COMPACT DISC PLAYER

CD-S700

SERVICE MANUAL

IMPORTANT NOTICE

This manual has been provided for the use of authorized YAMAHA Retailers and their service personnel.

It has been assumed that basic service procedures inherent to the industry, and more specifi cally YAMAHA Products, are already known

and understood by the users, and have therefore not been restated.

WARNING:

IMPORTANT:

The data provided is believed to be accurate and applicable to the unit(s) indicated on the cover. The research, engineering, and service

departments of YAMAHA are continually striving to improve YAMAHA products. Modifications are, therefore, inevitable and

specifi cations are subject to change without notice or obligation to retrofi t. Should any discrepancy appear to exist, please contact the

distributor's Service Division.

WARNING:

IMPORTANT:

Failure to follow appropriate service and safety procedures when servicing this product may result in personal injury,

destruction of expensive components, and failure of the product to perform as specifi ed. For these reasons, we advise

all YAMAHA product owners that any service required should be performed by an authorized YAMAHA Retailer or

the appointed service representative.

The presentation or sale of this manual to any individual or fi rm does not constitute authorization, certifi cation or

recognition of any applicable technical capabilities, or establish a principle-agent relationship of any form.

Static discharges can destroy expensive components. Discharge any static electricity your body may have

accumulated by grounding yourself to the ground buss in the unit (heavy gauge black wires connect to this buss).

Turn the unit OFF during disassembly and part replacement. Recheck all work before you apply power to the unit.

■ CONTENTS

TO SERVICE PERSONNEL ........................................2–4

PREVENTION OF ELECTROSTATIC DISCHARGE ......5

FRONT PANEL ...............................................................6

REAR PANELS ...........................................................6–8

REMOTE CONTROL PANEL .......................................... 8

SPECIFICATIONS /

INTERNAL VIEW .......................................................... 10

DISASSEMBLY PROCEDURES /

TEST MODE /

UPDATING FIRMWARE /

ファームウェアの書き込み

101118

参考仕様

テストモード

.........................................9

分解手順

...................................14–15

.....................................16–20

........... 11–13

Copyright © 2008 All rights reserved.

This manual is copyrighted by YAMAHA and may not be copied or

redistributed either in print or electronically without permission.

IC DATA ...................................................................21–26

DISPLAY DATA .............................................................27

PIN CONNECTION DIAGRAMS ...................................28

BLOCK DIAGRAM ........................................................ 29

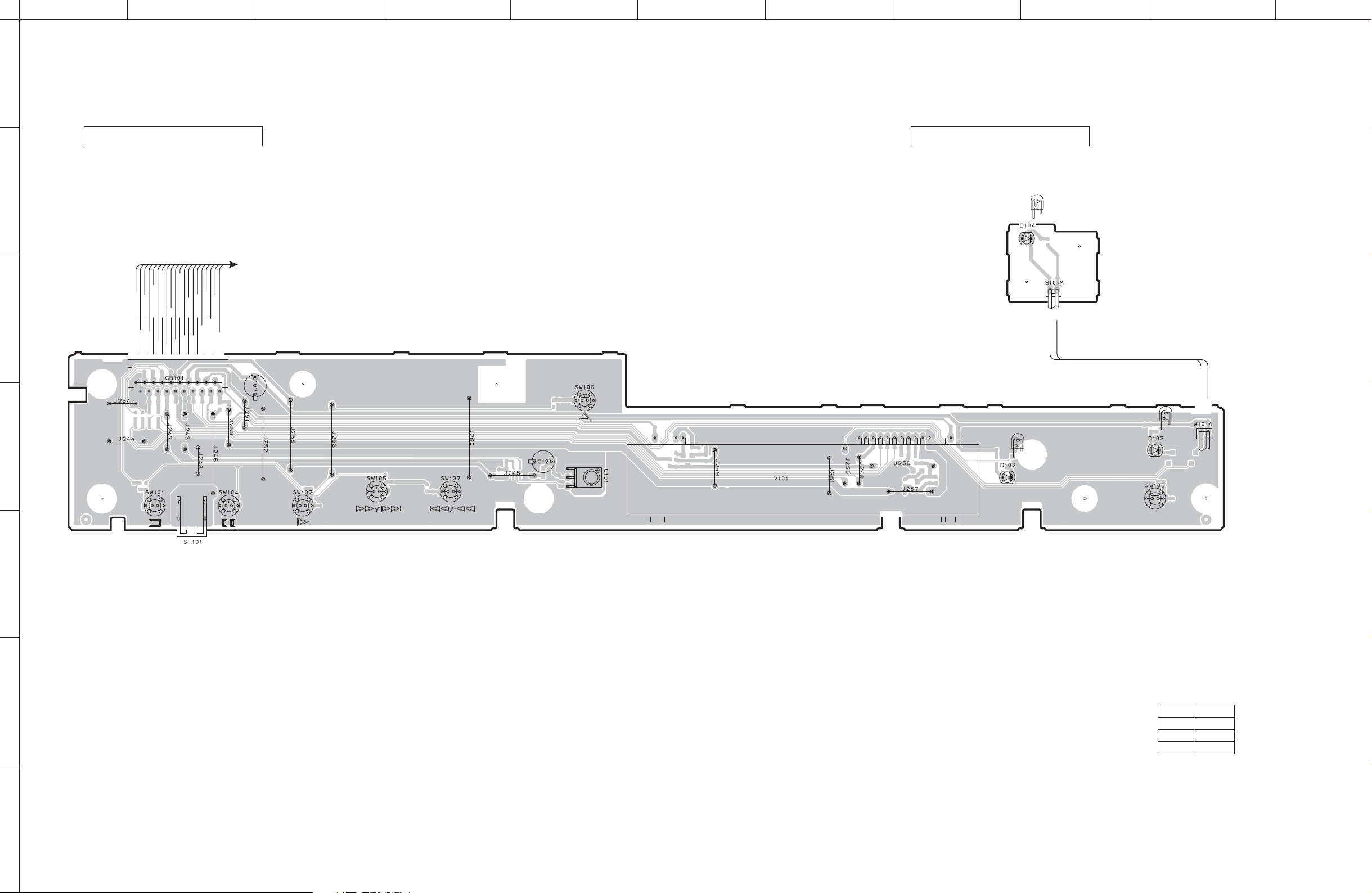

PRINTED CIRCUIT BOARDS .................................30–38

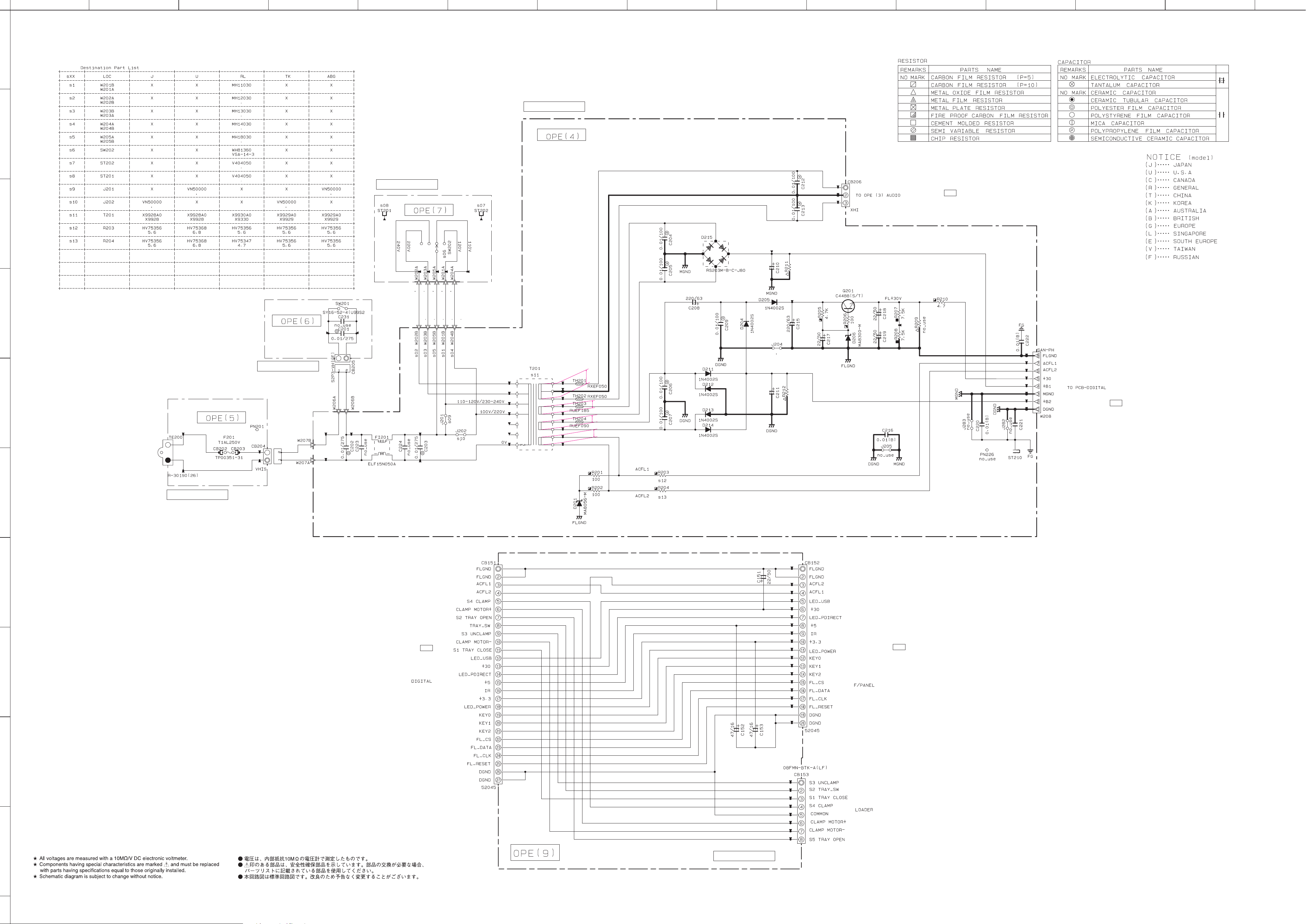

SCHEMATIC DIAGRAMS ....................................... 39–42

REPLACEMENT PARTS LIST ................................ 43–53

REMOTE CONTROL ...............................................54–55

P.O.Box 1, Hamamatsu, Japan

animate '08.10

CD-S700

CD-S700

■ TO SERVICE PERSONNEL

1. Critical Components Information

Components having special characteristics are marked ⚠ and

must be replaced with parts having specifications equal to those

originally installed.

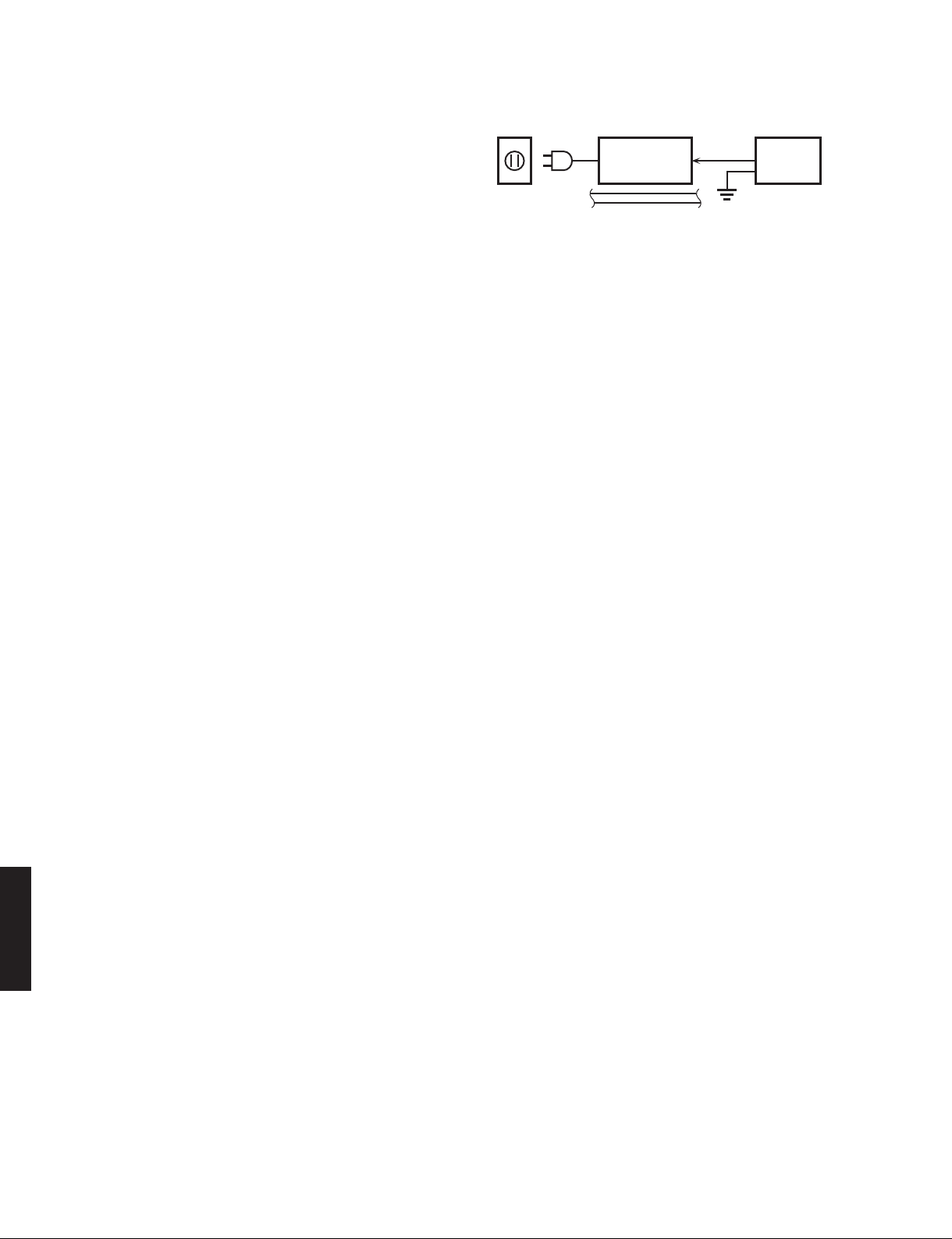

2. Leakage Current Measurement (For 120V Models Only)

When service has been completed, it is imperative to verify

that all exposed conductive surfaces are properly insulated

from supply circuits.

• Meter impedance should be equivalent to 1500 ohms shunted

by 0.15 μF.

WALL

OUTLET

• Leakage current must not exceed 0.5mA.

• Be sure to test for leakage with the AC plug in both polarities.

EQUIPMENT

UNDER TEST

INSULATING

TABLE

AC LEAKAGE

TESTER OR

EQUIVALENT

WARNING: CHEMICAL CONTENT NOTICE!

This product contains chemicals known to the State of California to cause cancer, or birth defects or other reproductive

harm.

DO NOT PLACE SOLDER, ELECTRICAL/ELECTRONIC OR PLASTIC COMPONENTS IN YOUR MOUTH FOR ANY REASON

WHATSOEVER!

Avoid prolonged, unprotected contact between solder and your skin! When soldering, do not inhale solder fumes or

expose eyes to solder/flux vapor!

If you come in contact with solder or components located inside the enclosure of this product, wash your hands before

handling food.

About lead free solder /

All of the P.C.B.s installed in this unit and solder joints are

soldered using the lead free solder.

Among some types of lead free solder currently available,

it is recommended to use one of the following types for

the repair work.

• Sn + Ag + Cu (tin + silver + copper)

• Sn + Cu (tin + copper)

• Sn + Zn + Bi (tin + zinc + bismuth)

Caution:

As the melting point temperature of the lead free solder

is about 30°C to 40°C (50°F to 70°F) higher than that of

無鉛ハンダについて

本機に搭載されているすべての基板およびハンダ付けに

よる接合部は無鉛ハンダでハンダ付けされています。

無鉛ハンダにはいくつかの種類がありますが、修理時に

は下記のような無鉛ハンダの使用を推奨します。

Sn+Ag+Cu(錫+銀+銅)

Sn+Cu(錫 + 銅)

Sn+Zn+Bi(錫 + 亜鉛 + ビスマス)

注意:

無鉛ハンダの融点温度は通常の鉛入りハンダに比べ 30 〜

40℃程度高くなっていますので、それぞれのハンダに合っ

たハンダごてをご使用ください。

the lead solder, be sure to use a soldering iron suitable

to each solder.

