Page 1

MANUAL FORMANUAL FOR

MANUAL FOR

MANUAL FORMANUAL FOR

MJK LIQUID SAMPLER 780MJK LIQUID SAMPLER 780

MJK LIQUID SAMPLER 780

MJK LIQUID SAMPLER 780MJK LIQUID SAMPLER 780

ContentsContents

Contents

ContentsContents

ApplicationApplication

Application

ApplicationApplication

1 General information page 2

2 Operation 2

MountingMounting

Mounting

MountingMounting

3 Specifications 2

4 Mounting 2

5 Terminals 3

6 Examples 3

SettingSetting

Setting

SettingSetting

7 Operation 5

8 Start-up 5

9 Sequence 6

10 Adjustment of sequence time 6

11 External sequence 7

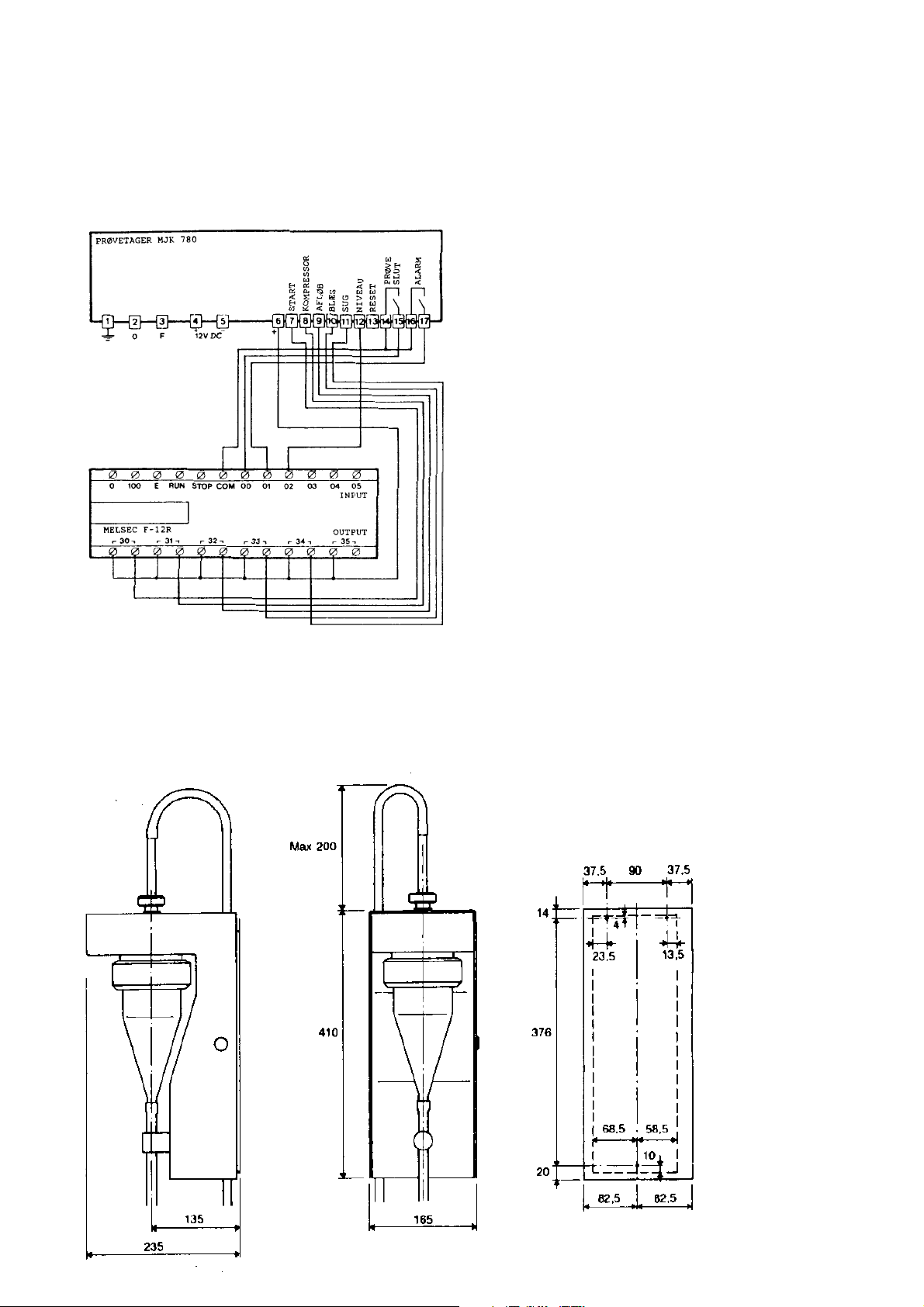

12 Example of control with PLC 7

MiscellaneousMiscellaneous

Miscellaneous

MiscellaneousMiscellaneous

13 Maintenance 7

14 Spare parts 8

15 Dimensions 8

M780GB/0911

1

Page 2

GeneralGeneral

General

GeneralGeneral

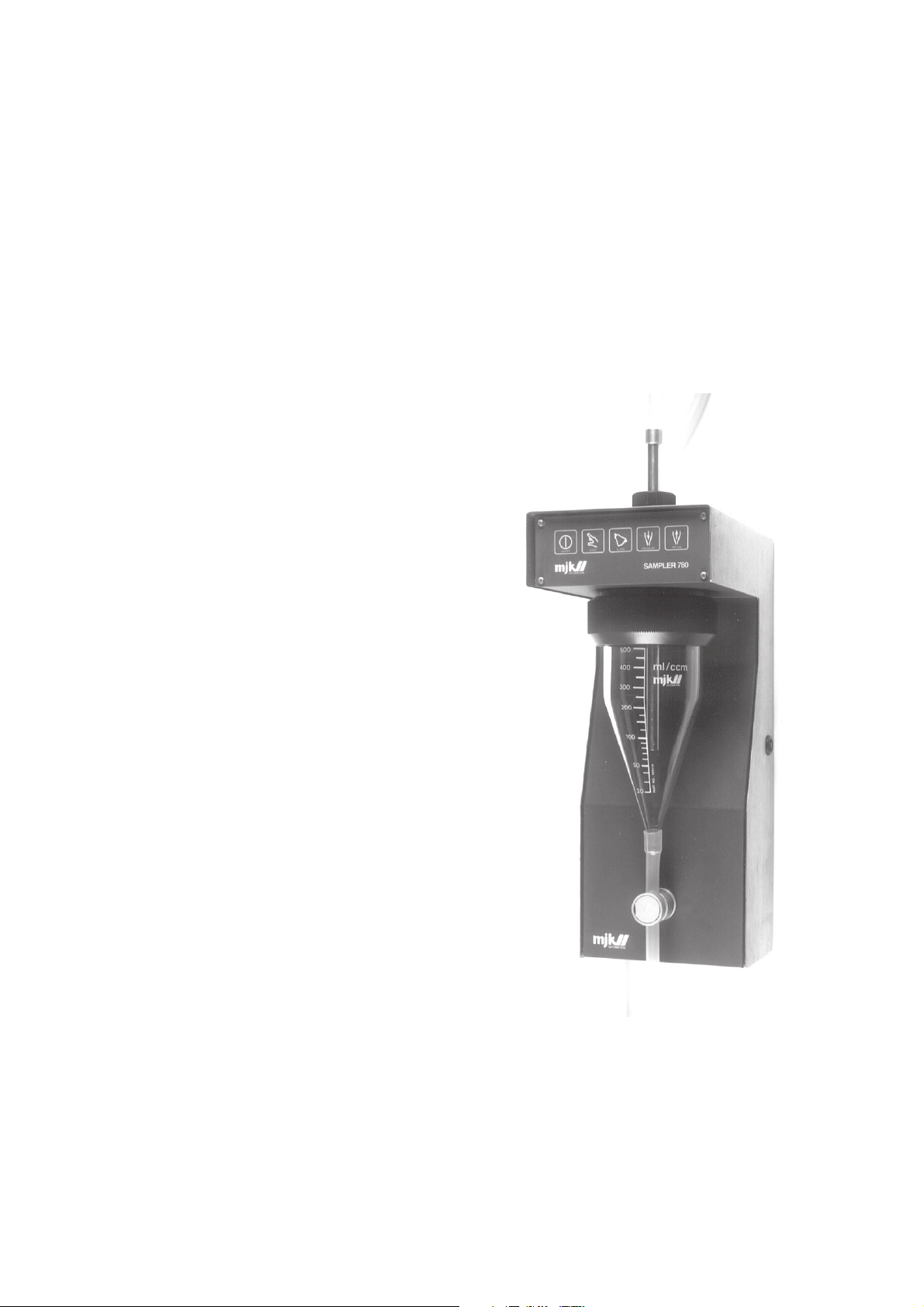

MJK Liquid Sampler 780 is designed to make samples

from lakes, rivers, sewage systems, pumping stations etc. It

can be used in fixed installations or as a portable unit. The

sampler operates from the manual panel, or is controlled

from a flowmeter or a timer.

