Yamaha FJR1300 AP 2010 Owner's manual

FJR1300AP

SUPPLEMENTARY MANUAL FOR POLICE VERSION

SUPPLEMENT AU MANUEL POUR LE MODELE DE POLICE

ERGÄNZENDE WARTUNGSANLEITUNG FÜR POLIZEI-MODELL

MANUALE SUPPLEMENTARE PER LA VERSIONE PER LA POLIZIA

MANUAL SUPLEMENTARIO PARA LA VERSIÓN DE POLICÍA

5P5-28199-52

SUPPLEMENTARY MANUAL FOR POLICE VERSION

SUPPLEMENT AU MANUEL POUR LE MODELE DE POLICE

ERGÄNZENDE WARTUNGSANLEITUNG FÜR POLIZEI-MODELL

MANUALE SUPPLEMENTARE PER LA VERSIONE PER LA POLIZIA

MANUAL SUPLEMENTARIO PARA LA VERSIÓN DE POLICÍA

WIRING DIAGRAM / SCHÉMA DE CÂBLAGE / SCHALTPLAN /

SCHEMA ELETTRICO / DIAGRAMA ELÉCTRICO

INTRODUCTION

This supplementary manual has been prepared to introduce new service and data for the

FJR1300AP. For complete information on service procedures, it is necessary to use this manual together with following manuals:

FJR1300A OWNER'S MANUAL (1CY-28199-E0, -F0, -G0, -H0, -S0)

FJR1300A SERVICE MANUAL (3P6-28197-E3, -F3, -G3, -H3, -S3)

FJR1300A ASSEMBLY MANUAL (3P6-28107-51)

IMPORTANT MANUAL INFORMATION

Particularly important information is distinguished in this manual by the following notations.

This is the safety alert symbol. It is used to alert you to potential personal

injury hazards. Obey all safety messages that follow this symbol to avoid

possible injury or death.

A WARNING indicates a hazardous situation which, if not avoided, could

result in death or serious injury.

A NOTICE indicates special precautions that must be taken to avoid damage to the vehicle or other property.

A TIP provides key information to make procedures easier or clearer.

Yamaha continually seeks advancements in product design and quality. Therefore, while this manual

contains the most current product information available at the time of printing, there may be minor

discrepancies between your vehicle and this manual. If you have any questions concerning this manual, please consult your Yamaha dealer.

FJR1300AP

SUPPLEMENTARY MANUAL

FOR POLICE VERSION

©2009 by Yamaha Motor Engineering Co., Ltd.

1st Edition, November 2009

All rights reserved.

Any reprinting or unauthorized use

without the written permission of

Yamaha Motor Engineering Co., Ltd.

is expressly prohibited.

Printed in Japan

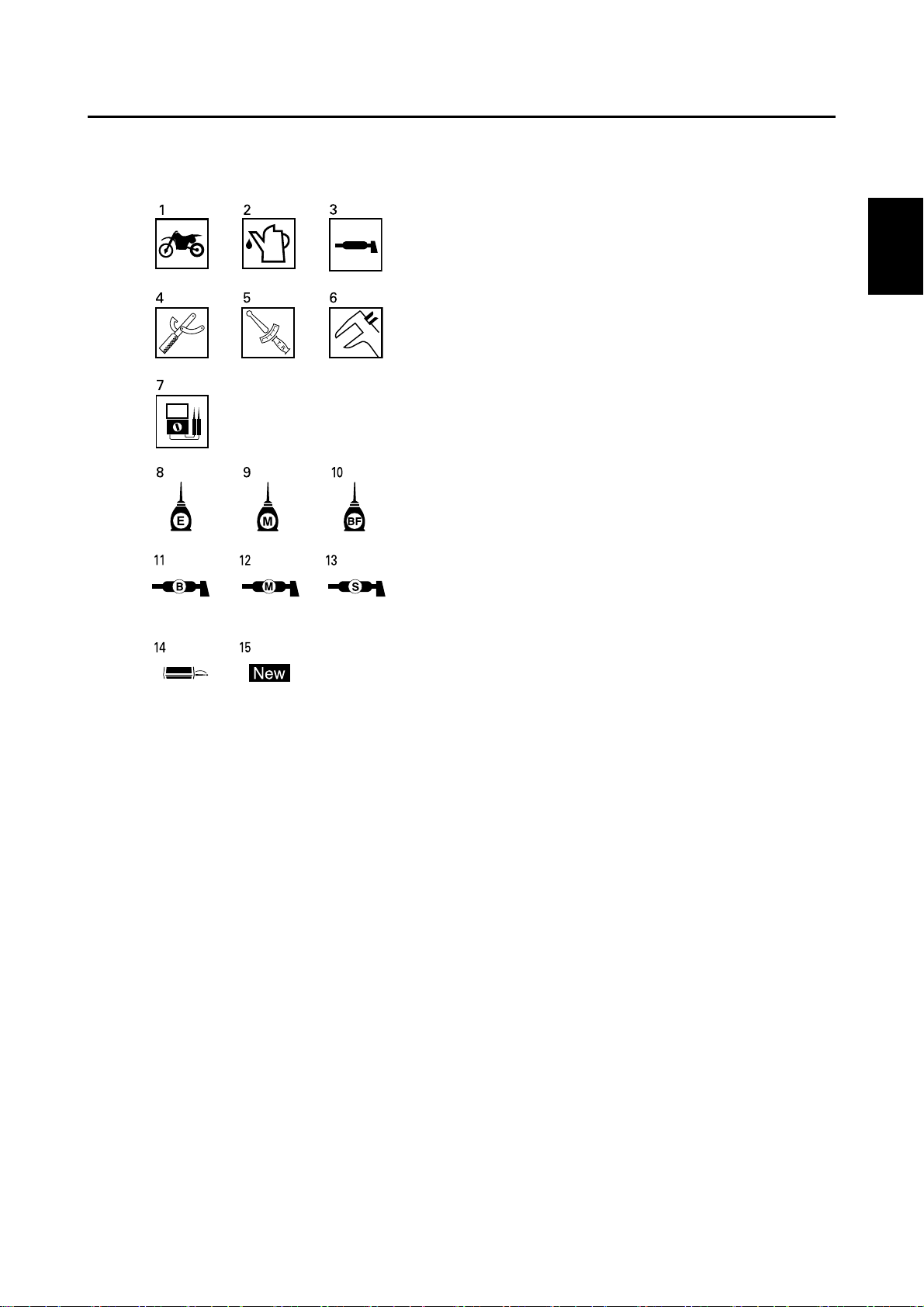

ILLUSTRATED SYMBOLS (Refer

to the illustration)

Illustrated symbols "1" to "7" are used to identify the specifications appearing in the text.

1. With engine mounted

2. Filling fluid

3. Lubricant

4. Special tool

5. Tightening

6. Specified value, Service limit

7. Resistance (Ω), Voltage (V), Electric current (A)

Illustrated symbols "8" to "13" in the exploded

diagrams indicate grade of lubricant and location of lubrication point.

8. Apply engine oil

9. Apply molybdenum disulfide oil

10. Apply brake fluid

11. Apply lightweight lithium-soap base grease

12. Apply molybdenum disulfide grease

13. Apply silicone grease

Illustrated symbols "14" to "15" in the exploded

diagrams indicate where to apply a locking

agent and where to install new parts.

14. Apply locking agent (LOCTITE

15. Use new one

®

)

