

POWER OUTPUTS

Component side

39

Page 40

NXAMP4x1

• OUTANL Circuit Board

40

Pattern side

2NA-WJ97320-10

Page 41

• RS232-GPI Circuit Board

to CONTROL CN10

RS232

GPIO

NXAMP4x1

Component side Pattern side

• OPT-AN Circuit Board

to CONTROL CN017

Expansion slot

Component side

• LCD SPACER Circuit Board

Component side Pattern side

Pattern side

2NA-WJ97170-10

1

41

Page 42

NXAMP4x1

• PN-AN Circuit Board

A

SELECT

PEAK

PROTECT

SIGNAL

1

MUTE

23

MUTE MUTE

42

Component side

A'

2NA-WJ97170-10

1

Page 43

NXAMP4x1

A

Encoder

4A

vol

MUTE

B

AMP PROTECT

STAND-BY

POWER

to CONTROL

CN009

A'

2NA-WJ97170-10

Component side

1

43

Page 44

NXAMP4x1

• PN-AN Circuit Board

B

44

Pattern side

B'

2NA-WJ97170-10

1

Page 45

NXAMP4x1

B

B'

2NA-WJ97170-10

Pattern side

1

45

Page 46

NXAMP4x1

• PAANL Circuit Board

to CONTROL

CN012, CN014

to OUTANL

CN805, CN807

Reduction: 9/10

A

to CONTROL

CN013, CN015

Component side

to OUTANL

CN806, CN808

A'

B

46

Pattern side

B'

2NA-WJ97310-10

1

Page 47

Reduction: 9/10

A

NXAMP4x1

A'

B

to PSANL

CN312, CN315

to PSANL CN307, CN310

to PSANL CN316, CN309

to PSANL CN305, CN308

Component side

B'

2NA-WJ97310-10

Pattern side

1

47

Page 48

NXAMP4x1

• PSANL Circuit Board

to OUTANL W802

to PAANL W404

to PAANL W402

to PAANL W401

to FUN

to CONTROL CN007

to PAANL

W403

Reduction: 7/10

A

to OUTANL CN202

to CONTROL CN011

to FUN

to PAANL CN401

to PAANL W402

to PAANL W404

to PAANL W403

to OUTANL

W805

7

6

8

5

9

4

10

3

11

2

12

1

48

Component side

B'

2NA-WJ97350-50

Page 49

Reduction: 7/10

A

NXAMP4x1

B'

2NA-WJ97350-50

Component side

49

Page 50

NXAMP4x1

• PSANL Circuit Board

Reduction: 7/10

B

50

Pattern side

B'

2NA-WJ97350-50

Page 51

Reduction: 7/10

B

NXAMP4x1

6

7

5

8

4

9

3

10

2

11

1

12

B'

2NA-WJ97350-50

Pattern side

51

Page 52

NXAMP4x1

■ TEST PROGRAM

1. Required items

Computer : DOS/V computer x1 (Pentium 200MHz or more, Windows XP, USB Port)

Software : Software for version up (JTAG Programmer)

Cable : RLINK-ST (USB-JTAG adapter)

Measuring equipment : Power consumption meter

Tools : RS-232C jig x1, GPI jig x1, SLOT jig x1

RS-232C jig

D-SUB 9 pin female connector

GPI jig

SW1

D-SUB 25 pin male connector

/ETH_CS

/ES_CS

SPI_CLK

SPI_MISO

SPI_MOSI

ES_SERIAL_RX

ES_SERIAL_TX

INT_FROM_ES

ES_GPI1

ES_GPI2

ES_GPI3

ES_I2S_DATA0

ES_I2S_DATA1

ES_MCLK

ES_SCLK

ES_LRCK

SOURCE_SEL

a-1

b-1

a-40 b-40

SLOT jig

3.3D

3.3D

XTAL

12.288MHz

Q0

Q1

LV169

Q2

Q3

Q0

Q1

LV169

Q2

Q3

2. Test connection imag e

52

SLOT, GPI, RS-232C jig

NXAMP

Measuring

instrument

Page 53

NXAMP4x1

3. Operation

3-1. Entry of the test program

While holding down the [SELECT4], [MUTE4] and [A]

buttons simultaneously, turn the power switch on. The start

up screen appears on the LCD.

Start Up Screen

Boot 1.00

WAIT...

Then release your fingers from the buttons.

The test program starts and the test menu screen appears on the LCD.

Test Menu Screen

00 CHOOSE TEST < >

01 SWITCH

3-2. Executing the test and judgment display

Select the desired test item from the table below using

the rotary encoder, and press the [B] button to start the

test.

Test Program List

01

SWITCH

02

ENCODER

03

LED

04

LCD

05

RS232

06

GPI

07

PORT (no use)

08

DSP

09

WORD CLOCK

10

12C

After executing the test, the display retur ns to the test

menu screen if the test result is OK. If an error occurs,

“ERROR” appears on the LCD and the test program is

stopped. In this case, tur n the power switch off and on

again as was done above in 3-1.

11

FLASH

12

FAN

13

SLOT

14

ATTENUATION

15

ANALOG

16

BRIDGE

17

CALIBRATION

18

STANDBY

19

QUIT

Press the switch displayed on the LCD as instructed.

If all instructed switches are OK, the display automatically returns to the test menu screen.

4-2. ENCODER test

00 CHOOSE TEST < >

02 ENCODER

Press the [B] button to start the test, and the following

display appears.

02 ENCODER

TURN RIGHT 0

Turn the ENCODER knob clockwise. The 2nd line on the

display changes as shown below.

TURN RIGHT 0 –> • • • • • –> TURN RIGHT 19

The following display appears after the 2nd line on the

display reaches TURN RIGHT 19.

02 ENCODER

TURN LEFT 0

Turn the ENCODER knob counterclockwise. The 2nd line

on the display changes as shown below.

TURN LEFT 0 –> • • • • • –> TURN LEFT 19

The display returns to the test menu screen after the 2nd

line on the display reaches TURN LEFT 19.

