Page 1

Manual

MJK Comtroller 702

Effective for software version 83XXXX

COMLI PROTOKOL

Unit ID:

Serial no.:

M702GB/0110 Rev. 111001

As our products are developed continuously, we reserve the right

to make any change in dimensions and specifications.

Page 2

CE - CERTIFICATE OF CONFORMITY

This product complies with the requirements concerning electromagnetic compatibility (EMC) stipulated in

Council directive no. 89/336/EEC of 3rd May 1989, altered at directive no. 92/31/EEC, on the

approximation of the laws of the Member States relating to electromagnetic compatibility.

We declare that the product complies to the values stipulated in EN 50081-1 and EN 50082-1.

M702GB/0110 Rev. 111001

2

Page 3

ComTroller 702

Contents

1 General .................................................5

1.2 MJK-Link™ ...................................................5

2 Operation .............................................. 6

3 Menus ................................................... 8

3.1 F0 - Unit type/ID, software version, clock and

protocol type .................................................8

3.2 F1 - Inputs on/off ........................................... 8

3.3 F2 - Outputs on/off........................................8

3.4 F3 - Limits high/low .......................................8

3.5 F4 - Analog inputs # ...................................... 8

3.6 F5 - Analog input scaled ................................8

3.7 F6 - Counter .................................................9

3.8 F7 - Hour ...................................................... 9

3.9.1 F8.1 - Alarm List ........................................... 9

3.9.2 F8.2 Alarm # ................................................. 9

3.10 F9.1 Storm flow volume.................................9

3.11 F9.2 Storm flow calculation ...........................9

4 Main functions ...................................10

4.1 Choose language ........................................10

4.2 Set time and date .......................................10

4.3 Password enabled/disabled ......................... 10

4.4 Summer time / winter time .......................... 10

4.5 Enter password ........................................... 10

4.6 Analog inputs averaging...............................10

4.7 Data logging interval (MM:SS) ...................... 10

4.8 Tone or pulse dialing .................................... 10

4.9 Telephone call at power failure ..................... 10

4.10 Number of incoming rings before answer ..... 10

4.11 Unit ID no. for Comtroller ............................. 10

4.12 Automatic reset of alarms............................ 10

4.13 Telephone number ...................................... 10

4.14 SMSC telephone numbers .......................... 10

4.15 Master or Slave ........................................... 10

6 Digital inputs ..................................... 12

6.1 Digital input # .............................................. 12

6.2 Alarm / in use .............................................. 12

6.3 Signal delayed ............................................. 12

6.4 NO / NC ..................................................... 12

6.5 Alarm - call by telephone ............................. 12

7 Digital outputs ................................... 12

7.1 Digital output # ............................................ 12

7.2 NO / NC ..................................................... 12

7.3 Time / Fixed ................................................ 12

7.4 Time before start ......................................... 12

7.5 Set ON-time ............................................... 12

7.6 Special functions for the digital outputs ........ 12

8 Interlock .............................................. 13

8.1 Interlock in use yes/no ................................ 13

8.2 Start of interlock .......................................... 13

8.3 Stop interlock .............................................. 13

8.4 Interlock on receivers output # ....................13

8.5 Receivers telephone number ....................... 13

8.6 Receivers output # ...................................... 13

9 Pump control ..................................... 13

9.1 Pump control activated YES / NO ............... 13

9.2 Pump control EMPTYING / FILLING ............ 13

9.3 Pump control DO 2 ACTIVE ........................ 13

9.4 Pump alternation YES / NO ......................... 13

9.5 Level 2 in use YES / NO .............................. 13

9.6 Pump control start level ...............................13

9.7 Pump control start level ...............................13

10 Telephone list for alarms .................. 14

10.1 Telephone number 1-9 ................................ 14

10.2 Key In PS Message .....................................14

10.3 Entering SMS messages ............................. 14

5 Analog inputs ....................................11

5.1 Analog input # ............................................. 11

5.2 Input no 1 0 - 20 / 4 / 20 mA ...................... 11

5.3 Input no 1 scaled 0 / 4 mA ..........................11

5.4 Input no 1 scaled 20 mA ............................. 11

5.5 High limit yes / no ........................................11

