Page 1

Installation Instructions

UniTrol Door Controls

UNI-50BC Series

UNI-51(BF) Series

®

Sized Closers

Multi-Sized Closers

“DL” suffix (Delayed Action) is an optional feature. A separate instruction.will be

packed with these instructions, showing valve locations and adjustment procedures

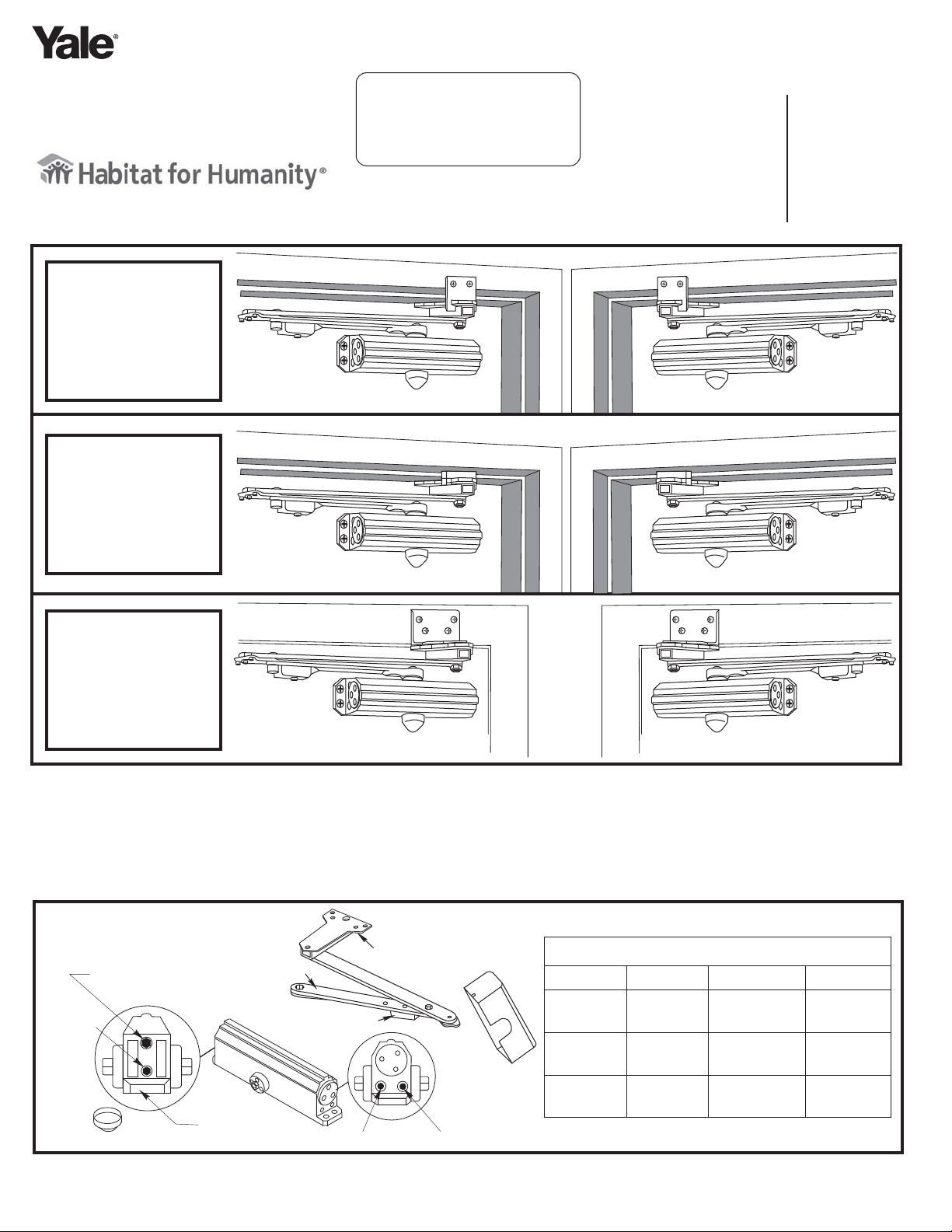

Standard Frame

Installation

1-7/8 to 4-5/8

Frame Reveals

(Uses 6190 Bracket).

Bracket illustration page 4.

