Yamaha E115A, 115B, 150A, L150A, 175A Owner's Manual

...

OWNER’S MANUAL

E115A

115B

140B

150A

L150A

175A

200A

L200A

60H-28199-E1

EMU01449

E

TO THE OWNER

Thank you for choosing a Yamaha outboard

motor. This Owner’s manual contains information needed for proper operation, maintenance and care. A thorough understanding of these simple instructions will help you

obtain maximum enjoyment from your new

Yamaha. If you have any question about

the operation or maintenance of your outboard motor, please consult a Yamaha

dealer.

In this Owner’s Manual particularly important information is distinguished in the following ways.

Q The Safety Alert Symbol means

ATTENTION! BECOME ALERT!

YOUR SAFETY IS INVOLVED!

w

Failure to follow WARNING instructions

could result in severe injury or death to

the machine operator, a bystander, or a

person inspecting or repairing the outboard motor.

EMU01447

cC

A CAUTION indicates special precautions that must be taken to avoid damage to the outboard motor.

NOTE:

A NOTE provides key information to make

procedures easier or clearer.

* Yamaha continually seeks advancements

in product design and quality. Therefore,

while this manual contains the most current product information available at the

time of printing, there may be minor discrepancies between your machine and

this manual. If there is any question concerning this manual, please consult your

Yamaha dealer.

NOTE:

The E115AE, E115AMH, E115AWH,

200AET, L200AET, and their standard

accessories are used as a base for the

explanations and illustrations in this manual. Therefore, some items may not apply to

every model.

E115A, 115B, 140B, 150A, L150A,

175A, 200A, L200A

OWNER’S MANUAL

©2002 by Yamaha Motor Co., Ltd.

1st Edition, March 2002

All rights reserved.

Any reprinting or unauthorized use

without the written permission of

Yamaha Motor Co., Ltd.

is expressly prohibited.

Printed in Japan

EMU00003

E

CONTENTS

GENERAL INFORMATION

BASIC COMPONENTS

OPERATION

MAINTENANCE

1

2

3

4

TROUBLE RECOVERY

INDEX

READ THIS OWNER’S MANUAL CAREFULLY

BEFORE OPERATING YOUR OUTBOARD MOTOR.

5

6

E

EMU00004

Chapter 1

GENERAL

INFORMATION

IDENTIFICATION NUMBERS

RECORD ............................................... 1-1

Outboard motor serial number ............ 1-1

Key number ........................................ 1-1

LABELS ................................................ 1-2

EC label .............................................. 1-2

EPA label ............................................ 1-2

EMISSION CONTROL

INFORMATION ..................................... 1-3

SAFETY INFORMATION ...................... 1-4

FUELING INSTRUCTIONS ................... 1-6

Gasoline............................................... 1-7

Engine oil ............................................ 1-7

BATTERY REQUIREMENT .................. 1-8

1

2

3

4

PROPELLER SELECTION .................... 1-8

START-IN-GEAR PROTECTION .......... 1-9

5

6

E

YAMAHA MOTOR CO., LTD.

