Page 1

6-Series

Multiparameter

Water Quality Sondes

User Manual

6-Series:

6600 V2

6600EDS V2

6920 V2

6820 V2

600 OMS V2

600XL

600XLM

600LS

600R

600QS

Page 2

SAFETY NOTES

TECHNICAL SUPPORT AND WARRANTY INFORMATION

Contact information for technical support and warranty information on YSI’s Environmental

Monitoring Systems products can be found in Section 9, Warranty and Service Information.

COMPLIANCE

When using the YSI 6-Series sondes in a European Community (CE) country, please be aware

that electromagnetic compatibility (EMC) performance issues may occur under certain

conditions, such as when the sonde is exposed to certain radio frequency fields.

If you are concerned with these issues, consult the Declaration of Conformity that was enclosed

with your instrument. Specific conditions where temporary sensor problems may occur are listed

in this document.

The Declaration of Conformity for your instrument can be found in Appendix H, EMC

Performance. A similar document for YSI Model 650 is located at the end of Section 3, 650

MDS.

SPECIFICATIONS

For general specifications for all YSI Environmental Monitoring Systems products included in

this manual, please see Appendix O, Specifications.

GENERAL SAFETY CONSIDERATIONS

For Health and Safety issues concerning the use of the calibration solutions with the sondes,

please see Appendix A, Health and Safety.

NOTICE

Information contained in this manual is subject to change without notice. Effort has been made to

make the information contained in this manual complete, accurate, and current. YSI shall not be

held responsible for errors or omissions in this operations manual.

WARNING:

When caring for your sonde, remember that the sonde is sealed at the factory, and there is never a

need to gain access to the interior circuitry of the sonde. In fact, if you attempt to disassemble the

sonde, you would void the manufacturer's warranty.

Page 3

TABLE OF CONTENTS

SECTION 1 INTR ODUCTION

1.1 ABOUT YSI 1-1

1.2 HOW TO USE THIS MANUAL 1-1

1.3 UNPACKING AND INSPECTION 1.2

SECTION 2 SONDES

2.1 GETTING STARTED 2-1

2.2 CONNECTING YOUR SONDE 2-2

2.3 PREPARING THE SONDE FOR USE 2-5

2.4 ECOWATCH FOR WINDOWS – GETTING STARTED 2-24

2.5 SONDE SOFTWARE SETUP 2-25

2.6 GETTING READY TO CALIBRATE 2-34

2.7 TAKING READINGS 2-49

2.8 USING ECOWATCH TO UPLOAD AND ANALYZE DATA 2-54

2.9 SONDE MENU 2-68

2.10 CARE, MAINTENANCE, AND STORAGE 2-111

SECTION 3 650 MDS DATA LOGGER

3.1 INTRODUCTION 3-1

3.2 GETTING STARTED 3-1

3.3 SETTING UP THE 650 3-18

3.4 SONDE MENU INTERFACE 3-21

3.5 LOGGING DATA WITH THE 650 3-27

3.6 MANAGING 650 FILES 3-46

3.7 UPLOADING DATA FROM SONDES 3-51

3.8 USING GPS WITH 650 3-51

3.9 USING THE 6 50 BAROMETER 3-53

3.10 UPGRADING 650 SOFTWARE 3-55

3.11 TROUB LES HOOTING 3-56

3.12 FERRITE BEAD INSTALLATION

3.13 SAFETY CONSIDERATIONS 3-58

3.14 650 MDS SPECIFICATIONS 3-61

SECTION 4 ECOWATCH FOR WINDOWS

4.1 INTRODUCTION 4-1

4.2 DATA ACQUISITION AND ANALYSIS 4-7

4.3 ECOWATCH MENU 4-12

SECTION 5 PRINCIPLES OF OPERATION

5.1 CONDUCTIVITY 5-1

5.2 SALINITY 5-2

5.3 TOTAL DISSOLVED SOLIDS (TDS) 5-2

5.4 OXIDATION REDUCTION POTENTIAL (ORP) 5-3

5.5 pH 5-4

5.6 DEPTH AND LEVEL 5-6

5.7 TEMPERATURE 5-7

5.8 DISSOLVED OXYGEN RAPID PULSE 5-7

5.9 DISSOLVED OXYGEN ROX OPTICAL 5-10

5.10 NITRATE 5-12

5.11 AMMONIUM AND AMMONIA 5-14

5.12 CHLORIDE 5-16

5.13 TURBIDITY 5-17

3-57

Page 4

5.14 CHLOROPHYLL 5-21

5.15 RHODAMINE 5-28

5.16 PHYCOCYANIN-CONTAIN ING BLUE-GRE EN ALGAE 5-31

5.17 PHYCOERYTHRIN-CONTAINING BLUE-GREE N ALGAE 5-37

5.18 FLOW 5-42

SECTION 6 TROUBLESHOOTING

6.1 CALIBRATION ERRORS 6-1

6.2 SONDE COMMUNICATION PROBLEMS 6-2

6.3 SENSOR PERFORMANCE PROBLEMS 6-3

SECTION 7 COMMUNICATION

7.1 OVERVIEW 7-1

7.2 HARDWARE INTERFACE 7-1

7.3 RS-232 INTERFACE 7-2

7.4 SDI-12 INTERFACE 7.2

SECTION 8 UPGRADING SONDE FIRMWARE 8.1

SECTION 9 WARRANTY AND SERVICE INFORMATION

9.1 LIMITATIONS O F WARRANTY 9-1

9.2 AUTHORIZED SERVICE CENTERS 9-2

9.3 CLEANING INSTRUCTIONS 9-2

9.4 PACKING INSTRUCTIONS 9-2

9.5 PRODUCT RETURN FORM 9-4

APPENDIX A HEALTH AND SAFETY A-1

APPENDIX B REQUIRED NOTICE B-1

APPENDIX C ACCESSORIES AND CALIBRATION STANDARDS C-1

APPENDIX D SOLUBILITY AND PRESSURE/ALTITUDE TABLES D-1

APPENDIX E TURBIDITY MEASUREMENTS E-1

APPENDI

APPENDIX G USING VENTED LEVEL G-1

APPENDIX H EMS PERFORMANCE H-1

APPENDIX I CHLOROPHYLL MEASUREMENTS I-1

APPENDIX J PERCENT AIR SATURATION J-1

APPENDIX K PAR SENSOR K-1

APPENDIX L PROTECTIVE ZINC ANODE L-1

APPENDIX M ROX OPTICAL DO SENSOR M-1

APPENDIX N NMEA APPLICATIONS N-1

APPENDIX O SPECIFICATIONS O-1

X F FLOW F-1

Page 5

Introduction Section 1

SECTION 1 INTRODUCTION

1.1 ABOUT YSI INCORPORATED

From a three-man partnership in the basement of the Antioch College science building in 1948, YSI has

grown into a commercial enterprise designing and manufacturing precision measurement sensors and

control instruments for users around the world. Although our range of products is broad, we focus on three

major markets: water testing and monitoring, health care, and bioprocessing.

In the 1950s, Hardy Trolander and David Case made the first practical electronic thermometer using a

thermistor. This equipment was developed to supply Dr. Leland Clark with a highly sensitive and precise

temperature sensor for the original heart-lung machine. The collaboration with Dr. Clark has been critical

to the success of the company. In the 1960s, YSI refined a Clark invention, the membrane covered

polarographic electrode, and commercialized oxygen sensors and meters which revolutionized the way

dissolved oxygen was measured in wastewater treatment plants and environmental water. Today,

geologists, biologists, environmental enforcement personnel, officials of water utilities and fish farmers

recognize us as the leader in dissolved oxygen measurement.

In the 1970s, YSI again worked with Clark to commercialize one of his many inventions, the enzyme

membrane. This development resulted in the first practical use of a biosensor, in the form of a membrane

based on immobilized glucose oxidase, to measure blood sugar accurately and rapidly. In the next few

years, this technology was extended to other enzymes, including lactate oxidase, for applications in

biotechnology, health care, and sports medicine.

In the early 1990s, YSI launched a line of multi-parameter water monitoring systems to address the

emerging need to measure non-point source pollution. Today we have thousands of instruments in the field

that operate with the push of a button, store data in memory, and communicate with computers. These

instruments (described in this manual) are ideal for profiling and monitoring water conditions in industrial

and wastewater effluents, lakes, rivers, wetlands, estuaries, coastal waters, and monitoring wells. If the

instrument has ‘on board’ battery power, it can be left unattended for weeks at a time with measurement

parameters sampled at the user’s setup interval and data securely saved in the unit's internal memory. The

fast responses of YSI’s sensors make the systems ideal for vertical profiling, and the small size of some our

sondes allows them to fit down 2-inch diameter monitoring wells. All of YSI’s multi-parameter systems

feature either the YSI-patented Rapid Pulse Dissolved Oxygen Sensor, which exhibits low-stirring

dependence and provides accurate results without an expensive, bulky, and power-intensive stirrer or an ROX

optical dissolved oxygen sensor which exhibits no flow dependence and is extremely stable in long-term

deployments.

