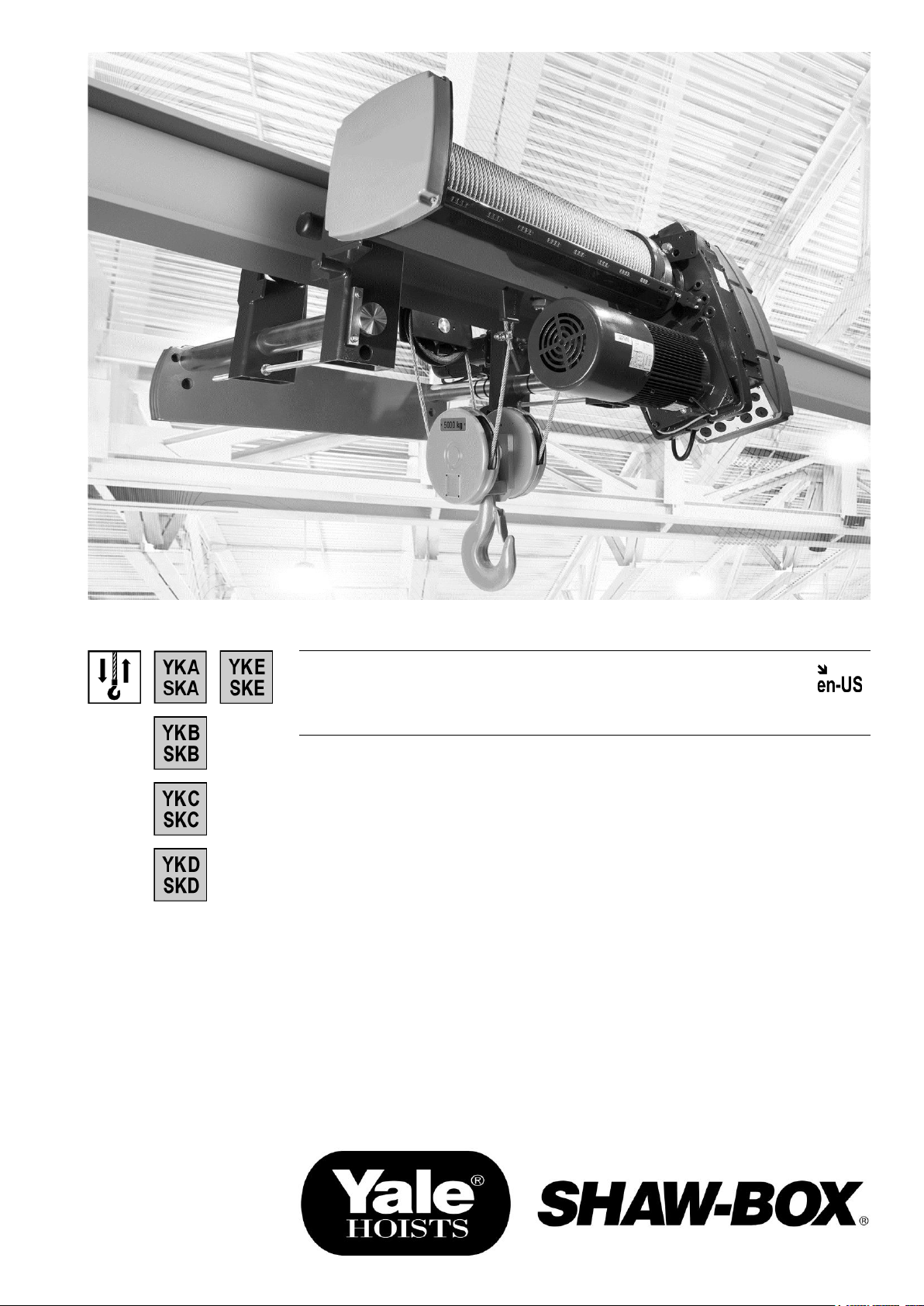

Page 1

ba-o.2.6.0-us-1.1-y | A11867501 Rev AA

Before installing hoist, fill in the information below.

Refer to the Hoist and Motor data plates.

Model No. ____________________________________________

Serial No. ____________________________________________

Purchase Date ____________________________________________

Voltage ____________________________________________

Rated Load ____________________________________________

Follow all instructions and warnings for inspecting, maintaining and operating this hoist.

The use of any hoist presents some risk of personal injury or property damage. That risk is greatly increased if proper

instructions and warnings are not followed. Before using this hoist, each operator should become thoroughly familiar with all

warnings, instructions and recommendations in this manual. Retain this manual for future reference and use.

Forward this manual to operator. Failure to operate equipment as directed in manual may cause injury.

Wire Rope Hoists

Operation & Service Manual

Page 2

ba-o.2.6.0-us-1.1-y | A11867501 Rev AA

YALE/SHAWBOX HOIST PARTS AND SERVICES ARE AVAILABLE IN THE UNITED

STATES AND IN CANADA

As a Yale/Shawbox Hoist and Trolley user you are assured of reliable repair and parts services through a network of

Master Parts Depots and Service Centers that are strategically located in the United States and Canada. These

facilities have been selected on the basis of their demonstrated ability to handle all parts and repair requirements

promptly and efficiently. To quickly obtain the name of the Master Parts Depot or Service Center located nearest you,

call (800) 888-0985, Fax: (716) 689-5644, visit www.cmworks.com

LAS PIEZAS Y REPARACIONES DE LOS POLIPASTOS DE YALE/SHAWBOX

ESTÁN ASEGURADAS EN ESTADOS UNIDOS Y CANADÁ

Como usuario de un polipasto y carro de Yale/Shawbox le aseguramos cualquier reparación o la disponibilidad de

cualquier pieza de repuesto a través de una red de almacenes de piezas de repuesto y centros de servicio situados

estratégicamente en Estados Unidos y Canadá. Estas instalaciones se han seleccionado en base a su capacidad

demostrada en la reparación de equipos y suminstro de piezas de repuesto de forma rápida y eficaz. Para obtener la

dirección del almacén de piezas de repuesto o del centro de servicio más cercano, llame al teléfono (800) 888-0985.

Fax: (716) 689-5644, visite www.cmworks.com (sólo en Estados Unidos y Canadá).

LE SERVICE DE RÉPARATION ET DE PIÈCES POUR PALANS YALE/SHAWBOX

EST DISPONIBLE AUX ÉTATS-UNIS ET AU CANADA

Soyez assurés qu'en temps d'utilisateur de palan et treuil Yale/Shawbox, d'un service de réparation et de pièces fiable

par l'entremise d'un réseau de Centres de service et de Dépôts de pièces maîtresses qui sont stratégiquement situés

aux États-Unis et au Canada. Ces établissements ont été sélectionnés sur une base de leur habileté démontrée à

s'occuper promptement et efficacement des besoins de réparation de pièces. Appelez le (800) 888-0985, Fax: (716)

689-5644, visite www.cmworks.com pour obtenir rapidement le nom du dépôt de pièces maîtresses ou du centre de

service situé le plus près.

Page 3

03.2018 3

ba-o.2.6.0-us-1.1-y | A11867501 Rev AA

Contents

1 General information ................................................................................................................................................................................................ 6

1.1 Information about safety messages .................................................................................................................................................................... 6

1.1.1 Explanation of signal words and symbols ..................................................................... 6

1.1.2 Safety instructions ........................................................................................................... 6

1.1.3 Section safety messages ................................................................................................ 6

1.1.4 Embedded safety messages .......................................................................................... 6

1.1.5 Safety alert symbols ........................................................................................................ 7

1.1.6 Additional symbol ............................................................................................................ 7

1.2 Spare parts ................................................................................................................................................................................................................ 7

1.3 Target audience and responsibilities .................................................................................................................................................................. 7

1.4 Crane logbook .......................................................................................................................................................................................................... 8

1.5 Transport and storage ............................................................................................................................................................................................ 8

1.6 Weight ........................................................................................................................................................................................................................ 8

1.7 Installation, commissioning, maintenance and repairs ................................................................................................................................... 8

1.8 After-sales service ................................................................................................................................................................................................... 9

1.9 Periodic inspections ............................................................................................................................................................................................... 9

1.10 Environmental information .................................................................................................................................................................................... 9

1.10.1 Life cycle assessment ..................................................................................................... 9

1.10.2 Energy consumption ....................................................................................................... 9

2 General safety notes ............................................................................................................................................................................................. 10

2.1 Use for intended purpose .................................................................................................................................................................................... 10

2.2 Inappropriate use ................................................................................................................................................................................................... 10

2.3 Residual hazards ................................................................................................................................................................................................... 11

2.4 Organizational safety precautions ..................................................................................................................................................................... 11

2.5 General regulations ............................................................................................................................................................................................... 11

2.6 Recommended PPE .............................................................................................................................................................................................. 11

2.7 Working above floor level .................................................................................................................................................................................... 12

2.8 Sound pressure level ............................................................................................................................................................................................ 12

2.9 Fire safety ................................................................................................................................................................................................................ 12

2.10 Safety-conscious operation ................................................................................................................................................................................ 13

2.11 Attaching load ........................................................................................................................................................................................................ 13

3 Introduction ............................................................................................................................................................................................................ 14

3.1 Incorporation .......................................................................................................................................................................................................... 15

4 Installation ............................................................................................................................................................................................................... 16

4.1 Stationary hoist ...................................................................................................................................................................................................... 16

4.1.1 Attachment at bottom .................................................................................................... 17

4.1.2 Attachment at top .......................................................................................................... 19

4.2 Fleet angle ............................................................................................................................................................................................................... 20

4.2.1 Attachment at bottom .................................................................................................... 20

4.2.2 Attachment at top .......................................................................................................... 21

4.2.3 Attachment at side ......................................................................................................... 22

4.2.4 Fleet angle ..................................................................................................................... 23

4.2.5 Angle of installation ....................................................................................................... 23

4.3 Monorail trolleys .................................................................................................................................................................................................... 24

4.3.1 Monorail trolley (KE-S33 - 76) ...................................................................................... 24

4.3.2 Drive shaft for travel drive (trolleys KE-S33 - KE-S65) ............................................... 25

4.3.3 Drive shaft for trolley drive (trolley KE-S76) ................................................................. 26

4.3.4 Monorail trolley (UE-S4) ................................................................................................ 27

4.3.5 Monorail trolley (UE-S776) ........................................................................................... 29

4.3.6 Articulated trolley (DKE-S4 / DKE-S6) ......................................................................... 31

4.4 End stops for monorail trolleys .......................................................................................................................................................................... 34

4.5 Double rail trolley (OE-S) ...................................................................................................................................................................................... 35

4.6 End stops for double rail trolleys ....................................................................................................................................................................... 36

4.6.1 Wheel diameter D = 3.9 in. ........................................................................................... 36

4.6.2 Wheel diameter D = 4.9 - 7.9 in.................................................................................... 36

4.7 Anti-jump catch ...................................................................................................................................................................................................... 37

4.7.1 Description of system .................................................................................................... 37

4.7.2 Procedure ....................................................................................................................... 37

Page 4

4 03.2018

ba-o.2.6.0-us-1.1-y | A11867501 Rev AA

4.8 Travel limit switches ............................................................................................................................................................................................. 40

4.8.1 Monorail trolley ............................................................................................................... 40

4.8.2 Double rail trolley ........................................................................................................... 40

4.9 Electrical equipment ............................................................................................................................................................................................. 41

4.9.1 Supply cables................................................................................................................. 41

4.9.2 Terminals........................................................................................................................ 41

4.9.3 Protection of equipment ................................................................................................ 42

4.9.4 Emergency stop ............................................................................................................. 42

4.9.5 Runway conductor disconnecting means .................................................................... 42

4.9.6 Disconnect switch .......................................................................................................... 42

4.9.7 Connection fuses ........................................................................................................... 42

4.9.8 Electromagnetic compatibility ....................................................................................... 43

4.9.9 Overload safety device.................................................................................................. 44

4.9.10 Connecting to mains...................................................................................................... 45

4.9.11 Control and control functions ........................................................................................ 46

4.9.12 Electric motors and related equipment ........................................................................ 47

4.10 YK/SK hoists with frequency inverter (VFD) .................................................................................................................................................... 47

4.11 Reeving rope .......................................................................................................................................................................................................... 48

5 Commissioning ...................................................................................................................................................................................................... 53

6 Operating................................................................................................................................................................................................................. 54

6.1 Operating precautions .......................................................................................................................................................................................... 54

6.2 Duties of crane operator....................................................................................................................................................................................... 56

6.3 Using control pendant .......................................................................................................................................................................................... 57

6.4 Operating hoist with frequency inverter ........................................................................................................................................................... 58

6.5 Emergency stop ..................................................................................................................................................................................................... 58

7 Inspection and maintenance ............................................................................................................................................................................... 59

7.1 Inspection intervals ............................................................................................................................................................................................... 60

7.2 Maintenance intervals ........................................................................................................................................................................................... 61

7.3 Motors ...................................................................................................................................................................................................................... 62

7.4 Hoist motor brake (RSM) ...................................................................................................................................................................................... 63

7.4.1 Checking brake .............................................................................................................. 63

7.4.2 Replacing brake disk (brake rotor) ............................................................................... 63

7.5 Hoist motor brake (NM) (pole-changing) ........................................................................................................................................................... 64

7.5.1 Checking brake .............................................................................................................. 64

7.5.2 Replacing brake disk (brake rotor) ............................................................................... 64

7.6 Hoist motor brake (NM) (4-pole) .......................................................................................................................................................................... 65

7.6.1 Checking brake .............................................................................................................. 65

7.6.2 Replacing brake disk (brake rotor ................................................................................ 65

7.7 Hoist motor brake (NM) 4HS. ............................................................................................................................................................................... 67

7.7.1 Checking brake .............................................................................................................. 67

7.7.2 Replacing brake disk (brake rotor) ............................................................................... 67

7.8 Travel motor brake ................................................................................................................................................................................................ 68

7.9 Hoist limit switch ................................................................................................................................................................................................... 69

7.9.1 Hoist limit switch (standard) .......................................................................................... 69

7.10 Hoist limit switch ................................................................................................................................................................................................... 70

7.10.1 Description of hoist limit switch system ........................................................................ 70

7.10.2 Testing emergency hoist limit switch, version 1 .......................................................... 70

7.10.3 Testing operational hoist limit switch, version 1 .......................................................... 70

7.10.4 Testing emergency hoist limit switch, version 2 .......................................................... 71

7.10.5 Testing operational hoist limit switch, version 2 .......................................................... 71

7.10.6 Setting hoist limit switch ................................................................................................ 72

7.10.7 Servicing hoist limit switch ............................................................................................ 75

7.11 Hook dimensions C for KE-S.. trolleys .............................................................................................................................................................. 76

7.12 Overload safety device ......................................................................................................................................................................................... 77

7.12.1 Testing overload safety device ..................................................................................... 77

7.12.2 Maintenance of overload safety device with pressure sensor ................................... 77

7.12.3 Maintenance of overload safety device with shear force sensor ............................... 77

7.13 Crane test ................................................................................................................................................................................................................ 77

7.14 Rope drive ............................................................................................................................................................................................................... 78

7.14.1 Rope and rope attachment - general information ....................................................... 78

7.14.2 Replacement of wire rope due to broken wires ........................................................... 79

Page 5

03.2018 5

ba-o.2.6.0-us-1.1-y | A11867501 Rev AA

7.14.3 Removing rope guide .................................................................................................... 79

7.14.4 Replacing wire rope ....................................................................................................... 80

7.14.5 Fitting rope guide ........................................................................................................... 81

7.14.6 Checking rope drum for wear ....................................................................................... 82

7.14.7 Inspection and maintenance of rope sheave .............................................................. 83

7.14.8 Checking load hook ....................................................................................................... 84

7.15 Trolley ...................................................................................................................................................................................................................... 85

7.16 Remaining service life .......................................................................................................................................................................................... 86

7.16.1 Operating hours counter in SLE load monitor ............................................................. 86

7.16.2 SMC multi-controller (optional) ..................................................................................... 86

7.17 General overhaul ................................................................................................................................................................................................... 86

8 Wearing parts ......................................................................................................................................................................................................... 87

8.1 Serial number ......................................................................................................................................................................................................... 87

8.2 Hoist ......................................................................................................................................................................................................................... 87

9 Troubleshooting .................................................................................................................................................................................................... 89

10 Decommissioning ................................................................................................................................................................................................. 91

10.1 Dismantling ............................................................................................................................................................................................................. 91

10.2 Scrap disposal ....................................................................................................................................................................................................... 91

11 Technical data ........................................................................................................................................................................................................ 92

11.1 Conditions of use .................................................................................................................................................................................................. 92

11.2 Hoist ......................................................................................................................................................................................................................... 93

11.2.1 Pole-changing hoist motors ../…-MF 50Hz ................................................................. 93

11.2.2 Pole-changing hoist motors ../…-MF 60Hz ................................................................. 94

11.2.3 Pole-changing hoist motors 50Hz ................................................................................ 95

11.2.4 Pole-changing hoist motors 60Hz ................................................................................ 95

11.2.5 Frequency-controlled hoist motors ../4H..-MF 100 Hz ................................................ 96

11.2.6 Frequency-controlled hoist motors ../4H..-MF 120 Hz ................................................ 96

11.2.7 Frequency-controlled hoist motors ../4HS.-MF 100 Hz .............................................. 97

11.2.8 Frequency-controlled hoist motors ../4HS.-MF 120 Hz .............................................. 97

11.3 Cable cross sections and lengths of supply cable ......................................................................................................................................... 98

11.3.1 Cable cross sections and lengths of supply cable for pole-changing hoist motors …-

MF ................................................................................................................................... 98

11.3.2 Cable cross sections and lengths of supply cable for pole-changing hoist motors .. 98

11.4 Tightening torques ................................................................................................................................................................................................ 99

11.5 Lubricants ............................................................................................................................................................................................................. 101

11.6 Lubricants for travel drive .................................................................................................................................................................................. 101

11.7 Circuit diagrams .................................................................................................................................................................................................. 101

Page 6

1 General information

6 03.2018

ba-o.2.6.0-us-1.1-y | A11867501 Rev AA

1 General information

You have purchased a Yale product.

