YAMAHA Z300A, LZ300A PARTS CATALOGUE

Z300A

LZ300A

292211

SUPPLEMENTARY

SERVICE MANUAL

6D0-28197-3F-1X

NOTICE

This Supplementary Service Manual has been prepared to introduce new service and new data

information for the Z300 and LZ300 which are based on the Z250 and LZ250. For complete information on service procedures, it is necessary to use this Supplementary Service Manual together with

the following manual.

Z250D, LZ250D SERVICE MANUAL: 60V-28197-3E-11

Important information

Particularly important information is distinguished in this manual by the following notations:

The Safety Alert Symbol means ATTENTION! BECOME ALERT! YOUR SAFETY IS

INVOLVED!

WARNING

Failure to follow WARNING instructions could result in severe injury or death to the machine

operator, a bystander, or a person inspecting or repairing the outboard motor.

CAUTION:

A CAUTION indicates special precautions that must be taken to avoid damage to the outboard motor.

NOTE:

A NOTE provides key information to make procedures easier or clearer.

CAUTION:

USE UNLEADED STRAIGHT GASOLINE ONLY

• Gasoline containing lead can cause performance loss and engine damage.

• Do not use gasoline mixed with oil during the break-in period or anytime thereafter.

YAMALUBE 2-STROKE OUTBOARD OIL IS RECOMMENDED.

1

Z300A, LZ300A

SUPPLEMENTARY SERVICE MANUAL

©2003 by Yamaha Motor Co., Ltd.

1st Edition, July 2003

All rights reserved.

Any reprinting or unauthorized use

without the written permission of

Yamaha Motor Co., Ltd.

is expressly prohibited.

Printed in the Netherlands

Contents

General information

Specifications

Periodic checks and adjustments

Fuel system

Power unit

GEN

INFO

SPEC

CHK

ADJ

FUEL

POWR

1

2

3

4

5

Lower unit

Bracket unit

Electrical systems

Troubleshooting

Index

LOWR

BRKT

–+

ELEC

TRBL

SHTG

6

7

8

9

General information

How to use this manual....................................................................................1

Manual format............................................................................................... 1

Symbols........................................................................................................ 2

Identification...................................................................................................... 3

Applicable models ........................................................................................ 3

Serial number ...............................................................................................3

Features and benefits.......................................................................................4

Crankcase and cylinders ..............................................................................4

Intake system ............................................................................................... 6

Upper case ...................................................................................................8

Lower case ...................................................................................................9

ECM (Electronic Control Module) ............................................................... 10

Wiring harness connector holder................................................................ 10

Propeller selection..........................................................................................11

Propeller size.............................................................................................. 11

Selection..................................................................................................... 11

Predelivery checks .........................................................................................12

Checking the fuel system ........................................................................... 12

Checking the gear oil level ......................................................................... 12

Checking the engine oil level......................................................................12

Checking the battery................................................................................... 12

Checking the outboard motor mounting height........................................... 13

Checking the remote control cables ........................................................... 13

Checking the steering system .................................................................... 14

Checking the gear shift and throttle operation............................................14

Checking the power trim and tilt system..................................................... 14

Checking the engine start switch and engine stop lanyard switch ............. 14

Checking the cooling water pilot hole ......................................................... 15

Test run ...................................................................................................... 15

Break-in ......................................................................................................15

After test run ............................................................................................... 15

6D03F1X

Specifications

General specifications.................................................................................... 16

Maintenance specifications ........................................................................... 18

Power unit................................................................................................... 18

Lower unit ................................................................................................... 20

Electrical ..................................................................................................... 20

Dimensions................................................................................................. 23

Tightening torques..........................................................................................25

Specified torques........................................................................................ 25

General torques.......................................................................................... 27

Periodic checks and adjustments

Special service tools ......................................................................................28

Maintenance interval chart............................................................................. 31

Oil injection system ........................................................................................ 32

Adjusting the oil pump link rod.................................................................... 32

Lower unit........................................................................................................ 32

Checking the lower unit for air leakage ...................................................... 32

General............................................................................................................. 33

Lubricating the outboard motor................................................................... 33

Fuel system

Fuel filter.......................................................................................................... 35

6D03F1X

Power unit

Power unit........................................................................................................ 36

Removing the power unit............................................................................ 37

Crankcase........................................................................................................39

Removing the crankcase covers ................................................................ 40

Installing the crankcase covers ..................................................................40

Installing the power unit.............................................................................. 40

Lower unit

Propeller shaft housing (regular rotation model) ........................................ 43

Shimming (regular rotation model) ............................................................... 45

Selecting the pinion shims.......................................................................... 46

Backlash (regular rotation model)................................................................. 47

Measuring the forward and reverse gear backlash ....................................47

Propeller shaft housing (counter rotation model) ....................................... 50

Drive shaft and lower case (counter rotation model) .................................. 52

Disassembling the reverse gear ................................................................. 54

Assembling the lower case......................................................................... 54

Shimming (counter rotation model) .............................................................. 56

Selecting the pinion shims.......................................................................... 57

Backlash (counter rotation model)................................................................ 58

Measuring the forward and reverse gear backlash ....................................58

Bracket unit

Bottom cowling ............................................................................................... 61

Upper case, steering arm, swivel bracket, and clamp brackets.................64

Power trim and tilt unit ................................................................................... 69

Checking the hydraulic pressure ................................................................ 69

6D03F1X

Electrical systems

Electrical components.................................................................................... 72

Port view..................................................................................................... 72

Top view .....................................................................................................73

Troubleshooting

Self-diagnosis..................................................................................................74

Diagnosing the electronic control system................................................... 74

Wiring diagram

6D03F1X

GEN

INFO

General information

How to use this manual

Only chapters containing revisions or additional items in the base manual have been included in this

manual.

All special service tools introduced in this manual are mentioned in Chapter 3.

Manual format

The format of this manual has been designed to make service procedures clear and easy to understand. Use the information below as a guide for effective and quality service.

1

Parts are shown and detailed in an exploded diagram and are listed in the components list.

2

Tightening torque specifications are provided in the exploded diagrams and after a numbered

step with tightening instructions.

3

Symbols are used to indicate important aspects of a procedure, such as the grade of lubricant

and lubrication point.

4

The components list consists of part names and part quantities, as well as bolt and screw dimensions.

5

Service points regarding removal, checking, and installation are shown in individual illustrations

to explain the relevant procedure.

1

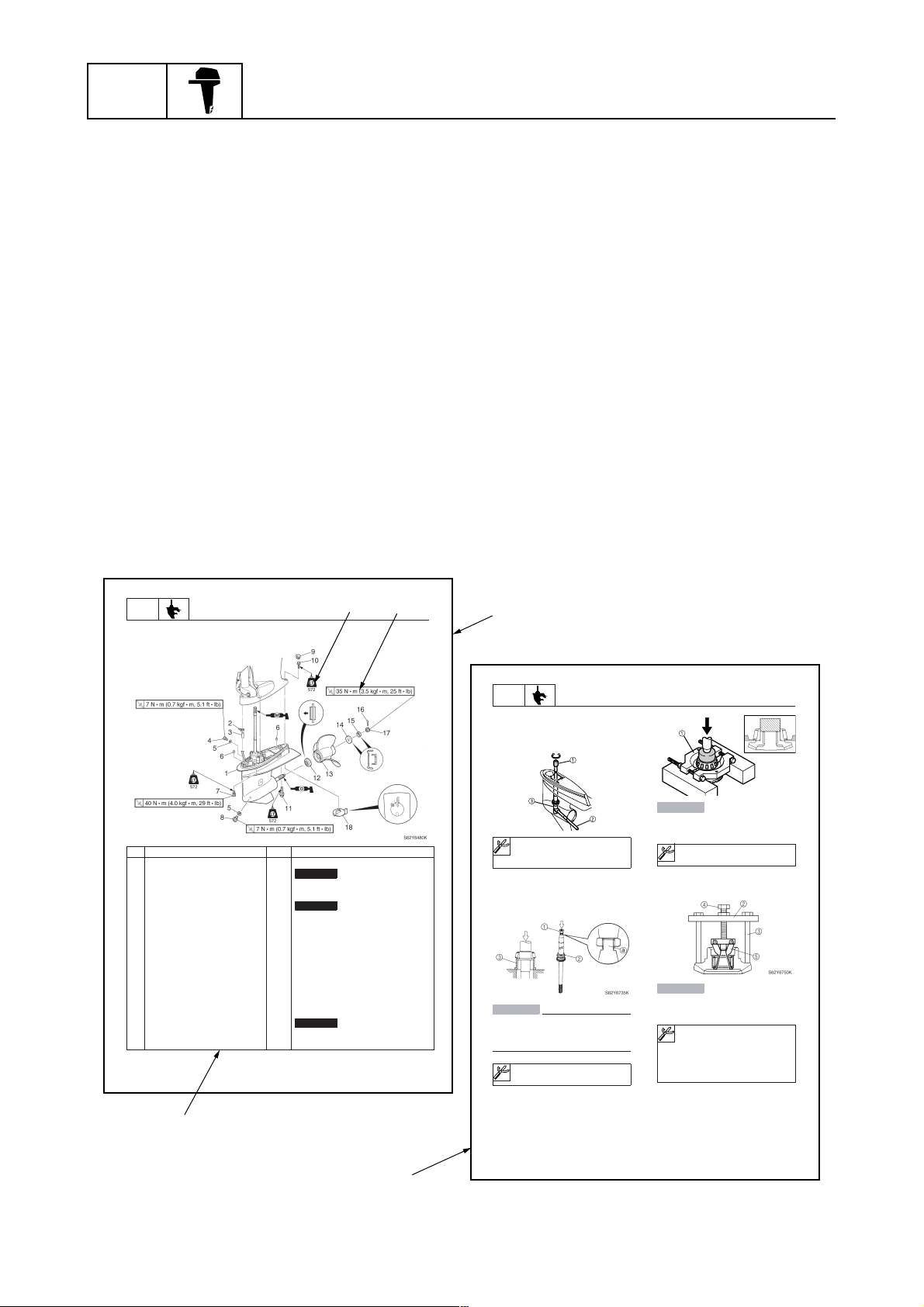

LOWR

Lower unit

No. Part name Q’ty Remarks

1 Lower unit 1

2 Plastic tie 1

3Hose 1

4 Check screw 1

5 Gasket 2

6 Dowel pin 2

7 Bolt 4 M10 40 mm

8 Drain screw 1

9Grommet 1

10 Bolt 1 M10 45 mm

11 Bolt 1 M8 60 mm

12 Thrust washer 1

13 Propeller 1

14 Washer 1

15 Washer 1

16 Cotter pin 1

17 Propeller nut 1

18 Trim tab 1

6-5

Lower unit

Not reusable

Not reusable

Not reusable

3

4

2

62Y5A11

1

LOWR

Removing the drive shaft

1. Remove the drive shaft assembly and

pinion, and then pull out the forward

gear.

