Yamaha CDRS-1000 Service manual

CDR-S1000

COMPACT DISC RECORDER

CDR-S1000

SERVICE MANUAL

CDR-S1000

This manual has been provided for the use of authorized YAMAHA Retailers and their service personnel.

It has been assumed that basic service procedures inherant to the industry, and more specifically YAMAHA Products, are already

known and understood by the users, and have therefore not been restated.

WARNING: Failure to follow appropriate service and safety procedures when servicing this product may result in personal

IMPORTANT: The presentation or sale of this manual to any individual or firm does not constitute authorization, certification or

The data provided is believed to be accurate and applicable to the unit(s) indicated on the cover. The research, engineering, and

service departments of YAMAHA are continually striving to improve YAMAHA products. Modifications are, therefore, inevitable

and specifications are subject to change without notice or obligation to retrofit. Should any discrepancy appear to exist, please contact

the distributor's Service Division.

WARNING: Static discharges can destroy expensive components. Discharge any static electricity your body may have accumu-

IMPORTANT: Turn the unit OFF during disassembly and parts replacement. Recheck all work before you apply power to the unit.

injury, destruction of expensive components and failure of the product to perform as specified. For these reasons,

we advise all YAMAHA product owners that all service required should be performed by an authorized

YAMAHA Retailer or the appointed service representative.

recognition of any applicable technical capabilities, or establish a principle-agent relationship of any form.

lated by grounding yourself to the ground buss in the unit (heavy gauge black wires connect to this buss).

■ CONTENTS

TO SERVICE PERSONNEL................................... 1—2

REAR PANELS............................................................. 3

SPECIFICATIONS.........................................................4

INTERNAL VIEW ..........................................................5

DISASSEMBLY PROCEDURES ............................ 5—7

SERVICE CHECK PROCEDURES ........................ 8—9

TEST PROGRAM ................................................ 10—13

IMPORTANT NOTICE

IC DATA .............................................................. 14—24

PIN CONNECTION DIAGRAM...................................25

PRINTED CIRCUIT BOARD ..............................26—33

BLOCK DIAGRAM .............................................. 34—35

SCHEMATIC DIAGRAM..................................... 36—39

REMOTE CONTROL TRANSMITTER .......................40

PARTS LIST........................................................ 41—50

100701

CDR-S1000

■ TO SERVICE PERSONNEL

CDR-S1000

1. Critical Components Information

Components having special characteristics are marked Z

and must be replaced with parts having specifications equal

to those originally installed.

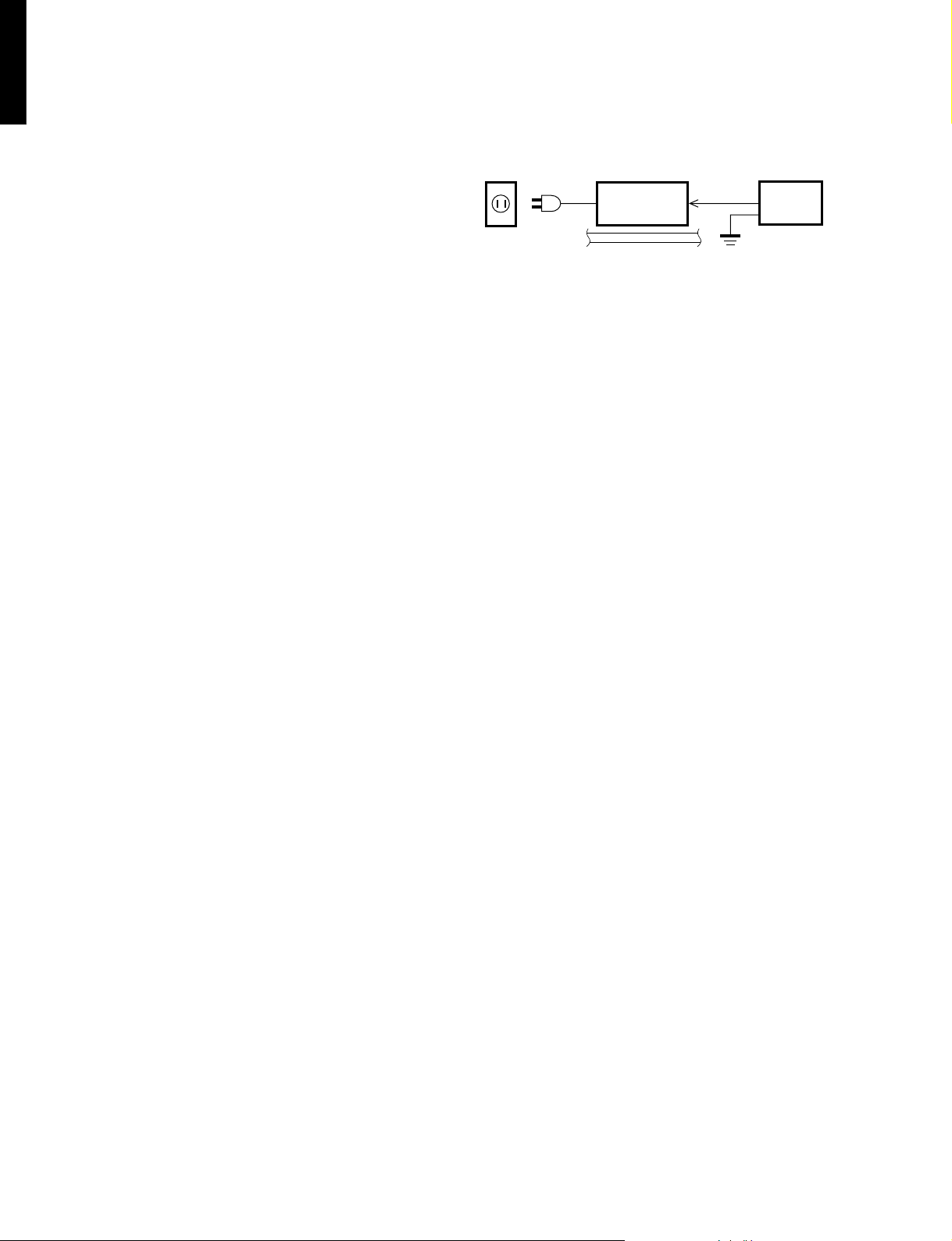

2. Leakage Current Measurement (For 120V Models Only)

When service has been completed, it is imperative to verify

that all exposed conductive surfaces are properly insulated

from supply circuits.

● Meter impedance should be equivalent to 1500 ohm shunted

by 0.15µF.

● Leakage current must not exceed 0.5mA.

WALL

OUTLET

● Be sure to test for leakage with the AC plug in both

polarities.

EQUIPMENT

UNDER TEST

INSULATING

TABLE

AC LEAKAGE

TESTER OR

EQUIVALENT

WARNING: CHEMICAL CONTENT NOTICE!

The solder used in the production of this product contains LEAD. In addition, other electrical/electronic and/or

plastic (where applicable) components may also contain traces of chemicals found by the California Health and

Welfare Agency (and possibly other entities) to cause cancer and/or birth defects or other reproductive harm.

DO NOT PLACE SOLDER, ELECTRICAL/ELECTRONIC OR PLASTIC COMPONENTS IN YOUR MOUTH FOR

ANY REASON WHATSOEVER!

Avoid prolonged, unprotected contact between solder and your skin! When soldering, do not inhale solder fumes

or expose eyes to solder/flux vapor!

If you come in contact with solder or components located inside the enclosure of this product, wash your hands

before handling food.

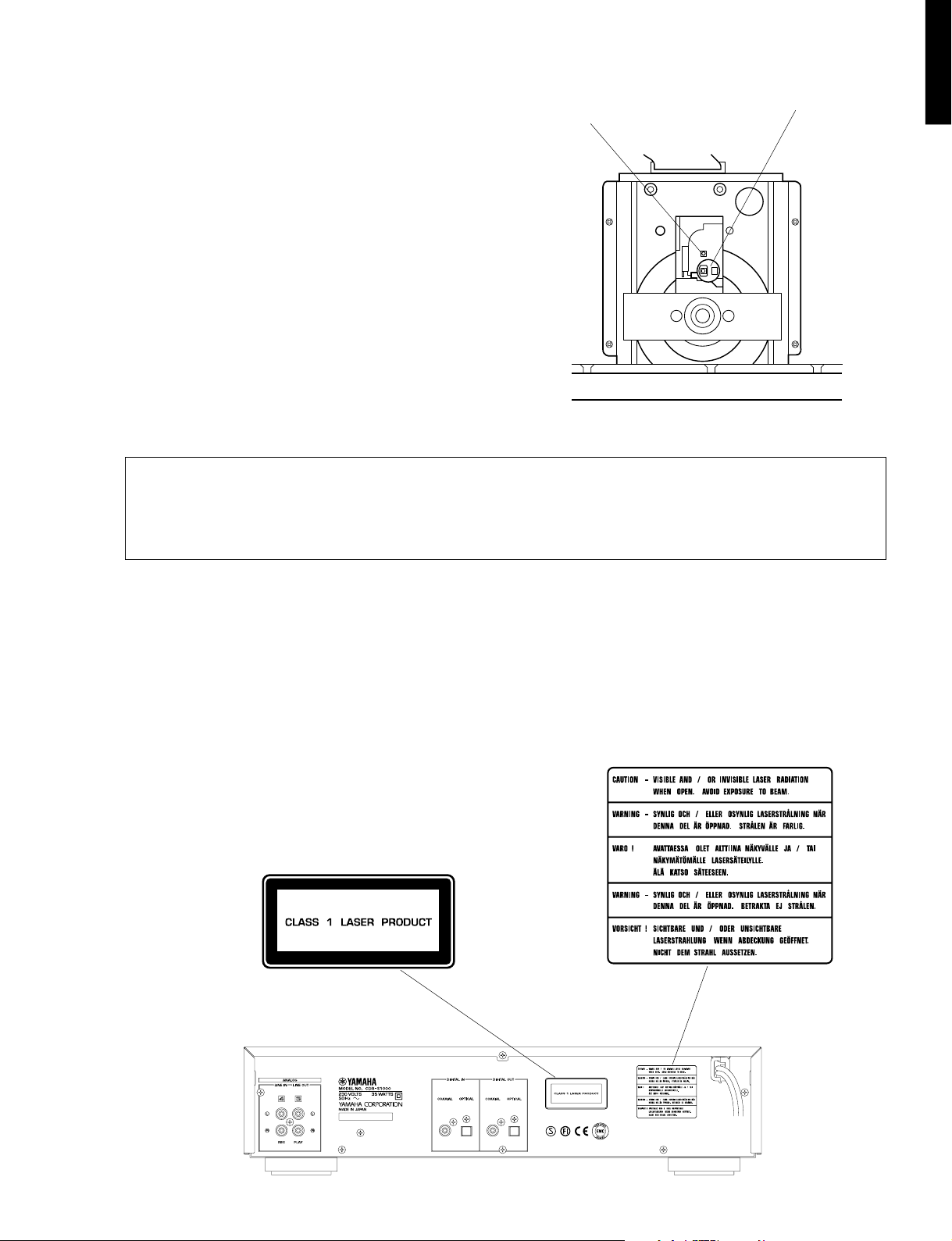

WARNING: Laser Safety

This product contains a laser beam component. This component may emit invisible, as well as visible radiation,