CD-S700

2

CD-S700

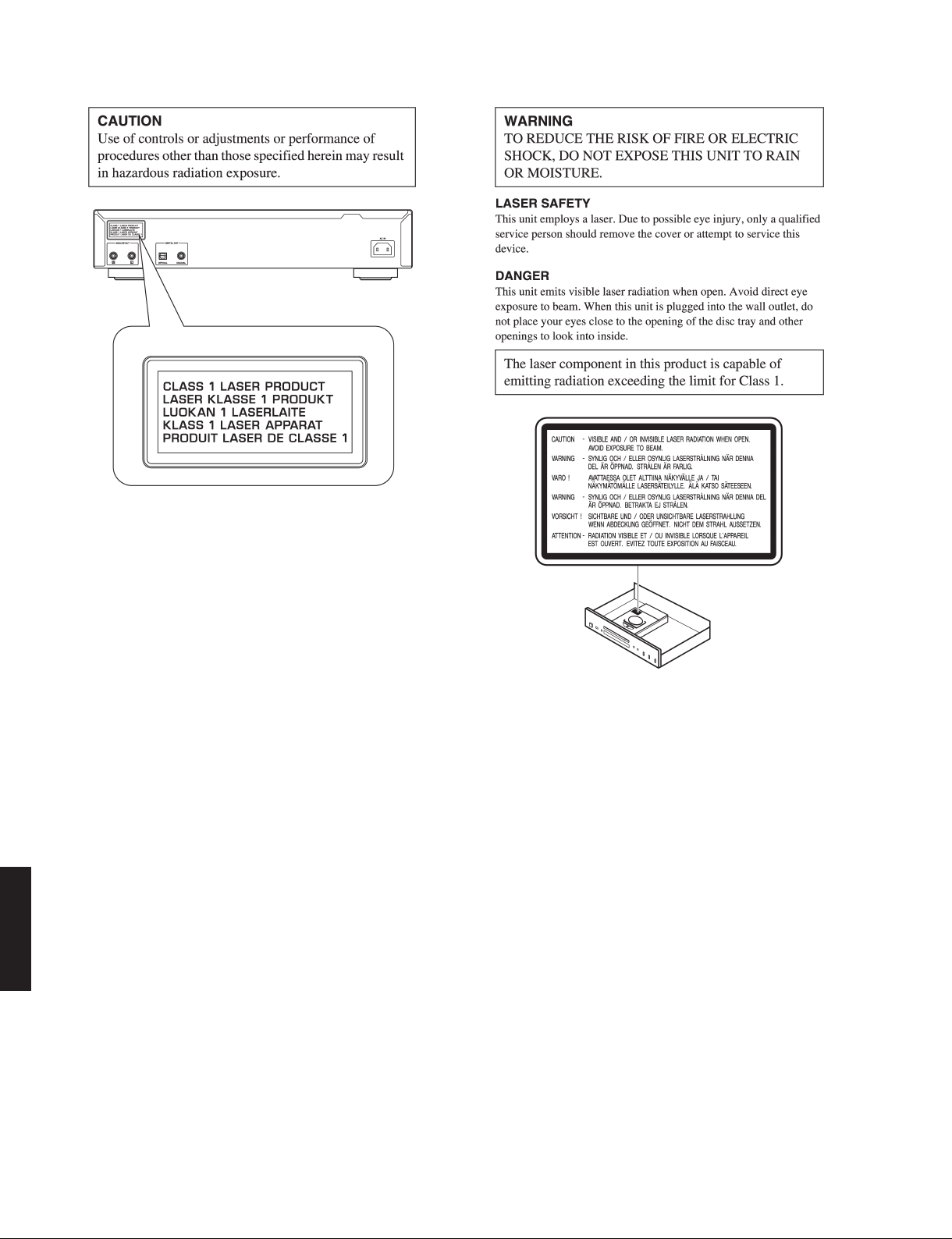

WARNING: Laser Safety

This product contains a laser beam component. This

component may emit invisible, as well as visible radiation, which may cause eye damage. To protect your

eyes and skin from laser radiation, the following precautions must be used during servicing of the unit.

1) When testing and/or repairing any component within

the product, keep your eyes and skin more than

30 cm/1 feet away from the laser pick-up unit at all

times. Do not stare at the laser beam at any time.

2) Do not attempt to readjust, disassemble or repair the

laser pick-up, unless noted elsewhere in this manual.

3) CAUTION: Use of controls, adjustments or performance of procedures other than those specified herein

may result in hazardous radiation exposure.

Laser Emitting conditions:

1) When the Top Cover is removed, and the STANDBY/

ON SW is turned to the “ON” position, the laser component will emit a beam for several seconds to detect if a disc is present. During this time (5-10 sec.)

the laser may radiate through the lens of the laser

pick-up unit. Do not attempt any servicing during this

period!

If no disc is detected, the laser will stop emitting the

beam. When a disc is loaded, you will not be exposed to any laser emissions.

2) The laser power level can be adjusted with the VR

on the pick-up PWB, however, this level has been set

by the factory prior to shipping from the factory. Do

not adjust this laser level control unless instruction is

provided elsewhere in this manual. Adjustment of this

control can increase the laser emission level from the

device.

警告:レーザーの安全対策

本機はレーザー光線を放射する部品を搭載しています。

この部品が放射するレーザー光線は目に損傷を起こしま

す。このレーザー光線から目及び肌を保護するために、

本機の修理作業中は下記の注意を厳守してください。

1) テスト時または修理時、目及び肌を光ピックアップか

ら 30cm 以上離してください。いかなる場合もレー

ザー光線を見つめないでください。

2) 光ピックアップの再調整及び分解はしないでくださ

い。

3) このマニュアル上で指定されている以外の制御、調整、

手順はレーザー光線を照射される結果を招く恐れがあ

ります。

レーザー放射条件

1) トップカバーを取り外し STANDBY/ON スイッチを ON

にすると、ディスク検知のため5〜10秒間、光ピッ

クアップからレーザー光線が放射されます。この間、

修理はしないでください。

ディスクが検知されなければ、レーザー光線の放射は

停止します。ディスクがセットされている場合、ディ

スクで遮られるのでレーザー光線は修理担当者に届き

ません。

2) レーザーパワーレベルは光ピックアップ基板上の VR

により調整可能ですが、工場出荷前に調整セット済み

なので、この VRは廻さないでください。この VRを廻

すと装置からのレーザー光線の放射レベルが上がる恐

れがあります。

Laser Diode Properties

Material: GaAlAs

Wavelength: 790 nm

Laser Output: max. 1.23 μW *

* This output is the value measured

at a distance of about 200 mm from

the objective lens surface on the

Optical Pick-up Block.

レーザー

レーザータイプ:GaAlAs

波長: 790nm

レーザー出力: 最大 1.23 μ W

CD-S700

3

CD-S700

Warning for power supply

The primary side of the power supply carries live mains voltage when the player is connected to the mains even

when the player is switched off !

This primary area is not shielded so it is possible to accidentally touch copper tracks and/or components when servicing

the player.

Service personnel have to take precautions to prevent touching this area or components in this area.

Note:

The screws on the DVD mechanism may never be touched, removed or re-adjusted.

Handle the DVD mechanism with care when the unit has to be exchanged!

The DVD mechanism is very sensitive for dropping or giving shocks.

CD-S700

4

CD-S700

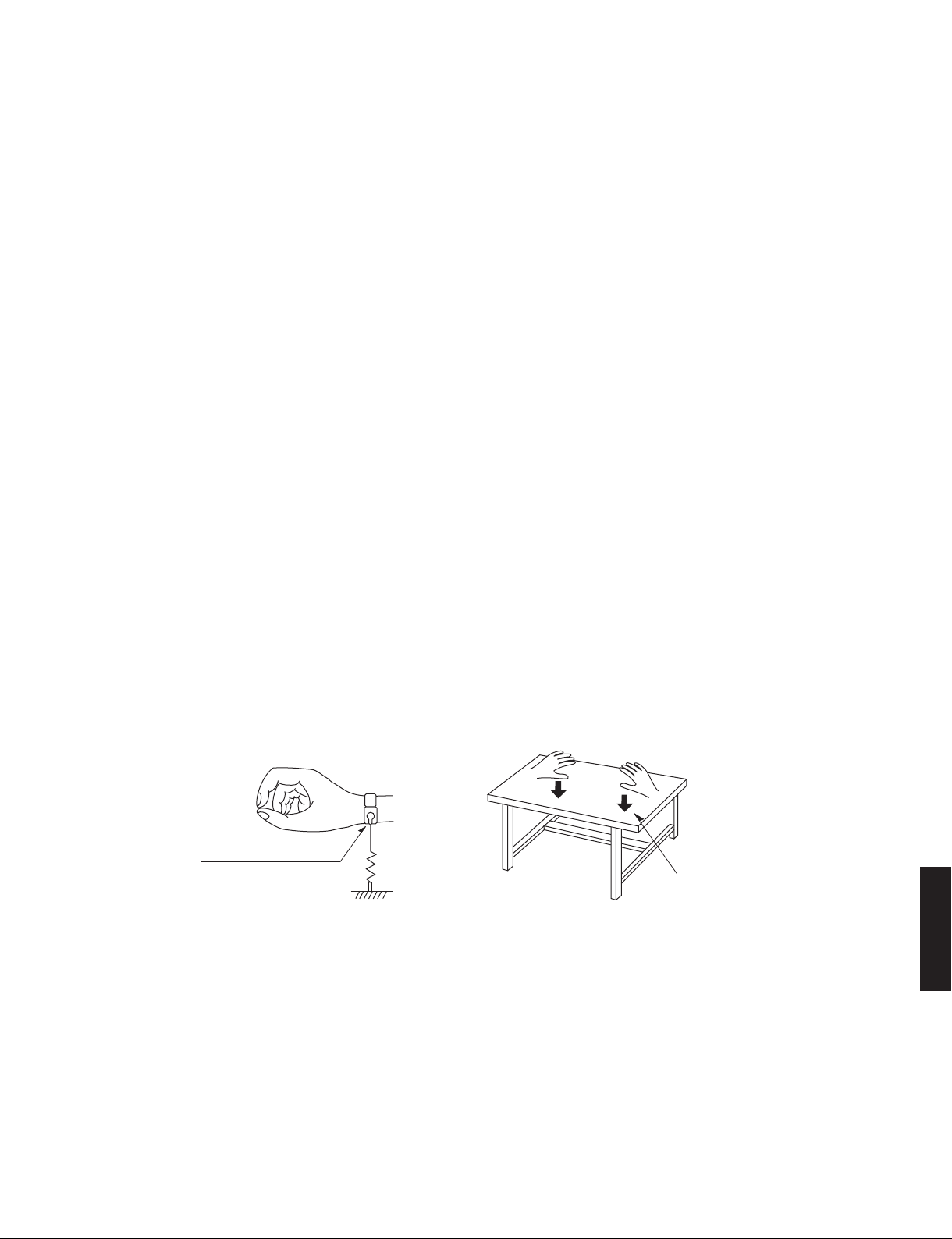

■ PREVENTION OF ELECTROSTATIC DISCHARGE

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such components commonly are

called Electrostatically Sensitive (ES) Devices. Examples of typical ES devices are integrated circuits and some field-effect

transistors and semiconductor “chip” components. The following techniques should be used to help reduce the incidence

of component damage caused by electro static discharge (ESD).

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off any ESD

on your body by touching a known earth ground. Alternatively, obtain and wear a commercially available discharging

ESD wrist strap, which should be removed for potential shock reasons prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ES devices, place the assembly on a conductive surface such as

aluminum foil, to prevent electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only an anti-static solder removal device. Some solder removal devices not classified as “anti-static (ESD protected)” can generate electrical charge sufficient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are ready to install it.

(Most replacement ES devices are packaged with leads electrically shorted together by conductive foam, aluminum foil

or comparable conductive material).

7. Immediately before removing the protective material from the leads of a replacement ES divice, touch the protective

material to the chassis or circuit assembly into which the device will be installed.

CAUTION: Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged replacement ES devices. (Otherwise harmless motion such as

brushing together of your fabric clothes or lifting of your foot from a carpeted floor can generate static electricity (ESD)

sufficient to damage an ES device).

Grounding for electrostatic breakdown prevention

1. Human body grounding.

Use the antistatic wrist strap to discharge the static electricity from your body.

2. Work table grounding.

Put a conductive material (sheet) or steel sheet on the area where the optical pickup is placed and ground the sheet.

Caution:

The static electricity of your clothes will not be grounded through the wrist strap. So take care not to let your clothes touch

the optical pickup.

Anti-static wrist strap

1M-ohms

Conductive material

(sheet) or steel sheet

CD-S700

5

CD-S700

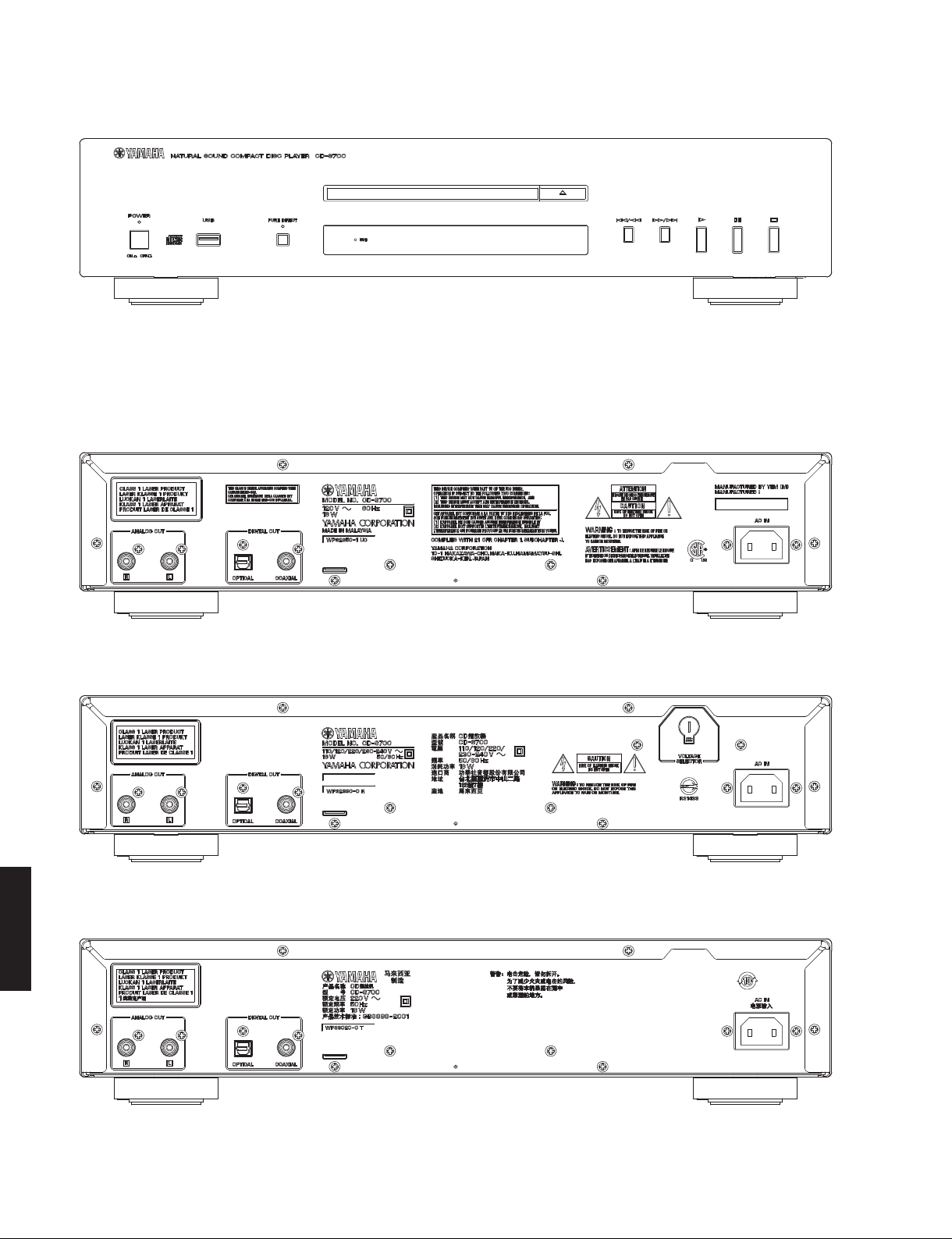

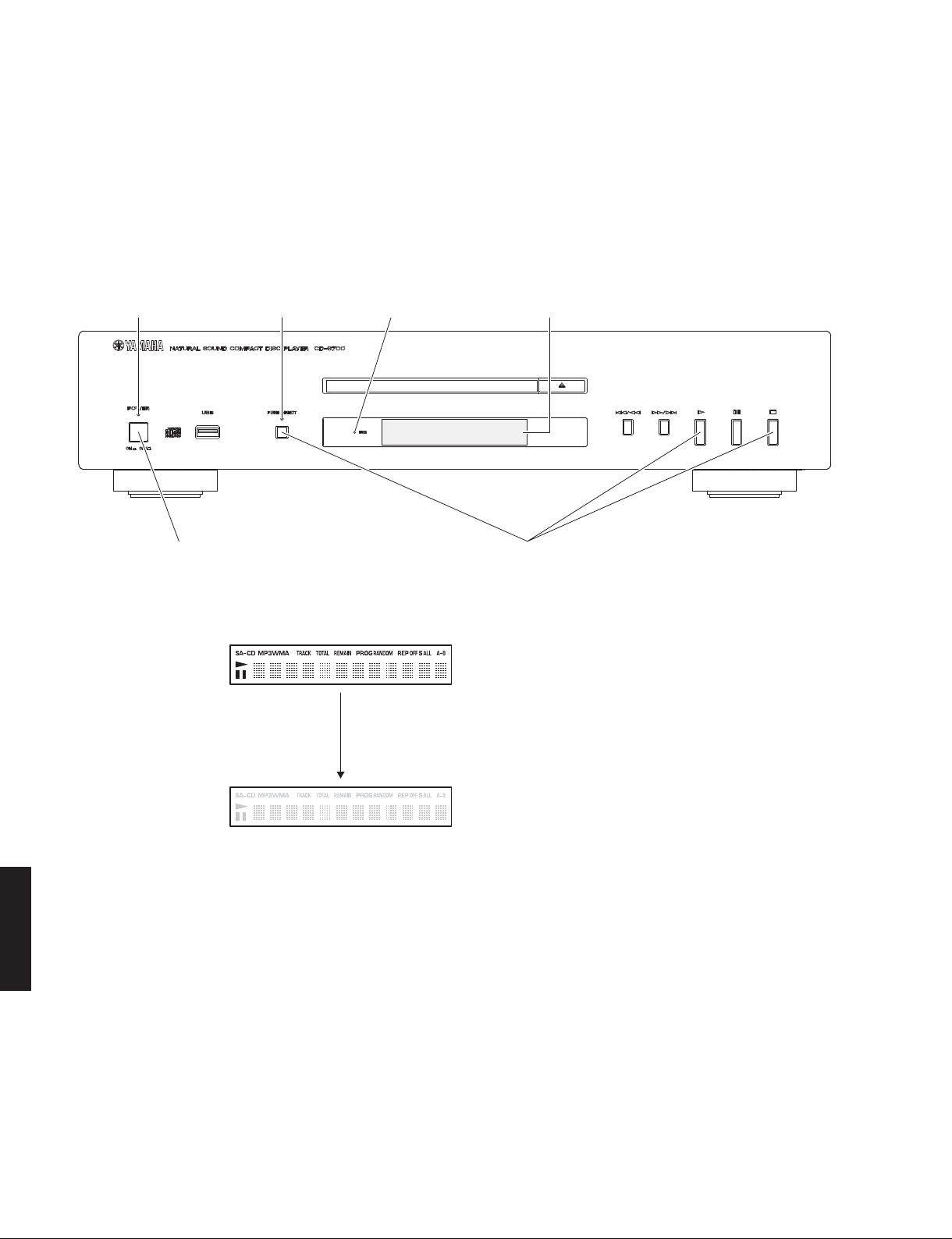

■ FRONT PANEL

CD-S700 (U, R, T, K, A, B, G, L, J models)