This product was constructed in accordance with the applicable European standards and

regulations.

Read carefully and observe this manual. Store the manual within easy reach at the place

of operation.

1.1 Information about safety messages

1.1.1 Explanation of signal words and symbols

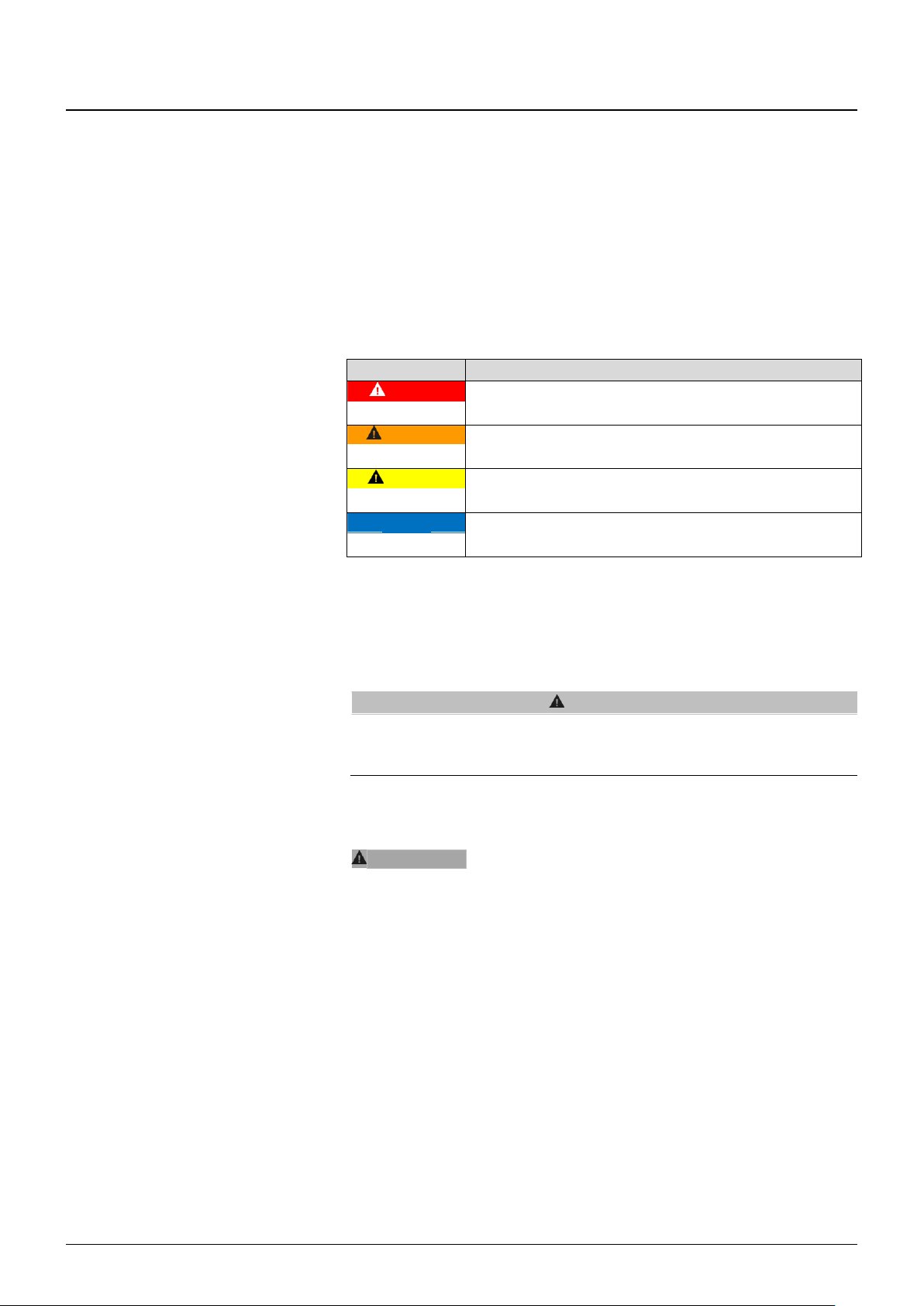

The following signal words are used in safety messages.

Signal word

Meaning

DANGER

Indicates a hazardous situation which, if not avoided, will result in

death or serious injury.

WARNING

Indicates a hazardous situation which, if not avoided, could result in

death or serious injury.

CAUTION

Indicates a hazardous situation which, if not avoided, could result in

minor or moderate injury.

NOTICE

Indicates possible material or environmental damage.

1.1.2 Safety instructions

The fundamental hazards and required safety measures are listed in section “General

safety notes”.

1.1.3 Section safety messages

Section safety messages relate to an entire section and are laid out as follows.

SIGNAL WORD

Type and source of hazard

Possible consequences if disregarded

➢ Measures to prevent the hazard

1.1.4 Embedded safety messages

Embedded safety messages are placed directly before or after a required action and are

structured as follows.

SIGNAL WORD Type and source of hazard, possible consequences if disregarded.

➢ Measures to prevent the hazard,

Page 7

1 General information

03.2018 7

ba-o.2.6.0-us-1.1-y | A11867501 Rev AA

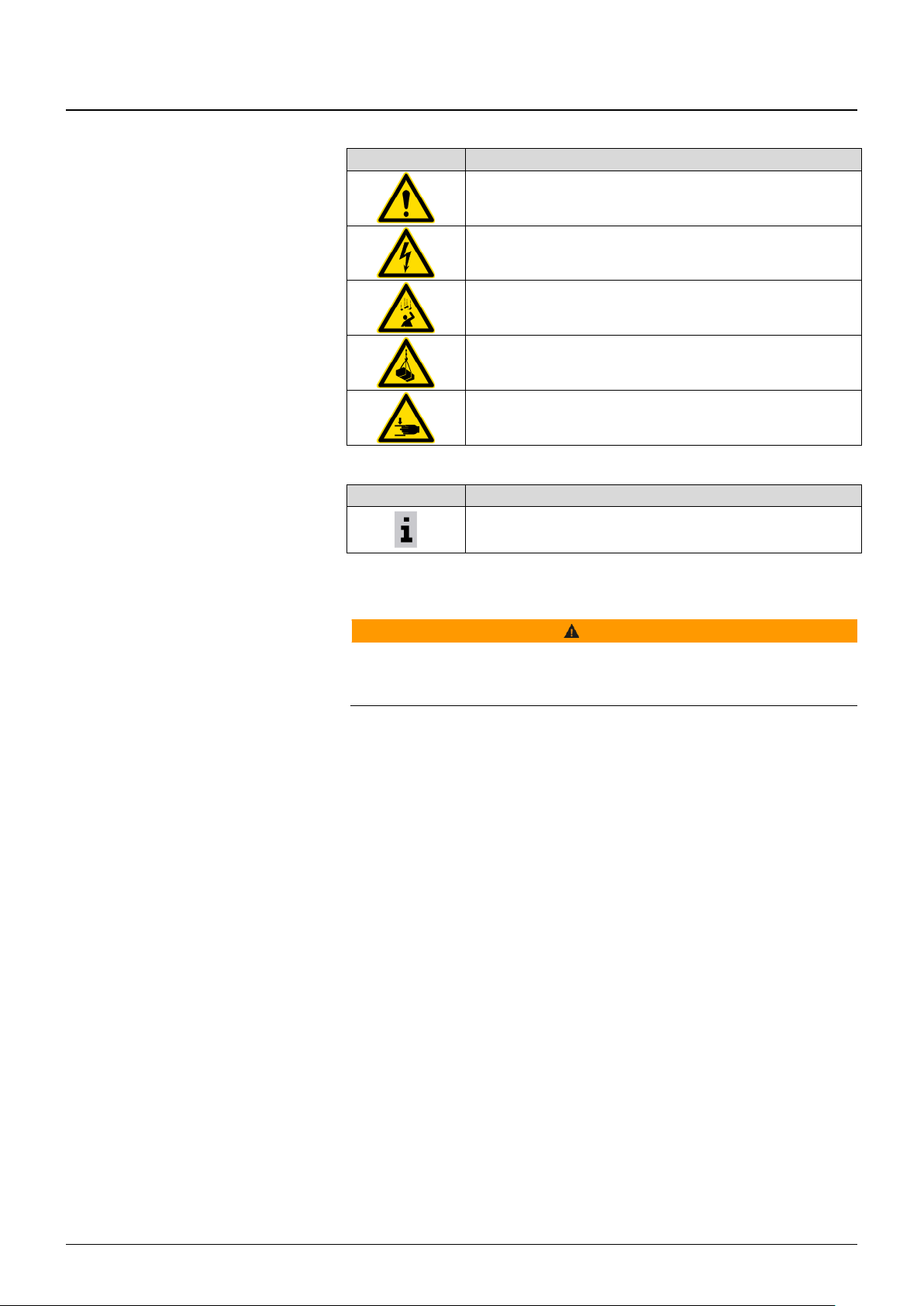

1.1.5 Safety alert symbols

Symbol

Meaning

General hazard

Electric shock hazard

Falling parts hazard

Suspended load hazard

Hand injury hazard

1.1.6 Additional symbol

Symbol

Meaning

Important note

1.2 Spare parts

WARNING

Safety hazard. Incorrect or defective spare parts may lead to damage, malfunctions or

the complete failure of the machine.

➢ Use only original spare parts.

1.3 Target audience and responsibilities

Owner

Whoever uses and employs the product or has it operated by suitable trained personnel

is considered to be the owner (employer/company).

Trained personnel

Trained personnel are persons who have been instructed and trained in the duties with

which they are entrusted and the risks which may arise from incorrect behavior, have

been advised on the necessary protective devices, precautions, applicable regulations,

accident prevention regulations and prevailing conditions and have proven their ability.

Qualified person

A qualified person is a person who by possession of a recognized degree, certificate, or

professional standing, or who by extensive knowledge, training, and experience,

successfully demonstrates the ability to solve/resolve problems relating to the subject

matter, the work, or the project.

Electrical qualified person

An electrical qualified person is defined as:

One who has received training in and has demonstrated skills and knowledge in the

construction and operation of electric equipment and installations and the hazard

involved.

Page 8

1 General information

8 03.2018

ba-o.2.6.0-us-1.1-y | A11867501 Rev AA

1.4 Crane logbook

A completed crane logbook must be kept for each hoist. The results of the periodic

inspections must be entered in the logbook.

1.5 Transport and storage

Transport

Fig. 1

The product is delivered on a special pallet. This enables it to be loaded and unloaded

safely with a fork-lift truck.

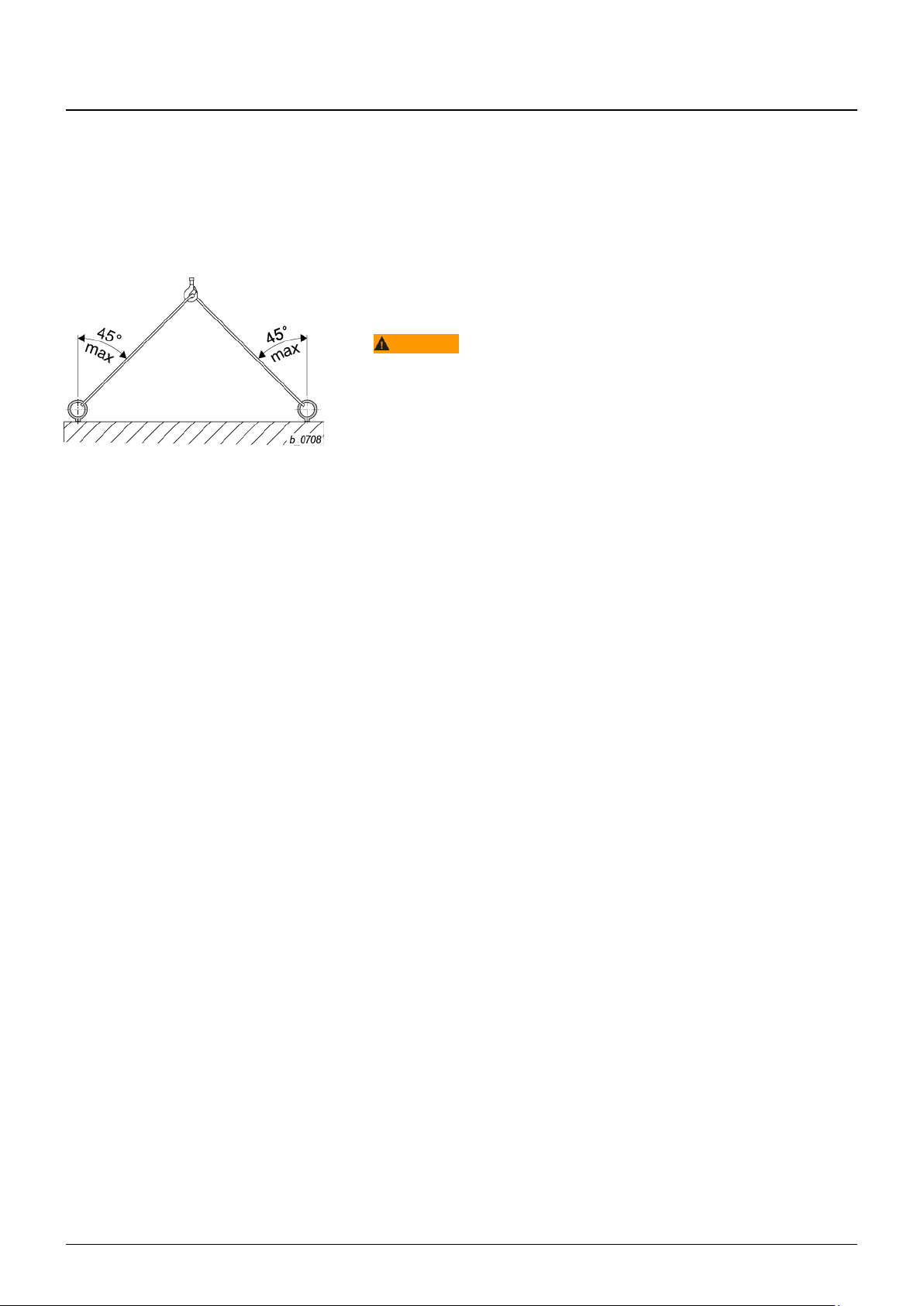

1. WARNING Falling parts hazard. If the product is to be transported suspended,

attach the product to the sling points provided. The sling points are designed for a

max. diagonal pull ≥ 45°.

2. Do not allow the hoist to drop. Set the product down on the ground correctly.

3. Avoid damage to the product and its components by loading and unloading it

correctly.

Storage

1. Store the product and its accessories in a dry place.

2. Store it in a stable position, secure it against toppling or overturning.

3. Observe environmental protection laws for storage (do not allow oil etc. to leak).

4. Make sure that the ground is firm and does not permit the machine to sink in.

5. Ensure the load is evenly distributed, support the hoist at several points.

6. Do not kink the ropes and avoid contact with the ground.

1.6 Weight

See factory certificate.