which may cause eye damage. To protect your eyes and skin from laser radiation, the following precautions must

be used during servicing of the unit.

1) When testing and/or repairing any component within the product, keep your eyes and skin more than 30 cm away from

the laser pick-up unit at all times. Do not stare the laser beam at any time.

2) Do not attempt readjustment, disassemble or repair of the laser pick-up, unless noted elsewhere in this manual.

3) CAUTION : Use of controls, adjustments or preformance of procedures other than those specified herein may result in

hazardous radiation exposure.

Laser Emitting conditions:

1) When the Top Cover is removed, and POWER SW is turned to the "ON" position, the laser component will emit a beam

for several seconds to detect if a disc is present. During this time (5-10 sec.) the laser may radiate through the lens of

the laser pick-up unit. Do not attempt any servicing during this period !

If no disc is detected, the laser will stop emitting the beam. When a disc is set, you will not be exposed to any laser

emissions.

2) The laser power level can be adjusted with VR on pick-up PWB, however, this level has been set by the factory prior to

shipping from the factory. Do not adjust this laser level control unless instruuction is provided elsewhere in this manual.

Adjustment of this control can increase the laser emission level from the device.

1

CDR-S1000

CDR-S1000

Laser Diode Properties

Material : GaAlAs

Variable resistor

(Do not turn)

Optical pick-up

Wavelength : 783 – 789 nm

Emission duration : Continuous

Laser output : Max. 44.6µW*

ANSI Class : Class 1

* This output is the value measured at a distance of about

200 mm from the objective lens surface on the Optical Pickup Block.

VARO! : AVATTAESSA JA SUOJALUKITUS OHITETTAESSA OLET ALTTIINA NÄKYMÄTTÖMÄLLE

LASER-SÄTEILYLLE. ÄLÄ KATSO SÄTEESEEN.

VARNING! : OSYNLIG LASERSTRÅLNING NÄR DENNA DEL ÄR ÖPPNAD OCH SPÄRREN ÄR URKOPPLAD.

BETRAKTA EJ STRÅLEN.

B, G models

A, B, G models

2

CDR-S1000

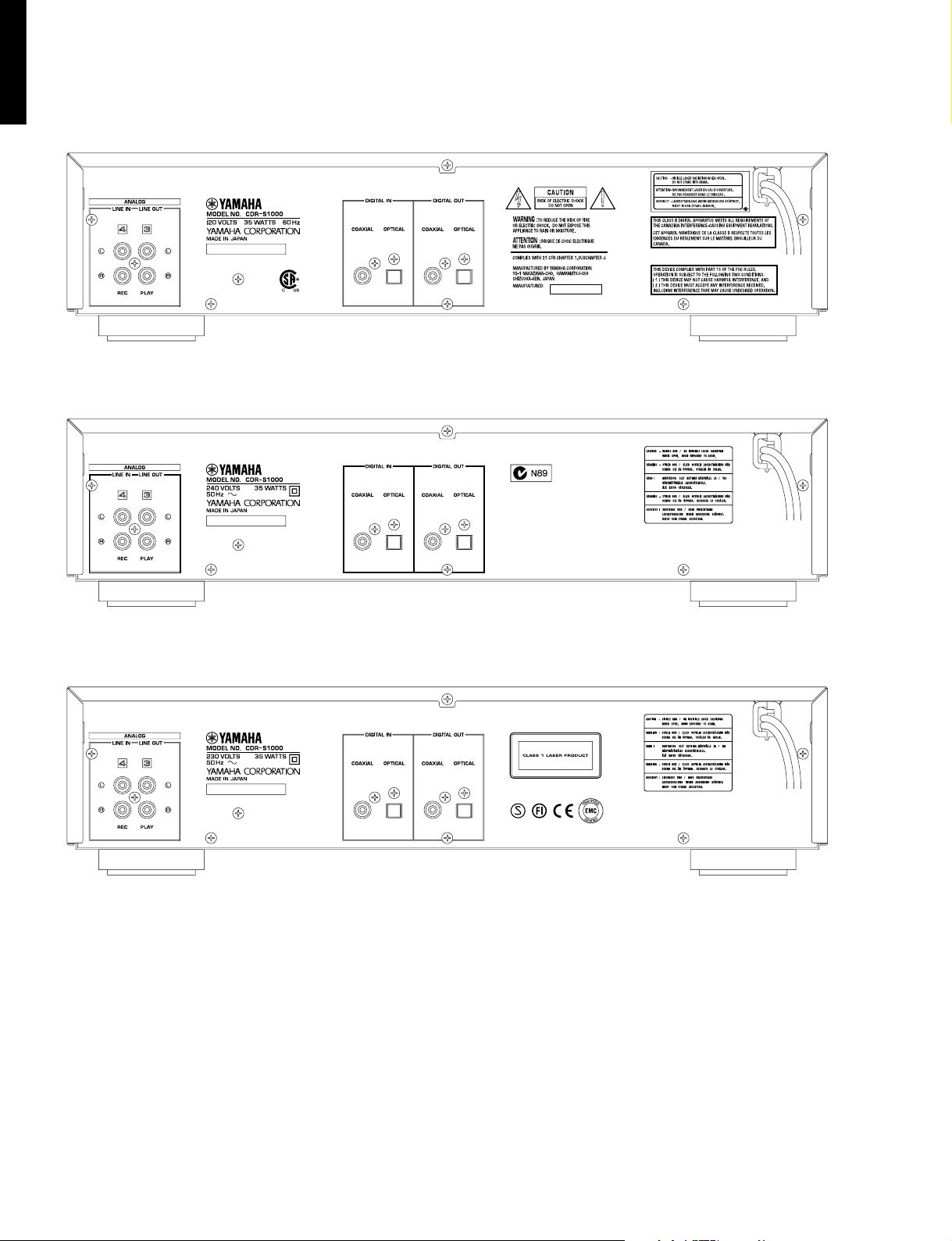

■ REAR PANELS

CDR-S1000

▼ U, C models

▼ A model

▼ B, G models

3

■ SPECIFICATIONS

CDR-S1000

CDR-S1000

GENERAL

Model Compact disc recorder

Application discs CDs, CD-Rs for AUDIO,

CD-RWs for AUDIO

Power Requirements

U, C models 120V AC 60Hz

B, G models 230V AC 50Hz

A model 240V AC 50Hz

Power Consumption 35W

Dimensions (W x H x D) 435 x 108 x 400mm

(17-1/8" x 4-1/4" x 15-3/4")

Weight 6.3kg (13 lbs 14 oz)

Operating Temperature Range +5˚C to +35˚C

Panel Color Black

AUDIO PERFORMANCE

Output Level

1kHz, 0dB 2.0 ± 0.5Vrms

Frequency Response (EIAJ)

5Hz — 20kHz ±0.5dB

Signal to Nosie Ratio (EIAJ)

Playback 107dB

Recording 90dB

INPUT/OUTPUT

Line Output

Output Level 2.0 Vrms

Output Impedance 990Ω

Line Input

Input Sensitivity 500m Vrms

Input Impedance 24kΩ (REC LEVEL Max.)

Digital Output

Coaxial Output Level 0.5Vp-p (75Ω)

Optical Output Level -20 dBm

Sampling Frequency 44.1kHz

Digital Input

Coaxial Input Level 0.5Vp-p (75Ω)

Optical Input Level -20 dBm

Input Gain ±12dB, with Digital Volume

Sampling Frequency

Tolerance 32kHz to 48kHz, with SRC

Headphone Output

Output Level 300m Vrms (-20dB, 150Ω load)

*Specifications are subject to change without notice.

U ...................U. S. A. model

C ................Canadian model

A .............. Australian model

±0dB, without Digital Volume

44.1kHz ±100ppm, without SRC

(CD DIRECT mode)

(PHONES LEVEL Max.)