■ REAR PANELS

CD-S700 (U model)

CD-S700 (R model)

CD-S700 (T model)

CD-S700

6

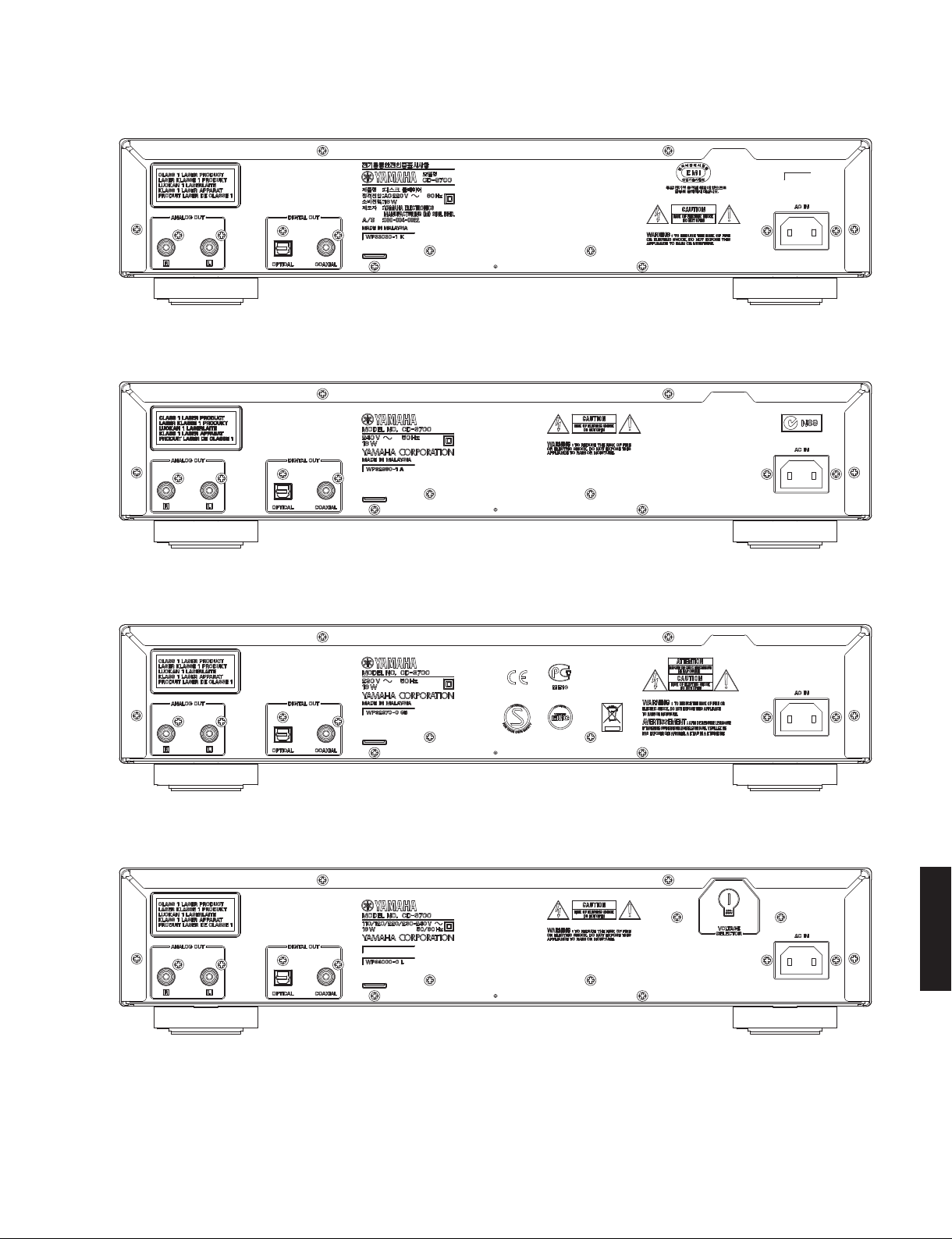

CD-S700 (K model)

CD-S700 (A model)

CD-S700

CD-S700 (B, G models)

CD-S700 (L model)

CD-S700

7

CD-S700

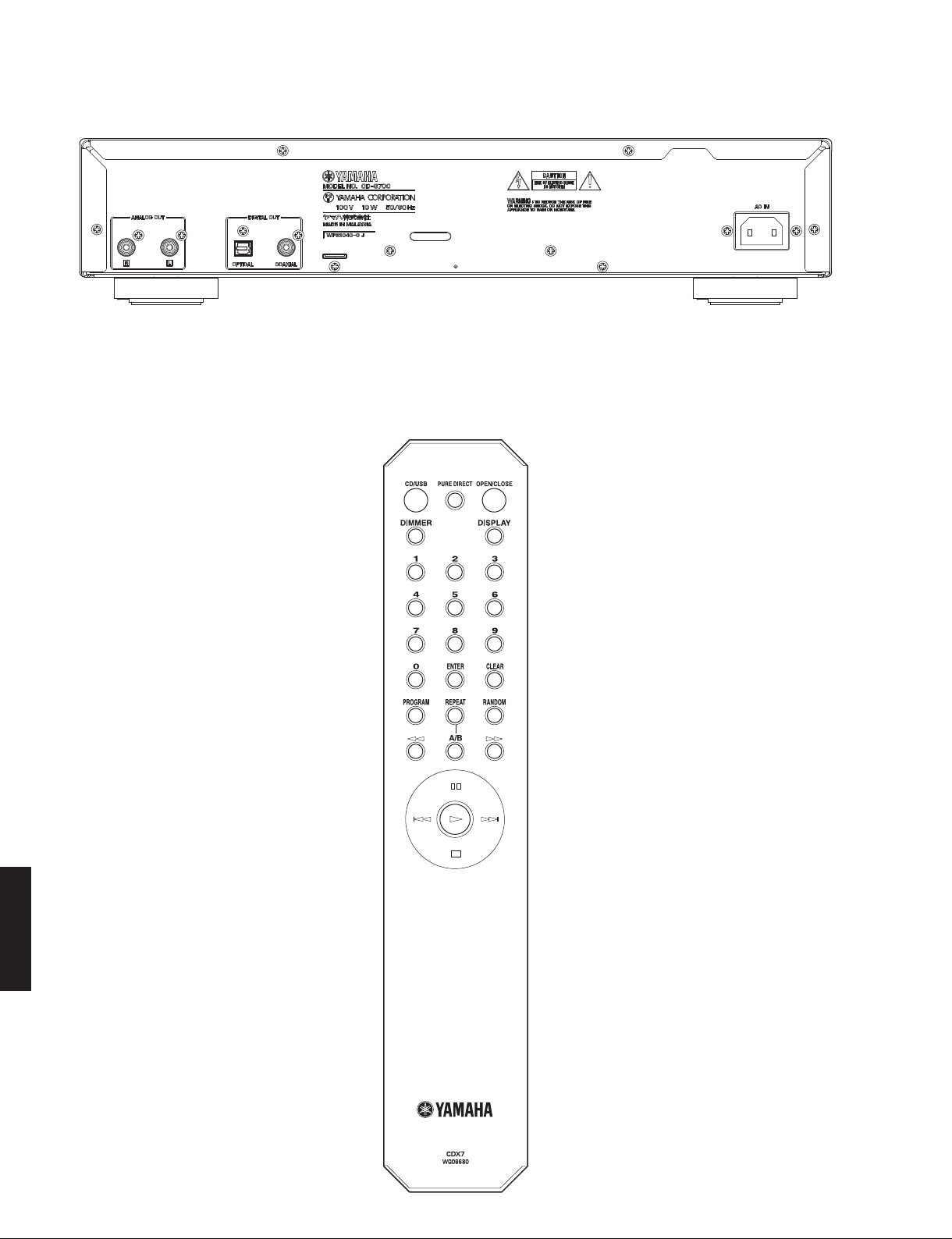

CD-S700 (J model)

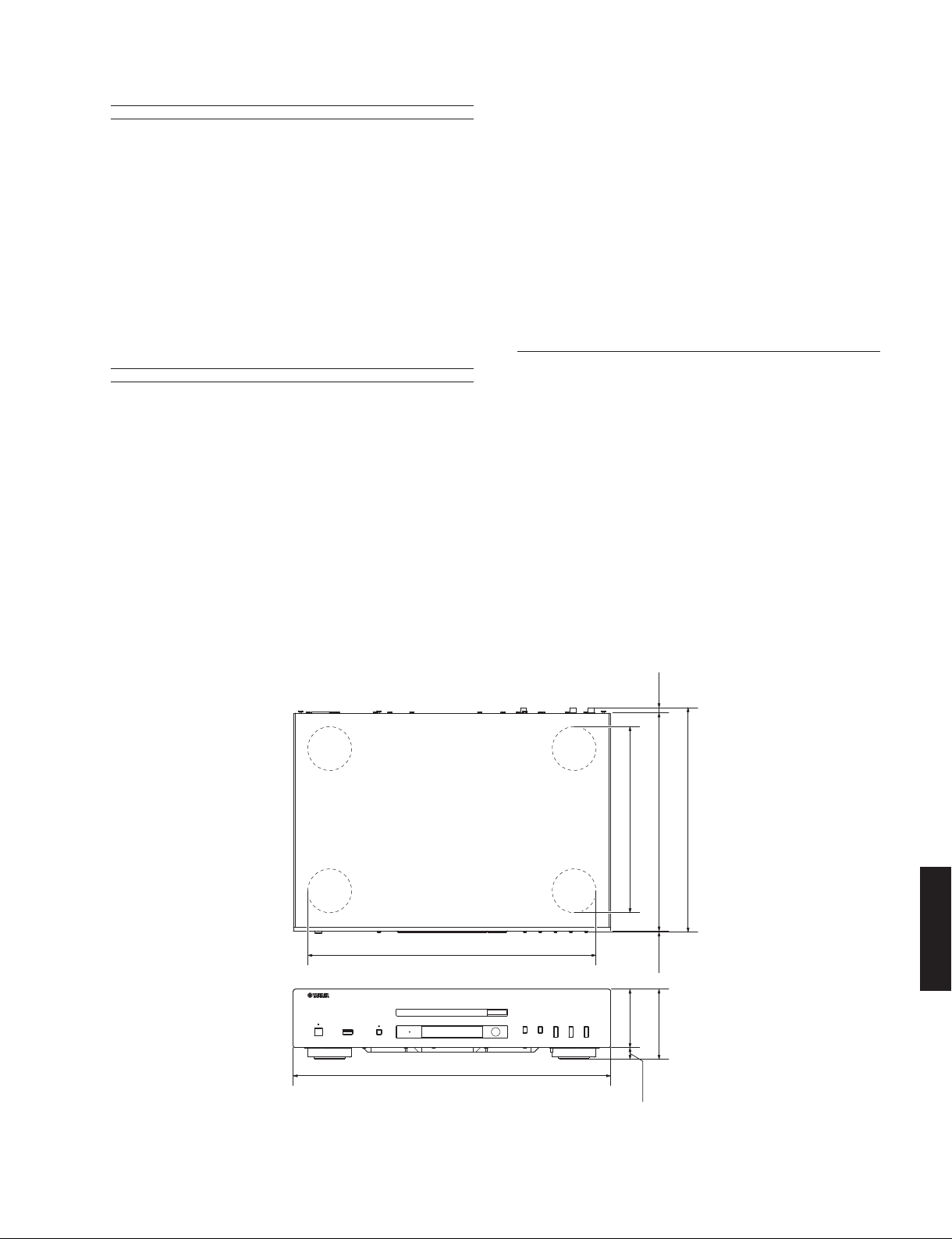

■ REMOTE CONTROL PANEL

CDX-7

CD-S700

8

CD-S700

■ SPECIFICATIONS /

■ Audio Section /

Output Level /

オーディオ部

出力レベル

(1 kHz, 0 dB)

参考仕様

................................................................................. 2 ±0.3 V

Signal to Noise Ratio /

信号対雑音比

......................................................................110 dB or more

Dynamic Range /

ダイナミックレンジ

......................................................................100 dB or more

Harmonic Distortion / 歪率 (1 kHz)

......................................................................0.002 % or less

Frequency Response /

周波数特性

...................................................................... 2 Hz to 20 kHz

Digital Output Terminal /

デジタル出力

.........................................................Optical x 1, Coaxial x 1

■ General /

Power Consumption /

総合

消費電力

U, R, T, K, A, B, G, L models ....................................... 16 W

J model .......................................................................... 10 W

Power Supply /

電源電圧

U model ........................................................... AC 120 V, 60 Hz

R, L models ..................... AC 110/120/220/230-240 V, 50/60 Hz

T model ............................................................ AC 220 V, 50 Hz

K model ............................................................ AC 220 V, 60 Hz

A model ............................................................ AC 240 V, 50 Hz

B, G models ..................................................... AC 230 V, 50 Hz

J model ....................................................... AC 100 V, 50/60 Hz

Dimensions (W x H x D) /

寸法(幅 × 高さ × 奥行き)

...................435 x 96 x 300 mm (17-1/8" x 3-3/4" x 11-3/4")

Weight / 質量

...........................................................6.2 kg (13 lbs. 11 oz.)

Finish /

仕上げ

Black color ........................U, R, T, K, A, B, G, L, J models

Silver color ........................U, R, T, K, A, B, G, L, J models

Accessories /

付属品

Remote control ................................................................ x 1

Battery (R6, AA, UM-3) ................................................... x 2

RCA stereo cable (1.5 m) ............................................... x 1

Power cable (2 m) .......................................................... x 1

* Specifications are subject to change without notice due to product

improvements.

