Yamaha CDXE-410, CDXE-420 Service manual

MICRO COMPONENT SYSTEM MCR-E410

CD PLAYER

CDX-E410

SERVICE MANUAL

The MCR-E410 is composed of the CDX-E410, RX-E410 and NX-E800.

This service manual is for the CDX-E410.

For service manual of the RX-E410 and NX-E800, please refer to the following publication number:

RX-E810/RX-E410/NX-E800 101019

This manual has been provided for the use of authorized YAMAHA Retailers and their service personnel.

It has been assumed that basic service procedures inherent to the industry, and more specifically YAMAHA Products, are already

known and understood by the users, and have therefore not been restated.

WARNING: Failure to follow appropriate service and safety procedures when servicing this product may result in personal

injury, destruction of expensive components, and failure of the product to perform as specified. For these reasons,

we advise all YAMAHA product owners that any service required should be performed by an authorized

YAMAHA Retailer or the appointed service representative.

IMPORTANT: The presentation or sale of this manual to any individual or firm does not constitute authorization, certification or

recognition of any applicable technical capabilities, or establish a principle-agent relationship of any form.

The data provided is believed to be accurate and applicable to the unit(s) indicated on the cover. The research, engineering, and

service departments of YAMAHA are continually striving to improve YAMAHA products. Modifications are, therefore, inevitable

and specifications are subject to change without notice or obligation to retrofit. Should any discrepancy appear to exist, please

contact the distributor's Service Division.

WARNING: Static discharges can destroy expensive components. Discharge any static electricity your body may have

accumulated by grounding yourself to the ground buss in the unit (heavy gauge black wires connect to this buss).

IMPORTANT: Turn the unit OFF during disassembly and part replacement. Recheck all work before you apply power to the unit.

■ CONTENTS

TO SERVICE PERSONNEL ...................................... 2–3

PREVENTION OF ELECTROSTATIC DISCHARGE .... 4

FRONT PANEL .............................................................. 5

REAR PANEL ................................................................ 5

SPECIFICATIONS.......................................................... 5

INTERNAL VIEW ........................................................... 6

REPAIR NOTES ............................................................. 6

HOW TO MANUALLY EJECT THE TRAY .................... 6

DISASSEMBLY PROCEDURES ................................... 7

IMPORTANT NOTICE

TEST MODE ................................................................... 8

IC DATA ................................................................... 9–13

BLOCK DIAGRAM ....................................................... 14

WIRING DIAGRAM ...................................................... 15

PRINTED CIRCUIT BOARDS................................ 16–18

SCHEMATIC DIAGRAMS ...................................... 19–20

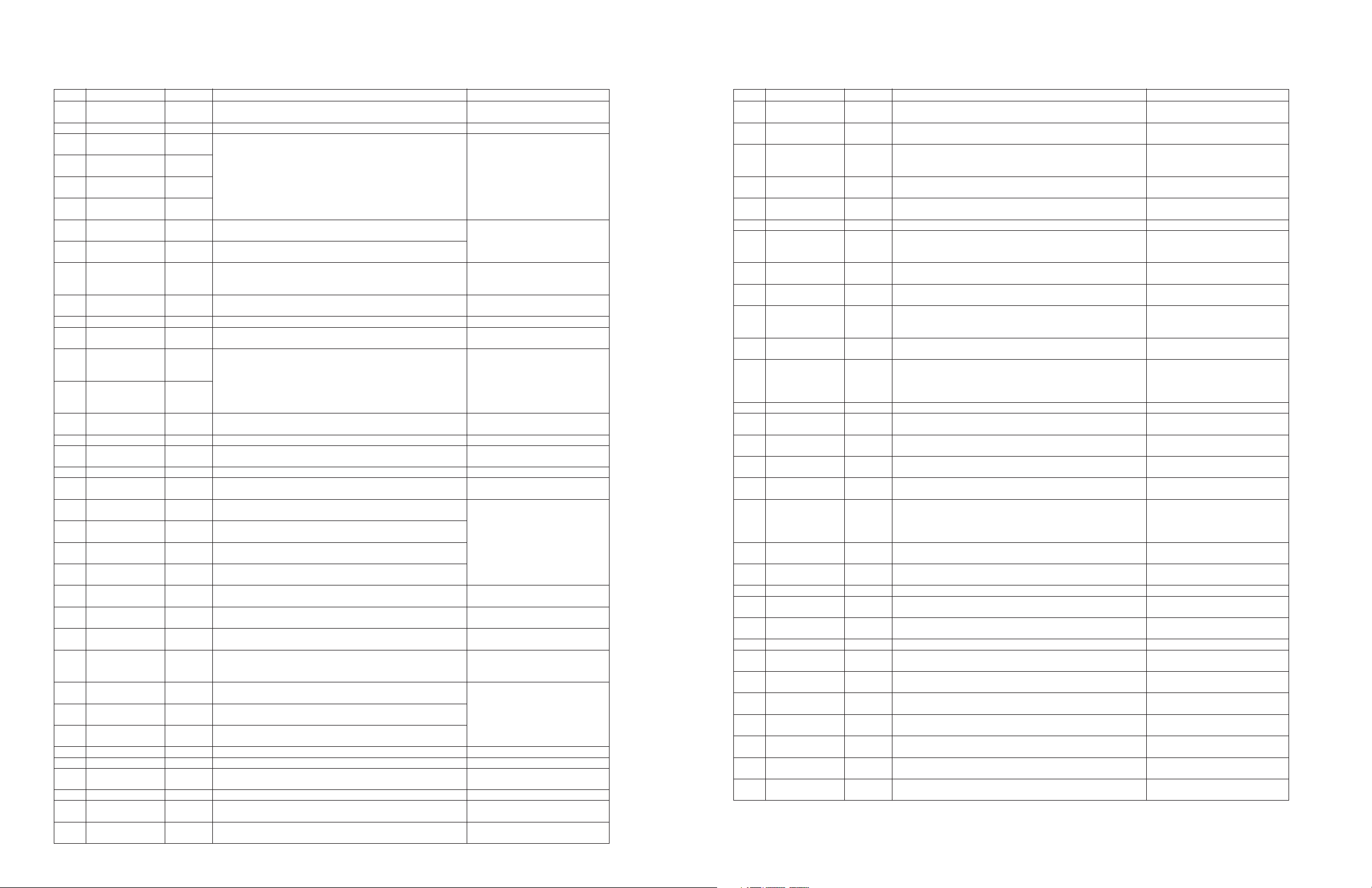

REPLACEMENT PARTS LIST .............................. 22–23

SYSTEM CONTROL .............................................. 24–31

CDX-E410

101018

2006 All rights reserved.

This manual is copyrighted by YAMAHA and may not be copied or

redistributed either in print or electronically without permission.

P.O.Box 1, Hamamatsu, Japan

'06.08

CDX-E410

■ TO SERVICE PERSONNEL

WARNING: CHEMICAL CONTENT NOTICE!

The solder used in the production of this product contains LEAD. In addition, other electrical/electronic and/or plastic

(where applicable) components may also contain traces of chemicals found by the California Health and Welfare

Agency (and possibly other entities) to cause cancer and/or birth defects or other reproductive harm.

DO NOT PLACE SOLDER, ELECTRICAL/ELECTRONIC OR PLASTIC COMPONENTS IN YOUR MOUTH FOR ANY

REASON WHATSOEVER!