CONTENTS

DESCRIPTION.....................................................................................................1

SPECIFICATION LIST .................................................................................. 2

SPECIFICATIONS...............................................................................................3

INSTRUMENT AND CONTROL FUNCTIONS.................................................... 4

RIGHT HANDLEBAR SWITCHES ................................................................4

SEAT .............................................................................................................4

RADIO BOX...................................................................................................5

SUSPENSION............................................................................................... 5

TROUBLESHOOTING .................................................................................. 7

MAINTENANCE...................................................................................................8

SETUP PROCEDURES ................................................................................8

CABLE ROUTING DIAGRAM ..................................................................... 12

TROUBLESHOOTING ................................................................................ 21

CHECKING THE ELECTRICAL COMPONENTS .......................................22

TIGHTENING TORQUES............................................................................27

RECOMMENDED SPECIFICATIONS............................................................... 30

INTRODUCTION........................................................................................ 30

RECOMMENDED PARTS LIST................................................................. 30

SETUP PROCEDURES ............................................................................. 31

CABLE ROUTING DIAGRAM .................................................................... 34

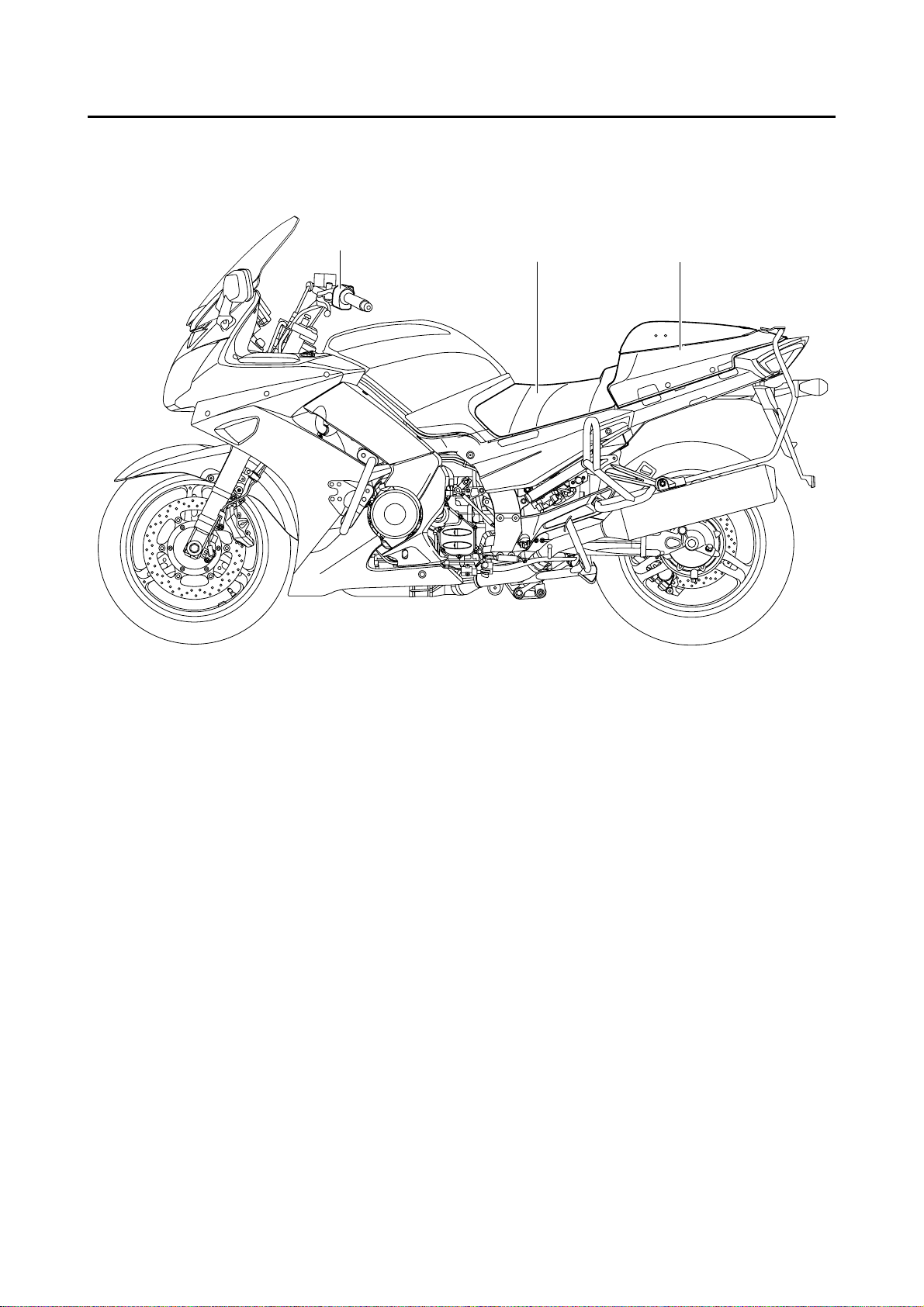

DESCRIPTION

DESCRIPTION

1

2

3

1. Right handlebar switches

2. Seat

3. Radio box

1

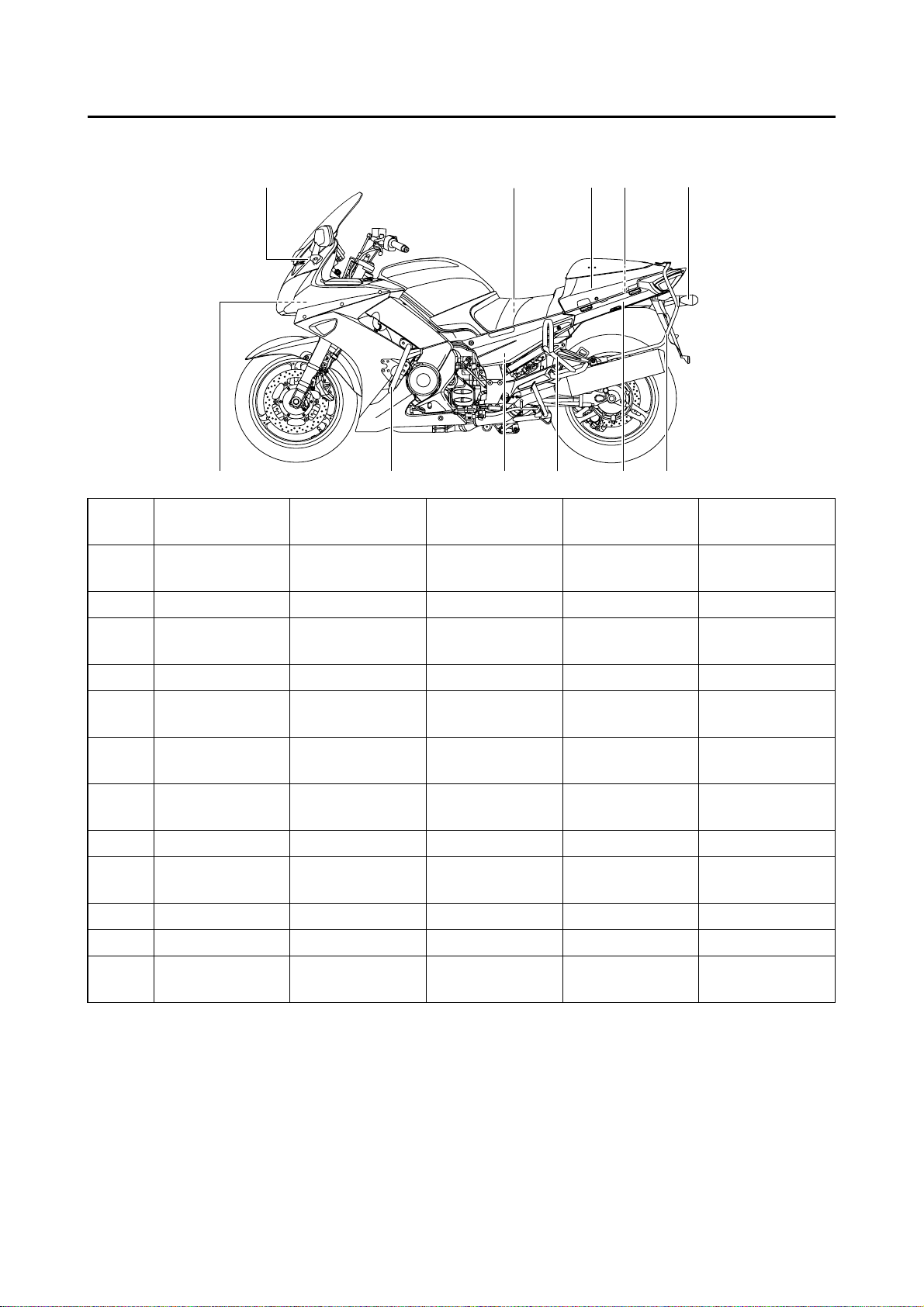

SPECIFICATION LIST

DESCRIPTION

1

12

No. Part name

Front flashing

1

light bracket

2 Sub-battery — — — Standard

5P5B (EU-

ROPE)

Option Standard ←←

11

5P5C (F, B) 5P5D (AUS) 5P5E (ZA, ET)

2,3 4

10

9

5

8

6

7

Sub-battery

3

bracket

4 Radio box Option Standard ←←

Rear sub-wire

5

harness

Rear turn signal

6

light

Rear flashing

7

light stay

8 Tail cover FJR1300A spec Standard ←←

Saddlebag

9

guard

10 Rectifier Standard — — Standard

11 Engine guard Option — Standard ←

12

Front sub-wire

harness

Standard — Standard ←

Standard — Standard ←

Option — Standard ←

Option

Option Standard ←←

Standard

Standard (5P5C

spec)

Standard (5P5C

spec)

Standard ←

Standard ←

2

SPECIFICATIONS

Model name: FJR1300AP

Model code number: 5P5B (EUROPE)

5P5C (F, B)

5P5D (AUS)

5P5E (ZA, ET)

Dimensions:

Overall length 2230 mm

Overall width 740 mm

Overall height 1450 mm

Minimum ground clearance 130 mm

Weight:

With oil and fuel 291.0 kg

Front suspension:

Spring rate, K1 10.0 N/mm

SPECIFICATIONS

Rear suspension:

Soft

Spring rate, K1 95.4 N/mm

Spring rate, K2 130.2 N/mm

Hard

Spring rate, K1 130.2 N/mm

Enclosed gas/air pressure (STD) 1800 kPa

Sub-battery:

Model GT7B-4

Voltage, capacity 12 V, 6.5 Ah

Manufacturer GS YUASA

Ten hour rate amperage 0.65 A

Bulb voltage, wattage × quantity:

Rear turn signal light 12 V, 21.0 W × 2

Sub-battery relay:

Model/manufacturer ACM33211 M05/MATSUSHITA

Coil resistance 96.0 Ω

Flashing light and siren relay:

Model/manufacturer ACM33211 M05/MATSUSHITA

Coil resistance 96.0 Ω

Fuses:

CHARGE 30 A

DISCHARGE 20 A

PATROL 10 A

SUB 30 A

3

INSTRUMENT AND CONTROL FUNCTIONS

INSTRUMENT AND CONTROL

FUNCTIONS

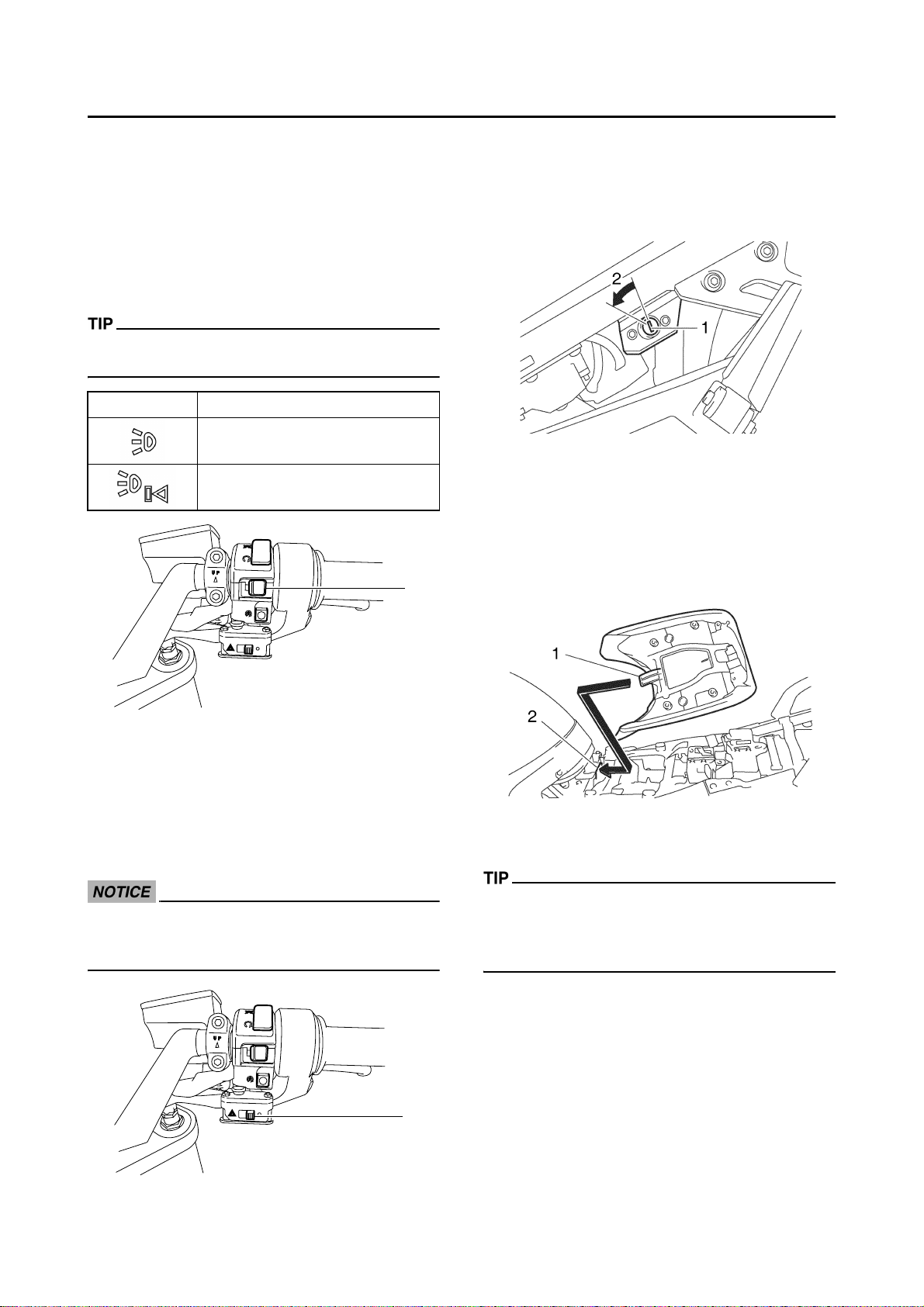

RIGHT HANDLEBAR SWITCHES

PATROL SWITCH

Patrol switch "1" activates the siren or flashing

light.

It is used when a siren or flashing light is installed.

○ OFF

This is for the flashing light.

This is for both siren and flashing light.

1

SEAT

TO REMOVE THE SEAT

1. Insert the key into the seat lock, and then

turn it counterclockwise.

1. Seat lock

2. Unlock

2. Lift the rear of the seat and pull it off.

TO INSTALL THE SEAT

1. Insert the projection on the front of the seat

into the seat holder as shown, and then push

the rear of the seat down to lock it in place.

HAZARD SWITCH

With the key in the "ON" or "P" position, use

hazard switch "1" to turn on the hazard lights

(simultaneous flashing of all turn signal lights).

The hazard lights are used in case of an emergency or to warn other drivers when your vehicle is stopped where it might be a traffic hazard.

Do not use the hazard lights for an extended

length of time with the engine not running,

otherwise the battery may discharge.

1

1. Projection

2. Seat holder

2. Remove the key.

Make sure that the seat is properly secured

before riding.

The seat height can be adjusted to change

the riding position.

