_YAMAHA

supp

Frame

[

Engine

LIT

-12618-00-22

serial number: 8J5-038101

serial number: S246-038101 ~ S246-049999

~

8J5-049999 ]

8J5-28197-10

CONTENTS

1980 ET250D

(

(

c

1.

NEW SERVICE PROCEDURE .....................

2.

MAINTENANCE INTERVALS

3.

SPECiFiCATIONS

4.

SPECIAL TOOLS ...........

5.

WIRING

DIAGRAM

6. WIRE ROUTING

CABLE

1.

NEW

(N

ew service procedure applied

A.

Primary

For better

SERVICE

sheave

clutch op eration and durability, a

DIAGRAM

.....

........

.....

.........................................

.. ..

......

....

.......

...........

........................................................

DIAGRAM/PIPING

...

........

...................

PROCEDURE

to

the

1980

ET250D)

new

............

...........

.............

............

................................. 1

...

...............

...

....................

..........

...

...................

....

...........

...

AND

CONTROL

.... ..

........................

...

...................

clutch has been adopped.

..

6

.............. 8

....

...

......

13

........

...

...

14

....

15

C

C

C

2

1.

Primary fixed sheave

2_

Primary sliding sheave

3 _

Bushing (Large)

4_

Cap

5_

Bushing (Small)

6_

Bolt

7_

Bolt

8_

Spring

20

4

5

9 _

10_

11.

12

13

14_

15_

16_

17_

18_

19_

20_

21.

22_

23_

24_

Spider

Sl

ider

Pin

_

Plate

_

Weight

Collar

Collar

Bolt

Plate

Cotter

Compr

Cam

Hexagon

U-

nut

Plate

Plate

washer

with

hole

washer

washer

pin

ession spring

bolt

washer

washer

-

1-

1980

ET250D

1.

Removal

a.

Remove the

bolt

using

primary

the

sheave holder.

sheave

mounting

Tool name

Sheave

1.

Sheave

b. Remove the

using the

bolt

Primary fixed sheave puller

bolt

(M

holder

holder

and

primary

Tool name

18

Pl.5)

primary

primary

Tool No.

90890-01880

sheave assembly,

fixed sheave puller

sheave holding tool.

Tool No.

90890-01881

b.

Install

the

Sheave

the

sheave sub-assembly

primary

Tool name

sub-assembly

sheave .

tool

tool

Tool No .

90890-01879

to

1.

Primary fixed sheave

puller

bolt

2. Disassembly

a.

Separate

from

the

sliding sheave assembly

the

fixed sheave by

sliding sheave counterclockwise.

rotating

the

1 Sheave sub-assembly

c.

Loosen the six

tool

bolts

primary sheave cap and

d.

Remove

The

sheave cap

the

primary

sheave subassembly tool.

sheave cap and sliding

now

be disassembled.

3. Inspection

a.

Check the tapered ends

shaft and

scratches.

primary

If scratched unduly, replac

fixed sheave for

If scratches are minor, burnish

emery

b.

Check the

and

cloth.

primary

sliding sheave

sheave cap bushing

bushing

beyond tolerance, replace

bushing clearance,

Small bushing

25

mm

Inside

Outside

0.

0.25

(0.01 in)

mm

(0 .01 in) 0.

securing the

sliding sheave .

of

the

crank-

with

for

wear.

the

bushing.

limit

Large bushing

0.

25

mm

(0 .01 in)

25

mm

(0.01 in)

)

e.

If

)