1.7 Installation, commissioning, maintenance and repairs

1. Make sure that installation, commissioning, maintenance and repairs are carried out

by qualified persons only.

2. We recommend having installation carried out by qualified personnel engaged by the

manufacturer.

3. Do not carry out any alterations or modifications.

4. Make sure that additional fitments are approved by the manufacturer.

(During welding work, electrode and ground must be in contact with the same

component!)

5. Use only original spare parts for repairs.

6. Make sure that dismantled guards are screwed down again and locked.

If the wire rope hoist is constantly operated out of doors and exposed to the elements

without protection, we recommend fitting a canopy or at least “parking” the hoist under a

roof.

• For detailed information about installation see section “Installation”.

• For detailed information about commissioning see section “Commissioning”.

• For detailed information and about maintenance and repairs see section “Inspection

and maintenance”.

Page 9

1 General information

03.2018 9

ba-o.2.6.0-us-1.1-y | A11867501 Rev AA

1.8 After-sales service

You have purchased a high-quality product. Our after sales service will give you advice

on its correct use.

In order to maintain the safety and constant availability of the product, we recommend

concluding a maintenance agreement.

Seminars:

Comprehensive understanding of material handling products is a prerequisite for the

correct use of equipment. Competent and practically oriented, we impart the specialist

knowledge required for the correct use, monitoring and care of your system.

Ask for our seminar program.

1.9 Periodic inspections

• Hoists and cranes must be inspected by a qualified person least once a year, more

frequently if so specified by national regulations.

• The results of the inspections must be recorded and filed in the test logbook.

• The remaining service life of the hoist must also be established during this inspection.

• The periodic inspections must be adapted to the hoist’s use. Intensive use or adverse

environmental conditions entail shorter maintenance intervals.

All tests must always be initiated by the owner!

1.10 Environmental information

Environmental aspects have been taken into account when developing and

manufacturing this equipment. Please note the instructions on safe lubrication and waste

disposal to avoid pollution risks during use. Appropriate use and correct maintenance will

improve the environmental performance of this product.

1.10.1 Life cycle assessment

The stages of the product service life are:

• Production of materials,

• components and energy,

• transport to factory,

• manufacture and assembly,

• transport to customer,

• on-site installation,

• operating phase including maintenance and modernization,

• dismantling and recycling of materials at end of service life.

1.10.2 Energy consumption

The energy consumption during the operating phase has the highest impact on the

environment. Electricity is required for starting and running the motors and for lighting,

heating, cooling and other optional electrical components and parts of the hoist.

Page 10

2 General safety notes

10 03.2018

ba-o.2.6.0-us-1.1-y | A11867501 Rev AA

2 General safety notes

The products are constructed according to the state of the art and recognised safety

rules. However, during use danger to the life and limb of the user or a third party can

arise, or adverse effects can affect the product and other property.

2.1 Use for intended purpose

• Wire rope hoists are intended for lifting freely movable loads. Depending on their

design, they are for stationary or mobile use.

• In the case of wire rope hoists with multiple load-bearing equipment, ensure that the

load is distributed evenly between the falls.

• Any fundamental alterations and modifications to the product, such as e.g. welding on

load-bearing components, structural alterations to load-bearing components,

alteration of drives, alteration of speeds and motor outputs, replacing trolleys, etc.

must be authorized by the manufacturer, otherwise the declaration of

conformity/declaration of incorporation will be invalidated.

• Also any work on or additions to the control must be authorized by the manufacturer.

The manufacturer cannot accept any liability for malfunctioning after unauthorized

work on the control.

• The conditions in the place of use of the hoist must correspond to the operating

conditions for which the hoist was designed (including indoor/outdoor use, ambient

temperature, radiation temperature, wind, dust, splash water, snow, water, etc.

• For hoists which work in combination and have more than one control (tandem

operation), action must be taken to coordinate the controls. This applies also to the

reaction of the protective devices. Controls must be constructed accordingly.

• For hoists intended for automatic operation, the control must be designed

accordingly.

2.2 Inappropriate use

• Use in areas with potentially explosive atmosphere.

• Transporting molten metal.

• Exceeding the maximum working load.

• Transporting persons.

• Pulling/towing or raising/lowering of a guided load.

• Using the hoist in applications in which the working load changes with the position of

the load, as the hoist is not equipped with a load display and additional warning

device when it cuts off at overload.

• Breaking away, pulling or towing of loads.

• Use of rope drive for “guided loads” without being designed for this type of

application.

• Breaking away of tilted loads if the rope drive is designed for the “guided load”

application.

• Pulling loads at an angle, dragging loads or moving vehicles with the load or load

suspension equipment.

• Do not knot load ropes or chains or shorten them with devices such as bolts, screws

or similar.

• Removing the safety latch from suspension and load hooks.

• Manipulating the overload safety device.

• Operation with slack rope (loose windings on the rope drum).

• If the product forms “part of a machine”, the person placing it on the market must

ensure that the product meets the specific regulations of the application.

Page 11

2 General safety notes

03.2018 11

ba-o.2.6.0-us-1.1-y | A11867501 Rev AA

2.3 Residual hazards

The machine has been subjected to a risk analysis. The design and construction based

on this correspond to the state of the art. However, residual hazards remain during

operation and maintenance and these could result in serious or even fatal injuries to

personnel.

• Risk of crushing

• Hazard due to falling parts (attached to the load or on the load)

• Load toppling due to unsuitable or damaged load-bearing equipment

• Risk of electric shock

Preventative measures:

1. Use LOTO (Lockout/Tagout) procedure in accordance to national, state and local

regulations and company policy.

2. Switch the machine off and ensure it cannot be switched on again before carrying out

maintenance, cleaning and repair work.

3. Switch off the power supply before all work on the electrical system. Check that the

components to be replaced are free of current and voltage.

4. Do not remove any safety devices or override them by manipulating them.

5. When lifting or lowering loads ensure that no-one is in the immediate danger area.

6. It is forbidden for anyone to stand in the danger area.

2.4 Organizational safety precautions

• The owner may only employ insured persons to operate a crane single-handedly

(crane operator), install or perform maintenance on the product if they are capable

both physically and mentally,

• have been instructed in operating and maintaining the crane and have shown him

proof of their competence and

• may be expected to perform the duties assigned them reliably.

• At regular intervals, check that work is being carried out in a safety-conscious

manner.

• Observe the intervals specified for periodic inspections. File the test reports in the

logbook.

2.5 General regulations

• Safety and accident prevention regulations.

• All national, state and local regulations.

2.6 Recommended PPE

Fig. 2

Personal protective equipment to be provided by the owner

• Safety shoes

• Gloves (only if there is no danger of them being drawn into equipment)

• Protective goggles

• Hart hat

• Hearing protection

• Closely fitting clothes (danger of clothing being drawn into equipment)

• When operating the hoist or standing close to the hoist, wire rope or chain there is a

danger of fingers, clothing, jewelry, etc. being drawn into equipment

Page 12

2 General safety notes

12 03.2018

ba-o.2.6.0-us-1.1-y | A11867501 Rev AA

2.7 Working above floor level

Personnel must be protected from falling. Observe the national, state, and local

regulations, and company policies when working above the floor level.

2.8 Sound pressure level

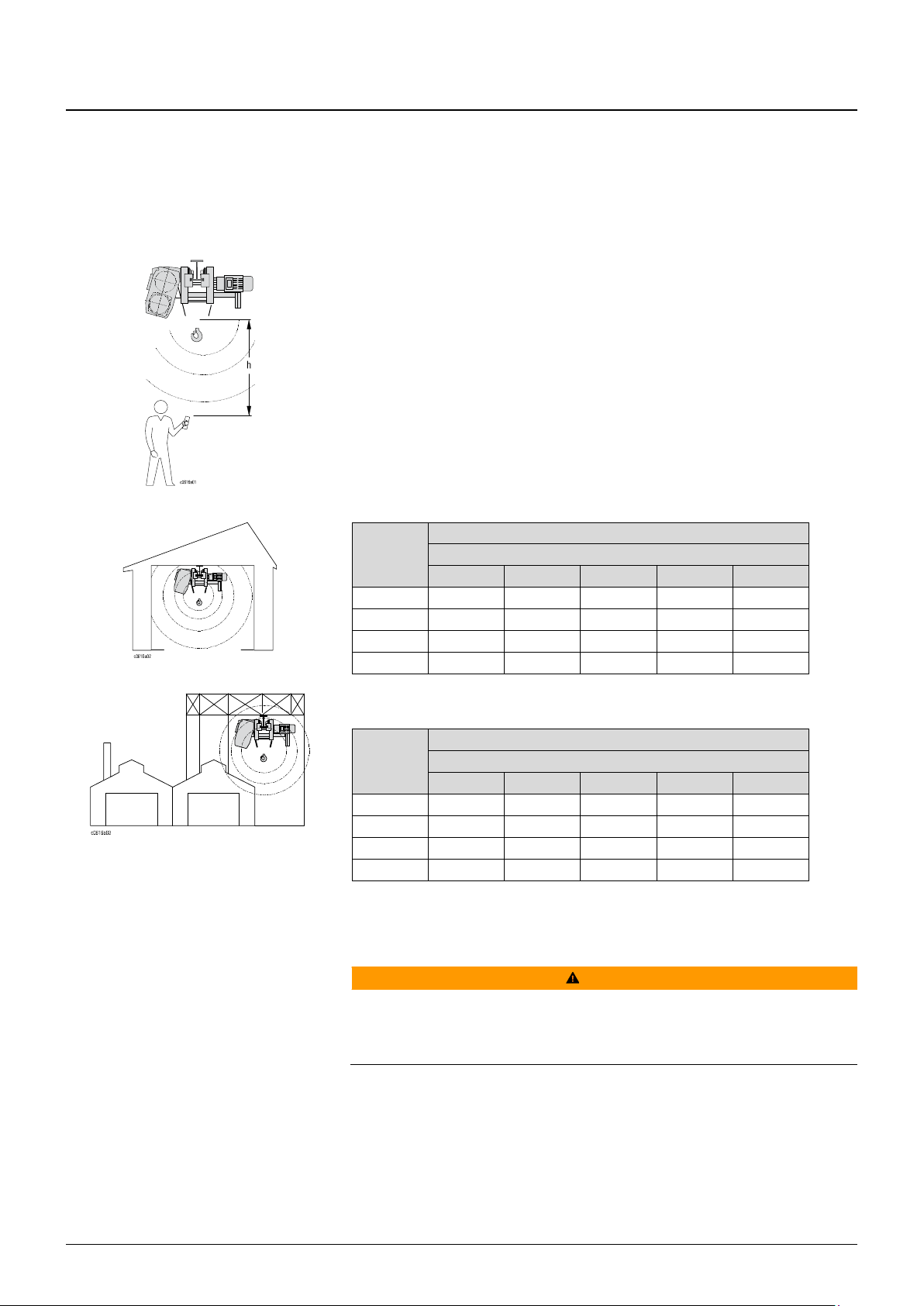

Fig. 3

The sound pressure level was measured at a distance of 3 ft from the wire rope hoist.

The mean sound pressure level is calculated for one operating cycle (50% with maximum

permissible load, 50% without load).

Instead of stating an emission value based on a workplace, the values from Tab. 1 and

Tab. 2 at measuring distance “h” can be used.

Fig. 4

Wire rope

hoist type

[db (A)] +/-3

h [ft]

3 ft

7 ft

13 ft

26 ft

52 ft

YKA/SKA

76

73

70

67

64

YKB/SKB

76

73

70

67

64

YKC/SKC

78

75

72

69

66

YKE/SKE

78

75

72

69

66

Tab. 1

Wire rope

hoist type

[db (A)] +/-3

h [ft]

3 ft

7 ft

13 ft

26 ft

52 ft

YKA/SKA

76

70

64

58

52

YKB/SKB

76

70

64

58

52

YKC/SKC

78

72

66

60

50

YKE/SKE

78

72

66

60

50

Tab. 2

2.9 Fire safety

WARNING

Safety hazard. Never use a powder extinguisher in the presence of high voltages.

Only fight the fire if this is possible without subjecting yourself to risk. Switch off the crane

if this is possible. Evacuate the area. Advise other persons on potential danger and call

for help.

Page 13

2 General safety notes

03.2018 13

ba-o.2.6.0-us-1.1-y | A11867501 Rev AA

2.10 Safety-conscious operation

YK/SK wire rope hoists are constructed according to the state of the art and equipped

with an overload safety device in standard version. In spite of this, dangers may arise

from inappropriate use or use for an unintended purpose.

1. The owner is responsible for ensuring that work is carried out with safety in mind and

avoiding risks.

2. Read the instructions before starting to work with the product.

3. Standing under a suspended load is forbidden. Danger to life and limb!

4. Observe the “Duties of crane operator”.

5. Before starting work, find out where the emergency stop button is (usually in the

control pendant).

6. Do not put your hand between edges which might crush or cut.

7. Do not grasp the moving rope.

8. Take note of the relevant instructions when attaching loads.

9. Do not stand between load and wall.

10. Start lifting the load carefully.

11. Never attempt to remedy a malfunction while the load is suspended.

12. Never use bent, open or distorted load hooks, or attempt to straighten them.

13. Have a damaged hook safety latch repaired.

14. Never anneal the hook.

15. Never lock the buttons of the control switch in place.

16. Never allow the load to drop into the hoist’s load-bearing equipment.

17. Before lifting loads, ensure that the stated maximum working load is not exceeded.

18. When lifting and setting down loads, ensure that they are in a stable position in order

to avoid accidents due to the load toppling or overturning.

19. Secure the load if the power is cut.

20. Do not kink or crush control cables.

21. Choose a safe place from which to operate the hoist.

22. Joining or mending ropes, chains or belts is not permitted.

23. Never touch metal components that are colder than 32°F or hotter than 131°F without

wearing protective gloves.

24. Do not use the emergency limit switch (ultimate limit switch for highest and lowest

hook position) as an operational limit switch.

25. Report damage and defects to the product (abnormal noises, impaired braking

function, deformations, etc.) to the person responsible immediately. Do not use the

product until the faults have been eliminated.

26. Do not remove information plates from the product. Replace illegible or damaged

plates.

27. Have hoist inspected by the relevant authority before commissioning.

2.11 Attaching load

1. Use only tested and approved slings for attaching the load.

2. The hoist rope must not be wound around the load.

3. The load must always be suspended from the base of the hook. The tip of the hook

must not be subjected to load.

4. Removing the safety latch from suspension and load hooks is not permitted.

5. Only attach hook block when stopped.

6. Hook or hook block turns under load – release the hook block and rope when lifting

the load.

7. Do not reach into the hook block opening at the rope inlet – crushing hazard!

8. Guide the hook block on the load hook bracket - not on the hook base! – crushing

hazard!

