Page 1

OWNER’S MANUAL

Read this manual carefully before operating this machine.

Generator

EF2000iS

LIT-19626-01-53

7DK-28199-10

Page 2

Read this manual carefully befor operating this machine.This manual should

stay with this machine if it is sold.

Page 3

AE00002

INTRODUCTION

Congratulations on your purchase of your new Yamaha.

This manual will provide you with a good basic understanding of the operation and maintenance of this machine.

If you have any questions regarding the operation or maintenance of your machine,

please consult a Yamaha dealer.

AE00022

EF2000iS

OWNER’S MANUAL

© 2009 by Yamaha Motor Corporation, U.S.A.

1st Edition, January 2009

All rights reserved.

Any reprinting or unauthorized use

without the written permission of

Yamaha Motor Corporation, U.S.A.

is expressly prohibited.

Printed in Japan

P/N LIT-19626-01-53

Page 4

NOTICE

WARNING

WARNING

IMPOTANT MANUAL INFORMATION

Particularly important information is distinguished in this manual by the following

notations.

This is the safety alert symbol. It is

used to alert you to potential personal

injury hazards. Obey all safety messages that follow this symbol to avoid

possible injury or death.

A WARNING indicates a hazardous situation which, if not avoided, could result

in death or serious injury.

A NOTICE indicates special precautions that must be taken to avoid damage to the machine or other property.

TIP

A TIP provides key information to make

procedures easier or clearer.

AE00032

PLEASE READ AND UNDERSTAND

THIS MANUAL COMPLETELY BEFORE

OPERATING THE MACHINE.

TIP

9 Yamaha continually seeks advance-

9 This manual should be considered a

ments in product design and quality.

Therefore, while this manual contains

the most current product information

available at the time of printing, there

may be minor discrepancies between

your engine and this manual. If there is

any question concerning this manual,

please consult a Yamaha dealer.

permanent part of this engine and

should remain with this engine when

resold.

* Product and specifications are subject to

change without notice.

Page 5

AE00041

CONTENTS

SAFETY INFORMATION.........................1

EXHAUST FUMES ARE

POISONOUS........................................1

FUEL IS HIGHLY FLAMMABLE AND

POISONOUS........................................1

ENGINE AND MUFFLER MAY BE

HOT ......................................................1

ELECTRIC SHOCK PREVENTION .....2

CONNECTION NOTES........................3

CONNECTION .....................................3

EXTENSION CORD NOTES................3

LOCATION OF IMPORTANT

LABELS...................................................4

DESCRIPTION ........................................6

Control Panel........................................6

CONTROL FUNCTION............................7

Engine switch .......................................7

Oil warning light (Red)..........................7

DC protector .........................................7

Economy control switch........................8

AC pilot light (Green)............................8

Overload indicator light (Red) ..............9

Fuel tank cap........................................9

Fuel tank cap air vent knob................10

Fuel cock knob ...................................10

Ground (Earth) terminal .....................10

Twin Tech ............................................10

PREPARATION .....................................11

Fuel.....................................................11

Engine oil............................................12

PRE-OPERATION CHECK ...................13

Pre-operation check ...........................13

OPERATION ..........................................14

Starting the engine .............................14

Stopping the engine ...........................16

Connection .........................................17

Battery charging .................................18

Application range................................20

PERIODIC MAINTENANCE..................21

Maintenance chart..............................21

Spark plug inspection .........................23

Carburetor adjustment........................24

Engine oil replacement.......................24

Air filter ...............................................26

Muffler screen and spark arrester ......27

Fuel tank filter.....................................29

STORAGE .............................................30

Drain the fuel ......................................30

Engine ................................................32

TROUBLESHOOTING...........................33

Engine won’t start...............................33

Generator won’t produce power.........34

SPECIFICATIONS .................................36

Dimensions.........................................36

Engine ................................................36

Generator ...........................................36

CONSUMER INFORMATION ................37

Identification number records .............37

Machine identification.........................37

LIMITED WARRANTY (EF- AND

EDL-SERIES) ........................................38

EXHAUST EMISSION CONTROL

SYSTEM AND COMPONENTS .........40

WIRING DIAGRAM ...............................41

Page 6

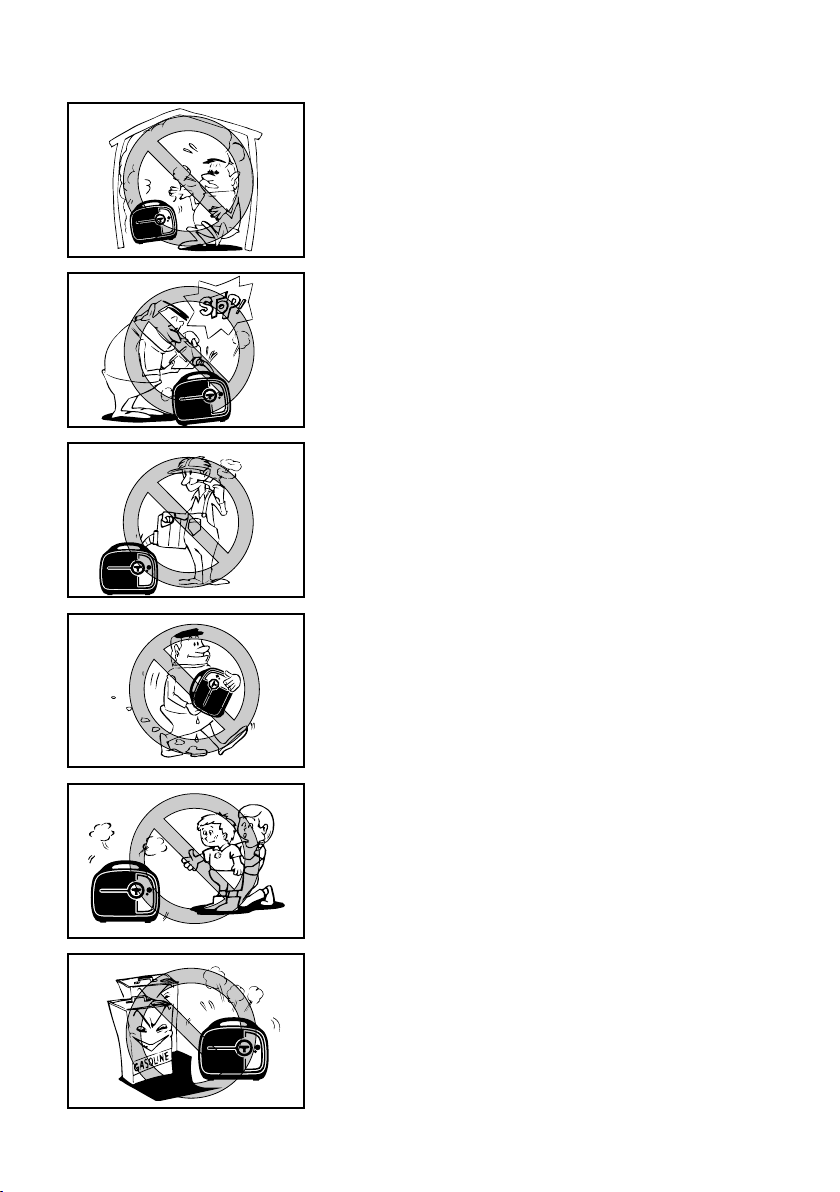

7DK-001

7DK-002

7DK-003

AE00071

SAFETY INFORMATION

AE00072

EXHAUST FUMES ARE POISONOUS

9 Never operate the engine in a closed area or it may

cause unconsciousness and death within a short

time. Operate the engine in a well ventilated area.

AE00075

FUEL IS HIGHLY FLAMMABLE AND

POISONOUS

9 Always turn off the engine when refuelling.

9 Never refuel while smoking or in the vicinity of an

open flame.

9 Take care not to spill any fuel on the engine or muf-

fler when refueling.

9 If you swallow any fuel, inhale fuel vapor, or allow

any to get in your eye(s), see your doctor immediately. If any fuel spills on your skin or clothing,

immediately wash with soap and water and change

your clothes.

9 When operating or transporting the machine, be

sure it is kept upright. If it tilts, fuel may leak from

the carburetor or fuel tank.

7DK-004

AE00843

ENGINE AND MUFFLER MAY BE HOT

9 Place the machine in a place where pedestrians or

children are not likely to touch the machine.

7DK-005

9 Avoid placing any flammable materials near the

exhaust outlet during operation.

