Page 1

GS-232A

Computer Control Interface

for Antenna Rotators

YAESU MUSEN CO., LTD.

4-8-8 Nakameguro, Meguro-Ku, Tokyo 153-8644, Japan

YAESU U.S.A.

17210 Edwards Rd., Cerritos, CA 90703, U.S.A.

YAESU EUROPE B.V.

P.O. Box 75525 1118 ZN, Schiphol, The Netherlands

YAESU UK LTD.

Unit 12, Sun Valley Business Park, Winnall Close

Winchester, Hampshire, SO23 0LB, U.K.

YAESU GERMANY GmbH

Am Kronberger Hang 2, D-65824 Schwalbach, Germany

YAESU HK LTD.

11th Floor Tsim Sha Tsui Centre, 66 Mody Rd.,

Tsim Sha Tsui East, Kowloon, Hong Kong

Page 2

Page 3

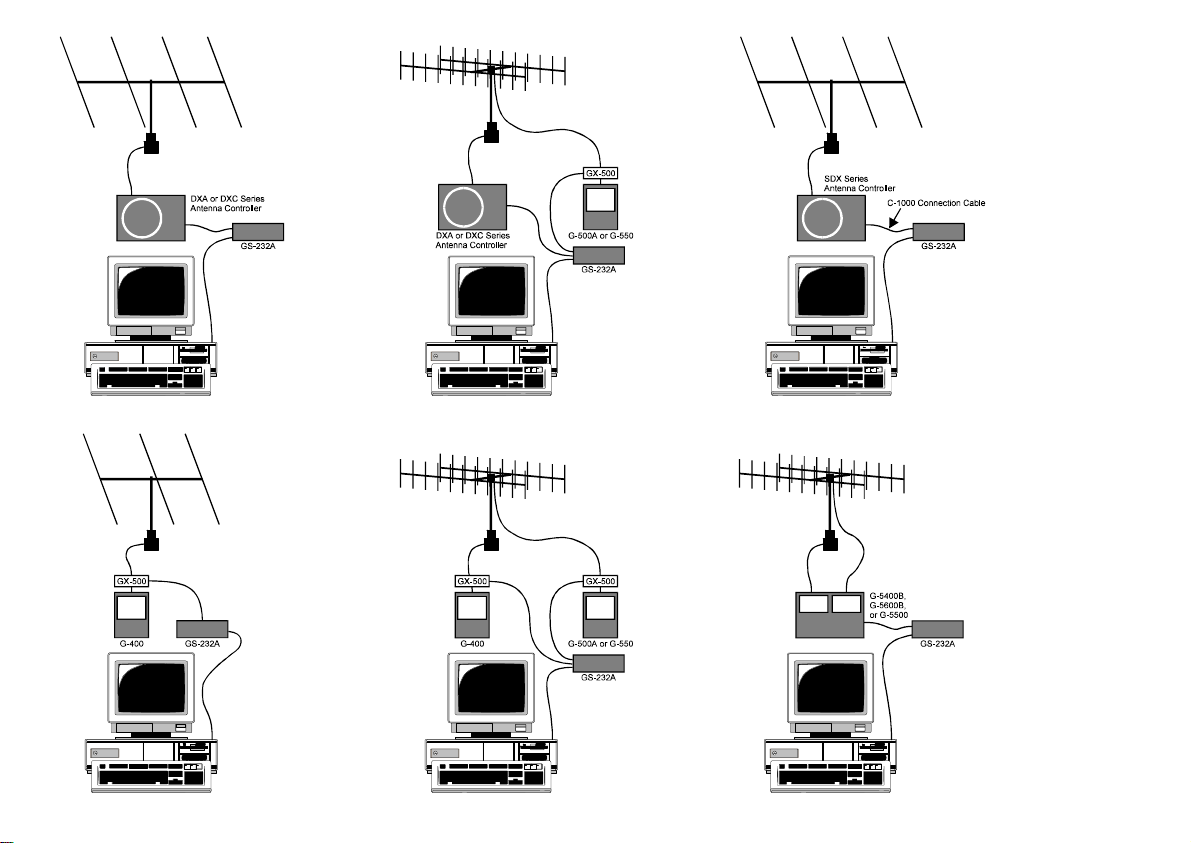

GS-232A Computer Control Interface

for Yaesu Antenna Rotators

The GS-232A provide digital control of most models of

Yaesu antenna rotatorsø from the serial port of an external

personal computer.

The GS-232A contains its own microprocessor with ROM

and RAM (memory), and a l0-bit analog-to-digital (A-D)

converter. The 3-wire async serial line can be configured for

serial data rates from 150 to 9600 baud. The GS-232A has a

DB-9 “male” connector for connection to the (RS-232C)

COM port of your computer. Purchase or construnct a

“straight” type serial cable, ensuring it has the correct gender and number of pins for connection to your system.

Firmware on the GS-232A supports either direct keyboard

control, or commands from programs written specifically to

support it (software is not supplied by Yaesu). In addition

to reading and setting antenna angle and rotation speed,

the firmware includes clocked positioning routines to auto-

matically step the antenna through up to 3800 angles at

programmable intervals, such as for tracking band openings or satellites (with an elevation rotator).

Please read this manual carefully to install the GS-232A. If

also installing a G-400, G-500A or G-550 with the GX-500

Automatic Control Adapter, follow the procedures in the

GX-500 manual before installing the GS-232A .

ø

G-800DXA/G-1000DXA/G-2800DXA

G-800DXC/G-1000DXC/G-2800DXC

G-400

Azimuth Rotator,

G-500A/G-550

G-5400B/G-5600B/G-5500

above Azimuth and Elevation rotator combination.