YSI has established a worldwide network of selling partners in over 50 countries that includes laboratory

supply dealers, manufacturers' representatives, and YSI’s sales force. A subsidiary, YSI UK, distributes

products in the United Kingdom, a sales office in Hong Kong supports YSI’s distribution partners in Asia

Pacific, and YSI Japan supports distribution partners in Japan.

Through an employee stock ownership plan (ESOP), every employee is one of the owners. In 1994, the

ESOP Association named YSI the ESOP Company of the Year. YSI is proud of its products and are

committed to meeting or exceeding customers' expectations.

1.2 HOW TO USE THIS MANUAL

The manual is organized to let you quickly understand and operate the YSI 6-Series environmental

monitoring systems. However, it cannot be stressed too strongly that informed and safe operation is more

than just knowing which buttons to push. An understanding of the principles of operation, calibration

YSI Incorporated Environmental Monitoring Systems Manual 1-1

Page 6

Introduction Section 1

techniques, and system setup is necessary to obtain accurate and meaningful results. Thorough reading and

understanding of this manual is essential to proper operation.

Because of the many features, configurations and applications of these versatile products, some sections of

this manual may not apply to the specific system you have purchased.

If you have any questions about this product or its application, please contact YSI’s Technical Support

Group or authorized dealer for assistance. See Section 9, Warranty and Service Information for contact

information.

1.3 UNPACKING AND INSPECTION

Inspect the outside of the shipping box for damage. If any damage is detected, contact your shipping carrier

immediately. Remove the equipment from the shipping box. Some parts or supplies are loose in the

shipping box so check the packing material carefully. Check off all of the items on the packing list and

inspect all of the assemblies and components for damage.

If any parts are damaged or missing, contact your YSI representative immediately. If you purchased the

equipment directly from YSI, or if you do not know from which YSI representative your equipment was

purchased, refer to Section 8, Warranty and Service Information for contact information.

YSI Incorporated Environmental Monitoring Systems Manual 1-2

Page 7

Sondes Section 2

SECTION 2 SONDES

2.1 GETTING STARTED

The 6-Series Environmental Monitoring Systems from YSI are multi-parameter, water quality

measurement, and data collection systems. They are intended for use in research, assessment, and

regulatory compliance applications. Section 2 concentrates on sondes and how to operate them during

different applications. A sonde is a torpedo-shaped water quality monitoring device that is placed in the

water to gather water quality data. Sondes may have multiple probes. Each probe may have one or more

sensors that read water quality data.

The following list contains parameters that your sonde may measure. See Appendix O, Specifications for

the specific parameters of each sonde.

Rapid Pulse Polarographic Dissolved Oxygen

ROX Optical Dissolved Oxygen

Conductivity

Specific Conductance

Salinity

Total Dissolved Solids

Resistivity

Temperature

pH

ORP

Depth

Level

Flow

Turbidity

Chlorophyll

Rhodamine WT

Phycocyanin-Containing Blue-green Algae

Phycoerythrin-Containing Blue-green Algae

Nitrate-N

Ammonia-N

Ammonium-N

Chloride

This section is designed to quickly familiarize you with the hardware and software components of the

sondes and their accessories. You will then proceed to probe installations, cable connections, software

installation and finally basic communication with your Sonde. Diagrams, menu flow charts and basic

written instructions will guide you through basic hardware and software setup.

YSI Incorporated Environmental Monitoring Systems Operations Manual 2-1

Page 8

Sondes Section 2

2.2 CONNECTING YOUR SONDE

There are a number of ways in which you may connect the sondes to various computers, data collection

devices and VT-100 terminal emulators. To utilize the configuration that will work best for your

application, make sure that you have all of the components that are necessary. The following list and