7DK-006

– 1 –

Page 7

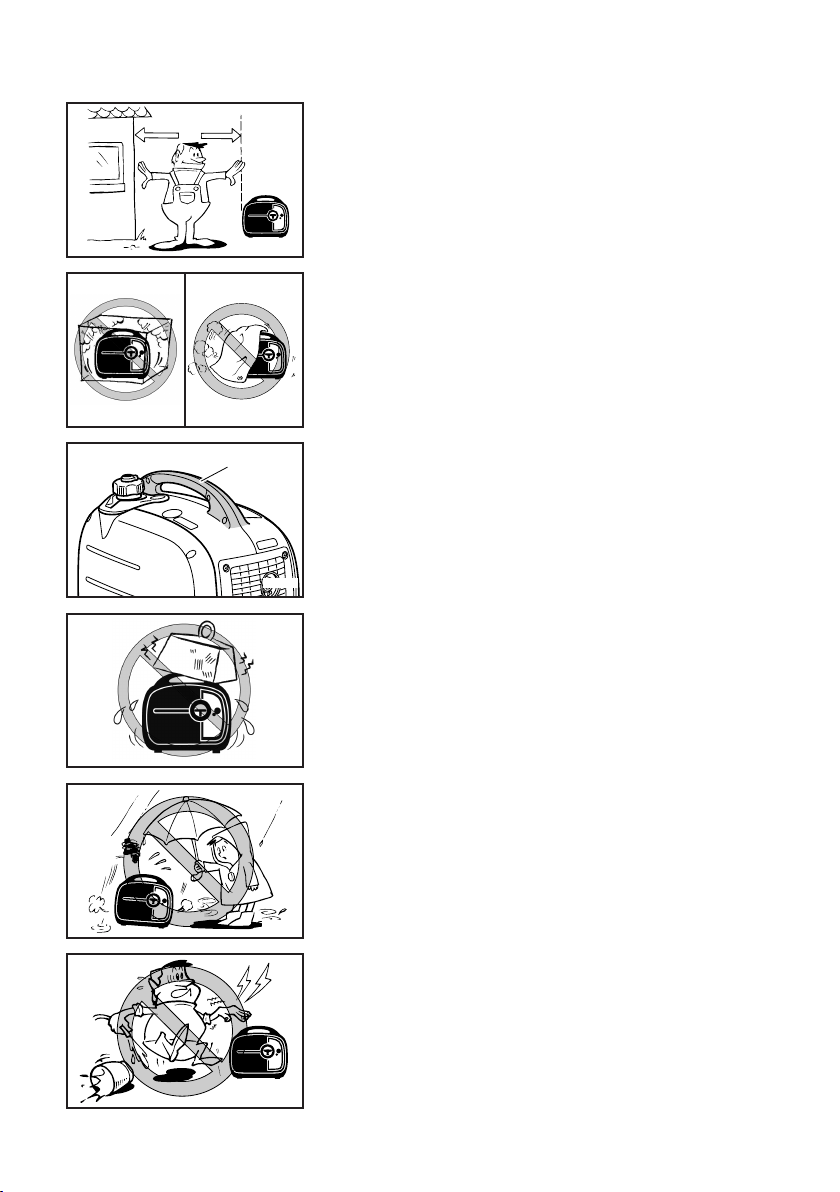

7DK-007

a

7DK-008a

1

7DK-036

9 Keep the machine at least 1 m (3 ft) from buildings

or other equipment, or the engine may overheat.

a 1 m (3 ft)

9 Do not operate the engine with a dust cover or

other objects covering it.

9 When covering the generator, be sure to do so only

after the engine and muffler have completely

cooled down.

9 Be sure to carry the generator only by its carrying

handles 1.

9 Do not place any obstacles on the generator.

AE00083

ELECTRIC SHOCK PREVENTION

9 Never operate the engine in rain or snow.

7DK-009

9 Never touch the machine with wet hands or electri-

cal shock will occur.

7DK-010

– 2 –

Page 8

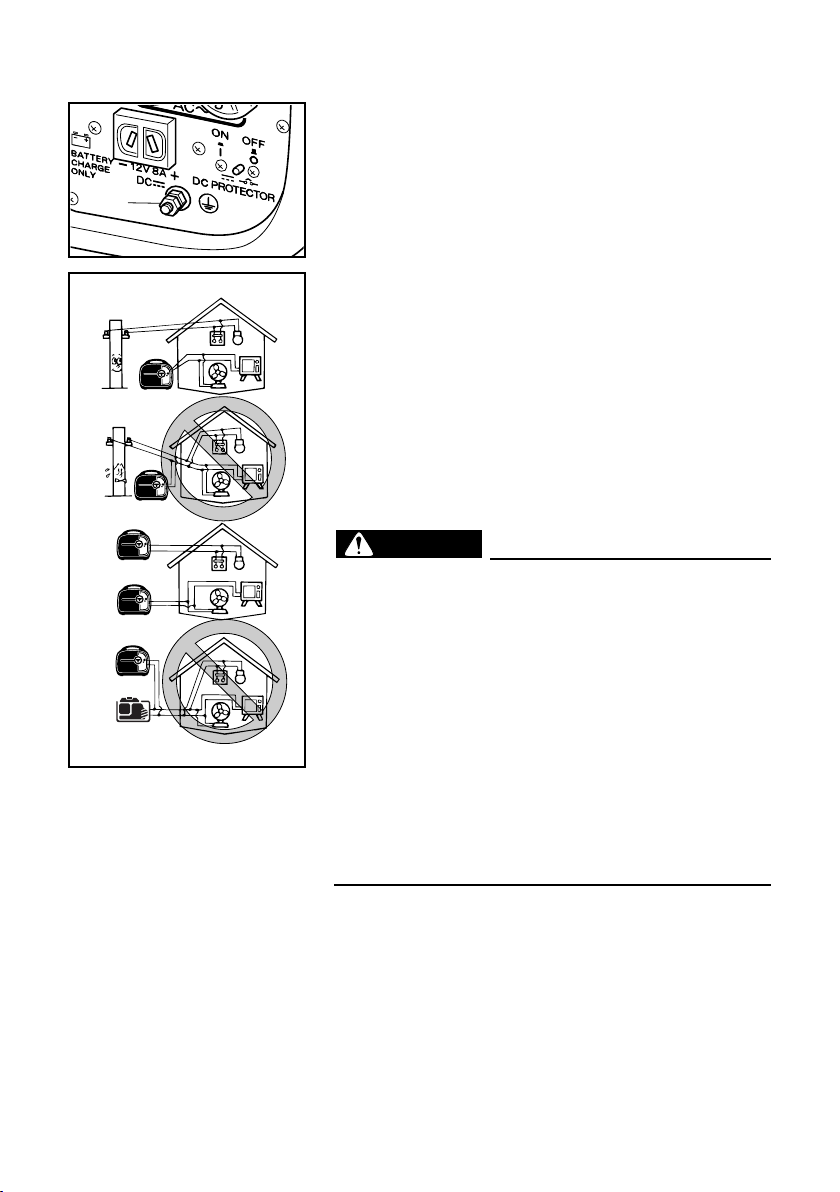

7DK-012

1

2

1

2

WARNING

9 Connect the ground lead of the machine to the

1

7DK-011

ground (Earth) terminal 1 and connect the end to

the ground electrode buried in the ground.

AE00088

CONNECTION NOTES

9 Avoid connecting the generator to commercial

power outlet.

9 Avoid connecting the generator in parallel with any

other generator.

1 Correct

2 Incorrect

AE00091

CONNECTION

Before the generator can be connected to a building’s electrical system, a licensed electrician must

install an isolation (transfer) switch in the building’s main fuse box. The switch is the connection

point for generator power and allows selection of

generator or main line power to the building. This

will prevent the generator from charging the main

power line (backfeeding) when the main power supply has failed or has been turned off for line repair.

Backfeeding can electrocute or injure line maintenance personnel. Also, generator and building

electrical system damage can occur when normal

operating power returns if unit is used without an

isolation switch.

AE00086

EXTENSION CORD NOTES

Extension cords should be protected by a tough flexible

rubber sheath (IEC 245) or the equivalent to withstand

mechanical stresses.

– 3 –

Page 9

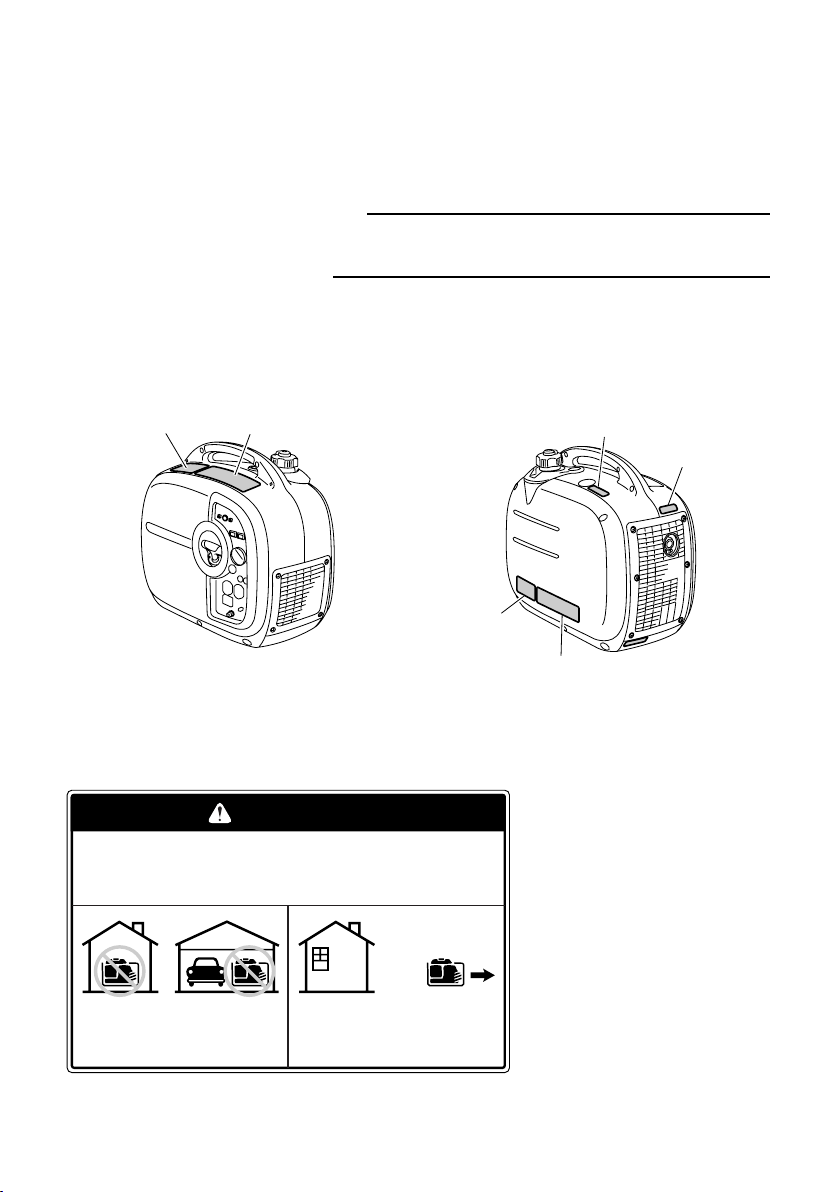

AE00062

DANGER

Using a generator indoors CAN KILL YOU IN MINUTES.

Generator exhaust contains carbon monoxide.

This is a poison you cannot see or smell.

NEVER use inside a home

or garage, EVEN IF doors

and windows are open.

Only use OUTSIDE and

far away from windows,

door, and vents.

