Page 1

Manual

MJK Data Transmitter 795

Valid from software version 830434

COMLI PROTOCOL

MJK Automation A/S

Byageren 7

DK-2850 Nærum

Denmark

Tel: +45 45 56 06 56

Fax: +45 45 56 06 46

www.mjk.com

Station ID:

795 Type:

795 Serial no:

M795GB0503

As our products are developed continuously,

we reserve the right to make any changes without prior notice.

Page 2

Data Transmitter 795

Konformitetserklæring

Vi, MJK Automation A/S,

DK-2850 Nærum, påtager os

det fulde ansvar for at produktet

som denne erklæring angår, er i

overensstemmelse med følgende

standard(er) eller andre

normdokument(er).

EN 50081-1:1995

EN 50082-1:1995

efter bestemmelserne i

direktiv

89/336/EØF; 93/68/EØF

Declaration of Conformity

We, MJK Automation A/S,

DK-2850 Nærum, declare under

our sole responsibility that the

product

MJK Data Transmitter 795

to which this declaration relates

is in conformity with the following

standard(s) or other normative

document(s).

EN 50081-1:1995

EN 50082-1:1995

following the provisions of

Directive

89/336/EWG; 93/68/EWG

Konformitätserklärung

Wir, MJK Automation A/S,

DK-2850 Nærum, erklären in

alleiniger Verantwortung, dass

das Produkt

auf das sich diese Erklärung

bezieht mit der/den folgenden

Nor me(en) oder normativen

Dokument(en) übereinstimmt.

EN 50081-1:1995

EN 50082-1:1995

Gemäss den Bestimmungen der

Richtlinie

89/336/EWG; 93/68/EWG

Declaration de conformite

Nous, MJK Automation A/S,

DK-2850 Nærum, déclarons

sous notre seule responsabilité

que le produit

auquel se réfère cette

déclaration est conforme á la

(aux) norme(s) ou autre(s)

document(s) normatif(s)

EN 50081-1:1995

EN 50082-1:1995

conformément aux dispositions

de Directive

89/336/EWG; 93/68/EWG

Dichiarazione di conformità

Noi, MJK Automation A/S,

DK-2850 Nærum, dichiariamo

sotto la nostra esclusiva

responsabilità che

l’apparecchio

MJK Data Transmitter 795

al quale questa dichiarazione

si riferisce, è conforme alla

seguente normativa(e) standard o ad altri documenti di

normativa(e)

EN 50081-1:1995

EN 50082-1:1995

conformemente alla

disposizioni della Direzione

89/336/EWG; 93/68/EWG

Declaración de Conformidad

Nosotros, MJK Automation A/S,

DK-2850 Nærum, declaramos

bajo nuestra única

responsabilidad que el producto

al cual se refiere esta

declaración, está en

conformidad con la(s)

siguente(e) norma(s) u otros

documentos normativos

EN 50081-1:1995

EN 50082-1:1995

según las disposiciones de la(s)

directiva(s)

89/336/EWG; 93/68/EWG

M795GB0503

2

SW ver. 830434

Page 3

Data Transmitter 795

Contents

1 Introduction .......................................... 5

1.1 Versions........................................................5

1.2 Communications protocols ........................... 5

1.3 MJK-Link™ .................................................. 6

1.4 About this manual ........................................ 6

1.5 Safety instructions ........................................6

1.6 Product identification .................................... 6

1.6.1 Standard versions 7

1.6.2 Versions with built-in options 7

2 Mechanical mounting ..........................8

2.1 Mounting on a wall ....................................... 8

3 Electrical mounting .............................. 9

3.1 Power supply................................................ 9

3.2 In- and output signals 9

3.2.1 I/O terminals, 8 DI/8 DO/4 AI 9

3.2.2 I/O terminals, 12 DI/4 DO/4 AI 10

3.2.3 I/O terminals, 16 DI/4 AI 10

3.3 Connection examples ................................. 11

3.3.1 Digital inputs 11

3.3.2 Digital outputs 11

3.3.3 Analogue inputs 11

3.3 Connection of Pump Controller 704 ...........12

3.4 Connection of communications ports ......... 12

3.4.1 Communications port 12

3.4.2 Built-in modem 12

4 The front panel ................................... 13

4.1 Display and keys 13

4.2 Menu structure ...........................................13

5 Functional menus ............................... 14

5.1.1 F0 - Program version, time and date 14

5.1.2 F0 - Interlock, operation or alarm signal 14

5.1.3 F0 - Internal flag, operation

or alarm signal 14

5.1.4 F0 - Limits, high/low 14

5.1.5 F0 - Digital inputs,

operation or alarm signal 14

5.2 F1 - Digital inputs on/off ............................. 14

5.3.1 F2 - Digital outputs on/off 14

5.3.2 F2 - Internal flag on/off 14

5.4 F3 - Limits - High/Low ................................ 15

5.5 F4 - Analogue input value # ........................ 15

5.5.1 F5 - Analogue input scaling 15

5.5.2 F5 - Analogue input on

Pump Controller 704 15

5.6 F6 - Counter for inputs ...............................15

5.7 F7 - Counter for time ..................................15

5.8 F8 - Alarm / Alarm number ........................16

5.9.1 F9.1 - Stormflow volume 16

5.9.2 F9.2 - Stormflow calculation 16

5.10 F# - Modem/Line status .............................16

5.11 F* - Communication status ......................... 16

6 Programming of main functions........ 17

6.1 Select language ..........................................17

6.2 Set time and date ....................................... 17

6.3 Automatic change between

summer time and winter time .....................17

6.4 Access code enabled/disabled ................... 17

6.4.1 Enter password 17

6.5 Calculation of average values on

analogue inputs .......................................... 17

6.6 Data logging interval ...................................17

6.7 Tone / pulse dialing ..................................... 17

6.8 Alarm call on power failure.......................... 17

6.9 Number of incoming rings before answer ... 18

6.10 ID. no. for the Data Transmitter ................... 18

6.11 Automatic reset of alarms ...........................18

6.11.1 Call on automatic alarm reset 18

6.12 Start time for operational reports ................18

6.13 795 telephone number ...............................18

6.14 SMSC telephone number ...........................18

6.15 RS485 function........................................... 18

6.15.1 Master ID number 18

7 Programming of analogue inputs ..... 19

7.1 Select analogue input ................................. 19

7.2 0 - 20 or 4 - 20 mA input ............................ 19

7.3 Scaling at 0 / 4 mA ..................................... 19

7.4 Scaling at 20 mA ........................................19

7.5 Monitoring of high limit ............................... 19

7.5.1 Set high limit 19

7.5.2 High limit operation / alarm 19

7.5.3 Dialout on high limit 19

7.5.4 Signal delay for exceeding high limit 19

7.6 Monitoring of low limit ................................. 19

7.6.1 Set low limit 20

7.6.2 Low limit operation / alarm 20

7.6.3 Dialout on high limit 20

7.6.4 Signal delay for exceeding low limit 20

7.7 Divisor ........................................................20

8 Programming of digital inputs ........... 20

8.1 Select a digital input ................................... 20

8.2 NO or NC ................................................... 20

8.3 Operational or alarm input ..........................20

8.3.1 Dialout on alarm 20

8.4 Signal delay ................................................20

9 Programming of digital outputs ........21

9.1 Select a digital output ................................. 21

9.2 NO or NC ................................................... 21

9.3 Time controlled output................................ 21

9.4 ON time ...................................................... 21

9.4.1 Time before start 21

M795GB0503

3

SW ver. 830434

Page 4

Data Transmitter 795

10 Programming of logical functions ..... 21

10.1 Select the output to receive the result

of the logical function.................................. 21

10.2 Select logical function .................................21

10.2.1 Select signals for the logical function 21

10.2.2 Operational or alarm signal on

internal flag 22

10.2.3 Dialout when alarm signal on

internal flag 22

10.2.4 Signal delay on internal flag 22

11 Programming of interlock .................. 22

11.1 Interlock of this station ................................ 22

11.2 Interlock interval.......................................... 22

11.3 Selection of substation ...............................22

11.4 Interlock active / inactive ............................ 23

11.4.1 Start of interlock 23

11.4.2 Stop interlock 23

11.4.3 Receivers telephone / ID number 23

11.4.4 Receiver's output 24

12 Programming of Pump Controller(s) . 25

12.1 704 connected ...........................................25

12.2 Call on alarm or system error on 704 .......... 25

12.2 Programming of the

internal Pump Controller .............................25

12.2.1 Select level signal 25

12.2.2 Start level for pump no. 1 25

12.2.2 Stop level for pump no. 1 25

12.2.3 Levels in use in 795 25

12.2.4 Start level for pump no. 2 25

12.3.2 Stop level for pump no. 2 25

12.3.3 Alternation of pumps 25

13 Telephone list for alarms ................... 26

13.1 Telephone number 1-9 ............................... 26

13.2 Number type .............................................. 26

13.2.1 Telephone number 26

13.2.2 Enter pager message 26

13.2.3 Enter SMS message 27

13.2.4 Pause between calls 27

15 Programming of 702 ComTroller ....... 29

15.1 Select 702 ..................................................29

16 Alarms ................................................. 30

16.1 Operational or alarm signal ......................... 30

16.2 Alarm calls .................................................. 30

16.3 Reset of alarms .......................................... 30

15.3.1 Automatic reset of alarms 30

17 Factory settings ................................. 31

18 Signal lists .......................................... 33

19 Register list ......................................... 37

20 Menu structure ................................... 44

20.1 Functional menus .......................................44

20.2 Programming menus ..................................45

A Appendix............................................. 50

A1 Technical specifications .............................. 50

A2 Number of signals available ........................50

A3 Inputs and outputs ..................................... 50

A4 Dimensions ................................................. 50

B Appendix............................................. 51

B1 Maintenance ............................................... 51

B2 Service codes ............................................. 51

B2.2 Forced setup

without reset of datalogger 51

B2.3 Forced setup

including reset of datalogger 51

B2.4 Baud rate and communication method 51

B2.5 Activation of SIM card for GSM/GPRS

modem 51

B2.6 Total reset 51

B3 Software upgrade .......................................51

B4 SMSC telephone numbers .........................52

B5 Spare parts................................................. 52

14 Programming of stormflow calculation .. 27

14.1 Stormflow calculation .................................27

14.2 Stormflow calculation in use ....................... 28

14.2.1 Zero point input no. 28

14.2.2 Level signal for flow calculation 28

14.2.3 Number of Q(h) points 28

14.2.4 Height value [h] for level point 28

14.2.5 Flow value [Q] for level point 28

M795GB0503

4

SW ver. 830434

Page 5

Data Transmitter 795

1 Introduction

Thank you for choosing an MJK Data Transmitter

795. A great effort has been put into developing a

product, which complies with all demands.

MJK Data Transmitter 795 is mounted in the field

and with its digital in- and output and analogue

input it is capable to receive and transmit most

types of digital and analogue signals. From a

built-in RS232 serial port, the MJK Data Transmitter 795 can communicate directly with other

equipment i.e. a pc, PLC or a Scada system.

