Yamaha NSP-336, NSP-330 Service manual

HOME CINEMA 5.1CH SPEAKER PACKAGE/

HOME CINEMA 6.1CH SPEAKER PACKAGE

NS-P330/NS-P336

SERVICE MANUAL

SERVICE MANUAL

NS-P330/NS-P336 consists of the NX-S200, NX-C200 and the SW-P330.

NS-P330/NS-P336 は NX-S200・NX-C200・SW-P330 で構成されています。

IMPORTANT NOTICE

This manual has been provided for the use of authorized YAMAHA Retailers and their service personnel.

It has been assumed that basic service procedures inherent to the industry, and more specifically YAMAHA Products, are already

known and understood by the users, and have therefore not been restated.

WARNING: Failure to follow appropriate service and safety procedures when servicing this product may result in personal

IMPORTANT: The presentation or sale of this manual to any individual or firm does not constitute authorization, certification or

The data provided is believed to be accurate and applicable to the unit(s) indicated on the cover. The research, engineering, and service

departments of YAMAHA are continually striving to improve YAMAHA products. Modifications are, therefore, inevitable and

specifications are subject to change without notice or obligation to retrofit. Should any discrepancy appear to exist, please contact the

distributor's Service Division.

WARNING: Static discharges can destroy expensive components. Discharge any static electricity your body may have

IMPORTANT: Turn the unit OFF during disassembly and part replacement. Recheck all work before you apply power to the unit.

injury, destruction of expensive components, and failure of the product to perform as specified. For these reasons,

we advise all YAMAHA product owners that any service required should be performed by an authorized YAMAHA

Retailer or the appointed service representative.

recognition of any applicable technical capabilities, or establish a principle-agent relationship of any form.

accumulated by grounding yourself to the ground buss in the unit (heavy gauge black wires connect to this buss).

■ CONTENTS

TO SERVICE PERSONNEL ......................................... 2

FRONT PANELS ........................................................... 3

REAR PANELS .......................................................... 3-4

SPECIFICATIONS /

INTERNAL VIEW .......................................................... 7

SW-P330 BLOCK DIAGRAM ....................................... 7

100929

参考仕様 ............................................ 5-6

SW-P330 DISASSEMBLY PROCEDURES /

SW-P330分解手順 ................................................................... 8

SW-P330 PRINTED CIRCUIT BOARD ........................ 9

SW-P330 SCHEMATIC DIAGRAM ............................ 10

PARTS LIST .......................................................... 11-15

NS-P330

NS-P336

NS-P330/NS-P336

■ TO SERVICE PERSONNEL

1. Critical Components Information

Components having special characteristics are marked Z

and must be replaced with parts having specifications equal

to those originally installed.

2. Leakage Current Measurement (For 120V Models Only)

When service has been completed, it is imperative to verify

that all exposed conductive surfaces are properly insulated

from supply circuits.

● Meter impedance should be equivalent to 1500 ohms shunted

by 0.15µF.

WALL

OUTLET

● Leakage current must not exceed 0.5mA.

● Be sure to test for leakage with the AC plug in both

polarities.

EQUIPMENT

UNDER TEST

INSULATING

TABLE

AC LEAKAGE

TESTER OR

EQUIVALENT

“CAUTION”

A V

“SW-P330 F1 : FOR CONTINUED PROTECTION AGAINST RISK OF FIRE, REPLACE ONLY WITH SAME TYPE 2.0A, 125V FUSE.”

CAUTION

SW-P330 F1

: REPLACE WITH SAME TYPE 2.0A, 125V FUSE.

ATTENTION

SW-P330 F1

: UTILISER UN FUSIBLE DE RECHANGE DE MEME TYPE DE 2.0A, 125V.

WARNING: CHEMICAL CONTENT NOTICE!

The solder used in the production of this product contains LEAD. In addition, other electrical/electronic and/or plastic (where

applicable) components may also contain traces of chemicals found by the California Health and Welfare Agency (and possibly

other entities) to cause cancer and/or birth defects or other reproductive harm.

DO NOT PLACE SOLDER, ELECTRICAL/ELECTRONIC OR PLASTIC COMPONENTS IN YOUR MOUTH FOR ANY REASON

WHATSOEVER!

Avoid prolonged, unprotected contact between solder and your skin! When soldering, do not inhale solder fumes or expose eyes

to solder/flux vapor!

If you come in contact with solder or components located inside the enclosure of this product, wash your hands before handling

food.