G-400

Azimuth Rotator and

one

GX-500

Elevation Rotator,

AZ-EL Rotator, and

G-500A/G-550

Automatic Control Adapter each.

Azimuth Rotator,

Azimuth Rotator,

Elevation Rotator requires

GENERAL DESCRIPTION

1

Page 4

GENERAL

Power Requirements: DC 12 V, 110 mA

Case Size: 110 (W) x 21 (H) x 138 (D) mm

Weight (approx.): 380 g

Semiconductors

Microprocessor: HD6303XP

ROM: 27C64

RAM: 6264

SPECIFICATIONS

A/D Converter: HD46508PA (10 bits)

Serial Comms: 3-wire Async. DCE

RS-232C voltage levels,

150 to 9600 baud, 8 data bits,

1 stop bit, no parity, no handshake

CONNECTOR PINOUTS

Serial I/O:

9-pin DB-9 connector (RS-232C connector)

Pin 2 - Tx Data

Pin 3 - Rx Data

Pin 5 - Signal Ground

Rotator Control:

5-pin connector (EL connector)

Pin 1 - UP switch (open collector)

Pin 2 - DOWN switch (open collector)

Pin 3 - analog output (0.5 - 4.5 V, four steps)

Pin 4 - analog input (0-5V elevation)

Pin 5 - analog ground

5-pin connector (AZ connector)

Pin 1 - RIGHT switch (open collector)

Pin 2 - LEFT switch (open collector)

Pin 3 - analog output (0.5 - 4.5 V, four steps)

Pin 4 - analog input (0-5V azimuth)

Pin 5 - analog ground

2

Page 5

SUPPLIED ACCESSORIES

r Control cable for the Azimuth Rotatorø1................1 pc

(“5-pin” 1 “Min-DIN” cable)

r Control cable for the AZ/EL Rotatorø2....................1 pc

(“Dual 5-pin” 1 “DIN” cable)

r DC cable w/coaxial plug.........................................1 pc

r Hook & loop fasteners (for mounting)...................1 pc

ø1: G-5400B-G-5600B/G-5500

ø2: G-800DXA/G-1000DXA/G-2800DXA &

G-800DXC/G-1000DXC/G-2800DXC

AVAILABLE OPTIONS

GX-500

C-1000 Connection Cable

NC-72B/C/F/U

(

GS-232A version

ø3:“B” suffix is for use with 117 VAC,

)

Control Adapter

(Check with your dealer)

(for SDX series Azuimuth Rotator)

ø3

AC Adapter

“C” suffix is for use with 220-240 VAC,

“F” suffix is for use with 220 VAC, or

“U” suffix is for use with 230 VAC

ACCESSORIES & OPTION

3

Page 6

During installation, a personal computer with a serial port

and terminal software is required to calibrate trimmers on

the Controller and on the Control Interface. Any simple interactive terminal program can be used - it only has to transmit keystrokes as typed, and display characters received

from the GS-232A.