Disassembling the drive shaft

1. Install the pinion nut 1, tighten it finger

tight, and then remove the drive shaft

bearing 2 using a press.

CAUTION:

• Do not press the drive shaft threads

directly.

• Do not reuse the bearing, always

replace it with a new one.

Disassembling the forward gear

1. Remove the taper roller bearing from the

forward gear using a press.

Lower unit

S62Y6850K

Drive shaft holder 4 1: 90890-06518

Pinion nut holder 2: 90890-06505

Socket adapter 2 3: 90890-06507

Bearing inner race attachment 3:

90890-06639

CAUTION:

Do not reuse the bearing, always replace

it with a new one.

Bearing separator 1: 90890-06534

2. Remove the needle bearing from the forward gear.

CAUTION:

Do not reuse the bearing, always replace

it with a new one.

a

Stopper guide plate 2: 90890-06501

Stopper guide stand 3:

90890-06538

Bearing puller 4: 90890-06535

Bearing puller claw 1 5:

90890-06536

S62Y6740K

6-19

62Y5A11

5

1

6D03F1X

Symbols

T

R

.

.

D

242

LT

The symbols below are designed to indicate the content of a chapter.

How to use this manual

General information

GEN

INFO

Specifications

SPEC

Periodic checks and adjustments

CHK

ADJ

Symbols 1 to 6 indicate specific data.

123456

Fuel system

FUEL

Power unit

POWR

Lower unit

LOWR

Bracket unit

BRKT

Electrical systems

ELEC

Troubleshooting

– +

TRBL

SHTG

1

2

3

4

Special tool

1

Specified oil or fluid

2

Specified engine speed

3

Specified tightening torque

4

Symbols 7 to C in an exploded diagram indicate the grade of lubricant and the lubrication point.

7890ABC

A M

E G

Apply 2-stroke outboard motor oil

7

Apply gear oil

8

Apply water resistant grease (Yamaha grease A)

9

Apply molybdenum disulfide grease

0

Symbols D to I in an exploded diagram indicate the type of sealant or locking agent and the application point.

DEFGHI

GM

4

LT

271

Specified measurement

5

Specified electrical value

6

(resistance, voltage, electric current)

C I

Apply corrosion resistant grease

A

(Yamaha grease D)

Apply low temperature resistant grease

B

(Yamaha grease C)

Apply injector grease

C

LT

572

SS

5

6

7

8

9

Apply Gasket Maker

D

Apply Yamabond No. 4

E

Apply LOCTITE 271 (red)

F

6D03F1X

Apply LOCTITE 242 (blue)

G

Apply LOCTITE 572

H

Apply silicon sealant

I

2

GEN

INFO

General information

Identification

Applicable models

This manual covers the following models.

Applicable models

Z300AETO, LZ300AETO

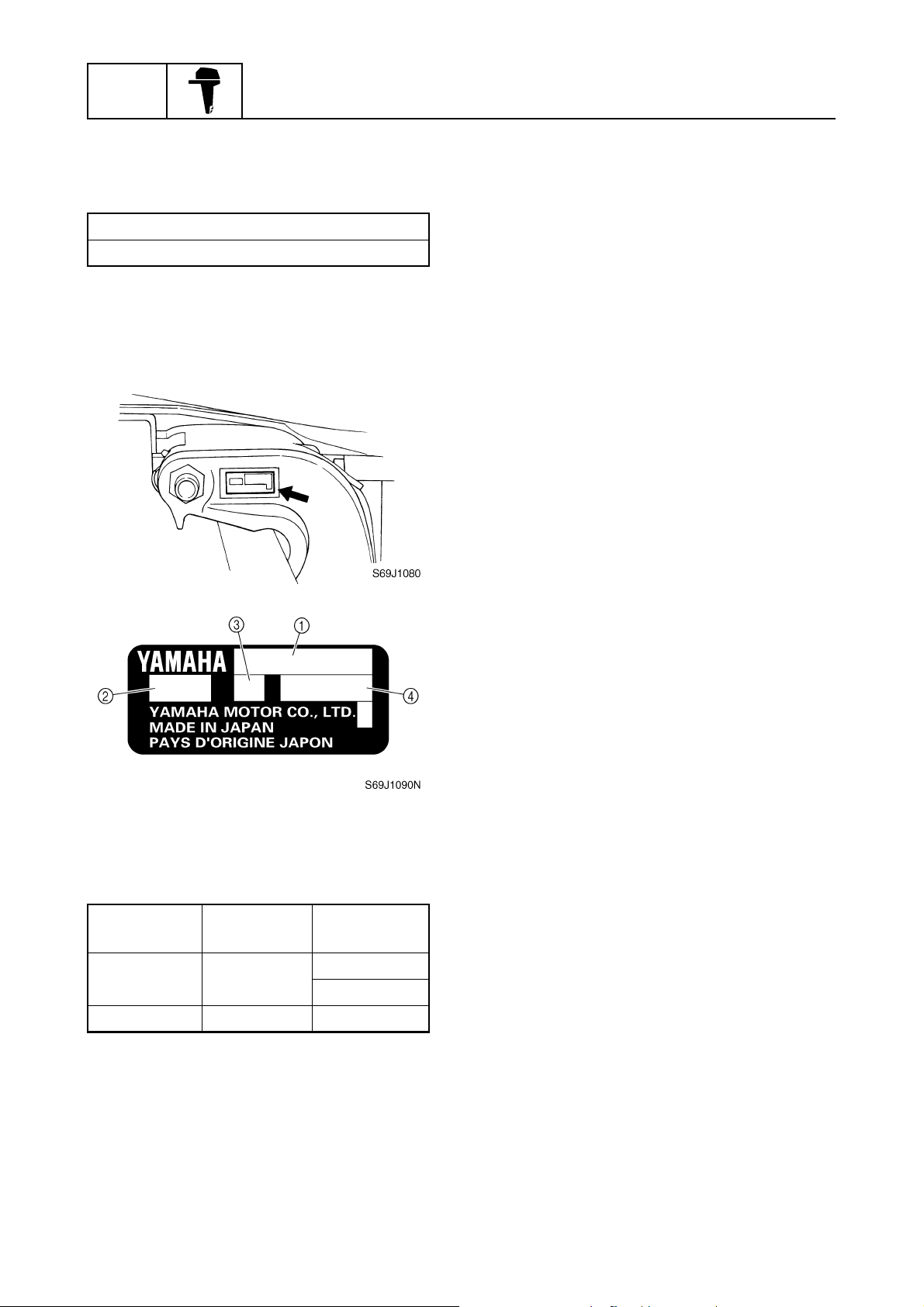

Serial number

The outboard motor serial number is

stamped on a label attached to the port

clamp bracket.

1

Model name

1

Approved model code

2

Transom height

3

Serial number

4

Model name

Approved

model code

Starting

serial No.