MJK Data Transmitter 795 can with one click on

the mouse or from a telephone call activate digital

output and/or read in- and outputs, alarm signal

type for the latest 9 alarms and all logged data.

All settings, alarms and logged data can be read

in the display, from easy to use functionnal

menus.

MJK Data Transmitter 795 can be supplied in

versions that communicates via a built-in GSM

modem or telephone modem, or in versions for

radio modem.

MJK Data Transmitter 795 is easy to install and

operate, but read the instruction manual carefully

in order to make optimum use of the unit.

You can allways contact your sales reprsentative

or the MJK Automation Hotline in case of doubt

or for guidance. Try also to log onto http://

www.mjk.com.

1.1 Versions

MJK Data Transmitter 795 is as standard

supplied in the following hardware versions:

- 8, 12 or 16 digital inputs

- 0,4 or 8 digital outputs

- 4 analogue inputs

- 1 or 2 RS232 ports

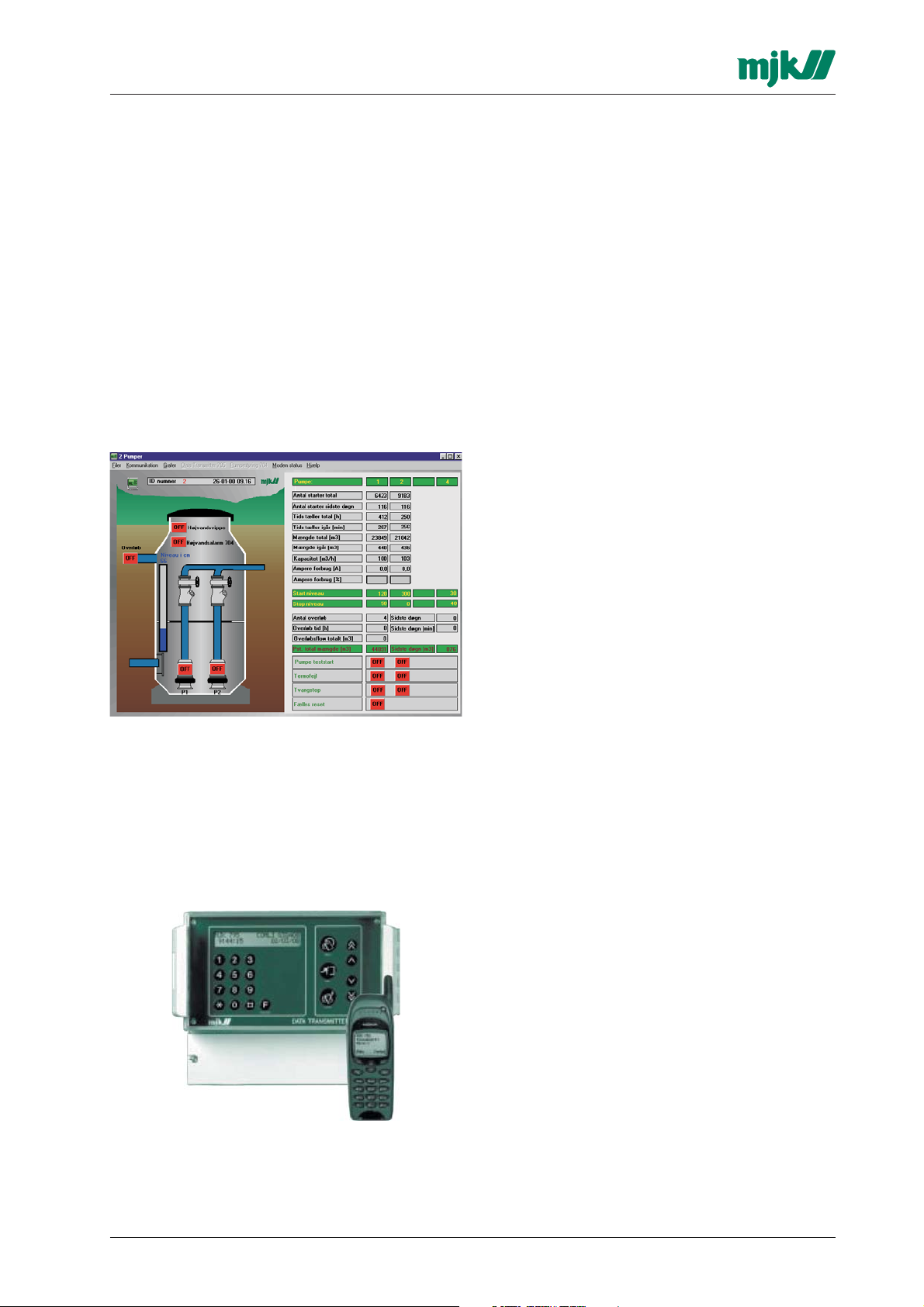

Display of a pumping station from a pc with the

monitoring program MJK-Link™.

MJK Data Transmitter 795 can also be programmed to make a telephone call when there is an

alarm and transmit the alarm as text to a pc or

SCADA system and to a cell phone as SMS text.

The Data Transmitter 795 has a bult in battery for

telephone calls at power failure.

The RS 232 ports is used as connection to MJK

Pump Controller 704 and to connection of a PC

for configuration or reading of data in the field for

i.e. a portable PC or for configuration or reading

of data, when the Data Transmitter 795 is used

as data

logger.

1.2 Communications protocols

MJK Data Transmitter 795 can be connected to a

distribution station either through a serial

connection (RS232-RS 485), a built-in Hayes

compatible telephone modem, a data radio or a

GSM modem.

Communication complies with one protocol

which must be followed by master and slave.

Data Transmitter 795 is always the slave, i.e. the

Data Transmitter must receive a command before

it can reply. MJK Data Transmitter 795 is supplied

with Comli PLC-protocol as standard. The

following historical data are available in this

protocol:

- Time counter on digital inputs, total, total

today, total yesterday and the latest 24 hours,

all with 1 hour interval.

An MJK Data Transmitter 795 with built-in modem

can transmit alarms as SMS messages directly to

the cell phone of employee on duty.

M795GB0503

- Analogue values stored with 5 min. interval 24

hours back, and in the extended log with a

user defined logging interval.

5

SW ver. 830434

Page 6

1.3 MJK-Link™

The Windows based program MJK-Link™ can be

applied to monitor one or several MJK Data

Transmitter 795. Via a PC with modem it is

possible with MJK-Link™ to read values, modify

setpoints and read datalogger for e.g. storm flow

values. All settings in Data Transmitter 795 can

be implemented via MJK-Link™.

Furthermore, MJK Link™ can be used to control

the MJK Pump Comtroller 704. This facitily is

used when e.g. MJK Data Transmitter 795 and

MJK Pump Controller 704 is used together.

This manual covers MJK Data Transmitter 795 in

Comli versions for communication via telephone

modem, GSM modem or closed radio networks.

1.4 About this manual

The manual is divided into 4 main sections:

1: Introduction

Presentation of Data Transmitter 795 and this

manual.

Data Transmitter 795

Explosion hazardous areas

MJK Data Transmitter 795 is not approved for

use in explosion hazardous areas.

All current local and national standards and

regulations regarding installation and use of Ex

approved material, certifications and safety

instructions for Ex equipment that have been

used in connection with installation of Data Transmitter 795 must be strictly observed.

1.6 Product identification

Check that the item(s) delivered corresponds to

the ordered item(s). The item number is printed

on a label that is sticked onto the packing.

2: Mounting

Information for performing mechanical and

electrical mounting.

3: Basic settings

A look through the most common settings.

4: Field operation

A look through all settings for special

applications of Data Transmitter 795.

1.5 Safety instructions

1: Read this manual carefully.

2: Be aware of the environment on the installa-

tion site. Wear necessary protective

equipment and follow all current safety

regulations.

3: MJK Data Transmitter 795 can give out start

signals to dangerous machinery. Therefore, it

must be ensured that eventually connected

machinery and other equipment are

effectively being put out of service by i.e.

removal of main fuses, lock main- and/or

security switches in off position before

commencing setting, fault finding, service and

maintenance work etc.

➀➀

➀

➀➀

➁➁

➁

➁➁

➂➂

➂

➂➂

➃➃

➃

➃➃

➀➀

➀ Item number

➀➀

➁➁

➁ Item description

➁➁

➂➂

➂ Serial number

➂➂

➃➃

➃ Communications program

➃➃

An identical marking can be found on the right

hand side of the cabinet:

4: There is a risk of lethal electrical shock from

some of the terminals on Data Transmitter

795. Be careful not touch these while the unit

is in operation.

Repair

1: Repair must only be made by MJK or a

representative approved by MJK.

M795GB0503

6

SW ver. 830434

Page 7

Data Transmitter 795

1.6.1 Standard versions

This manual covers the following standard versions with Comli protocol:

Item no.: In- and outputs: Communication:

204510

204511

204512

204520

204521

204522

MJK Data Transmitter 795 with 2 X RS232 and

4 AI / 8 DI / 8 DO

4 AI / 12 DI / 4 DO

4 AI / 16 DI / 0 DO

4 AI / 8 DI / 8 DO

4 AI / 12 DI / 4 DO

4 AI / 16 DI / 0 DO

built-in telephone modem.

(Item no. 204510/204511/204512)

2 × RS232 w. modem

2 × RS232 w. modem

2 × RS232 w. modem

1 × RS232 wo. modem

1 × RS232 wo. modem

1 × RS232 wo. modem

1.6.2 Versions with built-in options

The following type options can be built into Data

Transmitter 795:

Varenr.: Betegnelse:

204570 Galvanically insulated RS232 port

204571 Galvanically insulated RS485 port

204572 Galvanically insulated port for TP 6000

204573 Galvanically insulated port for Niros UHF

204574

205105 GSM modem complete w. aerial

205106 GPRS modem complete w. aerial

Galvanically insulated port for external modem

The factory mounted options can be determined

read on the terminal box lid:

MJK Data Transmitter 795 delivered from factory

with galvanically insulated communications port.

MJK Data Transmitter 795 with 1 X RS232 and 1 x

communications option port.

(Item no. 204520/204521/204522)

MJK Data Transmitter 795 delivered from factory

with built-in GSM-modem.

For both types of option applies that the data

transmitter is mounted and connected like a standard data transmitter.

Please see separate documentation for the builtin options.

M795GB0503

7

SW ver. 830434

Page 8

2 Mechanical mounting

Data Transmitter 795

explosion hazardous areas!

Data Transmitter 795 is IP65 enclosed, and can

be mounted outdoors directly on a wall or a

railing, eventually by means of MJK rain roof

200115 and MJK universal fitting 200205.

must not be mounted in

Data Transmitter 795

Dimensional drawing for mounting screws.

See also page 51.

MJK rain roof 200115 mounted on pole with MJK

universal bracket 200205.

Data Transmitter 795 can also be mounted in a

panel by means of MJK panel mounting kit

200105.

Data Transmitter 795 mounted in a panel with MJK

panel mounting kit 200105.

2.1 Mounting on a wall

The cabinet is mounted using three screws. The

upper screw is used for the suspension and the

two lower screws is used to fix the cabinet.

