Page 1

PUMP CONTROLLER 701

Instruction manual

General

Thank you for choosing Pump

Controller 701. Pump Controller 701

is a new compact unit for level

control of 1 pump and 1 level alarm,

or 2 pumps in alternation.

Pump Controller 701 is supplied in a

housing for DIN rail mounting and is

easy to install and operate from the

front panel.

Hydrostatic measuring system

Pump Controller 701 is supplied with Pressure Transmitter 7060

or 7070 covering measuring ranges from 0 - 3 m to 0 - 30 m.

Pressure Transmitter 7060 is manufactured in polypropylene

and developed for measuring in wastewater and liquids with

suspended solids. Pressure Transmitter 7070 is manufactured in

stainless steel, with small external diameter and is applied in

clean liquids such as water drillings. The pressure transmitters

are manufactured as 2-wire 4 - 20 mA transmitters, which

generates an output signal proportional with the level.

Measurement is based on the following principle:

The pressure transmitter is immersed to the bottom of the liquid

and measures the hydrostatic pressure. The pressure transmitter submits an electrical signal, which is proportional with the

pressure on the diaphragm of the pressure transmitter. The

pressure transmitter has an equalizing hose in the cable, for air

pressure compensation. The pressure transmitter is connected

to Pump Controller 701 where the signal is applied for start and

stop limits and alarm.

Specifications

Pump Controller 701

Dimension: 86 x 70 x 60 mm (h x w x d)

Supply: 230 VAC

(Can also be supplied for other voltages.)

Power consumption: 10 VA (For 230 VAC supply)

Temperature range: - 20 … + 60 °C

Input: 4 - 20 mA from pressure transmitter

Measuring range: Determined from pressure transmitter

Accuracy: ± 1 %

Output: 2 relays with potentialfree switch

Charge: 250 V, 4 A resistive,

max. 100 VA inductive

Enclosure: IP 22

MJK Automation A/S

M701GB/0106

1

Byageren 7

DK-2850 Nærum

Tel: 45 56 06 56

Fax: 45 56 06 46

Page 2

PUMP CONTROLLER 701

Pressure Transmitter 7060 or 7070

Measuring range: 0 - 3 m: Pressure Transmitter

7060 / 7070 - 1413

0 - 10 m:Pressure Transmitter

7060 / 7070 - 1423

0 - 30 m:Pressure Transmitter

7060 / 7070 - 1433

Dimension: Type 7060: Ø 60 x 140 mm

Type 7070: Ø 22 x 150 mm

Output: 4 - 20 mA

Supply: 12 - 30 VDC

Accuracy: ±1 % (0 - 50 °C)

Temperature: - 10 … + 60 °C

Materials: House 7060: Polypropylene

House 7070: Steel AISI 316

Membrane: Steel AISI 316

Cable: Dimension: 2 x 0,5 mm

Insulation: PVC, outer layer of oil

resistant PVC.

Length: 12 m (35 m for 7060 / 7070-1433)

Enclosure: IP 68, waterproof, max. 3 bar.