Avoid prolonged, unprotected contact between solder and your skin! When soldering, do not inhale solder fumes or

expose eyes to solder/flux vapor!

If you come in contact with solder or components located inside the enclosure of this product, wash your hands

before handling food.

About Lead Free Solder

All of the P.C.B.s installed in this unit are soldered using the lead free solder.

Among some types of lead free solder currently available, it is recommended to use one of the following types for the repair

work.

• Sn + Ag + Cu (tin + silver + copper)

• Sn + Cu (tin + copper)

• Sn + Zn + Bi (tin + zinc + bismuth)

Caution:

As the melting point temperature of the lead free solder is about 30°C to 40°C (50°F to 70°F) higher than that of the lead solder, be sure

to use a soldering iron suitable to each solder.

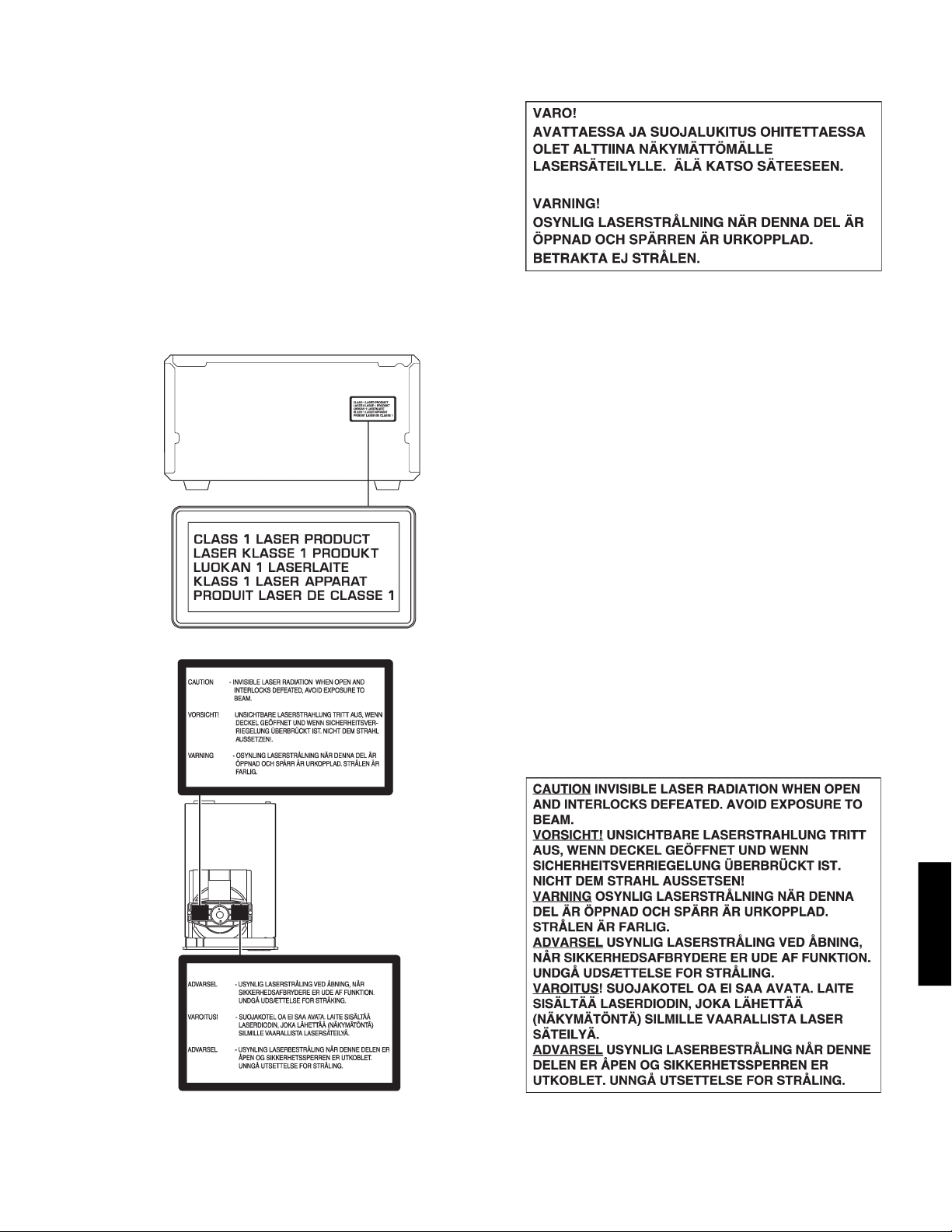

WARNING: Laser Safety

This product contains a laser beam component. This component may emit invisible, as well as visible radiation,

which may cause eye damage. To protect your eyes and skin from laser radiation, the following precautions must be

used during servicing of the unit.

1) When testing and/or repairing any component within the product, keep your eyes and skin more than 30 cm away from

the laser pick-up unit at all times. Do not stare at the laser beam at any time.

2) Do not attempt to readjust, disassemble or repair the laser pick-up, unless noted elsewhere in this manual.

3) CAUTION: Use of controls, adjustments or performance of procedures other than those specified herein may result in

hazardous radiation exposure.

Laser Emitting conditions:

1) When the top cover is removed, and the “STANDBY/ON” SW is turned to the “ON” position, the laser component will emit

a beam for several seconds to detect if a disc is present. During this time (5-10 sec.) the laser may radiate through the

lens of the laser pick-up unit. Do not attempt any servicing during this period!

CDX-E410

If no disc is detected, the laser will stop emitting the beam. When a disc is set, you will not be exposed to any laser

emissions.

2) The laser power level can be adjusted with the VR on the pick-up PWB. However, this level has been set by the factory

prior to shipping from the factory. Do not adjust this laser level control unless instruction is provided elsewhere in this

manual. Adjustment of this control can increase the laser emission level from the device.

2

Laser Diode Properties

Type: GaAlAs

Wave length: 780 nm

Emission duration: continuous

Laser output: max. 44.6 µW *

* This output is the value measured

at a distance of about 200 mm from

the objective lens surface on the

optical pick-up block.

