Page 1

Certification Exhibit

FCC ID: U4A-YRHCPZB0

IC: 6982A-YRHCPZB0

FCC Rule Part: 15.247

IC Radio Standards Specification: RSS-210

ACS Project Number: 12-0001

Manufacturer: Assa Abloy Inc.

Models: YRDZB, YRD210-ZB, YRD220-ZB, YRT210-ZB, YRT220-ZB

5015 B.U. Bowman Drive Buford, GA 30518 USA Voice: 770-831-8048 Fax: 770-831-8598

Manual – YRT220-ZB

Page 2

Yale Real Living™ Touchscreen Lever

Installation and Programming Instructions

NOTE TO INSTALLER

FAILURE TO FOLLOW THESE INSTRUCTIONS

COULD RESULT IN DAMAGE TO THE PRODUCT

AND VOID THE FACTORY WARRANTY

For Technical Assistance call Yale at 1-800-810-WIRE (9473)

This document is available on our website in printed Spanish and French. Go to www.yalerealliving.com.

Click "Product Information & Documentation" and then "Installation Instructions".

Este documento está disponible en español en nuestra página de internet. Vaya a www.yalerealliving.com.

Presione "Información del Producto y Documentación" y luego "Instrucciones de Instalación".

Ce document est disponible sur notre site Web dans le français imprimé. Allez à www.yalerealliving.com.

Cliquez sur le "Information sur le produit et Documentation" et puis "Installation Instructions".

An ASSA ABLOY Group brand

P/N AYRT-220-INST-FUL Rev A

Page 3

TABLE OF CONTENTS

Warnings .........................................................................................................................2

Return Lock to Factory Default ................................................................................3

Introduction .....................................................................................................................3

Installation

Components and Tools .............................................................................................4

Prepare Lock for Installation ................................................................................. 5-6

Install Lock .......................................................................................................... 6-11

Programming

Programming Features-Menus-Keys-Definitions ............................................. 12-13

Operation .......................................................................................................... 14-16

Miscellaneous Information

Hardware Troubleshooting .....................................................................................17

Programming Troubleshooting ...............................................................................18

Installing the Network Module ...............................................................................19

Sample Pin Code Management Sheets ........................................................... 23-24

WARNINGS

Warning: Changes or modifications to this device not expressly approved by Yale Security, Inc.

could void the user's authority to operate the equipment.

IMPORTANT: The accuracy of the door preparation is critical for the proper functioning and

security of this product. Misalignment can cause performance degradation and a lessening of

security.

Finish Care: This lockset is designed to provide the highest standard of product quality and performance. Care should be taken to ensure a long-lasting finish. When cleaning is required use a soft, damp

cloth. Using lacquer thinner, caustic soaps, abrasive cleaners or polishes could damage the coat-

ing and result in tarnishing.

FCC:

FCC ID: U4A-YRHCPZW0 (Z-Wave); U4A-YRHCPZB0 (Zigbee)

Model(s): YRT220-ZW, YRT220-ZB

This equipment has been tested and found to comply with the limits for a Class B digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against

harmful interference in a residential installation. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the instructions, may cause harmful

interference to radio communications. However, there is no guarantee that interference will not occur in a

particular installation. If this equipment does cause harmful Interference to radio or television reception,

which can be determined by turning the equipment off and on, the user is encouraged to try to correct

the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver

is connected.

• Consult the dealer or an experienced radio/TV technician for help.

An ASSA ABLOY Group brand

2

P/N AYRT-220-INST-FUL Rev A

Page 4

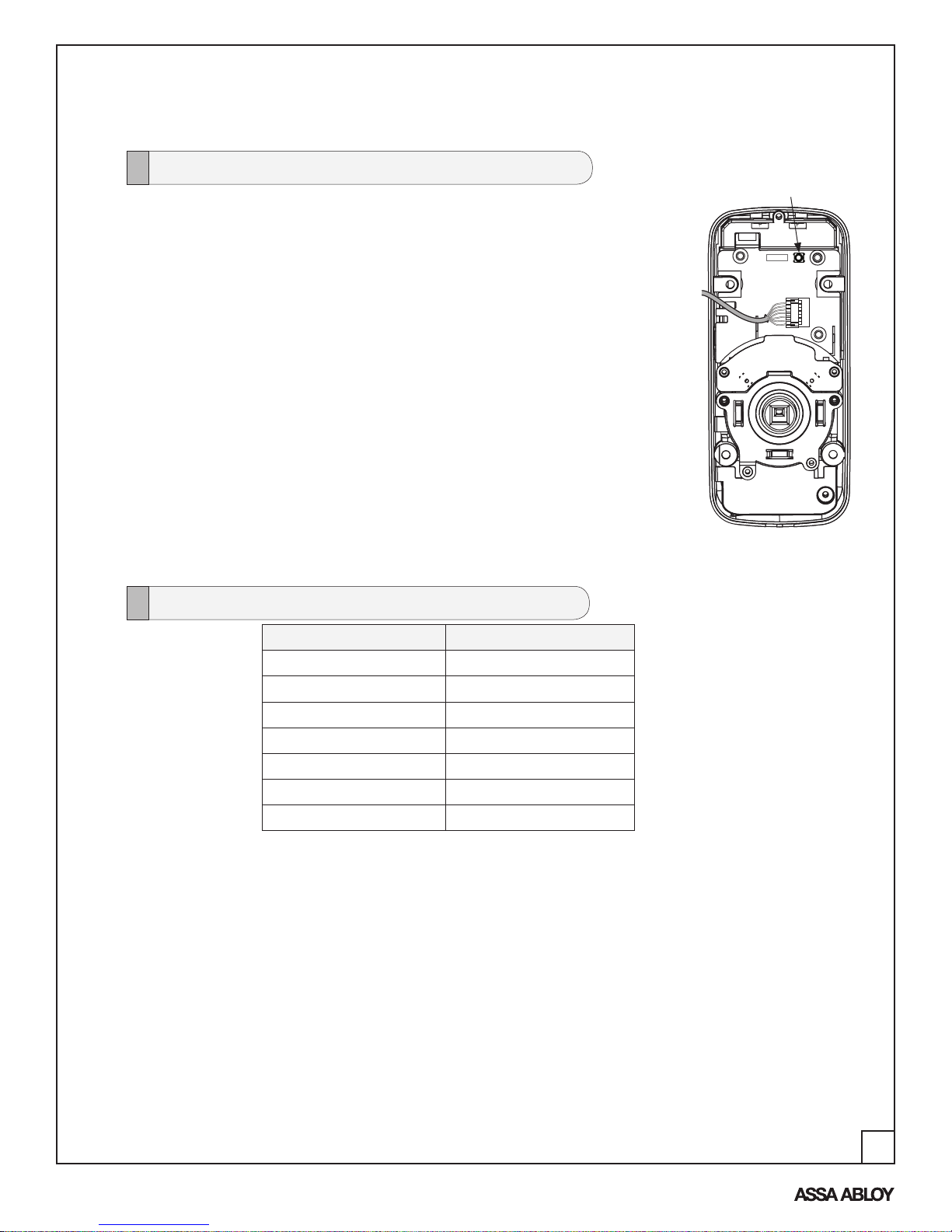

To reset the lock to factory default, see the following:

Reset Lock to Factory Default

Reset Button

The following procedure returns the lock to its factory defaults

by deleting all user codes (including the Master PIN code*) and

returning all programming features to their original default settings

(see below).