4

INSTRUMENT AND CONTROL FUNCTIONS

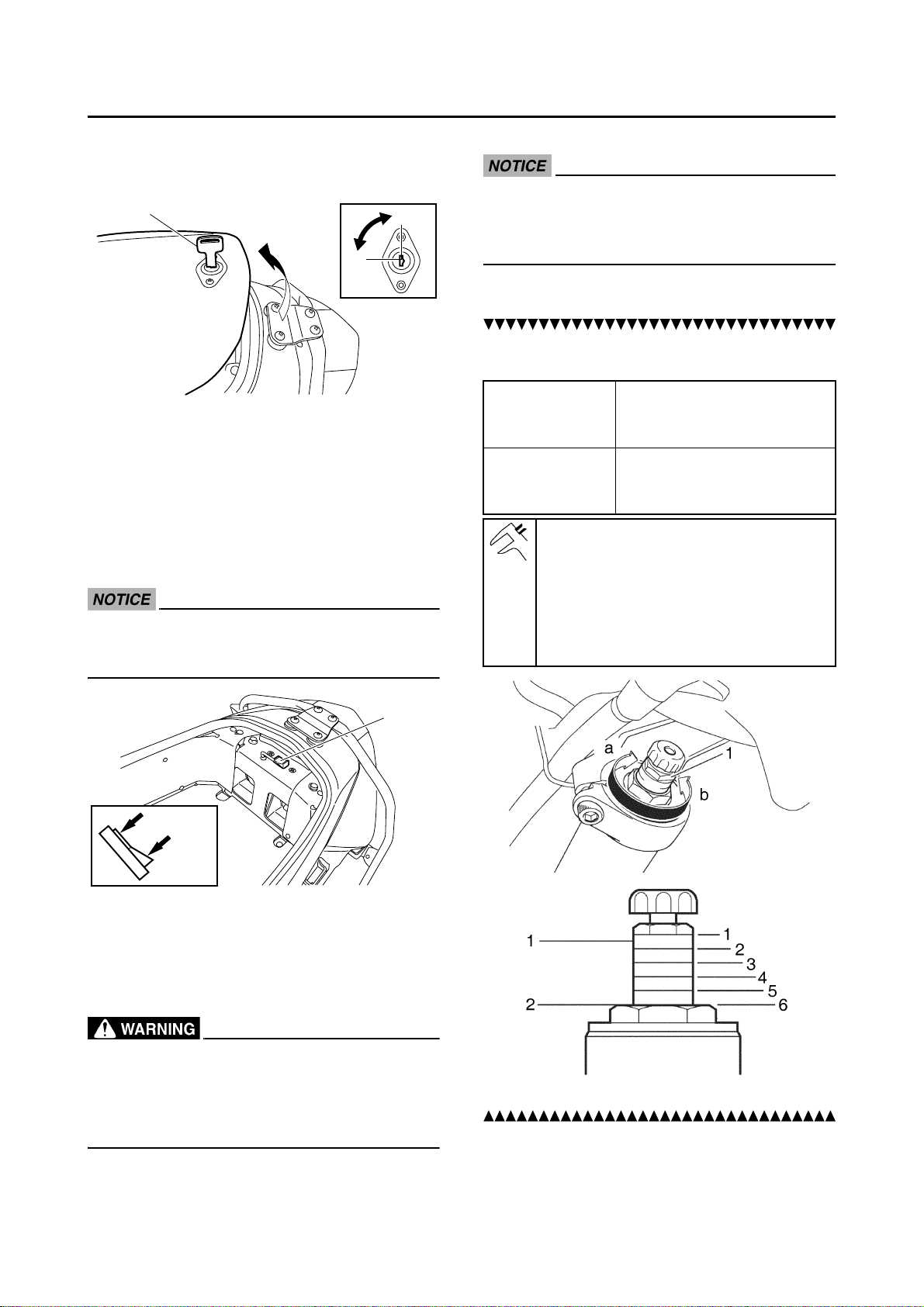

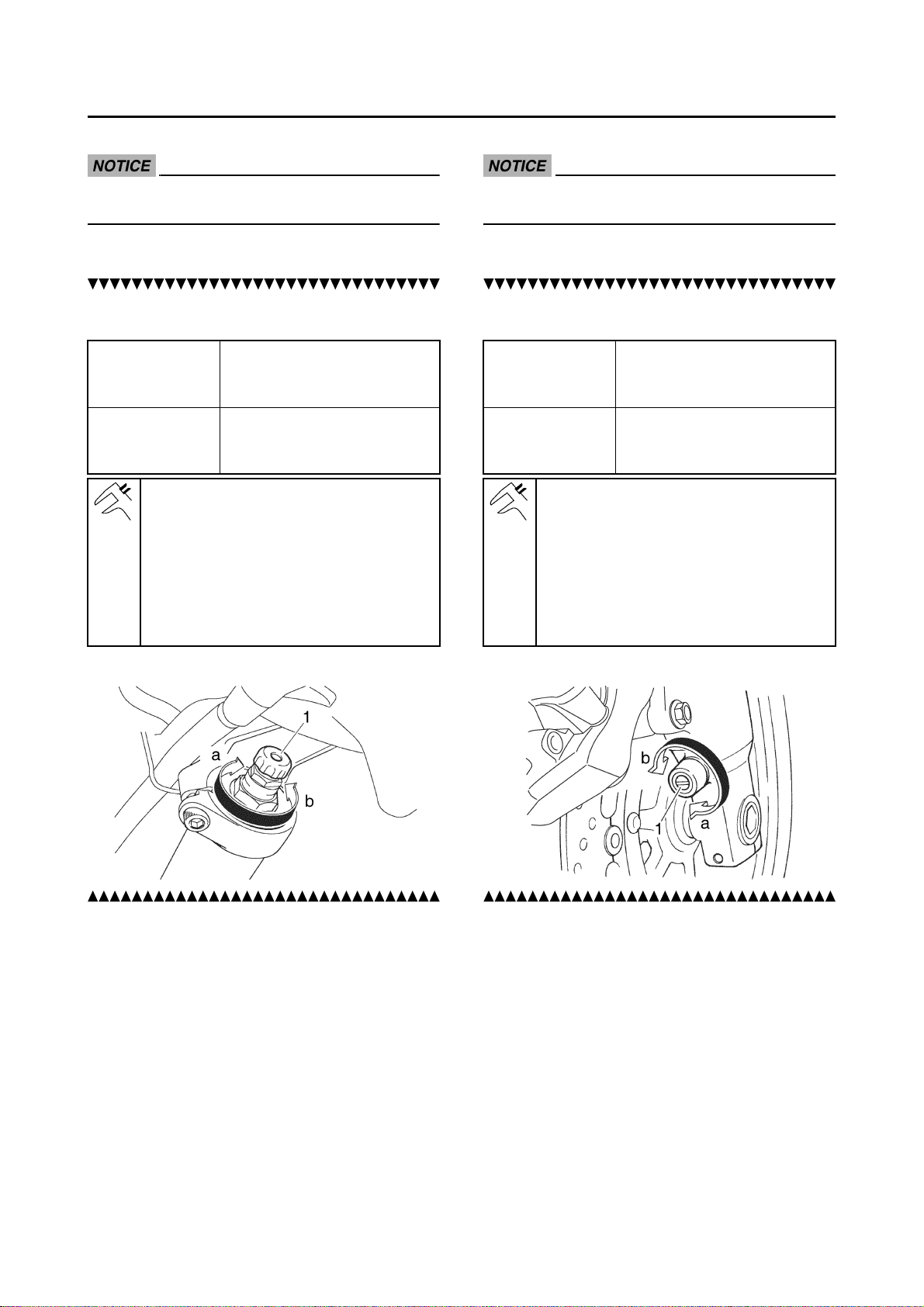

RADIO BOX

The lid can be locked by turning the inserted

key "1".

1

a. LOCK

b. OPEN

Changeover of the position of the switch "2"

can prevent the sub-battery from being discharged.

ON:

When an auxiliary instruments are used.

OFF:

When no auxiliary instruments are used.

Do not turn the switch to "ON" when no auxiliary instruments are used, otherwise the

sub-battery may discharge.

a

b

Spring preload

Grooves are provided to indicate the ad-

justment position.

Never go beyond the maximum or mini-

mum adjustment positions.

1. Adjust:

Spring preload

a. Turn the adjusting bolt "1" in direction "a" or

"b".

Spring preload is in-

Direction "a"

Direction "b"

Spring preload adjusting positions

Standard

4

Minimum

6

Maximum

1

creased (suspension is

harder).

Spring preload is decreased (suspension is

softer).

2

ON

OFF

SUSPENSION

ADJUSTING THE FRONT FORK LEGS

The following procedure applies to both of the

front fork legs.

Always adjust both front fork legs evenly.

Uneven adjustment can result in poor handling and loss of stability.

Securely support the vehicle so that there

is no danger of it falling over.

2. Current setting

5

INSTRUMENT AND CONTROL FUNCTIONS

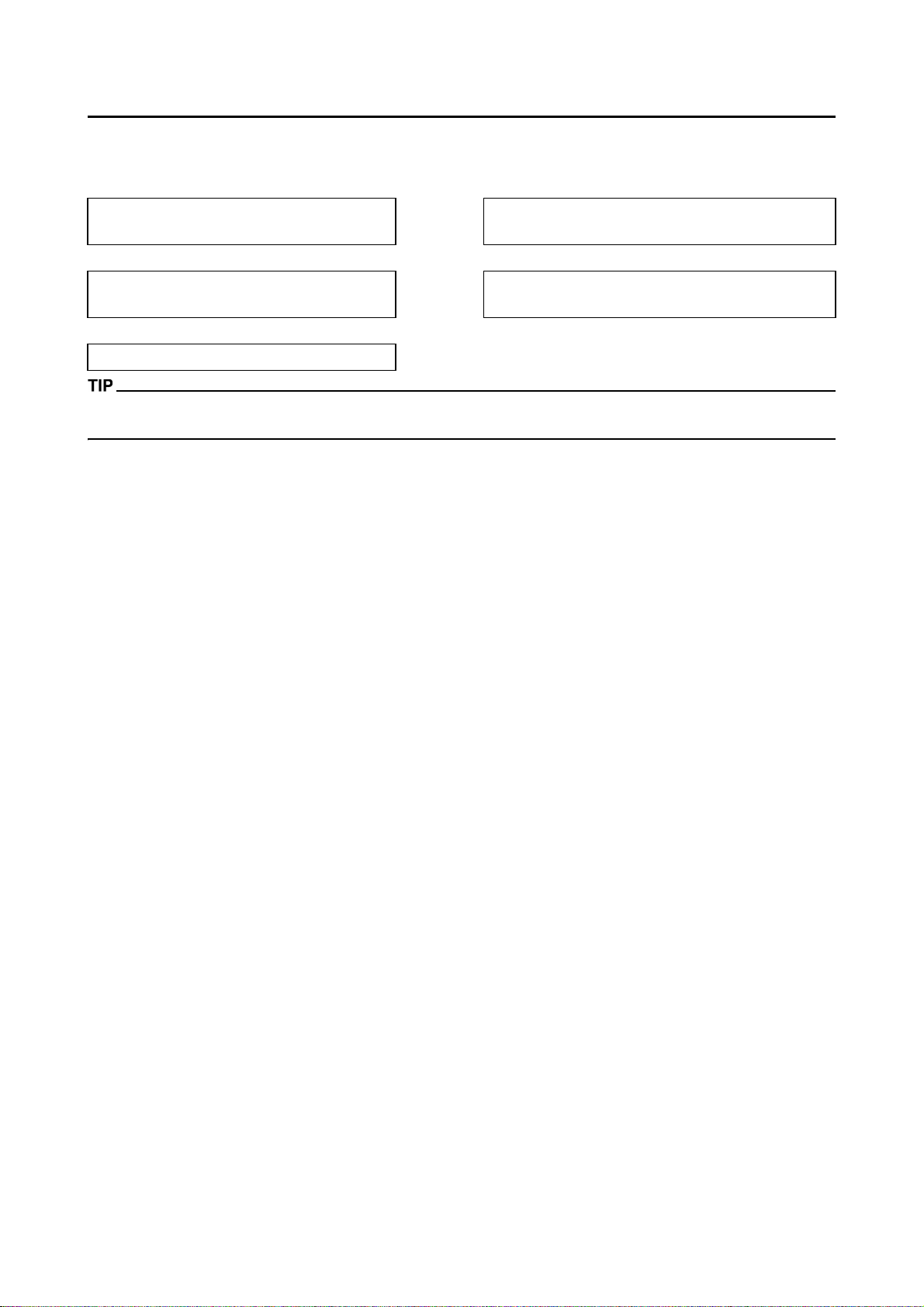

Rebound damping

Never go beyond the maximum or minimum

adjustment positions.

1. Adjust:

Rebound damping

a. Turn the adjusting knob "1" in direction "a" or

"b".

Rebound damping is in-

Direction "a"

Direction "b"

Rebound damping adjusting positions

Standard

12 clicks out*

Minimum

17 clicks out*

Maximum

1 clicks out*

creased (suspension is

harder).

Rebound damping is decreased (suspension is

softer).

Compression damping

Never go beyond the maximum or minimum

adjustment positions.

1. Adjust:

Compression damping

a. Turn the adjusting screw "1" in direction "a"

or "b".

Compression damping is

Direction "a"

Direction "b"

Compression damping adjusting

positions

Standard

10 clicks out*

Minimum

21 clicks out*

Maximum

1 clicks out*

increased (suspension is

harder).

Compression damping is

decreased (suspension is

softer).

*: With the adjusting knob fully turned in

*: With the adjusting screw fully turned in

6

INSTRUMENT AND CONTROL FUNCTIONS

TROUBLESHOOTING

If the auxiliary instruments is not operating normally, perform the following procedures in the order

given.

Checking the auxiliary instruments

switch.

ON ↓

OFF → Turn the auxiliary instruments switch to "ON".

Checking the fuses.

OK ↓

Ask the mechanic to repair.

Remove the following parts before inspection.

1. Seat

Blown

fuse →

Replace the fuse.

7

MAINTENANCE

SETUP PROCEDURES

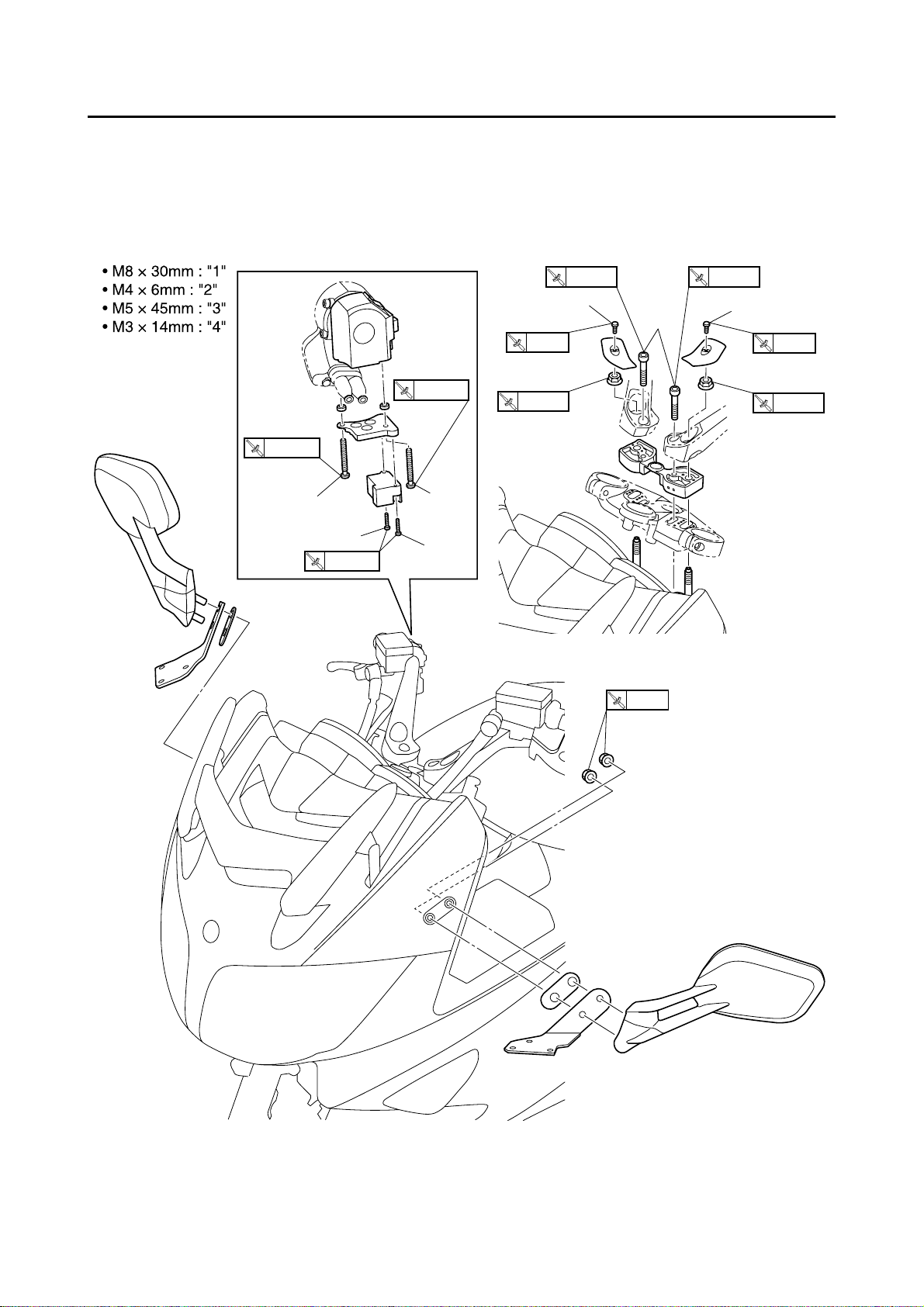

INSTALLING THE HANDLEBARS

MAINTENANCE

T

3.5 Nm

.R.