B .................... British model

G ............... European model

Dynamic Range (EIAJ)

Playback 100dB

Recording 94dB

Total Harmonic Distortion (1kHz)

Playback 0.004%

Recording 0.008%

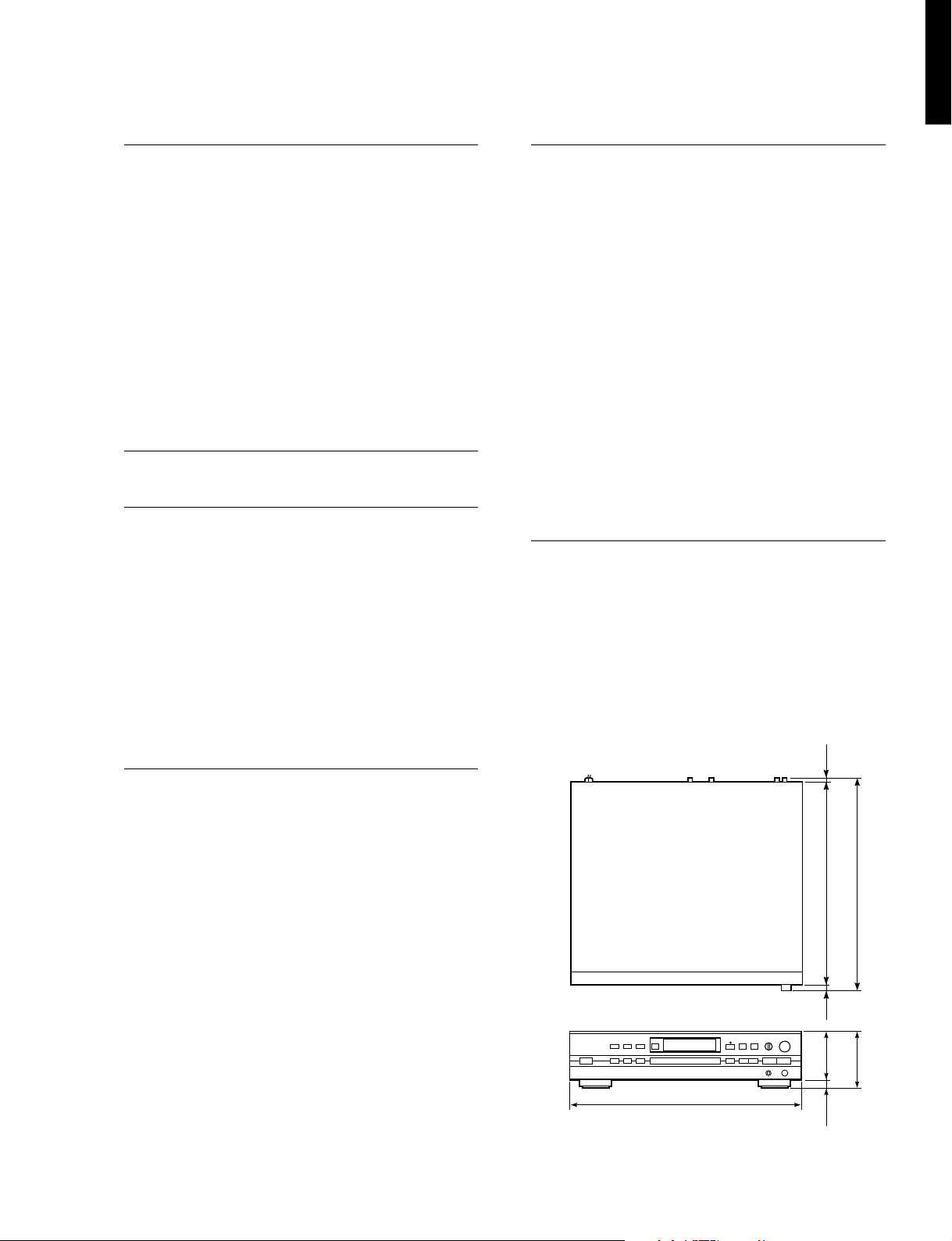

● DIMENSION

435 (17-1/8")

7

(1/4")

381 (15")

12

(1/2")

91

108

(3—9/16")

17

(11/16")

400 (15—3/4")

(4—1/4")

Unit : mm (inch)

4

CDR-S1000

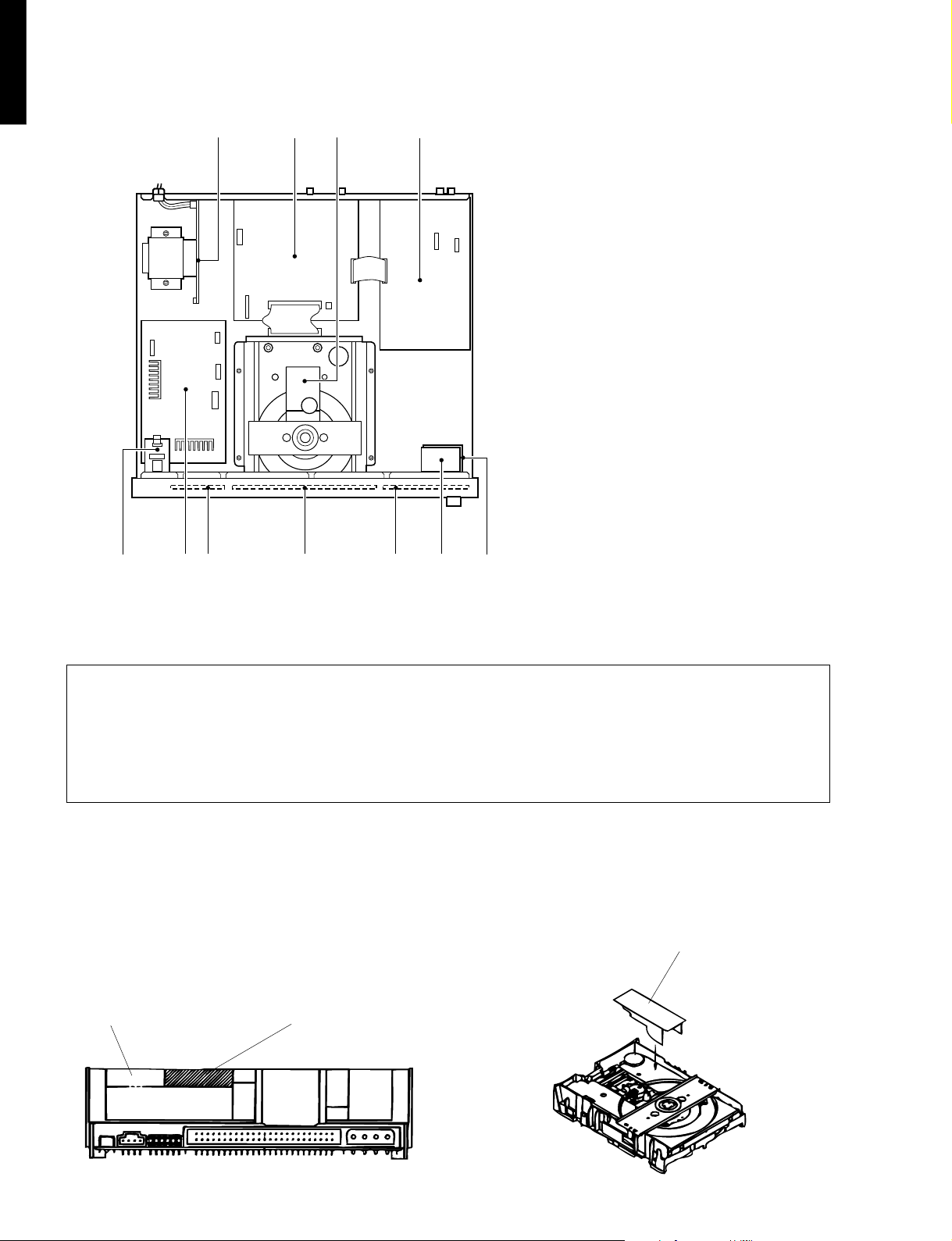

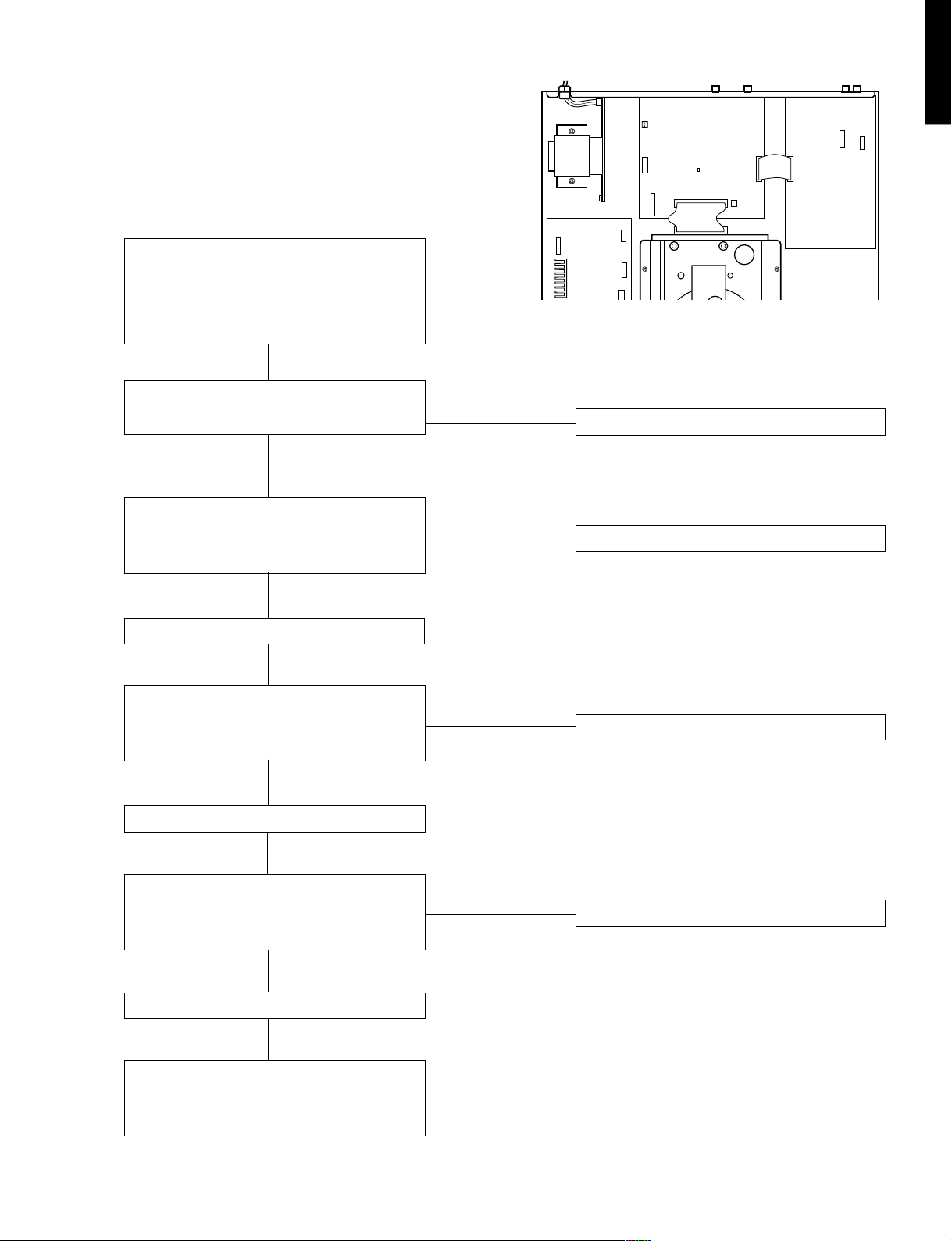

■ INTERNAL VIEW

CDR-S1000

q

w

e

r

q ANALOG P.C.B. (3)