Page 14

3 Introduction

14 03.2018

ba-o.2.6.0-us-1.1-y | A11867501 Rev AA

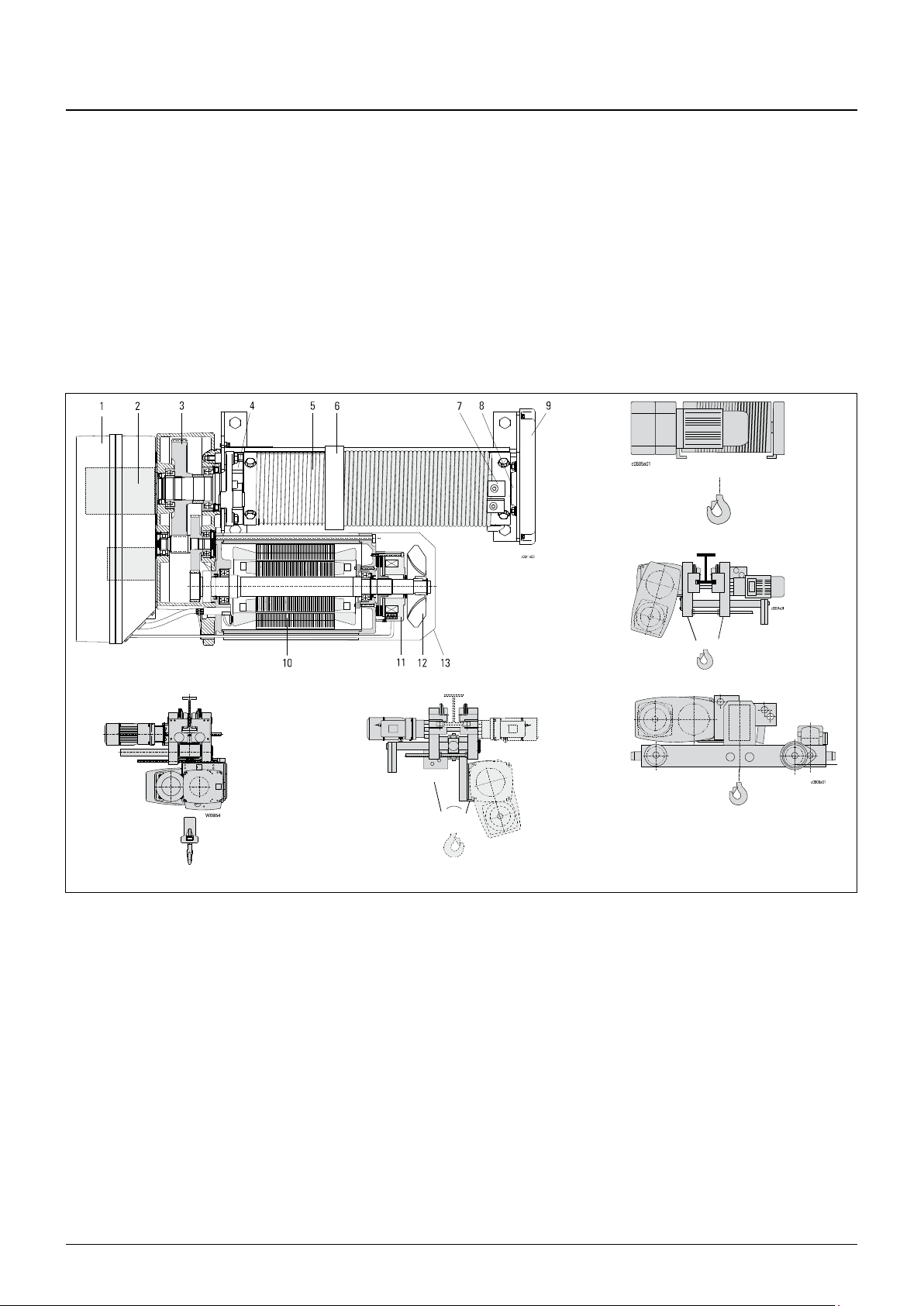

3 Introduction

Wire rope hoists are intended for lifting freely movable loads.

The modular concept of our series of wire rope hoists permits a multitude of variations on

the basis of series components.

The design is characterized by the rope drum and hoist motor being arranged in parallel.

The hoist drive is a cylindrical rotor motor with a separately activated D.C. brake. Its

design complies with the FEM calculation regulations which are adapted to the

requirements of hoist operation.

The main components of the wire rope hoist are the hoist motor, the gear, the rope drum

and the control box with connection parts.

Our certified quality assurance system to DIN ISO 9001 guarantees consistently high

quality.

14

15

16 17 18

Fig. 5

1 Panel box with connection parts

2 Emergency hoist limit switch, operational hoist limit switch

3 Gear

4 Mounting point for safety brake (YKB/SKB – YKE/SKE)

5 Rope drum

6 Rope guide with rope tensioning spring

7 Clamps for rope attachment

8 Rope drum bearing

9 End cover

10 Motor

11 Brake

12 Fan

13 Fan cover

14 Stationary wire rope hoist, hoist for incorporation

15 Wire rope hoist with “short headroom” monorail trolley

16 Wire rope hoist with “standard headroom” monorail trolley

17 Wire rope hoist with “articulated” monorail trolley

18 Wire rope hoist with double rail trolley

Page 15

3 Introduction

03.2018 15

ba-o.2.6.0-us-1.1-y | A11867501 Rev AA

3.1 Incorporation

Stationary hoist (hoist for incorporation)

The hoist is connected to a fixed structure by means of bolt joints permitting it to be

attached to a base, wall or ceiling.

Mobile hoist

The hoists can be mounted on 4 different types of travel carriage.

Page 16

4 Installation

16 03.2018

ba-o.2.6.0-us-1.1-y | A11867501 Rev AA

4 Installation

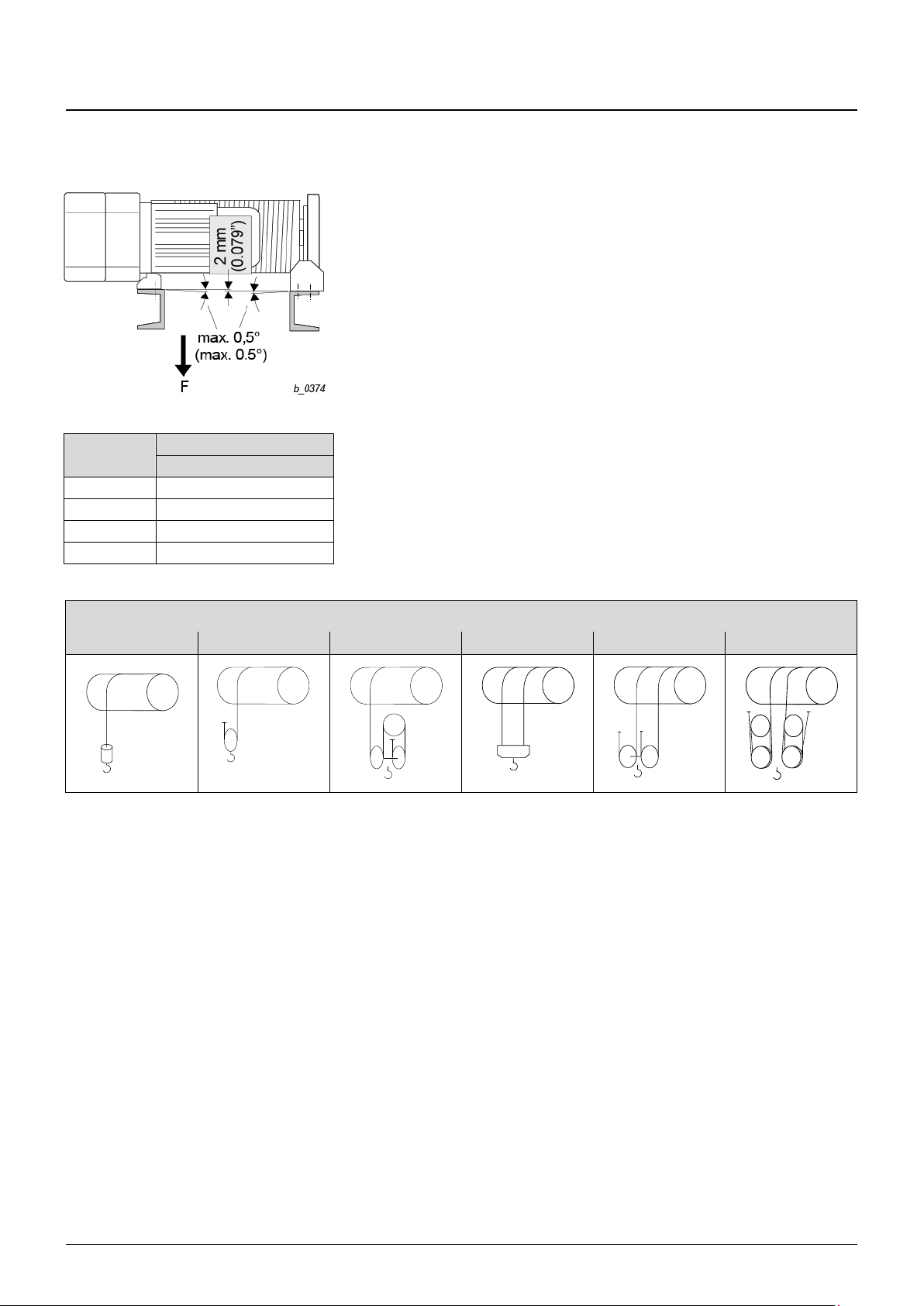

4.1 Stationary hoist

Fig. 6

Wire rope

hoist type

MT (rope drum torque)

[lbf in]

YKA/SKA

½ × F × 5 in

YKB/SKB

½ × F × 6.6 in

YKC/SKC

½ × F × 8.6 in

YKE/SKE

½ × F × 14 in

Possible mounting positions and fleet angles

Feet “at bottom” and “at top” are possible for designs with bottom hook block (rope leadoff vertically downwards).

The YK/SK wire rope hoist with 1PS and 1PS twin hook rope lead-off can be installed in

various positions (fleet angles see page 20-23, section 4.2 “Fleet angle”)

1. If possible, install the hoist in the preferred installation position ***

(see page 20, section 4.2 1 “Attachment at bottom”)

2. Use the fixing elements specified, see the following figures and tables.

3. Take care that no distortion arises from unevenness (max. 0.5°, max. 0.079 in.)

4. The customer's substructure must take up the torque M

T

from the rope drum. It must

therefore be torsion resistant.

5. If the rope lead-off is not vertical, the shearing forces arising must be taken up by a

shear bar.

6. For tightening torques see page 102, section 11.4 “Tightening torques”.

Standard reevings

1PS

2PS

4PS

1PD

2PD

4PD

Fig. 7

Page 17

4 Installation

03.2018 17

ba-o.2.6.0-us-1.1-y | A11867501 Rev AA

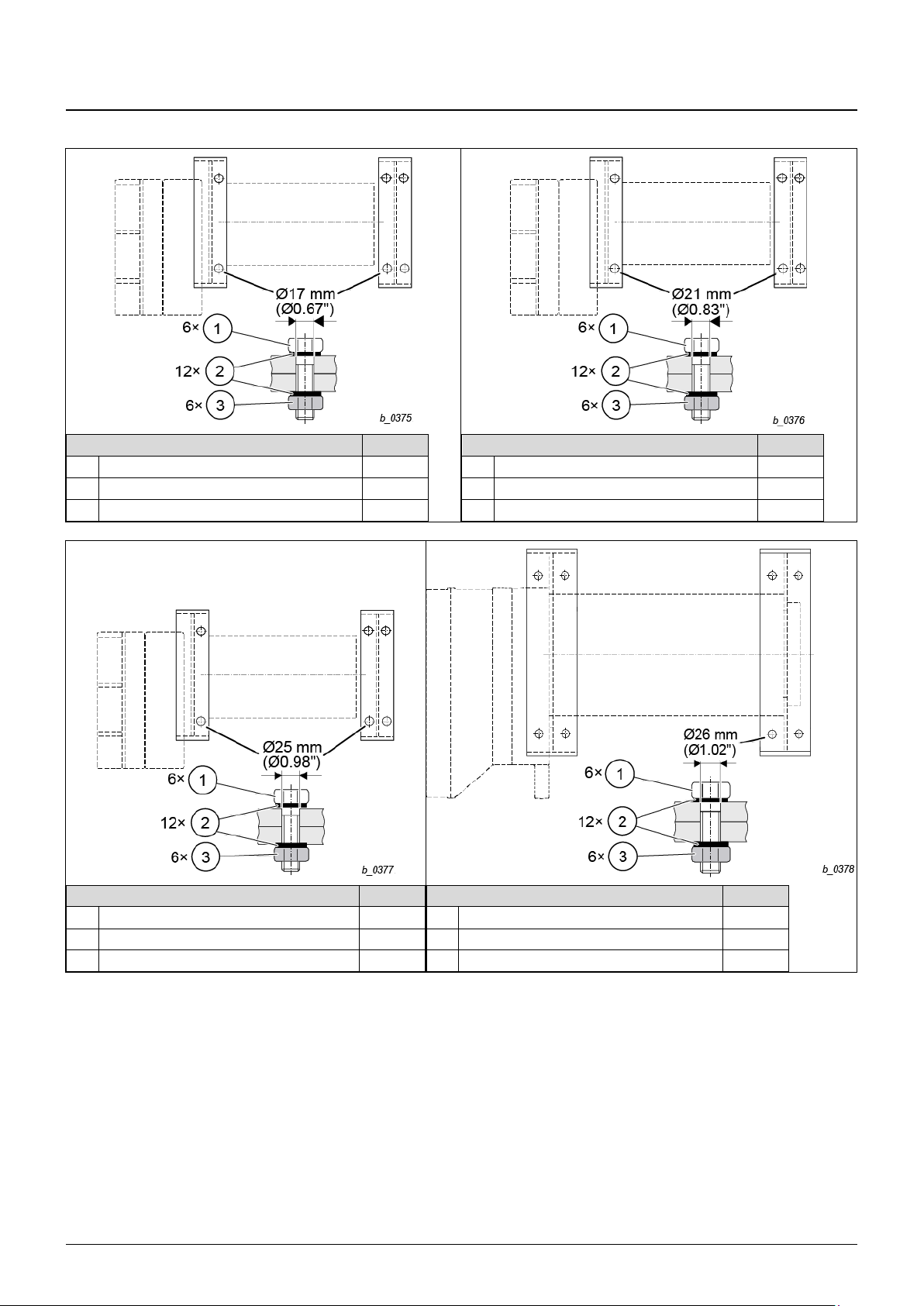

4.1.1 Attachment at bottom

Type YKA/SKA

pcs

(1)

Screw M16-8.8

6

(2)

SCHNORR® Safety Washer S16

12

(3)

Nut, M16-8

6

Type YKB/SKB

pcs

(1)

Screw M20-8.8

6

(2)

SCHNORR® Safety Washer S20

12

(3)

Nut, M20-8

6

Type YKC/SKC

pcs

(1)

Nut, M24-8

6

(2)

SCHNORR® Safety Washer S24

12

(3)

Screw M24-8.8

6

Type YKE/SKE, YKD/SKD (2PS, 4PS, 2PD)

pcs

(1)

Screw M30-8.8

8

(2)

SCHNORR® Safety Washer S24

16

(3)

Nut, M30-8

8

Page 18

4 Installation

18 03.2018

ba-o.2.6.0-us-1.1-y | A11867501 Rev AA

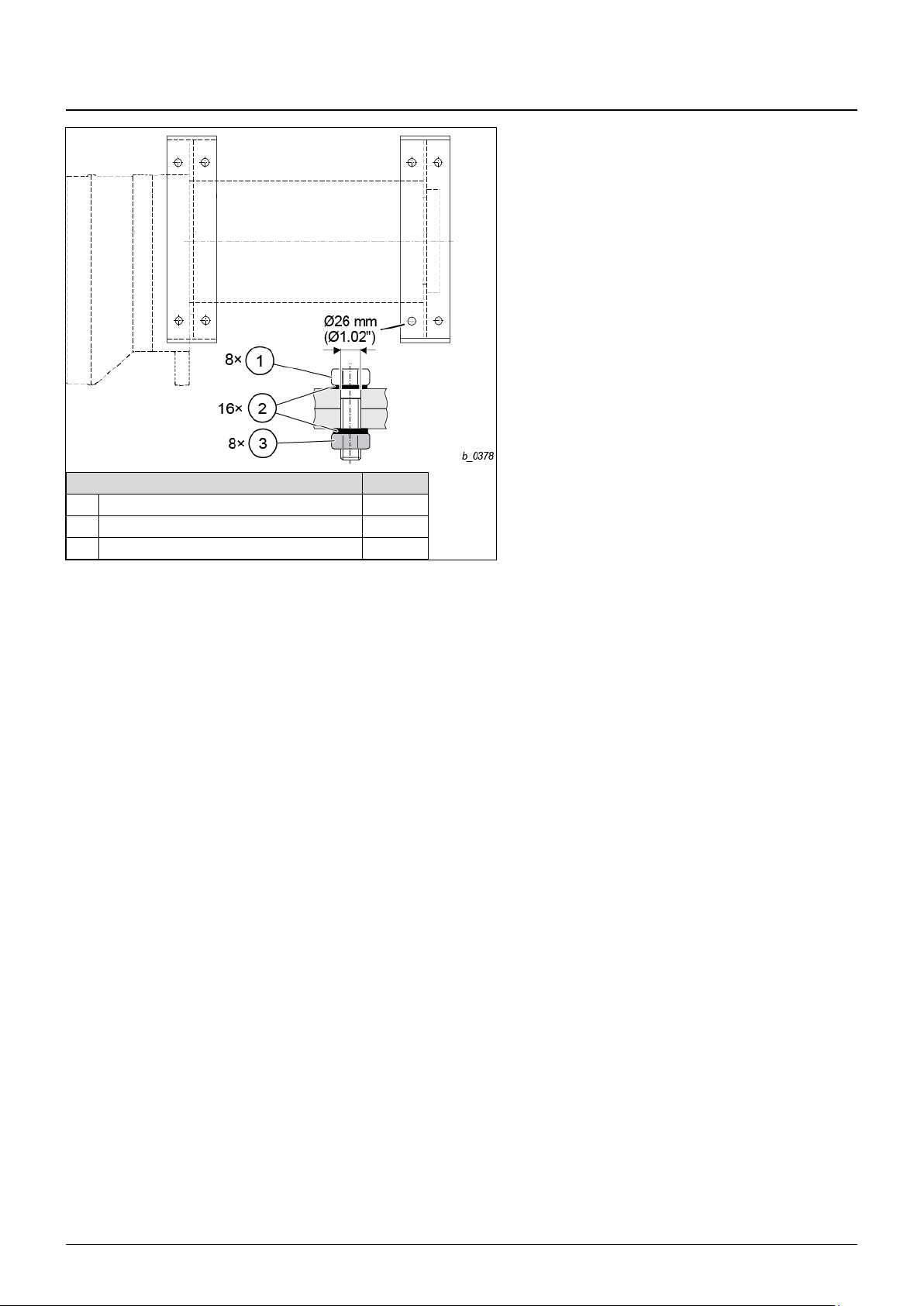

Type YKE/SKE (1PS)

pcs

(1)