X: 1000001–

Z300AETO 6D0

U: 1000001–

LZ300AETO 6D1 X: 1000001–

3

6D03F1X

Identification / Features and benefits

Features and benefits

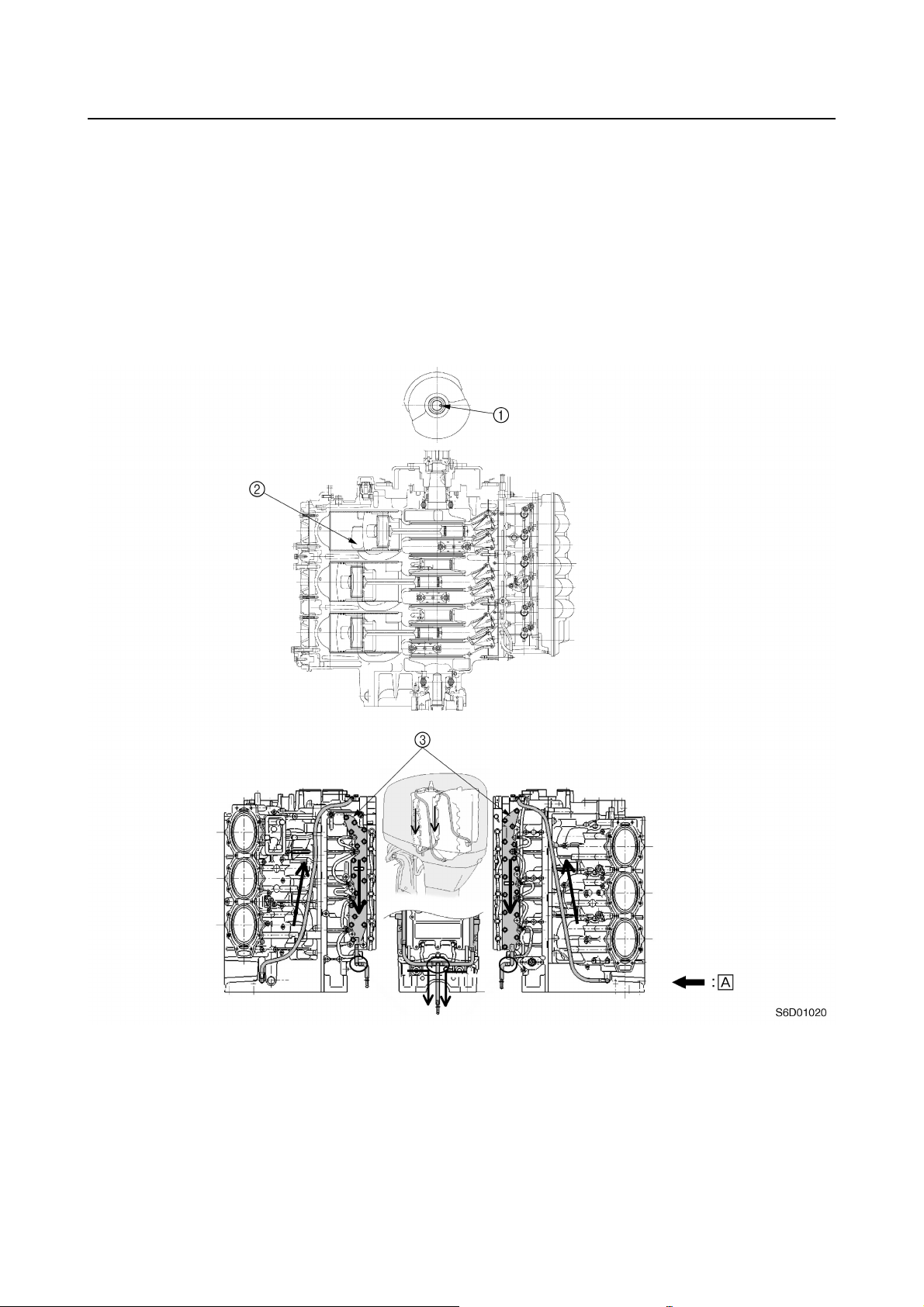

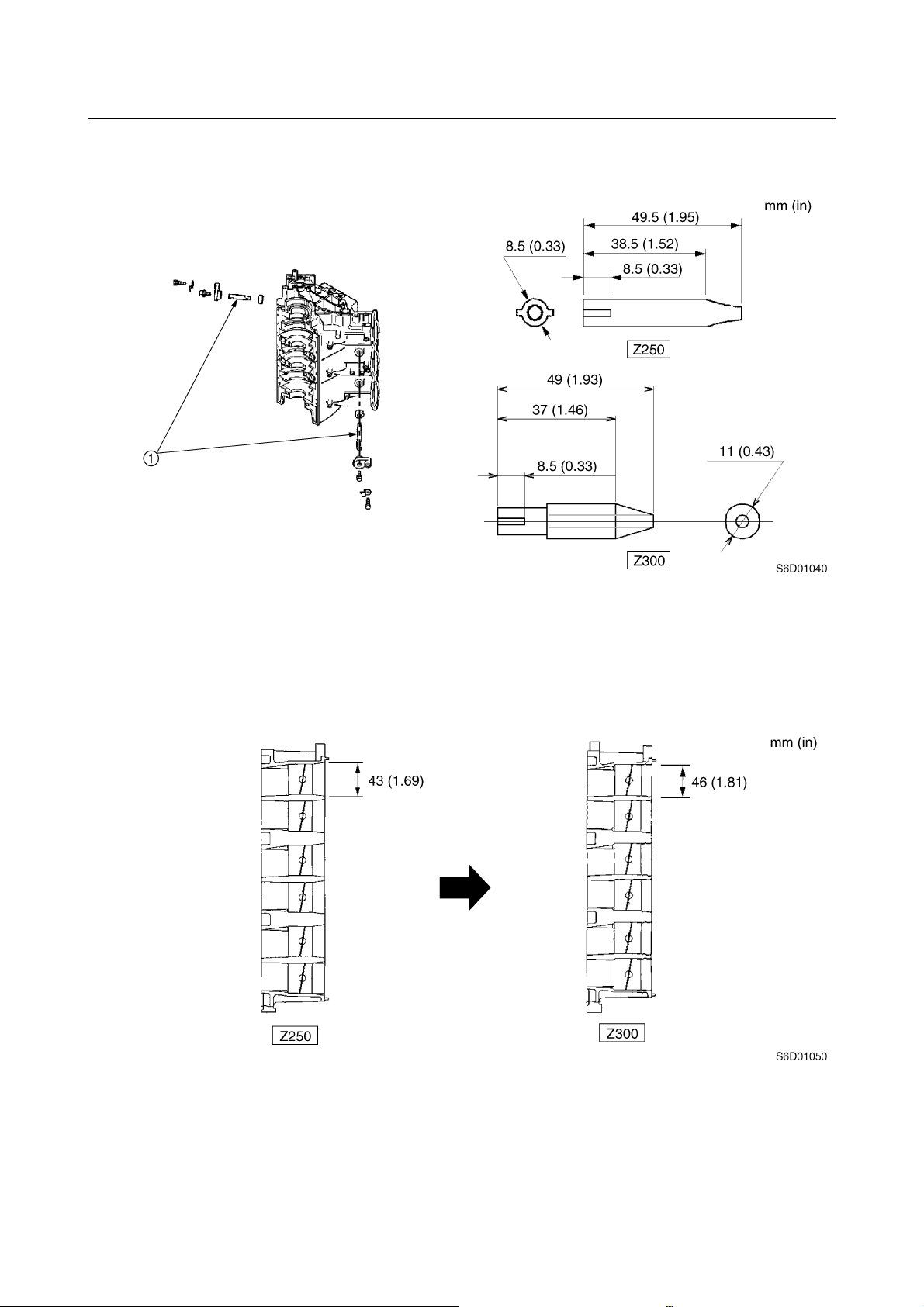

Crankcase and cylinders

The following modifications have been adopted to increase the output as compared to the Z250

power unit.

• The material of the crankshaft has been changed to a high-grade clean steel

bility against stress.

• Wider exhaust ports with planed-off edges have been adopted and the exhaust timing has been

changed to reduce the exchange loss of the exhaust gas.

• Cooling water jackets have been incorporated to the crankcase to increase engine-cooling ability.

*1: Steel with decreased nonmetallic inclusion content

(*1)

to increase dura-

1

Crankshaft identification

1

Identification mark: 2 mm (0.079 in) punch mark

Exhaust port

2

Crankcase water jackets

3

Water flow

È

6D03F1X

4

GEN

INFO

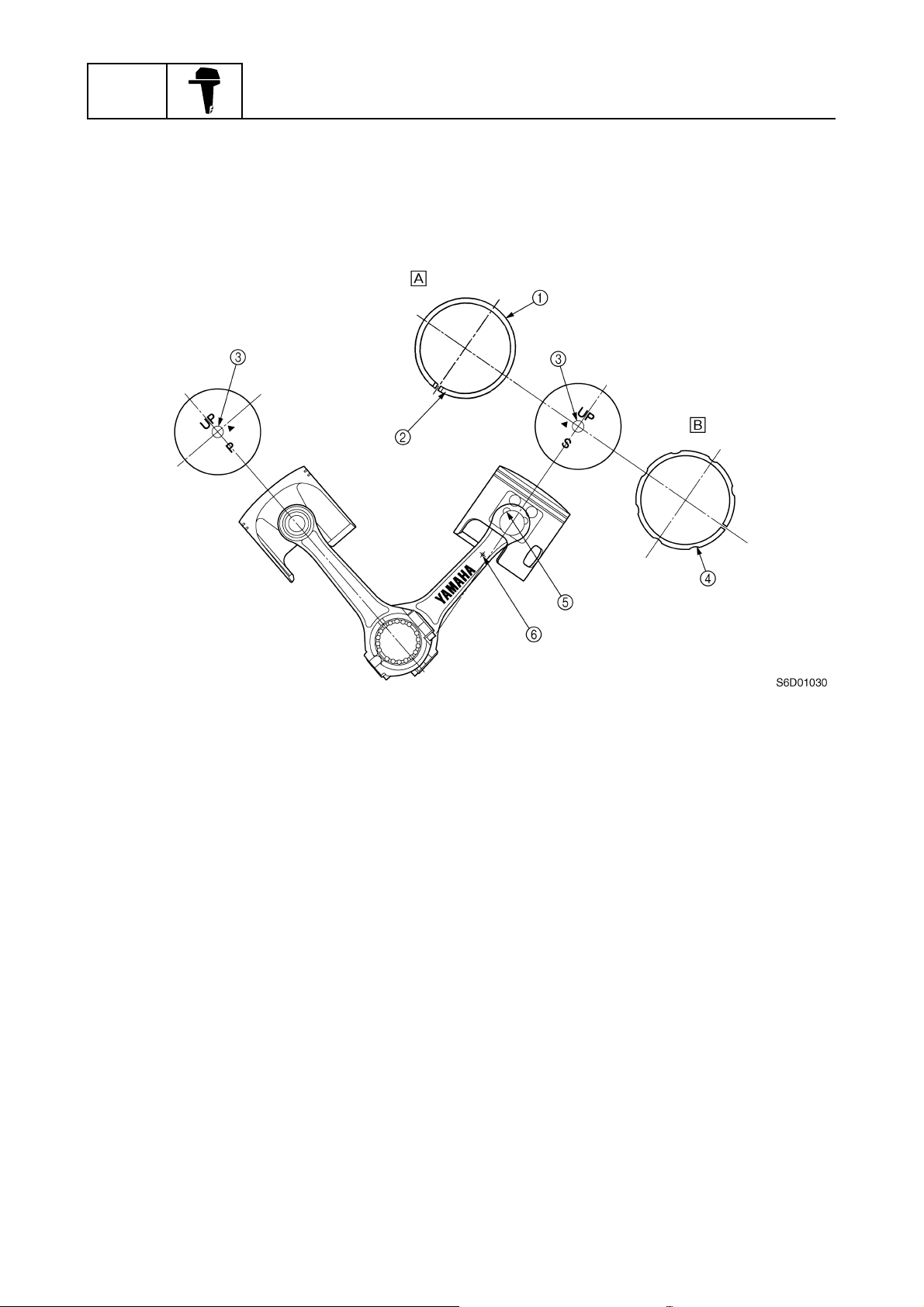

• Newly-forged lightweight pistons with a hard anodic coating on the piston pin boss have been

adopted to increase durability and reduce the inertia mass of the pistons.

• The top piston rings are made of steel and are ion-plated to increase durability.

• The heat treatments for the piston pins and connecting rods have been changed so that there is

multiphase carbonization to increase durability.

General information

Ion plating (chromium)

1

Identification mark: R

2

Identification mark: 6D0

3

Oil groove

4

Hard anodic coating

5

Identification mark

6

Top ring

È

Second ring

É

5

6D03F1X

Features and benefits

• The anti-corrosion anodes in the cooling water passages of the cylinder block are larger to

increase reliability and performance.

Anodes

1

Intake system

The openings in the throttle bodies were enlarged to a 46 mm (1.81 in) diameter to increase power

output.