INSTALLATION

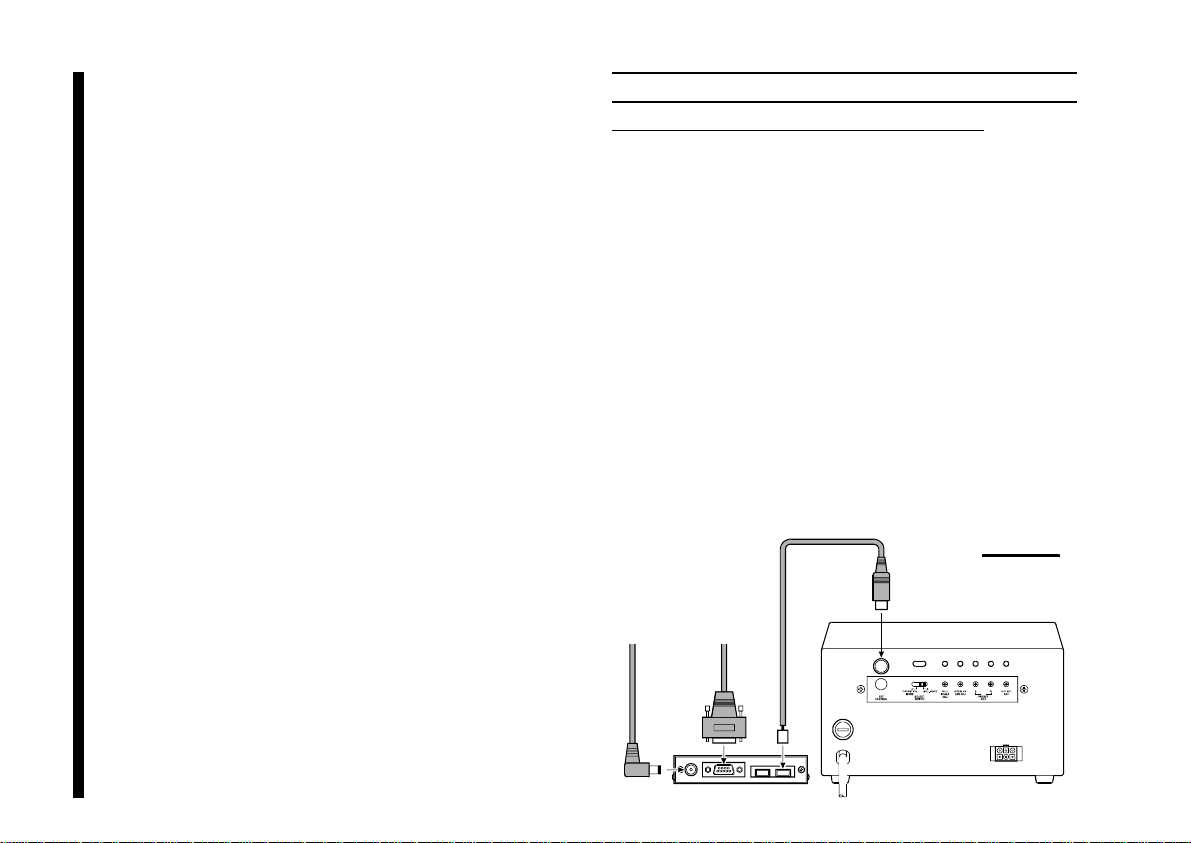

POWER & CONTROL CONNECTIONS

DXA or DXC Series Azimuth Rotator

Connect the supplied DC cable to a source of 12 VDC.

r

The red lead connects to the Positive (+) DC terminal,

and the black lead connects to the Negative

(–) DC terminal. The GS-232A requires 110 mA. The

supplied cable has a 500-mA fast-blow fuse. Use only

the same type fuse for replacement.

Plug the coaxial power connector into the DC 12V jack

r

on the GS-232A rear panel.

Connect the supplied Control cable (“5-pin” 1 “Mini-

r

DIN”) between the EXT CONTROL connector on the

rotator’s controller and AZ connector on the rear panel

of the GS-232A (Figure 1).

Figure 1

DXA or DXC series

Azimuth Rotator

To DC 12V Power Source

To Serial port of the computer

4

Page 7

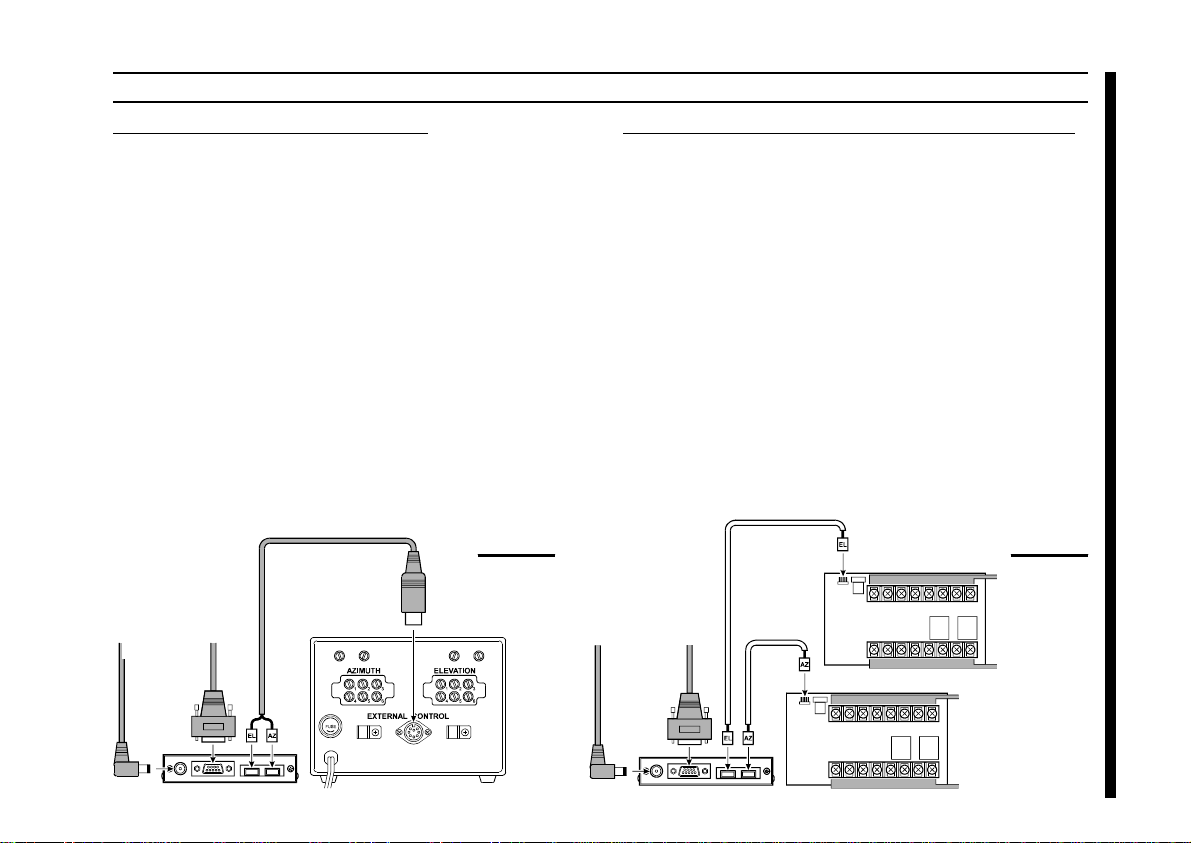

POWER & CONTROL CONNECTIONS

G-5400B/-5600B Az-EL Rotator

Connect the supplied DC cable to a source of 12 VDC.

r

The red lead connects to the Positive (+) DC terminal,

and the black lead connects to the Negative

(–) DC terminal. The

supplied cable has a 500-mA fast-blow fuse. Use only

the same type fuse for replacement.

Plug the coaxial power connector into the DC 12V jack

r

on the GS-232A rear panel.

Connect the supplied Control cable (“Dual 5-pin”

r

“DIN”) between the rotator’s controller and GS-232A.

Be careful to match the “AZ” and “EL” labels on the cable

with the same labels on the rear panel of the GS-232A

(Figure 2).

