Page 1

SERVICE MANUAL

PA

011553

HAMAMATSU, JAPAN

1.222K-496 Printed in Japan '00.11

CONTENTS

SPECIFICATIONS···································································· 3

PANEL LAYOUT······································································· 4

CIRCUIT BOARD LAYOUT······················································ 5

WIRING····················································································· 6

DIMENTIONS ··········································································· 7

BLOCK DIAGRAM···································································· 8

DISASSEMBLY PROCEDURE················································· 9

IC BLOCK DIAGRAM ····························································· 11

CIRCUIT BOARDS································································· 12

INSPECTIONS········································································ 17

PARTS LIST

OVERALL CIRCUIT DIAGRAM

POWER AMPLIFIER

This document is printed on chlorine free (ECF) paper with soy ink.

Page 2

CP2000

2

WARNING: CHEMICAL CONTENT NOTICE!

The solder used in the production of this product contains LEAD. In addition, other electrical/electronic and/or plastic (where

applicable) components may also contain traces of chemicals found by the California Health and Welfare Agency (and possibly

other entities) to cause cancer and/or birth defects or other reproductive harm.

DO NOT PLACE SOLDER, ELECTRICAL/ELECTRONIC OR PLASTIC COMPONENTS IN YOUR MOUTH FOR ANY REASON

WHAT SO EVER!

Avoid prolonged, unprotected contact between solder and your skin! When soldering, do not inhale solder fumes or expose eyes

to solder/flux vapor!

If you come in contact with solder or components located inside the enclosure of this product, wash your hands before handling

food.

IMPORTANT NOTICE

This manual has been provided for the use of authorized Yamaha Retailers and their service personnel. It has been assumed that

basic service procedures inherent to the industry, and more specifically Yamaha Products, are already known and understood by

the users, and have therefore not been restated.

WARNING: Failure to follow appropriate service and safety procedures when servicing this product may result in personal

injury, destruction of expensive components and failure of the product to perform as specified. For these

reasons, we advise all Yamaha product owners that all service required should be performed by an authorized

Yamaha Retailer or the appointed service representative.

IMPORTANT: This presentation or sale of this manual to any individual or firm does not constitute authorization, certification,

recognition of any applicable technical capabilities, or establish a principal-agent relationship of any form.

The data provided is belived to be accurate and applicable to the unit(s) indicated on the cover. The research engineering, and

service departments of Yamaha are continually striving to improve Yamaha products. Modifications are, therefore, inevitable and

changes in specification are subject to change without notice or obligation to retrofit. Should any discrepancy appear to exist,

please contact the distributor's Service Division.

WARNING: Static discharges can destroy expensive components. Discharge any static electricity your body may have

accumulated by grounding yourself to the ground bus in the unit (heavy gauge black wires connect to this bus).

IMPORTANT: Turn the unit OFF during disassembly and parts replacement. Recheck all work before you apply power to the

unit.

WARNING

Components having special characteristics are marked and must be replaced with parts having specification equal to those

originally installed.

IMPORTANT NOTICE FOR THE UNITED KINGDOM

Connecting the Plug and Cord

IMPORTANT. The wires in this main lead are coloured in

accordance with the following code:

BLUE: NEUTRAL

BROWN: LIVE

As the colours of the wires in the main lead of this apparatus may not

correspond with the coloured markings identifying the terminals in

your plug, proceed as follows:

The BLUE wire must be connected to the terminal that is marked with

the letter N (or coloured BLACK).

The BROWN wire must be connected to the terminal that is marked

with the letter L (or coloured RED).

Be certain that neither core is connected to the earth terminal of the

three pin plug.

Page 3

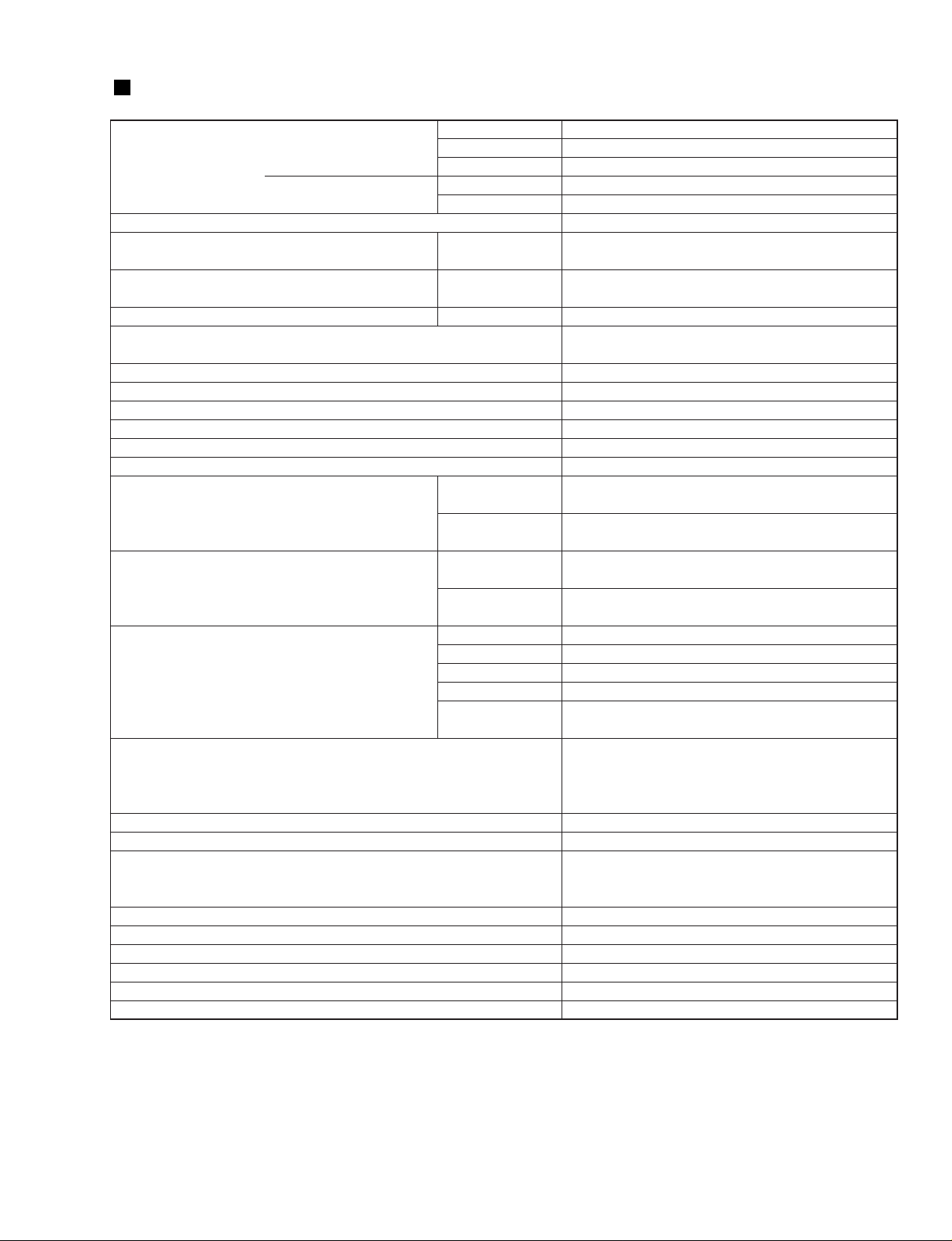

SPECIFICATIONS

CP2000

3

Power Output Level 8 Ω/STEREO

1 kHz, THD+N=1 %

4 Ω/STEREO

8 Ω/BRIDGE

1 kHz 2 Ω/STEREO

20 ms, non-clip 4 Ω/BRIDGE

Power Bandwidth THD+N=0.2 % (half power)

Total Harmonic Distortion (THD+N) 4–8 Ω/STEREO

20 Hz–20 kHz (half power) 8 Ω/BRIDGE

Intermodulation Distortion 4–8 Ω/STEREO

60 Hz:7 kHz, 4:1, half power 8 Ω/BRIDGE

Frequency Response 8 Ω, Po=1W

Channel separation Half power, RL=8 Ω

LEVEL=max., input 600 Ω shunt

Residual Noise LEVEL=min., 12.7 kHz LPF, IHF-A network

S/N Ratio 12.7 kHz LPF

Damping Factor RL=8 Ω, 1 kHz

Sensitivity LEVEL=max., rated power into 8 Ω

Voltage Gain LEVEL=max.

Input Impedance

Front panel

Controls

Rear panel

Input

Connectors

Output

POWER

PROTECTION

TEMP

Indicators

CLIP

SIGNAL

Protection Circuit

Fan Circuit

Limiter Circuit

Power requirements

Idle Power Consumption

1/8 Power Consumption (4 Ω)

Maximum Power Consumption (4 Ω)

Dimensions (W x H x D)

Weight

AC Power cord length

450 W + 450 W

650 W + 650 W

1300 W

1000 W + 1000 W

2000 W

10 Hz—40 kHz

0.1%

0.1%

0 dB, +0.5 dB, -1 dB f=20 Hz—50 kHz

≥70 dB, 1 kHz

≤ -70 dB

104 dB

≥200

+4 dB

33.8 dB

30 kΩ (balanced), 15 kΩ (unbalanced)

POWER switch (push on/push off)

LEVEL attenuator (31 position) x2

Mode switch (STEREO/BRIDGE/PARALLEL)

YAMAHA SPEAKER PROCESSING switch (ON/OFF)

XLR-3-31 type (balanced) L+R

1/4" phone jack (balanced) L+R

1/4" phone jack L+R

5-way binding post x1

x1 (green)

x1 (red)

x1 (red) heatsink temp ≥85 °C

x2 (red)

x2 (green) output voltage ≥2 V

x2 (yellow) output voltage ≥20 V

POWER switch on/off mute

DC detection

TEMP (heatsink temp ≥90 °C)

PC limiter: RL ≤1 Ω

Stop–low speed (50 °C)–variable–high Speed (70 °C)

Comp: THD≥0.5 %

U.S.A. & Canada 120 V AC, 60 Hz

Europe 230 V AC, 50 Hz

Australia 240 V AC, 50 Hz

30 W

400 W

2000 W

480 x 88 x 416 mm (18.9 x 3.46 x 16.4 inches)

14 kg (30.9 lbs)

2.3 m

* 0 dB=0.775 V rms, half power = 1/2 output level.