※ 参考仕様および外観は予告なく変更されることがあります。

U .... U.S.A. and Canadian models

R ......................... General model

T..........................Chinese model

K ...........................Korean model

A ......................Australian model

B ............................British model

G ...................... European model

L...................... Singapore model

J ........................Japanese model

• DIMENSIONS /

寸法図

395 (15-9/16")

435 (17-1/8")

6

(1/4")

300 (11-3/4")

255 (10-1/16")

4

(3/16")

80 (3-1/8")

96 (3-3/4")

16 (5/8")

310 (12-3/16")

CD-S700

Unit: mm (inch)

単位:mm(インチ)

9

CD-S700

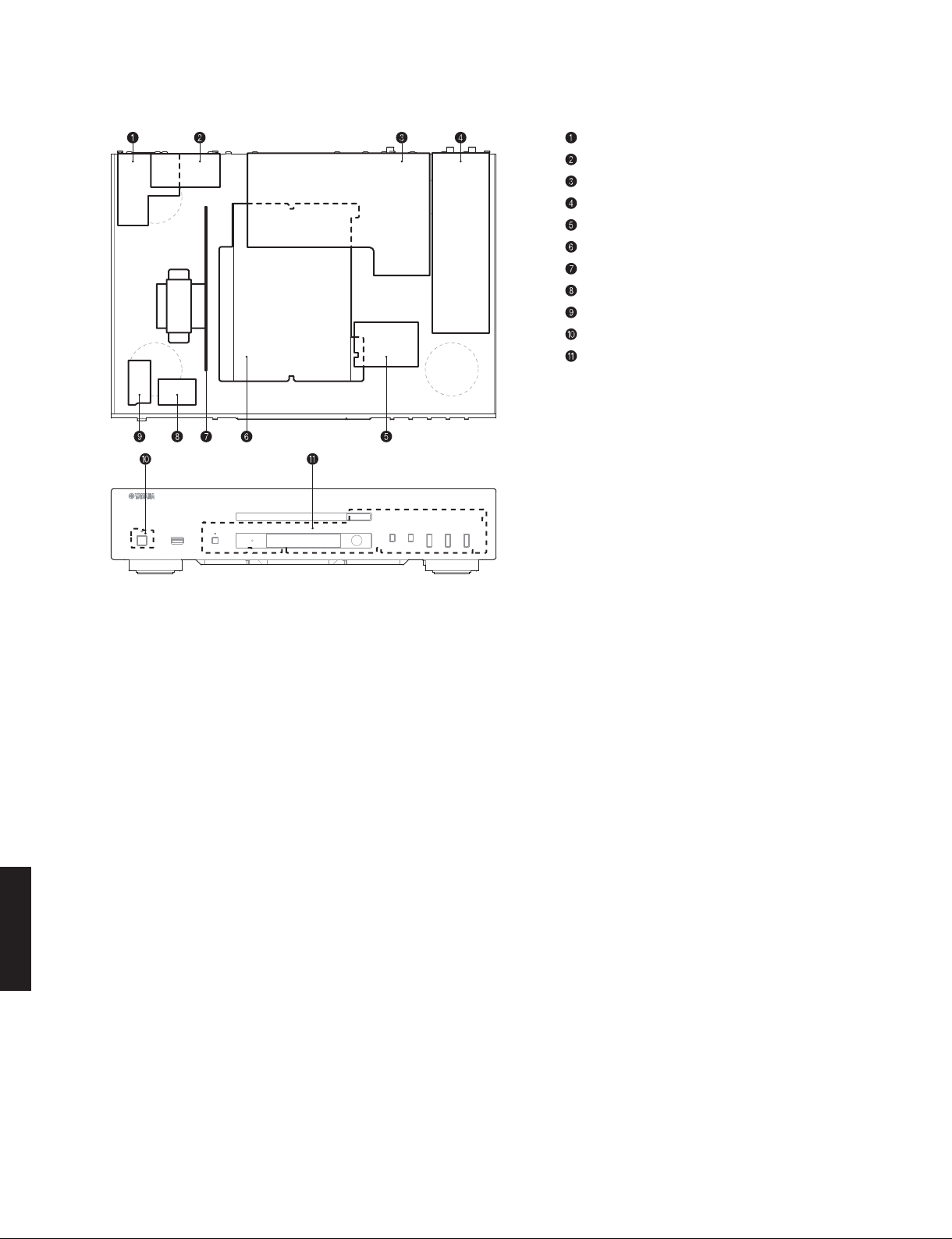

■ INTERNAL VIEW

OPERATION (5) P.C.B.

OPERATION (7) P.C.B. (R, L models)

DIGITAL P.C.B.

OPERATION (3) P.C.B.

OPERATION (9) P.C.B.

Loader Mechanism Ass'y

OPERATION (4) P.C.B.

OPERATION (8) P.C.B.

OPERATION (6) P.C.B.

OPERATION (2) P.C.B.

OPERATION (1) P.C.B.

CD-S700

10

CD-S700

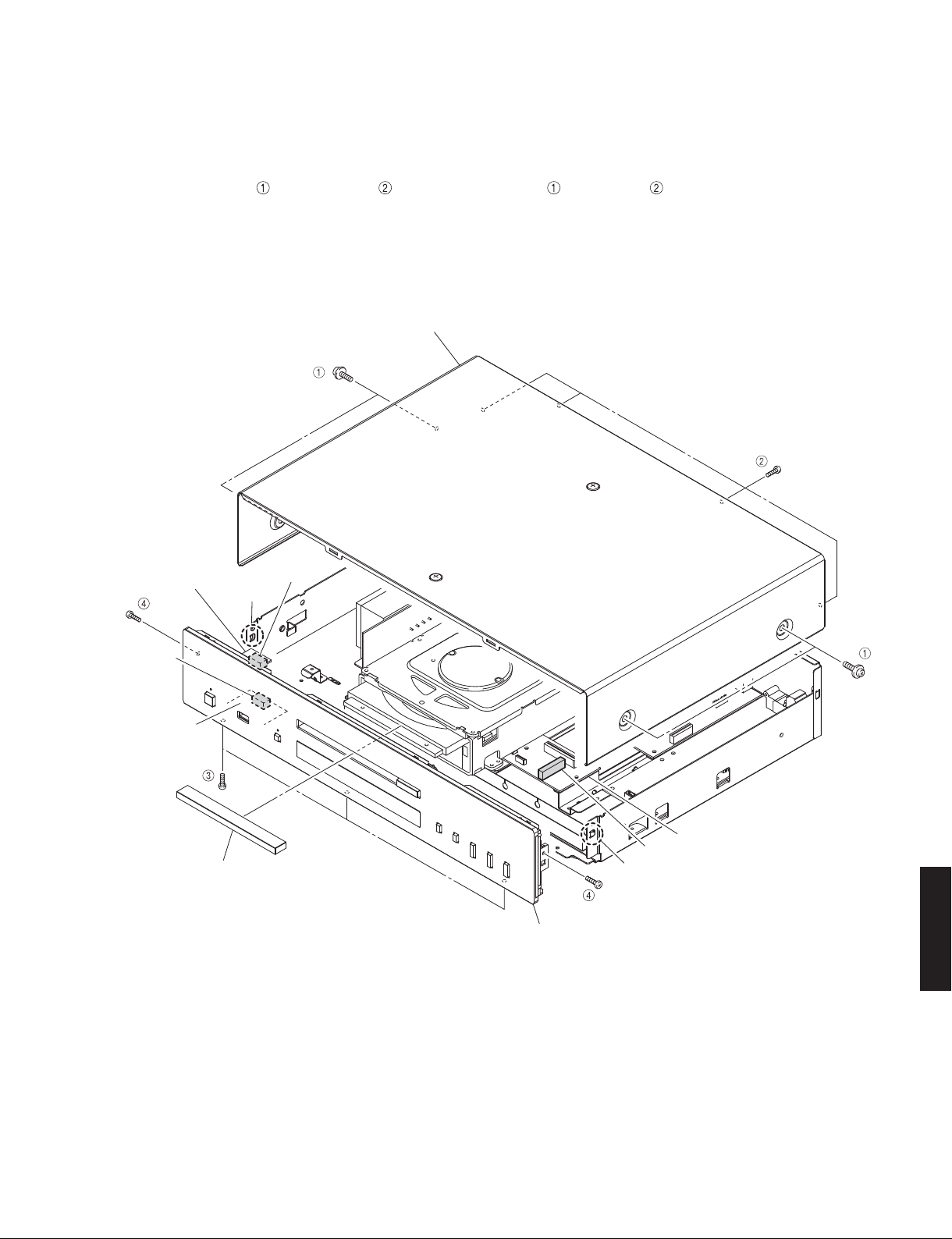

■ DISASSEMBLY PROCEDURES /

(Remove parts in the order as numbered.)

Disconnect the power cable from the AC outlet.

1. Removal of Top Cover

a. Remove 4 screws ( ) and 4 screws ( ). (Fig. 1)

b. Remove the top cover. (Fig. 1)

Top cover

トップ カ バ ー

分解手順

(番号順に部品を取り外してください。)

AC 電源コンセントから、電源コードを抜いてください。

1. トップカバーの外し方

a. ( ) ネジ 4 本、( ) のネジ 4 本を外します。(Fig.1)

b. トップカバーを取り外します。(Fig.1)

OPERATION (1)

P. C . B .

CB162

OPERATION (8)

P. C . B .

Lid

リッド

Hook

フック

CB205

Front panel ass'y

フロントパネルASSY

Fig. 1

CB152

Hook

フック

OPERATION (9) P.C.B.

CD-S700

11

CD-S700

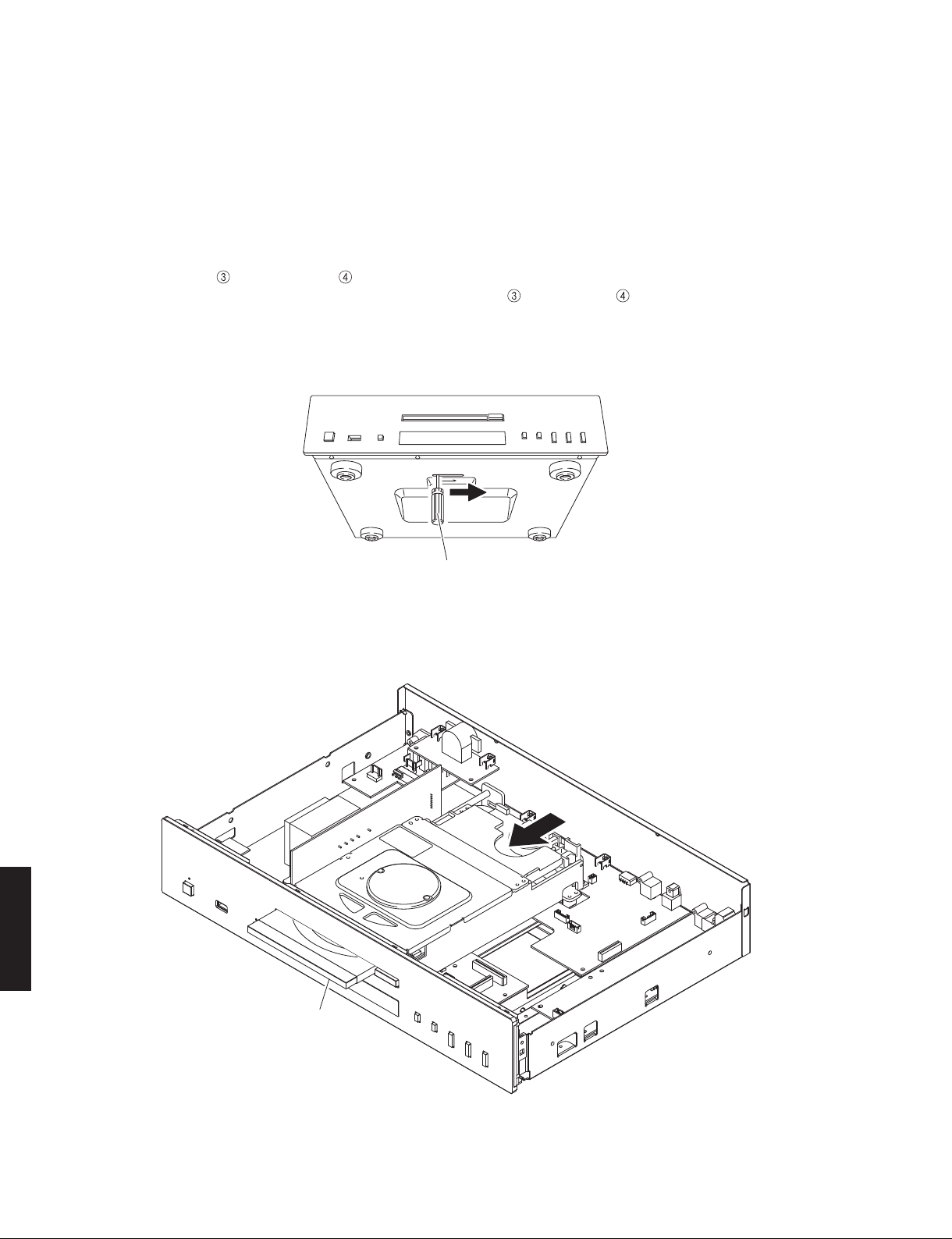

2. Removal of Front Panel Ass’y

a. Using a flatblade screwdriver, move the slider at the

bottom in the direction of the arrow shown below. (Fig. 2)

* The disc tray lock will be released but will not

come out.

b. Push out the disc tray by pushing its rear. (Fig. 3)

c. Remove the lid. (Fig. 1)

d. Close the disc tray by pushing its front.

e. Remove 4 screws (

f. Remove CB152, CB162 and CB205. (Fig. 1)

g. Release 2 hooks and then remove the front panel

ass’y. (Fig. 1)

) and 2 screws ( ). (Fig. 1)

2. フロントパネル ASSY の外し方

a. マイナスドライバーで底面のスライダーを下図の矢印

の方向に動かします。(Fig.2)

※ このとき、ディスクトレイは押し出されません。

b. ディスクトレイの後方を押し、ディスクトレイを押し

出します。(Fig.3)

c. リッドを取り外します。(Fig.1)

d. ディスクトレイの前方を押し、ディスクトレイを閉じ

ます。

e. (

) のネジ 4 本、( ) のネジ 2 本を外します。(Fig.1)

f. CB152、CB162、CB205 を外します。(Fig.1)

g. フック 2 箇所を外し、フロントパネル ASSY を取り外

します。(Fig.1)

Flatblade screwdriver

マイナスドライバー

Fig. 2

CD-S700

Disc tray

ディスクトレイ

12

Fig. 3

CD-S700

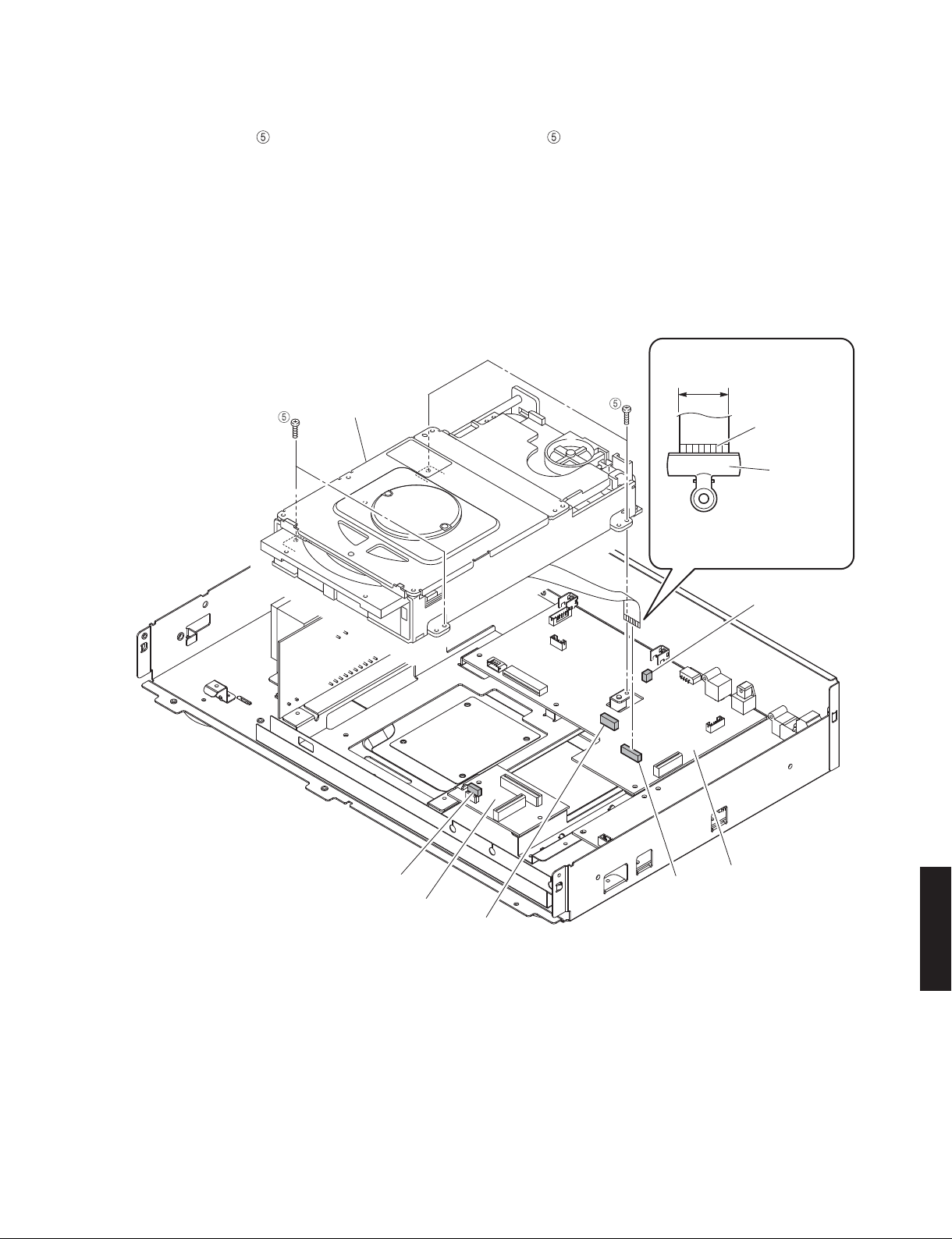

3. Removal of Loader Mechanism Ass’y

a. Remove 4 screws ( ). (Fig. 4)

b. Remove CB153, CB302 and CB602. (Fig. 4)

c. Remove CB604 and ground the terminal face of the

flexible flat cable with a clip or the like. (Fig. 4)

d. Lift loader mechanism ass’y up slightly and move it

backward to remove. (Fig. 4)

Loader mechnism ass'y

ローダーメカASSY

3.ローダーメカ ASSY の外し方

a. ( ) のネジ 4 本を外します。(Fig.4)

b. CB153、CB302、CB602 を外します。(Fig.4)

c. CB604 を外し、カード電線の端子面をクリップ等で

アースします。(Fig.4)

d. ローダーメカ ASSY を持ち上げて、後方へ取り外しま

す。(Fig.4)

17 mm

(0.67")

Terminal side

端子面

Clip

クリップ

Use a clip or the like to ground

the unit.

