Yamaha FJR1300N 2001 User Manual [ru]

2001

FJR1300

(

N

5JW1-AE1

)

SERVICEMANUAL

FJR1300R

5JW–28197–20

5JW9-AE1

SERVICE MANUAL

EAS00002

NOTICE

This manual was produced by the Yamaha Motor Company, Ltd. primarily for use by Yamaha dealers and their qualified mechanics. It is not possible to include all the knowledge of a mechanic in

one manual. Therefore, anyone who uses this book to perform maintenance and repairs on Yamaha

vehicles should have a basic understanding of mechanics and the techniques to repair these types

of vehicles. Repair and maintenance work attempted by anyone without this knowledge is likely to

render the vehicle unsafe and unfit for use.

Yamaha Motor Company, Ltd. is continually striving to improve all of its models. Modifications and

significant changes in specifications or procedures will be forwarded to all authorized Yamaha dealers and will appear in future editions of this manual where applicable.

NOTE:

@

Designs and specifications are subject to change without notice.

EAS00004

IMPORTANT MANUAL INFORMATION

Particularly important information is distinguished in this manual by the following.

The Safety Alert Symbol means ATTENTION! BECOME ALERT! YOUR

SAFETY IS INVOLVED!

WARNING

CAUTION:

NOTE:

Failure to follow WARNING instructions could result in severe injury or death to

the motorcycle operator, a bystander or a person checking or repairing the

motorcycle.

A CAUTION indicates special precautions that must be taken to avoid damage

to the motorcycle.

A NOTE provides key information to make procedures easier or clearer.

EAS00007

HOW TO USE THIS MANUAL

This manual is intended as a handy, easy-to-read reference book for the mecha nic. Co mprehensive

explanations of all installation, removal, disassembly, assembly, repair and check procedures are

laid out with the individual steps in sequential order.

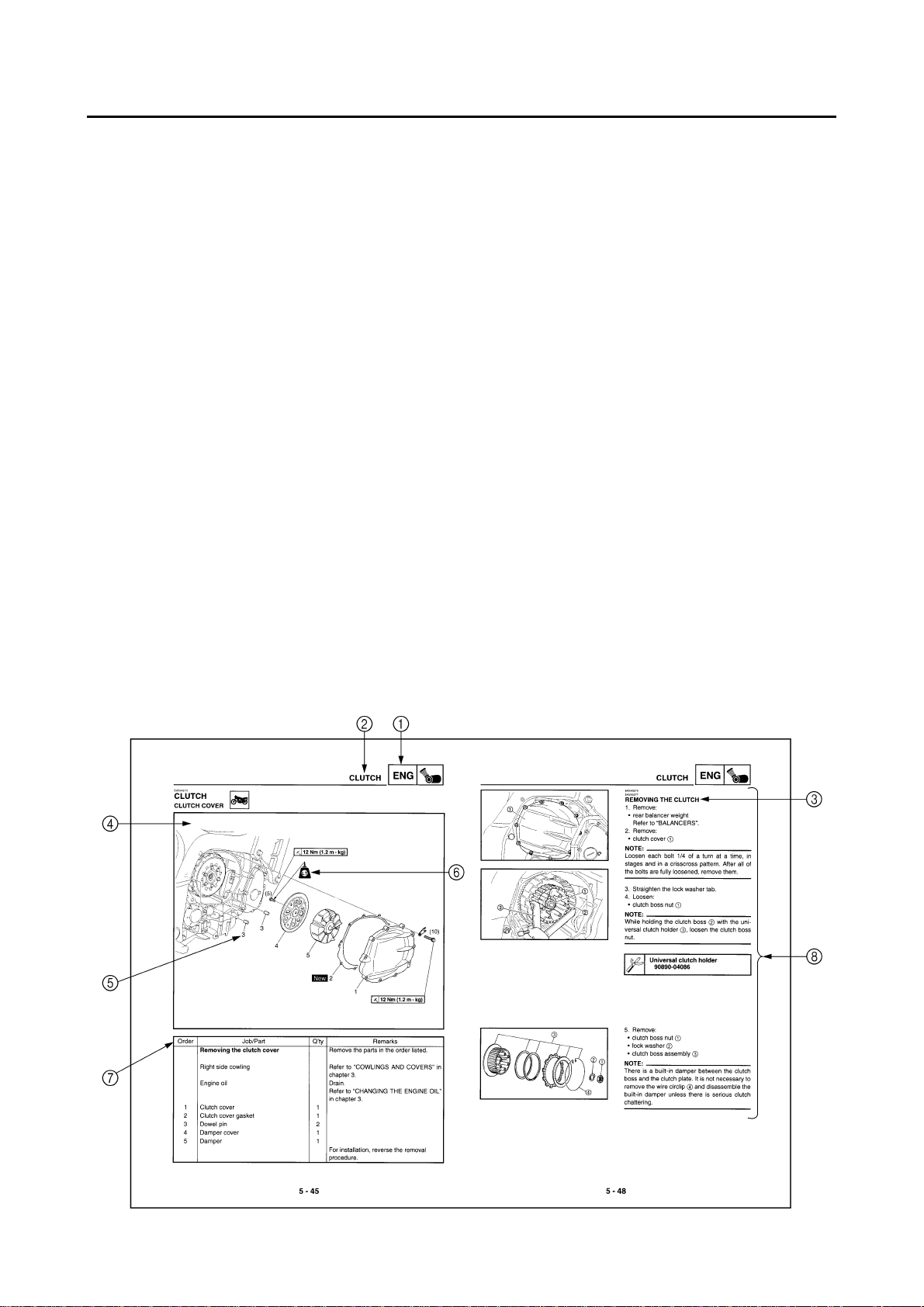

The manual is divided into chapters. An abbreviation and symbol in the upper right corner of

1

each page indicate the current chapter.

Refer to “SYMBOLS”.

Each chapter is divided into sections. The current section title is shown at the top of each page,

2

except in chapter 3 (“PERIODIC CHECKS AND ADJUSTMENTS”), where the sub-section title(s)

appears.

Sub-section titles appear in smaller print than the section title.

3

To help identify parts and clarify procedure steps, there are exploded diagrams at the start of

4

each removal and disassembly section.

Numbers are given in the order of the jobs in the exploded diagram. A circled number indicates a

5

disassembly step.

Symbols indicate parts to be lubricated or replaced.

6

Refer to “SYMBOLS”.

A job instruction chart accompanies the exploded diagram, providing the order of jobs, names of

7

parts, notes in jobs, etc.

Jobs requiring more information (such as special tools and technical data) are described sequen-

8

tially.

12

GEN

SPEC

INFO

34

CHK

CHAS

ADJ

56

ENG

78

COOL

EAS00008

SYMBOLS

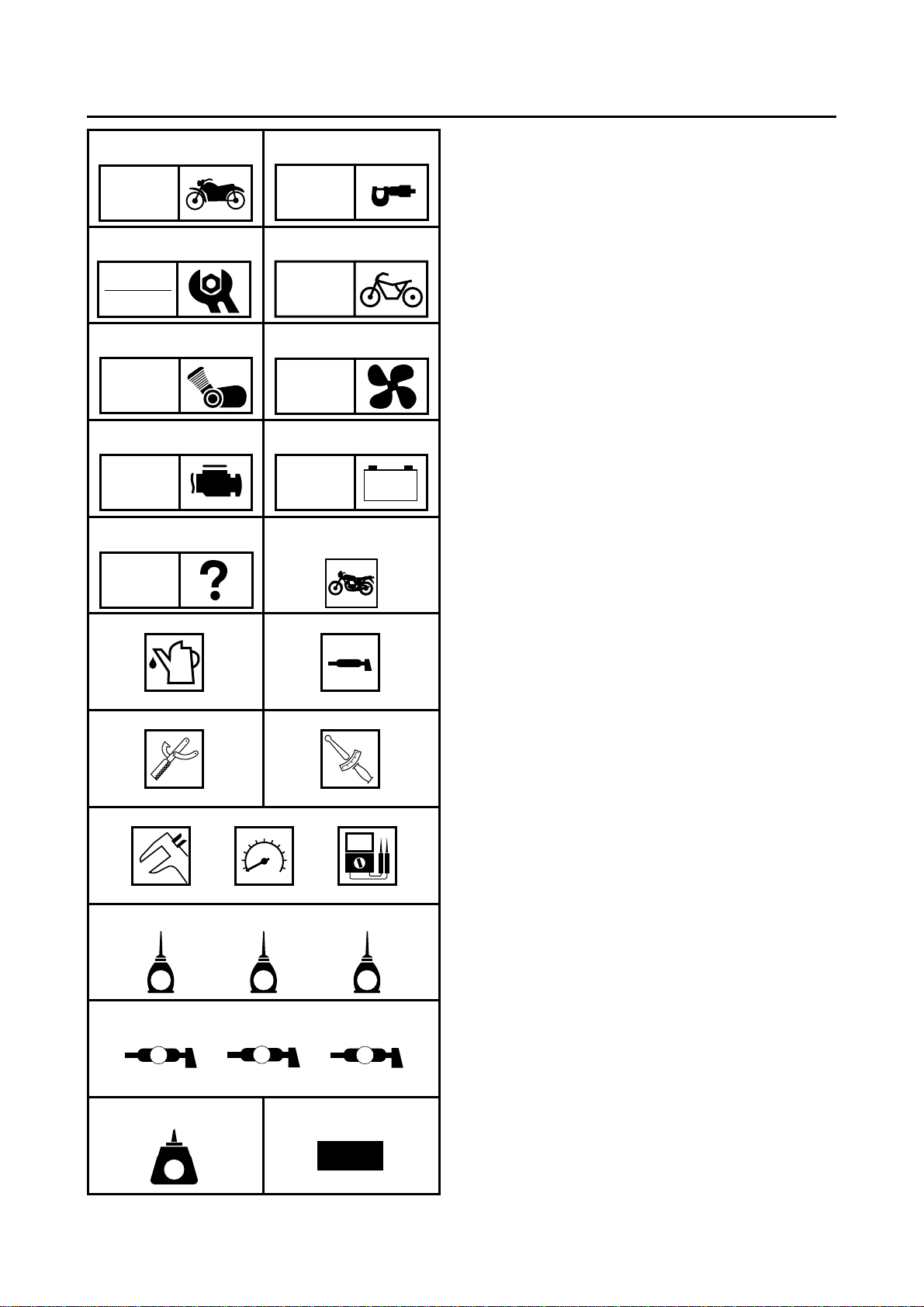

The following symbols are not relevant to

every vehicle.

Symbols 1 to 9 indicate the subject of each

chapter.

General information

1

Specifications

2

Periodic checks and adjustments

3

Chassis

4

Engine

5

Cooling system

6

Fuel injection system

7

Electrical system

8

Troubleshooting

9

FI

90

ELEC

–+

TRBL

SHTG

AB

CD

T

.

R

.

EFG

HIJ

Symbols 0 to G indicate the following.

Serviceable with engine mounted

0

Filling fluid

A

Lubricant

B

Special tool

C

Tightening torque

D

Wear limit, clearance

E

Engine speed

F

Electrical data

G

Symbols H to M in the exploded diagrams

indicate the types of lubricants and lubrication

points.

LS

G

M

M

New

E

KLM

B

NO

LT

Engine oil

H

Gear oil

I

Molybdenum disulfide oil

J

Wheel bearing grease

K

Lithium soap base grease

L

Molybdenum disulfide grease

M

Symbols N to O in the exploded diagrams

indicate the following.

®

Apply locking agent (LOCTITE

N

Replace the part

O

)

EAS00012

–+

Notice: This enhanced version has been prepared for persons who already own a copy of

the FJR Service Manual. The enhancements are distributed as freeware for the FJR

Owner's community. If you find them useful, please donate 5 or 10 units of your local

currency to a motorcycle charity or related event.

