YAMAHA

4RP-28197-20

EBOOOOOO

LB50 II AC/LBBO II

SERVICE

©1997

by

First

All

rights

reserved.

unauthorized

permission

is expressly

Yamaha

edition,

Any

use

without

of

Yamaha

AC

MANUAL

Motor

March

Co., Ltd.

1997

reproduction

the

Motor

prohibited.

or

written

Co., Ltd.

INDEX

GENERAL

PERIODIC

AND

,

ENGINE

CARBURETION

ADJUSTMENTS

INFORMATION

INSPECTIONS

OVERHAUL

CHASSIS

ELECTRICAL

APPENDICES

CHAPTER

FEATURES ....................................................................................................................... 1

MACHINE IDENTIFICATION ............................................................................................ 5

EXTERNAL

SPECIFICATIONS ............................................................................................................. 8

GENERAL SPECIFICATIONS ................................................................................... 8

MAINTENANCE

GENERAL TORQUE SPECIFICATIONS .........................................................................

CABLE ROUTING ........................................................................................................... 20

SPECIAL TOOLS ............................................................................................................

VIEW

............................................................................................................. 6

SPECIFICATIONS .......................................................................

1.

GENERAL

INFORMATION

11

19

29

FEATURES

CHAPTER

1.

GENERAL

INFORMATION

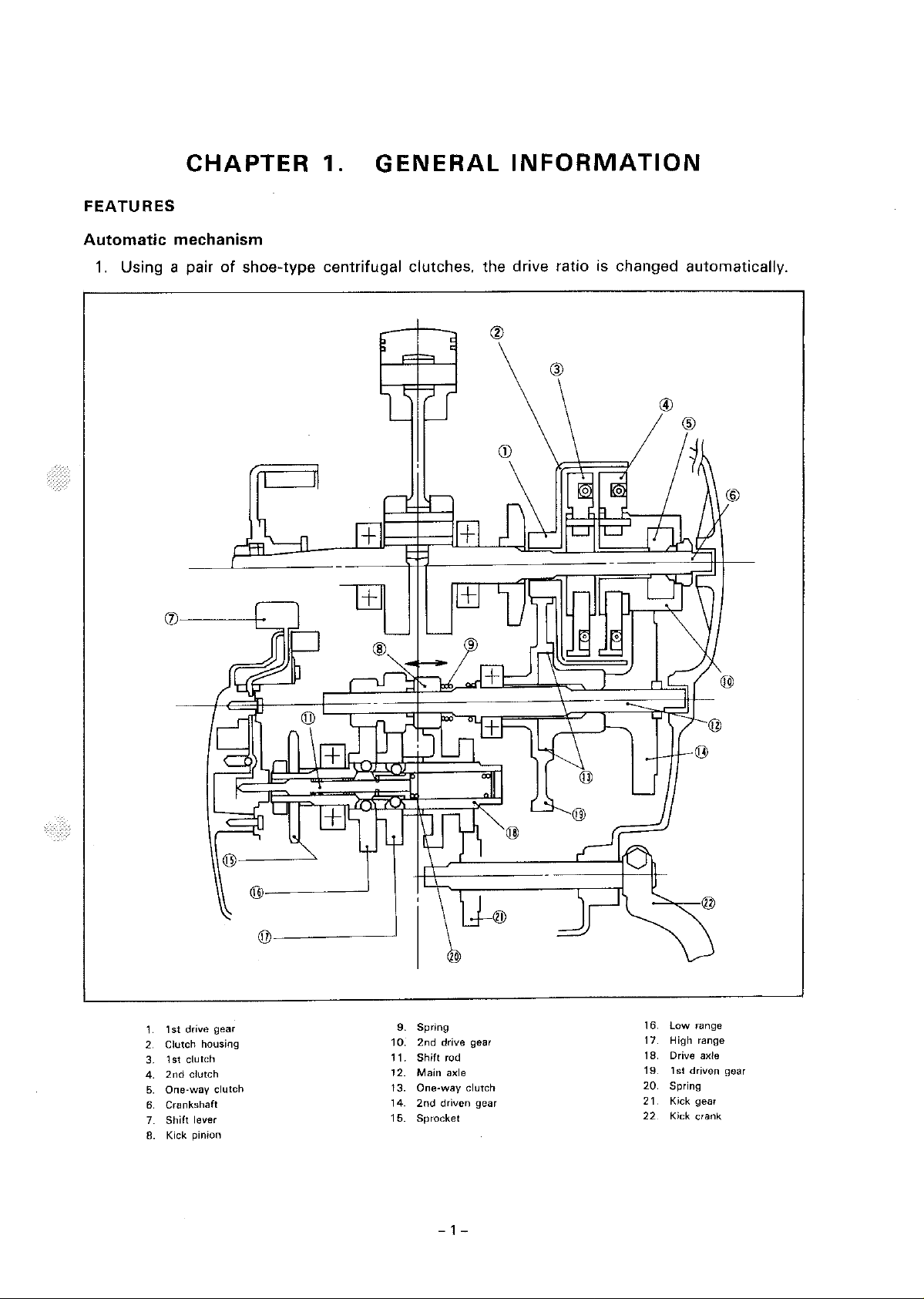

Automatic

1.

Using a pair

mechanism

of

shoe-type

centrifugal

clutches.

the

drive ratio is changed automatically.

®

1st

drive gear

1

Clutch housing

2.

1st

clutch

3.

2nd

clutch

4.

One-way

5.

Crankshaft

6

Shift

7.

Kick pinion

8.

lever

clutch

@-------'

©-----~

9. Spring

2nd

Shift

Main

2nd

driven gear

drive gear

rod

axle

10:

11.

12.

13. One-way clutch

14

15. Sprocket

- 1 -

®

low

16.

17. High range

18. Drive axle

19. 1st driven gear

20

21. Kick gear

22

range

Spring

Kick crank

2. The use

operation

the

rider.

according

of

an

automatic

of

the

shift

When

to

starting out,

engine load. This

2-speed

lever.

That

gears

will

centrifugal

is, ease

are

of

automatically

result in a

clutch

relieves

operation

longer

and

additional

shifted

life

of

the

into

the

rider

from

the

cumbersome

safety are ensured for

first, and

then

engine.

into

second

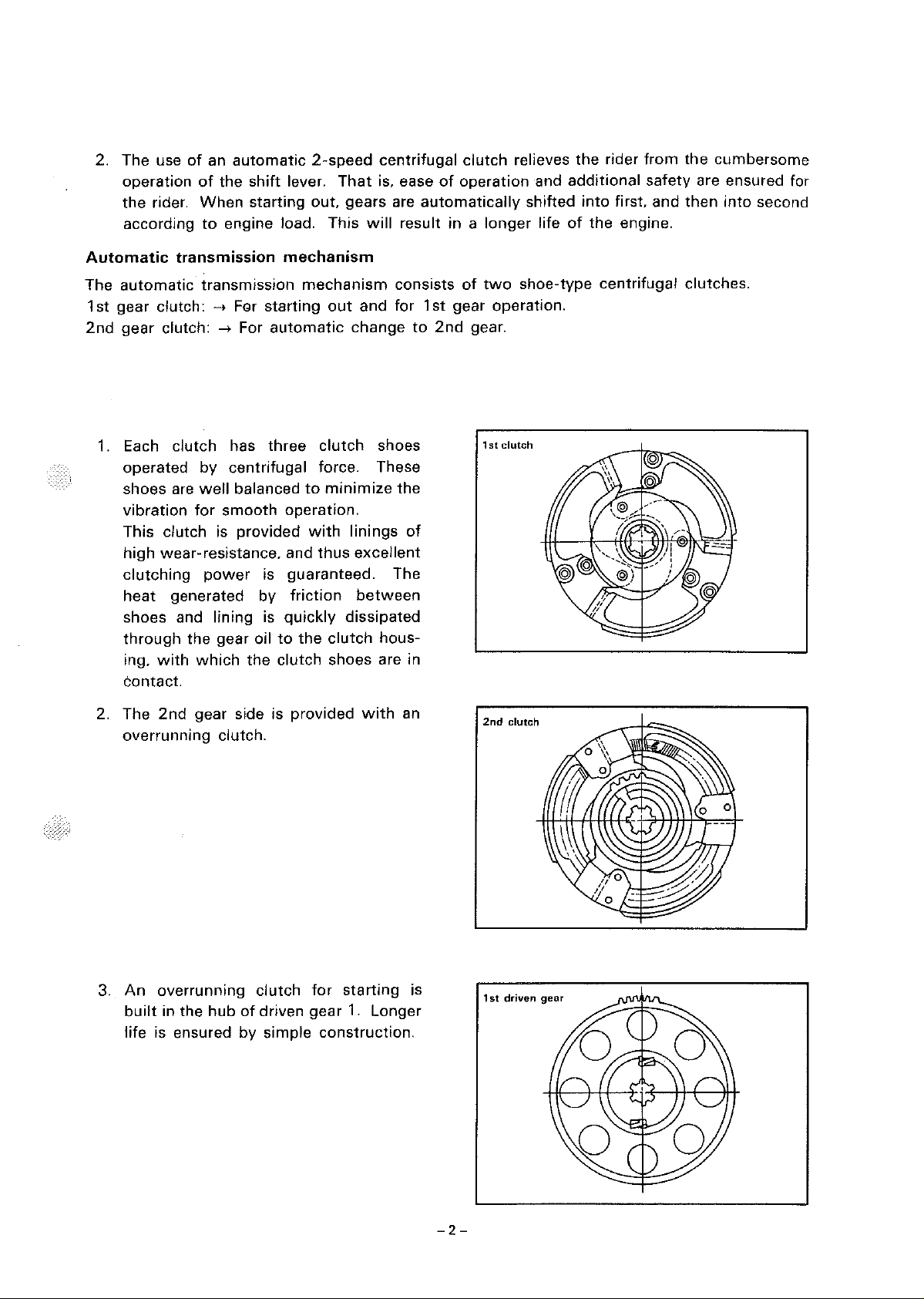

Automatic

The

automatic

1st

gear clutch:

2nd

gear

1.