w MAIN P.C.B. (1)

e CDR MECHANISM UNIT

r ANALOG P.C.B. (1)

t PANEL P.C.B. (5)

y ANALOG P.C.B. (2)

u PANEL P.C.B. (1)

i MAIN P.C.B. (2)

o PANEL P.C.B. (2)

!0 PANEL P.C.B. (3)

!1 PANEL P.C.B. (4)

t !1

y iu o !0

■ DISASSEMBLY PROCEDURES (Remove parts in disassembly order as numbered.)

CDR MECHANICAL UNIT REPLACEMENT

• When sending back the defective CDR mechanical unit for repair, send the whole unit.

• The CDR mechanical unit must be replaced as a unit. None of its components can be supplied separately.

• When sending back the defective CDR mechanical unit for repair, attach the disc which was used when the error

occurred as necessary . However, Yamaha shall not be liable even if the data in the disc has become unreadable while

the unit is being serviced/repaired.

Preparation before Replacement

a. When replacing the CDR mechanical unit, write down the following items.

• Serial No. of the product and the symptom in detail

• Mechanical serial No. / mechanical shipping serial No. of CDR mechanical unit

b. Prepare a lens cover (P/No. V4870500) to use when transporting the CDR mechanical unit.

Lens cover

Mechanical serial No. Shipping serial No.

5

CDR-S1000

CDR-S1000

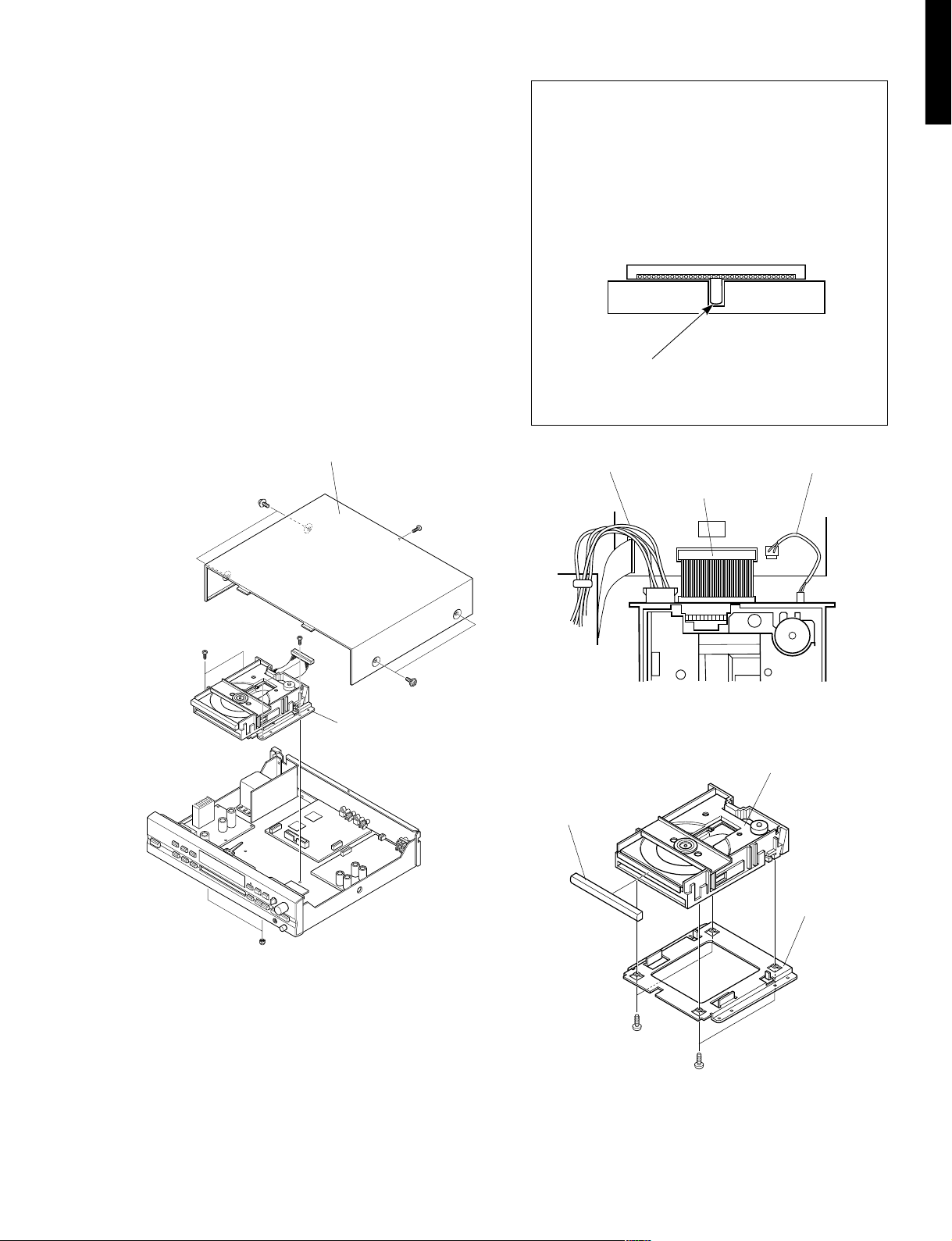

1. CDR Mechanical Unit Removal

a. Turn off the power and disconnect the power plug from

the service outlet.

CAUTION : Never disconnect any cable, remove any

screw or other part while the power switch is on.

b. Remove 4 screws marked q and 1 screw marked w,

and the Top Cover can be removed. (Fig. 1)

c. Disconnect the power cable / IDE cable / word clock

cable from the CDR mechanical unit. (Fig. 2)

d. Remove 2 hexagonal cap nuts marked e. (Fig. 1)

e. Remove 4 screws marked r, and take out the CDR

mechanical unit. (Fig. 1)

f. Remove the Lid.

g. Remove 4 screws marked t, and the Frame/CDR can

be removed. (Fig. 3)

Top Cover

q

w

IDE cable

a. Do not remove the cable from the female connector by

pulling on the cable.

b. Remove the connector from the female connector by in-

serting the minus driver into the insertion place and hooking the female connector as per fig. A.

A insertion place

Fig. A

Power Cable

IDE Cable

Word Clock Cable

r

r

q

CDR Mechanical Unit

Lid

e

Fig. 1

CDR Mechanical Unit

Fig. 2

CDR Mechanical Unit

Frame/CDR

t

Fig. 3

t

2. Transportation of CDR Mechanical Unit

a. When transporting the CDR mechanical unit, be sure to install the lens cover to it and put it in the anti-static bag before

packaging it.