1

2

7DK-013

3

4

5

6

7DK-014

LOCATION OF IMPORTANT LABELS

Please read the following labels carefully before operating this machine.

TIP

Maintain or replace safety and instruction labels, as

necessary.

1

– 4 –

Page 10

2

WARNING

q

8

Read the owner’s manual and all labels before operating.

8

Only operate in well-ventilated areas. Exhaust gas contains poisonous carbon monoxide.

8

Check for spilled fuel or fuel leaks.

8

Stop engine before refueling.

8

Do not operate near flammable materials.

8

Electrocution can occur if generator is used in rain, snow, or near water. Keep this unit dry at all times.

8

Electrocution or property damage can occur: Do not connect this generator to any building’s electrical

system unless an isolation switch has been installed by a licensed electrician. Refer to the owner’s manual.

8

When operating the generator:

Never place a partition or other barrier around the generator.

Do not cover the generator with a box.

Do not place any objects on the generator.

7DK-24162-10

Important Emissions Information The air index of this engine is 3

(California only)

MOST CLEAN LEAST CLEAN

0246810

YAMAHA MOTOR POWERED PRODUCTS CO.,LTD.

This engine meets **** California exhaust and evaporative

emission regulations for small off-road engines.

This engine conforms to Phase 2 U.S.EPA regulations for

small nonroad engines.

EMISSIONS COMPLIANCE PERIOD : CATEGORY A(EPA)

EF: ********* DISPLACEMENT: *** cc

EVAP F: ******** EMISSION CONTROL SYSTEM: EM

This engine is certified to operate on unleaded gasoline.

ENGINE OIL: SAE10W-30 TYPE: SE

No other adjustments needed.

Note: The lower the air index, the less the pollution.

This engine is certified to be emissions compliant

for the following use:

Check owner's manual for further details.

MODERATE

(*** HOURS)

INTERMEDIATE

(*** HOURS)

EXTENDED

(*** HOURS)

X

HOT EXHAUST

7WL-28176-10

NOTICE

Use the specified spark plug only.

Specified plug:BPR6HS(NGK)

7DK-24164-10

OIL

EF2000IS

YAMAHA MOTOR POWERED PRODUCTS CO.,LTD.

MADE IN JAPAN

AC output 60Hz

Rated 1.6kVA

120V

Phase

Single

DC output

12V 8A

Fuel

Gasoline

3

5

6

4

– 5 –

Page 11

1

2

3

4

7DK-015

123 45

7DK-017

5

6

7

7DK-016

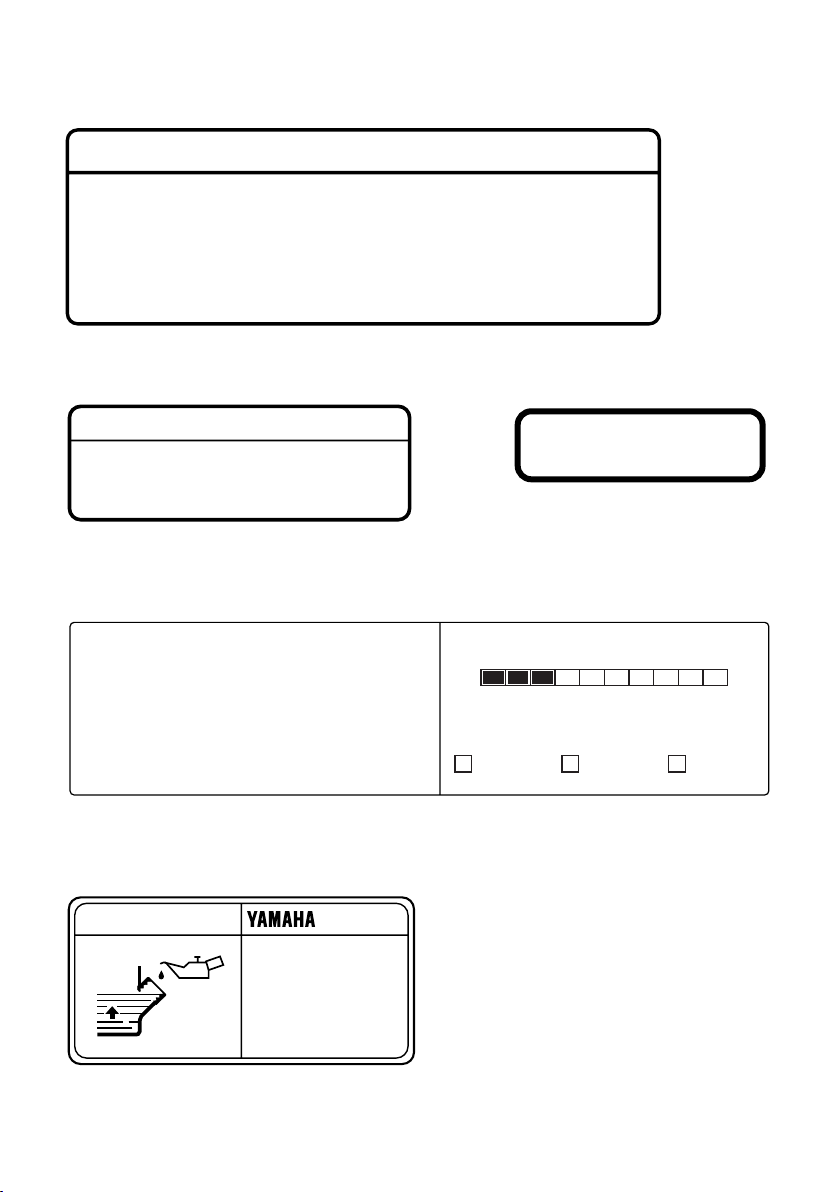

DESCRIPTION

1 Carrying handle

2 Fuel tank cap air vent knob

3 Fuel tank cap

4 Recoil starter

5 Fuel gauge

6 Muffler

7 Oil filler cap

w

0q

6

7

8

9

AE00103

Control panel

1 Oil warning light

2 AC pilot light

3 Overload indicator light

4 Economy control switch

(Black)

5 Engine switch (Red)

6 Fuel cock knob

7 Choke knob

8 Twin Tech (parallel running

terminal)