Each

transmission

clutch:

clutch

operated

shoes are

vibration

This clutch is

high

wear-resistance. and

clutching

heat

generated

shoes and lining is

through

ing,

the

with

contact.

transmission

-,

FGr

starting

-,

For

automatic

has

three

by

centrifugal

well

balanced

for

smooth

provided

power

is guaranteed. The

by

gear oil

which

the

mechanism

mechanism

out

change

clutch

force. These

to

minimize

operation.

with

linings

thus

friction

quickly

to

the

clutch

dissipated

clutch

shoes are in

consists

and for

shoes

the

of

excellent

between

hous-

of

1st

gear operation.

to

2nd

gear.

two

shoe-type

1st clutch

centrifugal

clutches.

2. The

2nd

overrunning

3.

An

overrunning

built

in

life is ensured

gear side is

clutch.

the

hub

of

by

provided

clutch

for

driven gear

simple

construction.

with

starting

1.

Longer

an

is

2nd

1st

clutch

driven

gear

-2-

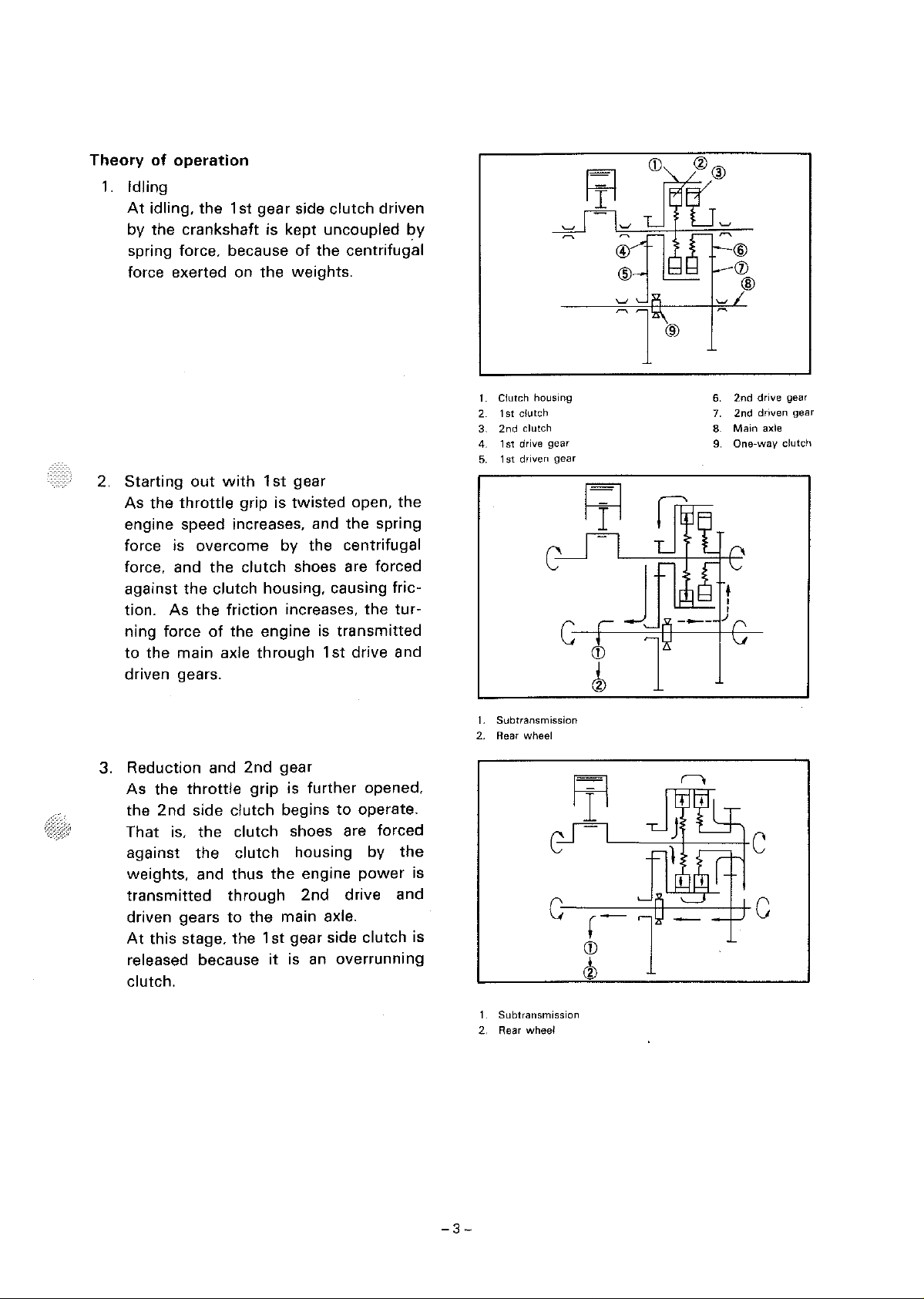

Theory

1.

2.

of

operation

Idling

At

idling, the 1st

gear

by the crankshaft is

spring force, because

with

grip is

the

1st

force exerted on

Starting

As

the

out

throttle

side

clutch

kept

uncoupled

of

the centrifugal

weights.

gear

twisted

engine speed increases, and the spring

force is

overcome

force, and

against

the

tion. As

ning force

to

the main axle

the

clutch housing, causing fric-

the

friction

of

the engine is

by the centrifugal

clutch

shoes are forced

increases,

through

1st

transmitted

driven gears.

driven

by

open,

the

the

tur-

drive and

t.

Clutch housing

1st

dutch

2

3.

2nd

clutch

4.

1st

drive

5.

1st

driven

gear

gear

CD

@

(j)

®

6.

2nd

drive

2nd

driven gear

7.

8. Main axle

9.

One-way

gear

dutch

3. Reduction and

As

the

throttle

2nd

the

That is,

against

side clutch begins

the

the

weights, and thus

transmitted

driven gears

At

this stage, the

to

released because

clutch.

2nd

gear

grip

is

further

opened,

to

operate.

clutch shoes are forced

clutch

through

housing by

the

engine

2nd

the

main axle.

1st

gear side clutch is

it

is an

the

power

drive and

overrunning

is

1.

Subtransmission

2.

Rear wheel

1.

Subtransmission

2. Rear

wheel

G

c-

_---1-1-----=-.l-l-

1

CD

c1

c

-3-

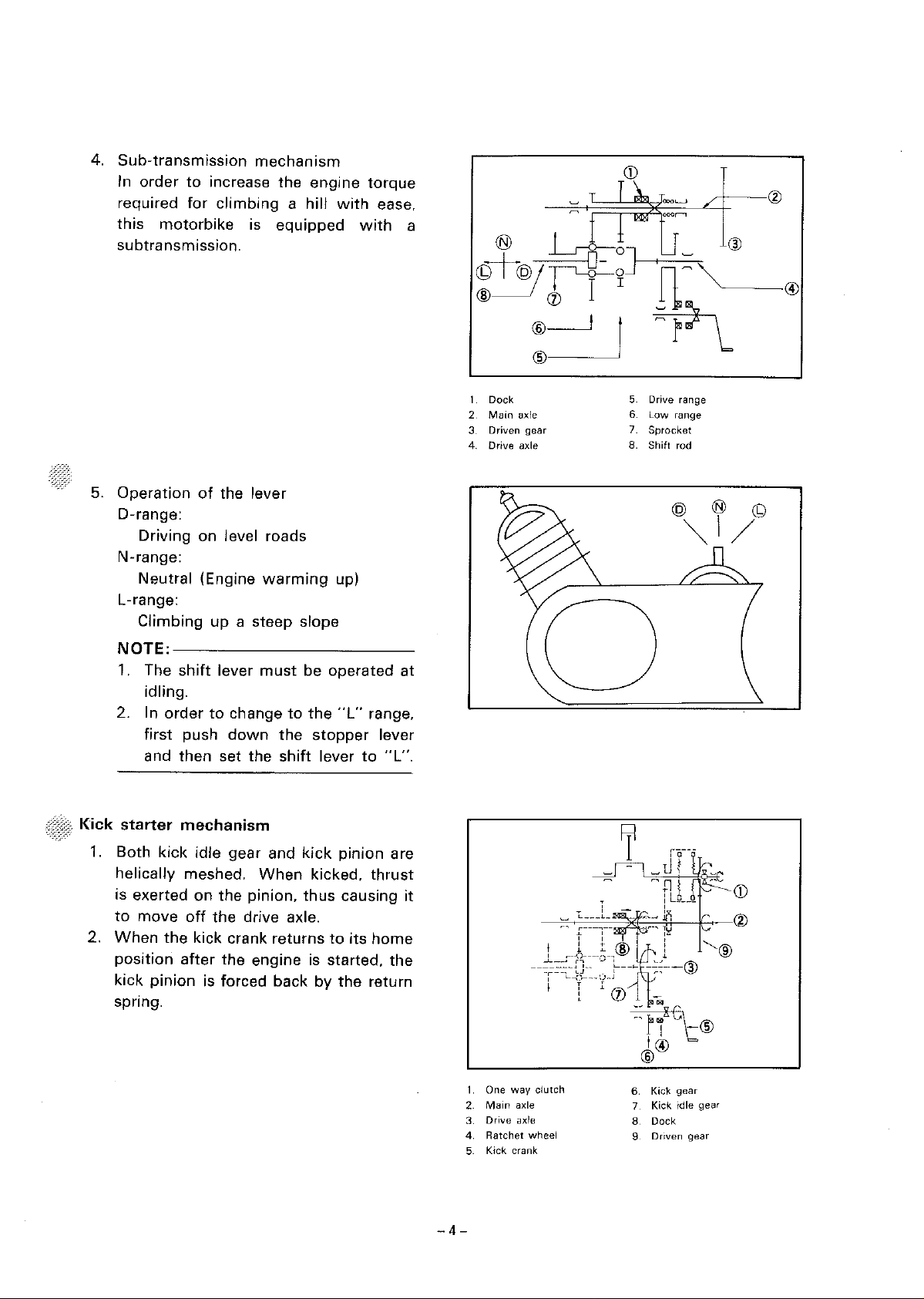

4.