5.6 Set high limit ...............................................11

5.7 High limit alarm / in use ............................... 11

5.8 High limit - signal delayed ............................ 11

5.9 High alarm - call by telephone ..................... 11

5.10 Low limit yes / no ........................................ 11

5.11 Set low limit................................................. 11

5.12 Low limit alarm / in use ................................ 11

5.13 Low limit - signal delayed............................. 11

5.14 Low limit - call by telephone ........................ 11

M702GB/0110 Rev. 111001

11 Programming of storm flow

calculation .......................................... 15

11.1 Stormflow calculation .................................. 15

11.2 Stormflow calculation in use Yes/no ............. 15

11.3 Zero-point DI # ............................................ 15

11.5 Key in the number of Q(h) points (1-9).......... 15

11.6 Key in the level mark ................................... 15

11.7 Key in the flow mark ................................... 15

12 Combi alarms ..................................... 15

12.1 Combi alarm # ............................................ 15

12.2 Combi alarm in use ..................................... 15

12.3 Combi alarm signals .................................... 15

12.4 Signal delay ................................................. 15

12.5 Combi alarm calls ........................................ 15

MJK Automation A/S

3

Byageren 7

2850 Nærum

Tlf: 45 56 06 56

Fax: 45 56 06 46

Page 4

ComTroller 702

13 Alarms ................................................. 16

13.1 Operational or alarm signal .......................... 16

13.2 Alarm calls .................................................. 16

13.3 Reset of alarms ........................................... 16

13.4 Special factory codes .................................. 16

13.5 Access code ............................................... 16

13.6 Setting up the serial port ............................. 16

13.7 Forced reset to factory settings ...................16

13.8 SMSC telephone numbers .......................... 16

14 Other information ..............................17

14.1 Specifications ..............................................17

14.2 Maintenance ............................................... 17

15 Electrical connection .......................... 18

15.1 Digital inputs ................................................ 18

15.2 Analog inputs .............................................. 18

15.3 Serial ports .................................................. 18

15.4 External 15 V DC supply .............................. 18

15.5 Software upgrade........................................ 18

16 Factory settings ................................. 20

M702GB/0110 Rev. 111001

4

Page 5

ComTroller 702

1 General

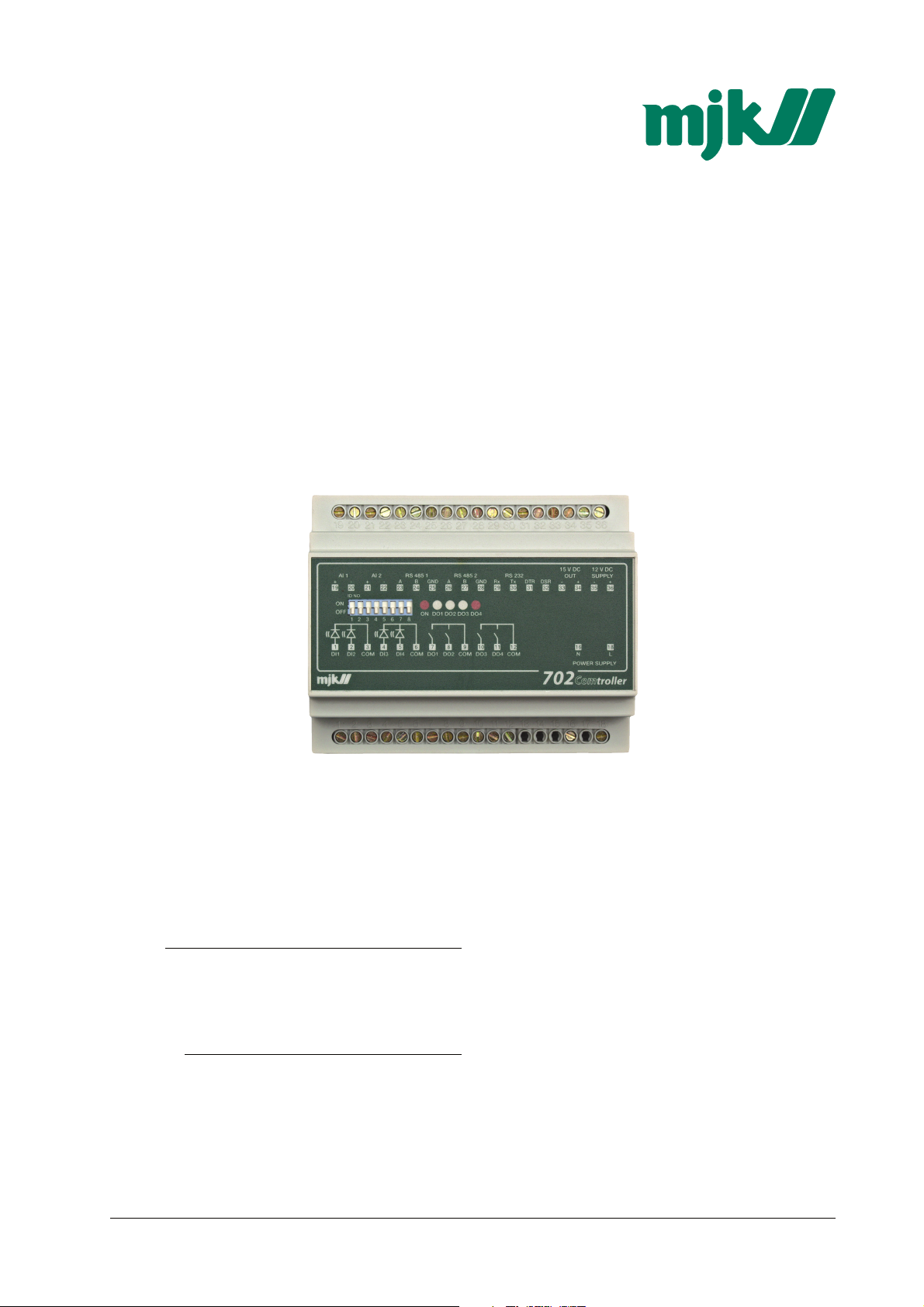

MJK Comtroller 702 is developed for control and

surveillance of small pumping stations and water

borings. Comtroller 702 is a complete unit with inand outputs, CPU, data logger, real time clock and

communications port for data transmission on

owned lines.

Comtroller 702 is an advanced product based on

the experience from the thousands of monitoring

systems delivered during the past 15 years.

Comtroler 702 is an advanced product for on-site

mounting with control, data logging storing and

transmission of analog and digital measuring values

to be used in both small and large SCADA systems.

Comtroller 702 is typically arranged in clusters

where each Comtroller is connected to a 2-wire

communications line. A Data Transmitter 795 is

then connected as a master communications unit.

Every single Comtroller 702 can be called

individually by their different ID numbers, and the

Data Transmitter 795 simply handles the data

transmission via a telephone modem, a radio

transceiver or a GSM modem directly to the

SCADA system.

Comtroller 702 has all necessary functions built in

such as interface to measuring and control

equipment, a data logger, counters and data

transmission. Comtroller 702 is programmed directly

from a PC, from the SCADA system or via a MJK

Data Transmitter 795 as a master communications

unit.

Comtroller 702 is a compact unit containing all

necessary functions such as communications interface and drivers, software, I/O ports, data storage

memory and RS485 repeater.

Comtroller 702 is simple and economic to utilize

since it contains all necessary facilities to decrease

the number of external components needed to

form a complete unit for control, monitoring and

data transmission.

The RS 232 port is used for interconnection

through external modems, GSM-modems or a PC

for configuring or data readout.

1.2 MJK-Link™

The MS-Windows™-based program MJK-Link™

can be used for monitoring one or more Comtroller

702. It is possible with MJK-Link™ via a PC with a

modem to read realtime values, stored values for

investigation of storm flows and changing of

setpoints.

This manual deals with MJK Comtroller 702 with

Comli-protocol for telephone modems. GSMmodems, RS 485 on owned lines, powerline

modems and closed radio networks.