The sampler can be connected directly to an MJK 713

Ultrasonic flow converter for flow proportional sampling.

The MJK Liquid Sampler 780 consists of 3 modules: a

combined valve / compressor unit, a control panel and a

power supply, all located inside a rugged stainless steel

enclosure. The parts that need to be cleaned are mounted

externally.

OperationOperation

Operation

OperationOperation

MJK Liquid Sampler 780 is operated from the front panel

or can be controlled via external signals from flowmeter,

timer, or MJK Integrator 783. The MJK Liquid Sampler 780

can be connected dirctly to MJK Flowmeter 713 for flow

proportional sampling.

MJK Liquid Sampler 780 uses pressure and vacuum for

sampling. When the sampler receives a start signal from

either the control panel or an external signal, the sample

tube is pressurized to clear residue from the previous

sample. The vacuum remains on until the sample glass is

full. Then the glass is again pressurized to clear the surplus

liquid from leaving the required sample (20 ml to 500 ml) in

the glass.

When the required level is reached, the outlet valve opens

and the sample runs into the collecting container.

MJK Liquid Sampler 780 has a built-in alarm system. If the

sample tube is blocked during the filling of the sample

glass, the alarm operation re-pressurizes the sampler to

clear the obstruction. The cycle then starts again. If the

sample glass is not filled at the second try within a preset

time, the sampler will not be blocked.

The control system of the sampler is in a sturdy design and

is unaffected by electrical noise. The sampler can be

operated manually or controlled from a flowmeter or timer.

Mechanical mountingMechanical mounting

Mechanical mounting

Mechanical mountingMechanical mounting

The sampler should be mounted on a wall or bracket. On

the back of the cabinet there is 2 'keyhole' slots at the top

and a slot at the bottom. Note, that 230 mm free space is

required at the left hand side of the cabinet in order to be

able to open the upper part of the cabinet. The sample

tube is immersed in the channel or the basin where the

sample will be taken from. The outlet tube runs to the

sample container, where the samples are stored until

analysed. The tubes may be extended as required.

Please observe the following when mounting the sampler:

- The sampler must be mounted vertically so the inlet and

outlet can have the most optimum position. Vertical

mounting is required for utilizing the measuring scale on

the sample glass.

- The maximum vacuum capacity of the sampler is 8m WG

(0,8 bar) and is used to lift the sample from an lower

liquid surface, and to overcome pressure loss in the

sample tube.

- The sampler must be mounted so the sample container

can be placed underneath. Under particular

circumstances it can be placed elsewhere, since the

measured sample is forced out of the sample measuring

chamber.

- During the summer months we recommend to avoid

exposing the sample container to the heat of the sun.

- During the winter it will be necessary to protect the

sampler from frost. The sampler is able to function down

to -20° C, since the sampler is drained after every

sample; there is only a minor risk for frost damages. On

the other hand, the sampler must be protected, warmed

and insulated when it is placed outdoors. Consideration

as to air temperature, temperature and size of every

sample as well as how long the samples have to be in

the sample container, must be taken.

However if another cycle is desired , all cycle functions are

located on a terminal block, so the control of the internal

functions and monitoring can be taken over via a PLC or pc.

SpecificationsSpecifications

Specifications

SpecificationsSpecifications

SamplingSampling

Sampling

SamplingSampling

Cycle time: App. 2 min (adjustable to 1 - 10 min)

Amount: 20 ml to 500 ml

Suction height: 0,75 bar abs

Pressure: Max. 1 bar (when flushing the sample hose)

Sample temp.: Max. +60

Environment: –20 - +60

Suction tube: PVC, inner dia. 9,0 mm x 2 m

Outlet tube: Silicone, inner dia. 9,5 mm x 1 m

Mechanical dataMechanical data

Mechanical data

Mechanical dataMechanical data

Housing: Stainless steel

Enclosure: IP 55

Weight: 5 Kg

Dimensions: 165 mm x 410 mm x 235 mm (w x h x d)

Electrical dataElectrical data

Electrical data

Electrical dataElectrical data

Supply: 110/220V AC and 12V DC

Consumption: 30 W during sample, 2 W stand by.