WARNING

CDX-E410

CDX-497/CDX-397

CDX-E410

3

CDX-E410

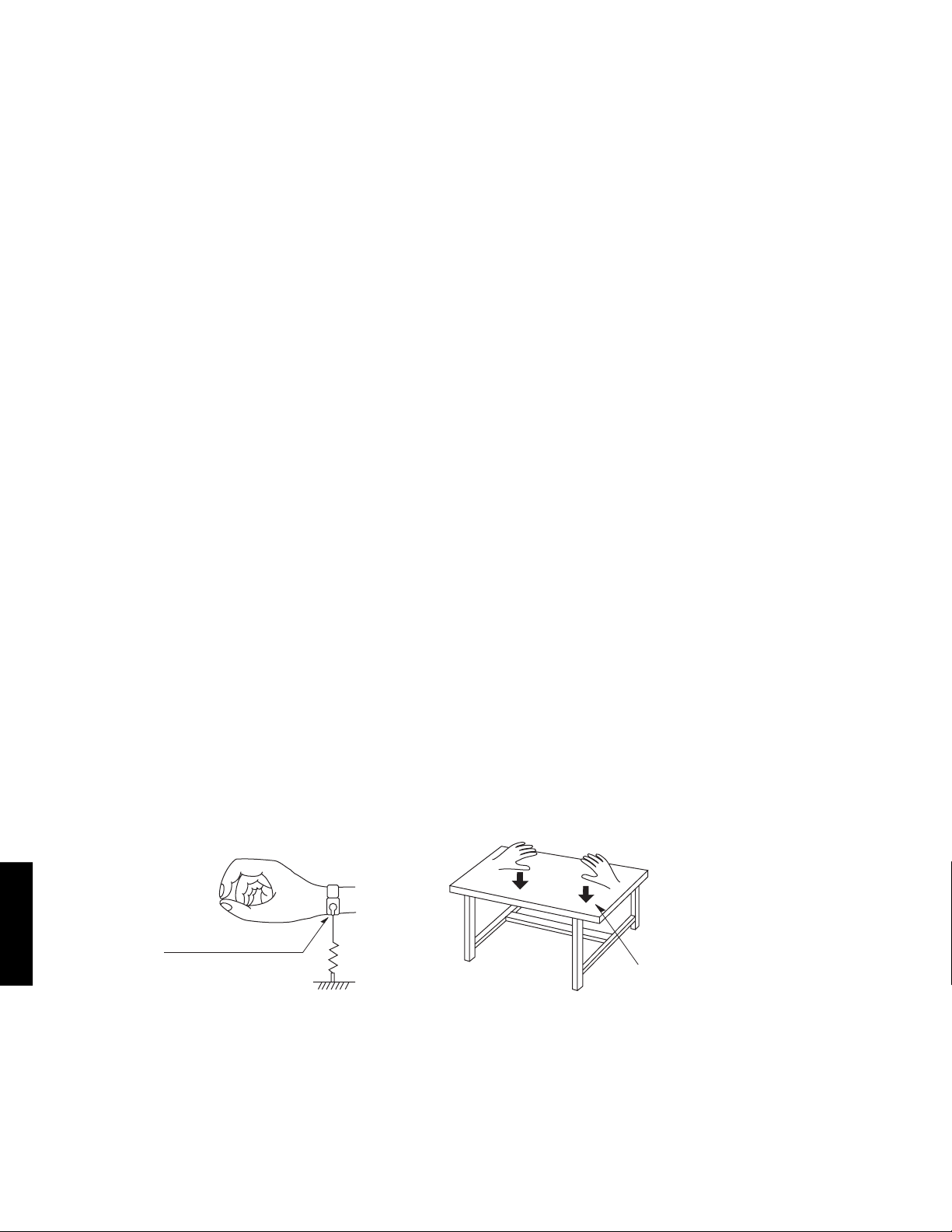

■ PREVENTION OF ELECTROSTATIC DISCHARGE

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such components commonly are called

Electrostatically Sensitive (ES) Devices. Examples of typical ES devices are integrated circuits and some field-effect transistors

and semiconductor “chip” components. The following techniques should be used to help reduce the incidence of component

damage caused by electro static discharge (ESD).

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off any ESD on

your body by touching a known earth ground. Alternatively, obtain and wear a commercially available discharging ESD wrist

strap, which should be removed for potential shock reasons prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ES devices, place the assembly on a conductive surface such as

aluminum foil, to prevent electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only an anti-static solder removal device. Some solder removal devices not classified as “anti-static (ESD protected)”

can generate electrical charge sufficient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are ready to install it. (Most

replacement ES devices are packaged with leads electrically shorted together by conductive foam, aluminum foil or compa-

rable conductive material).

7. Immediately before removing the protective material from the leads of a replacement ES divice, touch the protective material

to the chassis or circuit assembly into which the device will be installed.

CAUTION: Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged replacement ES devices. (Otherwise harmless motion such as the

brushing together of your clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity (ESD)

sufficient to damage an ES device).

Grounding for electrostatic breakdown prevention

1. Human body grounding.

Use the antistatic wrist strap to discharge the static electricity from your body.

2. Work table grounding.

Put a conductive material (sheet) or steel sheet on the area where the optical pickup is placed and ground the sheet.

Caution:

The static electricity of your clothes will not be grounded through the wrist strap. So take care not to let your clothes touch the

optical pickup.

Anti-static wrist strap

CDX-E410

1M-ohms

Conductive material

(sheet) or steel sheet

4

215 (8-7/16")

100 (3-15/16")

8

(5/16")

108 (4-1/4")

327 (12-7/8")

2

(1/16")

5

(3/16")

334 (13-1/8")

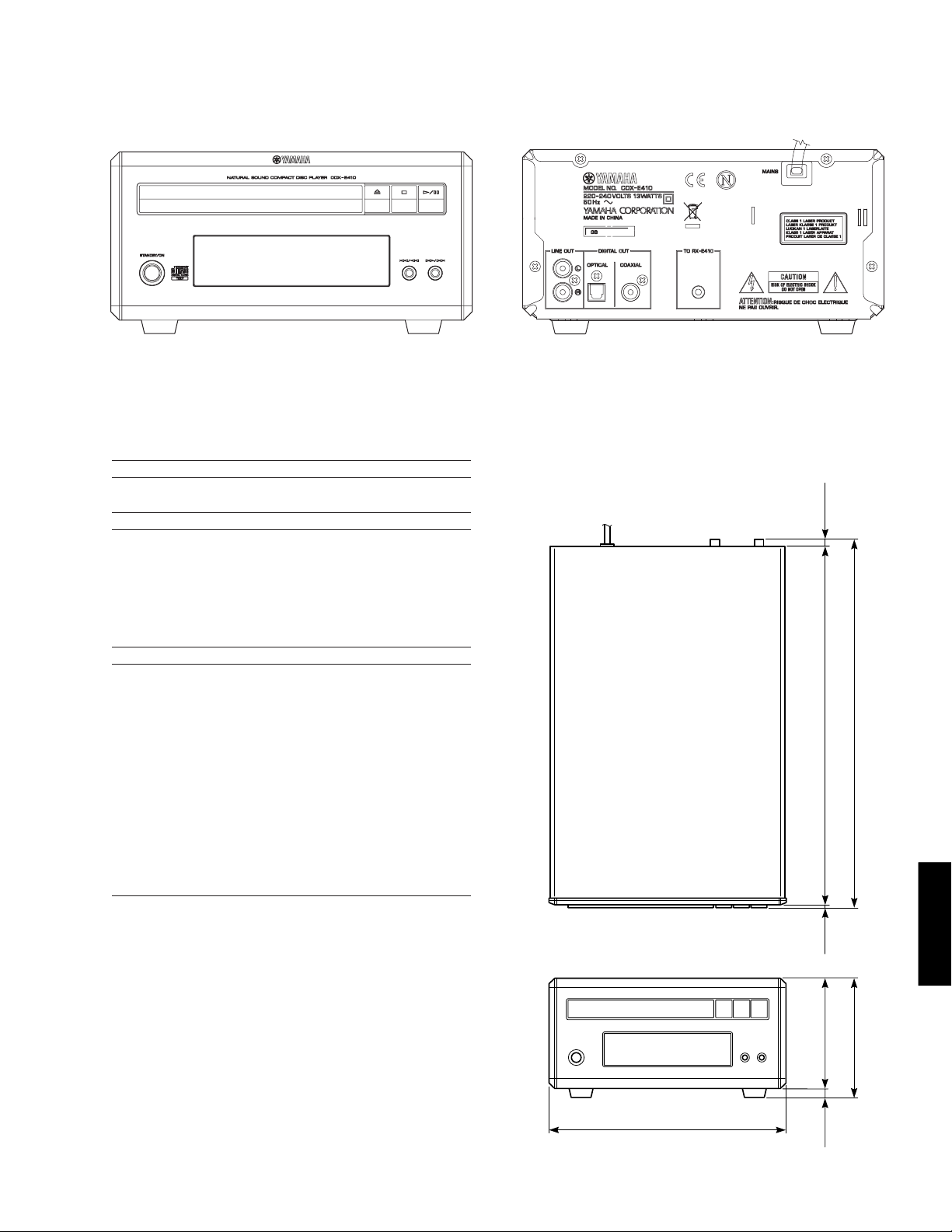

■ FRONT PANEL ■ REAR PANEL

CDX-E410

B, G models

■ SPECIFICATIONS

■ PLAYBACK SYSTEM

CD, CD-R/RW

■ AUDIO PERFORMANCE

Signal to Noise (1 kHz)

