Page 1

SCP4020/SCP4420 Series

Parallel Non Hold Open or Hold Open Arm

For closers with or without “T” suffix Hold Open Control

“T” indicates Thumbturn actuated hold open control.

For closers with or without suffix (Delayed Action) closing feature.“DL”

Series

Sized*

Closer

SCP4020 SCP4420

Multi-Sized **

Closer

Installation Instructions

80-9344-0625-010 (06-09)

CAUTION

An incorrectly installed or improperly

adjusted door closer can cause

property damage or personal injury.

These instructions should be followed

to avoid the possibility of

misapplication or misadjustment.

CAUTION

Product Type

Security Door Closer

(Door Closer with both a Security Cover and Security Arm)

488 Drop Plate is available for doors with narrow top rails.

Holder-Stop

Security Door Closer

* SCP4020 Series are sized door closers wi h 50% power increase capability.

t

Power size 2 weakest power, power size 6 strongest.

** SCP4420 Series can be adjusted from power size 1 thru 6.

Note: For Special Applications a separate door and frame preparation template is packed with these instructions.

Use this instruction sheet for installation sequence and closer adjustments only.

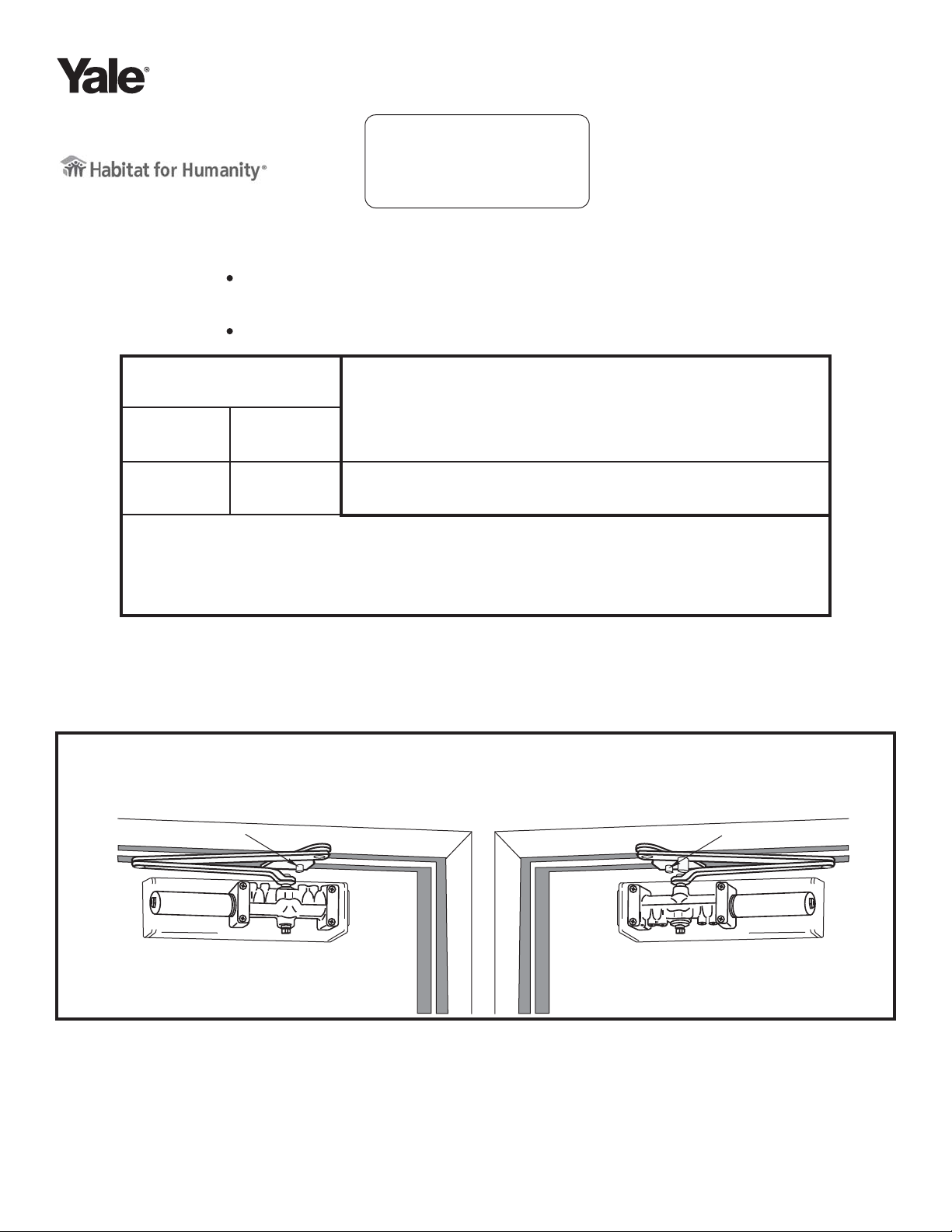

Push Side Installation

Closer mounts on opposite to hinge (push) side of door.