3

T

1.5 Nm

.R.

T

3.5 Nm

.R.

T

.R.

T

65 Nm

.R.

2 Nm

T

23 Nm

.R.

2

1

T

23 Nm

.R.

2

T

2 Nm

.R.

T

65 Nm

.R.

3

4

4

T

7 Nm

.R.

8

INSTALLING THE ENGINE GUARDS

T

64 Nm

.R.

2

T

.R.

3

7 Nm

2

3

4

T

7 Nm

.R.

A

MAINTENANCE

T

49 Nm

5

5

T

49 Nm

.R.

.R.

7

6

1

6

1

T

49 Nm

.R.

T

49 Nm

.R.

T

64 Nm

.R.

2

A

4

2

3

3

T

7 Nm

.R.

T

.R.

7 Nm

A. For installation of recommended parts

9

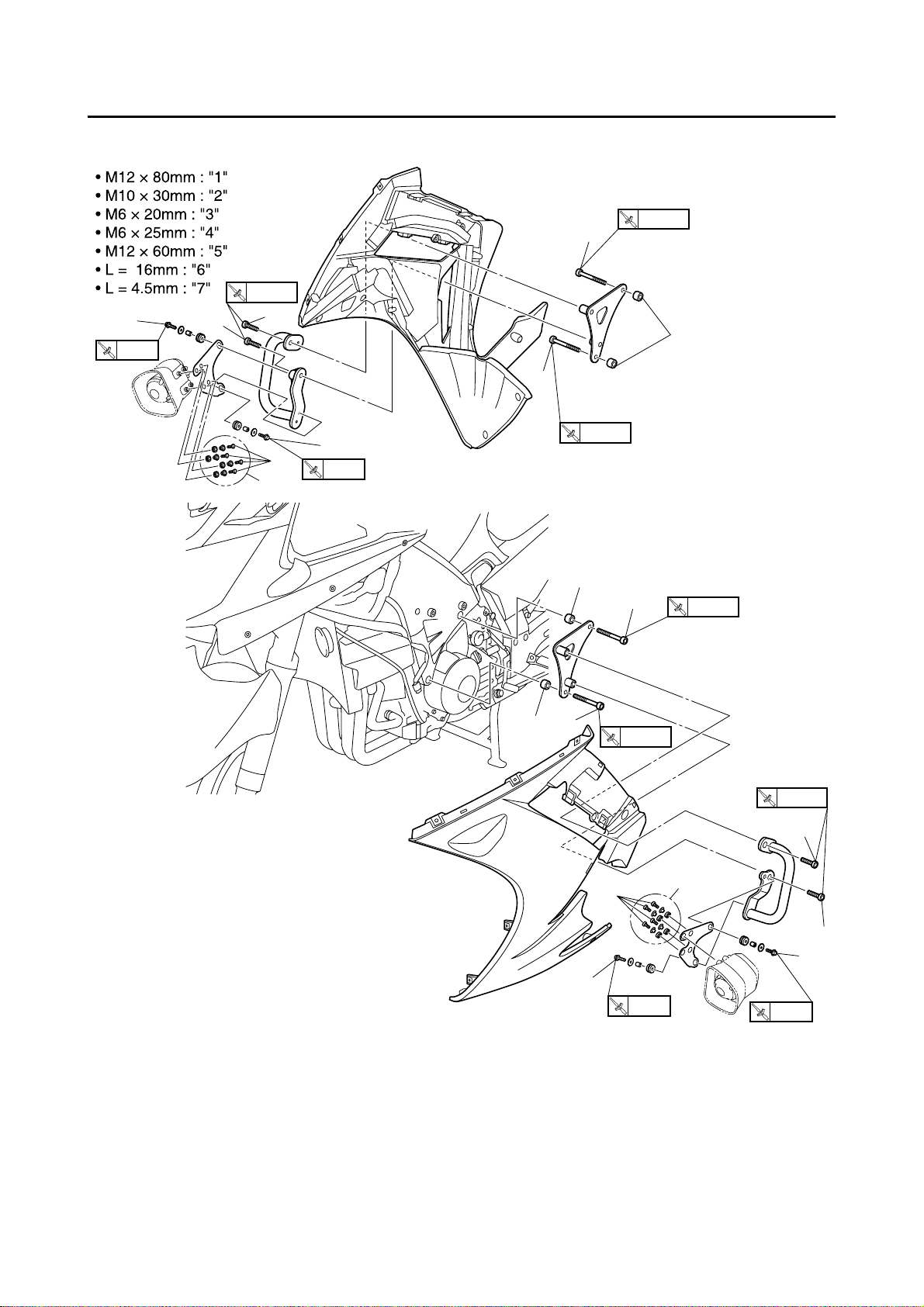

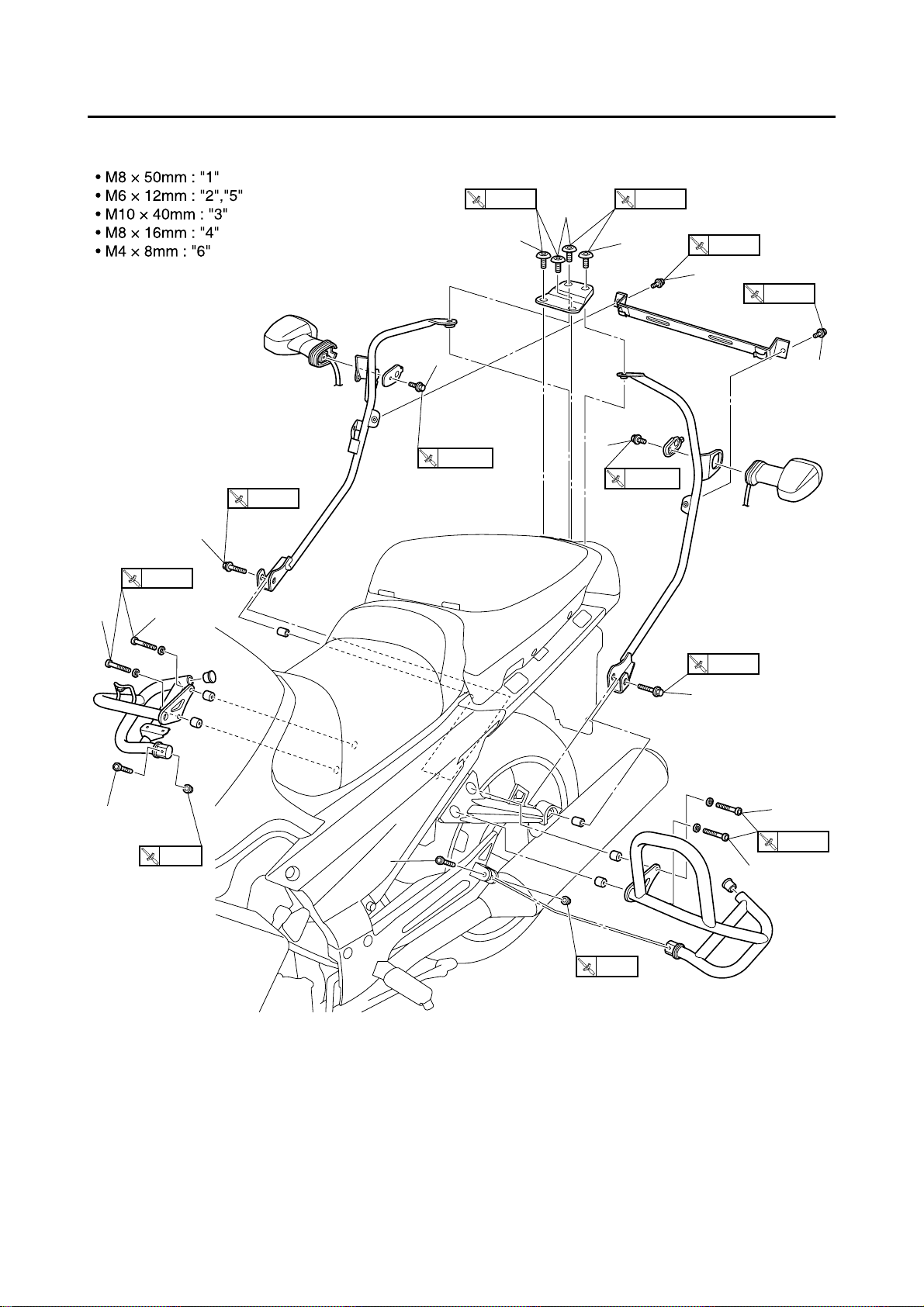

INSTALLING THE SADDLEBAG GUARDS

MAINTENANCE

T

29 Nm

.R.

4

4

T

.R.

4

29 Nm

T

10 Nm

.R.

5

T

10 Nm

.R.

T

25 Nm

.R.

6

T

1.5 Nm

.R.

6

T

1.5 Nm

.R.

5

3

T

28 Nm

.R.

1

1

T

25 Nm

.R.

3

2

T

9 Nm

.R.

2

T

9 Nm

.R.

1

T

28 Nm

.R.

1

10

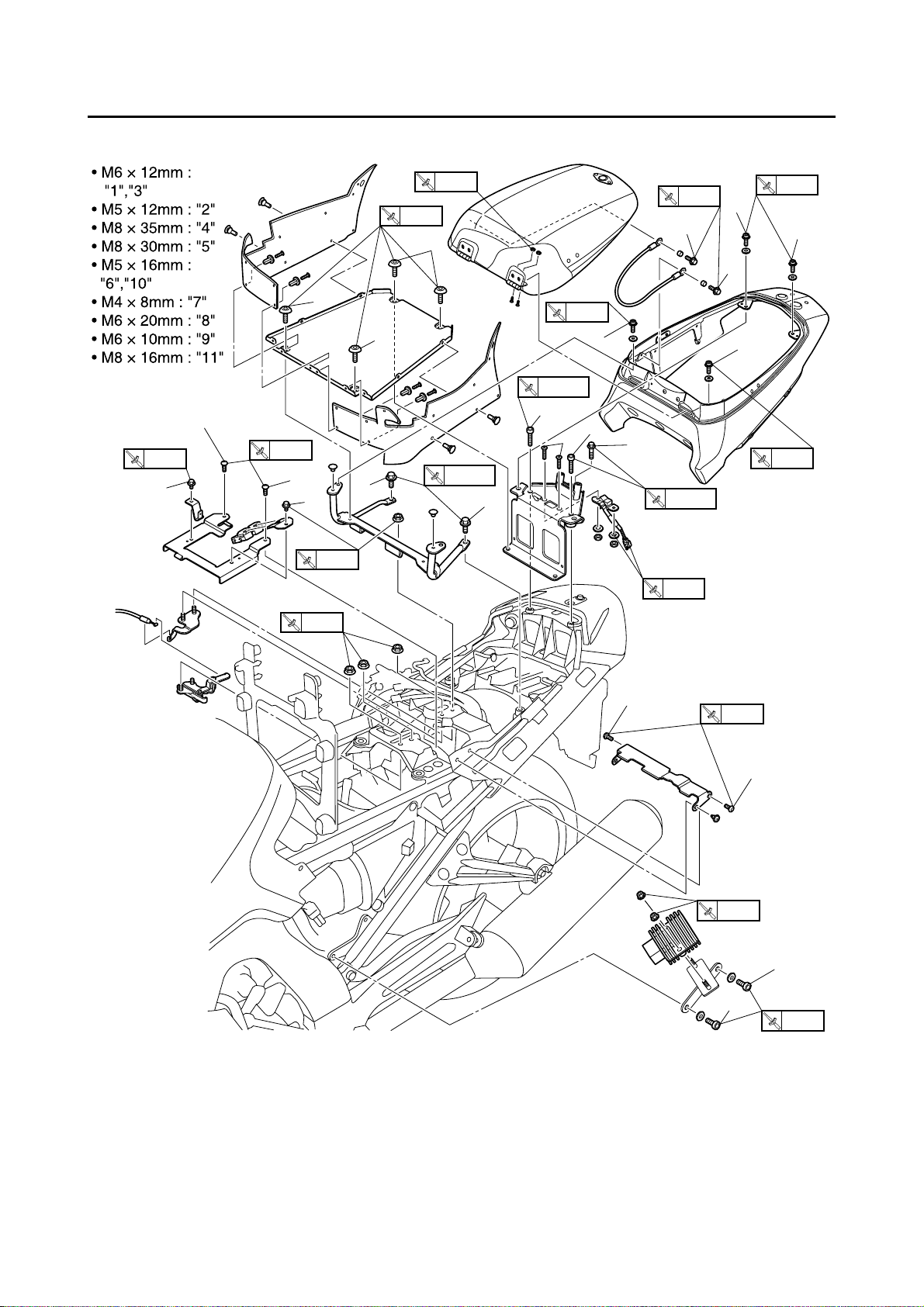

INSTALLING THE RADIO BOX

T

.R.