TABLE OF CONTENTS

GENERAL INFORMATION

SPECIFICATIONS

PERIODIC CHECKS AND

ADJUSTMENTS

CHASSIS

ENGINE

GEN

INFO

SPEC

CHK

ADJ

CHAS

ENG

1

2

3

4

5

COOLING SYSTEM

COOL

FUEL INJECTION SYSTEM

FI

ELECTRICAL SYSTEM

ELEC

TROUBLESHOOTING

TRBL

SHTG

6

7

8

9

GEN

INFO

1

CHAPTER 1

GENERAL INFORMATION

GEN

INFO

MOTORCYCLE IDENTIFICATION

VEHICLE IDENTIFICATION NUMBER.....................................................1-1

MODEL CODE ..........................................................................................1-1

FEATURES

OUTLINE...................................................................................................1-2

FI SYSTEM................................................................................................1-3

COMPONENTS.........................................................................................1-5

FUEL INJECTION SYSTEM....................................................................1-17

THREE-WAY CATALYTIC CONVERTER SYSTEM...............................1-26

AIR INDUCTION SYSTEM......................................................................1-30

COMPONENTS.......................................................................................1-31

IMPORTANT INFORMATION

PREPARATION FOR REMOVAL AND DISASSEMBLY.........................1-35

REPLACEMENT PARTS.........................................................................1-35

GASKETS, OIL SEALS AND O-RINGS..................................................1-35

LOCK WASHERS/PLATES AND COTTER PINS...................................1-36

BEARINGS AND OIL SEALS..................................................................1-36

CIRCLIPS................................................................................................1-36

CHECKING THE CONNECTIONS..........................................................1-37

......................................................................................................1-2

..................................................................1-1

.......................................................................1-35

SPECIAL TOOLS

..........................................................................................1-38

GEN

INFO

MOTORCYCLE IDENTIFICATION

EAS00014

GENERAL INFORMATION

MOTORCYCLE IDENTIFICATION

EAS00017

VEHICLE IDENTIFICATION NUMBER

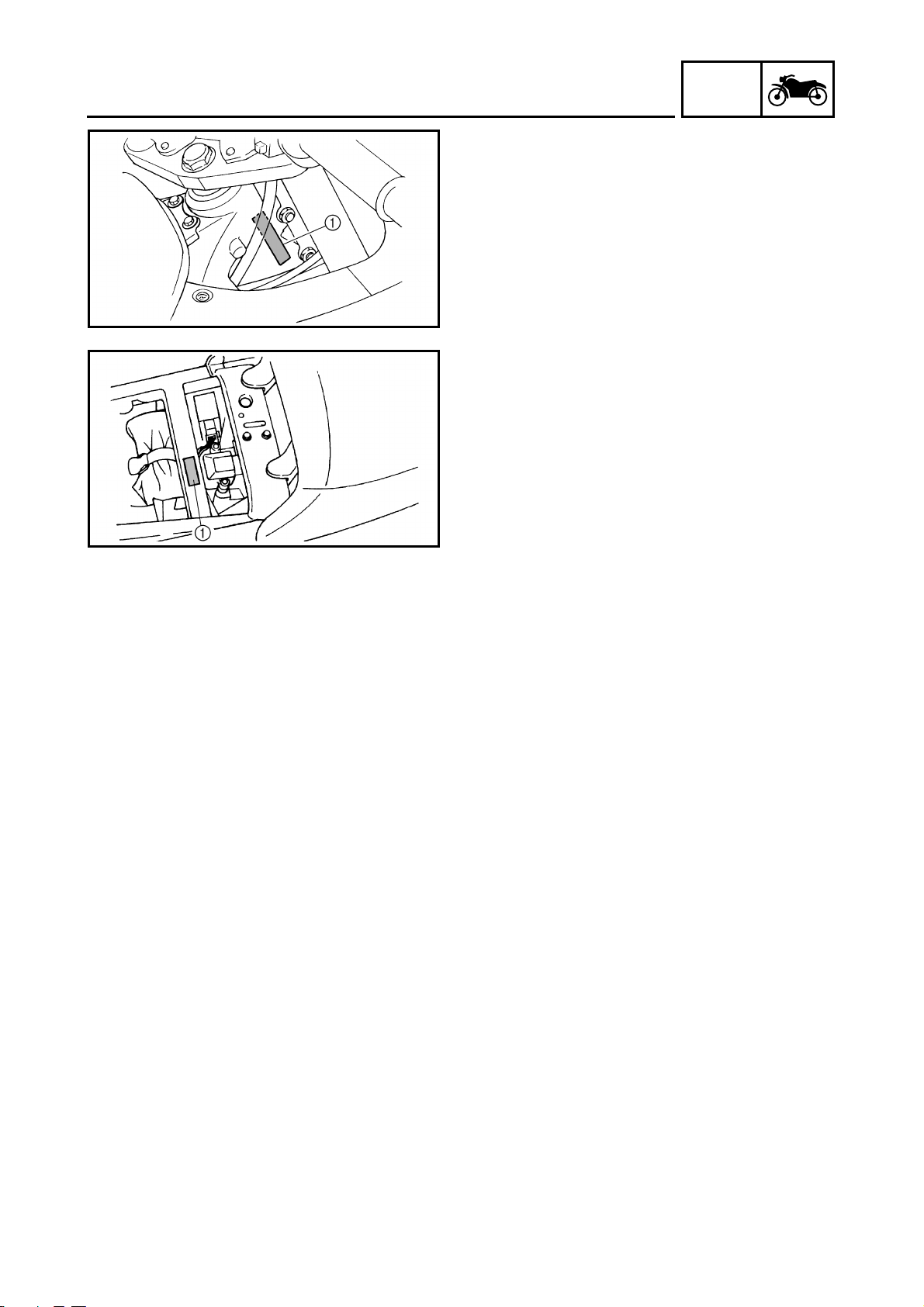

The vehicle identification number 1 is

stamped into the right side of the steering head

pipe.

EAS00018

MODEL CODE

The model code label 1 is affixed to the

frame. This information will be needed to order

spare parts.

GEN

INFO

1 - 1

GEN

FEATURES

FEATURES

OUTLINE

The main function of a fuel supply system is to provide fuel to the combustion chamber at the optimum air-fuel ratio in accordance with the engine operating conditions and the atmospheric temperature.

In the conventional carburetor system, the air-fuel ratio of the mixture that is supplied to the combustion chamber is created by the volume of the intake air and the fuel that is metered by the jet that

is used in the respective chamber.

Despite the same volume of intake air, the fuel volume requirement varies by the engine operating

conditions, such as acceleration, deceleration, or operating under a heavy load. Carburetors that

meter the fuel through the use of jets have been provided with various auxiliary devices, so that an

optimum air-fuel ratio can be achieved to accommodate the constant changes in the operating conditions of the engine.

As the requirements for the engine to deliver more performance and cleaner exhaust gases

increase, it becomes necessary to control the air-fuel ratio in a more precise and finely tuned manner. To accommodate this need, this model has adopted an electronically controlled fuel injection

(FI) system, in place of the conventional carburetor system. This system can achieve an optimum

air-fuel ratio required by the engine at all times by using a microprocessor that regulates the fuel

injection volume according to the engine operating conditions detected by various sensors.

The adoption of the FI system has resulted in a highly precise fuel supply, improved engine

response, better fuel economy, and reduced exhaust emissions. Furthermore, the air induction system (AI system) has been placed under computer control together with the FI system in order to

realize cleaner exhaust gases.

INFO

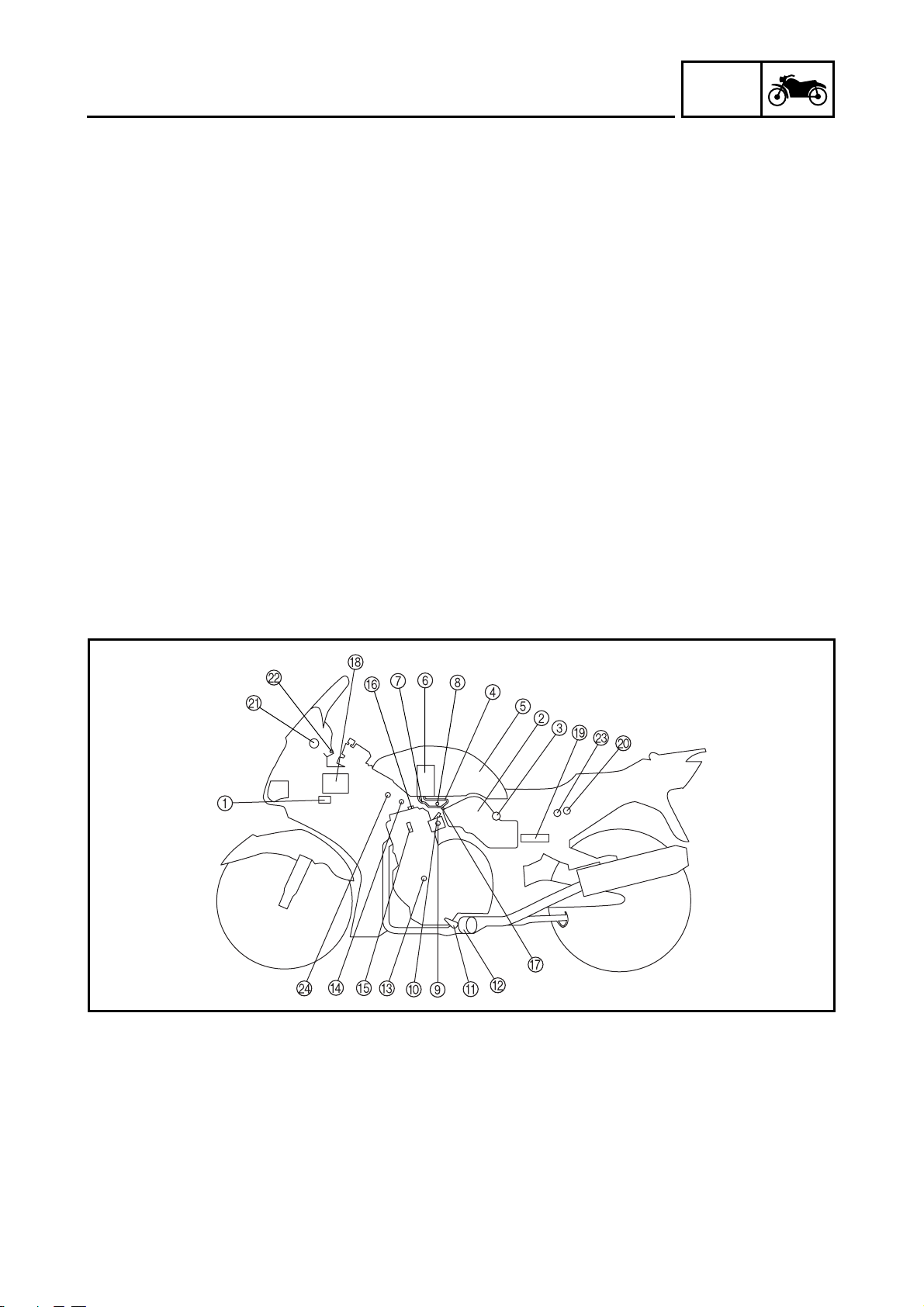

Ignition coil

1

Air filter case

2

Intake temperature

3

sensor

Fuel delivery hose

4

Fuel tank

5

Fuel pump

6

Fuel return hose

7

Intake air pressure

8

sensor

Throttle position sensor

9

Fuel injector

0

sensor

O

2

A

Catalytic converter

B

Crankshaft position

C

sensor

Coolant temperature

D

sensor

1 - 2

Spark plug

E

Cylinder identifica-

F

tion sensor

Pressure regulator

G

Battery

H

ECU

I

Atmospheric pressure

J

sensor

Fuel injection system

K

relay

Engine trouble warn-

L

ing light

Lean angle cut-off

M

switch

Air cut-off valve

N

GEN

FEATURES

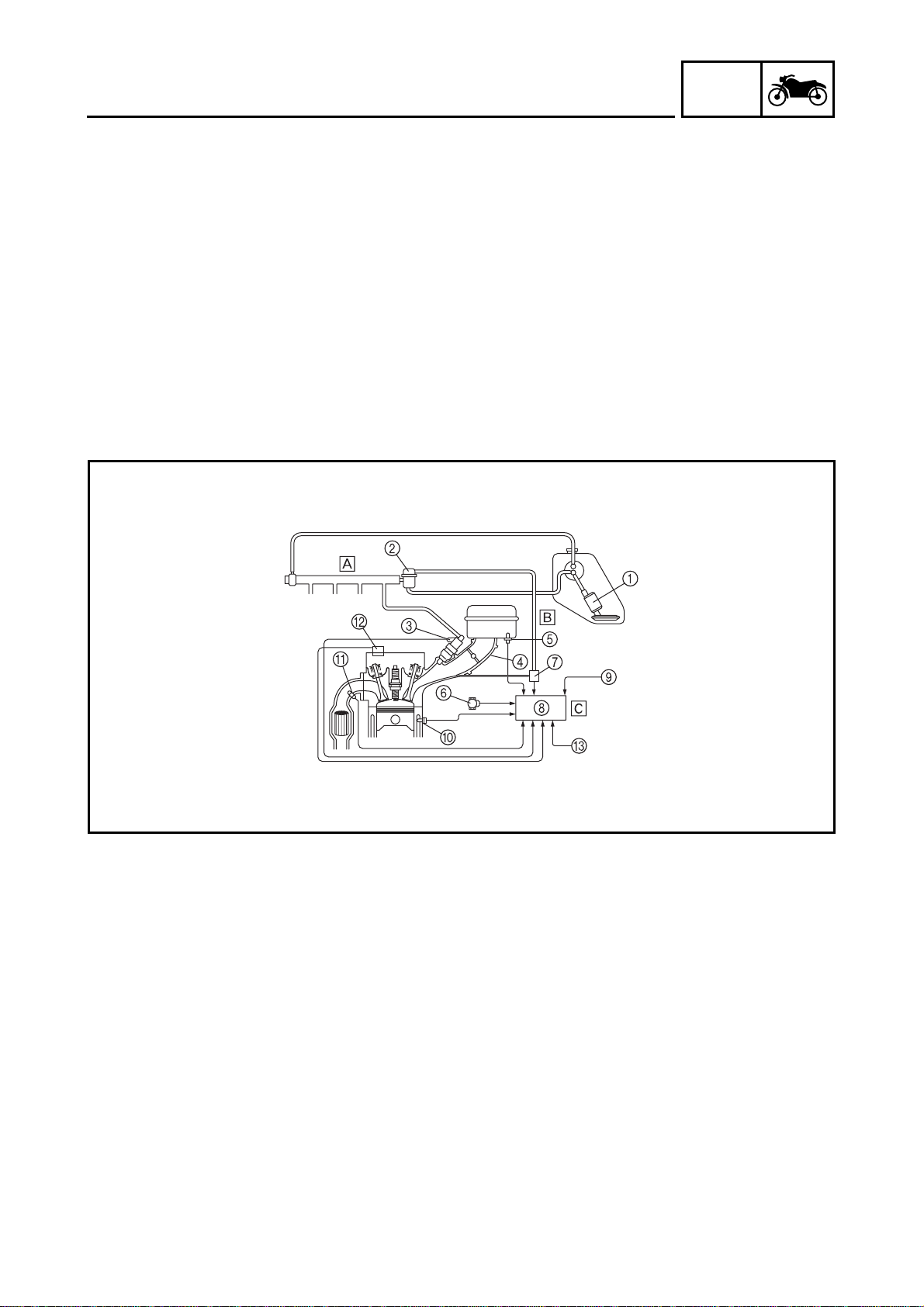

FI SYSTEM

The fuel pump delivers fuel to the injector via the fuel filter. The pressure regulator maintains the

2

fuel pressure that is applied to the injector at only 2.55 kg/cm

sure. Accordingly, when the energizing signal from the ECU energizes the injector, the fuel passage

opens, causing the fuel to be injected into the intake manifold only during the time the passage

remains open. Therefore, the longer the length of time the injector is energized (injection duration),

the greater the volume of fuel that is supplied. Conversely, the shorter the len gth of time the injector

is energized (injection duration), the lesser the volume of fuel that is supplied.