About lead-free solder / 無鉛ハンダについて

The P.C.B.s installed in this unit are soldered using the

following solder.

Among some types of lead free solder currently available, it is

recommended to use one of the following types for the repair work.

Caution:

1. As the melting point temperature of the lead free solder

NS-P330

NS-P336

2. If lead solder must be used, be sure to remove lead-

2

SIDE A / A 面 SIDE B /B 面

MAIN P.C.B — lead free solder / 無鉛ハンダ

SMT

Side A

Solder Dip

Side B

REFLOW

MI

• Sn + Ag + Cu (tin + silver + copper)

• Sn + Cu (tin + copper)

• Sn + Zn + Bi (tin + zinc + bismuth)

is about 30°C to 40°C (50°F to 70°F) higher than that of

the lead solder, be sure to use a soldering iron suitable

to each solder.

free solder from each terminal section of the parts to be

replaced and from the area around it completely before

soldering, or make sure that the lead free solder and

lead solder melt together fully.

FLOW

本機に搭載されている基板のハンダ付けに使用されている

ハンダは下記の通りです。

Process

Process

無鉛ハンダにはいくつかの種類がありますが、修理時には

下記のような無鉛ハンダの使用を推奨します。

・Sn+Ag+Cu(錫 +銀 +銅)

・Sn+Cu(錫 +銅)

・Sn+Zn+Bi(錫 +亜鉛 +ビスマス)

注意:

1. 無鉛ハンダの融点温度は通常の鉛入りハンダに比べ30〜

40℃程度高くなっていますので、それぞれのハンダに

合ったハンダごてをご使用ください。

2. 鉛入りハンダを使わざるを得ない場合は、あらかじめ交

換する部品端子部やその周辺部の無鉛ハンダをすべて取

り除くか、あるいは無鉛ハンダと鉛入りハンダが十分に

溶けた状態となるようにハンダ付けしてください。

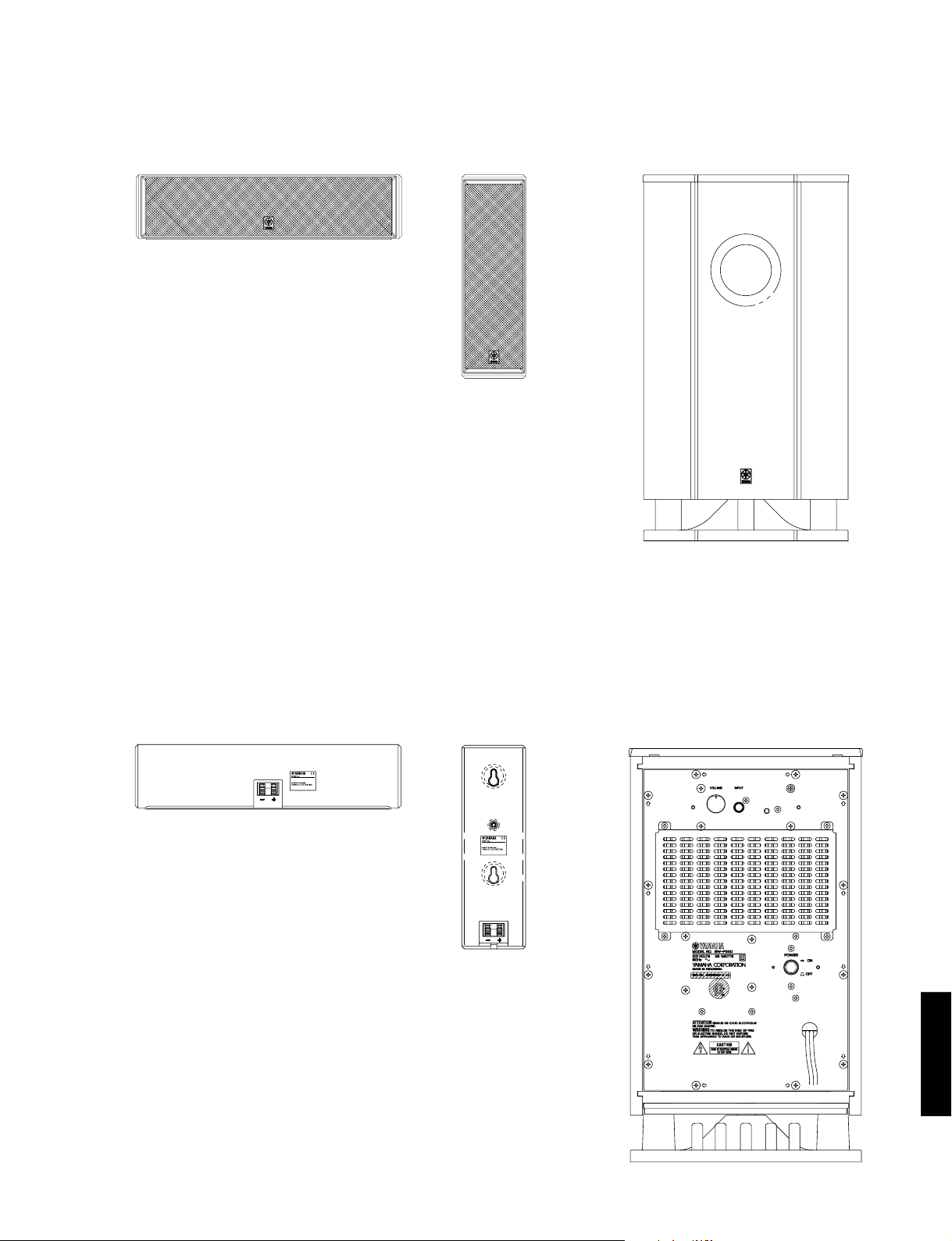

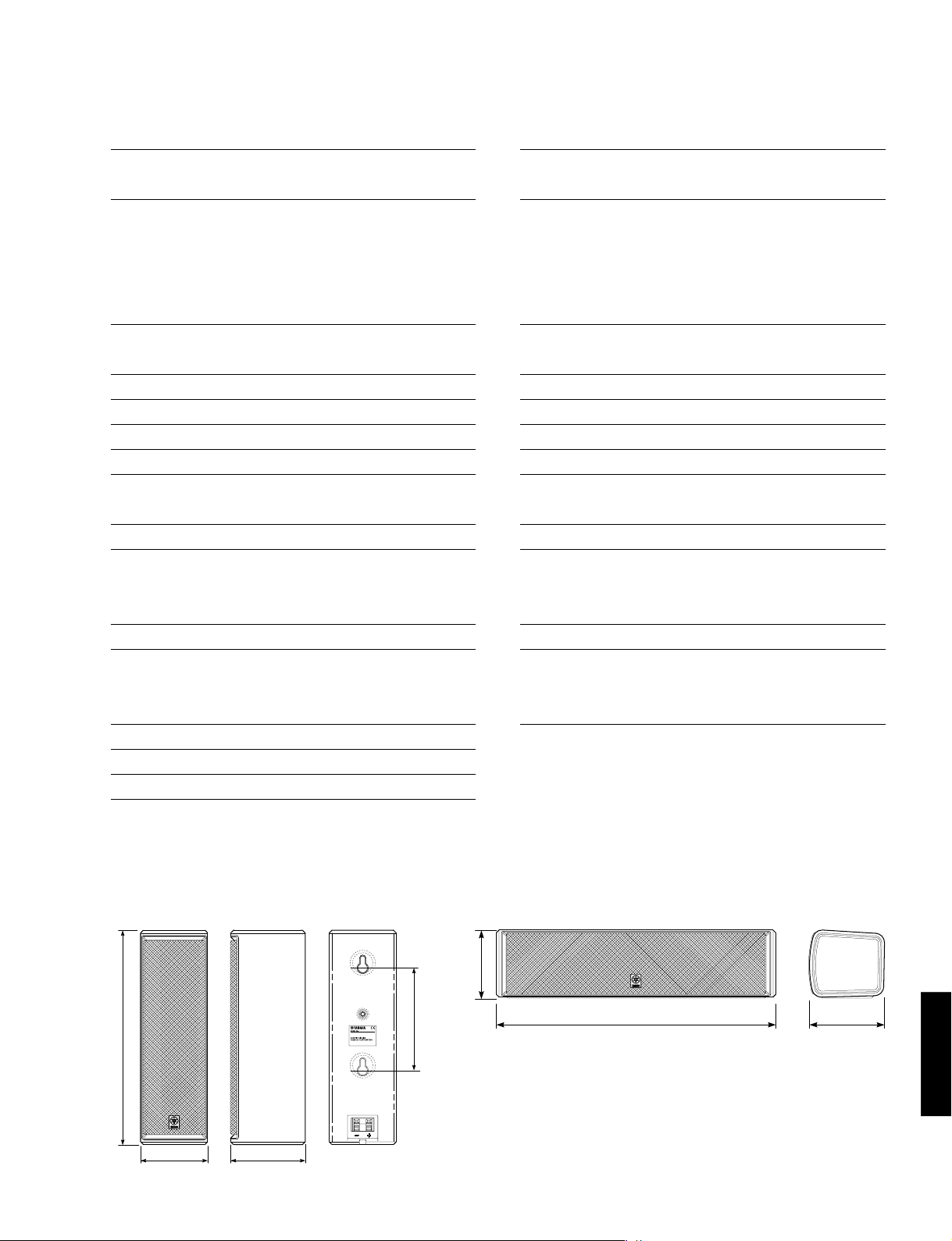

■ FRONT PANELS

NS-P330/NS-P336

▼ NX-C200

▼ NX-S200 ▼ SW-P330

x1

x4 for NS-P330

x5 for NS-P336

x1

■ REAR PANELS

▼ NX-C200

IMPEDANCE

NOMINAL

MAXIMUM

MADE ININDNESIA

SER. NO.

▼ NX-S200

NX-C200

6 OHMS

INPUT

30 WATTS

INPUT

100 WATTS

NX-S200

IMPEDANCE

6 OHMS

INPUT

NOMINAL

30 WATTS

INPUT

MAXIMUM

100 WATTS

MADE ININDNESIA

SER. NO.