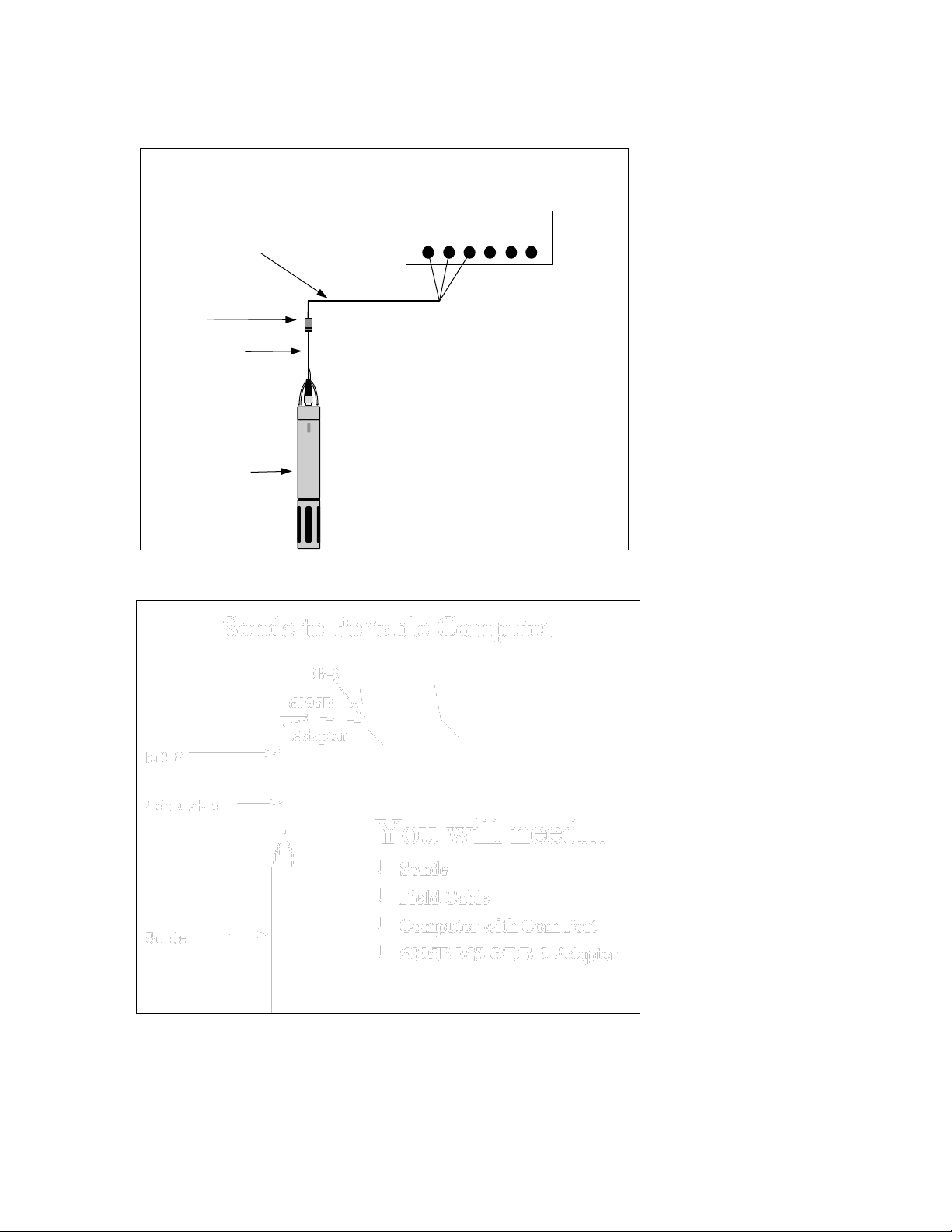

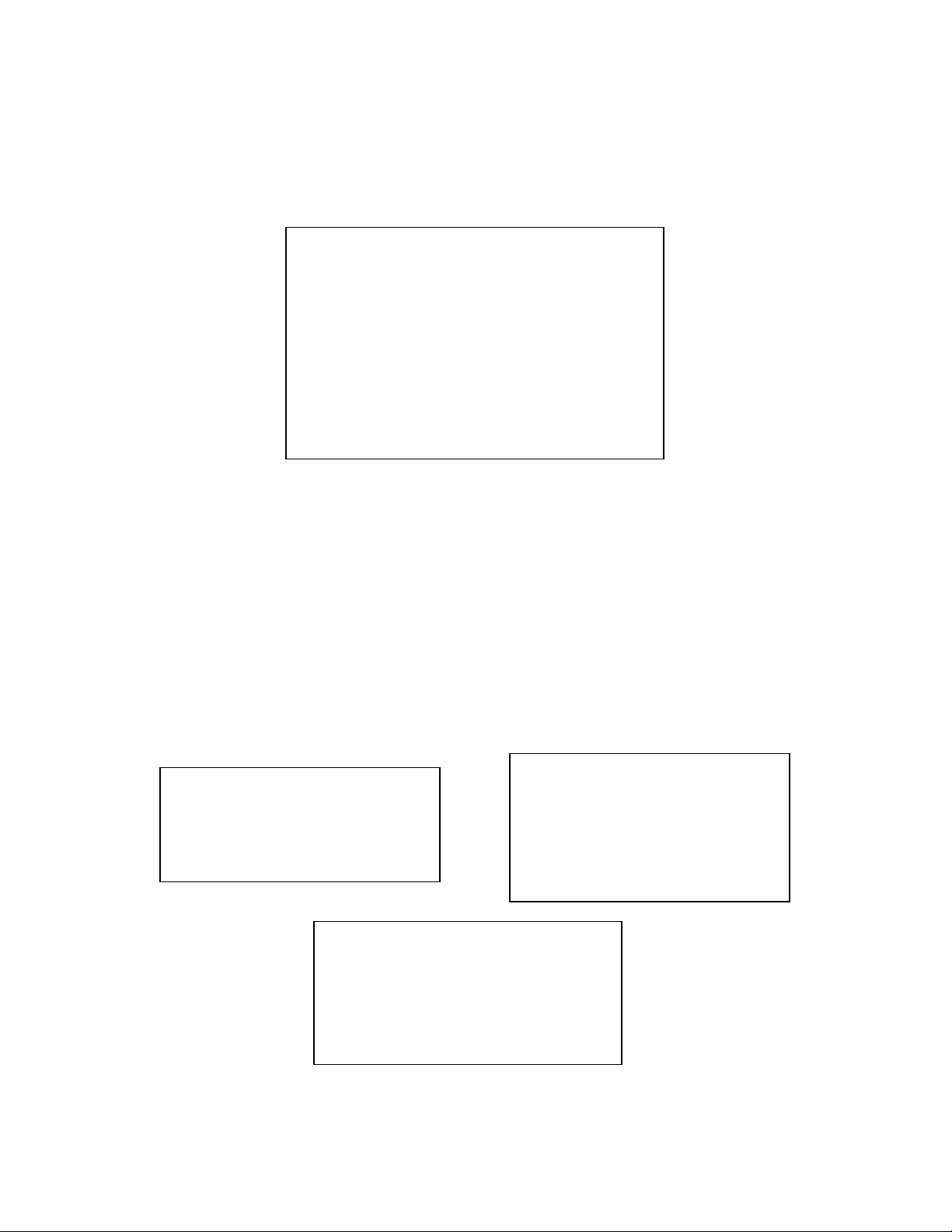

diagrams (Figures 1-4) are a few possible configurations.

Sonde to Lab Computer (recommended for initial setup)

Sonde to Data Collection Platform

Sonde to Portable Computer

Sonde to YSI 650 MDS Display/Logger

Figure 1

YSI Incorporated Environmental Monitoring Systems Operations Manual 2-2

Page 9

Sondes Section 2

Sonde to Data Collection Platform

You will need...

Sonde

Field Cable

6096 Adapter with leads

Data Collection Platform

6096 MS-8 Adapter with Flying Leads

DCP

Field Cable

MS-8

Sonde

YSI

692

0

+

+

-

-

Figure 2

Figure 3

YSI Incorporated Environmental Monitoring Systems Operations Manual 2-3

Page 10

Sondes Section 2

Sonde to 650 Display/Logger

You will need...

Sonde

Field Cable

650 MDS Display/Logger

YSI 650 operates on C-cells or rechargeable batteries.

650 MDS

610-DM

Environmental

Monitoring

Systems

YS

Field Cable

Sonde

YS I 69

20

YS I 69

20

+ + -

-

MS-8

Figure 4

YSI Incorporated Environmental Monitoring Systems Operations Manual 2-4

Page 11

1.

ADD DI OR DISTILLED

WATER

2.

PROTECTIVE CAP

DRY MEMBRANE

Sondes Section 2

2.3 PREPARING THE SONDE FOR USE

To prepare the sonde for calibration and operation, you need to install probes (sensors) into the connectors

on the sonde bulkhead. In addition to probe installation, you need to install a new membrane on the YSI

6562 DO Probe if you are using this item. It is recommended that you install the DO membrane before

installing the probe onto the bulkhead. For membrane changes in the future, you may be able to perform

this operation without removing the DO probe. This will largely depend on whether the other installed

probes interfere with your ability to install a membrane. The next step is providing power for the sondes,

through batteries or line power, and then connecting a field cable. The four steps necessary for getting your

sonde ready for use are listed below.

Step 1 Installing the Dissolved Oxygen Membrane – Section 2.3.1

Step 2 Installing the Probes – Section 2.3.2

Step 3 Supplying Power – Section 2.3.3

Step 4 Connecting a Field Cable – Section 2.3.4

2.3.1 STEP 1 - INSTALLING THE DISSOLVED OXYGEN MEMBRANE

Note: If you are using a ROX Optical DO sensor for your applications, please skip to Section 2.3.2 at

this time.

The 6562 Rapid Pulse Polarographic DO probe is shipped with a protective dry membrane on the sensor tip

held in place by an O-ring. Remove the O-ring and membrane. Handle the probe with care. It is very

important not to scratch or contaminate the sensor tip. See Section 2.10.2, Probe Care and Maintenance,

for information on how often the membrane should be replaced.

Unpack the YSI 6562 DO Probe Kit and follow the instructions below.

Open the membrane kit and prepare the electrolyte solution. Dissolve the KCl in the dropper bottle by

filling it to the neck with deionized or distilled water and shaking until the solids are fully dissolved. After

the KCl is dissolved, wait a few minutes until the solution is free of bubbles.