GS-232A requires 110 mA. The

G-400/G-500 or G-400/G-550 & pair of GX-500

Connect the supplied DC cable to a source of 12 VDC.

r

The red lead connects to the Positive (+) DC terminal,

and the black lead connects to the Negative

(–) DC terminal. The GS-232A requires 110 mA. The

supplied cable has a 500-mA fast-blow fuse. Use only

the same type fuse for replacement.

Plug the coaxial power connector into the DC 12V jack

r

on the GS-232A rear panel.

1

Connect the 5-pin to 5-pin cable (supplied with the GX-

r

500; requires two sets) between the GX-500(s) and GS232A (Figure 3).

INSTALLATION

To DC 12V Power Source

To Serial port

of the computer

Figure 2

G-5400B/-5600B

or G-5500

AZ/EL Rotator

To DC 12V Power Source

To Serial port of the computer

GX-500

GX-500

To Elevation

To Elevation

To Azimuth Controller

To Azimuth Rotator

Figure 3

Controller

Rotator

5

Page 8

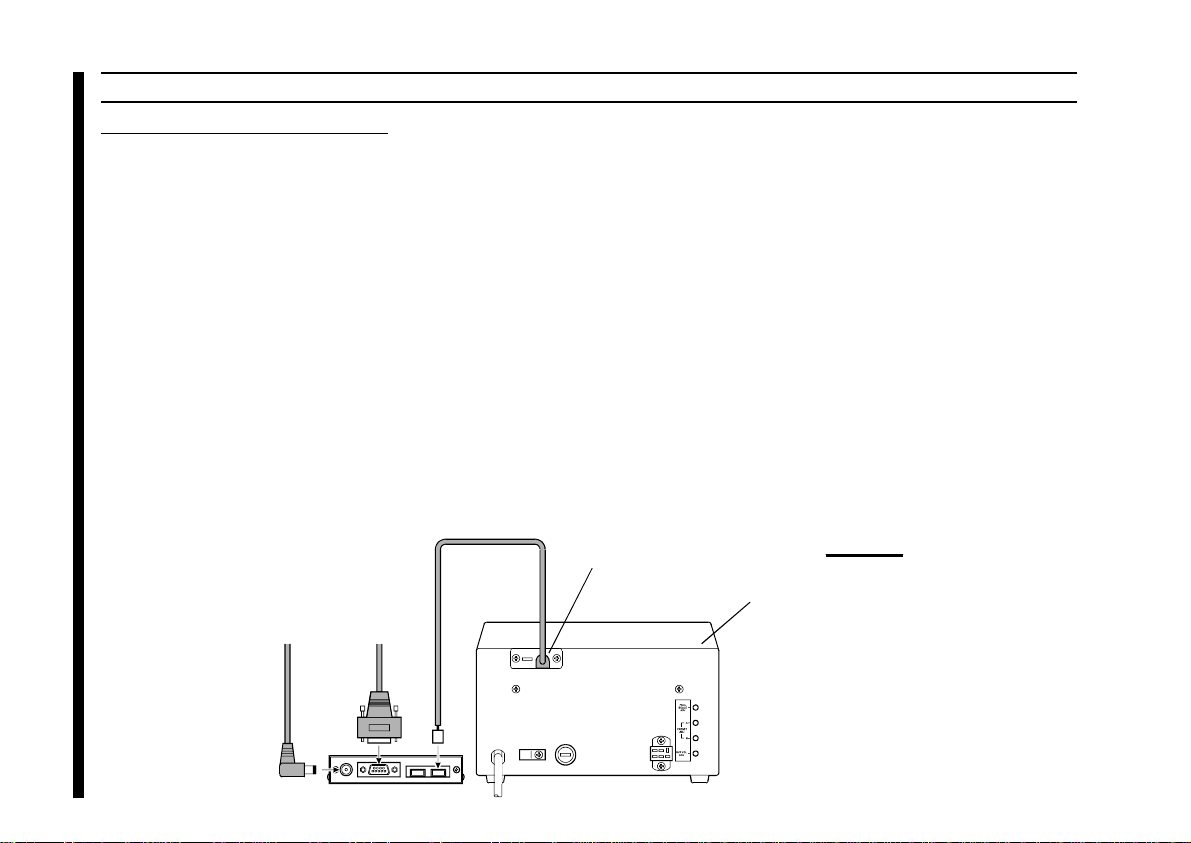

SDX Series Azimuth Rotator

Prepare the optional C-1000 Connection Cable.

r

Remove the Top cover from the controller.

r

Connect the 8-pin connector of the C-1000 Connection

r

cable to the exposed 8-pin connector located the rear

left corner in the controller.

Route the 5-pin connector of the C-1000 Connection

r

INSTALLATION

cable through out the rubber grommet on the rear panel

of the controller, and connect it to the AZ connector on

the rear panel of the GS-232A (Figure 4).

Replace the Top Cover.

r

POWER & CONTROL CONNECTIONS

Connect the supplied DC cable to a source of 12 VDC.

r

The red lead connects to the Positive (+) DC terminal,

and the black lead connects to the Negative

(–) DC terminal. The GS-232A requires 110 mA. The

supplied cable has a 500-mA fast-blow fuse. Use only

the same type fuse for replacement.

Plug the coaxial power connector into the DC 12V jack

r

on the GS-232A rear panel.