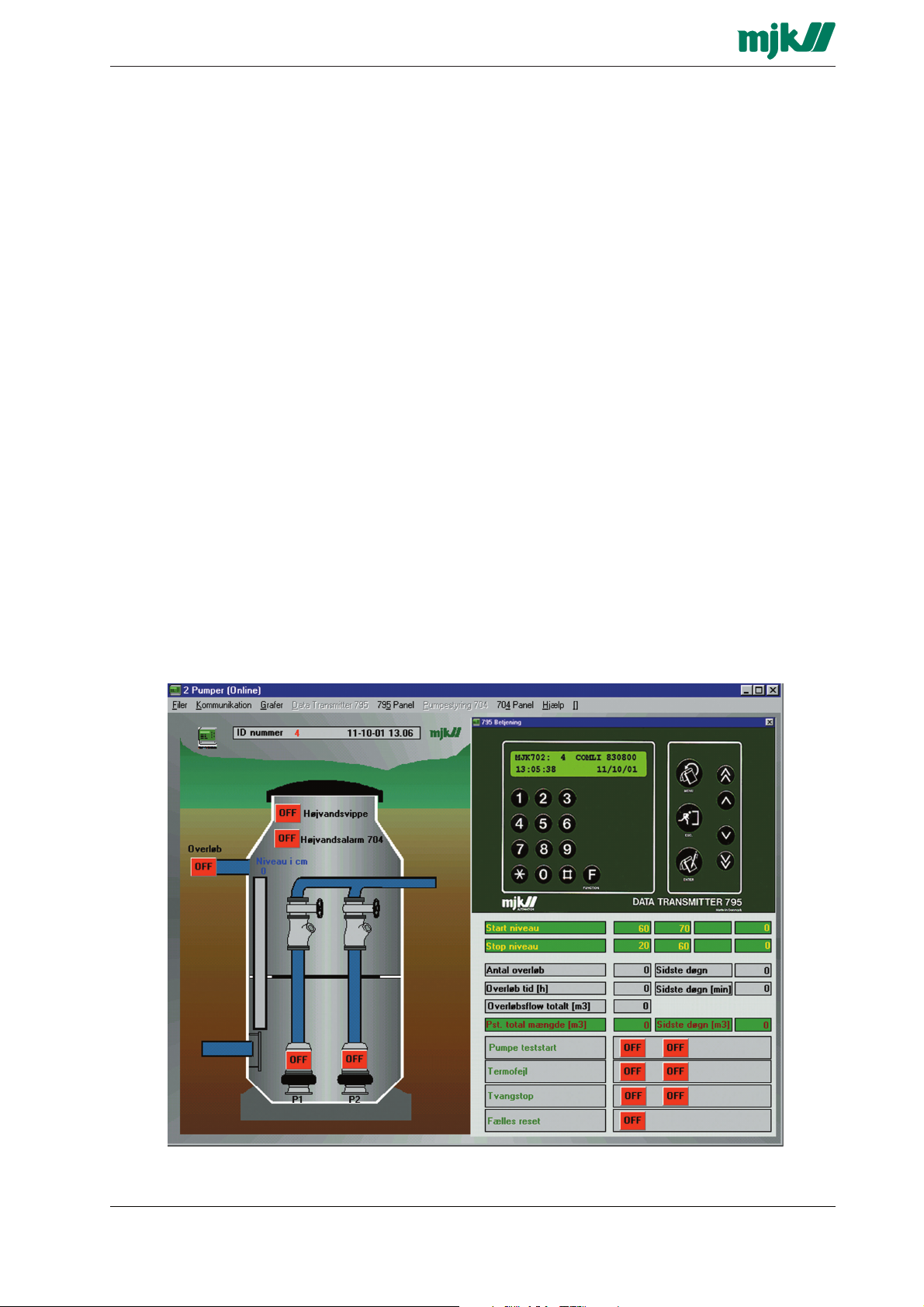

Screen dump from the monitoring program MJK-Link™, where a pumping station with 2 pumps, monitored and

controlled by a Comtroller 702 are operated in a window that appears as the well-known MJK Data Transmitter 795.

MJK Automation A/S

M702GB/0110 Rev. 111001

5

Byageren 7

2850 Nærum

Tlf: 45 56 06 56

Fax: 45 56 06 46

Page 6

ComTroller 702

2 Operation

A Comtroller 702 can be considered as a Data

Transmitter 795 without display and keypad and

with a built-in pump controller. Instead of display

and keypad the Comtroller 702 is operated via the

serial communications port from either a PC with

MJK-Link™ or a Data Transmitter 795.

MJK-Link™ is used for monitoring and operation of

Comtroller 702. The Comtroller 702 will appear

exactly as a Data Transmitter 795 in MJK-Link™

with its well-known 2 x 24 character display and

keypad. The kepad is simply operated via the PC

keyboard.

MJK-Link™ makes it possible to upload,

download and save the settings for one or more

Comtroller 702's interconnected on the same multidrop communications æline. It is thus possible to

download the setting from Comtroller no. 9, save

the setting as i.e. "Pumping station at the bend"

and upload the setting to Comtroller no. 14, placed

at "Pumping station at the pond". It is also possible

to name the in- and outputs individually.

A Data Transmitter 795 with Master-software can

also be used to operate a number of Comtroller

702's on the same multidrop communications line.

The desired Comtroller 702 is selected by entering

the corresponding ID-number on the Data Transmitter 795, after which the selected Comtroller can

be operated exactly as if it were a Data Transmitter

795. At the same time the Data Transmitter 795

contains a surveillance function that calls the

Comtrollers one by one over an adjustable interval.

If a Comtroller does not respond, the Data transmitter will send a system alarm.

A Data Transmitter 795 also manages

comunication to the SCADA system, MJK-Link™

etc.

A typical installation covers five to 20 Comtrollers in

an area where communication takes place via

owned lines or with MJK PowerLine modems

through the mains supply network.

On ie. the main pumping station, a Data Transmitter 795 with master software is installed, which will

be able to send alarms via a telephone- or GSM

modem to the SCADA system and/or one or more

mobile telephones as SMS messages.

M702GB/0110 Rev. 111001

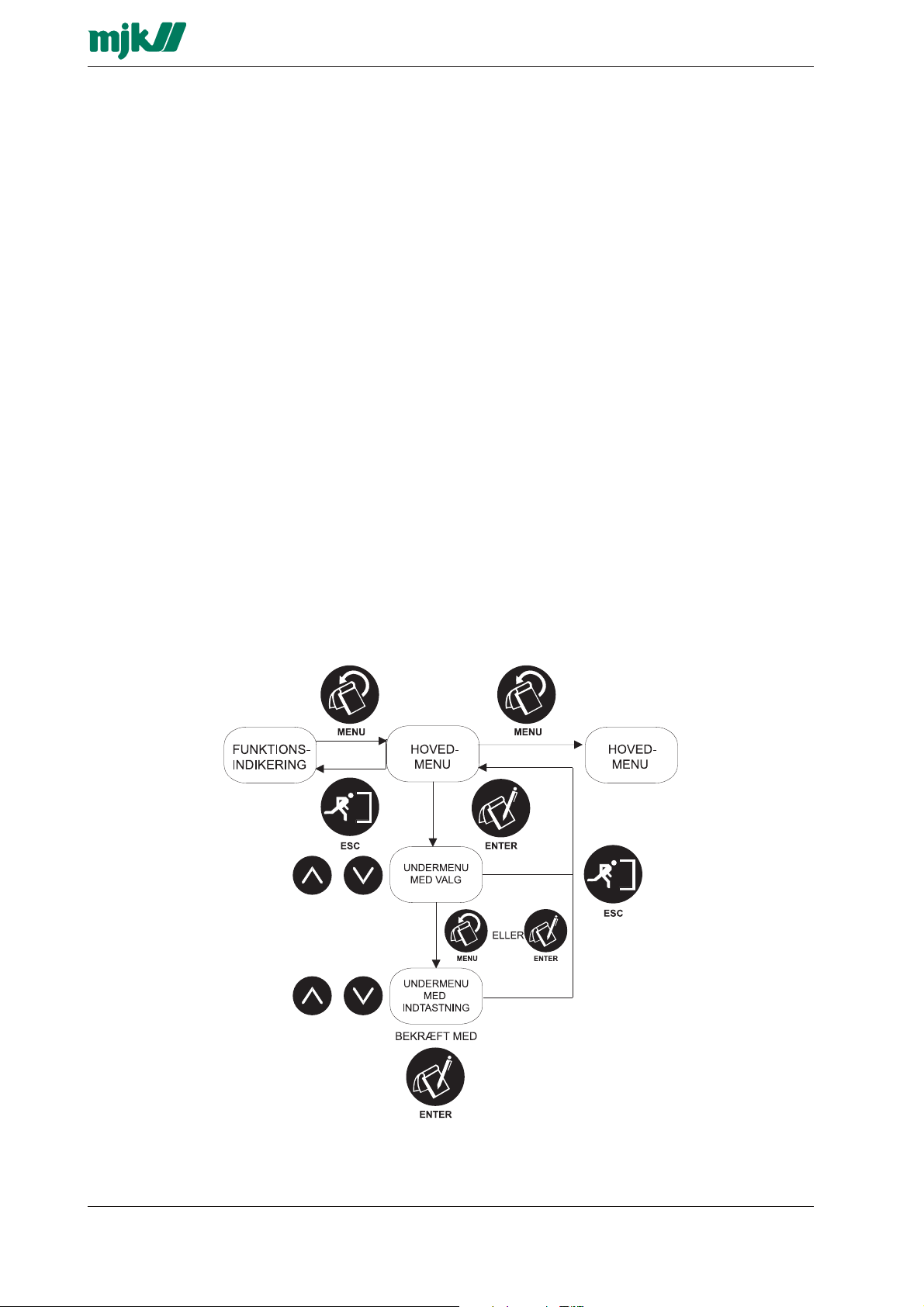

The figure shows an overview of the functional buttons and their general function.