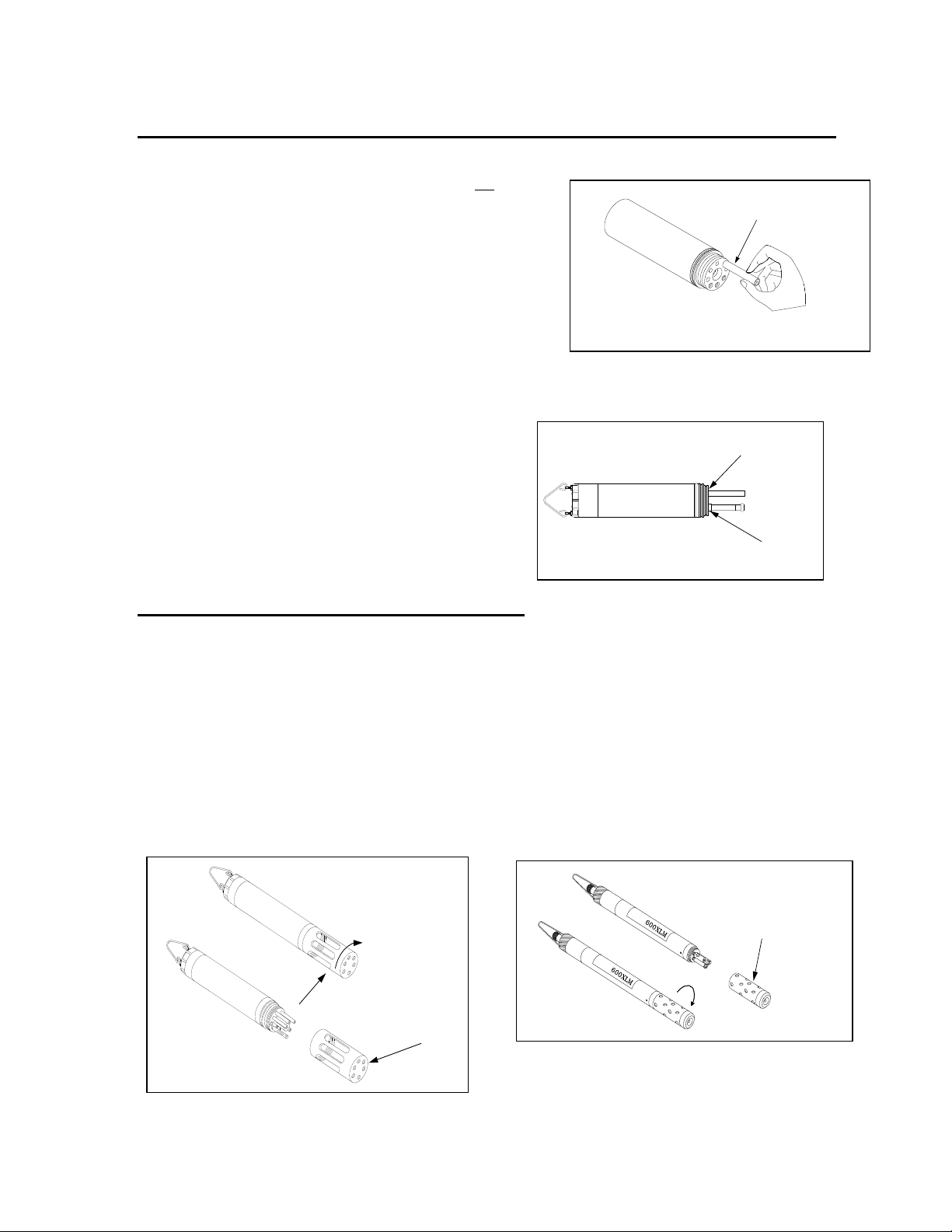

Figure 5 Figure 6

The DO membrane can be installed with the DO probe either free or installed in the sonde. Both methods

are described in detail below. CAUTION: If you install the membrane with the probe not installed in

the sonde, be sure that the protective cap is installed on the probe end away from the sensor face to

ensure that the connector is not contaminated with electrolyte.

YSI Incorporated Environmental Monitoring Systems Operations Manual 2-5

Page 12

Sondes Section 2

345

6

7

8

DO MEMBRANE INSTALLATION WITH THE PROBE NOT INSTALLED IN THE

SONDE

Remove the protective cap and the dry membrane from the YSI 6562 Dissolved Oxygen probe.

Make sure that the protective cap is installed on the connector end of the probe. Do not allow the

electrolyte solution to wet the probe‟s connector and O-ring seal areas. This solution is extremely corrosive

to the connector and is difficult to remove.

Before using any electrolyte, wrap a clean, dry paper towel around the capped probe to catch any spilled

electrolyte. Hold the probe in a vertical position and apply a few drops of KCl solution to the tip. The fluid

should completely fill the small moat around the electrodes and form a meniscus on the tip of the sensor.

Be sure no air bubbles are stuck to the face of the sensor. If necessary, shake off the electrolyte and start

over.

Figure 7

Secure a membrane between your left thumb and the probe body.

Always handle the membrane with care, touching it only at the

ends.

With the thumb and forefinger of your right hand, grasp the free

end of the membrane. With one continuous motion, gently stretch

it up, over, and down the other side of the sensor. The membrane

should conform to the face of the sensor.

Secure the end of the membrane under the forefinger of your left

hand.

Roll the O-ring over the end of the probe, being careful not to

touch the membrane surface with your fingers. There should be no

wrinkles or trapped air bubbles. Small wrinkles may be removed

by lightly tugging on the edges of the membrane. If bubbles are

present, remove the membrane and repeat steps 3-8.

Trim off any excess membrane with a sharp knife or scissors.

Rinse off any excess KCl solution, but be careful not to get any

water in the connector.

If you are concerned that electrolyte may have dripped onto the Oring seal area, probe connector, or bulkhead connectors, rub the

area clean with paper towels wetted with Deionized water and then

dry the affected area with a final dry towel, compressed air blasts,

or rinse with fresh alcohol.

NOTE: You may find it more convenient to mount the probe vertically in a vise with rubber jaws while

applying the electrolyte and membrane to the sensor tip.

YSI Incorporated Environmental Monitoring Systems Operations Manual 2-6

Page 13

Sondes Section 2

DO MEMBRANE INSTALLATION WITH THE PROBE INSTALLED IN THE SONDE

Secure the sonde in a vertical position using a vise or a clamp and ring stand such that the sensors are

upright. Remove the probe guard from the sonde.

Remove the old DO membrane and clean the probe tip with water and lens cleaning tissue. Make sure to

remove any debris or deposits from the O-ring groove.

Using the dropper bottle of electrolyte supplied, place electrolyte on the DO probe tip until a high meniscus

is formed as shown in Figure 8 below.

Figure 8 Figure 9

Hold the membrane so that all four corners are supported, but do not stretch the membrane laterally.

Position the membrane over the probe, keeping it parallel to the probe face as shown in Figure 9 above.

Using one continuous downward motion, stretch the membrane over the probe face as shown. See Figure

10 below. Do not hesitate to stretch the membrane.

Figure 10 Figure 11

Install a new O-ring by placing one side of the O-ring in the groove and rolling into place across the

membrane and into the groove on the opposite side of the probe face. Avoid touching the probe face with

YSI Incorporated Environmental Monitoring Systems Operations Manual 2-7

Page 14

Sondes Section 2

TRANSPORT CUP

BULKHEAD WITH

PROBE PORT PLUGS

your fingers. Once the O-ring is in position, squeeze it every 90 degrees to equalize the tension. See

Figure 11 above. DO NOT USE GREASE OR LUBICANT OF ANY KIND ON THE O-RING.

Using a hobby knife or a scalpel, trim the excess Teflon from the membrane, making your cut about 1/8

inch below the O-ring as shown in Figure 12 below. A razor blade can be used for the cut if no knife or

scalpel is available.

Figure 12 Figure 13

If the installation has been done properly, the finished product should have no bubbles, wrinkles, or tears as

shown in Figure 13 above.

NOTE: Observe the following cautions to assure that your membrane installation is proper:

Secure the sonde tightly so that it will not move during membrane installation.

Wash hands before installation and do not allow finger oils or O-ring lubricant to touch the probe face

or the membrane.

Use caution when replacing the probe guard that you do not touch the membrane. If you suspect that

the membrane has been damaged, replace it immediately.