The injection duration and the injection timing are controlled by the ECU. Signals that are input from

the throttle position sensor, crankshaft position sensor, intake air pressure sensor, atmospheric

pressure sensor, intake temperature sensor, coolant temperature sensor, and O

ECU to determine the injection duration. The injection timing is determined through the signals from

the crankshaft position sensor and the cylinder identification sensor. As a result, the volume of fuel

that is required by the engine can be supplied at all times in accordance with the driving conditions.

Illustration is for reference only.

higher than the intake manifold pres-

INFO

2

sensor enable the

Fuel pump

1

Pressure regulator

2

Fuel injector

3

Throttle body

4

Intake temperature

5

sensor

#4

#3

Throttle position sen-

6

sor

Intake air pressure

7

sensor

ECU

8

Atmospheric pressure

9

sensor

#2

#1

Coolant temperature

0

sensor

sensor

O

2

A

Cylinder identification

B

sensor

Crankshaft position

C

sensor

Fuel system

È

Air system

É

Control system

Ê

1 - 3

GEN

FEATURES

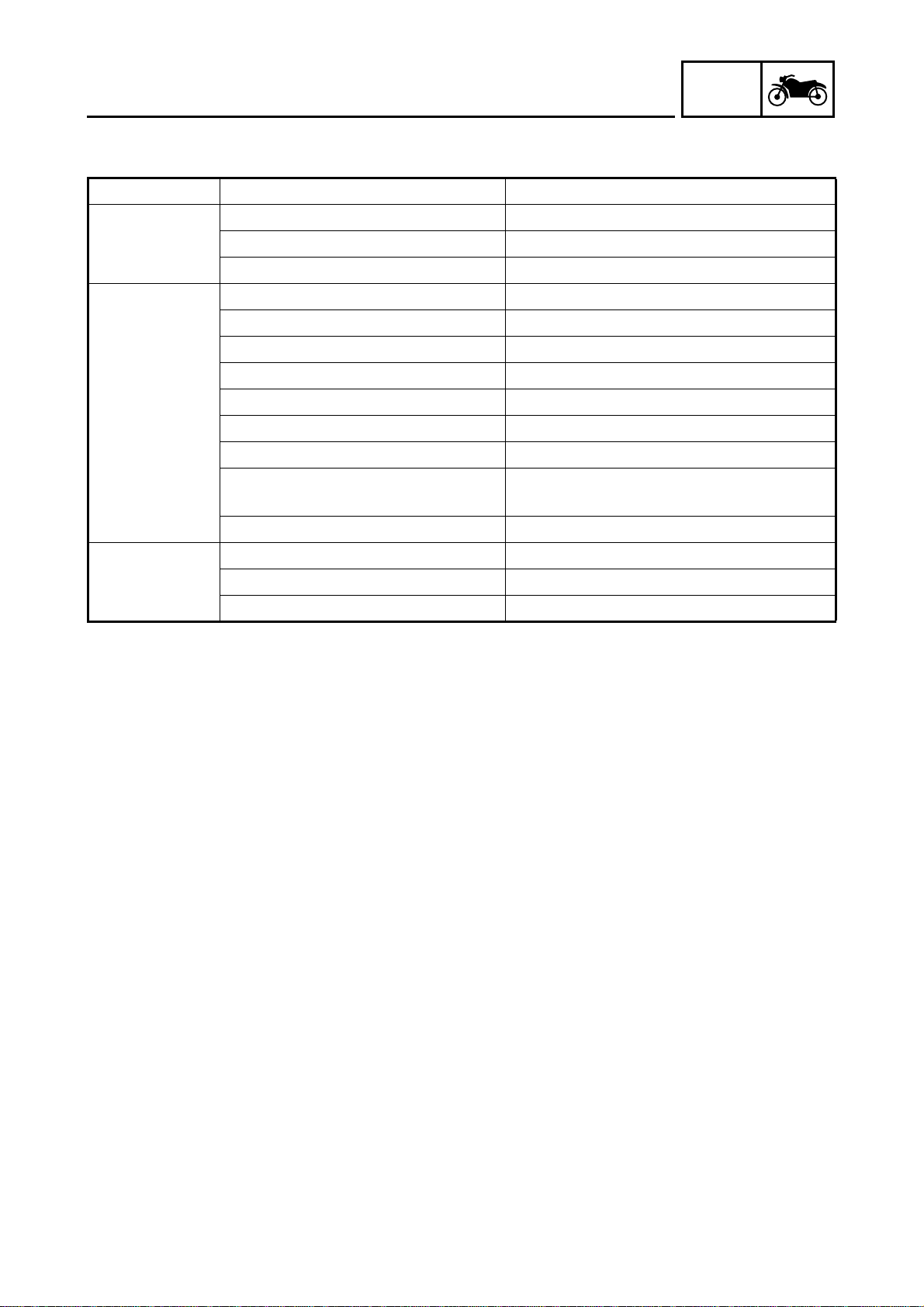

Fuel control block

The fuel control block consists of the following main components:

Component Function

Control block ECU Total FI system control

Throttle body Air volume control

Pressure regulator Fuel pressure detection

Sensor block Intake air pressure sensor Intake air pressure detection

Atmospheric pressure sensor Atmospheric pressure detection

Coolant temperature sensor Coolant temperature detection

Intake temperature sensor Intake temperature detection

Throttle position sensor Throttle angle detection

2

O

sensor Gas emission O2 concentration detection

Cylinder identification sensor Reference position detection

Crankshaft position sensor Crankshaft position detection and engine

RPM detection

Speed sensor Speed detection

INFO

Actuator block Injector Fuel injection

Fuel pump Fuel feed

Air Induction system, air cut valve Induction of secondary air

An FI warning light is provided on meter panel.

1 - 4

GEN

FEATURES

COMPONENTS

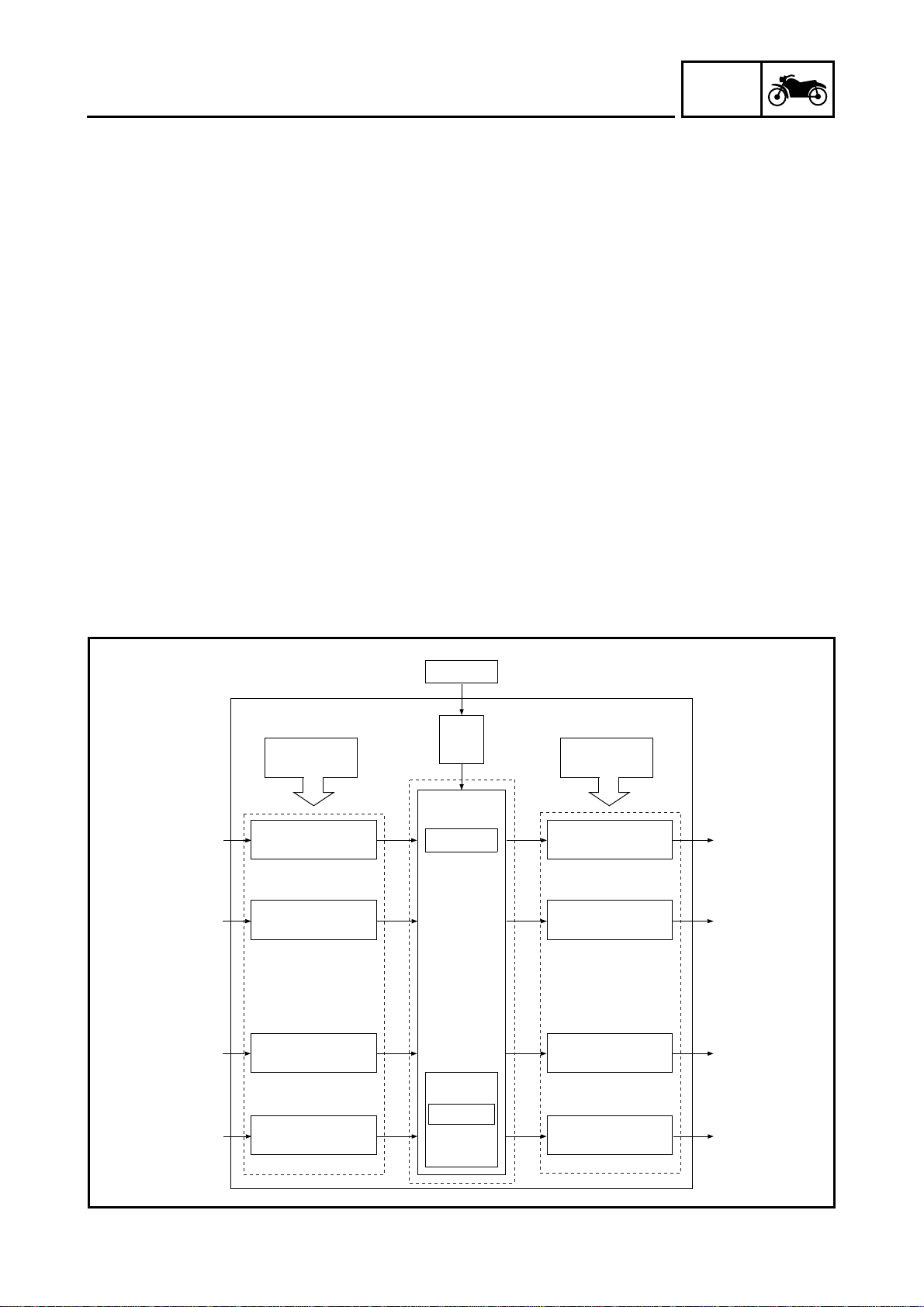

ECU (Electronic Control Unit)

The ECU is mounted underneath the seat, below the toolbox. The main fun ctio ns of th e ECU are

ignition control, fuel control, self-diagnosis, and load control.

• ECU’s internal construction and functions

The main components and functions of the ECU can be broadly divided into the following four

items:

A. Power supply circuit

The power supply circuit obtains power from the battery (12 V) to supply the power (5 V) that is

required for operating the ECU.

B. Input interface circuits

The input interface circuits convert the signals output by all the sensors into digital signals,

which can be processed by the CPU, and input them into the CPU.

C. CPU (Central Processing Unit)

The CPU determines the condition of the sensors in accordance with th e level of the signal that

is output by the respective sensor. Then, the signals are temporarily stored on the RAM in the

CPU. Based on those stored signals and the basic processing program on the ROM, the CPU

calculates the fuel injection duration, injection timing, and ignition timing, and then sends control commands to the respective output interface circuits.

D. Output interface circuits

The output interface circuits convert the control signals output by the CPU into actuating signals for the respective actuators in order to actuate them. They also output commands to the

indicator and relay output circuits as needed.

