Yamaha FJR1300 AP 2009 Owner's manual

FJR1300AP

SUPPLEMENTARY MANUAL FOR POLICE VERSION

SUPPLEMENT AU MANUEL POUR LE MODELE DE POLICE

ERGÄNZENDE WARTUNGSANLEITUNG FÜR POLIZEI-MODELL

MANUALE SUPPLEMENTARE PER LA VERSIONE PER LA POLIZIA

MANUAL SUPLEMENTARIO PARA LA VERSIÓN DE POLICÍA

5P5-28199-51

SUPPLEMENTARY MANUAL FOR POLICE VERSION

SUPPLEMENT AU MANUEL POUR LE MODELE DE POLICE

ERGÄNZENDE WARTUNGSANLEITUNG FÜR POLIZEIMODELL

MANUALE SUPPLEMENTARE PER LA VERSIONE PER LA

POLIZIA

MANUAL SUPLEMENTARIO PARA LA VERSIÓN DE POLICÍA

WIRING DIAGRAM / SCHÉMA DE CÂBLAGE / SCHALTPLAN /

SCHEMA ELETTRICO / DIAGRAMA ELÉCTRICO

INTRODUCTION

This supplementary manual has been prepared to introduce new service and new

service and new data for the FJR1300AP. For complete information on service

procedures, it is necessary to use this manual together with following manuals:

FJR1300 OWNER’S MANUAL (5P5-28199-E2, -F2, -G2, -H2, -S2)

FJR1300 SERVICE MANUAL (3P6-28197-E2, -F2, -G2, -H2, -S2)

FJR1300AP

SUPPLEMENTARY MANUAL

FOR POLICE VERSION

2008 Yamaha Motor Co., Ltd.

1 st Edition, March 2008

All right reserved. Any reprinting or unauthorized use

without the written permission of Yamaha Motor Co., Ltd.

is expressly prohibited.

Printed in Japan

IMPORTANT MANUAL INFORMATION

Particularly important information is distinguished in this manual by the following notations:

The Safety Alert Symbol means ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

Failure to follow WARNING instructions could result in severe injury or death to the motorcycle

operator, a bystander, or a person inspecting or repairing the motorcycle.

A CAUTION indicates special precautions that must be taken to avoid damage to the motorcycle.

NOTE:

A NOTE provides key information to make procedures easier or clearer.

NOTE:

Yamaha continually seeks advancements in product design and quality. Therefore, while this

manual contains the most current product information available at the time of printing, there may

be minor discrepancies between your motorcycle and this manual. If you have any questions

concerning this manual, please consult your Yamaha dealer.

CONTENTS

DESCRIPTION------------------------------------------------------------------------------------------------ 1

SPECIFICATIONS ------------------------------------------------------------------------------------------- 1

INSTRUMENT AND CONTROL FUNCTIONS ------------------------------------------------------- 2

RIGHT HANDLEBAR SWITCH ---------------------------------------------------------------------- 2

RADIO BOX (5P56, 5P57) ---------------------------------------------------------------------------- 3

CHANGEOVER OF COUPLERS FOR REAR TURN SIGNAL LIGHTS-------------------4

SUSPENSION SETTINGS ---------------------------------------------------------------------------- 4

MAINTENANCE ---------------------------------------------------------------------------------------------- 5

TIGHTENING TORQUE-------------------------------------------------------------------------------- 5

CABLE ROUTING DIAGRAM ------------------------------------------------------------------------ 7

CHECKING THE ELECTRICAL COMPONENTS --------------------------------------------- 15

WIRING DIAGRAM

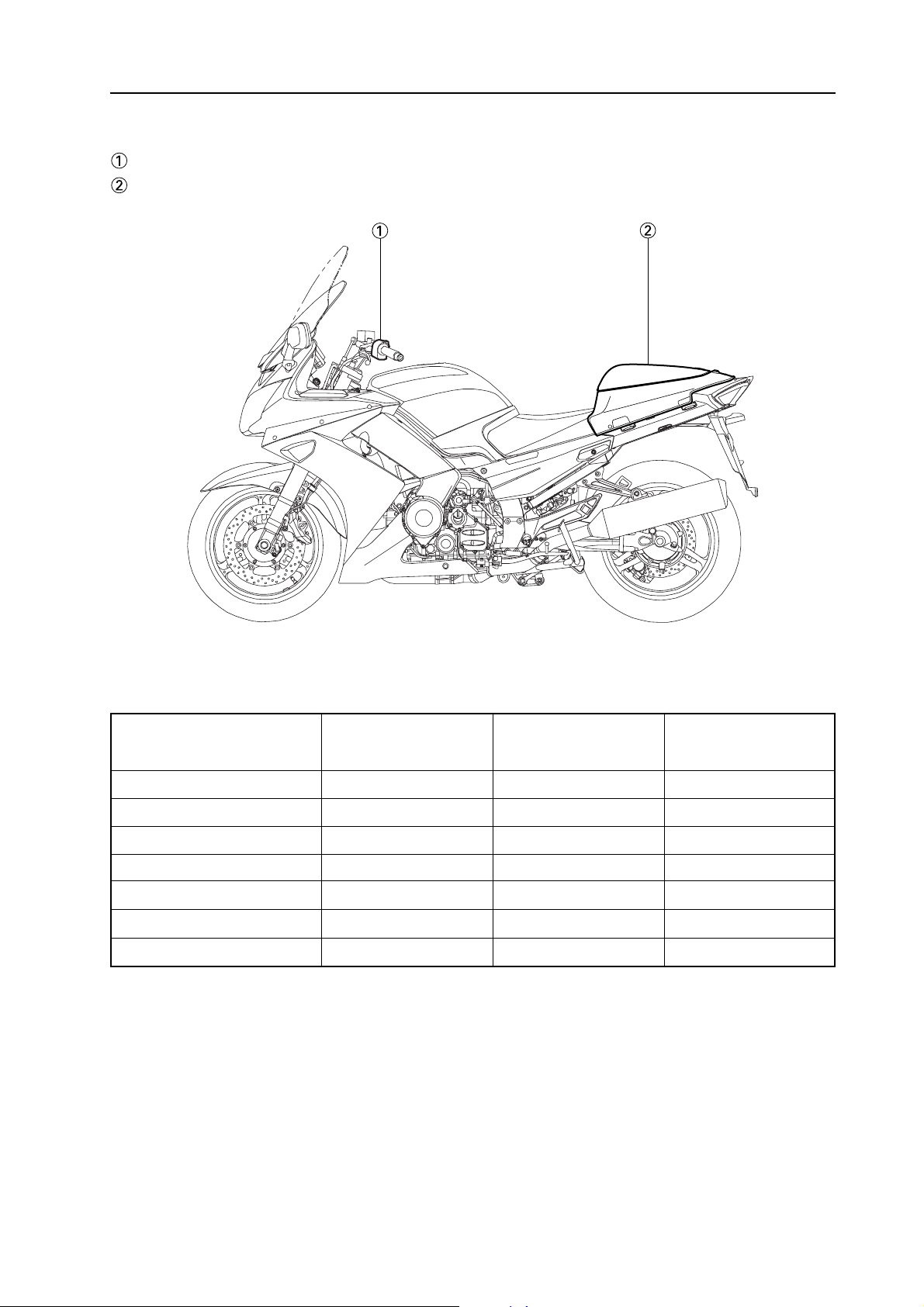

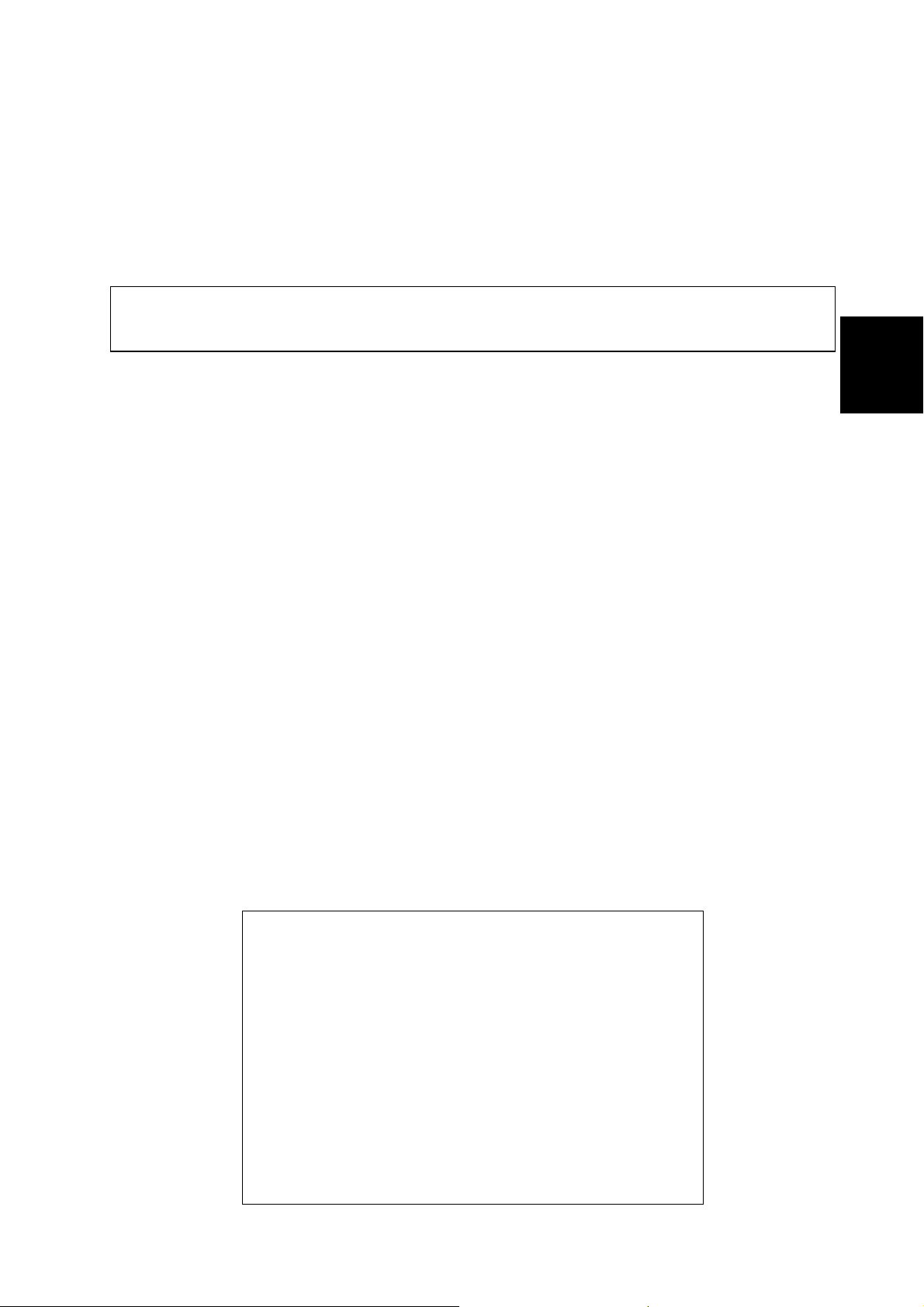

DESCRIPTION

Patrol switch

Radio box (5P56, 5P57)

DESCRIPTION / SPECIFICATIONS

SPECIFICATIONS

Model name

Approved model type

Registered model type

Overall length (mm)

Overall width (mm)

Overall height (mm)

Ground clearance (mm)

Weight (kg)