2.3.2 STEP 2 - INSTALLING THE PROBES

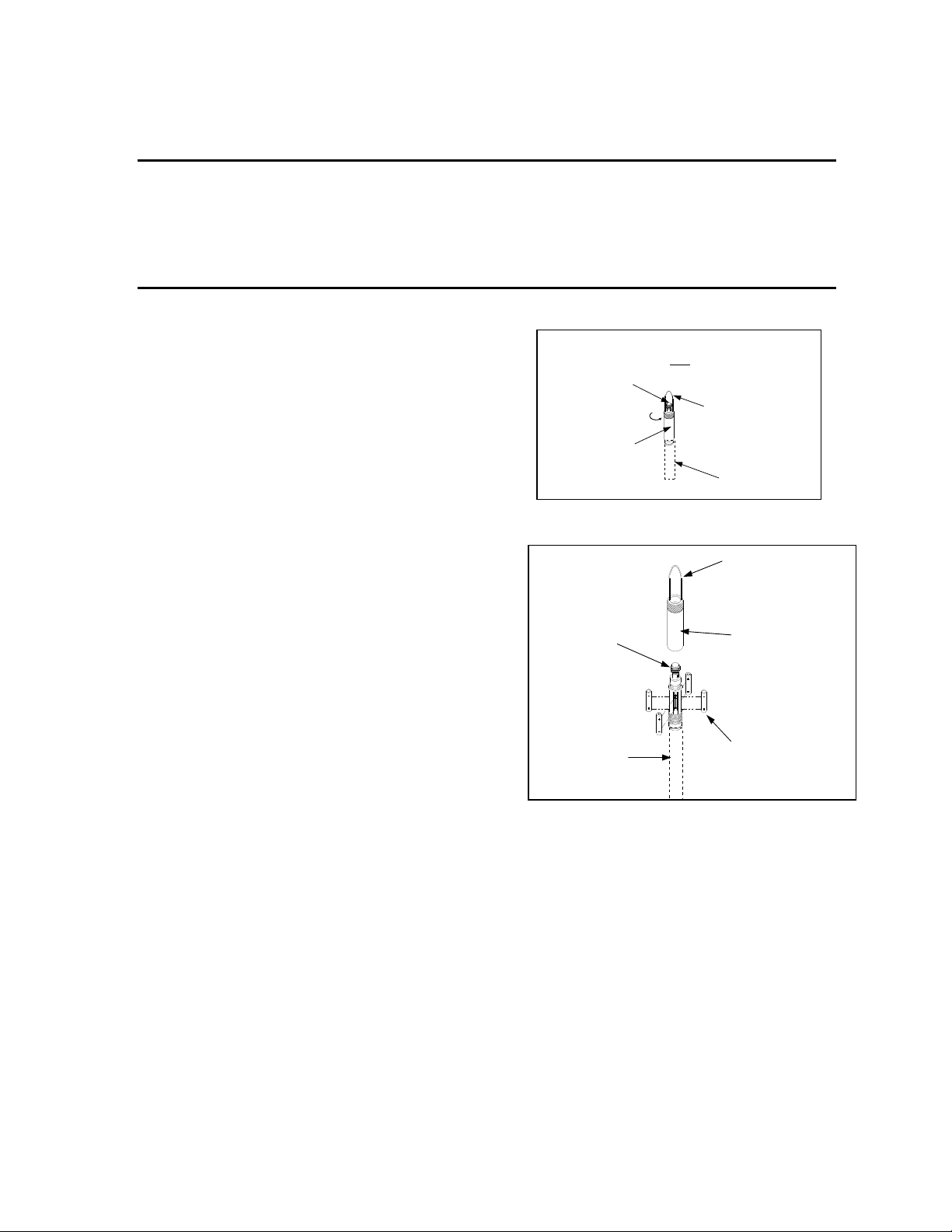

Remove the calibration cup from your sonde by hand as shown in Figure 14, to expose the bulkhead.

Figure 14

YSI Incorporated Environmental Monitoring Systems Operations Manual 2-8

Page 15

Sondes Section 2

OPTIC

PORT PLUG

INSTALLATION

TOOL

DO, COND., &

pH/ORP PORT

PLUGS

INSTALLATION

TOOL

ISE PORT PLUG

PLIERS

(SLIP JAWS)

REMOVING THE PORT PLUGS

Using the long extended end of the probe installation tool supplied in the YSI 6570

Maintenance Kit, remove the port plugs. Save all the port plugs Figure 15

for possible future use.

There are a variety of probe options for the sondes. Figures 15, 16 and 17

illustrate the uses of the common tool for port plug removal.

Note that this tool will also be used to install the various probes.

If the tool is misplaced or lost, you may use 7/64” and 9/64” hex keys as

substitutes.

Figure 16 Figure 17

Figure 18

NOTE: You may need pliers to remove the ISE port

plugs, but do not use pliers to tighten the ISE probes.

Hand-tighten only.

Now refer to Figures 19-24 to find the probe locations in

your sonde.

YSI Incorporated Environmental Monitoring Systems Operations Manual 2-9

Page 16

Sondes Section 2

DISSOLVED

OXYGEN

6562

CONDUCTIVITY/

TEMPERATURE

6560

ALL ISE

PROBES

Cond./Temp.

Optic T

pH/ORP

ISE‟s

ISE‟s

ISE‟s

Dissolved Oxygen

Optic C

600XL & 600XLM SONDE BULKHEAD

3 Port Sonde: 1 Rapid Pulse DO, 1 Conductivity/Temperature, and 1 pH/ORP

Figure 19

6562 Dissolved oxygen probe = 3-pin connector

6560 Conductivity/Temperature = 6-pin connector

6561 pH probe = 4 pin connector

6565 Combo pH/ORP probe = 4 pin connector

6600V2-2 SONDE BULKHEAD

8 Port Sonde: 1 Rapid Pulse DO, 1 Conductivity/Temperature, 2 Optical, 3 ISE, 1 pH/ORP

Figure 20A

6562 Dissolved oxygen probe = 3-pin connector

6560 Conductivity/Temperature = 6-pin connector

6561 or 6561FG pH probe = 4 pin connector

6565 or 6565FG pH/ORP probe = 4 pin connector

6566 Fouling Resistant pH/ORP probe = 4 pin connector

6882 Chloride Probe = leaf spring connector

6883 Ammonium Probe = leaf spring connector

6884 Nitrate Probe = leaf spring connector

6026 Turbidity Probe, Wiping = 8 pin connector

6136 Turbidity Probe, Wiping = 8 pin connector

6025 Chlorophyll Probe, Wiping = 8 pin connector

6130 Rhodamine WT Probe, Wiping = 8 pin connector

6150 Optical Dissolved oxygen probe = 8 pin connector

6131 PC-Blue-green Algae probe = 8 pin connector

6132 PE-Blue-green Algae probe = 8 pin connector

YSI Incorporated Environmental Monitoring Systems Operations Manual 2-10

Page 17

Sondes Section 2

Cond/Temp – 6 pin

pH/ORP – 4 pin

Cond//Temp – 6 pin

pH/ORP – 4 pin

Rapid Pulse DO – 3 pin

6600EDS V2-2 SONDE BULKHEAD

5 Port Sonde: 1 Rapid Pulse DO, 1 Conductivity/Temperature, 2 Optical, 1 pH/ORP

Figure 20B

6562 Dissolved oxygen probe = 3-pin connector

6560 Conductivity/Temperature = 6-pin connector

6561 or 6561FG pH probe = 4 pin connector

6565 or 6565FG pH/ORP probe = 4 pin connector

6566 Fouling Resistant pH/ORP probe = 4 pin connector

6026 Turbidity Probe, Wiping = 8 pin connector

6136 Turbidity Probe, Wiping = 8 pin connector

6025 Chlorophyll Probe, Wiping = 8 pin connector

6130 Rhodamine WT Probe, Wiping = 8 pin connector

6150 Optical Dissolved oxygen probe = 8 pin connector

6131 PC-Blue-green Algae probe = 8 pin connector

6132 PE-Blue-green Algae probe = 8 pin connector

6600V2-4 SONDE BULKHEAD

6 Port Sonde: 1 Conductivity/Temperature, 4 Optical, 1 pH/ORP

Figure 20C

6560 Conductivity/Temperature = 6-pin connector

6561 or 6561FG pH probe = 4 pin connector

6565 or 6565FG pH/ORP probe = 4 pin connector

6566 Fouling Resistant pH/ORP probe = 4 pin connector

6026 Turbidity Probe, Wiping = 8 pin connector

6136 Turbidity Probe, Wiping = 8 pin connector

6025 Chlorophyll Probe, Wiping = 8 pin connector

6130 Rhodamine WT Probe, Wiping = 8 pin connector

6150 Optical Dissolved oxygen probe = 8 pin connector

6131 PC-Blue-green Algae probe = 8 pin connector

6132 PE-Blue-green Algae probe = 8 pin connector

YSI Incorporated Environmental Monitoring Systems Operations Manual 2-11

Page 18

Sondes Section 2

MOUNTING

SCREW

3

5

4

DISSOLVED

OXYGEN

COND/TEMP

ISE1/ISE2

pH/ORP

ISE3

ISE4

ISE5

OPTICAL

6820V2-1 & 6920V2-1 SONDE BULKHEADS

7 Port Sonde: 1 Rapid Pulse DO, 1 Conductivity/Temperature, 1 Optical, 1 pH/ORP, 3 ISE

Figure 21A

6562 Dissolved oxygen probe = 3-pin connector

6560 Conductivity/Temperature = 6-pin connector

6561 or 6561FG pH probe = 4 pin connector

6565 or 6565FG pH/ORP probe = 4 pin connector

6566 Fouling Resistant pH/ORP probe = 4 pin connector

6882 Chloride Probe = leaf spring connector

6883 Ammonium Probe = leaf spring connector

6884 Nitrate Probe = leaf spring connector

6026 Turbidity Probe, Wiping = 8 pin connector

6136 Turbidity Probe, Wiping = 8 pin connector

6025 Chlorophyll Probe, Wiping = 8 pin connector

6130 Rhodamine WT Probe, Wiping = 8 pin connector

6150 Optical Dissolved oxygen probe = 8 pin connector

6131 PC-Blue-green Algae probe = 8 pin connector

6132 PE-Blue-green Algae probe = 8 pin connector

6820V2-2 & 6920V2-2 SONDE BULKHEADS

5 Port Sonde: 1 Conductivity/Temperature, 2 Optical, 1 pH/ORP, 1 ISE

Figure 21B

6560 Conductivity/Temperature = 6-pin connector

6561 or 6561FG pH probe = 4 pin connector

6565 or 6565FG pH/ORP probe = 4 pin connector

6566 Fouling Resistant pH/ORP probe = 4 pin connector

6882 Chloride Probe = leaf spring connector

6883 Ammonium Probe = leaf spring connector

6884 Nitrate Probe = leaf spring connector

6026 Turbidity Probe, Wiping = 8 pin connector

6136 Turbidity Probe, Wiping = 8 pin connector

6025 Chlorophyll Probe, Wiping = 8 pin connector

6130 Rhodamine WT Probe, Wiping = 8 pin connector

6150 Optical Dissolved oxygen probe = 8 pin connector

6131 PC-Blue-green Algae probe = 8 pin connector

6132 PE-Blue-green Algae probe = 8 pin connector

YSI Incorporated Environmental Monitoring Systems Operations Manual 2-12

Page 19

Sondes Section 2

TEMPERATURE

pH GLASS

pH REFERENCE

6850

CONDUCTIVITY

DISSOLVED

OXYGEN

TEMPERATURE

pH GLASS/ORP

pH REFERENCE

6850

CONDUCTIVITY

DISSOLVED

OXYGEN

Conductivity

Temperature

Depth

600LS BULKHEAD

If are working with a 600LS, all sensors will have been installed

at the factory.