クリップ 等 で ア ースしてくだ さい 。

CB153

OPERATION (9) P.C.B.

CB602

Fig. 4

CB604

CB302

DIGITAL P.C.B.

CD-S700

13

CD-S700

■ TEST MODE /

Check the FL display and indicators for display/indication

condition.

Check the FL display and Indicators

●

1. Press the “POWER ON/OFF” switch inward to the

ON position while simultaneously pressing those

3 keys of this unit as indicated in the figure below,

and keep pressing those 3 keys.

"POWER" indicator

テストモード

"USB" indicator"PURE DIRECT" indicator FL display

FL ディスプレイとインジケーターの表示状態をチェック

します。

● FL ディスプレイとインジケーターの確認

1. 本 機の下図に 示す 3 つのキーを同 時 に押しながら

“MASTER ON/OFF” スイッチを押してオンにし、3 つ

のキーを押し続けます。

"POWER ON/OFF" switch

2. With these 3 keys pressed continuously, check

that all indicators (POWER, PURE DIRECT, USB)

are lit. At the same time, check that all segments

of the FL display are lit.

CD-S700

3. Release these 3 keys. Then check that all indicators (POWER, PURE DIRECT, USB) as well as all

segments of the FL display are turned off.

4. The Test Mode is activated.

Press the "POWER ON/OFF" switch inward to the ON position while pressing these keys.

これらのキーを同時に押しながら、“POWERON/OFF” スイッチを押してオンにします。

FL display /

Release the key

キーを離す

FL ディスプレイ表示

All segments ON

全セグメント点灯

All segments OFF

全セグメント消灯

2. 3 つのキーを押したまま、全てのインジケーター

(POWER、PUREDIRECT、USB)が点灯しているこ

とを確認します。

同時に、FL ディスプレイの全セグメントが点灯し

ていることを確認します。

3. 3 つのキーを離します。

全てのインジケーター(POWER、PUREDIRECT、

USB)と、FL ディスプレイの全セグメントが消灯

していることを確認します。

4. テストモードが起動します。

14

CD-S700

Operation Procedure of Test Mode

●

Function list of panel keys /

Panel key /

OPEN/CLOSE Disc tray open/close /

PLAY Trace on /

STOP Trace off /

PAUSE – –

SKIP+/SEARCH+ Trace on /

SKIP-/SEARCH- – –

PURE DIRECT – –

パネルキー

Function list of remote control keys /

Key /

キー

CD/USB – –

PURE DIRECT – –

OPEN/CLOSE Disc tray open/close /

DIMMER – –

DISPLAY Firmware version is displayed. /

1 Laser on /

2 Focus on /

3 TE measure /

4

5 Traverce stop /

6

7

8 Spindle off /

9

0––

ENTER – –

CLEAR – –

PROGRAM – –

REPEART – –

RANDOM – –

SEARCH - – –

A-B REPEAT – –

SEARCH + – –

PAUSE – –

SKIP - – –

PLAY Trace on /

SKIP + Trace on /

STOP Trace off /

テストモード時のパネルキー

ディスクトレイ オープン/クローズ

トレースオン

トレースオフ

トレースオン

テストモード時のリモコンキー

ディスクトレイ オープン/クローズ

レーザーオン

フォーカスオン

TE 測定

Traverce in /

トラバースイン

トラバースストップ

Traverce out /

トラバースアウト

Spindle reverce /

スピンドルリバース

スピンドルオフ

Spindle on /

スピンドルオン

トレース オン

トレース オン

トレース オフ

* Press “5” key to stop traverce. /

※

* Press “5” key to stop traverce. /

※

* Press “8” key to stop spindle. /

※

* Press “8” key to stop spindle. /

※

Function /

Function /

ファームウェアバージョン表示

“5”

キーを押してトラバースを停止してください。

“5”

キーを押してトラバースを停止してください。

“8”

キーを押してスピンドルを停止してください。

“8”

キーを押してスピンドルを停止してください。

● テストモード時の操作

機能

機能

Display /

OPEN / CLOSE

TRACE on

TRACE off

TRACE on

Display /

OPEN / CLOSE

Yxxx xxxx

LASER on

FOCUS on

TE measure

TRV in

TRV stop

TRV out

SPDL rev

SPDL stop

SPDL on

TRACE on

TRACE on

TRACE off

表示

表示

CD-S700

Canceling Test Mode

●

Press the “POWER ON/OFF” switch of this unit to release it outward to the OFF position.

● テストモードの解除

本機の“POWERON/OFF”スイッチを押してオフにします。

15

CD-S700

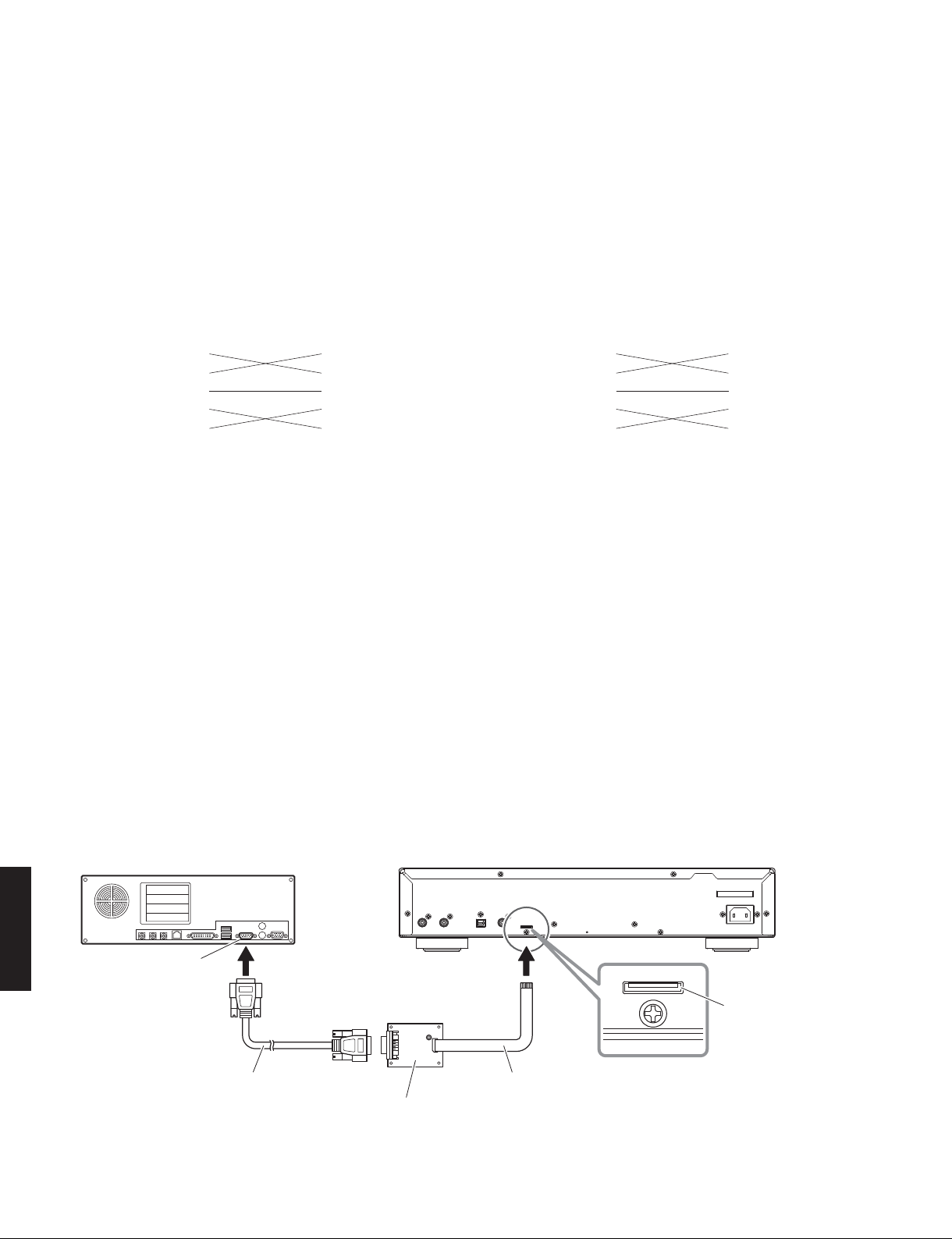

■ UPDATING FIRMWARE /

After replacing the following parts update the latest firmware according to the following procedure.

DIGITAL P.C.B.

Microprocessor (IC304) of DIGITAL P.C.B.

Required tools

●

• Program downloader programs ....... FlashSta.exe

• Firmware .............................................. CDS700.S

• RS232C cross cable “D-sub 9 pin female”

(Specifications)

Pin No.2 RxD Pin No.2 RxD

Pin No.3 TxD Pin No.3 TxD

Pin No.5 GND Pin No.5 GND

Pin No.7 RTS Pin No.7 RTS

Pin No.8 CTS Pin No.8 CTS

• RS232C conversion jig (Part No.: AAX88050)

Preparation and precautions before starting

●

ファームウェアの書き込み

CDS700.id

the operation

• Download firmware downloader program and

firmware from the specified source to the same

folder of the PC.

• Prepare the above specified RS232C cross cable.

• While writing, keep the other application software

on the PC closed.

It is also recommended to keep the software on

the task tray closed as well.

下記の部品を交換した場合、下記の手順により最新の

ファームウェアの書き込みを行ってください。

DIGITALP.C.B.

DIGITALP.C.B. のマイコン(IC304)

● 必要なツール

・ プログラム書き込み用プログラム....... FlashSta.exe

・ ファームウェア.....................................................CDS700.S

CDS700.id

・ RS232C クロスケーブル “D-sub9pin メス”

(仕様)

PinNo.2RxD PinNo.2RxD

PinNo.3TxD PinNo.3TxD

PinNo.5GND PinNo.5GND

PinNo.7RTS PinNo.7RTS

PinNo.8CTS PinNo.8CTS

・ RS232C変換冶具(部品番号:AAX88050)

● 操作前の準備と注意

・ PC へ指定のダウンロード先からファームウェア

書き込み用プログラムおよび、ファームウェアを

同じフォルダにダウンロードしてください。

・ RS232C クロスケーブルは必ず上記仕様のものを

用意してください。

・ 書き込み時は、PC 上の他のアプリケーションソ

フトは閉じてください。

さらに、タスクトレイ上にあるソフトも閉じてお

くことを推奨します。

Connection

●

Connect the writing port of this unit to the serial

port (RS232C) of the PC with RS232C cross cable,

RS232C conversion jig and flexible flat cable as

shown below. (Fig. 1)

PC

CD-S700

Serial port (RS232C)

RS232C cross cable

RS232Cクロスケーブル

RS232C conversion jig

RS232C変換冶具

This unit / 本機 Rear side

● 接続

本機の書き込み用ポートと PC のシリアルポート

(RS232C)を下記のように接続します。(Fig.1)

Writing port

書き込み用ポート

Flexible flat cable 8P

カード電線8P

Fig. 1

16

CD-S700

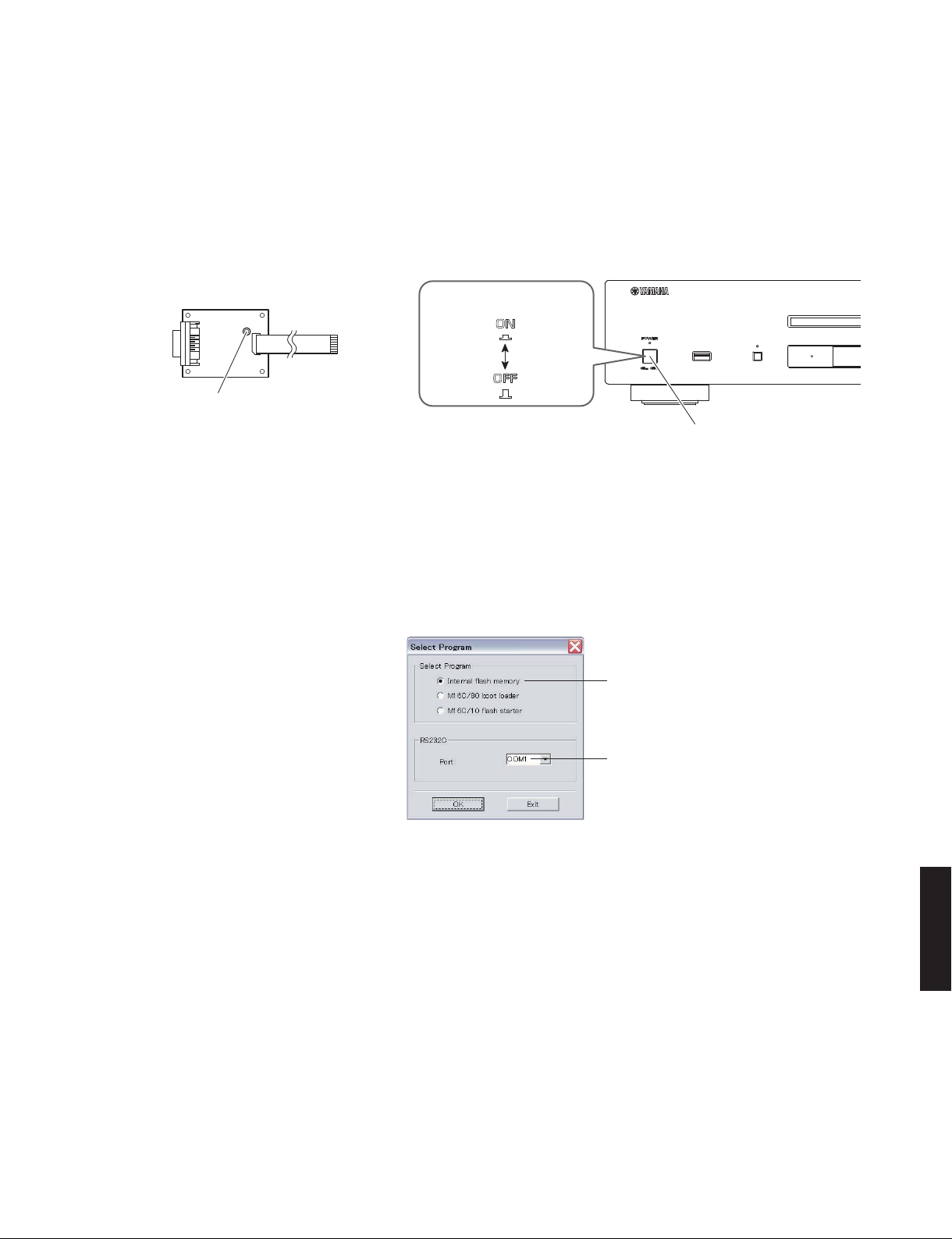

Operation Procedures

●

1. Connect the power cable of this unit to the AC

outlet.

2. While pressing the reset switch of RS232C conversion jig, press the “POWER ON/OFF” switch of

this unit inward to the ON position. (Fig. 2)

RS232C conversion jig

RS232C変換冶具

Reset switch

リセットスイッチ

● 操作手順

1. 本機の電源コードを AC コンセントに接続します。

2. RS232C 変換冶具のリセットスイッチを押しなが

ら、本機の “POWERON/OFF” スイッチを押して

オンにします。(Fig.2)

Front side Front side

"POWER ON / OFF" switch

"POWER ON / OFF" switch

Fig. 2

3. Start up FlashSta.exe, the screen will appear as

shown below. (Fig. 3)

4. Select the port and data to be transmitted. (Fig. 3)

• Select Program

Select Internal flash memory

• RS232C

Select the port of RS-232C

* For selection of the port, COM1 to 4 can be

used.

As COM5 or higher port cannot be used, select out of COM 1 to 4 of the setting on the PC

side.

3. FlashSta.exe を立ち上げます。

すると下記の画面が表示されます。(Fig.3)

Select Internal flash memory

Internalflashmemory を選択します

Select the port of RS-232C

接続している RS-232C ポートを選択します

Fig. 3

CD-S700

4. 送信データ、ポートを選択します。(Fig.3)

・ SelectProgram

Internalflashmemory を選択します。

・ RS232C

接続している RS-232 Cポートを選択します。

※ ポートの選択は COM1 〜 4 までが使用できま

す。

COM5 以上は使用できませんので、PC 側の設

定で COM1 〜 4 を選択してください。

17

CD-S700

5. Click [Refer...]. And select the firmware name.

(Fig. 4)

* The ID code and MCU type are loaded auto-

matically when the file is selected. (Fig. 4)

Click [OK]. (Fig. 4)

Click to open the window

ここをクリックすると

ウィンドウが開きます

5.[Refer...]をクリックし、書き込むファームウェア

を選択します。(Fig.4)

※ ID、および MCUType は書き込みファイル選

択時、自動的に取り込まれます。(Fig.4)

[OK]をクリックします。(Fig.4)

Fig. 4

6. Click [E.P.R.], the screen appears as shown below. (Fig. 5)

Click [OK] to start writing. (Fig. 5)

6.[E.P.R]をクリックすると、下記の画面が表示さ

れます。(Fig.5)

[OK]をクリックし、書き込みを開始します。

(Fig.5)

Writing being executed.