INFO

Hall sensor

signal

(for cylinder

identification)

Pickup coil signal

(for identifying the

crankshaft position)

Switches

Sensors

ECU

Input

interface circuit

Waveform

shaping circuit

Waveform

shaping circuit

Digital input circuit

A/D converter

input circuit

Battery

Power

supply

circuit

CPU

RAM/ROM

MEMORY

Output

interface circuit

Injector drive

output circuit

Ignition output circuit

Lamp drive

output circuit

Relay drive

output circuit

Injector

Ignition coil

Indicating lamp

Relay

1 - 5

GEN

FEATURES

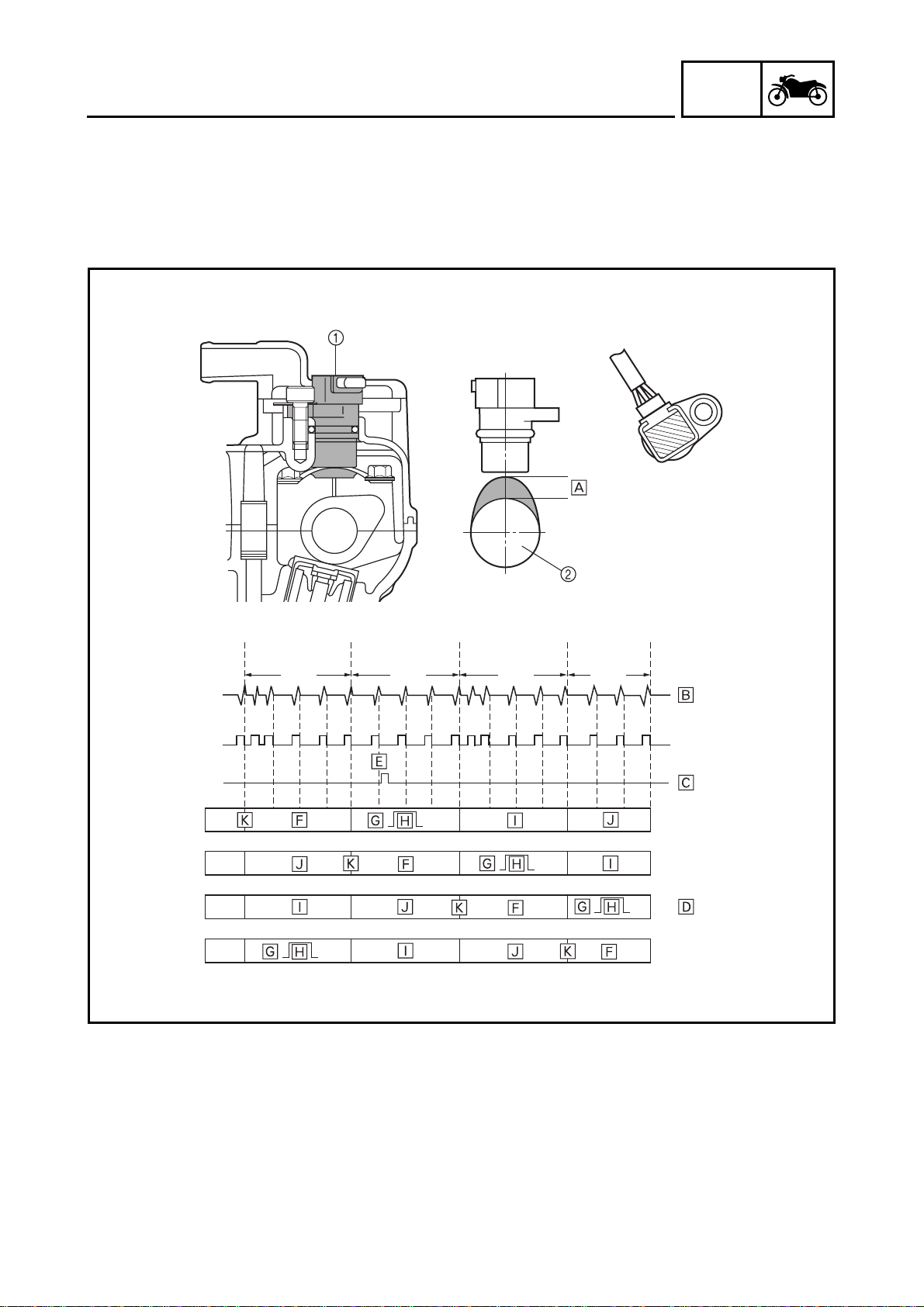

• Ignition control

The ignition control function of the ECU controls the ignition timing and the duration of ignition

energizing. The ignition timing control uses the signals from the throttle position sensor (to detect

the angle of the throttle), and the crankshaft position sensor and speed sensor (to detect the

speed of the engine). This control establishes an ignition timing that suits the operating condition

of the engine through compensations made to the basic ignition timing control map. The ignition

energizing duration control establishes the energizing duration to suit the operating conditions by

calculating the energizing duration in accordance with the signal received from the crankshaft

position sensor and the battery voltage.

• Fuel control

The fuel control function of the ECU controls the injection timing and injection duration. The injection timing control controls the injection timing during the starting of the engine and the injection

timing during the normal operation of the engine, based on the signals received from the crankshaft position sensor and the cylinder identification sensor. The injection duration control determines the duration of injection based on the signals received from the atmospheric pressure

sensors, temperature sensors, and the position sensors, to which compensations are made to suit

various conditions such as the weather, atmospheric pressure, starting, acceleration, and deceleration.

• Load control

The ECU effects load control in the following manner:

1. Stopping the fuel pump and injectors when the motorcycle overturns

The ECU turns OFF the fuel injection system relay when the lean angle cut-off switch is tripped.

2. Operating the headlight illumination relay

On the model for Europe, the ECU causes the headlight relay 2 to output a constant ON signal,

provided that the main switch is ON. On the model for Australia, the ECU controls the headlight

relay 2 in accordance with the engine speed as required by the daytime illumination specification.

3. Operating the radiator fan motor in accordance with the coolant temperature

The ECU controls the radiator fan motor relay ON/OFF in accordance with the coolant temperature.

4. Operating the AI system solenoid valve

The ECU controls the energizing of the solenoid valve in accordance with the driving conditions.

• Self-diagnosis function

The ECU is equipped with a self-diagnosis function to ensure that the engine control system is

operating normally. The ECU mode functions include a diagnosis mode in addition to the normal

mode.

Normal mode

• To check for any blown bulbs, this mode illuminates a warning light while the main switch is

turned ON, and while the starter switch is being pressed.

• If the starting disable warning is activated, this mode alerts the rider by blinking the warning light

while the start switch is being pressed.

• If a malfunction occurs in the system, this mode provides an appropriate substitute characteristic

operation, and alerts the rider of the malfunction by illuminating a warning light. After the engine

is stopped, this mode displays a fault code on the clock LCD.

Diagnosis mode

• In this mode, a diagnostic code is input into the ECU through the operation of the operating

switch on the meter, and the ECU displays the values output by the sensors or actuates the

actuators in accordance with the diagnostic code. Whether the system is ope ratin g nor mally can

be checked by observing the illumination of the warning light, the values displayed on the meter,

or the actuating state of the actuators.

INFO

1 - 6

GEN

FEATURES

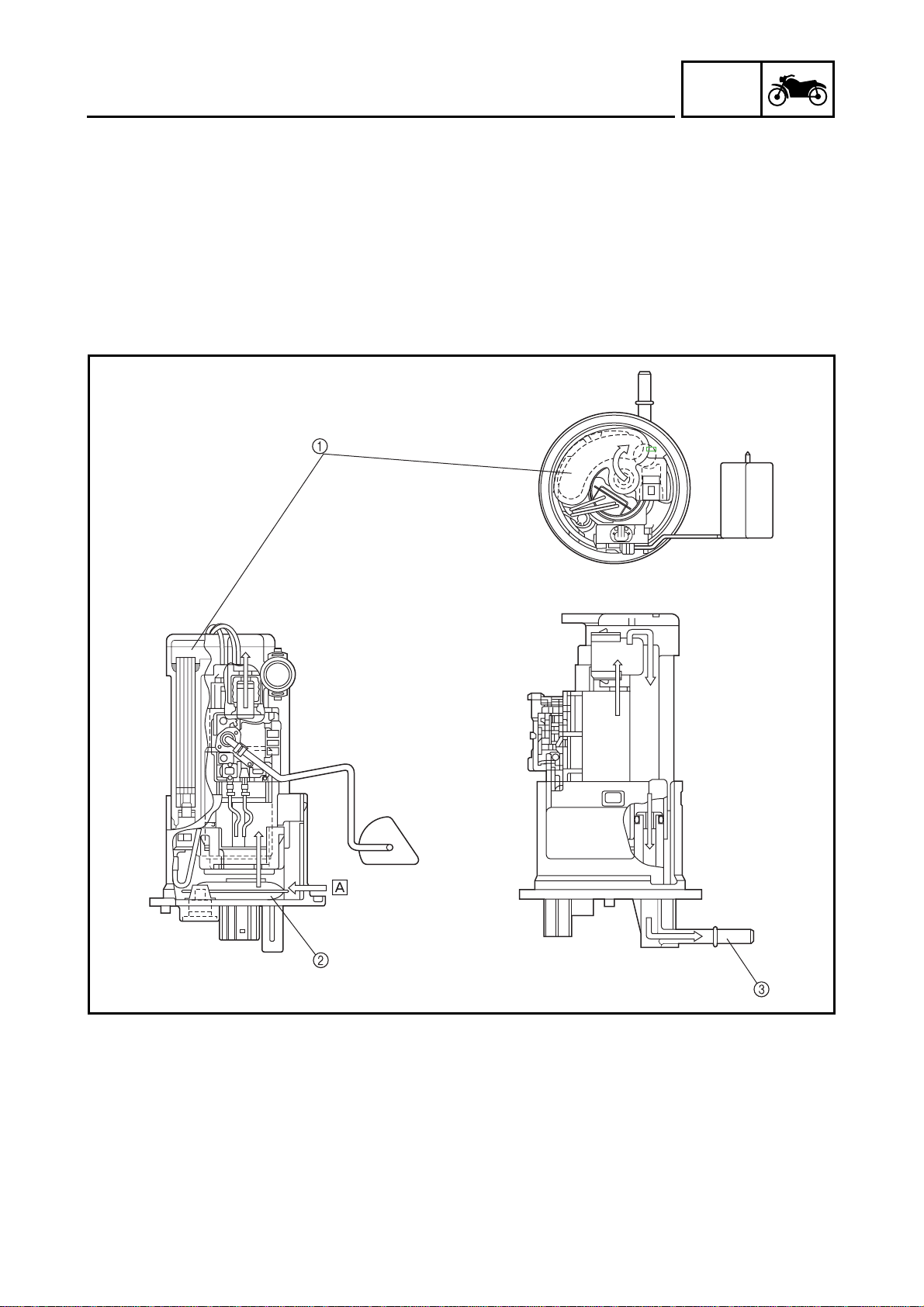

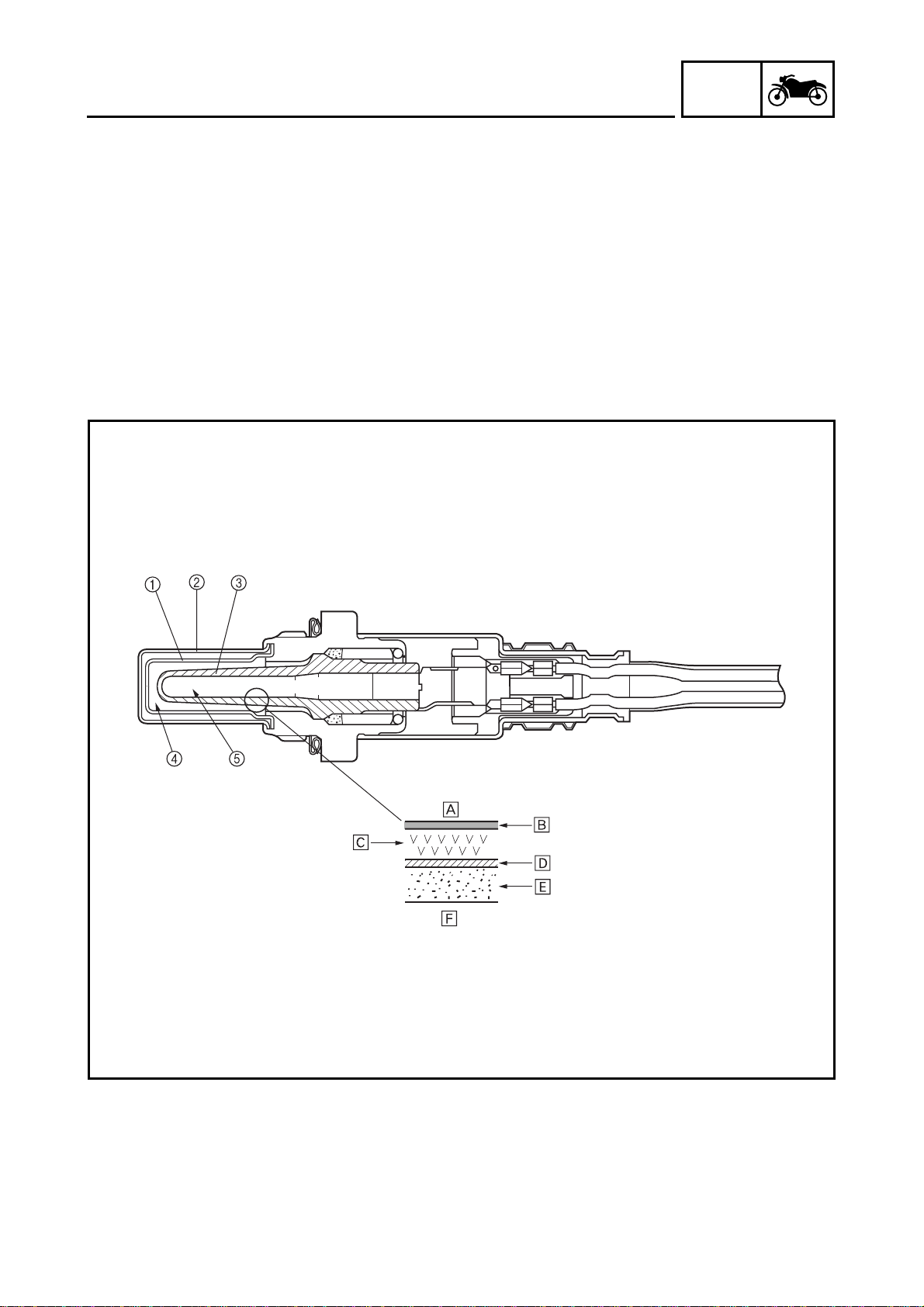

Fuel pump

The fuel pump, which is mounted in the fuel tank, draws the fuel directly from the tank and pumps it

to the injector.