1. Remove the batteries and then remove the inside escutcheon

to access the reset button.

2. The reset button (see image at right) is located above the

PCB cable connector.

3. Hold down the reset button for a minimum of 3 seconds and

then reinstall the batteries; once the batteries are properly

installed, release the reset button.

All features (including adjustable settings** (see below) should

now be returned to factory default.

Upon reset, Master Code Registration is the only option available

and must be performed prior to any other programming of the lock.

See "Operation" later in this manual for programming instructions.

Inside Escutcheon

Factory Default Settings

Master Code Registration required

Auto Re-lock Enabled

One Touch Re-Lock Enabled

Auto Re-lock Time **30 Seconds

Wrong Code Entry Limit **5 Times

Shutdown Time **60 Seconds

**Adjustable only when using Network Module

Settings Factory Default

Audio Enabled

An ASSA ABLOY Group brand

3

P/N AYRT-220-INST-FUL Rev A

Page 5

Industry Canada:

Canadian ID: 6982A-YRHCPZW0 (Z-Wave); 6982A-YRHCPZB0 (Zigbee)

Model(s): YRT220-ZW, YRT220-ZB

This Class B digital apparatus meets all requirements of the Canadian Interference Causing Equipment

Regulations. Operation is subject to the following two conditions: (1) this device may not cause harmful

interference, and (2) this device must accept any interference received, including interference that may

cause undesired operation.

Cet appareillage numérique de la classe B répond à toutes les exigences de l’interférence canadienne

causant des règlements d’équipement. L’opération est sujette aux deux conditions suivantes: (1) ce

dispositif peut ne pas causer l’interférence nocive, et (2) ce dispositif doit accepter n’importe quelle

interférence reçue, y compris l’interférence qui peut causer l’opération peu désirée.

For the U4A-YRHCPZB0 and 6982A-YRHCPZB0, the following statement applies:

“This equipment complies with FCC/IC radiation exposure limits set forth for an uncontrolled

environment. This equipment should be installed and operated with minimum distance 20cm between

the radiator and your body. This transmitter must not be co-located or operating in conjunction with any

other antenna or transmitter.”

Section 7.1.2 of RSS-GEN Under Industry Canada regulations, this radio transmitter may only operate

using an antenna of a type and maximum (or lesser) gain approved for the transmitter by Industry

Canada. To reduce potential radio interference to other users, the antenna type and its gain should be

so chosen that the equivalent isotropically radiated power (e.i.r.p.) is not more than that necessary for

successful communication.

En vertu des règlements d'Industrie Canada, cet émetteur radio ne peut fonctionner avec une antenne

d'un type et un maximum (ou moins) approuvés pour gagner de l'émetteur par Industrie Canada. Pour

réduire le risque d'interférence aux autres utilisateurs, le type d'antenne et son gain doivent être choisies

de façon que la puissance isotrope rayonnée équivalente (PIRE) ne dépasse pas ce qui est nécessaire

pour une communication réussie.

Section 7.1.3 of RSS-GEN This Device complies with Industry Canada License-exempt RSS standard(s).

Operation is subject to the following two conditions: 1) this device may not cause interference, and 2)

this device must accept any interference, including interference that may cause undesired operation of

the device.

Cet appareil est conforme avec Industrie Canada RSS standard exemptes de licence(s). Son

fonctionnement est soumis aux deux conditions suivantes: 1) ce dispositif ne peut causer des

interférences, et 2) cet appareil doit accepter toute interférence, y compris les interférences qui peuvent

causer un mauvais fonctionnement du dispositif.

The Yale Real Living™ Stand-alone Touchscreen Deadbolt Lock combines a robust lockset with a

contemporary electronic aesthetic.

Users benefit from an interactive touchscreen that makes day-to-day access effortless, as well as

offering voice-guided programming for simple updates to user information in the event of staffing

changes or security breaches. Yale Real Living™ is engineered for quick and easy installation and

fits in place of a standard deadbolt lock door prep (ANSI/BHMA A156.115).

If this is an RF-enabled network lock, it needs to be located within 50 - 100 feet of another network

controller. That distance is influenced by objects between the lock and the controller and may be

expanded depending on proximity to other RF network devices. Also, if the lock is connected to a

network controller, it is recommended that it is programmed through the centralized user interface

(PC or hand-held device) to ensure communication between the lock and the controller unit.