Arm Stop

Right Hand Door – RH

Left Hand Reverse – LHR

Hinge Edge

of Door

of Door

Hinge Edge

Arm Stop

Left Hand Door – LH

Right Hand Reverse – RHR

• Security Door Closers only. Door closer cover is handed and cannot be reversed. All other components are non handed.

• It is recommended that the door, on which the door closer will be installed, be hung on ball bearing hinges. Door must swing freely.

• A separate door stop, supplied by others, is recommended to prevent damage to the door closer, closer arm, or to the door, frame or

adjacent walls.

• Door and Frame must be properly reinforced, or use of special fasteners employed, to prevent the mounting screws from pulling out.

• All dimensions are given in inches with corresponding metric dimensions (mm) in parenthesis.

• Torx tamper resistant drive screws are normally supplied with this product.

Page 2

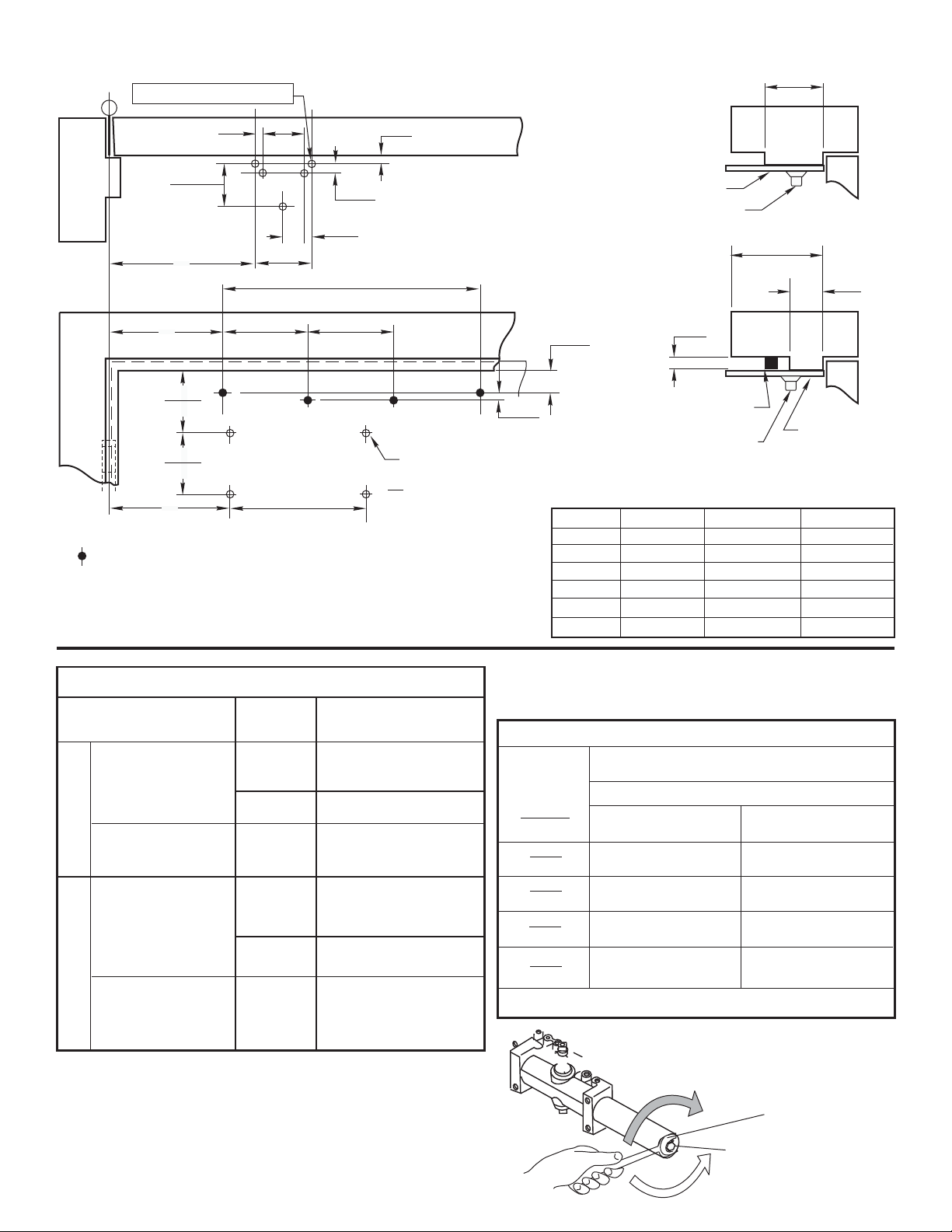

Template

5 Holes for Soffit Plate

3/8

(10)

2

(51)

Left Hand Door Shown

Right Hand Installation is Opposite

1/2

(13)

Page 2

2-3/4

(70)

Min.

2-1/16

(52)

B

C

2-3/4

(70)

4

(102)

2-9/16

(65)

2-3/8

(61)

A

C

Hinge or Pivot

L

6-3/4

(172)

Prepare These Holes Only When

No. 488/478 Drop Plate is Used

7/16

(11)

1-3/8

(35)

12-3/4

(324)

4-3/4

(121)

5/16

(8)

4 Holes for Closer

Do Not Scale Drawing

Left Hand Door Shown

Dimensions are in inches (mm).

Maximum Door Swing 180°,

conditions permitting.

1-1/16

(27)

Opening

85°

90°

95°

100°

105°

110°

Soffit Plate

Arm Stop

5/8

(16)

293S Block

Arm Stop

Narrow Stop Frame

Dim. A Dim. B

10-1/8 (257)

9-1/4 (235)

8-5/8 (219)

7-7/8 (200)

7-3/8 (187)

6-3/4 (171)

10-5/8 (270)

9-3/4 (248)