Sub-transmission

In

order

required

this

motorbike

subtransmission.

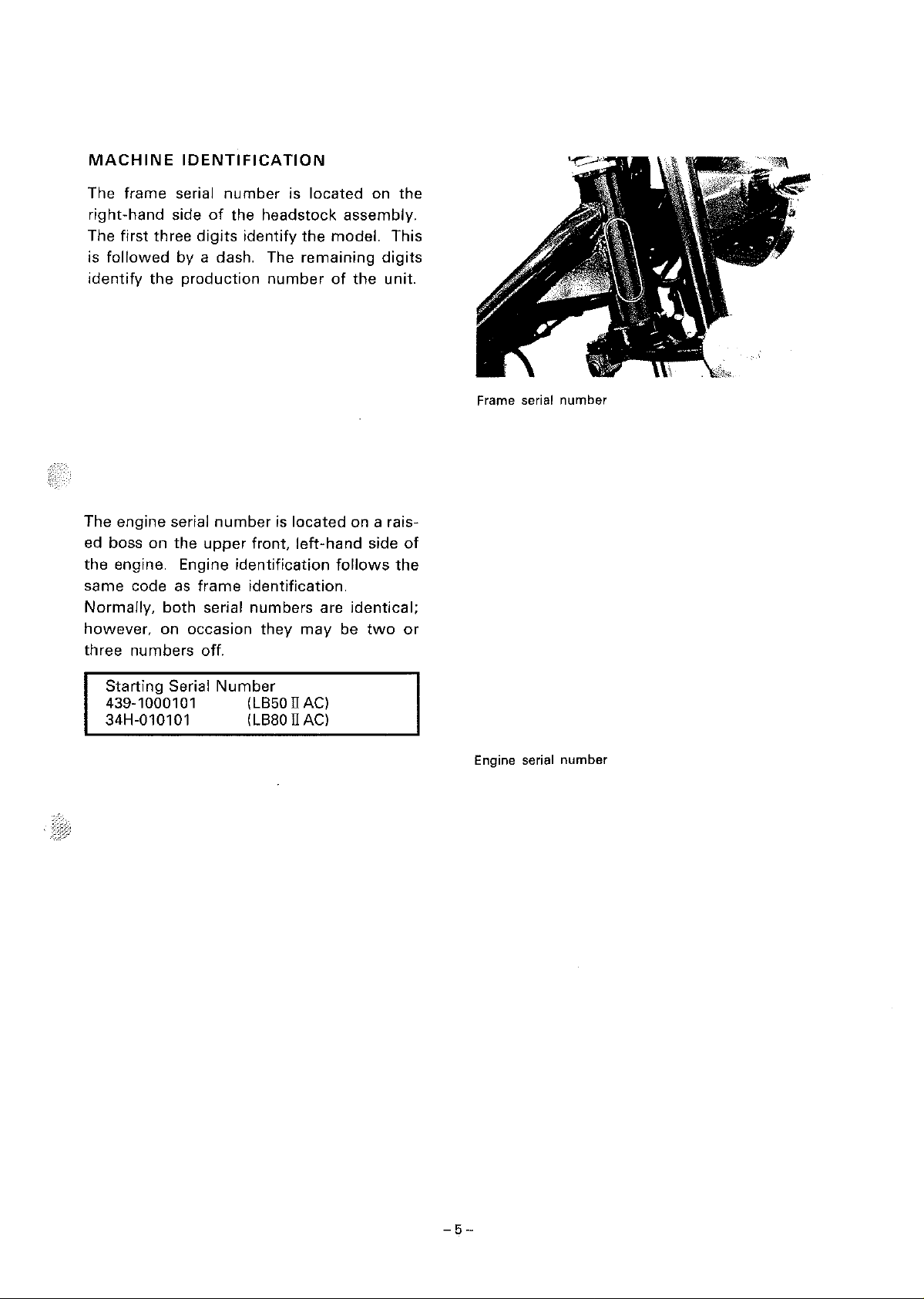

5.

Operation

D-range:

Driving on level roads

N-range:

Neutral (Engine

L-range:

Climbing

mechanism

to

increase the engine

for

climbing

a hill

is equipped

of

the lever

warming

up

a steep slope

with

up)

torque

ease,

with

a

1

Dock

2

Main

Driven

axle

gear

3

4. Drive axle

5 Drive range

6 Low range

7

Sprocket

8. Shift rod

@ ® ©

~I/

NOTE:-----------

1.

The

shift

lever

idling.

order

2. In

to

first push

then

and

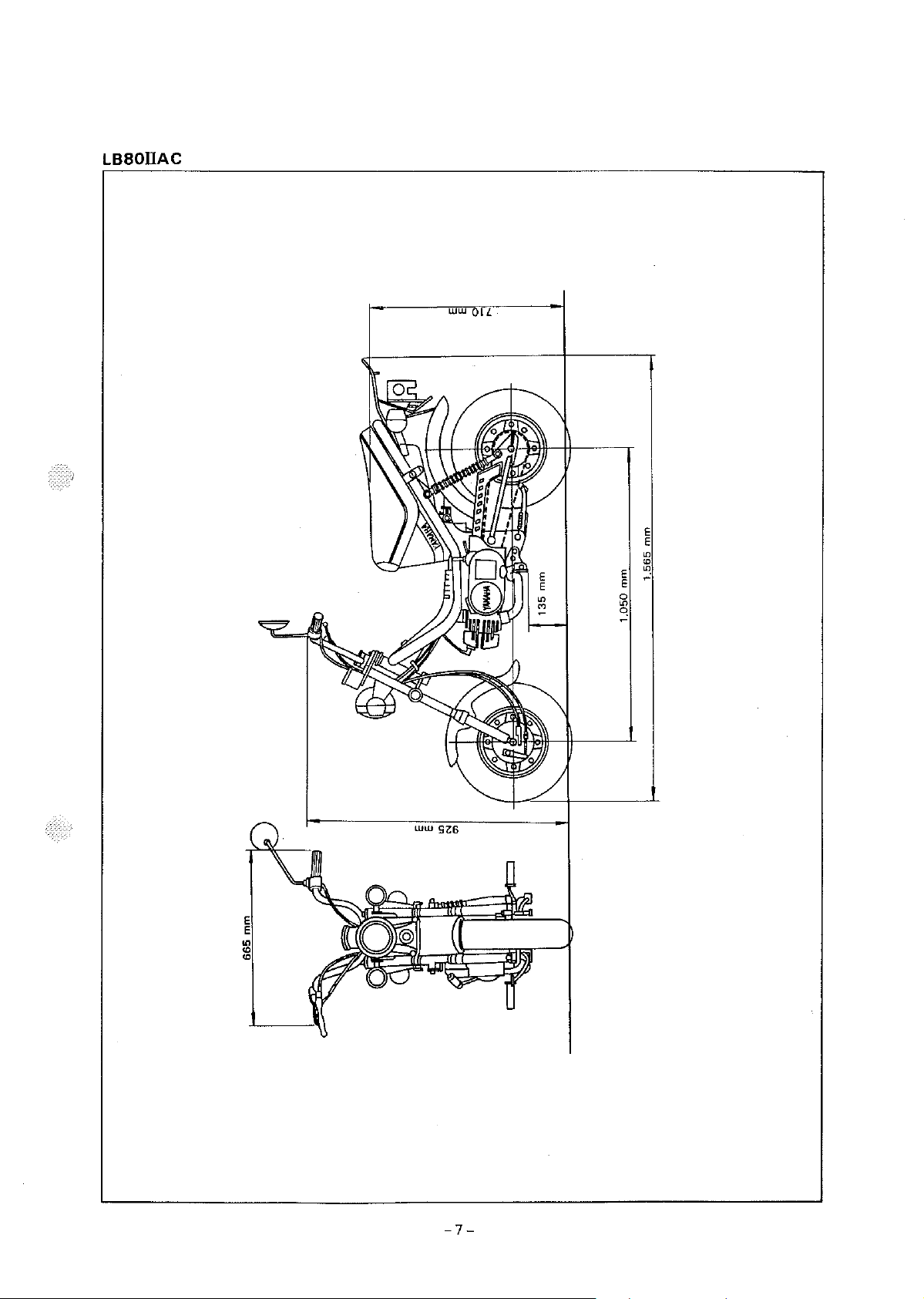

Kick

starter

1.

Both kick idle gear and

mechanism

helically meshed.

is exerted on the pinion,

to

2.

move

When

position

kick

off

the drive axle.

the

kick crank returns

after

pinion

is forced back by

spring.

must

be operated at

change

down

set the

to

the

shift

When

the

"L"

stopper

lever

kick

pinion are

kicked,

thus

to

range,

lever

to

"L".

thrust

causing

its

home

the engine is started, the

the

return

it

1 One

way

2

Main

Drive

Ratchet

axle

axle

3

4

5 Kick crank

clutch

wheel

6 Kick

gear

7 Kick idle gear

8

Dock

9

Driven

gear

-4-

MACHINE

The

frame

right-hand

The

first

is

followed

identify

the

IDENTIFICATION

serial

side

three

by

number

of

the

digits

identify

a dash. The

production

is

located

headstock

the

remaining

number

on

assembly.

model.

digits

of

the

unit.

the

This

Frame serial number

The engine serial

ed boss

the

same

Normally,

however,

three

on

engine. Engine

code

both

on

numbers

Starting

the

upper

as

frame

serial

occasion

off.

