Yamaha KXE-100 Service manual

COUNTER

RESET

MODE

REC/

PAUSE

REC LEVEL DIRECTION

MIN MAX

DOLBY NR

NATURAL SOUND STEREO CASSETTE DECK KX-E100

STANDBY/ON

P.O.Box 1, Hamamatsu, Japan

STEREO CASSETTE DECK

KX-E100

SERVICE MANUAL

IMPORTANT NOTICE

This manual has been provided for the use of authorized YAMAHA Retailers and their service personnel.

It has been assumed that basic service procedures inherent to the industry, and more specifically YAMAHA Products, are already known and understood by the users,

and have therefore not been restated.

WARNING: Failure to follow appropriate service and safety procedures when servicing this product may result in personal injury, destruction of expensive

IMPORTANT: The presentation or sale of this manual to any individual or firm does not constitute authorization, certification or recognition of any applicable

The data provided is believed to be accurate and applicable to the unit(s) indicated on the cover. The research, engineering, and service departments of YAMAHA are

continually striving to improve YAMAHA products. Modifications are, therefore, inevitable and specifications are subject to change without notice or obligation to

retrofit. Should any discrepancy appear to exist, please contact the distributor's Service Division.

WARNING: Static discharges can destroy expensive components. Discharge any static electricity your body may have accumulated by grounding yourself to the

IMPORTANT: Turn the unit OFF during disassembly and part replacement. Recheck all work before you apply power to the unit.

components, and failure of the product to perform as specified. For these reasons, we advise all YAMAHA product owners that any service required

should be performed by an authorized YAMAHA Retailer or the appointed service representative.

technical capabilities, or establish a principle-agent relationship of any form.

ground buss in the unit (heavy gauge black wires connect to this buss).