6

CDR-S1000

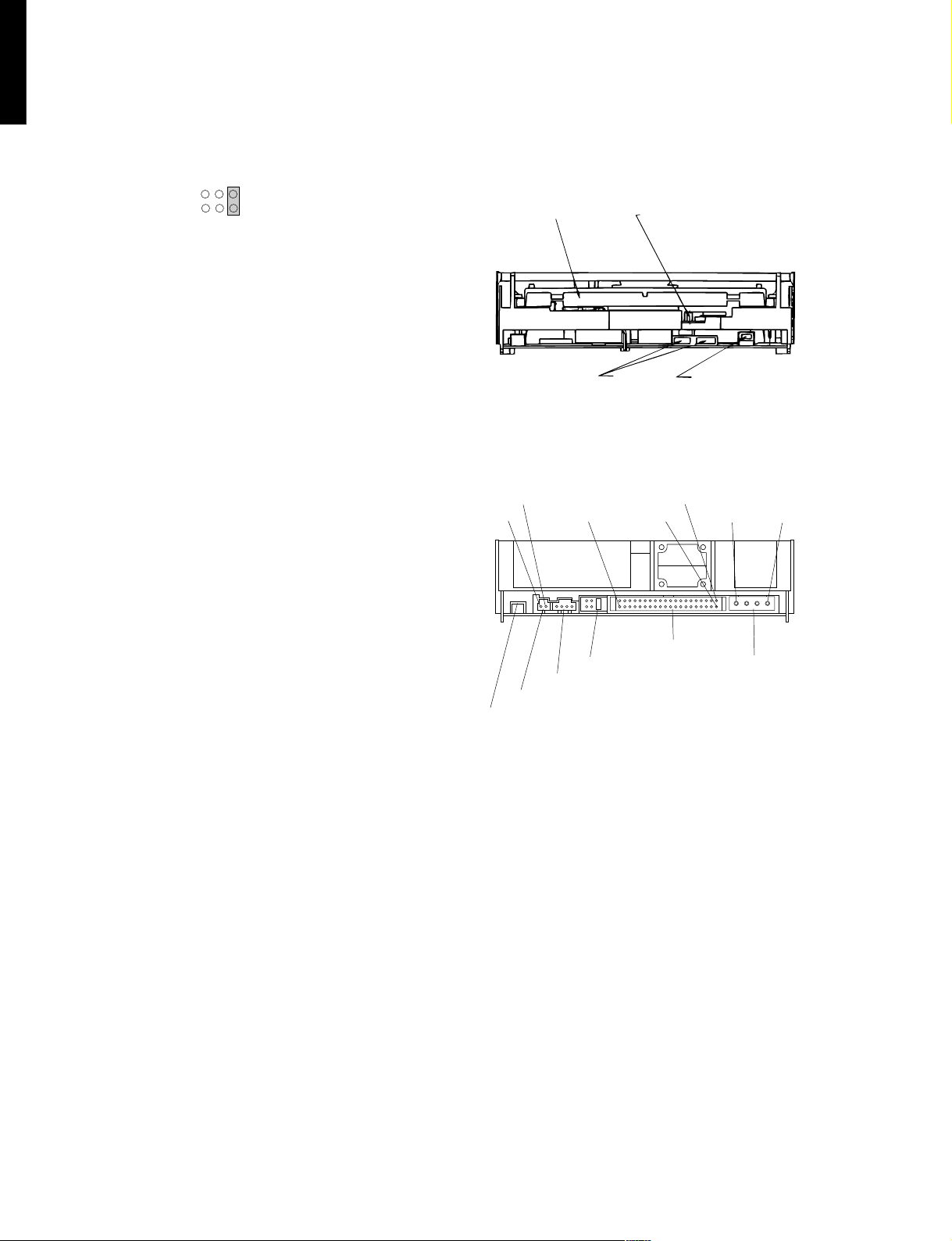

3. CDR Mechanical Unit Installation

a. Before installing the CDR mechanical unit, check that

CDR-S1000

the jumper pin on its rear panel is inserted in the MASTER jack.

MASTER

b. Install the components of the CDR mechanical unit cor-

rectly in the reverse order of the removal.

c. Use special care for the power cable of the CDR me-

chanical unit. If it is connected in reverse, the mechanical unit will be damaged and fail to operate.

The end of the power cable with a red line is the No.1

pin side (+12V). Connect it to No.1 pin of the DC power

input connector.

d. The No.1 pin side of the IDE cable of the CDR mechani-

cal unit can be identified by a red line. Connect it to

No.1 pin of the IDE interface connector.

WC

CDR mechanical unit

Usually called CDR/RW drive unit

Model name : ACRW100A

Front view (ACRW100A)

Tray

Rear view (ACRW100A)

GND

Pin 40

Manual Eject Lever

LED

Eject Switch

Pin 1

Pin 2 qr

4. Operation Check after Installation

1) Checking after turning on the power

When the power is supplied, the CDR mechanical unit

executes self-diagnosis automatically.

If an error is detected in the initial self-diagnosis, LED

segments (LED601: ON/DISC, LED602: Read/Write) on

the front panel of the mechanical unit light up (in orange) simultaneously and remain on.

If a malfunction has occurred, power on fails. (IDE command error)

2) Checking when malfunction has occurred

a. Check each cable for correct connection.

b. Check the power supply voltages. (Measure voltage at

the power connector of the mechanical unit.)

c. Check to ensure that the jumper pin on the rear panel is

inserted in the MASTER jack.

Word Clock Out

Frame Ground

Jumper Pin

Analog Audio Out

IDE Interface Connector

DC Input

7

■ SERVICE CHECK PROCEDURES

When the main unit fails to operate.

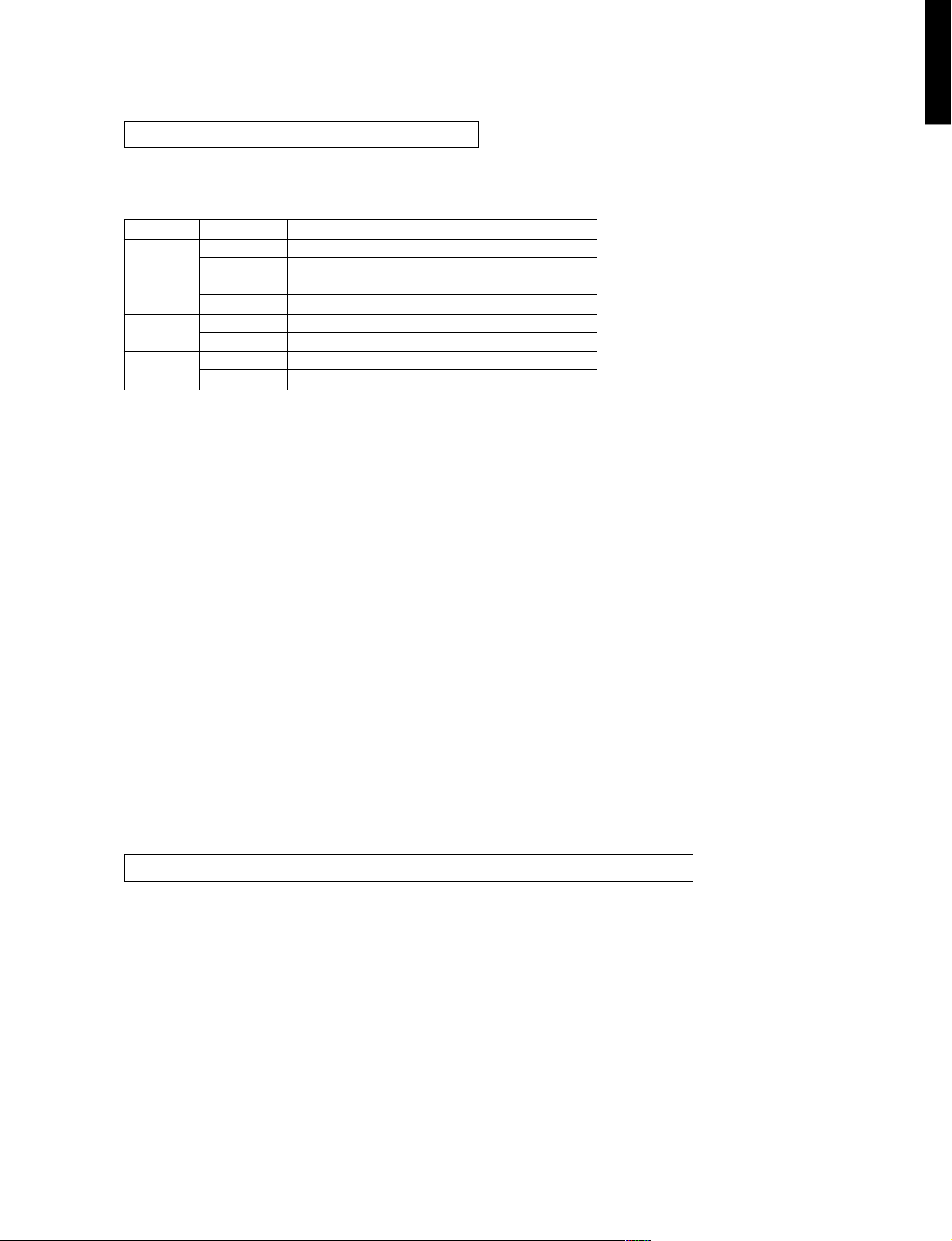

1. Check the power supply voltage of ANALOG P.C.B. (2).

CDR-S1000

CDR-S1000

Connector

W100

W201

CB601

Pin No.

1pin (+5V)

4pin (VP)

5pin (FL1)

6pin (FL2)

1pin (-VA)

3pin (+VA)

1pin (+12V)

4pin (+5V)

Specified voltage

5.0 ± 0.25V

-27.0 ± 1.5V

4.4 ± 0.4Vrms

4.4 ± 0.4Vrms

-9.5 ± 0.8V

7.3 ± 0.6V

12.0 ± 0.6V

5.0 ± 0.25V

+5V power supply (Main P.C.B.)

-27V power supply (FL display)

+4V(AC) power supply (FL display)

+4V(AC) power supply (FL display)

-VA power supply (Analog P.C.B.)

+VA power supply (Analog P.C.B.)

+12V power supply (CDR drive)

+5V power supply (CDR drive)

Remarks

2. Turn off the power to check the condition of the CDR drive section.

3. Disconnect the IDE cable.

4. Turn on the power and check the CDR drive section for proper operation.

(Check the condition of the CDR drive.)

The CDR drive should operate by itself.

(Focusing, disc motor revolution)

Operation failure means defective CDR drive.

5. Turn on the power again and check the CPU and FL display for proper operation.

Does the FL display light up after a few seconds?

Is the FL driver accessed?

(FL DATA, FL SCK, FL N CS)

6. Turn off the power and connect the IDE cable.

7. Start the TEST program and check the condition of the main P.C.B.(by using the self-

diagnosis function).

When skipping occurs from time to time, playback/recording is disabled.

1. Using a standard disc (TDK CD-RXA74 or TDK CD-RWXA74), check if recording and playback are executable.

CAUTION: How to handle discs

• Handle the disc with special care not to scratch it or make it dirty. Also do not expose it to ultra-violet rays when keeping it in

storage. (Greater care should be used than when handling a CD disc.)

• CD-RW74 can be used repeatedly but use a number of 20 times as a rough standard for the limit.

• If the CD-R is a self-record/playback type, it can be reused (for additional recording) unless it is finalized.

(Nothing can be recorded additionally if finalized.)

The CD-R disc which has not been finalized cannot be played back on a general type CD player..

• To play back the CD-RW, an applicable type CD player must be used.

