Page 1

Manual

Flow Converter 713

GB Flow Converter 713 0704

Page 2

Table of Contents

Page

Flow Converter 713 3

Technical section 3

Rectangular sharp edged weir 3

Triangular Weir 4

Parshall Flumes 5

Palmer & Bowlus Flumes 6

Venturi umes 7

Mounting of Sensor 8

Electrical Connection 8

Cable extensions 9

Ultrasonic sensor color codes 9

Cutting the cable 9

Control 10

Function keys 11

Flow key 11

Summation key 11

Alarm key 12

Sample key 13

Menu key 13

Conguring 14

Specications 17

Order numbers 17

Dimensions 17

Functional indications 18

Menues for conguring 19

Settings for the ow converter 20

CE - CERTIFICATE OF CONFORMITY

This product complies with the requirements concerning electromagnetic compatibility (EMC) stipulated in Council directive no.

89/336/EEC of 3rd May 1989, altered at directive no. 92/31/EEC,

on the approximation of the laws of the Member States relating to

electromagnetic compatibility.

MJK Automation A/S declare that the product complies to the

values stipulated in EN 50081-1 and EN 50082-1.

2

Page 3

Flow converter 713

Thank you for choosing Flow converter 713. Flow converter 713 is a modern construction, in which the relation

between functions, and "userfriendliness“ and precision

is optimum. In order to gain full use from the equipment,

we recommend that you read the instructions very thoroughly. Should any problems occur during installation or

operation, our technicians will be at your disposal.

Flow converter 713 is for the measurement of ow in

open umes and weirs. The method of measurement

and linearization complies with the norm ISO 1438. This

norm indicates how the head over the weir and umes

are constructed, and how the calculations for linearization are to be arrived at. The owrate is generaly speeking determined by using the following mathematical

function:

Flow Q = f(level

x

· constant)

where the exponent x and the constant depends on the

weir or the ume.

The ow converter has 3 different linearization systems

depending on how the volume of water is measured.

• One choose between a number of predened umes and

weirs, e.g. Parshall umes and V-notch weirs.

• If the ume or weir differ from the normal types of umes

and weirs, the formula Q(h)=k x hn can be applied, where

k and n are keyed in directly.

• Some times it can be desirable to linearizate a levelsignal

which does not follow a mathematical expression. As an

example a ow can be measured in a partly lled pipe,

where the menu point-linearization can be applied.

Technical section with the principles of measuring

Flowconverter 713 converts the level to ow from these

examples. Some of the examples are simplied. The ISO

1438 norm indicates a number af calculation methods

for umes and weirs. The Flowconverter 713 uses these

methods where it is possible.

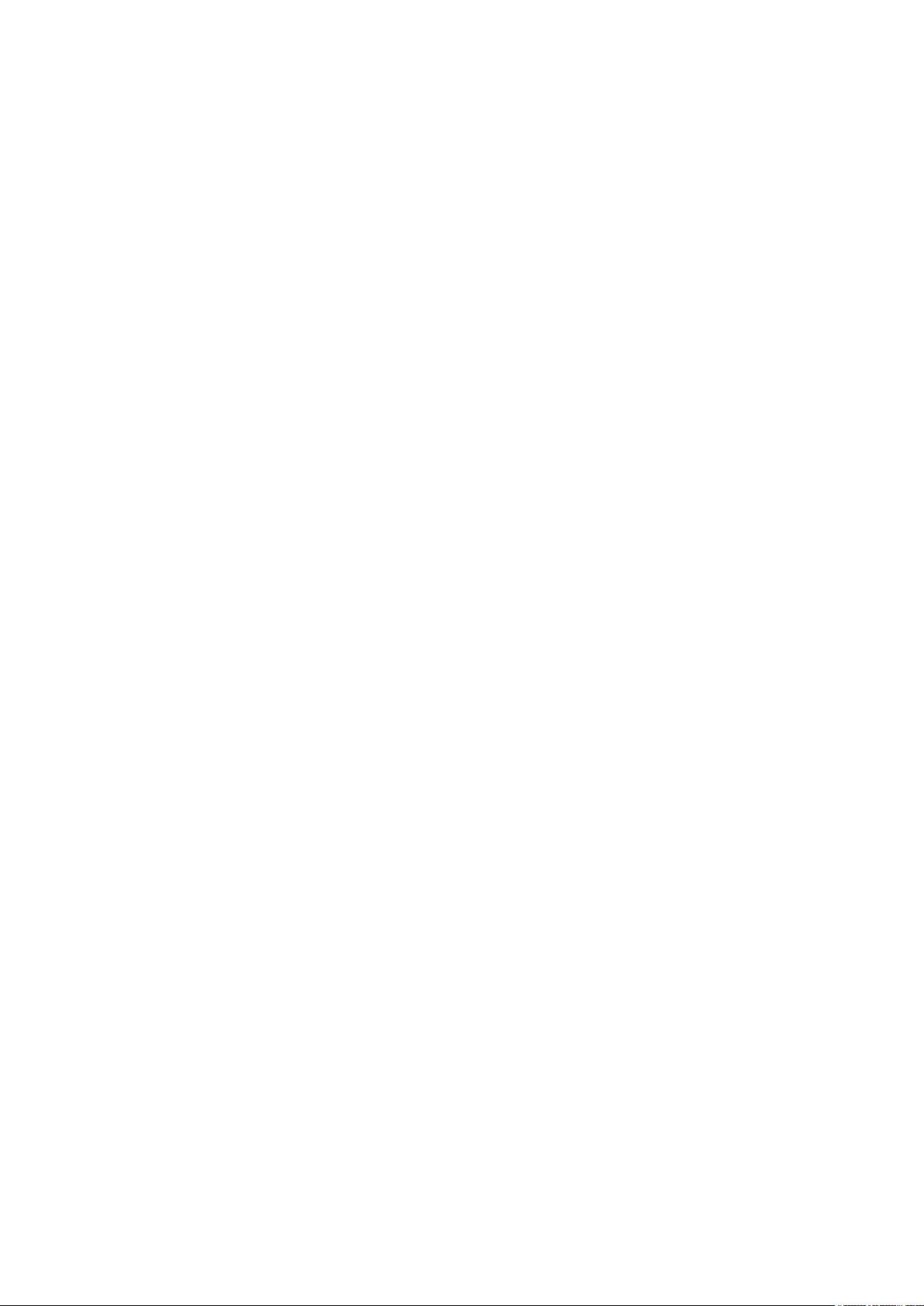

Rectangular sharp edged weir

according to ISO 1438

Rectangular sharp edged weir is supplied in two types:

- with side contraction

where the opening has a smaller width than the feeder

and

- without side contraction

where the width of the opening corresponds to the width

of the channel (B = b).

Rectangular sharp edged weir

with side contraction:

Universal formula: (Kindsvater/Carter)

Q = 3600 × Ce × 2/3 × 2g × be × h

where: Q = ow in m3/h

b = width of weir in [m]

be = effective width of weir in [m]

be = b + k

ha = height in [m]

b

he = effective height in [m]

he = ha+kh, kh = 0,001

hb = depth below edge in [m]

B = ume width in [m]

L = distance to sensor,

4 - 5 × h

g = acc. due to gravity = 9,81 m/s2

a max.

kb is a correction factor in meter.