9 AC receptacle

0 DC protector (breaker)

q Ground (Earth) terminal

w DC receptacle

– 6 –

Page 12

1

2

7DK-018

AE00101

1

2

7DK-052

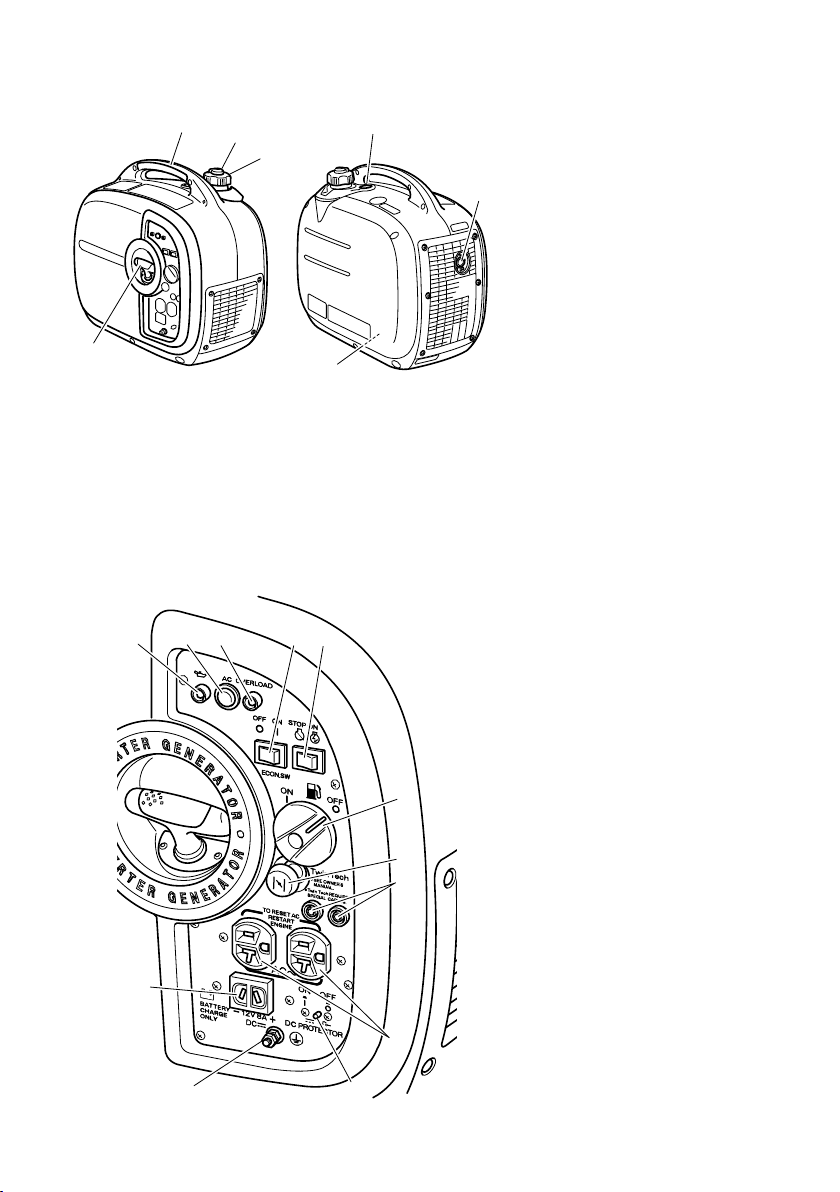

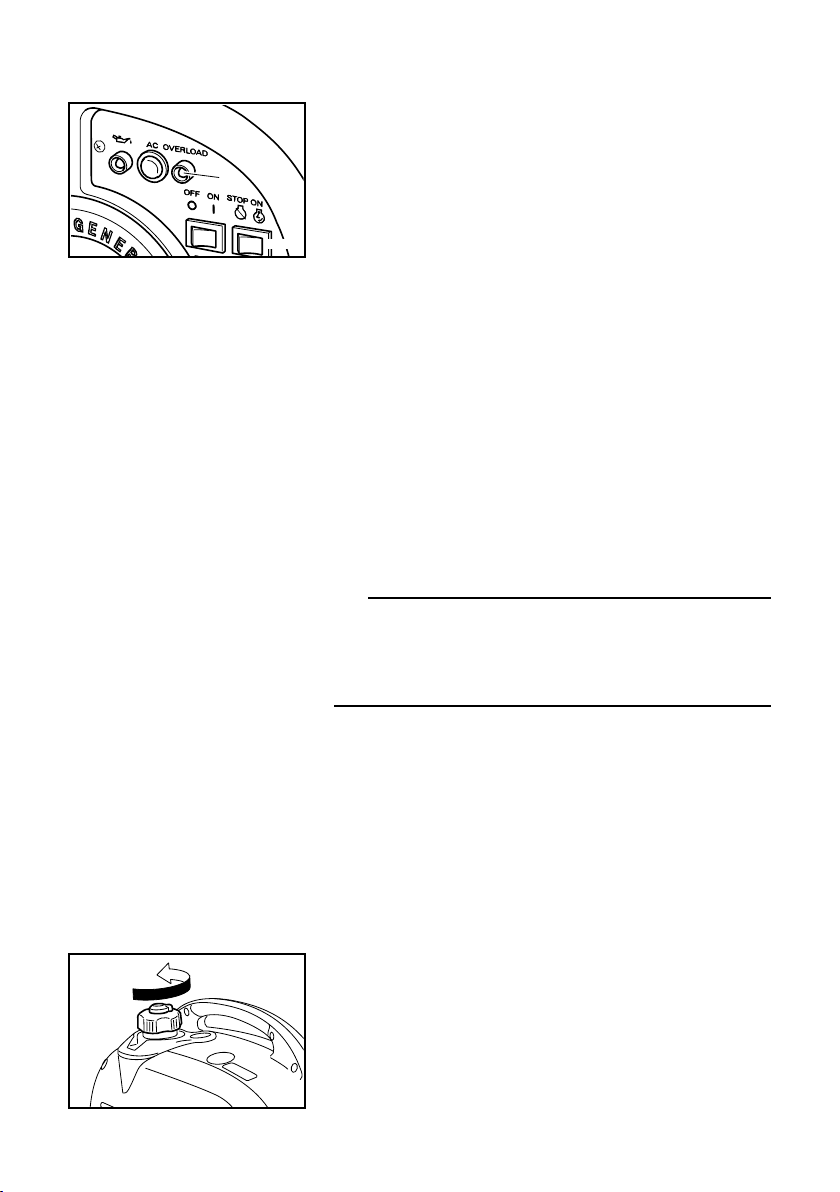

CONTROL FUNCTION

AE00121

Engine switch

The engine switch controls the ignition system.

1 7 “ON”

Ignition circuit is switched on.

The engine can be started.

2 5 “STOP”

Ignition circuit is switched off.

The engine will not run.

AE00111

Oil warning light (Red)

When the oil level falls below the lower level, the oil

warning light comes on and then the engine stops automatically. Unless you refill with oil, the engine will not

start again.

TIP

If the engine stalls or does not start, turn the engine

switch to “ON” and then pull the recoil starter. If the oil

warning light flickers for a few seconds, the engine oil is

insufficient. Add oil and restart.

700-115

DC protector

The DC protector turns off 2 automatically when electric device being connected to the generator is operating and current above the rated flows. To use this equipment again, turn on the DC protector by pressing its

button to “ON” 1.

1 “ON”

Direct current is output. (This is the default position.)

2 “OFF”

Direct current is not output.

– 7 –

Page 13

1

2

7DK-020

Reduce the load of the connected electric device

NOTICE

below the specified rated output of the generator if

the DC protector turns off. If the DC protector turns

off again, stop using the device immediately and

consult a Yamaha dealer.

AE00142

Economy control switch

1 I “ON”

When the economy control switch is turned to “ON” 1,

the economy control unit controls the engine speed

according to the connected load. The results are better

fuel consumption and less noise.

2 3 “OFF”

When the economy control switch is turned to “OFF” 2,

the engine runs at the rated r/min (4,500 r/min) regardless of whether is a load connected or not.

TIP

The economy control switch must be turned to “OFF” 2

when using electric devices that require a large starting

current, such as a compressor of a submergible pump.

AC pilot light (Green)

The AC pilot light 1 comes on when the engine starts

and produces power.

1

7DK-048

– 8 –

Page 14

AE01087

1

7DK-021

Overload indicator light (Red)

The overload indicator light 1 comes on when an overload of a connected electrical device is detected, the

inverter control unit overheats, or the AC output voltage

rises. Then, the AC protector will trip, stopping power

generation in order to protect the generator and any

connected electric devices. The AC pilot light (Green)

will go off and the overload indicator light (Red) will stay

on, but the engine will not stop running.

When the overload indicator light comes on and power

generation stops, proceed as follows:

1. Turn off any connected electric devices and stop

the engine.

2. Reduce the total wattage of connected electric

devices within the rated output.

3. Check for blockages in the cooling air inlet and

around the control unit. If any blockages are found,

remove.

4. After checking, restart the engine.

TIP

The overload indicator light may come on for a few seconds at first when using electric devices that require a

large starting current, such as a compressor or a submergible pump. However, this is not a malfunction.

Fuel tank cap

Remove the fuel tank cap by turning it counterclockwise.

7DK-022

– 9 –

Page 15

1

2

7DK-023

7DK-042a

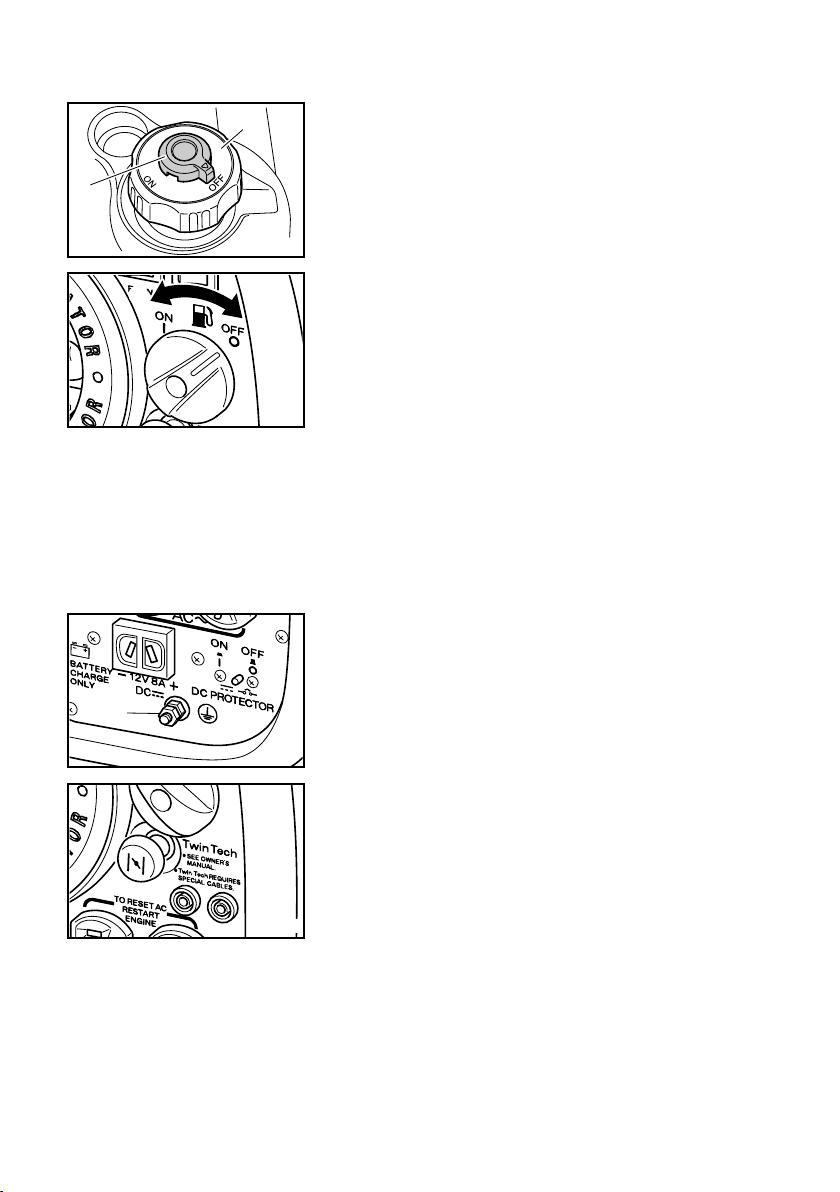

Fuel tank cap air vent knob

The fuel tank cap 2 is provided with an air vent knob

1 to stop fuel flow.

The air vent knob must be turned to “ON”. This will

allow fuel to flow to the carburetor and the engine to

run. When the engine is not in use, turn the air vent

knob to “OFF” to stop fuel flow.

2

1

Fuel cock knob

The fuel cock supplies fuel from the fuel tank to the carburetor.

The fuel cock has two positions.

1 “ON”

7DK-024

With the knob in this position, fuel flows to the carburetor. Normal using is done with the knob in this position.

2 “OFF”

With the knob in this position, fuel will not flow. Always

turn the knob to this position when the engine is not

running.

Ground (Earth) terminal

Ground (Earth) terminal 1 connects the earth line for

prevention of electric shock.

When the electric device is earthed, always the gener-

1

7DK-011

ator must be earthed.

Twin Tech

(Terminal for Connecting special cables for

parallel running)

This is the terminal for connecting special cables for

parallel running of two EF2000iS. The parallel running

requires two EF2000iS and the special cables. (The

rated output in parallel running is 3.0 kVA and the rated

current is 25.0 A.)

The handling, operation procedure and the notes on

usage are described in the PARALLEL RUNNING KIT

OWNER’S MANUAL included in the Parallel Running

Kit. Consult a Yamaha dealer for this Parallel Running

Kit.

– 10 –

Page 16

7DK-026

7DK-091

NOTICE

WARNING

707-095

PREPARATION

AE00856

Fuel

9 Fuel is highly flammable and poisonous. Check

“SAFETY INFORMATION” (See page 1) careful-

ly before filling.