Nut, M24-8

8

(2)

SCHNORR® Safety Washer S24

16

(3)

Screw M24-8.8

8

Fig. 8

Page 19

4 Installation

03.2018 19

ba-o.2.6.0-us-1.1-y | A11867501 Rev AA

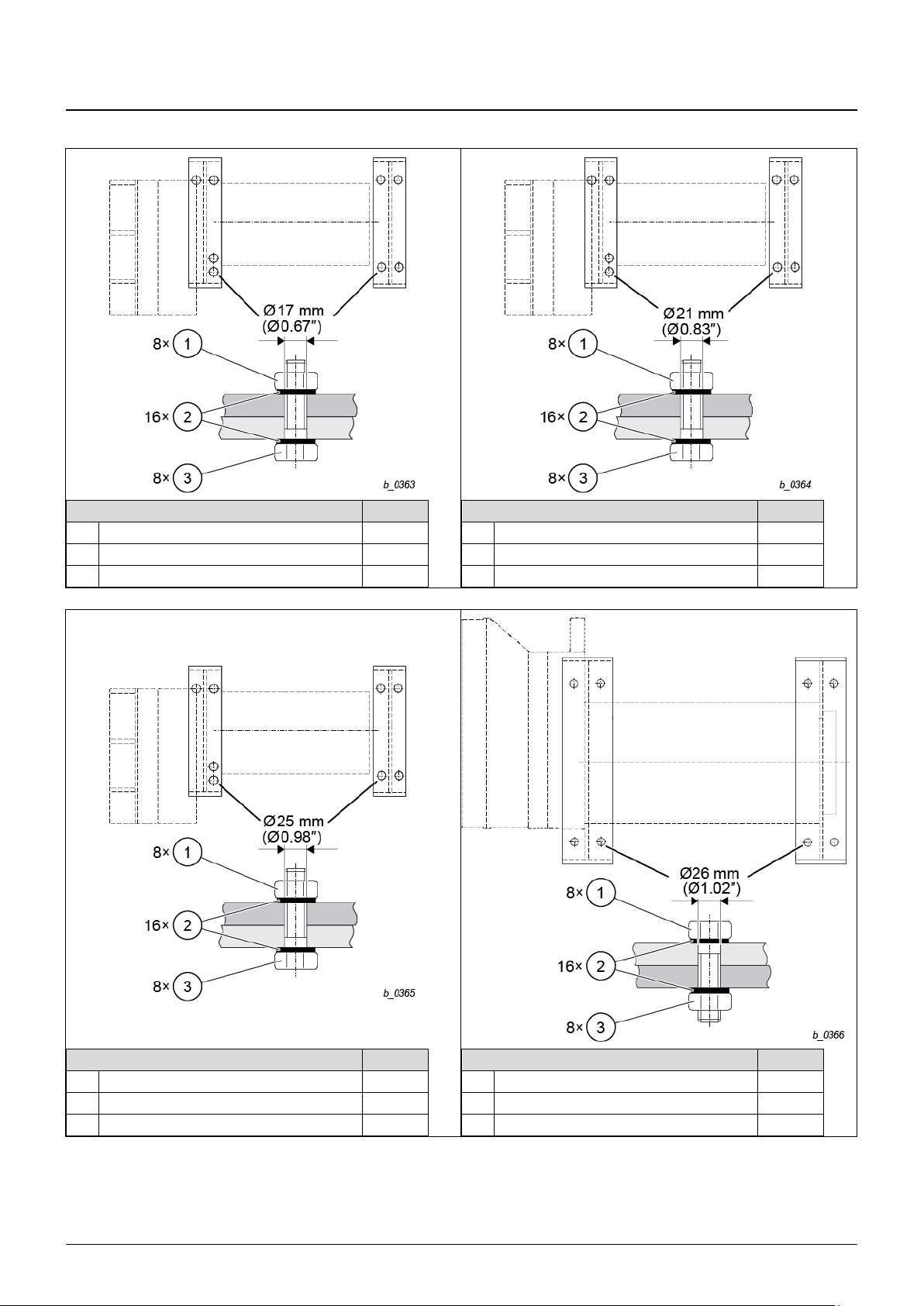

4.1.2 Attachment at top

Type YKA/SKA

pcs

(1)

Nut, M16-8

8

(2)

SCHNORR® Safety Washer S16

16

(3)

Screw M16-8.8

8 Type YKB/SKB

pcs

(1)

Nut, M20-8

8

(2)

SCHNORR® Safety Washer S20

16

(3)

Screw M20-8.8

8

Type YKC/SKC

pcs

(1)

Nut, M24-8

8

(2)

SCHNORR® Safety Washer S24

16

(3)

Screw M24-8.8

8

Type YKE/SKE (1PS)

pcs

(1)

Screw M24-8.8

8

(2)

SCHNORR® Safety Washer S24

16

(3)

Nut, M24-8

8

Fig. 9

Page 20

4 Installation

20 03.2018

ba-o.2.6.0-us-1.1-y | A11867501 Rev AA

4.2 Fleet angle

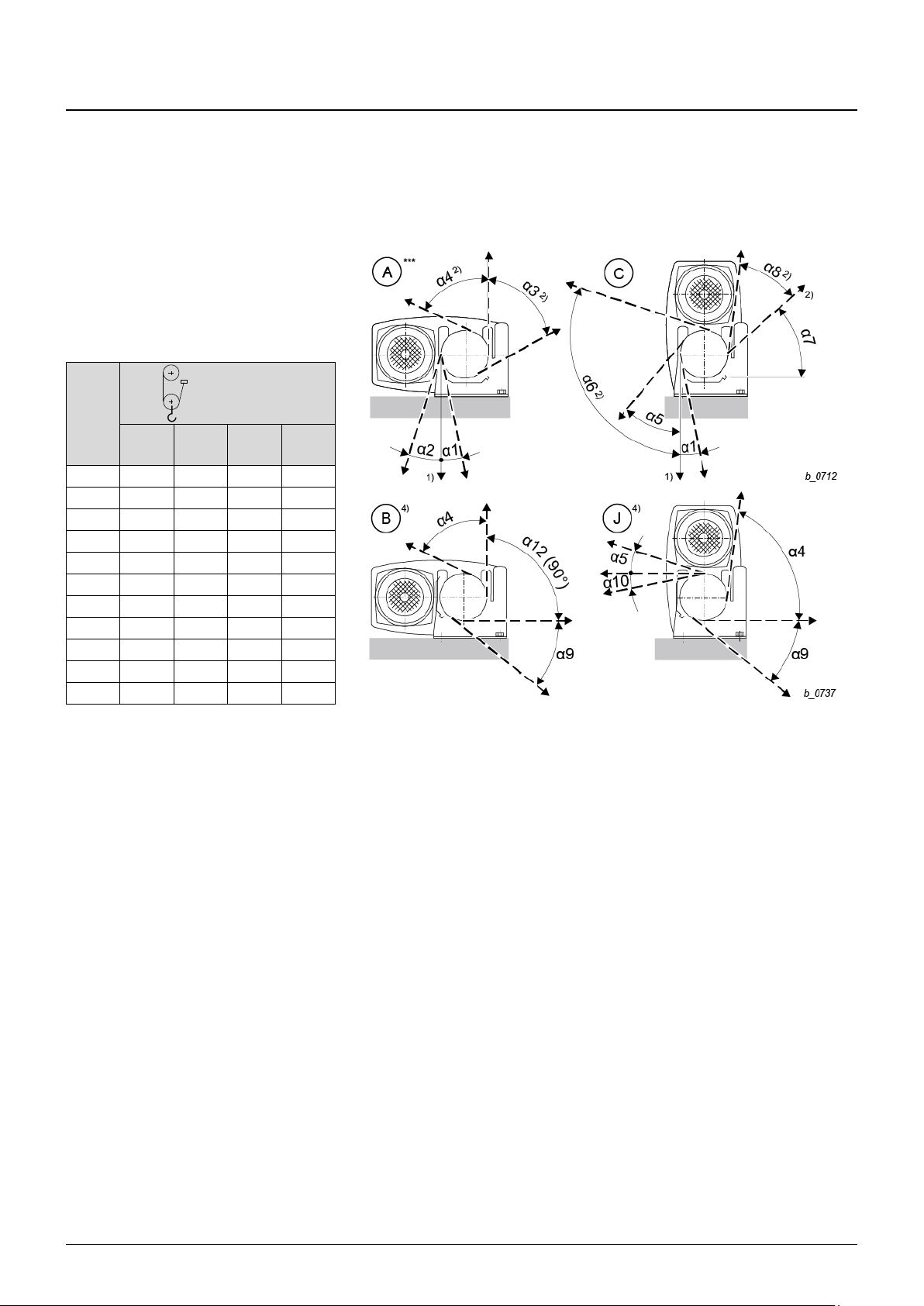

4.2.1 Attachment at bottom

Wire rope hoist types

YKA/SKA, YKB/SKB, YKC/SKC, YKE/SKE

1PS,

1PS twin hook

YKA/

SKA

YKB/

SKB

YKC/

SKC

YKE/

SKE

α1

4°

5°

8°

8°

α2

23°

13°

20°

18°

α3

27°

30°

30°

30°

α4

74°

73°

76°

80°

α5

30°

30°

30°

25°

α6

113°

103°

110°

108°

α7

63°

61°

60°

60°

α8

11°

12°

16°

20°

α9

24°

26°

30°

-

α10

7°

7°

8°

8°

α12

90°

90°

90°

-

Tab. 3

Fig. 10

***

Preferred installation position

1)

Standard

2)

By turning rope guide

4)

By turning rope guide and grease pan.

Type YKE/SKE: Version (G) not possible

Page 21

4 Installation

03.2018 21

ba-o.2.6.0-us-1.1-y | A11867501 Rev AA

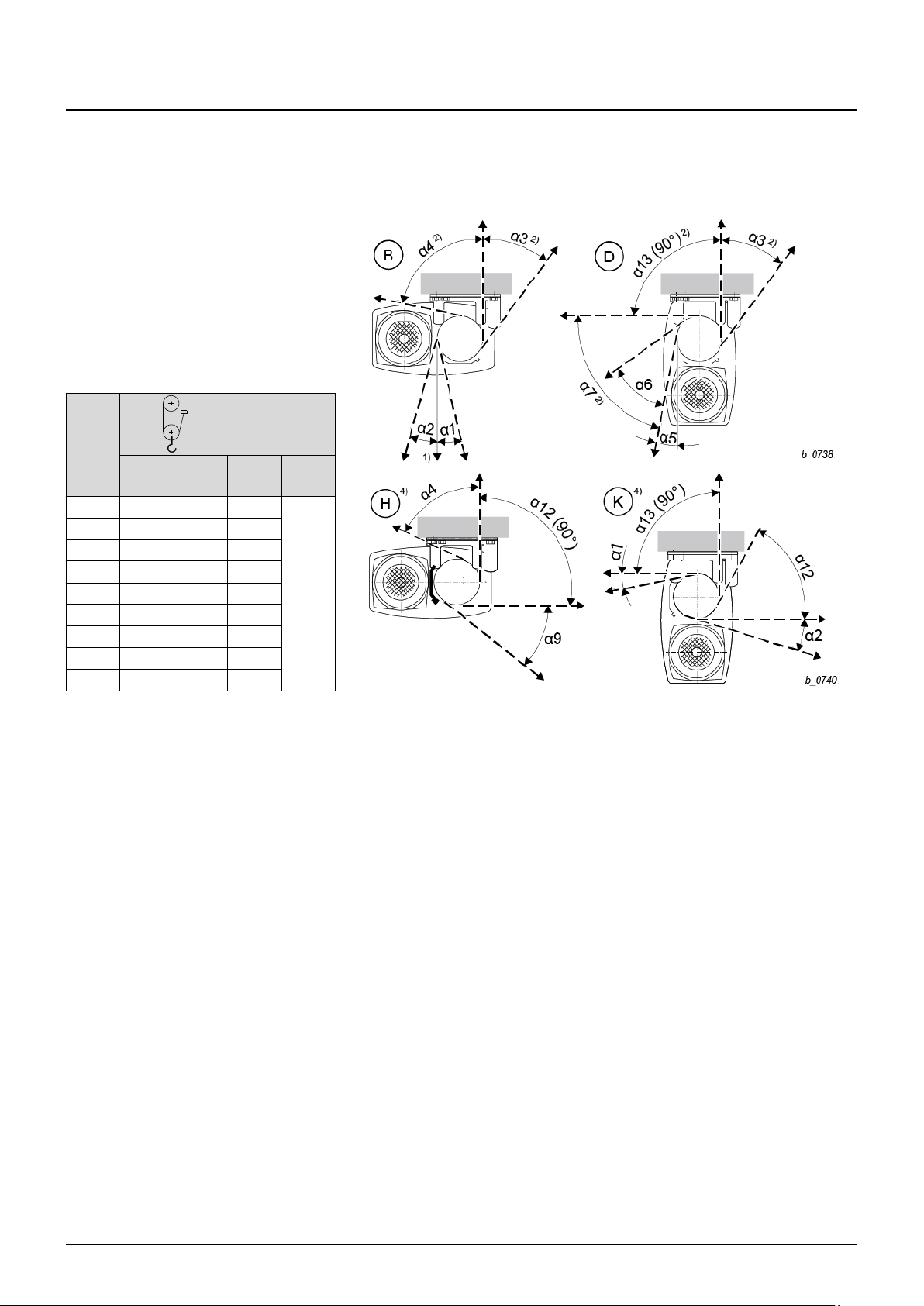

4.2.2 Attachment at top

Wire rope hoist types

YKA/SKA, YKB/SKB, YKC/SKC, YKE/SKE

1PS,

1PS twin hook

YKA/

SKA

YKB/

SKB

YKC/

SKC

YKE/

SKE

α1

4°

5°

8°

on

request

α2

23°

13°

20°

α3

27°

30°

30°

α4

74°

73°

76°

α5

16°

17°

14°

α6

35°

32°

36°

α7

74°

74°

76°

α12

90°

90°

90°

α13

90°

90°

90°

Tab. 4

Fig. 11

1)

Standard

2)

By turning rope guide

4)

By turning rope guide and grease pan.