For determination of k

b/B = 0 kb = 0,0024 m

b/B = 0,2 kb = 0,0024 m

b

b/B = 0,4 kb = 0,0027 m

b/B = 0,6 kb = 0,0036 m

b/B = 0,8 kb = 0,0042 m

b/B = 1,0 kb = -0,0090 m

1,5

e

d

β

ß = minimum 45°

d ~ 1-2 mm

Edge

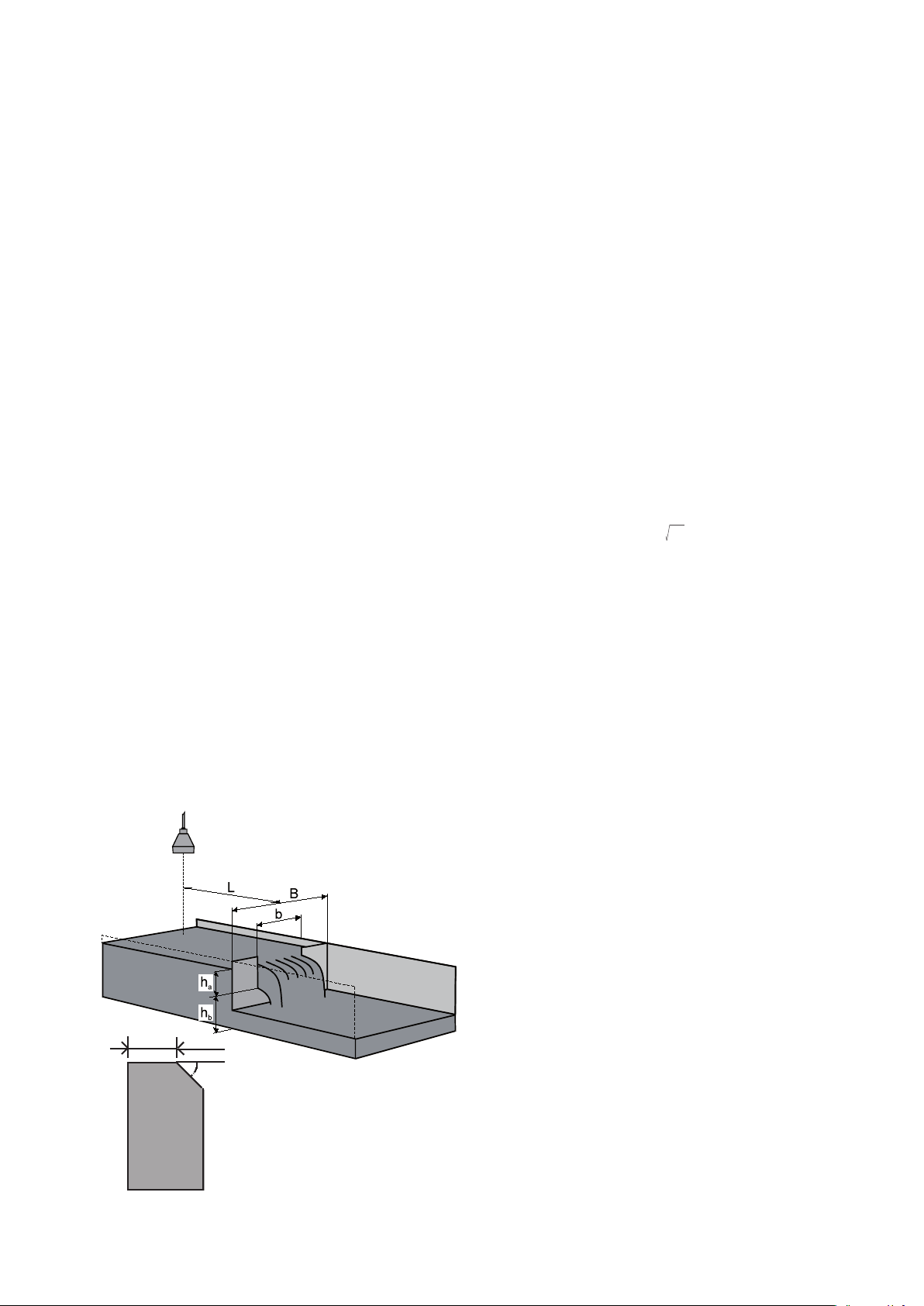

Ce is a contraction coefcient (no unit) depending on the

ratio of b/B and ha/h

b.

For determination of Ce

b/B = 1,0 Ce = 0,602+0,075 ha/h

b/B = 0,9 Ce = 0,598+0,064 ha/h

b/B = 0,8 Ce = 0,596+0,045 ha/h

b/B = 0,7 Ce = 0,594+0,030 ha/h

b/B = 0,6 Ce = 0,593+0,018 ha/h

b/B = 0,4 Ce = 0,591+0,0058 ha/h

b/B = 0,2 Ce = 0,588-0,0018 ha/h

b/B = 0 Ce = 0,587-0,0023 ha/h

b

b

b

b

b

b

b

b

3

Page 4

The following limitations apply for the values of ha/hb, ha,

hb and b:

ha/hb = max. 1,0

ha = min 0,03, max 0,75 m

hb = min 0,10 m

b = min 0,30 m

Formula: (Rehbock equation)

Determination of Ce for different values of b/B.

The following limitations apply for the values of ha/hb, ha,

hb and b:

ha/hb = max. 2,5

h

h

b = min 0,15 m

a

b

= min 0,03 m

= min 0,10 m

(B-b)/2 = min 0,10 m

Rectangular sharp edged weir without side

contraction:

Q = 3600 × Ce × 2/3 × 2g × b × h

where: Q = ow in m3/h

b = width of edge in [m]

Ce = 0,602+0,083 ha/h

ha = height in [m]

b

he = effective height in [m]

he = ha+kh, kh = 0,0012

g = acc. due to gravity = 9,81 m/s

Triangular weir

according to ISO 1438

h

a

h

b

1,5

e

2

h

a

h

b

The sides of the channel must continue at minimum 0,3

x h

after the weir.

a max.

ha = height

hb = depth below edge in [m]

B = ume width in [m]

L = distance to sensor,

4 to 5 × h

a max.

ß = minimum 45°

d = 1-2 mm

d

ha = height in [m]

hb = depth below edge in [m]

B = umewidth in [m]

L = distance to sensor,

4 to 5 × h

a max.

The following limitations apply:

α = 20° - 100°

ha/hb = max 0,4

ha/B = max 0,2

ha = min 0,06 m

hb = min 0,09 m

Formula: (Kindsvater-Shen).

Q = 3600 × Ce × 8/15 × 2g × tg(α/2) × h

where: Q = ow in m3/h

ha = height in [m]

he = the effective height in [m]

he = ha + kh, kh = 0,001

g = acc. due to gravity = 9,81 m/s

2

α = aperture angle

β

2,5

e

4

Page 5

kh is set to 0,001 m and is a correction factor.

The ow is calculated from the formula:

Ce is the coefcient of discharge (no unit). For determi-

nation of Ce, look at diagram below.

0,005

0,004

0,003

0,002

0,001

Diagram for determination of k

h

Diagram for determination of Ce.