0

C

0

C

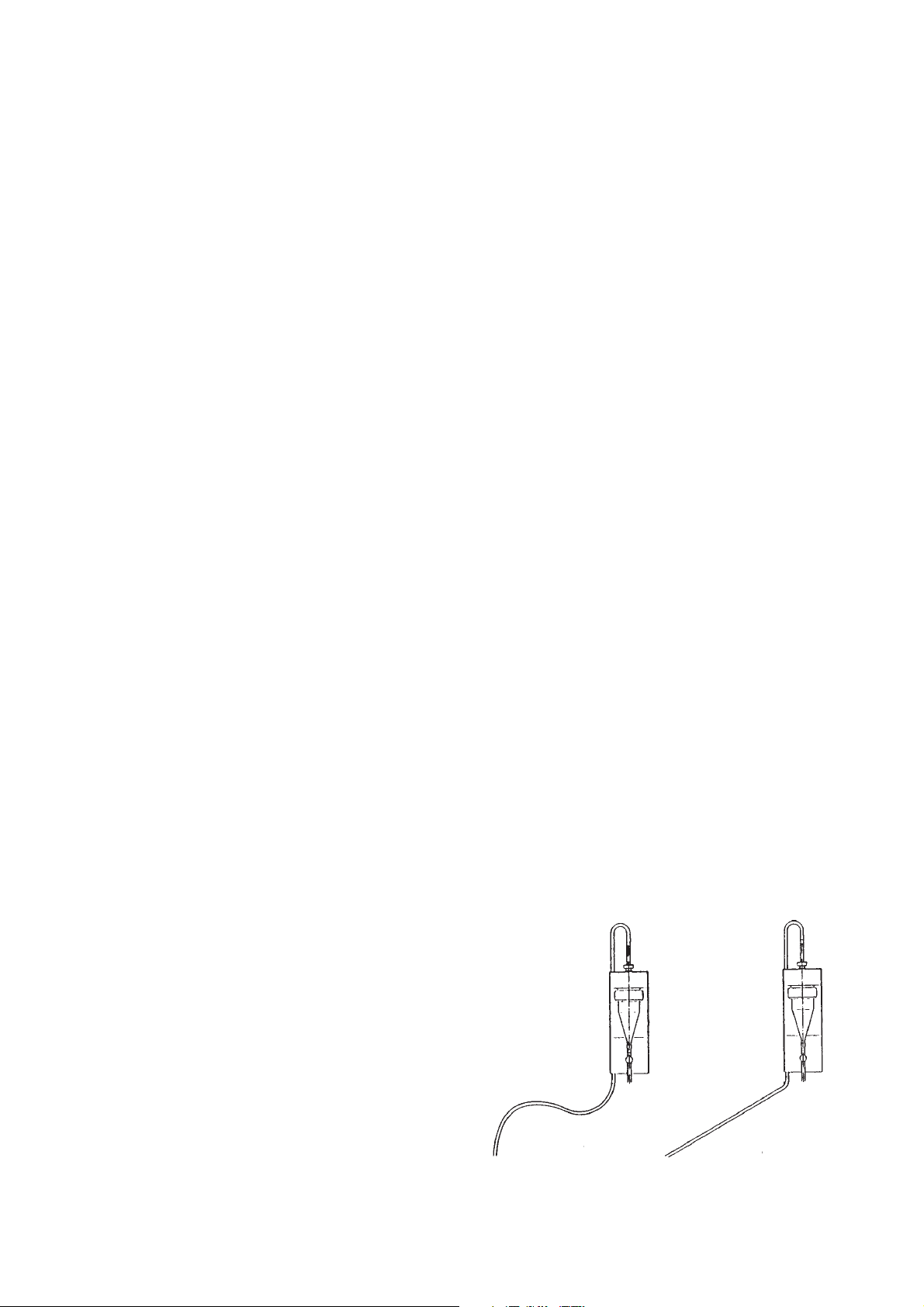

The sample tube must be straight without kinks when the

vacuum cycle begins. (See illustration below).