■ CONTENTS

TO SERVICE PERSONNEL .......................................... 1

SPECIFICATIONS.......................................................... 1

DIMENSIONS ................................................................. 2

INTERNAL VIEW ........................................................... 2

REAR PANELS .............................................................. 3

DISASSEMBLY PROCEDURES ............................... 4~5

ADJUSTMENT ........................................................... 6~9

DISPLAY DATA ........................................................... 10

IC DATA ................................................................. 11~12

BLOCK DIAGRAM ....................................................... 13

PRINTED CIRCUIT BOARD .................................. 14~21

SCHEMATIC DIAGRAM .............................................. 22

PARTS LIST ........................................................... 23~31

KX-E100

100687

KX-E100

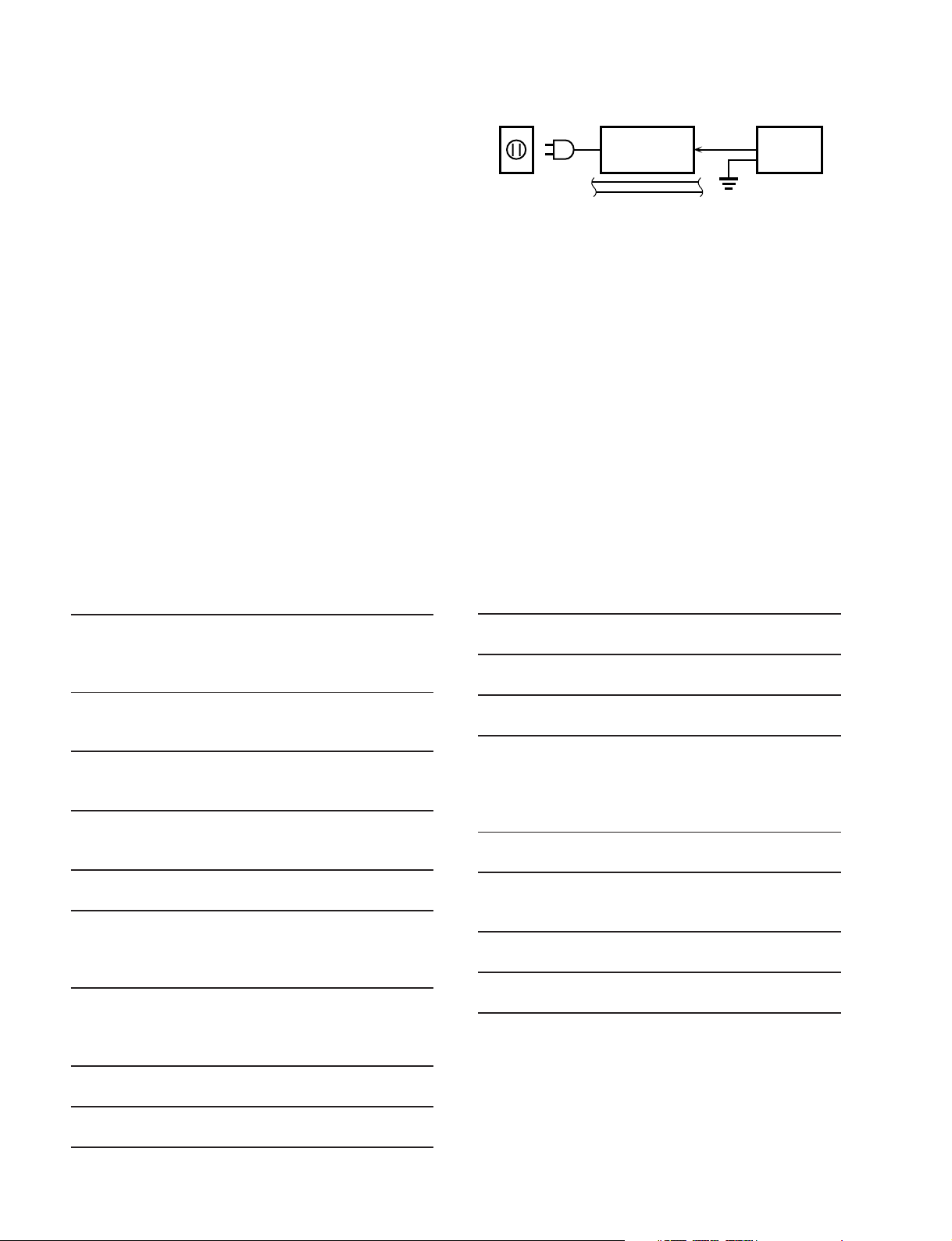

■ TO SERVICE PERSONNEL

Critical Components Information.

Components having special characteristics are marked

and must be replaced with parts having specifications

equal to those originally installed.

WALL

OUTLET

EQUIPMENT

UNDER TEST

INSULATING

TABLE

AC LEAKAGE

TESTER OR

EQUIVALENT

WARNING: CHEMICAL CONTENT NOTICE!

The solder used in the production of this product contains LEAD. In addition, other electrical/electronic and /or plastic

(where applicable) components may also contain traces of chemicals found by the California Health and Welfare Agency

(and possibly other entities) to cause cancer and/or birth defects or other reproductive harm.

DO NOT PLACE SOLDER, ELECTRICAL/ELECTRONIC OR PLASTIC COMPONENTS IN YOUR MOUTH FOR ANY REASON WHATSOEVER!

Avoid prolonged, unprotected contact between solder and your skin! When soldering, do not inhale solder fumes or expose

eyes to solder/flux vapor!

If you come in contact with solder or components located inside the enclosure of this product, wash your hands before

handling food.

■ SPECIFICATIONS

Type

Auto Reverse

4-Track 2-Channel Playback/Recording

Stereo Cassette Deck

Heads

REC/PB Hard permalloy

Erase Double Gap Ferrite

Motors

Main DC servo motor

Tray Loading DC motor

Wow & Flutter

W.PEAK (EIAJ) ±0.19 %

W.RMS 0.09 %

Fast Winding Time

about 100 seconds (C-60 tape)

Frequency Response

Type I (Normal) 30 – 15,000 Hz ±3 dB

Type II (CrO2) 30 – 16,000 Hz ±3 dB

Type IV (Metal) 30 – 18,000 Hz ±3 dB

S/N Ratio (S : 3rd harmonic distortion 3 %, N : Weighted)

NR off 58 dB

Dolby B NR on 66 dB

Dolby C NR on 74 dB

Harmonic Distortion

1.0 %

Channel Separation

More than 40 dB

Crosstalk (125 Hz)

More than 55 dB

Input Sensitivity/Impedance

Line 100 mV/30 kΩ

Output Level

Line 570 mV/3.0 kΩ

Power Requirements

U, C models AC120 V, 60 Hz

R model AC110-120/220-240 V, 50/60 Hz

A model AC240 V, 50 Hz

B, G models AC230 V, 50 Hz

Power Consumption

12 W (Standby 3W)

Dimensions (W x H x D)

217 x 88 x 293 mm

(8-9/16" x 3-7/16" x 11-9/16")

Weight

3.0 kg (6 lbs 10 oz.)

Accessories

Input & Output cords (RCA type) x 2, System cord x 1

* Specifications are subject to change without notice.