MADE IN JAPAN

PAYS D'ORIGINE JAPON

1

401012

000319

123

YAMAHA

q

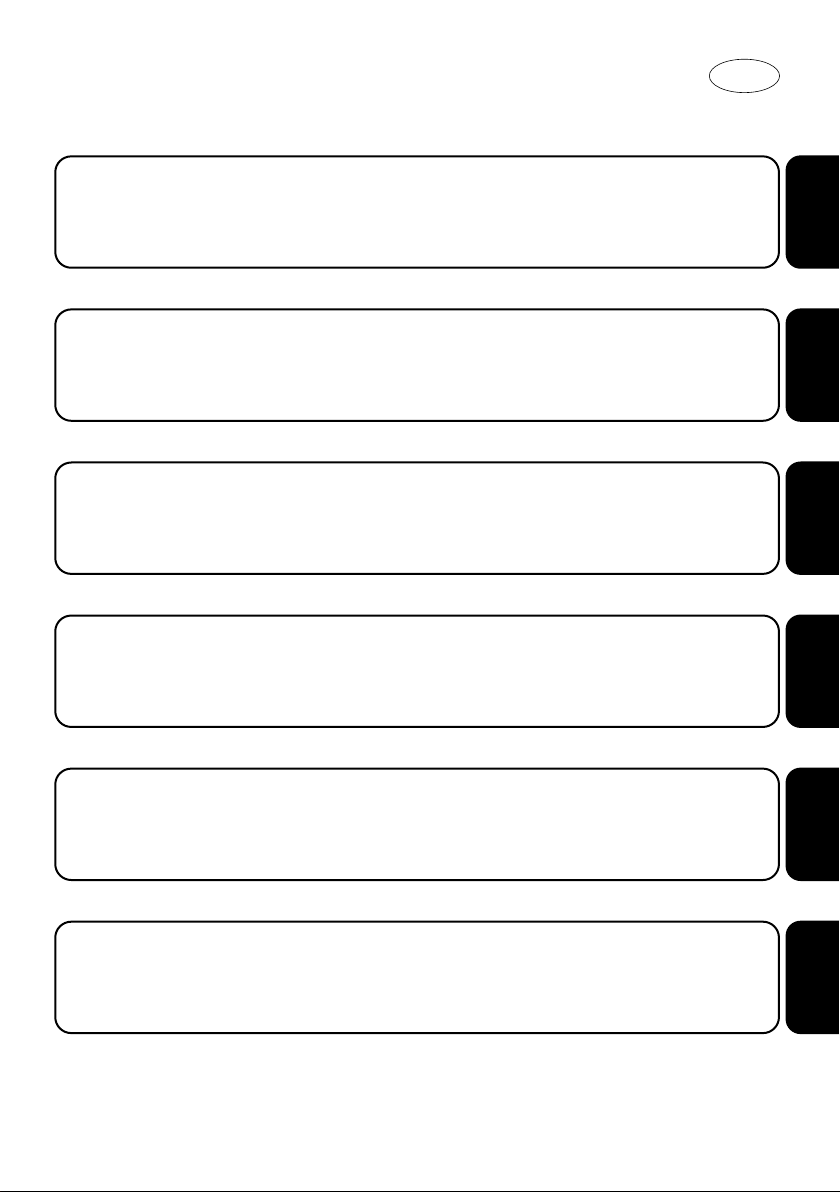

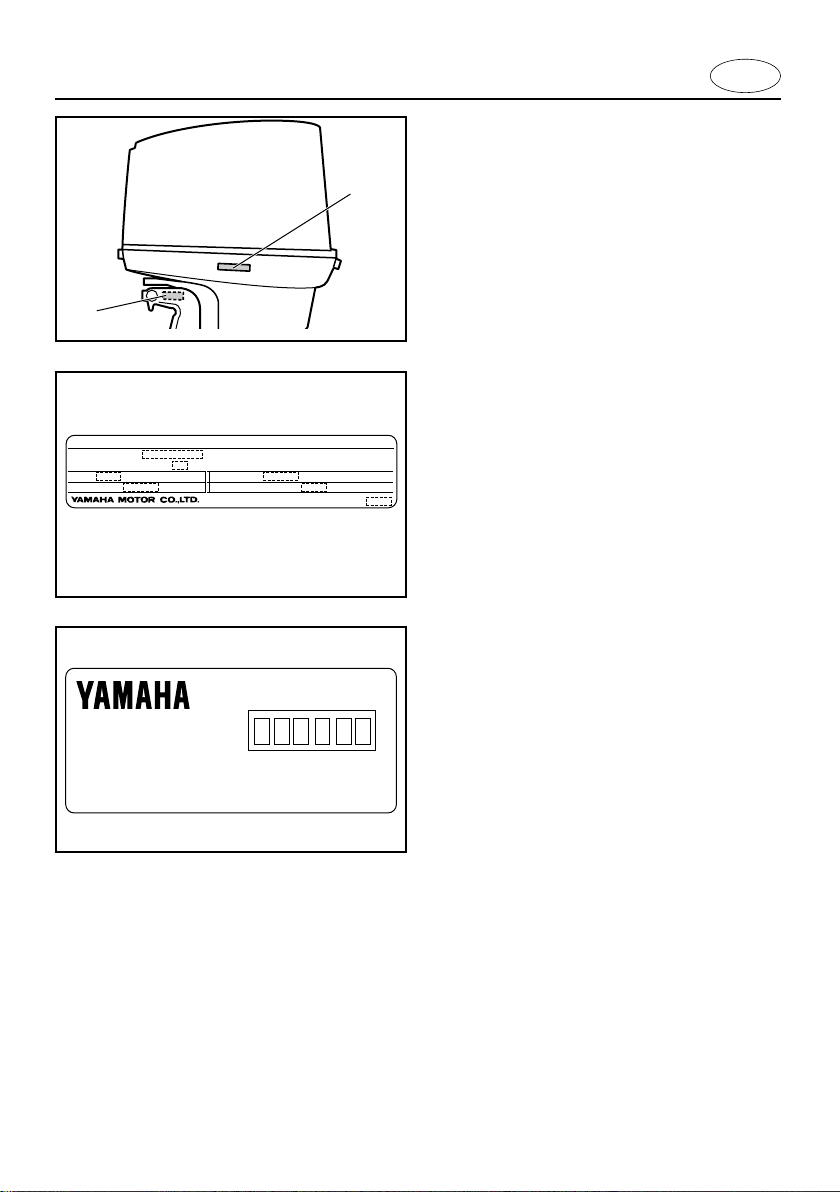

EMU00005

IDENTIFICATION NUMBERS

RECORD

EMU00007

OUTBOARD MOTOR SERIAL

NUMBER

The outboard motor serial number is

stamped on the label attached to the port

side of the clamp-bracket.

Record your outboard motor serial number

in the spaces provided to assist you in

ordering spare parts from your Yamaha

dealer or for reference in case your outboard motor is stolen.

1 Outboard motor serial number

1-1

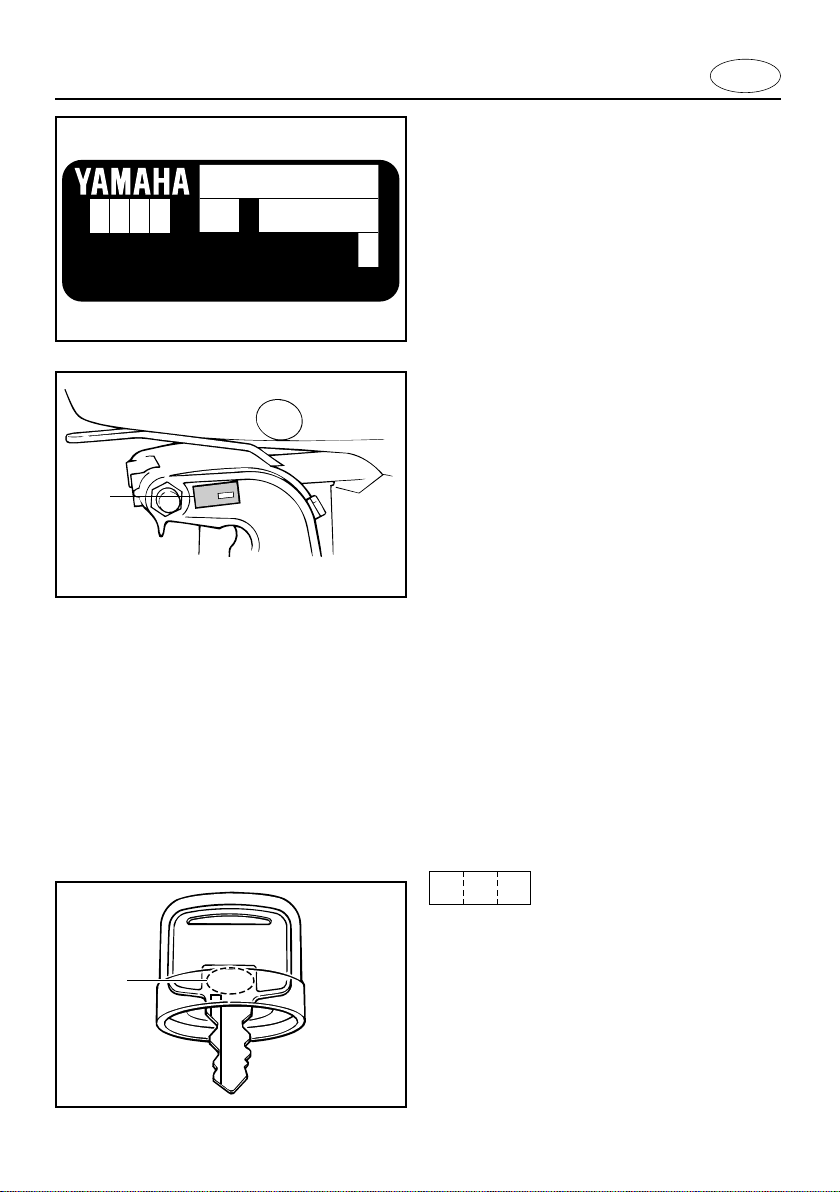

EMU00008

KEY NUMBER

If a main key switch is equipped with the

motor, the key identification number is

stamped on your key as shown in the illustration. Record this number in the space

provided for reference in case you need a

new key.

1 Key number

000769

YAMAHA MOTOR CO.,LTD.

2500 SHINGAI,IWATA,

SHIZUOKA,JAPAN

NOMINAL POWER

MASS

KW

Kg

EMISSION CONTROL INFORMATION

ENGINE FAMILY :

THIS ENGINE CONFORMS TO 2001 U.S. EPA REGULATIONS FOR MARINE SI ENGINES.

FELs :

SPARK PLUG :

g/kw-hr

IDLE SPEED :

SPARK PLUG GAP (mm) :

rpm IN NEUTRAL

000762

E

EMU01532

LABELS

EMU01526

EC LABEL

Engines affixed with this label conform to

certain portions of the European Parliament

directive relating to machinery. Refer to the

label and the EC Declaration of Conformity

for more details.

EMU01527

EPA LABEL

Engines affixed with this label conform to

U.S. Environmental Protection Agency

(EPA) regulations for marine SI engines.

Refer to the label for more details.

1-2

E

q

w

001336

EMU01385

EMISSION CONTROL

INFORMATION

EMU01390

U.S. INSULAR AREAS

Engines affixed with the label pictured

below conform to U.S. Environmental

Protection Agency (EPA) regulations for

marine SI engines. See the label affixed to

your engine for details.

EMISSION CONTROL INFORMATION

ENGINE FAMILY :

THIS ENGINE CONFORMS TO 2001 U.S. EPA REGULATIONS FOR MARINE SI ENGINES.

FELs :

SPARK PLUG :

g/kw-hr

IDLE SPEED :

SPARK PLUG GAP (mm) :

rpm IN NEUTRAL

000762

Manufactured:

1 Emission control information label

Approval label of Emission control certificate

This label is attached to the bottom cowling.

Existing Technology ; N/A

2 Manufactured date label

Manufactured date label

This label is attached to the clamp bracket

or the swivel bracket.

1-3

E

EMU00918

QSAFETY INFORMATION

8 Before mounting or operating the out-

board motor, read this entire manual.

Reading it should give you an understanding of the motor and its operation.

8 Before operating the boat, read any

owner’s or operator’s manuals supplied

with it and all labels. Be sure you understand each item before operating.

8 Do not overpower the boat with this out-

board motor. Overpowering the boat

could result in loss of control. The rated

power of the outboard should be equal to

or less than the rated horsepower capacity of the boat. If the rated horsepower

capacity of the boat is unknown, consult

the dealer or boat manufacturer.

8 Do not modify the outboard. Modifications

could make the motor unfit or unsafe to

use.

8 Never operate after drinking alcohol or

taking drugs. About 50% of all boating

fatalities involve intoxication.

8 Have an approved personal flotation

device (PFD) on board for every occupant. It is a good idea to wear a PFD

whenever boating. At a minimum, children and non-swimmers should always

wear PFDs, and everyone should wear

PFDs when there are potentially hazardous boating conditions.