FJR1300AP

RP13

5P55

2230

740

1315

130

264

FJR1300AP

←

5P56

←

←

←

←

←

FJR1300AP

←

5P57

←

←

←

←

←

-1-

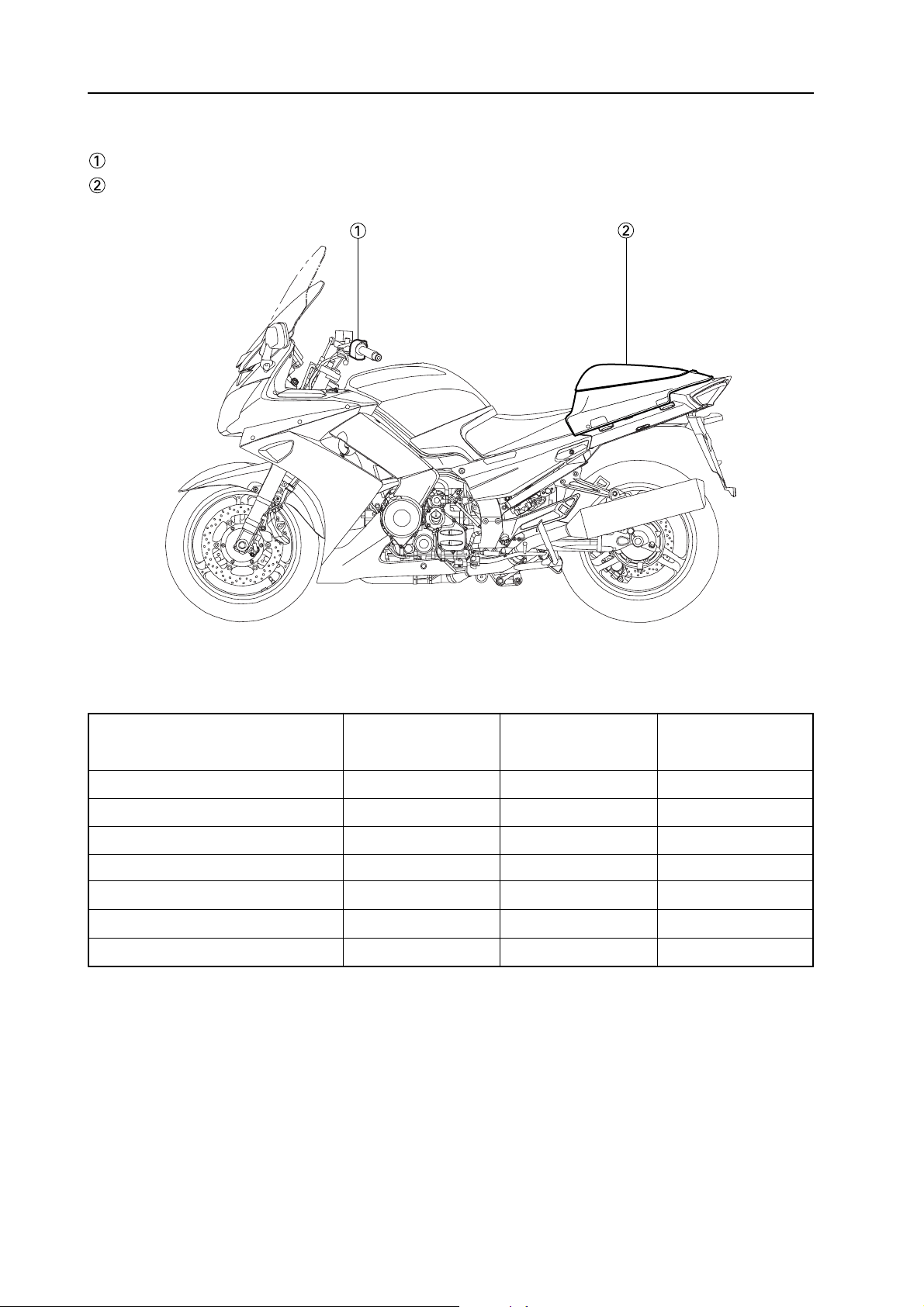

INSTRUMENT AND CONTROL FUNCTIONS

INSTRUMENT AND

CONTROL FUNCTIONS

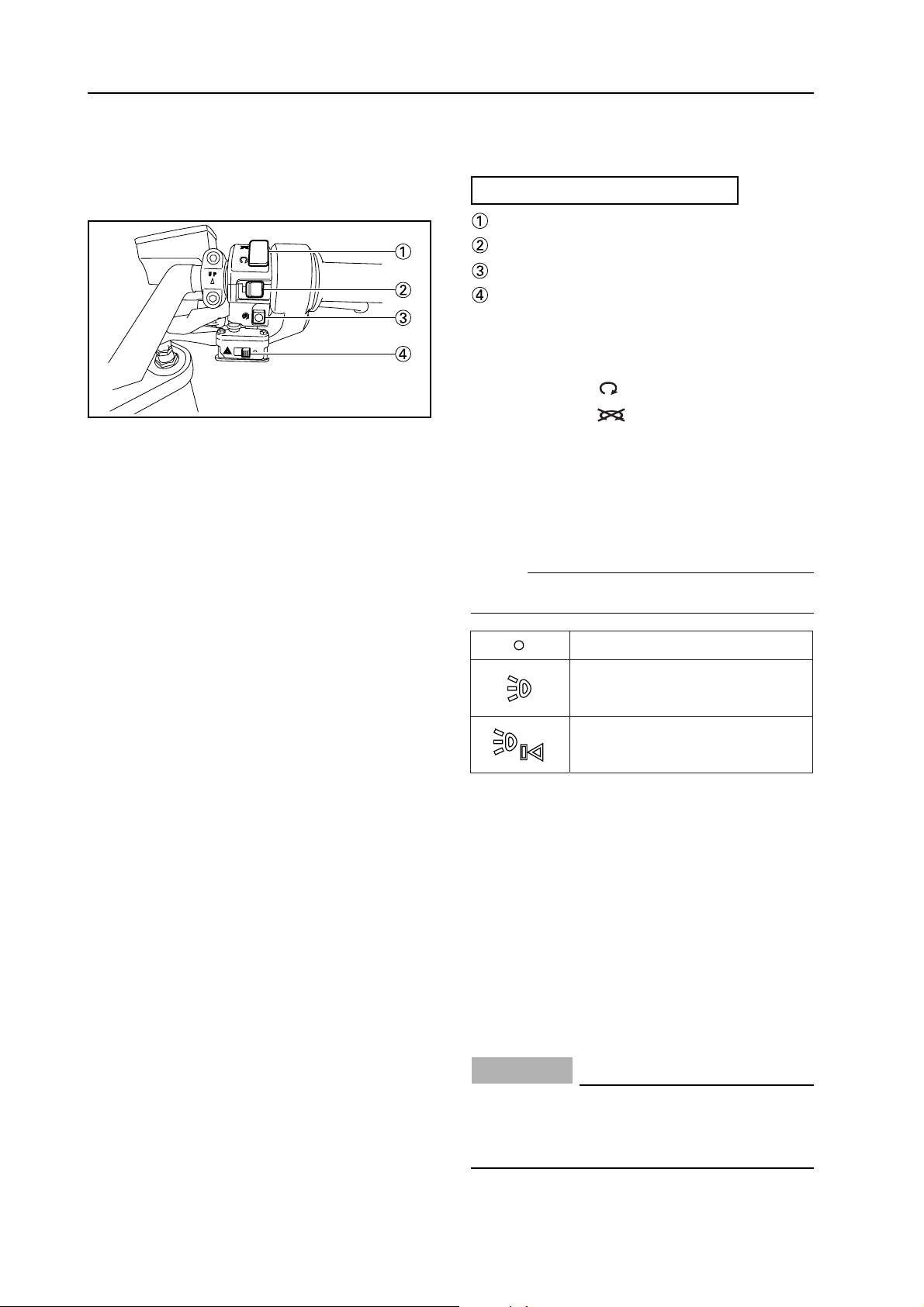

RIGHT HANDLEBAR SWITCH

Engine stop switch

Patrol switch

Start switch

Hazard switch

ENGINE STOP SWITCH

Set this switch to " " before starting the engine.

Set this switch to " " to stop the engine in case

of an emergency, such as when the motorcycle

overturns or when the throttle cable is stuck.

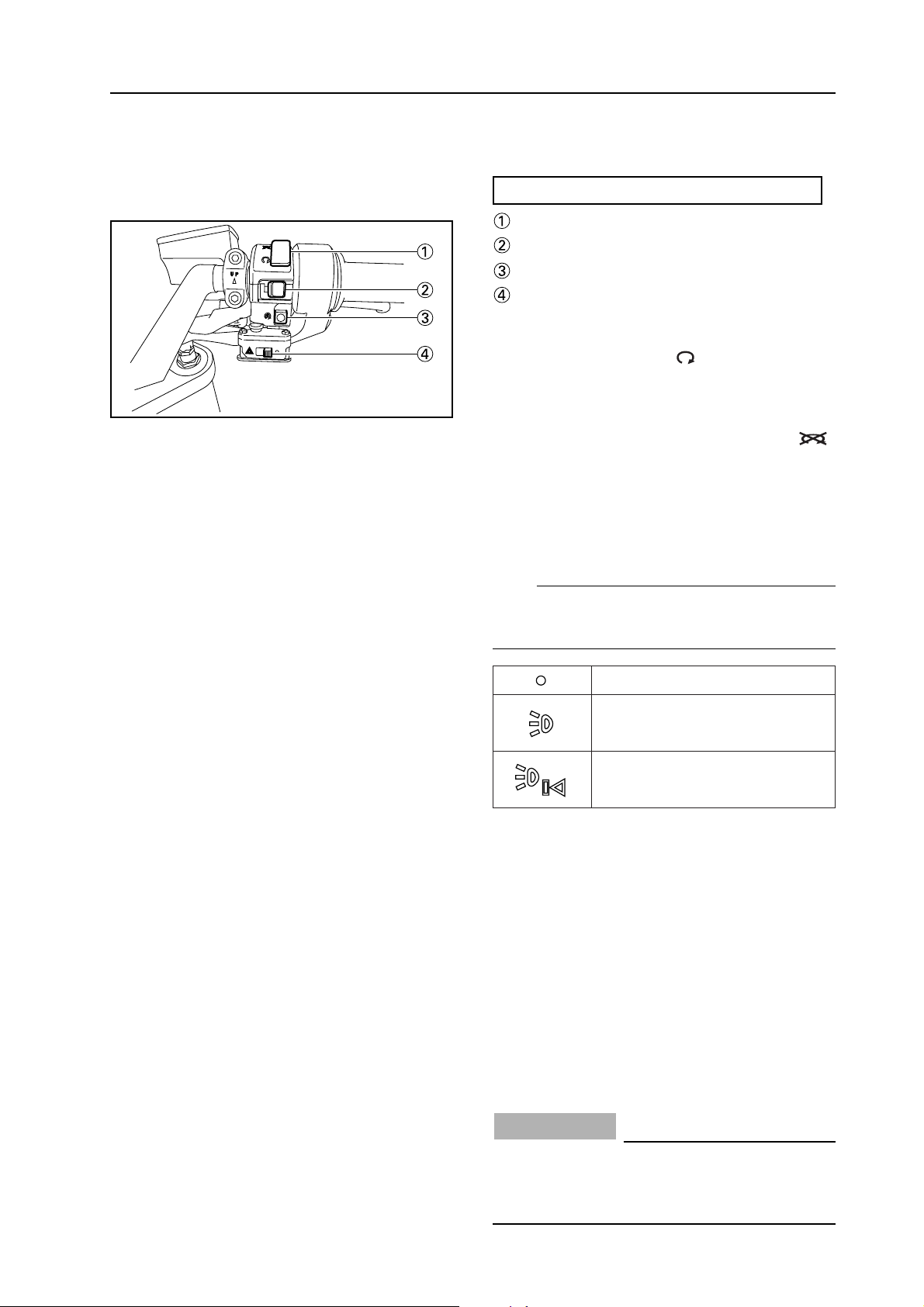

PATROL SWITCH

This switch activates the siren or flashing lamp.

NOTE:

It is used when a siren or flashing lamp is installed.

OFF

This is for the flashing lamp.

This is for both siren and

flashing lamp.

START SWITCH

Push this switch to crank the engine with the starter.

HAZARD SWITCH

With the key in the "ON" or "P" position, use this

switch to turn on the hazard lights (simultaneous

flashing of all turn signal lights).

The hazard lights are used in case of an emergency or to warn other drivers when your vehicle

is stopped where it might be a traffic hazard.

CAUTION:

Do not use the hazard lights for an extended

length of time with the engine not running, otherwise the battery may discharge.