Remove the terminal box lid to gain access to the

two lower mounting holes.

The cabinet is suspended by the upper screw and.

fastened with the two lower screws.

The distance between the mounting screws is

shown on the dimensional drawing.

Please observe minimum distance if more than

one cabinet is mounted.

You will find a jig in full size at the back of this

manual.

MJK Data Transmitter 795 must be mou

ted vertically in order to comply with the IP68

standard.

M795GB0503

X

Do not use a screw machine!

8

SW ver. 830434

Page 9

Data Transmitter 795

3 Electrical mounting

Data Transmitter 795

explosion hazardous areas!

Data Transmitter 795 must not be connected to

the power supply before all connections are

Remove the terminal lid and the front panel to

gain acces to all terminals.

3.1 Power supply

Data Transmitter 795 can be supplied from both

230 V AC and 24 V DC.

must not be mounted in

made.

Terminal: Designation:

Protective ground

N 230 V AC neutral

L 230 V AC live

- 24 V DC negative

+ 24 V DC positive

Please note, that 24 V DC will not be available on

the terminals marked '24 V DC forsyning' unless

the Data Transmitter is fed from the mains.

3.2 In- and output signals

Data Transmitter 795 is delivered in 3 different I/O

variants; 4AI / 8DI / 8DO, 4AI / 12DI / 4DO and

4AI / 16DI respectively.

Specifications:

DI: Passive with common negative, max. 24 V DC.

(Optocoupler med 10 kΩ serial resistor)

Trig voltage: < 1 V DC = Off, > 10 V DC = On,

pulse length > 100 ms.

DO: Voltage free relay contacts,

max. 1 A @ 24 V DC / 0,5 A @ 48 V AC.

AI: 0/4 - 20 mA or 0 - 1 V DC.

Input impedance = 50 Ω.

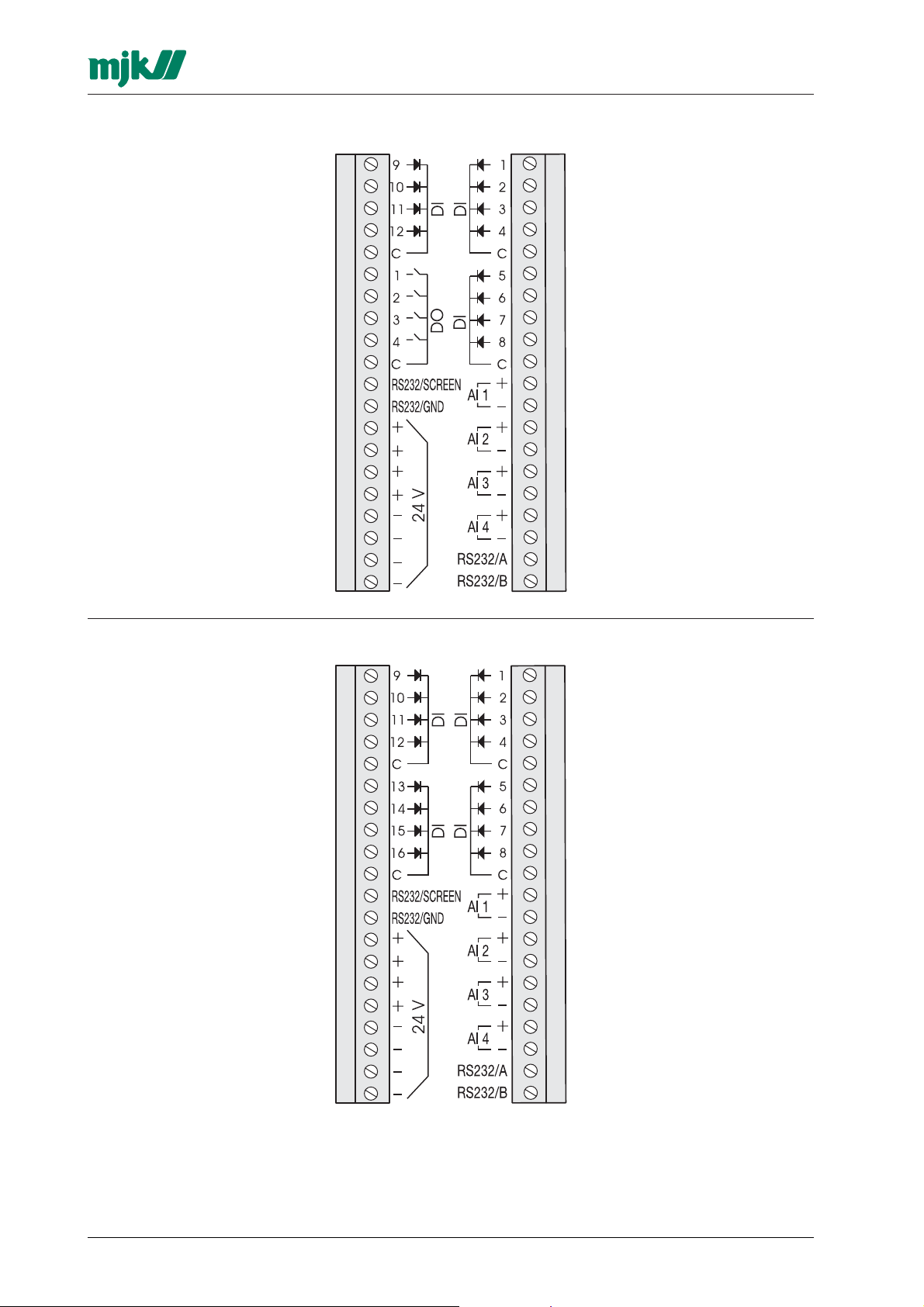

3.2.1 I/O terminals, 8 DI/8 DO/4 AI

DO 1

DO 2

DO 3

DO 4

DO 1/2/3/4 common -

DO 5

DO 6

DO 7

DO 8

DO 5/6/7/8 common -

Shield for RS232 to 704

Signal ground for RS232 to 704

24 V DC out +

24 V DC out -

DI 1 +

DI 2 +

DI 3 +

DI 4 +

DI 1/2/3/4 common DI 5 +

DI 6 +

DI 7 +

DI 8 +

DI 5/6/7/8 common AI 1 +

AI 1 AI 2 +

AI 2 AI 3 +

AI 3 AI 4 +

AI 4 Rx for RS232 to 704

Tx for RS232 to 704

M795GB0503

9

SW ver. 830434

Page 10

3.2.2 I/O terminals, 12 DI/4 DO/4 AI

Data Transmitter 795

DI 9 +

DI 10 +

DI 11 +

DI 12 +

DI 9/10/11/12 common -

DO 1

DO 2

DO 3

DO 4

DO 1/2/3/4 common -

Screen for RS232 to 704

Signal ground for RS232 to 704

24 V DC out +

24 V DC out -

DI 1 +

DI 2 +

DI 3 +

DI 4 +

DI 1/2/3/4 common DI 5 +

DI 6 +

DI 7 +

DI 8 +

DI 5/6/7/8 common AI 1 +

AI 1 AI 2 +

AI 2 AI 3 +

AI 3 AI 4 +

AI 4 Rx for RS232 to 704

Tx for RS232 to 704

3.2.3 I/O terminals, 16 DI/4 AI

DI 9 +

DI 10 +

DI 11 +

DI 12 +

DI 9/10/11/12 common -

DI 13 +

DI 14 +

DI 15 +

DI 16 +

DI 13/14/15/16 common -

Screen for RS232 to 704

Signal ground for RS232 to 704

24 V DC out +

24 V DC out -

DI 1 +

DI 2 +

DI 3 +

DI 4 +

DI 1/2/3/4 common DI 5 +

DI 6 +

DI 7 +

DI 8 +

DI 5/6/7/8 common AI 1 +

AI 1 AI 2 +

AI 2 AI 3 +

AI 3 AI 4 +

AI 4 Rx for RS232 to 704

Tx for RS232 to 704

M795GB0503

10

SW ver. 830434

Page 11

Data Transmitter 795

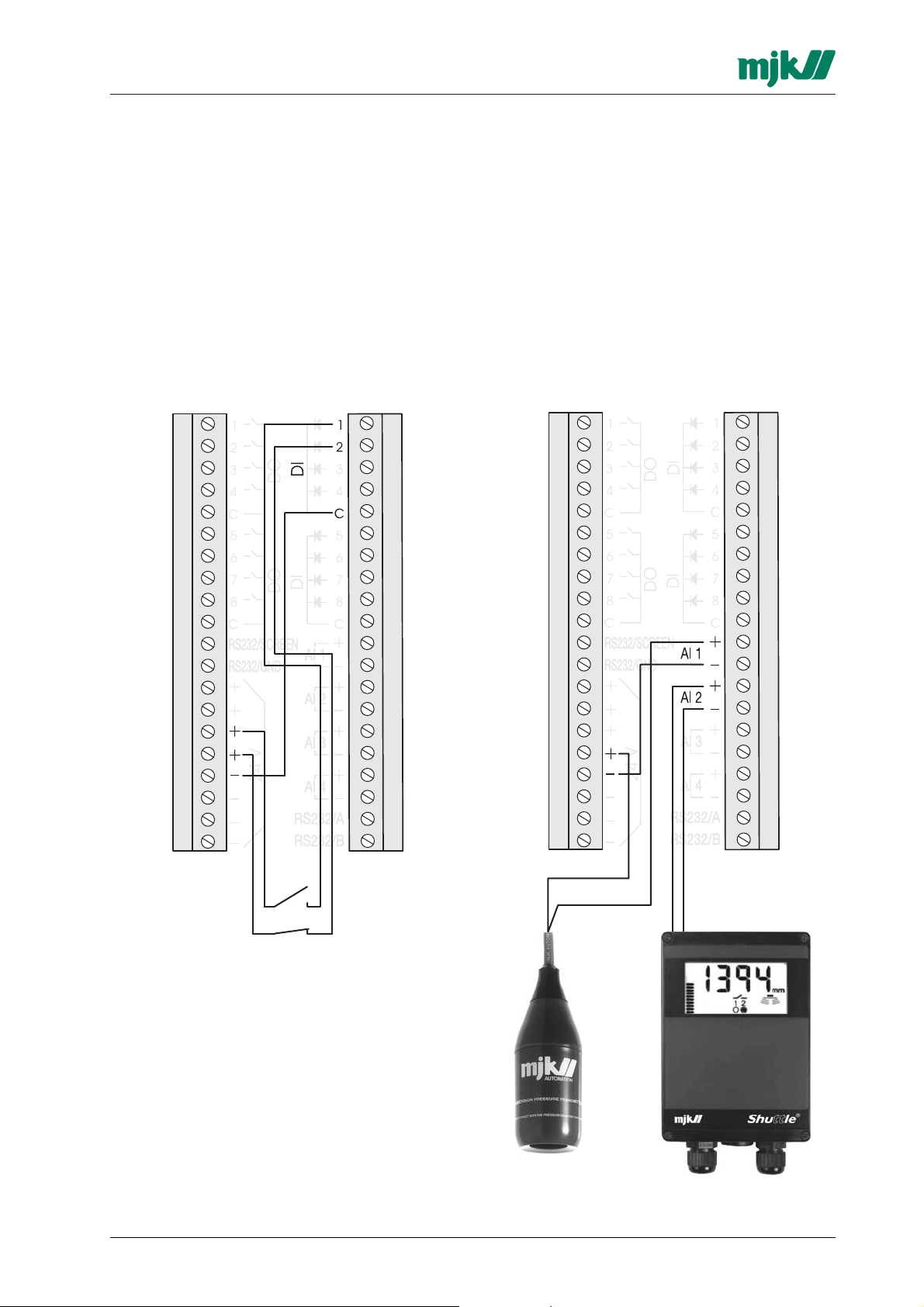

3.3 Connection examples

3.3.1 Digital inputs

The digital inputs are passive, i.e. they need to be

supplied from an external power source or from

the terminals marked '24 V'.