6D03F1X

6

GEN

INFO

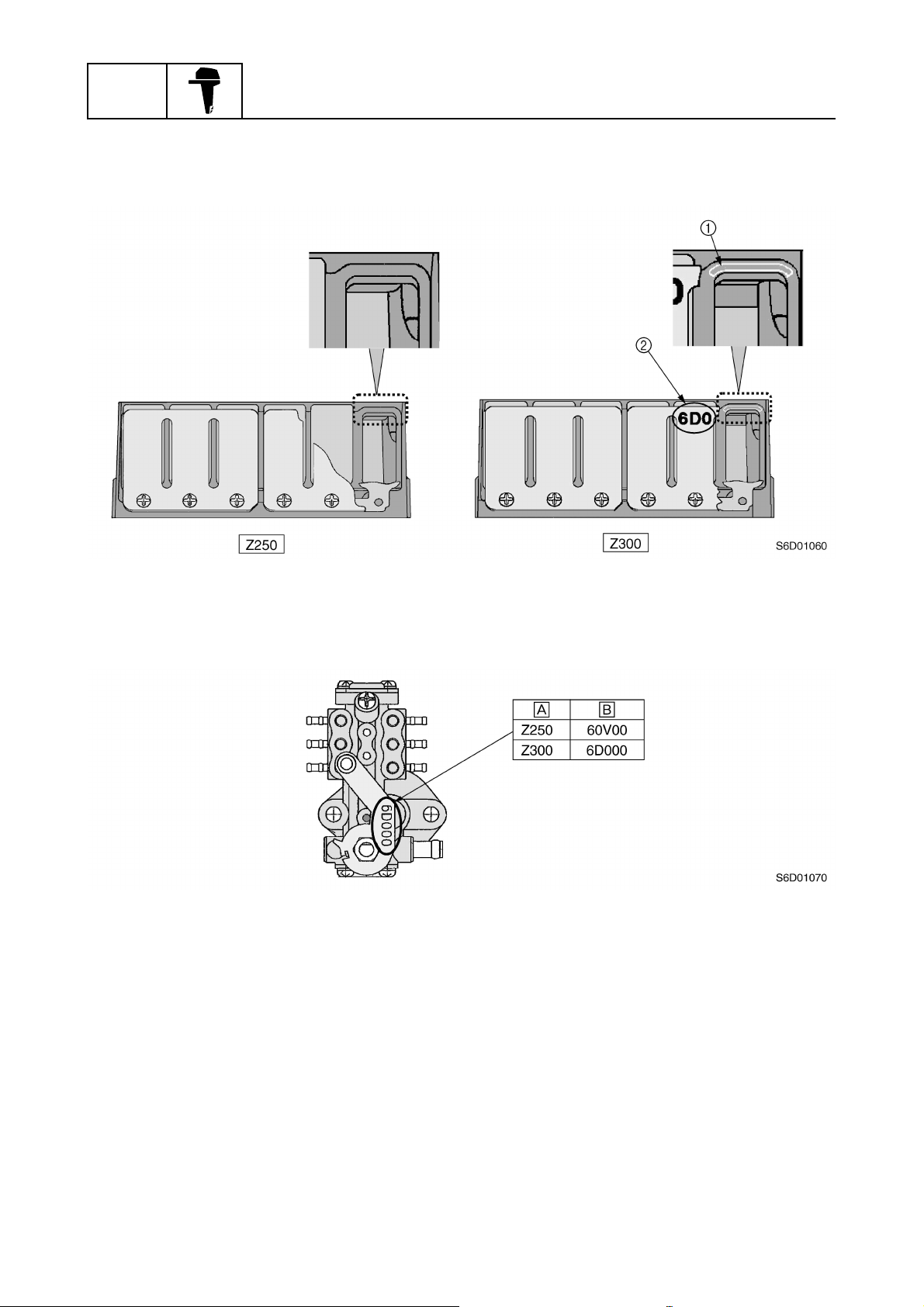

An oil groove has been added to each reed valve seat. Oil in the groove helps to reduce impact

when the reed valve contacts the reed valve seat.

The dimensions of the reed valve assembly are the same as those for the Z250.

General information

Oil groove

1

Identification mark: 6D0

2

The oil pump has been newly designed to obtain optimal oil supply.

Model

È

Identification mark

É

7

6D03F1X

Features and benefits

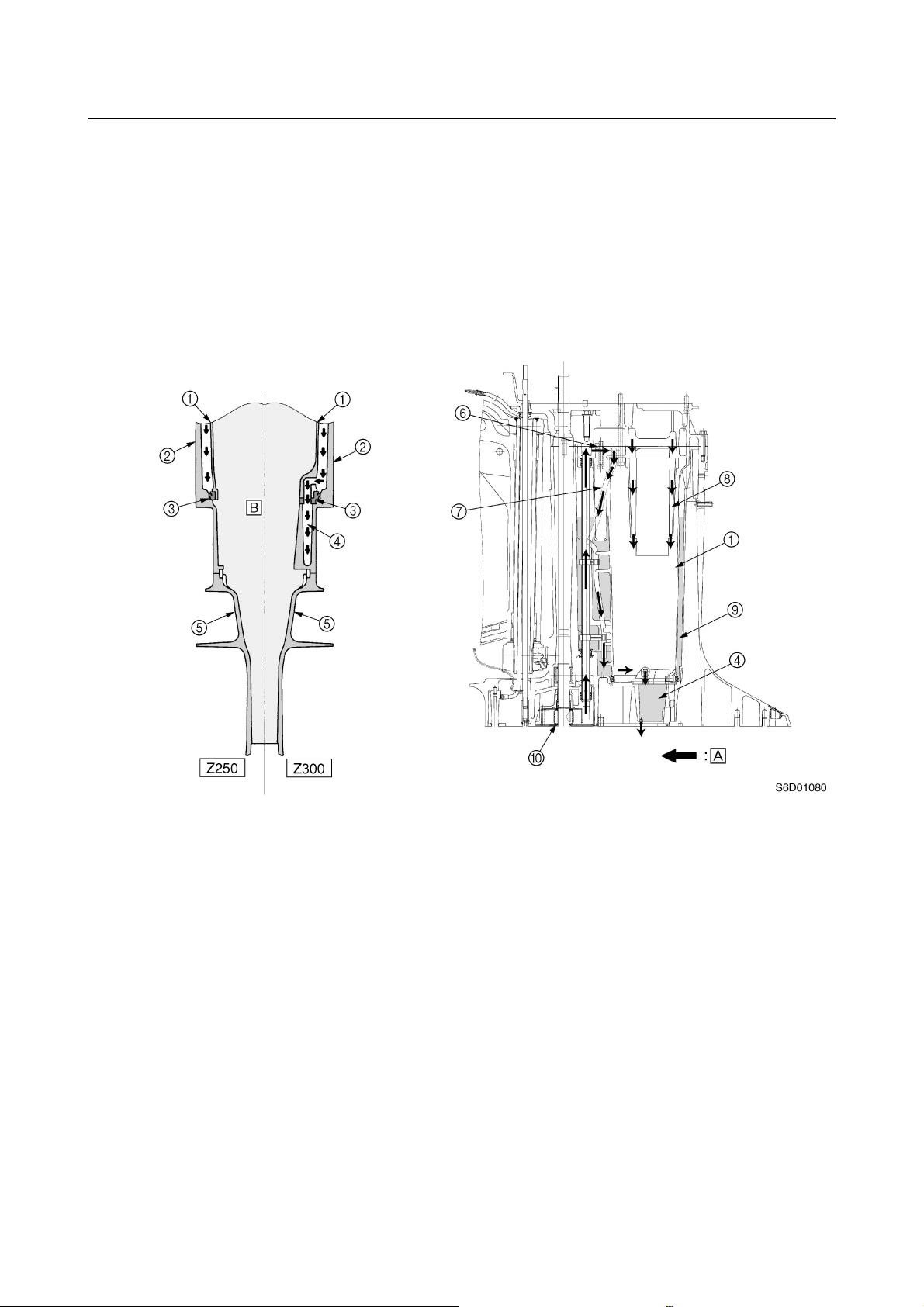

Upper case

Water jackets have been incorporated to both sides of the lower part of the upper case. This structure reduces the heat transfer to the upper case from the exhaust gas.

The cooling water discharged from the water pump is supplied to the upper case around the muffler

from the pipe connected to the exhaust guide, flows down into the water jacket, and then drains to

the lower case.

Water jackets have been incorporated to the exhaust manifold to protect it from the high-temperature exhaust gas.

Fresh cooling water from the water pump accumulates in the water jacket, and then drains into the

muffler.

Muffler

1

Upper case

2

Gasket

3

Upper case water jacket

4

Lower case

5

Exhaust guide

6

Hose

7

Exhaust manifold

8

Water

9

Water pump

0

6D03F1X

Water flow

È

Exhaust passage

É

8

GEN

INFO

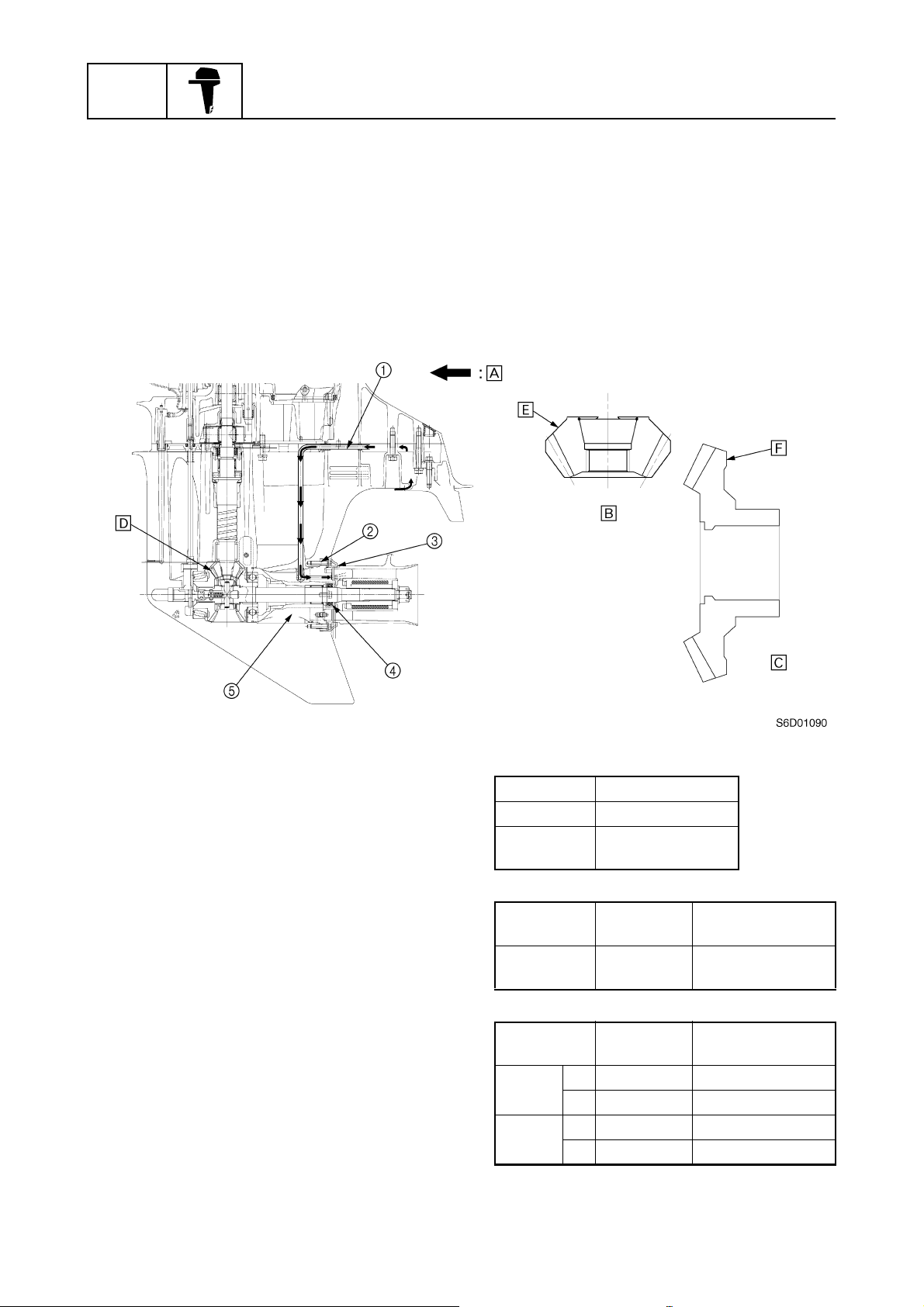

Lower case

The propeller shaft housing and the ring are newly designed to reduce the exhaust back-pressure

and cool the propeller damper.