9-1/8 (232)

8-3/8 (213)

7-7/8 (200)

7-1/4 (184)

Wide Stop Frame

2-3/4

(70)

Min.

1-1/8

(29)

Soffit Plate

Dim. C

9-7/8 (251)

9 (229.6)

8-3/8 (213)

7-5/8 (194)

7-1/8 (181)

6-1/2 (165)

Min.

Preparation for Fasteners

Fasteners

Self Drilling Screw

1/4” - 20

Standard

Machine Screw

Sleeve Nuts and

Bolts (SNB)

Optional

Door or

Frame

Aluminum

or Metal

Wood

Metal

Hollow

Metal

Aluminum

or Wood

Drill-Sizes

No drill required

3/16” (4.30 mm)

Drill: #7 (0.201” dia.)

Tap: 1/4” - 20

9/32” (7 mm); through

3/8” (9.5 mm) on door

opposite to closer

3/8” (9.5 mm) through

9/32” (7 mm); through

Through-bolts &

grommet-nuts

All

3/8” (9.5 mm) dia x

3/8” (9.5mm) deep on

door opposite to closer

Installation Sequence

• Use template above to locate holes on door and frame:

4 on door for closer or backplate.

5 on underside of frame stop for soffit plate.

• Prepare door and frame for fasteners using chart above.

• For SCP4420 Models Only

Set closer power for door size using chart below:

Power Adjustment Chart

Door

Size

inches

(mm)

28-32

(0.7 - 0.8)

33-36

(0.85 - 0.9)

37-42

(0.95 - 1.05)

42-48

(1.1 - 1.2)

Full Clockwise Turns of Closer Power Adjustment Nut

SCP4420 ONLY

Interior

Door

Exterior

Door

0

2

5

8

Closer is shipped set at median power setting.

NOTE: Maximum of 15 360° turns

of Power Adjustment Nut

Increase

11/16” wrench

or socket

Power Adjustment Nut

Decrease

2

5

8

11

Page 3

Installation Sequence (Con’t)

! Mount closer on door.

use on doors having narrow top rails)

Adjustment Nut

DOWN Left Hand Door UP

are for . Valves are for

Right Hand Door

(A drop plate is available for

Power

should be away from hinge. Valves

.