9 Do not overfill the fuel tank, otherwise it may

overflow when the fuel warms up and expands.

9 After fill the fuel, make sure the fuel tank cap is

tightened securely.

9 Immediately wipe off spilled fuel with a clean,

dry, soft cloth, since fuel may deteriorate painted surfaces or plastic parts.

9 Use only unleaded gasoline. The use of leaded

gasoline will cause severe damage to internal

engine parts.

Remove the fuel tank cap and fill the fuel into the tank

2

up to the red level 2.

The fuel level in the fuel tank can be checked through

the fuel level gauge 1.

1

7DK-037

3

1 Fuel level gauge

2 Red line

3 Fuel level

Recommended fuel:

Unleaded gasoline

Fuel tank capacity:

Total:

7DK-028

4.2 L (1.11 US gal, 0.92 Imp gal)

4 “F” Full

5 “E” Empty

4

5

Your Yamaha engine has been designed to use regular

unleaded gasoline with a pump octane number ((R +

M)/2) of 86 or higher, or research octane number of 91

7DK-093

or higher.

– 11 –

Page 17

7DK-031

1

AE00222

NOTICE

1

2

7DK-030

Engine oil

The generator has been shipped without engine oil.

Do not start the engine till fill with the sufficient

engine oil.

1. Place the generator on a level surface.

2. Remove the screws 1, and then remove the cover

2.

3. Remove the oil filler cap 1.

4. Fill the specified amount of the recommended

engine oil, and then install and tighten the oil filler

cap.

0°C

å

YAMALUBE 4 (10W-40)

∂

SAE 10Wç SAE #20∫ SAE #30

32°F

25°C

80°F

7DK-033

1

700-119

1 Upper level

Recommended engine oil:

å

YAMALUBE 4 (10W-40),

SAE 10W-30 or 10W-40

∫

SAE #30

ç

SAE #20

∂

SAE 10W

Recommended engine oil grade:

API Service SE type or higher

Engine oil quantity:

0.4 L (0.42 US qt, 0.35 lmp qt)

5. Install the cover and tighten the screws.

– 12 –

Page 18

AE00845

WARNING

PRE-OPERATION CHECK

If any item in the Pre-operation check is not working properly, have it inspected and repaired before

operating the generator.

The condition of a generator is the owner's responsibility. Vital components can start to deteriorate quickly

and unexpectedly, even if the generator unused.

TIP

Pre-operation checks should be made each time the

generator is used.

Pre-operation check

Fuel (See page 11)

9 Check fuel level in fuel tank.

9 Refuel if necessary.

Fuel line

9 Check fuel hose for crack or damage.

9 Replace if necessary.

Engine oil (See page 12)

9 Check oil level in engine.

9 If necessary, add recommended oil to specified

level.

9 Check generator for oil leakage.

The point where abnormality was recognized by

use

9 Check operation.

9 If necessary, consult a Yamaha dealer.

– 13 –

Page 19

7DK-047

AE00846

NOTICE

WARNING

1

7DK-034

OPERATION

9 Never operate the engine in a closed area or it

may cause unconsciousness and death within

a short time. Operate the engine in a well ventilated area.

9 Before starting the engine, do not connect any

electric devices.

The generator has been shipped without engine oil.

Do not start the engine till fill with the sufficient

engine oil.

Starting the engine

1. Turn the economy control switch (Black) to “OFF”

1.

1 3 “OFF”

2. While holding the fuel tank cap so that it will not

move, turn the air vent knob to “ON” 1.

1

7DK-035

1

7DK-038

1 Air vent knob

3. Turn the fuel cock knob to “ON” 1.

1 “ON”

4. Turn the engine switch (Red) to “ON” 1.

1 7 “ON”

1

7DK-039

– 14 –

Page 20

5. Pull the choke knob 1 fully out.

7DK-042

1

1 Choke knob

TIP

The choke is not required to start a warm engine.

7DK-040

Push the choke knob in to the original position.

6. Pull slowly on the recoil starter until it is engaged,

then pull it briskly.

TIP

Grasp the carrying handle firmly to prevent the genera-

7DK-041

tor from falling over when pulling the recoil starter.

7. After the engine starts, warm up the engine until

the engine does not stop when the choke knob is

returned to the original position.

TIP

When starting the engine, with the economy control

switch “ON”, and there is no load on the generator:

9 in ambient temperature below 0°C (32°F), the

engine will run at the rated r/min (4,500 r/min) for 5

minutes to warm up the engine.

9 in ambient temperature below 5°C (41°F), the

engine will run at the 4,500 r/min for 3 minutes to

warm up the engine.

The economy control unit operates normally after the

above time period, while the economy control switch is

“ON”.

– 15 –

Page 21

1

7DK-034

7DK-047

AE01025

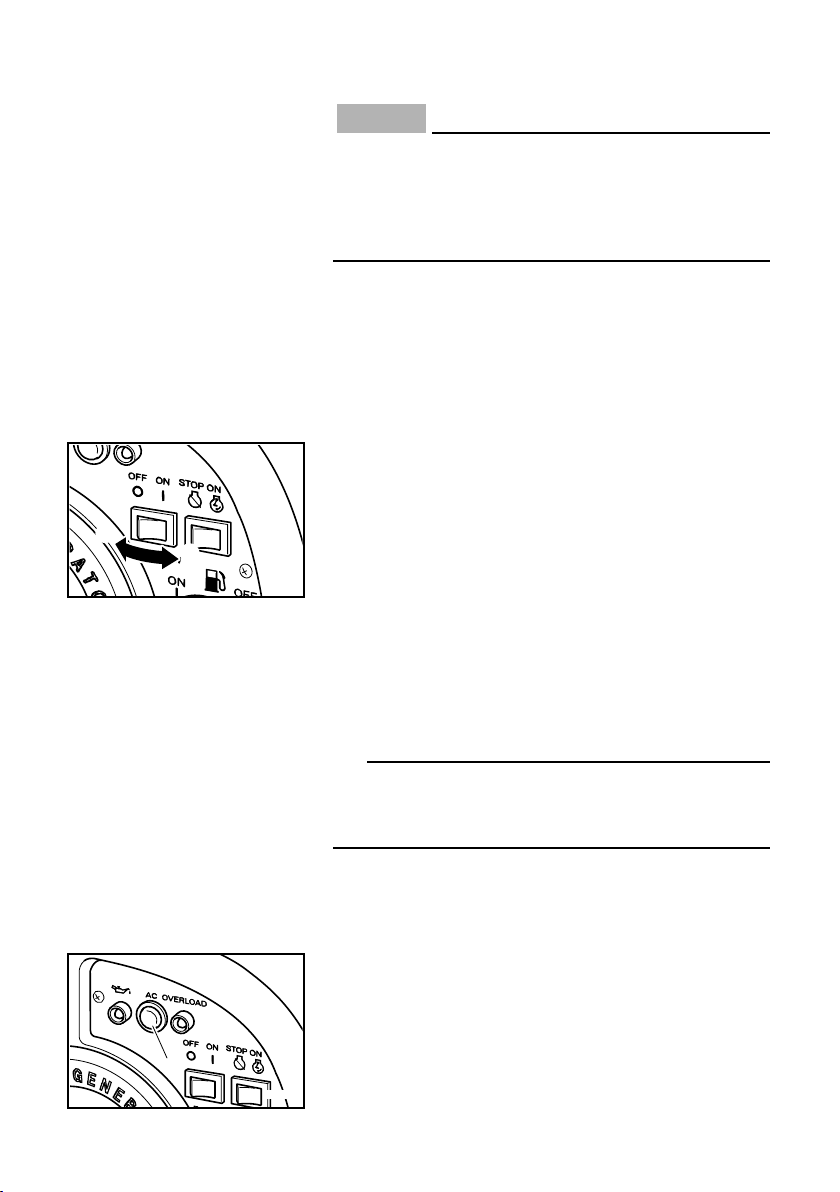

Stopping the engine

TIP

Turn off any electric devices.

1. Turn the economy control switch (Black) to “OFF”

1.

1 3 “OFF”

2. Disconnect any electric devices.

3. Turn the engine switch (Red) to “STOP” 1.

1 5 “STOP”

1

7DK-044

4. Turn the fuel cock knob to “OFF” 1.

1

7DK-045

1 “OFF”

5. Turn the fuel tank cap air vent knob to “OFF” 1

after the engine has completely cooled down.

1

7DK-092

– 16 –

Page 22

AE00839

NOTICE

WARNING

7DK-043

Connection

Alternating Current (AC)

Be sure any electric devices are turned off before

plugging them in.

9 Be sure all electric devices including the lines

and plug connections are in good condition

before connection to the generator.

9 Be sure the total load is within generator rated

output.

9 Be sure the receptacle load current is within

receptacle rated current.

TIP

Make sure to ground (Earth) the generator.

When the electric device is earthed, always the generator must be earthed.

1. Start the engine.

2. Plug in to AC receptacle.

3. Make sure the AC pilot light 1 is on.

1 AC pilot light

1

7DK-048

4. Turn the economy control switch to “ON” 1.

1 I “ON”

5. Turn on any electric devises.

TIP

1

7DK-049

The economy control switch must be turned to “OFF” to

increase engine speed to rated rpm.

– 17 –

Page 23

Battery Charging

NOTICE

762-040

1

2

TIP

9 The generator DC rated voltage is 12V.

9 Start the engine first, and then connect the gener-

ator to the battery for charging.

9 Before starting to charge the battery, make sure

that the DC protector is turned on.

1 Red wire

2 Black wire

1. Start the engine.

2. Connect the red battery charger lead to the positive (+) battery terminal.

3. Connect the black battery charger lead to the negative (-) battery terminal.

4. Turn the economy control switch off to start battery

charging.

6v 6v

12v

762-041

9 Be sure the economy control switch is turned

off while charging the battery.

9 Be sure to connect the red battery charger lead

to the positive (+) battery terminal, and connect

the black lead to the negative (-) battery terminal. Do not reverse these positions.