See Page 2

Right Hand Door - RH

Left Hand Reverse - LHR

Deep Frame

Installation

Frame Reveals Over 4-5/8

(Uses 6191 Clamp Kit).

Bracket illustration page 4.

80-9350-2514-010 (07-09)

An incorrectly installed or improperly

adjusted door closer can cause

property damage or personal injury.

These instructions should be followed

to avoid the possibility of misapplication

or misadjustment.

CAUTION

Hinge Edge of Door

Hinge Edge of Door

CAUTION

Non Hold Open (UL Listed)

Hold Open (H) (Not UL Listed)

Models:

Sized

(Sizes 2, 3, 4, 5, 6)

UNI-52BC(H)

UNI-53BC(H)

UNI-54BC(H)

UNI-55BC(H)

UNI-56BC(H)

Hinge Edge of Door

Right Hand Reverse - RHR

Multi-Sized

(Sizes 3 thru 6)

UNI-51BF(H)

(Sizes 1 thru 4)

UNI-51(H)

Left Hand Door - LH

See Page 3

Right Hand Door - RH

Left Hand Reverse - LHR

Hinge Edge of Door

Left Hand Door - LH

Right Hand Reverse - RHR

Flush Transom

Installation

Flush Partitions

(Uses 589L Bracket).

Bracket illustration page 4.

NOTE:

See Page 4

For special applications a separate door and frame preparation template is packed with these instructions

Right Hand Door - RH

Left Hand Reverse - LHR

Use this instruction sheet for installation sequence and closer adjustments only

• It is recommended that the door on which the door closer will be installed be hung on ball bearing hinges. Door must swing freely

• Door and Frame must be properly reinforced, or use of special fasteners employed, to prevent the mounting screws from pulling out.

• All dimensions are given in inches with corresponding metric dimensions (mm) in parenthesis.

Components:

Power Adjustment Screw

(1/8 Hex Drive)

51, 51BF Only

"BC" Valve

UniTrol Parallel

Arm Assembly

Main Arm

Hold-Open Option

Soffit Plate

Arm Identification

Door Width Main Arm

28” - 32”

(0.70 - 0.80m)

9-1/2”

(241mm)

Non Hold Open Hold Open

6100-11

Left Hand Door - LH

Right Hand Reverse - RHR

Arm Stamping

6100-1

Pinion Cap

33” - 41”

4

Closer

Size

Stamp

"L"Valve

"S"Valve

Optional

Cover

50P

(0.85 - 1.00m)

42” - 48”

(1.05 - 1.20m)

11”

(279mm)

12-1/2”

(318mm)

6100-13

6100-14

6100-3

6100-4

Page 1

Page 2

Template Information

• Door template is typical for all installations.

• Frame template must be selected according to frame reveal:

Frame Template at right

Frame Reveals 1-7/8 (48) to 4-5/8 (117).

(Uses 6190 Bracket) Bracket Illustration – Page 4.

Reveal

Reveal

Frame Template: Page 2

Frame Reveals Over 4-5/8 (117).

(Uses 6191 Clamp Kit) Bracket Illustration – Page 4.

Reveal Reveal

Frame Template: Page 3

Frame Reveals 0 to 1/8 (0 to 3).

Flush Partitions (Uses 589L Bracket).

Dimensions for Doors 28” to 32”Wide

Opening

Hold Open

85°

90°

95°

100°

105°

110°

Dimensions for Doors 33” to 41”Wide

Opening

Hold Open

85°

90°

95°

100°

105°

110°

Dimensions for Doors 42” to 48”Wide

Opening

Hold Open

85°

90°

95°

100°

105°

110°

Dimension A Dimension B

Stop

Inches

90°

10-1/2

95°

100°

105°

110°

115°

Dimension A Dimension B

Stop

Inches

90°

12-5/8

95°

100°

11-3/8

105°

10-7/8

110°

10-3/8

115°

Dimension A Dimension B

Stop

Inches

90°

95°

14-1/4

100°

13-5/8

105°

110°

12-1/2

115°

9-3/4

9-1/4

8-7/8

8-1/2

8-1/8

12

10

15

13

12

mm.

267

248

235

225

216

206

mm.

321

305

289

276

264

254

mm.