Serial

number

is

front,

identification

identification.

numbers

they

Number

439-1000101 (LB50 II AC)

34H-010101 (LB80 II AC)

located

left-hand

follows

are

may

be

on a rais-

side

of

the

identical;

two

or

Engine serial number

-5-

EXTERNAL VIEW

LB50

II

AC

1------ww

oiL--~-i

~

~

o_

E

E

0

~

E

"\

E

-6-

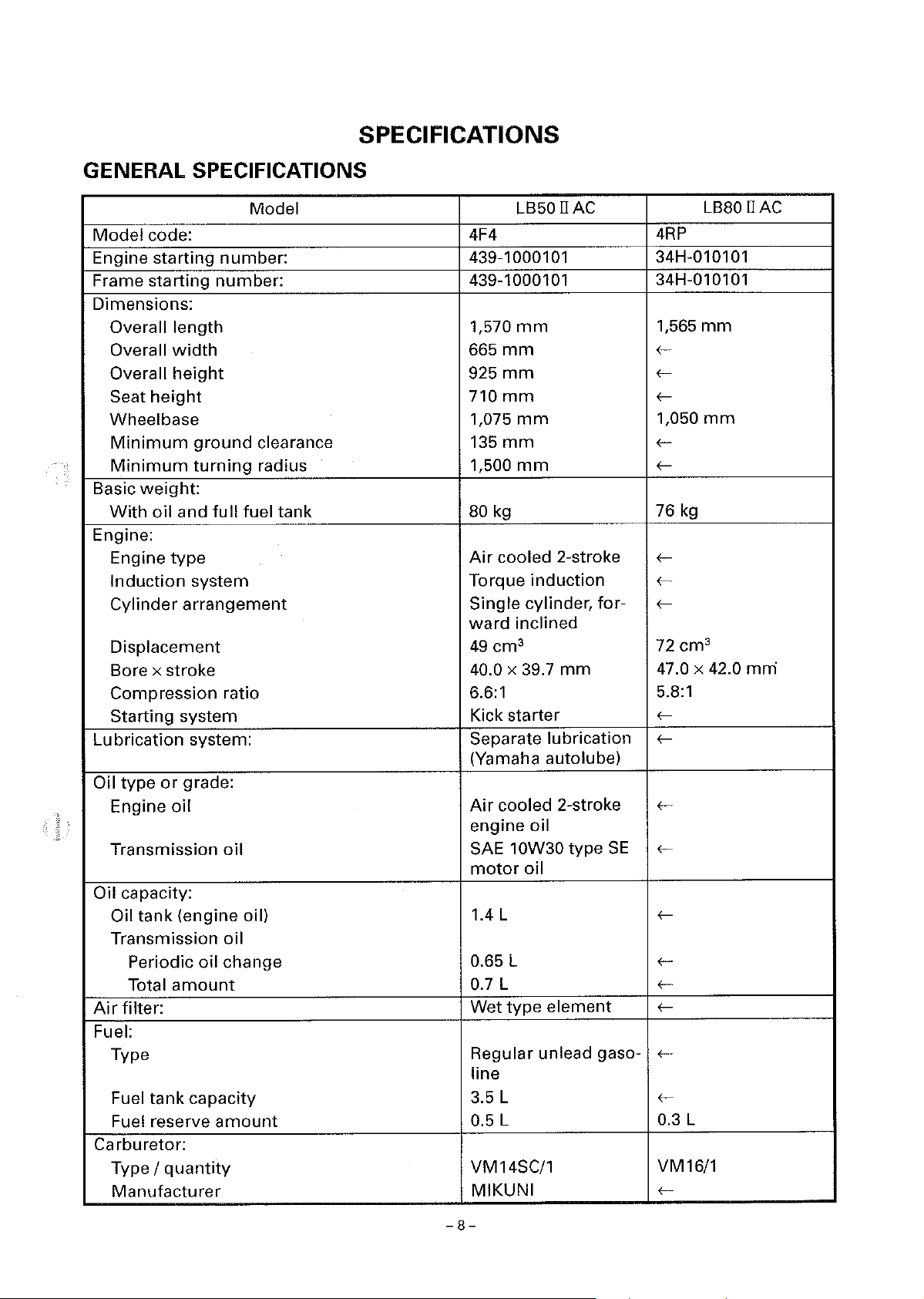

LB80IIAC

WW

QLL

E

E

0

q

E

E

"'

"'

"'

-7-

SPECIFICATIONS

GENERAL SPECIFICATIONS

Model

Engine

Frame

code: 4F4

starting

starting

Dimensions:

Overall length

Overall

Overall

Seat

width

height

height

Wheelbase

Minimum

Minimum

Basic

weight:

With

oil

ground

turning

and

Engine:

Engine

Induction

Cylinder

type

system

arrangement

Displacement

Bore x stroke

Compression

Starting

Lubrication

Oil type

Engine

system

system:

or

grade:

oil

Transmission

Oil capacity:

Oil

tank

(engine oil)

Transmission

Periodic oil change

Total

amount

Air

filter:

Fuel:

Type

Fuel

tank

capacity

Fuel reserve

Carburetor:

Type

I

quantity

Manufacturer

Model

number:

number:

clearance

radius

full

fuel tank

ratio

oil

oil

amount

LB50 II

AC

439-1000101

439-1000101

1,570

mm

665

mm

925mm

710

mm

1,075

135

1,500

mm

mm

mm

80 kg

Air

cooled

Torque

Single cylinder,

ward

49

cm

40.0 x 39.7

2-stroke

induction

for-

inclined

3

mm

6.6:1

Kick starter

Separate lubrication

(Yamaha autolube)

Air

cooled

engine

SAE 10W30 type

motor

2-stroke

oil

SE

oil

1.4 L

0.65 L

0.7 L

Wet

type

element

Regular unlead gasoline

3.5 L

0.5 L

VM14SC/1

MIKUNI

LB80 II

AC

4RP

34H-010101

34H-010101

1,565

mm

fff-

1,050

ff-

76

fff-

72

kg

cm

mm

3

47.0 x 42.0 mrn

5.8:1

ff-

f-

f-

f-

fff-

f-

f-

0.3 L

VM16/1

f-

-8-

Model

Spark plug:

Type

Manufacturer

Spark

plug

gap

B6HS

NGK

0.5 - 0.6

Clutch type: Wet,

matic

Transmission:

Secondary reduction system Chain

Secondary

Transmission

reduction

type

ratio 31/14 (2.214) 30/15 (2.000)

Constant mesh 2speed

Operation

Centrifugal

type

Gear ratio 1st

2nd

Sub-transmission

Sub-transmission

ratio

ratio

low

high

69/18 (3.833)

59/28 (2.107)

39/12 (3.250)

35/16 (2.188)

Chassis:

Frame type

Caster angle

Trail

Steel tube

26'

45mm

Tire:

Type

Size

Manufacturer

front

rear

front

With

4.00-8-4PR

4.00-8-4PR

INOUE

rear INOUE

Tire pressure (cold tire):

Loading

condition

A * 0 - 70

front

100

1.00 bar)

rear 125

1.25 bar)

Loading

condition

B *

front

70

100

1.00 bar)

rear

200

2.00 bar)

Brake:

Front

Rear brake

* Load

brake

1s

the

total

weight

type

operation

type

operation

of

cargo, rider, passenger and accessories.

Drum

Right hand

Drum

Left hand

LB50 II

mm

centrifugal

drive

automatic

underbone

tube

kg

kPa

(1.00

kPa

( 1.25

-140

kg

kPa

( 1.00

kPa

(2.00

brake

brake

operation

AC

auto-

automatic

kg/cm',

kg/cm',

kg/cm',

kg/cm',

operation

LB80 II

ffff-

f-

f-

f-

fff-

29/15 ( 1.933)

fff-

fffff-

0 - 74

f-

f-

kg

74-144kg

f-

150

kPa

( 150

1.50 bar)

ffff-

AC

kg/cm',

-9-

Suspension:

Front

Rear suspension

Shock absorber:

Front

Rear shock absorber

Wheel travel:

Front

Rear

Electrical:

Ignition

Generator system

Battery

Battery capacity

Headlight

Bulb

Headlight

Tail I brake

Flasher

Meter

High beam

Oil level

suspension

shock absorber

wheel travel

wheel

wattage

travel

system

type

type:

x quantity:

light

light

light

indicator

indicator

Model

light

light

LB50 II

Telescopic

Swingarm

Coil spring

damper

Coil spring

damper

75

mm

84mm

C.D.I.