8 Gasoline (Petrol) is highly flammable, and

its vapors are flammable and explosive.

Handle and store gasoline (Petrol) carefully. Make sure there are no gas fumes

or leaking fuel before starting the engine.

1-4

E

8 This product emits exhaust gases which

contain carbon monoxide, a colorless,

odorless gas which may cause brain

damage or death when inhaled.

Symptoms include nausea, dizziness,

and drowsiness. Keep cockpit and cabin

areas well ventilated. Avoid blocking

exhaust outlets.

8 Check throttle, shift, and steering for

proper operation before starting the

engine.

8 Attach the engine stop switch lanyard to a

secure place on your clothing, or your

arm or leg while operating. If you accidentally leave the helm, the lanyard will pull

from the switch, stopping the engine.

8 Know the marine laws and regulations

where you will be boating - and obey

them.

8 Stay informed about the weather. Check

weather forecasts before boating. Avoid

boating in hazardous weather.

8 Tell someone where you are going: leave

a Float Plan with a responsible person.

Be sure to cancel the Float Plan when

you return.

8 Use common sense and good judgment

when boating. Know your abilities, and be

sure you understand how your boat handles under the different boating conditions

you may encounter. Operate within your

limits, and the limits of your boat. Always

operate at safe speeds, and keep a careful watch for obstacles and other traffic.

8 Always watch carefully for swimmers dur-

ing the engine operation.

8 Stay away from swimming areas.

8 When a swimmer is in the water near you

shift into neutral and shut off the engine.

1-5

E

EMU00016

FUELING INSTRUCTIONS

w

GASOLINE AND ITS VAPORS ARE HIGHLY FLAMMABLE AND EXPLOSIVE!

8 Do not smoke when refueling, and

keep away from sparks, flames, or

other sources of ignition.

8 Stop engine before refueling.

8 Refuel in a well-ventilated area. Refuel

portable fuel tanks off the boat.

8 Take care not to spill gasoline. If gaso-

line spills, wipe it up immediately with

dry rags.

8 Do not overfill the fuel tank.

8 Tighten the filler cap securely after

refueling.

8 If you should swallow some gasoline

inhale a lot of gasoline vapor, or get

gasoline in your eyes, get immediate

medical attention.

8 If any gasoline spills onto your skin,

immediately wash with soap and

water. Change clothing if gasoline

spills on it.

8 Touch the fuel nozzle to the filler open-

ing or funnel to help prevent electrostatic sparks.

cC

Use only new clean gasoline which has

been stored in clean containers and is

not contaminated with water or foreign

matter.

1-6

E

EMU01799

GASOLINE

Recommended gasoline:

Regular unleaded gasoline

If knocking or pinging occurs, use a different brand of gasoline or premium unleaded

fuel. If unleaded gasoline is not available,

then premium gasoline can be used.

EMU01356

ENGINE OIL

Recommended engine oil:

YAMALUBE, TWO STROKE MOTOR

OIL FOR MARINE

If the recommended engine oil is not available, another 2-stroke engine oil with a

NMMA-certified TC-W3 rating may be used.

1-7

E

901015

UPPER LEVEL

LOWER LEVEL

EMU01775

BATTERY REQUIREMENT

cC

Do not use a battery that does not meet

the specified capacity. If a battery which

does not meet specifications is used, the

electric system could perform poorly or

be overloaded, causing electric system

damage.

For electric start models, choose a battery

which meets the following specifications.

EMU01857

Minimum cold cranking amps (CCA/EN):

430 amps at -18°C (-0.4°F)

Minimum rated capacity (20HR/IEC):

70 A·h

EMU01395

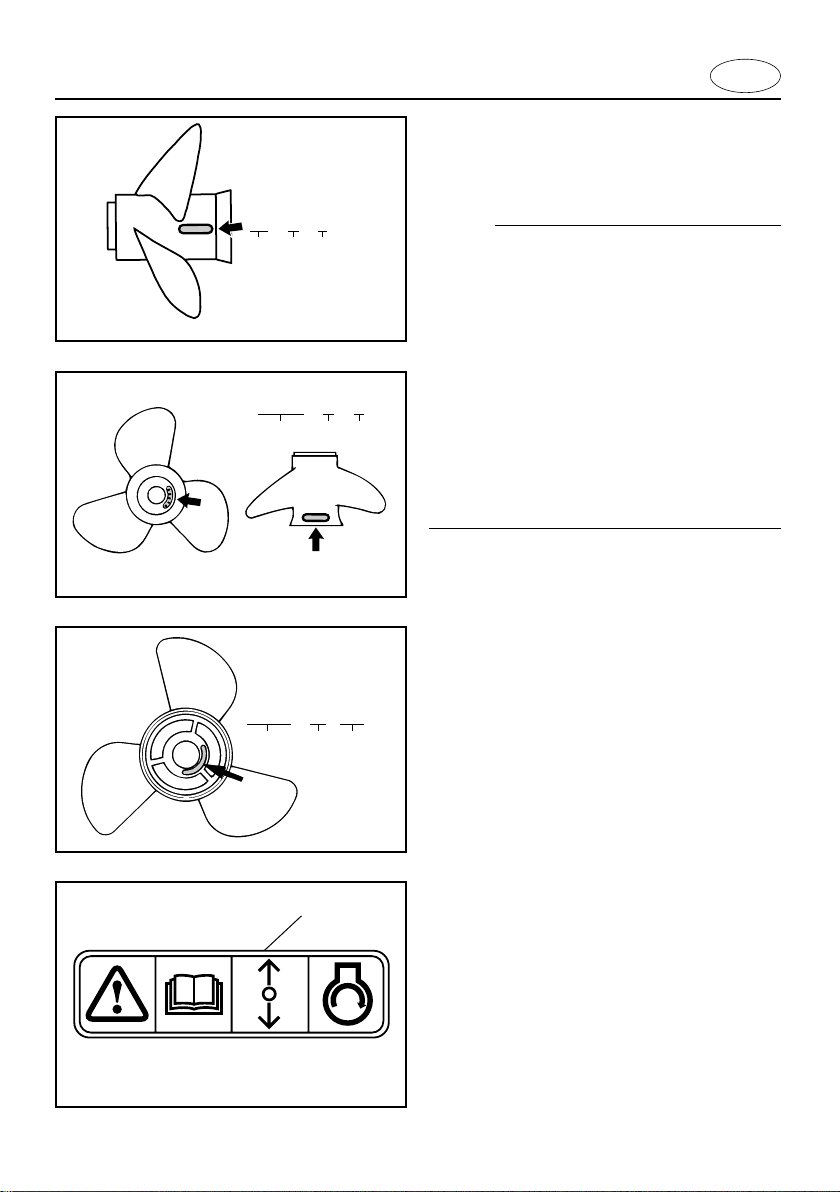

PROPELLER SELECTION

The performance of your outboard motor

will be critically affected by your choice of

propeller, as an incorrect choice could

adversely affect performance and could

also seriously damage the motor. Engine

speed depends on the propeller size and

boat load. If engine speed is too high or too

low for good engine performance, this will

have an adverse effect on the engine.

Yamaha outboard motors are fitted with

propellers chosen to perform well over a

range of applications, but there may be

uses where a propeller with a different pitch

would be more appropriate. For a greater

operating load, a smaller-pitch propeller is

more suitable as it enables the correct

engine speed to be maintained. Conversely,

a larger-pitch propeller is more suitable for

a smaller operating load.

1-8

13 x 17 - K

qwe

000933

14-1/2 x 17 - M

qwe

E

Yamaha dealers stock a range of propellers, and can advise you and install a

propeller on your outboard that is best suited to your application.

NOTE:

At full throttle and under a maximum boat

load, the engine’s rpm should be within the

upper half of the full throttle operating

range, as listed in “SPECIFICATIONS” on

page 4-1. Select a propeller which fulfills

this requirement.

If operating under conditions which allow

the engine’s rpm to rise above the maximum recommended range (such as light

boat loads), reduce the throttle setting to

maintain the rpm in the proper operating

range.