381

362

346

330

318

305

Inches

8-5/8

8

7-1/2

7-1/8

6-3/4

6-3/8

Inches

11

10-3/8

9-3/4

9-1/4

8-3/4

8-3/8

Inches

13-1/4

12-1/2

11-7/8

11-1/4

10-3/4

10-1/4

mm.

219

203

191

181

171

162

mm.

279

264

248

235

222

213

mm.

337

318

302

286

273

260

Dimension C

Inches

Dimension C

Inches

11-3/8

10-3/4

10-1/4

Dimension C

Inches

14-1/4

13-1/2

12-7/8

12-1/4

11-3/4

11-1/4

9-5/8

9

8-1/2

8-1/8

7-3/4

7-3/8

12

9-3/4

9-3/8

mm.

244

229

216

206

197

187

mm.

305

289

273

260

248

238

mm.

362

343

327

311

298

286

Door Template Typical for All Installations

Fr me Template for 1-7/8 to 4-5/8 Revealsa

A

5/16

(8)

FRAME

TEMPLATE

(19.1)

C

B

2-3/4

(69.9)

DOOR

TEMPLATE

C

Hinge

L

• Do not scale drawing.

• Left Hand door shown.

• Dimensions are in inches (mm).

3/4

(19.1)

or

Pivot

Preparation for Fasteners

Fasteners

Door or Frame

Self-Drilling Screw

1/4” - 20 machine screw

Sleeve nuts and bolts

Power Adjustment Chart

DOOR

INT

EXT

INT

EXT

*18 -360° TURNS MAXIMUM AVAILABLE

PARALLEL ARM

INSTALLATION

51BF

o

51

3/8

(9.5)

2

(50.8)

3/4

1-1/2

(38.1)

1-1/4

(31.8)

Aluminum

or Metal

Wood

Metal

Hollow

Metal

Aluminum

or Wood

34”

(0.85 m)

*

2

8

SHAFT

3

FULL 360 TURNS

5

OF POWER ADJUSTMENT

MAXIMUM DOOR SIZE

2-3/4

(69.9)

7/16

(11.1)

6190 Bracket

7

(177.8)

4

(101.6)

1-1/8

(29)

9-1/16

(230.2)

1-5/8

(41)

Drill-Sizes

No drill required

3/16” (4.30 mm)

Pilot hole required

Drill: #7 (0.201” dia.)

Tap: 1/4” - 20

9/32” (7 mm) through;

3/8” (9.5 mm) door face

opposite to closer

3/8” (9.5 mm) through

36”

(0.9 m)

2

9

5

7

40”

(1 m)

10

44”

(1.1 m)

3

4

NOT

RECOMMENDED

USE 51

101413

7

Reveal

1/2

(12.7)

Holes

for

1688

Dropplate

48”

(1.2 m)

5

16

Page 2

80-9350-2514-010 (07-09)

Page 3

Frame Template for Reveals Over 4-5/8

Door Template on Page 2

A

5/16

(8)

3/8

(9.5)

2

(50.8)

2-3/4

(69.9)

4-3/8

(111)

Reveal

Typical Installation

Left Hand Door

R

Z

Pinion Flat

L

Y

“S” and “L” Valves

7/16

(11.1)

C

L

Hinge

or

Pivot

5/16

(8)

2-1/8

(54)

6191 Clamp Kit

Frame Template for Flush Partitions

Door Template on Page 2

(C + 1/8)

1/2

(12.7)

2-1/2

(63.5)

C

L

Hinge

or

Pivot

Installation Sequence

1-1/2

(38.1)

589L Bracket

3/4

(19.1)

1-3/4

(44)

“S” and “L” Valves

6190 Bracket

Soffit Plate

Main Arm

Hold-Open

“S” Valve

Y

Z

“L” Valve

Right Hand Door

L

Pinion Flat

R

Pinion Cap

!

Read Front Page.

Installations and component identification are on this page.

Arm assembly must be correct for width of door, see chart.

!

Select Correct Door and Frame Template Combination.

Follow “Template Information” on Page 2 or Pages 2 and 3.

!

Mark Location of Mounting Holes.

Use dimensions for hold-open or door stop angle desired.

Mark position of 4 holes on door for closer (or drop plate) and

6 holes on frame for soffit plate (or 4 for 589L angle bracket).