Type YKE/SKE: Version (H) not possible

Page 22

4 Installation

22 03.2018

ba-o.2.6.0-us-1.1-y | A11867501 Rev AA

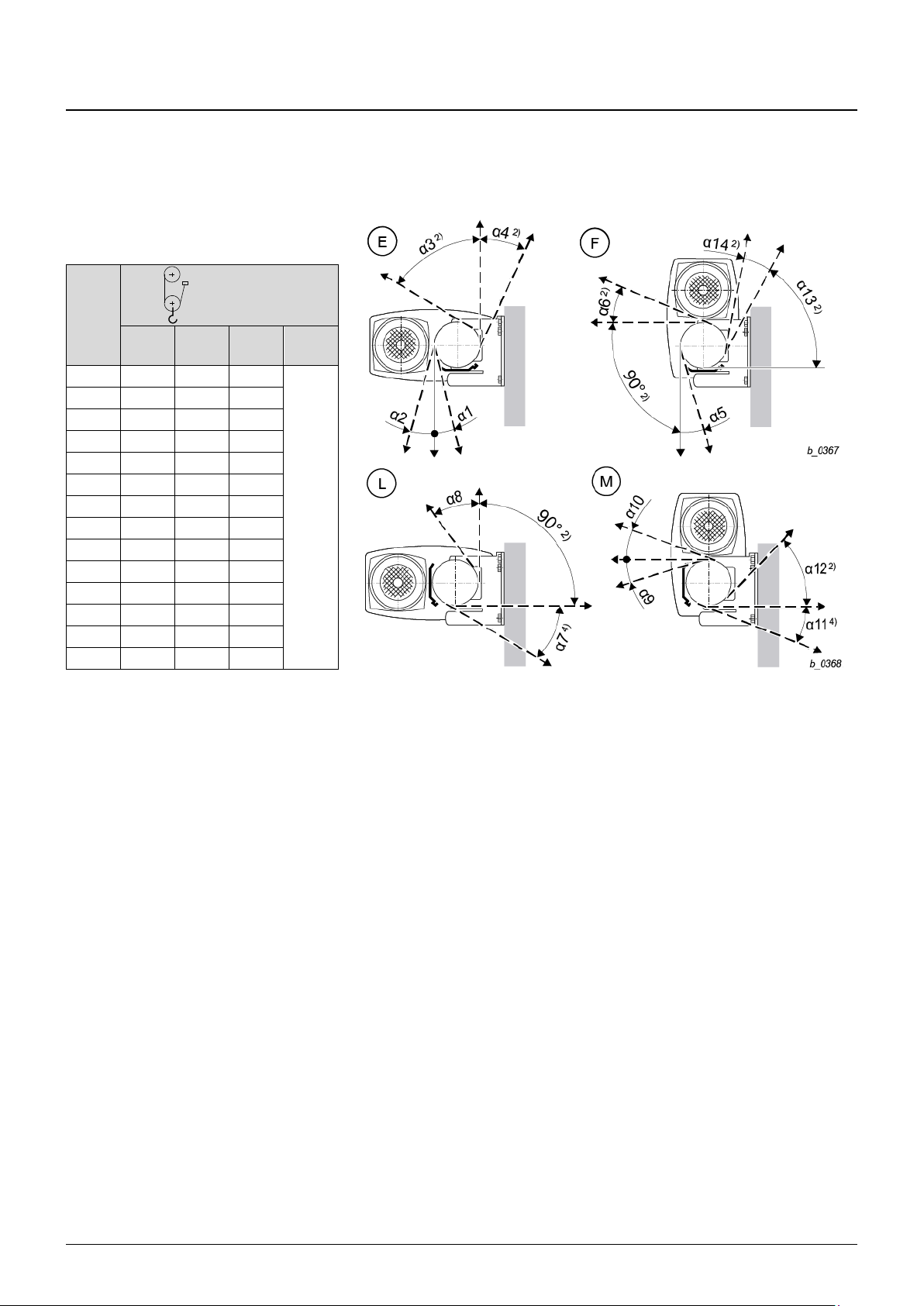

4.2.3 Attachment at side

Wire rope hoist types

YKA/SKA, YKB/SKB, YKC/SKC, YKE/SKE

1PS,

1PS twin hook

YKA/

SKA

YKB/

SKB

YKC/

SKC

YKE/

SKE

α1

21°

23°

18°

on

request

α2

12°

13°

20°

α3

74°

73°

76°

α4

10°

10°

20°

α5

21°

23°

18°

α6

23°

20°

20°

α7

27°

30°

30°

α8

74°

73°

76°

α9

4°

5°

8°

α10

23°

13°

20°

α11

27°

30°

30°

α12

74°

73°

76°

α13 - -

70°

α14 - -

6°

Tab. 5

Fig. 12

2)

By turning rope guide

4)

By turning rope guide and grease pan.

Type YKE/SKE: Version (H) not possible

Page 23

4 Installation

03.2018 23

ba-o.2.6.0-us-1.1-y | A11867501 Rev AA

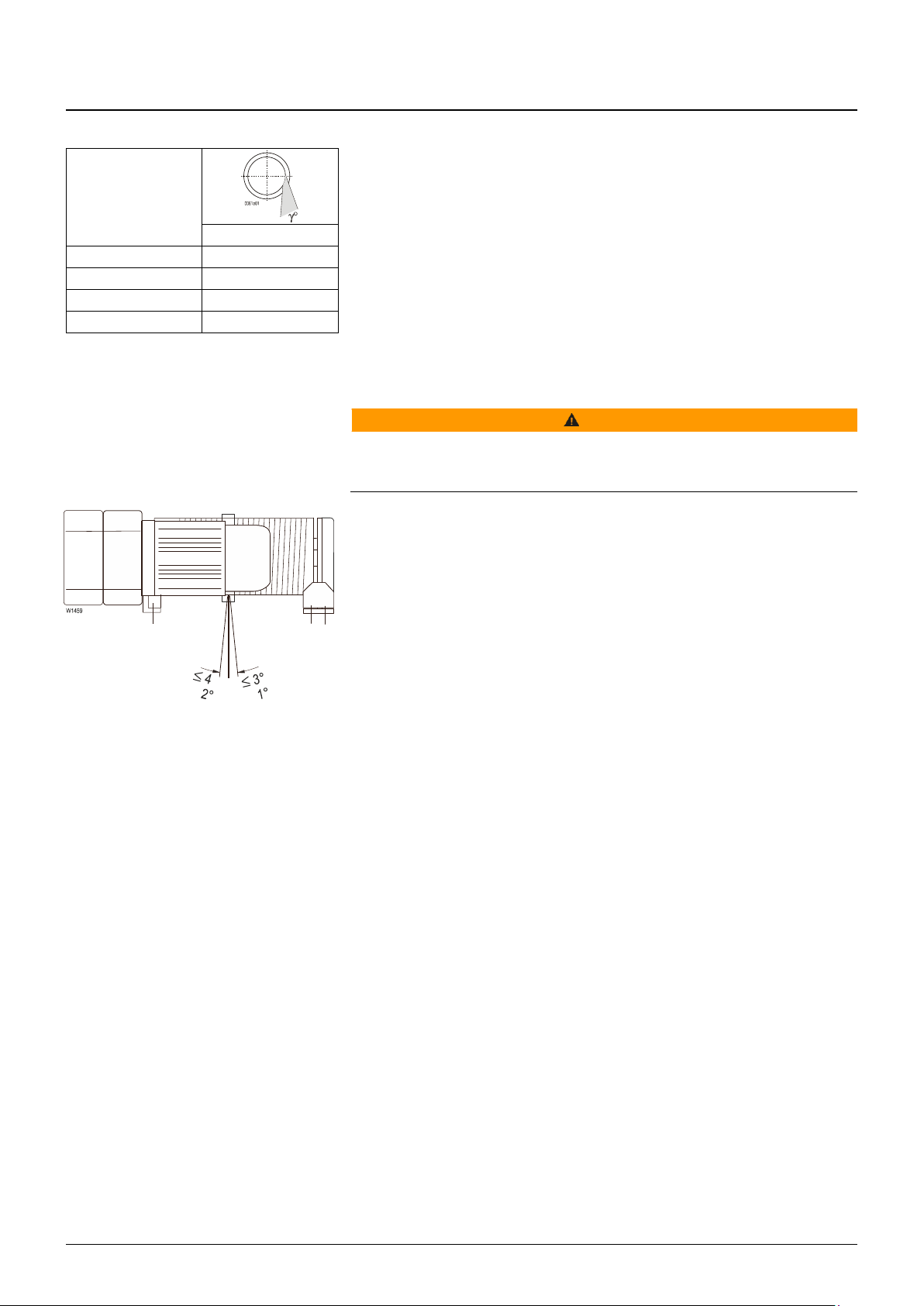

4.2.4 Fleet angle

Wire rope hoist

type

γ

YKA/SKA

39°

YKB/SKB

39°

YKC/SKC

39°

YKE/SKE

39°

Tab. 6

1. Adjust the rope guide to the fleet angle.

2. Observe also the radial rope exit angle γ.

4.2.5 Angle of installation

WARNING

Rope damage hazard. The wire rope must not touch the rope guide or structural

elements.

➢ Always install the hoist horizontal.

Fig. 13

1. Install hoists with rope drives with bottom hook blocks always horizontal to their

longitudinal axis.

2. Do not exceed the fleet angle to the direction of the rope drum groove and the rope

sheave of 4°/3° for non-rotation-resistant wire ropes, 2°/1° for rotation-resistant wire

ropes.

However even at these angles a reduction in service life is to be expected.

3. Equip rope sheaves with a suitable guard to prevent the rope jumping out of the

groove, max. clearance of the guard <0.5 × rope diameter.

The rope must not slip off the sheave axle if the sheave breaks.

The rope suspension must be designed to prevent kinking and other additional

stresses.

The rope suspension for non-rotation-resistant wire ropes must be designed so that it

cannot rotate around its longitudinal axis.

The rope spread angle of 45° in top hook position must not be exceeded.

Page 24

4 Installation

24 03.2018

ba-o.2.6.0-us-1.1-y | A11867501 Rev AA

4.3 Monorail trolleys

The trolleys are constructed according to the state of the art and supplied with mounted

buffers.

4.3.1 Monorail trolley (KE-S33 - 76)

with wire rope hoist types

YKA/SKA, YKB/SKB, YKC/SKC, YKD/SKD, YKE/SKE

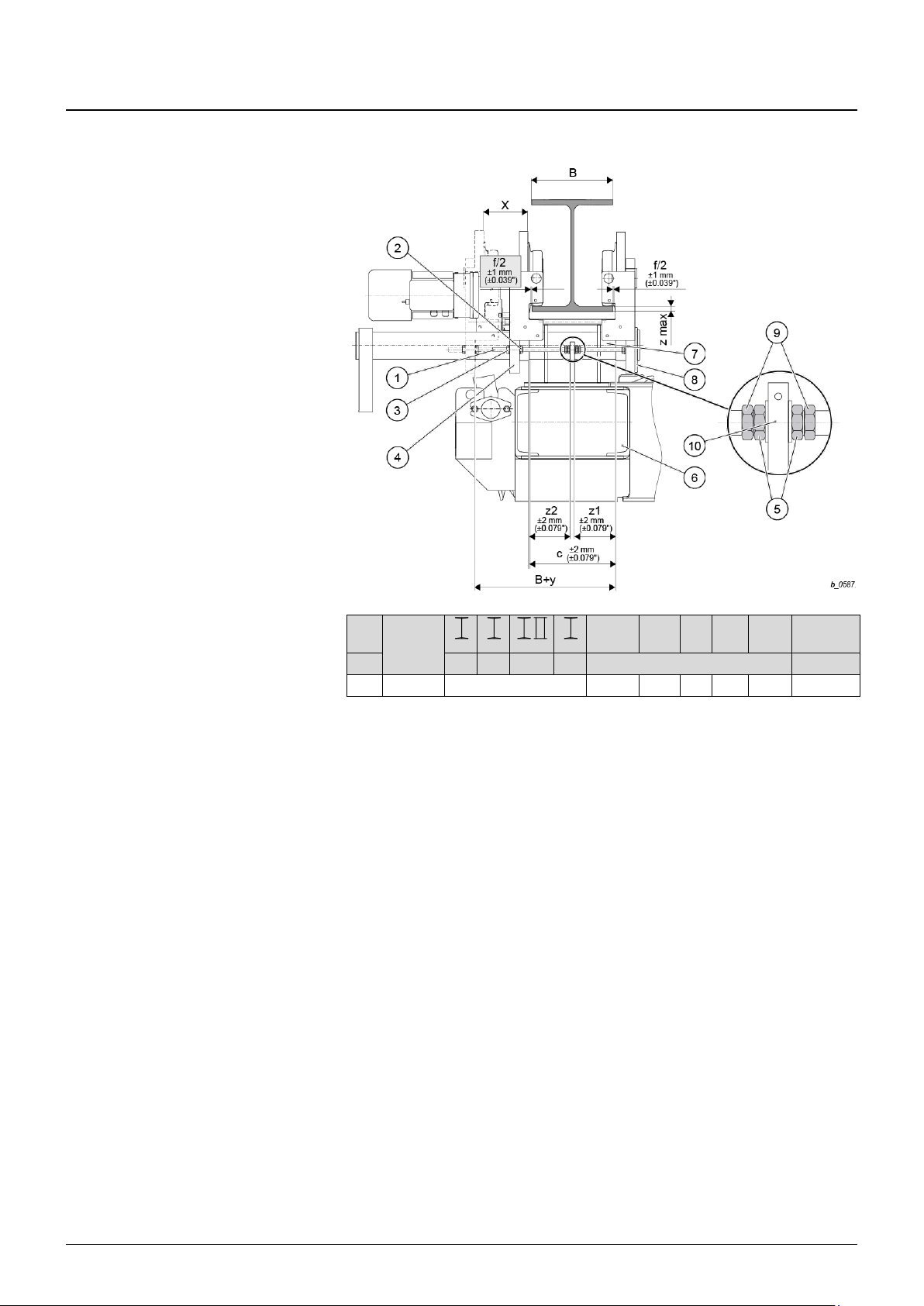

Fig. 14

NOTICE

Material damage hazard. If the flange width is altered (by customer), it may be

necessary to alter the counterweight to prevent the trolley canting.

Please have it checked by our after-sales service.

1. Check flange width “B” and clearance “c” against Tab. 7 and set trolley to beam

width if necessary.

Installation if end of runway is freely accessible

1. Slide trolley onto end of runway and check play “f/2”.

Installation if end of runway is not accessible

1. Unscrew nuts (2) on threaded bolts (1) and slide trolley side cheek (3) outwards by

approx. “x” in. or until dimension B+y is reached (Tab. 7).

2. Push hoist side of trolley onto lower flange of runway beam and secure against

slipping.

3. Push trolley side cheek (3) towards the runway beam on support bolt (4).

4. Adjust dimension “c” with nuts (2), tighten nuts (2).

5. Check track gage “c” and play f/2.

6. Tighten nuts (2) with torque spanner to the specified tightening torque (see table

below).

Hoist

Wheel

Ø D

Trolley

c

f/2 x y

z max

Tightening

torque

[in]

INP

IPE

IPB

"

[in]

[lbf ft]

YKA/SKA

3.1

KE-S33

B = 3.5…19.7 in

B+2.6 1)

0.059

2.8

5.4

1.04

155

YKB/SKB

3.9

KE-S44

B+2.6 1)

0.059

3.1

5.8

1.12

155

YKC/SKC

5.5

KE-S65

B = 4.7…19.7 in

B+2.6 1)

0.059

3.7

6.4

1.54

155

YKD/SKD

7.9

KE-S76

B = 4.9…19.7 in

B+3.6 1)

0.059

3.7

7.4

1.89

155

YKE/SKE

Tab. 7

1)

for INP beam: -0.079 in.

Page 25

4 Installation

03.2018 25

ba-o.2.6.0-us-1.1-y | A11867501 Rev AA

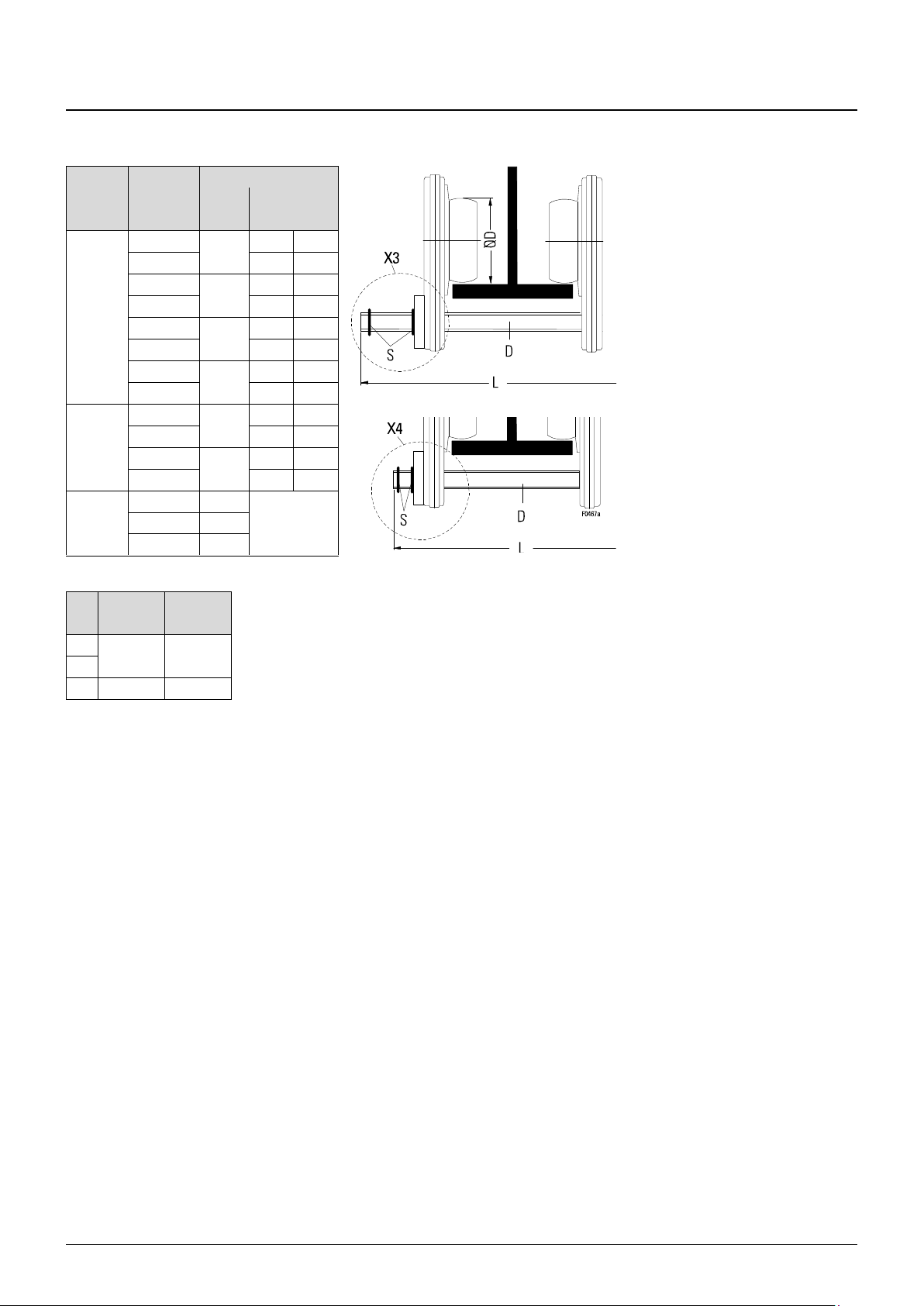

4.3.2 Drive shaft for travel drive (trolleys KE-S33 - KE-S65)

Drive shaft

Ø D B L

Position

[in]

[in]

[in]

3.1

3.9

SF17 1..