Note, that the inputs has common negative in

groups of 4 inputs.

A common installation error is that an input is

not connected to the correct negative terminal!

The inputs can be individually configured to be

normally open (NO) or normally closed (NC).

3.3.3 Analogue inputs

The analog inputs are passive. i.e. they must be

supplied from an external power source or from

the terminals marked '24 V'.

Every input have its own plus and negative terminal.

A common installation fault is that an input is

not connected to the correct negative terminal!

The input range can be individually configured to

0-20 mA or 4-20 mA.

Above diagram show an example of connecting two

switches to DI1 and DI2. Note the common

negative terminal!

3.3.2 Digital outputs

The digital outputs are voltage-free relay contacts

with a capacity of max. 24 V DC / 1 A or max. 48

V AC / 0,5 A resistive load.

The outputs can be individually configured to be

normally open (NO) or normally closed (NC).

M795GB0503

A passive mA signal

from a pressure

transmitter.

11

An active mA signal from

a level transmitter.

SW ver. 830434

Page 12

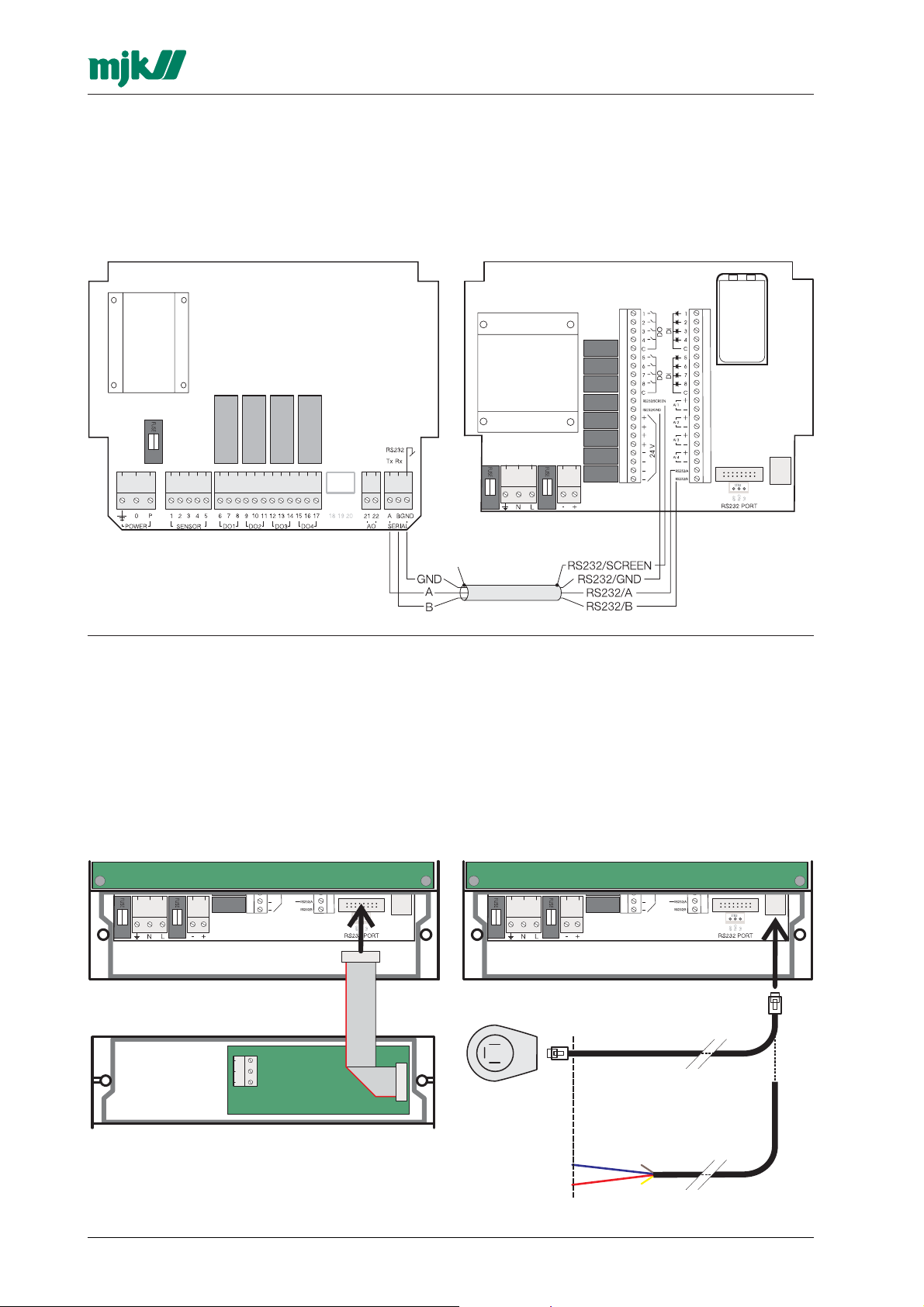

3.3 Connection of Pump Controller 704

Only the RS232 port on the plug-in terminals of

the Data Transmitter can be used for connecting

a MJK Pump Controller 704. A screened, twisted

pair cable must be used, and it should be

connected as shown below:

Data Transmitter 795

The shield must not be connected to the Pump

Controller 704.

Max. cable length is 15 metres.

DO NOT CONNECT

3.4 Connection of communications ports

(Only item no. 204520 / 21 / 22.)

3.4.1 Communications port

All options listed in section 1.6.2 is supplied with

a flat cable, that just need to be mounted in the

communications port socket on the lower PCB.

See also separate documentation for the option

in question.

THE SHIELD IN

THIS END!

3.4.2 Built-in modem

The built-in modem can be connected to a

telephone outlet with the enclosed RJ11 cable. If

the modem should be connected to a terminal,

the cable should be stripped and only the red og

blue wire need to be connected. The two other

wires are not used.

M795GB0503

12

SW ver. 830434

Page 13

Data Transmitter 795

4 The front panel

Display

2 x 24 digit backlit

alphanumerical display

for indication of user

menus and measuring

values.

4.1 Display and keys

Numerical keys

The keys 0-9, #,

used to enter

are

*

telephone numbers,

delays, analogue

scaling etc.

ESC. key

This key is used to go

back to the previous

menu, or to cancel a

selection. Press this

key 2 or 3 times to

revert to functional

indication.

Functional key F

The function key are

used for selecting the

different functional

menus to be displayed.

The illustration show

the function menu F0

for program version,

time and date.

MENU key

This key is used to

switch between main

menus and submenus.

ENTER key

The ENTER kry is used

to change between the

main menu and

submenus and to go

through the submenus.

The ENTER kay is

always used to confirm

a selection in a

submenu.

Arrow keys

The arrow keys are

sed for altering the

current setting. In a

sub-menu the current

selection is always

shown in the upper

line, and the alternative

selection is shown in

brackets in the lower

line. The arrow keys

are used to select an

alternative setting. The

arrow keys are also

used to select input

and output number.

The ↑ key increase

and the ↓ key

decrease a value.

4.2 Menu structure

Above figure is an overview of the general function of the functional keys.

INDICATION

MENUS

MAIN

MENU

SUBMENU W.

SELECTION

SUBMENU W.

SELECTION

See also page 42.

MAIN

MENU

M795GB0503

13

SW ver. 830434

Page 14

5 Functional menus

Data Transmitter 795

5.1.1 F0 - Program version, time and date

Menu F0 displays date og and time. Moreover, it

will display the current communications protocol

and program version.

5.1.2 F0 - Interlock, operation or alarm signal

Menu F0 followed by 1 x 'down arrow' will display

which signals that initiate the 9 programmable interlock sequences:

'A': alarm signal, '+': operation signal,

'-': not in use.

5.1.3 F0 - Internal flag, operation or alarm signal

Menu F0 followed by 2 x 'down arrow' will display

which signals that are linked to the internal flags:

5.2 F1 - Digital inputs on/off

Menu F1 indicates if the digital inputs are set ON

or OFF. Up to 8 inputs are shown simultaneously.

If there are more than 8 inputs, the remaining

inputs will be displayed by pressing one of the

arrow keys:

Note, that a delay period can be set for every digital input so that the digital input can go ON for a

short period without triggering an eventual alarm.

When the input is OFF, an empty field is

shown. When the input goes ON, a flashing field

is shown during the delay time, after which a field

is shown constantly.

5.3.1 F2 - Digital outputs on/off

Menu F2 displays whether the digital outputs are

set ON or OFF:

'A': alarm signal, '+': operation signal, '-':

not in use.