-

2-

r

c

(

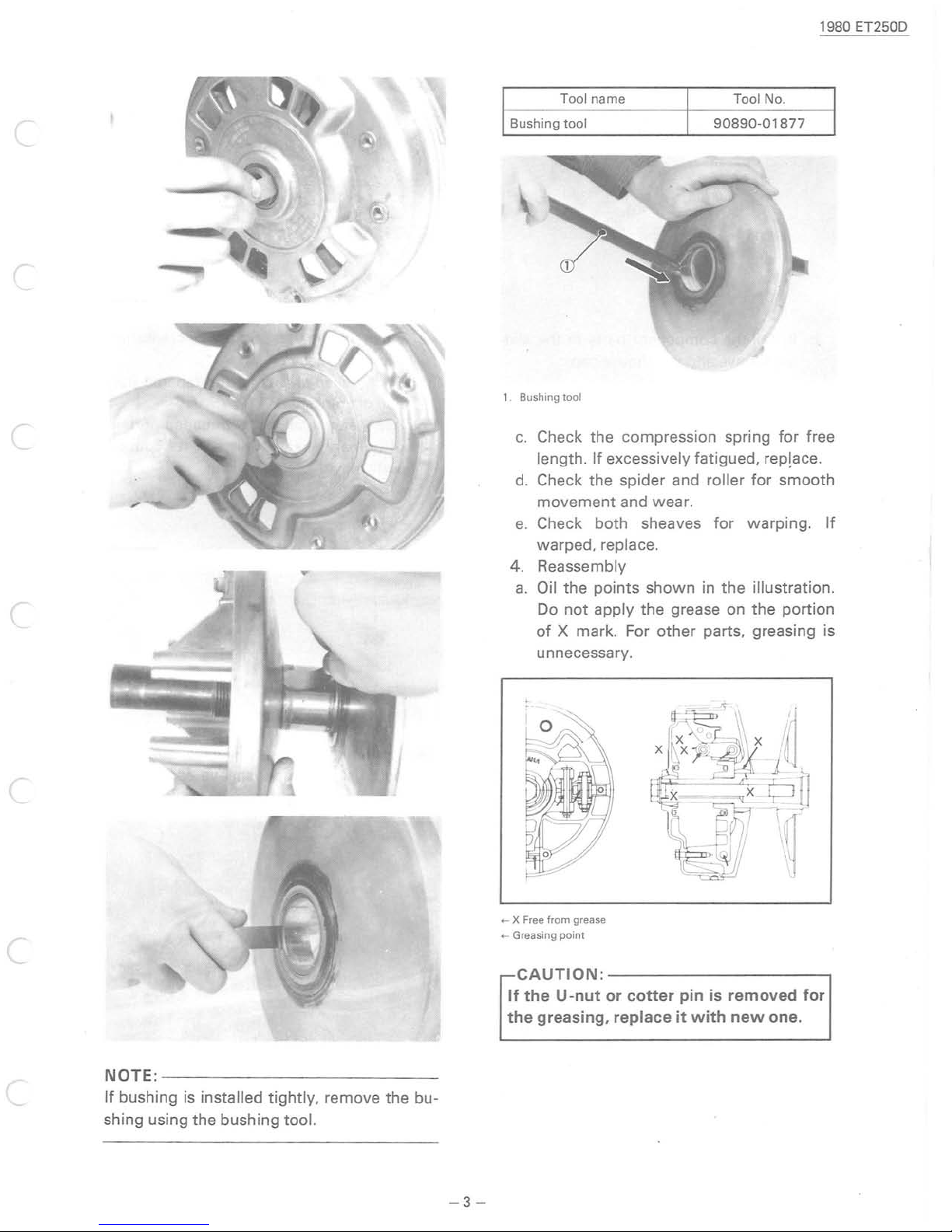

Tool name Tool No.

Bushing

1. Bushing tool

e.

4. Reassembly

a.

tool

c.

Check the compression spring for free

length.

d.

Check the spider and roller

movement

Check both sheaves

warped, replace.

Oil the points

Do

of

unnecessary.

If

excessively fatigued, rep!ace.

and wear.

shown

not

apply the grease on the portion

X mark. For

other

90890-01877

for

for

warping.

in

the

illustration .

parts, greasing is

1980 ET250D

smooth

If

c

c

NOTE:--------------------------

If

c

bushing is installed tightly, remove the bu-

shing using the bushing

tool.

-3-

+-

X Free

from

grease

+-

Greasing

point

CAUTION:-------------------,

If

the U -nut

the

greasing,

or

cotter

replace

pin

it

is

with

removed

new

for

one.

1980 ET25lJD

NOTE:--

When

the

the X mark

the

b.

Install

ing

primary

spider.

the

component

sheave and the sheave cap.

----

------------------

installing

the

primary

sliding sheave, be sure

on

the

sheave cap

parts

sheave cap

to

with

the

to

that

slid-

--

to

align

on

e.

Clean the

and fixed sheav

f.

Fit

the

fixed sheave

tion

of

crankshaft.

Apply

g.

of

surface

engine oil

primary

with

taper

ed

portions

e.

to

to

the

sheave

spring washer.

bolt

of

crankshaft

the

tapered por-

threaded

and its

portion

contact

c.

Install

tighten

d.

Tighten

and remove

Tightening

CAUTION:

Make

assembly slides in

fixed sheave boss.

the

the cap.

the

torque:

1.1

m-kg (8 ft-Ib)

sure

that

sheave subassembly

six

primary

the

subassembly tool.

--------------,

the

tool

and

sheave cap

primary sheave cap

contact

with

bolts

the

h. Tighten

bolt

using

tool.

the

primary

primary

,

sheave

sheave cap

mounting

holding

-4-

19

80

ET250D

Tightening

First

A

Retightened

B.

B.

Starter

The air

will

there

cording ly, the insert for

duct

on

torque

tight

en the

then

loosen it.

A.:

10m-kg

B.

: 6

m-kg

duct

is

no

be no

the

problem

starter case is

:

bolt

bolt

to

(72

(43.5

longer provided because

to a torque

a final torque

.5

ft-Ibl

ft-Ibl

of

overheating. Ac-

mounting

no

of

longer used.

of

of

the

air

1.

Air

duct ... No l

2.

3.

4.

Screw

Plain

Starter

...

wash

case

NOTE:------

. The

1979

installing

model can also be used

the

onger

No longer used

er

...

------

air

duct

used

No longer used

--------

.

------

without

- 5 -

Loading...

Loading...