6

Page 7

ComTroller 702

Display

2 x 24 character backlit

display for indication of

programming menus,

measuring values alarms

etc.

ESC.-key

This key changes back to

the previous menu or

cancels a selection. By

pressing the ESC.-key 2-3

times you will always

return to the functional

indication.

MENU

The MENU key are used to

switch between main

menus and submenus.

Arrow keys

The arrow keys are used

for altering the current

setting. In a submenu with

selections, the top line

shows the current setting

and the bottom line shows

the alternative setting (in

brackets). The arrow keys

are used to scroll between

the selections. The arrow

keys also alters the inand output no. By

activating the key, the

number in the display will

increase. By Activating the

key the number will

decrease.

Numerical keys

The keys 0-9,# and * are

used for configuring

telephone numbers,

delays, analog scaling etc.

Function key F

The function key is used

for selecting which

functional indication to

show on the display, e.g.

F0.

ENTER

Press ENTER to change

from a main menu to a sub

menu, as well as between

sub menus. Any choice

made in the sub menus

must be confirmed by

pressing ENTER.

M702GB/0110 Rev. 111001

MJK Automation A/S

7

Byageren 7

2850 Nærum

Tlf: 45 56 06 56

Fax: 45 56 06 46

Page 8

ComTroller 702

3 Menus

3.1 F0 - Unit type/ID, software version, clock

and protocol type

Menu F0 show the MJK unit type, protocol type,

program version and date / time.

MJK 702 : 3 COMLI 830802

16:07:29 24/10/01

In above example, the Data Transmitter is

connected to a Comtroller 702 with unit ID no. 3.

The Unit ID no. is set binary by means of 8

switches on the front panel. (All OFF = 0 - All ON =

255.) Note! The unit ID no. must be set within the

range 1 to 247.

3.2 F1 - Inputs on/off

In menu F1 is shown whether the digital inputs are

ON or OFF.

INPUTS 1 2 3 4

ON : OFF:

The first two fields indicate if the high limits are

exceeded and the last two show if the low limits

are exceeded.

LIMITS HIGH/LOW 1 2

3 4 5 6 1 2

ON : OFF:

A delay time can be set individually for each analog

input allowing the input to exceed the limit

momentarily without i.e. activating an alarm. (See

section 5.)

If the analog input are within limits, the field will be

empty. If the limits are exceeded, the field will flash

during the delay time. When the delay time has

expired, the field is shown in a steady state.

3.5 F4 - Analog inputs #

Menu F4 shows the immediate value of an analog input as a horizontal bar formed of up to 24 fields. If the

input signal is 4 (0) mA (see also section 5.2), none of

the fields is lit (0 %). If the input signal is 20 mA, all 24

fields is lit (100 %).

In above example, DI no. 1 and 2 are ON while DI

3 and 4 are OFF.

A delay time can be set individually for each digital

input in order to allow the input to go ON without

activating i.e. an alarm. (See section 6.)

When the input is OFF an empty field is shown.

When the input is ON, the field will flash for the

duration of the delay time. When the delay time

has expired, a full field will be lit.

3.3 F2 - Outputs on/off

Menu F2 show the status of the digital outputs.

OUTPUTS 1 2 3 4

ON : OFF:

In above example, DO no. 1 and 2 are ON while

DO 3 and 4 are OFF.

A delay time can be set individually for each digital

output in order to delay the activation of the

corresponding output relay. (See section 7.)

When the output is OFF an empty field is

shown. When the output is ON the field will flash

for the duration of the delay time. When the delay

time has expired, the output relay is activated and

the field will be shown in a steady state .

ANALOG INPUT NO #

Select the desired analog input with the arrow

keys or by keying the corresponding input number

(1 - 2).

3.6 F5 - Analog input scaled

Menu F5 shows the immediate value of an analog

input in digits rather than a horizontal bar as in the

previous menu.

The first set of digits read out the signal value as

the percentage between the low mA value (0/4

mA) (see also section 5.2) and the high mA value

(20 mA). The next set of digits read out the same

signal multiplied with a programmable scaling factor.

The readout scaling is determined by programming

the desired readout range corresponding to the

low mA value (0 / 4 mA) and the high mA value (20

mA) respectively. If e.g. a tank level is measured,

and the level varies between 2 metres and 3

metres, the low mA value is set to correspond to

"200" and the high mA value is set to "300". A level

measurement of i.e. 2,5 metres will corespond to a

signal value of 50 %, resulting in a readout of "250"

(See section 5.3 - 5.4)

3.4 F3 - Limits high/low

Menu F3 indicate if the high and low limits for the

analog inputs are exceeded.

M702GB/0110 Rev. 111001

ANALOG INPUT NO #

50 % SKALERET 250

Select the desired analog input with the arrow

keys or by keying the corresponding input number

(1 - 2).

8

Page 9

ComTroller 702

3.7 F6 - Counter

Menu F6 shows how many times a digital input or

an analog high or low limit has been set ON.

COUNTER DI #

RESET: ENTER 257

Every single input / high and low limit has its own

counter. Use the arrow keys to change the readout

between:

- digital input 1 - 4

- analog input high limit 1 - 2

- analog input low limit 1 - 2

(Pressing key 1 to 4 will change the display readout directly to digital input 1 to 4.)

If the ENTER button is keyed, the counter present

in the display - and only this - will be reset.

3.8 F7 - Hour

Menu F7 show the total time the digital inputs and

the analog high limits and low limits have been set

ON.

The ON time is registered continuously; meaning

that if an input or limit is set to OFF and later is set

back to ON, the timer continues from its previous

value.

HOUR : AI # LOW

RESET: ENTER 2:43

Every single input / high and low limit has its own

counter. Use the arrow keys to change the readout

between:

- digital input 1 - 4

- analog input high limit 1 - 2

- analog input low limit 1 - 2

(Pressing key 1 to 4 will change the display readout directly to digital input 1 to 4.)

ALARM NO 1 2 3 4 5 6 7 8 9

A flashing field indicates that the alarm is ON, an

empty field indicates that the alarm is OFF, and

a steady field indicates that the alarm has been

reset.

All alarms in the list will be reset by pressing

ENTER.

3.9.2 F8.2 Alarm #

By depressing an arrow key or 1-9, menu F8.2 will

appear displaying the input number and type

causing the alarm, the corresponding alarm designation, the immediate status of the alarm and the

time when the alarm was set.

ALARM # : AI 2 LAV

START 15:23:1724/12/95

Use either the arrow keys to scroll through the

alarm list or 1 to 9 to jump directly to the desired

alarm number.

The alarm shown in the display will be reset by

pressing ENTER.

Menu F8.1 will reappear by repetitous depressing

of the arrow keys or 0.

3.10 F9.1 Storm flow volume

Menu F9 display the volume of the overflow. The

volume meter is reset by depressing ENTER

STORM FLOW VOLUME

RESET: ENTER 1204 m

3

3.11 F9.2 Storm flow calculation

Menu F9.2 display the immediate flow.

If the ENTER button is keyed, the counter present

in the display - and only this - will be reset.

3.9.1 F8.1 - Alarm List

Menu F8.1 show a list of the last 9 alarms and their

immediate status.