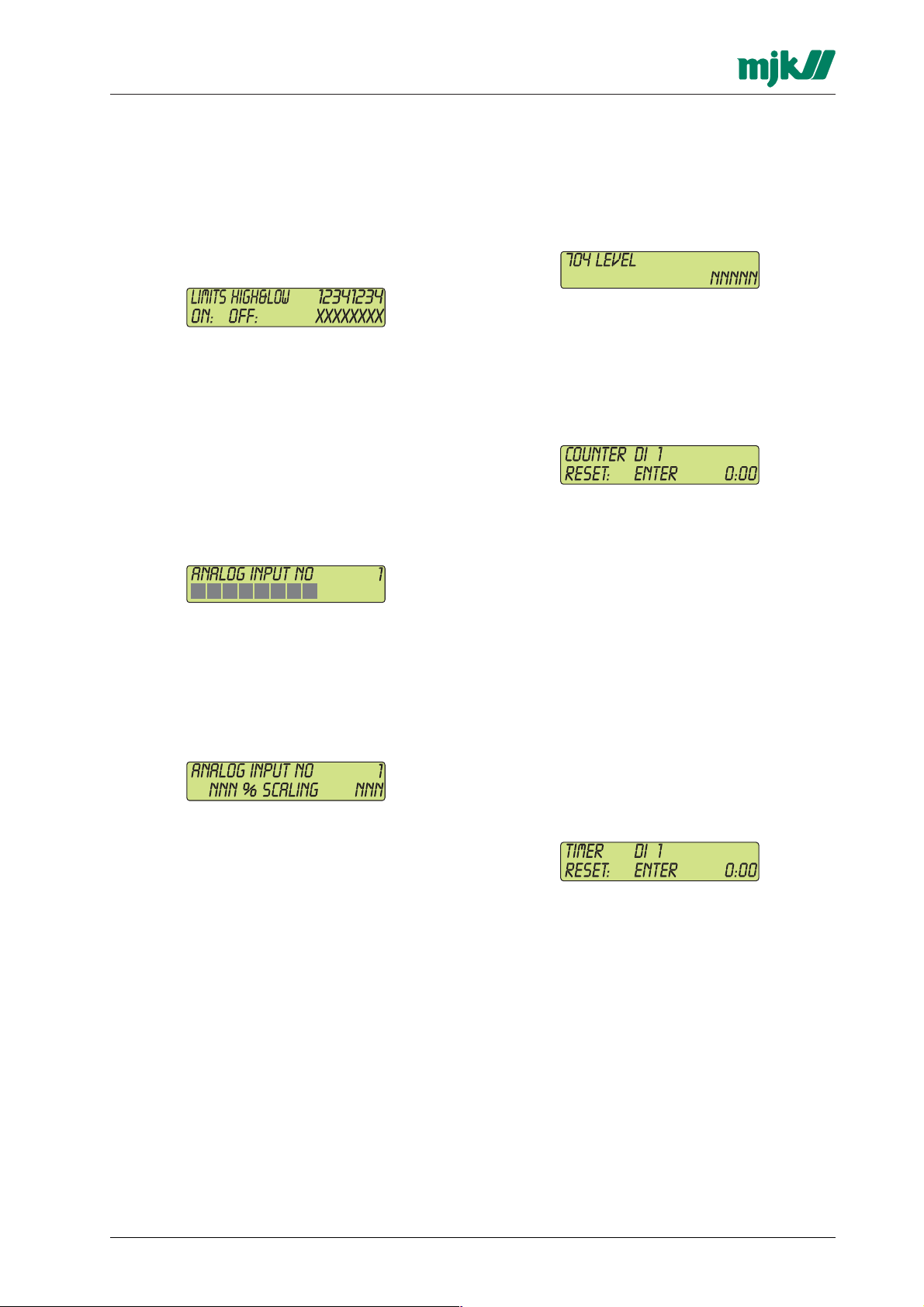

5.1.4 F0 - Limits, high/low

Menu F0 followed by 2 x 'down arrow' will

indicate which analogue inputs that are linked to

a high/low alarm limit, and also if the limit will

release an operational or alarm signal:

'A': alarm signal, '+': operation signal, '-':

not in use.

5.1.5 F0 - Digital inputs, operation or alarm signal

Menu F0 followed by 4 (and 5) x 'down arrow'

display which digital inputs, that releases an operation or alarm signal:

'A': alarm signal, '+': operation signal, '-':

not in use.

A delay period can be set for every digital output.

This delay period must run out before the output

are activated.

When the output is OFF, an empty field is

shown. When the output goes ON, a flashing field

are shown during the delay time, after which a

field are shown constantly.

5.3.2 F2 - Internal flag on/off

Menu F2 followed by 1 x 'down arrow' will display

the status for the internal flags.

M795GB0503

14

SW ver. 830434

Page 15

Data Transmitter 795

5.4 F3 - Limits - High/Low

Menu F3 indicates if high and low limit is ON or

OFF for the analogue inputs. The first four digits

indicate if the high limit setting is exceeded and

the last four digits indicate if the low limit setting is

exceeded:

A delay time can be set individually for each

analogue input in that the the input can exceed the

limit for a short period without activating an alarm.

An empty square is displayed when the limit is

not exceeded. When the limit is exceeded, a solid

square is displayed. If a delay period is set, the

square will flash during the delay period.

5.5 F4 - Analogue input value #

Menu F4 indicates the value of the analogue inputs

as a bargraph:

Select the desired input with the arrow keys or

the numeric keys.

5.5.1 F5 - Analogue input scaling

Menu F5 indicates the value of an analogue input

as a percentage and the mA signal and as a

scaled value:

Select the desired input with the arrow keys or

the numeric keys.

5.5.2 F5 - Analogue input on Pump Controller 704

Menu F2 followed by 1 x 'down arrow' display

the value of the analogue input on the Pump

Controller 704 (if connected):

Please observe that the value is collected directly

from the Pump Controller 704 and is not scaled.

5.6 F6 - Counter for inputs

Whenever a digital input or an analogue high/low

limit is active, it will be recorded by a counter. The

number is displayed in menu F6:

Use the arrow keys to change between:

- digital input 1 - 8/12/16

- analogue high limit 1 - 4

- analogue low limit 1 - 4

In addition, the numerical keys 1 - 8 can be used

to select the desired input.

The selected counter can be reset by pressing

the ENTER key.

5.7 F7 - Counter for time

Menu F7 indicate for how long the digital input

and the analogue high and low limits have been

active. Time counters is running continuously

such as if the input is set to OFF for some time

and then is set to ON, the counter will count from

the last value. The time is displayed in hours and

minutes:

The scaled value is determined by the

programming of the analogue input.

If the value represents e.g. a level measurement

in a tank, and the level normally varies between 2

m and 3 m, the analogue input will normally be

programmed so 2 m corresponds with '200' (low

value) and 3 m corresponds with '300' (high

value).

A level of 2,5 m will then give a scaled readout of

250 and 50 %.

If the scaled value should be shown as '2,5', it is

possible to set a divisor for each input. In this

example the divisor should have the value 100.

See also section 7.

M795GB0503

Use the arrow keys to change between:

- digital input 1 - 8/12/16

- analogue high limit 1 - 4

- analogue low limit 1 - 4

In addition, the numerical keys 1 - 8 can be used

to select the desired input.

The selected counter can be reset by pressing

the ENTER key.

15

SW ver. 830434

Page 16

Data Transmitter 795

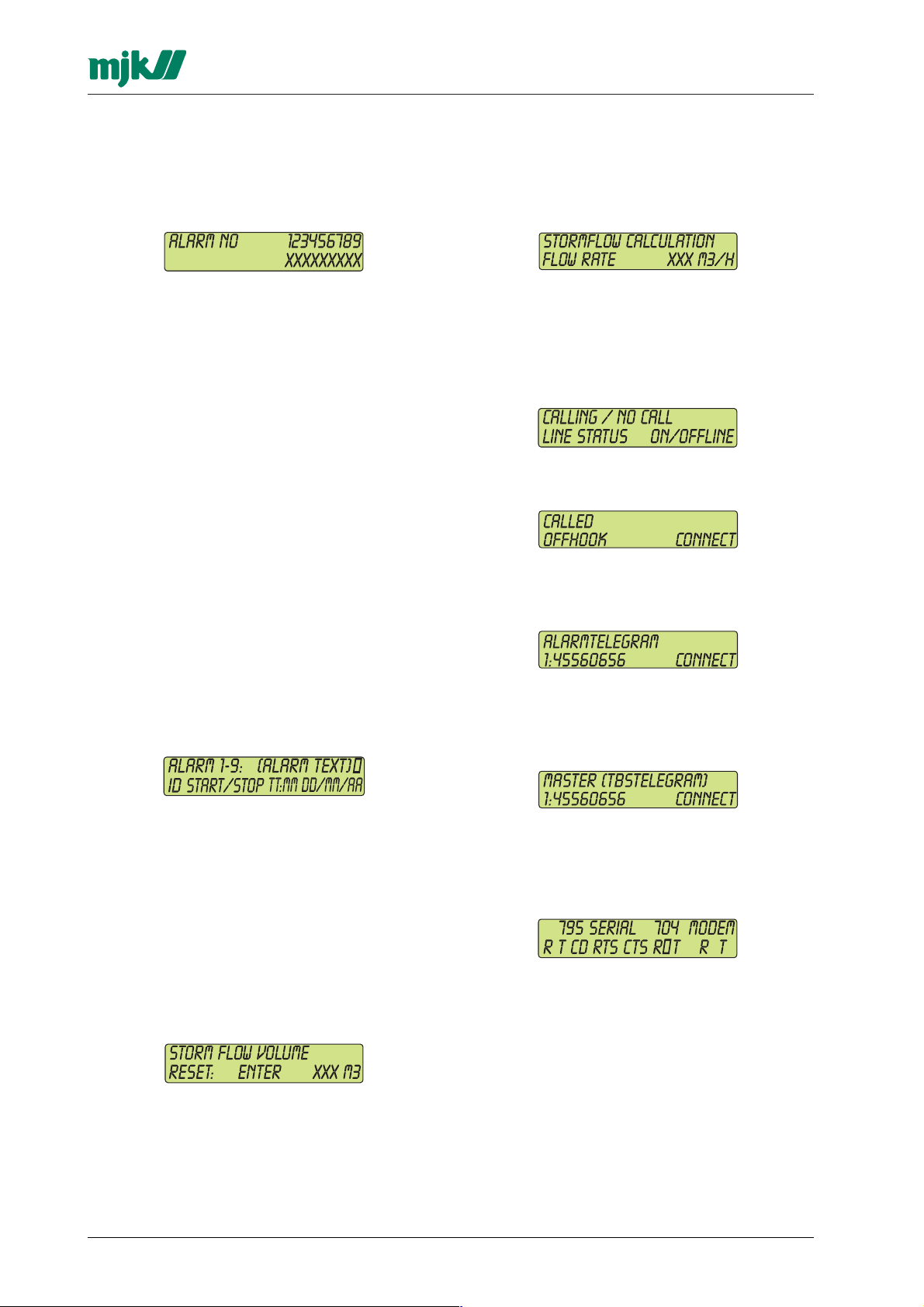

5.8 F8 - Alarm / Alarm number

Menu F8 indicate if the last 9 alarms are ON or

OFF:

Each time a new alarm is activated, it will be

recorded as alarm no. 1 and all other recorded

alarms will move down one place and alarm 9 will

be deleted. When the alarm for one input has

been ON one time it must be set to OFF before a

new alarm from the same input is accepted as an

alarm.

If the alarm has not been reset and another 9

alarms occur, i.e. the first alarm become no. 10

and therefore will become invisible in the alarm

list, this alarm will be reset automatically.

A flashing square is shown when an alarm

goes ON.

If the alarm are being reset but is still active, a solid square is shown constantly. When the alarm

goes OFF again, a square is shown constantly.

By means of the arrow keys or by entering the

alarm number, the status, type and timestamps

for on and off time can be displayed. Whenever

an alarm goes ON, the input number and start

time will be recorded. Similarly, when the alarm is

reset, the reset time is recorded, and when the

alarm goes OFF, the end time will be recorded:

5.9.2 F9.2 - Stormflow calculation

Whenever a stormflow occur, the flow is

3

displayed as m

/h in menu F9-2:

5.10 F# - Modem/Line status

(Only for versions with built-in telephone modem

or GSM modem.)

Menu F# displays the status of outgoing alarm

calls or incoming calls:

The following is displayed during an incoming

call:

The following is displayed during an outgoing

alarm call to one of the telephone numbers in the

telephone number list:

When Data Transmitter 795 interlocks another

Data Transmitter 795 i.e. in order to perform a

remote start or stop of a pump, the following is

displayed:

'ID' indicates the ID number of the Data Transmitter itself.

If the Data Transmitter are configured as a Master

in a multidrop system, the 'ID' can also be the ID

number of a connected Slave unit.