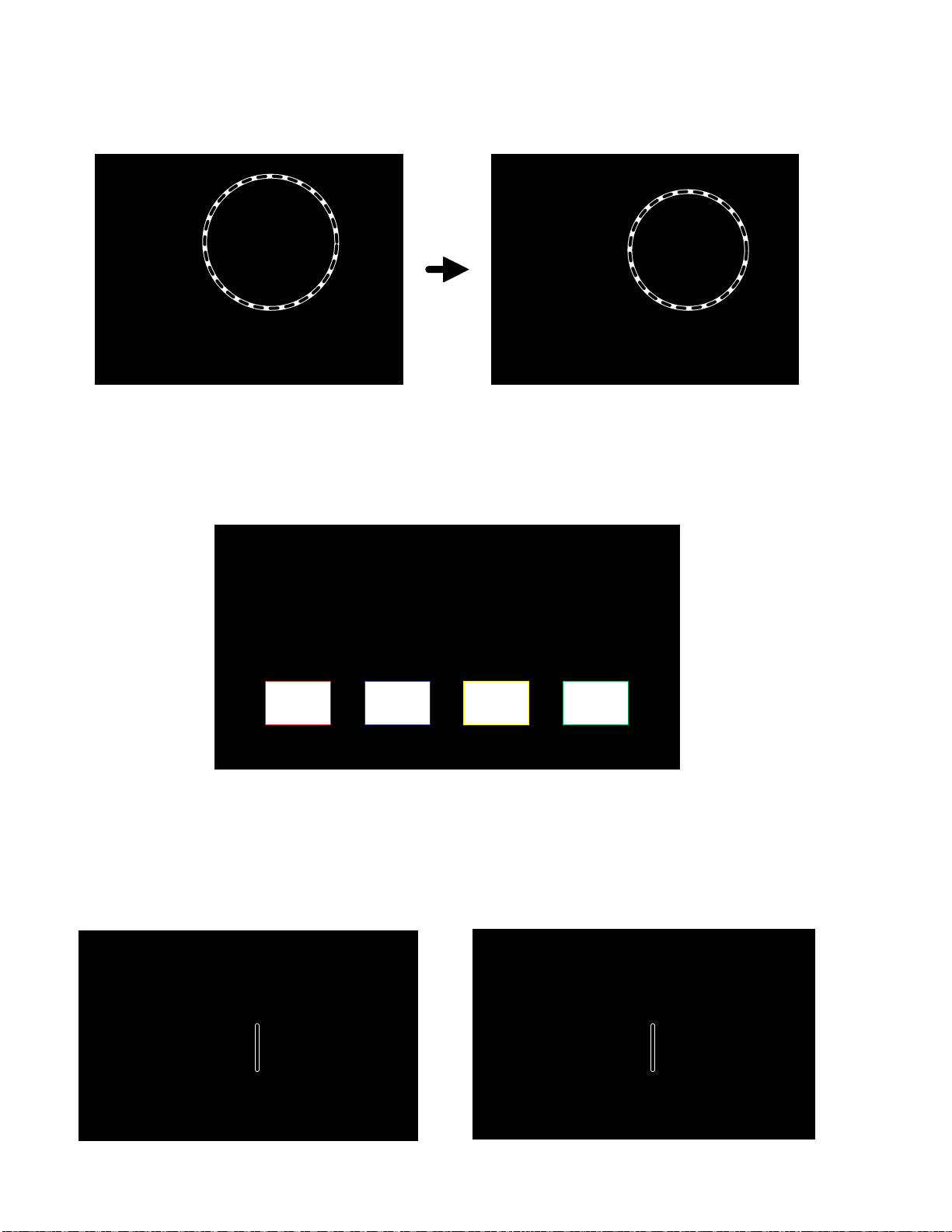

4-3. LED test

00 CHOOSE TEST < >

03 LED

Press the [B] button to start the test, and the following

display appears.

4. Outline of tests

4-1. SWITCH test

00 CHOOSE TEST < >

01 SWITCH

Press the [B] button to start the test. The LCD shows one

by one the switch name to be tested as shown below.

01 SWITCH

HIT SELECT CH1

03 LED

The LEDs automatically light up one by one in a specific

order as shown on the next page.

All LEDs will light at the same time after each LED individually has been tested. Confirm that each LED is lit

normally. If OK, press the [B] button to return the display

to the test menu screen.

