Page 1

OPE RATI NG ,

MAI NT EN ANC E &

PA RT S MA NUA L

MAN UA LLY LE VER

OPE R ATE D

CHA I N H O I S T

RS

22

Lever Hoist

Capacities: 3/4, 1-1/2, 3 ton

(750, 1500, 3000 kg.)

Follow all instructions and warnings for

inspecting, maintaining and operating this

hoist.

The use of any hoist presents some risk of personal

injury or property damage. That risk is greatly increased

if proper instructions and warnings are not followed.

Before using this hoist, each operator should become

thoroughly familiar with all warnings, instructions and

recommendations in this manual. Retain this

manual for future reference and use.

Forward this manual to operator.

Failure to operate equipment as directed in

manual may cause injury.

Before installing hoist, fill in the

information below.

Model No. __________________

Serial No. __________________

Purchase Date ______________

Rated Load _________________

73907 A

414 WEST BROADWAY AVENUE

MUSKEGON, MICHIGAN 49443

Manual No. Y673-A

Page 2

YALE HOIST PARTS AND SERVICES AVAILABLE IN THE UNITED STATES.

As a Yale Hoist and Trolley user, you are assured of reliable repair and parts services

through a network of Authorized Parts Depots that are strategically located in the United

States. These facilities have been selected on the basis of their demonstrated ability to

handle all parts and repair requirements promptly and efficiently. To quickly obtain the

name of the Authorized Parts Depot located nearest you, call (866) 805-2962,

Fax (800) 742-9270.

NOTES

i 11 12

Page 3

SAFETY PRECAUTIONS

Each Yale RS2 Manually Lever Operated Hoist is built in accordance with the specifications contained herein and at

the time of manufacture complies with our interpretation of applicable sections of *ASME B30.21, *ANSI/ASME HST3M and the Occupational Safety and Health Act-1970.

The safety laws for elevators and for dumbwaiters specify construction details that are not incorporated in Yale

industrial hoists. We recommend the use of equipment that meets state and national safety codes for such use. Yale

Hoists cannot be responsible for applications other than those for which Yale equipment is recommended.

THIS SYMBOL POINTS OUT IMPORTANT SAFETY INSTRUCTIONS WHICH IF NOT FOLLOWED

COULD ENDANGER THE PERSONAL SAFETY AND/OR PROPERTY OF YOURSELF AND OTHERS.

! !

*Copies of these standards may be obtained from ASME Order Department, 22 Law Drive, Box 2300, Fairfield, NJ 07007-2300.

READ AND FOLLOW ALL INSTRUCTIONS IN THIS MANUAL AND ANY PROVIDED WITH THE

EQUIPMENT BEFORE ATTEMPTING TO OPERATE YOUR YALE LEVER HOIST.

WARNING!

Improper operation of a hoist can create a potentially hazardous

situation which, if not avoided, could result in death or serious

injury. To avoid such a potentially hazardous situation, the

operator shall:

1. NOT operate a malfunctioning or unusually performing hoist.

2. NOT

3. NOT

4. NOT

5. NOT

6. NOT

7. NOT

8. NOT

9. NOT

10. NOT

11. NOT

12. Protect the hoist’s load chain from weld splatter or other

13. NOT

14. NOT

15. NOT

16. NOT

17. NOT

18. NOT

19. NOT

20. NOT

21. NOT

22. NOT

23. NOT

24. NOT

operate the hoist until you have thoroughly read and

understood this Operating, Maintenance and Parts Manual.

operate a hoist which has been modified without the

manufacturer’s approval or certification to be in conformity with

applicable OSHA regulations.

lift or pull more than rated load for the hoist.

use damaged hoist or hoist that is Not working properly.

use hoist with twisted, kinked, damaged, or worn load chain.

operate with any lever extension (cheater bar).

attempt to “free-chain” the hoist while a load is applied.

use the hoist to lift, support, or transport people.

lift loads over people and make sure all personnel remain

clear of the supported load.

attempt to lengthen the load chain or repair damaged load

chain.

damaging contaminants.

operate hoist when it is restricted from forming a straight

line from hook to hook in the direction of loading.

use load chain as a sling or wrap load chain around load.

apply the load to the tip of the hook or to the hook latch.

apply load unless load chain is properly seated in the chain

wheel(s) or sprocket(s).

apply load if bearing prevents equal loading on all load

supporting chains.

operate beyond the limits of the load chain travel.

leave load supported by the hoist unattended unless

specific precautions have been taken.

allow the chain or hook to be used as an electrical or

welding ground.

allow the chain or hook to be touched by a live welding

electrode.

remove or obscure the warnings on the hoist.

operate a hoist which has Not been securely attached to a

suitable support.

operate a hoist unless load slings or other approved single

attachments are properly sized and seated in the hook saddle.

25. NOT

26. NOT

27. Report malfunctions or unusual performances of a hoist, after it

28. NOT

29. Be familiar with operating controls, procedures, and warnings.

lift loads that are Not balanced and that the holding action is

Not

secure, taking up slack carefully.

operate a hoist unless all persons are and remain clear of

the supported load.

has been shut down until repaired.

operate a hoist on which the safety placards or decals are

missing or illegible.

CAUTION!

Improper operation of a hoist can create a potentially hazardous

situation which, if not avoided, could result in minor or moderate

injury. To avoid such a potentially hazardous situation, the

operator shall:

1. Maintain a firm footing or be otherwise secured when operating

the hoist.

2. Check brake function by tensioning the hoist prior to each lift or

pulling function.

3. Use hook latches. Latches are to retain slings, chains, etc. under

slack conditions only.

4. Make sure the hook latches are closed and not supporting any

parts of the load.

5. Make sure the load is free to move and will clear all

obstructions.

6. Avoid swinging the load or hook.

7. Avoid lever “fly-back” by keeping a firm grip on the lever until

operating stroke is completed and the lever is at rest.

8. Inspect the hoist regularly, replace damaged or worn parts, and

keep appropriate records of maintenance.

9. Use the hoist manufacturer’s recommended parts when repairing

the unit.

10. Lubricate load chain per hoist manufacturer’s recommendations.

11. NOT

12. NOT

13. NOT

14. NOT

15. NOT

16. NOT

use the hoist load limiting or warning device to measure

load.

operate except with manual power.

permit more than one operator to pull on lever at the same

time. More than one operator is likely to cause hoist overload.

allow your attention to be diverted from operating the hoist.

allow the hoist to be subjected to sharp contact with other

hoists, structures, or objects through misuse.

adjust or repair the hoist unless qualified to perform such

adjustments or repairs.

ii

Page 4

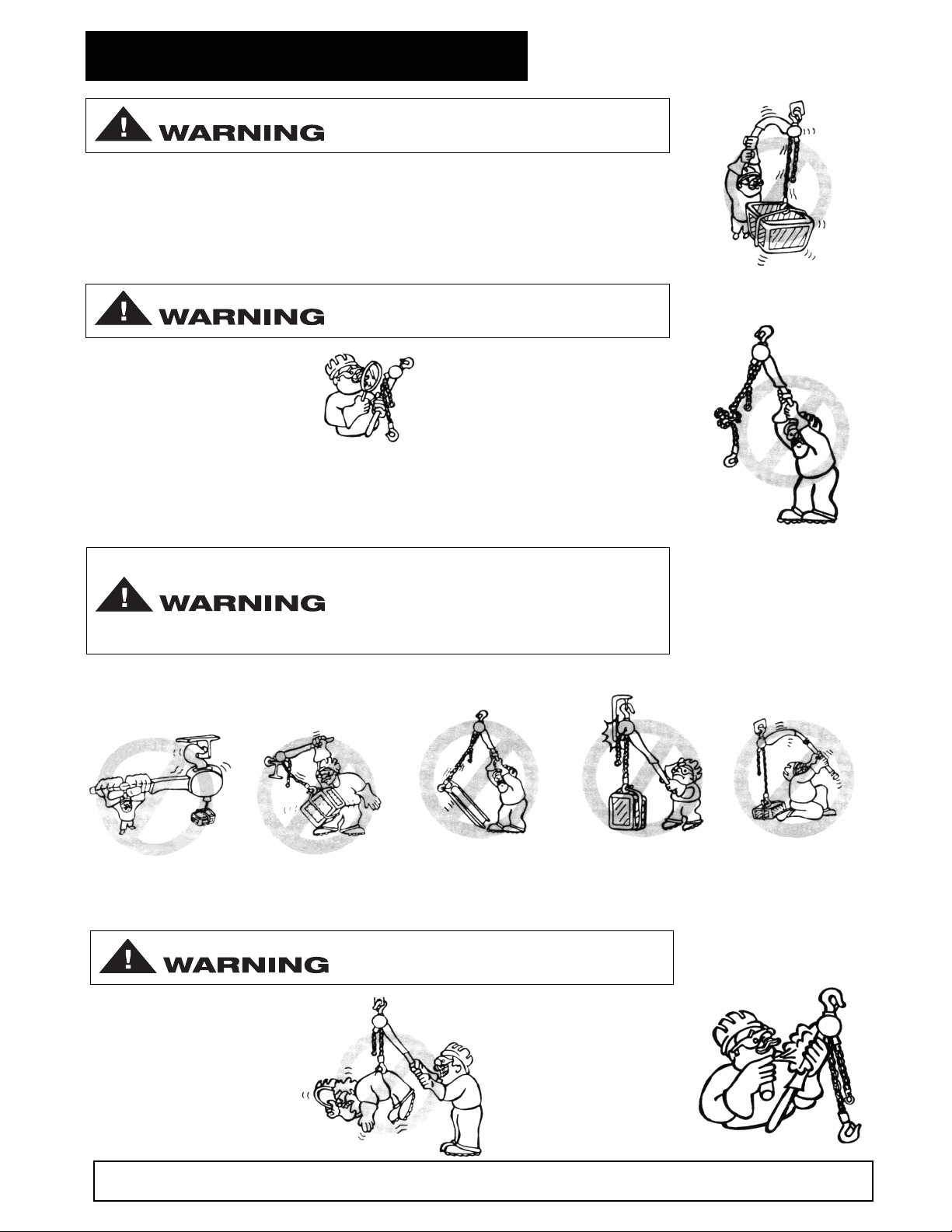

HOIST SAFETY IS UP TO YOU...