13-3/4 x 17 - ML

qwe

q

602022

602033

000376

1 Propeller diameter (in inches)

2 Propeller pitch (in inches)

3 Type of propeller (propeller mark)

Refer to the section “CHECKING PROPELLER” for instructions on propeller

removal and installation.

EMU01208

START-IN-GEAR PROTECTION

Yamaha outboard motors which have the

pictured label 1 affixed to them or Yamaha

approved remote control units are equipped

with start-in-gear protection device(s). This

feature permits the engine to be started

only when it is Neutral. Always select

Neutral before starting the engine.

1-9

E

EMU00037

Chapter 2

BASIC COMPONENTS

MAIN COMPONENTS ........................... 2-1

OPERATIONS OF CONTROLS AND

OTHER FUNCTIONS ............................ 2-5

Fuel tank ............................................. 2-5

Gear shift lever ................................... 2-6

Engine stop lanyard switch ................. 2-6

Choke knob ......................................... 2-7

Manual injection knob ......................... 2-7

Recoil starter handle ........................... 2-7

Main switch ......................................... 2-8

Tiller handle ........................................ 2-8

Remote control ................................. 2-10

Steering friction adjusting screw ....... 2-16

Trim tab ............................................. 2-17

Trim angle adjusting rod ................... 2-17

Tachometer ....................................... 2-18

Trim meter ........................................ 2-18

Digital hour meter ............................. 2-18

Tilt lock mechanism .......................... 2-19

Tilt support lever ............................... 2-20

Top cowling lock levers ..................... 2-20

WARNING SYSTEM ........................... 2-21

Overheat warning ............................. 2-21

1

2

3

4

5

6

EMU01206

!3

!4

!0

o

i

w

e

r

t

y

u

q

!1

!2

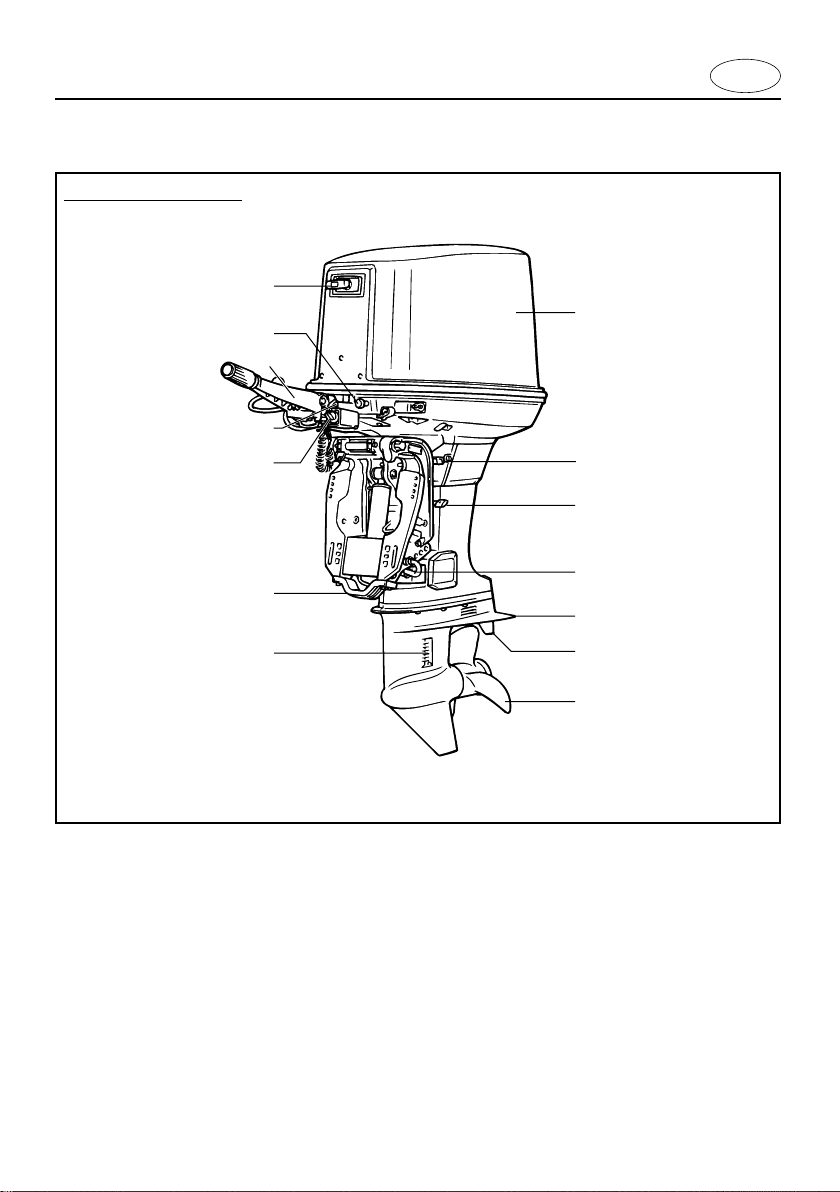

E115AMH, E115AWH

E

MAIN COMPONENTS

1 Top cowling

2 Tilt support lever

3 Tilt lock lever

4 Trim angle adjusting rod

5 Anti-cavitation plate

6 Trim tab (Anode)

7 Propeller

8 Cooling water inlet

9 Anode

0 Engine stop switch

2-1

*

q Main switch

w Tiller handle

e Manual injection knob

r Recoil starter handle

* May not be exactly as shown; also may not be

included as standard equipment on all models.

EMU01206

o

i

u

y

t

r

e

q

w

!0

!1

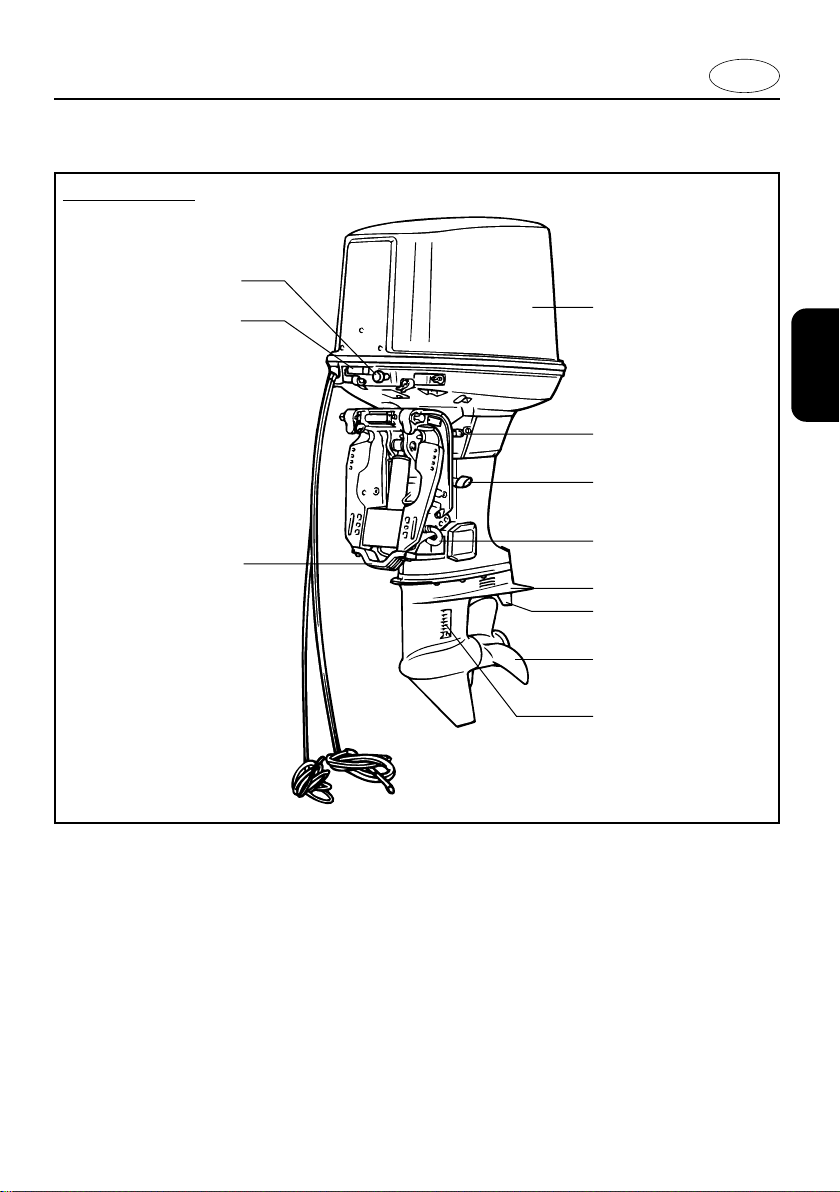

E115AE, 115BE

E

MAIN COMPONENTS

1 Top cowling

2 Tilt support lever

3 Tilt lock lever

4 Trim angle adjusting rod

5 Anti-cavitation plate

6 Trim tab (Anode)

7 Propeller

8 Cooling water inlet

9 Anode

0 Cowling lock lever

q Choke knob

* May not be exactly as shown; also may not be

included as standard equipment on all models.