Cooling water is taken in from the front of the trim tab, flows through the pipe in the lower case and

propeller shaft housing, and then is supplied directly to the propeller boss.

This prevents the cooling water from mixing with the exhaust gas in the exhaust passage in the

lower case and also prevents the cooling water from obstructing the exhaust gas.

Therefore, the exhaust back-pressure can be reduced.

A low gear ratio has been adopted to match the power output characteristics.

General information

Water pipe (for cooling the propeller boss)

1

Heli-sert bushing

2

Ring

3

Fluorine-coated oil seals

4

Propeller shaft housing (with water passage)

5

Water flow

È

Pinion gear

É

Reduction gear

Ê

Ë

Model Gear ratio

Z250 1.81

Z250F

Z300

Ì

Model

Z300

LZ300

Í

Model

Z300

LZ300

1.75

Identification

mark

60X1 Same as Z250F

Identification

mark

F 60X00 Same as Z250F

R 69L00 Same as 250C

F 6D100 New

R 6D100 New

Notes

Notes

9

6D03F1X

Features and benefits

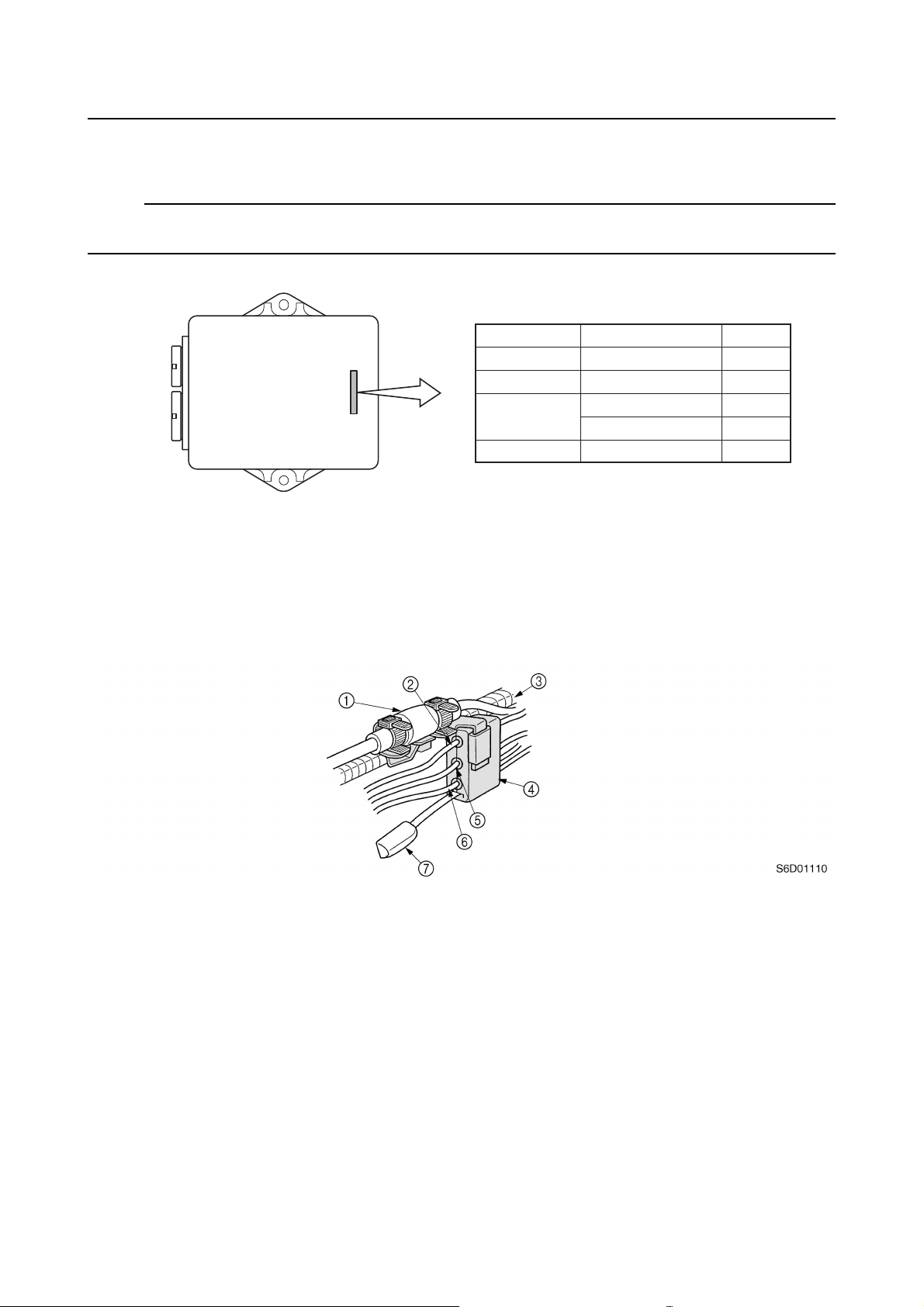

ECM (Electronic Control Module)

ECMs have been adopted that are specific to each model to control the ignition and injection timing.

NOTE:

The diagnostic codes are the same as those for the Z250, and the latest version of the YDIS covers

all previous models with fuel injection.

ÈÉÊ

VZ225 (Z250H) 60Y-01

VZ250 (Z250F) 60X-01

60V-01

60V-21

Ë

S6D01100

Model

È

ECM identification

É

Z250 (Z250D)

Z300 (Z300A) 6D0-00

Note

Ê

For Brazil

Ë

Wiring harness connector holder

A wiring harness connector holder has been added to the side of bottom cowling to secure the 10pin main harness, remote oil tank harness, warning indicator harness, and trim meter harness.

The wiring harness connector holder helps to organize the harnesses and hold them in place.

10-pin main harness

1

Remote oil tank harness (Blue connector)

2

Bottom cowling seal

3

Holder

4

Trim meter harness

5

Warning indicator harness

6

Isolator lead

7

6D03F1X

10

GEN

INFO

General information

Propeller selection

The performance of a boat and outboard

motor will be critically affected by the size

and type of propeller you choose. Propellers

greatly affect boat speed, acceleration,

engine life, fuel economy, and even boating

and steering capabilities. An incorrect choice

could adversely affect performance and

could also seriously damage the engine.

Use the following information as a guide for

selecting a propeller that meets the operating

conditions of the boat and the outboard

motor.

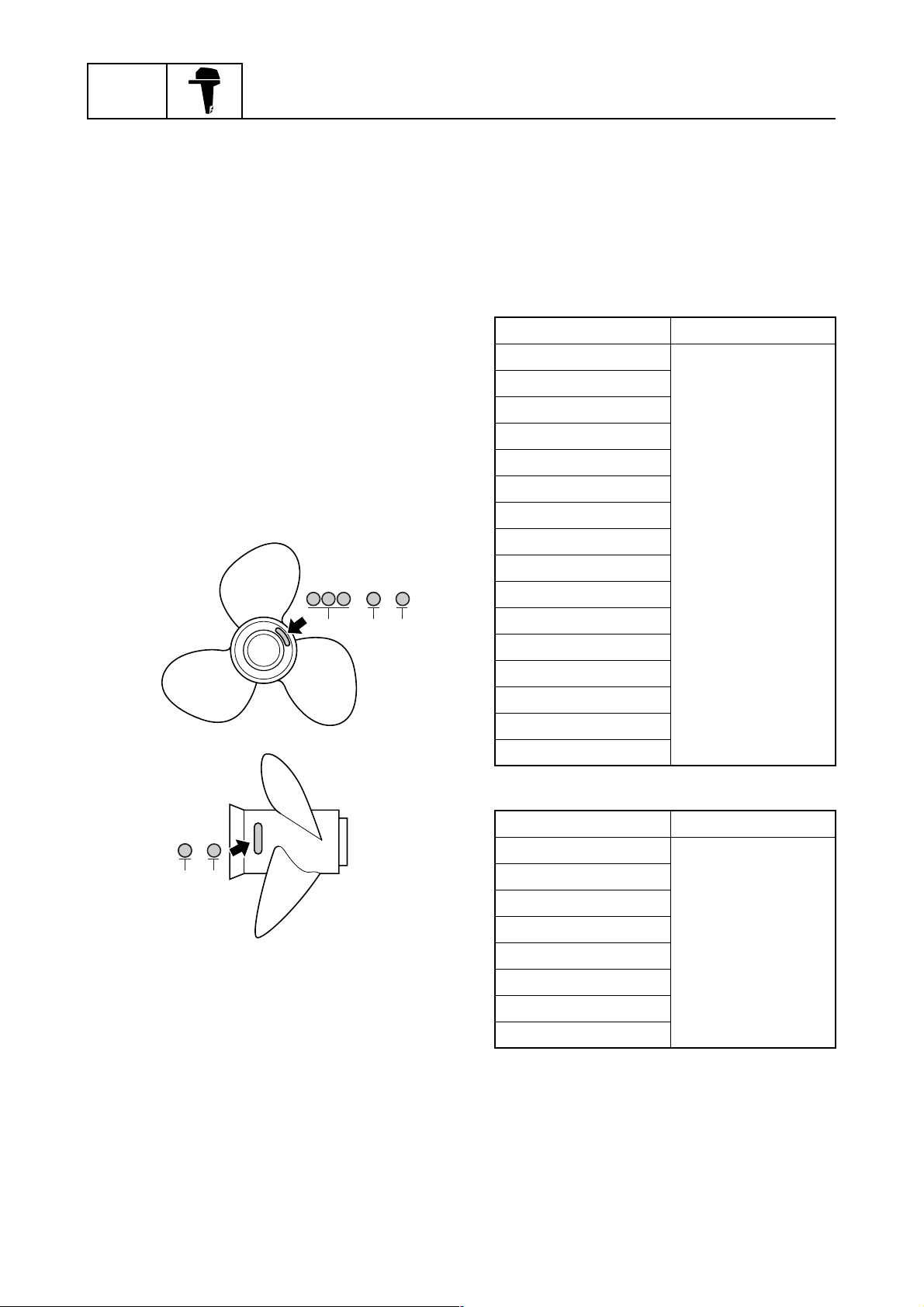

Propeller size

The size of the propeller is indicated on the

propeller boss end and on the side of the propeller boss.

× -

a

bc

S69J1100

1

Selection

When the engine speed is at the full throttle

operating range (4,500–5,500 r/min), the

ideal propeller for the boat is one that provides maximum performance in relation to

boat speed and fuel consumption.