6

To DC 12V Power Source

To Serial port of the computer

Optional C-1000 Connection Cable

Output Grommet for

C-1000 Connection Cable

SDX series

Azimuth Rotator

Figure 4

Exposed 8-pin Connector

(Inside of the Controller)

Page 9

COMPUTER CONNECTION

With the computer switched off, connect the RS-232C

r

cable to the serial port of the computer, then connect the

other end of your serial cable to the RS-232C connector on the rear panel of the GS-232A. Only three wires

are used for serial control, so there is no hardware handshaking.

If you are using a G-400 Azimuth Rotator, or G-5400B/

r

G-5600B AZ-EL Rotator, set the GS-232A’s DIP switch

(switch 5) to “OFF” position, to disable the 450° rotate

operation. If you are using a other rotators (except the

G-400/G-5400B and G-5600B), the GS-232A’s DIP

switch (switch 5) is still “ON.”

Baud Setting DIP Switches

Baud

150

300

600

1200

2400

4800

9600

1

ON

OFF

ON

ON

ON

OFF

ON

DIP Switch

2

ON

ON

ON

ON

ON

ON

ON

ON

OFF

ON

ON

OFF

OFF

OFF

3

4

ON

ON

ON

ON

OFF

ON

OFF

Select the desired data baud rate with the DIP switch

r

bank on the GS-232A’s bottom case.

The Control Interface serial data format uses 8 data bits,

r

no parity, and one stop bit, with no handshaking. Turn

on the computer, controller, and GS-232A, and set up

your terminal program for this format and your selected

data rate on the serial port to be used for rotator control.

GS-232A Rear Panel

GS-232A Bottom Case

INSTALLATION

7

Page 10

Azimuth Offset Null

Before calibrate the Rotator, check to see that the GS-

r

232A’s DIP switch (switch 5) must be “ON” position.

From the Controller panel, set the Rotator fully counter-

r

clockwise (set to 0°).

Press [O] Ž [↵] (the letter “oh”, and “ENTER”) on the

r

CALIBRATION

computer keyboard to activate the azimuth calibration

routine. The computer display should show AZaaaa =

bbbb returned from the Interface Board, where aaaa

and bbbb are four-digit numbers padded at the left with

zeroes.

Adjust the AZ trimmer (located on the bottom case of

r

the GS-232A ) while watching the computer display, until

the four-digit numbers aaaa and bbbb are the same

(the precise values are not important).

Turn off the GS-232A’s POWER switch to exit the azi-

r

muth calibration routine, then turn on the GS-232A’s

POWER switch again.

If your controller’s indicator needle starts from the point except 0° (North) (such as the default setting of the USA

version), align the starting point of the controller’s indicator needle to 0° (North) before calibration.

When finish the calibration, set the controller’s indicator needle to the desired point. Refer to the rotator’s user manual

for details regarding the indicator needle alignment.

8

DXA/DXC/SDX SERIES AZIMUTH ROTATOR

Azimuth A-D Calibration

From the Controller panel, set the Rotator fully clock-

r

wise (to the right).

Press [F] Ž [↵] (“F” and “ENTER”) on the computer key-

r

board to activate the Control Interface’s azimuth A-D

converter calibration routine. The computer’s display

should show +aaaa, where aaaa is a four-digit number which indicates the azimuth heading in degrees.

Adjust the OUT VOL ADJ potentiometer on Controller

r

rear panel so as to get a reading of “0450” on the

computer’s display. This reading (“450 degrees”) corresponds to the actual beam heading you established when

you pointed the azimuth rotator to the East.

Turn off the GS-232A’s POWER switch to exit the azi-

r

muth A-D converter calibration routine, then turn on the

GS-232A’s POWER switch again.

Imprtant Note !

Page 11

G-400 AZIMUTH ROTATOR

Azimuth Offset Null

Before calibrating the Rotator, check to see that the GS-

r

232A’s DIP switch (switch 5) is set to the “OFF” position.

From the Controller panel, set the Rotator fully counter-

r

clockwise (set to 180°).

Press [O] Ž [↵] (the letter “oh”, and “ENTER”) on the

r

computer keyboard to activate the azimuth calibration

routine. The computer display should show AZaaaa =

bbbb returned from the Interface Board, where aaaa

and bbbb are four-digit numbers padded at the left with

zeroes.

Adjust the AZ trimmer (located on the bottom case of

r

the GS-232A ) while watching the computer display, until

the four-digit numbers aaaa and bbbb are the same

(the precise values are not important).

Turn off the GS-232A’s POWER switch to exit the azi-

r

muth calibration routine, then turn on the GS-232A’s

POWER switch again.

Azimuth A-D Calibration

From the Controller panel, set the Rotator fully clock-

r

wise (to the right).

Press [F] Ž [↵] (“F” and “ENTER”) on the computer key-

r

board to activate the Control Interface’s azimuth A-D

converter calibration routine. The computer’s display

should show +aaaa, where aaaa is a four-digit number which indicates the azimuth heading in degrees.

Adjust the FULL SCALE ADJ on the GX-500 so as to

r

get a reading of “0180” on the computer’s display.

This reading (“180 degrees”) corresponds to the actual

beam heading you established when you pointed the

azimuth rotator to the South (the fully clockwise setting).

Turn off the GS-232A’s POWER switch to exit the azi-

r

muth A-D converter calibration routine, then turn on the

GS-232A’s POWER switch again to turn it back on.

CALIBRATION

9

Page 12

Azimuth Offset Null

Before calibrating the Rotator, check to see that the GS-

r

232A’s DIP switch (switch 5) is set to the “OFF” position.

From the Controller panel, set the Azimuth Rotator fully

r

counter-clockwise (set to 180°).