Flywheel

6N4-2A-2

6 V 4 AH

Bulb

type

6 V

25 W /25

6 V 5.3

6V10Wx4

6V3Wx1

6V3Wx1

6V3Wx1

WI

AC

fork

I Oil

I Oil

magneto

W

17

w

,---,----

,----

,----

,----

80

,---,----

,----

,----

,---,---,---,---,---,---,---,----

mm

LB80 II

AC

- 10 -

MAINTENANCE

ENGINE

SPECIFICATIONS

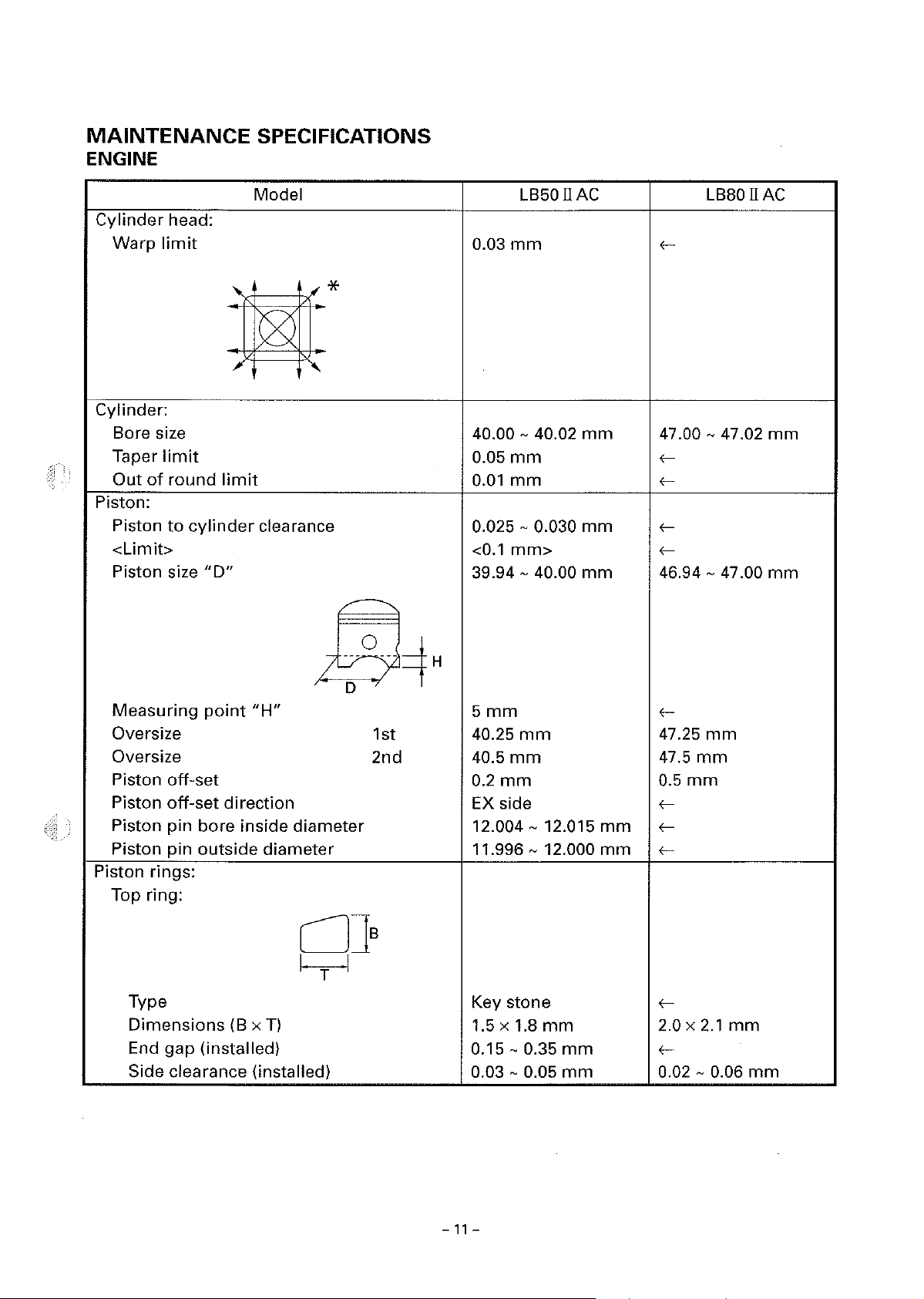

Cylinder

Warp

Cylinder:

Bore size

Taper

Out

of

Piston:

Piston

<Limit>

Piston size

head:

limit

limit

round

to

cylinder

limit

"D"

Model

,-*

clearance

LB50 II

0.03

mm

40.00 - 40.02

0.05

mm

0.01

mm

0.025 - 0.030

<0.1

mm>

39.94 - 40.00

AC

mm

mm

mm

LBBO

IIAC

47.00 - 47.02

ff-

46.94 -

47

.00

mm

mm

Measuring

Oversize

Oversize

Piston

Piston

Piston

Piston

Piston rings:

Top ring:

Type

Dimensions

End

Side clearance (installed)

point

off-set

off-set

pin

bore

pin

outside

gap

(installed)

"H"

direction

inside

(Bx

diameter

diameter

CJ]s

I T I

T)

1st

2nd

5mm

40.25

40.5

0.2

EX side

12.004 - 12.015

11.996 - 12.000

Key stone

1.5 x 1.8

0.15 - 0.35

0.03 - 0.05

mm

mm

mm

mm

mm

mm

mm

mm

f-

47.25

47.5

0.5

fff-

f-

2.0 x

f-

0.02 - 0.06

mm

mm

mm

2.1

mm

mm

-

11

-

2nd ring:

Type

Dimensions

End gap (installed)

Side clearance

2nd ring:

(8 x T)

Model LB50 II

C]Js

I

T

I

Keystone

1.5

x 1.8

mm

0.15-

0.03 - 0.05

0.35

mm

mm

AC

LB80 II

-

-

-

-

AC

T

F

l]s

I

-

-

-

- 0.02 - 0.06

Plain

2.0 x 2.1

0.15 - 0.35

mm

mm

mm

Type

Dimensions

End gap (installed)

Side clearance

Crankshaft:

I

I

(8 x T)

-

4~

E}D

A

Crank

Runout

Big

Big

Small end free play

Automatic

Clutch shoe thickness

<Wear

Clutch-stall revolution 2,800 - 3,200 r/min 2,700 - 3,200 r/min

Transmission:

Main

Drive axle deflection

Kick starter:

Kick starter

Kick

width

end

end

axle deflection

clip

"A"

limit

"C"

side clearance

radial clearance

centrifugal clutch:

limit>

type

friction

"F"

force

"D"

limit

limit

"E"

37.90 - 37.95

0.015

0.20 - 0.50

0.004 - 0.015

0.8 - 2.0

2.5mm

<2

0.015

0.015

Kick and mesh

8.0 - 20.0 N 8.0 (0.8 - 2.0 kg) (0.8 -

mm

mm>

mm

mm

mm

mm

mm

mm

type

fff-

0.004 - 0.017

f-

ff-

ff-

Ratchet type

15.0

1.5

N

kg)

mm

-

12

-

Model

Air

filter

oil grade:

Carburetor:

I.

D.

mark

Main

jet

Air

jet

Jet

needle

Needle

Cutaway

Pilot

Pilot

Air

Valve seat size

Starter

Float heigh

Reed valve:

Thickness

Valve

Valve

Lubrication system:

Autolube

Pulley

jet

outlet

jet

screw

jet

Engine

Plunger

Color code Grey

Minimum

Maximum

idle

stopper

bending

pump:

diameter

stroke 0.20 - 0.25

stroke

adjusting

speed

height

limit

mark

(M.J)

(A.J)

(J.N)

(N.J)

(C.A)

(P.0)

(P.

J)

(AS)

(V.S)

(G.S.1)

(F.H)

LB50 II AC

Form-air-filter

SAE10W30

motor

2T5

#95

2.5

3G9/3

E-4

2.5

0.9 - 1.5

#17.5

1

1.2

#20

22.0±

1,250 - 1,450 r/min

0.15

6.8 - 7.2

0.3

3.5mm

0.55 - 0.65

At

oil

00

2.5

mm

mm

idle

mm

mm

mm

mm

oil

type

SE

or

LB80 II

s--

1F5

01

s-s-s--

E-8

s-s--

#15

1-3/4

s--

#25

s-s--

s-s-s--

4.0

mm

Brown

0.25 - 0.30

0.80 - 0.95

s--

AC

mm

mm

-

13

-

CHASSIS

Steering system:

Steering bearing

No. I size

of

steel balls

Front suspension:

Front

Fork

Spring

fork

spring

rate

travel

free length

Stroke

Optional

spring

Oil capacity

Oil grade

Rear suspension:

Shock

Spring

Fitting

Spring

absorber

free

length

length

rate

Stroke

Optional

spring

Swingarm:

Free play

Front

wheel:

limit

Type

Rim size

Rim

material

Rim

runout

limit

Rear wheel:

Type

Rim size

Rim

material

Rim

runout

limit

Model

type

travel

LB50

Ball bearing

upper

lower

(K1)

(K2)

(K1)

(K2)

22

pcs I

19

pcs I 0.25 in

75

mm

482

mm

8.45

N/mm

(0.845

18.0

O -

kg/mm)

N/mm

48

mm

48-75

0.

mm

No

left

right

96

120

cm

cm

3

3

Fork oil 10W

valent

65

mm

212

mm

207

mm

(K1) 21.0 N/mm

(K2)

(K1)

(K2)

N/mm

28.5

(2.85

kg/mm)

O -

34

34 -65

mm

mm

No

end 1

side

mm

0.5

Disc

mm

wheel

2.50C x 8

Steel

radial

lateral

1mm

1mm

Disc

wheel

2.50C x 8

Steel

radial

lateral

1mm

1mm

II

AC

1875 in

(1.8

kg/mm) r

or

equi- r

(2.1

kg/mm) r

LB80 II

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

AC

-

14-

Model

Drive chain:

Type

I

No.