600R BULKHEAD

If are working with a 600R sonde, your instrument

will arrive with the probes installed.

600QS BULKHEAD

If are working with a 600QS sonde, your

instrument will arrive with the probes installed.

YSI Incorporated Environmental Monitoring Systems Operations Manual 2-13

Figure 21C

Figure 22

Figure 23

Page 20

Sondes Section 2

LUBRICATE O-RINGS

Conductivity Port

Optical Port

Temperature Sensor

600 OMS V2-1 BULKHEAD

Figure 24

The conductivity sensor (module/port) for the

600 OMS V2-1 is factory installed. Optical probes

(turbidity, chlorophyll, rhodamine WT, ROX

optical DO, BGA-PC, and BGA-PE) are

threaded into the optical port on the bottom

of the sonde by the user.

LUBRICATE O-RINGS

Apply a thin coat of O-ring lubricant, supplied in the YSI 6570 Maintenance Kit, to the O-rings on the

connector side of each probe that is to be installed.

Figure 25

CAUTION: Make sure that there are NO contaminants

between the O-ring and the probe. Contaminants that are present

under the O-ring may cause the O-ring to leak

when the sonde is deployed.

NOTE: Before installing any probe into the sonde bulkhead, be sure that the probe port is free of

moisture. If there is moisture present, you may use a can of compressed air to blow out the remaining

moisture.

YSI Incorporated Environmental Monitoring Systems Operations Manual 2-14

Page 21

Sondes Section 2

OPTIC

PROBE

INSTALLATION

TOOL

PROBE INSTALLATION

TOOL

DO PROBE

INSTALLING THE TURBIDITY, CHLOROPHYLL, RHODAMINE WT , BGA-PHYCOCYANIN, BGAPHYCOERYTHRIN, AND ROX OPTICAL DISSOLVED OXYGEN PROBES

If you are using any of optical probes listed, it is recommended that the optical sensors be installed first. If

you are not installing one of these probes, do not remove the port plug, and go on to the next probe

installation.

Figure 26

All optical probes, 6136 turbidity, 6025 chlorophyll, 6130

Rhodamine WT, 6131 Phycocyanin Blue-green algae, 6132

Phycoerythrin-Blue-green algae, and 6150 ROX Optical

DO are installed in the same way. Install the probe into the

center port, seating the pins of the two connectors before

you begin to tighten. Tighten the probe nut to the bulkhead

using the short extended end of the tool supplied with the

probe. Do not over-tighten.

CAUTION: Be careful not to cross-thread the probe nut.

The YSI 6820V2-1 and 6920V2-1 sondes can accept a single turbidity, chlorophyll, Rhodamine WT, BGAPC, BGA-PE, or ROX DO probe. The 6600V2-2, 6600EDS V2-2, 6820V2-2, and 6920V2-2 sondes can

accept and utilize two of the six optical sensors at the same time. The two optical ports of these sondes are

labeled “T” and “C” on the sonde bulkhead. Each port can accept any of the six sensors so be sure to

remember which sensor was installed in which port so that you will later be able to set up the sonde

software correctly. The 6600V2-4 sonde can accept and utilize four of the six optical sensors at the same

time. The four optical ports of this sonde are labeled “T” , “C”, “B”, and “O” on the sonde bulkhead. Each

port can accept any of the six sensors so be sure to remember which sensor was installed in which port so

that you will later be able to set up the sonde software correctly.

INSTALLING THE 6562 RAPID PULSE DISSOLVED OXYGEN PROBE, CONDUCTIVITY/TEMP AND

pH/ORP PROBES

Figure 27

Insert the probe into the correct port and gently rotate the

probe until the two connectors align.

The probes have slip nuts that require a small probe

installation tool to tighten the probe. With the connectors

aligned, screw down the probe nut using the long extended

end of the probe installation tool. Do not over-tighten.

CAUTION: Do not cross thread the probe nut.

YSI Incorporated Environmental Monitoring Systems Operations Manual 2-15

Page 22

Sondes Section 2

PROBE NUT TO SEAT

ON BULKHEAD

PROBE BODY TO SEAT

ON BULKHEAD

DO PROBE

ISE PROBE

BULKHEAD

(PROBES INSTALLED)

PROBE GUARD

TURN CLOCKWISE BY

HAND TO SECURE

PROBE GUARD

ISE PROBE

INSERT ISE PROBE,

SCREW IN AND TIGHTEN WITH FINGERS.

INSTALLING THE ISE PROBES

Figure 28

The Ammonium, Nitrate and Chloride ISE probes do not have slip

nuts and should be installed without tools. Use only your fingers

to tighten. Any ISE probe can be installed in any of the three ports

labeled “3”, “4”, and “5” on the sonde bulkhead of the 6820V2-1,

6920V2-1, and 6600V2-2 sondes or the single ISE port on the

6820V2-2 and 6920V2-2 bulkheads. Be sure to remember

which sensor was installed in which port so that you will later be

able to set up the sonde software correctly.

Figure 29

IMPORTANT: Make sure that the probe nut or probe body

of the ISE probes are seated directly on the sonde bulkhead.

This will ensure that connector seals will not allow leakage.

INSTALLING THE PROBE GUARD

Included with each sonde is a probe guard. The probe guard protects the probes during calibration and

measurement procedures. Once the probes are installed, install this guard by aligning it with the threads on

the bulkhead and turn the guard clockwise until secure.

CAUTION: Be careful not to damage the Rapid Pulse DO membrane during installation of the probe

guard.

Figure 30 shows the YSI 6820V2-1/6820V2-2/6920V2-1/6920V2-2 probe guard; the guard for the

6600V2-2/6600V2-4 is similar. The YSI 600R, 600QS, 600XL and 600XLM probe guards resemble

Figure 31.

Figure 30 Figure 31

YSI Incorporated Environmental Monitoring Systems Operations Manual 2-16

Page 23

Sondes Section 2

2.3.3 STEP 3 - POWER

Some type of external power supply is required to power the YSI 600R, 600QS, 600XL 6820V2-1, and the

non-battery version of the 600 OMS V2-1sondes. The YSI 6920V2-1, 6920V2-2, 6600V2-2,

6600EDS V2-2, 6600V2-4, 600XLM, and battery version of the 600 OMS V2-1sondes have internal

batteries or can run on external power.

If you have purchased a YSI 650 MDS display/logger, attaching your sonde to the display/logger will allow

your sonde to be powered from the batteries or the external power of the display/logger. See Section 3,

Displays/Loggers, for power options.

The battery-powered version of this instrument is powered by alkaline batteries, which the user must

remove and dispose of when the batteries no longer power the instrument. Disposal requirements vary by

country and region, and users are expected to understand and follow the battery disposal requirements for

their specific locale.

The circuit board in this instrument contains a manganese dioxide lithium "coin cell" battery that must be in

place for continuity of power to memory devices on the board. This battery is not user serviceable or

replaceable. When appropriate, an authorized YSI service center will remove this battery and properly

dispose of it, per service and repair policies.

POWER FOR LAB CALIBRATION

A YSI 6038 (110 VAC) or 6651 (64-240 VAC) Power Supply is required for sondes without internal

batteries when using them with a PC for calibration and setup. Sondes with internal batteries do not require

a power supply, but using the sonde with a power supply in the lab is often convenient and extends battery

life. Most adapters include a short pigtail for power that plugs into the power supply. After attaching the

four-pin connector from the power supply to the pigtail, simply plug the power supply into the appropr iate

AC outlet.

See Section 2.2, Connecting Your Sonde, for specific information on cables, adapters and power supplies

required for connecting your sonde to various devices.