-2-

INSTRUMENT AND CONTROL FUNCTIONS

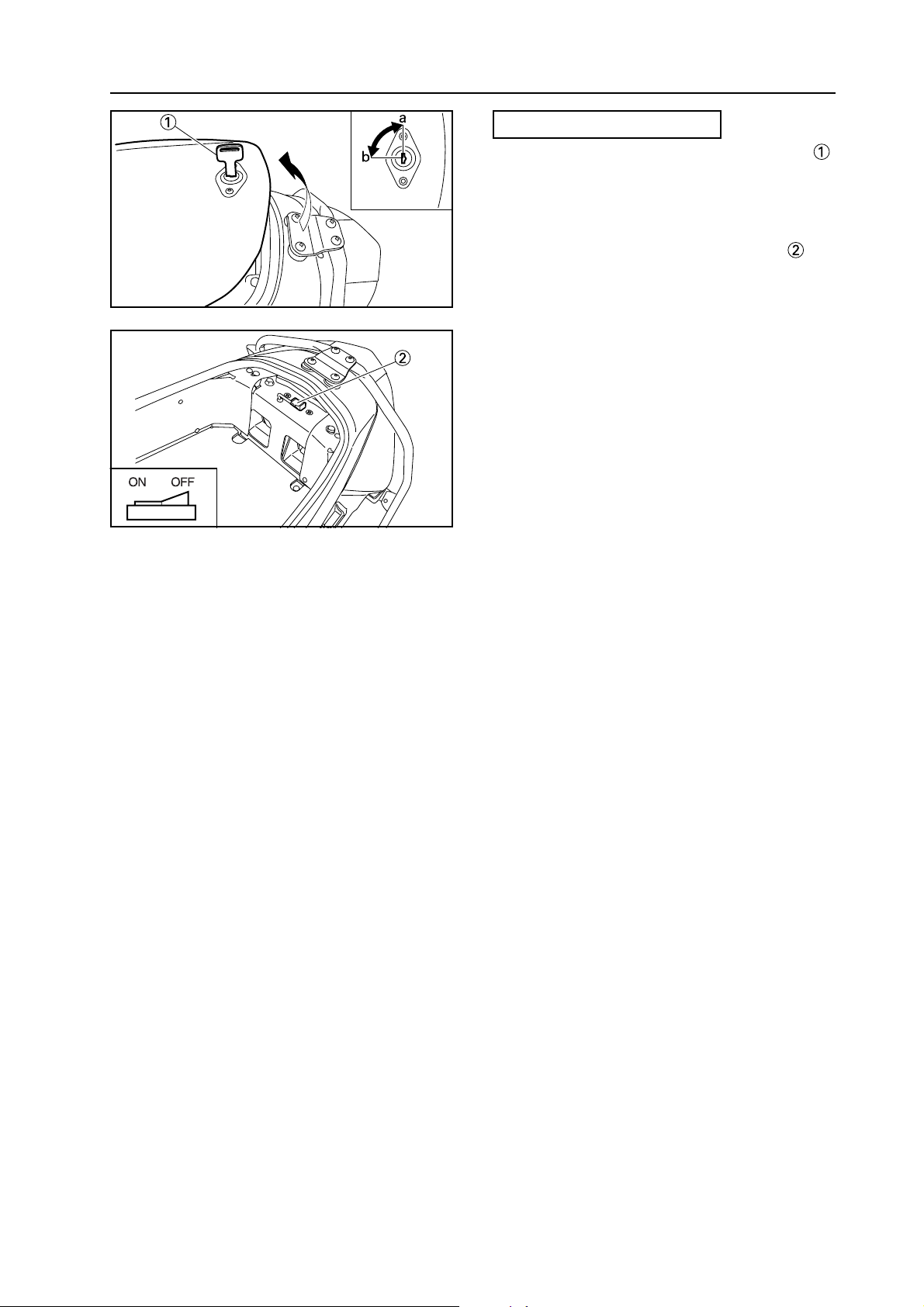

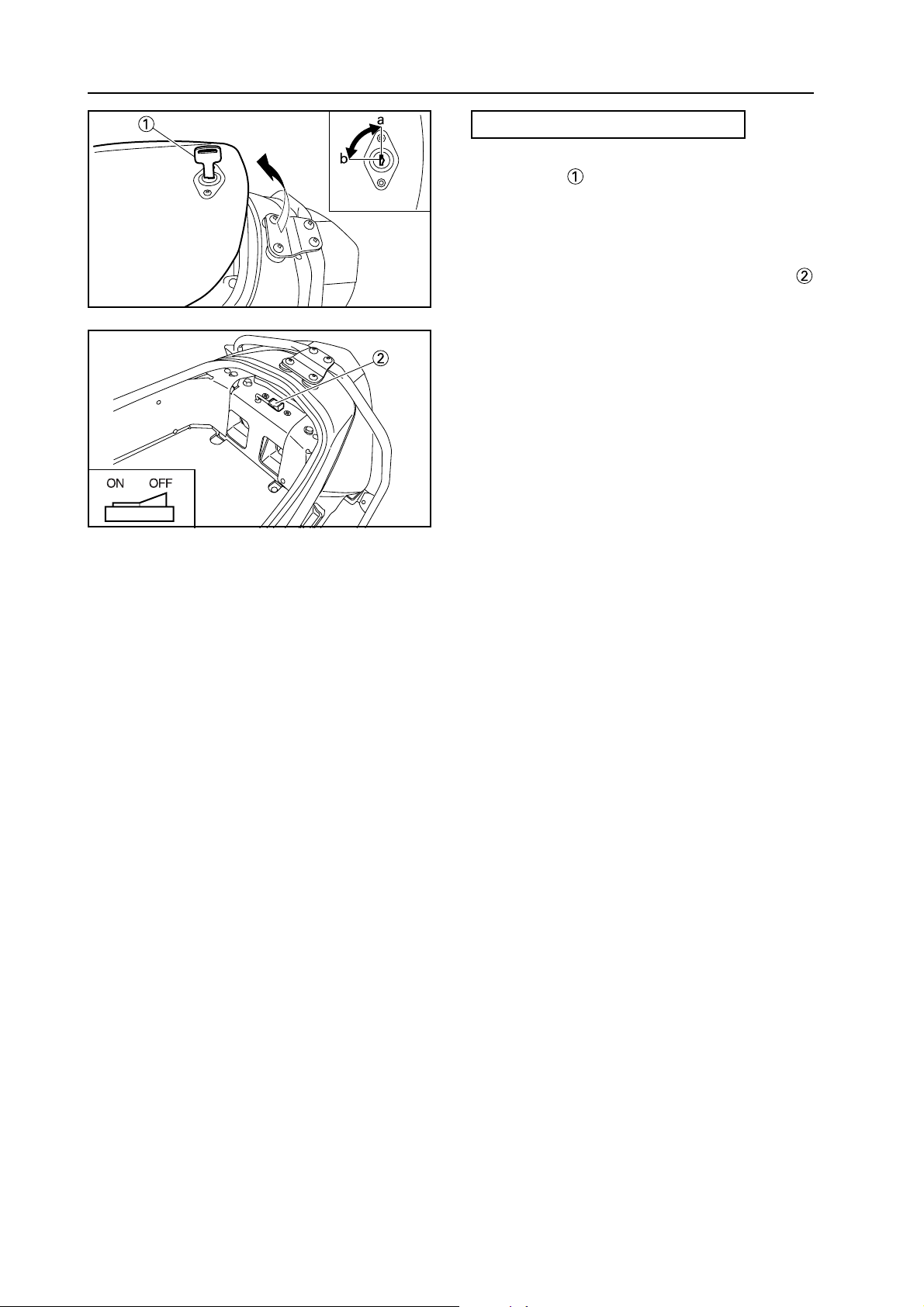

RADIO BOX (5P56, 5P57)

The lid can be locked by turning the inserted key .

[a] LOCK

[b] OPEN

• Changeover of the position of the switch can

prevent the battery from being discharged.

ON : When an auxiliary instrument is used

OFF : When no auxiliary instruments are used

-3-

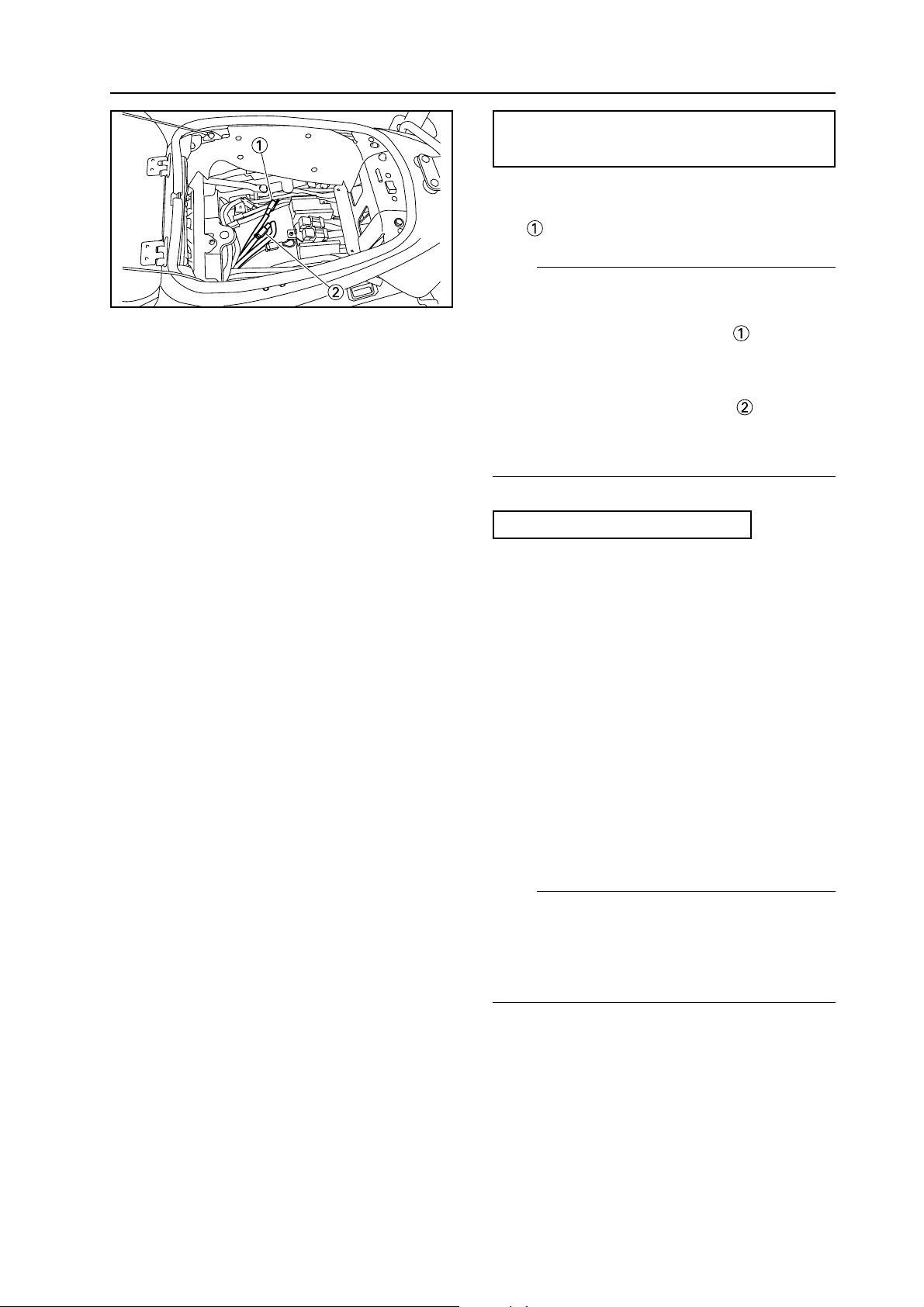

INSTRUMENT AND CONTROL FUNCTIONS

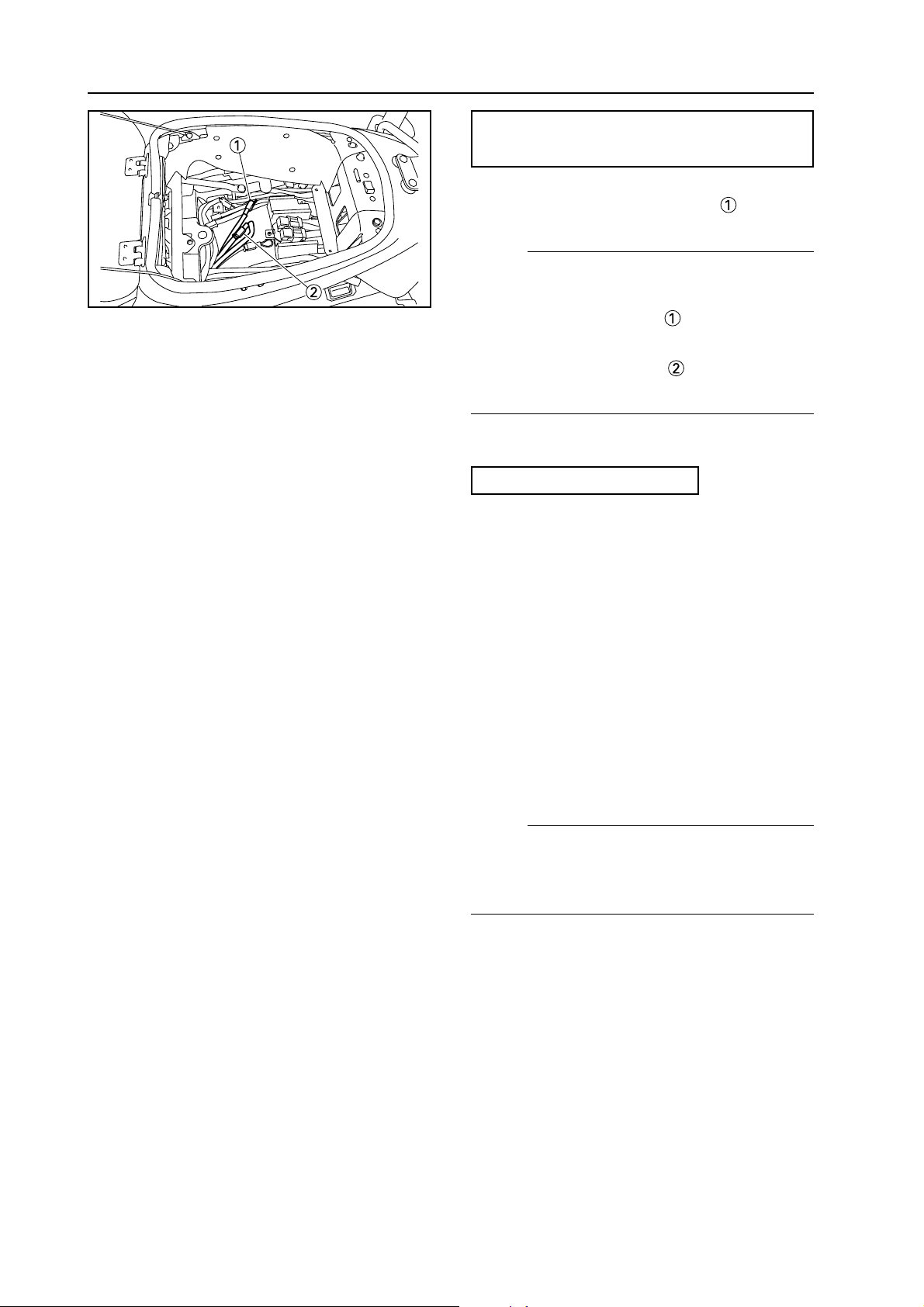

CHANGEOVER OF COUPLER FOR REAR

TURN SIGNAL LIGHTS

When a rear pole set (option) is installed to

the motorcycle, this blue coupler is used.

NOTE:

Changeover of the wire harness connection can

determine which lamp to light up.

• Connect to blue coupler : Rear turn signal

lights on the rear pole set side turn on.

• Connect to white coupler : Rear turn signal

lights in the rear combination lamps turn on.

SUSPENSION SETTINGS

When the motorcycle gains weight with auxiliary

instruments installed, perform the settings by reference to the following:

1.Front fork

• Increase pre-load.

• Decrease the rebound damping force (when

pre-load is increased).

•Decrease the compression damping force

(when pre-load is increased).