Chain

Front

manufacturer

of

links 94 88

free

play

drum

brake:

DK420 I DAIDO DID420 I DAIDO

20 -

Type Leading,

Brake

<Limit>

Lining thickness

<Limit>

Shoe

Rear

Type

Brake

<Limit>

Lining thickness

<Limit>

Shoe

Brake

Brake

Brake

drum

spring

drum

drum

spring

lever

lever

lever

inside

diameter

free length

brake:

inside

diameter

free length 50.5

& brake pedal:

free play (at pivot)

free play (at lever end)

110

<111

4mm

<2

mm>

50.5

Leading,

110

<111

4mm

<2

mm>

5-8mm

10-20mm

LB50 II

30

mm

mm>

mm

mm

mm>

mm

mm

trailing

trailing

AC

<c-

<c<c<c<c<c<c-

<c<c<c<c<c<c-

<c<c-

LB80 II

AC

-15-

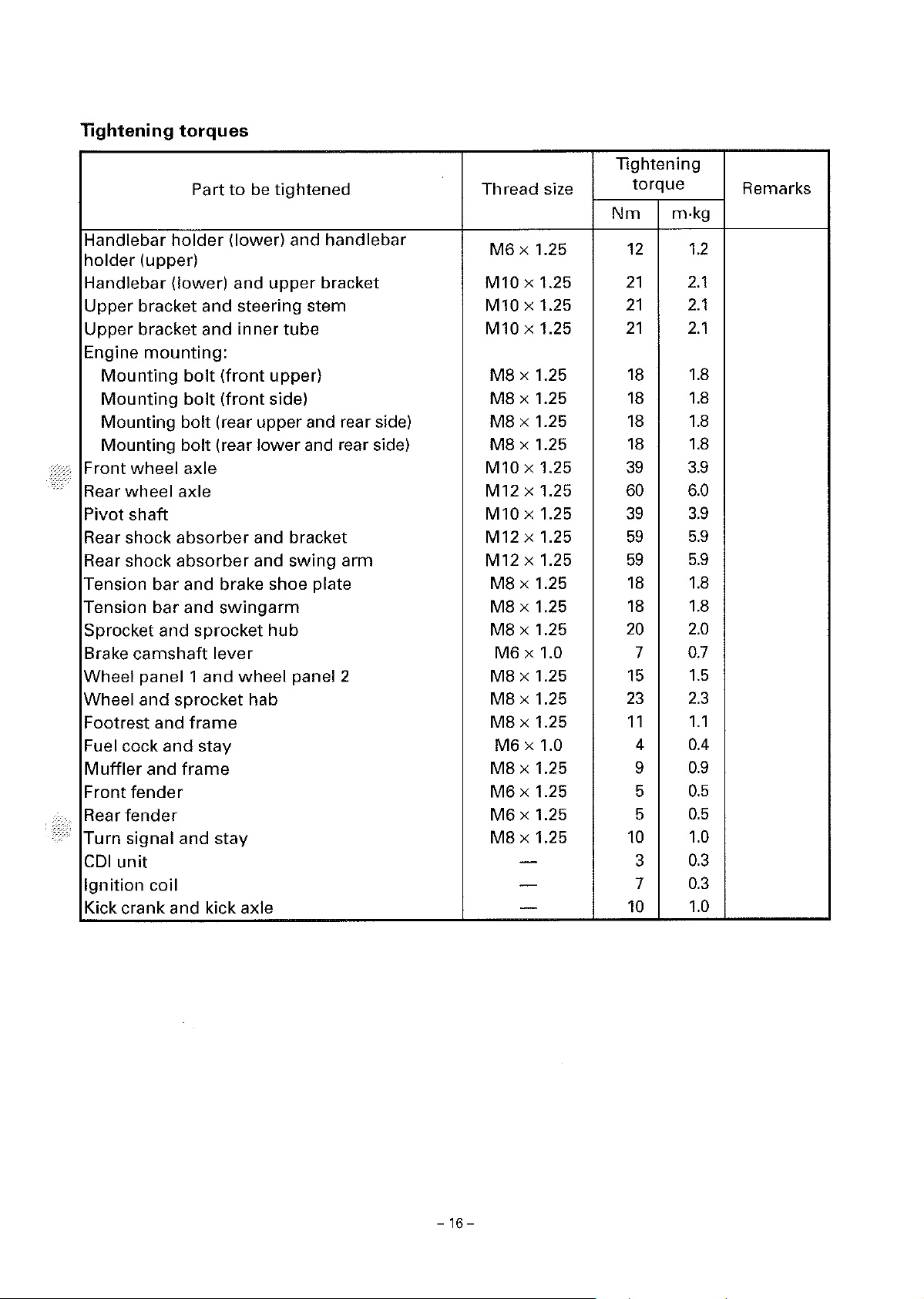

lightening

Handlebar

holder

Handlebar

Upper

Upper

Engine

Mounting

Mounting

Mounting bolt (rear upper and rear side)

Mounting bolt (rear

Front

Rear

Pivot

Rear shock

Rear shock

Tension

Tension

Sprocket and

Brake

Wheel panel 1

Wheel

Footrest and

Fuel cock

Muffler

Front

Rear

Turn

CDI

Ignition

Kick crank and kick axle

wheel

wheel

shaft

fender

fender

signal and

unit

torques

Part

holder

(upper)

(lower)

bracket

bracket

mounting:

bolt

bolt

axle

axle

absorber

absorber

bar

and brake shoe plate

bar

and

sprocket

camshaft

and

sprocket hab

frame

and

stay

and

frame

coil

to

be

(lower) and

and

and

steering stem

and

inner

(front

(front

lower

and bracket

and

swingarm

lever

and

wheel

stay

tightened

handlebar

upper

upper)

side)

hub

bracket

tube

and rear side)

swing

panel 2

arm

Thread size

M6

x 1.25

M10 x 1.25

M10 x 1.25

M10 x 1.25

MS

x 1.25

MS

x 1.25

MS

x 1.25

MS

x 1.25

M10 x 1.25

M12 x 1.25

M10 x 1.25

M12 x 1.25

M12 x 1.25

MS

x 1.25

MS

x 1.25

MS

x 1.25

M6

x 1.0 7

MS

x 1.25

MS

x 1.25

MS

x 1.25

M6

x 1.0

MS

x 1.25 9

M6

x 1.25 5

M6

x 1.25 5

MS

x 1.25

-

-

-

Tightening

torque

Nm

m-kg

12

21

21

21

18

18

18

18

39

60

39

59

59

18

18

20

15

23

11

4

10

3

7

10

Remarks

1.2

2.1

2.1

2.1

1.8

1.8

1.8

1.8

3.9

6.0

3.9

5.9

5.9

1.8

1.8

2.0

0.7

1.5

2.3

1.1

0.4

0.9

0.5

0.5

1.0

0.3

0.3

1.0

-

16

-

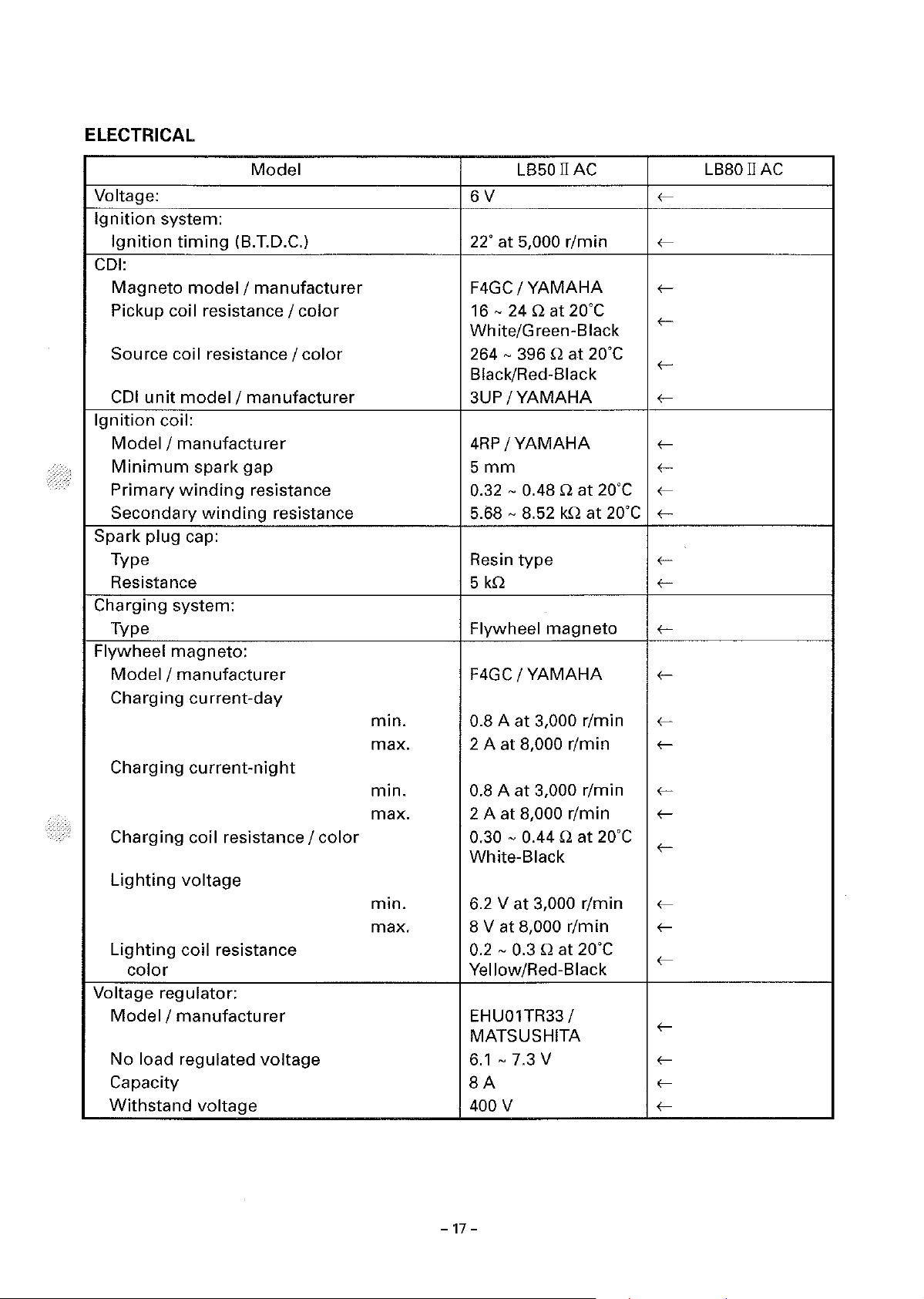

ELECTRICAL

Model

Voltage:

Ignition

Ignition

system:

timing

(B.T.D.C.)