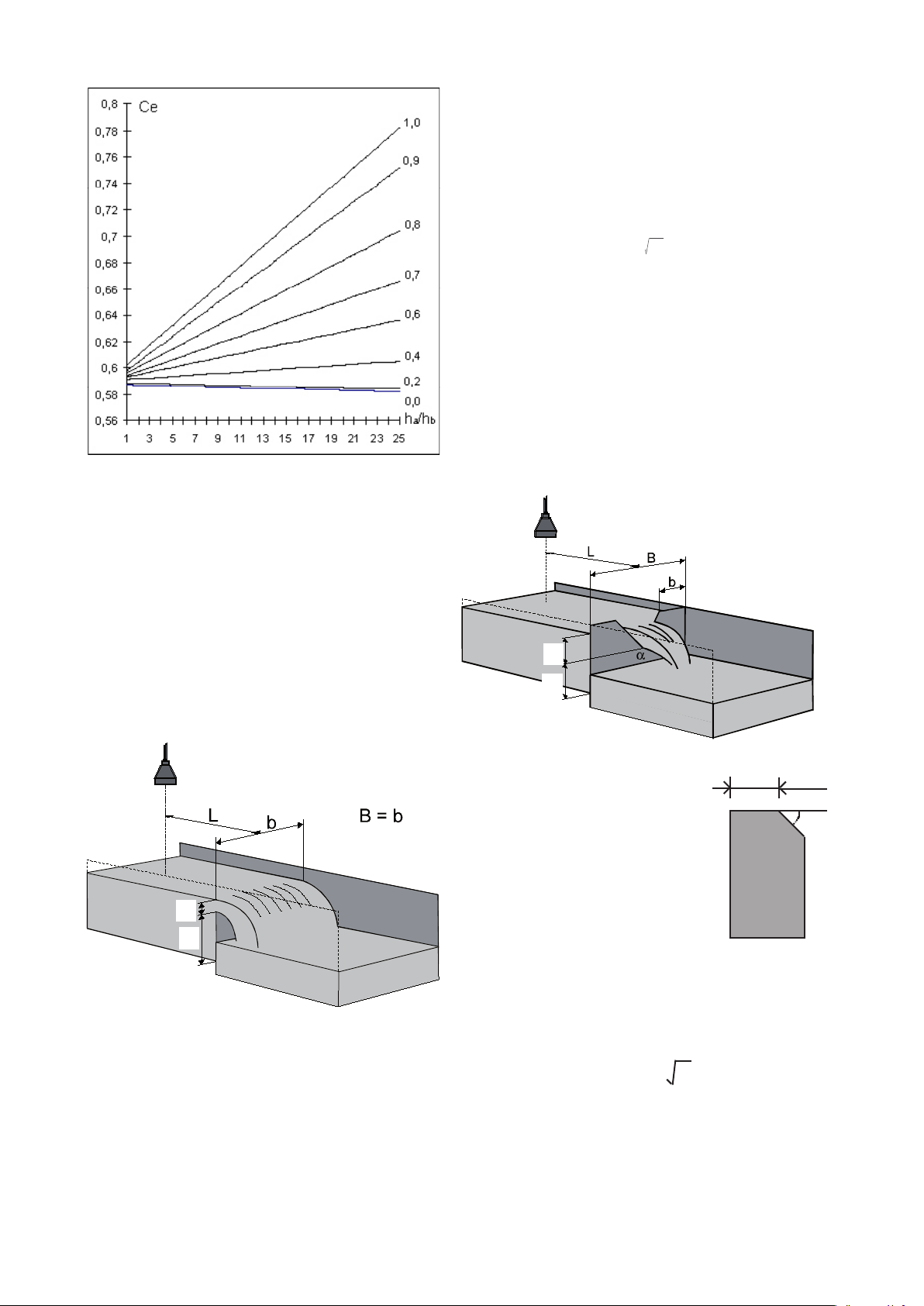

Q = k × h

n

where:

a

Q = ow in m3/h

b = width in the measuring ume in[ m]

ha = water level before the narrowing in [m]

hb = water level in the narrowing in [m]

L = distance to the sensor (use table below)

The factor k and exponent n are constants.

The formula complies to free ow, hb

< 0,7 × h

max

a max

b k n L

1" 217 1,548 0,24

2" 425 1,548 0,27

3" 630 1,548 0,30

6" 1310 1,574 0,41

9" 1851 1,528 0,58

12" 2407 1,519 0,89

24" 5142 1,55 0,99

36" 7863 1,566 1,09

Table for determination of the constants k, n and the

distance to the sensor.

12"

36"

9"

6"

3"

2"

1"

24"

Parshall ume

The most common type of ume is the Parshall ume.

The Parshall ume is a standardized Venturi ume.

h

a

h

b

At free ow, only the level ha is measured. The location

of the sensor is important and must be carried out as illustrated in the drawing and the table in the next column.

It is important to have a laminar ow (horizontal streaming calm water with no whirls) at the out- and inlet from

the ume. Upstream the measuring ume, must extend

at least ten times the width of the inlet section of the

ume.

On the outlet side the only demand is that the water

should run freely. This is the case when hb ≤ 0,7 × ha.

Q/h diagram for Parshall umes, the height ha is shown

as a function of the ow Q.

5

Page 6

Ark6 Diagram 1

0

0,05

0,1

0,15

0,2

0,25

0,3

0,35

0 50 100 150 200 250 300 350 400 450 500

8"

10"

12"

15"

24"

30"

Q [m3/h]

h

a

[m]

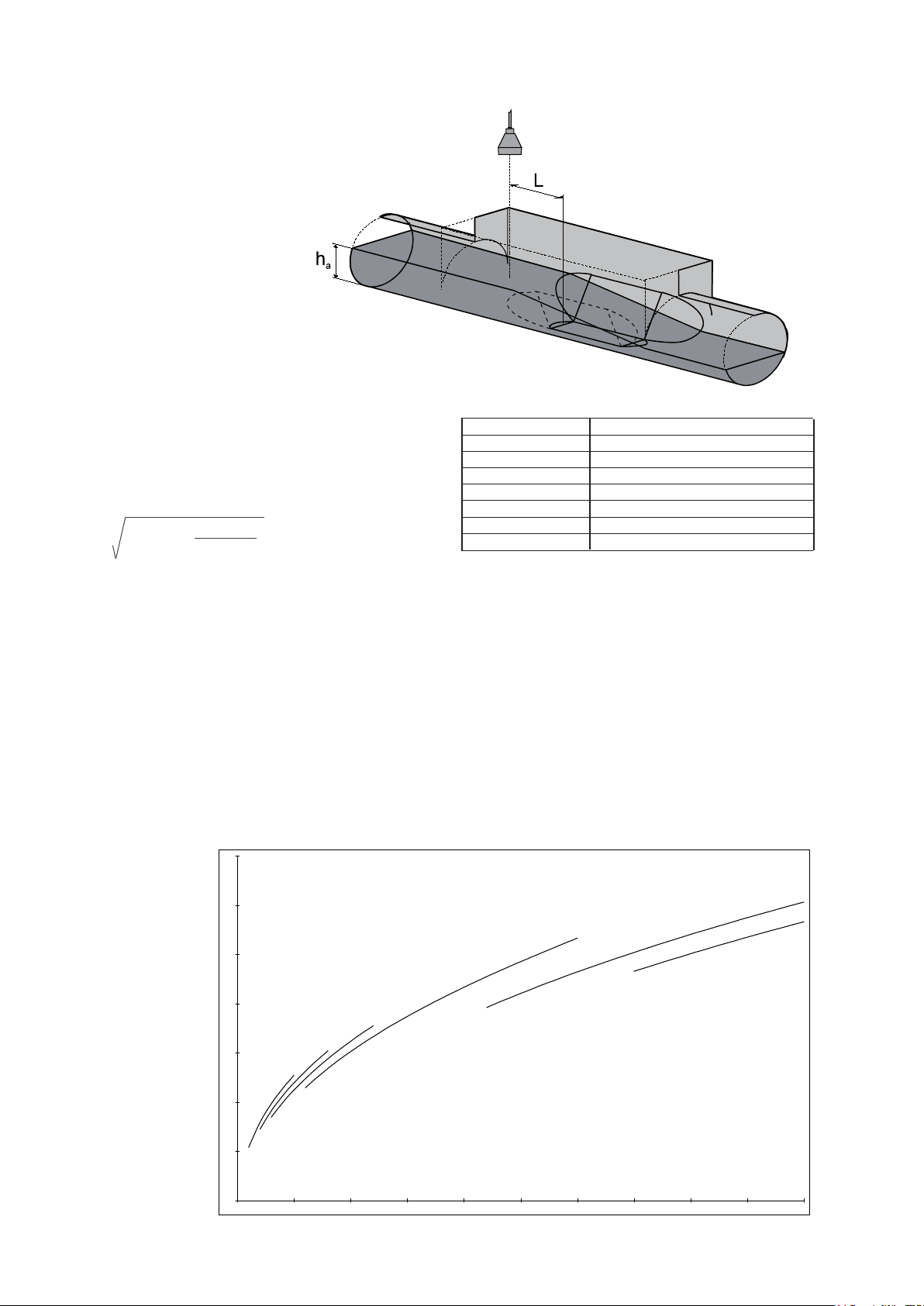

Palmer - Bowlus ume

The Palmer & Bowlus ume is characterized by its circular connection, which makes it easy to install in pipe-

lines. The ume is aimed at measurement in the scale of

20-100% of the prescribed ow.

where:

ha = water level before the narrowing

L = ½ × DN (the nominal diameter of the ume),

measured from the beginning of the meas. section.