8

CDR-S1000

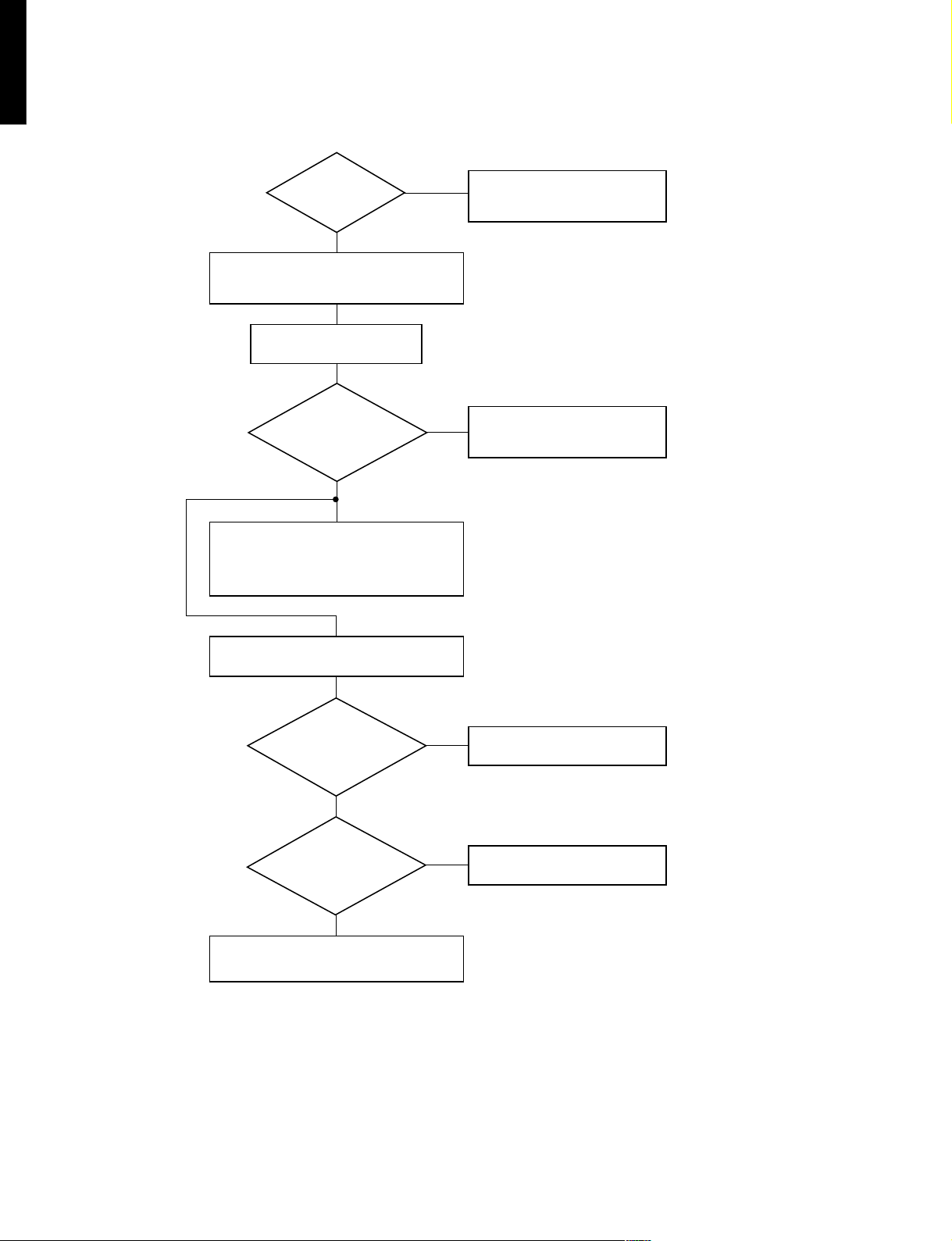

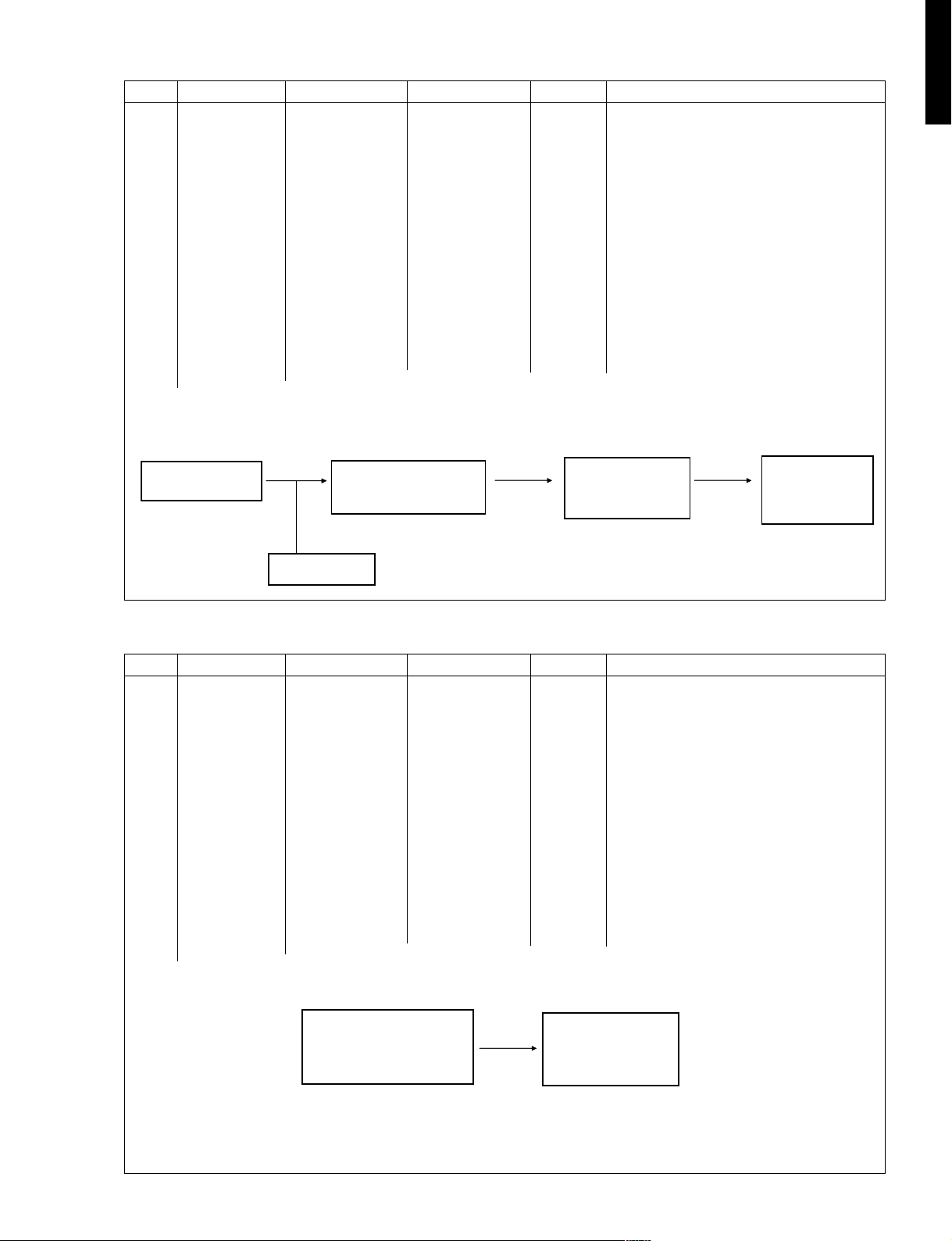

SERVICE CHECK FLOW CHART

CDR-S1000

Check the power

NG

supply

OK

Turn off the power to the drive section

to check its condition.

Disconnect the IDE cable.

Turn on the power and

NO

check the operation.

YES

If the drive starts operating by itself,

focusing functions properly and the

disc motor runs,

the drive section is in good condition.

Check the fault in the power

supply section.

If operation fails,

the drive section is defective.

Check the condition of the main P.C.B.

After some time

YES

Does the display light up?

NO

Is the FL driver

YES

accessed?

*1

NO

*1: FL_DATA, FL_SCK, FL_N_CS

CPU or connection may be defective.

Both main P.C.B and CPU

are in good condition.