–DO NOT APPLY MORE THAN RATED LOAD.

1 CHOOSE THE RIGHT HOIST FOR THE JOB...

Choose a Yale Lever Hoist with a capacity

or the job. Know the capacities of your

f

hoists and the weight of your loads. Then

atch them.

m

2 INSPECT

All hoists should be visually inspected

efore use, in addition to regular, periodic

b

maintenance inspections.

Inspect hoists for operational warning

notices and legibility.

Deficiencies should be noted and brought to

the attention of supervisors. Be sure

defective hoists are tagged and taken out of

service until repairs are made.

The application, the size and type of load,

he attachments to be used and the period

t

of use must also be taken into consideration

n selecting the right hoist for the job.

i

– DO NOT OPERATE DAMAGED OR MALFUNCTIONING UNIT.

– DO NOT OPERATE WITH TWISTED, KINKED OR DAMAGED

CHAIN.

nder no circumstances should you operate

U

a malfunctioning hoist.

Check chain for gouged, twisted, distorted

links and foreign material. Do not operate

hoists with twisted, kinked or damaged

chain links.

– DO NOT PULL AT AN ANGLE. BE SURE LEVER HOIST AND

LOAD ARE IN A STRAIGHT LINE.

– DO NOT USE UNLESS FRAME AND CHAIN FORM A

STRAIGHT LINE BETWEEN HOOKS.

– DO NOT USE IF FRAME IS IN CONTACT WITH ANY OBJECT.

– DO NOT USE LOAD CHAIN AS A SLING.

– DO NOT USE AN EXTENSION ON THE LEVER.

Remember the hoist was designed to ease

ur burden and carelessness not only

o

endangers the operator, but in many cases,

valuable load.

a

Load chain should be properly lubricated.

Hooks that are bent, worn or whose

penings are enlarged beyond normal

o

throat opening should not be used. If latch

does not engage throat opening of hook,

hoist should be taken out service.

Chains should be checked for deposits of

foreign material which may be carried into

the hoist mechanism.

Check brake for evidence of slippage under

load.

3 USE HOIST PROPERLY

Be sure the hoist is solidly held in

the uppermost part of the support

hook arc.

Be sure the hoist and load are in a

straight line. Do not use unless

frame and chain form a straight

line between hooks.

4 PRACTICE CAUTION ALWAYS

Do not lift co-workers with a Yale Lever

Hoist.

Make sure everyone is clear of the load

when you apply tension.

Do not remove or obscure operational

warning notices.

VIOLATION OF ANY OF THESE WARNINGS LISTED MAY RESULT SERIOUS PERSONAL INJURY TO THE

iii

OPERATOR OR NEARBY PERSONNEL BY RELEASED LOAD OR BROKEN HOIST COMPONENTS.

Be sure load is hooked securely.

Do not tip load the hook. Do not

load hook latch. Hook latch is to

prevent detachment of load under

slack chain conditions only.

– DO NOT LIFT PEOPLE OR LOADS OVER PEOPLE.

Do not operate with hoist frame

resting against any object. Apply

the load gently. Do not jerk it.

5 OPERATOR SERVICE

CLEANING: Lever Hoists should be kept

clean and free of dust, dirt, moisture, etc.,

which will in any way affect the operation or

safety of the equipment.

LUBRICATION: Chain should be properly

lubricated.

AFTER REPAIRS: Carefully operate the

hoist before returning it to full service.

Never use an extension on the

lever! You’re dangerously

overloading the hoist if you exceed

the rated lever pull or if you have

to use a lever extension to lift or

pull a load.

Page 5

SPECIFICATIONS

The Yale RS2 Lever Hoist is a highly versatile manually

lever operated chain hoist that can be used to efficiently pull,

lift, drag or stretch. Standard features of the hoist include:

• Alloy steel liftwheel to reduce chain wear.

• Hoistaloy

• Grease lubricated, hardened, alloy steel gears for smooth

operation.

• Forged steel upper and lower latch type hooks.

• Patented, free-chaining mechanism for quick and easy

attachment to the load.

• Lightweight, aluminum frame, covers and lever.

• Ball or needle bearings at rotating points.

• Compact, yet rugged, design provides minimum

headroom and long trouble free service.

• Sealed automatic brake with two holding pawls for

positive load control.

• Short lever (12 inches-305 mm long on 3/4 ton unit, 163/4 inches-425 mm long on 1-1/2 and 3 ton units) for

operation in close quarters.

• Rocking and swivel upper hook (3/4 and 1-1/2 ton units)

• Backed by Yale’s life-time warranty.

YALE REPAIR/REPLACEMENT POLICY

All Yale RS2 Lever Hoists are inspected and performance

tested prior to shipment. If any properly maintained hoist

develops a performance problem, due to a material or

workmanship defect, as verified by Yale, repair or

replacement of the unit will be made to the original

purchaser without charge. This repair/replacement policy

applies only to hoists installed, maintained and operated as

outlined in this manual, and specifically excludes hoists

subject to normal wear, abuse, improper installation,

improper or inadequate maintenance, hostile environmental

effects and unauthorized repairs/modifications.

®

load chain for long and dependable service.

Latchlok®Hooks

Latchlok hooks are available to replace the standard latch

type hooks. The unique design of the Latchlok hook assures

that it will stay locked until the operator releases it by

depressing the release button. It will not open accidentallyeven if the load chain goes slack. Once opened, it can be

shut with one hand or by the weight of the load when it is

lifted. Latchlok hooks can be supplied with the hoist or it can

be provided in kit form for lever hoists already in service.

We reserve the right to change materials or design if, in our

opinion, such changes will improve our product. Abuse,

repair by an unauthorized person, or use of non-Yale

replacement parts voids the guarantee and could lead to

dangerous operation. For full Terms of Sale, see Sales

Order Acknowledgment. Also, refer to the back cover for

Limitations of Warranties, Remedies and Damages, and

Indemnification and Safe Operation.

WARNING

ALTERATIONS OR MODIFICATIONS OF EQUIPMENT AND USE OF

NON-YALE REPAIR PARTS CAN LEAD TO DANGEROUS

OPERATION AND INJURY.

TO AVOID INJURY:

• DO NOT ALTER OR MODIFY EQUIPMENT.

• DO USE ONLY YALE PROVIDED REPLACEMENT PARTS.

OPTIONS

Load Limiter

The Load Limited is a friction device that is designed and

factory calibrated to prevent lifting excessive overloads. An

excessive overload is indicated by lever movement without

corresponding movement of the lower hook or load when the

hoist is operated in the up direction. Should this occur,

operate the lever in the down direction to remove the

overload. Reducing the load to rated capacity or less will

automatically restore normal operation. The Load Limiter

can be ordered as part of a new lever hoist or in kit form that

can be added to units now in service.

®

Anchor Sling (for 3/4 and 1-1/2 ton units only)

Anchor Sling is an upper hook extender that simplifies

attachment when application or space limitation makes it

impossible to pull in a straight line from hook to hook. A

swiveling hook block is securely anchored to the housing

and the upper hook swivels through a full 360°. Anchor

Sling may be ordered as a feature of your new hoist or in kit

form for simple installation on units now in use.

INSTALLATION

UNPACKING

After removing the hoist from the carton, check it for damage

that may have occurred during shipment. If there is

damage, refer to the packing slip envelope for claims

procedure.

INSTALLATION

The RS2 Lever Hoist is designed for operation at ambient

temperatures of 0° to 100° F (-17° to 38° C). It can be used

in any position for pulling a load at an angle, horizontal

pulling or vertical lifting, provided it is rigged to pull in a

straight line from hook to hook and the frame is free to

swivel on the upper hook.

1

Page 6

WARNING

IF THE UNIT IS NOT RIGGED IN A STRAIGHT LINE,

HOOK TO HOOK MANNER, AND IF THE FRAME IS

NOT FREE TO SWIVEL, LEVER PULL MAY BREAK

FRAME AND CAUSE PHYSICAL INJURY AND LOSS

OF LOAD.

TO AVOID INJURY:

RIG THE UNIT IN A STRAIGHT LINE HOOK TO

HOOK MANNER AND KEEP FRAME FREE TO

SWIVEL - SEE FIGURE ON PAGE 3.

Regardless of how the hoist is used, make sure that the

upper hook is firmly attached to a support or anchor that has

sufficient strength to hold several times the rated load of the

hoist.

H.Never operate the hoist when flammable materials or

vapors are present. Contact between metal parts may

produce sparks that can cause a fire or explosion.

I. STAY ALERT! Watch what you are doing and use

common sense. Do not use the hoist when you are tired,

distracted or under the influence of drugs, alcohol or

medication causing diminished control.

WARNING

MALFUNCTION OF UNIT, RIGGING SLIP OR LOSS

OF FOOTING MAY CAUSE USER TO SLIP

RESULTING IN INJURY.

TO AVOID INJURY:

ALWAYS HAVE A FIRM AND SECURE FOOTING

WHEN USING THE RS2 LEVER HOIST.

Using the upper hook, attach the hoist

to support.

Be sure hoist is solidly held in the

uppermost part of the hook arc and

the latch is tightly against the hook tip.