Page 4

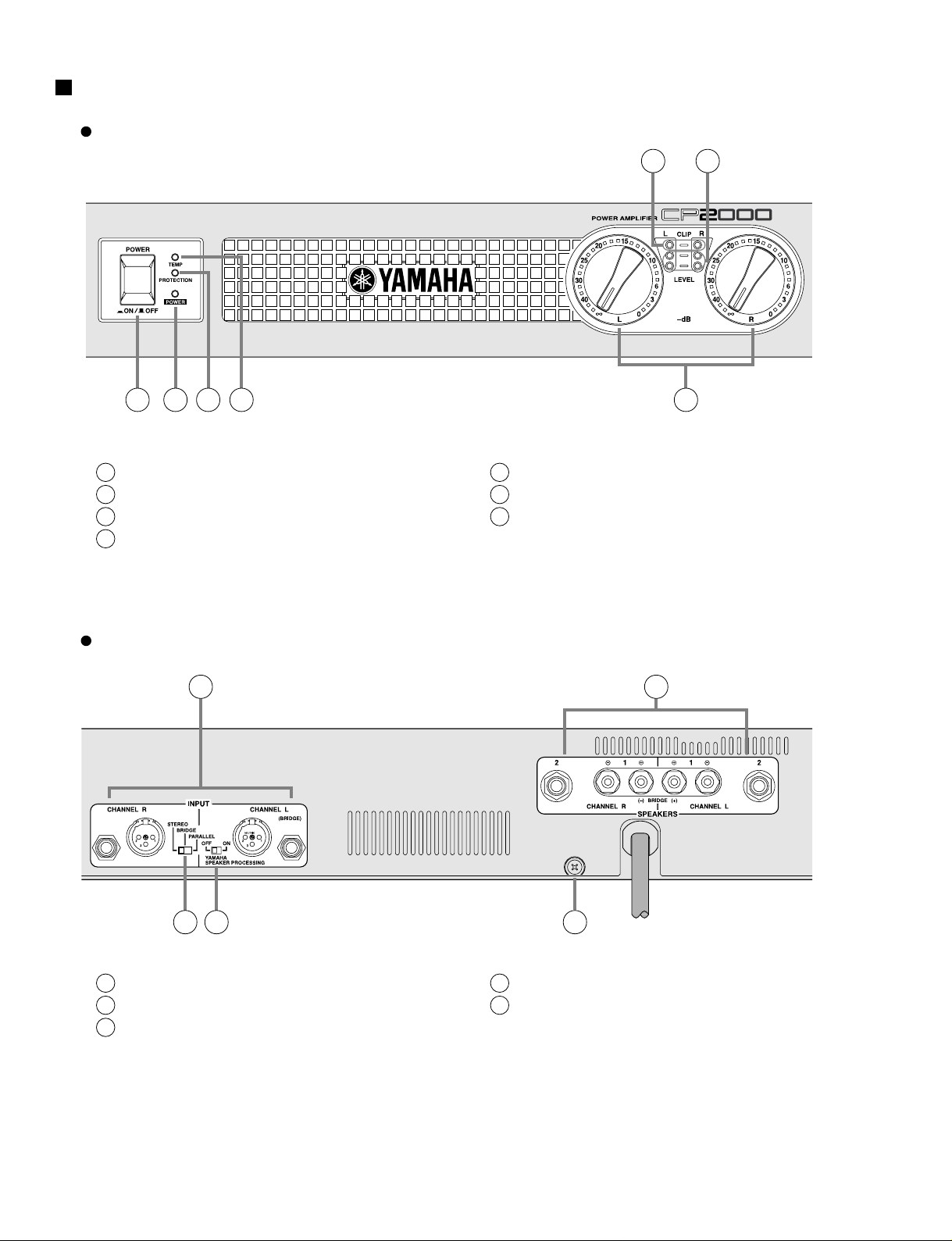

1

8

9 10 12

11

2 3 4 5

6 7

1

POWER switch

2

POWER indicator

3

PROTECTION indicator

4

TEMP indicator

5

Level controls

6

CLIP indicators

7

LEVEL indicators

8

INPUTs

9

Mode switch

10

YAMAHA SPEAKER PROCESSING switch

11

SPEAKERS connectors

12

GND terminal

CP2000

4

PANEL LAYOUT

Front Panel

Rear Panel

Page 5

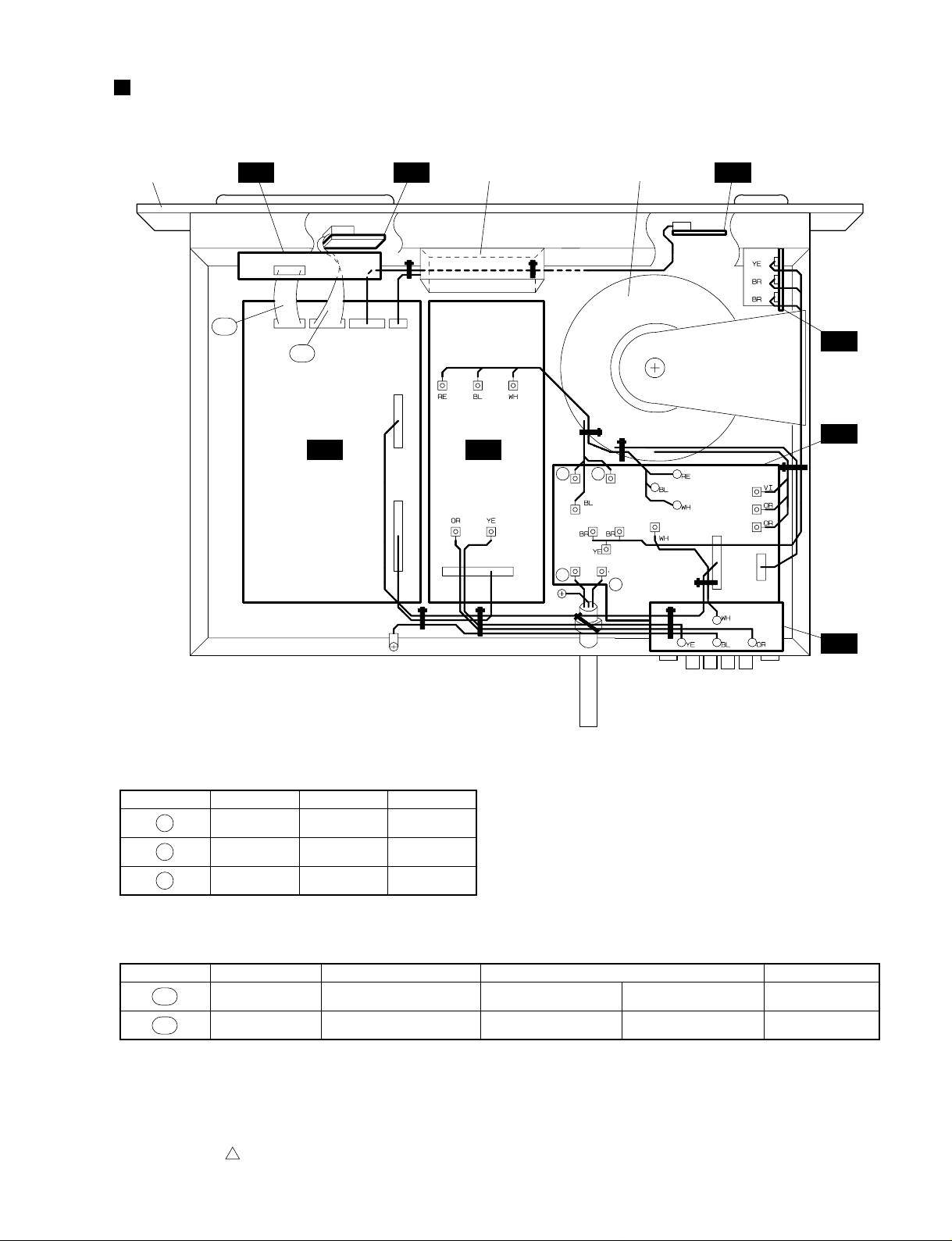

CIRCUIT BOARD LAYOUT

CP2000

5

70

80

CN615

CN303 CN305 CN304 CN302

CN616

CN606

CN607

CN608

CN612

CN610

CN609

CN611

CN614

CN313

CN603

CN604

CN605

CN601 CN602

CN301

CN102

CN105

CN106

CN101

CN103

CN104

CN306

CN617

AC 4/6

IN PA

AC 6/6 AC 5/6

AC 1/6

AC 2/6

AC 3/6

Power transformerFront panel Fan

AC 4/6-CN615 IN-CN303 7P 100mm

Connector AssemblyPart No.