An ASSA ABLOY Group brand

INTRODUCTION

4

P/N AYRT-220-INST-FUL Rev A

Page 6

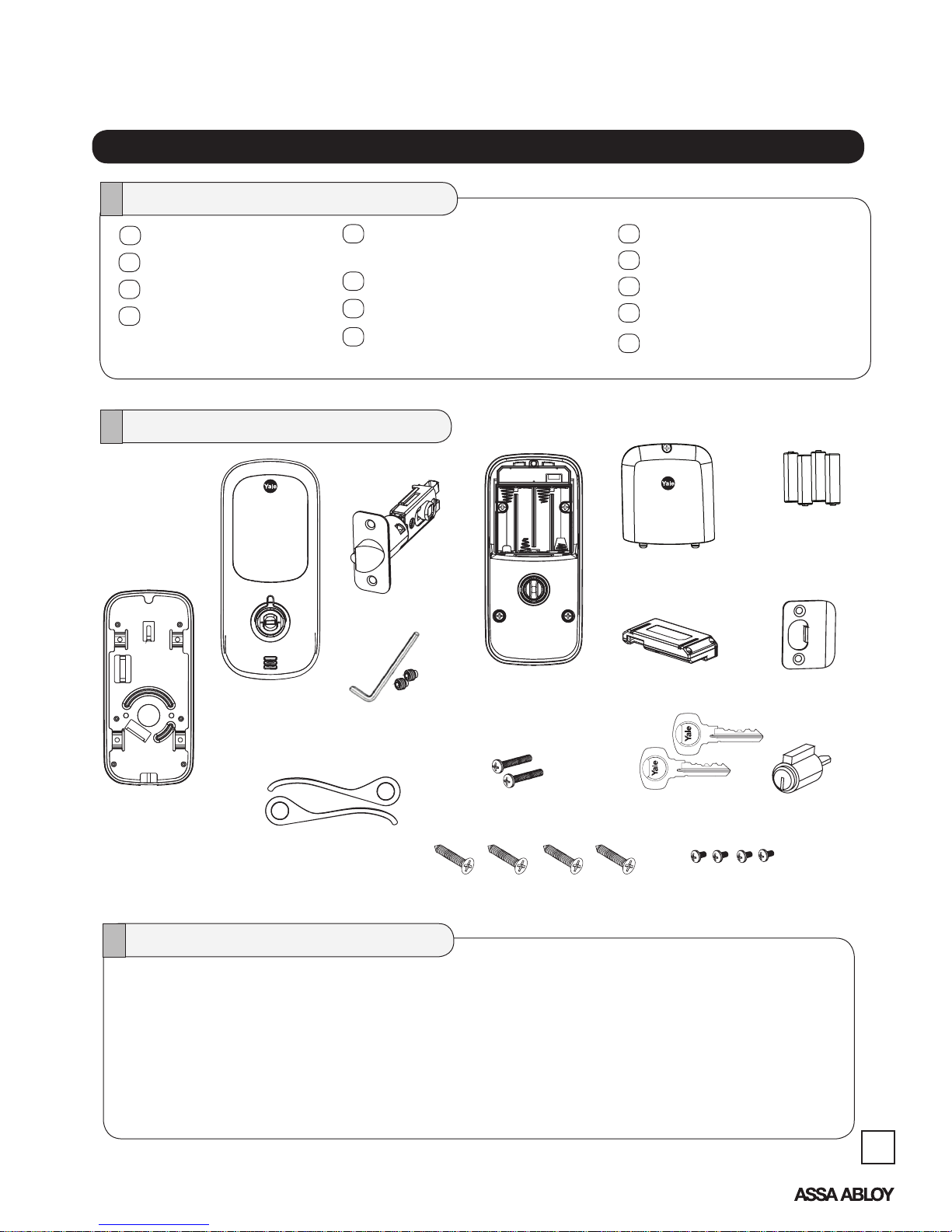

Included in the box. . .

INSTALLATION

COMPONENTS AND TOOLS

Installation Instructions

Template

Latch Bolt

Strike Plate

Parts Illustrations

Outside

Escutcheon

Inside Mounting Plate

(with gasket)

Inside Escutcheon

Outside Escutcheon

(2) Screw Packs (see below)

Latch

Allen Wrench

(2) Hex Set Screws

(Pack 1)

Inside

Escutcheon

Keys

Cylinder

Battery Cover

Allen Wrench

4 AA Alkaline Batteries

Battery Cover

Network Module

(Optional)

Keys

4 AA Alkaline

Batteries

Latch bolt

Strike

Inside Mounting Plate

with Gasket

(back of Inside Escutcheon)

Tools Needed

Outside & Inside Lever

Handles

Door Prep

2-1/8" (54mm) hole saw

1" (26mm) boring bit

7/64" (2.5mm) drill bit

Chisel & hammer

An ASSA ABLOY Group brand

(2) Inside Mounting Plate Screws

(Pack 1)

(2) Latch & (2) Strike Plate Mounting

Screws (Pack 2)

Lock Installation

#2 Phillips screw driver

Allen wrench (3mm) - provided

Cylinder

(4) Inside Escutcheon

Mounting Screws

(Pack 1)