! Use 1/8” hex wrench to close valves.Turn Clockwise.

For , close valves ‘S/D’ and ‘L’.

STANDARD CLOSER

DELAYED ACTION CLOSER

, close valves ‘S’ and ‘L’.

DO NOT BACK VALVES OUT OF

CAUTION!

!

Reopen valves closed in Step 2.Turn

Counterclockwise

With door closed, align soffit plate with mounting

!

holes in frame. Fasten soffit plate to frame with flat

head screws provided.

CLOSER OR A LEAK WILL RESULT

! Install Cover:

Security closers only, (SCP4420/SCP4020) Install

cover bracket to closer body. (See Illustration below).

Fasten bracket with 2 #8-32 x 5/16 RHMS screws

provided.

Page 3

! Set handing of “Arm Stop” on soffit plate. See

illustration on Page 1 for positions. If required, rotate

stop. Secure with 1/4-20 x 5/16 machine screw.

!

With door closed, use wrench to rotate pinion shaft

as illustrated below.

Caution: Closer arm is under spring tension and

may be difficult to rotate.

Start (wrench) here

Rotate

Install arm here

! Place main arm on shaft, aligning mark on arm with

pinion flat on pinion shaft; “Z” for Left Hand Door; “Y”

for Right Hand Door. Secure with 1/4-20 x 1/2 (13)

round head machine screw with lock washer.

Main Arm Screw with Lock Washer

R

L

Z

S

Y

Bracket must

extend

underneath

tube

Fasten cover to closer and cover bracket with 4 #832x1/4 round head screws provided.

80-9344-0625-010 (06-09)

Page 4

Unit Adjustment

Closing Speed Controls (Figure 1A or 1B And 2.)

Standard Closer Only

Valve “S/D” Controls Sweep Range.

Valve “L” Controls Latch Range.

Delayed Action Closer Only

Valve “S/D” Controls Delay Range.

Valve “S” Controls Sweep Range.

Valve “L” Controls Latch Range.

Page 4

Opening Door Control (Figure 4.)

!

Backcheck ( B ) valve controls the hydraulic resistance to

“”

door opening. NEVER close this valve completely – it is

not to provide a positive stop.

Backcheck position (”P”) valve controls the door angle

!

where backcheck cushioning starts. Valve normally closed.

Closing Speed Controls Figure 1.

E

E

W

P

S

H

C

T

A

L

Standard Closing Cycle

CLOSED

10°

D

E

L

A

Y

R

A

N

G

P

E

E

W

H

S

C

T

A

L

70°

10°

E

1A

CLOSED

Delayed Action

Closing Cycle

1B

Closing Speed Controls Figure 2.

Sweep &

Latch

Slow

1/8”

Hex

Key

L (Latch)

S/D (Sweep)

Standard

Fast

Delay

Increase

1/8”

Hex

Key

Decrease

Delayed Action

L (Latch)

S (Sweep)

S/D (Delayed

Action)

Opening Door Control Figure 4.

B

A

C

K

C

H

E

C

K

G

N

I

N

E

P

O

Opening Cycle

Backcheck Control Figure 5.

Backcheck Position

1/8”

Hex

Key

Open for backcheck

later in door-opening

cycle.

“P”

Normally

Closed

“B”

(NEVER

Close

Completely)

Backcheck Cushion

Increase

1/8”

Hex

Key

Decrease

Closing Power Adjustment (Figure 3.)

! Adjust as required.

Closing Power Control Figure 3.

Note: Maximum of 15 360°

turns of Power Adjustment

Nut.

Power

Adjustment

Nut

To increase power

11/16"

wrench

To decrease power

Yale ® is a registered trademark of Yale Security Inc., an ASSA ABLOY Group company.

Copyright © 2002, 2009, Yale Security Inc., an ASSA ABLOY Group company. All rights reserved.

Reproduction in whole or in part without the express written permission of Yale Security Inc. is prohibited.

11/16"

wrench

Door Holder Option

The Hold-Open feature is controlled by the knob located

on the arm of the unit. A quarter turn of this knob

engages or disengages the Hold-Open mechanism.

ON OFF

Thumbturn Action

(Units suffixed “T”)

An ASSA ABLOY Group brand

3000 Highway 74 East • Monroe, NC 28112

Tel: (800)-438-1951 • Fax:(800)-338-0965

www.yalecommercial.com

Loading...

Loading...