2-2

EMU01206

2

w

1

2

3

4

5

6

7

8

9

0

q

MAIN COMPONENTS

E115AET, 115BET, 140BET, 150AET, L150AET, 175AET, 200AET, L200AET

E

1 Top cowling

2 Cowling lock levers

3 Anti-cavitation plate

4 Trim tab(Anode)

5 Propeller

6 Cooling water inlet

7 Anode

8 Clamp bracket

9 Tilt support lever

0 Power trim/tilt switch

q Fuel joint

w Choke knob

2-3

* May not be exactly as shown; also may not be

included as standard equipment on all models.

EMU01206

i

w

e

r

t

y

q

u

YAMAHA

HOUR

YAMAHA

YAMAHA

x1000 r/min

7

6

5

43

1

2

E

MAIN COMPONENTS

*

1 Remote control box (side mount type)

*

2 Remote control box (binnacle mount type)

*

3 Switch panel (for use with 2)

*

4 Tachometer

*

5 Trim meter

*

6 Digital hour meter

*

7 Remote control cable

*

8 Fuel tank

* May not be exactly as shown; also may not be

included as standard equipment on all models.

2-4

E

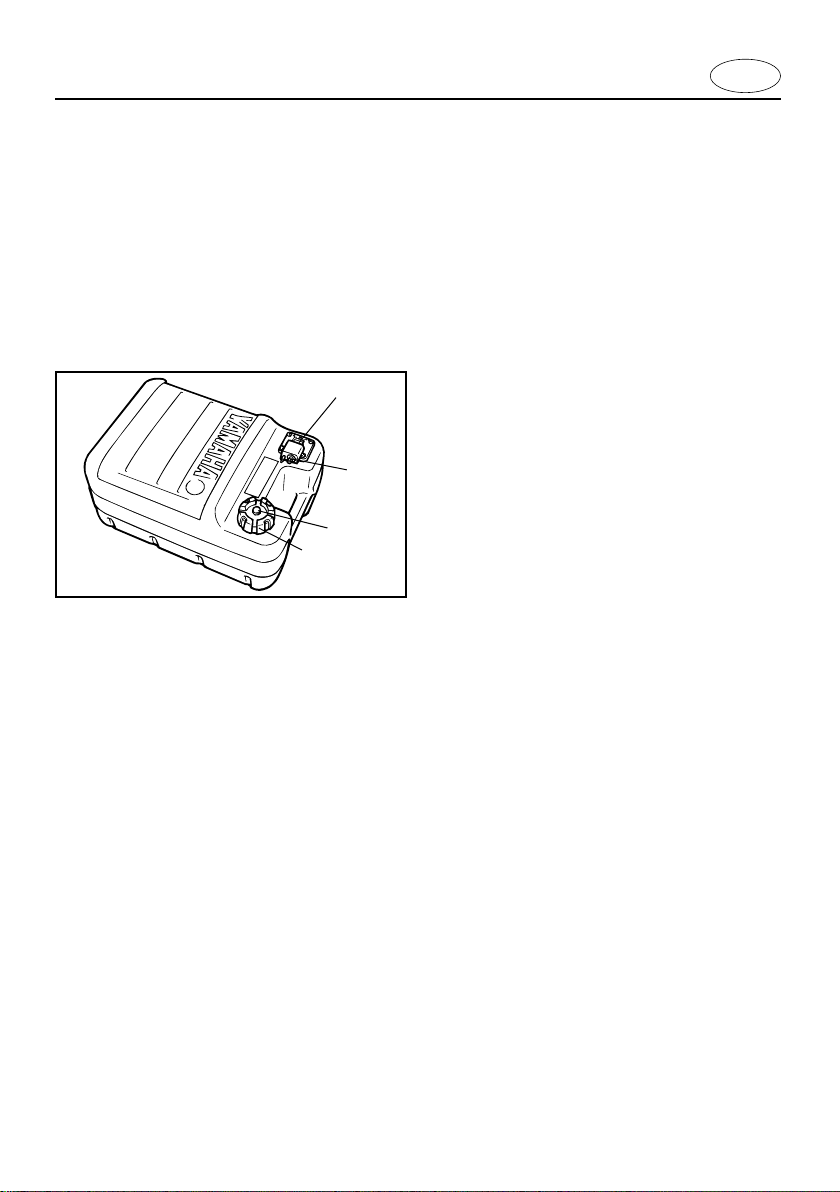

902016

e

q

r

w

EMU00039

OPERATIONS OF CONTROLS

AND

OTHER FUNCTIONS

EMU01465

FUEL TANK

If your model included a portable fuel tank,

its parts and functions are as follows.

1 Fuel hose joint

2 Fuel meter (if equipped)

3 Fuel tank cap

4 Air vent screw (if equipped)

EMU00042

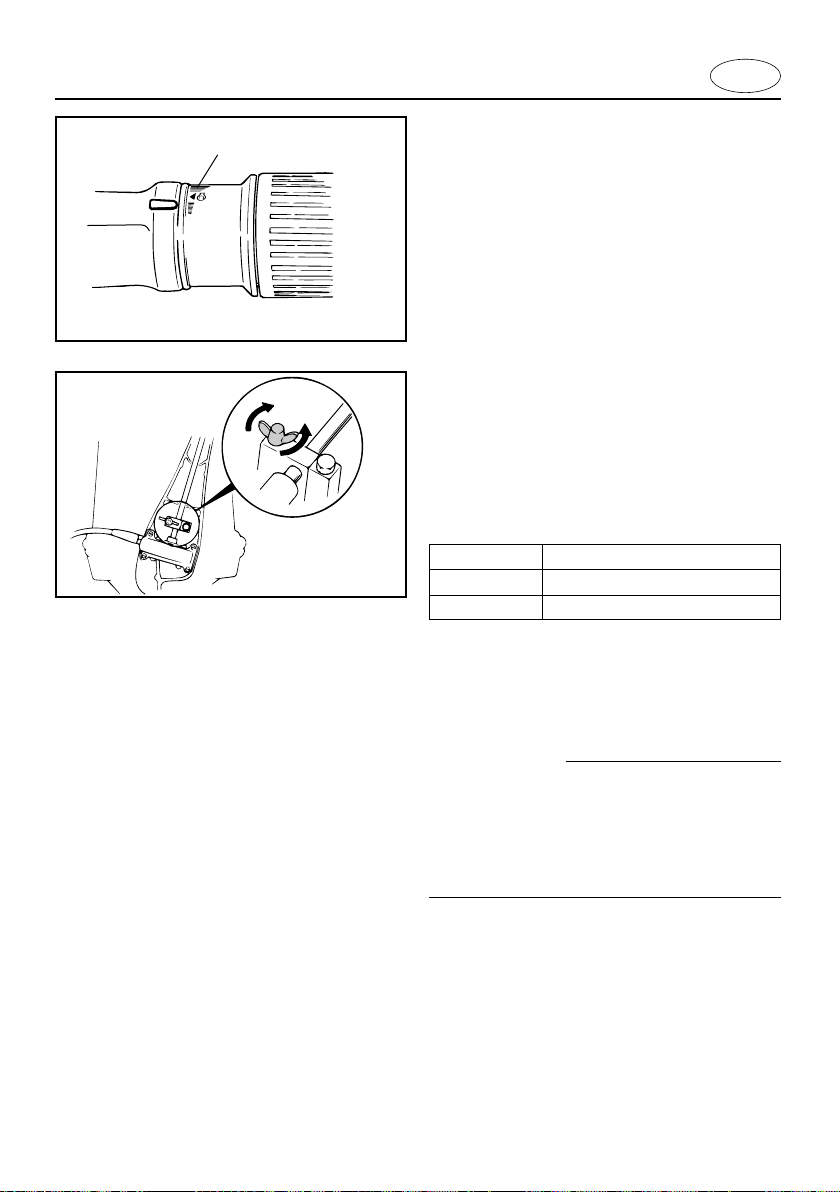

Fuel Hose Joint

This connector is provided for connecting or

disconnecting fuel hose.