A filter that is provided in the fuel pump prevents any debris in the fuel tank from entering the fuel

system downstream of the pump.

The pump consists of a pump unit, electric motor, filter, and valves.

The pump unit is a Wesco type rotary pump that is connected to the motor shaft.

A relief valve is provided to prevent the fuel pressure from rising abnormally if the fuel hose

becomes clogged. This valve opens when the fuel pressure at the discharge outlet reaches

between 440 and 640 kpa, and returns the fuel to the fuel tank.

INFO

Fuel filter

1

Fuel inlet strainer

2

Outlet

3

Fuel

È

1 - 7

GEN

FEATURES

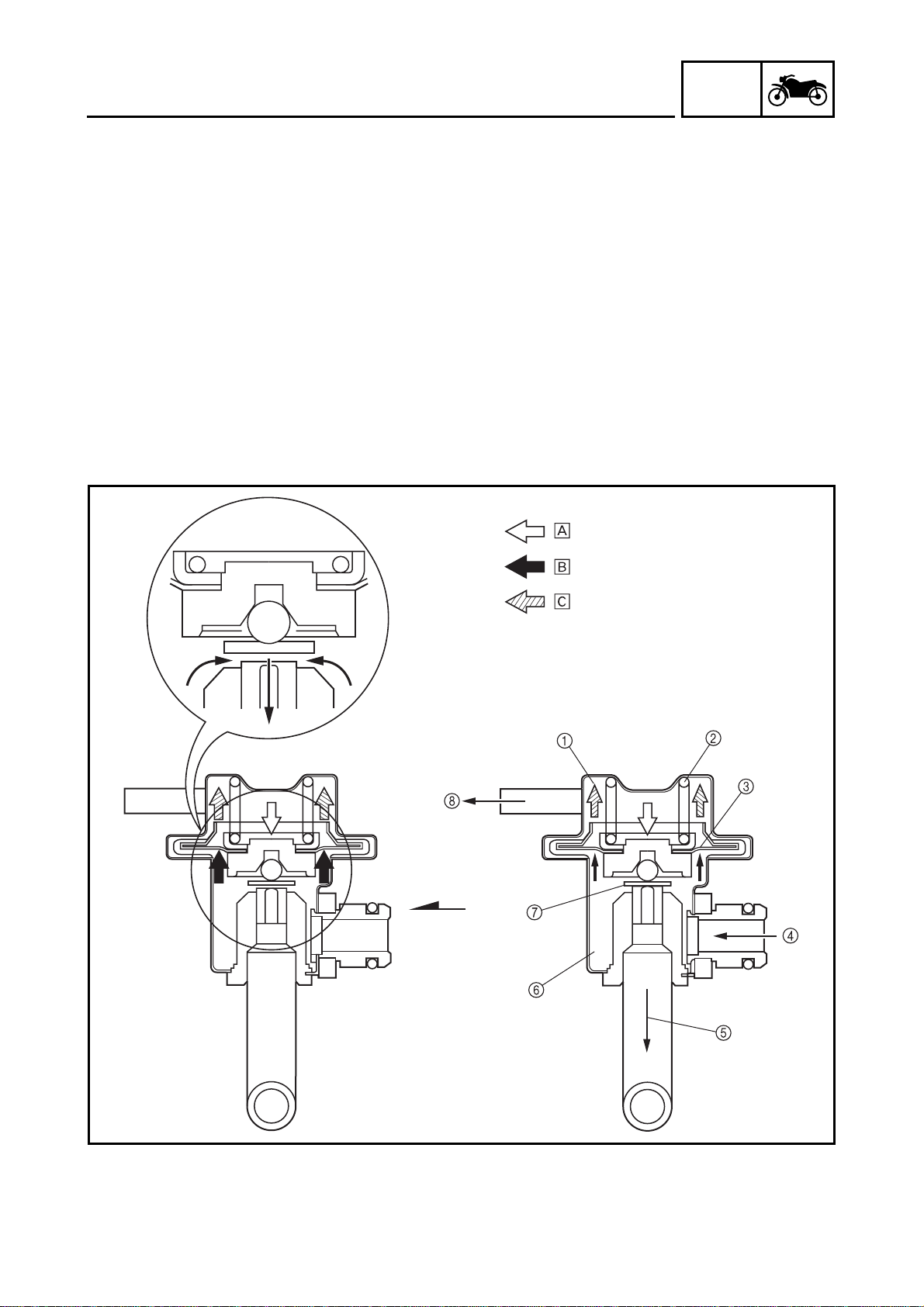

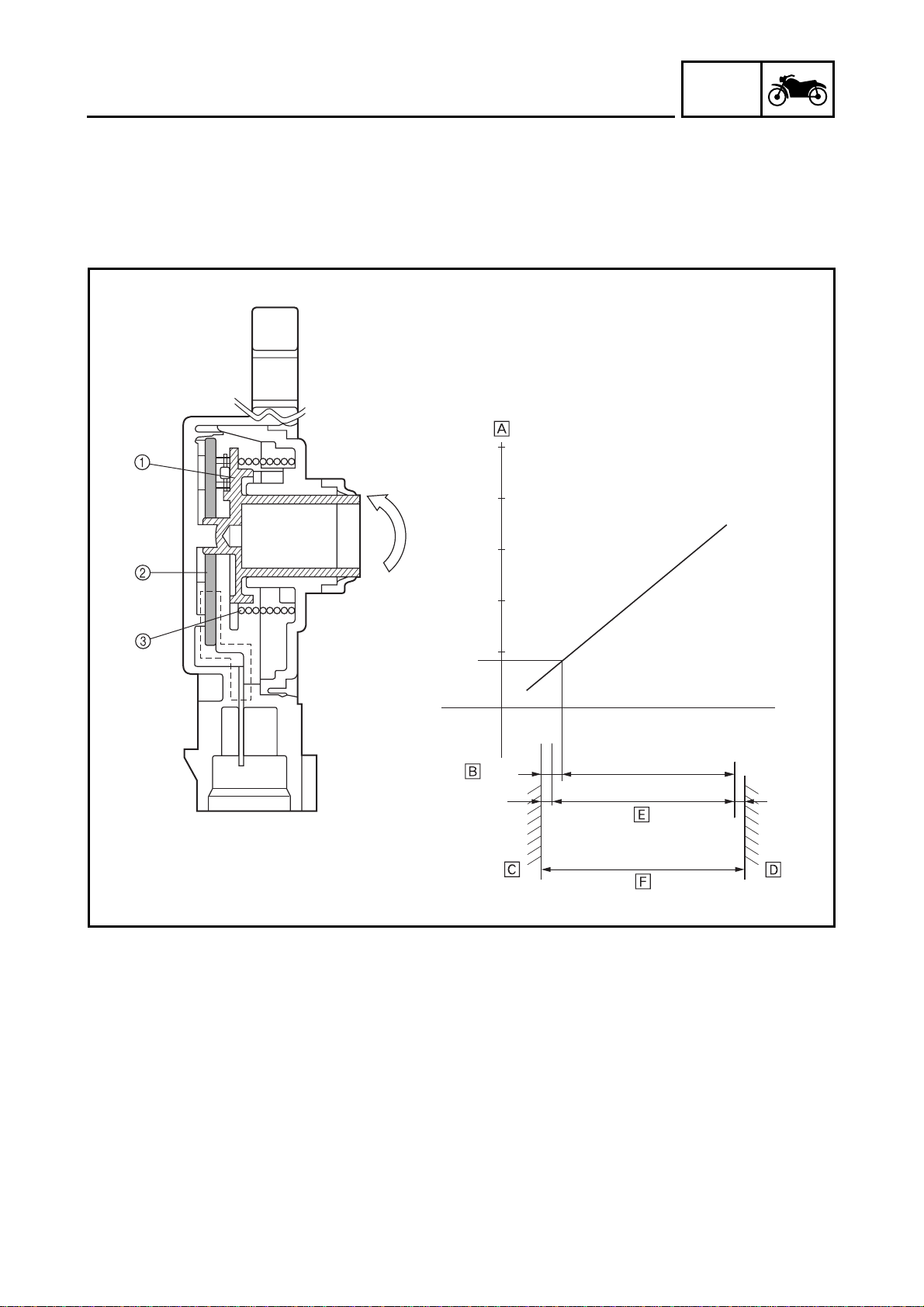

Pressure regulator

It regulates the fuel pressure that is applied to the injectors th at are provid ed in the cylind ers in order

to maintain a constant pressure difference with the pressure in the intake manifold.

The fuel that is delivered by the fuel pump fills the fuel chamber through the fuel inlet of the regulator

and exerts pressure on the diaphragm in the direction for opening the valve.

A spring that is provided in the spring chamber exerts pressure on the diaphragm in the dire ction for

closing the valve, in contrast to the pressure of the fuel. Thus, the valve cannot open unless the fuel

pressure overcomes the spring force.

An intake vacuum is applied to the spring chamber via a pipe. When the pressure of the fuel

exceeds the sum of the intake vacuum and the spring force, the valve that is integra ted with the diaphragm opens, allowing the fuel to return from the fuel outlet to the fuel tank, via the fuel return

hose.

As a result, because the intake vacuum fluctuates in accordance with the changes in the operating

conditions in contrast to the constant volume of fuel supplied by the pump, the valve opening/closing pressure also changes to regulate the return fuel volume. Thus, the difference between the fuel

pressure and the intake manifold pressure remains constant at a prescribed pressure.

INFO

Spring chamber

1

Spring

2

Diaphragm

3

Fuel inlet

4

Fuel outlet

5

Fuel chamber

6

7

8

1 - 8

Valve

Intake manifold vacuum pressure

Spring pressure

È

Fuel pressure

É

Vacuum pressure

Ê

GEN

FEATURES

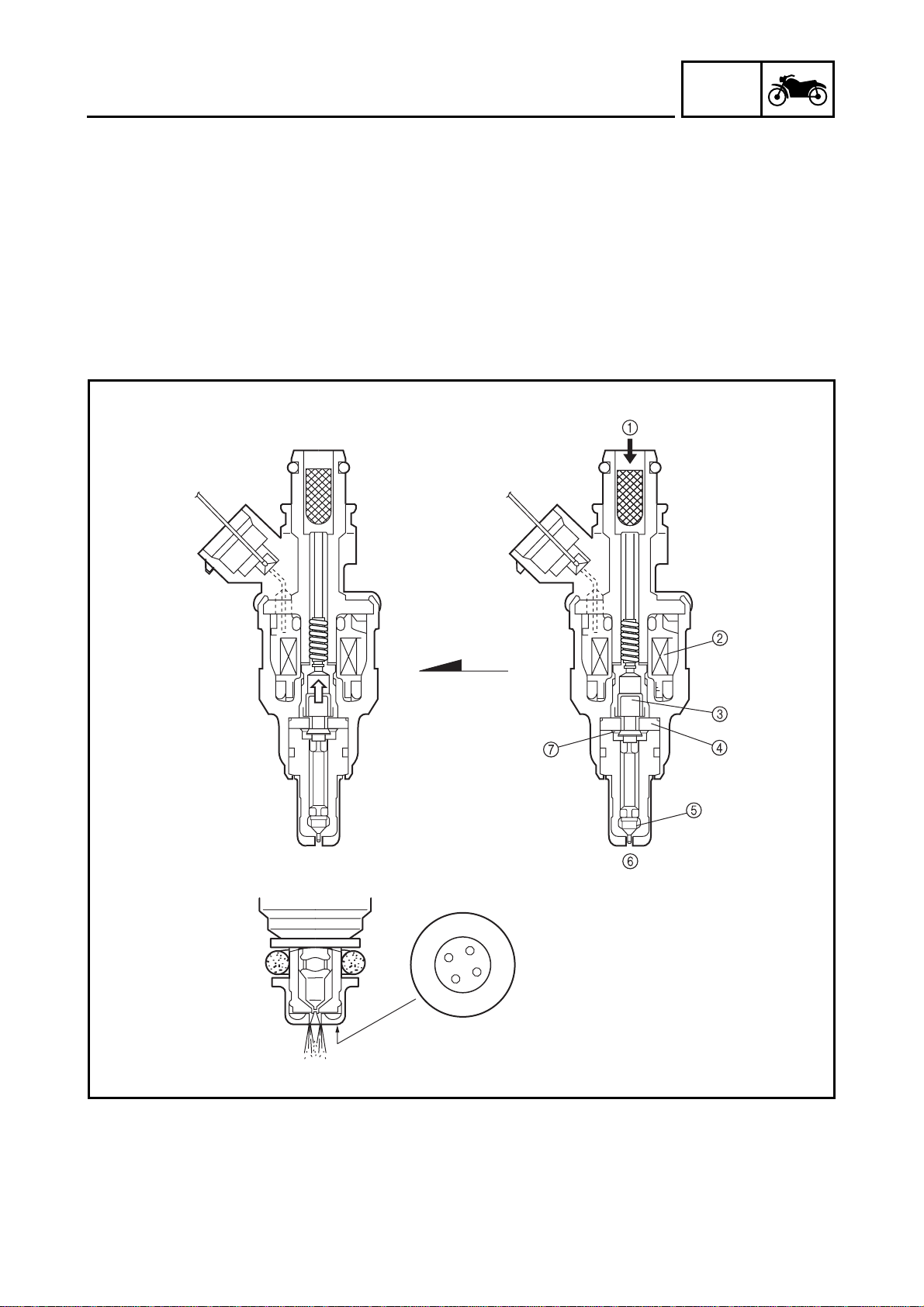

Fuel injector

Upon receiving injection signals from the ECU, the fuel injector injects fuel. In the normal state, the

core is pressed downward by the force of the spring, as illustrated. The needle that is integrated

with the bottom of the core keeps the fuel passage closed.