7 Nm

T

.R.

3

2 Nm

MAINTENANCE

T

7 Nm

T

4 Nm

.R.

2

.R.

1

1

2

T

7 Nm

.R.

3

3

8

T

1 Nm

.R.

T

16 Nm

9

8

T

.R.

9

T

.R.

7 Nm

7

7 Nm

.R.

7

T

21 Nm

.R.

4

T

.R.

6

7 Nm

1

4

1

5

T

21 Nm

.R.

T

4 Nm

.R.

T

.R.

7 Nm

10

T

1 Nm

.R.

T

.R.

7 Nm

11

10

11

T

.R.

8 Nm

11

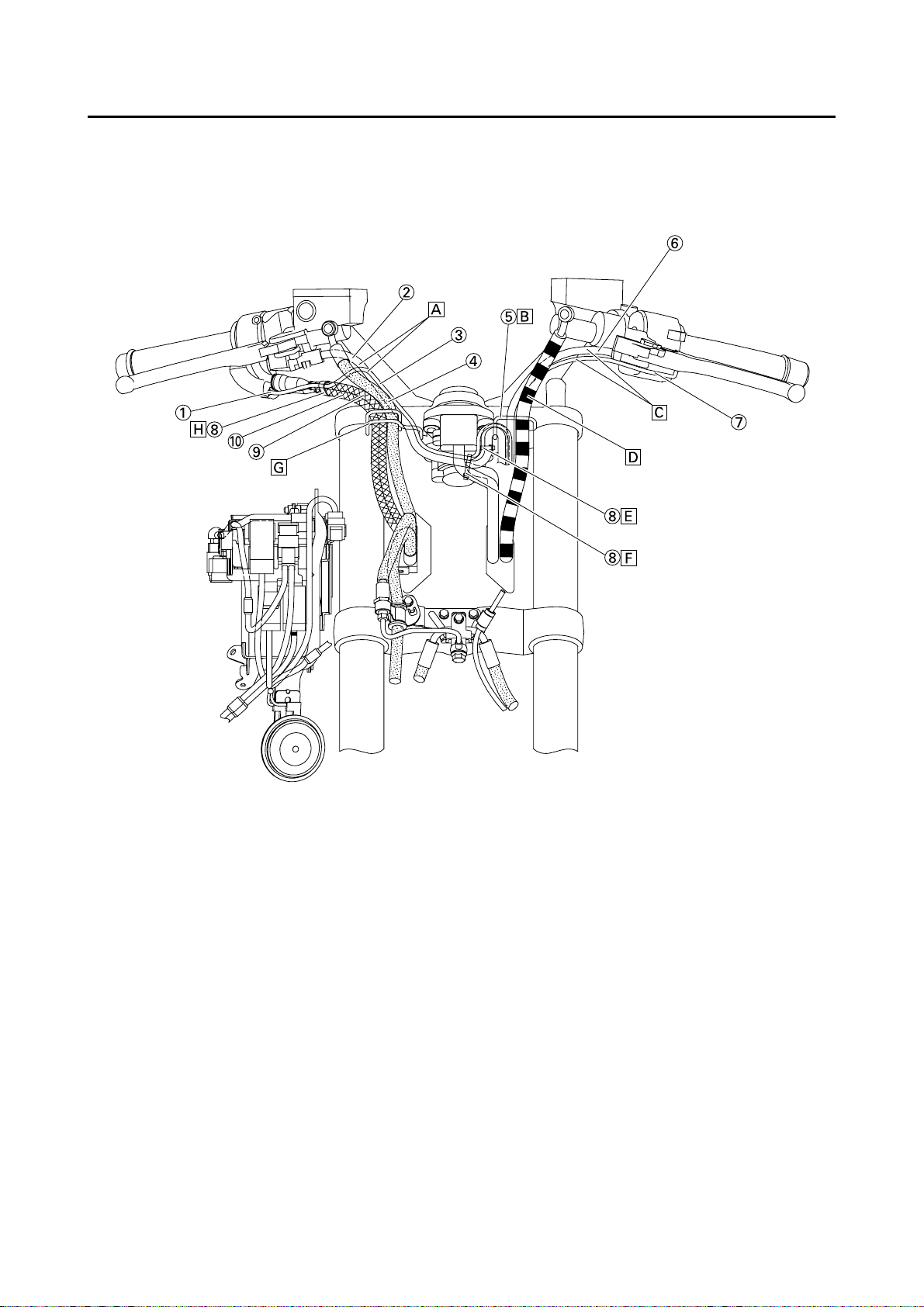

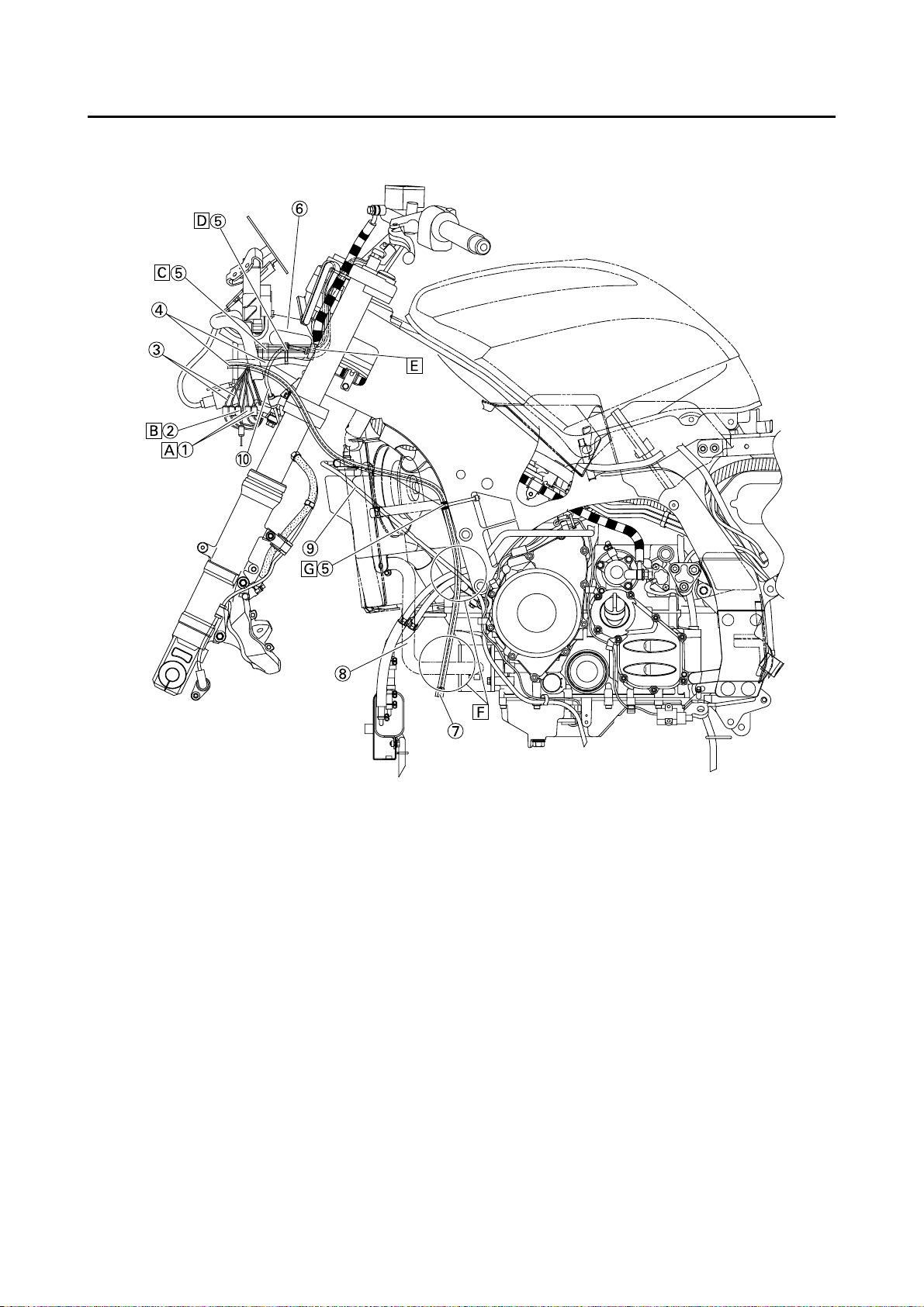

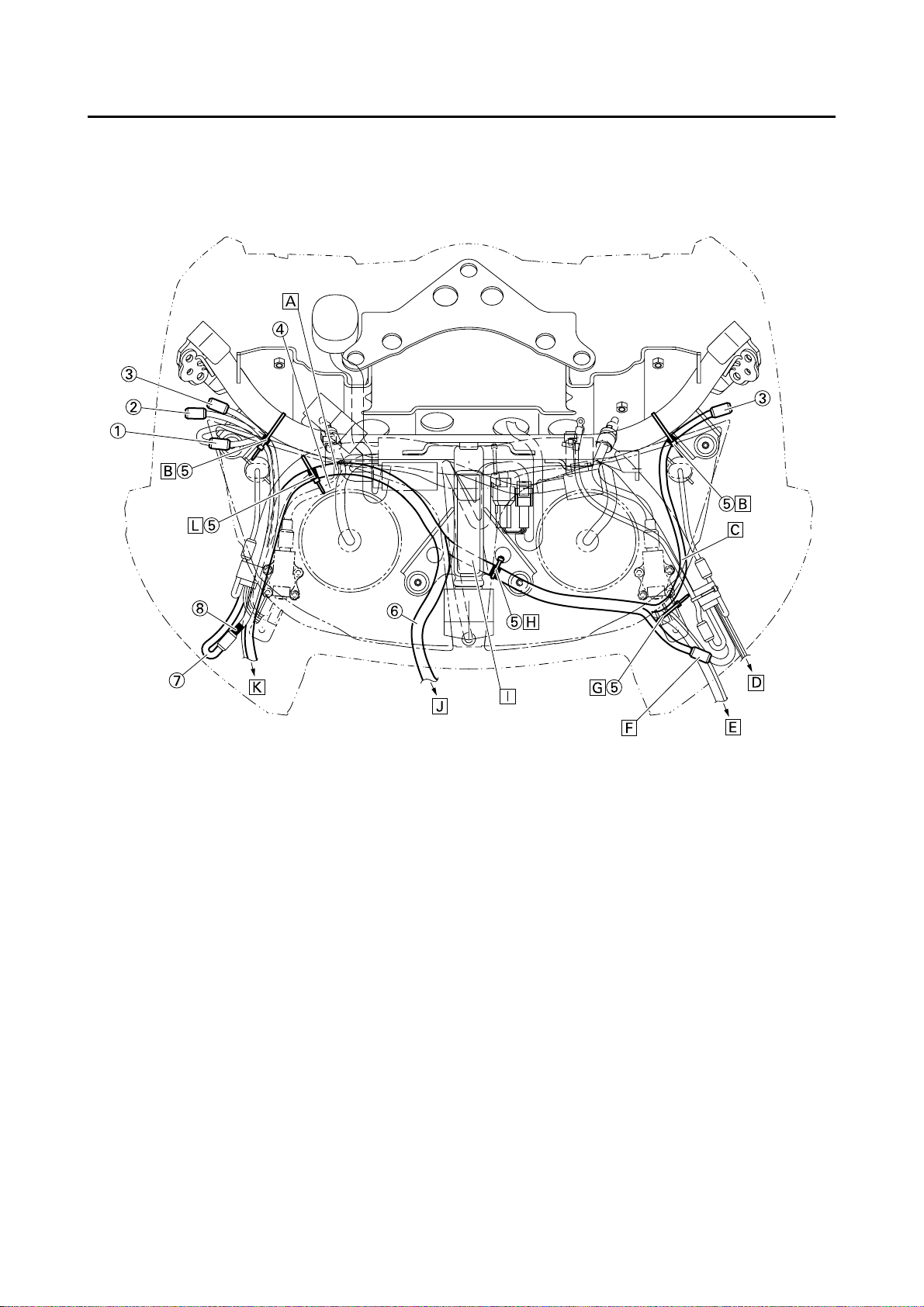

CABLE ROUTING DIAGRAM

MAINTENANCE

12

1. Right grip warmer lead

2. Right handlebar switch lead

3. Hazard switch lead

4. Front brake hose

5. Guide

6. Left handlebar switch lead

7. Left grip warmer lead

8. Clamp

9. Throttle cable (accelerator cable)

10. Throttle cable (decelerator cable)

A. Route the hazard switch lead, right handle-

bar switch lead and grip warmer lead under

the handlebar.

B. Route the hazard switch lead and grip

warmer lead over the right handlebar

switch lead while taking care not to have

them pinched between the guide and right

handlebar switch lead.

C. Route the left handlebar switch lead and

the grip warmer lead under the handlebar.

D. Pass the clutch hose, the handlebar switch

leads (left and right), the grip warmer leads

(left and right) and the hazard switch lead

through the guide.

E. Clamp the hazard switch lead and right

handlebar switch lead. Do not clamp the

grip warmer lead.

F. Clamp the hazard switch lead, right handle-

bar switch lead, grip warmer lead, main

switch lead and immobilizer unit lead.

G. Pass the front brake hose, the right handle-

bar switch lead, the right grip warmer lead,

the hazard switch lead, the throttle cable

through the guide.

