Page 1

CONTROLLER 712

CONTROLLER 712

Instruction

General

Thank you for choosing ConTroller 712, the compact unit for

control of 2 pumps or valves with alternation and level alarm.

ConTroller 712 can be connected to a GSM / GPRS modem

for transmission of system conditions and alarms from the

pumping station to the SCADA system.

ConTroller 712 is DIN rail mounted, and is easy to install and

set up from the front panel.

Specifications

ConTroller 712

Dimensions: 86 x 105 x 60 mm (h x w x d)

Power supply: 230 V AC +/- 10 %

Consumption: Approx. 5 VA

Temp. range: - 10 … + 60 °C

Inputs: 4 x level electrodes and 1 x ground electrode

Udgange: 3 x voltage free changeover relays.

(Max. load 4 A resistive / 250 V AC)

Status signas to MJK GSM/GPRS modem.

Enclosure: IP 22

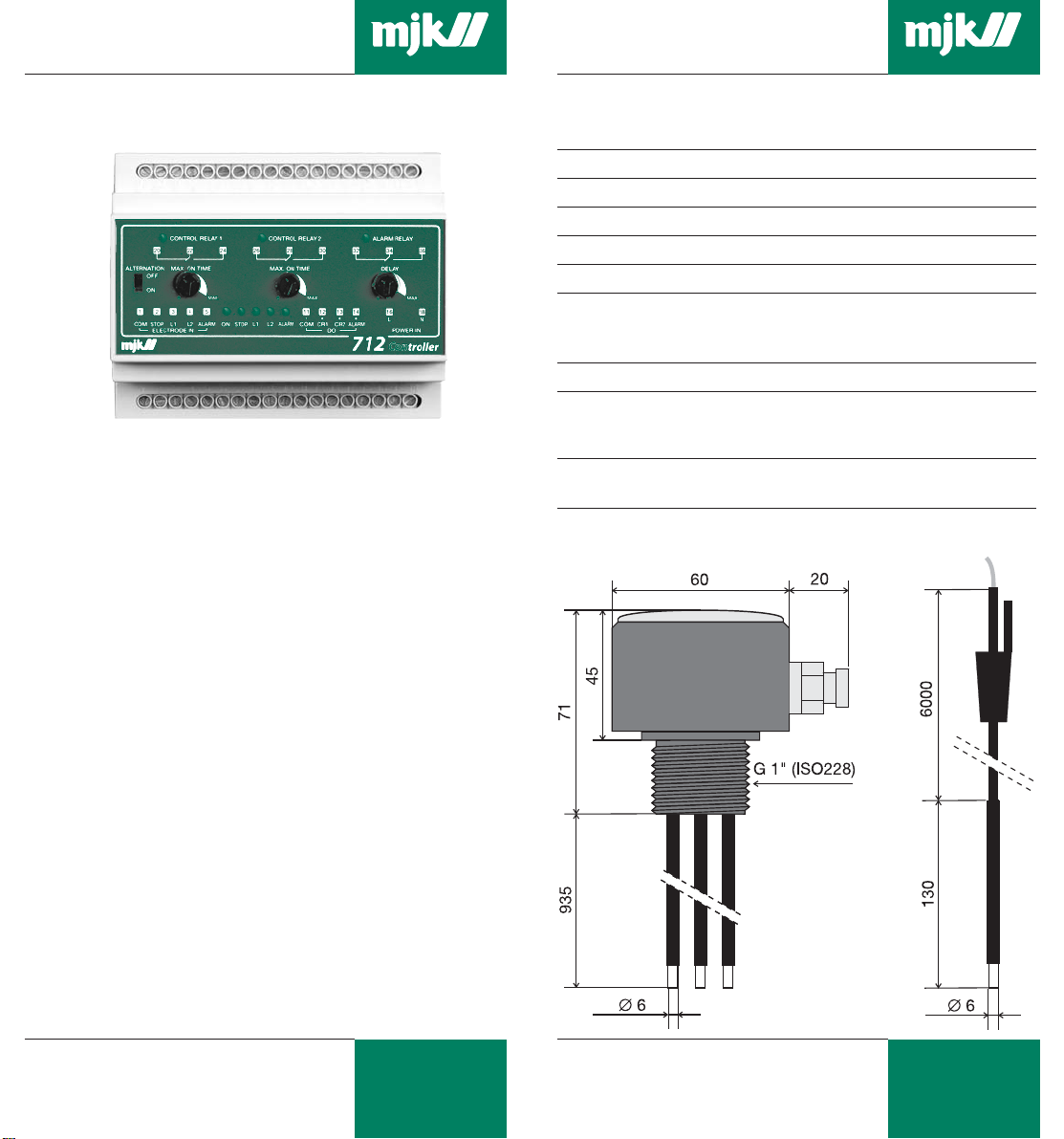

Electrodes With cable For base Base

Dimension:

∅ 6 x ∅ 6 x ∅ 60 x

130 mm 935 mm 71 mm

Level measurement with electrodes

ConTroller 712 is measuring the level in the well by means of

base mounted or suspended level electrodes.