SAMPLE SAMPLE

TUBE TUBE

WRONG! CORRECT!

2

Page 3

TT

erminalserminals

T

erminals

TT

erminalserminals

The terminals for the electrical connection is found underneath the lid behind the sample glass. The sampler

cabinet is opened with the enclosed cabinet key.

Connect the sampler in accordance with the diagram.

110 - 120V/220 - 240V AC 12VDC

EXT. START EXT. ALARM

RESET

SUPPLY EXT. CONTROL SIGNAL SAMPLE ALARM

ExamplesExamples

Examples

ExamplesExamples

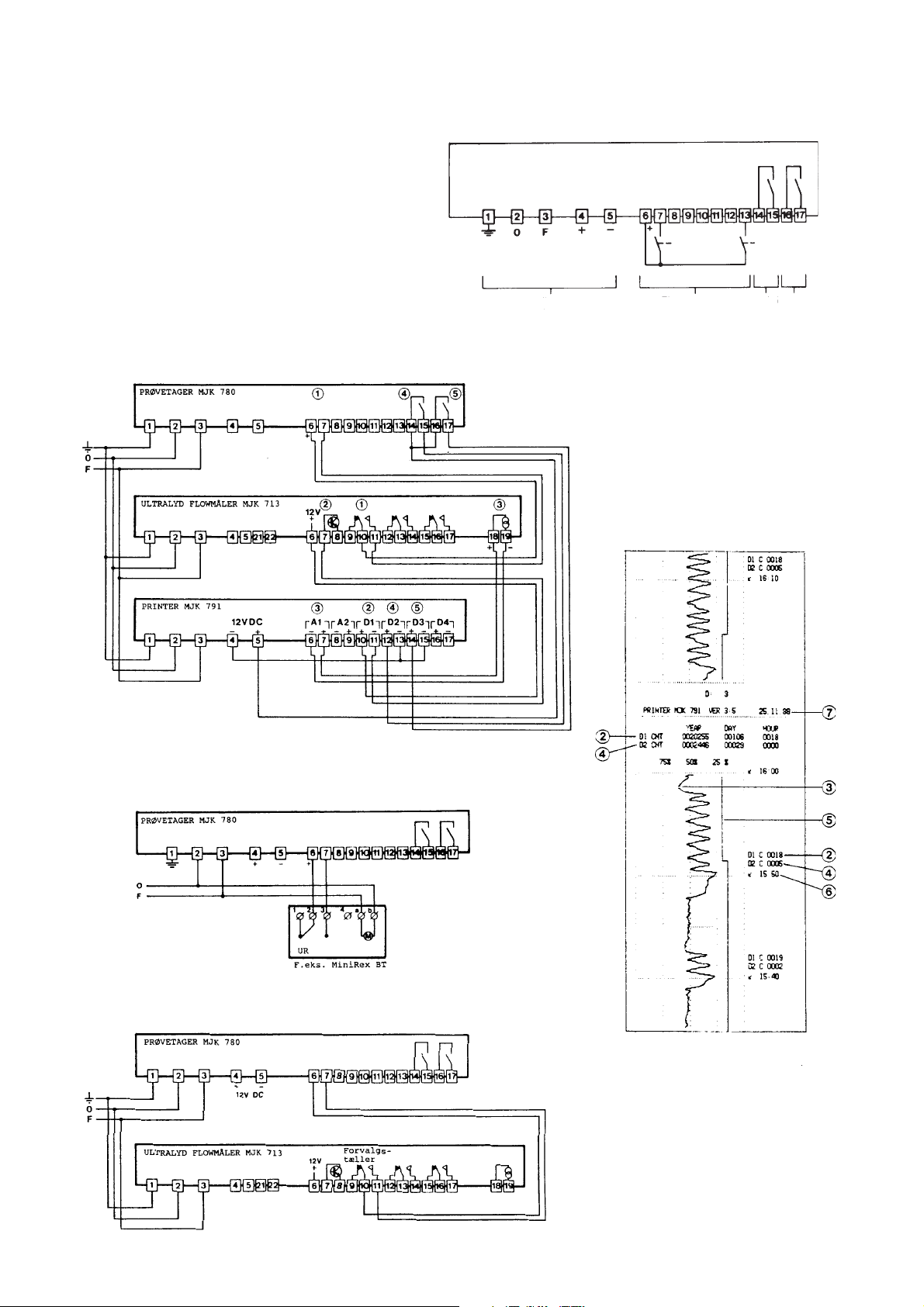

Flow proportional liquid sampling together with MJK Flow Converter 713Flow proportional liquid sampling together with MJK Flow Converter 713

Flow proportional liquid sampling together with MJK Flow Converter 713.