Regular rotation model

Propeller size (in) Material

13 3/8 × 23 - M

13 3/8 × 25 - M

13 3/4 × 17 - M2

13 3/4 × 19 - M2

13 3/4 × 21 - M

14 1/2 × 19 - T

14 1/2 × 21 - T

14 1/2 × 23 - M

Stainless

14 3/4 × 25 - T

14 7/8 × 21 - M

15 × 17 - T

15 1/8 × 27 - T

15 1/4 × 15 - M

15 1/4 × 17 - M

15 1/4 × 19 - M

15 3/4 × 13 - M

-

b

c

Propeller diameter (in inches)

a

Propeller pitch (in inches)

b

Propeller type (propeller mark)

c

S60C1125

Counter rotation model

Propeller size (in) Material

13 3/8 × 23 - ML

13 3/4 × 17 - ML1

13 3/4 × 19 - ML1

13 3/4 × 21 - ML

Stainless

14 1/2 × 19 - TL

14 1/2 × 21 - TL

15 × 17 - TL

15 1/4 × 15 - ML

11

6D03F1X

Propeller selection / Predelivery checks

Predelivery checks

To make the delivery process smooth and

efficient, the predelivery checks should be

completed as explained below.

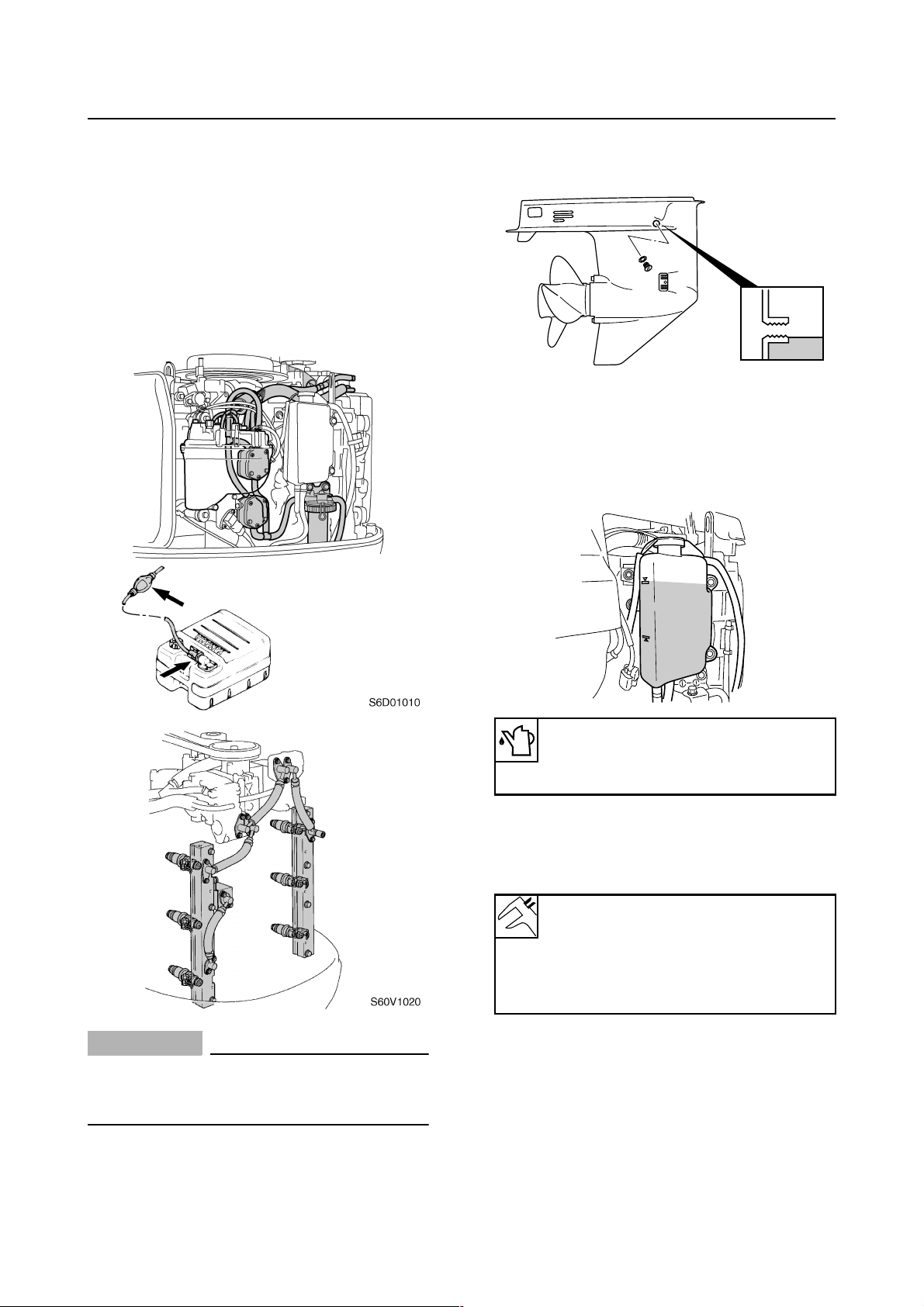

Checking the fuel system

1. Check that the fuel hoses are securely

connected and that the fuel tank is full

with fuel.

1

Checking the gear oil level

1. Check the gear oil level.

S60V1290

Checking the engine oil level

1. Check that the engine oil level is

between the maximum and minimum

level marks.

CAUTION:

• Use unleaded straight gasoline only.

• Do not use gasoline mixed with oil (pre-

mixed fuel).

S60V3260

Recommended engine oil:

YAMALUBE 2-stroke outboard

motor oil

Checking the battery

1. Check the capacity, electrolyte level, and

specified gravity of the battery.

Recommended battery capacity:

CCA/EN: 711 A

20HR/IEC: 100 Ah

Electrolyte specified gravity:

1.280 at 20 °C (68 °F)

2. Check that the positive and negative battery leads are securely connected.

6D03F1X

12

GEN

INFO

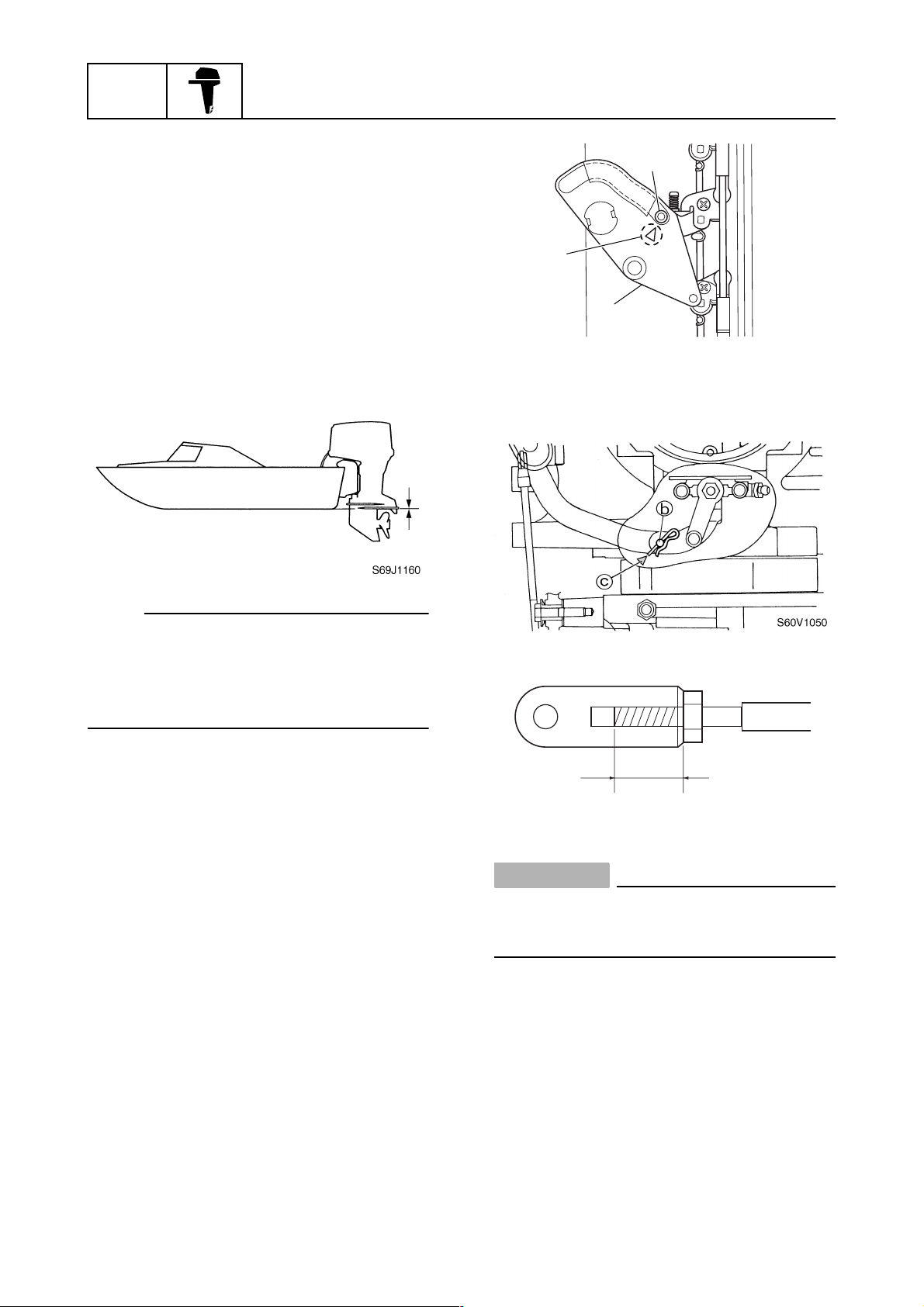

Checking the outboard motor

mounting height

1. Check that the anti-cavitation plate is

aligned with the bottom of the boat. If the

mounting height is too high, cavitation

will occur and propulsion will be reduced.

Also, the engine speed will increase

abnormally and cause the engine to

overheat. If the mounting height is too

low, water resistance will increase and

reduce engine efficiency.

General information

2

a

1

S60V1040

3. Check that the center of the set pin b is

aligned with the alignment mark c on

the bottom cowling.

NOTE:

The optimum mounting height is affected by

the combination of the boat and the outboard

motor. To determine the optimum mounting

height, test run the outboard motor at different heights.

2. Check that the clamp brackets are

secured with the clamp bolts.

Checking the remote control cables

1. Set the remote control lever to the neutral position and fully close the throttle

lever.

2. Check that the throttle cam 1 is in its

fully closed position and align the center

of the throttle cam roller 2 with the alignment mark a.

d

S60C1190

CAUTION:

The shift/throttle cable joint must be

screwed in a minimum of 8.0 mm (0.31 in)

d

.

13

6D03F1X

Predelivery checks

Checking the steering system

1. Check the steering friction for proper

adjustment.

2. Check that the steering operates

smoothly.

S60V1060

3. Check that there is no interference with

wires or hoses when the outboard motor

is steered.