U ........ U.S.A. model

C ........ Canadian model

R ........ General model

A ........ Australian model

B ........ British model

G ........ European model

1

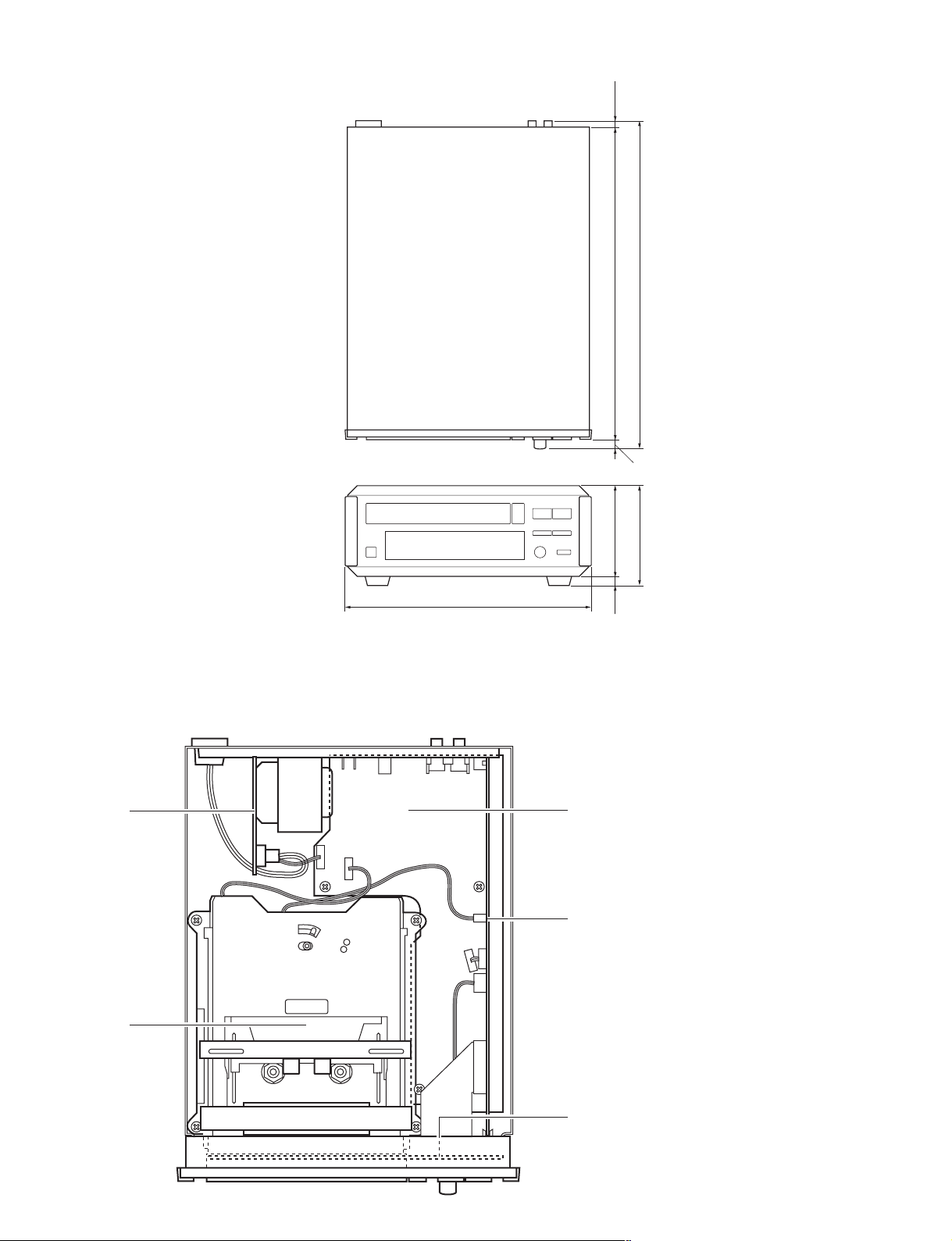

■ DIMENSIONS

293(11-9/16")

275(10-13/16") 7(1/4")

11(7/16")

KX-E100

■ INTERNAL VIEW

1

Unit : mm (inch)

217(8-9/16")

3

4

80(3-1/8")8(5/16")

88(3-7/16")