書き込み中

CD-S700

18

Fig. 5

CD-S700

7. When the program transmission is completed, the

screen appears as shown below. (Fig. 6)

Click [OK] to end the procedure. (Fig. 6)

7. プログラムの送信が終了すると、下記の画面が表

示されます。(Fig.6)

[OK]をクリックして完了します。(Fig.6)

Fig. 6

8. Press the “POWER ON/OFF” switch of this unit to

release it outward to the OFF position.

9. Disconnect the power cable of this unit from the

AC outlet.

10. End “FlashSta.exe”.

11. Disconnect the RS232C cross cable, RS232C

conversion jig and flexible flat cable.

8. 本機の “POWERON/OFF” スイッチを押してオフ

にします。

9. 本機の電源コードを AC コンセントから抜きます。

10.“FlashSta.exe” を終了します。

11.RS232C クロスケーブル、RS232C 変換アダプター

カード電線を取り外します。

CD-S700

19

CD-S700

Confirmation of firmware version

●

Press the “POWER ON/OFF” switch inward to the ON

position while simultaneously pressing the “PLAY”

and “STOP” keys of this unit, and then release these

two keys. (Fig. 7)

The firmware version is displayed. (Fig. 7)

"POWER ON / OFF" switch "PLAY" key

"POWER ON / OFF" switch

● ファームウェアバージョンの確認

本機の “PLAY” キーと “STOP” キーを押しながら、

“POWERON/OFF” スイッチを押してオンにし、これ

ら 2 つのキーを放します。(Fig.7)

ファームウェアバージョンが表示されます。(Fig.7)

"STOP" key

When the power is ON (All light up)

電源オン時(全点灯)

Every time you press the “DISPLAY” key, the display

changes in the order as shown below.

The firmware version of the microprocessor (IC304) and its date of update are displayed.(Initial

display)

The date of update

更新日付

The firmware version

ファームウェアバージョン

マイコン(IC304)のファームウェアバージョンおよび更新日付を表示します。(初期表示)

Firmware version of microprocessor is displayed.

マイコンのファームウェアバージョン表示

Fig. 7

リモコンの “DISPLAY” キーを押すたびに、下図の順

で表示が切り替わります。

Remote control

"DISPLAY" key

The firmware version of the CDLSI (IC602) is displayed.

CD-S700

CDLSI(IC602)のファームウェアバージョンを表示します。

The firmware version of the USB-microprocessor (IC604) is displayed.

USB マイコン(IC604)のファームウェアバージョンを表示します。

Fig. 8

* When the displayed firmware version is different

from written firmware version, follow the steps

from 1 to 11 of operation procedures again.

20

※ 表示されたファームウェアのバージョンが、書き

込んだファームウェアのバージョンと異なる場

合、操作手順の 1 から 11 までをもう一度実施し

てください。

T

■ IC DATA

IC304: M30302FAPFP (DIGITAL P.C.B.)

Single-chip 16-bit microprocessor

Port P08Port P18Port P28Port P38Port P48Port P58Port P6

CD-S700

8

Peripheral function

Timer (16-bit)

Input (timer A) x3

Output (timer B) x3

Watchdog timer

(15-bit)

DMAC

(2-channel)

Note 1: ROM contents vary depending on types.

RAM contents vary depending on types.

Note 2:

USB_DET

SYS_DET

SYS_ROCI_U

SYS_ROCI_C

A/D converter

(10-bit X 18-channel

UART or clock synchronous type

CRC arithmetic circuit (CCITT)

(Polynomial : X

R1H R1L

SYS_I/O

R_PLUG

SYS_RICO_C

)

serial I/O

(3-channel)

16+X12+X5

+1)

M16C/60 series

Microprocessor core

R0LR0H

R2

R3

A0

A1

A1

FB

FB

SYS_RICO_U

USB_/EN

USB_FLG

VSS

FL_CS

System clock generator

X

SB

USP

ISP

INTB

PC

FLG

VCC2

FL_RES

LED_USB

LED_PDIRECT

X

IN-XOUT

CIN-XCOUT

Memory

ROM

(Note 1)

RAM

(Note 2)

Multiplier

LED_POWER

DOUT_MUTE

PCON3

PCON2

DAC_RESET

DAC_CS1

Port P7

Port P8

Port P8_5

Port P9

Port P10

AMUTE

8

7

8

8

TP336

TP337

TP338

TP339

TP340

TP341

TP342

SYS_DM

SYS_DA

KEY0

KEY1

KEY2

AVSS

VDET

VREF

VCC1

TRAY_SW4

CLAMP_SW2

TRAY_SW3

CLAMP_SW1

TRAY_SW2

TRAY_SW1

BYTE

XCIN

CNVSS

XCOUT

/RESET

M30302FAPFP

XIN

VSS

XOUT

VCC1

IR

KEY_O/C

KEY_PLAY

SEL S700/1330

CLAMP_MOTOR2

CLAMP_MOTOR1

TRAY_MOTOR2

TRAY_MOTOR1

FL_CLK

PCON1

VER_SEL2

VER_SEL1

CD_INT

COMCS

USB_IN

CD_NRST

DRV_STBY

COMCLK

COMSTS

COMCMD

RTS

DAC_SCLK/C

RXDO

DAC_SO/TXO

FL_DATA

CD-S700

21

CD-S700

CD-S700

No. Port Name Function Name I/O Detail of Function

1 P9_6/ANEX1 (No connected)

2 CLAMP_SW2 P9_5/ANEX0 I Clamp SW2

3 CLAMP_SW1 P9_4 I Clamp SW1

4 TRAY_SW4 P9_3

5 TRAY_SW3 P9_2/TB2IN I Tray SW3 / Loader mechanism specification confirm

6 TRAY_SW2 P9_1/TB1IN I Tray SW2

7 TRAY_SW1 P9_0/TB0IN I Tray SW1

8 BYTE BYTE I GND

9 CNVSS CNVSS Usually GND but VCC1 when writing FLASH

10 XCIN P8_7/XCIN (No connected)

11 XCOUT P8_6/XCOUT (No connected)

12 /RESET /RESET

13 XOUT XOUT

14 VSS VSS GND

15 XIN XIN

16 VCC1 VCC1

17 P8_5/NMI Pull-up resistor required

18 KEY_O/C P8_4/INT2 GND when writing FLASH

19 KEY_PLAY P8_3/INT1 (No connected)

20 IR P8_2/INT0 I Remote control

21 P8_1 (No connected)

22 SEL S700/1330 P8_0

23 CLAMP_MOTOR2 P7_7 O Clamp motor 2

24 CLAMP_MOTOR1 P7_6 O Clamp motor 1

25 TRAY_MOTOR2 P7_5/TA2IN O Tray motor 2

26 TRAY_MOTOR1 P7_4/TA2OUT O Tray motor 1

27 P7_3/CTS2/RTS2/TA1IN (No connected)

28 FL_CLK P7_2/CLK2/TA1OUT O FL control

29 P7_1/RXD2/SCL2/TA0IN (No connected)

30 FL_DATA P7_0/TXD2/SDA2/TA0OUT O FL control

31 DAC_SO/TXO P6_7/TXD1/SDA1 O TxD for DAC control / Rewriting FLASH commonly used

32 RXDO P6_6/RXD1/SCL1 I RxD for rewriting FLASH commonly used

33 DAC_SCLK/CT P6_5/CLK1 O CTS for DAC control / Rewriting FLASH commonly used

34 RTS P6_4/CTS1/RTS1/CTS0/CLKS1 I RTS for rewriting FLASH commonly used

35 COMCMD P6_3/TXD0/SDA0 O MODULE control

36 COMSTS P6_2/RXD0/SCL0 I MODULE control

37 COMCLK P6_1/CLK0 I MODULE control

38 P6_0/CTS0/RTS0 (No connected)

39 P5_7/RDY/CLKOUT (No connected)

40 DRV_STBY P5_6/ALE O MODULE control

41 P5_5/HOLD GND when writing FLASH

42 CD_NRST P5_4/HLDA O MODULE control

43 USB_IN P5_3/BCLK O MODULE control

44 COMCS P5_2/RD O MODULE control

45 CD_INT P5_1/WRH/BHE I MODULE control

46 P5_0/WRL/WR VCC1 when writing FLASH

47 VER_SEL1 P4_7/CS3 (No connected)

48 VER_SEL2 P4_6/CS2 (No connected)

49 P4_5/CS1 (No connected)

50 PCON1 P4_4/CS0 O output RELAY

51 AMUTE P4_3/A19 O Analog mute

52 P4_2/A18 O DAC control

53 DAC_CS1 P4_1/A17 O DAC control

54 DAC_RESET P4_0/A16 O DAC control

55 PCON2 P3_7/A15 (No connected)

56 PCON3 P3_6/A14 (No connected)

57 DOUT_MUTE P3_5/A13 (No connected)

58 LED_POWER P3_4/A12 O Indicator of power supply

59 LED_PDIRECT P3_3/A11 O Indicator of pure direct

60 LED_USB P3_2/A10 O Indicator of SACD

22

No. Port Name Function Name I/O Detail of Function

61 FL_RES P3_1/A9 O FL control

62 VCC2 VCC2

63 FL_CS P3_0/A8 O FL control

64 VSS VSS

65 USB_FLG P2_7/A7 (No connected)

66 USB_EN P2_6/A6 (No connected)

67 SYS_RICO_C P2_5/A5 (No connected)

68 SYS_RICO_U P2_4/A4 (No connected)

69 R_PLUG P2_3/A3 (No connected)

70 SYS_I/O P2_2/A2 (No connected)

71 SYS_ROCI_C P2_1/A1 (No connected)

72 SYS_ROCI_U P2_0/A0 (No connected)

73 P1_7/D15 (No connected)

74 SYS_DET P1_6/D14/INT4 (No connected)

75 USB_DET P1_5/D13/INT3 (No connected)

76 P1_4/D12 (No connected)

77 P1_3/D11 (No connected)

78 P1_2/D10 (No connected)

79 P1_1/D9 (No connected)

80 P1_0/D8 (No connected)

81 P0_7/AN0_7/D7 O Test point

82 TP336 P0_6/AN0_6/D6 O Test point

83 TP337 P0_5/AN0_5/D5 O Test point

84 TP338 P0_4/AN0_4/D4 I LOAD- monitor

85 TP339 P0_3/AN0_3/D3 O Test point

86 TP340 P0_2/AN0_2/D2 I LOAD+ monitor

87 TP341 P0_1/AN0_1/D1 O Test point

88 TP342 P0_0/AN0_0/D0 O Test point

89 SYS_DM P10_7/AN7/KI3 (No connected)

90 SYS_DA P10_6/AN6/KI2 (No connected)

91 P10_5/AN5/KI1 (No connected)

92 P10_4/AN4/KI0 (No connected)

93 KEY0 P10_3/AN3 I Analog input

94 KEY1 P10_2/AN2 I Analog input

95 KEY2 P10_1/AN1 I Analog input

96 AVSS AVSS

97 VDET P10_0/AN0 I MODULE control

98 VREF VREFF

99 VCC1 AVCC

100 P9_7/ADTRG (No connected)

CD-S700

23

CD-S700

CD-S700

IC604: MN103SFB5KYAA (DIGITAL P.C.B.)

USB microprocessor

N.C.

N.C.

N.C.

33

34

35

N.C.

32

INTERFACE

SYSTEM control

N.C.

N.C.

31

30

MEMORY

8 KB

USB

SIF

x 2

I2C

x 1

I/O port

34 pcs (3 V type)

8 pcs (5 V type)

CLOCK &

N.C.

29

N.C.

28

N.C.

27

MEMORY

16-bit x 2

N.C.

26

ROM

256 KByte

FLASH

DATA

RAM

8 KByte

8-bit x 4

USB_IN

25

TIMER

N.C.

24

32 bit

MICRO-

PROCESSOR

CORE

WDTx1

N.C.

23

N.C.

22

INTERRUPT

CONTROL

N.C.

21

DMA 4 CH

35 Factor

N.C.

20

OCD_SCL

OCD_SDA

19

18

VPP

17

16

15

14

MMOD1

MMOD0

NRST

N.C.

N.C.

VDD3

N.C.

VSS

N.C.

VDDI

N.C.

N.C.

N.C.

I2C_SCL

36

37

38

39

40

41

42

43

44

45

46

13

12

11

10

9

8

7

6

5

4

3

VSS

OSCO

OSCI

VDDI

VDD3

N.C.

AVDD

USBD+

VSS

USBD-

USBNPP

CD-S700

N.C.

I2C_SDA

47

48

49

VDD3

50

N.C.

51

N.C.

52

N.C.

53

VSS

54

55

CS

STREQ

56

N.C.

57

TX

58

RX

59

STCLK

60

N.C.

61

62

VDDI

STDATA

63

N.C.

2

1

64

N.C.

USBNOC

N.C.

24

No. Port Name Function Name Detail of Function

1 N.C.

2 USBNOC USB over-current input (negative polarity)

3 USBNPP USB, VBUS power output control terminal (negative polarity)

4 USBD- USB D- terminal

5 VSS AVSS Ground / Analog power supply for USB / Connect to VSS.

6 USBD+ USB D+ terminal

7 AVDD Analog power supply for USB / Connect to VDD33.

8 N.C.

9 VDD3 VDD33

10 VDDI VDD18/VOUT

11 OSCI

12 OSCO High-speed oscillation output terminal

13 VSS Ground

14 NRST Reset signal input terminal (negative polarity)

15 MMOD0 Operation mode setting terminal

16 MMOD1 Operation mode setting terminal

17 VPP

18 OCD_SDA Clock, data input/output terminal for on-chip debugger

19 OCD_SCL Clock, data input/output terminal for on-chip debugger

20

21

N.C.

22

23

24

25 USB_IN General purpose input/output port 0

26

27

28

29

30

31

N.C.

32

33

34

35

36

37

38 VDD3 VDD33

39 N.C.

40 VSS Ground

41 N.C.

42 VDDI VDD18

43

N.C.44

45

46 I2C_SCL P35/SCL3 General purpose input/output port 3

47 N.C.

48 I2C_SDA P33/SDA3 General purpose input/output port 3

49 VDD3 VDD5 I/O power supply (5V type I/O

Power for on-chip regulator (2.7V to 3.6V)

I/O power supply (2.7V to 3.6V)

Power for internal circuit (1.8V t±0.15V)

Connect all VDD18 terminals outside of chip.

Also, connect a 10μF capacitor between VDD18 and VSS of No.10 pin and place it

near LSI.

On-chip regulator output (1.8V ±0.15V)

High-speed oscillation input terminal (fosc)

(When PLL used: 6.33 MHz to 20 MHz)

Power for rewriting built-in Flash memory (3.3V ±0.3V) / only for Flash built in model

Power for on-chip regulator (2.7V to 3.6V)

I/O power supply (2.7V to 3.6V)

Power supply for internal circuit (1.8V ±0.15V)

Connect all VDD18 terminals outside of chip.

Also, connect a 10μF capacitor between VDD18 and VSS of No.10 pin and place it

near LSI.

CD-S700

CD-S700

25

CD-S700

No. Port Name Function Name Detail of Function

50 N.C.

51

N.C.

52

53 VSS Ground

54 STREQ PD5/IRQ2 External interrupt request signal input terminal

55 CS PD4/IRQ1 External interrupt request signal input terminal

56 N.C.

57 TX PD1/SBI2 Clock synchronization/start stop synchronization serial terminal

58 RX PD0/SBO2 Clock synchronization/start stop synchronization serial terminal

59 STCLK P92/SBT0 Serial clock input/output termina

60 N.C.

61 STDATA P90/SBO0 Serial data output terminal

Power supply for internal circuit (1.8V ±0.15V)

62 VDDI VDD18

63

N.C.

64

Connect all VDD18 terminals outside of chip.

Also, connect a 10μF capacitor between VDD18 and VSS of No.10 pin and place it

near LSI.

CD-S700

26

■ DISPLAY DATA

● V101 : 13-ST-81GINK (OPERATION (1) P.C.B.)

CD-S700

43

1

● PIN CONNECTION

Pin No. 12345678910111213141516171819

13GNXNXNXNXNXNXNXNXNXNXNXNXNXNXConnection

22

23

24

25

26

27

28

29

30

31

32

33

35

CS

40

LGND

34

CP

39

PGND

DA

38

VH

TSA

TSB

NX

NX

NX

NX

NX

NX

NX

NX

36

Pin No.

Connection

Pin No.