Checking the gear shift and throttle

operation

1. Check that the gear shift operates

smoothly when the remote control lever

is shifted from neutral to forward or

reverse.

Checking the power trim and tilt

system

1. Check that the outboard motor tilts up

and down smoothly when operating the

power trim and tilt unit.

2. Check that there is no abnormal noise

produced when the outboard motor is

tilted up or down.

3. Check that there is no interference with

wires or hoses when the tilted-up outboard motor is steered.

4. Check that the trim meter points down

when the outboard motor is tilted all the

way down.

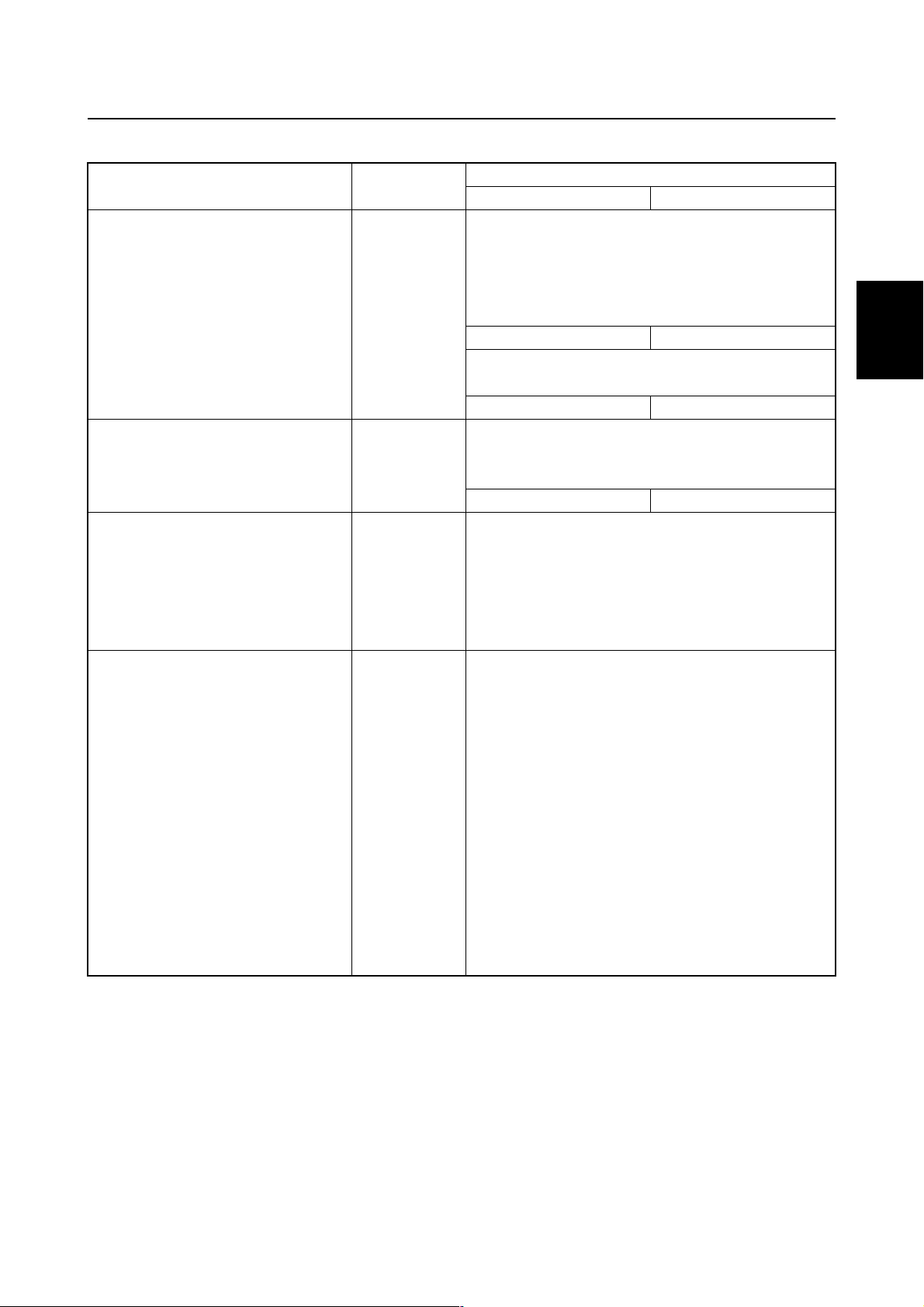

Checking the engine start switch and

engine stop lanyard switch

1. Check that the engine starts when the

engine start switch is turned to START.

2. Check that the engine turns off when the

engine start switch is turned to OFF.

2. Check that the throttle operates smoothly

when the remote control lever is shifted

from the fully closed position to the fully

open position a.

N

F

R

a

a

S69J1210

S60V1070

3. Check that the engine turns off when the

engine stop lanyard is pulled from the

engine stop lanyard switch.

6D03F1X

14

GEN

INFO

Checking the cooling water pilot

hole

1. Check that cooling water is discharged

from the cooling water pilot hole.

General information

cdaÈb

S60V3140

Test run

1. Start the engine, and then check that the

gear shift operates smoothly.

2. Check the engine idle speed after the

engine has been warmed up.

3. Operate at trolling speed.

4. Run the outboard motor for 1 hour at

3,000 r/min or at half throttle, then for

another hour at 4,000 r/min or at 3/4

throttle.

È

Hour

0

1

210

S60V1120

After test run

1. Check for water in the gear oil.

2. Check for fuel leakage in the cowling.

3. Flush the cooling water passage with

fresh water using the flushing kit and with

the engine running at idle.

5. Check that the outboard motor does not

tilt up when shifting into reverse and that

water does not flow in over the transom.

NOTE:

The test run is part of the break-in operation.

Break-in

During the test run, perform the break-in

operation in the following four stages.

1. First 10 minutes a of operation at idle

2. Fifty minutes b at 3,000 r/min or less

3. One hour c at 4,000 r/min or less

4. Eight hours d at 5,000 r/min or less with

repeated wide-open-throttle operation for

5 minutes or less

15

6D03F1X

Predelivery checks / General specifications

General specifications

Item Unit

Dimension

Overall length mm (in) 868 (34.2)

Overall width mm (in) 568 (22.4)

Overall height

(X) mm (in) 1,830 (72.0)

(U) mm (in) 1,957 (77.0) —

Boat transom height

(X) mm (in) 635 (25.0)

(U) mm (in) 762 (30.0) —

Weight

(with stainless propeller)

(X) kg (lb) 252 (556)

(U) kg (lb) 257 (567) —

Performance

Maximum output kW (hp) 220.7 (300) at 5,000 r/min

Full throttle operating range r/min 4,500–5,500

Maximum fuel consumption L (US gal,

lmp gal)/hr

Engine idle speed r/min 700–760

Power unit

Type 2-stroke, 76°, V6, HPDI

Total displacement cm

Bore × stroke mm (in) 93.0 (3.66) × 82.0 (3.23)

Compression ratio 6.2

Control system Remote control

Starting system Electric starter

Enrichment system Fuel injection

Ignition control system TCI

Maximum generator output V, A 12, 50

Spark plug BKR7EKU (NGK)

Cooling system Water

Exhaust system Propeller boss

Lubrication system Oil injection

3

(cu. in) 3,342 (203.9)

Z300AETO LZ300AETO

105.0 (27.7, 23.1) at 5,500 r/min

Model

2

1

2

3

4

5

6

7

8

6D03F1X

9

16

SPEC

Specifications

Item Unit

Z300AETO LZ300AETO

Model

Fuel and oil

Fuel type Regular unleaded gasoline

PON

(*1)

90

86

Fuel minimum rating RON

Engine oil

(*2)

YAMALUBE 2-stroke outboard motor oil

Engine oil tank capacity

Oil tank L (US gal,

1.2 (0.32, 0.26)

lmp gal)

Remote oil tank L (US gal,

10.5 (2.77, 2.31)

lmp gal)

Gear oil type Hypoid gear oil

Gear oil grade SAE 90

Gear oil quantity cm

3

(US oz,

1,150 (38.9, 40.6) 1,000 (33.8, 35.3)

lmp oz)

Bracket unit

Trim angle

Degree –3 to 16

(at 12° boat transom)

Tilt-up angle Degree 70

Steering angle Degree 30 + 30

Drive unit

Gear shift positions F-N-R

Gear ratio 1.75 (28/16)

Reduction gear type Spiral bevel gear

Clutch type Dog clutch

Propeller shaft type Spline

Propeller direction (rear view) Clockwise Counterclockwise

Propeller mark T, M TL, ML

Electrical

Battery minimum capacity

(*3)

CCA/EN A 711

20HR/IEC Ah 100

(*1)

RON: Research Octane Number

PON: Pump Octane Number =

(RON + Motor Octane Number)/2

(*2)

If 2-stroke outboard motor oil is not available, a 2stroke NMMA-certified TC-W3 oil of equivalent

quality must be used.

(*3)

CCA: Cold Cranking Ampere

EN: European Norm (European standard)