53

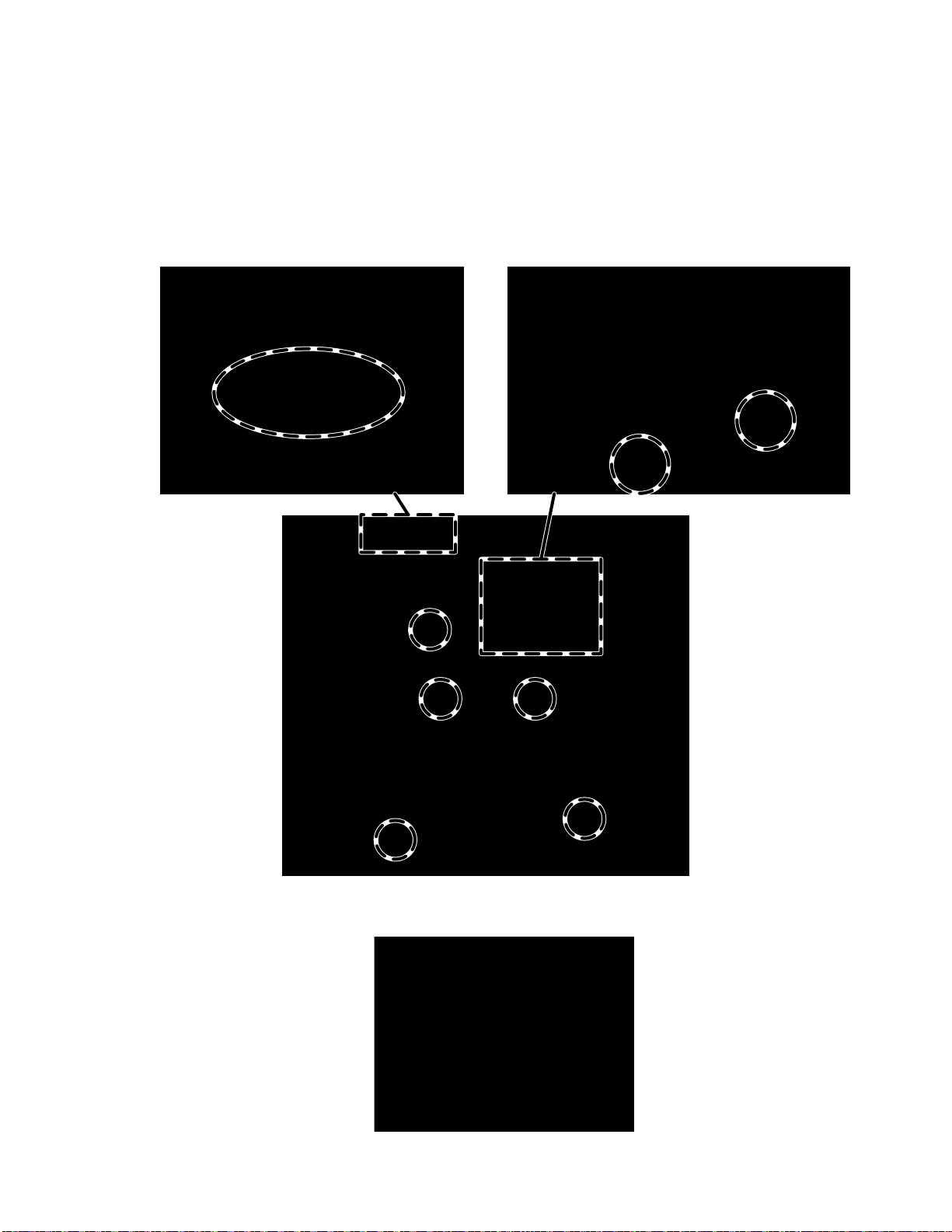

Page 54

NXAMP4x1

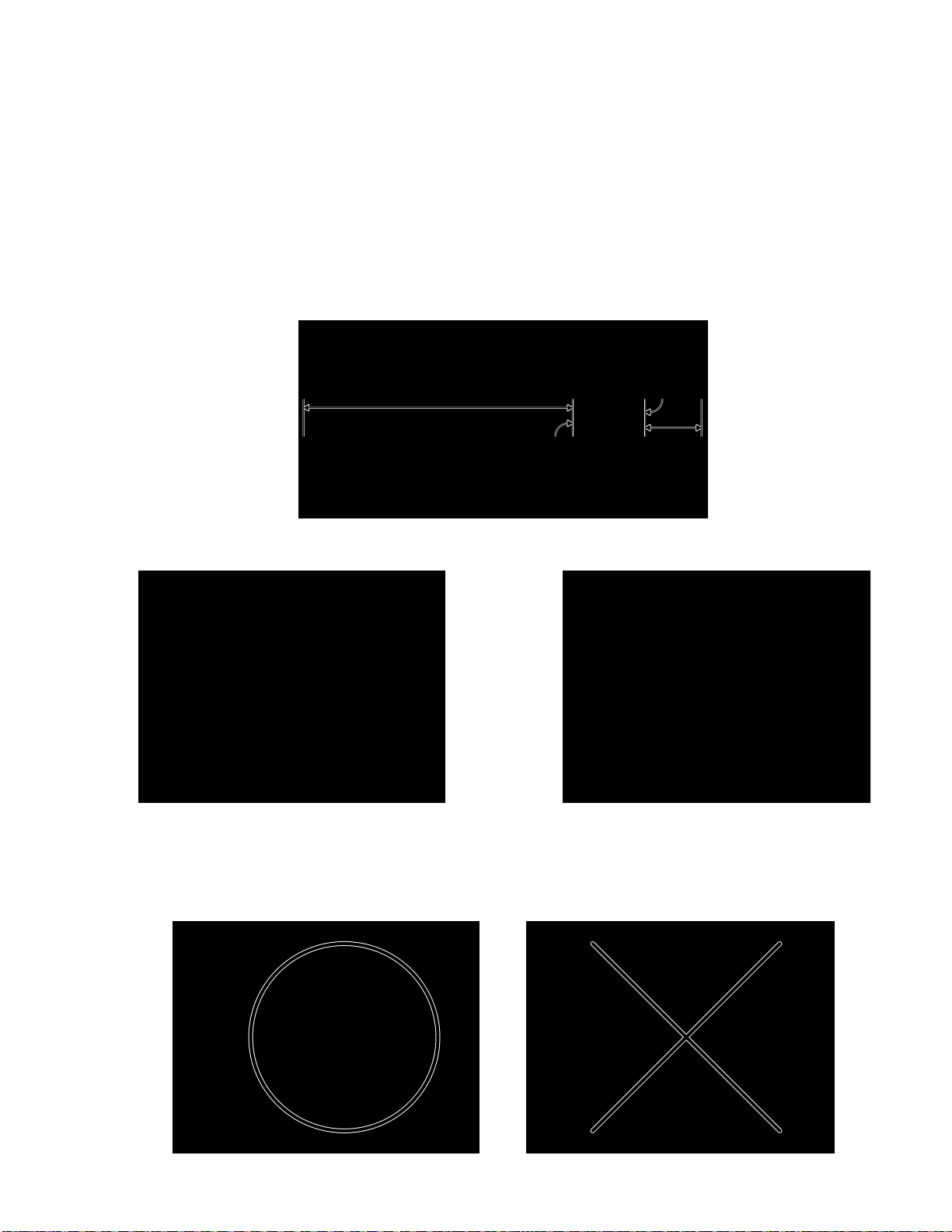

Lighting order

4-4. LCD test

00 CHOOSE TEST < >

04 LCD

Press the [B] button to start the test.

First the following display appears.

04 LCD

All the dots of the LCD go on and off two times. Finally, all

the dots of the LCD are lit. Confirm that all the dots of the

LCD have lit normally. If OK, press the [B] button to return the display to the test menu screen.

4-5. RS-232C test

00 CHOOSE TEST < >

05 RS-232C

Connect the RS-232C jig to the R232C port of the

NXAMP4x1.

Then press the [B] button to start the test, and the following display appears.

05 RS-232C

RS-232C OK ?

Press the [B] button to continue the test. The test e xecutes

automatically.

After executing the test, the following display appears.

(When an error occurs, the “ERROR” appears and the

test program is stopped.)

05 RS-232C

RELEASE RS-232C

Disconnect the RS-232C jig from the RC232C port. Press

the [B] button to return the display to the test menu screen.

4-6. GPI test

00 CHOOSE TEST < >

06 GPI

Connect the GPI jig to the GPIO port of the NXAMP4x1.