When the current flows to the coil in accordance with the signal from the ECU, the core is drawn

upward, allowing the flange that is integrated with the needle to move to the spacer. Since the distance of the movement of the needle is thus kept constant, the opening area of the fuel passage

also becomes constant. Because the pressure difference of the fuel to the intake manifold pressure

is kept constant by the pressure regulator, the fuel volume varies in proportion to the length of time

the coil is energized. The injector that has been recently adopted has a four-hole type injection orifice that enhances the atomization of fuel and improves combustion efficiency.

INFO

1

2

3

4

Fuel

Coil

Core

Spacer

5

6

7

Needle

Inject

Flange

1 - 9

GEN

FEATURES

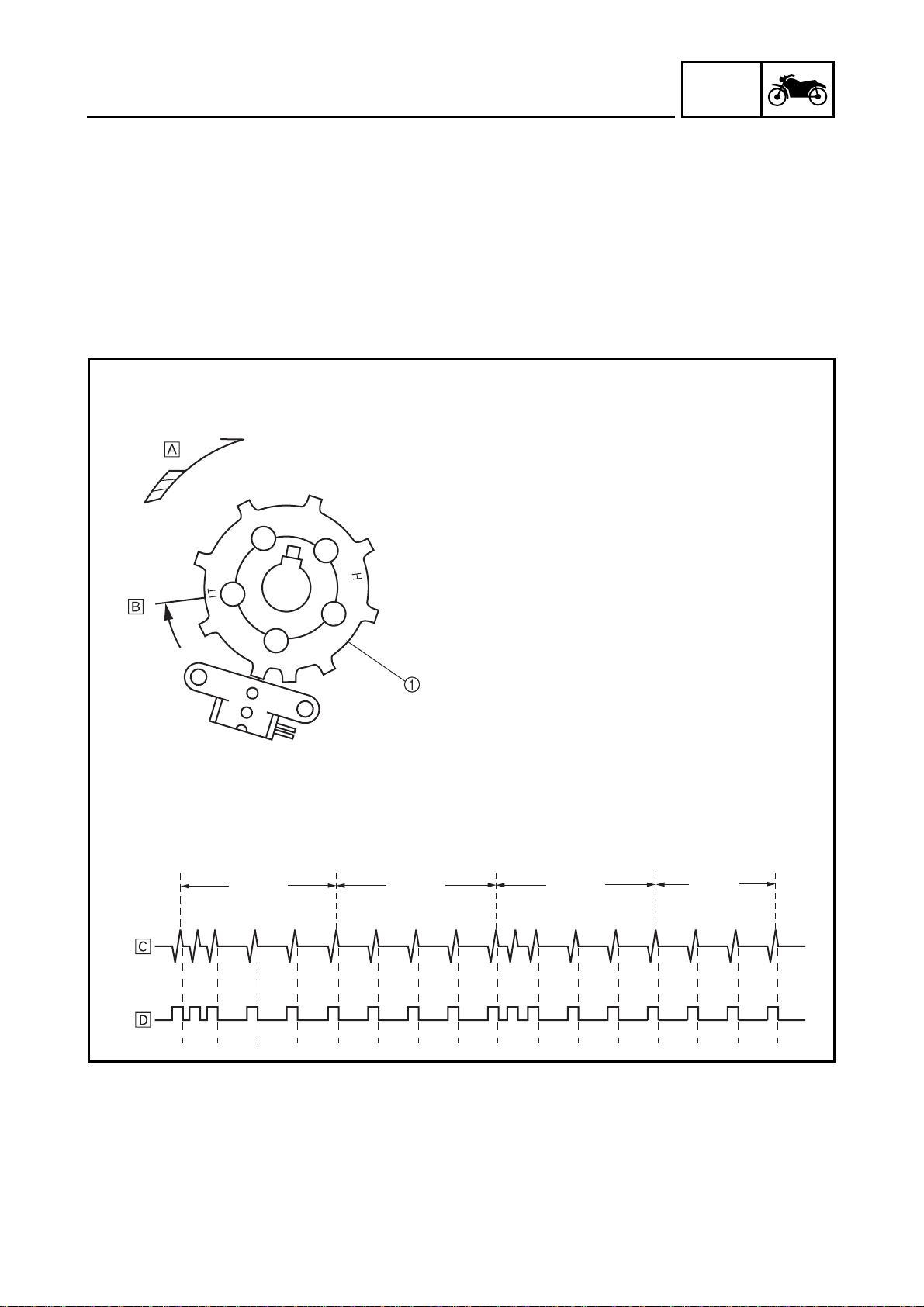

Crankshaft position sensor

The crankshaft position sensor uses the signals of the pickup coil that is mounted on the right side

of the crankshaft. When the rotation of the pickup rotor that is attached to the crankshaft causes the

projections on the rotor to pass by the pickup coil, an electromotive force is generated in the coil.

The voltage of this force is then input into the ECU, which calculates the position of the crankshaft

and the speed of the engine. The ignition timing is then determined in accordance with the calculated data, in order to determine the corresponding injection timing. Based on the changes in the

time intervals of the signals generated by the pickup coil, the ECU calculates the ignition timing

advance to suit the operating conditions. The injection timing is also advanced in accordance with

the ignition timing in order to supply fuel to the engine at an optimal timing.

INFO

5˚

F7T556

180˚

W

5

J

180˚

180˚

180˚

Pickup rotor

1

Direction of rotation

È

#1 cylinder compression stroke, 5° BTDC

É

Pickup signal

Ê

Trigger pole

Ë

1 - 10

GEN

FEATURES

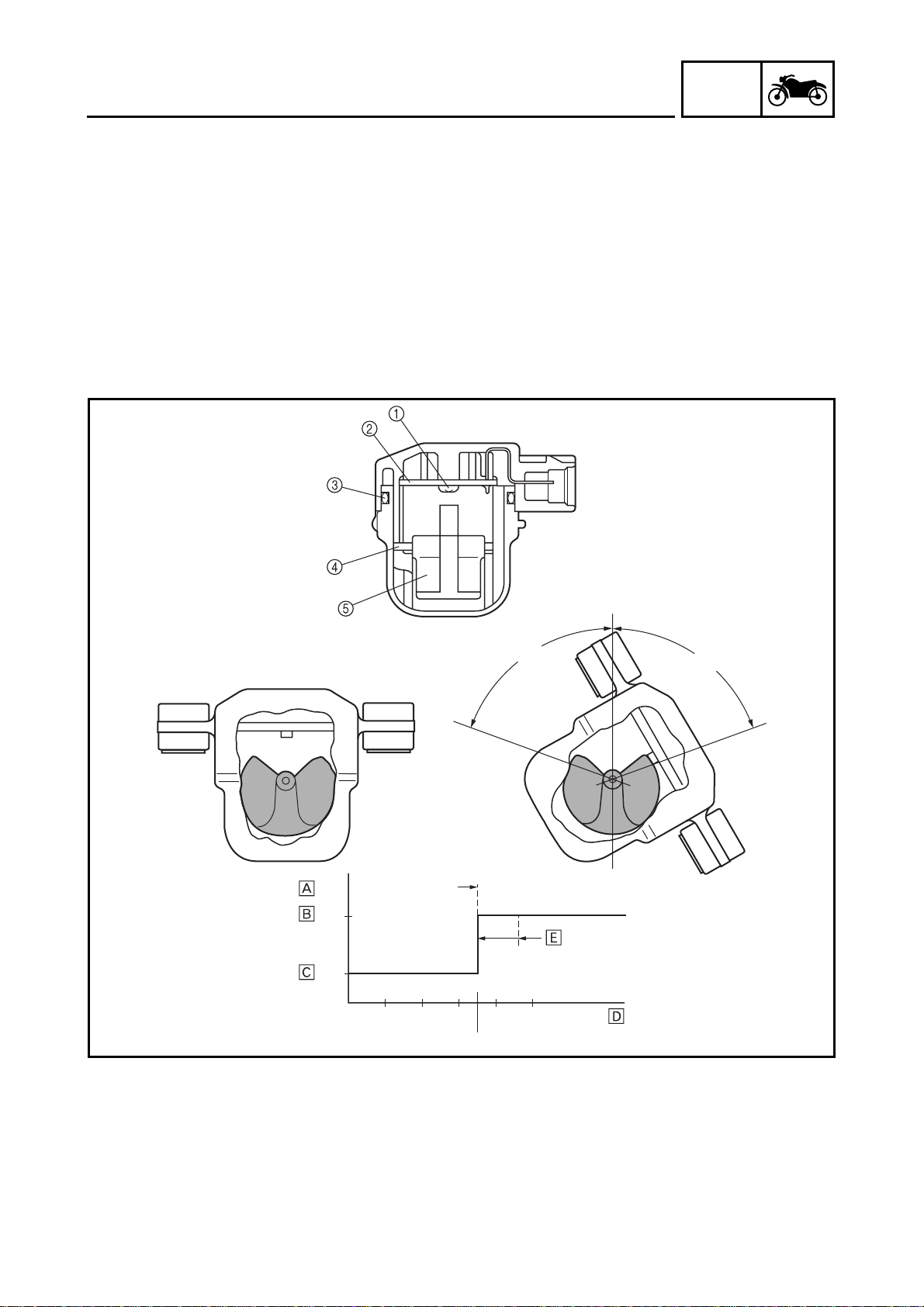

Cylinder identification sensor

The cylinder identification sensor is mounted on the exhaust head cover of the #4 cylinder. When

the exhaust cam of the #4 cylinder rotates and the lift of the cam passes by the sensor, the sensor

generates a signal and sends it to the ECU. Based on this signal and the signal from the crankshaft

position sensor, the ECU then actuates the injector of the cylinder that is currently in order to supply

fuel.

INFO

Cylinder identification

1

sensor

Cam

2

#1

#2

#4

#3

180˚

Cam lift

È

Crankshaft position

É

sensor signal

Cylinder identification

Ê

sensor signal

180˚

180˚

Cylinder firing order

Ë

#4 cam lobe onto

Ì

exhaust camshaft

Combustion

Í

180˚

Exhaust

Î

Injection

Ï

Intake

Ð

Compression

Ñ

Ignition

Ò

1 - 11

GEN

FEATURES

Throttle position sensor

The throttle position sensor measures the intake air volume by detecting the position of the throttle

valve. It detects the mechanical angle of the throttle valve through the positional relationship

between the moving contact that moves in unison with the throttle shaft and the resistor board. In

actual operation, the ECU supplies 5 V power to both ends of the resistor board and the voltage that

is output by the throttle position sensor is used to determine the angle of the throttle valve.