WARNING

ATTACHING THE HOIST FROM AN INADEQUATE

SUPPORT MAY ALLOW THE HOIST AND LOAD TO

FALL AND CAUSE INJURY AND/OR PROPERTY

DAMAGE.

TO AVOID INJURY:

MAKE SURE THE STRUCTURE HAS SUFFICIENT

STRENGTH TO HOLD SEVERAL TIMES THE HOIST

AND ITS RATED LOAD.

OPERATION

WARNING

IF NOT USED AS DIRECTED, HOIST MAY CAUSE

INJURY.

TO AVOID INJURY:

USE ONLY AS DIRECTED BELOW. READ ALL

INSTRUCTIONS BEFORE OPERATING THE RS2

LEVER HOIST.

GENERAL

A. The hoist must be kept clean to assure proper operation.

Before use, check to be sure the load chain is clean, that

there is no foreign material in the liftwheel area and that

the lever operates freely.

B. Do not load beyond the rated capacity. Overload can

cause immediate failure or cause damage resulting in

future failure, even at less than rated capacity.

C.Do not use this hoist or any other material handling

equipment for lifting or moving people, or lifting loads over

people.

D.Stand clear of all loads and warn other people of your

intention to move a load in their area.

E. Do not leave a load on the unit unattended.

F. Read warnings and instructions on the lever before each

use.

G. Do not hold the load chain while operating the hoist.

Should the hoist not operate properly, serious injury

may occur.

2

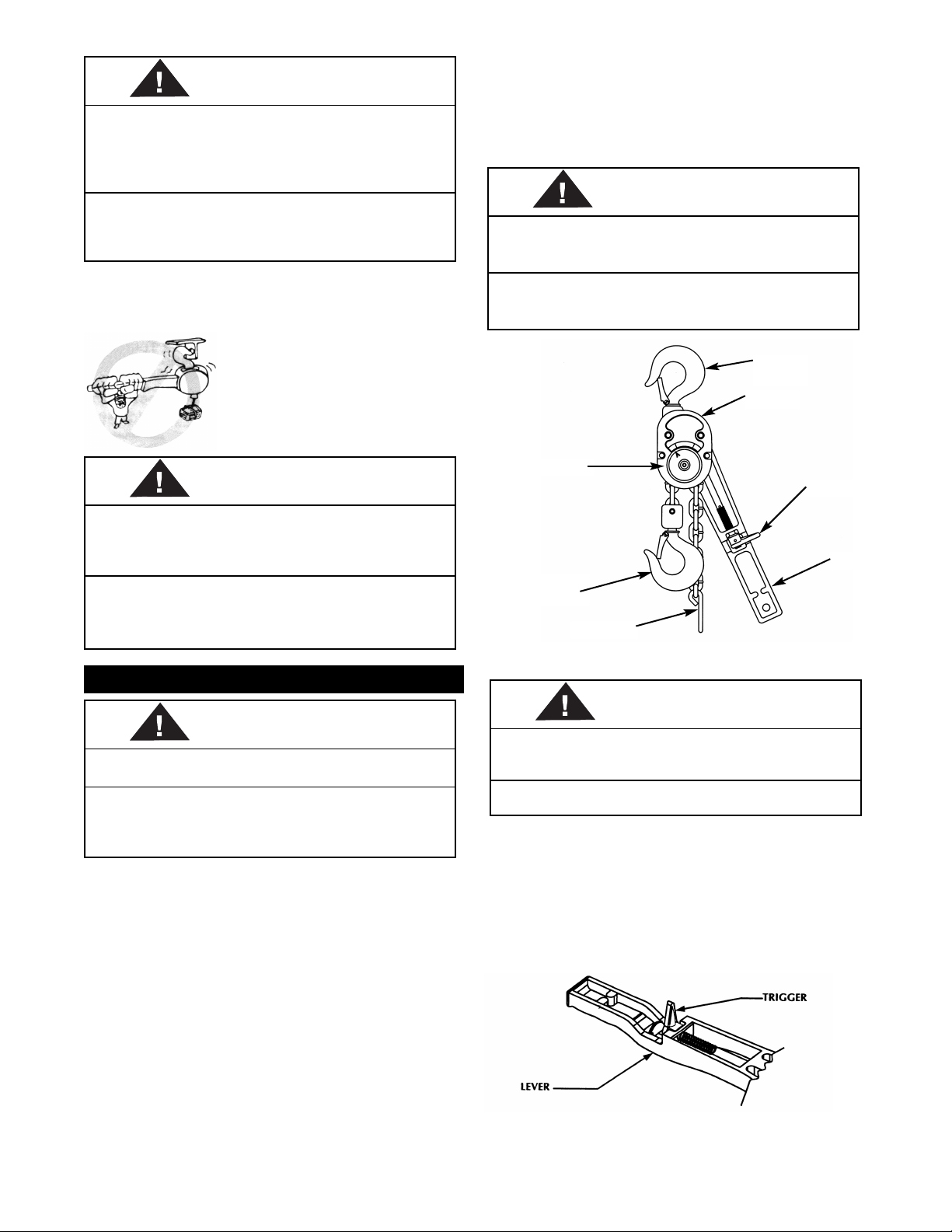

UPPER

HOOK

FRAME

CAM

TRIGGER

LEVER

LOWER

HOOK

END RING

FREE-CHAINING

WARNING

FAILURE TO PROPERLY USE THE FREE-CHAIN MECHANISM

MAY CAUSE INJURY AND/OR PROPERTY DAMAGE.

TO AVOID INJURY:

USE THE FREE-CHAIN MECHANISMAS DIRECTED BELOW.

In this mode of operation, the gearing is disengaged to allow

the chain to be easily pulled through the hoist by hand, for

quick attachment to the load.

To free-chain the RS2 Lever Hoist:

1. Make sure there is no load on the lower hook.

2. Turn the lever trigger 1/4 turn from “UP” or “DN”.

3. Rotate the cam knob 1/4 turn clockwise (to right) from

“OPERATE” to “FREE-CHAIN”. A “click” will be heard or

felt and the cam cannot be rotated further in the clockwise

position.

Page 7

ATTACHING TO LOAD

Attach the lower hook to the load so that it is seated in the

bowl of the hook and is not bearing against the tip of the

hook, and the latch is tight against the hook tip.

4. Pull on hook side and loose end side of load chain to

make sure chain feeds freely into and out of the hoist.

5. Grasp unit by frame or upper hook and pull on end ring or

lower hook to pull the chain through hoist to the length

required to attach lower hook to load. Pull on end ring to

take-up slack in chain and THEN LET GO OF END RING.

6. Rotate the cam counterclockwise (to left) until the arrow

points to “operate”.

WARNING

ALLOWING THE LOAD TO BEAR AGAINST THE

HOOK LATCH AND/OR HOOK TIP CAN RESULT IN

LOSS OF LOAD.

TO AVOID INJURY:

DO NOT ALLOW THE LOAD TO BEAR AGAINST THE

HOOK LATCH AND/OR HOOK TIP. APPLY LOAD TO

HOOK BOWL OR SADDLE ONLY.

Do not wrap the load chain around the load and hook onto

itself as a choker chain sling or bring the load in contact with

the hoist. Doing this will result in the loss of the swivel effect

of the hook which could cause twisted chain and a jammed

liftwheel. Also, the chain may be damaged at the hook.

Make sure the upper and lower hooks are in a straight line

and the frame is free to swivel on the upper hook. If the

proposed use prevents straight line attachment, use an

Anchor Sling (see page 1) or a chain sling to obtain a

straight line pull.

WARNING

IF THE UNIT IS NOT RIGGED IN A STRAIGHT LINE

HOOK TO HOOK MANNER, AND IF THE FRAME IS

NOT FREE TO SWIVEL, LEVER PULL MAY BREAK

FRAME AND CAUSE PHYSICAL INJURY AND LOSS

OF LOAD.

7. Pull sharply on the loose end of chain and THEN LET GO

OF CHAIN. Pull sharply on the lower hook side of chain,

to make sure gearing is fully engaged.

WARNING

FAILURE TO FULLY ENGAGE THE GEARING WILL

ALLOW LOAD TO RELEASE AND THUS CAUSE INJURY

TO AVOID INJURY:

AFTER ROTATING CAM KNOB TO “OPERATE”, PULL

EACH CHAIN SHARPLY TO RE-ENGAGE GEARING AS

DIRECTED ABOVE.

8. The hoist is now ready for operation. Move trigger to “UP”

position and operate lever in and up and down motion to

shorten the distance between hooks and thus pull or lift

load. Only move the load enough to slightly load the hoist.

Check free-play of cam knob. The arrow tip should

not move more than 3/16 inch (4.7mm). If

movement is greater than this, move trigger to

“DN” position and operate the

lever to remove the load. Repeat step 7 and if

the free-play is still more than 3/16 inch (4.7mm), the hoist

should be disassembled to check for damaged or worn

parts. Do not take up the load chain to the point where

the end ring or lower hook block becomes jammed

against the frame.

TO AVOID INJURY:

RIG THE UNIT IN A STRAIGHT LINE HOOK TO

HOOK MANNER AND KEEP FRAME FREE TO

SWIVEL - SEE BELOW.

SLING

UPPER AND

LOWER HOOKS

NOT A STRAIGHT

LINE BETWEEN

UPPER AND LOWER

HOOKS, FRAME NOT

FREE TO SWIVEL

LOAD

IMPROPER ATTACHMENT:

DANGEROUS PULLING

IN STRAIGHT

LINE. FRAME

FREE TO SWIVEL.