!

Prepare Holes for Fasteners.

See “Preparation for Fasteners” chart on Page 2.

!

UNI51 or UNI51BF Models Only. Set approximate closing

power using “Power Adjustment Chart” at bottom of Page

2.

!

Mount Closer to Door.

Drop Plate first, if used. Place end with “S” and “L” valves

toward the lock edge of the door. If using optional cover see

“Cover” instructions at bottom of Page 4.

! Mount Arm to Frame.

Fasten soffit plate (or 589L angle bracket if flush partition) to

frame. Mount 6190 bracket or 6191 clamps to reinforce soffit

plate.

!

Install Arm on Pinion Shaft.

Close valves “S” and “L”. Rotate pinion over 45° to align main

arm letter “R” (right hand) or “L” (left hand) with pinion flat.

Fasten with arm screw. See “Typical Installation” figure above

right. Re-open valves “S” and “L”.

!

Screw pinion cap onto the pinion shaft by hand or with a

Phillips screw driver - DO NOT OVER TIGHTEN. Skip this

step if optional cover is used.

!

Adjust Closer.

See “Unit Adjustment” on Page 4.

Page 3

Page 4

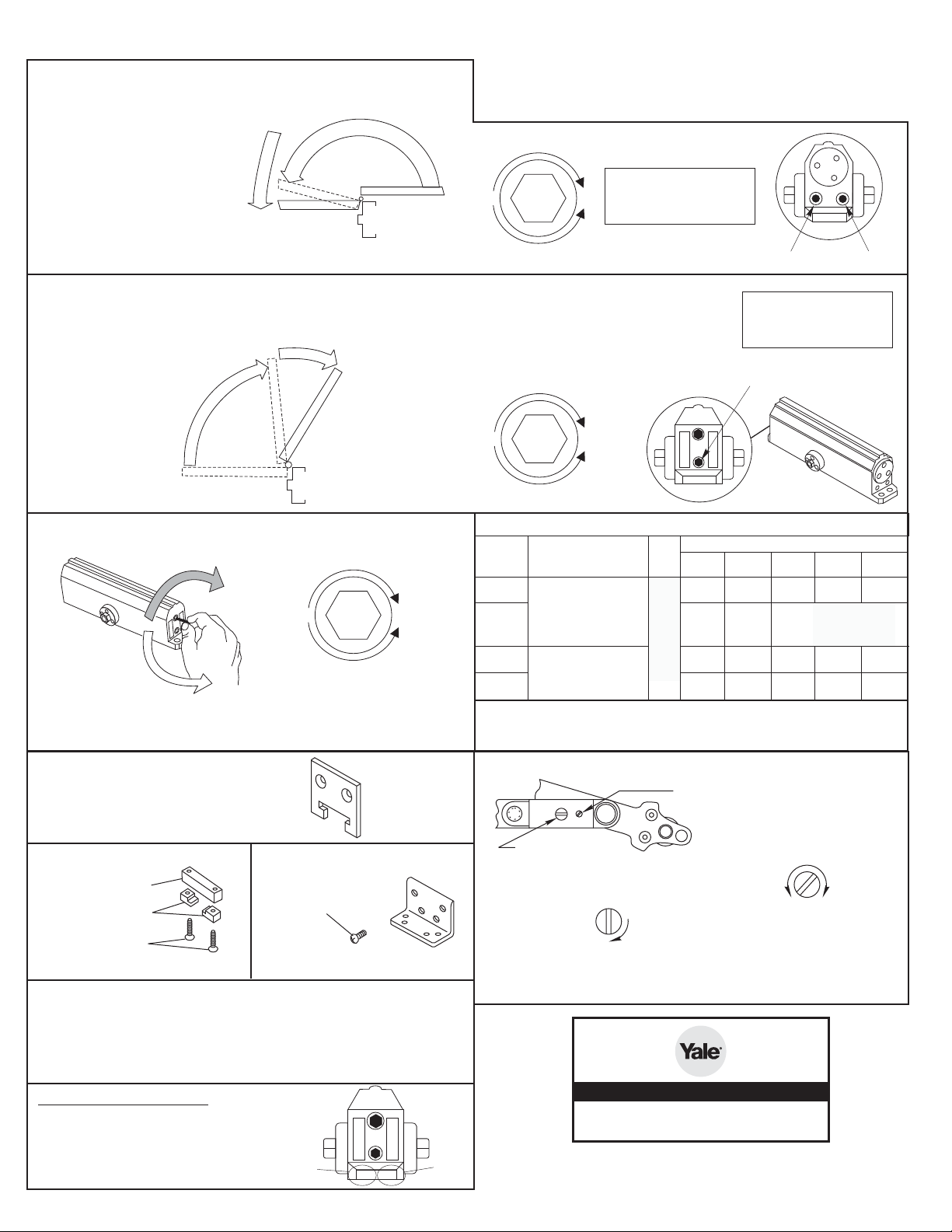

Unit Adjustment

Closing Speed Control

• Valve “S” controls Sweep Range.

• Valve “L” controls Latch Range.

Attention: Adjust Closing Speed

Time to between 4 to 7 seconds

from 90°. Use of the door by

handicapped, elderly or small

children may require greater

closing time. ADA code requires

that door take at least 3

seconds to close from 70° of

door opening to within 3”

(75mm) of the closed position.

Opening Door Control

H

C

T

A

L

10°

CLOSED

Closing Cycle

Figure 1

E

E

W

P

S

Figure 2

NOTE: By law the Americans with Disabilities Act (ADA) may

require that door closer installation comply with accessability

guidelines.

Slow

1/8”

Hex

Key

CAUTION:

DO NOT BACKVALVES OUT OF

CLOSER OR A LEAK WILL

RESULT

Fast

• Backcheck (”BC”) valve controls the hydraulic resistance to door opening in backcheck range.

NEVER close this valve completely – it is not to provide a positive stop.

C

B