Flow proportional liquid sampling together with MJK Flow Converter 713Flow proportional liquid sampling together with MJK Flow Converter 713

This example show also th econnection of a MJK PRINTER 791 for recording of flow and samlping.

Printout examplePrintout example

Printout example

Printout examplePrintout example

1 Start liquid sampler

2 Totalization of flow

3 Graphic presentation of the flow

4 Sample count

5 Alarm registration from the sampler

6 Time

7 Day - month - year

STO P

Timer controlled liquid samplingTimer controlled liquid sampling

Timer controlled liquid sampling

Timer controlled liquid samplingTimer controlled liquid sampling

Flow proportional liquid samplingFlow proportional liquid sampling

Flow proportional liquid sampling

Flow proportional liquid samplingFlow proportional liquid sampling

3

Page 4

OperationOperation

Operation

OperationOperation

The sampler is operated on the control panel. The symbols

have the following meaning and function.

Pressure indicator

Start/stop of the sampler.

The function is an electrical memory function, so the

chosen position (start or stop) is maintained also after a

power failure. The sampler will continue taking samples or

will stop according to the previous position. The green LED

indicates that the sampler is on and ready (stand by) when

a start signal occurs.

Manuel sampling.

By depressing the start key, a sample cycle is started. This

function is always active and can be used alone or together

with an external control signal. The green LED indicates

that the sampler is in operation.

Alarm (reset).

This LED (green) indicates that the compressor has

pressurized the sample glass in order to:

* to purge out the previous sample from the sample tube.

* to purge out excess liquid during adjustment of the

sample volume.

* to flush the set sample volume into the sample can.

Vacuum indicator.

This LED (green) indicates that there is vacuum in the

sample glass when

* the sampler pulls up the sample in the sample glass.

Start-upStart-up

Start-up

Start-upStart-up

When the sampler is mounted and electrical connections

completed, the sampler is ready for start-up.

Ensure that the sample tube is immersed in the channel or

basin where the sample will be taken. Position the outlet

tube so that it reaches the sample container.

Adjust the sample volume from 20 ml – 0,5 l. The

adjustment is made by loosen the nut and pushing the

measuring pipe until the lower edge of the pipe is on the

level with the line on the sample glass, which corresponds

to the desired flow.

The ALARM key resets the sample cycle.When there is an

alarm, the light diode flashes (yellow), as described in

section 9. It continues to flash until the key is activated to

reset the alarm.

Sample cycleSample cycle

Sample cycle

Sample cycleSample cycle

The sample sequence is presented below:

Function: Purge Suction Volume adjustment Sample pump out Purge

Signal: –––––T 1––––– ––––Level–––– –––––T 2––––– –––––T 3––––– ––––T 1–––––

Compressor: xxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxx

Pressure xxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxx

Vacuum xxxxxxxxxxxxxxx

Level detection x

Outlet valve open xxxxxxxxxxxxxx

Alarm –––––––T 4––––––––

Connect the power supply when the measuring pipe has

been adjusted to the correct height. The ON/OFF key

activates the green diode light and the sampler is ready for

start (standby) when the “Start” key is pressed.

When the sampler is started, the green diode light will light.

During operation the compressor will be audible. The green

diode lights in the symbols for pressure and the vacuum,

indicate the internal valves are controlling the compressor.

(outlet to sample can)

4

Page 5

As shown in the diagram, the compressor starts when the

sampler is started. When starting, the valves are switched

out to put pressure on the sample glass, to remove any

previous sample. The purge time is determined by the

timer T1 (purge).

When time T1 has elapsed, the valves switch to create a

vacuum. The sample glass and the water will be pulled into

the sample glass, until the level electrodes are activated.