LOAD

PROPER ATTACHMENT:

SAFE PULLING

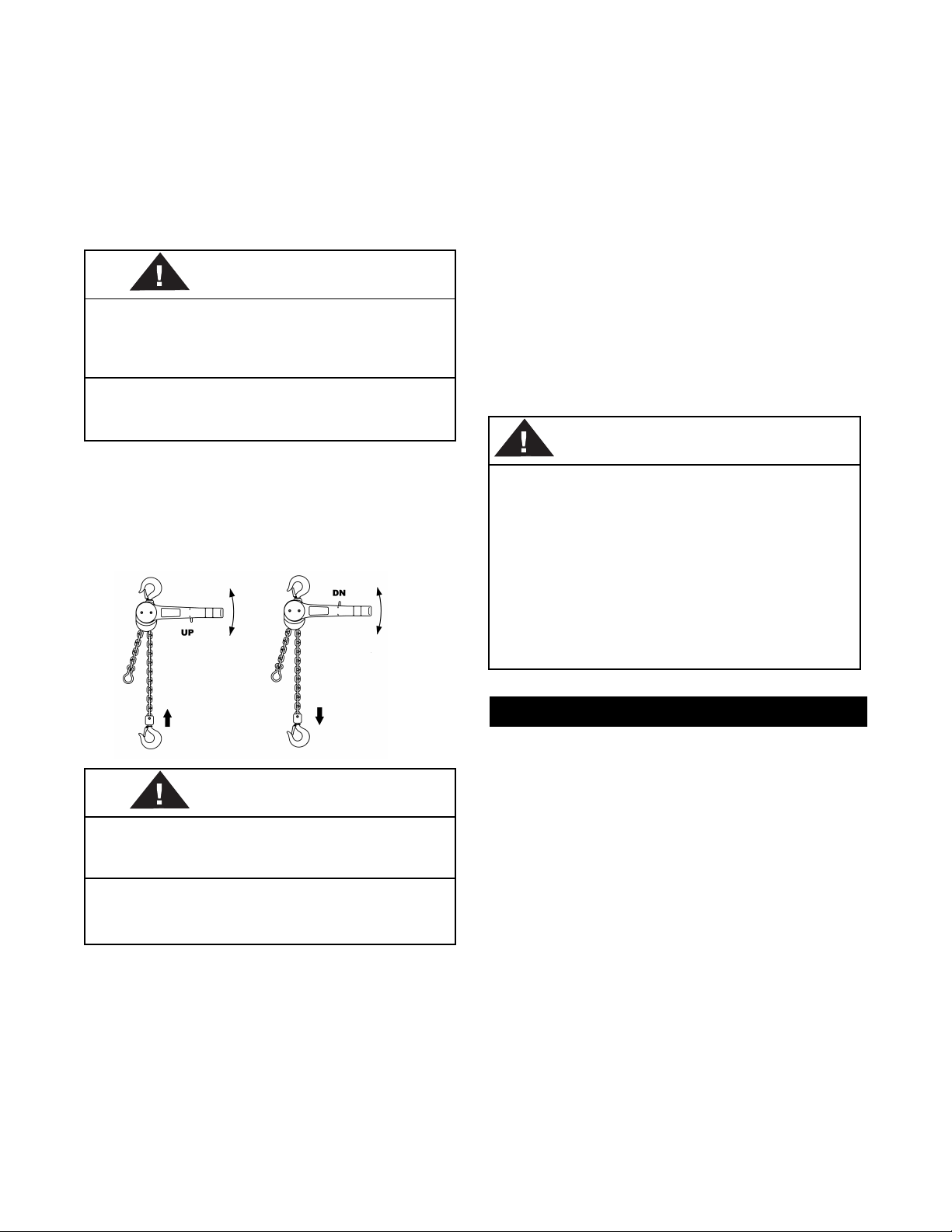

TO PULL OR LIFT LOAD

Move lever trigger to “UP” position. Operate lever in up and

down motion to shorten the distance between hooks and

thus pull or lift the load.

When pulling or lifting move the load only enough to slightly

3

Page 8

load the unit, then check to be sure that the attachments to

the hooks and load are firmly seated. Continue movement

only after you are assured the load is free of all obstructions.

The hoist has been designed for hand powered operation

only. Do not use an extension on the lever. Lever pulls of

45 pounds (21kg.) on the 3/4 ton unit, 55 pounds (25kg.) on

the 1-1/2 ton unit and 62 pounds (28kg.) on the 3 ton unit

will result in rated capacity on the unit. Any greater pull is

an indication of either an overload or an incorrectly

maintained unit.

TO LOOSEN OR LOWER LOAD

WARNING

POWER OPERATION MAY CAUSE STRUCTURAL

DAMAGE OR PREMATURE WEAR THAT IN TURN

MAY CAUSE A PART TO BREAK AND ALLOW THE

LOAD TO FALL.

TO AVOID INJURY:

OPERATE THE RS2 LEVER HOIST USING

HAND POWER ONLY!

As a result, the lever will move but, there will be no

corresponding movement of the lower hook or load, when

the unit is operated in the “up” direction. Should this occur,

immediately move the trigger to the “DN” position and

operate the lever until the overload is set down and removed

from the unit. Reducing the load to rated capacity or less

will automatically return the hoist to normal operation.

CAUTION: THE LOAD LIMITER IS SUBJECT TO

OVERHEATING AND WEAR WHEN EXCESSIVELY

OPERATED. FOR THIS REASON, WHEN AN OVERLOAD

IS DETECTED, THE EXCESS LOAD MUST BE REMOVED

AS QUICKLY AS POSSIBLE WITHOUT CONTINUED

OPERATION OF THE LEVER.

Under certain conditions, such as applying an overload and

removing it by external means, the brake may become

“locked”. This results in not being able to operate the unit in

the “down” direction. Should this occur, move the trigger to

the “DN” position and give the lever a sharp pull and then

additional strokes to lower the load and remove tension from

the unit.

Move lever trigger to “DN” position. Again, operate lever in

an up and down motion to increase the distance between

hooks and thus loosen or lower the load.

Note that the cam is NOT changed when changing from “up”

to “down” or from “down” to “up” operation.

WARNING

TURNING THE CAM WITH A LOAD ATTACHED WILL

ALLOW THE LOAD TO RELEASE AND MAY CAUSE

INJURY.

TO AVOID INJURY:

NEVER TURN THE CAM WHEN THE HOIST IS

UNDER LOAD.

INSPECT THE RS2 LEVER HOIST

Inspect the RS2 before each use and at specified intervals

as directed in the inspection section (see next column).

LOAD LIMITER

The operation of a RS2 Lever Hoist equipped with a Load

Limiter is the same as described above. In fact, as long as

you are pulling or lifting loads that are within the rated

capacity of the hoist, the Load Limiter will not function and

you will not notice any difference in operation. However, if

attempting to pull or lift load that is approximately 20%

greater than rated capacity, the Load Limiter will function.

®

WARNING -

Use as directed above. Failure to do so may cause

injury to you or others.

1. Do not exceed capacity shown on frame or lower

hook block.

2. Do not use to lift people or loads over people.

3. Do not use unless the hoist’s frame and chain form

a straight line between hooks.

4. Do not use if the frame is in contact with any object.

5. Do not use if the unit is damaged or malfunctions.

6. Do not use extension on lever. Use hand power

only.

7. Do not use if chain is twisted, kinked or damaged.

TO AVOID INJURY:

MAINTENANCE

INSPECTION

To maintain continuous and satisfactory operation, a regular

periodic inspection procedure must be initiated so that worn,

damaged and missing parts can be replaced before the unit

becomes unsafe. The frequency of inspection must be

determined by the individual application.

The following list gives an inspection procedure for

normal usage under normal conditions.

When the unit is subjected to heavy usage or dusty, gritty,

moist or corrosive atmospheric conditions, shorter time

periods must be assigned. Inspection must be made of all

parts for unusual wear, corrosion or damage, in addition to

those specifically mentioned in the schedule on page 5.

Make certain that the unit is complete and contains all parts

including hook latches and end ring.

Any parts that are deemed unserviceable must be replaced

with new parts before the unit is returned to service. It is

very important that the unserviceable parts be destroyed and

properly disposed of to prevent their possible future use as a

repair item. Use only Yale Hoist supplied repair parts as

other parts may look the same but may not be to proper

specifications.

4

Page 9

Inspection of hoists is divided into two general classifications

designated as “frequent” and “periodic”.

Frequent Inspections

Any hook that is twisted or has excessive throat opening

indicates abuse or overloading of the unit. Other loadsustaining components of the hoist should be inspected for

damage.

These inspections are by the operator or other designated

personnel. Frequent inspections are to be performed daily

or prior to each use and they are to include the following:

A. Check for free movement of the lever, trigger and cam.

B. Operate hoist with no load and check for visual signs or

abnormal noises that could indicate a potential problem.

C. Check brake for evidence of slippage.

D. Check chain for lubrication, wear damaged links or

foreign material (see page 6).

E. Check hooks for damage, cracks, twist, latch

engagement and latch operation (see below).

F. Check lever for bends, cracks and damage.

G. Check support or anchor for damage.

Any deficiencies noted during the frequent inspections must

be corrected before using the hoist.

Periodic Inspections

These are visual inspections by an appointed person who

records conditions to provide a basis for a continuing

evaluation of the hoist. Periodic inspections are to be

performed semi-annually and they should include the

following:

A. All items listed under frequent inspections.

B. Evidence of loose screws.

C. Evidence of worn, corroded, cracked or distorted upper

and lower hook blocks, frame, end ring, hook block

screws, covers, lever, suspension bolt, gears, bearings,

pawls, pawl springs, cam, cam pins, lever cover, freechaining spring, ratchet hub, stripper, Load Limiter (if

equipped with same), ratchet and hoist hanger.