9 Connect the battery charger leads to the bat-

tery terminals securely so that they are not disconnected due to engine vibration or other disturbances.

9 Charge the battery in the correct procedure by

following instructions in the owner’s manual

for the battery.

9 The DC protector turns off 2 automatically if

current above the rated flows during battery

1

2

7DK-052

charging.

To restart charging the battery, turn the DC pro-

tector on by pressing its button to “ON” 1.If

the DC protector turns off again, stop charging

the battery immediately and consult a Yamaha

dealer.

1 “ON”

2 “OFF”

– 18 –

Page 24

762-012

TIP

WARNING

9 Follow instructions in the owner’s manual for the

battery to determine the end of battery charging.

9 Measure the specific gravity of electrolyte to deter-

mine if the battery is fully charged. At full charge,

the electrolyte specific gravity is between 1.26 and

1.28.

9 It is advisable to check the specific gravity of the

electrolyte at least once every hour to prevent overcharging the battery.

Never smoke or make and break connections at the

battery while charging. Sparks may ignite the battery gas.

Battery electrolyte is poisonous and dangerous,

causing severe burns, etc. contains sulfuric (sulphuric) acid. Avoid contact with skin, eyes or clothing.

Antidote:

EXTERNAL-Flush with water.

INTERNAL-Drink large quantities of water or milk.

Follow with milk of magnesia, beaten egg or vegetable oil. Call physician immediately.

EYES: Flush with water for 15 minutes and get

prompt medical attention. Batteries produce explosive gases. Keep sparks, flame, cigarettes, etc.,

away. Ventilate when charging or using in closed

space. Always cover eyes when working near batteries. KEEP OUT OF REACH OF CHILDREN.

– 19 –

Page 25

AE00812

NOTICE

1

7DK-021

Application range

When using the generator, make sure the total load is within rated output of a generator.

Otherwise, generator damage may occur.

AC

Power factor 1 0.8–0.95

EF2000iS –1,600W –1,280W –544W

0.4–0.75

(Efficiency 0.85)

TIP

9 “–” means below.

9 Application wattage indicates when each device is

used by itself.

9 The simultaneous usage of AC and DC power is

possible but total wattage should not exceed the

rated output.

EX:

Generator rated output 1,600VA

Frequency Power factor

AC

DC —

1.0 –1,500W

0.8 –1,180W

9 The overload indicator light 1 comes on when

total wattage exceeds the application range. (See

page 9 for more details.)

DC

Rated voltage

12V

Rated current

8A

96W

(12V/8A)

9 Do not overload. The total load of all electrical appliances must not exceed the

supply range of the generator. Overloading will damage the generator.

9 When supplying precision equipment, electronic controllers, PCs, electronic

computers, microcomputerbased equipment or battery chargers, keep the generator a sufficient distance away to prevent electrical interference from the

engine. Also ensure that electrical noise from the engine does not interfere

with any other electrical devices located near the generator.

9 If the generator is to supply medical equipment, advice should first be obtained

from the manufacturer, a medical professional or hospital.

9 Some electrical appliances or general-purpose electric motors have high start-

ing currents, and cannot therefore be used, even if they lie within the supply

ranges given in the above table. Consult the equipment manufacturer for further advice.

– 20 –

Page 26

AE00401

NOTICE

WARNING

WARNING

PERIODIC MAINTENANCE

Safety is an obligation of the owner. Periodic inspection, adjustment and lubrication will

keep your generator in the safest and most efficient condition possible. The most important points of generator inspection, adjustment, and lubrication are explained on the following pages.

If you are not familiar with maintenance work, have a Yamaha dealer do it for you.

AE00403

Maintenance chart

Stop the engine before starting maintenance work.

Use only Yamaha specified genuine parts for replacement. Ask an authorized

Yamaha dealer for further attention.

Pre-

Item Routine

Spark plug

Fuel • Check fuel level and leakage. 1

Fuel hose • Check fuel hose for cracks or damage.

Engine oil

Air filter element

Muffler screen

Spark arrester

Fuel filter • Clean and replace if necessary. 1

• Check condition.

• Clean and replace if necessary.

Replace if necessary.

• Check oil level in engine. 1

• Replace 1(*1)

• Check condition.

• Clean

• Check condition.

• Clean and replace if necessary.

• Check condition.

• Clean and replace if necessary.

– 21 –

operation

check

1

Every

6 months

or 100 Hr

1

1(*2)

1

1

12 months

or 300 Hr

Page 27

Item Routine

Crankcase breather

hose

Cylinder head

Pre-

operation

check

• Check breather hose for cracks or

damage. 1

• Replace if necessary.

• Decarbonize cylinder head.

• More frequently if necessary.

6 months

or 100 Hr

Every

12 months

or 300 Hr

★

Valve clearance • Check and adjust when engine is cold. ★

Fittings / fasteners

• Check all fittings and fasteners.

• Correct if necessary.

★

The point where abnormality was recognized by use 1

*1·····Initial replacement of the engine oil is after one month or 20 hours of operation.

*2·····The air filter element needs to be cleaned more frequently when using in unusually wet or dusty areas.

★····· Since these items require special tools, data and technical skills, have a Yamaha dealer perform the service.

– 22 –

Page 28

4

3

7DK-053

a

760-001a

Spark plug inspection

1

2

7DK-030

The spark plug is important engine components, which

should be checked periodically.

1. Remove the screws 1, and then remove the cover

2.

2. Remove the spark plug cap 3 and cap 4, and

insert the tool 5 through the hole from the outside

of the cover.

6

5

7DK-054

3. Insert the handlebar 6 into the tool 5 and turn it

counterclockwise to remove the spark plug.

4. Check for discoloration and remove the carbon.

The porcelain insulator around the center electrode of spark plug should be a medium-to-light tan

color.

5. Check the spark plug type and gap a.

Standard Spark Plug:

BPR6HS (NGK)

Spark Plug Gap a:

0.6–0.7 mm (0.024–0.028 in)

TIP

The spark plug gap should be measured with a wire

thickness gauge and, if necessary, adjusted to specification.

– 23 –

Page 29

6. Install the spark plug.

1

2

7DK-030

WARNING

7DK-031

1

Spark Plug Torque:

20.0 N•m (2.0 kgf•m, 14.8 lbf•ft)

TIP

If a torque wrench is not available when installing a

spark plug, a good estimate of the correct torque is 1/41/2 turn past finger tight. However, the spark plug

should be tightened to the specified torque as soon as

possible.

7. Install the spark plug cap and cap.

8. Install the cover and tighten the screws.

AE00431

Carburetor adjustment

The carburetor is a vital part of the engine. Adjusting

should be left to a Yamaha dealer with the professional

knowledge, specialized data, and equipment to do so

properly.

AE00412

Engine oil replacement

Avoid draining the engine oil immediately after

stopping the engine. The oil is hot and should be

handled with care to avoid burns.

1. Place the generator on a level surface and warm

up the engine for several minutes.

Then stop the engine and turn the fuel cock knob,

fuel tank cap air vent knob to “OFF”.

2. Remove the screws 1 and then remove the cover

2.

3. Remove the oil filler cap 1.

– 24 –

Page 30

NOTICE

7DK-055

700-006a

q

0°C

NOTICE

å

YAMALUBE 4 (10W-40)

∂

SAE 10Wç SAE #20∫ SAE #30

25°C

7DK-033

4. Place an oil pan under the engine. Tilt the generator to drain the oil completely.

5. Replace the generator on a level surface.

Do not tilt the generator when adding engine oil.

This could result in overfilling and damage to the

engine.

6. Add engine oil to the upper level 1.

Recommended engine oil:

å

YAMALUBE 4 (10W-40),

SAE 10W-30 or 10W-40

∫

SAE #30

ç

SAE #20

∂

SAE 10W

Recommended engine oil grade:

API Service SE type or higher

Engine oil quantity:

0.4 L (0.42 US qt, 0.35 lmp qt)

32°F

80°F

7. Wipe the cover clean, and wipe up any spilled oil.

Be sure no foreign material enters the crankcase.

8. Install the oil filler cap.

9. Install the cover 2 and tighten the screws 1.

1

2

7DK-030

– 25 –

Page 31

AE01084

1

2

7DK-030

NOTICE

NOTICE

Air filter

1. Remove the screws 1, and then remove the cover

2.

2

2. Remove the screw 1 and then remove the air filter

case cover 2.

1

7DK-061

3. Remove the foam element 1.

4. Wash the foam element in solvent and dry it.

5. Oil the foam element and squeeze out excess oil.

1

The foam element should be wet but not dripping.

Recommended oil:

Foam-air-filter oil or SAE #20 motor oil

Do not wring out the foam element when squeezing

it. This could cause it to tear.

6. Insert the foam element into the air filter case.

TIP

Be sure the foam element sealing surface matches the

air filter so there is no air leak.

7DK-062

The engine should never run without the foam element; excessive piston and cylinder wear may

result.

7. Install the air filter case cover in its original position

and tighten the screw.

8. Install the cover and tighten the screws.

– 26 –

Page 32

7DK-026

AE01075

WARNING

Muffler screen and spark arrester

The engine and muffler will be very hot after the

engine has been run.

Avoid touching the engine and muffler while they

are still hot with any part of your body or clothing

during inspection or repair.

2

1

7DK-066

1. Remove the screws 1, and then pull outward on

the areas of the cover 2 shown.

1

2. Loosen the bolt 1 and then remove the muffler cap

2

1

3

7DK-063

7DK-064

4

2, the muffler screen 3 and spark arrester 4.

7DK-065

– 27 –

Page 33

2

1

7DK-065a

3. Remove the carbon deposits on the muffler screen

NOTICE

711-075

and spark arrester using a wire brush.

When cleaning, use the wire brush lightly to avoid

damaging or scratching of the muffler screen and

spark arrester.

4. Check the muffler screen and spark arrester.

Replace them if damaged.

5. Install the spark arrester.

TIP

Align the spark arrester projection 1 with the hole 2 in

the muffler pipe.