2

5

1 MAIN P.C.B. (4)

2 Cassette Mechanism Unit

3 MAIN P.C.B. (1)

4 MAIN P.C.B. (2)

5 MAIN P.C.B. (3)

2

KX-E100

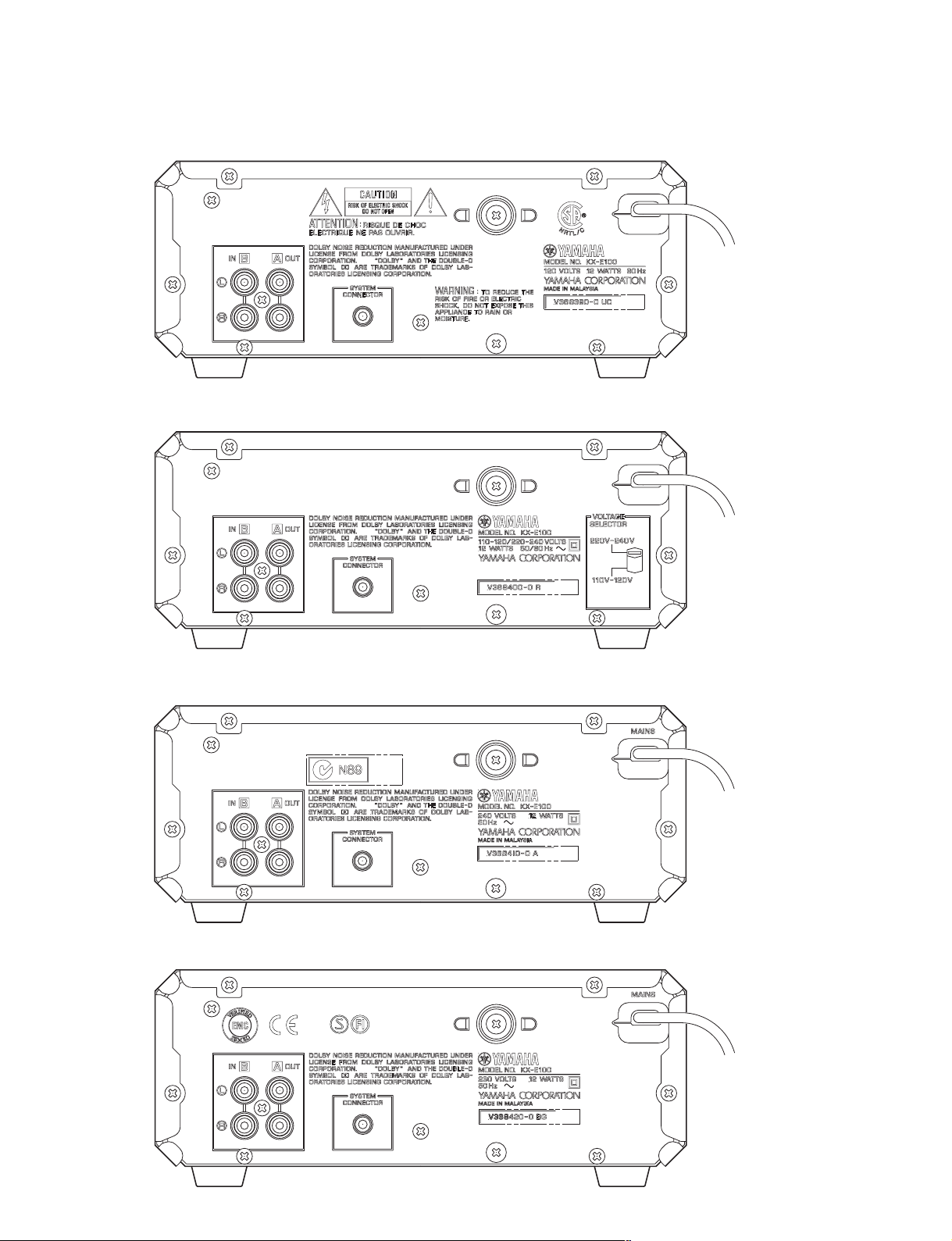

■ REAR PANELS

▼ U, C models

▼ R model

▼ A model

▼ B, G models

3

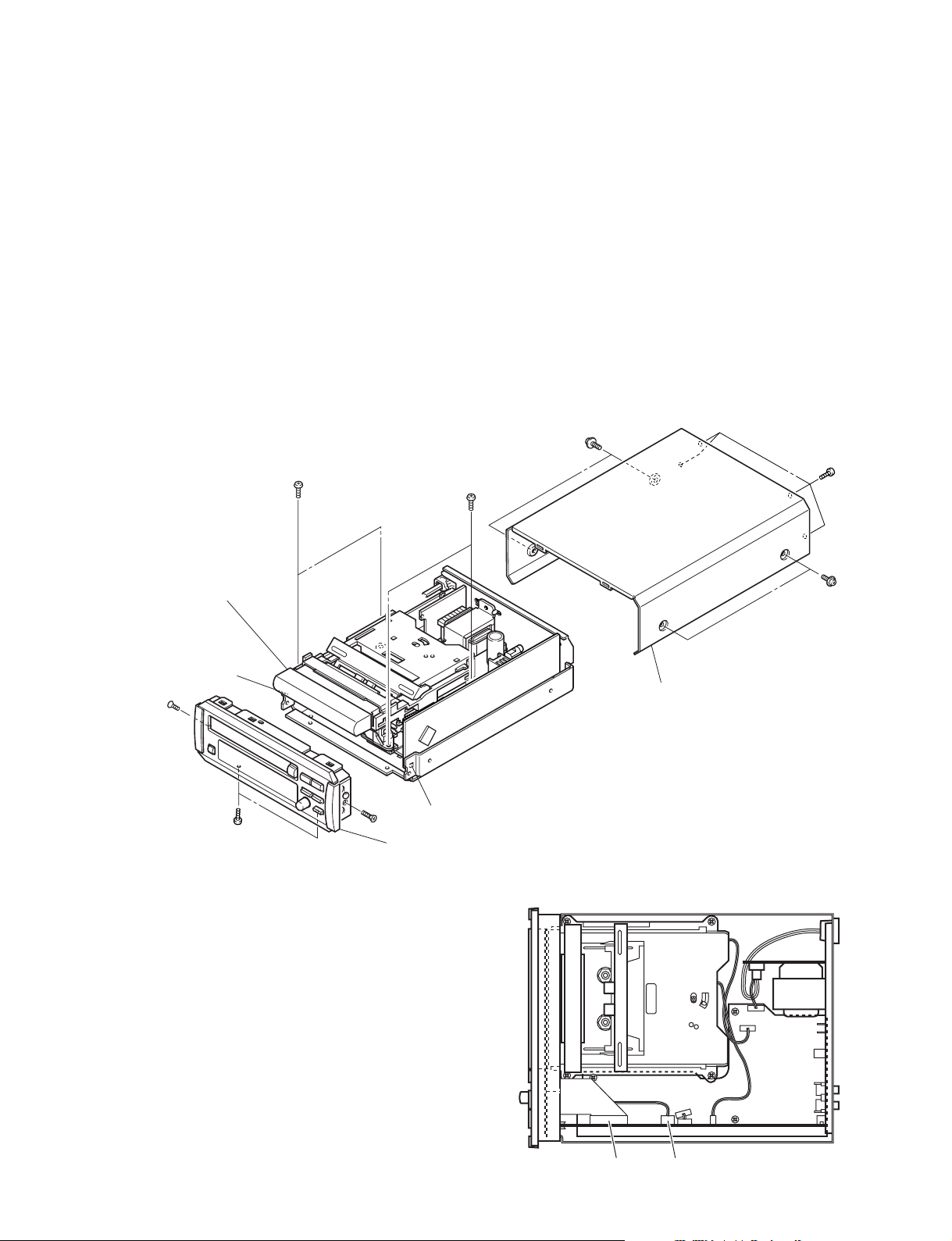

■ DISASSEMBLY PROCEDURES

Remove parts in disassembly order as numbered.

1. Removal of Top Cover

a. Remove 4 screws (1) and 4 screws (2) in Fig. 1.

b. Lift the Top Cover at the rear and move it rear-ward

slantingly.

2. Removal of Front Panel

a. Disconnect 2 connectors (CB201 and CB209) in Fig. 2.

b. Remove 2 screws (3) and 2 screws (4) in Fig. 1.

c. Detach the 2 hooks in Fig. 1 and then pull out the Front

Panel forward.

3. Removal of Cassette Mechanism Unit

a. Remove 4 screws (5) in Fig. 1.

b. Disconnect 3 connectors (CB1, CB2 and CB3) in Fig. 3.