2

Installation and connection

Pressure transmitter

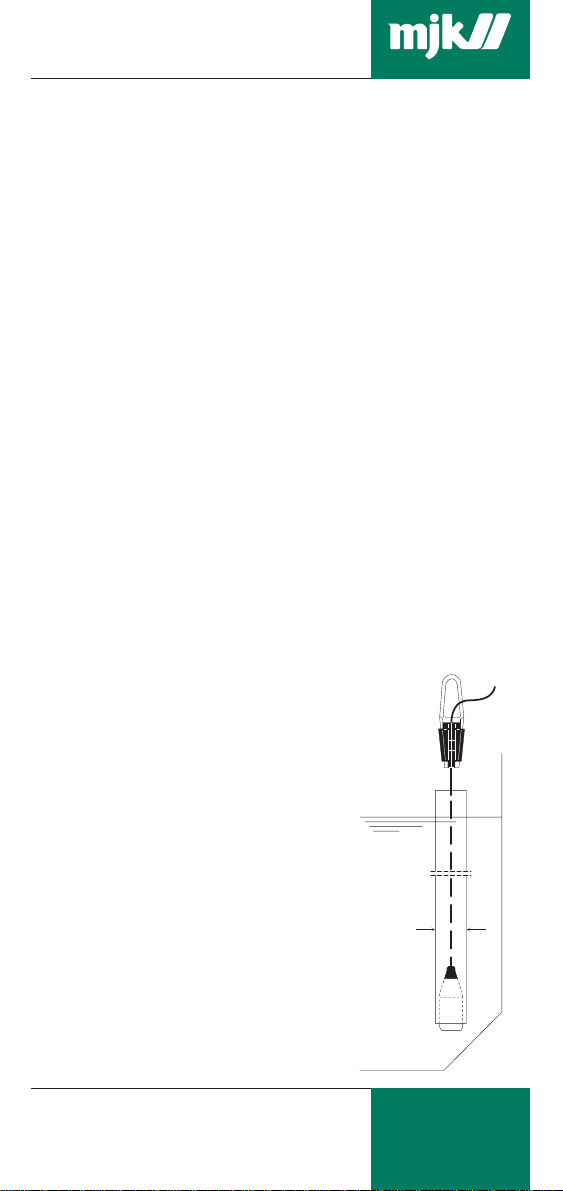

The pressure transmitter is immersed in

the well. The pressure transmitter can

be mounted in a tube, and fastened at

the top end of the tube, by means of

cable fittings.

If the pressure transmitter is

mounted in a tube, it facilitates

cleaning and inspection.

Internal diameter

min. 65 mm.

M701GB/0106

2

MJK Automation A/S

Byageren 7

DK-2850 Nærum

Tel: 45 56 06 56

Fax: 45 56 06 46

Page 3

PUMP CONTROLLER 701

Pump Controller

Supply

230 V AC

Settings

Pump Controller 701 is operated from the front panel, where

start- and stop levels, or alarm setpoint for each relay output

is adjusted with 2 potentiometers. The pump controller is

adjusted by connection of a voltmeter between the test

bushes, marked "TEST" and "COMMON" and by adjusting

the potentiometer to the desired level. Dependent of the

"LEVEL" switch position, 0 - 3 / 0 - 30 m measuring range is

proportional with 0 - 3 V on the voltmeter and measuring

range

0 - 10 m is equal with 0 - 1 V.

The switch for alternation "ALTERNATION" is set on "ON", if

the pump controller shall be set for alternation.

The voltmeter - (negative) cable is connected to the test bush

"COMMON" and + (positive) is connected to the test bush

"TEST", opposite the function which has to be adjusted.

The pump controller is in operation when connected to

voltage, and calibration can always be made during operation.

MJK Automation A/S

M701GB/0106

3

Byageren 7

DK-2850 Nærum

Tel: 45 56 06 56

Fax: 45 56 06 46

Page 4

PUMP CONTROLLER 701

Start- and stop setpoint

Start- and stop setpoint for the connected pump, is adjusted on

the two potentiometers. The circuit is implemented so the pump

is running when level reach the adjusted start setpoint, and

stops when level reach the adjusted stop setpoint.

Empty/ fill functions

The pump controller automatically changes between empty and

fill function. Dependent of start, set-point is adjusted to be

higher than stop set-point (pumping out), or stop set-point is

adjusted to be higher than start set-point (pumping in.)

Please note that the difference between start and stop set-point,

must be at least 2 % of the measuring range.

Alarm function

Pump Controller 701 can also be applied as level alarm if only

one pump is connected. Alarm set-point is adjusted on the

start- and stop potentiometer, opposite the chosen output.

Please note that the difference between start and stop set-point,

must be at least 2 % of the measuring range.

Various

Maintenance

The pump controller requires no special maintenance, just as

the pressure transmitter normally not requires cleaning.

Cleaning of the diaphragm of the pressure transmitter, must be

exercised with great care.

Spare parts

Item no: Description

202930 7060-1413 Pressure transmitter 0 - 3 m

202935 7060-1423 Pressure transmitter 0 - 10 m

202940 7060-1433 Pressure transmitter 0 - 30 m

202950 7070-1413 Pressure transmitter 0 - 3 m

202955 7070-1423 Pressure transmitter 0 - 10 m

202960 7070-1433 Pressure transmitter 0 - 30 m

201950 Pump Controller 701 without transmitter

550029 Fuse 40 mA

560915 Cable fitting for Presure Transmitter 7060

560916 Cable fitting for Presure Transmitter 7070

MJK Automation A/S

M701GB/0106

4

Byageren 7

DK-2850 Nærum

Tel: 45 56 06 56

Fax: 45 56 06 46

Page 5

PUMP CONTROLLER 701

Dimensions

Pump Controller 701

Pressure TransmitterPressure Transmitter

Pressure Transmitter

Pressure TransmitterPressure Transmitter

Type 7060Type 7060

Type 7060

Type 7060Type 7060

M701GB/0106

Pressure TransmitterPressure Transmitter

Pressure Transmitter

Pressure TransmitterPressure Transmitter

Type 7070Type 7070

Type 7070

Type 7070Type 7070

ø 22

MJK Automation A/S

5

Byageren 7

DK-2850 Nærum

Tel: 45 56 06 56

Fax: 45 56 06 46

215

Loading...

Loading...