6. Install the muffler screen and the muffler cap.

7. Install the cover and tighten the screws.

7DK-068

– 28 –

Page 34

7DK-069

1

AE00471

WARNING

WARNING

Fuel tank filter

Never use the gasoline while smoking or in the

vicinity of an open flame.

1. Remove the fuel tank cap and filter 1.

2. Clean the filter with gasoline.

If damaged, replace it.

3. Wipe the filter and install it.

4. Install the fuel tank cap.

Be sure the fuel tank cap is tightened securely.

– 29 –

Page 35

AE00601

1

7DK-044

NOTICE

WARNING

1

7DK-038

STORAGE

Long term storage of your machine will require some

preventive procedures to guard against deterioration.

AE01056

Drain the fuel

1. Turn the engine switch to “STOP” 1.

2. Remove the fuel tank cap. Extract the fuel from the

fuel tank into an approved gasoline container using

a commercially available handsiphon. Then, install

the fuel tank cap.

Fuel is highly flammable and poisonous. Check

“SAFETY INFORMATION” (See page 1) carefully.

7DK-025

Immediately wipe off spilled fuel with a clean, dry,

soft cloth, since fuel may deteriorate painted surfaces or plastic parts.

3. Turn the engine switch to “ON” 1.

1

7DK-039

1

4. Turn the fuel tank cap air vent knob and fuel cock

knob to “ON” 1.

7DK-035

5. Start the engine and leave it run until it stops.

The engine stops in approx. 20 mins. time by running out of fuel.

TIP

9 Do not connect with any electrical devices.

(unloaded operation)

9 Duration of the running engine depends on the

amount of the fuel left in the tank.

– 30 –

Page 36

6. Remove the screws 1, and then remove the cover

1

2

7DK-030

2.

3

drain screw 3 on the carburetor float chamber.

8. Turn the engine switch to “OFF”.

9. Turn the fuel cock knob to “OFF”.

10. Tighten the drain screw 3.

11. Install the cover and tighten the screws.

7. Drain the fuel from the carburetor by loosening the

7DK-071

12. Turn the fuel tank cap air vent knob to “OFF”.

13. Tighten further if any screws, bolts and nuts are

loose.

14. Store the generator in a dry, well-ventilated place,

with the cover placed over it.

– 31 –

Page 37

Engine

7DK-072

Perform the following steps to protect the cylinder, piston ring, etc. from corrosion.

1. Remove the spark plug, pour about one tablespoon of SAE 10W-30 or 20W-40 motor oil into the

spark plug hole and reinstall the spark plug. Recoil

start the engine by turning over several times (with

ignition off) to coat the cylinder walls with oil.

2. Pull the recoil starter until you feel compression.

Then stop pulling. (This prevents the cylinder and

valves from rusting).

3. Clean exterior of the generator and apply a rust

inhibitor.

4. Store the generator in a dry, well-ventilated place,

with the cover placed over it.

5. The generator must remain in a vertical position

when stored, carried or operated.

– 32 –

Page 38

7DK-091

AE00512

TROUBLESHOOTING

Engine won’t start

1. Fuel systems

No fuel supplied to combustion chamber.

2 No fuel in tank .... Supply fuel.

2 Fuel in tank .... Fuel tank cap air vent knob and fuel

cock knob to “ON” 1.

2 Clogged fuel line .... Clean fuel line.

2 Clogged carburetor .... Clean carburetor.

1

7DK-035

1

7DK-038

2. Engine oil system

Insufficient

2 Oil level is low .... Add engine oil.

700-006

– 33 –

Page 39

1

2

7DK-052

7DK-041

1

7DK-039

791-001d

3. Electrical systems

2 Engine switch to “ON” 1 and pull the recoil starter.

Poor spark

2 Spark plug dirty with carbon or wet .... Remove car-

bon or wipe spark plug dry.

2 Faulty ignition system .... Consult a Yamaha dealer.

AE00515

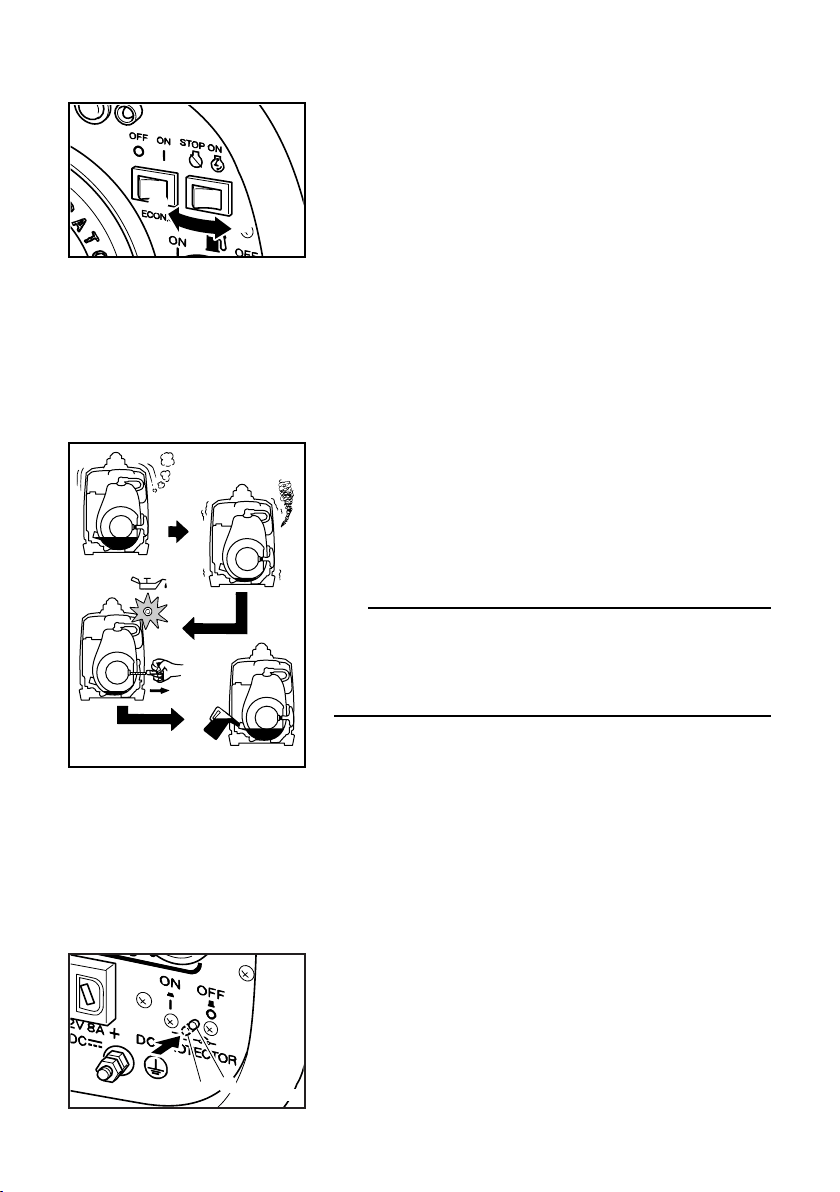

Generator won’t produce power

2 Safety device (DC protector) to “OFF” 2 ···· Press

the DC protector to “ON” 1.

2 Safety device (AC) to “OFF” .... Stop the

engine,then restart.

– 34 –

Page 40

AE00515

A ENGINE DOES NOT START

B

Turn the engine switch to “ON”, then pull

the recoil starter and check if the oil

warining light flickers.

C Does not flicker D Flickers.

H

Pull the recoil starter and check the

spark plug for spark strength.

(See “WARNING”)

w

9 To prevent FIRE HAZARDS be

sure fuel is not present in the

spark plug area.

9 To prevent FIRE HAZARDS be

sure to place the spark plug as far

way as possible from the spark

plug hole and carburetor area.

9 To prevent ELECTRIC SHOCK do

not hold spark plug lead with

hand while testing.

I J

OK

Dose not spark

E Check engine oil level.

F OK G Level low

Consult a

Yamaha dealer.

K Check the spark plug.

9 Type: BPR6HS

9 Gap: 0.6–0.7 mm (0.024–0.028 in)

L Incorrect M OK

Replace or

Adjust Gap.

Add engine oil.

Clean the spark

plug.

N

Check the following

9 Fuel line clogging

9 Air cleaner element

clogging.

O Clogged

POK

– 35 –

Q

Clean or Replace; Consult a

Yamaha dealer.

R Consult a Yamaha dealer.

Page 41

AE00701

SPECIFICATIONS

AE00702

Dimensions

Unit EF2000iS

Overall Length mm (in) 490 (13.3)

Overall Width mm (in) 280 (11.0)

Overall Height mm (in) 455 (17.9)

Dry Weight kg (lb) 20 (44)

AE00704

Engine

Unit EF2000iS

Type Air cooled 4-stroke gasoline OHV

Cylinder Arrangement

Displacement cm

3

Bore × Stroke mm (in) 48.6 × 43.0 (1.91 × 1.69)

Operation Hours Hr 4.2–10.5 (rated load–1/4 load)

Fuel Unleaded gasoline

Fuel Tank Capacity L (US gal, Imp gal) 4.2 (1.11, 0.92)

Engine Oil Quantity L (US qt, Imp qt) 0.4 (0.42, 0.35)

Ignition System CDI

Spark Plug: Type BPR6HS (NGK)

Gap mm (in) 0.6–0.7 (0.024–0.028)

Noise Level* dB (A) 61

* : Measured at rated operation from 7 m (23 ft) distance.

Inclined, 1 cylinder

79

AE00707

Generator

Unit EF2000iS

AC Output

Rated voltage V 120

Rated frequency Hz 60

Rated current A 13.3

Rated output kVA 1.6

Safety Device: Type

DC Output

Rated voltage V 12

Rated current A 8

Safety Device: Type

– 36 –

Electronic

DC protector

Page 42

7DK-073

7DK-24163-00

Serial NO.

7DK-

CONSUMER INFORMATION

PRI-I.D. NUMBER:

MODEL

PRI-I.D.

CODE

SERIAL No.

AE00012

Identification number records

Record your Primary I.D., and serial numbers in the spaces provided, to assist you in

ordering spare parts from a Yamaha dealer.