Whenever an alarm occurs, it will be registered as

alarm no. 1 and all other alarms in the list is moved

one place to the right. Furthermore, the previous

alarm no. 9 will be erased and also be

automatically reset if it has not already been reset

manually via the Data Transmitter keypad or via

the SCADA system. Also, an alarm deriving from a

specific input has to be reset before a new alarm

from that input will be put in the list.

M702GB/0110 Rev. 111001

STORM FLOW CALCULATION

FLOW RATE 12.40 m

9

3

/t

MJK Automation A/S

Byageren 7

2850 Nærum

Tlf: 45 56 06 56

Fax: 45 56 06 46

Page 10

ComTroller 702

4 Main functions

4.1 Choose language

The desired language is chosen using the arrow

keys - confirm with ENTER.

4.2 Set time and date

The time and date can be set using the arrow keys

or the numerical keys. Confirm the changes with

ENTER or press MENU if no changes are desired.

4.3 Password enabled/disabled

If password protection is enabled, a code must be

keyed in before access is given to the menus with

the MENU key.

If a password is desired, it must be keyed in

before the system can be set up.

Use the arrow keys to select and confirm with

ENTER.

4.4 Summer time / winter time

Select summer time or winter time with the arrow

keys and confirm the selection with ENTER.

4.5 Enter password

Enter the password number with the numerical

keys and confirm with ENTER.

4.6 Analog inputs averaging

Every second the value of the analog inputs are

registered, and for every 5 minutes the analog

values are logged. If averaging is wanted, a mean

of all the 1 sec. registrations for the last 5 minutes

is logged. If averaging is not wanted, the current

analog value is logged.

Use the arrow keys to select and press ENTER to

confirm.

that would be caused by very short voltage

failures.

This function is only available if the Comtroller is

supplied from an external 12 V DC source with

battery backup.

Use the arrow keys to select and confirm with

ENTER.

4.10 Number of incoming rings before answer

Select the number of rings before the Comtroller

702 should answer a call. The number of rings can

be set between 1 and 5. Use the arrow keys to

select and confirm with ENTER.

4.11 Unit ID no. for Comtroller

In this menu the Unit ID no. of the current

Comtroller is displayed. The Unit ID no. is used to

identify the different Comtroller 702's that may be

interconnected through the same multidrop line.

The Unit ID no. is set binary by means of 8

switches on the front panel. (All OFF = 0 - All ON =

255.)

Note! The unit ID no. must be set within the range

1 to 247.

4.12 Automatic reset of alarms

Select whether an active alarm should be reset

automatically if (1) the alarm cause disappears

before the alarm are transmitted or (2) the alarm is

not reset from the SCADA terminal. Use the arrow

keys to select and confirm with ENTER.

4.13 Telephone number

Enter the number of the telephone line to which the

Comtroller is connected. The telephone number is

used as ID-number when SMS alarms are

transmitted.

4.7 Data logging interval (MM:SS)

The data logging interval are used for the

enhanced logging function that stores the values

from the analog inputs. The logging interval can be

selected in the following fixed intervals: 30 sec.

(00:30), 1 min. (01:00), 5 min. (05:00), 10 min.

(10:00), 30 min. (30:00), and 60 min. (60:00).

Use the arrow keys to select and press ENTER to

confirm.

4.8 Tone or pulse dialing

Select whether the telephone call is to be carried

out with tone or pulse signals.

Use the arrow keys to select and confirm with

ENTER.

4.9 Telephone call at power failure

If this function is selected, the Comtroller will dial

the first number on the telephone list (see section

10) if the mains supply disappears for more than 30

seconds. The 30 second delay avoids alarm calls

M702GB/0110 Rev. 111001

Key in the number and confirm with ENTER.

This function is only available if a modem is

connected.

4.14 SMSC telephone numbers

In order to make the Comtroller able to transmit

SMS messages, the SMS message must be dialed

to a particular SMSC server. See section 10 for

telephone numbers to SMSC-servers.

Key in the number and confirm with ENTER.

This function is only available if a modem is

connected.

4.15 Master or Slave

Select whether the Comtroller 702 should act as a

Master or a Slave on the multidrop

communications line.

Use the arrow keys to select and confirm with

ENTER.

10

Page 11

ComTroller 702

5 Analog inputs

5.1 Analog input #

Select the input to be set by pressing 1. Confirm

with ENTER.

5.2 Input no 1 0 - 20 / 4 / 20 mA

Select if the signal range for the analog input

should be either 0 - 20 mA or 4 - 20 mA.

Use the arrow keys to select and confirm with

ENTER.

5.3 Input no 1 scaled 0 / 4 mA

Set the equivalent of the low mA value. If i.e. "200"

is entered, the display will read out "200" at an input value of 0 / 4 mA. Use the arrow keys or the

numeric keys and confirm with ENTER.

5.4 Input no 1 scaled 20 mA

Set the equivalent of the high mA value. If i.e.

"300" is entered, the display will read out "300" at

an input value of 20 mA. Use the arrow keys or the

numeric keys and confirm with ENTER.

5.5 High limit yes / no

Select if exceeding the high limit setting on the

analog input should be registered.

Use the arrow keys to select and confirm with

ENTER.

5.10 Low limit yes / no

Select if exceeding the low limit setting on the analog input should be registered.

Use the arrow keys to select and confirm with

ENTER.

5.11 Set low limit

Set the low limit that the analog input should

exceed before the event is registered.

Use the arrow keys to select and confirm with

ENTER.

5.12 Low limit alarm / in use

See section 13.1 for a description between "Limit

alarm" and "In use".

Use the arrow keys to select and confirm with

ENTER.

5.13 Low limit - signal delayed

Set the delay time that the input can exceed the

high limit setting without an alarm is being

activated. The format for the delay period is

MM:SS.

In the case of a power failure the analog input will

detect 0 mA. If analog low limit is set to ALARM

simultaneously with a alarm call at power failure

(see section 4.9), the delay time of the low limit

must be set to more than 30 sec.

5.6 Set high limit

Set the high limit that the analog input should

exceed before the event is registered.

Use the arrow keys to select and confirm with

ENTER.

5.7 High limit alarm / in use

See section 13.1 for a description between "Limit

alarm and In use".

Use the arrow keys to select and confirm with

ENTER.

5.8 High limit - signal delayed

Set the delay time that the input can exceed the

high limit setting without an alarm is being

activated. The format for the delay period is

MM:SS.

Use the arrow keys (double arrow for minutes and

single arrow for seconds) or the numeric keys and

confirm with ENTER.

5.9 High alarm - call by telephone

Select whether an activated high limit alarm is to

set off a telephone call.

Use the arrow keys (double arrow for minutes and

single arrow for seconds) or the numeric keys and

confirm with ENTER.

5.14 Low limit - call by telephone

Select whether an activated low limit alarm is to

set off a telephone call.

Use the arrow keys to select and confirm with

ENTER.

Use the arrow keys to select and confirm with

ENTER.

M702GB/0110 Rev. 111001

11

MJK Automation A/S

Byageren 7

2850 Nærum

Tlf: 45 56 06 56

Fax: 45 56 06 46

Page 12

ComTroller 702

6 Digital inputs

6.1 Digital input #

Use the arrow keys or enter 1 to 4 to select the input to be programmed.

6.2 Alarm / in use

See section 13.1 for a description between "Limit

alarm" and "In use".

Use the arrow keys to select and confirm with

ENTER.

6.3 Signal delayed

Set the delay time the input can be ON without an

alarm is being activated.

The format for the delay period is MM:SS.