2.Rear suspension

• Increase pre-load (from soft to stiff)

• No change in the rebound damping force

NOTE:

The above settings are just a rule of thumb. They

vary with the rider’s weight etc., so get the feeling in an actual run.

-4-

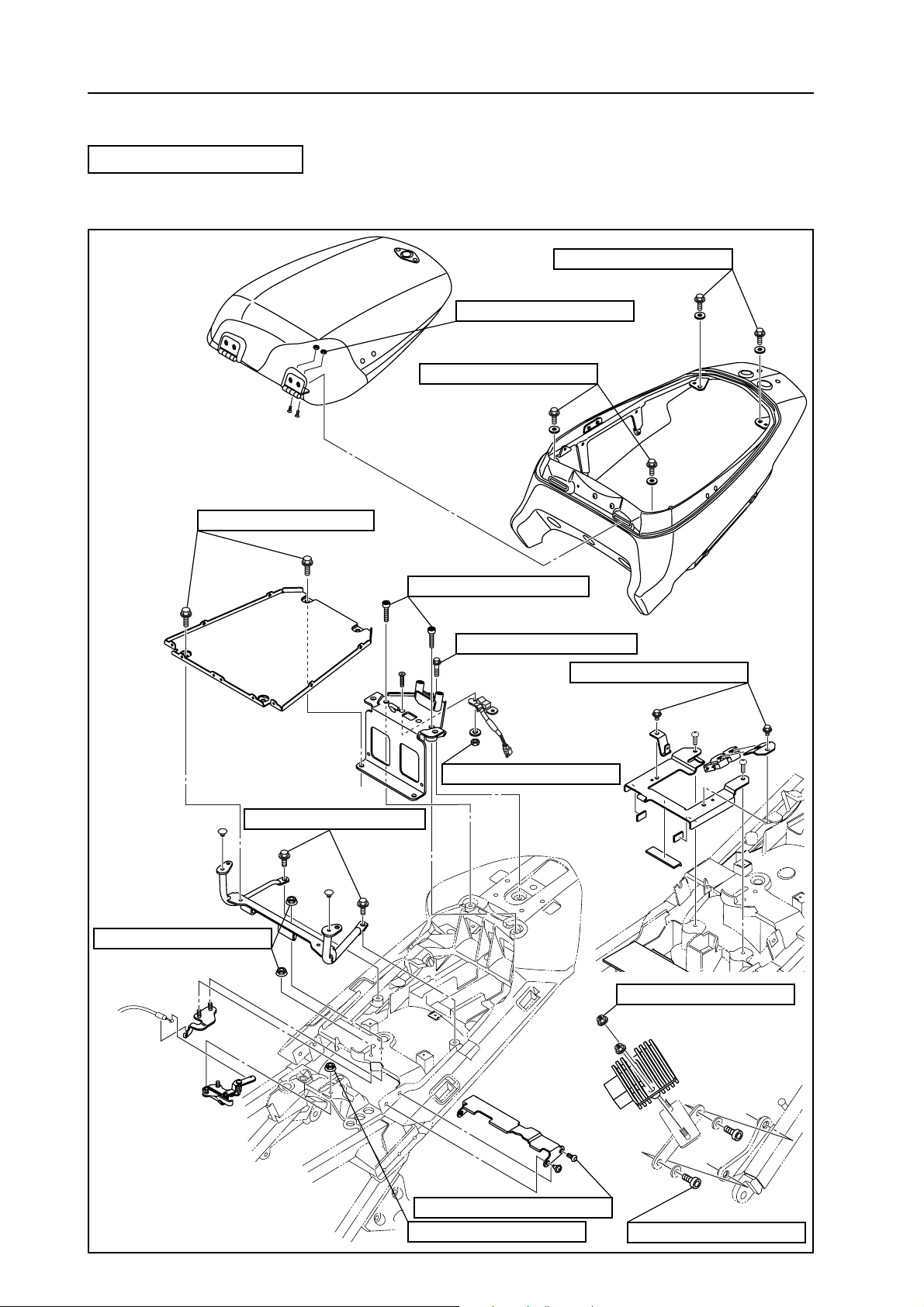

MAINTENANCE

MAINTENANCE

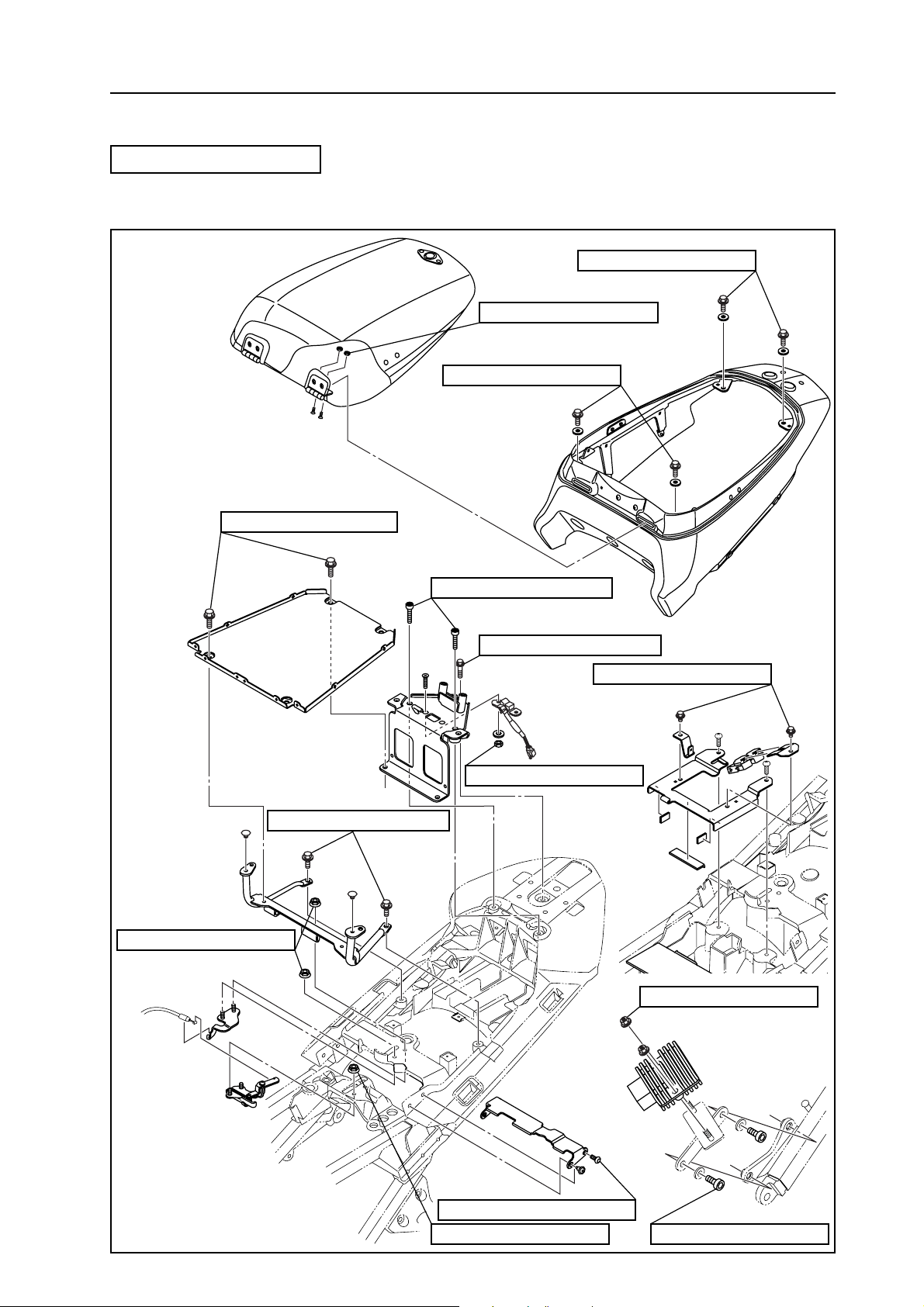

TIGHTENING TORQUE

Check each of the installed parts for any looseness during motorcycle inspection.