............................................................................... 105 dB or more

Dynamic Range (1 kHz)

................................................................................. 95 dB or more

Distortion and Noise (1 kHz)

............................................................................... 0.003 % or less

B, G models

• DIMENSIONS

CDX-497/CDX-397

■ GENERAL

Dimensions (W x H x D)

........................... 215 x 108 x 334 mm (8-7/16” x 4-1/4” x 13-1/8”)

Weight

............................................................ Approx. 2.8 kg (6 lbs. 3 oz)

Finish

Black color ........................................................................ G model

Silver color .................................................................. B, G models

Power Supply

B, G models ................................................. AC 220-240 V, 50 Hz

Power Consumption

.................................................................................. Approx. 13 W

Accessories

............................................................ Audio pin cable (1.5 m) x 1

* Specifications are subject to change without notice.

B .......... British model G ...... European model

CDX-E410

Unit: mm (inch)

5

CDX-E410

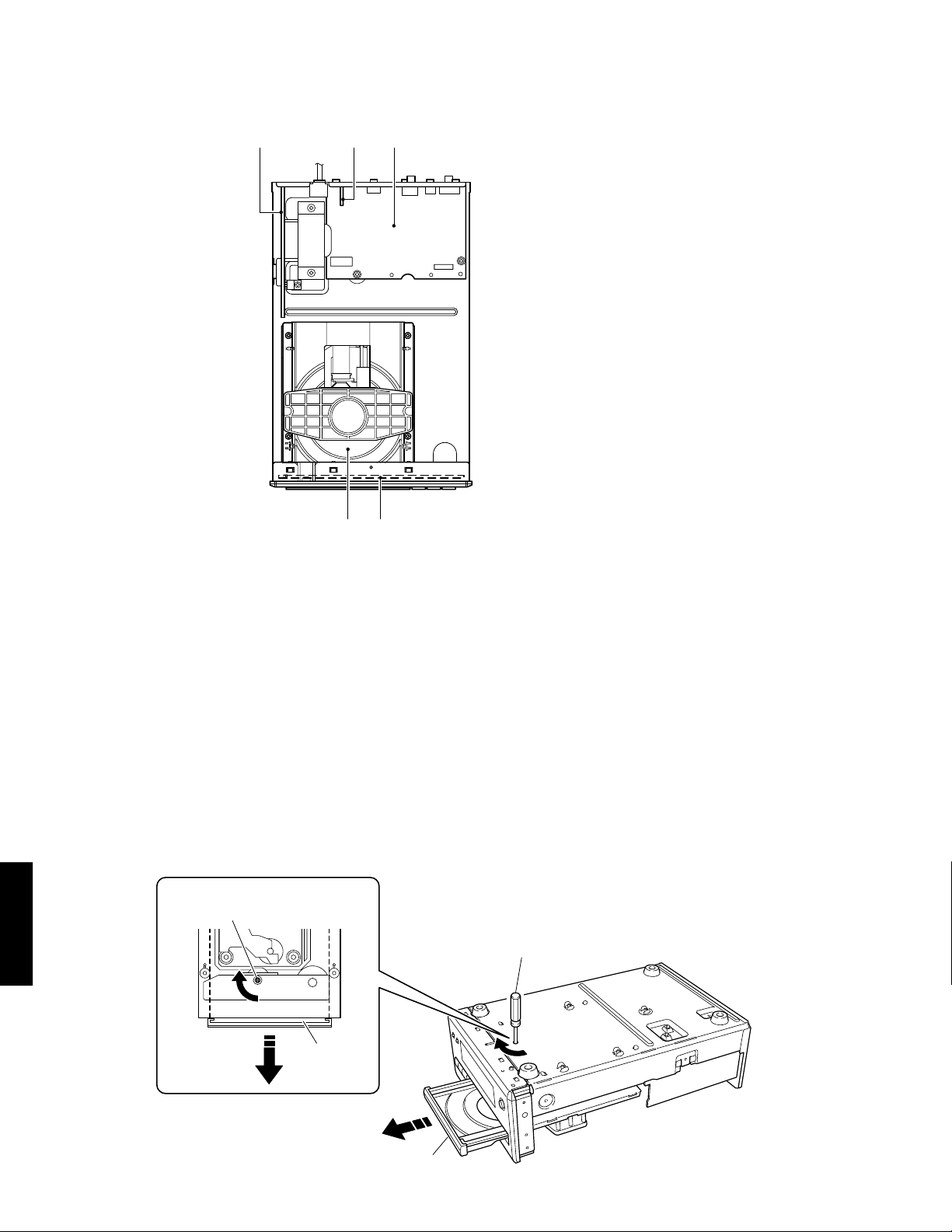

■ INTERNAL VIEW

4

2

5

1 3

1

FRONT (2) P.C.B.

2

MAIN (2) P.C.B.

3

MAIN (1) P.C.B.

4

CD Mechanism

5

FRONT (1) P.C.B.

■ REPAIR NOTES

None of the components of the following units can be supplied separately.

Each unit must be replaced as a whole in case of a failure.

• CD Mechanism

• MAIN P.C.B.

• FRONT P.C.B.

■ HOW TO MANUALLY EJECT THE TRAY

a. Turn the unit bottom up.

b. Using a flatblade screwdriver, turn the loading cam 90 degrees in the direction indicated by an arrow in the figure.

c. Gently pull the tray out.