KX-E100

1

Cassette Mechanism

Unit

Hook

3

4

5

3

Front Panel

2

5

1

Top Cover

Fig. 1

Hook

CB201CB209

Fig. 2

4

KX-E100

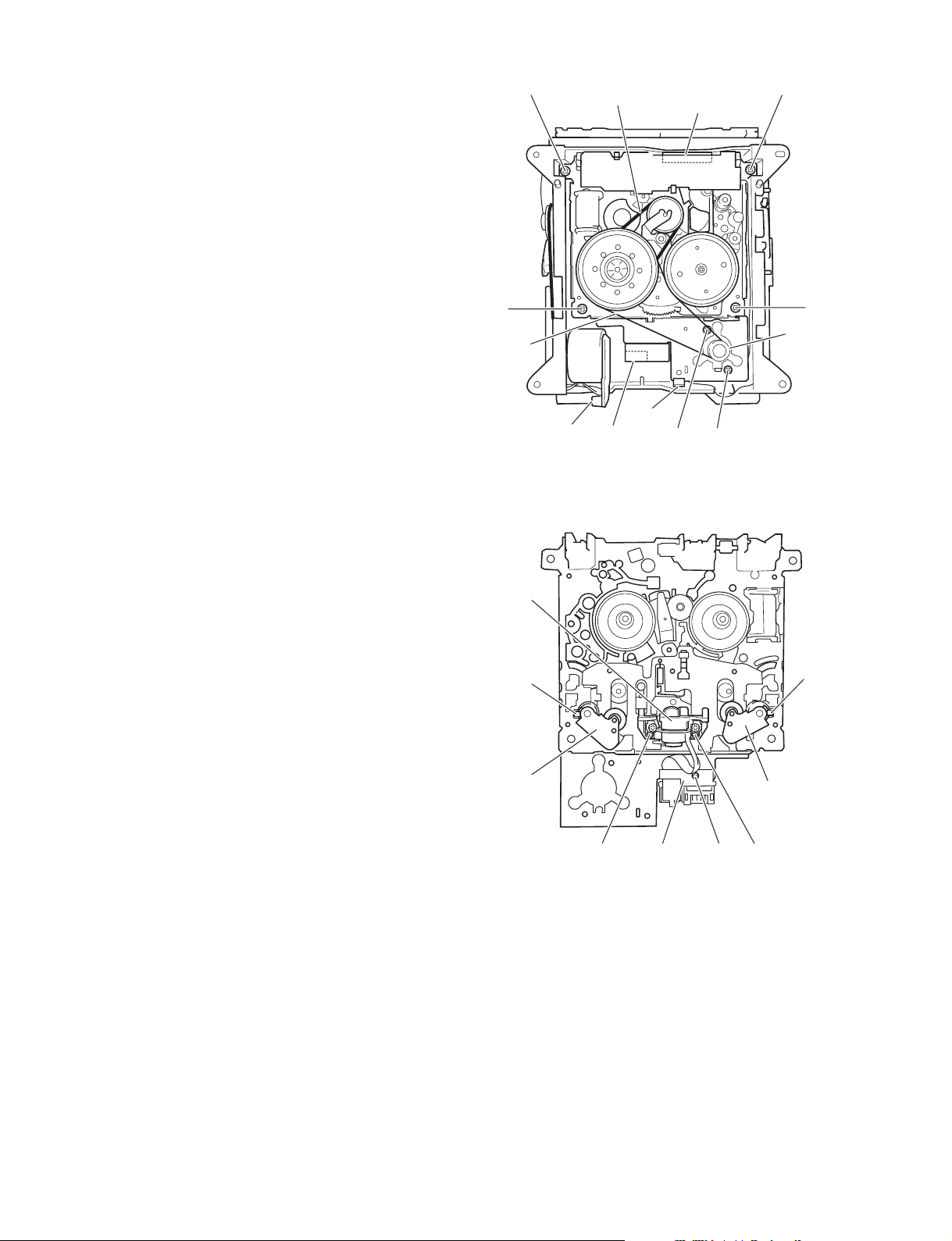

4. Removal of Cassette Mechanism

a. Remove 4 screws (6) in Fig. 3.

b. Detach the hook in Fig. 3 and then pull out the Cassette

Mechanism.

5. Removal of Main Motor

Remove 2 screws (7) in Fig. 3.

6. Removal of Pinch Roller

Detach the hook and then remove the Pinch Roller in

Fig. 4.

7. Removal of Head Ass’y

a. Remove 1 screw (8) and then remove the Relay

P.C.B. in Fig. 4.

b. Remove 2 screws (9) and then remove the Head Ass’y

in Fig. 4.

* Perform the adjustment of azimuth after installing the

Head Ass’y.

66

6

Main

Belt

F/R Belt

CB2 CB1

CB3

6

Main

Motor

Hook

77

Fig. 3

Head Ass'y

Hook

Hook

Pinch Roller (L)

Relay P.C.B.

Pinch Roller (R)

899

Fig. 4

5

■ ADJUSTMENTS

KX-E100

1. Before adjustment

● Since head magnetization, dust accumulations, etc. are

likely to introduce error in the various characteristics, it

is very important that the heads are properly

demagnetized and cleaned.

● Make adjustments of mechanical system, playback

system and recording system in that order.

● Except for azimuth adjustment, adjust in the forward

direction.