7 Nm (0.7 m • kg, 5.1 ft • lb)

2 Nm (0.2 m • kg, 1.4 ft • lb)

7 Nm (0.7 m • kg, 5.1 ft • lb)

7 Nm (0.7 m • kg, 5.1 ft • lb)

16 Nm (1.6 m • kg, 11 ft • lb)

7 Nm (0.7 m • kg, 5.1 ft • lb)

21 Nm (2.1 m • kg, 15 ft • lb)

21 Nm (2.1 m • kg, 15 ft • lb)

7 Nm (0.7 m • kg, 5.1 ft • lb)

4 Nm (0.4 m • kg, 2.9 ft • lb)

7 Nm (0.7 m • kg, 5.1 ft • lb)

1.5 Nm (0.15 m • kg, 1.1 ft • lb)

7 Nm (0.7 m • kg, 5.1 ft • lb)

-5-

8 Nm (0.8 m • kg, 5.8 ft • lb)

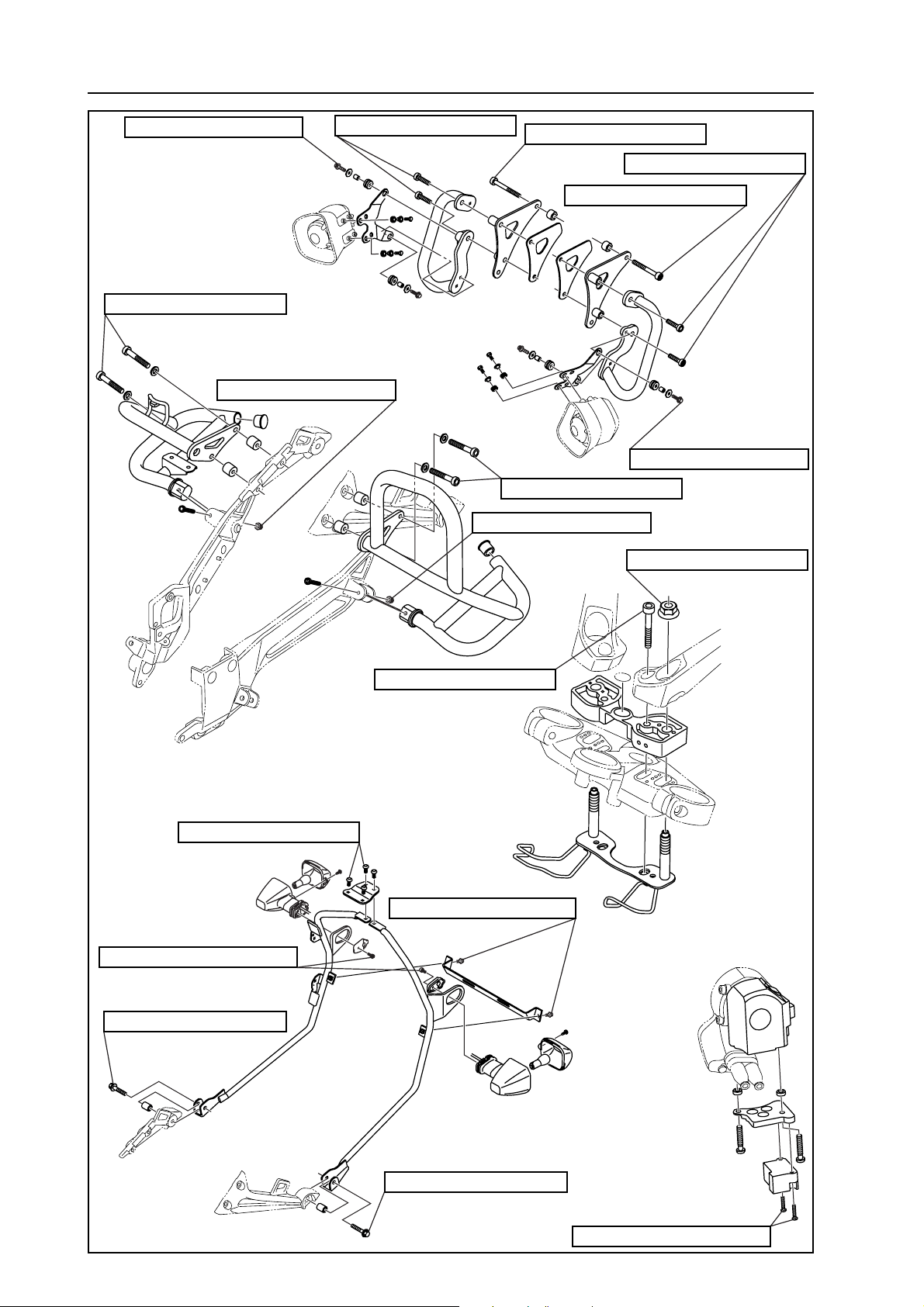

MAINTENANCE

7 Nm (0.7 m • kg, 5.1 ft • lb)

28 Nm (2.8 m • kg, 20 ft • lb)

9 Nm (0.9 m • kg, 6.5 ft • lb)

64 Nm (6.4 m • kg, 46 ft • lb)

9 Nm (0.9 m • kg, 6.5 ft • lb)

49 Nm (4.9 m • kg, 35 ft • lb)

64 Nm (6.4 m • kg, 46 ft • lb)

49 Nm (4.9 m • kg, 35 ft • lb)

7 Nm (0.7 m • kg, 5.1 ft • lb)

28 Nm (2.8 m • kg, 20 ft • lb)

65 Nm (6.5 m • kg, 47 ft • lb)

29 Nm (2.9 m • kg, 21 ft • lb)

1.5 Nm (0.15 m • kg, 1.1 ft • lb)

25 Nm (2.5 m • kg, 18 ft • lb)

23 Nm (2.3 m • kg, 17 ft • lb)

10 Nm (1.0 m • kg, 7.2 ft • lb)

25 Nm (2.5 m • kg, 18 ft • lb)

-6-

1.5 Nm (0.15 m • kg, 1.1 ft • lb)

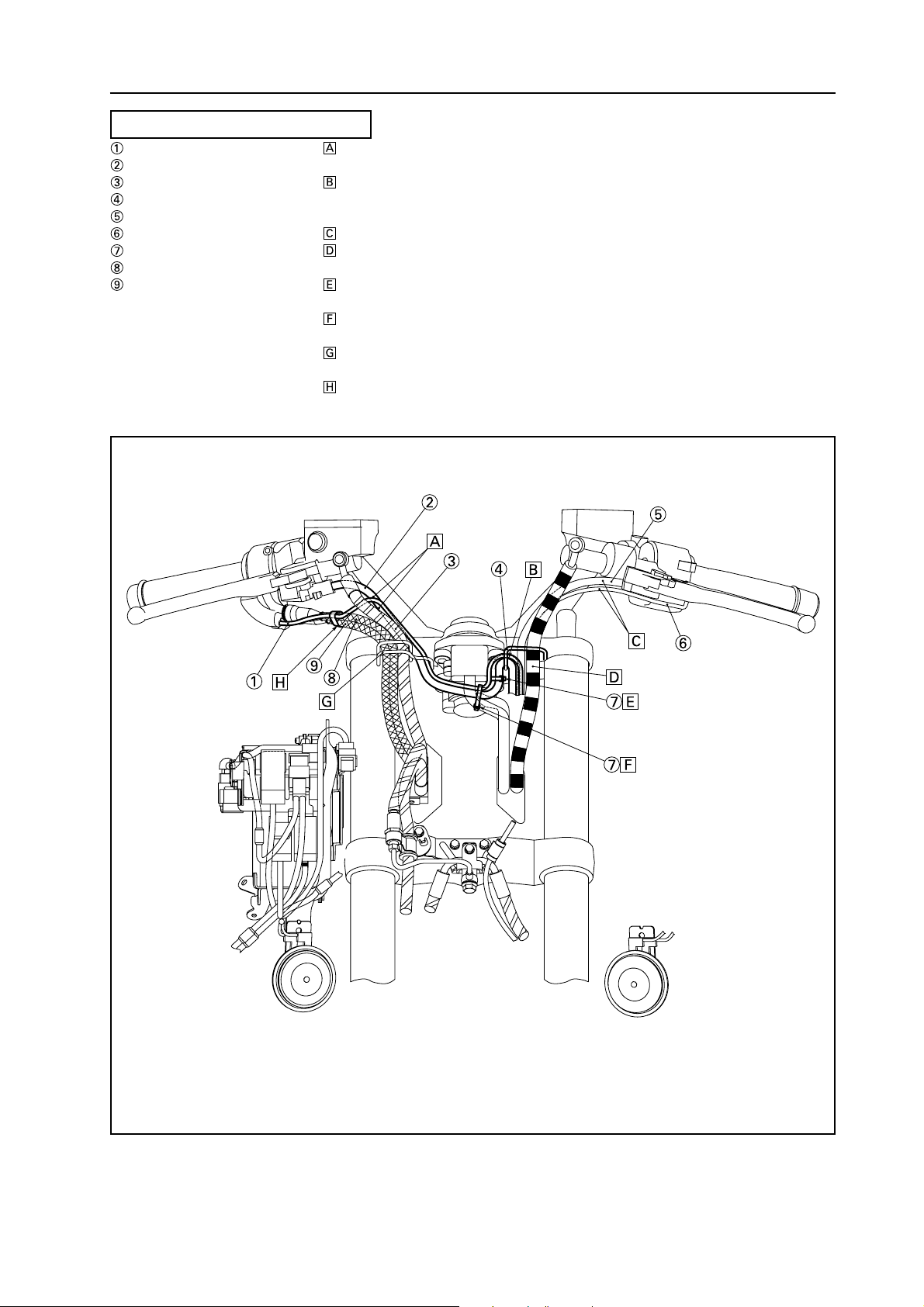

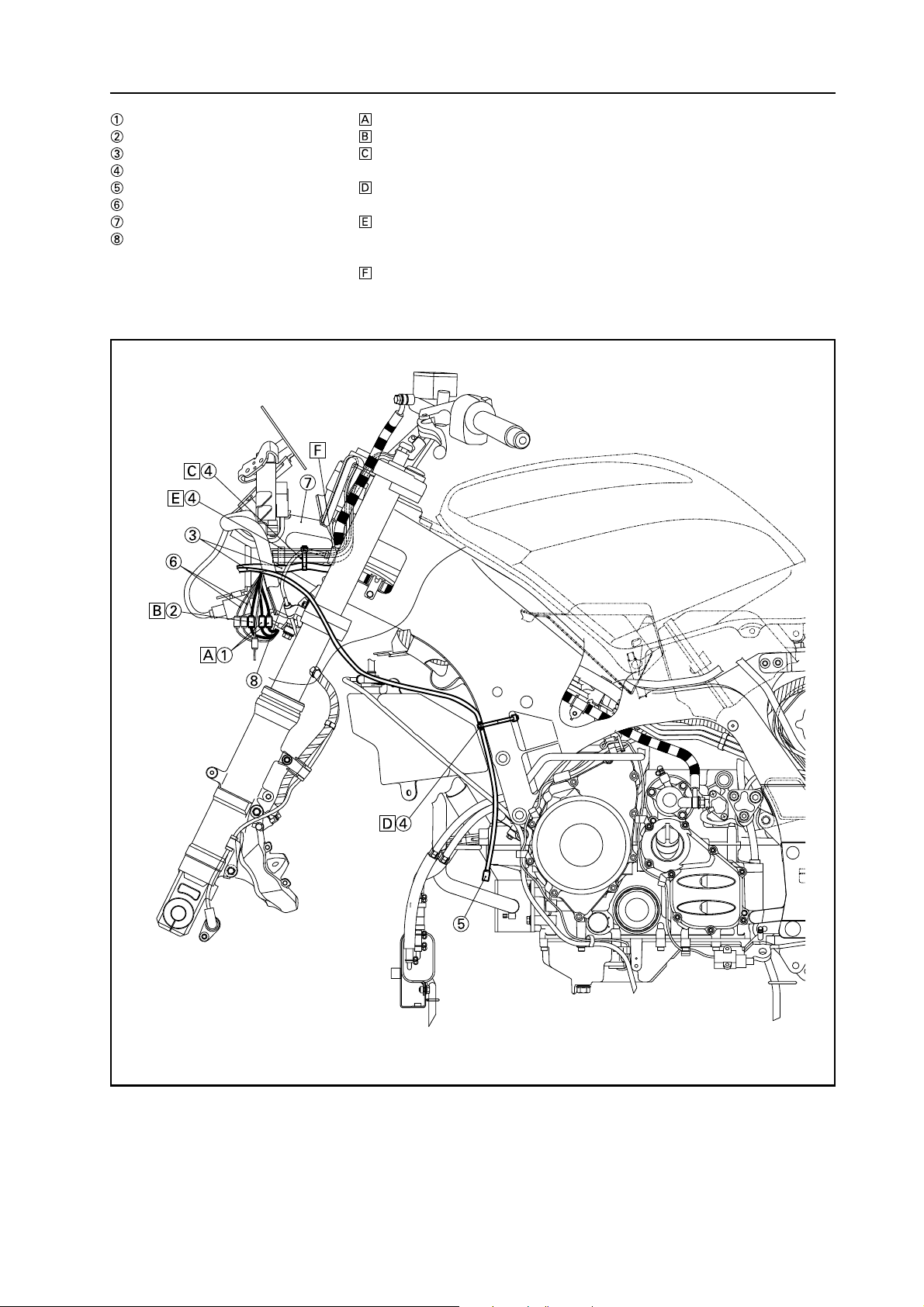

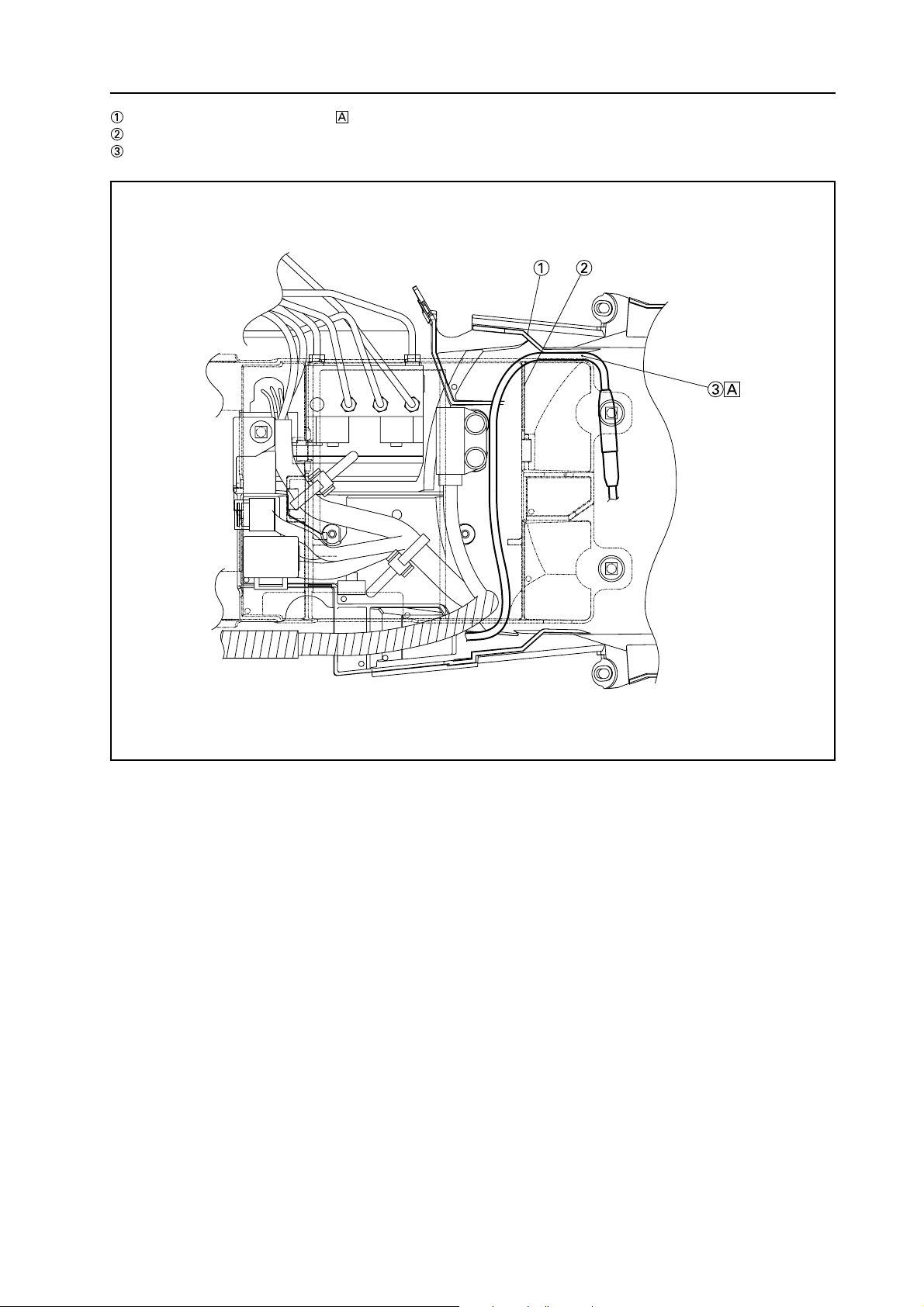

CABLE ROUTING DIAGRAM

Right grip warmer lead

Right handlebar switch lead

Front brake hose

Guide

Left handlebar switch lead

Left grip warmer lead

Clamp

Throttle cable 1

Throttle cable 2

Route the hazard switch lead, right handlebar switch lead and grip warmer lead under the

handlebar.

Route the hazard switch lead and grip warmer lead over the right handlebar switch lead

while taking care not to have them pinched between the guide and right handlebar switch

lead.

Route the left handlebar switch lead and the grip warmer lead under the handlebar.

Pass the clutch hose, the handlebar switch leads (left and right), the grip warmer leads

(left and right) and the hazard switch lead through the guide.

Clamp the hazard switch lead and right handlebar switch lead. Do not clamp the grip

warmer lead.

Clamp the hazard switch lead, right handlebar switch lead, grip warmer lead, main switch

lead and immobilizer unit lead.

Pass the front brake hose, the right handlebar switch lead, the right grip warmer lead, the

hazard switch lead, the throttle cable1 and 2 through the guide.

Clamp the grip warmer lead on the throttle cable1 and 2. Fasten the clamp where 10 mm

inside of the rubber boot end and cut off the clamp end.