Return to normal operating display with the arrow

keys or by prssing the '0' key.

5.9.1 F9.1 - Stormflow volume

Menu F9 displays the recorded stormflow

volume.

The counter can be reset with the ENTER key.

M795GB0503

5.11 F* - Communication status

Menu F* indicate the communication status on

the serial port, the port to Pump Controller 704,

and the built-in telephone modem:

795 serial: R = Rx, T = Tx, CD = Carrier Detect,

RTS = Request to send og CTS = Clear to send.

704: R = Rx, T = Tx and = Pump Controller

704 not interlocked / Pump Controller 704

interlocked. The Pump Controller 704 signal to

the Data Transmitter that the Pump Controller

704 will not activate any control outputs, because

the Pump Controller are interlocked.

16

SW ver. 830434

Page 17

Data Transmitter 795

6 Programming of main functions

6.1 Select language

Select the desired language with the arrow keys

and confirm with ENTER.

6.2 Set time and date

Enter time and date with the numerical keys or

the arrow keys. Confirm with ENTER:

Just press ENTER at all entries if changes are not

needed in order to proceed to the next menu.

6.3 Automatic change between summer

time and winter time

Select if the clock should change automatically

between summer time and winter time:

6.5 Calculation of average values on

analogue inputs

The value of an analogue input is recorded every

second, and every 5 minutes the values is logged. If averaging of the analogue values are

selected, an average of the analogue value over

the last 5 minutes will be calculated and logged.

If averaging is not selected, the analogue value at

the actual time will be logged.

Use the arrow keys to select and confirm with

ENTER.

6.6 Data logging interval

The data logging interval is used for the extended

logging function, where the value for the analogue

input and the level from MJK Pump Controller

704 is stored.

Use the arrow keys to select and confirm with

ENTER.

Just press ENTER at all entries if changes are not

needed in order to proceed to the next menu:

6.4 Access code enabled/disabled

Select if an access code is required to gain access to the remaining system menus. This

function make it possible to protect the system

configuration from unauthorized changes:

Use the arrow keys to select and confirm with

ENTER.

6.4.1 Enter password

If access code protection is selected, a 4-digit

access code is required in order to gain access

to the remaining system menus.

The interval between loggings can be chosen

amongst the following values: 30 sec. (00:30), 1

min. (01:00), 5 min. (05:00), 10 min. (10:00), 30

min. (30:00) and 1 hour (60:00).

Use the arrow keys to select and confirm with

ENTER.

6.7 Tone / pulse dialing

Select between pulse or tone dialing from a

telephone modem:

Use the arrow keys to select and confirm with

ENTER.

6.8 Alarm call on power failure

If alarm call at power failure is selected, the Data

Transmitter will call the first telephone number in

the telephone list when the power supply fail. A

power failure will not be detected before the

supply has been gone for minimum 30 sec.

Hereby alarm calls on short power surges are

avoided.

M795GB0503

Use the arrow keys to select and confirm with

ENTER.

17

SW ver. 830434

Page 18

Data Transmitter 795

6.9 Number of incoming rings before

answer

Set the number of rings (1 to 5) before Data

Transmitter 795 answer the call.

Use the arrow keys or numerical keys 1 to 5 to

select and confirm with ENTER.

6.10 ID. no. for the Data Transmitter

The ID number is used for identification of the

individual data transmitters.

Use the arrow keys or numerical keys and

confirm with ENTER.

6.11 Automatic reset of alarms

Select if incoming alarms should be automatically

reset when the alarm condition disappears.

6.13 795 telephone number

Enter the telephone number that the Data Transmitter is connected to. The number is used as ID

no. in connection with transmission of SMS

alarms through landlines.

Use the numerical keys and confirm with ENTER.

6.14 SMSC telephone number

SMS messages need to be dialed to a specific

SMS gateway, that will handle the further transmission through the cellphone network.

Use the numerical keys and confirm with ENTER.

Telephone numbers to SMSC gateway can be

found in Appendix B.

6.15 RS485 function

This function is only available on Data Transmitter

795 with RS485 port.

If 'NO' are selected, all incoming alarms need to

be reset manually.

Use the arrow keys and confirm with ENTER.

6.11.1 Call on automatic alarm reset

If 'Automatic reset of alarms' have been selected

as described in the previous section, there will be

an option to select if the Data Transmitter should

perform a call, if an alarm condition disappear

and therefore releases an automatic reset of an

alarm.

Use the arrow keys and confirm with ENTER.

6.12 Start time for operational reports

Many plant managers want to have the

operational reports displaced so they will elapse

between i. e. 07:00 to 06:59. Enter the desired

displacement counted from midnight:

Select if this Data Transmitter 795 should be a

Master (the unit sending out alarms), or if this

Data Transmitter 795 should be a Slave which is

interconnected to another Master via the RS485

port:

Use the arrow keys and confirm with ENTER.

6.15.1 Master ID number

Select the Master ID for this Data Transmitter 795

if it is set to Master, or select the Slave ID for the

unit in the multidrop cluster which should receive

alarms and relay them via modem or radio:

Use the arrow keys and confirm with ENTER.

Use the arrow keys or numerical keys and

confirm with ENTER.

M795GB0503

18

SW ver. 830434

Page 19

Data Transmitter 795

7 Programming of analogue inputs

7.1 Select analogue input

Select the desired analogue input with the arrow

keys and confirm with ENTER.

7.2 0 - 20 or 4 - 20 mA input

Select input type with the arrow keys and confirm

with ENTER.

7.3 Scaling at 0 / 4 mA

Set the scaling of the low (0/4) mA value.

NB! The setting for the low mA value must be

lower than the setting for the high mA value! (See

next section.)

Use the numerical keys and confirm with ENTER.

7.4 Scaling at 20 mA

Set the scaling of the high mA value.

7.5.1 Set high limit

Set the upper limit value that should cause a

recording in the operational or alarm log - see

also section 13, "Operational or alarm signal".

In case the input are not scaled, 20 mA on the

analogue input will correspond to 9999.

Use the arrow keys or numerical keys and

confirm with ENTER.

7.5.2 High limit operation / alarm

Select if a high limit excession should be

recorded in the alarm log or the operational log see also section 15, "Operational or alarm signal".

Use the arrow keys and confirm with ENTER.

7.5.3 Dialout on high limit

Select if a high limit activation should cause a

dialout attempt.

NB! The setting for the high mA value must be

higher than the setting for the low mA value! (See

previous section.)

Use the numerical keys and confirm with ENTER.

7.5 Monitoring of high limit

Select if exceeding a high limit should be

recorded or not.

Use the arrow keys and confirm with ENTER.

Use the arrow keys and confirm with ENTER.

7.5.4 Signal delay for exceeding high limit

Select the period in which the analogue value can

exceed the high limit without activating an alarm:

Use the arrow keys (double arrow for minutes

and single arrow for seconds) and confirm with

ENTER.

7.6 Monitoring of low limit

Select if exceeding a low limit should be recorded

or not.

Use the arrow keys and confirm with ENTER.

M795GB0503

19

SW ver. 830434

Page 20

Data Transmitter 795

8 Programming of digital inputs

7.6.1 Set low limit

Set the lower limit value that should cause a

recording in the operational or alarm log - see

also section 13, "Operational or alarm signal".

In case the input are not scaled, 0 / 4 mA on the

analogue input will correspond to 0.

Use the arrow keys or numerical keys and

confirm with ENTER.

7.6.2 Low limit operation / alarm

Select if a low limit excession should be recorded

in the alarm log or the operational log - see also

section 15, "Operational or alarm signal".

Use the arrow keys or numerical keys and

confirm with ENTER.

7.6.3 Dialout on high limit

Select if a low limit activation should cause a

dialout attempt.

(Maximum period is 8 hours.)

8.1 Select a digital input

Select the desired digital input with the arrow

keys and confirm with ENTER.

8.2 NO or NC

Select if the input should be active (ON) when

there is a signal on the input or passive (OFF)

when there is no signal on the input.

Use the arrow keys and confirm with ENTER.

8.3 Operational or alarm input

Select if an activation of the input should be

recorded in the alarm log or in the operational log

- see also section 15, "Operational or alarm signal".

Use the arrow keys and confirm with ENTER.

8.3.1 Dialout on alarm

Select if an activation of the digital input should

cause a dialout attempt:

Use the arrow keys and confirm with ENTER.

7.6.4 Signal delay for exceeding low limit

Select the period in which the analogue value can

exceed the low limit without activating an alarm:

Use the arrow keys (double arrow for hours/

minutes and single arrow for seconds) and

confirm with ENTER.

7.7 Divisor

Set the desired divisor value for the analogue input. The divisor has only significance for

displaying of analogue values in function menu

F5, and not to the values that are transmitted to

other data transmitters or SCADA systems.

The divisor has no significance for the setting of

high or low limits.

Use the arrow keys and confirm with ENTER.

8.4 Signal delay

Select the period in which the digital input can be

active without causing an alarm or a recording of

an operational signal: (Maximum period is 8

hours.)

Use the arrow keys (double arrow for hours/

minutes and single arrow for seconds) and

confirm with ENTER.

Use the arrow keys or numerical keys and

confirm with ENTER.

M795GB0503

20

SW ver. 830434

Page 21

Data Transmitter 795

9 Programming of digital outputs

9.1 Select a digital output

Select the desired digital output with the arrow

keys and confirm with ENTER.

9.2 NO or NC

Select if the relay contact should be open (NO) or

closed (NC), when the output is not active.

Use the arrow keys and confirm with ENTER.

9.3 Time controlled output

Select if the output should go ON and stay ON

when the Data Transmitter receive a start signal

('FIXED'), or if the output should go ON when the

Data Transmitter receive a start signal and stay

ON for a pre-set period of time ('TIME').

If 'FIXED' are selected, the Data Transmitter need

a stop signal in order to deactivate the output.

10 Programming of logical functions

This menu gives the possibility to program simple

logical functions like AND, OR, and SET/RESET

based on different digital signals in both Data

Transmitter 795 and the Pump Controller 704 (if

connected).

Since it is also possible to set internal flags in

Data Transmitter 795, it will be possible to make

combina-tions of several logical function and thus

obtain PLC-like logical functions in the Data Transmitter 795.

10.1 Select the output to receive the result of

the logical function

The result of a logical function can be sent to an

internal flag or directly to a digital output.

Select the desired signal with the arrow keys and

confirm with ENTER.

10.2 Select logical function

Select the desired logical function for the signal.

Use the arrow keys and confirm with ENTER.

9.4 ON time

Select the period in which the output should be

active, if the output is set to be 'TIME' controlled.

Use the arrow keys (double arrow for minutes

and single arrow for seconds) and confirm with

ENTER.

9.4.1 Time before start

Select the delay time for activation of the output

relay. The delay time is from the moment the Data

Transmitter receive an ON command and until the

relay output will be activated.

Use the arrow keys (double arrow for minutes

and single arrow for seconds) and confirm with

ENTER.

Use the arrow keys and confirm with ENTER.

10.2.1 Select signals for the logical function

Select the signals to be used for the logical function.