CDI:

Magneto

Pickup coil resistance I

Source coi I

CDI

Ignition

model I manufacturer

resistance/

unit

model I manufacturer

coil:

color

color

Model I manufacturer

Minimum

Primary

Secondary

Spark

plug

spark

winding

winding

cap:

gap

resistance 0.32 - 0.48 Q

resistance 5.68 - 8.52

Type

Resistance 5

Charging system:

Type

Flywheel

magneto:

Model I manufacturer

Charging

current-day

min.

max. 2 A at 8,000

Charging

current-night

min.

max.

Charging coil resistance I

Lighting

voltage

color

min.

max.

Lighting

coil resistance

color

Voltage regulator:

Model I manufacturer

No

load regulated

voltage

Capacity

Withstand

voltage

LB50 II AC LB80 II

6V

22"

at

5,000

r/min

F4GC I YAMAHA

16 -24

Q at 20"C

White/Green-Black

264 - 396 Q

at

20"C

Black/Red-Black

3UP

/YAMAHA

4RP

/YAMAHA

5mm

at

20°C

kQ

at

20°C

Resin

type

kQ

Flywheel

magneto

F4GC I YAMAHA

0.8 A

at

3,000 r/min

r/min

0.8 A

at

3,000 r/min

2 A at 8,000

0.30 - 0.44 Q

r/min

at

20"C

White-Black

6.2

Vat

8

Vat

0.2

- 0.3 Q at

3,000

8,000

r/min

r/min

20°C

Yellow/Red-Black

EHU01TR33 /

MATSUSHITA

6.1

- 7.3 V

8A

400 V

AC

f-

f-

f-

f-

f-

f-

ffff-

ff-

f-

f-

ff-

ff-

f-

ff-

f-

f-

fff-

-17-

Model

Horn:

Type

Quantity

Model I manufacturer

Maximum

amperage

Plane

1

GF-6/

1.5 A

Flasher relay:

Type Condenser

Model I manufacturer

Self cancelling device

Flasher

frequency

Wattage

FR-2212 I

No

60

- 120

10

Wx2

Oil level switch:

Model I manufacturer

2T5 I STANLEY

Circuit breaker:

Type

Amperage

Main

Reserve

for

individual

circuits

Fuse

10

Ax

10

Ax

L850 II

type

NIKKO

type

MITSUBA

cycle/min

1

1

AC

L880 II

(-

(-

(-

(-

(-

(-

(-

(-

(-

(-

(-

(-

(-

AC

-18-

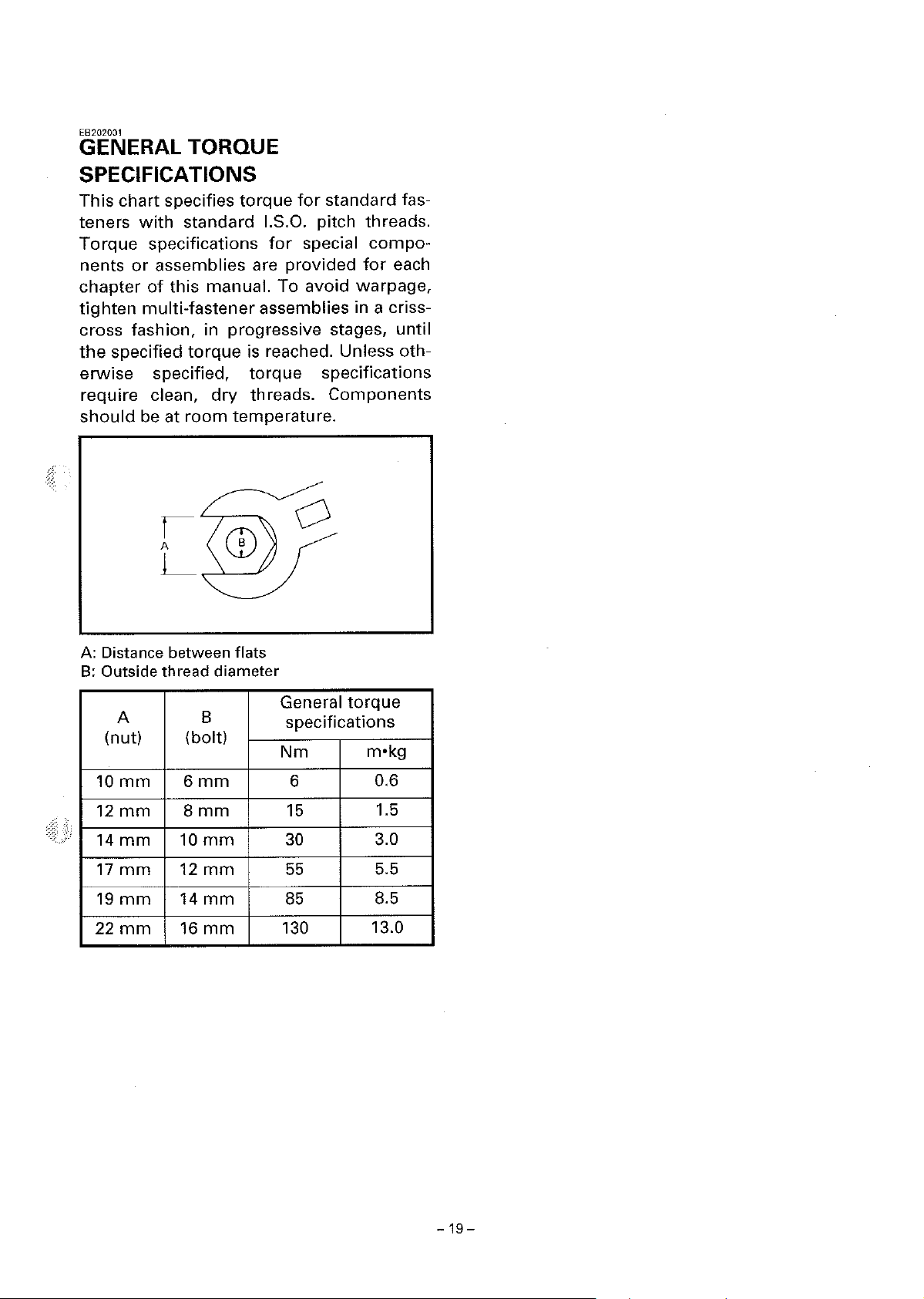

EB202001

GENERAL TORQUE

SPECIFICATIONS

This

chart specifies

teners

Torque

nents

chapter

tighten

with

standard I.S.O. pitch threads.

specifications

or

assemblies are provided

of

this

multi-fastener

cross fashion, in progressive stages,

the

specified

erwise

torque

specified,

require clean,

should

be at

room

torque

manual. To

for

for

standard fas-

special

avoid

assemblies in a criss-

is reached. Unless oth-

dry

torque

threads.

specifications

Components

temperature.

compo-

for

warpage,

each

until

A: Distance between flats

B:

Outside

A

thread

8

diameter

(nut) (bolt)