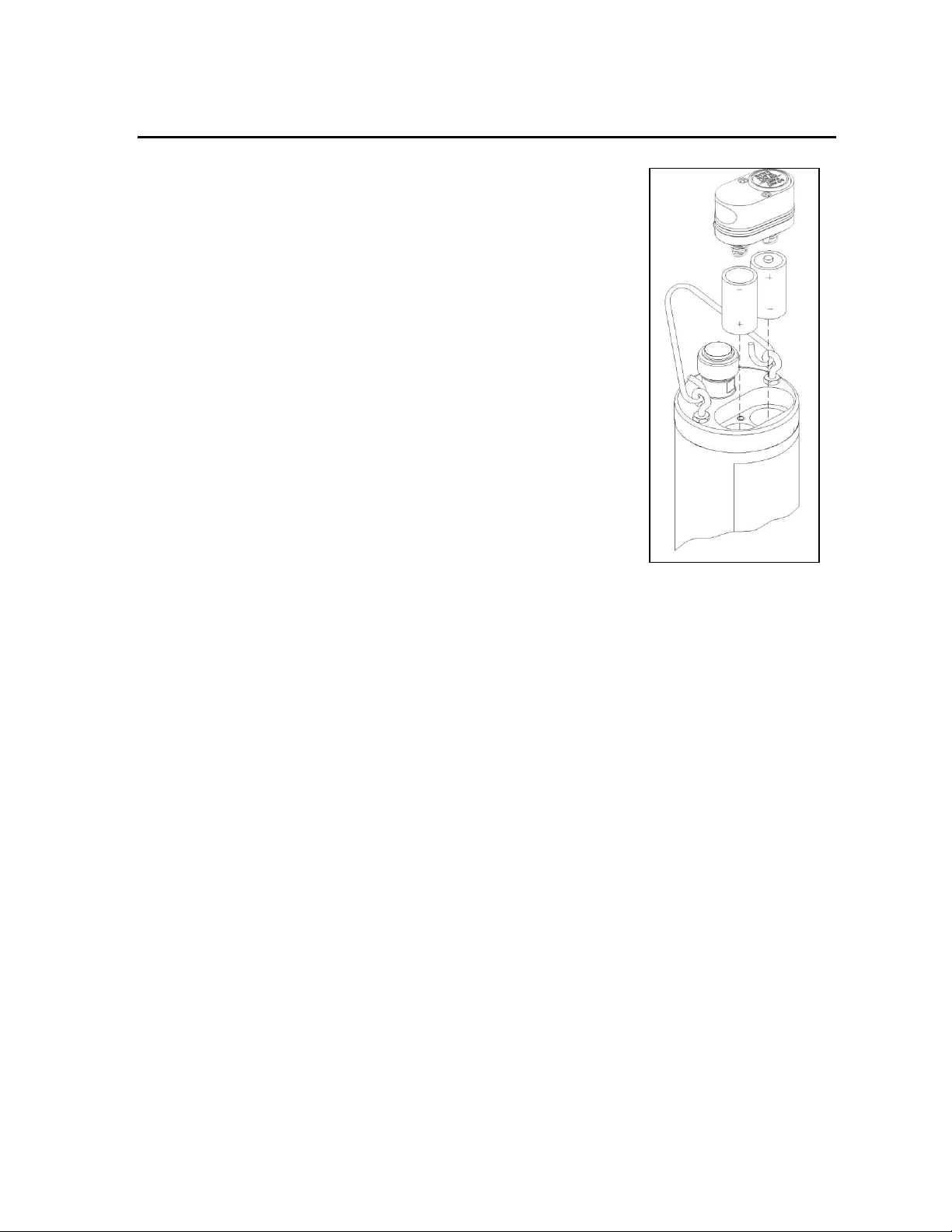

Figure 32

The system configuration best suited for

initial setup is shown in Figure 32.

YSI Incorporated Environmental Monitoring Systems Operations Manual 2-17

Page 24

Sondes Section 2

BAIL

BULKHEAD

CONNECTOR

WITH CAP

AA BATTERIES x 4

(NOTE POLARITY)

SONDE BODY

(NOT SHOWN)

SCREW ON

BATTERY CAP

BATTERY

CAP

BULKHEAD

CONNECTOR

SONDE

BODY

DO NOT USE BAIL FOR LEVERAGE

WHEN REMOVING BATTERY CAP!

BAIL

INSTALLING BATTERIES

The 600XLM, 6600V2-2, 6600EDS V2-2, 6600V2-4, 6920V2-1, 6920V2-2 and battery version of the 600

OMS V2-1are the sondes that use alkaline batteries for power. A set of batteries is supplied with each of

these sondes. If you do not have one of these sonde model types, you may skip this section.

INSTALLING BATTERIES INTO THE YSI 600XLM OR 600 OMS V2-1 SONDES

Figure 33

To install 4 AA-size alkaline batteries into the sonde, refer to

the following directions and Figure 33.

Grasp the cylindrical battery cover and unscrew by hand.

Then slide the battery lid up and over the bulkhead

connector. Insert batteries, paying special attention to

polarity. Labeling on the battery compartment posts

describes the orientation. It is usually easiest to insert the

negative end of battery first and then “pop” the positive

terminal into place.

Figure 34

Check the O-ring and sealing surfaces for any contaminants

that could interfere with the O-ring

seal of the battery chamber.

CAUTION: Make sure that there are NO contaminants

between the O-ring and the sonde. Contaminants that

are present under the O-ring may cause the O-ring to

leak when the sonde is deployed.

Lightly lubricate the o-ring on the outside of the battery

cover. DO NOT lubricate the internal o-ring.

Return the battery lid and tighten by hand.

DO NOT OVER-TIGHTEN.

YSI Incorporated Environmental Monitoring Systems Operations Manual 2-18

Page 25

Sondes Section 2

Align seal to groove

Retaining Tabs

Middle tabs

INSTALLING BATTERIES INTO THE YSI 6600V2-2, 6600EDS V2-2, AND 6600V2-4 SONDES

Figure 35

IMPORTANT SAFETY FEATURE: The 116003 battery lid for the

6600V2-2, 6600EDS V2-2, and 6600V2-4 is equipped with a safety

pressure-release valve. The valve will vent off any pressure build up

in the battery compartment from waste gas that could be created by

battery failure, improperly marked or installed batteries, flooding,

and dead or heavily discharged batteries. Pressure from the waste

gas can deform the battery compartment and cause the sonde to

shatter, projecting fragments from the sonde casing in all directions.

People near a sonde that shatters could suffer serious puncture

wounds and serious eye injuries. DO NOT defeat this safety feature

by blocking the valve or painting over or in close proximity to the

valve. DO NOT attempt to disassemble the safety valve.

Install 8 C-size alkaline batteries according to the following directions and

Figure 35.

Using the 9/64” hex driver supplied with the 6600V2-2, 6600EDS V2-2 and

6600V2-4 loosen the battery lid screws.

NOTE: The battery lid screws are captive. It is not necessary to remove them

from the lid completely.

Remove the battery lid and install the batteries, as shown. If installing or replacing the batteries, test

batteries for proper polarity and voltage and observe the correct polarity before installing the batteries into

the battery chamber.

CAUTION: Be sure the orange O-ring is installed in the groove of the lid. The o-ring is

designed with retention tabs to prevent it from falling out of the grove during installation.

Check the O-ring and sealing surfaces for any contaminates which could interfere with the

O-ring seal of the battery chamber. Remove any contaminates present. Also clean the

protective O-rings which are located the side of the battery lid. Apply a small amount of

grease to the threads of each screw to prevent binding. See the next section and Figures 35A

through 35L for details on proper installation of the battery lid o-ring.

The updated face seal for the 6600 sonde battery lid incorporates six retaining tabs to hold the face seal in

the seal groove during installation, allowing consistent and effective sealing after battery replacement. In

order for this feature to work properly, the retaining tabs must be correctly seated in the battery lid‟s seal

groove to prevent it from becoming dislodged during handling. If the seal is not installed correctly it can

fall out of its groove during battery lid installation and then can be crushed during assembly. This may

cause damage to the seal and cause battery compartment flooding when the sonde is deployed. The

following procedure is a recommended method to properly retain the seal in its groove:

1. Place seal on the battery lid groove so that it

follows the profile of the groove and is centered

about the two middle retaining tabs.

Figures 35A and 35B

YSI Incorporated Environmental Monitoring Systems Operations Manual 2-19

Page 26

Sondes Section 2

Press tabs into groove

Press tabs into groove

Stretch seal and press tab

into groove

Stretch seal and press tab

into groove

Press on tabs to verify they

have been seated

2. Press two of the outermost retaining tabs down

into the groove. It should be clear that the

retaining tabs have recessed into the groove along

with the seal so that the tabs outermost edges are

at or below the battery lid‟s mounting surface.