MF107100

Location Destination Remarks

AC 6/6-CN617 IN-CN305 9P 120mmMF109120

70

80

3NC2-V617020

1 1

2

3

U, V, T H, W, B A

BR

WH

BL

BE

BE

BR

RE

BE

BR

• Wire Colors

1

2

3

2

Page 6

to Rear panel

AC cord

AC 4/6

IN

PA

AC 6/6

AC 5/6

AC 1/6

AC 2/6

AC 3/6

FAN

KEC-92573

POWER

TRANSFORMER

POWER

switch

3

CP2000

6

WIRING

Page 7

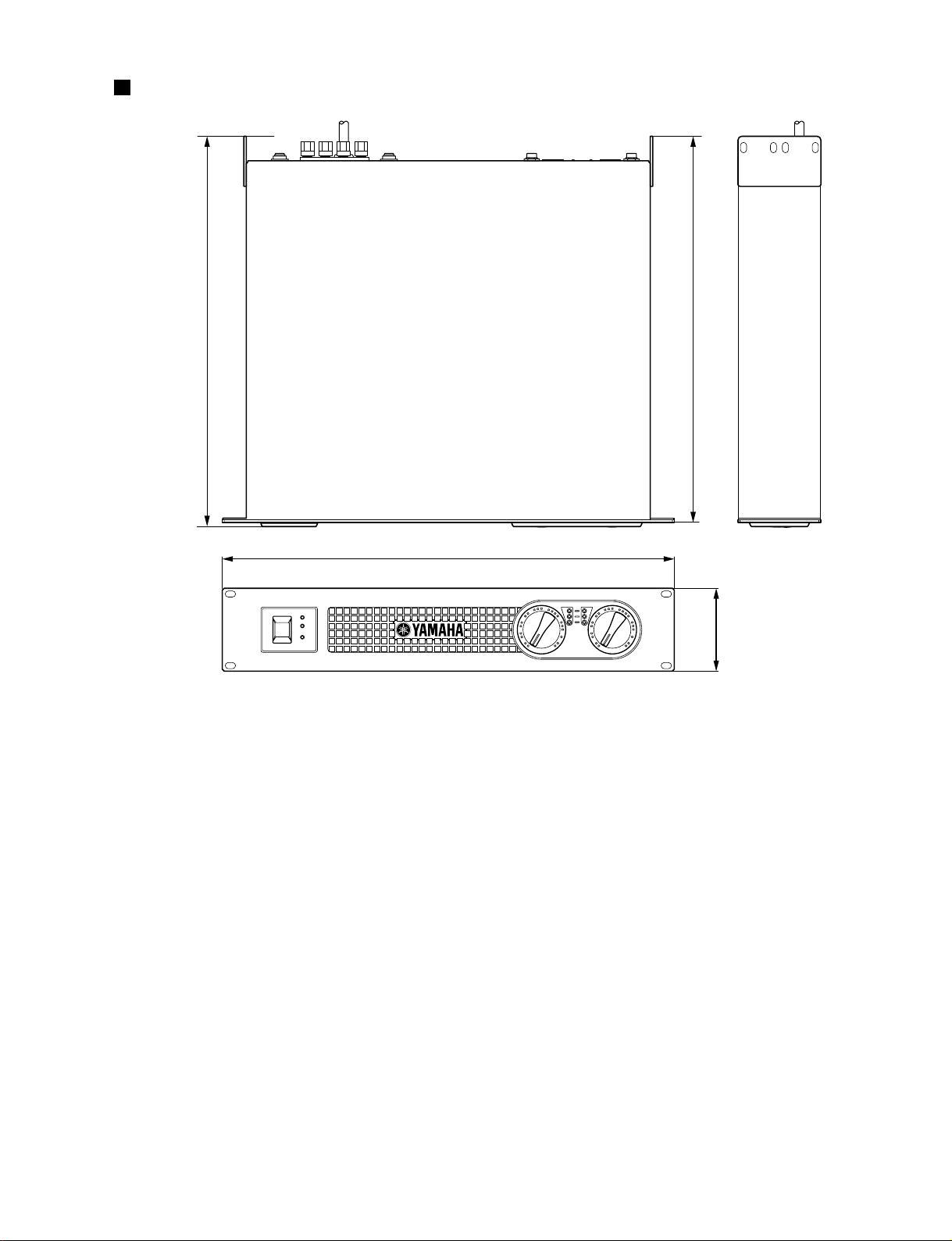

DIMENTIONS

CP2000

7

88

480

410

416

Unit: mm

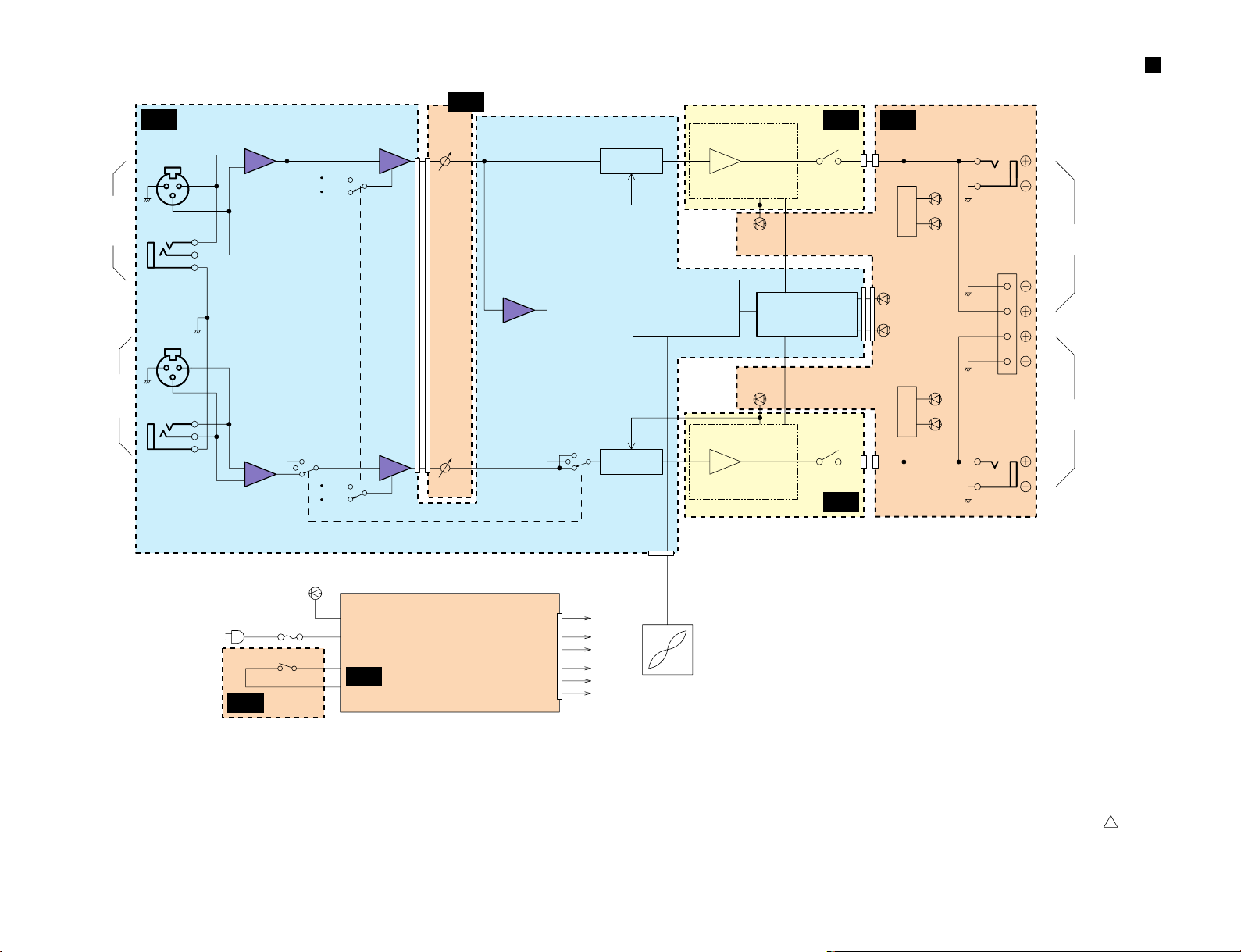

Page 8

KEC-92572

1

CHANNEL L

(BRIDGE)

(PARALLEL)

CHANNEL R

INPUT

JK301

JK303

12

3

2

3

1

JK302

JK304

12

3

2

5

7

6

+

-

3

1

BA

IC301

POWER

LD602

POWER CIRCUIT

AC Cord

POWER SW

SW601

3

1

2

+

-

BA

IC301

1

3

SW302

IC302

1

3

IC303

VR602

VR601

SW301

ON

OFF

CHANNEL

L

ATT

YAMAHA

SPEAKER

PROCESSING

SW302

ON

OFF

INV

CLIP

LD604

LD605

LD606

JK601

SP601

JK602

LD608

LD609

LD601

SIGNAL

SIGNAL

LD603

CLIP

LD607

CHANNEL

R

ATT

PARALLEL

BRIDGE

STEREO

Limiter

Lch Power Amp

Limiter

AC 4/6

AC 3/6, 5/6, 6/6

AC 1/6

AC 2/6,

CN615

IC302

76

CN303

IN

CN302

CN614

+B

E

-B

+24

E

-24

Rch Power Amp

Temperature

Sensor

(Heat Sink)

Protection

Circuit

CN304

CN616

PROTECTION

TEMP

PA

PA

W607

CN105

RY101

W609

CN106

RY102

SPEAKERS

CHANNEL L

L+R BRIDGE

CHANNEL R

FAN

Power transformer

8

CP2000

BLOCK DIAGRAM

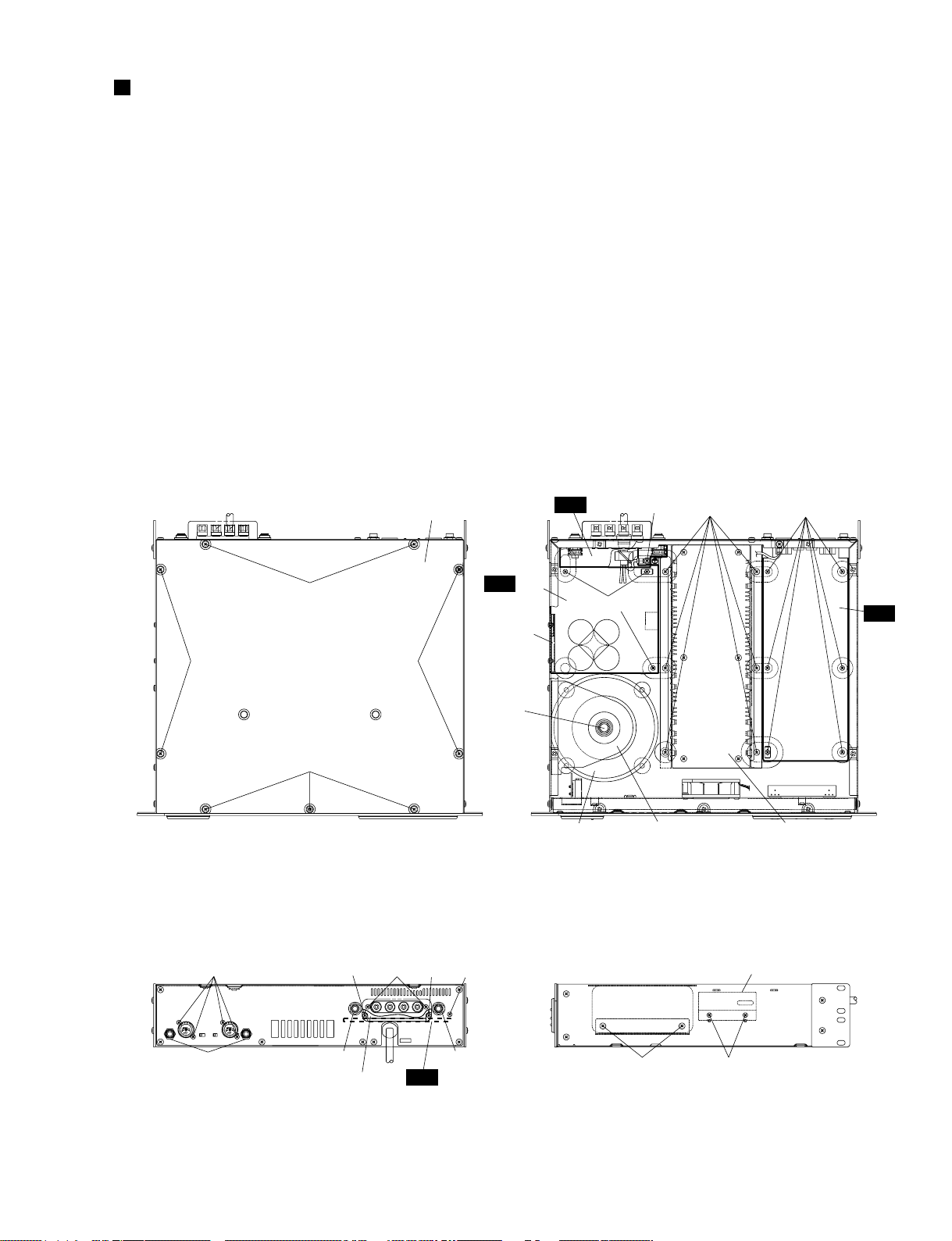

Page 9

(Fig. 1)

(Fig. 2)

(Fig. 3) (Fig. 4)

[420]

[420] [420]

[420]

[420]: Bind Head Tapping Screw-B 4.0X8 MFZN2BL (EG340190)

[290]: Bonding Tapping Screw-B 3.0X8 MFZN2BL (VN413300)

[300]: Bind Head Tapping Screw-B 3.0X12 MFZN2BL (VQ074600)

[320]: Bind Head Tapping Screw-B 3.0X8 MFZN2BL (EP600190)

[103]: Bind Head Tapping Screw-B 4.0X8 MFZN2BL (EG340190)

[140]: Bind Head Tapping Screw-B 3.0X8 MFZN2BL (EP600190)

[80A]: Bind Head Screw A4.0X8 MFZN2BL (VP156800)

[120]: Bind Head Tapping Screw-B 3.0X8 MFZN2BL (EP600190)

[160]: Bonding Tapping Screw-B 4.0X8 MFZN2BL (VR779900)

[180]: Bind Head Tapping Screw-B 3.0X8 MFZN2BL (EP600190)

Top cover

<Top view>

<Rear view> <Side view>

[180][160]

IN

AC 3/6

AC 2/6

[290A] [320] [300] [320]

[A] [B]

[290B]

Speaker terminal cover

[B]

AC 3/6

[80A]

[120]

DB angle

DB angle

[140][103]

[C]

Transformer holder PA unitPower transformer

DISASSEMBLY PROCEDURE

CP2000

9

1. Top Cover(time required: about 3 minutes)

1-1 Remove the nine (9) screws marked [420]. The top cover

can then be removed. (Fig. 1)

2. IN Circuit Board(time required: about 8 minutes)

2-1 Remove the top cover. (See procedure 1.)

2-2 Remove the six (6) screws marked [180], the four (4) screws

marked [290A] and the two (2) hexagonal nuts marked [A].

The IN circuit board can then be removed. (Fig. 2, Fig. 3)

3. AC3/6 Circuit Board

(time required: about 10 minutes)

3-1 Remove the top cover. (See procedure 1.)

3-2 Remove the two (2) screws marked [320]. The speaker

terminal cover can then be removed. (Fig. 3)

3-3 Remove the screw marked [290B], the two (2) screws

marked [300] and the two (2) hexagonal nuts marked [B].

The AC3/6 circuit board can then be removed. (Fig. 3)

4. AC2/6 Circuit Board

(time required: about 15 minutes)

4-1 Remove the top cover. (See procedure 1.)

4-2 Remove the AC3/6 circuit board. (See procedure 3.)

4-3 Remove the screw marked [80A], the three (3) screws

marked [120] and the two (2) screws marked [140]. The

AC2/6 circuit board and the DB angle can then be removed.

(Fig. 2, Fig. 4)

5. Power Transformer

(time required: about 8 minutes)

5-1 Remove the top cover. (See procedure 1.)