5

P/N AYRT-220-INST-FUL Rev A

Page 7

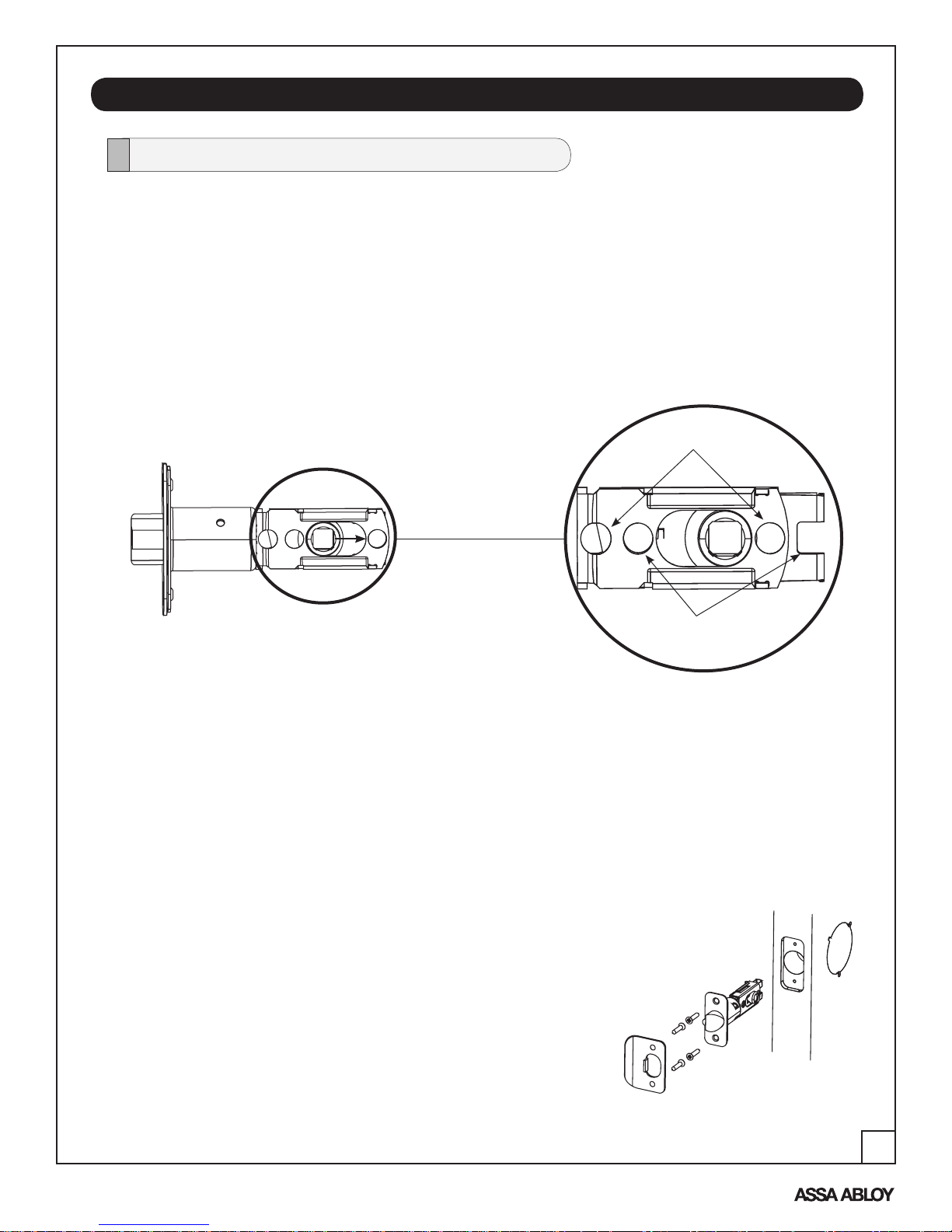

INSTALL LOCK

Install Latch

The lock is packed representative of how it will install on the door.

Before installing the lock on the door:

A. Remove the latch (Fig. 1) and strike plate from the packaging.

NOTE: Latch ships with backset in 2-3/8" position (Fig. 1).

Backset is the measurement from door edge to center

of 2-1/8" diameter hole (see template supplied with lock).

If required, pull to extend to 2-3/4" backset position (Detail 1A).

NOTE: Different holes are used for (2) through bolts depending on backset (see Detail 1A).

2-3/8" through bolt posts

Figure 1

2-3/4" through bolt posts

Detail 1A

NOTE: Make sure door has been prepped according to specifications in template included

with lock.

NOTE: The latch bolt (and strike) can be installed in only one of two ways -

with the bevel (slope) of latch facing out or facing in while standing

outside of the door.

If the door opens in, the bevel will face the outside; if the doors opens out, the

bevel will face in.

The strike plate is installed according to the orientation of the latch bolt. See

Figures 1 & 2 for an example of a RH door that opens in.

NOTE: Both latch face and strike plate have adhesive-backed covers to

prevent marring and should be removed upon installation.

B. Install latch bolt in door.

1. Attach with two (2) M4 x 25.4mm screws supplied.

C. Install strike on the door frame, using two (2) M4 x 25mm

screws supplied, making sure to allow for the latch to be

centered in the strike.

An ASSA ABLOY Group brand

(4) M4 x 25.4mm

Flat Head

Combination Screws

P/N AYRT-220-INST-FUL Rev A

Figure 2

6

Page 8

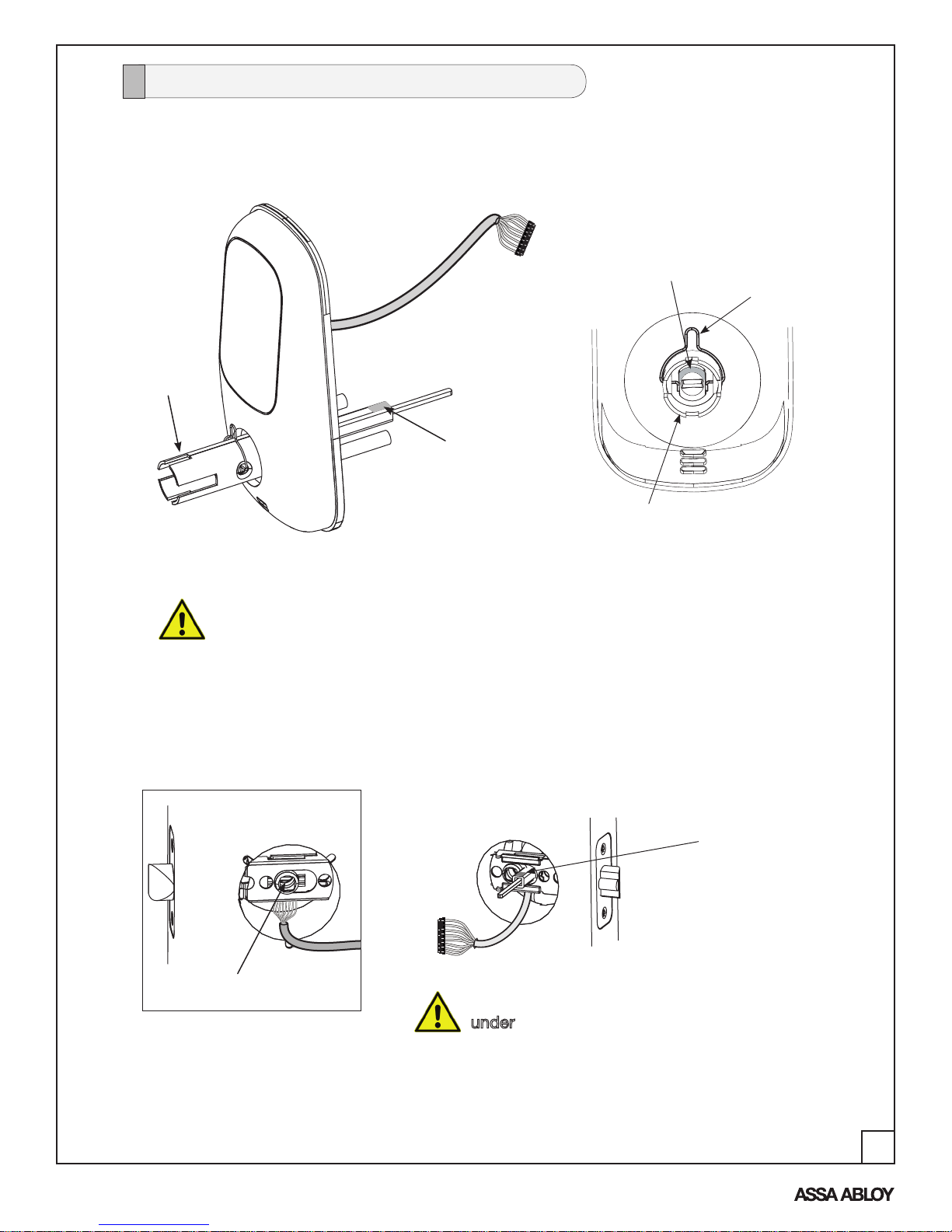

Install Outside Escutcheon

NOTE: The "tops" of both the square drive tube and the hub (in the shank) are marked to

indicate their orientation for proper installation (Figures A & B).