Connection

Note: 1) F1, F2 ..... Filament 2) NP ..... No pin 3) NX ..... No extended pin 4) DL ..... Datum line 5) LGND ..... Logic GND pin

6) PGND ..... Power GND pin 7) VH ..... High voltage supply pin 8) VDD ..... Logic voltage supply pin 9) CP ..... Shift register clock

10) DA ..... Serial data input 11) TSA, B ..... Test pin 12) CS ..... Chip select input pin 13) OSC ..... Pin for self-oscillation

14) RESET ..... Reset input 16) Q13G ..... Driver output port 17) 13G ..... Grid

37

VDD

43

F2

OSC

42

NP

RESET

41

NP

● GRID ASSIGNMENT

13G

21

NX

F1

NPNPQ13G

20

NX

1G

1-1 2-1 3-1 4-1 5-1

1-2 2-2 3-2 4-2 5-2

1-3 2-3 3-3 4-3 5-3

1-4 2-4 3-4 4-4 5-4

1-5 2-5 3-5 4-5 5-5

1-6 2-6 3-6 4-6 5-6

1-7 2-7 3-7 4-7 5-7

1G to 12G

2G 3G 4G 5G 6G 7G 8G 9G 10G 11 G 12G

● ANODE CONNECTION

1G to 12G

D0

D1

D2

D3

D4

D5

D6

D7

D8

D9

D10

D11

D12

D13

D14 5-3

1- 1

2-1

3-1

4-1

5-1

1- 2

2-2

3-2

4-2

5-2

1- 3

2-3

3-3

4-3

13G

1G to 12G

D15

D16

D17

D18

D19

D20

D21

D22

D23

D24

D25

D26

D27

D28

D29 5-6

1- 4

2-4

3-4

4-4

5-4

1- 5

2-5

3-5

4-5

5-5

1- 6

2-6

3-6

4-6

13G

–

–

–

–

–

–

–

–

–

–

–

–

–

D30

D31

D32

D33

D34

1G to 12G

1- 7

2-7

3-7

4-7

5-7

13G

–

–

–

–

–

CD-S700

27

CD-S700

■ PIN CONNECTION DIAGRAMS

• ICs

OP275GSR

8

BD9870FPS-E2

4

5

3

1

1

5

DSD1791DBR LB1641BD4829G-TR

28

1

14

1

10

M30302FAPFPM12L16161A-7TG MN103SFB5KYAA

80

81

50

1

4

1

25

100

1

PQ033ES3MXP R5523N001A-TR-F

1

3

R1172S331B-E2-F RP131S501D-E2-F

6

51

50

49

64

31

30

4

3

5

1

3

1

116

3348

32

17

6

3

1

TC7WU04F TS7ST00FTC74VHCT08AFT TC7SH08F

4

14

7

1

5

3

1

5

8

4

1

4

5

3

1

• Diodes

1N4002S 1SS355

D4SBN20-7101

FM203-W TE

MA-8039-H

MA8047-H

Anode

CD-S700

Cathode

MA8056-M 5.6V

MA8062-M

MA8130-M

MA8300-M 30.0V

RB050LA-40TR TP

RB501V-40

Cathode

Anode

–

AC

AC

+

RS203M-B-C-J80

+

AC

AC

–

• Transistors

2SA1037K

2SC2412K

2SD1938F

C

B

2SB1257

2SC44882SB709A

2SK208 DTC114EKA

2SD2014

C

E

B

C

E

E

B

B

C

E

G

D

S

3

1: GND

1

2: IN

2

3: OUT

28

ABCDEFGH I J

1

■ BLOCK DIAGRAM

CD-S700

OPERATION

CB161

USB Connector

V101

FL-Display

D104 POWER Indicator

D102 PURE DIRECT Indicator

D103 USB Indicator

SW101, SW102,

SW105-107

Front Panel Keys

2

USB+5

Loader Mechanism Ass'y

D+3.3V

IC606

Current

Limiter

USB Microprocessor:

MM1 (MN103SFB5K)

r Analyze Folder/File

/RST

IC604

D+/D-

USB IN

IC605

16Mbit SD-RAM

(Shock Proof)

TX/RX,

STCLK/DATA/REQ

3

Limit SW

A, B, C, D, E, F, PD

OPU

Focus

Tracking

Spindle Feed

4

OPEN/CLOSE

CLAMP UP/DOWN

LD, F+/F-, T+/T-

r Disc Control (Servo)

r EFM Demodulation

r Error Correction

r MP3/WMA Decode

r Output Digital Audio (I2S/SPDIF)

IC601

Actuator Driver

AN41010A

IC602

CD Controller:

./:"

SPDIF

M+8V

M

IC306

IC305

Loading Driver

Clamp Driver

FL_CLK/FL_Data

FL_CS/FL

/RST

COMCLK

COMCS

COMCMD

COMSTS

r $POUSPM'-%*41-":-&%

r %FUFDU3&.'SPOU1BOFM,FZ

r $POUSPM%"$

r %FUFDU48PG-PBEFSBOE$POUSPM

IC304

Microprocessor:

M30302FAPFP

OPEN/CLOSE

IC309

IC310

Buffer

Amp.

Remote

D+3.3V

IC307

Reset IC

X5868A0

BD4829G

U101

IN

DIGITAL

L307

Pulse

Trans

r 4FFQBHF→

SCHEMATIC DIAGRAM

Front Panel

r 4FFQBHF→

SCHEMATIC DIAGRAM

U300

OPTICAL

PJ300

COAXIAL

DC/DC Converter Regulator

5

OPERATION

Power Supply and Audio Out

6

7

r 4FFQBHF→

F201

SCHEMATIC DIAGRAM

SW201

Power Transformer

T201

±17V/80mA

D6 Q6

Q7

+20V/600mA

D215

+20V/600mA

+20V/200mA

D211-D214

+20V/120mA

Q201

A+12V

80mA

A-12V

-

80mA

+B1

+B2

FL +30V

21mA

FL AC+/- AC4.0V 150mA AUDIO OUT

Q5

+5DA

+3.3DA

IC4

Q102

FL +5V

3mA

IC1

Audio D/A Converter:

DSD1791

L+/L- R+/R-

IC2

Differential AMP. and L.P.F.

Q14-Q17

Mute Circuit

PJ1

L ch

MCLK

BCK

WCK

SDATA

R ch

DAC Control (SPI)

Zero Flag (Reserved)

AMUTE control

Q1

POWER MUTE

+B2

+20V/120mA

+B1

+20V/600mA

IC300

D+5V

30mA

DC/DC Converter

IC302

M+8V

500mA

IC303

D+3.3V

274mA

Regulator

USB+5V

500mA

IC311

29

ABCDEFGH I J

CD-S700

1

■ PRINTED CIRCUIT BOARDS

• Semiconductor Location

Ref no. Location

DIGITAL P.C.B. (Side A)

D300 G3

D302 G3

D303 G2

DIGITAL OUT

OPTICAL COAXIAL

2

IC310

5

Loader mechanism ass’y

Loading-

Loading+

148

IC309

1

253

25

26

IC605

Writing port

CB304

CB302

D309 E4

D601 C3

3

CB606

1

1

128

50

32

33

4

IC602

A-1

97

96 55

54

110110

IC307

13

54

C817

B-1

1

B-2

IC305IC306

100

2

81

Ref no. Location

D602 C3

D604 C4

IC300 G2

IC302 G3

IC303 F2

4

IC303

135

IC311

4

136

1

A-3

IC304

80 51

30

31

50

Ref no. Location

IC304 F4

IC305 E3

IC306 E3

IC307 E4

IC308 G5

IC300

INV

STBY

IC302

INV

STBY

(Writing port)

IC308

7

8

1

14

Ref no. Location

IC309 B3

IC310 B3

IC311 F3

IC601 D6

IC602 C4

FIN

VCC

OUT

FIN

VCC

OUT

CB608

32

17

IC604

A-2

Ref no. Location

IC604 H4

IC605 D3

IC606 H4

Q602 C3

CB300

4833

49

64

116

54

13

IC606

DGND

+B2

MGND

+B1

+30

ACFL2

ACFL1

FLGND

OPERATION (4)

(W208)

J810

POINT A-1 XL601 (Pin 109 of IC602)

POINT A-2 XL603 (Pin 12 of IC604)

POINT A-3 XL300 (Pin 13 of IC304)

DGND

DAC_CS

5

OPERATION (3)

6

(W2)

7

D+3.3V

DAC_SCLK

VDET

DAC_SO

AMUTE

DGND

PLRCK

PBCK

PDATA

MCLK

DAC_RESET

DGND/PCON3

CB301

CB604

142815

IC601

1

E

A

C

F+

T+

Vref

Vcc

VR

RFGND

F

B

D

T-

F-

LD

MD

Loader mechanism ass’y

CB602

GND

SLED M-

SLED M+

LIMIT SW

SPINDLE M-

SPINDLE M+

Loader mechanism ass’y

OPERATION (9)

(CB151)

ACFL2

FLGND

ACFL1

FLGND

S4 CLAMP/KEY3

TRAY_SW

CLAMP MOTOR+

S3UNCLAMP

S2 TRAY OPEN

LED_USB

CLAMP MOTOR-

+30

S1 TRAY CLOSE

CB303

IR

KEY1

LED_POWER

LED_PDIRECT

+5

+3.3

KEY0

FL_CS

KEY2

FL_CLK

FL_DATA

FL_RESET

DGND

DGND

1 pin

CB609

D-

D+

FG

VCC

GND

OPERATION (8)

(CB162)

POINT B-1 B-2 1 / Pin2, 2 / Pin1 of IC307

12 pin

2

2 pin

1 pin

1

2

POWER ON POWER OFF POWER OFF

30

ABCDEFGH I J

CD-S700

1

DIGITAL P.C.B. (Side B)

2

C816

3

4

5

J674

R650

R819

J811

• Semiconductor Location

Ref no. Location

6

R820

D304 F2

D306 E4

D307 E4

D308 F4

D310 E3

D311 D3

D312 G2

D313 G3

D314 F3

D317 F3

D603 B4

7

Q300 E4

Q601 C5

31

ABCDEFGH I J

CD-S700

1

OPERATION (1) P.C.B. (Side A) OPERATION (2) P.C.B. (Side A)

POWER

2

OPERATION (9)

(CB152)

FLGND

ACFL1

LED_USB

LED_PDIRECT

IR

LED_POWER

KEY1

FL_CS

FL_CLK

3

DGND

indicator

W101B

+5

FLGND

ACFL2

+30+5+3.3

CB101

KEY0

KEY2

FL_DATA

FL_RESET

DGND

OPEN/CLOSE

LED_POWER

W101A

LED_POWER

+5

4

PURE DIRECT

indicator

STOP PAUSE PLAY

USB

indicator

PURE DIRECT

5

6

• Semiconductor Location

Ref no. Location

D102 H4

D103 J4

D104 I2

7

32

ABCDEFGH I J

CD-S700

1

OPERATION (1) P.C.B. (Side B) OPERATION (2) P.C.B. (Side B)

2

3

4

IC802

12

53

5

6

• Semiconductor Location

Ref no. Location

D101 H4

IC802 D4

Q101 F4

Q102 H4

Q103 H4

Q104 J4

Q105 J4

7

33

ABCDEFGH I J

CD-S700

1

OPERATION (3) P.C.B. (Side A)

2

3

LR

IN

COM

OUT

CB1

AGND

4

ANALOG OUT

W2

5

DGND

D+3.3V

DAC_CS

VDET

DAC_SO

DAC_SCLK

Amute

DGND

PLRCK

PBCK

PDATA

MCLK

DAC_RESET

DGND/PCON3

DIGITAL (CB301)

6

OPERATION (4)

(CB206)

• Semiconductor Location

Ref no. Location

D1 I4

D2 I4

D6 H4

IC4 G4

Q5 F3

Q6 G3

Q7 G4

7

34

ABCDEFGH I J

CD-S700

1

OPERATION (3) P.C.B. (Side B)

2

3

J7

J8

28

85

IC2

4

14

114

15

IC1

5

• Semiconductor Location

Ref no. Location

D3 H4

D4 H5

D5 H5

D7 C5

D8 G3

D9 G4

D10 G4

6

7

D12 C5

D14 C3

D15 C3

IC1 E4

IC2 D4

Q1 H5

Q2 G3

Q3 G4

Q4 G4

Q14 C3

Q15 C4

Q16 C3

Q17 C4

35

ABCDEFGH I J

CD-S700

1

OPERATION (4) P.C.B. (Side A)

R, L models

• Semiconductor Location

Ref no. Location

D204 F2

D205 F2

D211 G3

D212 G3

2

W204B

W201B

W203B

W202B

D213 G3

D214 G3

D215 G3

W205B

DGND

T, K, J models

3

U, A, B, G models

W207A

W207B

W206A

CB206

W206B

W208

+B2

MGND

+B1

+30

ACFL2

ACFL1

FLGND

DIGITAL

(CB300)

Q201 G2

AGND

4

OPERATION (3)

(CB1)

OPERATION (5) P.C.B.

(Side A)

5

CB202

6

AC IN

CB203

CB204

OPERATION (6) P.C.B. (Side A)

POWER

(Side A)

OPERATION (7) P.C.B.

R, L models

ON

OFF

VOLTAGE SELECTOR

120V220V

110 V

W204A

W203A

240V

W202A W205A

W201A

CB205

7

36

ABCDEFGH I J

CD-S700

1

OPERATION (4) P.C.B. (Side B)

• Semiconductor Location

Ref no. Location

D201 H3

D206 G3

2

3

C221

4

OPERATION (5) P.C.B.

(Side B)

OPERATION (6) P.C.B. (Side B)OPERATION (7) P.C.B.

5

(Side B)

6

7

37

ABCDEFGH I J

CD-S700

1

OPERATION (8) P.C.B. (Side A)

OPERATION (8) P.C.B. (Side B)

USB

VCCD-D+

GND

2

CB161

CB162

3

D-

D+

FG

VCC

GND

DIGITAL (CB609)

OPERATION (9) P.C.B. (Side A)

DIGITAL (CB303)

OPERATION (9) P.C.B. (Side B)

4

DGND

FL_RESET

FL_DATA

KEY2

KEY0

+3.3

+5

+30

S1 TRAY CLOSE

S3 UNCLAMP

S2 TRAY OPEN

S4 CLAMP

ACFL1

FLGND

DGND

FL_CLK

FL_CS

KEY1

LED_POWER

IR

LED_PDIRECT

LED_USB

CLAMP MOTOR-

TRAY_SW

CLAMP MOTOR+

ACFL2

FLGND

5

FLGND

ACFL1

+30

+5

+3.3

KEY0

KEY2

6

FL_DATA

FL_RESET

DGND

OPERATION (1)

(CB101)

FLGND

ACFL2

LED_USB

LED_PDIRECT

LED_POWER

KEY1

FL_CS

FL_CLK

DGND

IR

CB152

CB153

COMMON

S3 UNCLAMP

S1 TRAY CLOSE

CLAMP MOTOR-

S4 CLAMP

S2 TRAY_SW

7

S5 TRAY OPEN

CLAMP MOTOR+

Loader mechanism ass’y

38

IC602

IC604

CB608

IC601

CB604

IC606

IC605

CB609

CB602

CB606

A

1

2

3

4

5

6

7

8

9

10

BCDEFGH I J K

L MN

CD-S700

39

SCHEMATIC DIAGRAMS

DIGITAL 1/2

A-1

A-2

3.3

0

3.4

2.0

2.6

2.0

2.6

3.3

2.6

0

0

0.8

0

1.9

0

0

3.3

1.7

1.7

1.7

1.8

1.800

3.2

3.2

3.2

3.2

3.3

1.6

1.601.7

1.7

3.3

1.7

1.801.9

2.0

3.3

3.2

3.2

3.3

3.4

0

3.4

0

1.9

3.4

3.4

0

0

0.8

3.4

0

3.3

000

0

0

0

1.9

0

1.7

1.7

1.7

1.7

3.2

3.2

3.3

1.7

3.3

3.3

1.8

1.8

0

1.8

1.8

3.3

1.7

1.8

0

1.7

1.5

0

0

3.3

1.9

1.7

2.4

1.7

1.7

1.7

0

7.9

1.7

3.6

3.7

3.3

4.0

7.9

1.7

3.3

3.3

0

0

0

3.5

3.7

3.7

3.6

1.5

5.8

0

1.2

3.3

1.0

1.7

0

0

1.7

3.3

1.7

0

1.9

1.9

0.2

2.4

2.0

1.8

1.3

1.8

3.3

1.2

1.3

1.7

1.7

0.9

1.5

1.5

0

1.2

1.8

1.9

1.9

1.9

1.9

1.9

1.8

1.7

3.3

3.3

1.8

1.8

1.7

1.7

1.7

3.2

3.2

3.2

1.7

1.7

1.7

1.4

3.2

3.301.7

1.8

1.8

1.8

1.8

1.7

0

0

1.6

1.5

1.6

1.6

1.7

1.7

1.7

2.0

1.9

1.8

1.6

0

3.3

3.3

1.6

1.6

0

1.3

1.7

1.7

1.7

1.7

1.7

3.4

3.43.4

1.7

0

0

0

3.3

3.3

1.7

0

1.7

3.3

1.703.3

3.3

3.303.3

3.3

1.6

1.7

0

0

3.303.303.3

3.3

3.3

3.3

0

1.6

3.3

3.3

1.6

3.3

0

CD IN

DIGITAL OUT

USB IN

AUDIO OUT

R820

J811

D803

MN6627971YA

USB

MICROPROCESSOR

CD CONTROLLER

ACTUATOR DRIVER

SDRAM

POINT A-1 XL601 (Pin 109 of IC602) POINT A-2 XL603 (Pin 12 of IC604)