5-2 Remove the two (2) screws marked [103] and the

hexagonal bolt marked [C]. The transformer holder and

the power transformer can then be removed. (Fig. 2, Fig. 4)

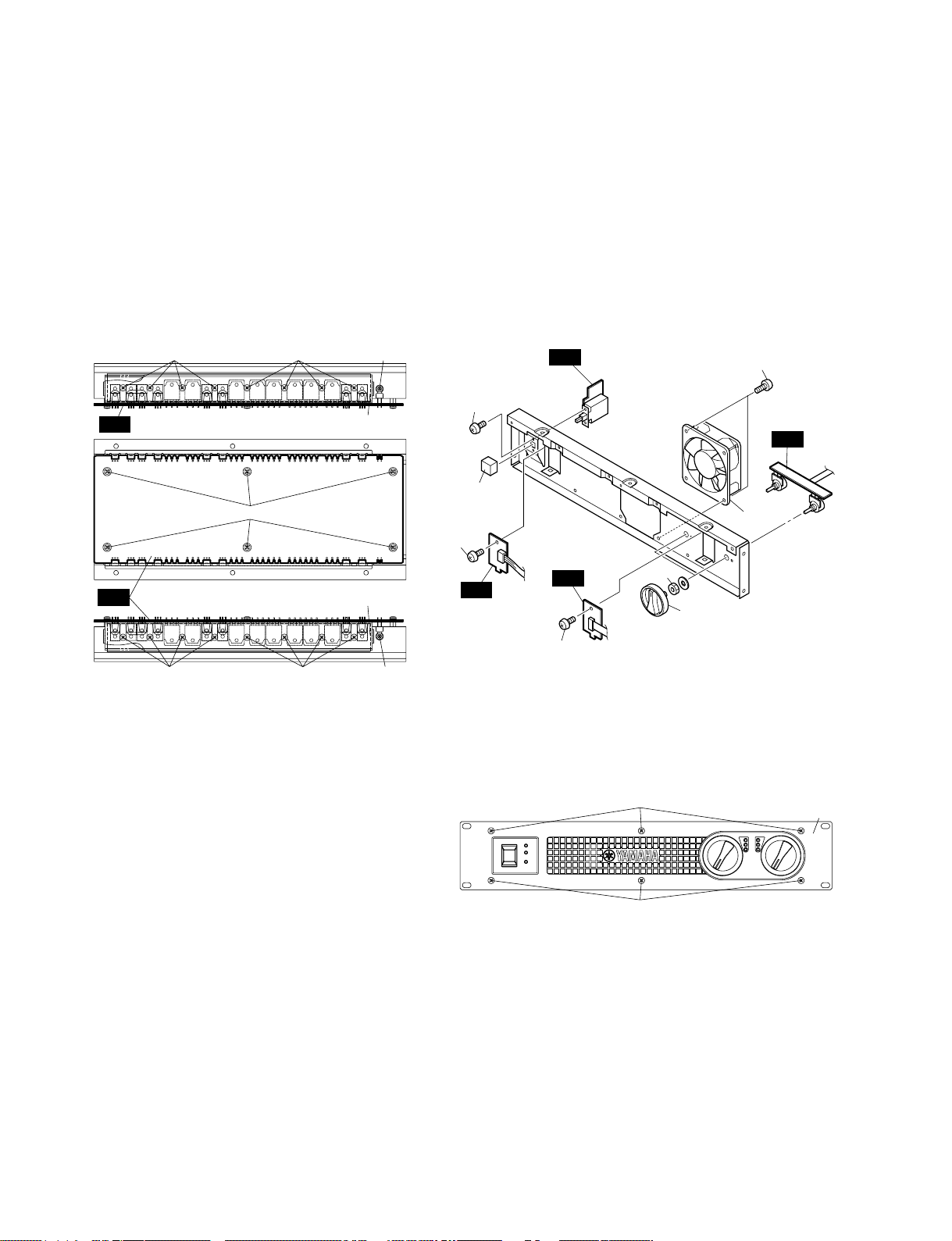

Page 10

[250]

(Fig. 7)

[250]

Front panel

<Front View>

[250]: Oval Head Screw 4.0X8 MFZN2BL (VS153600)

8. Front Panel (time required: about 5 minutes)

8-1 Remove the top cover. (See procedure 1.)

8-2 Remove the six (6) screws marked [250]. The front panel

can then be removed. (Fig. 7)

9.

AC1/6, A C4/6, AC5/6 and AC6/6 Cir cuit Boar d

(time required: about 20 minutes)

9-1 Remove the top cover. (See procedure 1.)

9-2 Remove the front panel (See procedure 8.)

9-3 AC1/6 Circuit Board:

Pull out the power switch knob. (Fig. 6)

Remove the two (2) screws marked [60]. The AC1/6 circuit

board can then be removed. (Fig. 6)

9-4 AC4/6 Circuit Board:

Pull out the attenuation knobs. (Fig. 6)

Remove the two (2) hexagonal nuts marked [D]. The AC4/6

circuit board can then be removed. (Fig. 6)

9-5 AC5/6 Circuit Board:

Remove the screw marked [100A]. The AC5/6 circuit board

can then be removed. (Fig. 6)

9-6 AC6/6 Circuit Board:

Remove the screw marked [100B]. The AC6/6 circuit board

can then be removed. (Fig. 6)

• PA Unit

[80B]

[80B]

[80B]

[80B]

[80B]

[80B]

(Fig. 5)

Transistor holder (L)

Transistor holder (R)

[40]

PA

PA

[40]: Bind Head Screw SP 3.0X8 MFZN2BL (EG330290)

[80B]: Bind Head Tapping Screw-B 3.0X12 MFZN2BL (VQ074600)

(Fig. 6)

[50]: Bind Head Screw 4.0X8 MFZN2BL (EG340360)

[60]: Bind Head Screw 3.0X8 MFZN2BL (VB659000)

[100]: Bind Head Tapping Screw-B 3.0X8 MFZN2BL (EP600190)

[60] x 2

[D]

[50]

Fan

AC 1/6

AC 4/6

Power switch

knob

Attenuation knob

AC 5/6

AC 6/6

[100A]

[100B]

CP2000

10

6. PA Unit & PA Circuit Board

(time required: about 15 minutes)

6-1 Remove the top cover. (See procedure 1.)

6-2 Remove the six (6) screws marked [160]. The PA unit can

then be removed. (Fig. 2)

6-3 Remove the eighteen (18) screws marked [80B]. And then

remove the left and right transistor holders from the PA unit.

(Fig. 5)

6-4 Remove the six (6) screws marked [40]. And then remove

the PA circuit board from the PA unit. (Fig. 5)

7. DC Fan (time required: about 8 minutes)

7-1 Remove the top cover. (See procedure 1.)

7-2 Remove the PA unit. (See procedure 6-2.)

7-3 Remove the two (2) screws marked [50]. The fan can then

be removed. (Fig. 6)

Page 11

IC BLOCK DIAGRAM

CP2000

11

M5238AP (XM085A00)

Dual Operational Amplifier

IN: IC301

NJM2068L-D (XM356A00)

Dual Operational Amplifier

IN: IC302, 303

1

2

3

4-V

8

7

6

5

Output A +V

Non-Inverting

Input A

-DC Voltage Supply

+DC Voltage

Supply

Output B

Inverting

Input B

Non-Inverting

Input B

Inverting

Input A

+-

+-

1A2 3 4 5 6 7 8

OUTA-INA+INA+INB-INBOUT

B

-V +V

-

+

B

-

+

CIRCUIT BOARDS CONTENTS

AC 1/6 Circuit Board (XY969B0)················································································ 12

AC 2/6 Circuit Board (XY969B0)················································································ 16

AC 3/6 Circuit Board (XY969B0)················································································ 13

AC 4/6 Circuit Board (XY969B0)················································································ 12

AC 5/6 Circuit Board (XY969B0)················································································ 12

AC 6/6 Circuit Board (XY969B0)················································································ 12

IN Circuit Board (XY968B0) ······················································································· 12

PA Circuit Board (XY970B0)······················································································ 14

Note: See parts list for details of circuit board component parts.

Page 12

to IN-CN303

Component side

LEVEL CONTROL L LEVEL CONTROL R

to IN-CN304

to IN-CN305

Component side

Component side

Component side

POWER ON/OFF

to AC 2/6-

CN601

to AC 2/6-

CN603

to AC 2/6-

CN602

POWER

PROTECTION

TEMP

LEVEL L

LEVEL R

CLIP L

CLIP R

A

A'

to FAN

to AC6/6

-CN617

to AC 5/6

-CN616

to AC 4/6

-CN615

to AC 2/6-CN614

CP2000

12

CIRCUIT BOARDS

IN: 3NA-V607200

AC 1/6, 4/6, 5/6, 6/6: 3NA-V607220

1

2

IN Circuit Board

AC 4/6 Circuit BoardAC 1/6 Circuit Board

AC 5/6 Circuit Board

AC 6/6 Circuit Board

Page 13

INPUT

CHANNEL R

CHANNEL L

YAMAHA

SPEAKER

PROCESSING

PARALLEL

BRIDGE

STEREO

(BRIDGE)

ON

OFF

A

A'

to PA-CN101

Component side

CP2000

13

Component side

SPEAKERS

(-) BRIDGE (+)

12 21

CHANNEL L CHANNEL R

to PA-CN106

to AC 2/6-CN612to PA-CN105

to REAR PANEL

IN: 3NA-V607200

AC 3/6: 3NA-V607220

1

2

AC 3/6 Circuit Board

Page 14

CP2000

14

B

B'

CN101:

CN102:

to IN-CN306

to AC 2/6-W604

CN103:

CN104:

to AC 2/6-W605

to AC 2/6-W606

CN105:

CN106:

to AC 3/6-W607

to AC 3/6-W609

PA Circuit Board

3NA-V60721

1

Page 15

CP2000

15

B

B'

Component side

3NA-V60721

1

Page 16

Component side

CN601:

CN602:

CN603:

CN604:

CN605:

to AC 1/6-W601

to AC 1/6-W602

to AC 1/6-W603

to AC cord (L)

to AC cord (N)

CN606:

CN607:

CN608:

CN609:

CN610:

to Power transformer

to Power transformer

to Power transformer

to Power transformer

to Power transformer

CN611:

CN612:

W604:

W605:

W606:

to Power transformer

to AC 3/6-W608

to PA-CN102

to PA-CN103

to PA-CN104

to IN-CN301

to Power

transformer

U, V, T

H, W, B

A

BL

CN604

BR

BR

WH

CN605

BE

BE

BR

CN606, CN607

BE

RE

• Wire Colors

CP2000

16

AC 2/6 Circuit Board

3NA-V607220

2

Page 17

INSPECTIONS

CP2000

17

1. Inspection during stereo mode and parallel mode

1.1 Preparations

1.2 Inspection and adjustment

1.2.1 Fan and temperature indicator

The fan shall operate when the two jumper wires inside the frame marked

FAN-C inside sheet IN are shorted. Next, the temperature indicator shall

come on when the two jumper wires inside the frame marked TM-C are

shorted. (Refer to the figure to the right for FAN-C, TM-C.)

1.2.2 Power on muting time

At t=2.5 ± 1 seconds after the power switch is turned on, the muting shall be cancelled and the protection indicator shall go off.

1.2.3 Idling current

Ground the input terminal and adjust VR101 (L ch) and VR102 (R ch) so that the CN108 (L ch) and CN107 (R ch) No. 1 and 2

terminals show DC voltage of Vb=0.5 ± 0.1 mV.

Once all inspections have been completed, re-inspect Vb and adjust so that it is Vb=0.5 ± 0.1 mV.

1.2.4 Output terminal DC voltage

Ground the input terminal and measure the Vdc (direct current voltage) of the output terminal. It shall be Vdc=0 ± 75 mV.

1.2.5 Gain

An output voltage of +24.0 ± 0.5 dBu shall be attained when 1 kHz, -10.0 dBu sine wave is input to the input terminal.

This inspection shall also be performed in the PARALLEL mode.

1.2.6 Frequency characteristics

* YAMAHA SPEAKER PROCESSING OFF:

Using 1 kHz as a standard for the output voltage, the output voltage shall be within -0.5 ± 0.5 dB at 20 kHz when 20 Hz, 1 kHz,

20 kHz, -10 B dBu sine waves are input to the input terminal.

* YAMAHA SPEAKER PROCESSING ON:

Using 1 kHz as a standard for the output voltage, with the Yamaha speaker processing off, the output voltage shall be within +

6.5 ±1.5 dB when a 70 Hz, -10 dBu sine wave is input to the input terminal.

1.2.7 Total harmonic distortion ratio characteristics

The total harmonic distortion ration shall be THD=1 % or less when a 1 kHz high definition sine wave is input to the input terminal

and the rated output of 650 w + 650 w / 4 ohm (36.4 dBu/ch) has been attained. This inspection shall be completed within 30 seconds.

1.2.8 Channel separation load resistance 8 Ω

When the input terminal for one of the channels has attained a 1kHz, -5dBu sine wave has and that input terminal is grounded by

the introduction of 600 Ω resistance, the measured output voltage of the other channel shall by -70 dB or less, using a output voltage

with (0 dB) as the reference level.

1.2.9 Output noise level

Measure the noise level at the output terminal when the input attenuator has been set to MAX and a input terminal has been grounded

by the introduction of a 600 Ω resistance. It shall be -67 dBu or less. Next, set the input attenuator to MIN and measure. It shall be

-70 dBu or less.

Input attenuator

Input terminal

Mode SW

Yamaha speaker processing

Output terminal

Others

MAX

Cannon connector No. 2 hot; No. 1, 3 ground

Stereo

Off

Resistance load 4 Ω, Non inductance resistor, input capacitance 500 W or more.

Unless otherwise specified, drive both channels unless otherwise specified.