MAINTENANCE

-7-

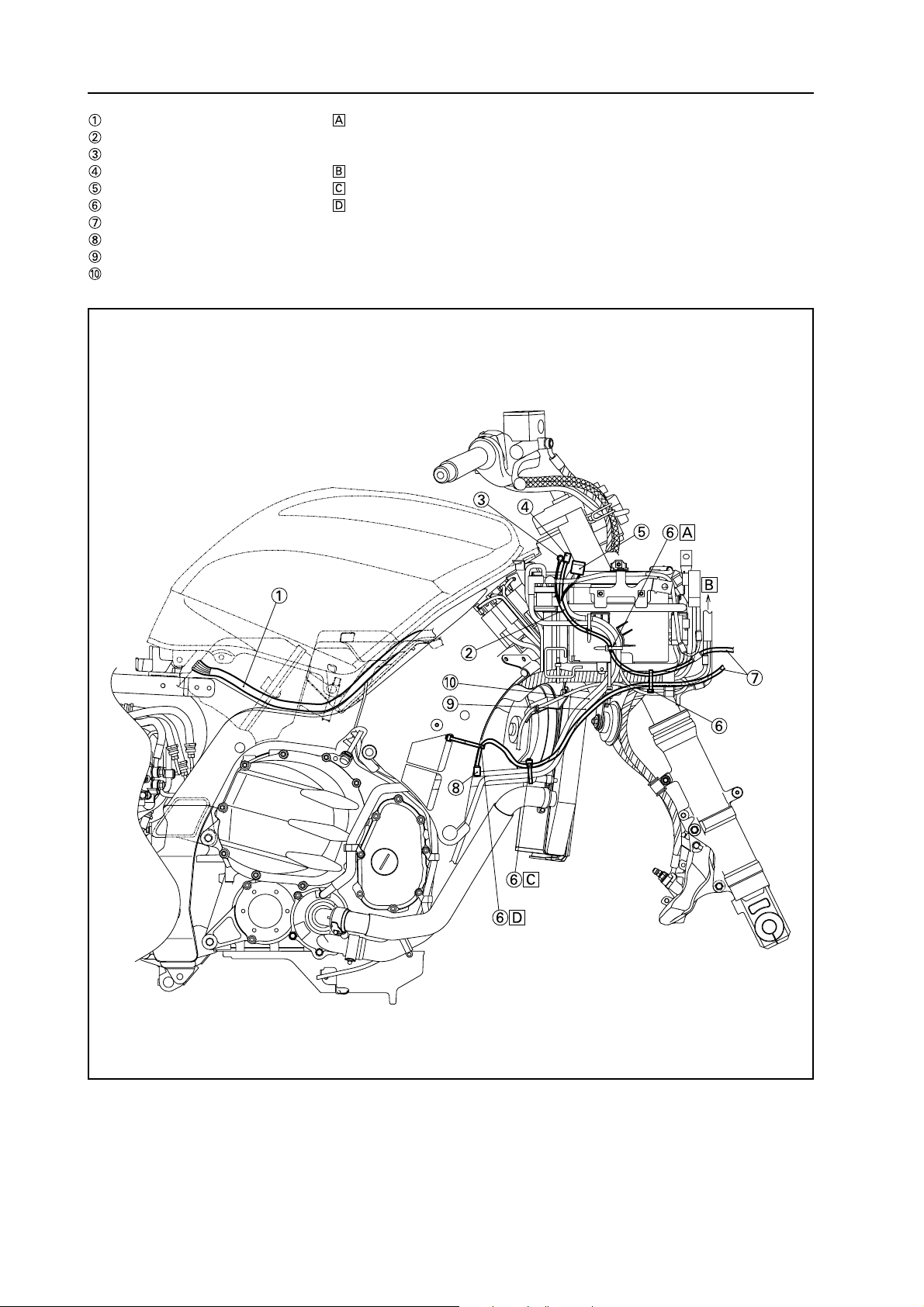

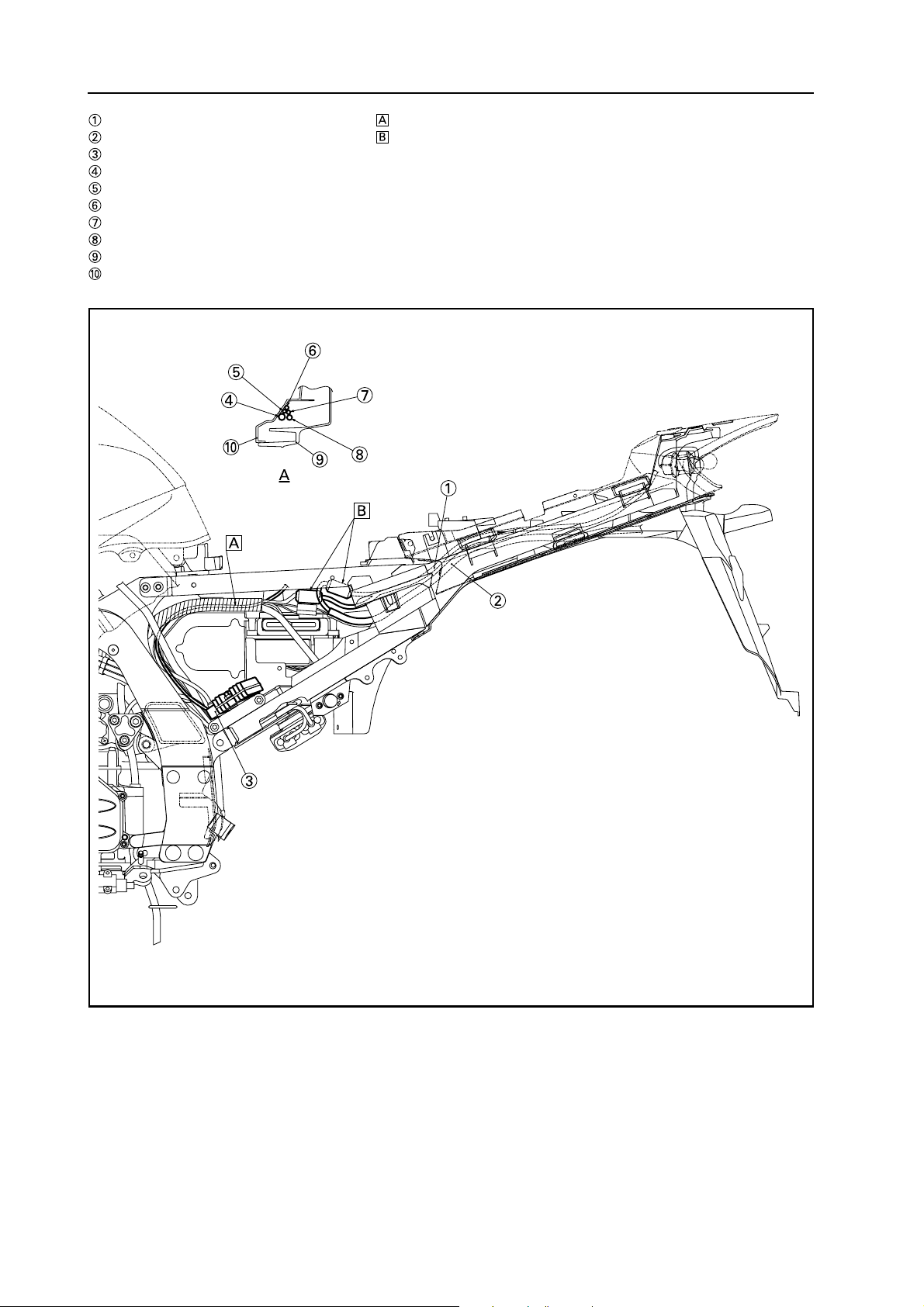

MAINTENANCE

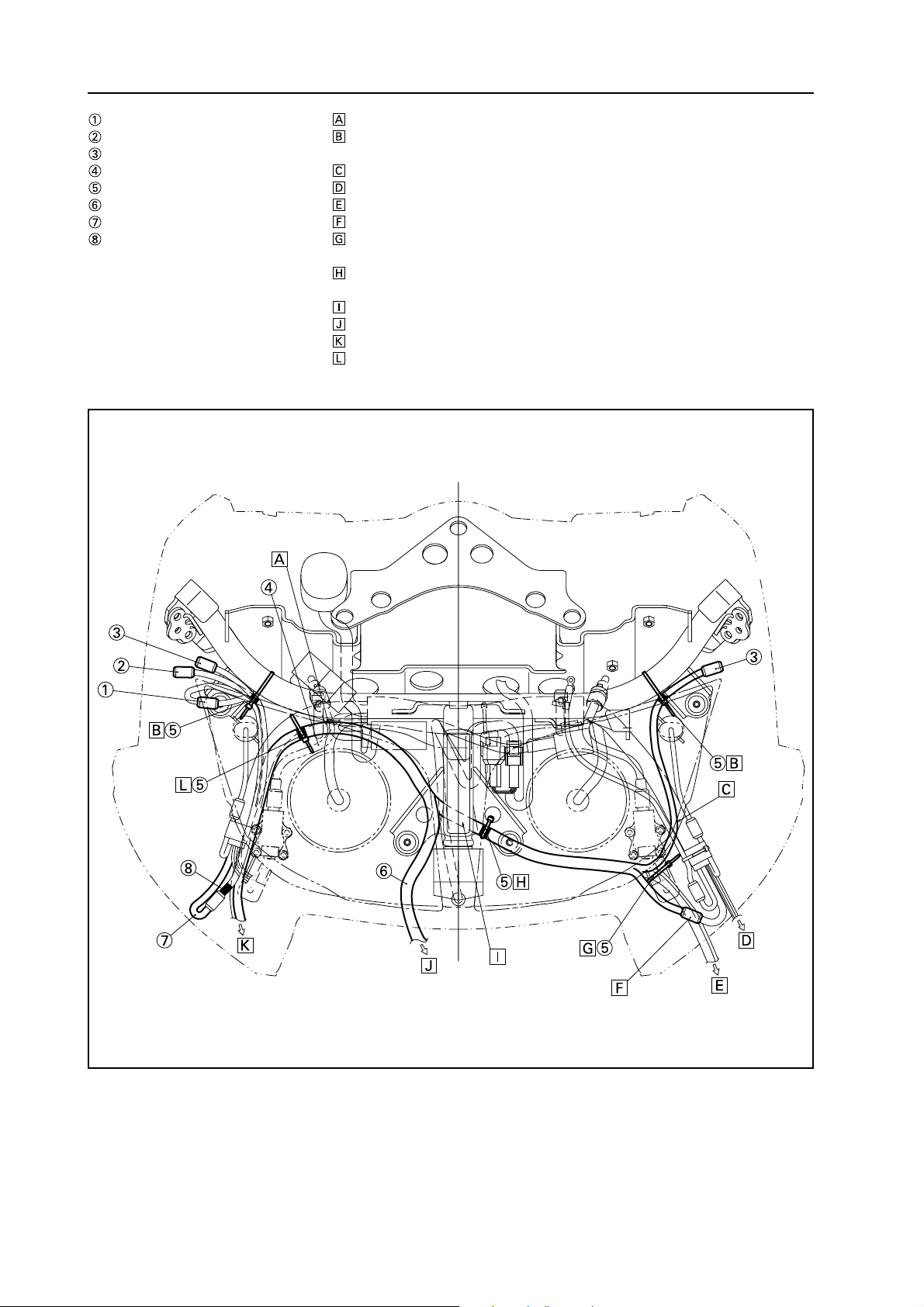

Extension wire lead

Wire lead (for battery charging)

Negative lead (for battery charging)

Coupler (for battery charging)

Fuse (SUB)

Clamp

Wire harness

Coupler (for siren)

Negative battery lead

Starter motor lead

Clamp the wire lead, the negative battery lead, the starter motor lead on the battery

box. Clamp the wire lead on the white tape marking section and turn the clamp end

toward the rear.

To the headlight lead

Clamp at the white tape.

Route the wire harness along the front side of the frame and clamp the white tape

marking section of harness at the top of the hole in the frame.

-8-

MAINTENANCE

Right handlebar switch lead

Hazard switch lead

Wire harness

Clamp

Coupler (for siren)

Grip warmer lead

Stay

Front wheel sensor lead

Connect the right handlebar switch lead to the wire harness.

Connect the hazard switch lead to the wire harness.

Clamp the wire harness, hazard switch lead, handlebar switch lead and grip warmer

lead. Do not clamp the front wheel sensor lead.

Route the wire harness along the front side of the frame and clamp the white tape

marking section of harness at the top of the hole in the frame.

Clamp the handlebar switch lead, the grip warmer lead and the hazard switch lead,

and pass them through the hole of the stay. Set the clamp end downward without

cutting it off.

Clamp the handlebar switch lead, the grip warmer lead, front wheel sensor lead and

the hazard switch lead, and pass them through the hole of the stay. Set the clamp

end downward without cutting it off.