Use the arrow keys (double arrow for minutes and

single arrow for seconds) or the numeric keys and

confirm with ENTER.

6.4 NO / NC

Select the input as normally open (NO) or normally

closed (NC). At NO the input is ON when the

power is connected; at NC the input is ON when

the power is disconnnected.

Use the arrow keys to select and confirm with

ENTER.

6.5 Alarm - call by telephone

Select if a digital input is to set off a telephone call

when going ON.

Use the arrow keys to select and confirm with

ENTER.

7 Digital outputs

7.1 Digital output #

Use the arrow keys or enter 1 to 4 to select the

output to be programmed.

7.2 NO / NC

Select the relay function to normally open (NO) or

normally closed (NC). At NO the relay switch will

go ON when the output is activated; at NC the

relay switch will go OFF when activated.

Use the arrow keys to select and confirm with ENTER.

At power failure all the outputs will go OFF.

7.3 Time / Fixed

A time controlled output is only ON for a certain

period of time (the ON-time) whereafter it goes

OFF. A fixed output which is turned ON must

receive a command in order to set the output OFF.

Use the arrow keys to select and confirm with

ENTER.

7.4 Time before start

Enter the delay time before start - which is the time

passing from an ON-command is transmitted until

the output responds.

The format for the delay period is MM:SS.

Use the arrow keys (double arrow for minutes and

single arrow for seconds) or the numeric keys and

confirm with ENTER.

7.5 Set ON-time

Enter the ON-time for the output. The On-time is

the period of time the output is turned ON if the

output is set to "time controlled".

The format for the delay period is MM:SS.

Use the arrow keys (double arrow for minutes and

single arrow for seconds) or the numeric keys and

confirm with ENTER.

7.6 Special functions for the digital outputs

(This menu is only accessible if 'Fixed' is selected

as described in section 7.3.)

It is possible to perform AND logic sequences by

means of the digital in- and outputs.

For example the Comtroller 702 can be programmed to activate a digital output when 2 digital

inputs are ON. The digital signals can also derive

from exeeding a limit value on an analog input - or

a combination of a signal caused by exceeding a

limit value and an active digital input.

The following signals can be combined:

- digital input 1 - 4

- analog limit HIGH 1 - 2

- analog limit LOW 1 - 2

- combi alarm 1 - 8

M702GB/0110 Rev. 111001

12

Page 13

ComTroller 702

8 Interlock

When interlocking two MJK Comtroller 702's they

will communicate with one another. In this way one

data transmitter can control a digital output

remotely on the other.

8.1 Interlock in use yes/no

Select whether the interlock function is to be used

or not.

Use the arrow keys to select and confirm with

ENTER.

8.2 Start of interlock

Select the signal which - when it goes ON - will

make the Comtroller call the other Comtroller and

set an output ON.

Use the arrow keys to select and confirm with

ENTER.

The following signals can be selected:

- digital input 1 - 4

- analog limit HIGH 1 - 2

- analog limit LOW 1 - 2

- combi alarm 1 - 8

As long as the signal is ON, calls will take place in

10 minutes interval. The remote controlled output

must therefore be set to "time controlled" and

configured with an ON-time of more than 10

minutes (e.g. 15 min.), thus securing that the output is not constantly ON if an error situation should

occur (e.g. a broken telephone cable). This way

the output is certain to go OFF even in the case of

communication failure.

At faultless communication the ON time of the

remote controlled output will be initialised at each

call and the remote controlled output will stay ON

as long as the controlling signal is active.

8.3 Stop interlock

Select the signal which - when it goes ON - will

make the Comtroller call the other Comtroller and

set an output ON.

Use the arrow keys to select and confirm with

ENTER.

The following signals can be selected:

- digital input 1 - 4

- analog limit HIGH 1 - 2

- analog limit LOW 1 - 2

- combi alarm 1 - 8

Only one call attempt will be made. If the same

signal is chosen both as start and finish condition

for the inter lock, the finish condition will be when

the signal goes OFF.

8.4 Interlock on receivers output #

Select which digital output of the remote Comtroller

is to be controlled.

Use the arrow keys to select and confirm with

ENTER.

8.5 Receivers telephone number

Enter the ID number of the remote Comtroller and

confirm with ENTER or start press ENTER to

correct a number already keyed in.

If Powerline modems, radio modems, or the RS485

port are used, the ID number of the remote

Comtroller should also be used.

8.6 Receivers output #

Select which output on the remote Comtroller to

be controlled.

Use the arrow keys to select and confirm with ENTER.

9 Pump control

9.1 Pump control activated YES / NO

Select if the pump controller should be activated.

Use the arrow keys to select and confirm with

ENTER.

9.2 Pump control EMPTYING / FILLING

Select if output no. 1 or 2 should be configured for

either emptying or filling.

Use the arrow keys to select and confirm with

ENTER.

9.3 Pump control DO 2 ACTIVE

Select if 1 og 2 pumps are used.

Use the arrow keys to select and confirm with ENTER.

9.4 Pump alternation YES / NO

Select if the pumps should alternate. This menu is

only available when 2 pumps are selected in

section 9.2.

Use the arrow keys to select and confirm with ENTER.

9.5 Level 2 in use YES / NO

Select if both pumps may start at the same time.

This menu is only available when 2 pumps are

selected in section 9.2.

Use the arrow keys to select and confirm with ENTER.

9.6 Pump control start level

Set the start level for the pump(s)

Use the arrow keys to select and confirm with ENTER.

9.7 Pump control start level

Set the stop level for the pump(s)

Use the arrow keys to select and confirm with

ENTER.

M702GB/0110 Rev. 111001

13

MJK Automation A/S

Byageren 7

2850 Nærum

Tlf: 45 56 06 56

Fax: 45 56 06 46

Page 14

ComTroller 702

10 Telephone list for alarms

(This section applies is only

10.1 Telephone number 1-9

In this menu up to 9 telephone numbers are keyed

in which will be dialed chronologically at an alarm

situation.

Press key 1 - 9 to select the number which is to be

changed, press ENTER to change the receiver

type (PC, Pager, ph [phone], SMS), press ENTER

to correct the number - key in the number with the

numerical keys, and confirm with ENTER.

After keying in the telephone number the MENU

key must be used in order to move on to the next

menu, the ENTER key will be of no use here.

When calling through a switchboard, a * can be

used for awaiting a dialtone. A * gives a pause of 2

seconds. I.e. 0*00454556,656##23 means:

First dial 0 to get an external line, await the dialling

tone, then dial 0045 45560656, wait for 4 seconds,

then dial 23.

In the parenthesis following the number, it is stated

which type of reciever the call has been made to.

When calling a modem set to 1 [PC]. When calling

a beeper / pager set to 2 [Pager]. When calling an

ordinary telephone set to 3 [PHONE].

10.2 Key In PS Message

If a telephone number has been chosen as a PS

number, a message of up to 8 digits can be typed

in (e.g. the telephone number of the data transmitter), the message can be different for the various

telephone numbers. The message for the pager is

shown in the pager display together with a code

for the alarm, which has caused the call.

E.g. a datatransmitter with telephone number

455660656 where digital input 5 has an active

alarm input; will give the following alarm message

in the PS:

05-45560656

The configuration is stored in a EEPROM which is

not lost even if the supply is disconnected

10.3 Entering SMS messages

Up to 8 characters can be entered here if a receiver type is selected as an SMS type.