In the left hand side of the display is shown the

previous selected signal type to receive the result

of the logical function together with the selected

logical function.

In the right hand side of the display is shown the

input signals for the selected logical function.

M795GB0503

21

SW ver. 830434

Page 22

1: Select the upper input signal with the arrow

keys and confirm with ENTER.

2: After that, select the lower input signal and

confirm with ENTER.

Please note, that DO1 and DO2 may be used

by the pump controller function - see also

section 12.

10.2.2 Operational or alarm signal on internal flag

If the signal type is selected as internal flag it is

possible to select if an internal flag should be an

operational signal or alarm signal.

Data Transmitter 795

11 Programming of interlock

With this function it will be possible for two Data

Transmitters to send command to each other.

E.g. one Data Transmitter can control a digital

output on another Data Transmitter.

Furthermore, if a Pump Controller 704 is

connected to a Data Transmitter, the output

relays on the Pump Controller 704 can be

controlled by another Data Transmitter 795.

11.1 Interlock of this station

This menu makes it possible to block remote

commands from other Data Transmitters

(substations).

Use the arrow keys and confirm with ENTER.

10.2.3 Dialout when alarm signal on internal flag

Selct if the internal flag should release an alarm

call attempt on an alarm.

Use the arrow keys and confirm with ENTER.

10.2.4 Signal delay on internal flag

This menu is used to set the period in which both

input signals should be active in order to set the

internal flag.

Use the arrow keys and confirm with ENTER.

Note, that interlock of a connected Pump

Controller 795 also will be blocked.

Use arrow keys and confirm with ENTER.

11.2 Interlock interval

This menu is used to set the interval for how often

other Data Transmitters should be dialed for

remote control.

The actual application and communication

method is decisive for setting the interlock interval. As an example, in case communication are

taking place through a dialed line, it would be

expensive to exchange interlock commands

between two Data Transmitters every 5 minutes, if

it is about stopping a waste water pump in

connection with an overrun.

Use arrow keys and confirm with ENTER.

The setting will be valid for all Data Transmitters

(substations) that are being set to interlock in the

following menus.

M795GB0503

11.3 Selection of substation

Select the Data Transmitter (substation) to be

interlocked.

Use arrow keys and confirm with ENTER..

22

SW ver. 830434

Page 23

Data Transmitter 795

11.4 Interlock active / inactive

Select if the previously chosen Data Transmitter

(substation) should be interlocked.

Use arrow keys and confirm with ENTER.

11.4.1 Start of interlock

Select the signal initiating an interlock on the

selected Data Transmitter (substation):

The following signals are available:

- internal flag 1-8

- digital input 1-8/12/16

- analogue limit HIGH 1-4

- analogue limit LOW 1-4

- 704 system error

- power failure

- 704 output 1-2

The following signals are available:

- internal flag 1-8

- digital input 1-8/12/16

- analogue limit HIGH 1-4

- analogue limit LOW 1-4

- 704 system error

- power failure

- 704 output 1-2

As long as the signal is ON, all calls will take

place in the interlock interval previously chosen.

If the interlock interval is set to 10 minutes or

more, the remote controlled output should be

configured as time controlled with an ON-time set

to more than 10 minutes (e.g. 15 minutes) to

avoid a situation where the remote output is ON

constantly caused by a communications error.

(E.g. a broken telephone cable.) In this way it is

ensured, that the output is switched OFF, if

communications fail.

On error-free communication the ON-timer on the

remote controlled output will be initialized on

every call, and with that the output will stay ON as

long as the controlling signal is active.

Only one call attemt will be made. In case the

same signal are selected as both start condition

and stop condition, the stop condition will be

when the digital signal goes OFF.

Use the arrow keys and confirm with ENTER.

11.4.3 Receivers telephone / ID number

Enter the telephone number / ID number of the

Data Transmitter to be interlocked.

Enter the ID number if radio modems are used.

If the receiver is another Data Transmitter which is

directly connected to the same multidrop line via

the RS485 port, the ID number of the Data Trans-

preceeded with a minus. (The F key is used

mitter

to enter the minus character.)

Use arrow keys and confirm with ENTER.

11.4.2 Stop interlock

Select the digital signal that - when switched OFF

- will cause the Data Transmitter to call the other

Data Transmitter and set an output OFF:

M795GB0503

Ex.: Data Transmitter ID 001 is supposed to

remote control Data Transmitter ID 003:

Enter the ID number "- 003" into Data

Transmitter 001.

If the receiver is another Data Transmitter which is

communicating via data radio, the Data Transmitter's ID-nummer should be entered

without a

preceeding minus.

23

SW ver. 830434

Page 24

Eks.: Data Transmitter ID 001 is supposed to

remote control Data Transmitter ID 003:

Enter the ID number "003" into Data

Transmitter 001.

If the receiving unit is another Data Transmitter

which is communicating via telephone/GSM modem, the telephone number to the Data Transmitter is entered here.

Data Transmitter 795

Please note, that only a Master Data Transmitter

can directly remote control other Data Transmitters belonging to other clusters.

Use the numeric keys and confirm with ENTER.

11.4.4 Receiver's output

Select the desired digital output on the

interlocked Data Transmitter:

Use the arrow keys and confirm with ENTER.

Ex.: Data Transmitter no. 1 is supposed to

remote control the Data Transmitter no. 3:

Enter the telephone number "45560656"

into Data Transmitter no. 1.

If the receiving unit is a Data Transmitter

belonging to another cluster of Data Transmitters,

the ID number / telephone number belonging to

the Master in the cluster should be entered

followed by the ID number of the desired Data

Transmitter in the cluster.

Eks.: Data Transmitter 001 in the lower cluster is

remote controlling Data Transmitter 003 in

the upper cluster: Enter telephone / IDnumber "45560656-003" into Data Transmitter no. 001.

M795GB0503

24

SW ver. 830434

Page 25

Data Transmitter 795

12 Programming of Pump Controller(s)

12.1 704 connected

Select if a MJK Pump Controller 704 are

connected to the Data Transmitter:

Use the arrow keys and confirm with ENTER.

12.2 Call on alarm or system error on 704

Select if the Data Transmitter should perform a

call caused by an alarm signal, a control signal or

a system error signal from Pump Controller 704.

Calls will be made to the telphone numbers entered in the telephone number list in Data Transmitter 795.

Use the arrow keys and confirm with ENTER.

12.2 Programming of the internal Pump

Controller

Select the number of pumps connected to Data

Transmitter 795:

12.2.2 Start level for pump no. 1

Select the desired start level for pump no. 1:

Use the arrow keys and confirm with ENTER.

12.2.2 Stop level for pump no. 1

Select the desired stop level for the pump(s).

Use the arrow keys and confirm with ENTER.

12.2.3 Levels in use in 795

If 2 pumps are connected to Data Transmitter

795, two different start and stop levels are

available.

Use the arrow keys and confirm with ENTER.

12.2.4 Start level for pump no. 2

Select the desired start level for pump no. 2:

Note, that DO1 and DO2 will be assigned to the

internal pump controller. If '1' is selected, DO1

will be assigned as control relay for pump no. 1,

and if '2' is selected, DO2 will also be assssigned

as control relay (for pump no. 2).

Use the arrow keys and confirm with ENTER.

12.2.1 Select level signal

Select the desired level signal:

Select between one of the analogue inputs on

Data Transmitter 795 or the analogu input on

Pump Controller 704.

Use the arrow keys and confirm with ENTER.

Use the arrow keys and confirm with ENTER.

12.3.2 Stop level for pump no. 2

Select the desired stop level for pump no. 2:

Use the arrow keys and confirm with ENTER.

12.3.3 Alternation of pumps

Select if the pumps should be alternated.

Use the arrow keys and confirm with ENTER.

M795GB0503

25

SW ver. 830434

Page 26

13 Telephone list for alarms

(Not valid for versions with radio modem.)

13.1 Telephone number 1-9

This menu contain a list where up to 9 telephone

numbers can be entered.

The numbers in the list will be called in the same

order they are entered.

Data Transmitter 795

The message can be different for the individual

telephone numbers. Pager messages will be

displayed in the pager together with a code for

the alarm type that have caused the call.

An example: When digital input no. 5 on a Data

Transmitter with telephone number 45560656

receives an alarm input, the code 05-45560656

will be sent to the pager.

The alarm codes are:

Use the numerical keys and confirm with ENTER.

13.2 Number type

Select the telephone number type for the current

entry.

Select between SMS, ordinary telephone, pager

or PC.

Note, that 'PAGER' will only be available on

versions with built-in modem.

Use the arrow keys and confirm with ENTER.

13.2.1 Telephone number

Enter the telephone number.

The '#' key can be used to wait for dialing tone

for calls from a local exchange. The '#' key can

also give a 2 second break. E.g. 0#45 56 06

56**39: Dial 0, wait for dialing tone from city line,

call 45560656, wait 4 seconds, and then call 39.

Use the numerical keys and confirm with ENTER.

Max. number of digits is 17.

13.2.2 Enter pager message

If a telephone number is selected as a pager

number, a pager message/code (e.g. the Data

Transmitter's own telephone number) of

maximum 17 digits can be entered here.

01 : Digital input no. 1

02 : Digital input no. 2

03 : Digital input no. 3

04 : Digital input no. 4

05 : Digital input no. 5

06 : Digital input no. 6

07 : Digital input no. 7

08 : Digital input no. 8

09 : Digital input no. 9 (option)

10 : Digital input no. 10 (option)

11 : Digital input no. 11 (option)

12 : Digital input no. 12 (option)

13 : Digital input no. 13 (option)

14 : Digital input no. 14 (option)

15 : Digital input no. 15 (option)

16 : Digital input no. 16 (option)

21 : Analogue limit no. 1 LOW

22 : Analogue limit no. 2 LOW

23 : Analogue limit no. 3 LOW

24 : Analogue limit no. 4 LOW

31 : Analogue limit no. 1 HIGH

32 : Analogue limit no. 2 HIGH

33 : Analogue limit no. 3 HIGH

34 : Analogue limit no. 4 HIGH

40 : MJK 704 system error

41 : MJK 704 output no. 1

42 : MJK 704 output no. 2

43 : MJK 704 output no. 3

44 : MJK 704 output no. 4

51: Internal flag no. 1

52: Internal flag no. 2

53: Internal flag no. 3

54: Internal flag no. 4

55: Internal flag no. 5

56: Internal flag no. 6

57: Internal flag no. 7

58: Internal flag no. 8

Use the numerical keys and confirm with ENTER.

M795GB0503

26

90 : MJK 795 power failure

SW ver. 830434

Page 27

Data Transmitter 795

14 Programming of stormflow calculation

13.2.3 Enter SMS message

If the current telephone number type is selected

as an SMS type, enter an SMS message/code of

up to 8 digits:

Use the numerical keys and confirm with ENTER.

If the message is entered via the keypad of the

Data Transmitter, the message can only consist

of numbers, but with MJK-Link™ it will be

possible to enter text messages.

The SMS message will be displayed on the cell

phone with 'MJK 795' as headline followed by

location and cause of the alarm and the SMS

message.