No simple ow formulas can be set up for the Palmer

& Bowlus umes, the formulas are dened individually

for every ume. The Flow formulas are derived from the

continuity equation and Bernoulli’s equation:

2

2

A

x A

1

Q = 2g(h1- h2) x

where:

A1 and h1= cross section and height in the inlet of the

ume

2

2

2

A

- A

1

2

Size D Max Flow

6'' (DN 150) 35 m3/h

8'' (DN 200) 70 m3/h

10'' (DN 250) 110 m3/h

12'' (DN 315) 200 m3/h

15'' (DN 400) 325 m3/h

18'' (DN 450) 545 m

3

/h

24'' (DN 600) 1100 m3/h

30'' (DN 800) 1750 m3/h

Table showing the size of D, and the max. ow for the

Palmer & Bowlus umes.

A2 and h2= cross section and height in the outlet of the

ume

For the Palmer & Bowlus umes with the dimensions 6'',

8", 10", 12", 15", 18'', 21'', 24" and 30", the ow formulas

are dened and incorporated in the ow converter. In

the menu „Programming of ow calculation“ the relevant

ume is chosen.

Q/h diagram for the MJK Palmer & Bowlus umes, the

height ha is shown as a function of the ow Q.

6

Page 7

Venturi ume - long throated

according to ISO 1438

The following formula and diagram concern the long

throated Venturi ume.

Venturi ume - Khafagi

The following formula and diagram concern the Khafagi

Venturi ume.

L

b

h

a

713 follows the calculation method for long throated

Venturi umes described in ISO 1438. The connection between level and ow is complex and can not be

described in a simple formula. When dimensioning the

following simplied formula can be applied.

Q = 6495 x b x h

where:Q = ow in [m3/h]

b = width in the ume in [m]

ha = water level before the narrowing

L = distance to the sensor = 3 - 4 x h

1,5

(NB: not ISO 1438!)

a

a max

L

h

a

b

The ow is calculated from the following formula.

Q = 6278 x b x h

1,5

+ 328 x h

a

2,5

a

where:Q = ow in [m3/h]

b = width in the ume in [m]

ha = level

L = distance to sensor = 3 - 4 x h

H = height of the ume

a max

160mm

120mm

H

200mm

200mm

160mm

120mm

Q/h diagram for the long throated Venturi umes,

the height ha is shown as a function of the ow Q.

Q/h diagram for the Khafagi Venturi umes, the

height ha is shown as a function of the ow Q.

Size b H Max Flow

5" (DN 120) 150 mm 35 m3/h

5'' (DN 120) 300 mm 120 m3/h

6'' (DN 160) 300 mm 150 m3/h

8'' (DN 200) 320 mm 200 m3/h

8'' (DN 200) 520 mm 450 m3/h

Table showing the size of b, and max. ow for the

Venturi ume - Khafagi.

7

Page 8

Mounting of sensor

Ultrasonic measuring system

The Ultrasonic sensor must be placed correctly according to the actual

measuring stormows. The sensor has to be installed at right angles

above the liquid surface (level tube). We recommend using bracket

type MJK 200270, and if necessary it can be used together with universal brackets of type MJK 200205.

The following distances ensure a correct function:

Measuring range 0-30 cm 0-1 m 0-3 m

Blocking distance 40 cm 40 cm 75 cm

Min. meas. range 10 cm 10 cm 30 cm

Max. meas. range 30 cm 1 m 3 m

Max. sensor height 70 cm 140 cm 3,75 m

When measuring stormows, it might be necessary to mount a reection plate, within the measuring range, to ensure that the echo signals

are returned. E.g. if the distance at low levels exceeds the maximal

sensor height.

The distance from the reection plane to the 0-level of the measuring (=

normally the height of the weir) is set as the 0-level suppression. Notice

that the 0-level suppression must be added to the measuring range, to

respect the maximal sensor height

The following always applies to ultrasonic measuring systems:

Maximal sensor height = blockingdistance + measuring range +

optional 0-level suppression

Hydrostatisc measuring system

The pressure transmitter must be placed correctly according to actual

measuring stormows. The sensor must be fasted possibly mounted

on a pipe with a 1 inch. internal screw thread. In some case it might be

necessary to mount the pressure transmitter in a measuring well, so the

transmitter will not effect current of water.

The following distances ensures a correct function:

Without 0-level suppression - recommended at

normal ow measuring in

umes and weirs

Blocking

distance

Measur-

ing-

range

Sensor height

With 0-level suppression -

recommended at stormow

measurings

Blocking

distance

Opt. reflection plate

Measuring

range

0-level

suppression

Sensor height

Recommended at ow- and

stormow measurings

Measuring range 0-30 cm 0-1 m 0-3 m

Measuring range

Min. range 10 cm 30 cm 1 m

Max. range 30 cm 100 cm 3 m

The following always applies to hydrostatic measuring systems:

Maximal sensor height = measuring range + optional 0-level suppression

Notice that the 0-level suppression must be added to the measuring

range.

Measuring range

0-level suppression

Electrical connection

Electrical connection of the Flow Converter 713, for hydrostatical, and ultrasonic measurement systems respectively.

Flow Converter 713

Hydrostatic measuring

system

Supply

Hydrostatic sensor 7062

Flow Converter 713

4-20 mA supplied

Supply

Flow Converter 713

Ultrasonic measuring

system

Supply

Level Transmitter 511U

4-20 mA output signal

+ -

Relais 1 to 4 Puls output Analog

output

Ultrasonic sensor 7005

An example of an installation, with long distance

(more than 50 m) between the measuring location

and the amplier. A MJK 511 Level transmitter (with

a 3-wire, 4-20 mA supply) is applied as preamplier,

and the signal is transmitted via an ordinary 3-wire

cable. The 511 level transmitteren is set for 100%

measuring range, this allows any adjusting of the

measuring range to be carried out from the owconverter. This mounting allows you to have a distan-ce

8

between sensor and amplier of more than 1000 m.

Page 9

Cable extensions

One of the most common faults on a MJK 713 installation is bad or faulty cable connections.

It is recommended to use a MJK connection box if the

sensor cable must be extended.

Ultrasonic sensor color codes

The ultrasonic sensor are standard delivered with 40 ft

of cable. The ultrasonic sensor can be delivered with up

to 150 ft of cable on order, or the standard 40 ft cable

can be extended to max. 150 ft.

The cable is a special low capacity cable,

so extensions should always be made with

the same type of cable.

MJK Connection

Box (NEMA 4X),

order no.

200590.

Cutting the cable

The cable is delivered with the wires stripped as shown

with the black wire (no. 5) soldered to the shield:

When the cable is cut, only 4 wires will appear:

To ultrasonic

sensor

Max. 150 ft.

To MJK 713

flow meter

The ultrasonic sensor cable has 5 wires with both color

code and number:

Number Color Designation

1 Brown Ultrasonic pulse

2 Red Ultrasonic pulse

3 Orange Temperature compensation

4 Yellow Temperature compensation

5 Black Shield *)

*) This wire is connected to the cable shield.

The wires are mounted according to the terminal markings on the connection box PCB and on the MJK 713

respectively.

When the cable has been cut, the shield

should be mounted in terminal 5 instead

of the black wire !

9

Page 10

Control

On the front of the Flow Converter, you will nd 4 function keys: the ow key, the summation key, the alarm key

and the sample key.

When one of these keys are pressed once or more the

different function menues appear. The avaliable menus

depend on how the Flow Converter is congured.

The conguring of the Flow Converter takes place in the

conguring menus, which in turn is divided into several

submenus. You gain access to the conguring menus by

pressing the MENU key. In each menu the different settings are obtained by pressing the arrow keys.

A complete diagram of the menus can be found on page

17 in this manual.

On the following pages every submenu is described.

The figure below shows the genel function of the key on

the Flow Converter:

Display

2 x 24 characters text display for indication of menus

and values. The background

of the display is illuminated.