EMU00045

Fuel Tank Cap

This cap is for filling fuel. To remove it, turn

it counterclockwise.

2-5

EMU00046

Air Vent Screw

This screw is on the fuel tank cap. To

loosen it, turn it counterclockwise.

E

507014

12

3

EMU00051

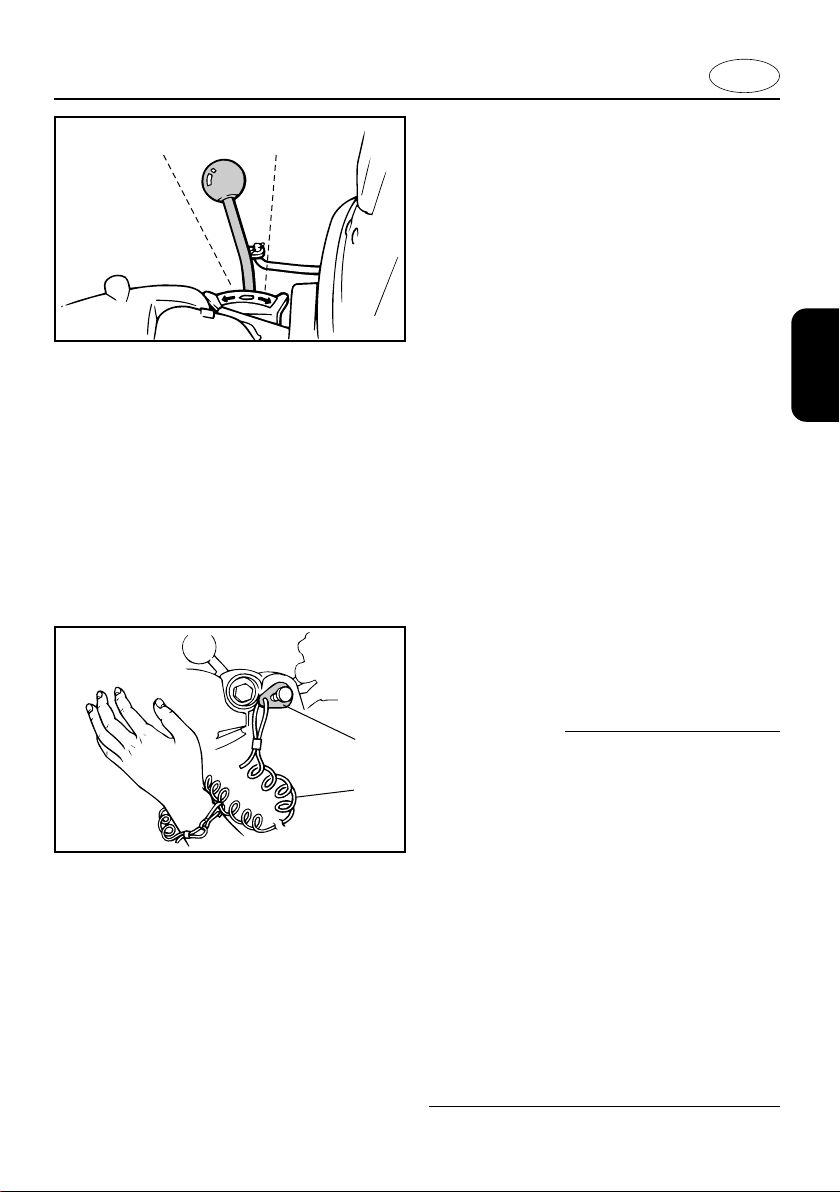

GEAR SHIFT LEVER (for Tiller

control model)

Turning the gear-shift lever towards you

engages the clutch with the forward gear so

that the boat moves ahead. Turning the

lever away from you engages the reverse

gear so that the boat moves astern.