50

40

INFO

Moving contact

1

Resistor board

2

Spring

3

Output voltage

È

Idling output position

É

Mechanical stopper

Ê

Mechanical stopper

Ë

Effective electrical

Ì

angle

Sensor operating

Í

angle

30

20

10

0.68 V

10°

5°

95°

100°

110°

5°

1 - 12

GEN

FEATURES

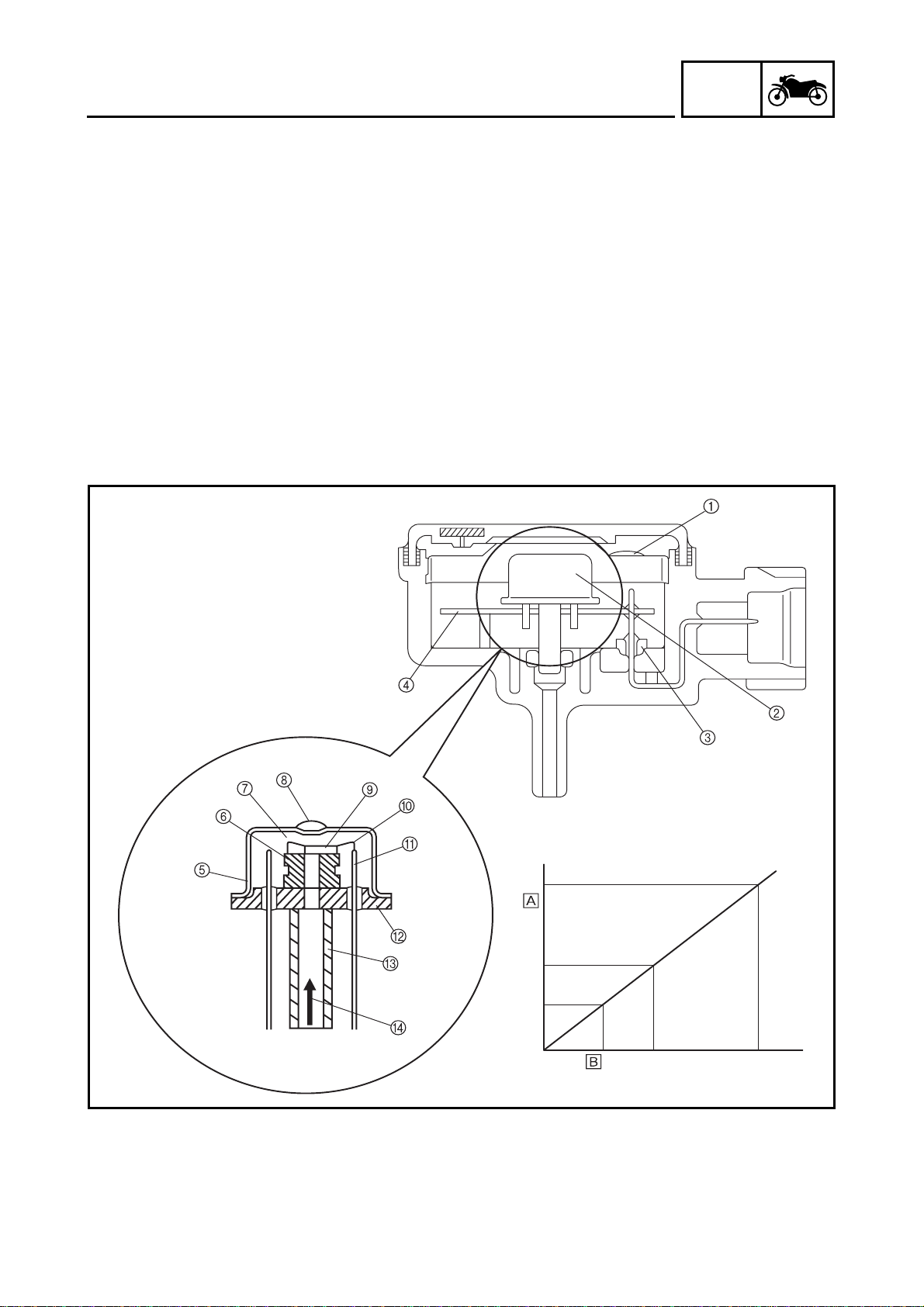

Intake air pressure sensor and atmospheric pressure sensor

• Intake air pressure sensor

The intake air pressure sensor is used for measuring the intake air volume. The intake air volume of

every intake stroke is proportionate to the intake air pressure. Therefore, the intake air volume can be

measured by measuring the intake air pressure. The intake air pressure sensor converts the measured intake air pressure into electrical signals and sends those signals to the ECU. When the intake

air pressure is introduced into the sensor unit, which contains a vacuum chamber on one side of the

silicon diaphragm, the silicon chip that is mounted on the silicon diaphragm converts the intake air

pressure into electrical signals. Then, an integrated circuit (IC) amplifies and adjusts the signals and

makes temperature compensations, in order to generate electrical signals that are proportionate to

the pressure.

• Atmospheric pressure sensor

The atmospheric pressure sensor is used for making compensations to the changes in the air

density caused by the changes in the atmospheric pressure (particularly at high altitudes). The

operating principle and function of the atmospheric pressure sensor are the same as those of the

aforementioned intake air pressure sensor.

INFO

EMI shield

1

Sensor unit

2

Through condenser

3

Hybrid IC

4

Cap

5

Silicon diaphragm

6

Vacuum chamber

7

Solder

8

Silicon chip

9

Gold wire

0

A

B

C

D

1 - 13

(V)

P

Lead pin

Stem

Pressure induction pipe

Atmospheric pressure,

intake air pressure

Output voltage

È

Input pressure

É

GEN

FEATURES

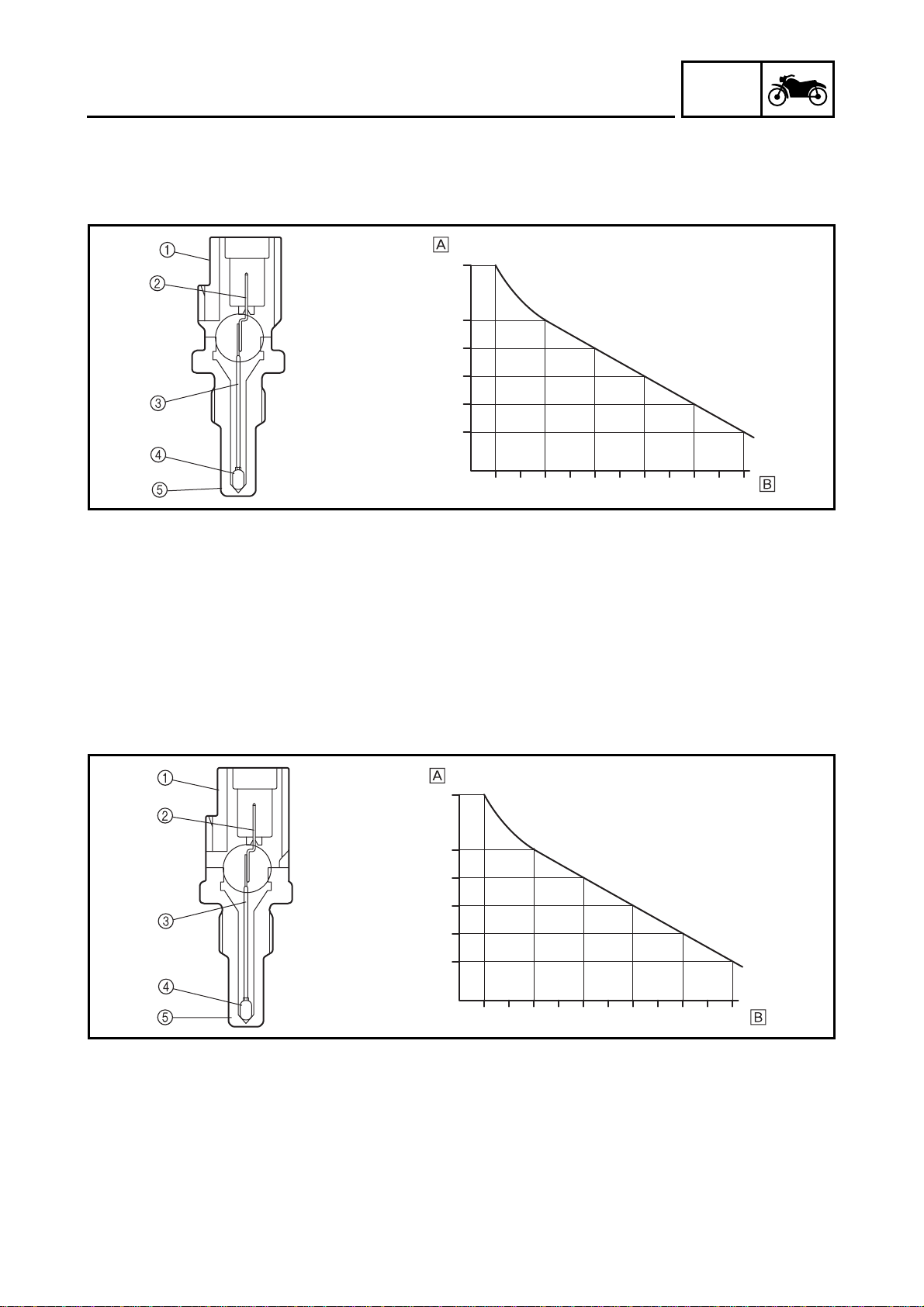

Coolant temperature sensor

The signals from the coolant temperature sensor are used primarily for making fuel volume compensations during starting and warm-up. The coolant temperature sensor converts the temperature of

the coolant into electrical signals and sends them to the ECU.

15.5

0.322

INFO

80

Ω

Connector

1

Terminal

2

Tube

3

Thermistor

4

-20 0 20 40 60

Holder

5

Resistance k

È

Temperature °C

É

Intake temperature sensor

The intake temperature sensor corrects the deviation of the air-fuel mixture that is associated with

the changes in the intake air density, which are created by the changes in the intake air temperature

that occur due to atmospheric temperatures. This sensor uses a semi-cond ucto r the rmistor that has

a large resistance at low temperatures and a small resistance at high temperatures. The thermistor

converts the temperature-dependent changes in resistance into electrical resistance values, which

are then input into the ECU.

6.0

Connector

1

Terminal

2

Tube

3

Thermistor

4

Holder

5

Resistance k

È

Temperature °C

É

0.34

-20 0 20 40 60

Ω

80

1 - 14

GEN

FEATURES

O2 sensor

2

The O

maintaining the air-fuel mixture near the stoichiometric ratio (14.7:1). This sensor, which is a zirconia type, utilizes the oxygen ion conductivity of the solid electrolyte for detecting the oxygen concentration levels. In actual operation, a zirconia tube made of solid electrolyte is exposed in the exhaust

gas, so that the exterior of the zirconia tube is in contact with the exhaust gas and the interior is in

contact with the atmosphere whose oxygen concentration level is known. When a difference in the

oxygen concentration level is created between the outside and the inside of the zirconia tube, the

oxygen ion passes through the zirconia element and generates an electromotive force. The electromotive force increases when the oxygen concentration level is low (rich air-fuel ratio) and the electromotive force decreases when the oxygen concentration level is high (lean air-fuel ratio). As

electromotive force is generated in accordance with the concentration of the exhaust gas, the resultant voltage is input into the ECU in order to correct the duration of the injection of fuel.

sensor has been adopted to enable the catalyst to function at a high degree of efficiency by

INFO

Inner cover

1

Outer cover

2

Zirconia tube

3

Exhaust gas

4

Atmosphere

5

È

É

Ê

1 - 15

Atmosphere

Inner electrode

Zirconia element

Outer electrode

Ë

Porous ceramic layer

Ì

Exhaust gas

Í

GEN

FEATURES

Lean angle cut-off switch

The lean angle cut-off switch stops the supply of fuel to the engine in case the motorcycle overturns.

When the motorcycle is in the normal state, the cut-off switch outputs a constant voltage of approximately 1.0 V (low level). When the motorcycle tilts, the float in the switch tilts in proportion to the tilt

of the motorcycle. However, the voltage output to the ECU remains unchanged at the low level.

When the tilt of the motorcycle exceeds 70 degrees (according to the tilt of the float), the signal from

the sensor increases to approximately 4.0 V (high level). When the ECU receives the high-level voltage, it determines that the motorcycle has overturned, and stops the delivery of fuel to the engine by

turning OFF the fuel injection system relay that powers the fuel pump and the injectors. Once the

cut-off switch is tripped, the ECU maintains this state; therefore, even if the motorcycle has recovered its upright position, this state will not be canceled unless the main switch is turned OFF, and

then turned back ON.

INFO

Thyristor

1

IC unit

2

O-ring

3

Shaft

4

Float

5

V

4.0

1.0

20° 40° 60° 80°

Output voltage

È

High level

É

Low level

Ê

Cut-off switch tilt angle

Ë

Fuel injection system

Ì

relay OFF

70°

70°

70°

1 - 16

GEN

FEATURES

FUEL INJECTION SYSTEM

Operation and control

The fuel injection timing, injection duration, ignition timing, and the coil energizing duration are controlled by the ECU. To determine the basic injection timing, the ECU calculates the intake air volume

through the signals from the intake air pressure sensor, throttle position sensor, cylinder identification sensor, and crankshaft position sensor.

Furthermore, the ECU calculates the final injection timing by adding the following compensations to

the aforementioned basic injection duration: those obtained from the state of acceleration, as well

as those based on the signals from various sensors such as the coolant temperature, intake temperature, atmospheric, and exhaust pipe oxygen concentration level. At the same time, the ECU

assesses the crankshaft position through the signals from the cylinder identification sensor and the

crankshaft position sensor. Then, when the ECU determines that it is time to inject fuel, it sends an

injection command to the injectors. Furthermore, the ECU also controls the length of time the coil is

energized by calculating the ignition timing and the coil energizing duration based on the signals

from these sensors.

Determining the basic injection duration

The intake air volume determines the basic injection duration. In order to operate the engine in an

optimal condition, it is necessary to supply fuel at an air-fuel ratio that corresponds appropriately to

the volume of intake air that is constantly changing, and to ignite it an appropriate timing. The ECU

controls the basic injection duration based on the intake air volume and engine speed data.

INFO

Detection of intake air volume

The intake air volume is detected primarily through the signals from the throttle position sensor and

the intake air pressure sensor. The intake air volume is determined in accordance with the signals

from the atmospheric pressure sensor, intake temperature sensor, and the engine speed data.