Then press the [B] button to start the test, and the following display appears.

06 GPI

GPO[0:4] TEST OK ?

Switch the GPI jig to the GPO [0:4] position and press

the [B] button to continue the test.

The test executes automatically.

If normal, the following display appears. (If an error occurs, “ERROR” appears and the test program is stopped.)

54

06 GPI

GPO[5:7] TEST OK ?

Page 55

NXAMP4x1

Switch the GPI jig to the GPO [5:7] position. Press the

[B] button to continue the test.

The test executes automatically. If the test result is OK,

the display automatically returns to the test menu screen.

(If an error occurs, “ERROR” appears and the test pro-

gram is stopped.)

Disconnect the GPI jig from the GPIO port.

4-7. PORT test

Test for factory inspection only.

4-8. DSP test

00 CHOOSE TEST < >

08 DSP

Press the [B] button to start test. The following display

appears.

08 DSP

CPU to DSP TEST OK ?

Press the [B] button to continue the test. The test e xecutes

automatically.

If normal, the following display appears.

Press the [B] button to start the test. The following display appears.

09 WORD CLOCK

LRCK 48k TEST OK ?

Press the [B] button to continue the test. The test is executed automatically.

If normal, the following display appears.

09 WORD CLOCK

LRCK 96k TEST OK ?

Press the [B] button to continue the test. The test is executed automatically.

If the test result is OK, the display automatically returns

to the test menu screen.

(If an error occurs, “ERROR” appears and the test pro-

gram is stopped.)

4-10. 12C test

00 CHOOSE TEST < >

10 12C

08 DSP

DSP to DSP TEST OK ?

Press the [B] button to continue the test. The test e xecutes

automatically.

If the test result is OK, the display automatically returns

to the test menu screen.

(If an error occurs, “ERROR” appears and the test pro-

gram is stopped.)

4-9. WORD CLOCK test

00 CHOOSE TEST < >

09 WORD CLOCK

Press the [B] button to start the test. The following display appears.

10 12C

12C TEST OK ?

Press the [B] button to continue the test. The test e xecutes

automatically.

If the test result is OK, the display automatically returns

to the test menu screen.

(If an error occurs, “ERROR” appears and the test pro-

gram is stopped.)

55

Page 56

NXAMP4x1

4-11. FLASH test

00 CHOOSE TEST < >

11 FLASH

Press the [B] button to start the test. The following display appears.

11 FLASH

FLASH TEST OK ?

Press the [B] button to continue the test. The test e xecutes

automatically.

If the test result is OK, the display automatically returns

to the test menu screen.

(If an error occurs, “ERROR” appears and the test pro-

gram is stopped.)

4-12. FAN test

00 CHOOSE TEST < >

12 FAN

Press the [B] button to start the test. The following display appears.

The FAN starts rotating at low speed.

12 FAN

LOW

Check that the FAN rotates at low speed, and press the

[B] button to continue the test. The following display appears, and the FAN rotates at middle speed.

12 FAN

MIDD

4-13. SLOT test

00 CHOOSE TEST < >

13 SLOT

Rear panel

(Remove the [610] plate on the rear panel of the NXAMP4x1,

and insert the SLOT jig into the expansion slot.)

Press the [B] button to start the test. The test executes

automatically.

If every signal is normal, the following display appears

and the LED of the SLOT jig lights.

(If an error occurs, “ERROR” appears and the test pro-

gram is stopped.)

[610]

13 SLOT

ANALOG TEST OK ?

Input the 1 kHz, -10 ± 1 dBu sine wave to the channel 1

input terminal and confirm that the output voltage obtained

at the channel 1 output terminal is +19.1 ± 2.0 dBu.

If OK, press the [B] button to return the display to the test

menu screen.

4-14. ATTENUATION test

00 CHOOSE TEST < >

14 ATTENUATION

Check that the FAN rotates at middle speed, and press

the [B] button to continue the test. The following display

appears, and the FAN rotates at high speed.

12 FAN

HIGH

Check that the FAN rotates at high speed, and press the

[B] button to return the display to the test menu screen.

56

Press the [B] button to enter the attenuation test mode.

The following display appears.

14 ATTENUATION

NOISE TEST OK ?

Perf orm the test according to the “Inspection with attenuation test mode”. (See page 60).

If OK, press the [B] button to return the display to the test

menu screen.

Page 57

NXAMP4x1

4-15. ANALOG test

00 CHOOSE TEST < >

15 ANALOG

Press the [B] button to enter the analog test mode. The

following display appears.

15 ANALOG

ANALOG TEST OK ?

Perform the test according to the “Inspection with analog

test mode”. (See page 61, 62).

Press the [B] button. The following display appears.

15 ANALOG

MUTE TEST OK ?

If OK, press the [B] button to return the display to the test

menu screen.

4-16. BRIDGE test

00 CHOOSE TEST < >

16 BRIDGE

Press the [B] button to enter the bridge test mode. The

following display appears.

16 BRIDGE

ANALOG TEST OK ?

Input the 1 kHz, +10 dBu sine wave to the channel 2 input terminal, and press the [B] button. The analog input

level is automatically calibrated, and the following display appears.

17 CALIBRATION

CH3 INPUT SIGNAL OK ?

Input the 1 kHz, +10 dBu sine wave to the channel 3 input terminal, and press the [B] button. The analog input

level is automatically calibrated, and the following display appears.

17 CALIBRATION

CH4 INPUT SIGNAL OK ?

Input the 1 kHz, +10 dBu sine wave to the channel 4 input terminal, and press the [B] button. The analog input

level is automatically calibrated, and the following display appears.

17 CALIBRATION

CH1 SET TO 39.1 dBu ?

Input the 1 kHz, +10 dBu sine wave to the channel 1 input terminal.

Adjust the ENCODER so that the output voltage obtained

at the channel 1 output terminal is +39.1 dBu, and press

the [B] button.

The analog output level is automatically calibrated, and

the following display appears.

Perf orm the test according to the “Inspection with BRIDGE

mode”. (See page 63).

If OK, press the [B] button to return the display to the test

menu screen.

4-17. CALIBRATION

00 CHOOSE TEST < >

17 CALIBRATION

Press the [B] button to start the calibration. The following

display appears.

17 CALIBRATION

CH1 INPUT SIGNAL OK ?