The mounting height of the electrodes determines the start and

stop levels for the pumps and the alarm level.

ConTroller 712 is equipped with 3 voltage free control relays, of

which 2 are used for control of 2 pumps/valve actuators, and

the remaining is alarm output.

Up to 5 level electrodes can be connected, of which 1

electrode is common/ground electrode.

MJK Automation A/S

M712GB0505

1

Byageren 7

DK-2850 Nærum

Denmark

mjk@mjk.com

www.mjk.com

M712GB0505

MJK Automation A/S

2

Byageren 7

DK-2850 Nærum

Denmark

Tel.: +45 45 56 06 56

Fax: +45 45 56 06 56

Page 2

CONTROLLER 712

CONTROLLER 712

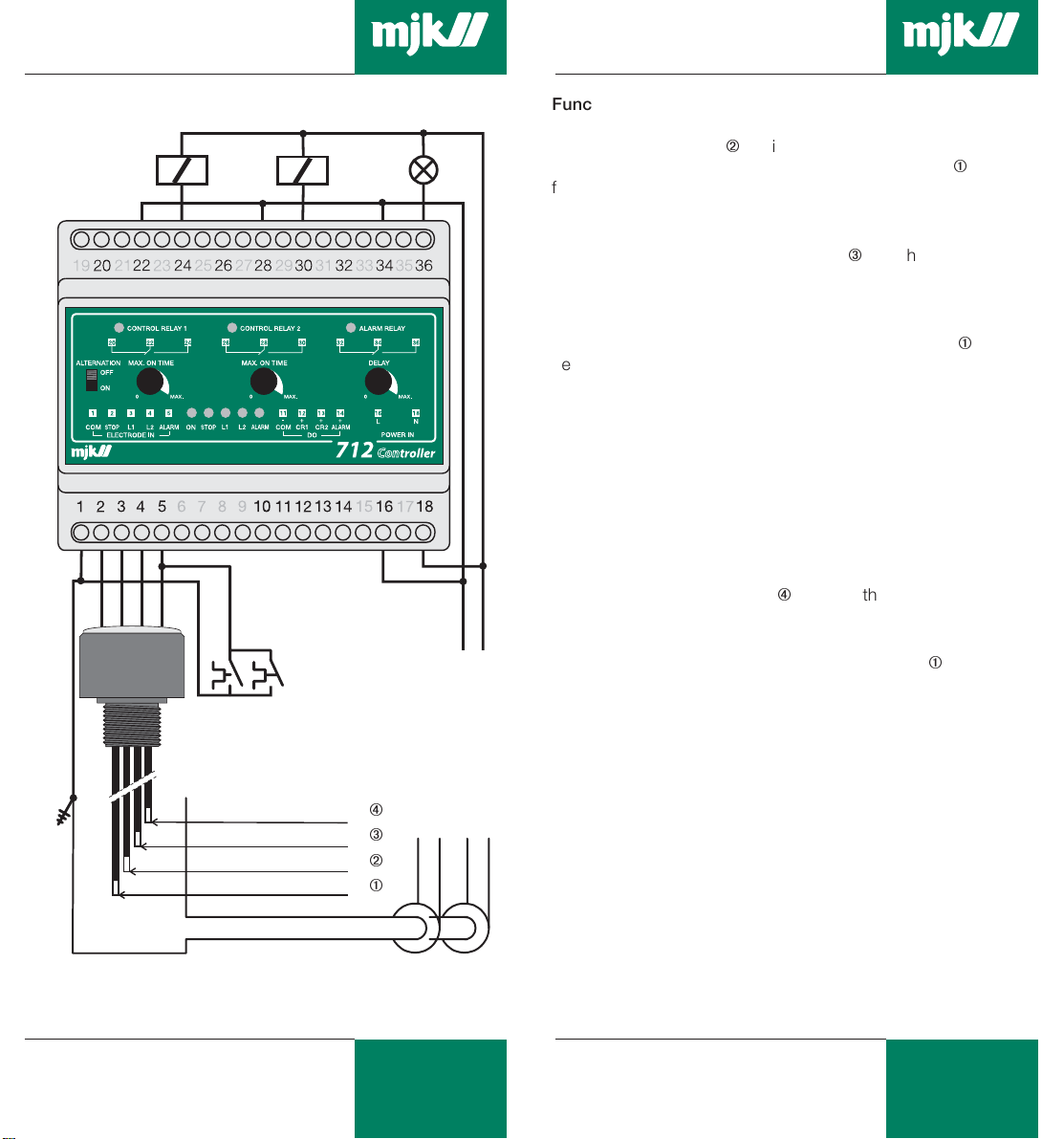

Electrical connection

K1 K2 Alarm

Ground connection in well

Auxiliary switches

on thermal

overload relay

Q1 Q2

activates the alarm

output on overload

trip.

Max. level alarm

Start level pump 2

Start level pump 1

Stop level

Function

Relay no. 1 is activated when the level in the well has reached

the first start electrode Á, which will start pump no. 1. The

pump will be stopped again when the stop electrode À goes

free of the level surface OR when the preset running time has

exeeded.

Relay no. 2 will be activated if the level continues to rise and the

level reaches the second start elektrode Â, which will start pump

no. 2. (Note: BOTH pumps will be started if pump no. 1 in the

meantime has been stopped because of runout of the preset

running time.)

The pump(s) will be stopped when the stop electrode À goes

free of the level surface.

Alarm output

The alarm output is equipped with a timer which is set by means

of the potmeter 'DELAY' on the front panel. This means that an

alarm condition will not activate the alarm relay before runout of

the preset delay time.

The following situations will activate the alarm:

1: When a pump has been in uninterrupted service during a

period beyond the preset maximum running time.

(The pump will also be stopped.)

2: When the alarm electrode Ãÿreaches the liquid surface.

(The pumps are kept running until the preset maximum

running time is reached.)

LN

The alarm is deactivated when the stop electrode À goes free of

the level surface.

Function with short-circuited electrodes