CALIBRATION

Press [O] Ž [↵] (the letter “oh”, and “ENTER”) on the

r

computer keyboard to activate the azimuth calibration

routine. The computer display should show AZaaaa =

bbbb returned from the Interface Board, where aaaa

and bbbb are four-digit numbers padded at the left with

zeroes.

Adjust the AZ trimmer (located on the bottom case of

r

the GS-232A ) while watching the computer display, until

the four-digit numbers aaaa and bbbb are the same

(the precise values are not important).

Turn off the GS-232A’s POWER switch to exit the azi-

r

muth calibration routine, then turn on the GS-232A’s

POWER switch again.

G-5400B/-5600B AZ-EL ROTATOR

Azimuth A-D Calibration

From the Controller panel, set the Azimuth Rotator fully

r

clockwise (to the right).

Press [F] Ž [↵] (“F” and “ENTER”) on the computer key-

r

board to activate the Control Interface’s azimuth A-D

converter calibration routine. The computer’s display

should show +aaaa, where aaaa is a four-digit number which indicates the azimuth heading in degrees.

Adjust the OUT VOL ADJ potentiometer on the “AZI-

r

MUTH” (left) side of the Controller rear panel so as to get

a reading of “0180” on the computer’s display. This

reading (“180 degrees”) corresponds to the actual beam

heading you established when you pointed the azimuth

rotator to the South.

Turn off the GS-232A’s POWER switch to exit the azi-

r

muth A-D converter calibration routine, then turn on the

GS-232A’s POWER switch again.

10

Page 13

G-5400B/-5600B AZ-EL ROTATOR

Elevation Offset Null

From the Controller panel, set the Elevation Rotator to

r

the “left” horizon (down, set to 0°).

Press [O2] Ž [↵] (the letter “oh,” “2,” and “ENTER”) on

r

the computer keyboard to activate the elevation calibration routine. The computer will return AZaaaa = bbbb,

as in the previous procedure, plus ELcccc = dddd to

the right, where cccc and dddd are four-digit numbers

padded at the left with zeroes.

Adjust the EL trimmer (located on the bottom case of

r

the GS-232A), so as to make the numbers cccc and

dddd are the same (again, the actual values are unim-

portant).

Turn off the GS-232A’s POWER switch to exit the el-

r

evation calibration routine, then turn on the GS-232A’s

POWER switch again to turn it back on.

Elevation A-D Calibration

From the Controller panel, set the Elevation Rotator to

r

full scale (180°: “right” horizon).

Press [F2] Ž [↵] (F, 2, and ENTER) on the computer key-

r

board to activate the Control Interface’s elevation A-D

converter calibration routine. The computer will display

+aaaa+eeee, where eeee is a four-digit number which

indicates the elevation heading in degrees. For the purposes of this alignment, you may ignore the (azimuth)

aaaa numbers.

Adjust the OUT VOL ADJ potentiometer on the “EL-

r

EVATION” (right) side of the Controller rear panel so as to

get a reading of “0180” on the computer’s display.

This reading (“180 degrees”) corresponds to the actual

beam heading you established when you pointed the

elevation rotator to the 180° position.

Turn off the GS-232A’s POWER switch to exit the el-

r

evation A-D converter calibration routine, then turn on

the GS-232A’s POWER switch again to turn it back on.

CALIBRATION

11

Page 14

Azimuth Offset Null

Before calibrating the Rotator, check to see that the GS-

r

232A’s DIP switch (switch 5) is set to the “ON” posi-

tion.

From the Controller panel, set the Rotator fully counter-

r

clockwise (set to 0°).

CALIBRATION

Press [O] Ž [↵] (the letter “oh”, and “ENTER”) on the

r

computer keyboard to activate the azimuth calibration

routine. The computer display should show AZaaaa =

bbbb returned from the Interface Board, where aaaa

and bbbb are four-digit numbers padded at the left with

zeroes.

Adjust the AZ trimmer (located on the bottom case of

r

the GS-232A ) while watching the computer display, until

the four-digit numbers aaaa and bbbb are the same

(the precise values are not important).

Turn off the GS-232A’s POWER switch to exit the azi-

r

muth calibration routine, then turn on the GS-232A’s

POWER switch again.

G-5500 AZ-EL ROTATOR

Azimuth A-D Calibration

From the Controller panel, set the Azimuth Rotator fully

r

clockwise (to the right).

Press [F] Ž [↵] (F and ENTER) on the computer keyboard

r

to activate the Control Interface’s azimuth A-D converter

calibration routine. The computer’s display should show

+aaaa, where aaaa is a four-digit number which indicates the azimuth heading in degrees.

Adjust the OUT VOL ADJ potentiometer on the “AZI-

r

MUTH” (left) side of the Controller rear panel so as to get

a reading of “0450” on the computer’s display. This

reading (“0450: 360 degrees + 90 degrees”) corresponds to the actual beam heading you established when

you pointed the azimuth rotator fully clockwise.

Turn off the GS-232A’s POWER switch to exit the azi-

r

muth A-D converter calibration routine, then turn on the

GS-232A’s POWER switch again.

12

Page 15

G-5500 AZ-EL ROTATOR

Elevation Offset Null

From the Controller panel, set the Elevation Rotator to

r

the “left” horizon (down, set to 0°).

Press [O2] Ž [↵] (the letter “oh,” “2,” and “ENTER”) on

r

the computer keyboard to activate the elevation calibration routine. The computer will return AZaaaa = bbbb,

as in the previous procedure, plus ELcccc = dddd to

the right, where cccc and dddd are four-digit numbers

padded at the left with zeroes.

Adjust the EL trimmer (located on the bottom case of

r

the GS-232A), so as to make the numbers cccc and

dddd are the same (again, the actual values are unim-

portant).