SF17 2..

3.5 - 5.7

15.4

X3

-

5.7 - 7.7

-

X4

7.7 - 9.8

19.5

X3 - 9.9 - 12

-

X4

12.1 - 13.8

23.4

X3 - 13.8 - 15.7

-

X4

15.8 - 17.7

27.4

X3

-

17.8 - 19.7

-

X4

5.5

SF17 2..

4.7 - 7.9

19.9

X3

-

7.9 - 12.2

-

X4

12.2 - 15.7

27.4

X3

-

15.8 - 19.7

-

X4

7.9

SF17 2..

4.9 - 8.7

20.1

see next page

8.7 - 15.7

29.1

15.8 - 19.7

30.7

Tab. 8

Fig. 15

Ø D

L3 ±0.079

L4 ±0.079

[in]

[in]

[in]

3.1

3.8

1.83

3.9

5.5

4.91

1.83

Tab. 9

1. Fit drive shaft in mounting position X3 or X4 depending on flange width (B) of runway

beam and length (L) of drive shaft (D).

2. Fit circlips (S).

Page 26

4 Installation

26 03.2018

ba-o.2.6.0-us-1.1-y | A11867501 Rev AA

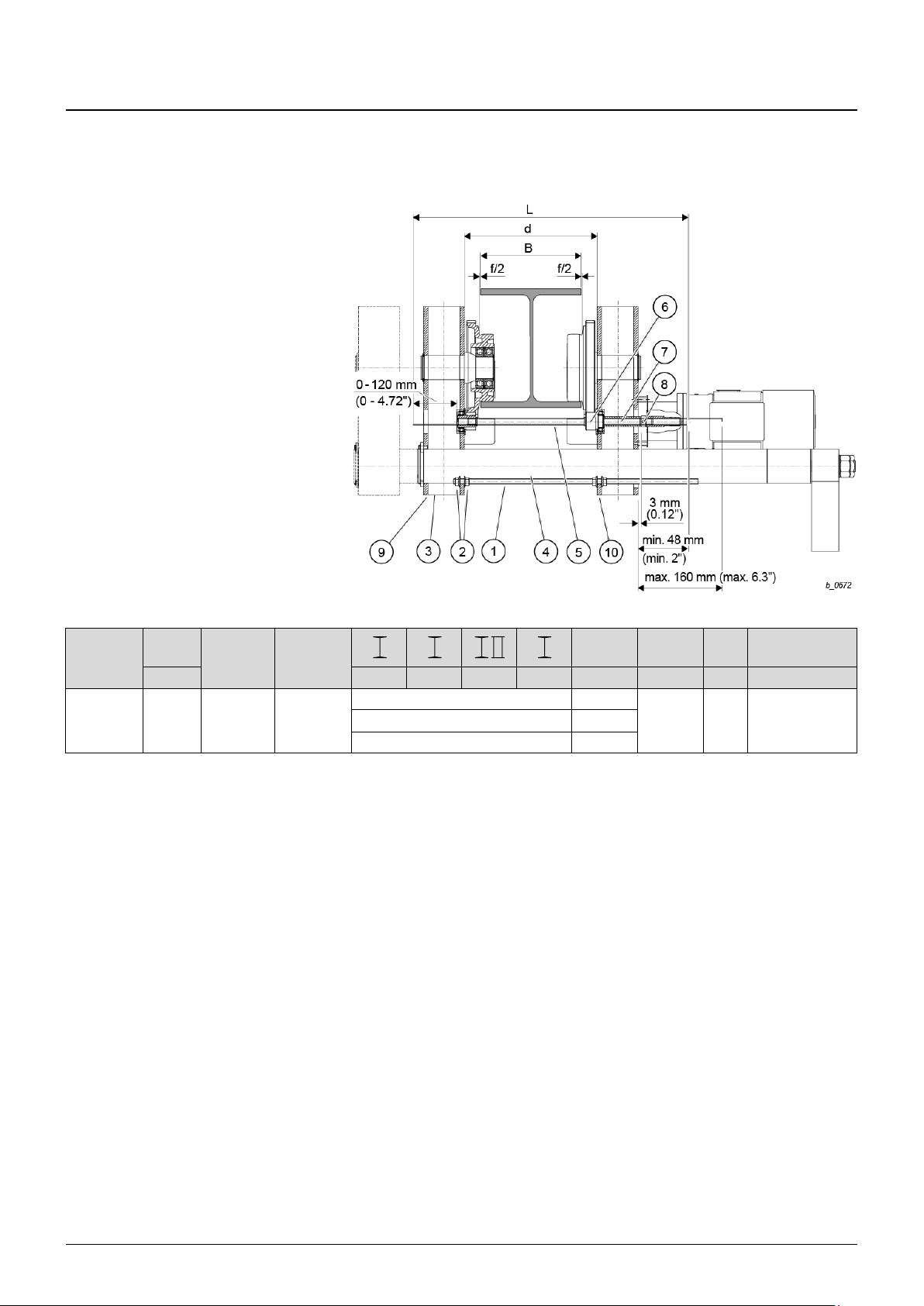

4.3.3 Drive shaft for trolley drive (trolley KE-S76)

The drive shaft is suitable for girder flange widths “B” from 4.9 in. to 19.7 in.

Fig. 16

Wire rope

hoist type

Wheel

Ø D

Trolley

Travel drive

L d f/2

Tightening torque

[in]

INP

IPE

IPB " [in]

[in] [lbf ft]

YKD/SKD

YKE/SKE

7.9

KE-S76

SF17 2..

B = 4.9 - 8.7 in

20

B+3.6 1)

0.059

155

B = 8.7 - 15.7 in

29

B = 15.8 - 19.7 in

31

1)

for INP beam: -0.079 in.

1. Insert drive shaft (5) into the two drive pinions (6) from the counterweight side, then

assemble spacer tube (7) and adjusting ring (8).

2. Adjust drive shaft (5) so that on the hoist side the shaft end projects by between

min. 0 in. and max. 4.72 in. beyond the drive pinion (6) and on the counterweight

side the shaft end projects by between min. 1.9 in. and max. 6.3 in. beyond the

trolley side cheek (10).

3. Lock adjusting ring (8) with adjusting screw so that on spacer tube (7) lying against

drive pinion (6) there is a play of approx. 0.079 - 0.157 in. to adjusting ring (8).

4. After fitting travel drive, check drive shaft (5) for ease of movement.

Page 27

4 Installation

03.2018 27

ba-o.2.6.0-us-1.1-y | A11867501 Rev AA

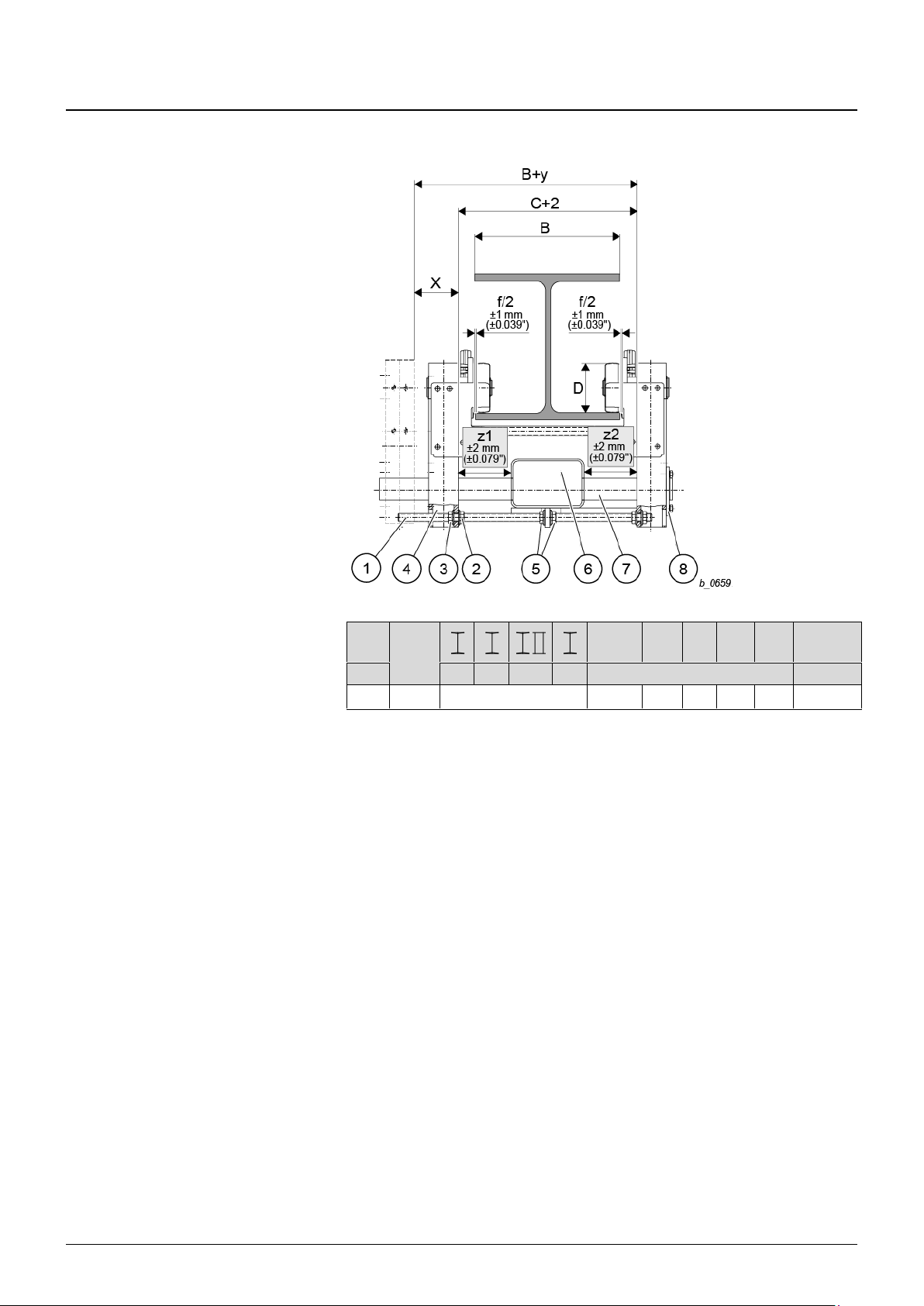

4.3.4 Monorail trolley (UE-S4)

with YKB/SKB, YKC/SKC, 1PS wire rope hoists (single fall)

Fig. 17

Ø D

Trolley

c

f/2 x y

z

max

Tightening

torque

[in]

INP

IPE

IPB

"

[in]

[lbf ft]

3.9

UE-S4

B = 3.5…19.7 in

B+2.6 1)

0.059 3 5.6

1.12

155

Tab. 10

1)

for INP beam: -0.079 in.

1. Check flange width “B” and clearance c ±0.079 in. against Tab. 10 and set trolley to

beam width if necessary. Ensure that the connection piece (square tube) (6) is in the

center (of dimension “c”) between the trolley side cheeks (z1 = z2).

2. After unscrewing nuts (3) together with nuts (2), adjust clearance c ±0.079 in. and

tighten nuts (3).

3. Tighten nuts with torque spanner to the specified tightening torques (see table

above).

4. Clearance “c” results in a flange play of f/2 +0.039 in. on each side. If necessary,

correct flange play by means of clearance “c”.

Installation if end of runway is freely accessible

1. Slide trolley onto end of runway and check play f/2.

Installation if end of runway is not accessible

1. Loosen nuts (3) on threaded bolts (1) in the square tube of the trolley side cheeks (4)

and unscrew by dimension “x”.

2. Push trolley side cheeks (4) apart in parallel up to the unscrewed nuts (3) until

dimension B+y or c+x is reached.

3. Slide trolley onto the bottom flange of the runway beam on the axle keep plate side

(8) and secure against shifting.

4. Push trolley side cheeks (4) back to nuts (2), retighten nuts (3).

5. Check track gage c ±0.079 in. and play of guide rollers f/2.

6. Tighten nuts with torque spanner to the specified tightening torques (see table

above).

Page 28

4 Installation

28 03.2018

ba-o.2.6.0-us-1.1-y | A11867501 Rev AA

Centering connection piece

1. Loosen nuts (5) and shift connection piece (6) on connecting bolt (7) so that

dimensions “z1” and “z2” between trolley side cheeks (4) and connection piece (6)

are equal on both sides.

2. Tighten nuts (5) with torque spanner to the specified tightening torques (see table

above).

Connecting bolt and drive shaft

Drive shaft

Ø D B L

Position

[in]

[in]

[in]

3.1

3.9

SF17 1..

SF17 2..

3.5 - 5.7

15.4

X3

-

5.7 - 7.7

-

X4

7.7 - 9.8

19.5

X3

-

9.9 - 12

-

X4

12.1 - 13.8

23.4

X3

-

13.8 - 15.7

-

X4

15.8 - 17.7

27.4

X3 - 17.8 - 19.7

-

X4

5.5

SF17 2..

4.7 - 7.9

19.9

X3 - 7.9 - 12.2

-

X4

12.2 - 15.7

27.4

X3

-

15.8 - 19.7

-

X4

7.9

SF17 2..