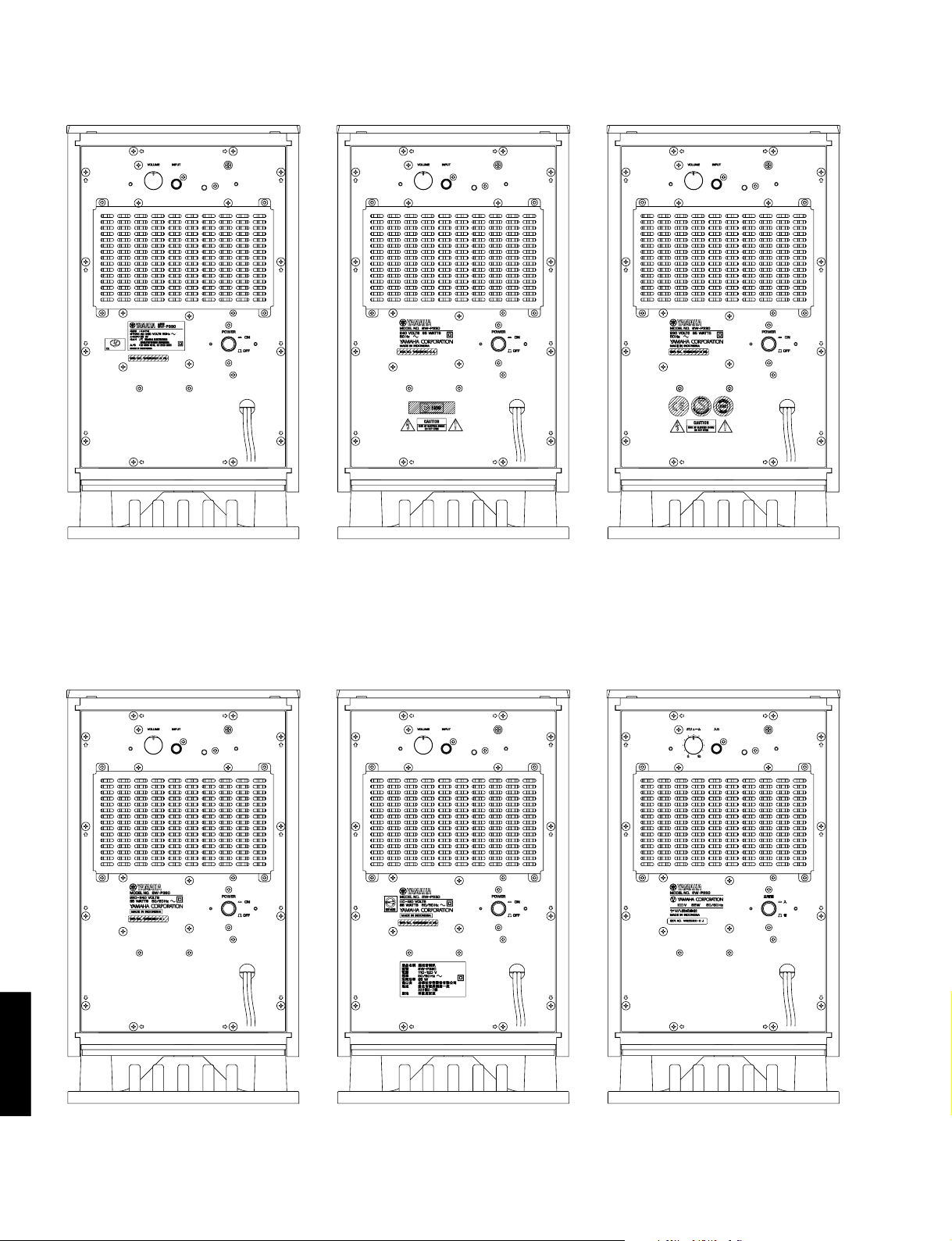

▼ SW-P330 (U, C models)

NS-P330

NS-P336

3

NS-P330/NS-P336

▼ SW-P330 (K model) ▼ SW-P330 (B, G model)▼ SW-P330 (A model)

▼ SW-P330 (L model)

NS-P330

NS-P336

▼ SW-P330 (V model)

▼ SW-P330 (J model)

4

■ SPECIFICATIONS/参考仕様

NS-P330/NS-P336

● NX-S200

Type / 型式............................. 2-way Acoustic Suspension

Magnetic Shielding Type

Driver / スピーカーユニット

Tweeter ............................. 2.5 cm (1”) Balanced Dome

Magnetic Shielding Type

Woofer ........................................... 5 cm (2”) Cone x 2

Magnetic Shielding Type

Frequency Response / 再生周波数帯域

............................................... 100 Hz to 40 kHz

Impedance /インピーダンス ............................... 6 ohms

Nominal Input /許容入力 .......................................... 30 W

Maximum Input / 最大入力 ..................................... 100 W

Sensitivity /出力音圧レベル .................... 85 dB/2.83 V/m

Crossover Frequency /クロスオーバー周波数

................................................................. 7 kHz

Input Terminal / 入力端子 ................................ Push Type

Dimensions (W x H x D) /寸法(幅×高さ×奥行き)

............................... 72 mm x 230 mm x 81 mm

(2-13/16” x 9-1/16” x 3-3/16”)

Weight / 質量 ...................................... 1.0 kg (2 lbs. 3 oz.)

Finish / 仕上げ

Black color ................................... U, C, A, B, G models

Silver color ................... U, C, K, A, B, G, L, V, J models

Appropriate Speaker Stand /適応スピーカースタンド ... SPS-200

Appropriate Speaker Bracket /適応ブラケット ......... SPM-8S

Speaker Bracket Accessory Screw Size

............

M4 x 12

● NX-C200

Type / 型式............................. 2-way Acoustic Suspension

Magnetic Shielding Type

Driver / スピーカーユニット

Tweeter ............................. 2.5 cm (1”) Balanced Dome

Magnetic Shielding Type

Woofer ........................................... 5 cm (2”) Cone x 2

Magnetic Shielding Type

Frequency Response / 再生周波数帯域

............................................... 100 Hz to 40 kHz

Impedance /インピーダンス ............................... 6 ohms

Nominal Input /許容入力 .......................................... 30 W

Maximum Input / 最大入力 ..................................... 100 W

Sensitivity /出力音圧レベル .................... 85 dB/2.83 V/m

Crossover Frequency /クロスオーバー周波数

................................................................. 7 kHz

Input Terminal / 入力端子 ................................ Push Type

Dimensions (W x H x D) / 寸法(幅×高さ×奥行き)

............................... 300 mm x 72 mm x 81 mm

(11-13/16” x 2-13/16” x 3-3/16”)

Weight /質量 .................................... 1.1 kg (2 lbs. 6 oz.)

Finish / 仕上げ

Black color ................................... U, C, A, B, G models

Silver color ................... U, C, K, A, B, G, L, V, J models

* Specifications subject to change without notice.

*参考仕様は予告なく変更されることがあります。

* Specifications subject to change without notice.

*参考仕様は予告なく変更されることがあります。

● DIMENSIONS / 寸法図

▼ NX-S200 ▼ NX-C200

72 (2-13/16")

NX-S200

IMPEDANCE

6 OHMS

NOMINAL

INPUT

30 WATTS

MAXIMUM

INPUT

100 WATTS

230 (9-1/16")

72 (2-13/16") 81 (3-3/16")

MADE ININDNESIA

SER. NO.

Unit : mm (inch)

110 (4-6/16")

300 (11-13/16") 81 (3-3/16")

Unit : mm (inch)

NS-P336

5

NS-P330

Loading...

Loading...