Loading Cam

Flatblade Screwdriver

CDX-E410

Tr ay

Tr ay

6

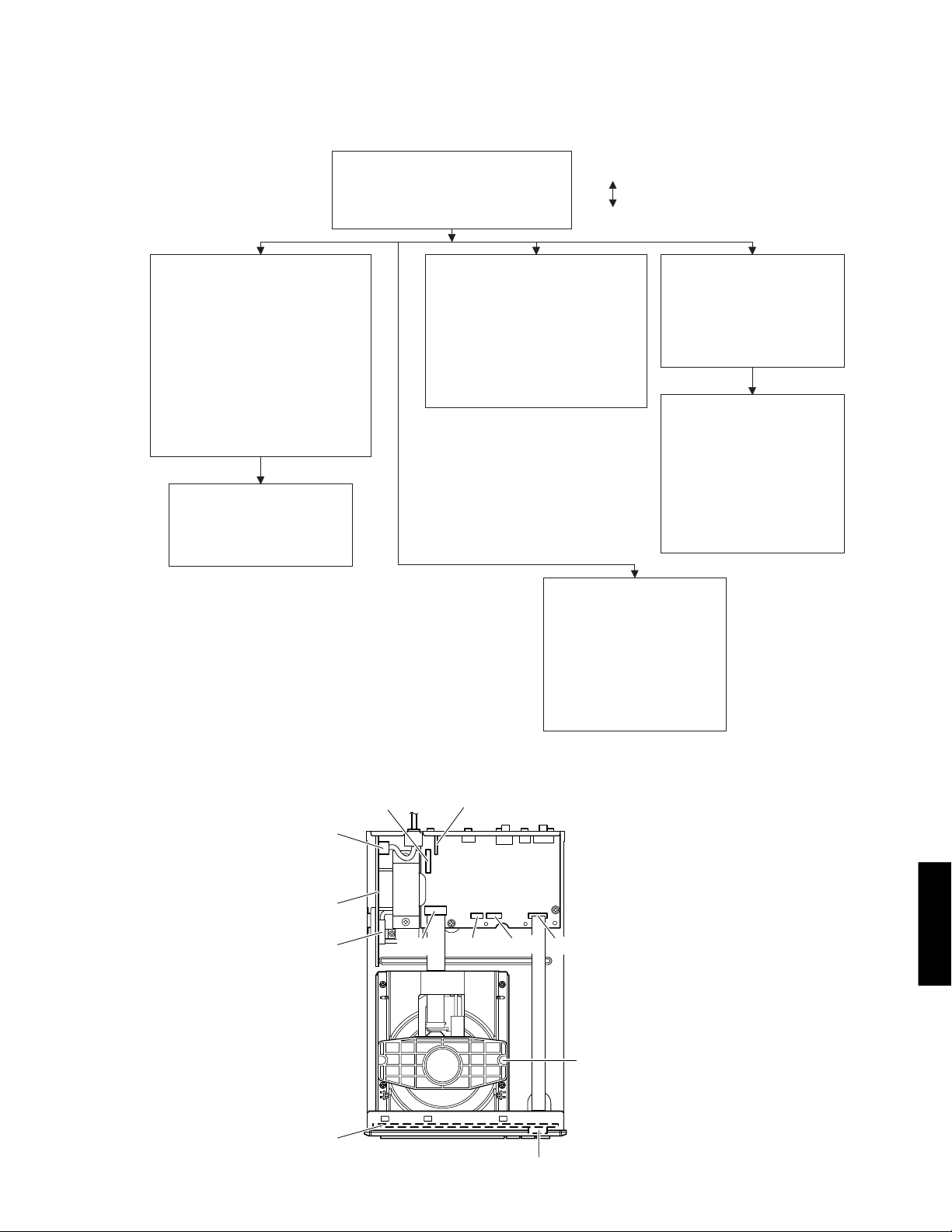

■ DISASSEMBLY PROCEDURES

See REPLACEMENT PARTS LIST for item numbers.

CDX-E410

→ Remove 4 screws. [60] (4 on side)

→ Remove 4 screws. [51]

(4 on rear side)

→ Lift top cover from rear side to remove.

→ Open tray. (See "

→ Unlock tray lid and close tray.

→ Remove CN52. (MAIN (1) P.C.B.)

→ Remove 2 screws. [53]

→ Remove 2 screws. [51]

→ Unlock front panel ass'y from frame

→ Remove front panel ass'y.

Front Panel Ass'y

EJECT THE TRAY

(Front panel ass'y to side frame)

(Front panel ass'y to bottom frame)

by releasing successively 2 snaps.

(2 on the side)

FRONT (1) P.C.B. [32 (1)]

→ Remove 10 snaps.

(P.C.B. to front panel ass'y)

→ Remove FRONT (1) P.C.B..

HOW TO MANUALLY

")

Top Cabinet [28]

CD Mechanism [36]

→ Open tray. (See "

EJECT THE TRAY

→ Unlock tray lid and close tray.

→ Remove CN21-23.

→ Remove 4 screws. [52]

(CD mechanism to P.C.B.

support)

→ Remove CD mechanism.

HOW TO MANUALLY

")

Mounting

Dismounting

MAIN (2) P.C.B. [34 (2)]

→ Remove 1 screw. [61]

(P.C.B. to rear panel)

→ Remove MAIN (2) P.C.B.

which is connected directly

to the lower P.C.B. with

connectors.

MAIN (1) P.C.B. [34 (1)]

→ Remove CN21-23, CN41

and CN52 (MAIN (1) P.C.B.).

→ Remove 3 screws. [59]

(P.C.B. to rear panel)

→ Remove 1 screw. [54]

(P.C.B. to bottom frame)

→

Remove 1 screw. [58]

(P.C.B. to bottom frame)

→ Remove MAIN (1) P.C.B..

FRONT (2) P.C.B. [32 (2)]

→ Remove CN41 (FRONT (2)

P.C.B.) and CN41 (MAIN (1)

P.C.B.).

→ Remove 1 screw. [56]

(P.C.B. to bottom frame)

→ Remove 2 screws. [57]

(P.C.B. to bottom frame)

→ Remove FRONT (2) P.C.B..

CDX-497/CDX-397

• Cable Connections

CN41

(FRONT (2) P.C.B.)

FRONT (2) P.C.B.

BN41

FRONT (1) P.C.B.

CN41

(MAIN (1) P.C.B.)

CN21

MAIN (2) P.C.B.

MAIN (1) P.C.B.

CN22CN23

CN52

(FRONT (1) P.C.B.)

CDX-E410

CN52 (MAIN (1) P.C.B.)