10

12

14

17

19

22

mm

mm

mm

mm

mm

mm

6mm

8mm

10mm

12

mm

14

mm

16mm

General

torque

specifications

Nm

6

15

30

55

85

130

m•kg

0.6

1.5

3.0

5.5

8.5

13.0

-19-

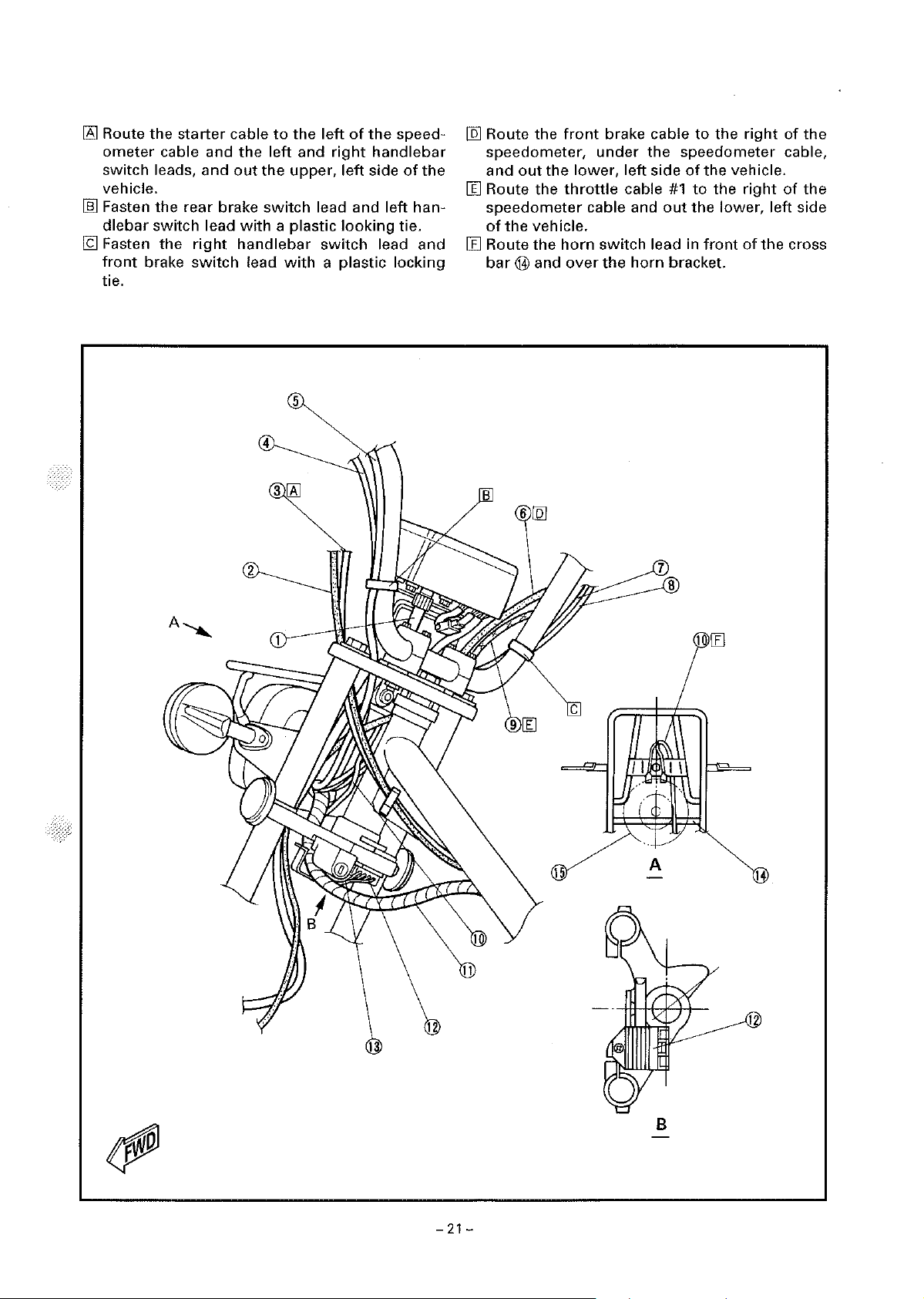

EB206000

CABLE ROUTING

CD

Speedometer

® Rear brake cable

G)

Starter cable

@ Rear brake switch lead

® Left

@ Front brake cable

(!) Right

®

®

handlebar

handlebar

Front

brake switch lead

Throttle

cable

cable

switch

switch

#1

2

lead

@)

Horn

switch

@

Wire

harness

@ Rectifier/regulator

@)

Rectifier/regulator lead

@Cross

@)

5

bar

Horn

lead

B

A-.......

13

15

c

A

10

[El

14

B

-

20-

16]

Route

the

starter

ometer

switch leads, and

vehicle.

ill] Fasten

dlebar

19

Fasten

front

tie.

cable and

the

switch lead

the

brake

rear

right

switch

cable

the

out

the

brake

switch

with

handlebar

lead

4

2

to

the

left

and

upper,

a plastic

with

5

left

of

the

speed-

right

handlebar

left

side

of

the

lead and left han-

looking

switch

a plastic locking

tie.

lead and

[l5]

Route the

speedometer,

out

and

the

III Route the

speedometer

of

the

vehicle.

III Route

bar@

B

the

and

front

brake cable

under

lower,

throttle

cable and

horn

switch lead in

over

the

the

left

side

cable

horn

to

the

right

speedometer cable,

of

the

vehicle.

#1

to

the

right

of

out

the

lower, left side

front

of

the

bracket.

of

the

the

cross

A-...,..,,

15

c

A

1 III

14

B

-

21

-

G)

Autolube

®

Throttle

@

Throttle

@

Throttle

®

Right

@

Front

(j)

Front

@ Rectifier/regulator

pump

cable

cable

#1

cable

junction

cable

#2

handlebar

brake switch lead

brake cable

switch lead

® Rectifier/regulator lead

@)

Wire

harness

3

box

@

Speedometer

@ Rear brake cable

@)

Left

handlebar

@)

Rear brake

@)

Starter cable

12\J

Fasten

ITll

19

Faster

cable.

Pass

ness

the

the

through

the

cable

switch

switch

wire

rectifier/regulator

the

front

lead

lead

cylinder.

lead and

cable guide.

brake cable and

wire

har-

speedometer

2

14

4

6

-22-

c

(j)

Front brake cable

®

Throttle

@

Autolube

© Spark

cable

plug

#1

pump

lead

® Rear brake cable

®

Autolube

(J)

Oil feed hose

®

Wire

®

CDI

@)

Fuel cock

pump

harness

magneto

vacuum

lead

® Fuel hose

cable

hose

@I

Band

@

Mixing

chamber

air

vent

hose

® Carburetor

@

Throttle

(@

Starter cable

@ Horn switch lead

[6l Fasten

feed hose and

2

cable

the

#2

spark

wire

plug

lead, rear brake cable, oil

harness

with

a plastic clip.

8

9

[§]

-23-

[§]

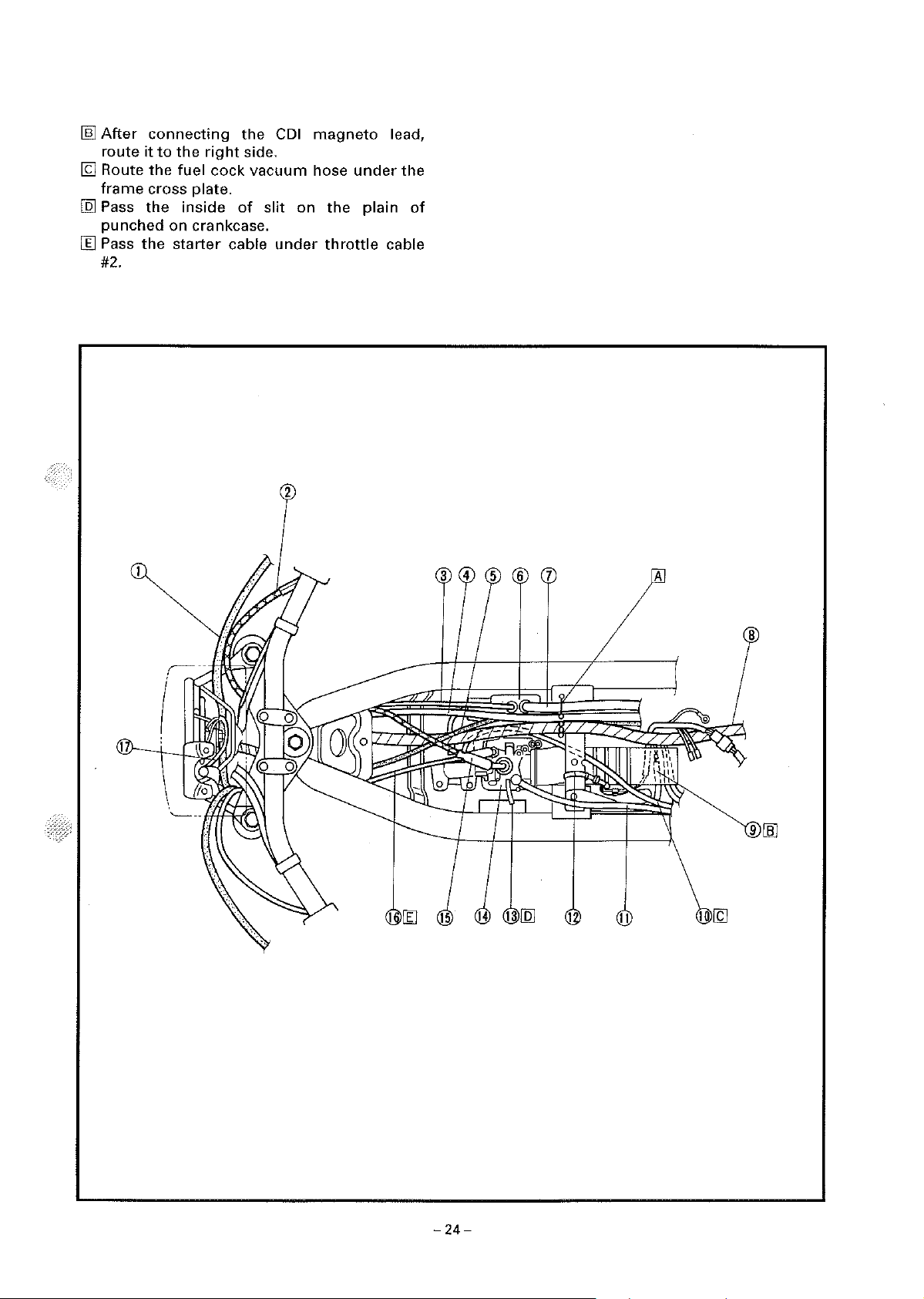

After

route

19

Route

frame

[Q]

Pass

punched

II]

Pass

#2.

connecting

it

to

the

the

fuel cock vacuum hose

cross plate.

the

inside

on crankcase.

the

starter

right

cable

the

side.

of

slit

CDI

on

under

magneto

under

the

plain

throttle

lead,

the

of

cable

8

9

[ID

-24-

CD

Starter

cable

® Rear brake cable

@ Fuel cock

@Fuse

@ Battery

vaccum

® Fuel hose

(j) Flasher relay

® Flasher relay lead

®

Ignition

@)

Ignition

®

Battery

coil lead

coil

breather

hose

hose

2

@

Spark

@)

CDI

magneto

@

Wire

[!';]

Pass

fender

[ill Fasten

on

lead

[l;J

Fasten

section

plug

lead

harness

the

fuel hose

bracket.

the

the

left, inside section

the

spark

of

the

lead

flasher

frame.

through

relay lead and

plug

lead

the

on

of

frame.

the

inside

of

ignition

right, inside

rear

coil

D

A

11

-

25-