Input the 1 kHz, +10 dBu sine wave to the channel 1 input terminal, and press the [B] button. The analog input

level is automatically calibrated, and the following display appears.

17 CALIBRATION

CH2 INPUT SIGNAL OK ?

17 CALIBRATION

CH2 SET TO 39.1 dBu ?

Input the 1 kHz, +10 dBu sine wave to the channel 2 input terminal.

Adjust the ENCODER so that the output voltage obtained

at the channel 2 output terminal is +39.1 dBu, and press

the [B] button.

The analog output level is automatically calibrated, and

the following display appears.

17 CALIBRATION

CH3 SET TO 39.1 dBu ?

Input the 1 kHz, +10 dBu sine wave to the channel 3 input terminal.

Adjust the ENCODER so that the output voltage obtained

at the channel 3 output terminal is +39.1 dBu, and press

the [B] button.

The analog output level is automatically calibrated, and

the following display appears.

17 CALIBRATION

CH4 SET TO 39.1 dBu ?

57

Page 58

NXAMP4x1

Input the 1 kHz, +10 dBu sine wave to the channel 4 input terminal.

Adjust the ENCODER so that the output voltage obtained

at the channel 4 output terminal is +39.1 dBu, and press

the [B] button.

The analog output level is automatically calibrated, and

the following display appears.

17 CALIBRATION

CH1 OUTPUT SIGNAL OK ?

Adjust the input signal voltage so that the output voltage

obtained at the channel 1 output terminal is 24 Vrms (=

+29.8 dBu), and press the [B] button.

The output voltage monitor is automatically calibrated,

and the following display appears.

17 CALIBRATION

CH2 OUTPUT SIGNAL OK ?

Adjust the input signal voltage so that the output voltage

obtained at the channel 2 output terminal is 24 Vrms (=

+29.8 dBu), and press the [B] button.

The output voltage monitor is automatically calibrated,

and the following display appears.

17 CALIBRATION

CH3 OUTPUT SIGNAL OK ?

Adjust the input signal voltage so that the output voltage

obtained at the channel 3 output terminal is 24 Vrms (=

+29.8 dBu), and press the [B] button.

The output voltage monitor is automatically calibrated,

and the following display appears.

17 CALIBRATION

CH4 OUTPUT SIGNAL OK ?

Adjust the input signal voltage so that the output voltage

obtained at the channel 4 output terminal is 24 Vrms (=

+29.8 dBu), and press the [B] button.

The output voltage monitor is automatically calibrated,

and the following display appears.

17 CALIBRATION

CH1 CONNECT 8 OHM LOAD

Connect the 8 ohms resistor to the channel 1 output terminal.

Adjust the input signal voltage so that the output voltage

obtained at the channel 1 output terminal is 24 Vrms (=

+29.8 dBu), and press the [B] button.

The output current monitor is automatically calibrated,

and the following display appears.

17 CALIBRATION

58

CH2 CONNECT 8 OHM LOAD

Connect the 8 ohms resistor to the channel 2 output terminal.

Adjust the input signal voltage so that the output voltage

obtained at the channel 2 output terminal is 24 Vrms (=

+29.8 dBu), and press the [B] button.

The output current monitor is automatically calibrated,

and the following display appears.

17 CALIBRATION

CH3 CONNECT 8 OHM LOAD

Connect the 8 ohms resistor to the channel 3 output terminal.

Adjust the input signal voltage so that the output voltage

obtained at the channel 3 output terminal is 24 Vrms (=

+29.8 dBu), and press the [B] button.

The output current monitor is automatically calibrated,

and the following display appears.

17 CALIBRATION

CH4 CONNECT 8 OHM LOAD

Connect the 8 ohms resistor to the channel 4 output terminal.

Adjust the input signal voltage so that the output voltage

obtained at the channel 4 output terminal is 24 Vrms (=

+29.8 dBu), and press the [B] button.

The output current monitor is automatically calibrated,

and the display returns to the test menu screen.

(If an error occurs, “ERROR” appears and the test pro-

gram is stopped.)

4-18. STANDBY test

00 CHOOSE TEST < >

18 STANDBY

Press the [B] button to enter the standby mode, and the

following display appears.

18 STANDBY

Measure the primary power consumption, and check that

the measured value is 23 W or less. Press the [B] button

for one second or more, and the display retur ns to the

test menu screen.

4-19. QUIT (Exit the test program)

00 CHOOSE TEST < >

19 QUIT

Press the [B] button to exit the test program, and the

NXAMP enters the ordinary mode.