CD Mechanism

7

CDX-E410

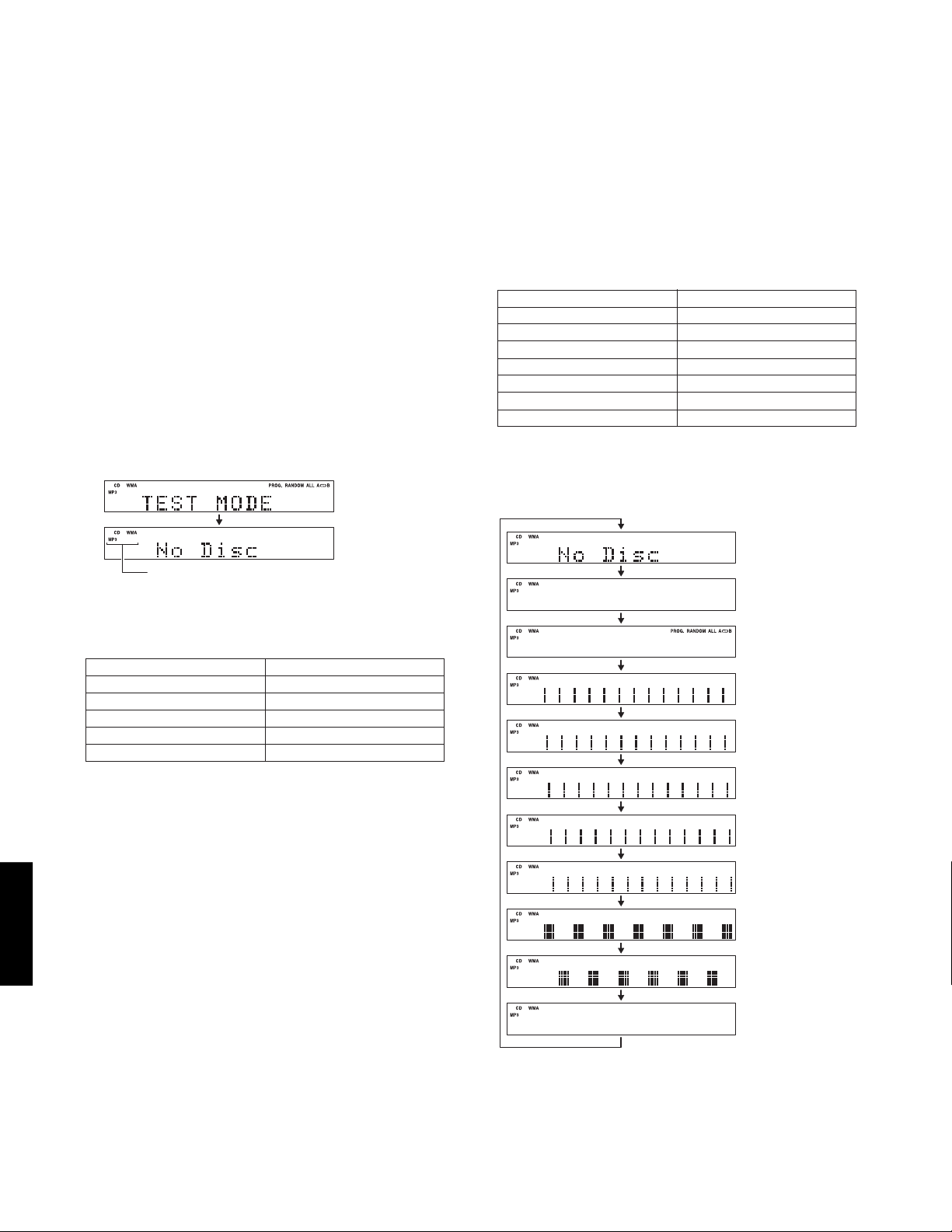

■ TEST MODE

With CDX-E410 alone, it is not possible to start the TEST mode.

Be sure to prepare, receiver (RX-E410), system control cable and remote control.

Preparation and precautions before starting the operation

Connect the “TO RX-E410” terminal of the CDX-E410 to the “TO CDX-E410” terminal of the RX-E410 with the system

control cable.

• Starting Test Mode

a. Connect the power cable of CDX-E410 and RX-

E410 to the AC outlet.

b. Press the “STANDBY/ON” key of the CDX-E410.

RX-E410 and CDX-E410 will start up.

c. Press the “FILE/A-E” key of the remote control while

simultaneously pressing “STOP” key of the CDXE410.

When in the TEST mode, the “TEST MODE” is displayed for 2 seconds.

2 seconds

Starting

TEST mode

This part is always displayed

when in the TEST mode.

2. Function list of remote control keys.

Panel key Function

WW

W

(PLAY)

WW

DD

D (PAUSE)

DD

AA

A

(STOP)

AA

TT

T

(SKIP-)

TT

YY

Y (SKIP+)

YY

TIME/INFO

RANDOM

*1 Check FL display

The display condition varies as shown below according to the “TIME/INFO” key of the remote control.

Playback.

Pause.

Stop.

Move traverse reverse.

Move traverse forward.

Check FL display. (*1)

Spindle servo on/off.

Initial display

Icon (left)

1. Function list of panel keys.

Panel key Function

FF

F (OPEN/CLOSE)

FF

WW

DD

W /

D (PLAY/PAUSE)

WW

DD

AA

A (STOP)

AA

TT

EE

T /

E (SKIP-/SEARCH-)

TT

EE

RR

YY

R /

Y (SKIP+/SEARCH+)

RR

YY

CDX-E410

• Canceling Test Mode

Press the “STANDBY/ON” key of the CDX-E410.

Tray open/close.

Playback/Pause.

Stop.

Move traverse reverse.

Move traverse forward.

Icon (right)

Pattern 1

Pattern 2

Pattern 3

Pattern 4

Pattern 5

Pattern 6

Pattern 7

Icon (left)

8

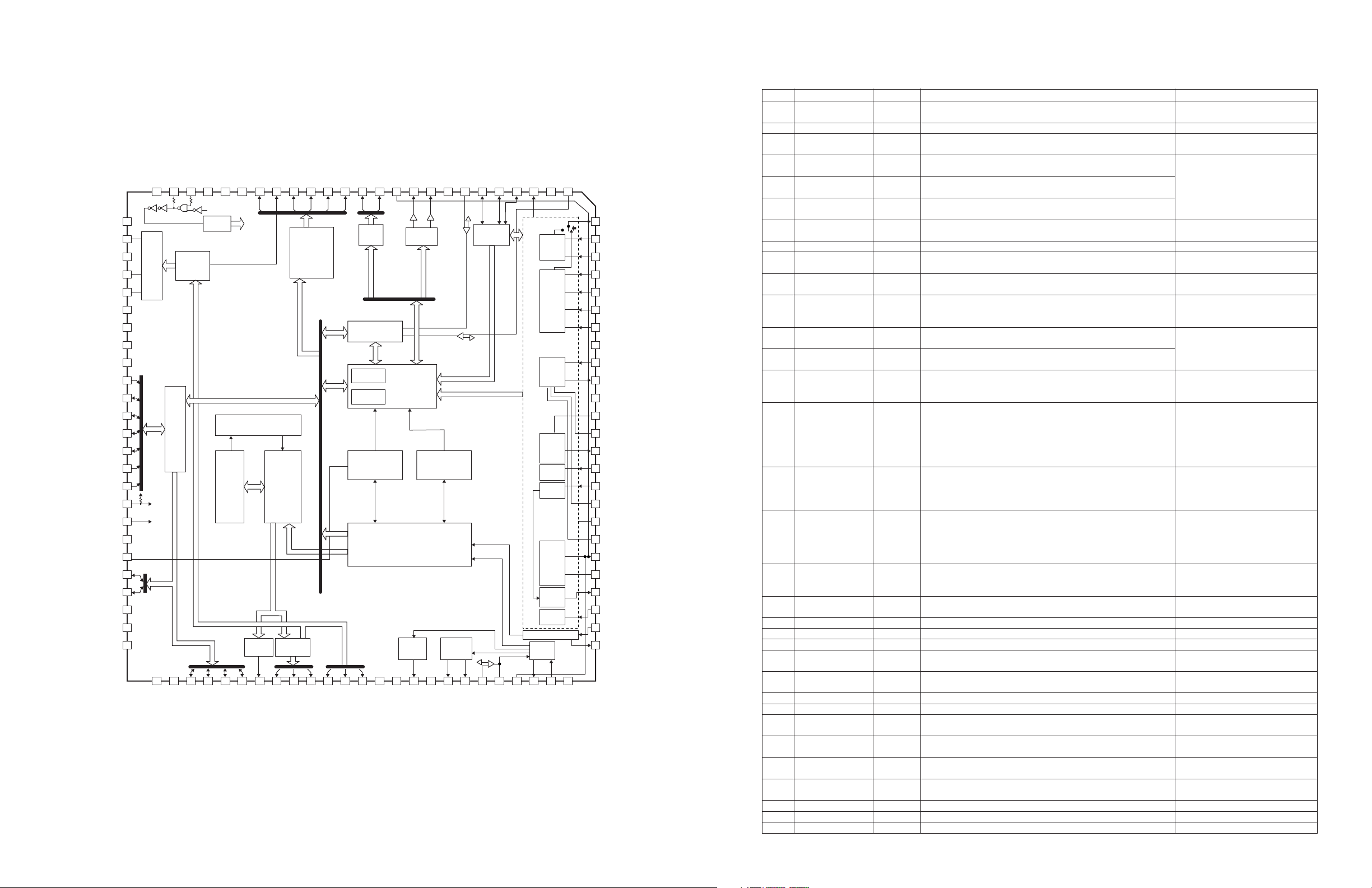

■ IC DATA

IC21 : TC94A54 (MAIN P.C.B)

DSP

* No replacement part available.