VDD

A3

A2

A1

A0

A10/AP

BA

CS

RAS

CAS

WE

LDQM

DQ7

V

SSQ

DQ2

V

DDQ

DQ4

V

SSQ

DQ6

V

DDQ

DQ1

DQ5

DQ3

DQ0

VDD

VSS

A4

A5

A6

A7

A8

A9

N.C

CKE

CLK

UDQM

N.C/RFU

DQ8

V

SSQ

DQ13

V

DDQ

DQ11

V

SSQ

DQ9

V

DDQ

DQ14

DQ10

DQ12

DQ15

V

SS

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

IC605: M12L16161A-7TG

512 K x 16-bit x 2 banks synchronous DRAM

Bank Select

Data Input Register

Column Decoder

Latency & Burst Length

Programming Register

Timing Register

LWCB R

LDQM

DQi

LDQM

LWE

LCAS

LWELCBRLRAS

CLK CKE CS RAS CAS WE L(U)DQM

LCKE

LCBR

LRAS

ADD

CLK

512K x 16

512K x 16

Address Register

Row DecoderCol. Buffer

Sense AMP

Output Buffer I/O Control

Row Buffer

Refresh Counter

VIN

4

EN

1

2

5

GATE

CONTROL

UVLO

THERMAL

SHUTDOWN

CURRENT

LIMIT

FLAG

DELAY

V

OUT

3 FLG

GND

IC606: R5523N001A-TR-F

High side switch IC

IC604: MN103SFB5KYAA

USB microprocessor

TIMER

INTERRUPT

CONTROL

WDTx1

35 Factor

INTERFACE

MEMORY

8 KB

256 KByte

8 KByte

8-bit x 4

16-bit x 2

DMA 4 CH

USB

ROM

32 bit

MICRO-

PROCESSOR

CORE

FLASH

MEMORY

DATA

RAM

SIF

x 2

I2C

x 1

34 pcs (3 V type)

8 pcs (5 V type)

CLOCK &

SYSTEM control

I/O port

to OPERATION (8)_CB162

(Writing port)

To Loader ass’y

Page 41

H4

To Loader ass’y

IC304

IC305

CB301

CB300

IC311

IC302

IC300

IC303

IC306

IC307

IC309

IC310

IC310

CB304

CB303

IC308

IC308

IC308

IC308

IC310

A

1

2

3

4

5

6

7

8

9

10

BCDEFGH I J K

L MN

CD-S700

40

DIGITAL 2/2

A-3

B-2

B-1

4.9

4.2

4.9

4.9

3.3

3.3

0

4.2

4.2

0

4.2

0

20.0

20.0

4.901.0

10.0

7.9

7.9

7.9

7.4

7.4

0

0

7.4

0

0

0

3.3

3.3

0

1.7

4.9

1.7

0

3.3

3.3

3.3

3.3

3.3

3.3

0

0

7.9

7.9

0.6

0.8

0.8

0

1.0

0

0.4

0.6

0

0

0

7.9

7.9

0.6

3.3

3.3

0

0.8

0.8

0.6

0

3.1

3.3

3.3

0

0

3.3

3.3

3.3

0

0

3.3

3.3

4.9

4.9

4.9

0

3.3

0

4.9

0

0

0

3.3

3.3

3.3

3.3

0

0

0

3.3

1.701.5

3.3

3.3

3.3

000

0

3.3

0

3.3

3.3

3.3

3.3

0

0

3.30003.2

3.2

3.3

3.3

3.3

3.3

0

1.6

3.3

3.3

0

3.3

3.3

3.3

0

0

0

3.3

3.3

0

4.9

0

2.5

2.5

0

2.5

5.0

2.5

2.5

0

5.0

2.5

0

20.0

20.0

7.901.1

20.0

1

2

DIGITAL OUT

AUDIO OUT

C816

BD5229G–TR

J812

J810

C817

2200P(B)

MICROPROCESSOR

CLAMP DRIVER

LOADING DRIVER

BUFFER AMP.

LEVEL

SHIFTER

OPTICAL

COAXIAL

DIGITAL OUT

Vref

Vout

GND

V

DD

N.C.

N.C.

4

1

2

3

5

–

+

IC307: BD4829G-TR

Voltage detector IC

IC305, 306: LB1641

Motor driver

INPUT LOGIC

IN 1

IN 2

VZ

P1

P2

OUT 1

OUT 2

VCC 2

VCC 1

GND

PRE DRIVER

1

3281097

4

6

5

IC304: M30302FAPFP

Single-chip 16-bit microprocessor

Timer (16-bit)

Peripheral function

Input (timer A) x3

Output (timer B) x3

Watchdog timer

(15-bit)

DMAC

(2-channel)

A/D converter

(10-bit X 18-channel

)

System clock generator

X

IN-XOUT

X

CIN-XCOUT

M16C/60 series

Microprocessor core

Port P08Port P18Port P28Port P38Port P48Port P58Port P6

8

8

R0LR0H

R1H R1L

R2

R3

ISP

USP

INTB

SB

CRC arithmetic circuit (CCITT)

(Polynomial : X

16+X12+X5

+1)

Multiplier

7

8

Port P9

8

Port P10

Port P8_5

Port P8

Port P7

Memory

ROM

(Note 1)

RAM

(Note 2)

FB

A1

FB

A1

A0

FLG

PC

UART or clock synchronous type

serial I/O

(3-channel)

Note 1: ROM contents var y depending on types.

RAM contents vary depending on types.

Note 2:

VDD

CE

Pin No.

1

2, 5

3

4

6

Symbol

V

OUT

GND

CE

NC

V

DD

Description

Output Pin of Voltage Regulator

Ground Pin

Chip Enable Pin

No Connection

Input Pin

Vref

61

3 2,5

Current Limit

VOUT

GND

IC303: R1172S331B-E2-F

CMOS-based positive-voltage regulator IC

IC308: TC74VHCT08AFT

Quad 2-input AND gate

Vcc14

4B

4A

4Y

3B

3A

3Y

1A 1

2

3

13

12

11

10

9

8

4

5

6

7

1B

1Y

2A

2B

2Y

GND

1

3

2

5

4

GND

V

CC

IC309: TS7ST00F

2-input NAND gate

IN A

IN B

OUT Y

IC310: TC7WU04F

Triple inverter

1

2

3

4

8

7

6

5

1A

3Y

2A

GND

V

CC

1Y

3A

2Y

VDD

CE

Pin No.

1

2

3

4

5

6

Symbol

V

OUT

GND

CE

NC

V

DD

Description

Output Pin of Voltage Regulator

Ground Pin

GND Ground Pin

Chip Enable Pin (“H” Active)

No Connection

Input Pin

Vref

16

2,54

Current Limit

VOUT

GND

IC311: RP131S501D-E2-F

Voltage regulator

POINT B-1 B-2 1 / Pin2, 2 / Pin1 of IC307

12 pin

1 pin

2 pin

1 pin

2

1

2

AC cable ON AC cable OFF AC cable OFF

POINT A-3 XL300 (Pin 13 of IC304)

OSC

PWM COMP DRIVER

STBY

STBY

OUT

INV

GND

VCC

TSD

OCP

Error AMP

SS

CTL

LOGIC

IC300, 302: BD9870FPS-E2

High stand voltage 1 channel step-down switching regulator

VREF

1

5

FIN

4

2

to OPERATION (4)_W208

Page 42

L5

to OPERATION (3)_W2

Page 41

G6

to OPERATION (9)_CB151

Writing port

Page 42

F8

To Loader ass’y

CB101

IC802

W2

CB162

CB161

W101BW101A

CB1

IC4

IC2

IC2

IC1

A

1

2

3

4

5

6

7

8

9

10

BCDEFGH I J K

L MN

CD-S700

41

OPERATION 1/2

5.5

0.6

0.8

0

0

4.9

4.9

4.9

3.5

5.1

30.3

0.8

0.8

5.5

0.6

30.3

30.3

5.7

0

30.3

5.1

5.7

3.4

3.4

4.9

3.3

0

3.3

3.4

0

0

4.9

3.5

0

3.3

0

1.9

0

0

0.8

16.10

14.8

16.1

3.9

3.7

3.9

-11.6

3.7

5.8

16.2

16.2

4.8

4.8

5.8

16.2

16.2

-12.9

-12.9

-11.7

11.5

0

3.0

0

0.7

0.7

0.6

0.6

0

11.5

-11.6

-11.6

-11.6

-11.6

0

-11.6

0

0

-11.6

0

0

-11.6

-11.5

-11.6

-11.5

-11.6

0

0

-11.6

0

1.7

1.7

0.901.6

0

0

4.7

0

1.1

1.1

2.2

3.3

3.0

3.3

3.3

3.3

000

0

4.7

4.7

0

1.1

1.1

0

4.7

-11.6

0

5.8

-16.2

0

16.2

-16.2

-16.2

0

16.2

-12.9

0

16.0

16.2

0

16.1

16.10

AUDIO OUT

330

s16

s16

s18

s17

s18

s17

330

100/50

100/50

330

1000/16

GSR

D/A CONVERTER

OPERATION (1)

ANALOG OUT

OPERATION (8)

OPERATION (3)

OPERATION (2)

USB

POWER

indicator

PURE DIRECT

indicator

USB indicator

Power Supply

DSDL

SCK

Advanced

Segment

DAC

Modulator

V

OUT

L+

V

OUT

L

Bias

and

Vref

V

CC

F

V

DD

AGNDR

V

CC

R

AGNDL

AGNDF

D/S and Filter

8

Oversampling

Digital

Filter

and

Function

Control

Audio

Data Input

I/F

PLRCK

PBCK

PDATA

MDI

MC

MS

AGNDC

V

CC

C

DGND

Current

Segment

DAC

and

I/V Buffer

V

COM

Function

Control

I/F

Zero

Detect

ZEROL

ZEROR

System

Clock

Manager

DSDR

DBCK

V

CC

L

V

OUT

R

V

OUT

R+

D/S and Filter

Current

Segment

DAC

and

I/V Buffer

RST

1

2

3

4

5

6

7

8

9

10

11

12

13

14

28

27

26

25

24

23

22

21

20

19

18

17

16

15

PLRCK

PBCK

PDATA

DBCK

SCK

RST

V

DD

DGND

AGNDF

V

CC

R

AGNDR

V

OUT

R

V

OUT

R+

V

COM

MS

MC

MDI

DSDL

DSDR

ZEROL

ZEROR

V

CC

F

V

CC

L

AGNDL

V

OUT

L

V

OUT

L+

AGNDC

V

CC

C

IC1: DSD1791DBR

24-bit, 192 kHz sampling, advanced segment, audio stereo digital-to-analog converter

IC4: PQ033ES3MXP

Low power loss regulator

3

DC input (Vin)

1

DC output (Vo)

2

GND

IC

IC2: OP275GSR

Dual bipolar/JFET, audio operational amplifier

OUT A

-IN A

V-

V+

OUT B

1

2

3

4

5

+IN A -IN B

+IN B

6

7

8

1

3

2

5

4

GND

AB Y

V

CC

IC802: TC7SH08F

2-input AND gate

IN A

IN B

OUT Y

LL L

LH L

HL L

HH H

to DIGITAL_CB301

Page 40

D7

to OPERATION (4)_CB206

Page 42

J3

to DIGITAL_CB609

Page 39

M6

to OPERATION (9)_CB152

Page 42

I7

CB151

CB153

CB152

W208

CB206

W202A

W203A

W205A

W201A

W204A

W202B

CB205

W207B

CB204

W207A

W206B

W206A

W203B

W205B

W201B

W204B

A

1

2

3

4

5

6

7

8

9

10

BCDEFGH I J K

L MN

CD-S700

42

OPERATION 2/2

0

29.6

10.0

29.6

20.0

20.0

39.1

20.0

10.0

20.0

10.0

0

10.0

5.4

0

0

30.3

31.0

39.1

31.0

0

10.0

10.0

AC27.4

AC15.9

AC16.1

AC4.6

s16

s17

s18

IC2

C27

C28

C34

C33

XV763A0

OP275GSR

WJ60860

560P/100

WJ60990

6800P/100

YA089A0

LME49723MA

WE10140

560P/100

WE10270

6800P/100

YA089A0

LME49723MA

WE10140

560P/100

WE10140

560P/100

YA089A0

LME49723MA

WE10140

560P/100

WE10140

560P/100

YA089A0

LME49723MA

WE10140

560P/100

WE10140

560P/100

2200/35

1P22K

0.01(B)

4700/35

1P22K

OPERATION (7)

OPERATION (6)

OPERATION (5)

OPERATION (9)

OPERATION (4)

POWER ON/OFF

AC IN

R, L models

VOLTAGE

SELECTOR

to OPERATION (1)_CB101

Page 41

A2

to DIGITAL_CB303

Page 40

M4

to DIGITAL_CB300

Page 40

B5

to OPERATION (3)_CB1

Page 41

G10

To Loader ass

’y

■ REPLACEMENT PARTS LIST

• ELECTRICAL COMPONENT PARTS

WARNING

● Components having special characteristics are marked ⚠ and must be replaced with parts having specifications

equal to those originally installed.

● The chip resistor is not supplied as a replacement part.

* When a chip resistor is necessary, use the following part.

AAX60720: CHIP RESISTOR SAMPLE BOOK

● ⚠印のある部分は、安全確保部品を示しています。部品の交換が必要な場合、パーツリストに記載されている部品を使用し

てください。

● チップ抵抗はサービス部品として供給しません。

※ チップ抵抗が必要な場合は、下記の部品をご利用ください。

AAX60720:CHIPRESISTORSAMPLEBOOK

● 部品価格ランクは、予告なく変更することがあります。

ABBREVIATIONS IN THIS LIST ARE AS FOLLOWS:

C.A.EL.CHP : CHIP ALUMI.ELECTROLYTIC CAP

C.CE : CERAMIC CAP

C.CE.ARRAY : CERAMIC CAP ARRAY

C.CE.CHP : CHIP CERAMIC CAP

C.CE.ML : MULTILAYER CERAMIC CAP

C.CE.M.CHP : CHIP MULTILAYER CERAMIC CAP

C.CE.SAFTY : RECOGNIZED CERAMIC CAP

C.CE.TUBLR : CERAMIC TUBULAR CAP

C.CE.SMI : SEMI CONDUCTIVE CERAMIC CAP

C.EL : ELECTROLYTIC CAP

C.MICA : MICA CAP

C.ML.FLM : MULTILAYER FILM CAP

C.MP : METALLIZED PAPER CAP

C.MYLAR : MYLAR FILM CAP

C.MYLAR.ML : MULTILAYER MYLAR FILM CAP

C.PAPER : PAPER CAPACITOR

C.PLS : POLYSTYRENE FILM CAP

C.POL : POLYESTER FILM CAP

C.POLY : POLYETHYLENE FILM CAP

C.PP : POLYPROPYLENE FILM CAP

C.TNTL : TANTALUM CAP

C.TNTL.CHP : CHIP TANTALUM CAP

C.TRIM : TRIMMER CAP

CN : CONNECTOR

CN.BS.PIN : CONNECTOR,BASE PIN

CN.CANNON : CONNECTOR,CANNON

CN.DIN : CONNECTOR,DIN

CN.FLAT : CONNECTOR,FLAT CABLE

CN.POST : CONNECTOR,BASE POST

COIL.MX.AM : COIL,AM MIX

COIL.AT.FM : COIL,FM ANTENNA

COIL.DT.FM : COIL,FM DETECT

COIL.MX.FM : COIL,FM MIX

COIL,OUTPT : OUTPUT COIL

DIOD.ARRAY : DIODE ARRAY

DIODE.BRG : DIODE BRIDGE

DIODE.CHP : CHIP DIODE

DIODE.VAR : VARACTOR DIODE

DIOD.Z.CHP : CHIP ZENER DIODE

DIODE.ZENR : ZENER DIODE

DSCR.CE : CERAMIC DISCRIMINATOR

FER.BEAD : FERRITE BEADS

FER.CORE : FERRITE CORE

FET.CHP : CHIP FET

FL.DSPLY : FLUORESCENT DISPLAY

FLTR.CE : CERAMIC FILTER

FLTR.COMB : COMB FILTER MODULE

FLTR.LC.RF : LC FILTER,EMI

GND.MTL : GROUND PLATE

GND.TERM : GROUND TERMINAL

HOLDER.FUS : FUSE HOLDER

IC.PRTCT : IC PROTECTOR

JUMPER.CN : JUMPER CONNECTOR

JUMPER.TST : JUMPER,TEST POINT

L.DTCT : LIGHT DETECTING MODULE

CD-S700

L.EMIT : LIGHT EMITTING MODULE

LED.DSPLY : LED DISPLAY

LED.INFRD : LED,INFRARED

MODUL.RF : MODULATOR,RF

PHOT.CPL : PHOTO COUPLER

PHOT.INTR : PHOTO INTERRUPTER

PHOT.RFLCT : PHOTO REFLECTOR

PIN.TEST : PIN,TEST POINT

PLST.RIVET : PLASTIC RIVET

R.ARRAY : RESISTOR ARRAY

R.CAR. : CARBON RESISTOR

R.CAR.CHP : CHIP RESISTOR