It is possible to enter digits as an SMS message

via Data Transmitter 795, and with MJK-Link32™ it

is also possible to enter a text.

The SMS message will be shown on the cellular

phone with "MJK-702" as the opening text,

followed by the cause of the alarm and the

corresponding SMS message. If a GSM modem

are used as communications unit, the pager

message will be changed to an SMS message.

Check the SIM card in a cellular phone if no SMS

message is transmitted, and check, if the phone

number to the SMSC-server is correct. The phone

number to the SMSC-server depends on the GSM

network service provider.

When sending SMS messages and pager

messages, it is not possible to check whether the

message is sent to the recipient or not, since the

messages are delivered to an external server.

The alarm codes are:

01 : Digital input no 1

02 : Digital input no 2

03 : Digital input no 3

04 : Digital input no 4

21 : Analog limit no 1 LOW

22 : Analog limit no 2 LOW

31 : Analog limit no 1 HIGH

32 : Analog limit no 2 HIGH

51 : Combi alarm no. 1

52 : Combi alarm no. 2

53 : Combi alarm no. 3

54 : Combi alarm no. 4

55 : Combi alarm no. 5

56 : Combi alarm no. 6

57 : Combi alarm no. 7

58 : Combi alarm no. 8

90 : Comtroller power failure

M702GB/0110 Rev. 111001

14

Page 15

ComTroller 702

11 Programming of storm flow

calculation

11.1 Stormflow calculation

Comtroller 702 can be applied for calculation of

storm flow by means of one digital and analogue

input. Generally Comtroller 702 is applied to a level

meter with measuring range adapted to the pump

controller. This measuring range is normally

considerably higher, than what is necessary for

flow measurement, generally 10m for the pump

controller and 10-20cm for flow calculation. The

accuracy of the pump controller’s level

measurement is as the whole measuring range.

The data transmitter will compensate by means of

a digital input. An electrode relay, e.g. MJK 501

and a level electrode e.g. MJK 222860 are

applied.

The level electrode is applied where the storm flow

starts. By this, the chosen level meter will be in

zero position and calculate flow on the level signal.

This will improve the accuracy 10 to 15 times in

short term. The system provides a simple and

accurate measurement to a reasonable price.

11.2 Stormflow calculation in use Yes/no

Indicate application of stormflow calculation.

Use the arrow keys and confirm with enter key.

11.3 Zero-point DI #

Indicates the digital input that sets zero-point and

activates the flow calculation.

Choose between AI 1-2

Use the arrow keys, confirm with ENTER.

11.5 Key in the number of Q(h) points (1-9)

Indicate the number of Q/H points for single

linearization of the actual flow. The number can be

set between 1 and 9, as zero-point is set to a flow

3

of 0 m

/h.

12 Combi alarms

It is possible by means of a combi alarm to set off an

alarm call when 2 digital signals is activated

simultaneously. A digital signal can derive from a

digital input or from a limit alarm.

12.1 Combi alarm #

Use the arrow keys or enter 1 to 8 to select the

combi alarm to be programmed.

12.2 Combi alarm in use

Select if the combi alarm should be used. Use the

arrow keys and confirm with ENTER.

12.3 Combi alarm signals

Select the two digital signals to be AND'ed to

activate a combi alarm. The following digital signal

can be selected:

- digital input 1 - 4

- analog limit HIGH 1 - 2

- analog limit LOW 1 - 2

- power failure

12.4 Signal delay

Select the delay for the combilalarm. The delay

time is the time the two digital signals should be

active at the same time to set a combi alarm.

The format for the delay period is MM:SS.

Use the arrow keys (double arrow for minutes and

single arrow for seconds) or the numeric keys and

confirm with ENTER.

12.5 Combi alarm calls

Select if a combi alarm should set off an alarm call.

Use the arrow keys and confirm with ENTER.

Use the arrow keys and confirm with ENTER.

11.6 Key in the level mark

Key in the level (h) in a Q(h) – point. Use the keys

0-9, confirm with ENTER.

The level must be higher than the previous.

11.7 Key in the flow mark

Key in the volume (Q) in a Q(h) point. Use the keys

0-9 and confirm with ENTER.

M702GB/0110 Rev. 111001

15

MJK Automation A/S

Byageren 7

2850 Nærum

Tlf: 45 56 06 56

Fax: 45 56 06 46

Page 16

ComTroller 702

13 Alarms

13.1 Operational or alarm signal

The digital signals can be chosen as either

operational or alarm signals.

A operational signal can be defined as non-critical,

i.e. a signal, that one want to be registered.

Typically a signal, that indicate if a pump is running

or not.

An alarm signal is on the other hand a signal, that

normally is inactive and only will be active, when a

fault condition occurs. A thermal cutout on a pump

is a typical alarm signal.

Alarm signals has memory and reset, i.e, when the

alarm signal becomes non-active, it will be

memorized that the signal has been active. The

"active" state must be reset by the user before a

new active signal can be accepted as an alarm

signal. For both types of signals applies that both

the number of active conditions and the time frame

within the signal has been active, will be

registered.

13.2 Alarm calls

If the function "Alarm - call by telephone" is

selected (see section 6.5), the Comtroller 702 will

start a call routine by making a call attempt to the

first number in the phone list, then the next number

etc.

There will be a pause between the call attemps.

See also section 10.

When dialing to a telephone modem, it will be the

SCADA terminal that will be responsible for

resetting the alarm and stop the call routine.

When dialing a pager or telephone, the call routine

must be stopped with a telephone call back to the

Comtroller. This procedure will not reset the alarm,

only stop the call routine. If an alarm occurs during

the call routine, the call routine will not stop, i.e.

the new alarm will not be reported until the next

call succeeds.

The telephone list is not used if the RS485 port are

used for communication (via radio modem,

Powerline modem owned lines etc.). All alarm calls

is sent to the Master communications unit.

13.3 Reset of alarms

When a digital alarm signal becomes active, it will

be displayed in function menu F 8.1. Function

menu F 8.2 will display the input number and type

causing the alarm, the corresponding alarm designation, the immediate status of the alarm and the

time when the alarm was set.

indicating the status. The symbol flashes until the

alarm is registered which makes the symbol

permanently lit. The symbol stays lit until the alarm

signal is no longer active, then the signal disapears

and the stop time will show instead of the start

time.

To reset an alarm directly from the Data Transmitter keyboard, the display must show indication

F8.1. With the arrow keys the alarm to cancel is

chosen then press ENTER. The symbol will then

stop flashing and the alarm is registered.

An alarm can also be reset from the SCADA station via modem. This is carried out via the

communications protocol. If you do not wish to

have more calls on the account of a specific alarm

signal, it can be left unregistered, and there will be

no more calls, even if the signal changes from not

active to active.

If the alarm is not registered, and a further 9 alarms

occur, i.e. the unregistered alarm becomes no 10

the alarm will be cancelled.

13.4 Special factory codes

Comtroller 702 is provided with functions which

should not be served by the final user.

13.5 Access code

If the access code is lost, the code 1111 can always

be used.

13.6 Setting up the serial port

If the service code 2222 is used, it gives access to

adjustment of the baud rate. Contact the technical

hotline for help.

13.7 Forced reset to factory settings

It is possible to reset all settings to factory setting,

meaning that all settings must be made once

again. Use service code 2045.