Q(t)

Registers for flow:

- Instantaneous value

- Average flow 1 hour

- Average flow i day

- Average flow 24 hours

The ESCape-key

The key will change back to

the head menu, or undo a

new choice. By pressing the

ESC.-button two or three

MENU

By activating the MENUkey, the display will change

to the next head menu in

the outline of the menu.

times you will always return

to the indication of functions.

ALARM

Alarm record with the previous

nine alarms incl. date and time

of occurance.

As well as time for voltage

coupling.

Σ Q(t)

Registers for either: or:

- Summed flow total - Number of stormflows

- Summed flow 1 hour - Time of stormflow

- Summed flow today - Total stormflow

- Summed flow 24 hours - Amount of most recent stormflow

- 99 days log - Start/finish time for last

stormflow

10

The arrow keys

The arrow keys are used

for changing a current

setting. An arrow key is

pressed to change between a current and not

current setting. Activating

of the arrow keys also

changes the values. By

activating the

↑-key, the number in

the display will increase.

When activating the ↓-key

the value decreases.

ENTER

A shift from the

head menu to

submenu, as

well as between

submenus is

carried out by

activating the

ENTER-key. A

choice from a

submenu also

needs confirming

by pressing the

ENTER-key.

SAMPLER

Registration of:

- Total number of samples

- Number of samples today

- Number of samples within

24 hours

Page 11

Function keys

Flow key

Q(t)

This key gives access to a number of menues that dis-

playes the values of the current ow, as well as various

average values.

F1 Flow

Press once for:

21/06/95 13:34:12

FLOW : 3196 m3/h

The instantaneous current ow is shown. The ow is calculated from the chosen Q(h)-formula. Measuring value

with time and date is indicated.

F2 Average ow 1 HR

Press twice for:

AVERAGE FLOW: 1 HR

FLOW : 3120 m3/h

The summation key

Σ Q(t)

If the ow converter is set up for continuous measuring,

this key will give access to indication of summed quanti-

ties. If the ow converter is set up for stormow measuring the stormow quantities and number of stormows

are indicated.

Measuring of volume

F5 Σ volume

Press once for:

21/06/95 13:34:12

Σ VOLUME: 223196 m

The total volume is indicated, from when the value was

last reset or since start-up.

F6 Σ volume 1 HR

3

The average ow for the last full hour is indicated.

F3 Average ow today

Press three times for:

AVERAGE FLOW: TODAY

FLOW : 3120 m3/h

The average ow from 00:00:00 to the current time is

indicated.

F4 Average ow 24 HR

Press four times for:

AVERAGE FLOW : 24 HR

FLOW : 3120 m3/h

The average ow for the last 24 hours is indicated

(00:00:00 til 23:59:59).

Press twice for:

1 HR 11:00 - 12:00

Σ VOLUME : 77376 m

Here the summed volume for the previous full hour is

indicated (e.g. 14.00-15.00).

3

F7 Σ volume today

Press three times for:

TODAY 00:00 - 13:51

Σ VOLUME: 776 m

The summed volume for today is indicated. The result

along with the time interval is updated every full minute

(xx:xx:00).

3

F8 Σ volume 24 HR

Press four times for:

24 HR : 21/05/95

Σ VOLUME: 77376 m

3

The summed volume for the previous 99 days is indicated. The daily quantity is logged every day at (00:00:00).

Use the arrowkeys to browse through the last 99 days

log.

Quantity values can be reset by pressing ENTER, see

menu F19.

11

Page 12

Stormow measuring

F9 No. of stormows

Press once for:

Alarmkey

21/06/95 13:34:12

NO. OF STORMFLOWS 19621

The total number of stormows is calculated from the last

time the value was reset or the system was restarted.

F10 Stormow time

Press twice for:

21/06/95 13:34:12

STORMFLOW TIME : 00:21

Here the total time (hours:minutes) of stormow is indicated.

F11 Stormow volume total

Press three times for

STORMFLOW VOLUME

TOTAL : 1084 m

The total volume of stormows is indicated. The volume

is calculated from the last time the value was reset or the

system was restarted.

3

F12 Volume last stormow

Press four times for:

STORMFLOW

LAST STORMFLOW : 1084 m

The volume of the last stormow is displayed.

3

F13 Stormow start/stop

Press ve times for:

ALARM

The digital outputs can be congured as alarms of one

of the following alarm types: high ow, low ow, 24 hour

volume, one hour volume and sensor error. Press the

alarm key to see the previous nine alarms. A new alarm

is registered as alarm no 1, the other alarms are moved

one place, and the alarm which was previously regis-

tered as alarm no 9 is erased.

F15 Alarm display

After pressing the key once alarm no. 1 is shown, which

is the latest alarm; press again and alarms 2-9 come up.

By using the arrow keys it is possible to move back-

wards and forwards between the alarms.

The instant an alarm is registered, the alarm type, the

digital output and the time shows on the display:

ALARM 1: HIGH FLOW D#

13/03 23:33

When the alarm is no longer active, the time of switch

off is registered. Beware that different alarms could have

been activated in the meantime, meaning the alarm is no

longer no. 1:

ALARM 2: HIGH FLOW D#

13/03 23:33 13/03 23:54

ALARM 3: VOLTAGE FAILURE

21/06 00:22 21/06 11:23

When a new alarm appears the display will change from

the previous chosen main menu to F14 - alarm indica-

tion, alarm 1.

START 25/12 12:32

STOP 25/12 13:01 00:29

Start and stop times are indicated as well as the duration

of the last stormow. All values can be reset by pressing

ENTER, see under F18.

F14 99 days log

Press six times for:

log 12 138 m

The last 99 stormows is saved in a log. Use the arrowkeys to browse through the log.

18/6 12:56 18´/6 14:21

3

The start time for voltage failure is detected every 5 min.,

and the stop time is registered immediately after the volt-

age is cennected again.

12

Page 13

Sample key

Menu key

SAMPLE

If one or several of the digital outputs are congured for

controlling a sampler, pressing this key will give following

indications:

F16 Number of samples

Press once for:

22/02/95 04:39:12

NUMBER OF SAMPLES: 34245

This display indicates how many samples have been

taken since last reset or system start up. Press ENTER

for reset, see menu F19.

F17 Number of samples today

Press twice for:

TODAY 00:00 - 17:22

NUMBER OF SAMPLES: 45

MENU

This key allows access to the menus with reading and

programming of the readings and functions of the ow

converter. In menus with various options the choices will

be seen on top of one another, the top choice being the

current value. By pressing one arrow (up or down) the

choice varies. A choice is conrmed by pressing ENTER.

Non conrmed choices will ash on the display, where

as a current/conrmed choice stands rm.

0.1 Level

Press once for:

LEVEL= 543.2 I= 12.3 mA

D1=0 D2=0 D3=1 D4=1 D5=0

Here the measured level (LEVEL), the value for the

analog output (I) is indicated. The digital outputs are indicated as D1-D5. 0 indicates non activated output, where

as 1 indicates activated outputs. Outputs chosen to "not

in use" are not shown.

0.2 Language

Press twice for:

This display indicates how many samples have been

taken within 24 hours (00:00:00 - now).

F18 Number of samples 24 HR

Press three times for:

24 HR : 30/06/95

NUMBER OF SAMPLES: 11

This menu indicates how many samples were taken

yesterday. Value and date for the previous 24 hours are

indicated.

F19 Reset value

Reset is possible from the menues F5, F6, F7, F9, F10,

F11. By using the enter key and the following menu will

appear:

RESET type

YES: Enter NO: Menu

LANGUAGE ENGLISH

DANSK

By pressing arrows the languages can be altered. When

changing to a new language the display will be clear for

a few seconds.

0.3 Enter access code

Press three times for:

KEY IN ACCESS CODE

USE ARROW KEYS 0000

This menu shows, when an access code has been cho-

sen (four gures) in the conguring menus. Double arrows changes the rst two digits, single arrows changes

the last two digits. Press ENTER for conrmation of

choice of access key. When the access code is correctly

keyed in access to the conguring menus will be given

for 5 min. since last key pressed.