NOTE: RED marking

indicates "top" of hub

Clip

Shank

Square

Drive Tube

is marked

(WHITE) to

indicate

"top"

Figure A Figure B

Outside Escutcheon

(with gasket)

Shank

Do not remove clip from Outside Escutcheon shank until correct handing has

been determined and Outside Lever Handle is to be installed.

(See page 9)

1. From outside of door, position the outside escutcheon by first routing the cable

through 2-1/8" diameter hole and under the latch (Fig. 3A & B), then insert

posts* and tailpiece into the latch.

Tailpiece

Outside of Door

Figure 1A

Inside of Door

Figure 1B

NOTE: Cable goes

under latch (Fig. 1A & 1B).

"Top" of Drive Tube

(marked WHITE)

*Posts are inserted in holes according to

backset adjustment. (Refer back to Detail 1A

under "Install Lock")

An ASSA ABLOY Group brand

7

P/N AYRT-220-INST-FUL Rev A

Page 9

Install Outside Escutcheon

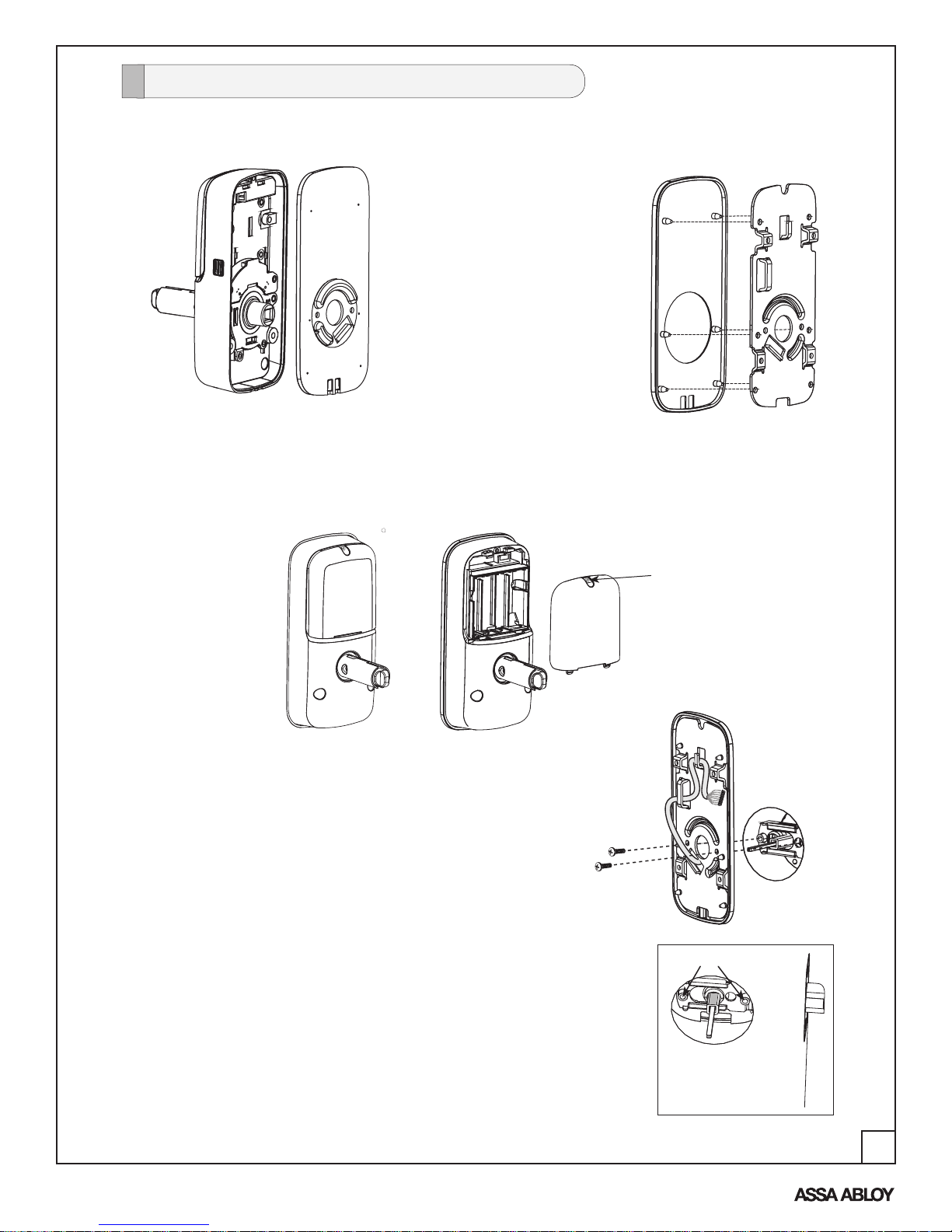

2. Remove the inside mounting plate (with gasket) from

the back (door side) of the inside escutcheon (Fig. 2A).

A. Ensure that gasket on

inside mounting plate

is properly fitted (Fig. 2B).

Figure 2A

Inside Escutcheon & Mounting Plate

(with gasket)

Figure 2B

3. Remove the battery cover from the back of the inside escutcheon (Fig. 3) by loosening

the captive Phillips head screw.

Screw

Battery Cover

Figure 3

Inside of Door

4. Holding the outside escutcheon flush to the door,

position the inside mounting plate by routing the

cable/connector through the mounting plate's 1/2"

rectangular hole below center hole (Fig. 4A).

5. Secure both assemblies by inserting (2) M4 x 25mm

pan head machine screws through the mounting

plate and into the slightly extended through posts of

Figure 4A

the outside escutcheon (Fig. 4B).

Ensure that outside escutcheon is vertically aligned.

Through posts here

Tighten securely with a #2 Phillips screwdriver.

Do not over-tighten.

6. Finish routing the cable and connector through the left

upper slot, then behind center rib as shown in Fig. 4A.

An ASSA ABLOY Group brand

Figure 4B

8

P/N AYRT-220-INST-FUL Rev A

Page 10

7. Attach cable assembly to the inside escutcheon printed circuit board (PCB) by lining up

notches on top of cable connector to slots on PCB connector (Fig. 7A & 7B).

Press connector in firmly using thumbs until completely seated (properly seated position

indicated by arrows on PCB as in Fig. 7B).

Reset Button

Inside Escutcheon

Cable Connector

Figure 7B

Figure 7A

8. Install and secure inside escutcheon to inside mounting plate using (4) M4 x 8mm

[8-32 x 5/16"] pan head machine screws through the inside escutcheon into the

mounting plate (Fig. 8).