13.8 SMSC telephone numbers

SMS-beskederne from Data transmitter 795 and

Comtroller 702 is sent to an SMSC server on the

following telephone numbers:

Denmark: (0045) 43 62 52 50

Nederlands: (0031) 653 14 14 14

Norge: (0047) 90 00 21 98

Portugal: (0035) 19 62 11 3000

Sweden: (0046) 7 40 93 00 00

Germany: (0049) 172 227 80 20

When a digital alarm signal become active, the

alarm status will be shown in funtional indication

F8.1. In functional indication F8.2 will be shown:

the type of alarm, the time of start and a symbol

M702GB/0110 Rev. 111001

16

Page 17

ComTroller 702

14 Other information

14.1 Specifications

Supply: 230 V AC / 12 V DC.

Fuse: 63 mA T built-in

Analog inputs: 2 AI, 0-20 / 4-20 mA

or 0 - 1 V DC

Digital inputs: 4 DI, optocoupler with10 kΩ

serial resistor

Digital outputs: 4 DO, relays, maxs. 48 V AC, 1A

Consumption: Approx. 5 VA

Temp. range: – 20 … + 60 °C

Material: Polystyrol

Enclosure: IP 21

Clock: Real time clock with built in

backup battery

Data- 1 x RS 232 for modem, UHF

communication: radio, GSM modem,

Data Transmitter 795 or PC.

2 x RS 485 for owned lines /

APL lines (multidrop)

Indication: 5 LED's for power indication and

for indication of the relay state.

14.2 Maintenance

MJK Comtroller 702 requires no particular

maintenance.

M702GB/0110 Rev. 111001

17

MJK Automation A/S

Byageren 7

2850 Nærum

Tlf: 45 56 06 56

Fax: 45 56 06 46

Page 18

ComTroller 702

15 Electrical connection

Al connections are shown on the front panel.

15.1 Digital inputs

The digital inputs (DI 1-4) has optocouplers with

10 kΩ serial resistors. The inputs can be

configured individually to normally open (NO) or

normally closed (NC).

15.2 Analog inputs

The input can be configured for either 0 - 20 mA or 4

- 20 mA. Below is shown a connection example with

an active a non-active signal source. The pressure

transmitter is an non-active signal source. The active

power source is fed from a separate power supply.

15.5 Software upgrade

If a software upgrade becomes necessary, it is

possible to perform the upgrade yourself. The software is loaded into an EPROM. Do the following to

change the EEPROM::

Select NO in the menu "Alarm - call by telephone"

is selected (see section 6.5)

Disconnect the Comtroller 702.

Remove the old EPROM from the socket and

insert the new one. Note that the little notch in the

EEPROM is oriented correctly in relation to the

socket.

Connect the Comtroller 702.

Remember to select "Alarm - call by telephone".

15.3 Serial ports

The Comtroller 702 is equipped with 1 x RS232port on terminal 28 - 32, that can be used for

communication to i.e. a PC or PLC that supports

the current communications protocol.

2 RS485 ports is available on terminal 23 - 25 and 26

- 28 for communication via owned lines / APL-lines.

Comtroller 702 is equipped with a repeater, so

maximum distance between every Comtroller on the

multidrop line can be obtained.

15.4 External 15 V DC supply

Terminal 33 / 34 is a 15 V DC output for external

use. Max. load 100 mA.

M702GB/0110 Rev. 111001

18

Page 19

ComTroller 702

M702GB/0110 Rev. 111001

19

MJK Automation A/S

Byageren 7

2850 Nærum

Tlf: 45 56 06 56

Fax: 45 56 06 46

Page 20

ComTroller 702

16 Factory settings

Main functions: Setting:

Language English

Access code No

Change between summer and winter time No

Analog input averaging No

Data logging interval 00:30 (30 sek.)

Tone/Pulse dialing Tone

Alarm - call by telephone No

Rings before answer 1

ID-nr. for Comtroller Set via switches on the front

Automatic reset of alarms No

702 phone number SMSC phone number Master or Slave Slave

Analog inputs: Analog input 1: Analog input 2:

0-20mA/4-20mA 4-20 mA 4-20 mA

Min. scaling 0 00

Max. scaling 999 999

High limit Nej Nej

High limit setting 999 999

High limit operation /alarm Operation Operation

Alarm delay (sec.) 0 0

Call by phone No No

Low limit No No

Low limit setting 0 0

Low limit operation / alarm Operation Operation

Alarm delay (sec.) 0 0

Call by phone No No

Digital inputs: Operation/Alarm: Signal delayed: NO/NC: Call by phone:

Digital input no. 1 Operation 0 NO No

Digital input no. 2 Operation 0 NO No

Digital input no. 3 Operation 0 NO No

Digital input no. 4 Operation 0 NO No

Digital outputs: NO/NC: Timer/Fixed: Time before start: On-time:

Digital output no. 1 NO Tid 5 10

Digital output no. 1 NO Tid 5 10

Digital output no. 1 NO Tid 5 10

Digital output no. 1 NO Tid 5 10

M702GB/0110 Rev. 111001

20

Page 21

ComTroller 702

Pump Controller: Setting:

Pump control activated Yes / No No

Telephone list:

Telephone no 1 Available 0 0

Telephone no 2 Available 0 0

Telephone no 3 Available 0 0

Telephone no 4 Available 0 0

Telephone no 5 Available 0 0

Telephone no 6 Available 0 0

Telephone no 7 Available 0 0

Telephone no 8 Available 0 0

Telephone no 9 Available 0 0

Storm flow calculation: Setting:

In use Yes / No No

Zero level DI 1

Level measurement AI 1

Number of points 9

Q/H point no 1 Level: 10 (cm) ; Flow (m

Q/H point no 2 Level: 20 (cm) ; Flow (m

Q/H point no 3 Level: 30 (cm) ; Flow (m

Q/H point no 4 Level: 40 (cm) ; Flow (m

Q/H point no 5 Level: 50 (cm) ; Flow (m

Q/H point no 6 Level: 60 (cm) ; Flow (m

Q/H point no 7 Level: 70 (cm) ; Flow (m

Q/H point no 8 Level: 80 (cm) ; Flow (m

Q/H point no 9 Level: 90 (cm) ; Flow (m

Combi alarms: In use: Alarm signals: Signal delayed: Alarm call:

Combi alarm 1 No DI 1 AND DI 1 00:00 No

Combi alarm 2 No DI 1 AND DI 1 00:00 No

Combi alarm 3 No DI 1 AND DI 1 00:00 No

Combi alarm 4 No DI 1 AND DI 1 00:00 No

Combi alarm 5 No DI 1 AND DI 1 00:00 No

Combi alarm 6 No DI 1 AND DI 1 00:00 No

Combi alarm 7 No DI 1 AND DI 1 00:00 No

Combi alarm 8 No DI 1 AND DI 1 00:00 No

Type (PC/OPS/ Telephone OPS/SMS-

Telefon/SMS): number: message:

3

/h) : 1.11

3

/h) : 2.22

3

/h) : 3.33

3

/h) : 4.44

3

/h) : 5.55

3

/h) : 6.66

3

/h) : 7.77

3

/h) : 8.88

3

/h) : 9.99

Pause in min.:

M702GB/0110 Rev. 111001

21

MJK Automation A/S

Byageren 7

2850 Nærum

Tlf: 45 56 06 56

Fax: 45 56 06 46

Page 22

Loading...

Loading...