H. Clamp the grip warmer lead on the throttle

cable. Fasten the clamp where 10 mm inside of the rubber boot end and cut off the

clamp end.

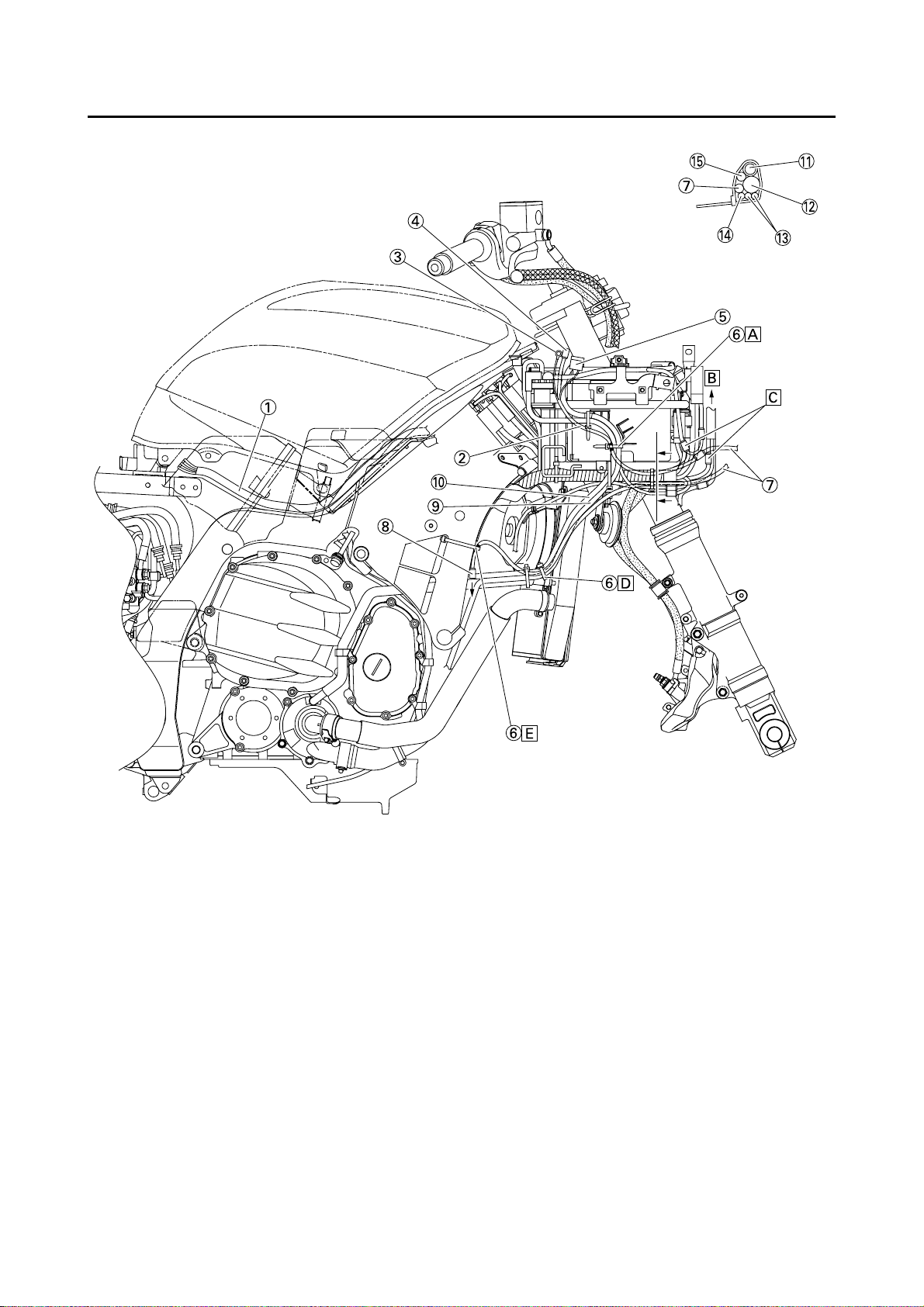

MAINTENANCE

13

MAINTENANCE

A-A

A

A

1. Extension wire lead

2. Wire lead (for battery charging)

3. Negative lead (for battery charging)

4. Coupler (for battery charging)

5. Fuse (SUB)

6. Clamp

7. Wire harness

8. Coupler (for speaker)

9. Negative battery lead

10. Starter motor lead

11. Stay

12. Wire harness assembly

13. Horn lead

14. Fan lead

15. Wire lead

A. Clamp the wire lead, the negative battery

lead, the starter motor lead on the battery

box. Clamp the wire lead on the white tape

marking section and turn the clamp end to-

ward the rear.

B. To the headlight lead

C. Remove the battery positive lead and con-

nect the sub-harness for recharge.

D. Clamp the wire harness assembly, nega-

tive battery lead and starter motor lead.

E. Route the wire harness assembly along the

front side of the frame and clamp the white

tape marking section of harness at the top

of the hole in the frame. Set the clamp end

inward without cutting it off.

14

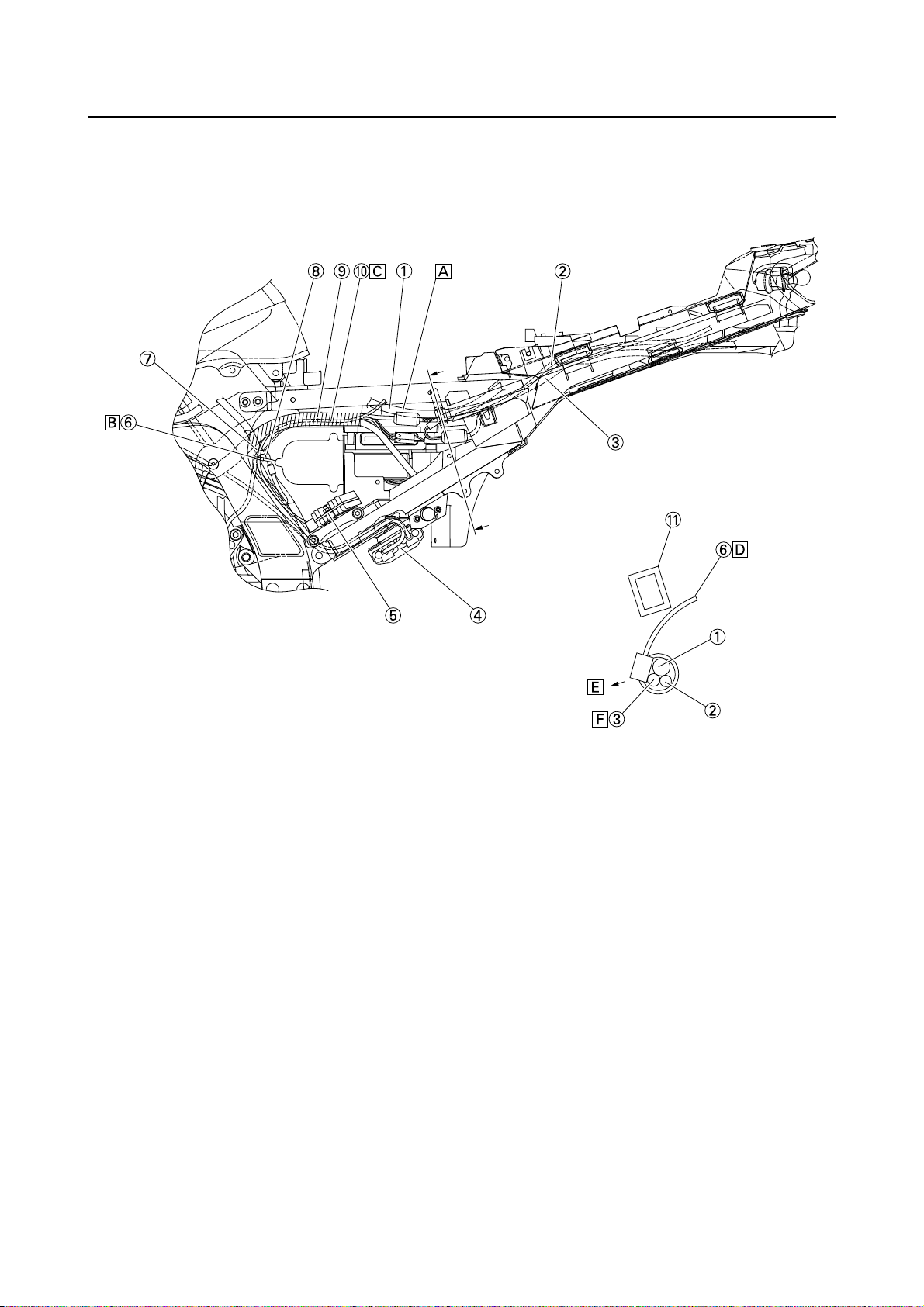

MAINTENANCE

1. Right handlebar switch lead

2. Hazard switch lead

3. Grip warmer lead

4. Wire harness assembly

5. Clamp

6. Stay

7. Coupler (for siren)

8. Radiator hose

9. Coolant reservoir hose

10. Front wheel sensor lead

A. Connect the right handlebar switch lead to

the wire harness assembly.

B. Connect the hazard switch lead to the wire

harness assembly.

C. Clamp the handlebar switch lead, the grip

warmer lead and the hazard switch lead,

and pass them through the hole of the stay.

Set the clamp end downward without cutting it off.

D. Clamp the wire harness assembly, hazard

switch lead, handlebar switch lead and grip

warmer lead. Do not clamp the front wheel

sensor lead.

E. Clamp the handlebar switch lead, the grip

warmer lead, front wheel sensor lead and

the hazard switch lead, and pass them

through the hole of the stay. Set the clamp

end downward without cutting it off.

F. Route the wire harness assembly outside

the coolant reservoir hose and radiator

hose.

G. Route the wire harness assembly along the

front side of the frame and clamp the white

tape marking section of harness at the top

of the hole in the frame. Set the clamp end

inward without cutting it off.

15

MAINTENANCE

A

A

1. Wire harness assembly

2. Wire lead

3. Rear combination light lead

4. Rectifier/regulator

5. Rectifier

6. Clamp

7. Rectifier/regulator lead

8. Neutral switch lead

9. Main harness

10. Sub-lead wire

11. Rear frame

A. Connect the coupler having the wire lead

ID tape on it to the main harness.

B. Clamp the neutral switch lead, rectifier/reg-

ulator lead and sub-lead wire.

C. Route the sub-lead wire inside the main

harness.

D. Put the clamp tip on the inside of the frame.

E. Outside

A-A

F. Route the rear combination light lead on

the outside of the vehicle.

16

MAINTENANCE

B

U

S

1. Coupler (for battery charging)

2. Negative lead (for battery charging)

3. Fuse box

4. Extension wire lead

5. Air filter case

6. Insulator

7. Wire harness assembly

A. Route the wire lead through the clearance

between the battery and fuse box.

B. Install the fuse (SUB) in the inner fuse box

inserting it from underneath.

C. Align the white taped portion with the front

edge of the T-bar.

D. In installing the fuel tank, take care not to

have the extension wire lead pinched be-

tween the fuel tank and frame.

E. Route the extension wire lead along the

side of the air filter case.

F. Connect the connectors of the identical col-

or.

G. Route the wire harness assembly through

the hole in the frame to the left of the head

pipe and over the insulator.

17

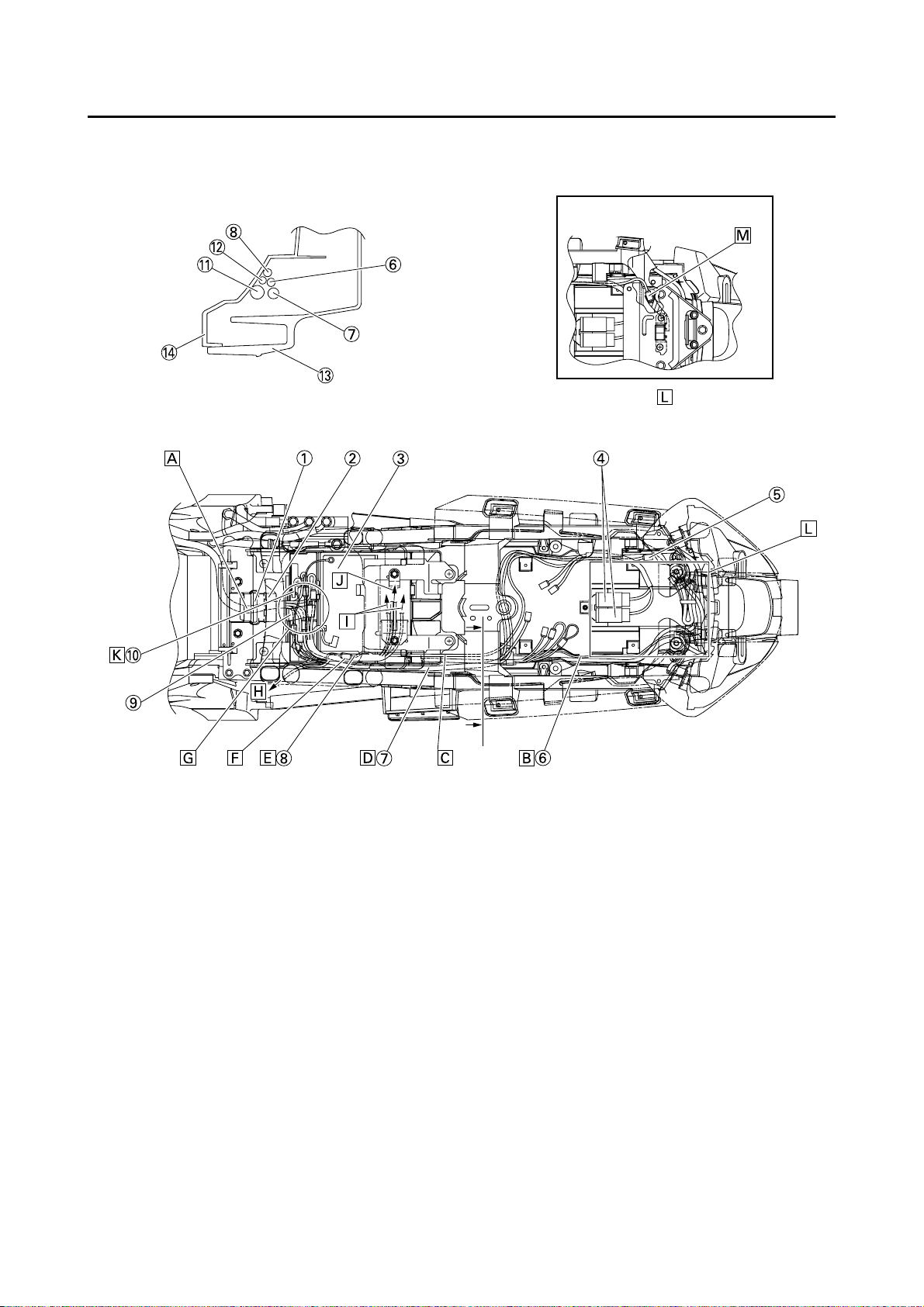

A-A

MAINTENANCE

1. Fuel tank fitting bracket

2. Seat bracket

3. Sub-battery box

4. Relay

5. Coupler (for radio box)

6. Wire lead

7. Wire harness assembly

8. Sub-lead wire

9. Tool band

10. Fuse (PATROL)

11. Rear combination light lead

12. License plate light lead

13. Rear frame

14. Rear fender

A. Route the extension wire lead in the middle

under the tank fitting bracket and seat

bracket.