Page 59

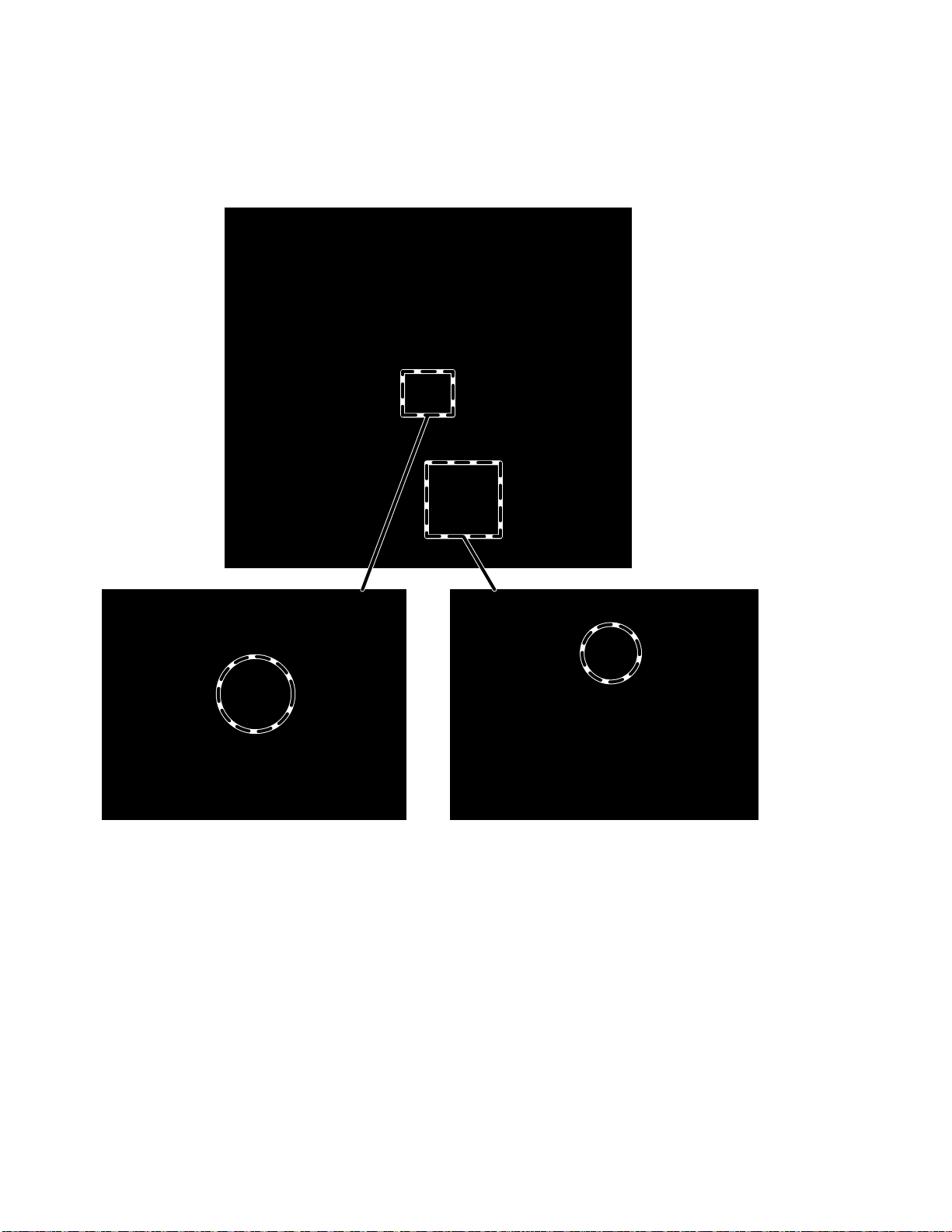

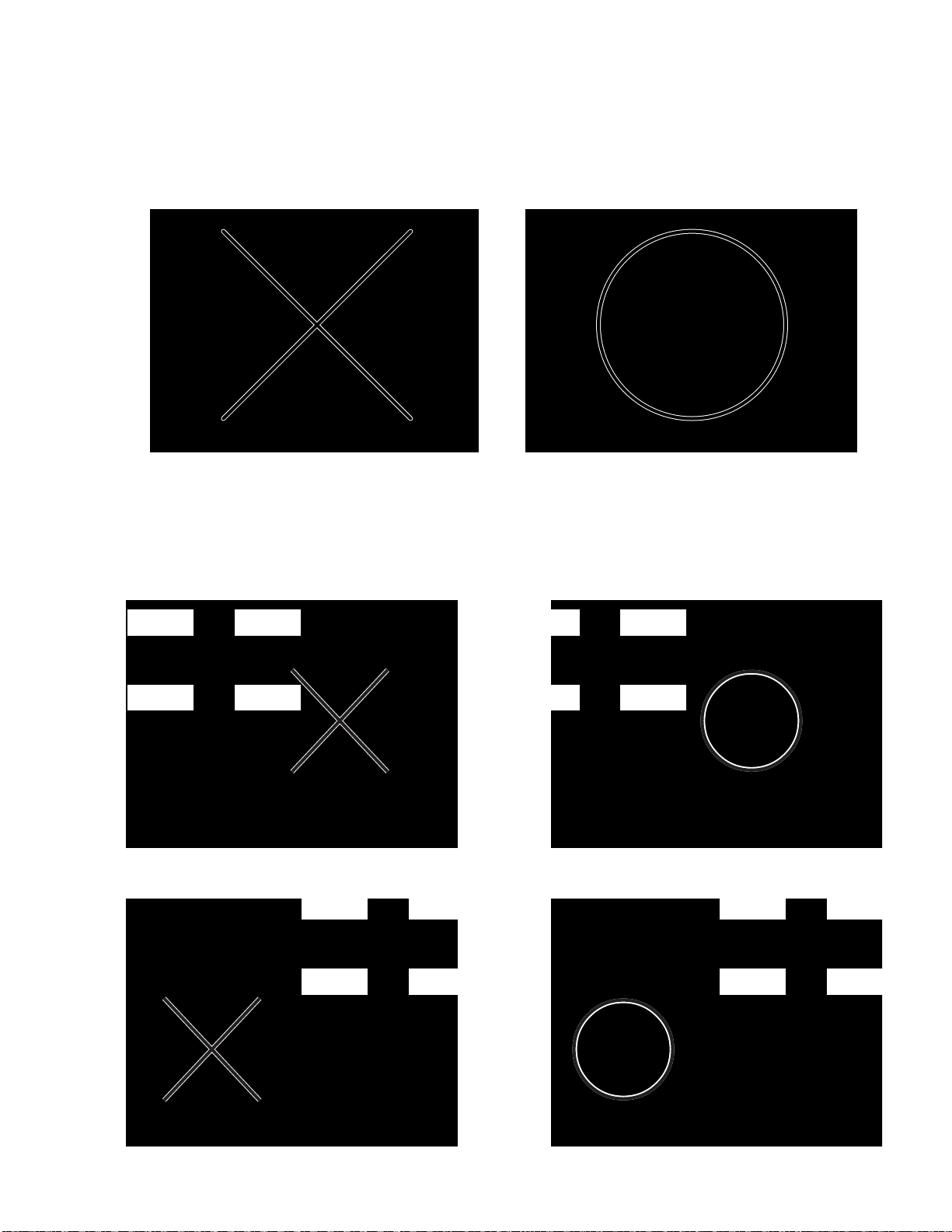

■ INSPECTIONS

1. Measurement Conditions

1-1. Environment

• Normal temperature: From 10 ˚C to 35 ˚C

• Normal humidity: From 45 % to 85 %

1-2. Power Source

• When measuring the electrical characteristics, set the power supply voltage and frequency as specified in the tab le below.

Destination

U

CHN

1-3. Measuring Instruments

• Use a reliable measuring device capable of precisely measuring the specification values indicated in this document.

• Input impedance of the measuring instrument should be more than 1 MΩ.

• The noise level should be measured with a 22 Hz-22 kHz band pass filter.

When you use the Audio Analyzer System made by Audio Precision, Inc. for noise measurement, set the filter characteristics as follows.