Driver IC, FL display failure

9

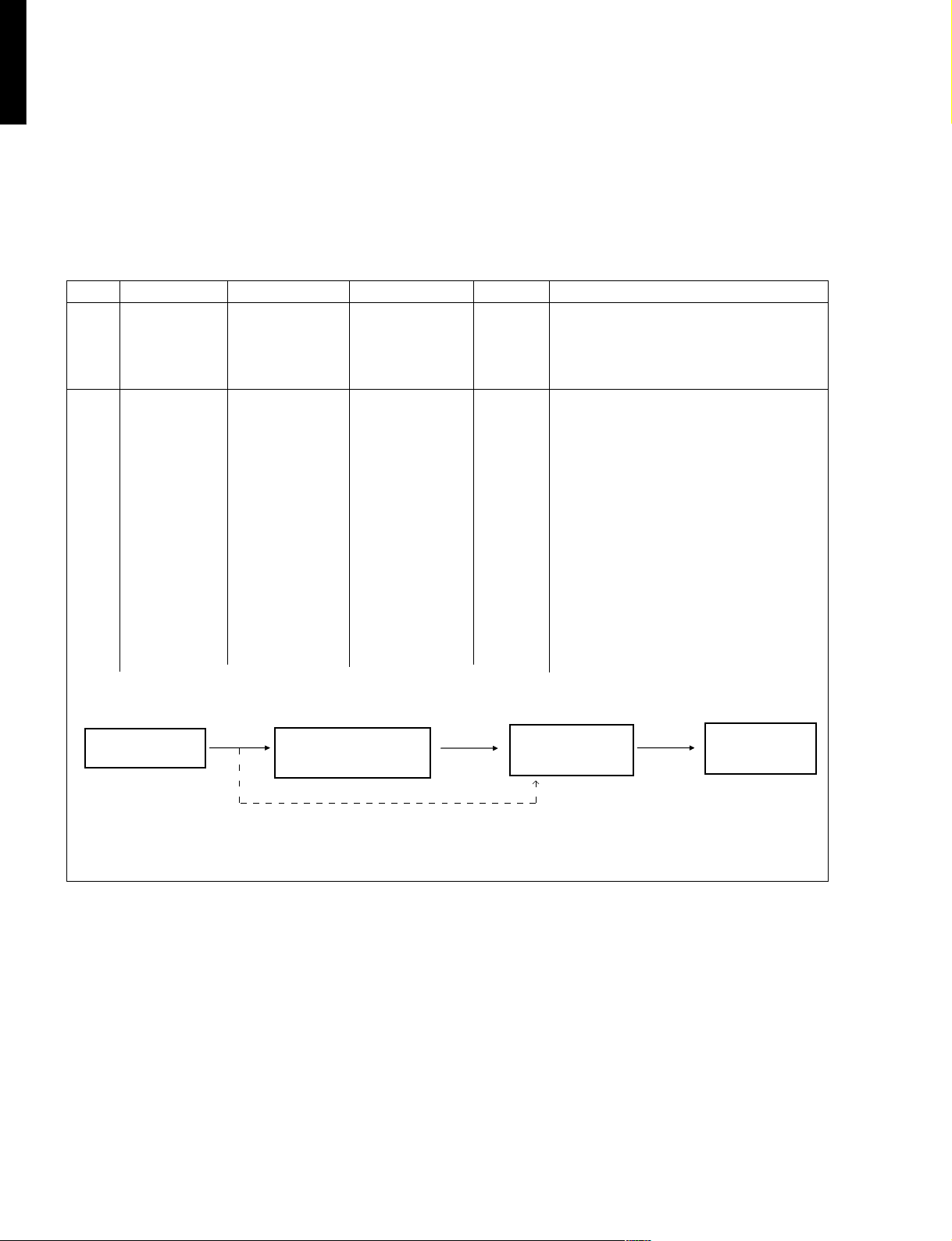

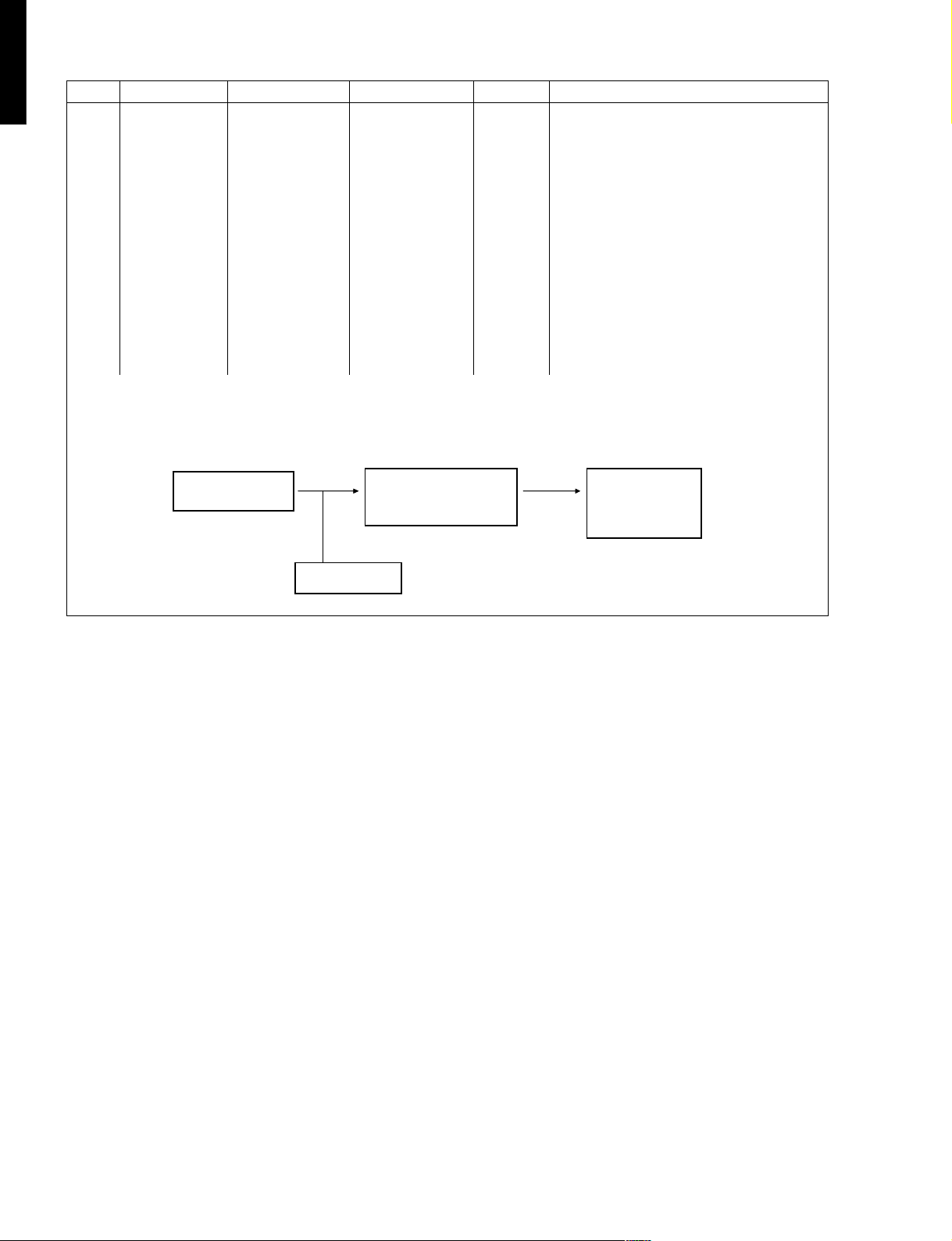

■ TEST PROGRAM

CDR-S1000

CDR-S1000

When the test program is started, the memory and register are checked automatically. If nothing is found faulty,

the AUDIO measurement mode is set.

Starting the test program

Short the connector CB7 (2P).

+

POWER ON

Main memory check

Check the external memory (IC7).

OK

DSP3 register check

Check the DSP3 (IC205).

"DSP Reg" on the FL display

NG

NG

CB7

D3

D3 (red) LED flashes at a high speed

"DSP Reg Err" on the FL display

OK

"DSP Reg End" on the FL display

ACDR register check

Check the ACDR (IC4).

"ACDR Reg" on the FL display

OK

"ACDR Reg End" on the FL display

EEPROM check

Check the EEPROM (IC6).

"EROM Mem" on the FL display

OK

"EROM Mem End" on the FL display

NG

NG

"ACDR Reg Err" on the FL display

"EROM Mem Err" on the FL display

End of the test program

AUDIO measurement mode is started.

"AMT mode" on the FL display

When canceling the test program or the AUDIO measurement mode, turn off the power and correct short

circuit of the connector CB7 (2P).

10

CDR-S1000

INSPECTION SPECIFICATIONS

CDR-S1000

Instruments Required for Inspection

• CD test disc (YEDS-18: TX911730) • CD-RW disc (TDK CD-RW AUDIO 74min [XA74])

• CD player with digital output (optical/coaxial) function (used as a digital signal generator)

• AV amplifier with digital input (optical/coaxial) function (used as a D/A converter)

• Signal generator (for analog signals) • Oscilloscope • Level meter

• Distortion meter

Step

1

2

CD player

DIGITAL OUT

(OPTICAL)

YEDS-18

Track 15 (1kHz, -20dB)

Item

Display

SRC

Mode

Audio measurement mode

(ATM mode)

Audio measurement mode

(ATM mode)

CDR-S1000

DIGITAL IN

(OPTICAL)

DIGITAL OUT

(OPTICAL)

Input signal

DIGITAL IN

(OPTICAL)

1kHz, -20dB

Disc

No disc

No disc

DIGITAL IN

(OPTICAL)

Check method and standard

1. Check that all FL display units light up and go

off properly by pressing the DISPLAY key.

2. Cancel the all on or off state of display units by

pressing the ERASE key.

1. Set the INPUT selector to the OPTICAL position.

2. Set the CD DIRECT key to the ON position.

3. Apply a 1kHz, -20dB digital signal to DIGITAL

IN (OPTICAL).

4. Check that the digital output level at DIGITAL

OUT (OPTICAL) is -20 ± 2dB.

5. Set the CD DIRECT key to the OFF position.

6. Set the REC LEVEL control knob to the maximum position.

7. Check that the digital output level of at DIGITAL OUT (OPTICAL) is -8 ± 2dB.

8. Return the REC LEVEL control knob close to

the center position and check that the digital

output level at DIGITAL OUT (OPTICAL) can

be set to -20dB.

AV amplifier

PRE OUT

Oscilloscope

Level meter

AUDIO measurement function of the main unit panel

INPUT selector (at CD STOP)

• Selects the input signal.

• The selected input signal passes through DSP3 and is output to LINE

OUT (Analog) and DIGITAL OUT (Digital). Also, the level meter reading is displayed in response to the input signal.

• In case of the digital signal, the sampling frequency is read from the

channel status and displayed as 32, 44.1 or 48 (kHz).

• When the subcode Q data is included in the digital signal, a part of

the subcode Q data appears on the FL display.

CD DIRECT key (at CD STOP)

• Selects the digital input signal passage, whether through SRC (Sample

Rate Converter) or direct. CD DIRECT LED lights up when the direct

signal passage is selected but this does not apply when the sampling

frequency is other than 44.1kHz ± 200ppm.

11

The output level of the digital signal (optical/coaxial) should be

checked by using the relative value of the analog demodulated

signal.

REC LEVEL control knob

• When the digital input is selected, SRC is activated as the digital

volume controller.

If CD DIRECT is selected, however, the digital volume is set to through

(0dB) state.

• When the analog input is selected, this control knob functions as the

analog volume control.

DISPLAY key

Turns on and off all the display units.

To cancel the all on or off state of display units, press the ERASE key

and the original display state will be restored.