B. Route the wire lead along and over the rear

combination light lead.

A

A

C. Route the wire lead under the sub-battery

box.

D. Route the wire harness assembly outside

the sub-battery box.

E. Route the sub-lead wire inside the sub-bat-

tery box.

F. Connect the sub-lead wire to the wire har-

ness assembly. Place the coupler under

the wire harness assembly.

G. Connect the couplers of the identical color.

H. To the rectifier

I. To the relay

J. To the fuse

K. Insert the fuse (PATROL) into the stay.

L. The wiring within the radio box is shown in

the square.

M. Clamp the sub-lead wire and auxiliary in-

struments switch assembly lead.

18

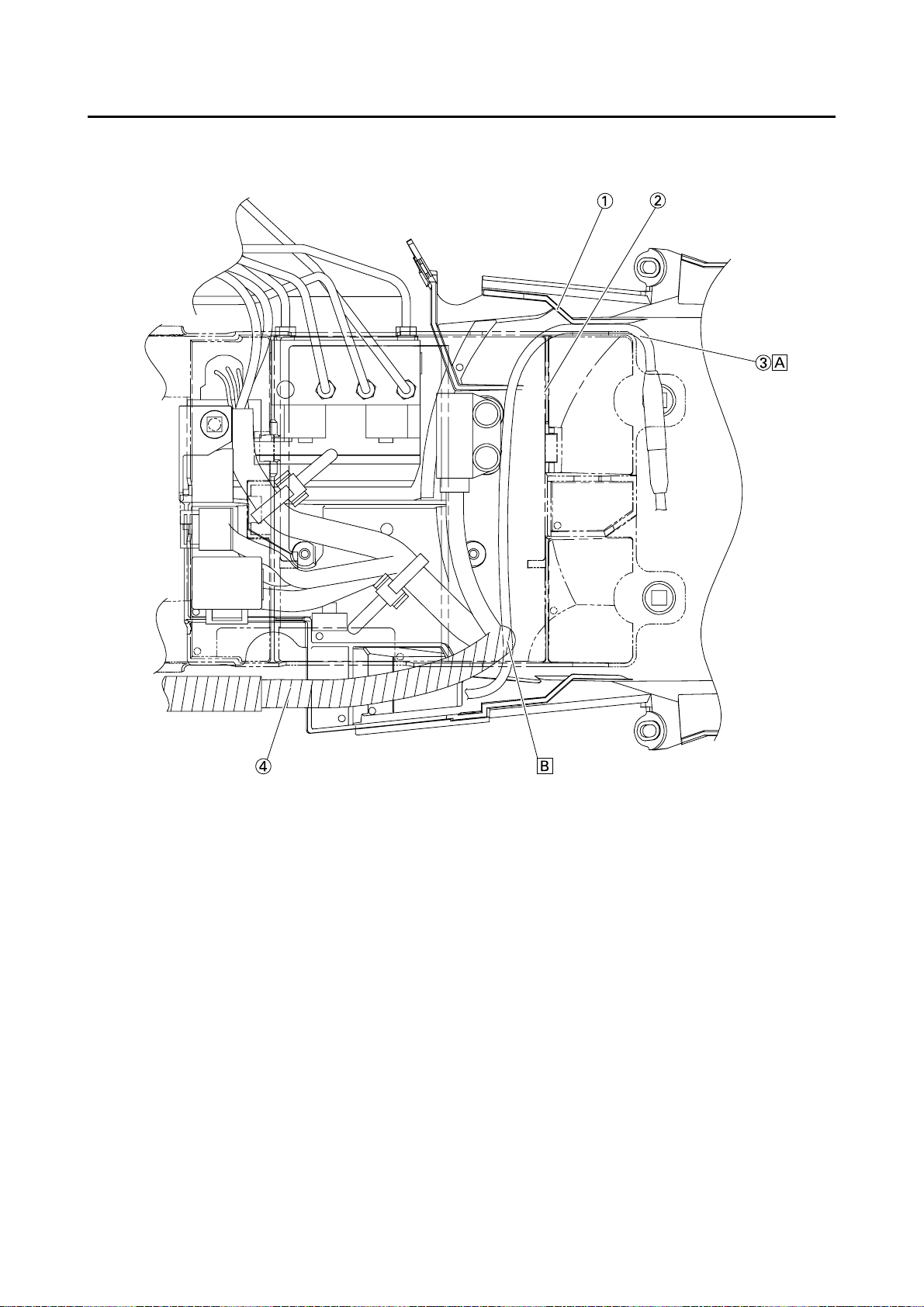

MAINTENANCE

1. Fender

2. Box

3. Seat lock cable

4. Wire harness assembly

A. Route the seat lock cable between the

fender and the box, and pass it under the

box.

B. Route the seat lock cable under the wire

harness assembly.

19

MAINTENANCE

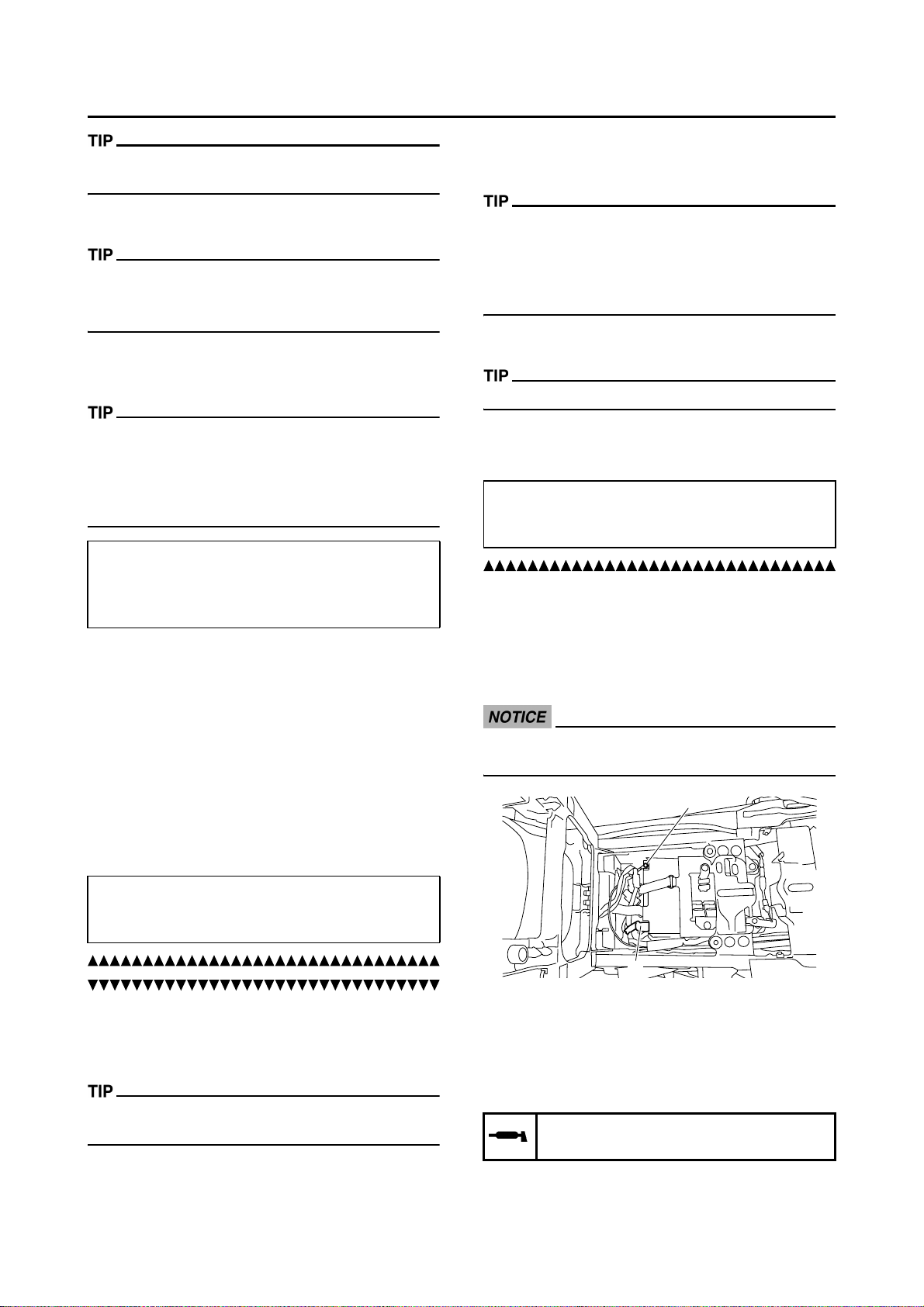

1. Coupler (for controller)

2. Coupler (for microphone)

3. Coupler (for front flashing light)

4. Headlight beam adjusting cable

5. Clamp

6. Wire harness assembly

7. Right handlebar switch lead

8. Identification red tape

A. Route the wire harness assembly at the

back of the headlight beam adjusting cable.

B. Route the wire harness assembly along the

bottom of the square pipe frame and clamp

it at the white tape. Direct the clamp end

downward.

C. Route the wire harness assembly just at

the head.

D. To the turn signal light and horn

E. To the main battery, including the speaker,

etc.

F. Connect the headlight lead and wire har-

ness assembly. (Connect the couplers of

the identical color.)

G. Fix the headlight cord and wire harness as-

sembly to the headlight mounting stay with

the clamp. Leave the clamp end to lie on

the inside of the cowling.

H. Route the clamp through the hole in the

stay and fix the wire harness assembly at

the white tape. Cut off the clamp end.

I. Route the wire harness assembly under

the stay.

J. To the extension wire lead under the fuel

tank

K. To the handlebar switch lead and siren

L. Clamp the wire harness assembly at the

white tape together with the headlight lead.

Direct the clamp end downward.

20

MAINTENANCE

TROUBLESHOOTING

If the auxiliary instruments is not operating normally, perform the following procedures in the order

given.

Checking the fuses.

OK ↓

Blown

fuse →

Replace the fuse.

Checking the wire harness connections.

OK ↓

Checking the patrol switch.

OK ↓

Checking the auxiliary instruments

switch.

OK ↓

Checking the sub-battery.

OK ↓

*Checking the auxiliary instruments.

(Refer to the instruction manual for the

auxiliary instruments.)

*marked: Not covered by warranty

Remove the following parts before inspection.

1. Seat

Use the following special tools in this inspection.

No good

→

No good

→

No good

→

No good

→

→ Please consult your Yamaha dealer.

Properly connect or repair the wire harness.

Replace the right handlebar switch.

Replace the auxiliary instruments switch.

Recharge or replace the sub-battery.

Pocket tester:

90890-03112

21

CHECKING THE ELECTRICAL COMPONENTS

CHECKING AND CHARGING THE SUBBATTERY

Batteries generate explosive hydrogen gas

and contain electrolyte which is made of

poisonous and highly caustic sulfuric acid.

Therefore, always follow these preventive

measures:

Wear protective eye gear when handling or

working near batteries.

Charge batteries in a well-ventilated area.

Keep batteries away from fire, sparks or

open flames (e.g., welding equipment,

lighted cigarettes).

DO NOT SMOKE when charging or han-

dling batteries.

KEEP BATTERIES AND ELECTROLYTE

OUT OF REACH OF CHILDREN.

Avoid bodily contact with electrolyte as it

can cause severe burns or permanent eye

injury.

FIRST AID IN CASE OF BODILY CONTACT:

EXTERNAL

Skin — Wash with water.

Eyes — Flush with water for 15 minutes

and get immediate medical attention.