DVSS3

RO

DVDD3

DVR

LO

DVSS3

VSS3

VDD3

VDDM

VSS1S

BUS0

BUS1

BUS2

BUS3

BUCK

/CCE

/RST

STBY

VDDT

FGIN

IO0

IO1

TESTD

VSSP

VCOI

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

XVDD3XOXI

ANA

LPF

PULL-UP

VDDP

CPU

I/F

TESTC

1-bit

DAC

PIO0

XVSS3

CLOCK

GEN

PIO1

VDD1

VSS1S

GPIN

ZDET

ADRRESS CIRCUIT

16k

DIGITAL

OUT

PIO3

DOUT

RAM

AUDIO

OUT

AOUT

CIRCUIT

CORRECTION

PIO2

SFSY

IPF

SUBCODE

DEMOCULA

TION

CDRCUIT

BCKO

LRCKO

SBSY

SBOK

AIN

DMO

PMO

PWM

SERVO

CONTROL

ROM

DIGITAL EQ

AUTO ADJ

RAN

CAV SERVO

SYNC SIGNAL PROTECTION

EFM DEMODULATION

BCKI

LRCKI

VDD1S

VREF

5-bit

R-2R DAC

AWRC

VSS1S

TRO

FOO

CLV SERVO

TMAX

AWRC

PVDD3

AVDD3

PLL

PDO

TEZI

TEI

10-bit

SAR ADC

LPPN

TMAX

SBAD/RFDC

FEI

RFRP

RF

BLOCK

EFM SLICE

VCO

LPFO

PVREF

VCOF

AVSS3

TE

FE

APC

RF

RFDC

AGC

VRO

RFEQ

RFRP

VCOREF

RFZI

12345678910111213141516171819202122232425

75747372717069686766656463626160595857565554535251

PVSS3

100

99

98

97

96

95

94

93

92

91

90

89

88

87

86

85

84

83

82

81

80

79

78

77

76

FTE

TNI

TPI

FPI1

FPI2

PNI1

PNI2

RVSS3

MDI

LDO

RVDD3

PNSEL

RFO

Pin No. Pin name Description Remark

1

2

3

RFZI

AVSS3

RFRP

I/O

I

3AI/F

–

O

Input pin for the RF ripple zero-cross signal.

Grounding pin for 3.3V analog circuits.

RF ripple signal output pin.

To be connected to the RFRP via

0.033 uF.

–

–

3AI/F

4

FEI

O

Focus error signal input pin.

3AI/F

5

SBAD/RFDC

O

Subbeam addition signal input pin.

Monitor pin for various signals.

3AI/F

6

TEI

O

Tracking error signal input pin.

3AI/F

7

TEZI

I

Input pin for tracking error signal zero-cross.

3AI/F

8

9

AVDD3

FOO

–

Supply voltage pin for 3.3V analog circuit.

O

Forcus equalizer output pin.

To be connected to the TEI via

0.033 uF.

–

–

3AI/F

10

TRO

O

Tracking equalizer output pin.

–

3AI/F

11

VREF

O

3AI/F

Analog reference supply voltage pin.

Connected to the VRO and

PVREF within the IC.

To be connected 0.1 uF.

12

13

FMO

DMO

O

3AI/F

O

Speed error/feed equalizer output pin.

Disc equalizer output pin.

PWM ternary output (AVDD3,

GND, and VREF).

3AI/F

14

SBSY

(SPCK)

O

3I/F

Pin for outputting the subcode block sync signal. It is “H” at

position S1 when the subcode sync signal is detected.

“H” at S1 when Subcode Sync is

detected.

(CD Processor Status Read Clock (176.4 kHz) output)

15

SBOK

(FOK)

(CLCK)

(MBOV)

O

3I/F

Pin for outputting the CRCC check result of a subcode Q data

check. It is “H” when the check result is OK.

(Focus OK signal)

(Input/output pin for the clock used in reading the subcode P

–

to W data.)

(CD Buffer memory overflow output)

16

IPF

(SPDA)

O

3I/F

Correction flag output pin.

“H” if the AOUT pin outputs an uncorrectable symbol in C2

–

correction.

(CD Processor Status signal output)

17

18

19

20

21

22

23

SFSY

(EMPH)

(LOCK)

(MONIT)

ZDET

(DATA)

(COFS)

GPIN

VSS1

VDD1

XVSS3

XI

O

3I/F

O

3I/F

I/O

3I/F

–

–

–

I

Pin for outputting the playback frame sync signal.

(Emphasis fiag output pin. ENPH on: “H”. EMPH off: “L”. The

output polarity can be switched, using a command.)

(LOCk signal)

(Pin for monitoring signals in the DSP.)

Output pin for zero detection flag for the 1-bit DAC.

(Pin for outputting subcode P to W data)

(Error Correstion Frame Clock 7.35 kHz output)

General-purpose I/O (DSP)

1.5V grounding pin dedicated to the Digital circuit.

1.5V supply voltage pin dedicated to the Digital circuit.

Grounding pin for the system clock oscillation circuit.

Input pin for the system clock oscillation circuit.

7.35kHz (At this pin, flags in the

DSP and PLL-circuit clock can be

monitored, using microcontroller

commands. The pin also outputs

text data serially.)

Valid also for 1-bit DAC external

inputs.

General-purpose I/O (input after a

reset).

–

–

–

–

3AI/F

24

XO

O

Output pin for the system clock oscillation circuit.

Input to the internal MCK.

3AI/F

25

26

27

28

XVDD3

DVSS3

RO

DVDD3

–

–

O

3AI/F

–

3.3V supply voltage pin for the system clock oscillation circuit.

Grounding pin for the 1-bit DAC.

Output pin for normal R-channel data for the 1-bit DAC.

3.3V supply voltage pin for the 1-bit DAC.

No capacitor is required at the

DVR pin unless the built-in 1-bit

DAC is used.

–

–

3.3V must be applied across the

29

DVR

O

Reference voltage pin for the 1-bit DAC.

DVDD3 and DVSS3 pins, however.

30

LO

O

Output pin for normal L-channel data for the 1-bit DAC.

–

3AI/F

31

32

33

DVSS3

VSS3

VDD3

–

Grounding pin for the 1-bit DAC.

–

3.3V grounding pin dedicated to the I/F circuit

–

3.3V supply voltage pin dedicated to the I/F circuit.