A

K

C

H

E

C

K

G

N

I

N

E

P

O

Opening Cycle

Increase

1/8”

Hex

Key

Decrease

"L"Valve

CAUTION:

DO NOT BACKVALVES OUT OF

CLOSER OR A LEAK WILL

"BC" Valve

4

"S"Valve

RESULT

Closing Power Control Figure 3

Increase

Increase

1/8”

Hex

Key

Decrease

Decrease

Adjust as required. Product is shipped

at mid range power setting.

Bracket Illustrations

Standard 6190 Bracket

Deep Reveal Option

Spacer Block

Clamps

Flush Partition Option

4 Bracket

Screws

2 Clamp Screws

No. 6191 Reinforcing Kit No. 589L Bracket

Cover (Optional Cover 50P)

Thread in screws before mounting closer. Leave enough gap

between the head of the screw and the closer to slide the

cover on. Slide the cover over the closer and secure the

mounting screws after installation is complete.

To identify your model:

2=52BC

3=53BC

3 - 6=51

1- 4=51BF

4=54BC

5=55BC

6=56BC

Size

Code

3-6

BE

Page 4

Date

Code

Power Adjustment Chart

DOOR

INT

EXT

INT

EXT

*18 -360° TURNS MAXIMUM AVAILABLE

PARALLEL ARM

INSTALLATION

51BF

51

*

o

SHAFT

FULL 360 TURNS

OF POWER ADJUSTMENT

Door Holder Option

MAXIMUM DOOR SIZE

34”

(0.85 m)

36”

(0.9 m)

2

2

8

9

5

3

5

7

40”

(1 m)

44”

(1.1 m)

3

4

NOT

RECOMMENDED

USE 51

101413

7

10

Figure 4

48”

(1.2 m)

5

16

Hold-Open Force

Hold-Open

Press & Turn

“On”

Turn 90°

To “Off”

To Decrease

Force

To Increase

Force

Hold-Open option is found at the arm elbow. To select

hold-open “on” or hold-open “off” and to adjust the holdopen force ... use screwdriver as illustrated.

An ASSA ABLOY Group brand

3000 Highway 74 East • Monroe, NC 28112

Tel: (800)-438-1951 • Fax: (800)-338-0965

Yale ® is a registered trademark of Yale Security Inc., an ASSA ABLOY Group company.

Copyright © 1999, 2009, Yale Security Inc., an ASSA ABLOY Group company. All rights reserved.

Reproduction in whole or in part without the express written permission of Yale Security Inc. is prohibited.

www.yalecommercial.com

Loading...

Loading...