IEC: International Electrotechnical Commission

17

6D03F1X

General specifications / Maintenance specifications

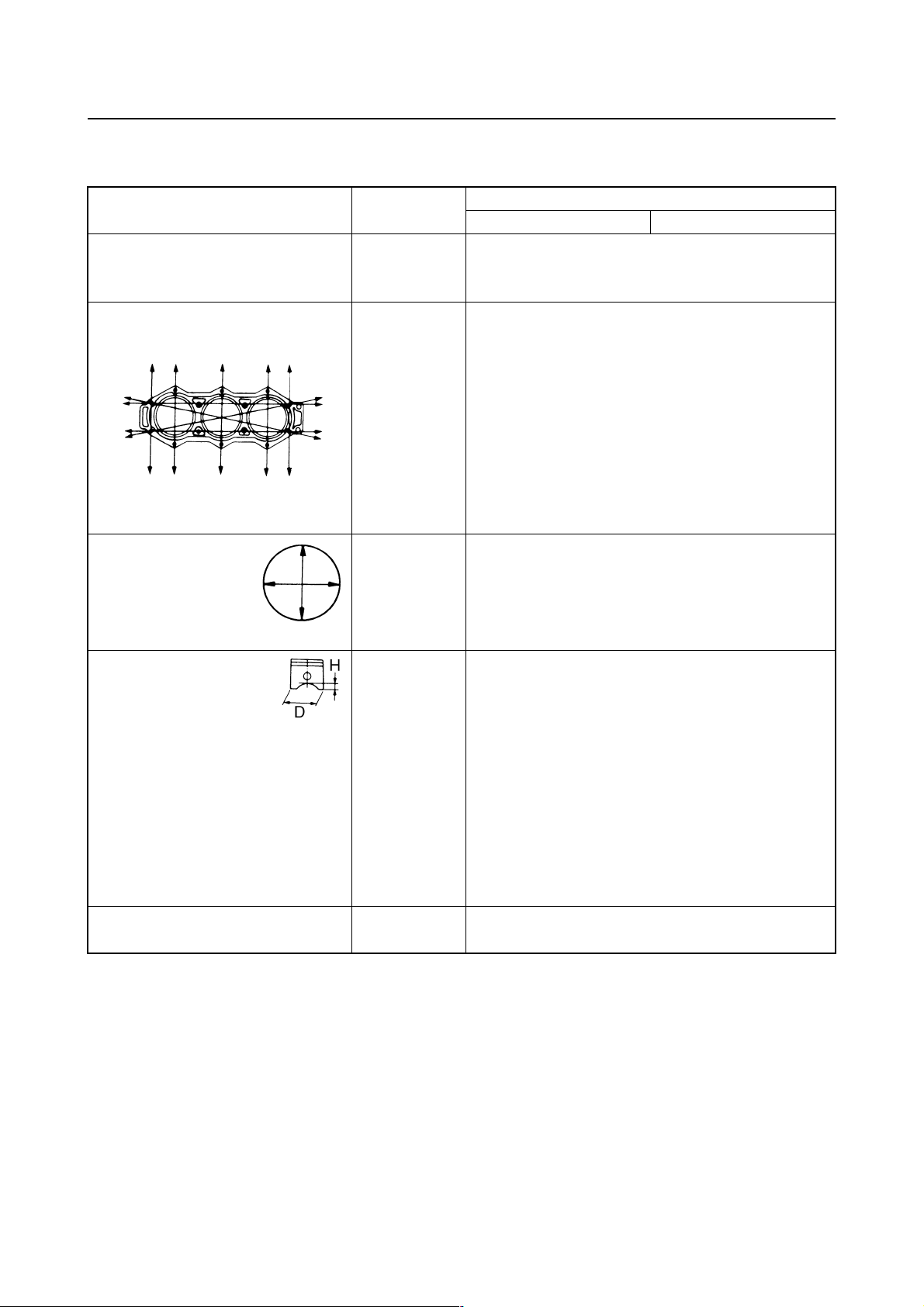

Maintenance specifications

Power unit

Item Unit

Z300AETO LZ300AETO

Power unit

Minimum compression

pressure*

kPa

(kgf/cm

2

, psi)

Cylinder heads

Warpage limit mm (in) 0.1 (0.004)

(lines indicate straightedge

position)

Cylinders

Bore size mm (in) 93.000–93.020 (3.6614–3.6622)

Bore size limit mm (in) 93.100 (3.6654)

Taper limit mm (in) 0.08 (0.0031)

Out-of-round limit mm (in) 0.05 (0.0020)

Pistons

Piston diameter (D) mm (in) 92.830–92.850 (3.6547–3.6555)

Measuring point (H) mm (in) 10 (0.39)

Piston-to-cylinder clearance mm (in) 0.165–0.171 (0.0065–0.0067)

Piston pin boss bore mm (in) 26.004–26.015 (1.0238–1.0242)

Oversize piston

1st mm (in) 0.25 (0.010)

2nd mm (in) 0.50 (0.020)

Oversize piston diameter

1st mm (in) 93.080–93.100 (3.6646–3.6653)

2nd mm (in) 93.330–93.350 (3.6744–3.6752)

Piston pins

Outside diameter mm (in) 25.995–26.000 (1.0234–1.0236)

Model

580 (5.8, 84)

2

* Measuring conditions:

Ambient temperature 20 °C (68 °F), wide open throttle, with spark plugs removed from all

cylinders.

The figures are for reference only.

6D03F1X

18

SPEC

Specifications

Item Unit

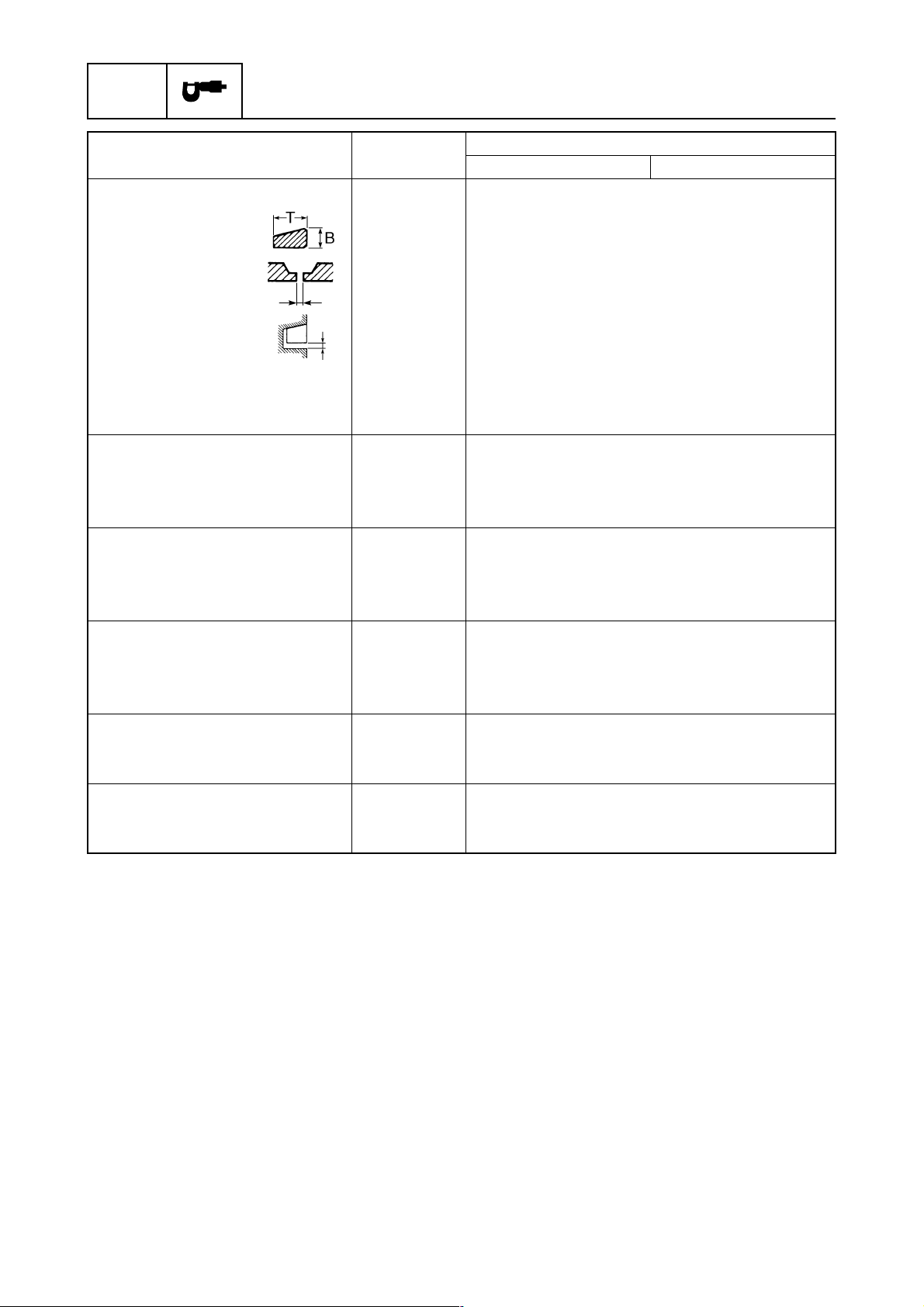

Piston rings

Top ring

Dimension B mm (in) 2.05 (0.0807)

Dimension T mm (in) 3.00–3.20 (0.118–0.126)

End gap mm (in) 0.30–0.50 (0.0118–0.0197)

Side clearance mm (in) 0.02–0.06 (0.0008–0.0024)

2nd piston ring

Dimension B mm (in) 2.05 (0.0807)

Dimension T mm (in) 2.70–2.90 (0.106–0.114)

End gap mm (in) 0.30–0.45 (0.0118–0.0177)

Side clearance mm (in) 0.02–0.06 (0.0008–0.0024)

Connecting rods

Small end inside diameter mm (in) 31.000–31.012 (1.2205–1.2209)

Big end side clearance mm (in) 0.12–0.26 (0.0047–0.0102)

Small end axial play limit mm (in) 2.0 (0.08)

Crankshaft

Crankshaft journal diameter mm (in) 58.975–58.991 (2.3219–2.3225)

Crankpin diameter mm (in) 40.485–40.500 (1.5939–1.5945)

Runout limit mm (in) 0.02 (0.0008)

Thermostats

Opening temperature °C (°F) 48–52 (118–126)

Fully open temperature °C (°F) 60 (140)

Valve open lower limit mm (in) 4.3 (0.17)

Oil pump

Identification mark 6D000

Bleeding Screw type

Reed valves

Valve stopper height limit mm (in) 8 (0.31)

Valve bending limit mm (in) 0.2 (0.008)

Z300AETO LZ300AETO

Model

19

6D03F1X

Lower unit

Maintenance specifications

Item Unit

Gear backlash

Pinion-to-forward gear mm (in) 0.12–0.44

Pinion-to-reverse gear mm (in) 0.61–0.90 (0.0240–0.0354)

Pinion shims mm 0.10, 0.12, 0.15, 0.18, 0.30, 0.40, 0.50

Forward gear shims mm 0.10, 0.12, 0.15, 0.18, 0.30, 0.40, 0.50

Reverse gear shims mm 0.10, 0.12, 0.15, 0.18, 0.30, 0.40, 0.50

Propeller shaft shims mm — 0.10, 0.12, 0.15, 0.18,

Propeller shaft

End play mm (in) — 0.25–0.35

Z300AETO LZ300AETO

(0.0047–0.0173)

Model

0.30–0.62

(0.0118–0.0244)

0.30, 0.40, 0.50

(0.0098–0.0138)

Electrical

Item Unit

Ignition and ignition control

system

Ignition timing (cylinder #1) Degree ATDC 7 at engine idle speed

Degree BTDC 14 at 5,500 r/min

Spark plug gap mm (in) 1.5–1.6 (0.059–0.063)

Ignition coil resistance

Primary coil (R – B/W)

at 20 °C (68 °F)

Secondary coil

(R – spark plug wire)

at 20 °C (68 °F) kΩ 7.31–9.89

ECM output peak voltage

(R – B/W)

at cranking (loaded) V 265

at 1,500 r/min (loaded) V 240

at 3,500 r/min (loaded) V 240

Pulser coil output peak voltage

(W/R, W/B, W/Y, W/G,

W/L, W/Br – B)

at cranking (unloaded) V 3.5

at cranking (loaded) V 3.5

at 1,500 r/min (loaded) V 20.0

at 3,500 r/min (loaded) V 30.0

Ω

1.36–1.84

Z300AETO LZ300AETO

Model

6D03F1X

20

Loading...

Loading...