When the level electrodes have been activated, the valves

are switched over again, to put pressure on the sample

glass. Excess sample will be blown back in the sample

tube. Pressure continues until the time, determined by the

timer T2 has elapsed.

The outlet valve opens under pressure and the sample is

dropped into the sample container. The outlet valve

remains open for time T3 (purge).

It is possible to switch off the last purge by cutting off the

connection “Purge“ 2.

The sequence contains an alarm, which activates if the

sample does not contact the electrodes by a preset time

T4 (alarm). This alarm protects the sampler from continuous

cycles caused by blockage. However since the

compressor creates a 4 bar pressure, it is not very likely

that blockage will occur.

There are no dangerous voltages present at the control

unit, so it can be touched during operation. When the

desired adjustment has been made, depress (“ON/OFF”

key) to avoid short circuit during mounting, and the control

unit attachment.

External sequenceExternal sequence

External sequence

External sequenceExternal sequence

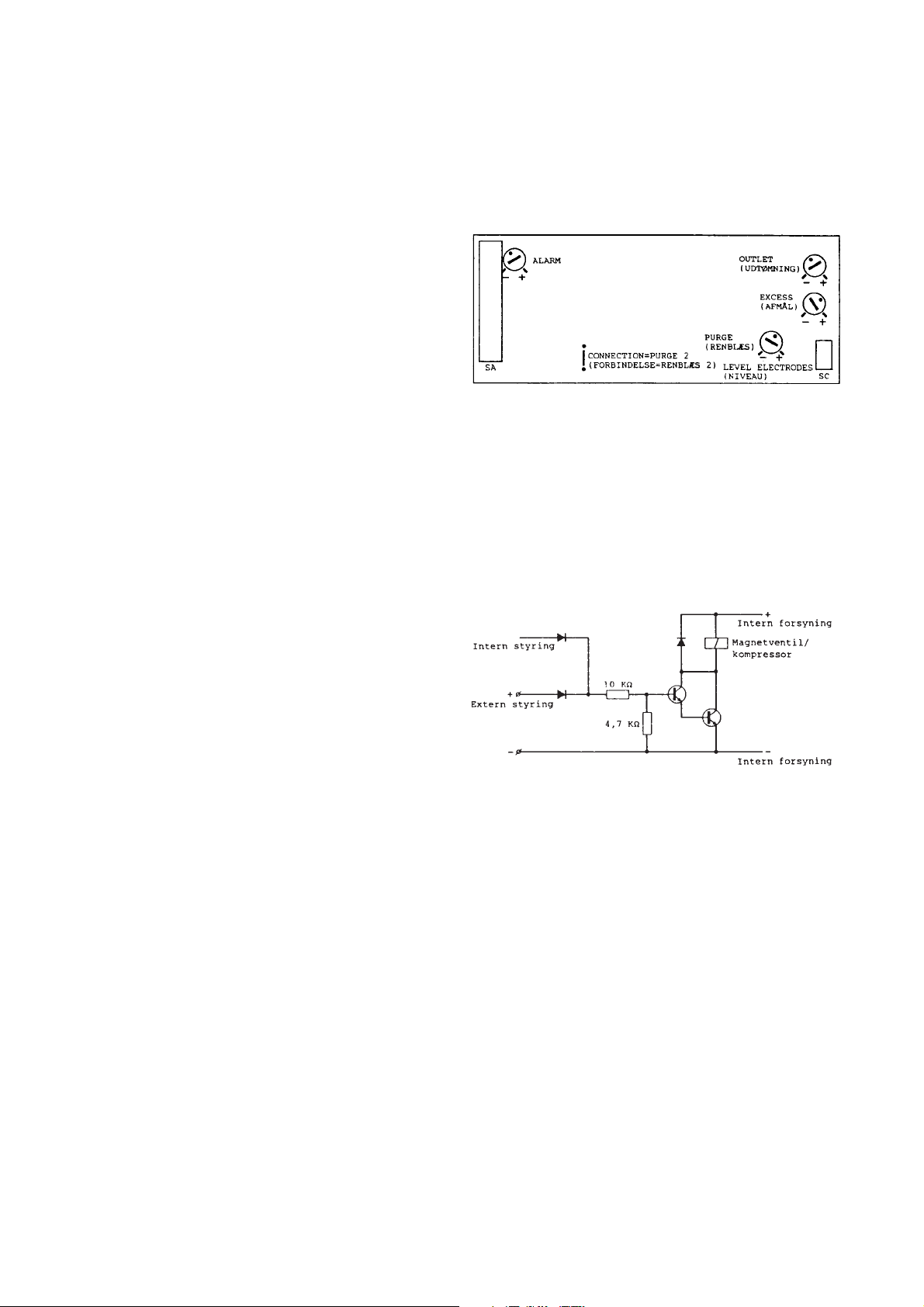

The sampler can be controlled externally, e.g. from a PLC.

When an external control is connected, it works in parallel

with the internal control, so that it is possible to select a

manual sample controlled by the internal system of the

sampler, at the same time as the external control.

The inputs are semi-conductor inputs as indicated at the

diagram.

If the sampler does not succeed to activate the level

electrodes the second time before the time T4 has run out,

the sampler will stop and prevent further starts. To indicate

the alarm, the yellow alarm flashes and the alarm relay is

activated. To make the sampler start again, the alarm state

has to be reset by activating the “alarm” key.

Setting of sequence timesSetting of sequence times

Setting of sequence times

Setting of sequence timesSetting of sequence times

The sequence time is factory adjusted, to a total sample

time of approx. 2 minutes.

The 4 timers have the following time ranges:

Timer (function)Timer (function)

Timer (function)

Timer (function)Timer (function)

Purge T 1: 30 - 150 sec 30 sec

Volume T 2: 30 - 150 sec 30 sec

adjustment

Outlet T 3: 30 - 150 sec 30 sec

(outlet)

Alarm T 4: 30 - 150 sec 60 sec

The sequence times are adjusted with the potentiometers

on the back of the control unit. To adjust the time, the