INTERNAL

Drink large quantities of water or milk fol-

lowed with milk of magnesia, beaten egg

or vegetable oil. Get immediate medical at-

tention.

This is a sealed battery. Never remove the

sealing caps because the balance between

cells will not be maintained and battery

performance will deteriorate.

Charging time, charging amperage and

charging voltage for an VRLA (Valve Reg-

ulated Lead Acid) battery are different

from those of conventional batteries. The

VRLA (Valve Regulated Lead Acid) battery

should be charged as explained in the

charging method illustrations. If the bat-

tery is overcharged, the electrolyte level

will drop considerably. Therefore, take

special care when charging the battery.

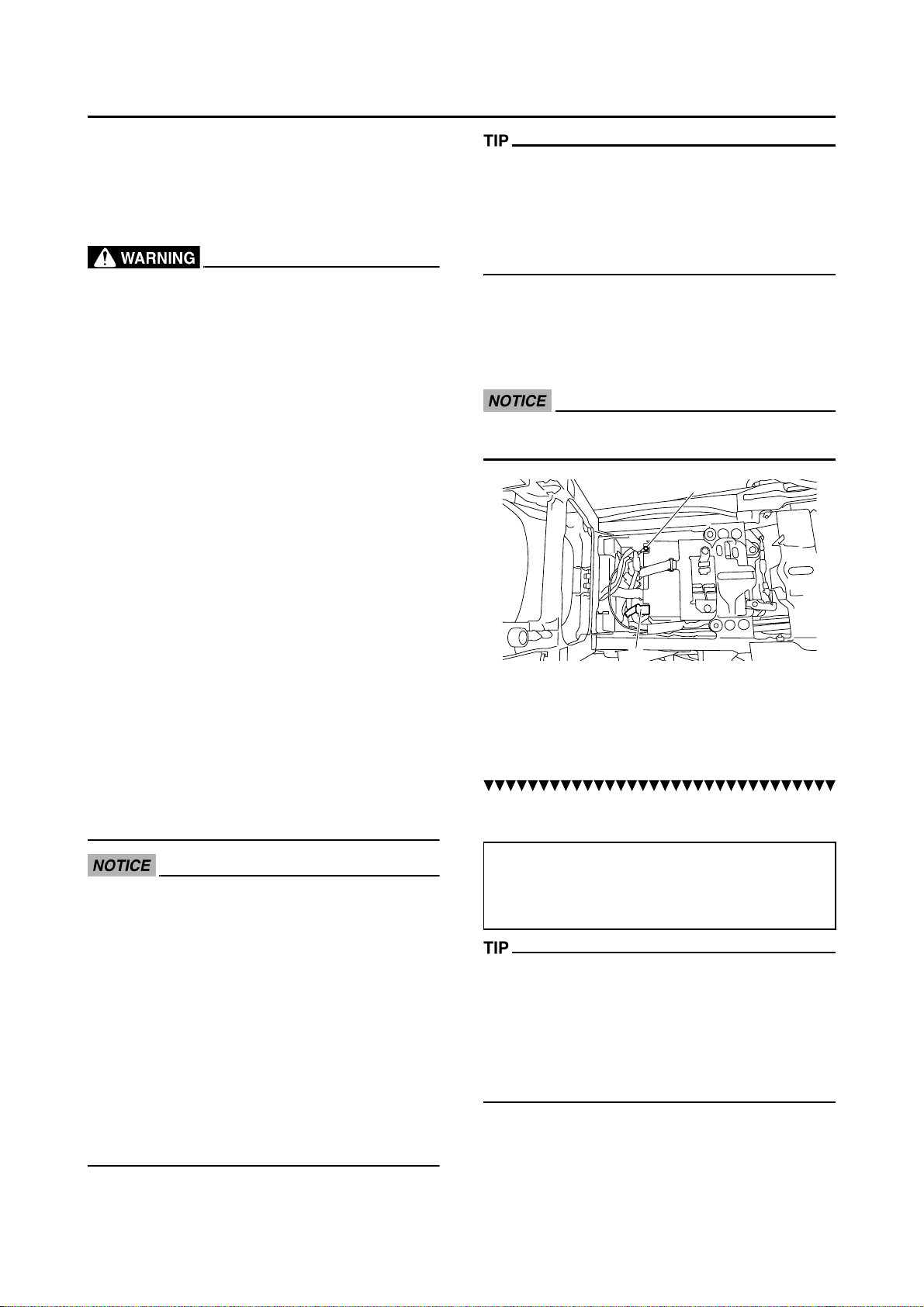

MAINTENANCE

Since VRLA (Valve Regulated Lead Acid) batteries are sealed, it is not possible to check the

charge state of the battery by measuring the

specific gravity of the electrolyte. Therefore, the

charge of the battery has to be checked by

measuring the voltage at the battery terminals.

1. Remove:

Seat

2. Disconnect:

Sub-battery leads

(from the sub-battery terminals)

First, disconnect the battery negative lead

"1", and then battery positive lead "2".

1

2

3. Remove:

Battery band

Sub-battery

4. Measure:

Battery charge

a. Connect a pocket tester to the battery termi-

nals.

Tester positive probe → battery positive

terminal

Tester negative probe → battery negative

terminal

The charge state of an VRLA (Valve Regulat-

ed Lead Acid) battery can be checked by

measuring its open-circuit voltage (i.e., the

voltage when the positive battery terminal is

disconnected).

No charging is necessary when the open-cir-

cuit voltage equals or exceeds 12.4 V.

b. Check the charge of the battery, as shown in

the charts and the following example.

22

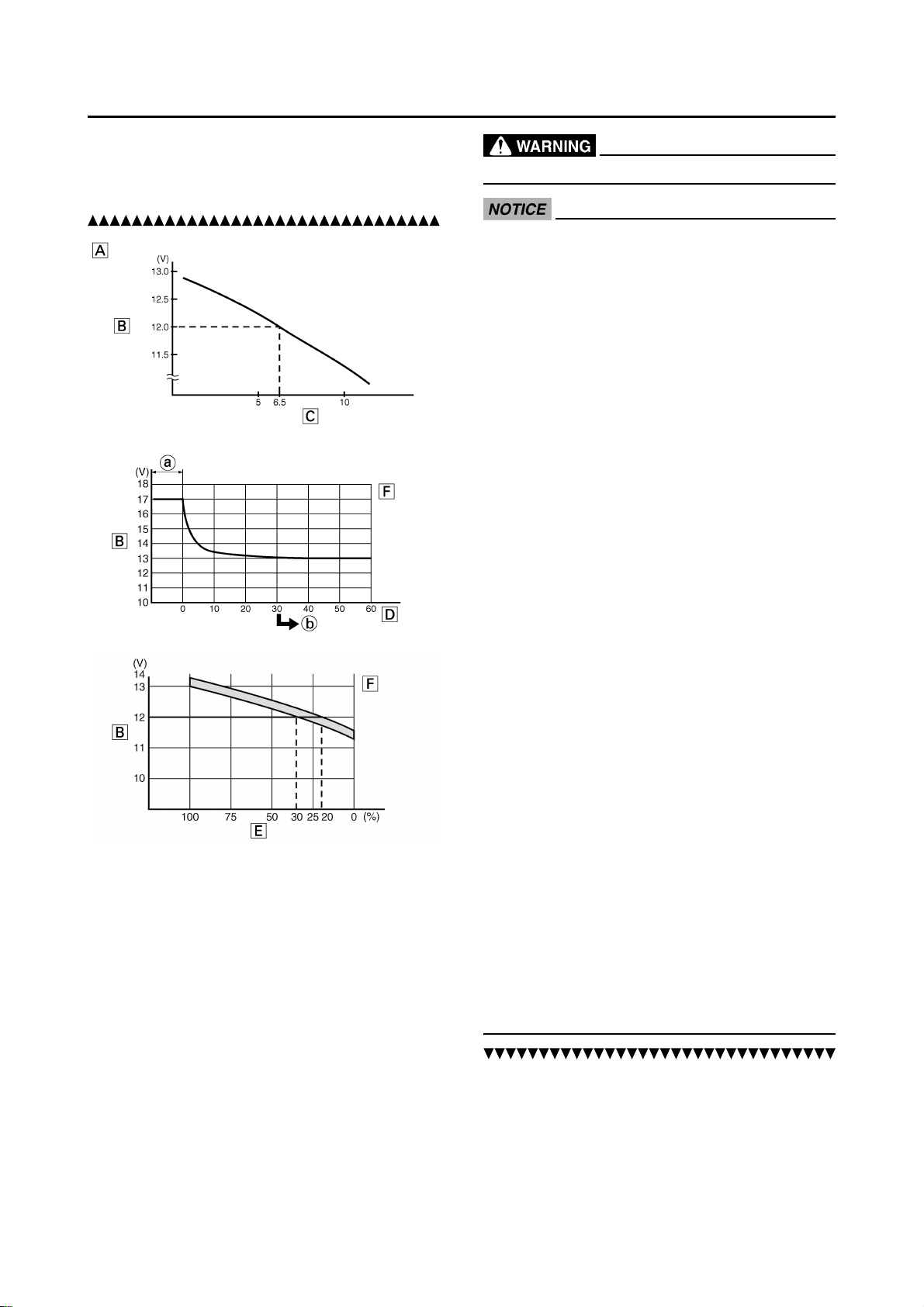

Example

Open-circuit voltage = 12.0 V

Charging time = 6.5 hours

Charge of the battery = 20–30%

A. Relationship between the open-circuit

voltage and the charging time at 20 °C

(These values vary with the temperature,

the condition of the battery plates, and

the electrolyte level.)

B. Open-circuit voltage (V)

C. Charging time (hours)

D. Time (minutes)

E. Charging condition of the battery (%)

F. Ambient temperature 20 °C

a. Charging

b. Check the open-circuit voltage

5. Charge:

Sub-battery

(refer to the appropriate charging method illustration)

MAINTENANCE

Do not quick charge a battery.

Never remove the VRLA (Valve Regulated

Lead Acid) battery sealing caps.

Do not use a high-rate battery charger

since it forces a high-amperage current

into the battery quickly and can cause battery overheating and battery plate damage.

If it is impossible to regulate the charging

current on the battery charger, be careful

not to overcharge the battery.

When charging a battery, be sure to re-

move it from the vehicle. (If charging has

to be done with the battery mounted on the

vehicle, disconnect the battery negative

lead from the battery terminal.)

To reduce the chance of sparks, do not

plug in the battery charger until the battery

charger leads are connected to the battery.

Before removing the battery charger lead

clips from the battery terminals, be sure to

turn off the battery charger.

Make sure the battery charger lead clips

are in full contact with the battery terminal

and that they are not shorted. A corroded

battery charger lead clip may generate

heat in the contact area and a weak clip

spring may cause sparks.

If the battery becomes hot to the touch at

any time during the charging process, disconnect the battery charger and let the

battery cool before reconnecting it. Hot

batteries can explode!

As shown in the following illustration, the

open-circuit voltage of an VRLA (Valve

Regulated Lead Acid) battery stabilizes

about 30 minutes after charging has been

completed. Therefore, wait 30 minutes after charging is completed before measuring the open-circuit voltage.

Charging method using a variable-current

(voltage) charger

a. Measure the open-circuit voltage prior to

charging.

23

Voltage should be measured 30 minutes after

the engine is stopped.

MAINTENANCE

c. Make sure that the current is higher than the

standard charging current written on the battery.

b. Connect a charged and ammeter to the bat-

tery and start charging.

Set the charging voltage at 16–17 V. If the setting is lower, charging will be insufficient. If too

high, the battery will be over-charged.

c. Make sure that the current is higher than the

standard charging current written on the battery.

If the current is lower than the standard charging current written on the battery, set the charging voltage adjust dial at 20–24 V and monitor

the amperage for 3–5 minutes to check the battery.

Reach the standard charging current → Bat-

tery is good.

Does not reach the standard charging cur-

rent → Replace the sub-battery.

d. Adjust the voltage so that the current is at

the standard charging level.

e. Set the time according to the charging time

suitable for the open-circuit voltage.

f. If charging requires more than 5 hours, it is

advisable to check the charging current after

a lapse of 5 hours. If there is any change in

the amperage, readjust the voltage to obtain

the standard charging current.

g. Measure the battery open-circuit voltage af-

ter leaving the battery unused for more than

30 minutes.

If the current is lower than the standard charging current written on the battery, this type of

battery charger cannot charge the VRLA (Valve

Regulated Lead Acid) battery. A variable voltage charger is recommended.

d. Charge the battery until the battery's charg-

ing voltage is 15 V.

Set the charging time at 20 hours (maximum).

e. Measure the battery open-circuit voltage af-

ter leaving the battery unused for more than

30 minutes.

12.4 V or more --- Charging is complete.

12.3 V or less --- Recharging is required.

Under 12.0 V --- Replace the battery.

6. Install:

Sub-battery

Battery band

7. Connect:

Sub-battery leads

(to the sub-battery terminals)

First, connect the battery positive lead "1",

and then the battery negative lead "2".

2

12.4 V or more --- Charging is complete.

12.3 V or less --- Recharging is required.

Under 12.0 V --- Replace the battery.

Charging method using a constant voltage

charger

a. Measure the open-circuit voltage prior to

charging.

Voltage should be measured 30 minutes after

the engine is stopped.

b. Connect a charger and ammeter to the bat-

tery and start charging.

1

8. Check:

Battery terminals

Dirt → Clean with a wire brush.

Loose connection → Connect properly.

9. Lubricate:

Battery terminal

Recommended lubricant

Dielectric grease

10.Install:

Seat

24

Loading...

Loading...