INPA

AC 3/6

AC 2/6

TM-C

FAN-C

<Top View>

Page 18

1.2.10 Stability

The following conditions shall be met when a 10 kHz, -10dBu rectangular pulse is input and a capacitance of 10 pf ~ 0.47 µF is

connected in parallel with a load resistance of 4 Ω.

Overshoot Vp/Vo 1.8

Ringing: Within 5 waves

Next, when there is only a pure capacitance of 10 pf ~ 0.47 µF the following conditions shall be met.

Vp/Vo 2.5

Ringing: There shall be convergence within 7 waves and no oscillation, etc.

1.2.11 Protection circuit

The protection circuit shall operate and the relay shall not open when a 10 Hz, +5.4 dBu sine wave is input and the output wave is

made to clip. Next, the protection circuit shall operate within two seconds and break the output when a 1 Hz, 0.0 dBu sine wave is

input. In addition, when the input signal is cut, it shall automatically recover within 10 seconds.

1.2.12 Efficiency

(1) The primary electrical power shall be measured and be within the range shown below when a 1 kHz, -6.6 dBu sine wave is input

to the input terminal.

330 W ± 50 W (U: 4.0 A ± 0.6 A, H: 2.0 A ± 0.3A)

(2) The primary electrical power shall be measured and be within the range shown below when the input terminal is grounded by the

introduction of the input terminal.

25 W ± 10 W (U: 0.33 A ± 0.13 A, H: 0.20 A ± 0.08 A)

1.2.13 PC limiter and comp

Input a 1 kHz, -1.5 dBu sine wave to the input terminal and connect 1 Ω (± 5 %) as a load to the output terminal. Under these conditions,

a 10 V Vrms 16 V sine wave shall be attained at the output. The total harmonic distortion ratio shall be THD=5 % or less.

Also at this time, the clip indicator shall come on. This inspection shall be completed within 30 seconds.

1.2.14 Signal indicator

The green signal indicator shall come on when a 1 kHz, -23 dBu sine wave is input.

In addition, the green and yellow signal indicators shall come on when a 1 kHz, -4 dBu sine wave is input.

2. Bridge mode

2.1 Preparations

2.2 Inspection

2.2.1 Gain

An output voltage of +24.0 ± 1.0 dBu shall be attained when a 1 kHz, -10 dBu sine wave is input to the input terminal.

<

=

<

=

<

=

<

=

CP2000

18

Input attenuator

Input terminal

Mode SW

Yamaha speaker processing

Output terminal

Load resistance

Measurement connection

L channel only operates. Set to MAX.

L channel cannon connector (No. 2 hot, No. 1, 3 ground)

Bridge

Off

Use L channel +, R channel +.

4 Ω + 4Ω, Non inductance resistor, input capacitance 500 W or more.

Set to a floating ground and connect at center point of load resistance.

SPEAKERS

INPUT

MEASURING

INSTRUMENT

GND

Page 19

CP2000

19

2.2.2 Frequency characteristics

Using 1 kHz as a standard for the output voltage, the output voltage shall be within -0.5 ± 0.5 dB at 20 kHz when 20 Hz, 1 kHz, 20

kHz, -10 B dBu sine waves are input to the input terminal.

2.2.3 Total harmonic distortion ratio characteristics

The total harmonic distortion ration shall be 1 % or less when a 1 kHz high definition sine wave is input to the input terminal and the

output voltage of 36.4 dBu has been attained. This inspection shall be completed within 30 seconds.

2.2.4 Output noise level

Measure the noise level at both terminals of the load resistance when the input attenuator has been set to MAX and the input

terminal has been grounded by the introduction of a 600 Ω resistance. It shall be -60 dBu or less. Next, set the input attenuator to

MIN and measure. It shall be -60 dBu or less.

3. Process after completion of inspection

Close up the input attenuator in a half-clockwise direction.

Set YAMAHA SPEAKER PROCESSING to on.

Set the mode switch to STEREO.

4. Others

A DIN audio filter shall be used for the measurement of the noise level.

0 dBu=0.775 V

Page 20

CONTENTS

OVERALL ASSEMBLY······························································································································ 2

ELECTRICAL PARTS ·························································································································5~12

PARTS LIST

WARNING

Components having special characteristics are marked and must be replaced with parts having

specification equal to those originally installed.

A: Australian model

B: British model

C: Canadian model

D: German model

E: European model

F: French model

H: North European model

I : Indonesian model

J: Japanese model

M: South African model

O: Chinese model

Q: South-east Asia model

T: Taiwan model

U: U.S.A. model

V: General export model (110 V)

W: General export model (220 V)

N,X:General export model

Y: Export model

Notes: DESTINATION ABBREVIATIONS

• The numbers in “ QTY ” show quantities for each unit.

• The parts with “ - - ” in “ PART NO. ” are not available as spare parts.

• The mark “ ” in the remarks column indicates that these parts are interchangeable.

• The second letter of the shaded ( ) part number is O, not zero.

• The second letter of the shaded ( ) part number is I, not one.

POWER AMPLIFIER

Page 21

420

400

40 40a

70

50

60

330

300

310

320

360

290

280

190

Front Sub

Assembly

120

F70

F50

F10

P80

P40

P30

P80

P80

P20

P10

P70

P50

150

PA Unit

P60

F60

F90

F80

F110

F100

F100

F120

F20

330

360

390

430

111

112

10

130

350

340

140

210

220

230

270

260

250

240

113

160

180

170

80

100

101

95

97

96

145

102

103

90

20

30

370

380

200

290

410

110f

110e

110a

110d

110b

110c

340

350

CP2000

2

OVERALL ASSEMBLY

Page 22

CP2000

3

OVERALL ASSEMBLY

Overall Assembly

Overall Assembly

Overall Assembly

Overall Assembly

Overall Assembly

Main Chassis

Main Chassis

Protection Sheet

Protection Sheet

AC Cord

AC Cord

AC Cord

AC Cord Assembly

AC Cord

Cord Strain Relief

Bushing

Ferrite Core

Cord Holder

Bind Head Screw

Label

Shield sheet

Shield sheet

Shield sheet

Power Transformer

Power Transformer

Power Transformer

Holder, Transformer

Bushing

Bind Head Tapping Screw-B

Circuit Board

Circuit Board

Circuit Board

Circuit Board

Circuit Board

Circuit Board

Circuit Board

Circuit Board

Circuit Board

Circuit Board

Circuit Board

Vibration-proof Rubber

Vibration-proof Rubber

Vibration-proof Rubber

Bind Head Tapping Screw-B

DB Angle

Bind Head Tapping Screw-B

Shield sheet

PA Unit

Bonding Tapping Screw-B

Circuit Board

Bind Head Tapping Screw-B

Front Sub Assembly

Bind Head Tapping Screw-B

Bonding Tapping Screw-B

Front Grille

Bind Head Tapping Screw-B

Front Panel

Oval Head Screw

Escutcheon, ATT

Escutcheon, PSW

Rear Panel

Rear Panel

Rear Panel

Rear Panel

Bonding Tapping Screw-B

Bind Head Tapping Screw-B

Cover, Speaker Terminal

Bind Head Tapping Screw-B

Bonding Tapping Screw-B

DESCRIPTION

10

10

20

30

40

40

40

40

40a

50

50

60

70

80

90

95

96

97

100

100

100

101

102

103

110

110

110

110a

110b

110b

110b

110c

110d

110e

110f

111

112

113

120

130

140

145

150

160

170

180

190

200

210

220

230

240

250

260

270

280

280

280

280

290

300

310

320

330

REF NO.

- -

- -

- -

- -

- V6170900

V6308400

V6171000

V6171100

VZ021200

V2944000

VZ021600

- VD280500

VV103100

VB669000

V3225000

VV104600

VP156800

- -

- -

- -

- XY980A00

XY981A00

XZ157A00

V6305500

V6305600

EG340190

- -

- -

- AAX20810

AAX20820

AAX20830

AAX20840

AAX20850

AAX20860

AAX20870

AAX20880

V6511200

V6511300

V6800300

EP600190

- EP600190

- V6170800

VR779900

V6072000

EP600190

- EG340190

VR779900

V6171300

EP600190

V6171400

VS153600

V6171500

V6171600

V6171700

V6171800

V6171900

V6172000

VN413300

VQ074600

VY938700

EP600190

VR779900

PART NO.

A PPE T=0.3

B PPE T=0.3

SJT 3X#18 10A

H05VV-F0.75X3 6A

H05VV-F 13A

U 3P 15A 2.5m

SR-6P1

SR-7P-2

FR25/15/12-D40

A4.0X8 MFZN2BL

GND

A

B

C

UL E

CE E

A E

TKK

4.0X8 MFZN2BL

AC U

AC H

AC A

AC 1/6

AC U 2/6

AC H 2/6

AC A 2/6

AC 3/6

AC 4/6

AC 5/6

AC 6/6

A

B

C

3.0X8 MFZN2BL

3.0X8 MFZN2BL

D

4.0X8 MFZN2BL

IN

3.0X8 MFZN2BL

4.0X8 MFZN2BL

4.0X8 MFZN2BL

3.0X8 MFZN2BL

4.0X8 MFZN2BL

3.0X8 MFZN2BL

3.0X12 MFZN2BL

P-SERIES

3.0X8 MFZN2BL

4.0X8 MFZN2BL

CP2000

U,V (V617020)

H,W (V617030)

B (V617040)

A (V617050)

T (V617060)

U,V,H,W,B,A

T

U,V

H,W,A

B

T (V245650)

T

U,V,H,W,B,A

T

H,W,B

H,W,B

H,W,B (V542870)

H,W,B (V701980)

H,W,B (V701990)

H,W,B (V702000)

U,V,T

H,W,B

A

U,V,T (V607220)

H,W,B (V607230)

A (V688310)

U,V,T

H,W,B

A

(V617120)

H,W,B (V702010)

(V617410)

U,V

H,W,B

A

T

REMARKS

2

2

2

3

2

6

6

2

4

3

6

5

2

2

6

QTY

RANK

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

06

06

08

08

01

02

03

01

01

01

01

01

01

01

01

01

01

01

01

01

03

01

01

*

:

New Parts RANK: Japan only

Page 23

CP2000

4

Rear Angle

Bind Head Tapping Screw-B

Bind Head Screw

Connector Assembly

Connector Assembly

Cord Holder

Top Cover

Cover

Bind Head Tapping Screw-B

Label

PA Unit

Heat Sink

Support

Circuit Board

Bind Head Screw

Insulation Sheet

Transistor Holder

Transistor Holder

Bind Head Tapping Screw-B

Front Sub Assembly

Front Chassis

Fan

Bind Head Screw

Bind Head Screw

Connector Assembly

Connector Assembly

Connector Assembly

Bind Head Tapping Screw-B

Power Switch Knob

Attenuation Knob

DESCRIPTION

340

350

360

370

380

390

400

410

420

430

P10

P20

P30

P40

P50

P60

P70

P80

F10

F20

F50

F60

F70

F80

F90

F100

F110

F120

REF NO.

VY937100

EG340190

VP156800

- -

- VV104600

VY937600

V6172200

EG340190

VA039300

V6170800

- VV086500

V6072100

EG330290

V6172500

V6172600

V6172700

VQ074600

- -

- V6622900

EG340360

VB659000

MF107100

MF109120

V6186100

EP600190

VU859000

VY938500

PART NO.

P-SERIES

4.0X8 MFZN2BL

A4.0X8 MFZN2BL

PA 15P

AC-IN 8P

P-SERIES

PPE T=0.3

4.0X8 MFZN2BL

H=7.4 B=5.5

PA

SP 3.0X8 MFZN2Y

TBM51W T=0.15

LEFT

RIGHT

3.0X12 MFZN2BL

KDE2408PTS1-6A-318

4.0X8 MFZN2BL

3.0X8 MFZN2BL

7P 100mm P=1.25

9P 120mm P=1.25

IND 4P

3.0X8 MFZN2BL

P-SERIES

(V618590)

(V618600)

U,V

(V617230)

(V617410)

(V617280)

POWER

LEVEL CONTROL

REMARKS

2

4

2

9

2

9

6

6

2

18

2

2

2

2

QTY

RANK

*

*

*

*

*

*

*

*

*

*

03

01

01

01

10

01

03

01

01

01

01

01

01

01

03

*

:

New Parts RANK: Japan only

Page 24

CP2000

5

ELECTRICAL PARTS

Circuit Board

Circuit Board

Circuit Board

Circuit Board

Circuit Board

Circuit Board

Circuit Board

Circuit Board

Circuit Board

Circuit Board

Circuit Board

Circuit Board

Circuit Board

Circuit Board

Circuit Board

Circuit Board

Circuit Board

Circuit Board

Circuit Board

Circuit Board

Circuit Board

Circuit Board

Circuit Board

Circuit Board

Fuse Holder

LED Spacer

Jumper Wire

Mylar Capacitor

Mylar Capacitor

Capacitor

Capacitor

Mylar Capacitor

Mylar Capacitor

Capacitor

Electrolytic Cap.