control unit must be removed. Switch off the sampler (ON/

OFF) key and unscrew the 4 screws, which hold the front

panel to the control panel. The control unit is integral with

the front panel. When the control unit has been removed

the sampler can be started again and the adjustment

made.

RangeRange

Range

RangeRange

Factory settingFactory setting

Factory setting

Factory settingFactory setting

The input signal should be not activated <0,5 V DC

Activated 5-24 V DC.

5

Page 6

Example of PLC controlled sampleExample of PLC controlled sample

Example of PLC controlled sample

Example of PLC controlled sampleExample of PLC controlled sample

The sampler is connected to a PLC. In the example a

MITSUBISHI MELSEC F-12R is displayed, but any PLC can

be used.

MiscellaneousMiscellaneous

Miscellaneous

MiscellaneousMiscellaneous

MaintenanceMaintenance

Maintenance

MaintenanceMaintenance

The sampler must be kept clean of dirt on the following

points:

* The sampler glass must be kept clean on the inside

* The level electrodes in the top of the sample glass must

be cleaned

* The sample tube and the outlet tube must be cleaned

How often the cleaning is necessary, depends on how often

the sampler is used. In municipal sewage plant, we

recommend monthly cleansing, where the sampler tube is

put in a bucket with 10% diluted hydrochloric acid.

Hydrochloric acid is a degreaser and cleans grease and

sludge from all inside surfaes.

Start the sampler 2-5 times dependent on how much

coating there is on the inside surfaces.

The plastic house inside between the electrodes should be

cleaned.

The outlet tube should be removed during cleaning.

Spare partsSpare parts

Spare parts

Spare partsSpare parts

Item nr.:Item nr.:

Item nr.:

Item nr.:Item nr.:

Complete unitsComplete units

Complete units

Complete unitsComplete units

803510 control unit complete with front panel

803515 Power supply unit

813510 Valve / pumping unit

Description:Description:

Description:

Description:Description:

115/230V AC and 12V DC

Other partsOther parts

Other parts

Other partsOther parts

595120 Suction hose, PVC, dia. 9,0mm.

Specify length.

595121 Discharge hose, Silicone, dia. 9,5mm,

Specify length.

595110 Sample glass

570025 O ring for sample glass, silicone,

dia. 75mm x 8mm

570027 O ring for measuring pipe, nitril, dia. 10 x 3mm

Dimensions Dimensions

Dimensions

Dimensions Dimensions

6

Loading...

Loading...