2. Instruments required

● Audio frequency oscillator

● ACVM or dual channel (ACVM)

● DCVM

● Wow/flutter meter

● Oscilloscope

● Frequency counter

● Torque meter

TW-2111A (TX911580) ... Take up/back tension (FWD)

TW-2121A (TX911570) ... Take up/back tension (RVS)

CT-160L (TX911120) ...................................... FF/REW

3. Test tape required

● MTT-111N (TX911650) .......................... Normal speed

● MTT-114N (TX911680) .................................... Azimuth

● MTT-212N (TX911660) ..........................Playback level

● MTT-256 (TX911300) ................... Playback frequency

response (Normal)

● MTT-356 (TX911310) ................... Playback frequency

response (CrO

● Reference tape

Type I/Normal (LH) ............... TDK AC225 (VU167200)

Type II/High (CrO2) ............... TDK AC514 (VU167300)

Type IV/METAL ..................... TDK AC713 (VU167400)

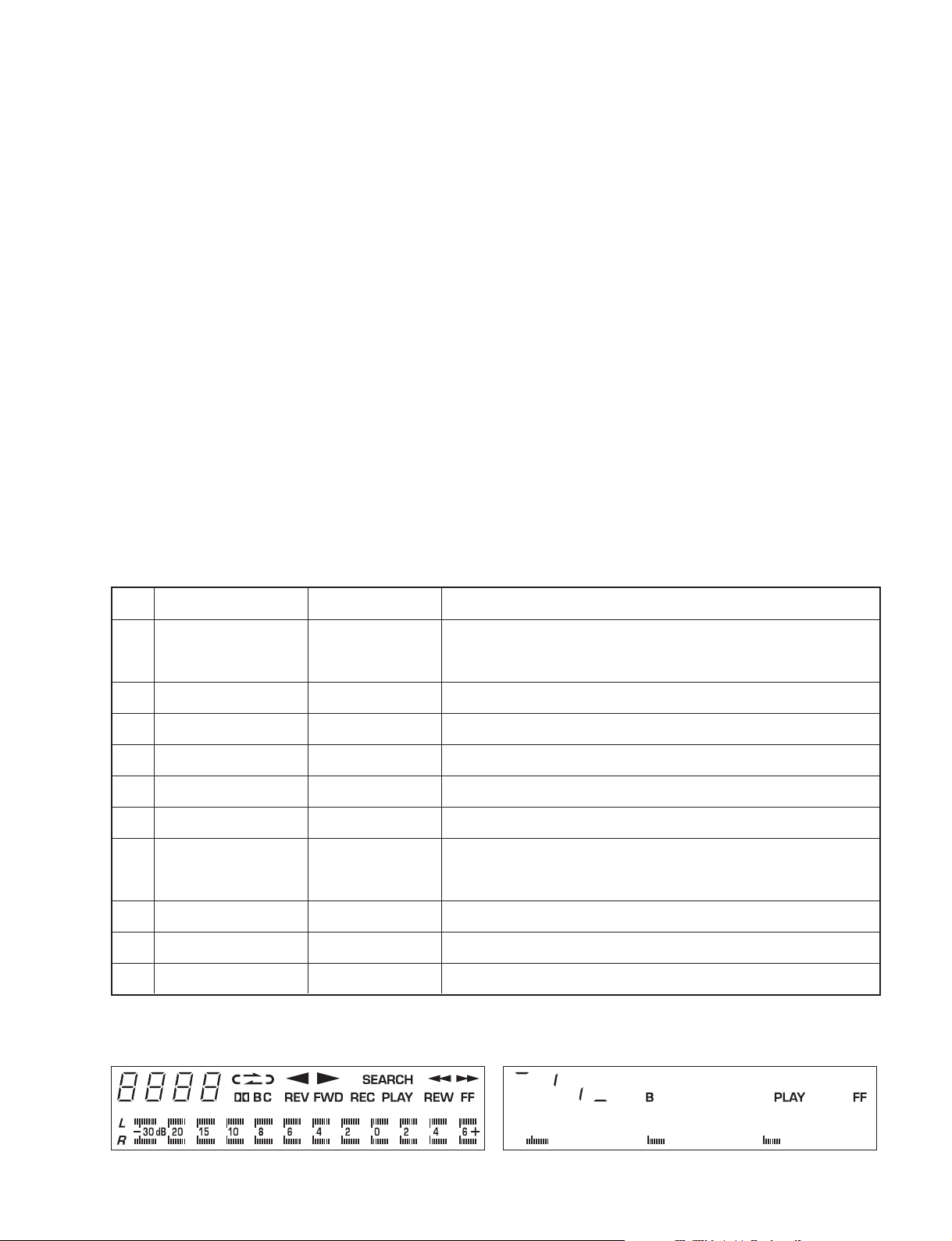

TEST MODE (Operation and Display Check)

Enter the TEST MODE by pressing the STANDBY/ON key while pressing the STOP key and FF key when the power is OFF.

2)

NO. KEY FUNCTION ACTION

1 PLAY PLAY Playback mode without the cassette tape. In this mode, cleaning

the REC/PB head.

2 STOP STOP Stop the playback mode.

3 DIRECTION DIRECTION Change the playback direction.

4 FF DIMMER Dimmed display when pressing the FF key. (6 step)

5 REW PHOTO MODE Photograph mode.

6 DOLBY NR All display segments lit.

7 REC/PAUSE Version Display the program version and date when pressing the REC/

PAUSE key.