Electrolytic Cap.

Capacitor

Electrolytic Cap.

Electrolytic Cap.

Electrolytic Cap.

Electrolytic Cap.

Electrolytic Cap.

Capacitor

Ceramic Capacitor-B

Ceramic Capacitor-B

Ceramic Capacitor-B

Ceramic Capacitor-B

Diode

Diode

Diode Stack

Diode

Fuse

Fuse

Fuse

Fuse

Fuse

Fuse

Fuse

Fuse

GND Plate

Terminal Plate

Flame Proof C. Resistor

Flame Proof C. Resistor

Carbon Resistor

Flame Proof C. Resistor

Flame Proof C. Resistor

Flame Proof C. Resistor

Flame Proof C. Resistor

DESCRIPTION

C601

C602

C603

C604

C605

C606

C607

C608

C609

C610

C611

C612

C613

C614

C615

C616

C617

-620

C621

-623

D601

-604

D605

D606

F601

F601

F602

F602

F603

F603

F604

F604

K601

K602

R601

R602

R603

R604

R605

R606

R607

REF NO.

- -

- -

- AAX20810

AAX20820

AAX20830

AAX20840

AAX20850

AAX20860

AAX20870

AAX20880

V6072000

V6072100

- -

- -

- AAX20810

AAX20820

AAX20830

AAX20840

AAX20850

AAX20860

AAX20870

AAX20880

VV319600

VV307300

- V3148500

V3148500

V6113500

V6185400

VZ004200

VZ004200

V6113500

V6183300

V6183300

V6185400

V6183300

V6183300

V5482000

V5482000

UR866470

VZ411400

VZ012200

VZ012200

VV314600

VV314600

VU801600

VU801600

V4833600

VU801600

KB001540

VT943200

KB001540

VT943200

VV070300

VV071200

VV070300

VV071200

VZ703700

VV075700

VV276700

VV276700

HF457150

VV276700

VV276700

VZ008800

VV276700

PART NO.

AC U

AC H

AC A

AC 1/6

AC U 2/6

AC H 2/6

AC A 2/6

AC 3/6

AC 4/6

AC 5/6

AC 6/6

IN

PA

AC U

AC H

AC A

AC 1/6

AC U 2/6

AC H 2/6

AC A 2/6

AC 3/6

AC 4/6

AC 5/6

AC 6/6

CQ-05CT

0.60

0.33 250V M

0.33 250V M

1000P 400V J.U.C.S

3300P 400V J.U.C.S

0.1000 100V M

0.1000 100V M

1000P 400V J.U.C.S

3300 160V

3300 160V

3300P 400V J.U.C.S

3300 160V

3300 160V

1000 35.0V

1000 35.0V

4.70 50.0V

0.22 275V UCS

0.001 500V K

0.001 500V K

0.0022 500V K

0.0022 500V K

1N4004L 26

1N4004L 26

RBV2506 25.0A 600V

1N4004L 26

12.00A UL

TH 5.00A S

12.00A UL

TH 5.00A S

TDS 1A 250V J/U/C

TSD 1A 250V SEMKO

TDS 1A 250V J/U/C

TSD 1A 250V SEMKO

P-SERIES

4.7 1/4 J

4.7 1/4 J

15.0K 1/4 J

4.7 1/4 J

4.7 1/4 J

22.0 1/4 J

4.7 1/4 J

CP2000

U,V,T (V607220)(XY969C0)

H,W,B (V607230)(XY969C0)

A (V688310)(XY969C0)

(XY969C0)

U,V,T (XY969C0)

H,W,B (XY969C0)

A (XY969C0)

(XY969C0)

(XY969C0)

(XY969C0)

(XY969C0)

(XY968B0)

(XY970B0)

U,V,T (V607220)(XY969B0)

H,W,B (V607230)(XY969B0)

A (V688310)(XY969B0)

(XY969B0)

U,V,T (XY969B0)

H,W,B (XY969B0)

A (XY969B0)

(XY969B0)

(XY969B0)

(XY969B0)

(XY969B0)

(VV29140)

U,V,T

H,W,B

U,V,T

H,W,B

U,V,T

H,W,B

U,V,T

H,W,B

REMARKS

8

9

QTY

RANK

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

01

01

01

01

01

01

01

01

01

01

01

01

01

01

04

01

04

01

04

01

01

01

01

01

01

01

01

01

01

01

01

01

01

ELECTRICAL PARTS

*

:

New Parts RANK: Japan only

Page 25

CP2000

6

Flame Proof C. Resistor

Relay

Connector Assembly

Connector Assembly

Connector Assembly

Connector Assembly

Connector Assembly

Connector Assembly

Connector Assembly

Connector Assembly

Connector Assembly

Connector Assembly

Fasten Terminal

Fasten Terminal

Base Post Connector

Connector Base Post

Connector, FFC

Connector Base Post

Connector, FFC

Base Post Connector

Phone Jack

Phone Jack

LED Red

LED Green

LED Red

LED Red

LED Yellow

LED Green

LED Red

LED Yellow

LED Green

Speaker Terminal

Push Switch

Rotary Variable Resistor

Rotary Variable Resistor

Circuit Board

Jumper Wire

Ceramic Capacitor-SL

Ceramic Capacitor-SL

Electrolytic Cap.

Ceramic Cap.-B

Ceramic Capacitor-SL

Ceramic Capacitor-SL

Electrolytic Cap.

Electrolytic Cap.

Ceramic Capacitor-SL

Ceramic Capacitor-SL

Ceramic Capacitor-SL

Electrolytic Cap.

Electrolytic Cap.

Electrolytic Cap.

Electrolytic Cap.

Ceramic Capacitor-F

Mylar Capacitor

Mylar Capacitor

Mylar Capacitor

Mylar Capacitor

Electrolytic Cap.

Electrolytic Cap.

Mylar Capacitor

Mylar Capacitor

Ceramic Capacitor-F

Mylar Capacitor

Mylar Capacitor

Ceramic Capacitor-B

Ceramic Capacitor-B

Electrolytic Cap.

Electrolytic Cap.

Ceramic Cap.-B

DESCRIPTION

R608

RY601

W601

W602

W603

W604

W605

W606

W607

W608

W609

W610

CN601

-612

CN613

CN614

CN615

CN616

CN617

CN618

JK601

JK602

LD601

LD602

LD603

LD604

LD605

LD606

LD607

LD608

LD609

SP601

SW601

VR601

VR602

C301

-304

C305

C306

C307

C308

C309

C310

C311

C312

C313

C314

C315

C316

C317

C318

C319

-322

C323

C324

C325

C326

C327

C328

C329

C330

C331

C332

C333

C334

C335

C336

REF NO.

VZ008800

VZ003600

V6186600

V6186600

V6186500

V6186300

V6186200

V6186400

V6185800

V6185500

V6185700

V6186700

VZ005700

VZ005700

LB932030

V3764600

VQ044300

V3765600

VQ044400

LB932020

VV089300

VV089300

VV620800

VV621000

VV620800

VV620800

VV938100

VV621000

VV620800

VV938100

VV621000

VZ956900

VY898100

VI575600

VI575600

V6072000

- VZ352800

VZ352800

UR866100

VZ353900

VZ353300

VZ353300

UR867100

UR867100

VZ353300

VZ353300

VZ352800

VV330700

UR847470

UR867100

UR867100

VZ354000

VV062900

VV062900

V5868900

V5868900

UR867100

UR866470

V5868900

V5868900

VZ354000

V5868900

V5868900

VV314600

VV314600

UR867100

UR867100

VZ353900

PART NO.

22.0 1/4 J

24V

SWR, BR

SWR, BR

SWY, YE

+B, RE

CENT, BL

-B, WH

L, OR

GND, WH

R, YE

EARTH, BL

TP82223-22

TP82223-22

VH- 3P TE

M24185XX 8P TE

52044 7P SE

M24185XXR 4P SE

52044 9P SE

VH- 2P TE

H30280072N

H30280072N

LT311G-41-C13

LT321-41-C13

LT311G-41-C13

LT311G-41-C13

LT331-41-C13

LT321-41-C13

LT311G-41-C13

LT331-41-C13

LT321-41-C13

STB-403AU 4P

SDDFA3107U-YL UCS

5K

5K

IN

0.60

22P 50V J

22P 50V J

1.00 50.0V

1000P 50V K

56P 50V J

56P 50V J

10.00 50.0V

10.00 50.0V

56P 50V J

56P 50V J

22P 50V J

470.00 10.0V

47.00 25.0V

10.00 50.0V

10.00 50.0V

0.0100 50V Z

0.12 50V J

0.12 50V J

0.1 50V J

0.1 50V J

10.00 50.0V

4.70 50.0V

0.1 50V J

0.1 50V J

0.0100 50V Z

0.1 50V J

0.1 50V J

0.0022 500V K

0.0022 500V K

10.00 50.0V

10.00 50.0V

1000P 50V K

H,W,B

SPEAKERS 2 LEFT

SPEAKERS 2 RIGHT

PROTECTION

POWER

TEMP

ACLP

ASIGH

ASIGL

BCLP

BSIGH

BSIGL

SPEAKERS 1

POWER ON/OFF

LEVEL CONTROL L

LEVEL CONTROL R

(XY968B0)

(VV29140)

REMARKS

QTY

RANK

*

*

*

*

*

*

*

*

*

*

*

*

*

01

01

01

01

01

01

01

02

02

01

01

01

01

01

01

01

01

01

06

05

03

03

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

*

:

New Parts RANK: Japan only

Page 26

CP2000

7

Electrolytic Cap.

Electrolytic Cap.

Electrolytic Cap.

Electrolytic Cap.

Electrolytic Cap.

Ceramic Capacitor-SL

Ceramic Capacitor-SL

Electrolytic Cap.

Electrolytic Cap.

Mica Capacitor

Mica Capacitor

Ceramic Cap.-B

Electrolytic Cap.

Electrolytic Cap.

Mylar Capacitor

Mylar Capacitor

Electrolytic Cap.

Electrolytic Cap.

Electrolytic Cap.

Connector Base Post

Connector Base Post

Connector, FFC

Connector Base Post

Connector, FFC

Connector Base Post

Zener Diode

Diode

Diode

Zener Diode

Diode

Diode

Diode

Zener Diode

Diode

Diode

Noise Filter

Noise Filter

IC

IC

IC

IC

IC

XLM Connector

XLM Connector

Phone Jack

Phone Jack

GND Plate

Photo Coupler

Photo Coupler

Transistor

Transistor

Transistor

Transistor

Transistor

Transistor

Transistor

Transistor

Transistor

Transistor

Transistor

Digital Transistor

Digital Transistor

Transistor

Digital Transistor

Transistor

Transistor

Transistor

Transistor

Digital Transistor

Digital Transistor

DESCRIPTION

C337

C338

C339

C340

C341

C342

C343

C344

C345

C346

C347

C348

C349

C350

C351

C352

C353

C354

C355

CN301

CN302

CN303

CN304

CN305

CN306

D301

D302

-307

D308

D309

D310

D311

D312

D313

-320

EM301

-304

IC301

IC302

IC303

IC304

IC305

JK301

JK302

JK303

JK304

K301

PH301

PH302

Q301

Q302

Q303

Q304

Q305

Q306

Q307

Q308

Q309

Q310

Q311

Q312

Q313

Q314

Q315

Q316

Q317

Q318

Q319

Q320

Q321

REF NO.