D. Evidence of worn, glazed or oil contaminated friction

discs. Friction discs should be replaced if their thickness

is less than .075 inch (2 mm).

E. Warning label for legibility.

NOTE: To perform some of the periodic inspections, it is

necessary to partially disassemble the hoist. Refer

to Disassembly-Assembly starting on page 7. Also,

the external conditions may show the need for more

detailed inspection which, in turn, may require the

use of non-destructive type testing.

Any deficiencies noted during the periodic inspection must

be corrected before using the hoist.

Hook Inspection

On latch type hooks, check to make sure that the latch is not

damaged or bent and that it operates properly with sufficient

spring pressure to keep the latch tightly against the tip of the

hook and allow the latch to spring back to the tip when

released. If the latch does not operate properly, it must be

replaced. See previous illustration to determine when the

hook must be replaced.

Replace Hook If

Opening Is

Greater Than

1-1/8” (28.5 mm)

on 3/4 and 1-1/2

ton units or 115/16”(49.2mm)

on 3 ton unit.

Replace Hook If Seat Is Less

Than 21/32” (16.7 mm) on 3/4

and 1-1/2 ton units or 1-1/8”

(28.5mm) on 3 ton unit.

On Latchlok type hooks, measure seat wear and throat

opening as shown above and replace hook if measurements

indicate the need to do same.

LOAD CHAIN

Chain should feed smoothly into and away from the hoist. If

chain binds, jumps or is noisy, first clean and lubricate it (see

below). If trouble persists, inspect chain and mating parts

for wear, distortion or other damage.

Chain Inspection

First clean chain with a non-caustic/non-acid type solvent

and make a link by link inspection for nicks, gouges, twisted

links, weld spatter, corrosion pits, striations (minute parallel

lines), cracks in weld areas, wear and stretching. Chain with

any one of these defects must be replaced.

Slack the portion of the chain that normally passes over the

.250 (6.3 mm) for 3/4 ton unit

.312 (7.9 mm) for 1-1/2 and 3 ton units

Weld

Hooks damaged from chemicals, deformations, or cracks, or

that have more than a 10° twist from the plane of the unbent

hook or excessive opening or seat wear must be replaced.

10°

MAX.

Twisted

Do Not Use

Normal Ok

To use

3/4 ton: 1-1/8”(28.5mm)

1-1/2 ton: 1-5/16”(33.3mm)

3 ton: 1-7/16”(36.5mm)

Replace Hook

When

Opening Is

Greater Than

the following:

Wear In These

Areas

liftwheel. Examine the interlink area for the point of

maximum wear (polishing). Measure and record the stock

diameter at this point of the link. Then measure stock

diameter in the same area on a link that does not pass over

the liftwheel (use the link adjacent to the end ring for this

purpose). Compare these two measurements. If the stock

diameter of the worn link is 0.010 inches (0.254mm), or

more, less than the stock diameter of the unworn link, the

chain must be replaced.

5

Page 10

Vernier Caliper

When lubricating the chain, apply sufficient lubricant to

obtain natural run-off and full coverage, especially in the

interlink area.

LUBRICATION

Refer to Exploded View and Parts List pages 10 thru 13.

Measure

11 Pitches

Also check chain for stretch using a vernier caliper as shown

above. Select an unused, unstretched section of chain

(usually at the loose end) and measure and record the

length over 11 chain links (pitches). Measure and record the

same length on a worn section of chain. Obtain the amount

of stretch and wear by subtracting the measurement of the

unworn section from the measurement of the worn section.

If the result (amount of stretch and wear) is greater than

0.145 inch (3.7 mm), the chain must be replaced.

One

Pitch

WARNING

USING OTHER THAN YALE SUPPLIED LOAD CHAIN MAY

CAUSE THE CHAIN TO JAM IN THE HOIST AND/OR ALLOW THE

CHAIN TO BREAK AND THE LOAD TO DROP.

TO AVOID INJURY:

DUE TO SIZE REQUIREMENTS AND PHYSICAL PROPERTIES,

USE ONLY HOISTALOY

HOIST.

Use only a “Knife-Edge” caliper to eliminate possibility of

false reading by not measuring full pitch length. Note that

worn chain can be an indication of worn hoist components.

For this reason, the hoist’s frame, stripper, and liftwheel

should be examined for wear and replaced as necessary

when replacing worn chain.

Also, the load chain is specially heat treated and hardened

and should never be repaired.

IMPORTANT:

Do not use replaced chain for other purposes such as

lifting or pulling. Load chain may break suddenly

without visual deformation. For this reason, cut

replaced chain into short lengths to prevent use after

disposal.

®

LOAD CHAIN IN THE RS2 LEVER

Chain Lubrication

A small amount of lubricant will greatly increase the life of

load chain. Do not allow the chain to run dry. Keep it clean

and lubricate at regular intervals with Lubriplate

Chain Oil 10-R (Fiske Bros. Refining Co.) or equal lubricant.

Normally, weekly cleaning and lubrication is satisfactory, but

under hot and dirty conditions, it may be necessary to clean

the chain at least once a day and lubricate it several times

between cleanings.

®

Bar and

WARNING

USED MOTOR OILS MAY CONTAIN KNOWN

CARCINOGENIC MATERIALS.

TO AVOID INJURY:

NEVER USE USED MOTOR OILS AS A CHAIN

LUBRICANT. ONLY USE LUBRIPLATE

OIL 10-R AS A LUBRICANT FOR THE LOAD CHAIN.

®

BAR AND CHAIN

WARNING

THE LUBRICANTS USED IN AND RECOMMENDED

FOR THE RS2 LEVER HOIST MAY CONTAIN

HAZARDOUS MATERIALS THAT MANDATE SPECIFIC

HANDLING AND DISPOSAL PROCEDURES.

TO AVOID CONTACT AND

CONTAMINATION:

HANDLE AND DISPOSE OF LUBRICANTS ONLY AS

DIRECTED IN APPLICABLE MATERIAL SAFETY

DATA SHEETS AND IN ACCORDANCE WITH

APPLICABLE LOCAL, STATE, AND FEDERAL

REGULATIONS.

NOTE: To assure extra long life and top performance, be

sure to lubricate the various parts of the hoist using the

recommended lubricants. These lubricants may be

purchased from Yale. Refer to page 13 for information on

ordering the lubricants.

Except for lubricating the load chain frequently, the hoist

requires no additional lubrication, unless it has been

disassembled for cleaning, inspection and/or repairs. If the

unit has been disassembled, remove the “old” lubricant from

the parts and apply new lubricants as follows:

A. A light coat of Texaco Novatex #2, or equal, grease to:

• Needle bearings in gear cover (673-5) and frame

(673-2).

• Inside of pinion bushing (673-25).

• Outside surface of cam pins (673-47).

• Inside diameter and the cam pin slots in cam (673-18).

• Outside surface of suspension bolt (673-48).

• Spline of liftwheel (673-10).

• Outside surface of locking pins (673-78).

B. A light coat of Lubrico M-32 (Master Lubricant Co.) or

equal grease to inside diameter of lever head (673-39).

C. A light coat of Moly-Duolube #67 (Hercules Packing Co.)

or equal dry film lubricant to threads and spline of pinion

(673-9).

D. A light coat of a *graphite/grease mixture to knob of

upper and lower hooks (673-35) and bearing journals of

3 ton lower sheave (673-70).

E. 1/2 oz. on 3/4 ton unit and 2/3 oz. on 1-1/2 and 3 ton

units of Texaco Novatex #2, or equal grease to pinion

(673-9) teeth, liftwheel gear (673-11) teeth and in gear

cavity of frame (673-2).

F. A light coat of a **graphite/oil mixture to tip of lever

plunger (673-46) for approximately 1 inch (25.4mm) and

threaded end (up to including the spline) of the pinion

shaft (673-9).

G. See above for lubricating load chain.

* graphite/grease mixture consists of 1 lb. (.46 Kg.) Superior

Graphite Co. #590 flake graphite and 2 lb (.92 Kg.) of Master

Lubricant Co. Lubricko M-32 grease.

**graphite/oil mixture consists of 1 oz. of Superior Graphite

Co. #590 flake graphite and 1 qt. (946 ml) of Acheson

Industries #DAG-154RFU oil.

6

Page 11

WARNING

USING ANY GREASE OR LUBRICANT ON THE

BRAKING SURFACES WILL CAUSE BRAKE

SLIPPAGE AND LOSS OF LOAD CONTROL WHICH

MAY RESULT IN INJURYAND/OR PROPERTY

DAMAGE.

TO AVOID INJURY:

DO NOT USE ANY GREASE OR LUBRICANT ON

BRAKING SURFACES. THE BRAKE IS DESIGNED

When lubricating parts adjacent to the brake, DO NOT use

an excessive amount of lubricant which could seep onto the

brake surfaces.

EXTERIOR FINISH

The exterior surface of the RS2 Lever Hoist has a durable,

scratch resistant baked powder coating. Normally, the

exterior surfaces can be cleaned by wiping with a cloth.

However, if the finish is damaged, compatible touch-up paint

can be purchased from Yale. Refer to page 13 for

information on ordering paint.

PREVENTATIVE MAINTENANCE

A preventative maintenance program should be established

to prolong the useful life of the hoist and maintain its

reliability and continued safe use. The program should

include frequent and periodic inspections (see page 5) with

particular attention paid to lubrication of various components

using the recommended lubricants (see Lubrication section

for lubricating load chain and other parts).

RECOMMENDED SPARE PARTS

To insure continued operation, it is recommended that two

friction discs (Key No. 673-13) be kept on hand at all times

to replace friction discs that are worn, glazed or

contaminated. Refer to page 12 for ordering information).