-9-

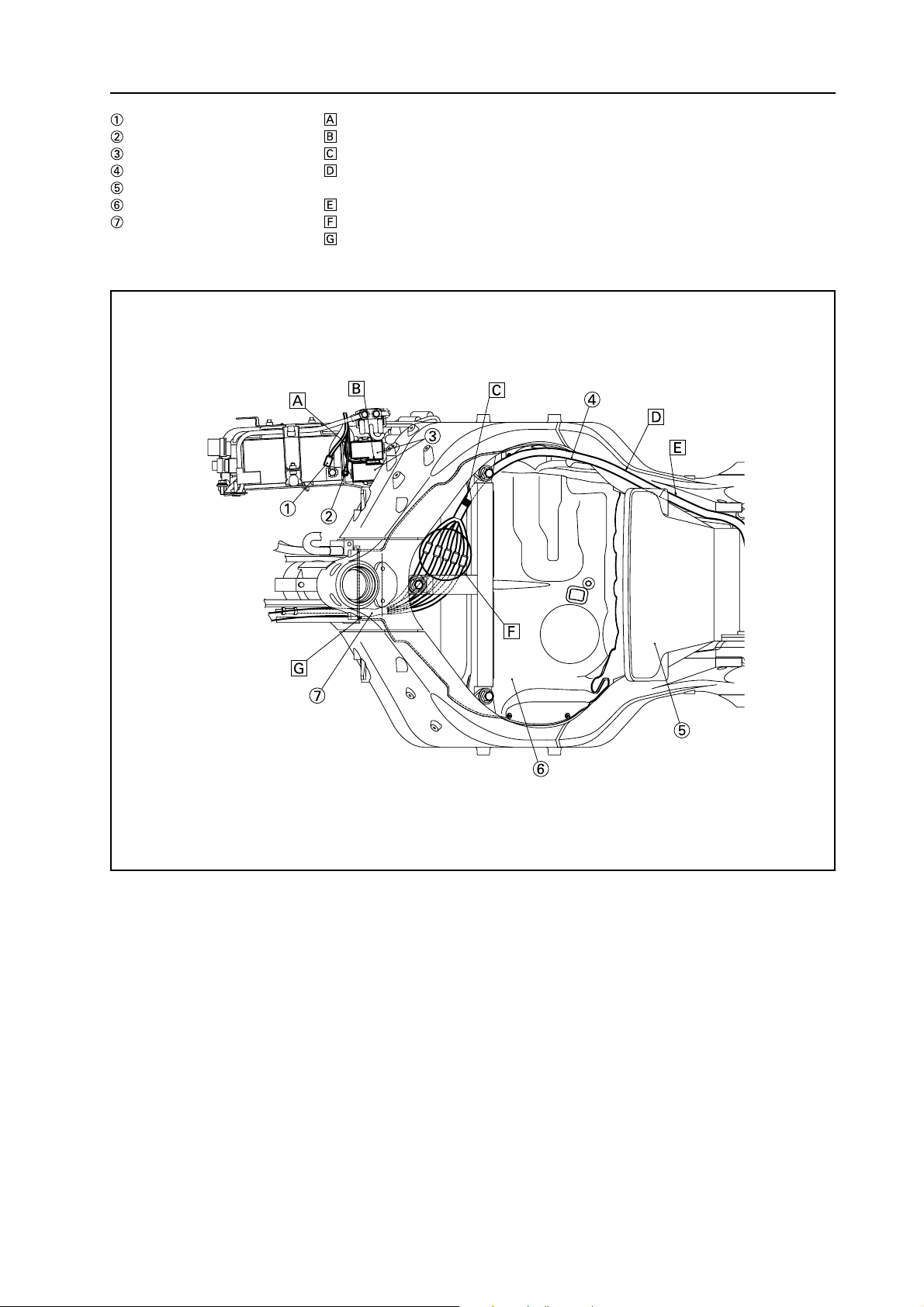

MAINTENANCE

Wire lead

Rear combination light lead

Rectifier

Rear combination light lead

License plate light lead

Sub-lead wire

Wire lead

Wire harness assembly

Rear frame

Rear fender

Route the rectifier lead inside the main harness.

Connect the wire lead between the main harness and rear combination light.

-10-

MAINTENANCE

Coupler (for battery charging)

Negative lead (for battery charging)

Fuse box

Extension wire lead

Air filter case

Insulator

Wire harness

Route the wire lead through the clearance between the battery and fuse box.

Install the fuse (SUB) in the inner fuse box inserting it from underneath.

Align the white taped portion with the front edge of the T-bar.

In installing the fuel tank, take care not to have the extension wire lead pinched between

the fuel tank and frame.

Route the extension wire lead along the side of the air filter case.

Connect the connectors of the identical color.

Route the wire harness through the hole in the frame to the left of the head pipe and over

the insulator.

B

U

S

-11-

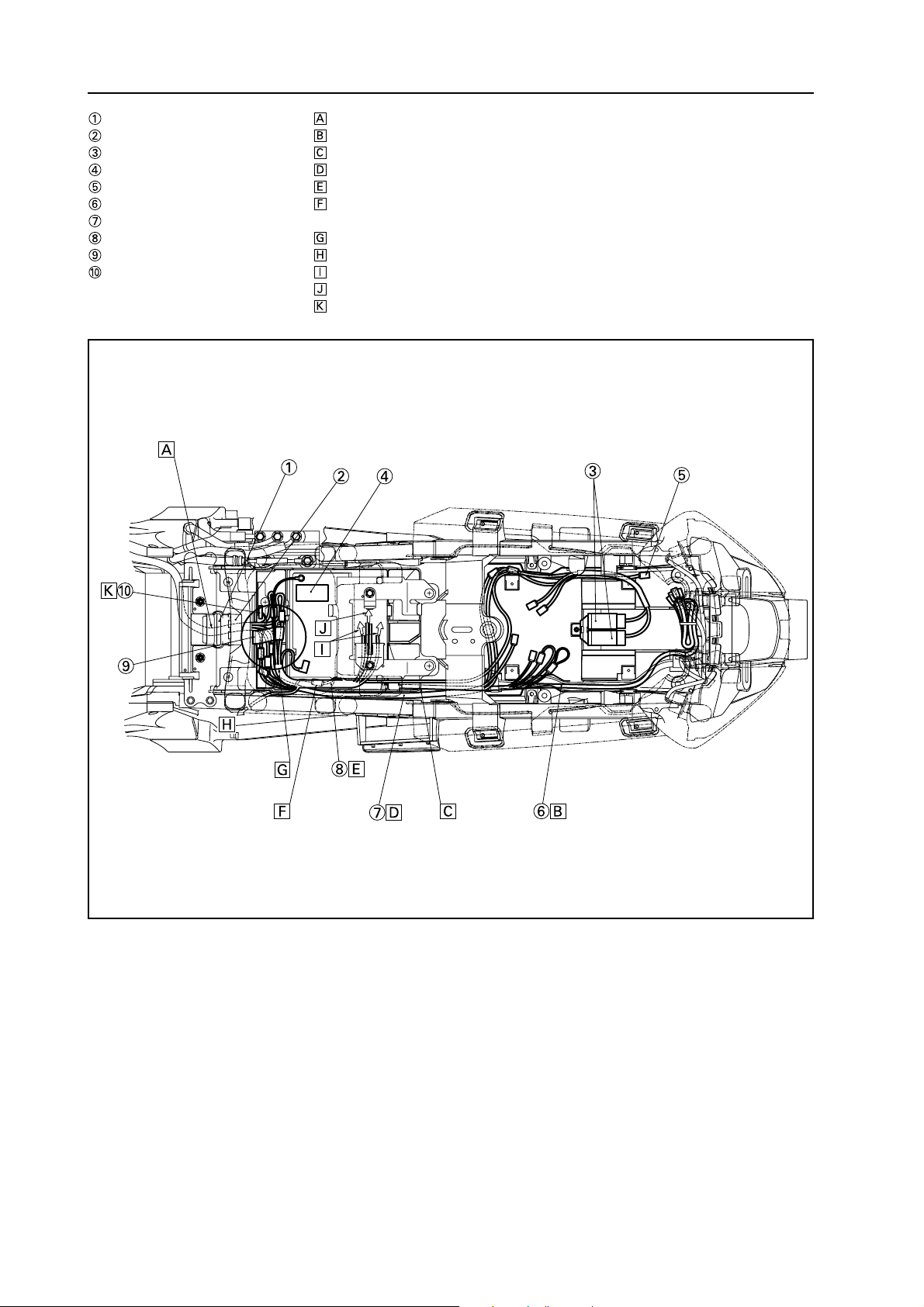

MAINTENANCE

Fuel tank fitting bracket

Seat bracket

Relay

Sub-battery box

Coupler (for radio box)

Wire lead

Wire harness assembly

Sub-lead wire

Tool band

Fuse (PATROL)

Route the extension wire lead in the middle under the tank fitting bracket and seat bracket.

Route the wire lead along and over the rear combination light lead.

Route the wire lead under the sub-battery box.

Route the wire harness assembly outside the sub-battery box.

Route the sub-lead wire inside the sub-battery box.

Connect the sub-lead wire to the wire harness assembly. Place the coupler under the

wire harness assembly.

Connect the couplers of the identical color.

To the rectifier

To the relay

To the fuse

Insert the fuse (PATROL) into the stay.

-12-

MAINTENANCE

Fender

Box

Seat lock cable

Route the seat lock cable between the fender and the box, and pass it under the box.

-13-

MAINTENANCE

Coupler (for siren controller)

Coupler (for microphone)

Coupler (front flashing light)

Headlight beam adjusting cable

Clamp

Wire harness

Right handlebar switch lead

Identification red tape

Route the wire harness at the back of the headlight beam adjusting cable.

Route the wire harness along the bottom of the square pipe frame and clamp it at the

white tape. Direct the clamp end downward.

Route the wire harness just at the head.

To the turn signal light and horn

To the main battery, including the siren, etc.

Connect the headlight lead and wire harness. (Connect the couplers of the identical color.)

Fix the headlight cord and wire harness to the headlight mounting stay with the clamp.

Leave the clamp end to lie on the inside of the cowling.

Route the clamp through the hole in the stay and fix the wire harness at the white

tape. Cut off the clamp end.

Route the wire harness under the stay.

To the extension wire lead under the fuel tank

To the handlebar switch lead and siren

Clamp the wire harness at the white tape together with the headlight lead. Direct the

clamp end downward.

-14-

MAINTENANCE

CHECKING THE ELECTRICAL COMPONENTS

CHECKING THE FUSE

1.Check the fuse. If it is found blown, replace it

with a new one.

SUB : 30A

CHARGE : 30A

DISCHARGE : 20A

PATROL : 10A

R/Y L L/B

Ch

(OFF)

(ON)

Br/W Dg

R/Y

L

L/B

Br/W

Ch

Dg

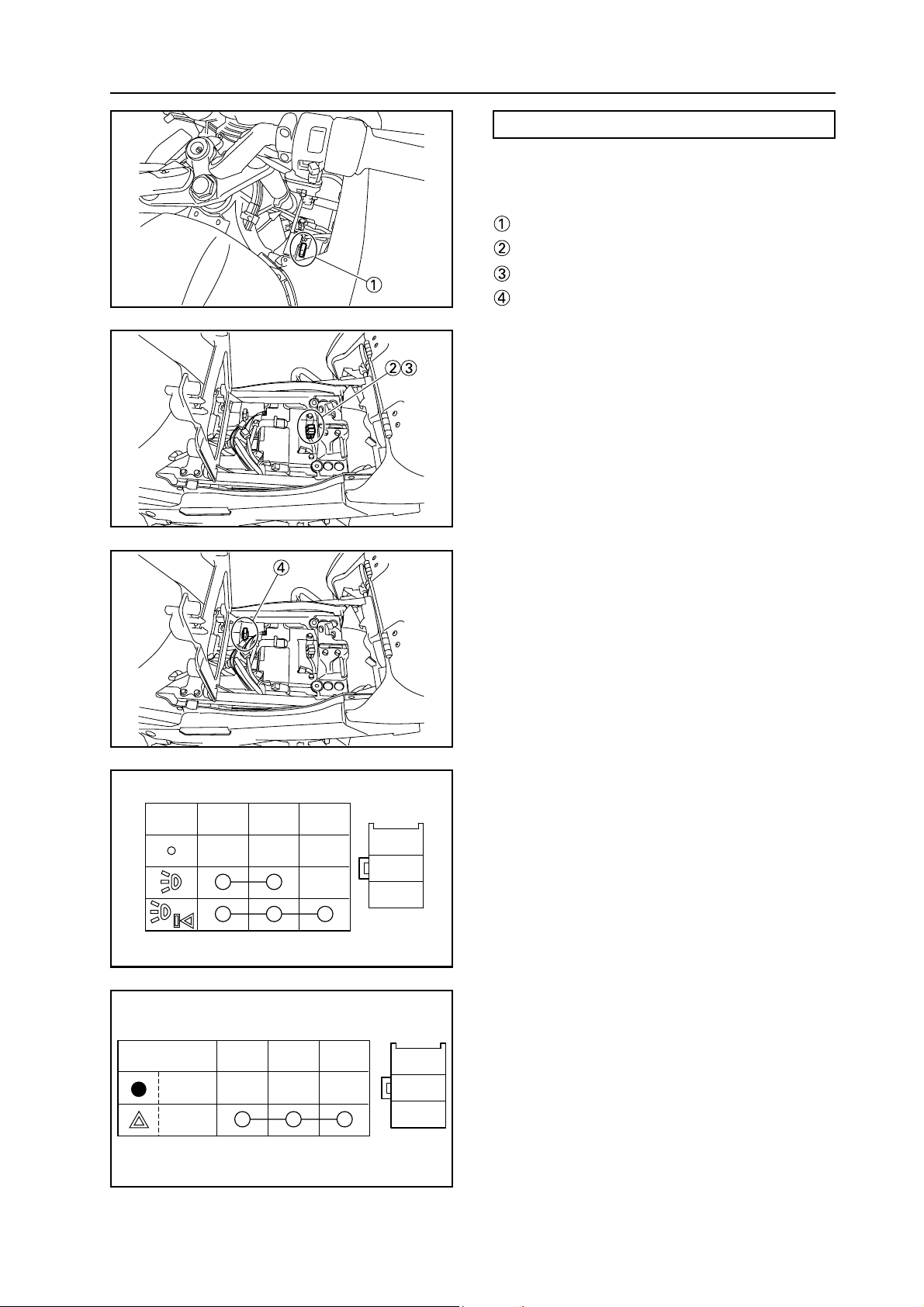

CHECKING THE PATROL SWITCH

1.Disconnect the right handlebar switch coupler

from the wire harness.

2.Connect the pocket tester (Ω × 1) to the right

handlebar switch coupler.