UR866100

V6638400

V6638400

UR866100

UR866100

FG652100

FG652100

UR828100

UR828100

FU451220

FU451220

VZ353900

UR866100

UR866100

VV060300

VV060300

UR847100

UR847100

UR866100

V3764600

V3764000

VQ047100

V3764200

VQ047200

V3765300

VG440800

VD631600

VD631600

VG440300

VU801600

VU801600

VD631600

VG437700

VD631600

VD631600

V3260500

V3260500

XM085A00

XM356A00

XM356A00

XD853A00

XD854A00

VS133800

VS133800

VY898300

VY898300

VZ703700

VP116000

VP116000

V2797600

V2797700

V2797600

V2797700

V2797700

V2797600

V2797700

V2797600

V2797600

VS883300

V2797700

VD678500

VD678500

V2797700

VD678500

V2797600

V2797600

V2797700

V2797700

VD678500

VD678500

PART NO.

1.00 50.0V

22.00 25.0V

22.00 25.0V

1.00 50.0V

1.00 50.0V

100P 50V J

100P 50V J

100.00 10.0V

100.00 10.0V

22P 500V J

22P 500V J

1000P 50V K

1.00 50.0V

1.00 50.0V

2200P 50V J

2200P 50V J

10.00 25.0V

10.00 25.0V

1.00 50.0V

M24185XX 8P TE

M24185XX 2P TE

52045 7P TE

M24185XX 4P TE

52045 9P TE

M24185XX 15 TE

MTZ J 15.0B 15.0V

1SS133,176,HSS104

1SS133,176,HSS104

MTZ J 12.0C 12.0V

1N4004L 26

1N4004L 26

1SS133,176,HSS104

MTZ J 5.6B 5.6V

1SS133,176,HSS104

1SS133,176,HSS104

ZJSR5101-271TA

ZJSR5101-271TA

M5238AP

NJM2068L-D

NJM2068L-D

NJM7815FA

NJM7915FA

NC3FAH1-0

NC3FAH1-0

ST JY6313-02-030

ST JY6313-02-030

P-SERIES

P873-G35-552

P873-G35-552

2SA1993 E,F

2SC5395 E,F

2SA1993 E,F

2SC5395 E,F

2SC5395 E,F

2SA1993 E,F

2SC5395 E,F

2SA1993 E,F

2SA1993 E,F

2SB1565 E,F

2SC5395 E,F

DTA114ES

DTA114ES

2SC5395 E,F

DTA114ES

2SA1993 E,F

2SA1993 E,F

2SC5395 E,F

2SC5395 E,F

DTA114ES

DTA114ES

OP AMP

OP AMP

OP AMP

REGULATOR +15V

REGULATOR -15V

CHANNEL L

CHANNEL R

CHANNEL L

CHANNEL R

REMARKS

QTY

RANK

*

*

*

*

*

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

03

02

02

03

03

04

04

02

02

01

06

06

01

01

01

01

01

01

01

01

01

02

01

01

01

01

01

01

01

01

01

01

01

*

:

New Parts RANK: Japan only

Page 27

CP2000

8

Digital Transistor

Transistor

Transistor

Digital Transistor

Digital Transistor

Transistor

Transistor

Transistor

Transistor

Transistor

Transistor

Transistor

Transistor

Transistor

Transistor

Transistor

Transistor

Transistor

Transistor

Transistor

Transistor

Digital Transistor

Transistor

Transistor

Digital Transistor

Digital Transistor

Transistor

Transistor

Digital Transistor

Carbon Resistor

Carbon Resistor

Metal Film Resistor

Metal Film Resistor

Carbon Resistor

Metal Film Resistor

Carbon Resistor

Carbon Resistor

Metal Film Resistor

Metal Film Resistor

Carbon Resistor

Carbon Resistor

Metal Film Resistor

Metal Film Resistor

Carbon Resistor

Metal Film Resistor

Carbon Resistor

Carbon Resistor

Carbon Resistor

Carbon Resistor

Carbon Resistor

Carbon Resistor

Carbon Resistor

Carbon Resistor

Metal Film Resistor

Metal Film Resistor

Carbon Resistor

Carbon Resistor

Metal Film Resistor

Metal Film Resistor

Carbon Resistor

Carbon Resistor

Carbon Resistor

Carbon Resistor

Carbon Resistor

Carbon Resistor

Metal Film Resistor

Carbon Resistor

Carbon Resistor

Carbon Resistor

Flame Proof C. Resistor

DESCRIPTION

Q322

Q323

Q324

Q325

-327

Q328

Q329

Q330

-333

Q334

Q335

Q336

Q337

Q338

Q339

Q340

Q341

Q342

Q343

Q344

Q345

Q346

Q347

Q348

Q349

Q350

Q351

Q352

Q353

R301

R302

R303

-306

R307

R308

R309

R310

R311

R312

R313

R314

R315

R316

R317

R318

R319

R320

R321

-323

R324

R325

R326

R327

R328

R329

R330

R331

R332

R333

R334

R335

R336

R337

R338

R339

R340

R341

R342

-345

R346

REF NO.

VD678700

V2797700

V2797700

VD678500

VD678500

IC1815M0

IC1815M0

VU418400

VU418400

VU418600

VU418600

VU418400

VU418400

IC1815M0

IC1815M0

V2797700

V2797700

IC1815M0

IC1815M0

IA101590

IA101590

VD678700

VU418600

VU418600

VD678500

VD678500

VU418400

VU418400

VD678500

HF458150

HF458150

VZ009900

VZ009900

HF456820

VV065200

HF457220

HF457470

VZ009900

VZ009900

HF455330

HF456560

VZ009900

VZ009900

HF457560

VV065200

HF458150

HF456820

HF454180

HF454180

HF457100

HF456820

HF455220

HF457100

VV312400

VV312400

HF457470

HF457470

V5909400

V5909400

HF457680

HF456120

HF454180

HF454180

HF457560

HF457820

VV065200

HF456220

HF456120

HF456120

VV276700

PART NO.

DTC114ES

2SC5395 E,F

2SC5395 E,F

DTA114ES

DTA114ES

2SC1815 Y,GR

2SC1815 Y,GR

2SA1371 D,E

2SA1371 D,E

2SC3468 D,E

2SC3468 D,E

2SA1371 D,E

2SA1371 D,E

2SC1815 Y,GR

2SC1815 Y,GR

2SC5395 E,F

2SC5395 E,F

2SC1815 Y,GR

2SC1815 Y,GR

2SA1015 O,Y

2SA1015 O,Y

DTC114ES

2SC3468 D,E

2SC3468 D,E

DTA114ES

DTA114ES

2SA1371 D,E

2SA1371 D,E

DTA114ES

150.0K 1/4 J

150.0K 1/4 J

15K 1/4 F

15K 1/4 F

8.2K 1/4 J

4.7K 1/4 F

22.0K 1/4 J

47.0K 1/4 J

15K 1/4 F

15K 1/4 F

330.0 1/4 J

5.6K 1/4 J

15K 1/4 F

15K 1/4 F

56.0K 1/4 J

4.7K 1/4 F

150.0K 1/4 J

8.2K 1/4 J

18.0 1/4 J

18.0 1/4 J

10.0K 1/4 J

8.2K 1/4 J

220.0 1/4 J

10.0K 1/4 J

3.9K 1/4 F

3.9K 1/4 F

47.0K 1/4 J

47.0K 1/4 J

82K 1/4 F

82K 1/4 F

68.0K 1/4 J

1.2K 1/4 J

18.0 1/4 J

18.0 1/4 J

56.0K 1/4 J

82.0K 1/4 J

4.7K 1/4 F

2.2K 1/4 J

1.2K 1/4 J

1.2K 1/4 J

4.7 1/4 J

REMARKS

QTY

RANK

*

*

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

05

01

01

01

01

01

01

01

01

01

05

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

05

01

01

01

01

*

:

New Parts RANK: Japan only

Page 28

CP2000

9

Flame Proof C. Resistor

Carbon Resistor

Carbon Resistor

Carbon Resistor

Carbon Resistor

Carbon Resistor

Carbon Resistor

Carbon Resistor

Carbon Resistor

Carbon Resistor

Carbon Resistor

Carbon Resistor

Carbon Resistor

Carbon Resistor

Carbon Resistor

Carbon Resistor

Carbon Resistor

Carbon Resistor

Carbon Resistor

Carbon Resistor

Carbon Resistor

Carbon Resistor

Carbon Resistor

Carbon Resistor

Carbon Resistor

Carbon Resistor

Carbon Resistor

Carbon Resistor

Carbon Resistor

Carbon Resistor

Carbon Resistor

Metal Film Resistor

Carbon Resistor

Metal Film Resistor

Carbon Resistor

Carbon Resistor

Carbon Resistor

Carbon Resistor

Carbon Resistor

Carbon Resistor

Carbon Resistor

Carbon Resistor

Carbon Resistor

Carbon Resistor

Carbon Resistor

Carbon Resistor

Carbon Resistor

Carbon Resistor

Carbon Resistor

Metal Film Resistor

Metal Film Resistor

Metal Film Resistor

Metal Film Resistor

Carbon Resistor

Carbon Resistor

Carbon Resistor

Carbon Resistor

Carbon Resistor

Carbon Resistor

Carbon Resistor

Carbon Resistor

Carbon Resistor

Carbon Resistor

Carbon Resistor

Flame Proof C. Resistor

Flame Proof C. Resistor

Carbon Resistor

Carbon Resistor

Flame Proof C. Resistor

Carbon Resistor

DESCRIPTION

R347

R348

R349

R350

R351

R352

R353

R354

R355

-358

R359

R360

R361

R362

R363

R364

R365

R366

R367

R370

R371

R372

R373

R374

R375

R376

R377

R378

R379

R380

R381

R382

R383

R384

R385

R386

R387

-390

R391

R392

R393

R394

R395

R396

R397

R398

R399

R400

R401

R402

R403

R404

R405

R406

R407

R408

-411

R412

-415

R416

-423

R424

-427

R428

R429

-431

R432

-435

R436

R437

REF NO.

VV276700

HF456680

HF456120

HF456120

HF455330

HF455330

HF456100

HF456100

HF457220

HF457220

HF456470

HF455330

HF456220

HF455330

HF456220

HF457560

HF457220

HF457560

HF457220

HF455220

HF456470

HF456470

HF458330

HF458330

HF457100

HF457100

HF455220

HF455220

HF456120

HF456120

HF457220

V4604800

HF457220

V4604800

HF455560

HF455560

HF456120

HF456120

HF455560

HF457100

HF455560

HF457100

HF455560

HF455560

HF457560

HF457560

HF456470

HF457100

HF457100

V2440400

VV065600

V2440400

VV065600

HF455220

HF455220

HF457470

HF457470

HF455200

HF455220

HF457470

HF457470

HF455330

HF455330

HF455220

V6252000

V6252000

HF456120

HF456120

V6252000

HF456120

PART NO.

4.7 1/4 J

6.8K 1/4 J

1.2K 1/4 J

1.2K 1/4 J

330.0 1/4 J

330.0 1/4 J

1.0K 1/4 J

1.0K 1/4 J

22.0K 1/4 J

22.0K 1/4 J

4.7K 1/4 J

330.0 1/4 J

2.2K 1/4 J

330.0 1/4 J

2.2K 1/4 J

56.0K 1/4 J

22.0K 1/4 J

56.0K 1/4 J

22.0K 1/4 J

220.0 1/4 J

4.7K 1/4 J

4.7K 1/4 J

330.0K 1/4 J

330.0K 1/4 J

10.0K 1/4 J

10.0K 1/4 J

220.0 1/4 J

220.0 1/4 J

1.2K 1/4 J

1.2K 1/4 J

22.0K 1/4 J

470.0 1/4 F

22.0K 1/4 J

470.0 1/4 F

560.0 1/4 J

560.0 1/4 J

1.2K 1/4 J

1.2K 1/4 J

560.0 1/4 J

10.0K 1/4 J

560.0 1/4 J

10.0K 1/4 J

560.0 1/4 J

560.0 1/4 J

56.0K 1/4 J

56.0K 1/4 J

4.7K 1/4 J

10.0K 1/4 J

10.0K 1/4 J

12K 1/4 F

11K 1/4 F

12K 1/4 F

11K 1/4 F

220.0 1/4 J

220.0 1/4 J

47.0K 1/4 J

47.0K 1/4 J

200.0 1/4 J

220.0 1/4 J

47.0K 1/4 J

47.0K 1/4 J

330.0 1/4 J

330.0 1/4 J

220.0 1/4 J

470 1/4 J

470 1/4 J

1.2K 1/4 J

1.2K 1/4 J

470 1/4 J

1.2K 1/4 J

REMARKS

QTY

RANK

*

*

*

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

05

01

05

01

01

01

01

01

01

01

01

01

01

01

01

01

01

*

:

New Parts RANK: Japan only

Page 29

CP2000

10

Carbon Resistor

Carbon Resistor

Carbon Resistor

Carbon Resistor

Slide Switch

Slide Switch

Circuit Board

Jumper Wire

Mica Capacitor

Mica Capacitor

Ceramic Capacitor-F

Ceramic Capacitor-F

Electrolytic Cap.