NOTE: Make sure cable does not obstruct path of the mounting screws.

An ASSA ABLOY Group brand

Figure 8

9

P/N AYRT-220-INST-FUL Rev A

Page 11

Determine Lever Handing

RH

RHR

Lever

Hinges on Right Hinges on Left

Right handed

lever position

Both outside and inside lever handles should

always point toward the door hinges.

Left handed

lever position

LH

LHR

Lever

Determine Lever Position

Correct "curved" position

Incorrect Incorrect

Before proceeding with the next step, ensure correct lever handing for proper installation.

Correct "curved" position

An ASSA ABLOY Group brand

10

P/N AYRT-220-INST-FUL Rev A

Page 12

Install the Exterior Lever (Right Hand shown)

1. Install cylinder in exterior lever.

(If necessary, remove key from cylinder)

A. Drop cylinder in exterior lever handle as shown.

B. Insert key in cylinder.

While supporting cylinder tailpiece (with finger);

rotate key 90° clockwise (CW) to vertical position

(Figure 1B).

NOTE: RH shown; with LH lever, rotate key 90°

counter-clockwise (CCW)

2. Remove clip from shank.

A. Once correct handing is determined, remove the

clip that has held the hub in its correct position by

spreading clip ends to extract clip from shank as

shown in Figure 1C with detail.

Do not rotate cam from its original position.

Tailpiece

Figure 1A

90°

Figure 1B

("top" is marked RED)

3. Install hex set screw.

NOTE: For correct lever handing, the

hex set screw for the outside

lever shank must be installed

as shown (Fig. 8B).

A. Place set screw in hole on side of

shank toward edge of door (opposite

lever handle); turn CW to allow placement

of lever handle over shank.

Do not overtighten.

Figure 8B

RH/RHR

Figure 1C

Hex Screw

LH/LHR

CW

An ASSA ABLOY Group brand

11

P/N AYRT-220-INST-FUL Rev A

Page 13

E. Push lever handle (with key & cylinder)

over shank until hole on handle aligns

with set screw in shank (Figure 1E).

E

Figure 1E

F. Secure lever handle by inserting allen wrench and rotating set screw CCW (Fig. 1F).

Do not overtighten.

G. Turn key 90° CCW; pull to remove key and test operation of lever handle, ensuring

that the latch moves smoothly.

90°

CCW

Figure 1F

F

An ASSA ABLOY Group brand

G

12

P/N AYRT-220-INST-FUL Rev A

Page 14

Install the Exterior Lever (Right Hand shown)

1. Rotate thumbturn counter-clockwise to horizontal position (Fig. 9A).

Figure 9A

2. Insert set screw on side of shank (toward

edge of door); turn CW to allow placement

3. Turn set screw CCW to tighten

and secure lever handle to shank.

of inside lever handle over shank.

Figure 9B

Figure 9C

IMPORTANT: Before installing the batteries, test the mechanical operation of lock

by rotating both the outside and inside lever handles. Also try using both the thumbturn

and key. The movement of the latch should be smooth and unobstructed.

If operation is not smooth, review the previous steps to ensure proper installation, while

maintaining proper alignment of escutcheons.

Install Batteries

1. Insert four (4) AA alkaline batteries; the lock

will flash and beep several times.

2. Install battery cover and tighten Phillips

head screw.

An ASSA ABLOY Group brand

13

P/N AYRT-220-INST-FUL Rev A

Page 15

PROGRAMMING

Programming Features-Menus-Keys-Definitions ............................................. 12-13

Operation .......................................................................................................... 14-17

PROGRAMMING FEATURES - MENUS - KEYS - DEFINITIONS

Outside

Touch Screen

Low Battery

Indicator

Menu and Icons

" P " Key

(Return to Previous)

Numbers

Lockout Mode

Cylinder

Speaker Hole

Inside

Phillips Screw

Battery Cover

Network Module Slot

Alkaline Batteries

4 AA Type

Status Indicator

Inside Handle

Touch the screen with palm of hand or

fingers to begin and end actions.

~

*The Master Pin Code must be registered prior to any further programming of the lock.

An ASSA ABLOY Group brand

Click the indicated number.

Press the Star key on the touchscreen to

Enter or Accept entry.

Press the Pound key on the touchscreen to

enter Menu mode.

Press this key to return to the previous

step or menu setting.

M

U

Repeat operation using settings indicated.

Enter Value 1 -10 (times or seconds).

Enter Master PIN code* (4-8 digits in length).

Advanced Mode only.

Enter User PIN. Can be 4-8 digits in length.

User Serial Number (01 - 25);

RF Controlled (01-250).

14

P/N AYRT-220-INST-FUL Rev A

Page 16

Status Indicators

Return to previous step

3

Definitions

Low Battery Warning

1

Lockout Mode

2

Lockout Mode: This feature is enabled by the Master code. When enabled, it restricts all user PIN

code access. When attempting to enter a code while the unit is in Lockout, the Status Indicator

flashes RED and BLUE; the keypad flashes as well.

Low Battery: When battery power is low, the Status Indicator flashes RED. If battery power is

completely lost, use the key override.

Master PIN Code: The Master code is used for programming and for feature settings. NOTE: The

Master Pin Code must be registered prior to programming the lock. The Master code will also

operate the lock.

Auto Re-lock Time: After successful code entry and the unit unlocks, it will automatically re-lock

after a default of thirty (30) seconds. Re-lock time is adjustable from five (5) to thirty (30) seconds.

One Touch Re-Lock: When the bolt is retracted, activating the keypad will extend the bolt

(during Auto Re-Lock duration or when Auto Re-Lock is disabled).

Shutdown Time: The unit will shutdown for a default of sixty (60) seconds and not allow operation

after the wrong code entry limit has been met. When the unit is in Shutdown, the Status Indicator

flashes RED and BLUE; the keypad flashes as well.

Audio Mode: Choosing Disable (3) in Audio mode shuts off the code confirmation tone playback

for use in quiet areas. Audio mode is enabled or disabled through feature programming by the

Master code.

Status LED: Located on inside escutcheon.

User PIN Code: The User code operates the lock. Maximum number of user codes is 250 with

Network Module; without Network Module, maximum is 25 user codes.

Wrong Code Entry Limit: After a specified number of unsuccessful attempts at entering a valid

PIN code the unit will shut down and not allow operation. Wrong code entry limit is adjustable from

three (3) to ten (10) times through feature settings (up to 5 times with no RF network enabled - de-

fault is 5; 10 with RF network enabled).