8 MODE Display grid and segments short/open check. (Fig. A is OK)

9 COUNTER RESET EXIT To escape the TEST MODE.

10 POWER EXIT To escape the TEST MODE and power off.

DISPLAY (Light the all segment) DISPLAY CHECK (Light a segment of each grid)

Fig. A

6

KX-E100

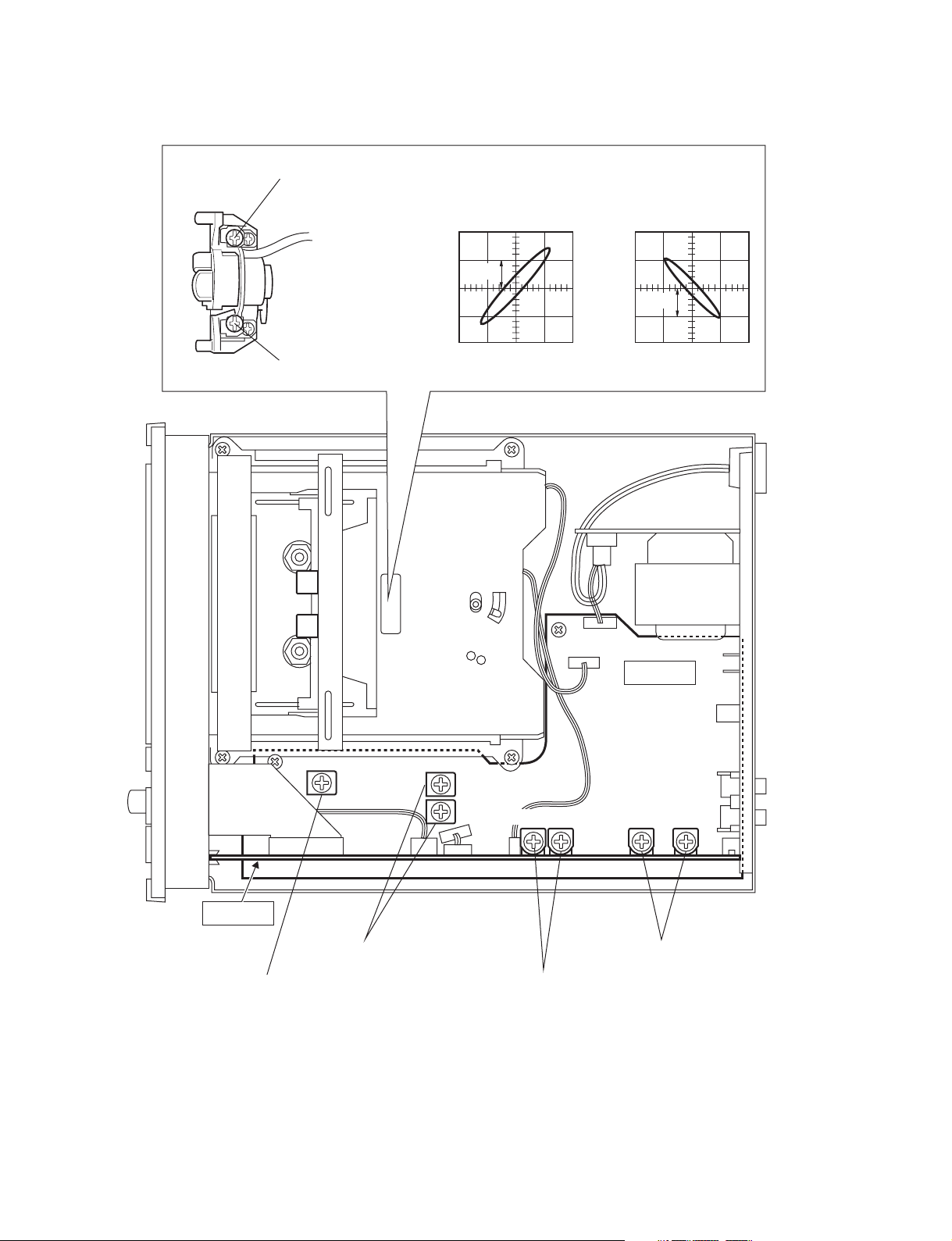

Azimuth adjustment

screw. (REVERSE)

Azimuth adjustment

screw. (FORWARD)

Rec out L : ch 1

Rec out R : ch 2

DC input, X-Y (Resurge) mode

OK

0.2V

NG

0.2V

Fig. B

VR101 VR103

L

R

VR104

VR201VR202

R

LL

MAIN (2)

RECORDING LEVEL & BIAS ADJ. RECORDING LEVEL & BIAS ADJ.

TAPE SPEED ADJ. PLAYBACK LEVEL ADJ.

MAIN (1)

VR203VR204

R

7

MECHANICAL ADJUSTMENT

Step

1

Check each

torque

2

Check FF, REW

take up time

3

Azimth

4

Tape Speed

5

Wow/ Flutter

Item to be

Adjusted

Tape

CT-160L (FF, REW)

TW-2111A (FWD)

TW-2121A (RVS)

AC-514 (C-60)

MTT-114N

10kHz, –10dB

MTT-111N

3kHz, –10dB

MTT-111N

3kHz, –10dB

Instrument

required

Torque meter

ACVM

oscilloscope

Frequency

counter

Wow/Flutter

meter

Mode

FF REW

PLAY

FF REW

PLAY

PLAY

PLAY

Adjustment

part

Azimuth

adjustment

screw.

(Fig. B)

VR101

ELECTRICAL ADJUSTMENT

● Use 560 mV (250 nwb/m) for 0 dB as the standard level of the unit.