Electrolytic Cap.

Ceramic Capacitor-F

Ceramic Capacitor-F

Mylar Capacitor

Mylar Capacitor

Ceramic Capacitor-SL

Ceramic Capacitor-SL

Electrolytic Cap.

Electrolytic Cap.

Ceramic Capacitor-B

Mylar Capacitor

Mylar Capacitor

Mylar Capacitor

Mylar Capacitor

Electrolytic Cap.

Electrolytic Cap.

Ceramic Capacitor-B

Ceramic Capacitor-B

Electrolytic Cap.

Electrolytic Cap.

Connector Base Post

Fasten Terminal

Fasten Terminal

Connector Base Post

Connector Base Post

Diode

Diode

Diode

Diode

Zener Diode

Zener Diode

Zener Diode

Zener Diode

Diode

Diode

Diode

Diode

Diode Stack

Diode Stack

Diode

Diode

Diode

Diode

Diode

Diode

Diode

Diode

Diode

Coil

Coil

Coil

Coil

Coil

Coil

Positive Thermistor

Positive Thermistor

DESCRIPTION

R438

R439

R440

R441

SW301

SW302

C102

-105

C106

C107

C108

-111

C112

-115

C116

-119

C120

-123

C124

C125

C126

C127

-130

C131

C132

C133

C134

C138

C139

C140

C141

CN101

CN102

-106

CN107

CN108

D101

-104

D105

-108

D109

D110

D111

D112

D113

-120

D121

-125

D126

D127

D128

D129

D130

D131

D132

D133

D134

D135

D136

L101

L102

L103

L104

L105

L106

PR101

PR102

REF NO.

HF456120

HF455330

HF457150

HF457150

VY898200

V5909200

V6072100

- FU451220

FU451220

VZ354000

VZ354000

UR896470

UR896470

VZ354000

VZ354000

VV060300

VV060300

V4567500

V4567500

VZ004000

VZ004000

VV314600

VV062800

VV062800

V5097700

V5097700

VZ004000

VZ004000

VV314600

VV314600

VZ003800

VZ003800

V3765300

VZ005700

VZ005700

V3764000

V3764000

VD631600

VD631600

VQ469600

VQ469600

VG438900

VG438400

VG438900

VG438400

VQ469600

VQ469600

VU801600

VU801600

V4816400

V4816400

VU801600

VU801600

VN478200

VN771700

VN771700

V6351700

V6351700

VN478200

VN478200

VR150900

VR150900

V4668300

V4668300

GD900470

GD900470

VL965100

VL964800

PART NO.

1.2K 1/4 J

330.0 1/4 J

15.0K 1/4 J

15.0K 1/4 J

SSSF123NB2-YL L=9

SSSF122NB2-YL L=9

PA

0.60

22P 500V J

22P 500V J

0.0100 50V Z

0.0100 50V Z

4.7 100.0V

4.7 100.0V

0.0100 50V Z

0.0100 50V Z

2200P 50V J

2200P 50V J

10P 500V K

10P 500V K

2.2 200.0V

2.2 200.0V

0.0022 500V K

0.1 50V J

0.1 50V J

3.3000 250V K

3.3000 250V K

2.2 200.0V

2.2 200.0V

0.0022 500V K

0.0022 500V K

100.0 160.0V

100.0 160.0V

M24185XX 15 TE

TP82223-22

TP82223-22

M24185XX 2P TE

M24185XX 2P TE

1SS133,176,HSS104

1SS133,176,HSS104

HSS82

HSS82

MTZ J 8.2B 8.2V

MTZ J 6.8C 6.8V

MTZ J 8.2B 8.2V

MTZ J 6.8C 6.8V

HSS82

HSS82

1N4004L 26

1N4004L 26

FMU-22U 10A 200V

FMU-22U 10A 200V

1N4004L 26

1N4004L 26

D1NL20U

D1NS4

D1NS4

SF20L60U

SF20L60U

D1NL20U

D1NL20U

RZ-001 21mm

RZ-001 21mm

OH-20 100uH

OH-20 100uH

RZ-001 1.5uH

RZ-001 1.5uH

PTH9M04BE222TS2

PTH9M04BH222TS2

STEREO/BRIDGE/PARALLEL

SPEAKER PROCESSING ON/OFF

(XY970B0)

(VV29140)

REMARKS

QTY

RANK

*

*

*

*

*

*

*

*

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

05

05

01

01

01

01

02

02

01

01

01

01

01

01

01

01

01

01

01

01

01

01

03

03

01

01

01

01

01

01

01

02

02

08

08

01

01

04

04

*

:

New Parts RANK: Japan only

Page 30

CP2000

11

Transistor

Transistor

Transistor

Transistor

Transistor

Transistor

Transistor

Transistor

Transistor

Transistor

Transistor

Transistor

Transistor

Transistor

Transistor

FET

FET

Pair Transistor

Pair Transistor

Pair Transistor

Pair Transistor

Pair Transistor

Pair Transistor

Pair Transistor

Pair Transistor

Pair Transistor

Pair Transistor

Pair Transistor

Pair Transistor

Pair Transistor

Pair Transistor

Carbon Resistor

Carbon Resistor

Carbon Resistor

Carbon Resistor

Carbon Resistor

Carbon Resistor

Carbon Resistor

Carbon Resistor

Carbon Resistor

Carbon Resistor

Carbon Resistor

Carbon Resistor

Carbon Resistor

Carbon Resistor

Flame Proof C. Resistor

Flame Proof C. Resistor

Flame Proof C. Resistor

Flame Proof C. Resistor

Flame Proof C. Resistor

Flame Proof C. Resistor

Flame Proof C. Resistor

Flame Proof C. Resistor

Flame Proof C. Resistor

Flame Proof C. Resistor

Flame Proof C. Resistor

Flame Proof C. Resistor

Wire Wound Resistor

Wire Wound Resistor

Flame Proof C. Resistor

Flame Proof C. Resistor

Flame Proof C. Resistor

Flame Proof C. Resistor

Wire Wound Resistor

Wire Wound Resistor

Flame Proof C. Resistor

Flame Proof C. Resistor

Flame Proof C. Resistor

Flame Proof C. Resistor

Wire Wound Resistor

DESCRIPTION

Q101

Q102

Q103

Q104

Q105

Q106

Q107

Q108

Q109

Q110

Q111

Q112

Q113

Q114

-117

Q118

-123

Q124N

Q124P

Q125N

Q125P

Q126N

-131N

Q126P

-131P

Q132N

Q132P

Q133N

Q133P

Q134N

Q134P

R101

R102

R103

R104

R105

R106

R107

R108

R109

-116

R117

-120

R121

-124

R125

-128

R129

-132

R133

-136

R137

-140

R141

-144

R145

-148

R149

-152

R153

-156

R157

-160

R161

-164

R165

-168

R169

-172

R173

REF NO.

VQ547300

VQ547300

V2797600

V2797600

V2797700

V2797700

VR152900

VR152900

VR152800

VR152800

VU418600

VU418400

V4096100

V4096000

V4096000

V6452100

V6452100

VR732800

VR732800

VR732800

VR732800

VZ222300

VZ222300

VZ222300

VZ222300

VR732800

VR732800

VZ222300

VZ222300

VZ222300

VZ222300

HF455100

HF455100

HF456160

HF455200

HF456160

HF455200

HF455180

HF455180

HF457470

HF457470

HF456270

HF456270

HF457240

HF457240

VV313900

VV313900

VZ009300

VZ009300

VV276800

VV276800

VZ009100

VZ009100

VV276700

VV276700

VZ008800

VZ008800

V4833200

V4833200

VV276700

VV276700

VZ008800

VZ008800

V4833200

V4833200

VV276700

VV276700

VZ008800

VZ008800

V4833200

PART NO.

2SC4793 (HFE)

2SC4793 (HFE)

2SA1993 E,F

2SA1993 E,F

2SC5395 E,F

2SC5395 E,F

2SC3790 E,F

2SC3790 E,F

2SA1480 E,F

2SA1480 E,F

2SC3468 D,E

2SA1371 D,E

2SC4614 S,T

2SA1770 S,T

2SA1770 S,T

2SK3460

2SK3460

A1859A/C4883A

A1859A/C4883A

A1859A/C4883A

A1859A/C4883A

A1492C3856(Z)(210)

A1492C3856(Z)(210)

A1492C3856(Z)(210)

A1492C3856(Z)(210)

A1859A/C4883A

A1859A/C4883A

A1492C3856(Z)(210)

A1492C3856(Z)(210)

A1492C3856(Z)(210)

A1492C3856(Z)(210)

100.0 1/4 J

100.0 1/4 J

1.6K 1/4 J

200.0 1/4 J

1.6K 1/4 J

200.0 1/4 J

180.0 1/4 J

180.0 1/4 J

47.0K 1/4 J

47.0K 1/4 J

2.7K 1/4 J

2.7K 1/4 J

24.0K 1/4 J

24.0K 1/4 J

680.0 1/4 J

680.0 1/4 J

330.0 1/4 J

330.0 1/4 J

100 1/4 J

100 1/4 J

33.0 1/4 J

33.0 1/4 J

4.7 1/4 J

4.7 1/4 J

22.0 1/4 J

22.0 1/4 J

0.22 5W K

0.22 5W K

4.7 1/4 J

4.7 1/4 J

22.0 1/4 J

22.0 1/4 J

0.22 5W K

0.22 5W K

4.7 1/4 J

4.7 1/4 J

22.0 1/4 J

22.0 1/4 J

0.22 5W K

REMARKS

QTY

RANK

*

*

03

03

01

01

01

01

02

02

02

02

01

01

02

03

03

04

04

04

04

06

06

06

06

04

04

06

06

06

06

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

*

:

New Parts RANK: Japan only

Page 31

CP2000

12

Wire Wound Resistor

Flame Proof C. Resistor

Carbon Resistor

Carbon Resistor

Metal Oxide Film Resistor

Metal Oxide Film Resistor

Flame Proof C. Resistor

Flame Proof C. Resistor

Flame Proof C. Resistor

Flame Proof C. Resistor

Metal Oxide Film Resistor

Metal Oxide Film Resistor

Flame Proof C. Resistor

Flame Proof C. Resistor

Flame Proof C. Resistor

Flame Proof C. Resistor

Flame Proof C. Resistor

Wire Wound Resistor

Wire Wound Resistor

Flame Proof C. Resistor

Flame Proof C. Resistor

Flame Proof C. Resistor

Wire Wound Resistor

Wire Wound Resistor

Flame Proof C. Resistor

Flame Proof C. Resistor

Flame Proof C. Resistor

Metal Oxide Film Resistor

Carbon Resistor

Flame Proof C. Resistor

Flame Proof C. Resistor

Metal Oxide Film Resistor

Flame Proof C. Resistor

Metal Oxide Film Resistor

Flame Proof C. Resistor

Flame Proof C. Resistor

Flame Proof C. Resistor

Flame Proof C. Resistor

Flame Proof C. Resistor

Carbon Resistor

Carbon Resistor

Flame Proof C. Resistor

Flame Proof C. Resistor

Relay

Relay

Trimmer Potentiometer

Trimmer Potentiometer

AC Cord

AC Cord

AC Cord

AC Cord

Power Transformer

Power Transformer

Power Transformer

Fan

DESCRIPTION

-176

R177

R178

R179

R180

R181

R182

R183

R184

R185

R186

R187

R188

R189

R190

R191

R192

R193

R194

R195

R196

R197

R198

R199

R200

R201

R202

R203

R204

R205

R206

R207

R208

R209

R210

R211

-217