Electrode controls are sensitive to smudging and short-circuiting

of the electrodes, and a piece of wet paper will typically shortcircuit the stop electrode to the ground electrode.

Ã

Â

Á

À

ConTroller 712 will therefore run the pumps on the preset

running time if the electrodes are smudged or short-circuited.

Status outputs

ConTroller 712 is equipped with status outputs for transmission

of service and alarm status to MJK GSM/GPRS-COM for

communication to i.e. a SCADA system.

M712GB0505

Pump 1

Pump 2

MJK Automation A/S

3

Byageren 7

DK-2850 Nærum

Denmark

mjk@mjk.com

www.mjk.com

M712GB0505

4

MJK Automation A/S

Byageren 7

DK-2850 Nærum

Denmark

Tel.: +45 45 56 06 56

Fax: +45 45 56 06 56

Page 3

CONTROLLER 712

Settings

'Max. on time:'

2 potmeters for each relay output are placed in the front panel.

The setting of the potmeters determines the maximum

continuous activation time for the belonging relay:

Setting of the maximum

continuous running time for

the pump for each start.

(Approx. 0,1 to 8 min.)

'Delay:'

If the level for any reason should reach the alarm electrode, or if

one of the pumps has been stopped because of runout of the

preset maximum continuous running time, the caused alarm will

be delayed for a period set by means of this potmeter.

An alarm will also occur if the level does not reach the stop

electrode within a fixed running period.

CONTROLLER 712

'Alternation:'

Relay no. 1 will always be activated first, if the alternation switch

is set to 'OFF'. Thereafter, relay no. 2 is activated if the level

continues to rise

If the switch is set to 'ON', ConTroller 712 will alternate the two

relay outputs so that they will be leading every second time and

thus distribute the service hours equally between the two

pumps.

Maintenance

ConTroller 712 requires no particular maintenance.

The electrodes should be cleaned periodically.

M712GB0505

Setting of activation delay for

the alarm relay.

(Approx. 0,2 to 30 min.)

5

MJK Automation A/S

Byageren 7

DK-2850 Nærum

Denmark

mjk@mjk.com

www.mjk.com

M712GB0505

MJK Automation A/S

6

Byageren 7

DK-2850 Nærum

Denmark

Tel.: +45 45 56 06 56

Fax: +45 45 56 06 56

Loading...

Loading...