Factory Default Settings

Settings Factory Default

Master Code Registration required

Auto Re-lock Enabled

One Touch Re-Lock Enabled

Audio Enabled

Auto Re-lock Time **30 Seconds

Wrong Code Entry Limit **5 Times

Shutdown Time **60 Seconds

15

An ASSA ABLOY Group brand

*Adjustable with Network Module

P/N AYRT-220-INST-FUL Rev A

Page 17

OPERATION

Lock Activation

The touchscreen can be activated in several ways:

Press the key to

activate.

Touch lock with

back of hand or

fingers to activate.

Touch lock with

fingers spread to

activate.

Lock Operation

Master Code Set*

1. Touch the screen with the back of your hand or fingers to activate .

2. Press the

Lock Response: “Register Master Code; press the

3. Press the

Lock Response: “Enter a 4 to 8 digit pin code followed by the pound key."

4. Enter new 4-8 digit Master PIN code followed by the

Lock visually confirms pin code selection, announces "Handing lock", the motor engages

and the lock responds, "Completed".

*This step is required prior to programming of the lock.

key.

key to continue.”

key.

key.

1

Press the

An ASSA ABLOY Group brand

key.

Enter the new Master PIN code (4~8

digits), followed by the

key.

16

P/N AYRT-220-INST-FUL Rev A

Page 18

PIN code structure

Maximum number of user codes is 250 with Network Module; without Network Module,

maximum is 25 user codes.

Set Up User PIN Codes

User PIN Codes can only be programmed through the Master PIN Code*.

1. Touch the screen with the back of your hand or fingers to activate

2. Enter the 4-8 digit Master PIN code followed by the

Lock Response: “Menu mode, enter number, press the

3. Enter “2” followed by the

4. Enter “1” followed by the

key.

key.

key.

key to continue.”

5. Enter the User Number to be registered (1-25) followed by the

6. Enter a 4-8 digit PIN code for the User number followed by the

To continue adding users press the key.

7.

8. Press the

key to complete the process and conclude the programming session.

Note: When registering User codes, the code must be entered within 20 seconds or

time expires, Lock Response: “Time expired”, no codes are registered and the process

must be re-started.

.

key.

key.

*Master PIN code must be registered before User codes can be added.

Open Door with PIN Code

2 1

Touch lock with

back of hand or

fingers to activate.

Enter PIN code.

3

Press the key

to confirm the

selection.

An ASSA ABLOY Group brand

17

P/N AYRT-220-INST-FUL Rev A

Page 19

Feature Programming Through Menu Mode Using Master PIN code*

1. Touch the screen with the back of your hand or fingers to activate .

2. Enter the 4-8 digit Master PIN code* followed by the

Lock Response: “Menu mode, enter number, press the

3. Enter digit corresponding to the function to be performed followed by the

Follow the voice commands.

*The Master PIN code must be registered prior to any other programming of the lock.

key.

key to continue.”

key.

1 2 3

M

Master PIN Code Setting

User PIN Code Registration

Advanced Lock Settings

M

Register

Delete

Auto Re-lock Setting

One Touch Locking Setting

Inside Escutcheon LED

User Number (UN)

1~25: without network module

1~250: with network module

U

Continue

Complete

Enable

Disable

Enable

Disable

Enable

Disable

Continue

Complete

Volume Setting

Language Setting mode

Lockout Mode

**Network Module Setting

**This function appears

only with RF network

module installed.

An ASSA ABLOY Group brand

High

Low

Silent

English

Spanish

French

Enable

Disable

Register

Note: If the lock is connected to a network controller, it is

recommended that it is programmed through the centralized user interface (PC or hand-held device) to ensure

Delete

communication between the lock and the controller unit.

18

P/N AYRT-220-INST-FUL Rev A

Page 20

MISCELLANEOUS

Hardware Troubleshooting ......................................................................................17

Programming Troubleshooting ...............................................................................18

Installing the Network Module ...............................................................................19

Change Lever Handing .................................................................................... 20-21

Replace/Install Cylinder .........................................................................................22

Sample Pin Code Management Sheets ........................................................... 23-24

TROUBLESHOOTING

Hardware Troubleshooting

Cycle the lock in both the locked and the unlocked positions. If problems are found:

Symptom Suggested Action

Door is binding a. Check that door and frame are properly aligned and door is free swinging.

b. Check hinges: They should not be loose or have excessive wear on knuckles.

Latch will not deadlock a. Check for sufficient clearance of the latch within the strike-side jamb. Correct this by

increasing the depth of the pocket for the latch.

b. Check for misalignment of latch and/or strike which may be preventing latch from

properly entering the strike. With the door open, extend and retract the latch; if it is

smooth, check the strike alignment.

Latch does not extend or retract smoothly a. Latch and strike are misaligned, see above.

b. Check the backset of door relative to adjustments already made to latch.

c. Verify proper door preparation and re-bore holes that are too small or misaligned.

d. Verify keypad cable/connector is routed under the latch (see Fig. A).

e. Verify latch is installed with correct side up (Fig. A).

Inside of Door

Figure A

An ASSA ABLOY Group brand

19

P/N AYRT-220-INST-FUL Rev A

Page 21

Programming Troubleshooting

Symptom Suggested Action

Lock does not respond – door is open and

accessible.

Lock does not respond – door is locked and

inaccessible.

The unit is on for a while, and then shows

no reaction. Lights dim.

The touchscreen will become active when pressed with the back of hand or fingers in at least 3 areas

simultaneously.

Use a larger area of the hand or fingers and verify contact with at least 3 areas.

If touchscreen numbers are visible, check to see if they respond when pressed.

Check batteries are installed and oriented correctly in the battery case.

Check batteries are in good condition; replace batteries* if discharged.

Check to see if touchscreen cable is fully connected and not pinched.

Mechanical key will grant access.

Batteries may be completely discharged.

Use mechanical key to gain entry and replace batteries*.

The batteries do not have enough power. Replace the batteries*.

Unit chimes to indicate code acceptance,

but the door will not open.

Unit operates to allow access, but will not

automatically re-lock.

PIN codes will not register. PIN codes must consist of 4 to 8 digits to register.

Upon entering a PIN code and pressing the

star (*) key, the unit displays an “invalid

code” error or the lock times out without

responding.

Upon entering a PIN code and pressing the

(*) key, the red padlock icon appears and

there are different tones.

Check to see if there is an existing lock device on the door.

Check the door gaps for any foreign objects between door and frame.

Check that the cable is firmly connected to the PCB.

Check to see if Passage Mode** is enabled (Network module units only).