0 dB = 250 nwb/m (315 Hz) = –7 dBV (Rec out level)

Rating

FF, REW torque : within 70 ~ 150g/cm.

Take up torque : 30 ~ 70g/cm.

Back tension : 1.5 ~ 6g/cm.

80 to 120 seconds.

Playback output of L and R is

maximum and phase difference should

be minimum both directions. (Fig. B)

2980 Hz ±15 Hz

Less than 0.19% (WRMS)

KX-E100

Remarks

After the adjustment

make sure to apply screw

lock paint.

Perform adjustment at

the center of the test

tape, if possible.

Confirm at center of the

test tape, if possible.

<Playback section>

Item to be

Step

1

2

Adjusted

Playback

level

(315Hz)

Confirmation

of playback

frequency

response

MTT-212N

315Hz,

250nwb/m

Test tape for frequency check.

3180µs + 120µs (LH) (MTT-256)

3180µs + 70µs (CrO

Tape

2) (MTT-356)

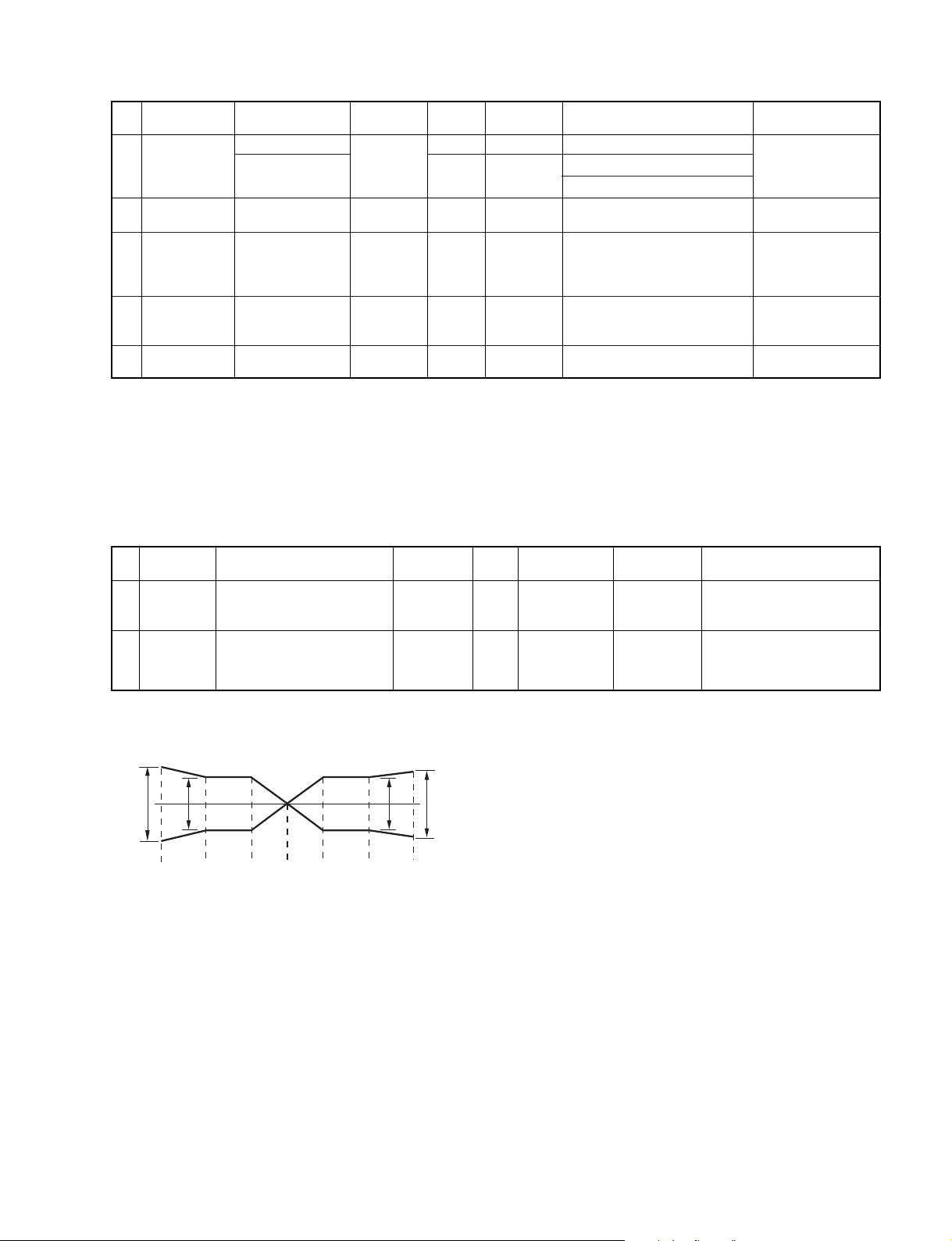

● PLAYBACK FREQUENCY RESPONSE

± 3dB

± 4dB

1k

Fig. C

± 3dB

3k 10kHz31525050 12.5kHz

Instrument

required

ACVM

ACVM

oscilloscope

± 3.5dB

Mode

PLAY

PLAY

Points of

measurement

LINE OUT

LINE OUT

Adjustment

parts

VR201 (L ch)

VR202 (R ch)

Rating

– 5 dBV ± 0.3 dBV

Check that the 10kHz playback level

is within 0 ± 3 dB of the 1kHz

playback level. (Fig. C)

8

Loading...

Loading...