Test the SIM card in a cell phone if the SMS

messages are not received. Also, check if the

telephone number to the receiving SMS gateway

is correct.

Pager messages and SMS messages are

delivered as telegraphic alarm to an external server, which implies that Data Transmitter 795 has

no option to test that the telegraphic alarm has

been received by the recipient.

13.2.4 Pause between calls

Enter a pause between the call attempts to the

telephone numbers on the telephone list:

Use the numerical keys and confirm with ENTER.

14.1 Stormflow calculation

Data Transmitter 795 can calculate the flow of an

overrun via a digital input an an analogue input.

MJK 795

MJK 501

MJK 7062

In above example, MJK Pressure Transmitter

7062 provides the level signal to the Data Transmitter, and an MJK Level Electrode 501 is

mounted where the stormflow starts. By this, the

level measurement is set to zero and flow is

calculated by means of the level signal.

Usually, the Data Transmitter is connected to a

Pump Controller 704 with a level transmitter with

its measuring range adopted to the pump

controller. The measuring range is normally higher

than necessary for flow measurement, typically

10 m for the pump control and 10-20 cm for flow

calculation. The accuracy on the level

measurement of the pump controller is as the total measuring range of the flow measurement.

M795GB0503

The Q/h curve of the weir must be entered in this

menu such as the data transmitter can calculate

the stormflow. Include as many Q(h) points as

possible in order to obtain the highest possible

calculation accuracy.

Below is demonstrated Q(h) curve and Q(h) table

for a rectangular weir with side contraction:

Q(h) point no.: h[m] Q[m3]

1 0,00 0,00

2 0,01 48,71

3 0,02 137,78

4 0,03 253,12

5 0,04 389,70

6 0,05 544,62

7 0,06 715,92

8 0,07 902,17

27

SW ver. 830434

Page 28

Data Transmitter 795

If these Q(h) values are entered in this menu, the

resulting Q(h) curve will be as shown below, and

the Data Transmitter will calculate the flow

according to this curve:

Note, that Q

must be no more than

MAX

59.999 m3/

h.

14.2 Stormflow calculation in use

Select if stormflow calculation should be used:

Use the arow keys and confirm with ENTER.

14.2.3 Number of Q(h) points

In this menu the number of Q(h) points that are

desired for the piece by piece linearization of the

flow calculation.

The number of Q(h) points can be set from 1 and

9, as the zero point value will be provided to be 0

3

/h.

m

Use the arow keys and confirm with ENTER.

14.2.4 Height value [h] for level point

Enter the height [h] for the Q(h) point.

The entered value MUST be higher than that for

the previous Q(h) point.

Use the numerical keys and confirm with ENTER.

14.2.5 Flow value [Q] for level point

Enter the volume [Q] for the Q(h) point.

14.2.1 Zero point input no.

Select the input that the level electrode are

connedted to. This input will activate the stormflow calculation.

The following inputs can be selected:

- 795: DI 1 - 8 / 12 / 16

- 795: High/low limit 1 - 4

- 704: Output 1 - 4

- Combi alarm 1 - 8

Use the arow keys and confirm with ENTER.

14.2.2 Level signal for flow calculation

Select the input that provide the level signal for

the stormflow calculation:

The following inputs can be selected:

- 795: Al 1-4

- 704: Level

Use the numerical keys and confirm with ENTER.

The current flow value and the total stormflow

value can be read in functional menu F9. See also

section 5.10.

Use the arow keys and confirm with ENTER.

M795GB0503

28

SW ver. 830434

Page 29

Data Transmitter 795

15 Programming of 702 ComTroller

If one or more 702 ComTrollers is connected to

the Data Transmitter as multidrop units on the

RS485 port, they can all be programmed via the

Data Transmitter's keyboard and display. (The

Data Transmitter must be the Master in the

cluster.)

15.1 Select 702

Enter the ID number for the desired 702

ComTroller:

Use the arow keys and confirm with ENTER.

The Data Transmitter will now attempt to

establish a connection with the selected 702

ComTroller:

If the selected 702 ComTroller does not respond,

the connection attempt can be interrupted by

pressing the

ComTroller can be selected.

When the selected 702 ComTroller responds,

svarer, the Data Transmitter's display and keyboard can now be used for remote programming

of the ComTroller:

The function will be interrupted by pressing the

key.

key, whereafter another

*

*

M795GB0503

29

SW ver. 830434

Page 30

16 Alarms

Data Transmitter 795

16.1 Operational or alarm signal

The digital inputs can be set to be either a

operational or alarm signals.

An operational signal defines a non-critical condition, e.g. a signal that only need to be recorded

in the operational log. It would typically be a signal indicating whether a pump is running or not.

An alarm signal is a signal, which normally is not

active and only becomes active when critical conditions occur, e.g. a thermal overload signal from

a pump. Furthermore, an alarm signal has memory and reset, i.e. when the alarm signal

becomes no-active, the previous active condition

are remembered. This previous active condition

must be reset by the user before a new change

to active condition will be accepted as an alarm

signal.

For both types of signals are applied that both the

number of changes to active condition and the

period of time where the signal has been active

will be recorded in the alarm record.

16.2 Alarm calls

If 'Call on alarm' is selected, the Data Transmitter

will call all the numbers in the telephone list starting with the first entry. Proceeding to the next

number in the list will take place after a preset

period of time -'Pause between calls'. See also

section 13.

If a call is made to a modem on a SCADA main

station, it will be the main station's task to reset

the alarm and stop the dialout routine. If call are

made to a pager or telephone, the dialout routine

is stopped by making a call to the Data Transmitter. A tone will be heard in the handset. This will

not reset the alarms, but only stop the dialout

routine. See also section 15.3.1.

If another alarm occur during the dialout routine,

the dialout routine will continue, and the new

alarm will be reported in to the next number in the

telephone list.

16.3 Reset of alarms

When an alarm signal becomes active, it will be

visible in menu F8 (see section 5.8).

Whenever a digital alarm signal becomes active,

the alarm will be present in menu F8.1. This menu

will show the alarm type and start time together

with a flashing symbol ''. The symbol will flash

as long as the alarm has not been reset, and the

symbol will appear solid when the alarm has been

reset but still active.

The symbol disappear when the alarm has been

reset and the alarm signal is inactive. When the

symbol disappear, the stop time for the alarm is

displayed instead of the start time.

In order to reset an alarm from the front panel of

MJK Data Transmitter 795, the menu F8 must be

shown. Then use the arrow keys to select the

alarm to be reset. Reset the selected alarm by

pressing ENTER. The symbol '' will then appear

solid if the alarm signal is still active or disappear,

if the alarm signal is no longer active. An alarm

can also be reset from a SCADA system.

An alarm signal must have been reset and

change from non-active to active condition in

order to be visible in the alarm list again. This

means that if you do not want to receive the

same alarm call several times on the SCADA station, the alarm should not be reset. The Data

Transmitter will then stop further alarm calls

concerning that particular alarm even if the alarm

signal change from non-active to active condition.

15.3.1 Automatic reset of alarms

If an alarm has not been reset, and another 9

alarms occur, meaning that the not yet reset

alarm becomes no. 10 and therefore no longer

will be visible in the alarm list, the alarm will be

reset automatically, if the function 'Automatic

reset of alarms' has been activated. See also

section 6.11.

Versions with radio modem transmit all alarms to

the main station (ID no. 0).

M795GB0503

30

SW ver. 830434

Page 31

Data Transmitter 795

17 Factory settings

Main functions: Settings: Main functions: Settings:

Language English No. of rings before answer 1

Autochange summer/winter time No ID no. for data transmitter 1

Access code No Automatic alarm reset No

Averaging of analog inputs No Call on auto alarm reset No

Datalogging interval 00:30 (30 sek.) Start time for operational report 00:00

Tone/Pulse dialing Tone 795 telephone number Alarm call on power failure No SMSC telephone number -

Analogue inputs: AI1: AI2: AI3: AI4:

0-20mA/4-20mA 4-20 mA 4-20 mA 4-20 mA 4-20 mA

Scaling @ 0/4 mA 0 0 0 0

Scaling @ 20 mA 9999 9999 9999 9999

High limit yes/no No No No No

High limit value 999 999 999 999

High limit operational/alarm Operational Operational Operational Operational

Signal delay (sec.) 0 0 0 0

Dialout on high limit No No No No

Low limit yes/no No No No No

Low limit value 0 0 0 0

Low limit operational/alarm Operational Operational Operational Operational

Signal delay (sec.) 0 0 0 0

Dialout on high limit No No No No

Divisor 0 0 0 0

Digital inputs: NO/NC: Operational/Alarm Alarm call Signal delay:

Digital indgang nr. 1-8/12/16 NO Operational No 0

Digital outputs: NO/NC: Time/Fixed: On time: Time before start:

DO no. 1-4/8 NO Time 10 sec. 5 sec.

Interlock: Setting: (Station 1-9)

Interlock of this station No

Interlock interval 5 min + 0

Start of interlock DI 1

Stop of interlock DI 1

Receivers tel/ID no. 0

Receivers output DO 1

Pump control: Setting:

704 connected No

704 output alarm call No

704 system errror alarm call No

795 no. of pumps 0

795 start level 1 0

795 stop level 1 0

795 level 2 in use No

795 start level 2 0

795 stop level 2 0

795 alternation No

Telephone list:

Telephone no. 1-9 Available 0 0

M795GB0503

Type (PC/pager/ Telephone Pager/SMS

Tel/SMS): number: message:

31

Pause in min.:

SW ver. 830434

Page 32

Storm flow calculation: Setting:

In use Yes/No No

Zero point DI1

Level signal 704 level

No of Q(h) points 9

Q(h) point no. 1 Level: 10 ; Flow (m

Q(h) point no. 2 Level: 10 ; Flow (m

Q(h) point no. 3 Level: 10 ; Flow (m

Q(h) point no. 4 Level: 10 ; Flow (m

Q(h) point no. 5 Level: 10 ; Flow (m

Q(h) point no. 6 Level: 10 ; Flow (m

Q(h) point no. 7 Level: 10 ; Flow (m

Q(h) point no. 8 Level: 10 ; Flow (m

Q(h) point no. 9 Level: 10 ; Flow (m

3

/h) : 1.11

3

/h) : 2.22

3

/h) : 3.33

3

/h) : 4.44

3

/h) : 5.55

3

/h) : 6.66

3

/h) : 7.77

3

/h) : 8.88

3

/h) : 9.99

Data Transmitter 795

M795GB0503

32

SW ver. 830434

Page 33

Data Transmitter 795

g

18 Signal lists

PUMP STATION NO: MJK 795 ID NO: PUMP CONTROLLER TYPE:

NAME: SERIAL NO. MJK 795: CONTROLLER SERIAL NO.:

TELEPHONE NO.: DATE: SENSOR SERIAL NO.:

DATA TRANSMITTER MJK 795

MAIN FUNCTIONS

CODE: ANALOG

AVERAGING

YES NO TONE PULSE YES NO

ANALOG INPUT:

AI 1-4 SIGNAL NAME: 0-20 mA 4-20 mA Zero Span