If the Passage Mode icon on the touchscreen and the status indicator on the

interior escutcheon flicker for several seconds, it is set at Passage Mode.

Disable Passage Mode to lock the door.

If low battery indicator is lit, replace batteries*.

The same PIN code cannot be used for multiple users.

Registration/management of PIN codes is set by the authority of Master Code.

The Master PIN code must be registered prior to adding any users.

Contact the Master user.

User codes must be entered within 20 seconds (while the touchscreen is active) or the process will have

to be restarted.

The star

Lockout Mode is enabled.

Only the Master Code can enable Lockout Mode.

Contact the Master user.

Check to see if lock is set** at Lockout Mode.

Setting/managing Lockout Mode is done through Master Code only. Contact the Master user.

(*) or pound (#) can not be used as part of the PIN code.

The unit operates, but it makes

no sound.

The unit responds “Low Battery” This is the voice alarm alerting that it is time to replace the batteries. Replace all four (4) batteries with

Upon entering a PIN code and pressing

the star (*) key, the unit responds “Wrong

number of digits.”

* When batteries are replaced, Network Module locks have a real time clock that will be set through the User Interface; it is

recommended to verify correct date and time particularly those locks operating under Daylight Saving Time (DST).

** Network module units only

An ASSA ABLOY Group brand

Check to see if Silent Mode is enabled (pages 8, 11).

new AA Alkaline batteries*.

The digits entered were incorrect or incomplete. Re-enter the correct code.

20

P/N AYRT-220-INST-FUL Rev A

Page 22

Installing the Network Module

IMPORTANT: The batteries must be removed prior to removing and/or inserting the

network module:

• Remove batteries

• Remove and/or insert network module

• Reinstall batteries

Use Feature Programming step 7 (page 16) for enrollment of the Network Module.

21

An ASSA ABLOY Group brand

P/N AYRT-220-INST-FUL Rev A

Page 23

How to Change Handing of Lever (Reverse Levers)

1. Remove the outside lever handle:

A. Insert key in cylinder (outside lever handle); rotate key 90° clockwise.

B. Insert allen wrench (included) in set screw on side of lever (toward edge of

door); turn clockwise to loosen.

C. Pull to remove lever handle/key/cylinder.

CCW

B

90°

A

90°

An ASSA ABLOY Group brand

F

C

22

P/N AYRT-220-INST-FUL Rev A

Page 24

2. Remove the inside lever handle:

A. Insert allen wrench (included) in set screw on side of lever

(towards edge of door); turn clockwise to loosen lever handle.

B. Pull to remove lever handle.

B

A

3. Change the lever handing:

A. Remove and switch handles (inside to outside, outside to inside).

B. Remove cylinder from outside lever handle.

C. Insert cylinder in "new" outside lever (Fig. 3A).

D. Push handle in allowing holes for set screw to align.

E. Insert set screw and tighten by turning set screw counter-clockwise.

Correct

Figure 3A

Figure 3B

An ASSA ABLOY Group brand

Incorrect

NOTE: "Swoop" of lever handle

must be oriented in upward direction

as shown in Fig. 3A

23

P/N AYRT-220-INST-FUL Rev A

Page 25

How to Replace or Install Cylinder

1. Remove cylinder:

A. Repeat previous steps for removing the outside lever handle.

B. Remove cylinder.

2. Install new cylinder:

A. Insert cylinder in "new" outside lever.

B. Push handle in allowing holes for set screw to align.

C. Insert set screw and tighten by turning set screw counter-clockwise.

D. Verify that new cylinder fits and rotates freely.

E. Test operation of the new cylinder/key.`

An ASSA ABLOY Group brand

24

P/N AYRT-220-INST-FUL Rev A

Page 26

PIN CODE MANAGEMENT SAMPLE SHEETS

PIN Code Management (No Network Module - Up to 25 Users)

Location: Door Number:

User Type User Name User # PIN Code

Master User 13

User 01 User 14

User 02 User 15

User 03 User 16

User 04 User 17

User 05 User 18

User 06 User 19

User 07 User 20

User 08 User 21

User 09 User 22

User 10 User 23

User 11 User 24

User 12 User 25

User User Name User # PIN Code

An ASSA ABLOY Group brand

25

P/N AYRT-220-INST-FUL Rev A

Page 27

PIN Code Management (With Network Module - Up to 250 Users) - Duplicate Sheet to record entries

User Type User Name User # PIN Code User User Name User # PIN Code

Master User ___

User ___ User ___

User ___ User ___

User ___ User ___

User ___ User ___

User ___ User ___

User ___ User ___

User ___ User ___

User ___ User ___

User ___ User ___

User ___ User ___

User ___ User ___

User ___ User ___

User ___ User ___

User ___ User ___

User ___ User ___

User ___ User ___

User ___ User ___

User ___ User ___

User ___ User ___

User ___ User ___

User ___ User ___

User ___ User ___

User ___ User ___

User ___ User ___

User ___ User ___

User ___ User ___

User ___ User ___

User ___ User ___

User ___ User ___

User ___ User ___

User ___ User ___

User ___ User ___

User ___ User ___

User ___ User ___

User ___ User ___

User ___ User ___

User ___ User ___

User ___ User ___

User ___ User ___

User ___ User ___

User ___ User ___

User ___ User ___

User ___ User ___

26

An ASSA ABLOY Group brand

P/N AYRT-220-INST-FUL Rev A

Page 28

ONLINE LITERATURE AND TEMPLATES

For the latest information on Yale products visit our website at

www.yalelocks.com. Click on the “Literature” button to find the

most up-to-date catalogs, parts manuals, templates, specifications and installation instructions.

100 Yale Avenue, Lenoir City, TN 37771 • Product Support Tel 800.810.WIRE (9473) • www.yalelocks.com

Yale Locks & Hardware is a division of Yale Security Inc., an ASSA ABLOY Group company.

Yale® is a registered trademark of Yale Security Inc., an ASSA ABLOY Group company. All rights reserved.

Copyright © 2012, Yale Security Inc., an ASSA ABLOY Group company. All rights reserved. Reproduction in whole or in part without express

written permission of Yale Security Inc., an ASSA ABLOY Group company is prohibited.

YALE, with its unique global reach and range of products, is the world’s favorite lock — the preferred solution for securing your home, family

ASSA ABLOY is the global leader in door opening solutions, dedicated to satisfying end-user needs for security, safety and convenience.

An ASSA ABLOY Group brand

Yale Locks & Hardware

Yale Real Living™ is a trademark of

and personal belongings.

P/N AYRT-220-INST-FUL Rev A

Loading...

Loading...