–

–

CDX-E410

9

CDX-E410

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

VDDM

VSS1

BUS0

BUS1

BUS2

BUS3

BUCK

/CCE

/RST

STBY

VDDT

FGIN

IO0A

(/HSO)

IO1A

(/UHSO)

TESTD

VSSP

VCOI

VDDP

TESTC

PIO0

PIO1

PIO2

PIO3

DOUT

AOUT

BCK

LRCK

AIN

BCKI

LRCKI

VDD1

VSS1

AWRC

PVDD3

PDO

TMAX

–

–

I/O

3I/F

I/O

3I/F

I/O

3I/F

I/O

3I/F

I

3I/F

I

3I/F

I

3I/F

I

3I/F

–

I

3AI/F

I/O

3I/F

I/O

3I/F

I

3I/F

–

O

1.5AI/F

–

I

3I/F

I/O

3I/F

I/O

3I/F

I/O

3I/F

I/O

3I/F

O

3I/F

O

3I/F

O

3I/F

O

3I/F

I

3I/F

I

3I/F

I

3I/F

–

–

O

3AI/F

–

O

3AI/F

O

3AI/F

1.5V supply voltage pin dedicated to the DSP/1Mbit SRAM

circuit.

1.5V groundind pin dedicated to the DSP/1Mbit SRAM circuit.

Data input/output pin for the microcontroller interface.

Clock input pin for the microcontroller interface.

Chip enable signal input pin for the microcontroller interface.

BUS3 to BUS0 are active if this pin is “L”.

Reset signal input pin. The internal registers and servo section

registers are reset, respectively, when the reset signal is “L”

and on the positive-going edge of the reset signal.

STANDBY control pin dedicated to the DSP/1Mbit SRAM

circuit.

3.3V supply voltage pin dedicated to the Digital I/O circuit.

FG signal input pin for CAV.

CLV: “L”. CAV: FG input.

Genelal-purpose input/output pins.

(Pin for outputting the playback speed mode flag.)

DSP/Test input pin. Usually fixed at “L”.

1.5V grounding pin dedicated to the DSP/VCO circuit.

PD output pin dedicated to the DSP/VCO circuit.

1.5V supply voltage pin dedicated to the DSP/VCO circuit.

CD/Test input pin. Usually fixed at “L”.

General-purpose I/O (CD/DSP)

General-purpose I/O (CD/DSP)

General-purpose I/O (DSP)

General-purpose I/O (DSP)

Digital-out output pin. Digital data for up to double speed can

be output when a frequency of 16.9344 MHz is used.

Audio data output pin. Which bit is first (MSB first or LSB first)

can be selected, using a command.

Bit clock output pin. 32fs, 48fs, and 64fs can be selected,

using a command.

LR channel clock output pin. L for the L-channel and “H” for

the R-channel. The output polarity can be inverted, using a

command.

1-bit DAC external input: AIN

1-bit DAC external input: BCKI

1-bit DAC external input: LRCKI

1.5V supply voltage pin dedicated to the DSP circuit.

1.5V grounding pin dedicated to the DSP circuit.

VCO control pin for active wide range.

3.3V supply voltage pin dedicated to the PLL circuit.

Pin for outputting a phase difference signal between the EFM

signal and PLCK signal.

Pin for outputting the result of TMAX detection.

The TMAX pin output the same signal.

RemarkPin No. Pin name FunctionPin name

–

–

To be fixed at “H” or “L” when communication is not in progress, so

that the pin will not become HiZ.

To be fixed at “H” when communication is not in progress, so that

the pin will not become HiZ.

To be connected to 0.1 uF.

–

–

–

Genelal-purpose I/O (input after a

reset).

The playback speed mode flag

output can be switched, using

command bits.

–

–

–

–

–

General-purpose I/O (input after a

reset).

As per CP-1201

–

Normal speed: 32fs = 1.4112 MHz

Normal speed: 44.1kHz

1-bit DAC external input

Controllable in CLV/CAV.

–

Quaternary output (PVDD3, HiZ,

VSS, and PVREF).

Ternary output (PVDD3, VSS, and

Hiz).

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

LPFN

LPFO

PVREF

VCOF

VCOREF

PVSS3

SLCO

RFI

RFRPI

RFEQO

RESIN

VRO

VMDIR

TESTR

INVSEL

AGCI

AGCI

RFO

PNSEL

EQSET

RVDD3

LDO

MDI

RVSS3

FNI2

FNI1

FPI2

FPI1

TPI

TNI

FTE

I/OPin No. Pin name Description Remark

I

3AI/F

3AI/F

3AI/F

3AI/F

3AI/F

3AI/F

3AI/F

3AI/F

3AI/F

3AI/F

3AI/F

3AI/F

3AI/F

3AI/F

3AI/F

3AI/F

3AI/F

3AI/F

3AI/F

3AI/F

3AI/F

3AI/F

3AI/F

3AI/F

3AI/F

3AI/F

Pin for receiving an inverted output of the PLL-circuit low-pass

filter amp.

O

Pin for the PLL-circuit low-pass filter amp output.

–

1.65V reference supply voltage pin dedicated to the PLL

circuit.

O

VCO filter pin.

I

Input pin for the VCO center frequency reference level.

–

3.3V grounding pin dedicated to the PLL circit.

O

EFM slice level output pin.

For both analog and digital slice modes, the output impedance

= 2.5 k-ohms.

I

RF signal input pin.

The input resistance can be selected, using a command.

I

RF ripple signal input pin.

O

RF equalizer circuit output pin.

I

Pin for connecting a reference current generating resistance.

O

1.65V reference voltage output pin.

–

Reference voltage poutput pin for the APC circuit.

O

LPF pin for RFEQO offset correction.

I

Test pin, usually fixed at “L”.

I

Pin for RF signal amplitude adjustment amp input.

I

RF signal peak detsction input pin.

O

RF signal generation amp output pin.

I

Test pin, usually fixed at “H”.

O

External connection pin for the RF signal equalizer.

–

3.3V supply voltage pin for the Rfamp core section.

O

Laser diode amp output pin.

I

Monitor photodiode amp input pin.

–

3.3V grounding pin for the RF amp core section.

I

Main beam input pin.

Connected to PIN diode C.

I

Main beam input pin.

Connected to PIN diode A.

I

Main beam input pin.

Connected to PIN diode D.

I

Main beam input pin.

Connected to PIN diode B.

I

Subbeam input pin.

Connected to PIN diode F.

I

Subbeam input pin.

Connected to PIN diode E.

O

Focus /tracking signal output.

(Test pin for servo characteristic measurement.)

Note: “3AI/F : 3V circuit analog input/output pin.”

“3I/F : 3V circuit digital input/output pin.”

“1.5AI/F : 1.5V circuit analog input/output pin.”

The resistance side is connected.

See an applicable circuit diagram.

The capacitor side is connected.

See an spplicable circuit diagram.

Connected to the VREF and PVREF

within the IC.

A 0.1 uF capacitor is connected.

–

To be connected to the PVREF if

the AWRC is not used.

–

A capacitor to be connected is selected according to the servo operation band.

Zin: 20 k-ohms, 10 k-ohms, 5 kohms

–

To be connected to the RFRPI via

0.1 uF and to the RFI via 4700 pF

or higher.

To be connected to 22 k-ohms

and 680 pF in parallel.

Connected to the VREF and

PVREF within the IC

To be connected to 0.1uF anf 100

uF.

To be connected to 0.1uF.

To be connected to 0.015 uF or

higher.

–

–

–

To be connected directly to the

RFDCI.

To ne connected to the AGCI via

0.1 uF.

To be kept open when the RFEQ

is used.

–

Reference to 178 mV (typ.)

–

–

–

–

–

–

–

Switchable using a command.

10

Loading...

Loading...