0.4 Access denied

What happens when the wrong access code is keyed in:

ACCESS DENIED

It will not be possible to make changes in the set up. Return to the previous chosen functional menu by pressing

the ESC-key once.

13

Page 14

Conguring

2.1 Sensor and range

1.0 Programming of main functions

Press Enter to obtain access to the conguring menues.

1.1 Set date and time

Time and date is adjusted with the arrow keys, followed

by ENTER, if no change is desired, press the MENU key.

1.2 Access code enabled/disabled

Choose whether access code is desired or not. The

code blocks the access to the conguring menus, but

allows reading and operation of the ow converter. Use

the arrow keys to change between options and conrm

with ENTER.

1.3 Enter new access code

This menu shows a chosen access code (4 gures) on

the conguring menus. The arrow keys are used for

keying in the code as well as for conguring. Double arrows changes the rst two digits, single arrows changes

the last two digits. Press ENTER to conrm choice of

access codes.

1.4 Measurement Stormow /

Continuous

In this menu a choice can be made of whether the ow

converter measures a continous ow or a stormow. Use

the arrow keys to change between choices and conrm

with ENTER.

1.5 Calc. for stormow delayed

In this menu a delay of the level reading is chosen, in order to ensure that the level is over the setpoint for a certain time before the calculation begins. This time interval

is keyed in with the arrow keys. Double arrow shows a

rapid reading of the value with 10 second jumps. Single

arrow runs the value slowly with one second jumps. The

scale is in seconds (0-999).

1.6 Stormow counter delayed

Here a time interval is keyed in, where the stormows

must be 0 before a new stormow can be registered in

the stormow counter. Use the arrow keys. Double arrow

runs the value rapidly with one hour jumps. Single arrow

runs the value slowly with one minute jumps.

The format is hours:minutes. Maximum time interval is

99 hours and 59 minutes.

2.0 Sensor, data for mounting

The ow converter is delivered with one of two measuring principles, hydrostatic measuring or ultrasonic measurement, In menu 2.0 the setting is shown.

When hydrostatic measurement is applied this is where

the type of sensor applied can be keyed in, use the ar-

row keys to choose between options, and conrm with

ENTER. When ultrasonic measurement is applied, the

type of sensor applied is preset by the factory, the sen-

sor type can be read here.

2.2A Sensor optional range

This menu is only accessible in connection with hydro-

static measurement. When optional range is chosen

the sensor range is set using the arrow keys, double

arrow change the value with 10,0 cm steps, single ar-

row change the value with 0,1 cm steps, conrm with

ENTER.

2.2B Sensor level

This menu is only accessible in connection with ultrason-

ic measurement. The sensors height above the actual

zero is keyed in, use the arrow keys to adjust the value,

and conrm with ENTER.

2.3 Flow measurement 0-point level

The level where the ow is to start being registered is

keyed in. At measurement in e.g. a Palmer/Bowlus weir,

the level is measured from the bottom of the weir. That

is, a ow does not occur further down than 54 mm from

the bottom due to the bulge at the bottom. Therefore

5.4 cm is keyed in as the zero point of owmeasuring.

Another possibility is when a pressure sensor is placed

under a sharp edged plate. Meaning that the ow will be-

gin at ex. 10.4 cm. This height is keyed in with the arrow

keys. Double arrow runs the value fast with 10 cm steps,

single arrow runs the value slowy with 0,1 cm steps.

2.4 Min. level for ow calculations

Here the level for 0-point can be keyed in over the ow

calculation for starts of the ow measurement. This func-

tion is used for instance when a weir has to be meas-

ured. The ow calculation is not done before the level is

above the minimum level, while the actual cal-culation is

made from the 0-point for ow measurements.

2.5 Level for max. ow

Here the span for ow measuring is keyed in. This is the

level at the maximum ow. This level is keyed in with the

arrow keys. Double value runs the value fast with 10 cm

steps. Single arrow runs the value slowly with 0,1 cm

steps. When the chosen level has been conrmed by the

enter key, the ow converter calculates the max. ow ac-

cording to the chosen weir/type of storm ow. By choos-

ing the linearization point this menu does not appear, as

the highest level automatically provides the span.

2.6 Averaging of level over time

In this menu the time for which the level measurement

is to be averaged is keyed in before Q(h) is calculated.

The interval is optional between 1 and 60 seconds. Use

arrow keys; double arrow runs the value fast with 10

second steps, single arrow runs the value slowly with 1

second steps. The format is seconds.

14

Page 15

3.0 Programming of ow calculation

3.6.3 V-notch weir ume width

Here the type and size of ume/weir used for the ow

measuring is chosen.

3.1 Flow measuring unit

Here the unit is chosen between m3/h and l/s. Use arrow

keys to move between options, and conrm with ENTER.

3.2 Select type and range

There are six options for calculation of ow: Parshall

ume, Palmer/Bowlus ume, V-notch weir, rectangular

weir, linearization and optional ow formula. Select the

desired parameter with arrow keys and conrm choice

with ENTER.

3.3 Venturi umes

If a Venturi-ume has been selected, there is a choice

between various sizes: 5", 6" and 8". Change between

the various types withe the arrow keys. Conrm with

ENTER. Both the longthroated and the Khafagi umes

can be chosen.

3.4 Parshall umes

Here the width of the ume where the v-notch weir is

placed, is keyed in. Double arrow runs the value fast

with 10 cm steps, single arrow runs the value slowly with

0,1 cm steps.

3.6.4 V-notch weir depth below edge

Here the depth of the ume below the bottom of the trianglular weir is keyed in with the arrow keys. Double arrow

runs the value fast with 10 cm steps. Single arrow runs

the value slowly with 0,1 cm steps.

3.7.1 Rectangular weir ume width

Here the total width of the channel where the rectangular

weir is placed is keyed in. Use arrow keys. Double arrow

runs the value fast with 10 cm steps, single arrow keys

runs the value slowly with 0,1 cm steps.

3.7.2 Rectangular weir edge width

Here the width of the rectangular weir is keyed in with

the arrow keys. Double arrow runs the value fast with 10

cm steps, single arrow runs the value slowly with 0,1 cm

jumps.

If a Parshall-ume has been selected, there is a choice

between various sizes: 1", 2", 3", 6", 9", 1', 2' og 3'.

Change between the various sizes with the arrow keys.

Conrm choice with ENTER.

3.5 Palmer/Bowlus umes

If a Palmer/Bowlus-ume has been selected there is a

choice between various sizes: 6", 8", 10”, 12”, 15” 18”,

24” og 30”. Change between the various sizes with the

arrow keys. Conrm choice with ENTER.

3.6.1 V-notch weir

If a V-notch weir has been selected there is a choice

between 28.1°, 53.1°, 90° and optional weirs. Below the

weir type the measuring range is shown. Change be-

tween the various types with arrow keys. Conrm choice

with ENTER.

The ISO 1438 standard describes the height and ow

relations in detail for a stormow of 90°, if this angle is

chosen the width of weir and depth under weir must be

keyed in. For other angles only the angle is keyed in.

Provided that a straight inow on at least 10 x width of

the letter V, and free ow from the under weir of the letter

V.

3.7.3 Rectangular weir depth below edge

Here the depth of the channel below the bottom of the

rectangular weir is keyed in with the arrow keys. Double

arrow runs the value fast with 10 cm steps, single arrow

key runs the value slowly with 0,1 cm steps.

3.8.1 Linearization number of Q(h) points

The desired number of Q(h)-points, are indicated for

the linearization. The gure can range between 1 and

10. Use arrow keys. The number of points decides how

many times you run through the menus 3.8.2 og 3.8.3.

Always start with the lowest value, then the next and so

on until the largest value is reached.

3.8.2 Linearization height point

Here level [h] in a Q(h)-point is keyed in. The level is

keyed in with the arrow keys. Double arrow runs the

value fast with 10 cm steps, single arrow runs the value

slowly with 0,1 cm steps. The level can be set in the level

span area. The level MUST be higher than previously

keyed in levels. The quantity can only be shown in total

of m3/h or l/sec. The highest Q(h)-point automatically

gives the measuring range.