DISASSEMBLY

When disassembling and assembling the RS2 Lever Hoist,

refer to the exploded view and parts list on pages 10 thru 13.

These show the proper relationship of the parts, part names

and the required quantities of the parts. In addition, please

observe the following:

A. The liftwheel gear (673-11) is under spring pressure and

may spring out when the gear cover (673-5) is removed.

B. Needle bearings are pressed into the gear cover (673-5)

and frame (673-2). Unless they are to be replaced, do

not attempt to remove these bearings.

C. If so equipped, do not attempt to disassemble the Load

Limiter (673-59). The Load Limiter is calibrated by Yale,

and no attempt should be made to recalibrate the device.

If it is not functioning properly, the entire Load

Limiter must be replaced.

D. Refer to page 8 for removal and installation of load chain.

E. The brake cover (673-8) includes a rubber seal and care

should be taken to make sure it is not cut or damaged.

Lever

Plunger

673-46

U

P

Trigger

673-43

(673-25) to pinion (673-9) and slide this assembly into

the frame (673-2).

C. Place liftwheel bearing (673-1) on liftwheel (673-10) and

slide this assembly into frame (673-2).

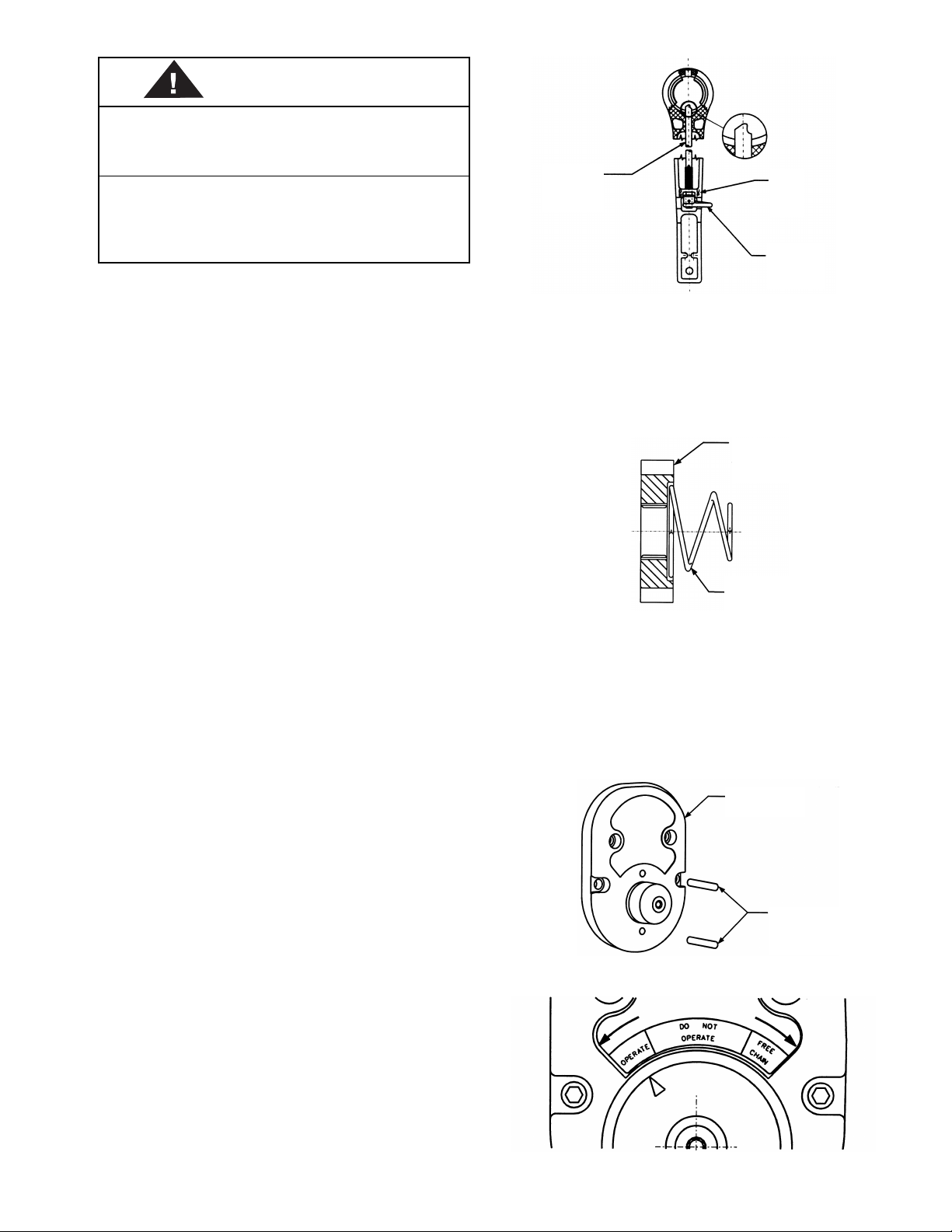

D. Place the large end of the free-chain spring (673-20) in

the recess of the liftwheel gear (673-11) and slide the

gear onto the liftwheel (673-10) spline-spring end first.

E. Assemble snap ring (673-33) to suspension bolt (673-

48). Assemble upper hook (673-35) and hook blocks

Liftwheel

Gear

673-11

Free Chain

Spring

673-20

(673-16). Place this assembly in recess on top of frame

(673-2) and secure by sliding the suspension bolt thru

holes in frame and hook block. Snap ring on suspension

bolt must be on gear side of frame.

F. Push on liftwheel gear to compress the spring and attach

the gear cover (673-5) to the frame (673-2)

G. Insert the cam pins (673-47) - ROUND END OUT - in the

holes above and below boss on gear cover (637-5).

H. Assemble the cam (673-18) to the gear cover (673-5) so

that the arrow is pointing towards “operate”.

Gear Cover

673-5

Cam Pins

673-47

Round End Out

I. Secure the cam using the cam washer (673-60) and

ASSEMBLY

When reassembling the unit, lubricate the various parts as

specified on page 6 and observe the following:

A. Maintain the proper relationship of the lever plunger

(673-46) tip and the trigger (673-43) as shown above.

B. Assemble pinion washer (673-26) and then bushing

screw (673-29).

7

Page 12

J. Assemble pawls (673-19) to pawl shafts (673-22) and

secure with snap rings (673-32). Place pawl springs

(673-21) on pawl shafts and insert these assemblies into

frame (673-2).

K. Slide friction hub (673-12) onto pinion (673-9) and place

one friction disc (673-13) on top of friction hub.

B. Put unit in free-chaining - see page 2

C. Pull on the end ring (673-53) and pull the chain out of the

hoist (and out of the lower hook block on the 3 ton unit).

D. Remove the end ring from the load chain.

INSTALLING LOAD CHAIN

3/4 ton unit uses 1/4 in.(6.3mm) stock disc grade load

Frame

673-2

Pawl

Spring

673-21

Pawl Shaft

673-22

Pawl Snap

Ring

673-32

Pawl

673-19

Assemble ratchet bushing (673-24) to ratchet (673-23).

Spring apart pawls and slide ratchet/bushing assembly

on friction hub as shown below.

L. To assemble and adjust the brake, place the second

friction disc (673-13) on top of the ratchet. Thread the

Ratchet Bushing

673-24

Frame

673-2

Ratchet

673-23

Pawl Assembly

ratchet hub (673-14) or Load Limiter (673-59) onto the

pinion (673-9). Insert the two locking pins (673-78) into

the holes of the ratchet hub or Load Limiter. Holding the

pinion steady, rotate the ratchet hub or Load Limiter from

the stop in the full clockwise position to the stop in the full

counterclockwise position. From stop to stop there

should be 10 to 45° of rotation. If the rotation does not fall

within this range, remove the locking pins, ratchet hub or

Load Limiter, pawl assemblies (see step J), friction discs,

ratchet and ratchet bushing. Slide the friction hub

partially off of the pinion until the splines disengage.

Rotate the friction hub slightly clockwise if the rotation is

more than 45° or counterclockwise if the rotation is less

than 10°. Repeat steps 1-4 until the rotation from stop to

stop is 10 to 45°. Note: The ratchet hub or Load Limiter

can be started onto the thread of the pinion in one of four

poisons. Each time the ratchet hub or Load Limiter is

threaded onto the pinion, maintain the same orientation.

Install the pawl assemblies per step K.

M. Assemble the snap ring (673-31) to the stripper pin (673-

34). Slide the stripper (673-15) into the recess in the

bottom of the frame and secure by sliding the stripper pin

thru the holes in the frame and stripper.

N. Assemble brake cover (673-8) to frame.

O. Assemble the lever assembly (step A) to ratchet hub

(673-14) or Load Limiter (673-59) and secure by

attaching the lever cover (673-17) to the ratchet hub or

Load Limiter.

P. Install load chain (673-52) - see removal and installation

of load chain.

Q. After assembly, test the unit as indicated on page 9.

REMOVAL OF LOAD CHAIN

WARNING

IMPROPER INSTALLATION (REEVING) OF THE LOAD CHAIN

CAN RESULT IN A DROPPED LOAD.

TO AVOID INJURY:

• VERIFY USE OF PROPER SIZE AND TYPE OF LOAD

CHAIN FOR SPECIFIC RS2 LEVER HOIST.

• INSTALL LOAD CHAIN PROPERLY AS INDICATED BELOW

chain.

1-1/2 and 3 ton units use 5/16 in.(7.9mm) stock disc

grade load chain.

A. Feed a piece of soft wire thru one chain opening in the

Liftwheel

673-10

Welds Out And

Welds Out And

Away From

Away From

Liftwheel.

Liftwheel.

Load Chain

673-52

bottom of the frame, up and over the liftwheel, until it

comes out the other opening.