Incorrect continuity → Replace the right handlebar switch.

CHECKING THE HAZARD SWITCH

1.Disconnect the hazard switch coupler from the

wire harness.

2.Connect the pocket tester (Ω × 1) to the haz-

ard switch coupler.

Incorrect continuity → Replace the hazard switch.

-15-

MAINTENANCE

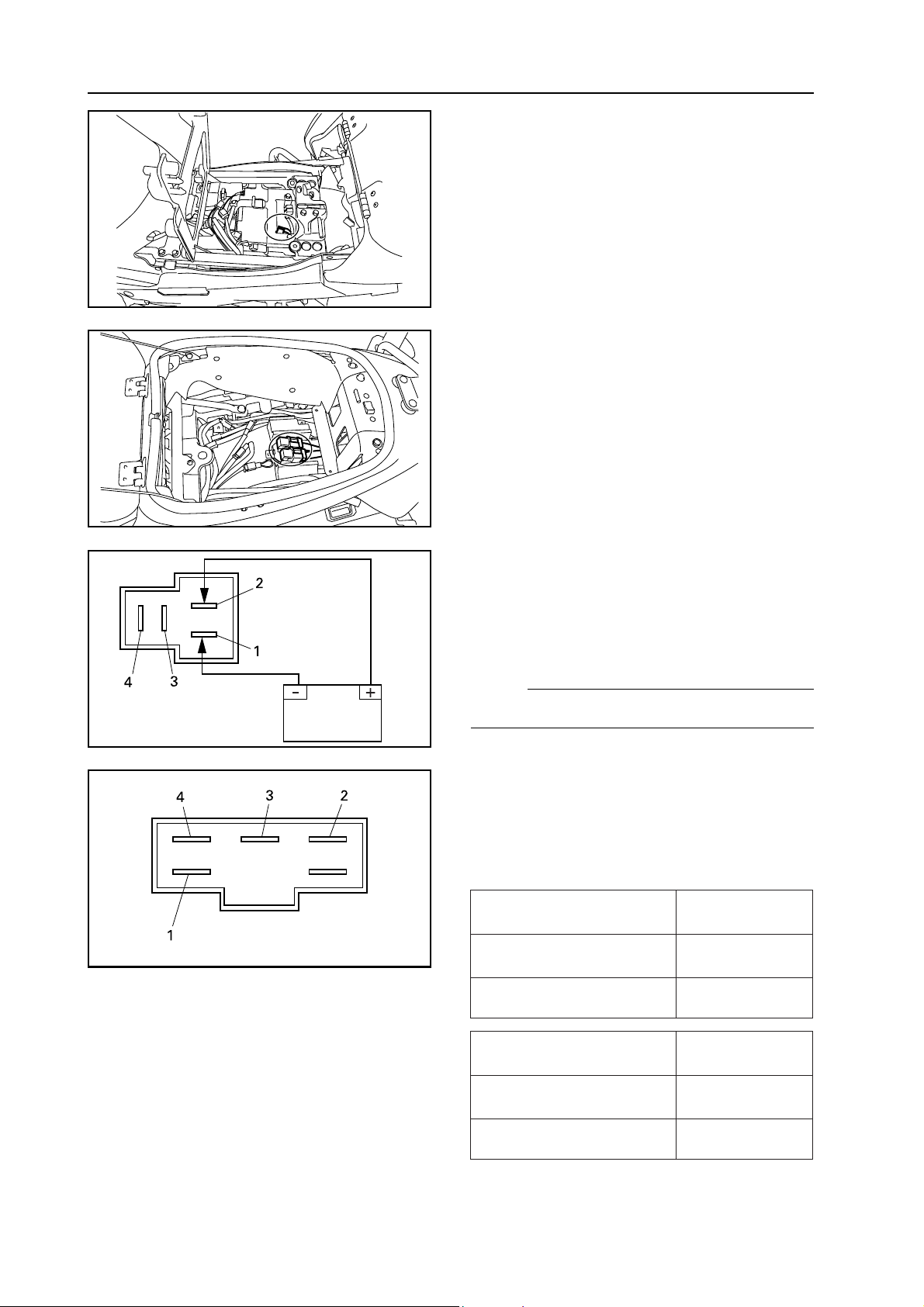

CHECKING THE RELAY

1.Disconnect the relay from the wire harness.

2.Connect the pocket tester (Ω × 1) and battery

terminal (12V) to the relay terminal as shown.

No continuity between terminals 3 and 4 when

battery is connected → Replace the relay.

1.Connected to the battery (+) lead

2.Connected to the battery (-) lead

3.Connected to the tester (+) lead

4.Connected to the tester (-) lead

NOTE:

Inspect the four relays by the same procedure.

CHECKING THE RECTIFIER

1.Disconnect the rectifier from the wire harness.

2.Connect the pocket tester (Ω × 1) to the recti-

fier terminal as shown.

Tester (+) lead → Terminal 1

Tester (-) lead → Terminal 2

Tester (+) lead → Terminal 1

Tester (-) lead → Terminal 3

Tester (+) lead → Terminal 1

Tester (-) lead → Terminal 4

Continuous

Continuous

Continuous

Tester (+) lead → Terminal 2

Tester (-) lead → Terminal 1

Tester (+) lead → Terminal 3

Tester (-) lead → Terminal 1

Tester (+) lead → Terminal 4

Tester (-) lead → Terminal 1

Incorrect continuity → Replace the rectifier.

Not continuous

Not continuous

Not continuous

-16-

INTRODUCTION

Ce supplément au manuel a été rédigé en vue de proposer les nouvelles méthodes d'entretien et

les nouvelles données concernant la FJR1300AP. Pour des renseignements complets relatifs

aux méthodes d'entretien, il convient d'utiliser ce manuel de concert avec ceux qui suivent :

FJR1300 MANUEL DU PROPRIÉTAIRE (5P5-28199-E2, -F2, -G2, -H2, -S2)

FJR1300 MANUEL D'ATELIER (3P6-28197-E2, -F2, -G2, -H2, -S2)

FJR1300AP

SUPPLEMENT AU MANUEL

POUR LE MODELE DE POLICE

2008 par la Yamaha Motor Co., Ltd.

Première édition, mars 2008

Tous droits réservés

Toute reproduction ou utilisation

sans la permission écrite de la

Yamaha Motor Co., Ltd.

est formellement interdite.

INFORMATIONS IMPORTANTES CONCERNANT LE MANUEL

Les informations particulièrement importantes sont repérées par les notations suivantes :

Le symbole de danger incite à ÊTRE VIGILANT AFIN DE GARANTIR LA SÉCURITÉ !

AVERTISSEMENT

Le non-respect des instructions données sous un AVERTISSEMENT peut entraîner des blessures

graves ou la mort du pilote, d'une personne se trouvant à proximité ou d'une personne inspectant

ou réparant la moto.

ATTENTION:

La mention ATTENTION indique les précautions particulières à prendre pour éviter d'endommager

la moto.

N.B.:

Un N.B. fournit les renseignements nécessaires à la clarification et la simplification des divers

travaux.

N.B.:

Yamaha est sans cesse à la recherche d'améliorations dans la conception et la qualité de ses

produits. Par conséquent, bien que ce manuel contienne les informations les plus récentes

disponibles au moment de l'impression, il peut ne pas refléter de petites modifications apportées

ultérieurement à ce modèle. Au moindre doute concernant le fonctionnement ou l'entretien du

véhicule, ne pas hésiter à consulter un concessionnaire Yamaha.

TABLE DES MATIÈRES

DESCRIPTION------------------------------------------------------------------------------------------------ 1

CARACTÉRISTIQUES ------------------------------------------------------------------------------------- 1

COMMANDES ET INSTRUMENTS --------------------------------------------------------------------- 2

COMMUTATEUR DE GUIDON DROIT ------------------------------------------------------------ 2

COFFRET RADIO (5P56, 5P57)--------------------------------------------------------------------- 3

CHANGEMENT DU COUPLEUR POUR LES FEUX CLIGNOTANTS ARRIÉRE ------ 4

RÉGLAGE DE SUSPENSION------------------------------------------------------------------------ 4

ENTRETIEN --------------------------------------------------------------------------------------------------- 5

COUPLE DE SERRAGE ------------------------------------------------------------------------------- 5

ACHEMINEMENT DU CABLAGE ------------------------------------------------------------------- 7

VERIFICATION DES COMPOSANTS ELECTRIQUES ------------------------------------- 15

SCHÉMA DE CÂBLAGE

DESCRIPTION

Commutateur de patrouille

Coffret radio (5P56, 5P57)

DESCRIPTION / CARACTÉRISTIQUES

CARACTÉRISTIQUES

Désignation du modèle

Type de modèle approuvé

Type de modèle enregistré

Longueur hors-tout (mm)

Largeur hors-tout (mm)

Hauteur hors-tout (mm)

Garde au sol (mm)

Poids (kg)

FJR1300AP

RP13

5P55

2230

740

1315

130

264

FJR1300AP

←

5P56

←

←

←

←

←

FJR1300AP

←

5P57

←

←

←

←

←

-1-

COMMANDES ET INSTRUMENTS

COMMANDES ET

INSTRUMENTS

COMMUTATEUR DE GUIDON DROIT

Coupe-circuit du moteur

Commutateur de patrouille

Contacteur du démarreur

Contacteur des feux de détresse

COUPE-CIRCUIT DU MOTEUR

Placer ce contacteur sur " " avant de mettre le

moteur en marche. En cas d'urgence, comme

par exemple, lors d'une chute ou d'un blocage

de câble des gaz, placer ce contacteur sur " "

afin de couper le moteur.

COMMUTATEUR DE PATROUILLE

Ce commutateur active la sirène ou le lanternon

à éclats.

N.B.:

Il sert quand une sirène ou un lanternon à éclats

est installé.

DESACTIVE

Cela sert pour le lanternon à

éclats.

Cela sert à la fois pour la sirène

et le lanternon à éclats.

CONTACTEUR DU DÉMARREUR

Appuyer sur ce contacteur afin de lancer le

moteur à l'aide du démarreur.

CONTACTEUR DES FEUX DE DÉTRESSE

Quand la clé de contact est sur "ON" ou "P", ce contacteur

permet d'enclencher les feux de détresse, c.-à-d. le

clignotement simultané de tous les clignotants.

Les feux de détresse s'utilisent en cas d'urgence ou pour

avertir les autres automobilistes du stationnement du

véhicule à un endroit pouvant représenter un danger.

ATTENTION:

Ne pas laisser les feux de détresse trop

longtemps allumés lorsque le moteur est coupé,

car la batterie pourrait se décharger.

-2-

COMMANDES ET INSTRUMENTS

COFFRET RADIO (5P56, 5P57)

Le couvercle peut être verrouillé en tournant la

clé introduite

[a] VERROUILLE

[b] OUVERT

Le changement de position du commutateur

•

peut éviter de décharger la batterie.

ON : Lorsqu'on utilise un instrument auxiliaire

OFF : Lorsqu'on n'utilise pas d'instrument auxiliaire

.

-3-

COMMANDES ET INSTRUMENTS

CHANGEMENT DU COUPLEUR POUR

LES FEUX CLIGNOTANTS ARRIÈRE

Lorsqu'un ensemble de montants arrière (en option) est installé sur la motocyclette, ce coupleur

bleu doit être utilisé.

N.B.:

Le changement de connexion de faisceau de fils

peut déterminer quel feu à allumer.

• Connexion au coupleur bleu : Les feux

clignotants arrière de l'ensemble des montants

arrière latéraux s'allument.

• Connexion au coupleur blanc : Les feux

clignotants arrière du combiné de feux arrière

s'allument.

RÉGLAGE DE SUSPENSION

Lorsque la motocyclette s'alourdit à cause des

instruments auxiliaires installés, effectuer les

réglages en se référant aux points suivants :

1.Fourche avant

• Accroître la précharge.

• Diminuer la force d'amortissement de rebond

(lorsque la précharge s'accroît).

• Diminuer la force d'amortissement de compression (lorsque la précharge s'accroît).

2.Suspension arrière

• Accroître la précharge (réglage doux à réglage dur).

• Pas de changement dans la force d'amortissement

de rebond.

N.B.:

Les réglages ci-dessus constituent seulement

une indication générale. Ils dépendent du poids

du motocycliste, etc. Il convient donc de se fier

surtout à un essai de conduite.

-4-

ENTRETIEN

ENTRETIEN

COUPLE DE SERRAGE

Durant l'inspection de la motocyclette, vérifier chacune des pièces installées pour s'assurer qu'il n'y

ait pas de desserrage.

7 Nm (0.7 m • kg, 5.1 ft • lb)

2 Nm (0.2 m • kg, 1.4 ft • lb)

7 Nm (0.7 m • kg, 5.1 ft • lb)

7 Nm (0.7 m • kg, 5.1 ft • lb)

16 Nm (1.6 m • kg, 11 ft • lb)

7 Nm (0.7 m • kg, 5.1 ft • lb)

21 Nm (2.1 m • kg, 15 ft • lb)

21 Nm (2.1 m • kg, 15 ft • lb)

7 Nm (0.7 m • kg, 5.1 ft • lb)

4 Nm (0.4 m • kg, 2.9 ft • lb)

7 Nm (0.7 m • kg, 5.1 ft • lb)

1.5 Nm (0.15 m • kg, 1.1 ft • lb)

7 Nm (0.7 m • kg, 5.1 ft • lb)

-5-

8 Nm (0.8 m • kg, 5.8 ft • lb)

Loading...

Loading...