1 Neutral

2 Forward

3 Reverse

EMU00931

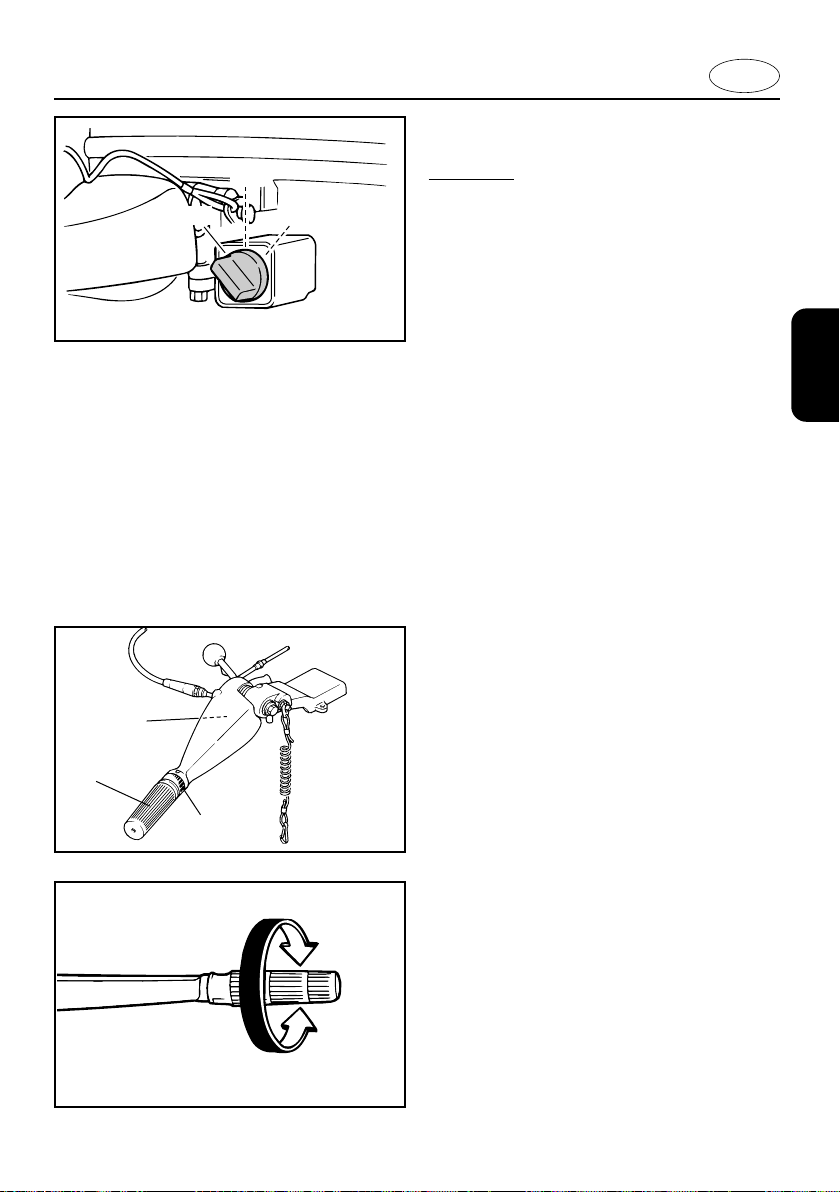

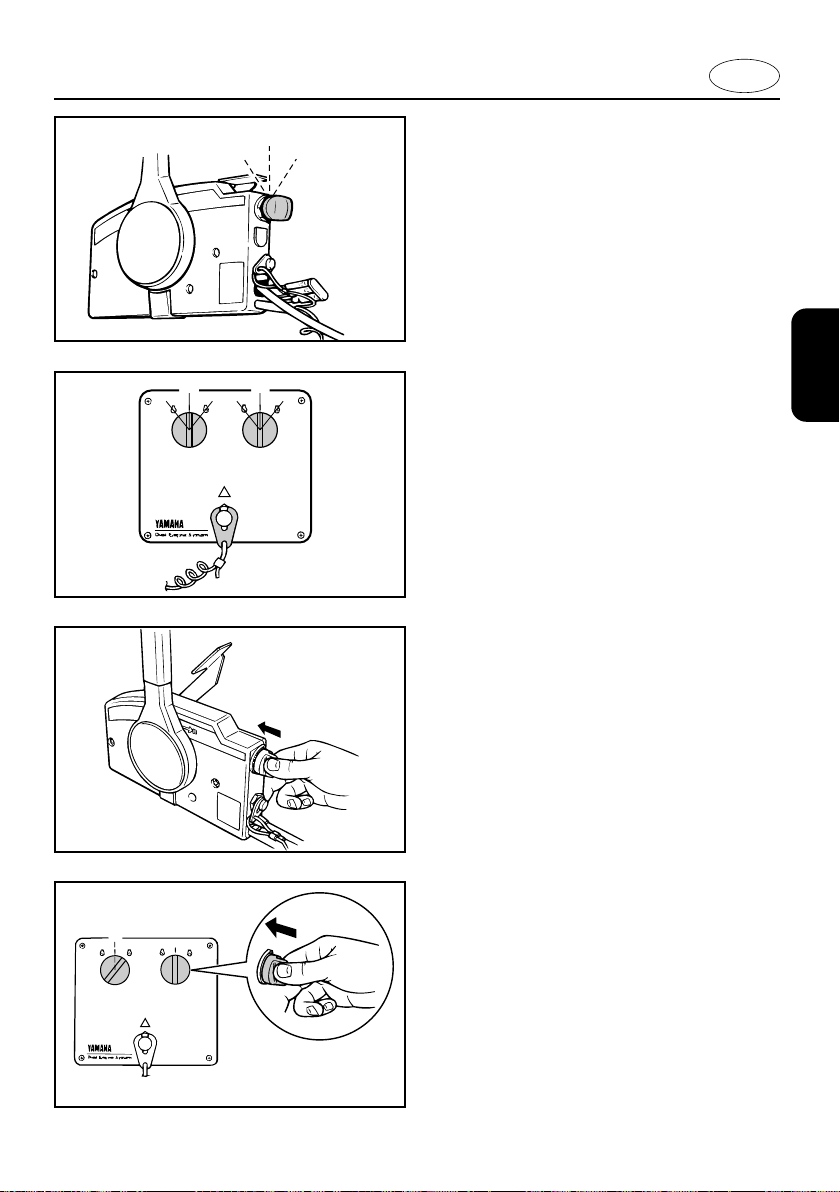

ENGINE STOP LANYARD SWITCH

(for Tiller control model)

The lock-plate 1 must be attached to the

engine stop lanyard switch for the engine to

run. The lanyard 2 should be attached to a

secure place on the operator’s clothing, or

arm or leg. Should the operator fall overboard or leave the helm, the lanyard will pull

out the lock plate, stopping ignition to the

engine. This will prevent the boat from running away under power.

w

q

w

000974

8 Attach the lanyard to a secure place

on your clothing, your arm or leg while

operating.

8 Do not attach the lanyard to clothing

that could tear loose. Do not route the

lanyard in such a way that it could

become entangled, preventing it from

functioning.

8 Avoid accidentally pulling the lanyard

during normal operation. Loss of

engine power means the loss of most

steering control. Also, without engine

power, the boat could slow rapidly.

This could cause people and objects

in the boat to be thrown forward.

2-6

305034

001310

E

NOTE:

The engine cannot be started with the lockplate removed.

EMU00055

CHOKE KNOB

Pulling out this knob (setting it to ON) supplies a rich mixture required to start the

engine.

NOTE:

The choke knob for Remote control model

has the same function as the choke switch

on the remote control box.

EMU01703

MANUAL INJECTION KNOB

E115AMH, E115AWH

The manual injection knob is used to supply

a rich fuel mixture to the carburetor when

starting the engine. To use the manual

injection knob, fully pull out the knob firmly.

Release the knob to allow it to automatically

return to its home position. For further information, see Chapter 3, “Starting engine.”

EMU00059

RECOIL STARTER HANDLE (If

equipped)

Pull the handle gently until resistance is felt.

Then vigorously pull the handle straight out

to crank the engine to start it.

2-7

209015

000530

OFF

ON

START

q

e

w

000952

E

EMU01292

MAIN SWITCH

E115AWH

The main switch controls the ignition system; its operation is described below.

8 OFF

Electrical circuits switched off.

(The key can be removed.)

8 ON

Electrical circuits switched on.

(The key cannot be removed.)

8 START

Starter-motor will turn and start engine.

(When the key is released, it returns automatically to “ON”.)

EMU00062

TILLER HANDLE (for Tiller control

model)

Moving the tiller handle sideways to adjust

the steering direction. In addition, this handle contains the functions as follows.

1 Throttle control grip

2 Throttle indicator

3 Throttle friction adjusting knob/screw

EMU00065

Throttle Control Grip

The throttle control grip is on the tiller handle. Turn the grip counterclockwise to

increase speed and clockwise to decrease

speed.

000529

2-8

502025

q

E

EMU00067

Throttle Indicator

The fuel consumption curve on the throttle

indicator shows the relative amount of fuel

consumed for each throttle position.

Choose the setting that offers the best performance and fuel economy for the desired

operation.

000559

1 Throttle indicator

EMU01293

Throttle friction adjusting screw/ knob

A friction device in the tiller handle provide

resistance to movement of the throttle grip.

This is adjustable for operator preference.

An adjusting screw/knob is located within

the tiller handle.

Resistance Knob/Screw

Increase Turn clockwise

Decrease Turn counterclockwise

When constant speed is desired, tighten the

adjusting screw/bolt to maintain the desired

throttle setting.

w

Do not over tighten the friction adjusting

screw/ knob.

If there is too much resistance, it may be

difficult to move the throttle grip, which

could result in an accident.