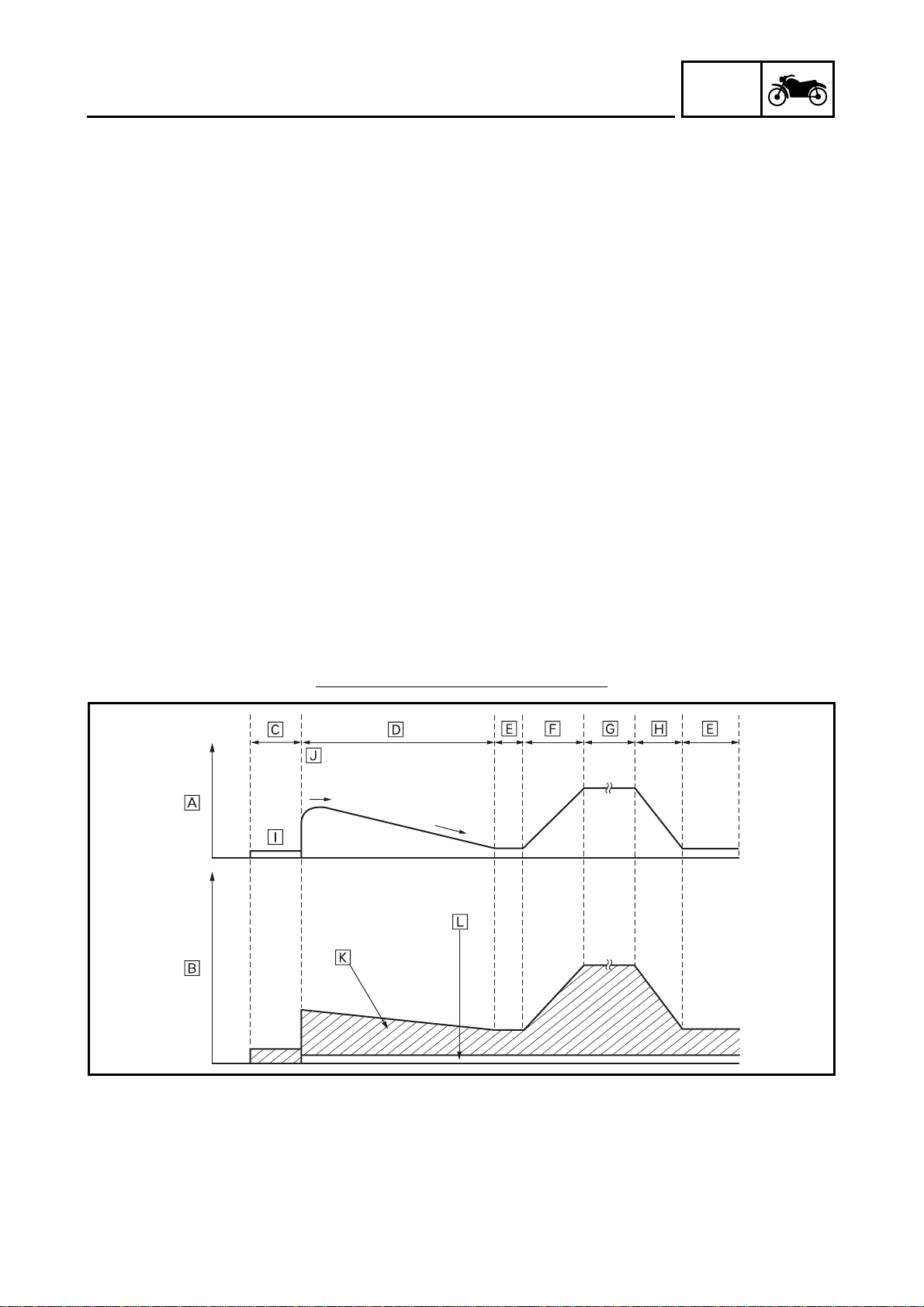

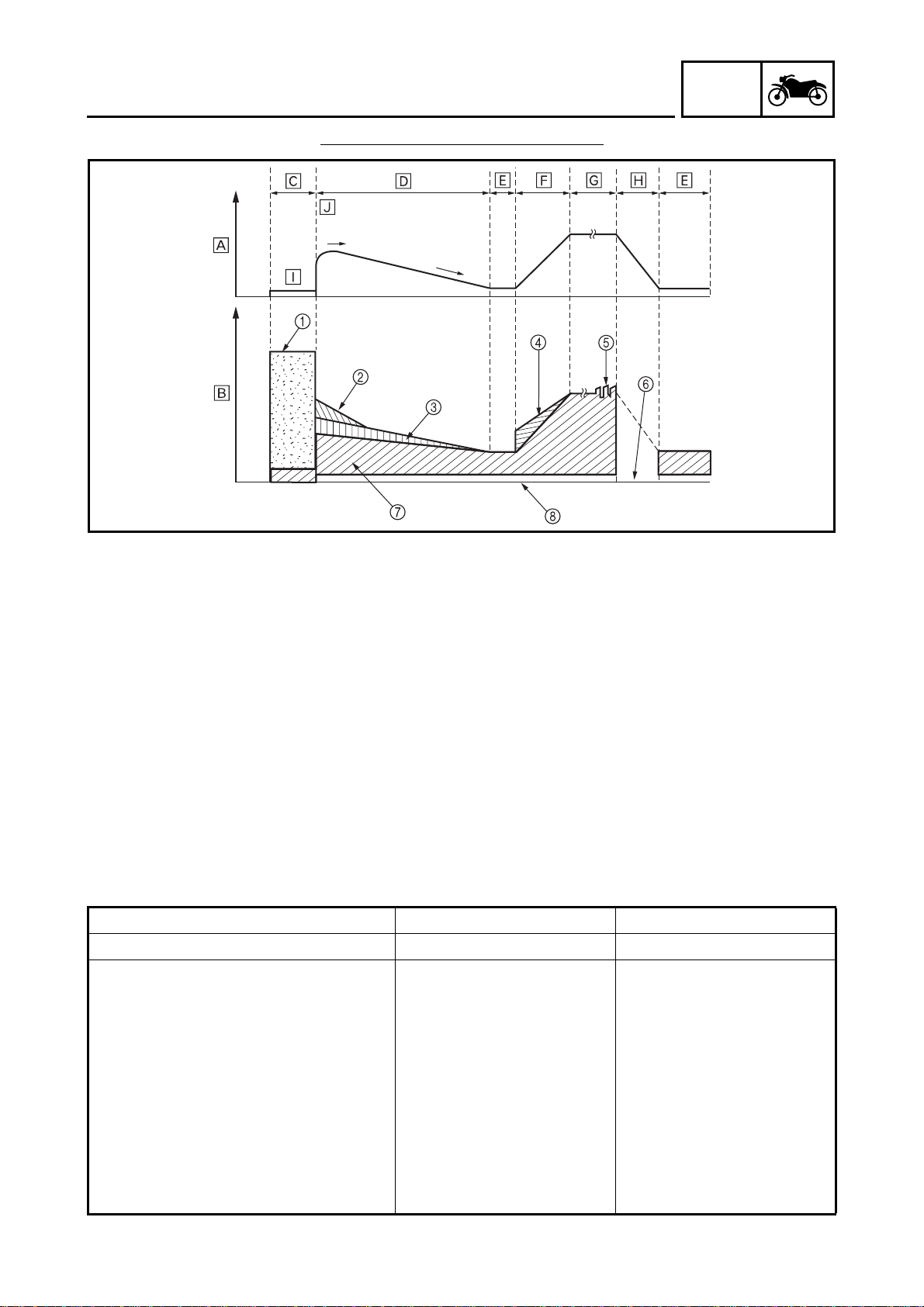

Composition of basic injection duration

RPM

È

Injection duration

É

Cranking

Ê

Warm-up

Ë

Idle

Ì

Acceleration

Í

Î

Ï

Ð

1 - 17

Constant

Deceleration

Start

After start

Ñ

Basic injection dura-

Ò

tion

Voltage compensation

Ó

duration

GEN

FEATURES

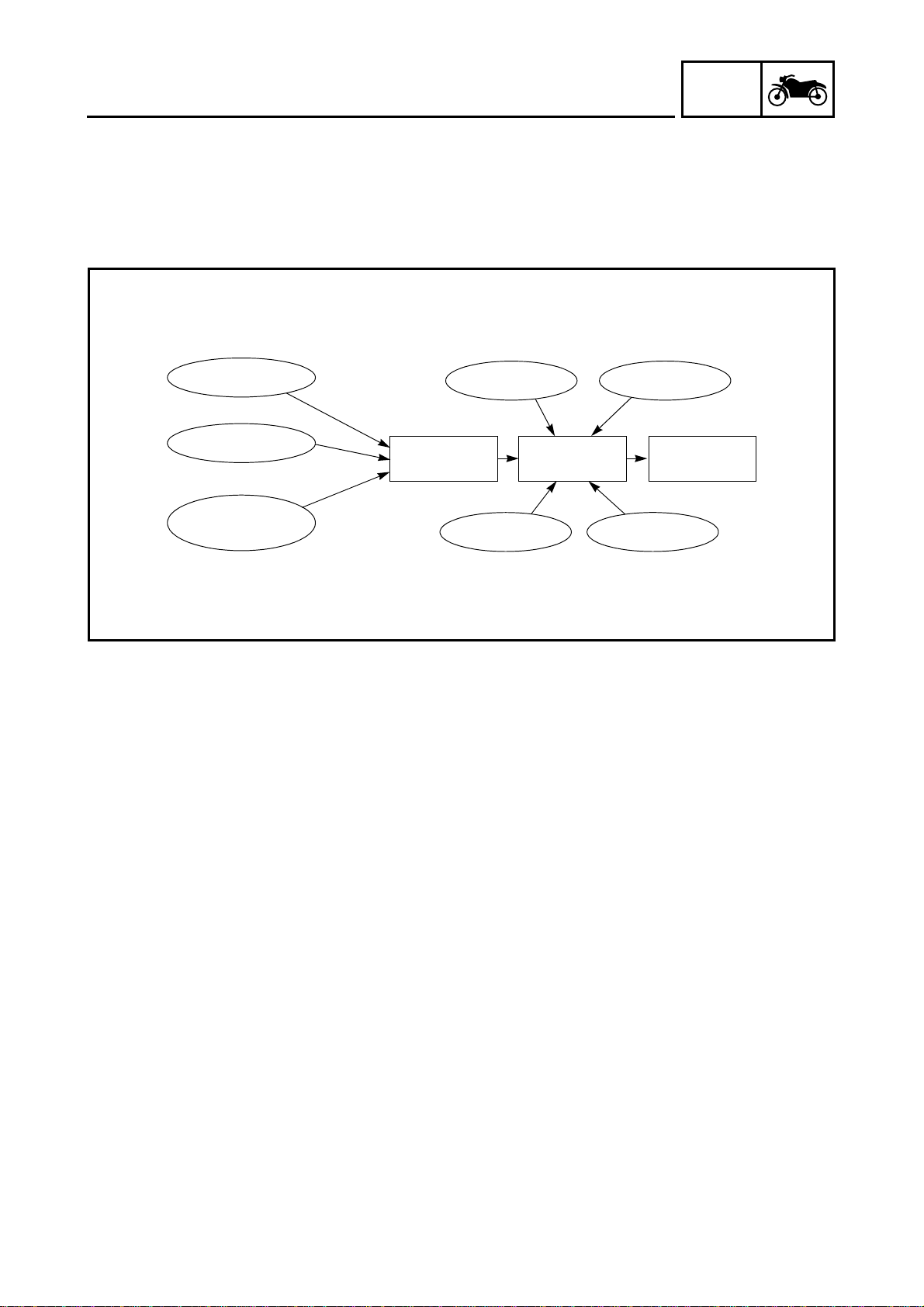

Determining the final injection duration

The intake air volume determines the basic injection duration. However, at a given intake air volume, the volume of fuel that is required varies by the engine operating conditions such as acceleration or deceleration, or by weather conditions. This system uses various sensors to precisely check

these conditions, applies compensations to the basic injection duration, and determines the final

injection duration based on the operating condition of the engine.

INFO

Intake air pressure

Engine rpm

Degree of

opening of

throttle

Basic injection

quantity

Atmospheric

pressure

Water

temperature

Compensation

Battery voltage

Injection

command

Intake air

temperature

The fuel is cut off under conditions that do not require fuel, in order to stop the injection.

1 - 18

FEATURES

Composition of final injection duration

GEN

INFO

Injection at start *1

1

After-start enrichment

2

*2

Warm-up enrichment

3

*3

Acceleration compen-

4

sation *5

Oxygen feedback *6

5

Fuel cut-off

6

Deceleration compensation *5

Basic injection dura-

7

tion

Voltage compensation

8

duration

RPM

È

Injection duration

É

Cranking

Ê

Warm-up

Ë

Idle

Ì

Acceleration

Í

Constant

Î

Deceleration

Ï

Start

Ð

After start

Ñ

Reactive injection duration:

A lag is created between the time the ECU outputs a fuel injection signal to the injector and the time

the injector actually opens. Therefore, the ECU calculates this lag in advance before sending the

actuation signal to the injector. The battery voltage determines the reactive injection duration.

• High voltage → short reactive injection duration

• Low voltage → long reactive injection duration

LIST OF FUEL INJECTION COMPENSATIONS

Compensation item Check item Sensor used

Starti ng injection *1 Coolant temperature Coolant temperature sensor

After-start injection:

After-start enrichment *2 Coolant temperature Coolant temperature sensor

Warm-up enrichment *3 Coolant temperature Coolant temperature sensor

Intake temperature compensation *4 Intake temperature Intake temperature sensor

Acceleration compensation/decelera-

Intake air pressure Intake air pressure sensor

tion compensation *5

Throttle position Throttle position sensor

Coolant temperature Coolant temperature sensor

Air-fuel ratio feedback compensation*6Exhaust gas residual oxy-

gen concentration

1 - 19

2

O

sensor

Loading...

Loading...