BW : 22 Hz-22 kHz

Filter (Fltr) : None

Power supply voltage

120 V +2/-0 %

230 V +2/-0 %

Frequency

60 Hz

50 Hz

NXAMP4x1

1-4. Connections

Each input and output terminal of channels 1-4 are as shown in the figure below.

Ch4

OUT

Ch3

OUT

Ch2

OUT

Ch1

OUT

Ch3INCh2INCh1

Ch4

IN

Ch4

Ch3

LINK

LINK

OUT

OUT

Ch2

LINK

OUT

Fig. 1

1-4-1. Input connector

The XLR-3-31 (female) type connectors are used for channel 1-4 input terminals.

Condition : Balanced input

Wiring : pin 1 to ground, pin 2 to hot (+), pin 3 to cold (-)

1-4-2. Output connector

Neutrik SPEAKON connectors are used for output terminals in channels 1-4.

Connect the load resistor between pin 1+ and pin 1- of the Neutrik SPEAKON connector.

1-4-3. Load resistor

Use a load resistor with no inductivity and a power rating high enough to perform each test safely.

IN

Ch1

LINK

OUT

1-4-4. Link out connectors

XLR-3-32 (male) type connectors are used for input terminals in channels 1-4.

Condition : Balanced output

Wiring : pin 1 to ground, pin 2 to hot (+), pin 3 to cold (-)

59

Page 60

NXAMP4x1

1-5. Other

0 dBu is defined as 0.775 Vrms in these inspections.

2. Inspection with ordinary mode

Condition:

• Ground each input terminal via a 600 Ω resistor.

• Do not connect the load resistor to the output terminal.

2-1. Power ON sequence

1) Turn the power switch on. Confirm that the latest firmware version appears on the LCD and the four (4) MUTE LEDs light

up.

Example of firmware version 1.00

-- [v 1.00] --

(c) NEXO 2007.

2) Confirm that all the fans start rotation at low speed within 4 seconds after turning the power switch on.

3) Confirm that the following display appears on the LCD within 18 ± 3 seconds after turning the power switch on. Also

confirm that the POWER LED and only one of the VOLUME LEDs for each channel light up.

-20.0 -20.0 -20.0 -20.0 Vol(dB)

[MAIN ][MAIN ][SUB ][SUB ] < >

2-2. Power consumption when idling

Measure the primary power consumption and confirm that the measured value is 70 ± 20 W.

2-3. Output terminal DC voltage

Measure the DC voltage (Vdc) of each output terminal and confirm that the measured value is Vdc = 0 ± 50 mV.

3. Inspection with attenuation test mode

Condition:

• Perform each test in this section in the attenuation test mode. (See page 56)

• Connect a 8 Ω load resistor to each output terminal.

• Ground each input terminal via a 600 Ω resistor.

3-1. Residual noise

Confirm that each output terminal’ s residual noise level is -65 dBu or less.

60

Page 61

4. Inspection with analog test mode

Condition:

• Perform each test item in this section with the analog test mode of the test program. (See page 57)

• Unless otherwise specified, perform the test with a 8 Ω resistor is connected to each output terminal.

4-1. Link out

Input the 1 kHz, -10 dBu sine wav e to each input terminal and confirm that the output voltage obtained at each link out terminal

is -10 ± 0.5 dBu.

4-2. Efficiency

Input the 1 kHz sine wave to the channel 1 input terminal and confirm that the primary power consumption is 175 ± 10 W when

the output voltage obtained at the channel 1 output terminal is +29.2 dBu.

Perform the same test for channels 2-4 in the same manner.

4-3. Gain

Input the 1 kHz, 0 dBu sine wave to each input terminal and confirm that the output voltage obtained at each output terminal

is +29.1 ± 1.2 dBu.

NXAMP4x1

4-4. Frequency response

Perform the following test at each channel.

Input the 10 Hz, 1 kHz, 20 kHz, 0 dBu sine wave to the input terminal and one by one measure the output voltage obtained at

the output terminal for each frequency.

Confirm that the output voltage at 10 Hz is 0 ± 0.5 dB when compared with the output voltage at 1 kHz (0 dB).

Confirm that the output voltage at 20 kHz is +0.5 ± 0.5 dB when compared with the output voltage at 1 kHz (0 dB).

4-5. Distortion

Input the 1kHz sine wave to each channel input terminal and confirm that the distortion in each channel output terminal is 1.0