B. Attach the wire to the load chain to be installed.

C. Make sure the unit is in free-chaining (see page 2).

D. Position the chain so that the welds on the upstanding

links will be up and away from the liftwheel and the first

link entering the hoist is an upstanding link.

E. Pull on the wire to pull the chain up and over the

liftwheel.

F. On 3/4 and 1-1/2 ton units, attach the lower hook block to

the strand of chain that enters the “hook side” of the

frame (printed on the nameplate). Tighten the hook

block screw (673-51) firmly and then lock it in place by

prick punching two spots 180° apart on edge of

counterbore to drive metal into serrations on head of

Dead

End Pin

673-76

A. Remove the lower hook block assembly from the load

chain on the 3/4 and 1-1/2 ton units. On the 3 ton unit,

disengage the load chain from the hoist hanger (673-75)

by removing the dead end pin (673-76).

8

Page 13

screw. If screw has been removed and replaced, always

use new spots for locking.

On the 3 ton unit, hang it in the vertical position. Making

sure there are no twists in the chain, feed the end of

chain thru the hook block (673-71) and around lower

sheave (637-70). Secure end of chain to hoist hanger

using the dead end pin (673-76).

G. Assemble the end ring (673-53) to the free (loose) end of

chain by rotating the last link 1/4 turn and passing the

ends of the ring thru the link as shown below. Hammer

or squeeze the ends of the ring together to secure it to

the chain.

Load

Chain

673-52

Rotate Last

Link Of

Chain 90°

As Shown.

End Ring

673-53

Bend

Ends To

Secure To

Chain

WARNING

CUTTING CHAIN CAN PRODUCE FLYING

PARTICLES.

TO AVOID INJURY:

• WEAR EYE PROTECTION.

• PROVIDE A SHIELD, SUCH AS A HEAVY RAG,

OVER THE CHAIN TO PREVENT FLYING PARTICLES.

TESTING

Prior to initial use, all altered or repaired hoists or hoists that

have not been operated for the previous 12 months must be

tested by the user for proper operation.

Test the unit first in the unloaded state and then with a light

load of 50 pounds (23kg.) times the number of load

supporting strands of load chain to be sure it operates

properly and the brake holds the load when the lever is

released; then test with a load of *125% of rated capacity.

In addition, hoists in which load sustaining parts have been

replaced shall be tested with *125% of rated capacity by or

under the direction of an appointed person and a written

report prepared for record purposes.

CUTTING CHAINS

Hoistaloy®load chain is hardened for wear resistance and is

difficult to cut. However, the following methods are

recommended when cutting a length of new chain from

stock or cutting off a length of worn chain.

(1) Use a grinder and nick the link on both sides, then

secure the link in a vise and break off with a hammer.

(2) Use a 7 inch(177.8mm) minimum diameter by 1/8 inch

(3.175mm) thick abrasive wheel (of type recommended

by wheel supplier) that will clear adjacent links.

Cutting Chain by Nicking

(3) Chain may also be cut using a bolt cutter with special

jaws for cutting hardened chain (1 inch (25.4mm) long

cutting edge).

*If unit is equipped with a Load Limiter, it may refuse to lift

the 125% overload. Should this occur, reduce the test load

to rated capacity. Also, on such units, the function of the

Load Limiter should be checked. To do this attach the lower

hook to a load of 180% of rated capacity and operate the

unit in the “up” direction. When attempting to lift this load,

the lever should slip. If it does not, the Load Limiter must be

replaced. After this test, operate the unit in the “down”

direction to remove tension in the chain.

NOTE: For additional information on inspection and

testing, refer to the current issue of ASME B30.21

“Manually Lever Operated Hoists” obtainable from

ASME Order Department, 22 Law Drive, Box 2300,

Fairfield, NJ 07007-2300, U.S.A.

Cutting Chain with a Bolt Cutter

9

Page 14

RS2 LEVER HOIST PARTS LIST

KEY NO. PART NAME PART NUMBER

NO. REQ’D. 3/4 TON 1 1/2 TON 3 TON

673-1 1 Liftwheel Bearing 88645 88442

673-2 1 Frame (includes 673-3 and (4) 673-4) 73304Y 73331Y

673-3 1 Pinion Bearing, frame end 88642 88439

673-4 4 Frame Pin 920720 73737

673-5 1 Gear Cover (includes 673-6 and 73305Y 73328Y

673-7)

673-6 1 Pinion Bearing, gear end 88644 88441

673-7 1 Liftwheel bearing 88643 88439

673-8 1 Brake Cover with seal 73306 73329

673-9 1 Pinion 73345 73348

673-10 1 Liftwheel 73308 73332

673-11 1 Liftwheel Gear 73309 73325

673-12 1 Friction Hub 73343 73350

673-13 2 Friction Disc 73709 73742

673-14 1 Ratchet Hub 73338 73323

673-15 1 Chain Guide (Stripper) 73772 73745

673-16 2 Upper hook block half 73701 73346 –

673-17 1 Lever Cover 73153 73154

673-18 1 Cam 73708 73746

673-19 2 Pawl 73700 73728

673-20 1 Free-Chain Spring 73712 73743

673-21 2 Pawl Spring 73713 73731

673-22 2 Pawl Shaft 73315 73733

673-23 1 Ratchet 73313 73326

673-24 1 Ratchet Bushing 73710 73741

673-25 1 Pinion Bushing 73711 73730

673-26 1 Pinion Washer 73720 73729

673-27 2 Lever Cover Screw 73718 73715

673-28 6 Cover Screw 73715 73736

673-29 1 Cam Screw 73717

673-30 2 Upper Hook Block Screw 73716 73735 –

673-31 1 Stripper Pin Snap Ring 73722

673-32 2 Pawl Snap Ring 73721 73738

673-33 1 Suspension Bolt Snap Ring 73723 73734

673-34 1 Stripper Pin 73318 73739

*673-35 2 Hook with Latch (Latch type) 23030 40604 –

673-36 2 Latch Kit 595522 45662 45663

673-39 1 Lever Assembly (Includes 673-40, 73600Y 73604Y

673-41, 673-42, 673-43, 673-44,

673-45 and 673-46)

673-40 1 Expansion Plug 940801

673-41 1 Lever Plunger Spring 40735

673-42 1 Lever Plunger Spring Pin 983766

673-43 1 Trigger 40113Y

673-44 1 Warning Label 40955

673-45 1 Trigger Pin 983768

673-46 1 Lever Plunger 73310 40462

673-47 2 Cam Pin 73314 73744

673-48 1 Suspension Bolt 73317 73770

673-49 1 Hook Block, Drilled 40120 40142 673-50 1 Hook Block, Tapped 40121 40143 -

10

Page 15

Page 16

Load Limiter

(Optional)

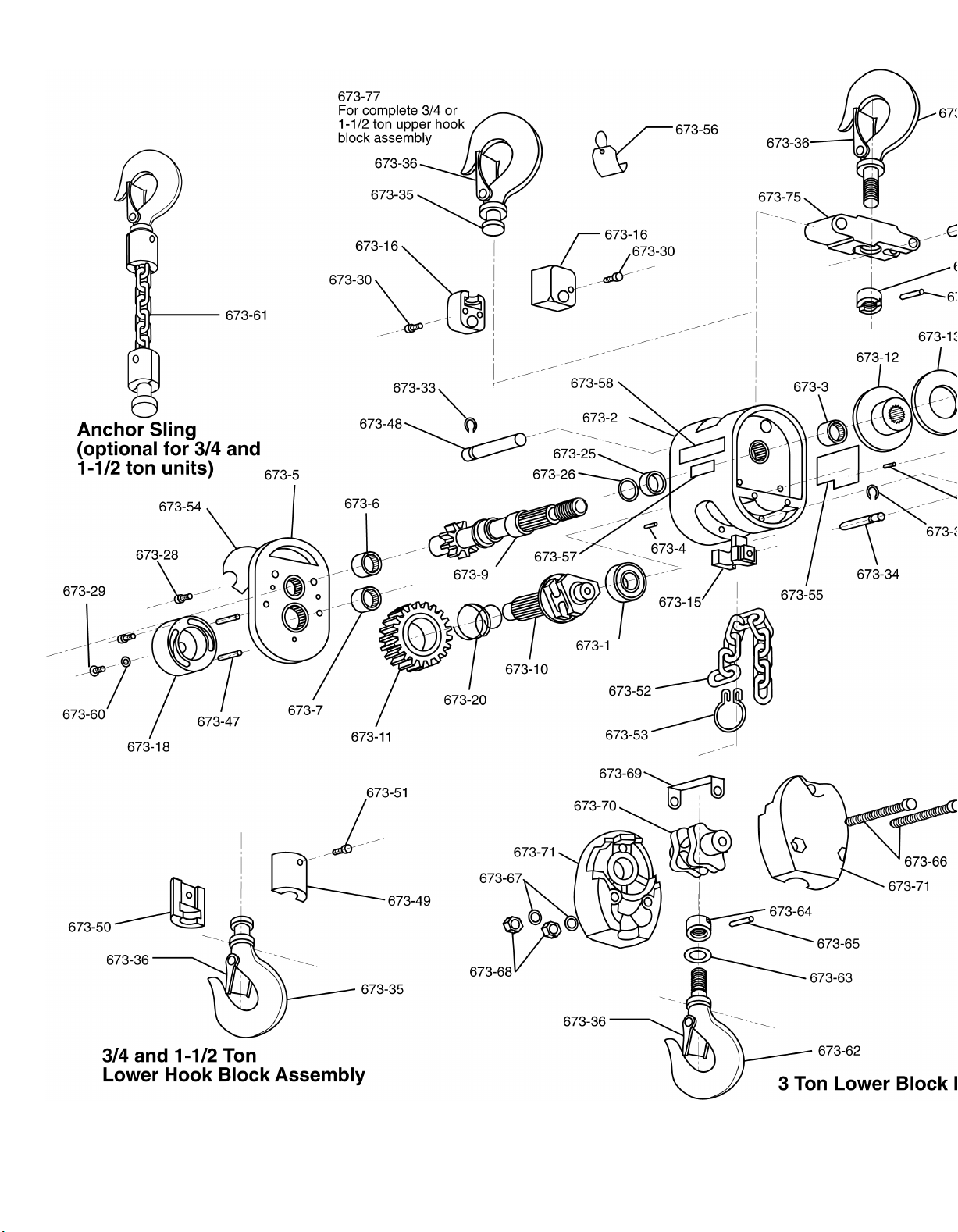

Exploded View

RS2 Lever Hoist

The following information must accompany all correspondence or repair parts orders:

1) Capacity

2) Serial Number - this is stamped on the frame

For parts orders also specify:

1) Quantity desired

2) Key number of part

3) Part Name

4) Part number of the part

When ordering replacement parts, consideration should be given to the need to replace other items,

(bushings, fasteners, etc.) and items that may be damaged or lost during disassembly or just unfit for future

use because of deterioration from age or service.