Also record and keep these I.D. numbers in

a separate place in case your machine is

stolen.

AE00011

Machine identification

The machine serial number is stamped in

the location as shown.

TIP

The first three digits of these numbers are

for model identification; the remaining digits

are the unit production number. Keep a

record of these numbers for reference

when ordering parts from a Yamaha dealer.

– 37 –

Page 43

AE01119

YAMAHA MOTOR CORPORATION U.S.A.

EF- AND EDL-SERIES GENERATOR LIMITED WARRANTY

Yamaha Motor Corporation, U.S.A. hereby warrants

that new Yamaha consumer generators purchased

from an authorized Yamaha consumer generator

dealer in the continental United States will be free

from defects in material and workmanship for the

period of time stated herein, subject to certain stated limitations.

THE PERIOD OF WARRANTY Any new EF-series

or EDL-series Yamaha Generator purchased for

private, non-commercial use from an authorized

Yamaha consumer generator dealer in the continental United States will

be warranted against defects in material or workmanship for a period two (2) years from date of purchase, subject to exclusions noted herein. Any

Yamaha non-commercial

generator purchased and utilized for commercial or

rental applications will be warranted for a period

one (1) year from the date of purchase, subject to

exclusions noted herein.

DURING THE PERIOD OF WARRANTY any

authorized Yamaha consumer generator dealer will,

free of charge, repair or replace, at Yamaha’s

option, any part adjudged defective by Yamaha due

to faulty workmanship or material from the factory.

Parts used in warranty repairs will be warranted for

the balance of the product’s warranty period. All

parts replaced under warranty become property of

Yamaha Motor Corporation U.S.A.

GENERAL EXCLUSIONS from this warranty shall

include any failures caused by:

a. Installation of parts or accessories that are not

qualitatively equivalent to genuine Yamaha

parts.

b. Abnormal strain, neglect, or abuse.

c. Lack of proper maintenance.

d. Accident or collision damage.

SPECIFIC EXCLUSIONS from this warranty shall

include parts replaced due to normal wear or routine maintenance.

THE CUSTOMER’S RESPONSIBILITY under this

warranty shall be to:

1. Operate and maintain the generator as speci-

fied in the appropriate Owner’s Manual;

2. Give notice to an authorized Yamaha consumer generator dealer of any and all apparent

defects within ten (10) days after discovery,

and make the unit available at that time for

inspection and repairs at such dealer’s place of

business.

WARRANTY TRANSFER: To transfer the warranty

from the original purchaser to any subsequent purchaser(s), it is imperative that the unit be inspected

and registered for warranty by an authorized

Yamaha consumer generator dealer. In order for

this warranty to remain in effect, this inspection and

registration must take place within ten (10) days

after transfer. An inspection and registration fee will

be charged for this service. In no case will the warranty be extended beyond the original period.

YAMAHA MOTOR CORPORATION, U.S.A. MAKES

NO OTHER WARRANTY OF ANY KIND,

EXPRESSED OR IMPLIED. ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS

FOR A PARTICULAR PURPOSE WHICH EXCEED

THE OBLIGATIONS AND TIME LIMITS STATED IN

THIS WARRANTY ARE HEREBY DISCLAIMED BY

YAMAHA MOTOR CORPORATION, U.S.A. AND

EXCLUDED FROM THIS WARRANTY.

SOME STATES DO NOT ALLOW LIMITATIONS ON

HOW LONG AN IMPLIED WARRANTY LASTS, SO

THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

ALSO EXCLUDED FROM THIS WARRANTY ARE

ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES INCLUDING LOSS OF USE. SOME STATES

DO NOT ALLOW THE EXCLUSION OR LIMITATION

OF INCIDENTAL OR CONSEQUENTIAL DAMAGES,

SO THE ABOVE EXCLUSION MAY NOT APPLY TO

YOU.

THIS WARRANTY GIVES YOU SPECIFIC LEGAL

RIGHTS, AND YOU MAY ALSO HAVE OTHER

RIGHTS WHICH VARY FROM STATE TO STATE.

YAMAHA MOTOR CORPORATION, U.S.A.

Post Office Box 6555

Cypress, California 90630

– 38 –

Page 44

WARRANTY QUESTIONS AND ANSWERS

Q. What costs are my responsibility during the

warranty period?

A. The customer’s responsibility includes all costs

of normal maintenance service, non-warranty

repairs, accident damages, as well as oil and

spark plugs.

Q. What are some examples of “abnormal” strain,

neglect, or abuse?

A. These terms are general and overlap each

other in areas. Specific examples include:

Running the machine out of oil; lack of proper

maintenance; operating the machine with a

broken or damaged part which causes another part to fail; and so on. If you have any specific questions on operation or maintenance,

please contact your dealer for advice.

Q. Does the warranty cover incidental costs such

as transportation due to a failure?

A. No. The warranty is limited to repair of the

machine itself.

Q. May I perform any or all of the recommended

maintenance shown in the Owner’s Manual

instead of having the dealer do them?

A. Yes, if you are a qualified mechanic and follow

the procedures specified in the Owner’s and

Service Manual. We do recommend, however,

that items requiring special tools or equipment

be done by a Yamaha generator dealer.

Q. Will the warranty be void or cancelled if I do not

operate or maintain my new Yamaha exactly as

specified in the Owner’s Manual?

A. No. The warranty on a new Yamaha cannot be

“voided” or “cancelled.”

However, if a particular failure is caused by

operation or maintenance other than as

shown in the Owner’s Manual, that failure

may not be covered under warranty.

Q. What responsibility does my dealer have under

this warranty?

A. Each Yamaha generator dealer is expected to:

1. Check the operation of the generator

before sale.

2. Explain the operation, maintenance, and

warranty requirements to your satisfaction

at the time of sale, and upon your request

at any later date.

In addition, each Yamaha generator dealer is

held responsible for his setup, service and warranty repair work.

Q. Is the warranty transferable to second owners?

A. Yes. The remainder of the existing warranty

can be transfered upon request.

The unit has to be inspected and reregistered

by an authorized Yamaha generator dealer for

the policy to remain effective.

CUSTOMER SERVICE

If your machine requires warranty service, you

must take it to any authorized Yamaha generator

dealer within the continental United States. Be sure

to bring your warranty registration identification or

other valid proof of the original date of purchase. If

a question or problem arises regarding warranty,

first contact the owner of the dealership. Since all

warranty matters are handled at the dealer level,

this person is in the best position to help you. If you

are still not satisfied and require additional assistance, please write:

YAMAHA MOTOR CORPORATION U.S.A.

CUSTOMER RELATIONS DEPARTMENT

P.O. BOX 6555

Cypress, California 90630

CHANGE OF ADDRESS

The federal government requires each manufacturer to maintain a complete, up-to-date list of all first

purchasers against the possibility of a safety-related defect and recall. This list is compiled from the

purchase registrations sent to Yamaha Motor

Corporation, U.S.A. by the selling dealer at the time

of your purchase. If you should move after you have

purchased your new generator, please advise us of

your new address by sending a postcard listing

your Yamaha model name, engine number, dealer

number (or dealer’s name) as it is shown on your

warranty identification, your name and new mailing

address. Mail to:

YAMAHA MOTOR CORPORATION, U.S.A.

WARRANTY DEPARTMENT

P.O. Box 6555

Cypress, California 90630

This will ensure that Yamaha Motor Corporation,

U.S.A. has an up-to-date registration record in

accordance with federal law.

– 39 –

Page 45

AE00789

EXHAUST EMISSION CONTROL SYSTEM AND COMPONENTS

Item Acronym

9 CARB. ASSY., LH. & JT., .......................CARB (Carburetor)

CARBURETOR2

9 T.C.I. MAGNETO ASSY. & .....................EI (Electronic Ignition)

PLUG, SPARK

9 CRANKCASE1 & HEAD, .......................PCV (Positive Crankcase

CYLINDER1 Ventilation)

9 AIR FILTER ASSY. . ................................ACL (Air Cleaner)

9 MUFF., 2, CAP, NET, WIRE2 &

ARRESTER, SPARK

The above items and the corresponding acronyms are provided in accordance with U.S.

EPA REGULATIONS FOR NEW NONROAD SPARK-IGNITION NONHANDHELD

ENGINES and the CALIFORNIA REGULATIONS FOR 1995 AND LATER SMALL OFFROAD ENGINES.

The acronyms conform to the latest version of the SAE’s recommended practice docu-

ment J1930, “Diagnostic Acronyms, Terms, and Definitions For Electrical/Electronic

System”.

It is recommended that these items be serviced by a Yamaha dealer.

– 40 –

Page 46

W

Br

R

R

Br

R

Br

R

Br

R

Br

R

Br

Br

B

B

B

B

B

BB

B

B

B

Y

Y

O

O

O

Y

Y

Y

Y

YY

Y

Y

Y

Y

R

RR

R

R

L

L

L

L

L

L

L

L

L

G

G

Y

Y

O

O

O

O

O

OLO

O

B/W

B/W

R/W

Br

BrBr

R/W R/W R/W

G/Y

G/Y

O

G/Y

2

1

3

u

o

i

p

4

5

6

7

8

9

q

0

e

w

r

y

t

7DK-10

AE00751

WIRING DIAGRAM

1 Sub coil

2 DC coil

3 Main coil

4 DC rectifier

5 DC protector (breaker)

6 Twin Tech (parallel

running terminal)

7 DC receptacle

8 AC pilot light

9 AC receptacle

0 Economy control switch

q Overload indicator light

w Engine switch

e Oil warning light

r Ground (Earth) terminal

t Control unit

y CDI unit/Ignition coil

u Stepping motor

i Spark plug

o CDI magneto

p Oil level gauge

– 41 –

Color code

B Black

Br Brown

G Green

Gy Gray

L Blue

O Orange

R Red

W White

Y Yellow

B/W Black/White

G/Y Green/Yellow

R/W Red/White

Page 47

Page 48

PRINTED ON RECYCLED PAPER

PRINTED IN JAPAN

2009.01-1.0×1 !

(E)

Loading...

Loading...