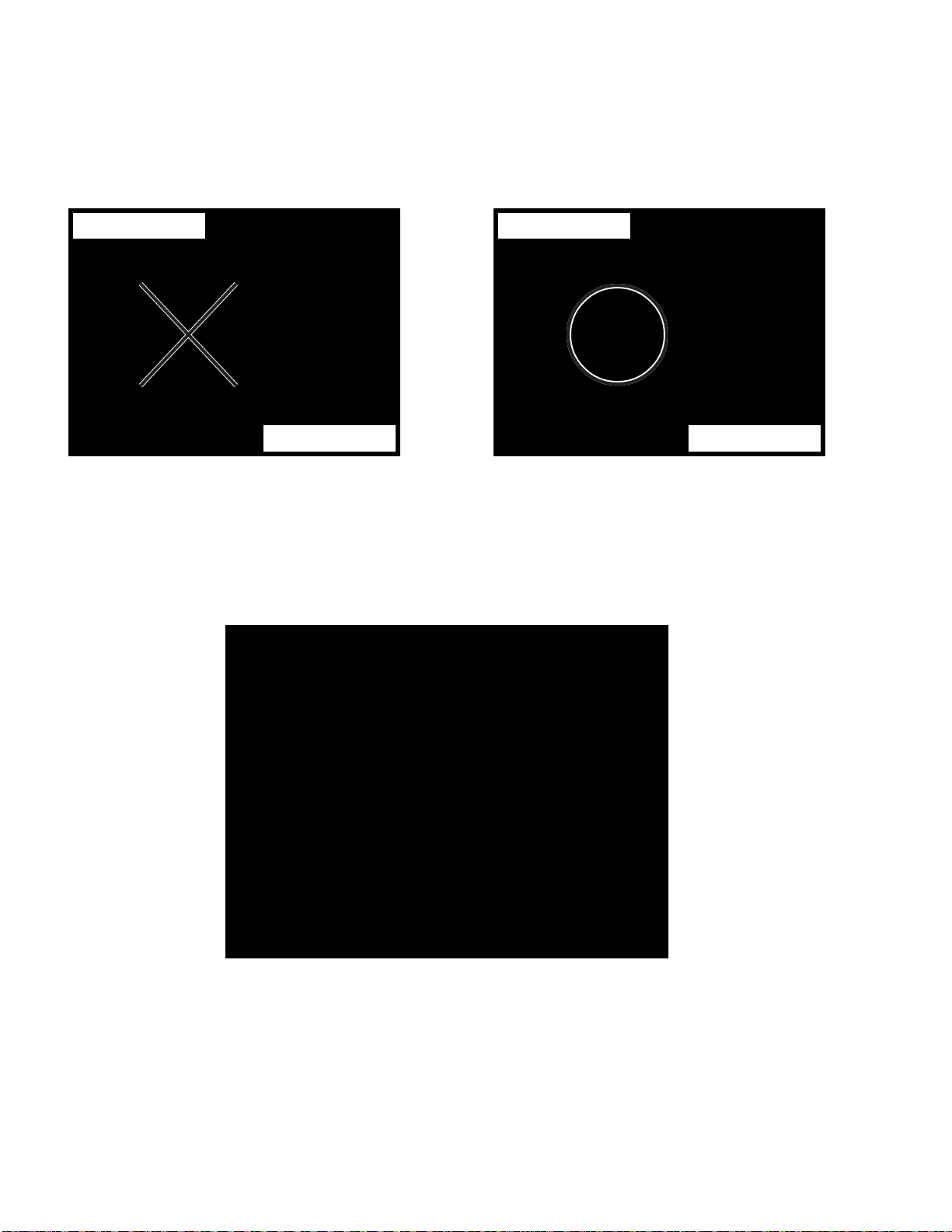

% or less when 500 W (with 8 ohms load) output is obtained for each terminal at the same time.

4-6. Maximum output

Connect the 4 ohms 500 W resistor to each output terminal.

Input the BURST signal as shown in fig. 2 to each input terminal and adjust the input signal le vel so that a Vburst voltage of 174

Vp-p (volt peak to peak) is obtained in each channel output terminals.

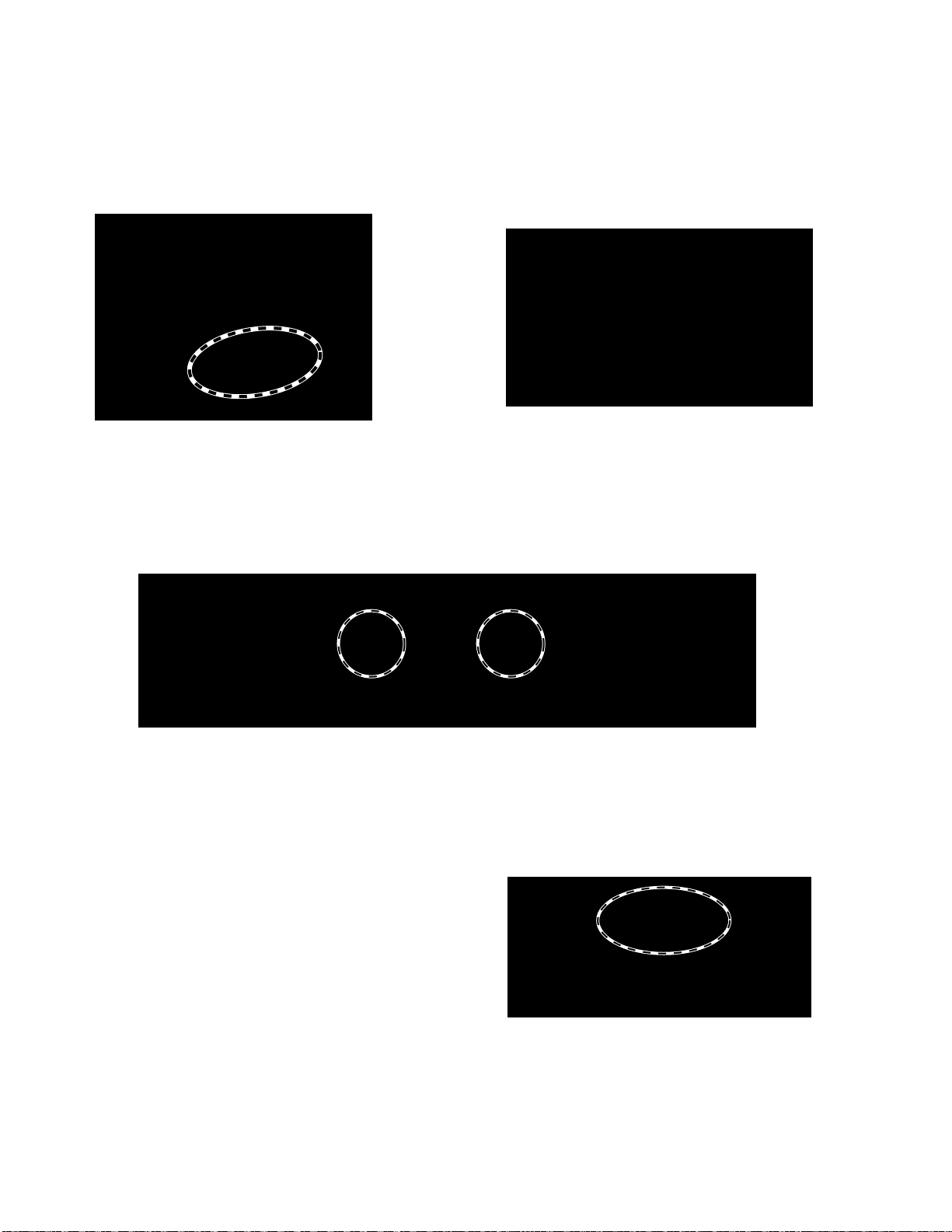

Measure the last wave of the BURST signal peak to peak by the oscilloscope's MEASURE function. Confirm that the measured voltage is 170 volt or more. (See fig. 2)

Note: Perform the test of all channels at the same time.

500 msec

1 msec

20 msec

Close-up

The center of the emission line shall

be adopted as the measurement value.

Signal

Cursor

Fig. 2

Vburst