Turn off the GS-232A’s POWER switch to exit the el-

r

evation calibration routine, then turn on the GS-232A’s

POWER switch again to turn it back on.

Elevation A-D Calibration

From the Controller panel, set the Elevation Rotator to

r

full scal (180°: “right” horizon).

Press [F2] Ž [↵] (F, 2, and ENTER) on the computer key-

r

board to activate the Control Interface’s elevation A-D

converter calibration routine. The computer will display

+aaaa+eeee, where eeee is a four-digit number which

indicates the elevation heading in degrees. For the purposes of this alignment, you may ignore the (azimuth)

aaaa numbers.

Adjust the OUT VOL ADJ potentiometer on the “EL-

r

EVATION” (right) side of the Controller rear panel so as to

get a reading of “0180” on the computer’s display.

This reading (“180 degrees”) corresponds to the actual

beam heading you established when you pointed the

elevation rotator to the 180° position.

Turn off the GS-232A’s POWER switch to exit the el-

r

evation A-D converter calibration routine, then turn on

the GS-232A’s POWER switch again to turn it back on.

CALIBRATION

13

Page 16

Elevation Offset Null

From the Controller panel, set the Elevation Rotator to

r

the “left” horizon (down, set to 0°).

Press [O2] Ž [↵] (the letter “oh,” “2,” and “ENTER”) on

r

the computer keyboard to activate the elevation calibration routine. The computer will return AZaaaa = bbbb,

CALIBRATION

as in the previous procedure, plus ELcccc = dddd to

the right, where cccc and dddd are four-digit numbers

padded at the left with zeroes.

Adjust the EL trimmer (located on the bottom case of

r

the GS-232A), so as to make the numbers cccc and

dddd are the same (again, the actual values are unim-

portant).

Turn off the GS-232A’s POWER switch to exit the el-

r

evation calibration routine, then turn on the GS-232A’s

POWER switch again to turn it back on.

G-500 ELEVATION ROTATOR

Elevation A-D Calibration

From the Controller panel, set the Elevation Rotator to

r

full scale (180°: “right” horizon).

Press [F2] Ž [↵] (F, 2, and ENTER) on the computer key-

r

board to activate the Control Interface’s elevation A-D

converter calibration routine. The computer will display

+aaaa+eeee, where eeee is a four-digit number which

indicates the elevation heading in degrees. For the purposes of this alignment, you may ignore the (azimuth)

aaaa numbers.

Adjust the OUT VOL ADJ potentiometer on the GX-

r

500 so as to get a reading of “0180” on the computer’s

display. This reading (“180 degrees”) corresponds to

the actual beam heading you established when you

pointed the elevation rotator to the 180° position.

Turn off the GS-232A’s POWER switch to exit the el-

r

evation A-D converter calibration routine, then turn on

the GS-232A’s POWER switch again to turn it back on.

14

Page 17

GENERAL

If you wish, you can mount the GS-232A on top of your

Rotator Controller using the two supplied hook-and-loop

fastener strips. Just remove the backing from one side of

each strip, and press into place on the bottom of the GS-

232A. Then remove the backing from the other side, and

press the GS-232A into place on the Controller.

After installation and calibration, the Control Interface can

accept commands entered directly from the keyboard, or

from a program written specifically to support it (not supplied by Yaesu). For brief summaries of the commands recognized by the Control Interface, press [H] Ž [↵] for a list

of azimuth commands, or [H2] Ž [↵] for elevations commands. Keep in mind that all commands require that the

ENTER key be pressed after the command letter (or “0Dh”

be sent by a control program), although we will not repeat

this when discussing the commands. Also note that any

command letter may be sent in either upper or lower case.

The info screens shown on the next page will be returned

by the Control Interface.

Most commands have two versions: one for azimuth, and

one for elevation. Commands are not echoed by the Control

Interface, but a carriage return character (“0Dh”) is returned

after every command, and also a line feed character (“0Ah”)

if the command invoked returned data. Invalid commands

cause “? >” to be returned and the input buffer cleared.

Note that all angles are in degrees, beginning with zero at

the most counterclockwise azimuth (or horizontal elevation).

Angles sent to the Control Interface must be 3 digits long

(left-zero-padded), and angles returned will, in some cases,

be 4 digits long with a leading “+0.”

OPERATION

15

Page 18

In the following command descriptions, the elevation version of each command, where there is one, is shown in parentheses (but don’t type the parentheses). Remember that

elevation commands require the G-5400B, G-5600B or G-

5500 AZ/EL Rotators, or the GX-500 adapter and the G-

OPERATION

500 or G-550 Elevation Rotator.

0 (02

Offset calibration for internal AZ (EL) trimmer potentiometer: preset rotator manually fully counter-clockwise, send

command, and adjust trimmer on Control Interface until returned values are equal. Turn off the GS-232A’s POWER

switch to store settings.

H (H2

Returns list of commands (see page 19).

F (F2

Full Scale Calibration: preset rotator manually to full scale,

send command, adjust OUT VOL ADJ trimmer on rear of

controller (or GX-500 elevation adapter) until the returned

data is “+0180 or +0450” (“+0nnn+0180” for elevation). Turn off the GS-232A’s POWER switch to save new

settings.

)

)

)

COMMAND LIST

R (U

Start turning the rotator to the right (up)

L (D

Start turning the rotator to the left (down).

A (E

Stop azimuth (elevation) rotation.

S

Stop: cancel current command before completion.

C (B

Return current azimuth (elevation) angle in the form “+0nnn”

degrees.