4.9 - 8.7

20.1

see next page

8.7 - 15.7

29.1

15.8 - 19.7

30.7

1. Use connecting bolt and drive shaft suitable for beam range “B”.

Page 29

4 Installation

03.2018 29

ba-o.2.6.0-us-1.1-y | A11867501 Rev AA

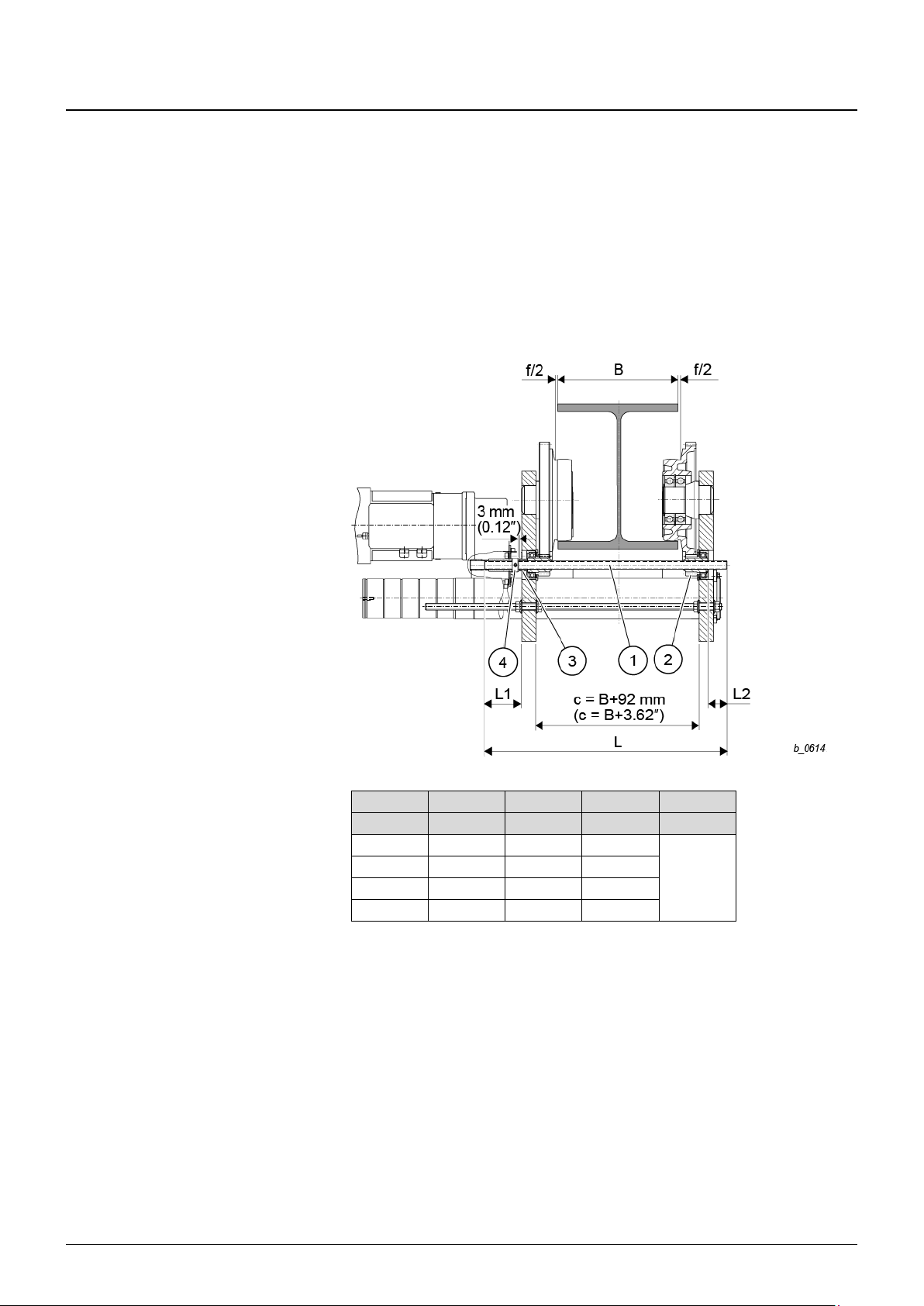

4.3.5 Monorail trolley (UE-S776)

with YKE/SKE, 4PS wire rope hoist (four-fall)

Fig. 18

Ø D

Trolley

c

f/2 x y

z max

Tightening

torque

[in] INP

IPE

IPB

"

[in]

[lbf ft]

7.9

UE-S776

B = 7.3…19.7 in

B+3.6

0.059

3.7

7.4

1.9

155

Tab. 11

1. Check flange width “B” and clearance c ± 0.079 in. against Tab. 11 and set trolley to

beam width if necessary. Ensure that the connection piece (square tube) (6) is in the

center (of dimension “c”) between the trolley side cheeks (z1 = z2).

2. After unscrewing nuts (3) together with nuts (2), adjust clearance c ± 0.079 in. and

tighten nuts (3).

3. Do not distort plate (10). Tighten nuts (5) lightly and then unscrew by a quarter turn.

Lock nuts (9) against nuts (5) with a torque spanner (see table above).

4. Tighten nuts (3) with a torque spanner to the specified tightening torque (see table

above).

5. Clearance “c” results in a flange play of f/2 +0.039 in. on each side. If necessary,

correct flange play by means of clearance “c”.

Installation if end of runway is freely accessible

1. Slide trolley onto end of runway and check play f/2.

Installation if end of runway is not accessible

1. Loosen nuts (3) on threaded bolts (1) in the square tube of the trolley side cheeks (4)

and unscrew by dimension “x”.

2. Push trolley side cheeks (4) apart in parallel up to the unscrewed nuts (3) until

dimension B+y or c+x is reached, and lift trolley onto runway from below.

3. Slide trolley onto the bottom flange of the runway beam on the axle keep plate side

(8) and secure against shifting.

4. Push trolley side cheeks (4) back to nuts (2), retighten nuts (3).

5. Check track gage c ± 0.079 in. and play of guide rollers f/2.

6. Tighten nuts (3) with a torque spanner to the specified tightening torque (see table

above).

Page 30

4 Installation

30 03.2018

ba-o.2.6.0-us-1.1-y | A11867501 Rev AA

Centering connection piece

1. Loosen nuts (5) and shift connection piece (6) on connecting bolt (7) so that

dimensions “z1” and “z2” between trolley side cheeks (4) and connection piece (6)

are equal on both sides.

2. Tighten nuts (5) with a torque spanner to the specified tightening torque (see table

above).

Connecting bolt and drive shaft

3. Use connecting bolt and drive shaft suitable for beam range “B” (for dimensions, see

Fig. 19).

Drive shaft for trolley drive (trolley UE-S776)

Fig. 19

B L L1

L2

f/2

[in]

[in]

[in]

[in]

[in]

7.3 - 8.7

20.1

3.3

5.1 - 3.7

0.059

8.7 - 14.2

24.4

3.3

6.8 - 1.3

14.2 - 17.7

29.1

5.3

3.9 - 0.35

17.8 - 19.7

29.1

3.3

2.3 - 0.35

Tab. 12

The drive shaft is suitable for girder flange widths “B” from 7.3 in. to 19.7 in. (see Tab.

12 for length “L”).

1. Insert drive shaft (1) into the two drive pinions (6) from the counterweight side, then

assemble spacer tube (3) and adjusting ring (4).

2. Adjust drive shaft (1) to dimension “L1”, dimension “L2” must lie between the values

given in the table.

3. Lock adjusting ring (4) with adjusting screw.

4. After fitting travel drive, check drive shaft (1) for ease of movement. The axial play

must be approx. 2 – 4 mm (0.08 – 1.57 in.)

Page 31

4 Installation

03.2018 31

ba-o.2.6.0-us-1.1-y | A11867501 Rev AA

4.3.6 Articulated trolley (DKE-S4 / DKE-S6)

with YKA/SKA, YKB/SKB, YKC/SKC wire rope hoists

Fig. 20

Wire rope

hoist type

Ø D

Trolley

B

f/2 c x y Z max

Tightening torque

Nut (3)

Nut (5)

[in]

[in]

[lbf ft]

YKA/SKA,

YKB/SKB

3.9

DKE-S4

3.5 - 11.8

0.059

B+3.1

2.6

5.8

1.1

159

63

YKC/SKC

5.5

DKE-S6

4.7 - 11.8

0.059

B+3.3

3

6.3

1.6

159

63

Tab. 13

1. Check flange width “B” and clearance “c” against Tab. 13 and set trolley to beam

width if necessary.

2. Ensure that the connection piece (square tube) (6) is in the center (of dimension “c”)

between the trolley side cheeks.

3. After unscrewing nuts (3) together with nuts (2), adjust clearance “c” and tighten

nuts (3).

4. Tighten nuts (3) with a torque spanner to the specified tightening torque (see table

above).

5. Clearance “c” results in a flange play of f/2 +0.039 in. on each side. If necessary,

correct flange play by means of clearance “c”.

Installation if end of runway is freely accessible

1. Slide trolley onto end of runway.

Page 32

4 Installation

32 03.2018

ba-o.2.6.0-us-1.1-y | A11867501 Rev AA

Installation if end of runway is not accessible

1. Loosen nuts (3) on threaded bolts (1) in the square tube of the trolley side cheeks (4)

and unscrew by dimension “x”.

2. Push trolley side cheeks (4) apart in parallel up to the unscrewed nuts (3) until

dimension B+y or c+x is reached, and lift trolley onto runway from below.

3. Lift trolley onto runway from below.

4. Slide trolley onto the bottom flange of the runway beam on the hoist side and secure

against shifting.

5. Push trolley side cheeks (4) back to nuts (2), retighten nuts (3).

6. Check track gage “c” and play of guide rollers f/2.

7. Tighten nuts (3) with a torque spanner to the specified tightening torque (see table

above).

Centering bogie

1. Loosen nuts (5) and shift bogie (6) on connecting bolt (7).

2. Dimension “z” between trolley side cheeks (4) and bogie (6) is equal on both sides.

3. Tighten nuts (5) with a torque spanner to the specified tightening torque (see table

above).

Page 33

4 Installation

03.2018 33

ba-o.2.6.0-us-1.1-y | A11867501 Rev AA

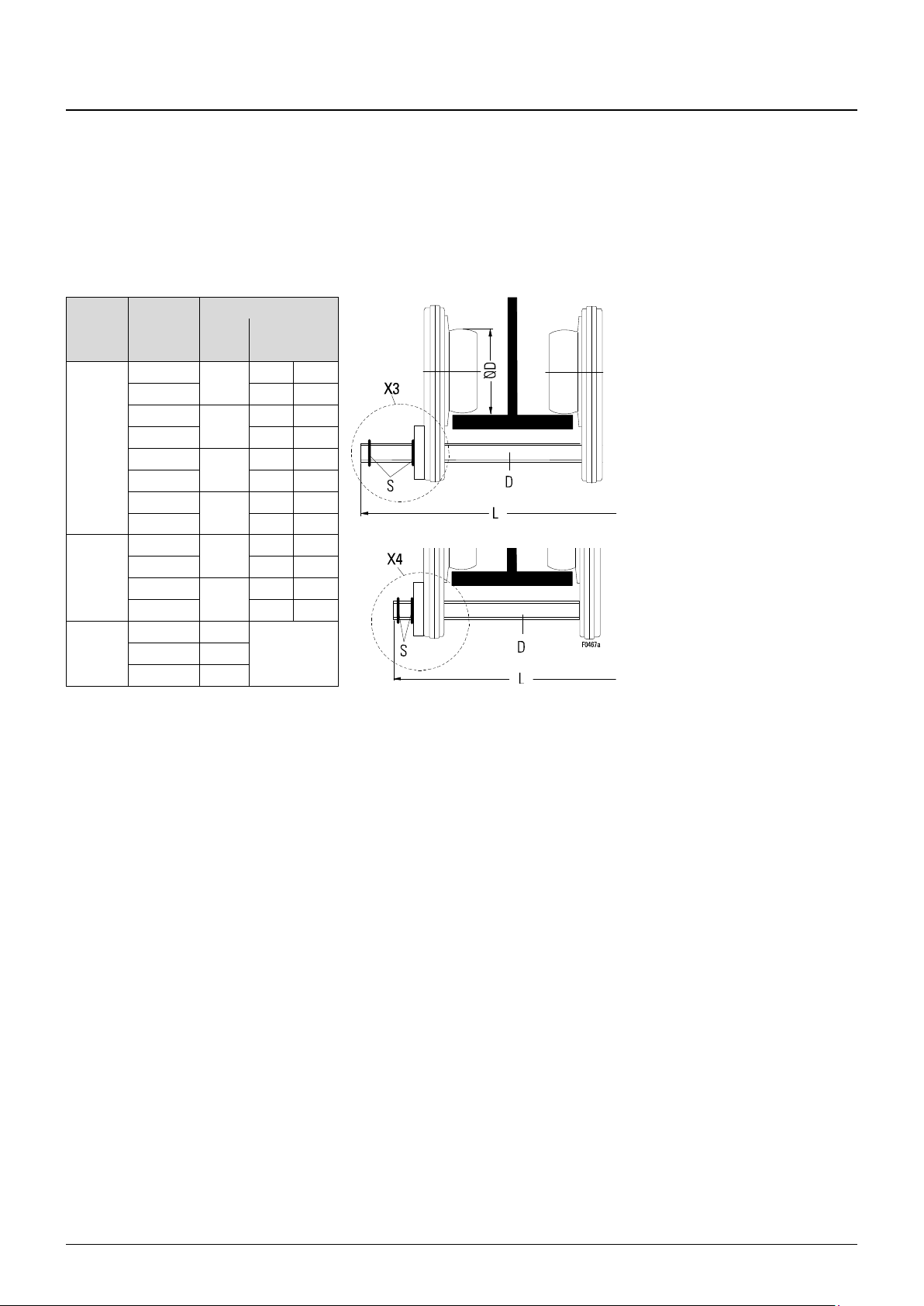

Drive shaft for travel drive (DKE-S4 / DKE-S6)

Trolleys with one travel drive

Fig. 21

Drive shaft D

Ø D B L

L4 ±0.079

[in]

[in]

[in]

[in]

3.9

3.5 - 5

15.4

1.83

5.1 - 8.7

19.5

5.5

4.7 - 11

19.5

11.1 - 11.8

28

Tab. 14

The drive shaft “D” is suitable for beam widths “B” from 3.5 in. to 11.8 in.

1. Fit lock washers “S” acc. to dimension “L4”.

The mounting position of the drive shaft does not change over the corresponding

beam range “B”.

Trolleys with two travel drives

Ø D 3.9 in

Ø D 5.5 in

Fig. 22

The drive shaft is completely independent of the beam width.

1. Mount lock washers “S” acc. To Fig.21 and Fig. 22. Drawings above

Page 34

4 Installation

34 03.2018

ba-o.2.6.0-us-1.1-y | A11867501 Rev AA

4.4 End stops for monorail trolleys

WARNING

Falling parts hazard. If there are no end stops, the trolley can travel over the end of the

runway.

➢ Mount suitable end stops at the end of the runway before commissioning the hoist.

The monorail trolleys are supplied as standard with buffers. Suitable runway end stops, to

be clamped onto the lower flange of the runway, can be supplied.

WARNING

Falling parts hazard.

➢ With inclined flanges use supplied special screws.

[mm]

[in]

A

112

4.41

B

134

5.28

C

56

2.2

D

≥ 15

≥ 0.59

E

70

2.76 F 63

2.48 G 33

1.3

H

see table below

see table below

J

7 - 35

0.28 - 1.38

K

25 - 40

0.98 - 1.57

L

70

2.76

M

40

1.57

N

94

3.7

P

134

5.28

Q

≥ 15

≥ 0.59

R

56

2.2 S 105

4.13 T 190

7.48

Fig. 23

Type

1)

b max.

Weight

Trolley

E max.

Max. buffer force

Order No.

[in]

[lb]

Type

max. [ton]

[lbf ft]

[lbf]

PA1/300

≤11.8

13

≤YKD/SKD, 4PS

(≤KE-S76)

17.6

207

9663

01 740 57 27 0

PA1/500

11.8-19.7

14

01 740 58 27 0

PA1/1000

19.7-39.4

14

01 740 64 27 0

PA2/500

≤19.7

31

≤YKE/SKE, 4PS

(≤UE-S77)

35.3

251

8989

01 740 59 27 0

PA2/1000

>19.7-39.4

32

01 740 65 27 0

PA1/300

≤11.8

13

≤YKD/SKE, 4PS

(≤KE-S76)

17.6

207

9663

01 740 57 27 0

01 740 00 92 0 2)

Tab. 15

1)

Limit switches necessary for travel speeds

> 105 fpm (PA1)

> 82 fpm (PA2)

2)

Special screw (must also be ordered)

Page 35

4 Installation

03.2018 35

ba-o.2.6.0-us-1.1-y | A11867501 Rev AA

4.5 Double rail trolley (OE-S)

The double rail trolleys are supplied with mounted buffers.

NOTICE

The trolley must run smoothly over the whole runway without jamming or increased

friction at the wheel flanges. Increased friction at the flanges due to poor beam quality or

incorrect trolley adjustment may lead to increased wear.

➢ Ensure that the trolley runs smoothly without increased friction at the wheel flanges.

1. The runway must meet the requirements of ISO 12488-1.

2. Make sure that the rail joints are even on both running and guide surfaces. Grind

down if necessary.

Check track gage

Ø D

S

[in]

[in]

3.9

0.1 - 0.2

4.9

0.1 - 0.2

6.3

0.14 - 0.24

7.9

0.18 - 0.28

Tab. 15

Fig. 24

1. Check track gage “S” on trolley and rail (Smax – Smin = 0.197 in.)

2. Check lateral play “S” between rail and flange.

3. “S” as per Tab. 15, if trolley is positioned symmetrically on runway.

If asymmetrically, S

left

+ S

right

= 2 × S.

Transport anchor screws