Parts should be ordered from Yale Master Parts Depots conveniently located throughout the United States.

Refer to the back of front cover of this manual to locate the Parts Depot nearest you.

WARNING

USING “COMMERCIAL” OR OTHER

MANUFACTURER’S PARTS TO REPAIR THE RS2

LEVER HOIST MAY CAUSE LOAD LOSS.

TO AVOID INJURY:

USE ONLY YALE SUPPLIED REPLACEMENT PARTS.

PARTS MAY LOOK ALIKE BUT YALE PARTS ARE

MADE OF SPECIFIC MATERIALS OR PROCESSED

TO ACHIEVE SPECIFIC PROPERTIES.

ORDERING INFORMATION

Page 17

KEY NO. PART NAME PART NUMBER

NO. REQ’D. 3/4 TON 1 1/2 TON 3 TON

673-51 1 Hook Block Screw 40854 40855 –

673-52 - Load Chain (Specify Length Req’d.) 85839 85847

673-53 1 End Ring 40471

673-54 1 Capacity Label 73759 73751 73752

673-55 1 I.D. Label 73901 73903

673-56 1 Warning Tag 73905

673-57 1 Patent Label

(no longer available order 673-55)

–

673-58 1 Load Limiter Label (Only for units 73763

with Load Limiter)

673-59 1 Load Limiter (Optional) 7310 P 7311 P 7311 P

673-60 1 Cam Washer 73316

673-61 1 Anchor Sling 7309 P 7312 P –

*673-62 1 Lower Hook with latch (Latch type) -- 40606

673-63 1 Lower Hook Washer -- 50454

673-64 1 Lower Hook Nut -- 40382

673-65 1 Lower Hook Nut Pin -- 982335

673-66 3 Lower Hook Block Screw -- 940812

673-67 3 Lower Hook Block Screw L.W. -- 940830

673-68 3 Lower Hook Block Screw Nut -- 945820

673-69 1 Reeving Caution Plate -- 45757

673-70 1 Lower Sheave -- 40166

673-71 2 Lower Hook Block -- 40689

*673-72 1 Upper Hook with latch (latch type) -- 40606

673-73 1 Upper Hook Nut -- 40382

673-74 1 Upper Hook Nut Pin -- 982335

673-75 1 Hoist Hanger -- 73324

673-76 1 Dead End Pin -- 40851

**673-77 1 Upper hook block assembly (includes 73606 73607 -

673-16,673-30 and 673-35)

673-78 2 Lock Pin 73340 73342

* If latchlok hook is required, part numbers are: 3/4 ton upper and lower hooks - 1001, 1 1/2 ton upper and lower hooks - 1002

3 ton lower hook - 1004, 3 ton upper hook - 1010

** If latchlok hook is required, contact Yale.

PART NUMBERS FOR PACKAGED LUBRICANTS USED IN THE RS2 LEVER HOISTS

(REFER TO PAGE 6 FOR LUBRICATION INSTRUCTIONS)

LUBRICANT TYPE OF PART NUMBERS AND

USAGE LUBRICANT PACKAGED QUANTITIES

OF LUBRICANTS

3 TON LOWER SHEAVE BEARING GREASE-GRAPHITE 40626 (1 LB., .46 Kg. CAN)

JOURNALS AND SEAT FOR HOOK KNOB MIXTURE

(3/4 AND 1-1/2 TON)

TIP OF LEVER PLUNGER AND DRY-LUBE OIL- 40628 (1 PT., .5L CAN)

THREADED END OF PINION SHAFT GRAPHITE MIXTURE

INSIDE OF LEVER HEAD GREASE 40630 (1 LB., .46 Kg. CAN)

GEARS, LIFTWHEEL SPLINE, NEEDLE

BEARINGS, PINION BUSHING, CAM AND 28610 (1 LB., .46 Kg. CAN)

LOCK PINS, CAM SLOTS, AND I.D. OF CAM GREASE 28632 (4 LB., 1.8 Kg. CAN)

THREADS OF PINION SPRAY DRY 46698 (16 OZ. CAN)

LUBRICANT

LOAD CHAIN OIL 28608 (1 PT., .5L CAN)

When ordering lubricants, specify the type of lubricant, part number and packaged quantity required.

Touch-up paint for the RS2:

*(1) case (12-12 oz. Aerosol Cans) of Yellow Touch-up Paint Part Number 40215.

*Touch-up paints are only available in case quantities.

NOTE: When painting the hoists, also order warning labels and

capacity labels that may be coating during painting.

13

Page 18

Note: When ordering parts, always furnish rated load and serial number of hoist on which the parts are

to be used.

For the location of the nearest Yale Authorized Hoist Parts Depot, see inside front cover.

LIMITATION OF WARRANTIES, REMEDIES AND DAMAGES

THE WARRANTY STATED BELOW IS GIVEN IN PLACE OF ALL

OTHER WARRANTIES, EXPRESS OR IMPLIED, OF

MERCHANTABILITY, FITNESS FOR A PARTICULAR

PURPOSE, OR OTHERWISE, NO PROMISE OR AFFIRMATION

OF FACT MADE BY ANY AGENT OR REPRESENTATIVE OF

SELLER SHALL CONSTITUTE A WARRANTY BY SELLER OR

GIVE RISE TO ANY LIABILITY OR OBLIGATION.

and recommendations; or (3) installed, repaired, altered or

modified without compliance with such law, instructions or

recommendations.

UNDER NO CIRCUMSTANCES SHALL SELLER BE LIABLE

FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES AS

THOSE TERMS ARE DEFINED IN SECTION 2-715 OF THE

UNIFORM COMMERCIAL CODE.

Seller warrants that on the date of delivery to carrier the goods

are free from defects in workmanship and materials.

SELLER’S SOLE OBLIGATION IN THE EVENT OF BREACH OF

WARRANTY OR CONTRACT OR FOR NEGLIGENCE OR

OTHERWISE WITH RESPECT TO GOODS SOLD SHALL BE

EXCLUSIVELY LIMITED TO REPAIR OR REPLACEMENT,

F.O.B. SELLER’S POINT OF SHIPMENT, OF ANY PARTS

WHICH SELLER DETERMINES TO HAVE BEEN DEFECTIVE or

if Seller determines that such repair or replacement is not

feasible, to a refund of the purchase price upon return of the

goods to Seller.

Any action against Seller for breach of warranty, negligence or

otherwise, must be commenced within one year after such cause

of action occurs.

NO CLAIM AGAINST SELLER FOR ANY DEFECT IN THE

GOODS SHALL BE VALID OR ENFORCEABLE UNLESS

BUYER’S WRITTEN NOTICE THEREOF IS RECEIVED BY

SELLER WITHIN ONE YEAR FROM THE DATE OF SHIPMENT.

Seller shall not be liable for any damage, injury or loss arising out

of the use of the goods if, prior to such damage, injury or loss,

such goods are (1) damaged or misused following Seller’s

delivery to carrier; (2) not maintained, inspected, or used in

compliance with applicable law and Seller’s written instructions

INDEMNIFICATION AND SAFE OPERATION

Buyer shall comply with and require its employees to comply with

directions set forth in instructions and manuals furnished by Seller

and shall use and require its employees to follow such

instructions and manuals and to use reasonable care in the use

and maintenance of the goods. Buyer shall not remove or permit

anyone to remove any warning or instruction signs on the goods.

In the event of personal injury or damage to property or business

arising from the use of the goods, Buyer shall within 48 hours

thereafter give Seller written notice of such injury or damage.

Buyer shall cooperate with Seller in investigating any such injury

or damage and in the defense of any claims arising therefrom.

If Buyer fails to comply with this section or if any injury or damage

is caused, in whole or in part, by Buyer’s failure to comply with

applicable federal or state safety requirements, Buyer shall

indemnify and hold Seller harmless against any claims, loss or

expense for injury or damage arising from the use of the goods.

WARNING

ALTERATIONS OR MODIFICATIONS OF EQUIPMENT AND USE OF

NON-FACTORY REPAIR PARTS CAN LEAD TO DANGEROUS

OPERATION AND INJURY.

• DO NOT ALTER OR MODIFY EQUIPMENT

• DO USE ONLY FACTORY PROVIDED REPLACEMENT PARTS

414 WEST BROADWAY AVENUE

1-866-805-2962 • Fax: 1-800-742-

© 2001 Yale Hoist Printed in USA

TO AVOID INJURY:

MUSKEGON, MICHIGAN 49443

SS-5/2001

Loading...

Loading...