2-9

E

000322

w

q

e

t

y

u

i

A

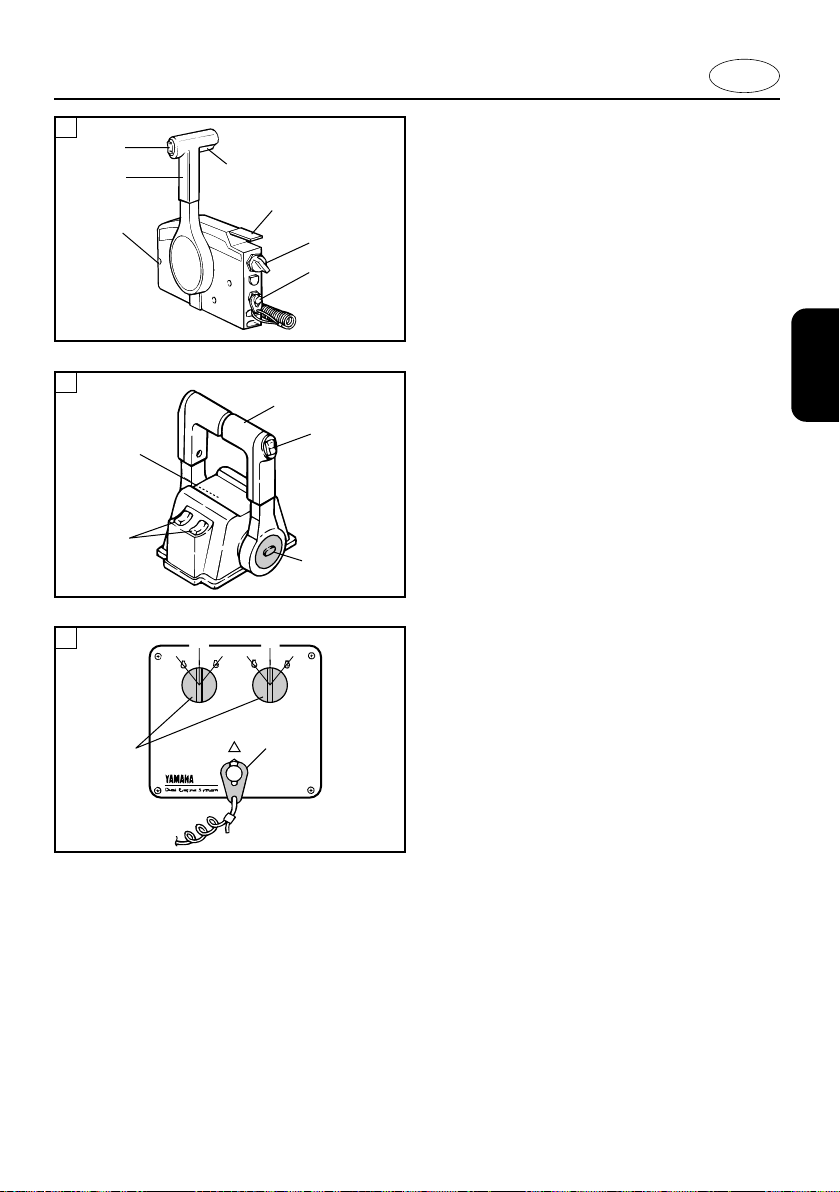

EMU01691

REMOTE CONTROL

Both the shifter and the throttle are actuated

by the remote control lever. Additionally, the

remote control also has the electrical

switches.

å Side mount remote control box

∫ Binnacle mount remote control box

ç Switch panel (for use with ∫)

1 Remote control lever

B

q

u

i

2 Neutral interlock trigger

3 Neutral throttle lever

4 Free accelerator

5 Main switch / choke switch

6 Engine stop lanyard switch

7 Power trim and tilt switch

8 Throttle friction adjusting screw

u

r

001276

C

ON

ON

STARTOFF

STARTOFF

t

y

001277

2-10

R

N

F

q

w

e

r

t

y

u

u

t

r

y

701031

u

w

E

EMU00098

Remote Control Lever

Moving the lever forward from the Neutral

position engages Forward gear. Pulling the

lever back from Neutral engages Reverse.

The engine will continue to run at idle until

the lever is moved about 35° (a detent can

be felt). Moving the lever farther opens the

throttle, and the engine will begin to accelerate.

1 Neutral

q

rr

e

tty

y

u

702032

UP

DN

2 Forward

3 Reverse

4 Shift

5 Fully closed

6 Throttle

7 Fully open

EMU00099

Neutral Interlock Trigger

To shift out of Neutral, the neutral interlock

trigger of the remote control lever must first

be pulled up.

2-11

EMU00100

Neutral Throttle Lever

000323

N

q

w

000324

To open the throttle without shifting into

either Forward or Reverse, place the

remote control lever in the Neutral position

and lift the neutral throttle lever.

NOTE:

The neutral throttle lever will operate only

when the remote control lever is in Neutral.

The remote control lever will operate only

when the neutral throttle lever is in the

closed position.

1 Fully open

2 Fully closed

E

ON

STARTOFF

701021

EMU00101

Main switch

The main switch controls the ignition system; its operation is described below.

8 OFF

Electrical circuits switched off.

(The key can be removed.)

8 ON

Electrical circuits switched on.

(The key cannot be removed.)

8 START

ON

ON

STARTOFF

STARTOFF

001242

Starter-motor will turn and start engine.

(When the key is released, it returns automatically to “ON”.)

EMU00102

Choke Switch

While the main switch is being pressed in at

“ON” or “START”, the choke system will

switch on, to supply a rich mixture required

to start the engine. (When the key is

released, it will switch off automatically.)

701055

ON

STARTOFF

703031

2-12

000569

q

w

w

E

EMU00934

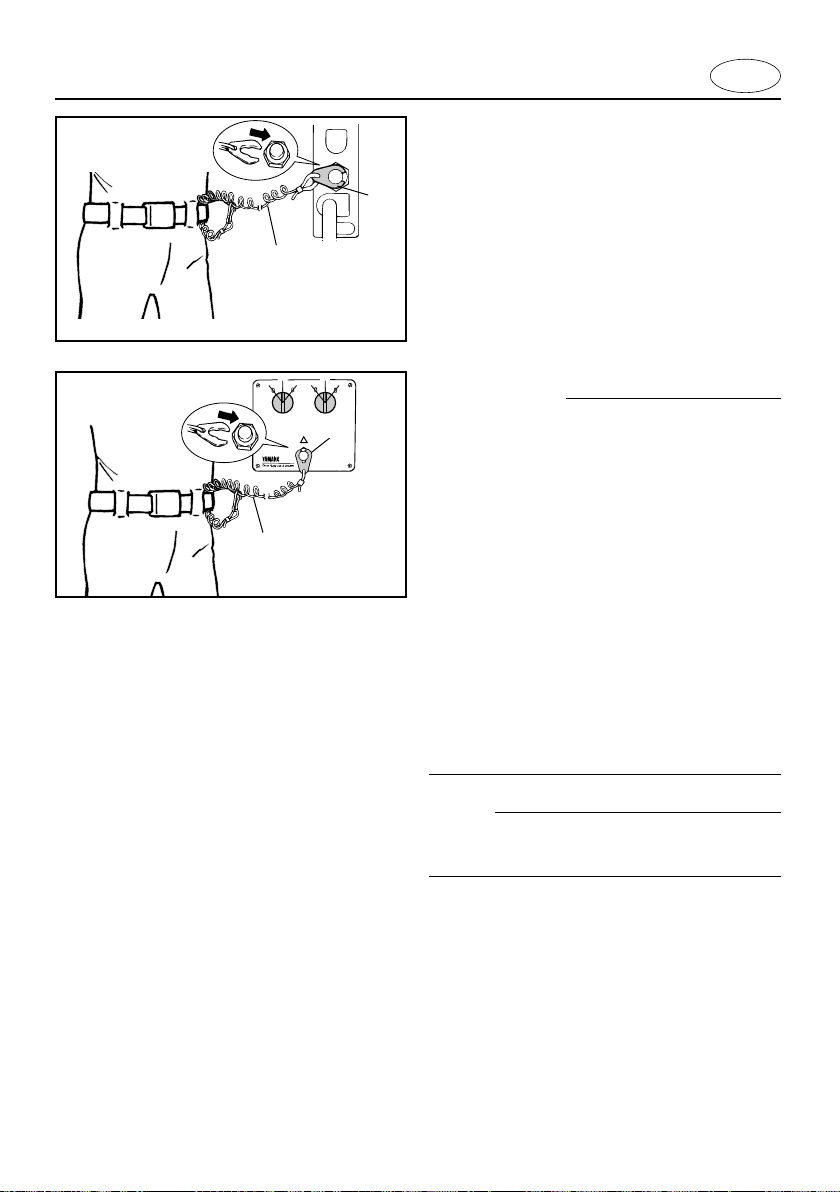

Engine Stop Lanyard Switch

The lock-plate 1 must be attached to the

engine stop lanyard switch for the engine to

run. The lanyard 2 should be attached to a

secure place on the operator’s clothing, or

arm or leg. Should the operator fall overboard or leave the helm, the lanyard will pull

out the lock plate, stopping ignition to the

engine. This will prevent the boat from run-

ON

ON

STARTOFF

STARTOFF

q

000715

ning away under power.

w

8 Attach the lanyard to a secure place

on your clothing, your arm or leg while

operating.

8 Do not attach the lanyard to clothing

that could tear loose. Do not route the

lanyard in such a way that it could

become entangled, preventing it from

functioning.

8 Avoid accidentally pulling the lanyard

during normal operation. Loss of

engine power means the loss of most

steering control. Also, without engine

power, the boat could slow rapidly.

This could cause people and objects

in the boat to be thrown forward.

2-13

NOTE:

The engine cannot be started with the lockplate removed.

Loading...

Loading...