C2

Return azimuth and elevation (“+0aaa+0eee”, where aaa

= azimuth, eee = elevation).

Xn

Select azimuth rotator turning speed, where n = l (slowest)

to 4 (fastest). This command can be issued during rotation,

and takes effect immediately. There is no equivalent for elevation.

)

)

)

)

16

Page 19

COMMAND LIST

Maaa

Turn to aaa degrees azimuth, where aaa is three digits between “000” and “360 or 450: vary according to con-

troller type.” Rotation starts.

Msss aaa bbb ccc

This command, together with the [T] command, provides

automatic, timed tracking of moving objects or propagation

by the Control Interface itself. This command stores the

time value sss seconds to wait between stepping from azimuth aaa to bbb, and then to ccc, etc. (from “2” to as many

as “3800” angles may be stored with one command).

Note that this command is completely different than the [T

command with only one parameter: when multiple parameters

are present, the first one is interpreted by the Control Interface

as the rotation interval sss, not an angle. Valid ranges are

“001” to “999” for sss, and “000” to “360 or 450: vary

according to controller type” for the angles. When this command is sent, the parameters are stored in the Control Interface’s

RAM, and the rotator turns to angle aaa and waits for a subsequent [T] command to begin the actual stepping. All numbers

must be 3 digits, space-separated. Stored values remain in

effect until another [M] command is issued (this may have no

parameters, in which case the “? >” error prompt is returned,

but memories are still cleared), or until the controller is turned

off or by toggling the GS-232A off and on.

T

See the [M] (above) and the [W] (below) command. Start

automatic stepping routine (both azimuth and eievation):

turn rotator to next sequentially memorized azimuth (or az-el

pair, for the [W] command), wait sss seconds, and turn to

next angle (or pair), etc. This command works only if a longform [M] or [W] has been issued since power-up or the last

reset.

N

Return serial number of currently selected memorized point

[nnnn], and total number of memorized points [mmmm],

in the form +nnnn+mmmm. Must be proceeded by either

]

a long-form [M] or [W], and a T command. Used only during stepping (see [T] command).

The meaning of a “point” in this command following an [M

command is only an azimuth angle, so in this case nnnn

and mmmm can range up to “3800” (the limit of available RAM in the Control Interface). However, when elevation is involved, a “point” following a [W] command is represented by both an azimuth and an elevation angle, in which

case nnnn and mmmm can range up to only “1900,” since

each “point” is a pair of angles.

OPERATION

]

17

Page 20

Elevation Control Commands

These commands are only for az-el operation. Note that an

azimuth angle must always be supplied when changing elevation, and that a setting point consists of a pair of angles.

OPERATION

Waaa eee

Turn to aaa degrees azimuth and eee degrees elevation,

where aaa is three digits between “000” and “360 or

450: vary according to controller type,” and eee is three

digits between “000” and “180.” Rotators respond im-

mediately.

Wsss aaa eee aaa sss ...

This command is similar to the [M] command: the first parameter is a time interval, and succeeding parameters are

angles. With this command, however, angles are in azimuthelevation pairs, each pair representing one antenna location. At most “1900” pairs can be sent and stored in the

Control Interface. As with the other commands, the time

interval range is limited to “001” to “999” (seconds),

azimuth to “000” to “360 or 450: vary according to

controller type,” and elevation to “000” to “180.”

COMMAND LIST

When this command is sent, the rotators turn to the first

aaa azimuth parameter and the first eee elevation parameter, and wait for a subsequent [T] command to begin the

actual stepping (to the next azimuth-elevation pair). Stored

values remain in effect until another [W] command is issued (this may have no parameters, in which case the “? >”

error prompt is returned, but memories are still cleared), or

until the controller is turned off or by toggling the GS-

232A off and on.

18

Page 21

COMMAND LIST

Returned by [H] Command:

----------

COMMAND LIST 1

R Clockwise Rotation

L Counter Clockwise Rotation

A CW/CCW Rotation Stop

C Antenna Direction Value

M Antenna Direction Setting. MXXX

M Time Interval Direction Setting.

MTTT XXX XXX XXX --(TTT = Step value)

(XXX = Horizontal Angle)

T Start Command in the time interval direction setting

mode.

N Total number of setting angles in “M” mode and traced

number of all datas (setting angles)

X1 Rotation Speed 1 (Horizontal) Low

X2 Rotation Speed 2 (Horizontal) Middle 1

X3 Rotation Speed 3 (Horizontal) Middle 2

X4 Rotation Speed 4 (Horizontal) High

S All Stop

O Offset Calibration

F Full Scale Calibration

----------

Returned by [H2] Command:

----------

HELP COMMAND 2

U UP Direction Rotation

D DOWN Direction Rotation

E UP/DOWN Direction Rotation Stop

C2 Antenna Direction Value

W Antenna Direction Setting.

WXXX YYY

W Time Interval Direction Setting.

WTTT XXX YYY XXX YYY --(TTT = Step value)

(XXX = Horizontal Angle)

(YYY = Elevation Angle)

T Start Command in the time interval direction setting

mode.

N Total number of setting angle in “W” mode and traced

number of all datas (setting angles)

S All Stop

02 Offset Calibration

F2 Full Scale Calibration

B Elevation Antenna Direction Value

----------

OPERATION

19

Page 22

NOTE

20

Page 23

Page 24

Copyright 2000

Yaesu Musen Co., Ltd.

All rights reserved.

E A A 1 4 X 1 0 0

No portion of this manual

may be reproduced

without the permission of

Yaesu Musen Co., Ltd.

Printed in Japan

Loading...

Loading...