ERASE key

Cancels the all on or off state of display units.

CDR-S1000

CDR-S1000

Step

3

A/D converter

Signal genarator

1kHz/20Hz/20kHz

Item

Mode

Audio measurement mode

(ATM mode)

CD player

500mVrms

LINE IN

(ANALOG)

Input signal

LINE IN (ANALOG)

1kHz, 20Hz, 20kHz

500mVrms

DIGITAL OUT

(COAXIAL)

Disc

No disc

DIGITAL IN

(COAXIAL)

Check method and standard

1. Set the INPUT selector to the ANALOG position.

2. Apply a 1kHz, 500mVrms analog signal to the

LINE IN (ANALOG).

3. Demodulate the digital signal of DIGITAL OUT

(COAXIAL) to analog.

4. Adjusting the REC LEVEL control knob, check

that the demodulated signal level can be set

to 1Vrms. (The level meter should indicate 6dB on display.)

5. At this time, check that the REC LEVEL control knob is close to the 12 o’clock position.

6. Check that the distortion factor is 0.03% or less.

7. Check that the S/N is 80dB or more. (Input

shorted, REC LEVEL max.)

8. Check that the frequency response (at 20Hz

and 20kHz) is 0 ± 1.5dB.

AV amplifier

PRE OUT

Oscilloscope

Level meter

Distortion meter

Step

4

Item

D/A converter

Level meter

Mode

Normal mode

CDR-S1000

Input signal

Disc

YEDS-18

Check method and standard

1. Cancel the audio measurement mode.

2. Turn on the power. (In normal mode)

3. Load the CD test disc (YEDS-18: TX911730).

4. Play track 2 (1kHz, 0dB).

5. Check that the output level of LINE OUT (ANALOG) is 2 ± 0.5Vrms.

6. Check that the distortion factor (1kHz) is 0.01%

or less.

7. Play tracks 3 (20Hz) and 6 (20kHz) and check

that the frequency response is 0 ± 1.5dB.

8. Play track 7 and check that S/N is 100dB or

more.

(ANALOG)

YEDS-18

Track 2 (1kHz, 0dB)

Track 3 (20Hz, 0dB)

Track 6 (20kHz, 0dB)

Track 7

LINE OUT

Oscilloscope

Level meter

Distortion meter

12

CDR-S1000

Step

CDR-S1000

5

Item

Recording

Playback

Signal genarator

1kHz/20Hz/20kHz

Mode

Normal mode

370mVrms

Input signal

LINE IN (ANALOG)

1kHz, 20Hz, 20kHz

370mVrms

CDR-S1000

LINE IN

(ANALOG)

LINE OUT

(ANALOG)

Disc

XA74

Check method and standard

1. Load the CD-RW disc (XA74).

2. Set the INPUT selector to the ANALOG position.

3. Apply a 1kHz, 370mVrms analog signal to the

LINE IN (ANALOG).

4. Set the REC LEVEL control knob to the maximum position.

5. Execute recording/playback and check that the

output level at LINE OUT (ANALOG) is 2.0 ±

0.5Vrms.

6. Check that the distortion factor (1kHz) is 0.1%

or less.

7. Apply a 20Hz, 20kHz signals, execute recording/playback and check that the level difference

is within 0 ± 1.5dB.

Oscilloscope

Level meter

Distortion meter

Level meter

13

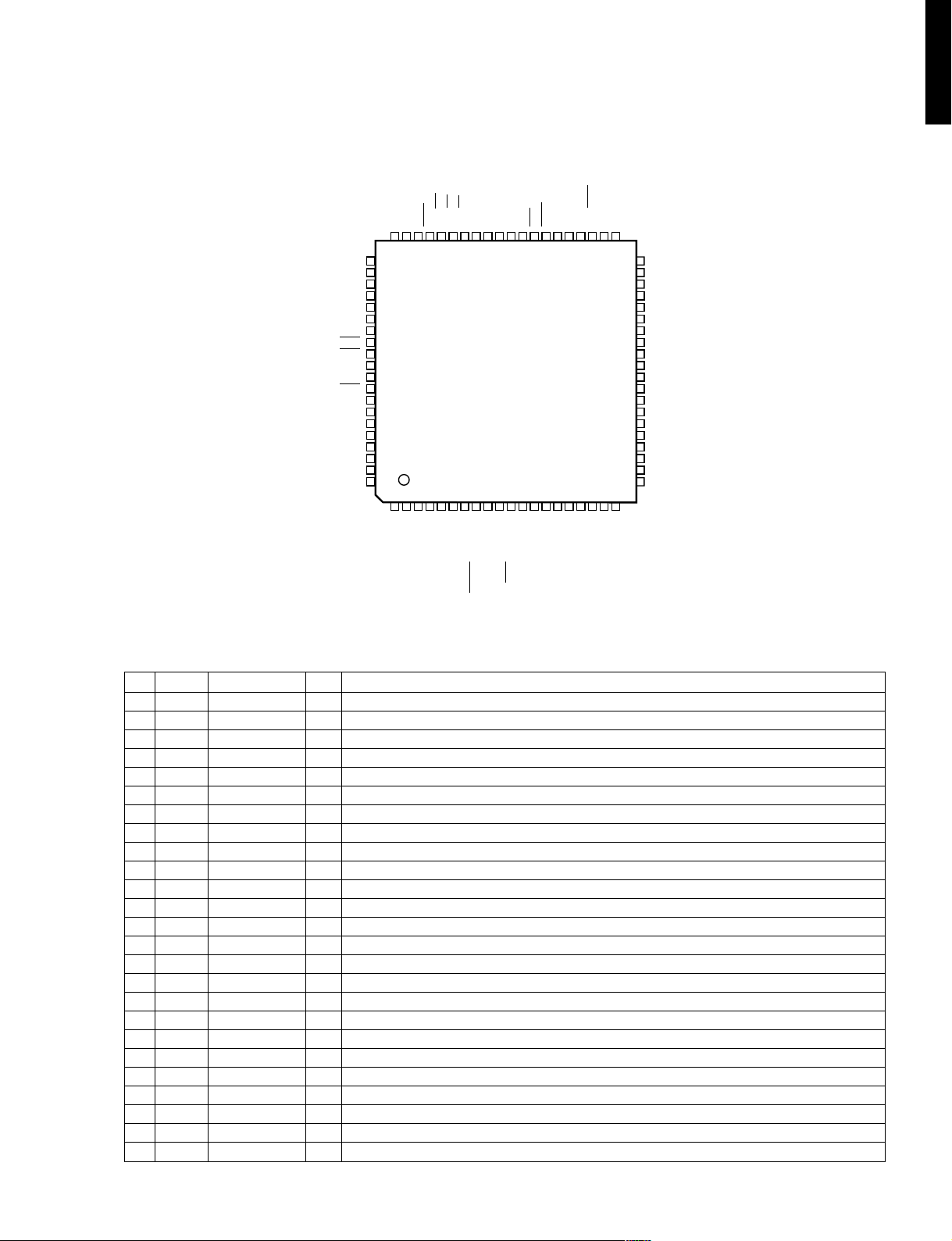

■ IC DATA

IC5 : HD64F3039F18

CPU

P71/AN1

P70/AN0

AVSS

RESO/FWE

P65/WR

P64/RD

P63/AS

VCC

CDR-S1000

CDR-S1000

XTAL

EXTAL

VSS

NMI

RES

STBYØMD1

MD0

P60/WAIT

P53/A19

P52/A18

NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

PORT

PB0

PB1

PB2

PB3

PB4

PB5

MD2

PB7

TXD0

RXD0

/IRQ4

VSS

D0

D1

D2

D3

D4

D5

D6

D7

VCC

A0

A1

A2

A3

PA2/TP2/TIOCA0/TCLKC

PA3/TP3/TIOCB0/TCLKD

A23/PA4/TP4/TIOCA1

A22/PA5/TP5/TIOCB1

A21/PA6/TP6/TIOCA2

A20/PA7/TP7/TIOCB2

Name

N_DEV_RST

MUTE

DIP0

LED0

FL_SCK

FL_DATA

MD2

FL_N_CS

TXD0

RXD0

N_IRQ4

VSS

D0

D1

D2

D3

D4

D5

D6

D7

VCC

A0

A1

A2

A3

P72/AN2

P73/AN3

P74/AN4

P75/AN5

P76/AN6

P77/AN7

AVCC

P80/IRQ0

P81/IRQ1

P91/TXD1

P93/RXD1

P95/SCK1/IRQ5

PA0/TP0/TCLKA

PA1/TP1/TCLKB

I/O

O

O

I

O

O

O

I

O

O

I

I

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

O

O

O

O

60595857565554535251504948474645444342

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

12345678910111213141516171819

MD2

TXD0/P90

RXD0/P92

TIOCA3/TP8/PB0

TIOCA3/TP9/PB1

TIOCA4/TP10/PB2

ADTRG/TP15/PB7

TIOCB4/TP11/PB3

TOCXA4/TP12/PB4

TOCXB4/TP13/PB5

Function

Resetting peripheral devices

Muting output

DIP SW data

Operation check LED

Clock for FL driver control

Data for FL driver control

Setting CPU operation mode

Chip select for FL driver control

SCI0 output

SCI0 input

External interrupt (Blank)

GND

Data bus

Data bus

Data bus

Data bus

Data bus

Data bus

Data bus

Data bus

+ 5V power

Address bus

Address bus

Address bus

Address bus

VSS

D0/P30

D1/P31

D2/P32

IRQ4/SCK0/P94

D3/P33

D4/P34

D5/P35

D6/P36

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

20

D7/P37

A17/P51

A16/P50

A15/P27

A14/P26

A13/P25

A12/P24

A11/P23

A10/P22

A9/P21

A8/P20

VSS

A7/P17

A6/P16

A5/P15

A4/P14

A3/P13

A2/P12

A1/P11

A0/P10

VCC

14

Loading...

Loading...