3.6.2 Key in optional angle

If optional angle is choosen, key in the angle with the

arrow keys. The angle can be choosen between 10° and

89°, conrm selection with the ENTER key.

3.8.3 Linearization ow point

The volume [Q] in a Q(h)-point is keyed in. The volume

is keyed in with the arrow keys. Double arrow runs the

value fast with 1 m3 jumps, single arrow runs the value

slowly with 0.1 m3 jumps. The volume can be set in the

volume-span area. The quantity MUST be greater than

15

Page 16

previously keyed in quantities. The ow can only be set

in whole numbered m3/h or l/s. The highest Q(h) gives

the measuring eld.

3.9.1 Optional formula enter exponent

The exponent in the ow formula (Q(h)=K*hx) is keyed

in. Q is the ow in m3/h, h presents the level in meters,

K is a factor between 1 and 9999 and x is the exponent

which is between 1.000 and 2.500, K and x is unitless.

Key in with the arrow keys. Double arrow runs the value

fast with 0.1 steps. Single arrow runs the value slowly

with 0.001 steps.

3.9.2 Optional formula enter factor

The factor K in the ow formula (Q(h)=K*hx) is keyed in.

Key in with the arrow keys. Double arrow runs the value

fast with 100 steps. Single arrow runs the value slowly

with 1 steps. The factor can be adjusted in the area 1

- 99999.

4.0 Programming of digital outputs

4.1 Enter digital output

Conguring of the 5 digital outputs. Select with the arrow keys which digital output to program, conrm with

ENTER.

Digital output 5 (DO5) is standard an output for an external counter. DO5 can be ordered as an option for a relay

output.

4.2 Select function for DO

For digital output 1-4 select with arrow keys between

8 various functions: counter output, sampler, ow>0%,

ow high, ow low, alarm 24 hour volume, alarm 1 hour

volume and alarm sensor error. The choice is conrmed

with ENTER.

Counter output: After a programmed number of m3,

the output is activated for an

external counter.

Sampler: After a programmed number of m3,

the output is activated for start up

of an externally connected

sampler, or to a possibly connected

chemical dosing.

Flow>0%: Signal to indicate that ow is

greater than 0, is applied i.e. when

measuring emergency stormow.

Alarm ow high: Activated if ow exceeds an

adjusted value.

Alarm ow low: Activated if ow drops below an

adjusted value.

24 hour volume: Activated is 24hour volume alarm

exceeds a programmed value.

Hour volume: Activated if hourly volume exceeds

a programmed value.

Sensor error: Activated at sensor error.

Out of action: Is chosen when the output is not

applied.

4.3 Alarm ow high

The limit for ow high is keyed in with the arrow keys.

Double arrow runs the value fast with 10cm steps, single

arrow runs the value slowly with 0,1 cm steps. The area

is 0.0 to (maximum ow+10%).

4.4 Alarm ow low

The limit for ow low is keyed in with the arrow keys.

The area is 0.0 to (maximum ow+10%).

4.5 Alarm 24 HR volume

The limit for max. 24 hour volume is keyed in with the

arrow keys.

4.6 Alarm 1 HR volume

The limit for max. hourly volume is keyed in with the ar-

row keys.

4.7 Enter signal delay

The time a limit for an alarm can be exceeded before a

DO is activated, is set. The format is as follows - hours:

minutes. The maximum delay is 99 hours and 59 min-

utes. The delay is working for chamge from not active to

active mode as well as change from active to not active

mode.

4.8 Enter volume between pulses

The volume in m3 that passes between each time a pulse is

sent to a DO is keyed in.

4.9 Digital output ON-time

In this menu the ON-time for the DO is keyed in. Key in

with arrow keys. The area is (0,1-30 sec).

4.10 Digital output NC/NO

In this menu the relay function for digital output is keyed

in, as Normally Open (NO) or Normally Closed (NC).

Select with arrow keys, conrm with ENTER.

5.0 Programming of analog output

In this menu the mA-output of the ow converter is

adjusted.

5.1 Analog output 0-20 / 4-20 mA

Here you select between mA-output 0-20 or 4-20 mA.

Select with arrow keys, conrm with ENTER. The output

follows the ow at max ow, keyed in menu 2.5 gener-

ated 20mA.

16

Page 17

Specications

Ultrasonic sensor 7005-1013 7005-1023

Measuring range: 3 m (10 m) 30 cm or 100 cm

Frequency: 30 kHz 100 kHz

Spreading: 3

Temperature

compensation: built-in

Temperature: -20 - +60oC

Dimensions: ø103 x 94 mm

Materials: PP Green / POM Black

Cable: Screened oil resistant PVC, length 12 m

Can be extended to:100 m 50 m

Housing: IP 68, water proof, withstands immersion, max. 1 bar

Pressure Transmitter 7062-1413 7062-1423 7062-1433

Measuring ranges: 0-30 cm 0-1 m 0-3 m

Function: 2-wire, 4-20mA

Accuracy: ±0,5%

Temperature: -10 - +60oC

Dimensions: ø60 x 132 mm

Materials: House: PP

Diaphragm: Gold-plated ceramic, socket in steel (AISI 316L)

Cable: 2x0,5mm2, length 12 m, can be extended.

Mounting: 1" thread. Mounted on pipe.

Housing: IP 68, water proof, max. 0,5-2 bar

Flow Converter 713

Measuring ranges: 0 - 30 cm, 0 - 1 m, 0 - 3 m

Supply: 220-240, 110-120 or 24V AC, ca. 10 VA

Temperature: -20 - +60oC

Input signal: From ultrasonic sensor or pressure transmitter, 4-20 mA

Accuracy: ±1% (min. ±1 mm)

Outputs: plug 6-17 Relay 1 to 4, max. 250V, 4A ohmic, max. 100 VA

Inductive load 100VA. Can be chosen as alarm,

counter, Flow>0 or sampler outputs.

plug 18-20 Relay 5 (as 1-4) or Pulse (optocoupler) max. 36 V, 50 mA

one shot, 100msec. - 10 sec. programmable

plug 21-22 Analogue: 0-20 / 4-20 mA max. 500W galvanic isolation

Facultativeformula: Q =k.hx; Q=Flow, h=heigth, k=factor, x=exponent (ISO 1438)

or point linearization

Indication: 2x24 characters LCD display for reading and programming

Dimensions: 185 x 240 x 115mm (HxWxD)

CE: EN50081-1, EN50082-1

Housing: IP 65

o

Dimensions

Ultrasonic sensor 7005

Pressure transmitter 7062

Flow Converter 713

Order numbers

Part no: Specifications:

201450 713U-1111 Ultrasonic measuring system, range 0-30 cm

201455 713U-1121 Ultrasonic measuring system, range 0-1 m

201460 713U-1131 Ultrasonic measuring system, range 0-3 m

202600 713-1104 Flow Converter without sensor, 4-20 mA input

202650 713P-1114 Hydrostatic measuring system, range 0-30 cm

202655 713P-1124 Hydrostatic measuring system, range 0-1 m

202660 713P-1134 Hydrostatic measuring system, range 0-3 m

Accessories Flow Converter 713:

200105 Panel Mounting kit

200115 Local mounting set with rain roof

200205 Universal bracket

Accessories Pressure Transmitter 7062:

202922 Connection box for cable for pressure transmitter 7062

Accessories Ultrasonic Sensor 7005:

200205 Universalbracket

200220 Bracket for ultrasonic sensor 7005

200590 Connection box for cable for ultrasonic sensor 7005

690010 Cable for ultrasonic sensor 7005

Sensors:

200570 Ultrasonic sensor 7005-1013, 30 kHz

200575 Ultrasonic sensor 7005-1023, 100 kHz

202942 Pressure Transmitter 7062-1413, 0-30 cm

202943 Pressure Transmitter 7062-1423, 0-1 m

202944 Pressure Transmitter 7062-1433, 0-3 m

17

Accessories for mounting:

Universal bracket

Bracket for ultrasonic sensor 7005

Page 18

F1

24/12/96 21:05:00

FLOW: 3196 m

3

/h

F2

AVERAGE FLOW: 1HR

FLOW: 3120 m

3

/h

F3

AVERAGE FLOW:

TODAY

FLOW: 177 m

3

/h

F4

AVERAGE FLOW: 24 HR

FLOW: 170 m

3

/h

F19

RESET

YES: Enter NO : Menu

F5

24/12/96 21:05:00

Ȉ VOLUME: 223196 m

3

F6

1 HR 20:00 -

21:00

Ȉ ҏVOLUME: 176 m

3

F7

TODAY 00:00 -

21:05

Ȉ VOLUME: 3717 m

3

F8

24 HR 23/12/96

Ȉ VOLUME: 1080 m

3

F9

24/12/96 21:05:00

NO. OF STORMFLOWS:

15

F10

24/12/96 21:05:00

STORMFLOW TIME:

9:51

F11

STORMFLOW VOLUME:

TOTAL: 1084 m

3

/h

F12

STORMFLOW VOLUME:

LAST: 54 m

3

/h

F13

START 24/12 13:05

STOP 24/12 13:55

00:50

F15

ALARM: Alarm type

24/12 13:01 24/12

13:55

F16

24/12/96 21:05:00

NUMBER OF SAMPLES:

937

F17

TODAY: 00:00 -

21:05

NUMBER OF SAMPLES:

45

F18

24 HR 23/12/96

NUMBER OF SAMPLES:

56

0.1

LEVEL = 0.00 i = 4.00 mA

D1=0 D2=0 D3=0 D4=0 D5=0

0.2

LANGUAGE ENGLISH

DANISH

0.3

ENTER ACCESS CODE

USE ARROW KEYS 0000

0.4

ACCESS NOT ALLOWED

Menues for configuring

Q(t) Ȉ Q(t) ALARM SAMPLER

MENU

CONTINOUS

STORMFLOW

Functional Indications

ENTER

ENTER

F14

LOG 22 138

m318/6 12:56 18/6

14:21

18

Page 19

1.0

PROGRAMMING OF

MAIN FUNCTIONS

1.1

SET DATE AND TIME

24/12/96

12:30:55

1.2

ACCESS CODE

ENABLED

DISABLED

1.3

ENTER NEW ACCESS CODE

USE THE ARROW KEYS

XXXX

1.4

MEASUREMENT STORMFLOW

CONTINOUS

1.6

STORMFLOW COUNTER

DELAYED hh:mm

XX:XX

1.5

CALC. FOR STORMFLOW

DELAYED mm:ss XX:XX

2.0A

HYDROSTATIC SENSOR

DATA FOR MOUNTING

2.0B

ULTRASONIC SENSOR

DATA FOR MOUNTING

2.1A

SELECT SENSOR AND

RANGE

7062-1413 30.0

cm

2.1B

SENSOR AND RANGE

7005

30.0 cm

2.2B

SENSOR HEIGHT

XXX.X

cm

2.2A

ENTER SENSOR AND RANGE

OPTIONAL RANGE

XX.X

cm

2.3

FLOW MEASUREMENT 0

-

PUNKT

LEVEL XXX.X

cm

2.4

MIN. LEVEL FOR FLOW

CALCULATION XXX.X

cm

2.5

LEVEL FOR

MAX. FLOW XXX.X

cm

2.6

AVERAGING OF LEVEL

OVER XX seK

3.0

PROGRAMMING OF

FLOW CALCULATION

3.1

FLOW MEASURING UNIT

m

3

/t

l/s

3.2

SELECT TYPE AND RANGE

type

3.4

PARSHALL FLUME

dimension

3.5

PALMER/BOWLUS FLUME

dimension

3.6.3

90° V-NOTCH WEIR

FLUME WIDTH

XXX.X m

3

3.7.2

RECTANGULAR WEIR

EDGE WIDTH XXX.X

cm

3.6.1

V-NOTCH WEIR

type

3.7.3

RECTANGULAR WEIR

DEPTH BELOW EDGE

XXX.X

cm

3.8.2

ENTER HEIGHT POINT #

XXX.X cm

3.6.2

V-NOTCH WEIR

ANGLE XXX °

3.9.1

OPTIONAL FORMULA

ENTER EXPONENT X.XXX

3.9.2

OPTIONAL FORMULA

ENTER FACTOR

XX.XXX

3.6.4

90° V-NOTCH WEIR

DEPTH BELOW EDGE

XXX.X

cm

4.1

ENTER DIGITAL OUTPUT

(1.5) X

4.0

PROGRAMMING OF

DIGITAL OUTPUT

3.7.1

RECTANGULAR WEIR

FLUME WIDTH

XXX.X cm

3.8.1

NUMBER OF Q(h)-POINTS

(1-10) X

5.0

PROGRAMMING OF

ANALOG OUTPUT

5.1

ANALOG output

4-20mA

0-20mA

4.8

ENTER VOLUME BETWEEN

PULSES XXX.X

m

3

4.2

SELECT FUNCTION FOR DO#

FUNCTION

4.4

ENTER SETPOINT FOR

FLOW LOW XXX.X

m

3

/h

4.5

ENTER MAX 24 HR VOLUME

ALARM XXX.X

m

3

4.10

DIGITAL OUTPUT # NO

NC

4.6

ENTER MAX 1 HR

VOLUME ALARM

XXX.X m

3

4.9

DIGITAL OUTPUT #

ON-TIME XX.X

sec

3.8.3

ENTER FLOW POINT ##

XXX.X

m

3

/h

4.7

ENTER DELAY ON

SIGNAL mm:ss XX:XX

PRINCIPLES OF MEASUREMENT

HYDROSTATIC ULTRASONIC

ENABLED

STORMFLOW

OPTIONAL

RANGE

DO 1-4

DO 5

COUNTER

SAMPLER

COUNTER

OUTPUT

SENSOR

ERROR

1 HR VOLUME24 HR VOLUME

FLOW

LOW

FLOW

HIGH

Menues for configuring

Return to

functional

indications

PARSHALL

FLUME

PALMER/BOWLUS

FLUME

V-NOTCH WEIR RECTANGULAR WEIR Q(h) LINEARIZATION

OPTIONAL

FORMULA

FLOW > 0

4.3

ENTER SETPOINT FOR

FLOW HIGH XXX.X

m

3

/h

3.3

VENTURI FLUME

dimension

VENTURI

FLUME

19

Page 20

Setting of MJK 713 Open Channel Flow Converter

Measuring range: Series No.:

Date:

Measuring station:

PROGRAMMING OF MAIN FUNCTIONS

Access key Wanted / Un wanted Access key:

Measuring Continiuosly / Storm flow

Calculations for storm flow delayed min sec

Storm flow counter delayed h min

HYDROSTATIC SENSOR / ULTRASONIC SENSOR - DATA FOR MOUNTING

Sensor type:

Sensor range:

Ultra sonic sensor height cm

0-point for flow measuring cm

Min. level for flow calculation cm

Level for max. flow cm

Averaging of level over sec

PROGRAMMING OF FLOW CALCULATION

Flow measuring unit m3/h / l/sec

Parshall flume / Palmer & Bowlus flume Range: m3/h

Triangular weir / Rectangular weir Weir width: cm

Flume width: cm

Depth below edge: cm

Q(h) Linearization High point: h

Flow point: Q

Optional formular Exponent: Factor:

PROGRAMMING OF DIGITAL OUTPUTS

DO1

NO / NC

Function: Setting: Delay on

signal

m3 between

pulses

On-time:

DO2

NO / NC

Function: Setting: Delay on

signal

m3 between

pulses

On-time:

DO3

NO / NC

Function: Setting: Delay on

signal

m3 between

pulses

On-time:

DO4

NO / NC

Function: Setting: Delay on

signal

m3 between

pulses

On-time:

DO5

NO / NC

Counter output m3 between

pulses

On-time

PROGRAMMING OF ANALOG OUTPUTS

Analog output 4-20mA / 0-20mA

20

Loading...

Loading...