Figures 35C and 35D

3. Press the remaining two outermost retaining tabs

into the groove and check to make sure the tabs

have been recessed as before. Verify that the

other two previously seated retaining tabs have

not been forced from their position in the groove.

Figures 35E and 35F

4. Place your thumbs on the seal about a ¼” or so

from the sides of the center retaining tab and

press the seal down into the groove while sliding

your thumbs towards each other. This stretches

the seal to fit the profile of the groove allowing

the center tab to be seated properly. You may

need to use the tip of one of your thumbs to finish

pressing the tab into place.

Figures 35G and 35H

5. Press the remaining middle retaining tab into the

groove as before and verify that none of the other

retaining tabs have been forced from their

positions in the groove during this part of the seal

installation.

Figures 35I and 35J

6. To ensure that all the retaining tabs are properly

seated in the seal groove you can apply pressure

to the seal forcing it into the groove at the

location of each tab. This will further seat each

tab into the groove allowing it to capture the seal.

Figures 35K and 35L

CAUTION: Before installing the battery lid, ensure that the pressure release valve is closed.

If the pressure release valve is open, DO NOT install (see Figures 35M and 35N). The valve

YSI Incorporated Environmental Monitoring Systems Operations Manual 2-20

Page 27

Sondes Section 2

BAIL

SONDE BODY

BATTERY CAP

GRASP BAIL WITH HAND.

TURN COUNTERCLOCKWISE TO LOOSEN.

BULKHEAD CONNECTOR

WITH CAP

Figure 35M: Closed valve

OK to Deploy

Figure 35N: Open valve

DO NOT Deploy

cannot be reset and the battery lid must be replaced before sonde deployment. Contact YSI

Technical Support for instructions.

Lightly lubricate the o-rings on the outside of the battery cover. DO NOT lubricate the orange internal oring.

Return the battery lid and HAND tighten the screws with the hex driver until snug. DO NOT OVER

TIGHTEN.

CAUTION: Over-tightening the screws may cause the battery compartment to flood. Do

NOT use power tools to tighten the battery lid screws.

With the battery cover installed and secured, check the battery voltage in the sondes Status Menu. The

voltage must be 12.0 volts or higher with new cells. A voltage less then 12.0 volts could indicate that a cell

was installed upside down or that one of the cells is not at full strength.

CAUTION: Remove Batteries When Not in Use. As with any battery-powered

instrumentation, batteries should be removed before short or long-term storage. Even with

the new battery lid, batteries can leak, releasing toxic and corrosive battery acid and

damaging equipment.

INSTALLING BATTERIES IN THE 6920V2-1 AND 6920V2-2 SONDES

To install the 8 AA-size alkaline batteries into the sonde, refer to the following directions and Figures 36

and 37.

Figure 36

Position the bail so that it is perpendicular to the sonde and use it as

a lever to unscrew the battery cap by hand. Then slide the battery lid

up and over the bulkhead connector.

Insert batteries, paying special attention to polarity. Labeling on the

top of the sonde body describes the orientation.

YSI Incorporated Environmental Monitoring Systems Operations Manual 2-21

Page 28

+--

+

BATTERY CAP

BULKHEAD

CONNECTOR

BAIL

O-RINGS

REMOVE

WATERPROOF CAP

SONDE

CONNECTOR

FIELD CABLE

CONNECTOR

BAIL

STRAIN RELIEF

CONNECTOR

Sondes Section 2

Check the O-rings and sealing surfaces for any contaminants that

could interfere with the seal of the battery chamber.

CAUTION: Make sure that there are NO contaminants between

the O-ring and the sonde. Contaminants that are present under

the O-ring may cause the O-ring to leak when the sonde is

deployed.

Lightly lubricate the o-rings on the bottom of the threads and on the

connector stem as shown in Figure 37.

Return the battery lid and tighten by hand. DO NOT OVER-

TIGHTEN.

Figure 37

2.3.4 STEP 4 - CONNECTING A FIELD CABLE

Figure 38

All YSI 6600V2-2, 6600EDS V2-2, 6600V2-4,

6920V2-1, 6920V2-2, 6820V2-2, 600XLM, 600QS,

and 600 OMS V2-1sondes have a sonde-mounted

cable connector for attachment of the field cable.

Some versions of the 600R, 600XL, and 6820V2-1

sondes also have this connector.

However, some versions of the YSI 600R, 600XL,

and 6820V2-1sondes have permanently attached

“integral” cables. If your sonde has a cable that is

non-detachable, the next section will not be

relevant.

To attach a field cable to the sonde connector,

remove the waterproof cap from the sonde

connector and set it aside for later reassembly

during deployment or storage. Then connect your

field cable to the sonde connector.

A built-in “key” will ensure proper pin alignment. Rotate the cable gently until the “key” engages and then

tighten the connectors together by rotating clockwise. Attach the strain relief connector to the sonde bail.

Rotate the strain relief connector nut to close the connector's opening.

For all of the sondes, the other end of the cable is a military-style 8-pin connector (MS-8). Through use of

a YSI 6095B MS-8 to DB-9 adapter, the sonde may be connected to a computer for setup, calibration, realtime measurement, and uploading files.

This MS-8 connector also plugs directly into the 650 MDS display/logger. This instrument contains a

microcomputer that allows it to be used in a similar manner to that of a terminal interface to a PC.

As an alternative to the field cable, you may use a YSI 6067B calibration cable for laboratory interaction

with the sonde. In this case, simply plug the proper end of the cable into the sonde connector and attach

the DB-9 connector of the cable to the Com port of your computer.

YSI Incorporated Environmental Monitoring Systems Operations Manual 2-22

Page 29

Sondes Section 2

CAUTION: The 6067B cable is for laboratory use only -- it is not waterproof and should not be

submersed!

Sondes that are equipped with level sensors use vented cables. See Appendix G, Using Vented Level, for

detailed information.

YSI Incorporated Environmental Monitoring Systems Operations Manual 2-23

Page 30

Sondes Section 2

2.4 ECOWATCH FOR WINDOWS -GETTING STARTED

This section will describe how to get started with EcoWatch for Windows, but detailed information is

provided in Section 4, EcoWatch for Windows, or a convenient Windows Help section that is part of the

software. It is recommended that you thoroughly read Section 4 or use the Help function for a

comprehensive understanding of EcoWatch for Windows.

2.4.1 INSTALLING ECOWATCH FOR WINDOWS

EcoWatch for Windows software must be used with an IBM-compatible PC with a 386 (or better)

processor. The computer should also have at least 4MB of RAM and Windows Version 3.1 or later.

Place the EcoWatch for Windows compact disk in your CD ROM drive. Select Start, then Run and type

d:\setup.exe at the prompt. Press Enter or click on “OK” and the display will indicate that EcoWatch is

proceeding with the setup routine. Simply follow the instructions on the screen as the installation proceeds.

2.4.2 RUNNING ECOWATCH FOR WINDOWS

To run EcoWatch for Windows, simply select the EcoWatch icon on your desktop or from the Windows

Program Menu. For help with the EcoWatch program, see Section 4, EcoWatch or use the Help section of

the software.

2.4.3 ECOWATCH FOR WINDOWS SETUP

To setup the EcoWatch software for use with a sonde, select the sonde icon on the toolbar, and then

the proper Com port to which your sonde is connected. If the default setting is correct, it does not need to

be changed. Click “OK” to open a terminal window.

From the Comm Menu, select the Settings option to check the baud rate. The baud rate should be 9600. If

it is not, select 9600 from the list and press Enter.

From the Settings Menu, select the Font/Color and Background Color options to choose a color scheme

for the EcoWatch for Windows menus.

YSI Incorporated Environmental Monitoring Systems Operations Manual 2-24

Page 31

Sondes Section 2

2.5 SONDE SOFTWARE SETUP

There are two sets of software at work in any YSI environmental monitoring system. One is resident in

your PC and is called EcoWatch for Windows. The other software is resident in the sonde itself. In this

section, you will first make sure that the language associated with your sonde software is appropriate to

your application and change it if necessary. You will set up the sonde software using EcoWatch for

Windows as the interface device between the sonde and your PC.

SETTING UP THE SONDE SOFTWARE LANGUAGE

The menus in the sonde software can be viewed in English, German, or French. However, the choice of

language CANNOT be made from the sonde software itself. Rather the choice must be selected via a

complete update of the software itself from the YSI Website as described below. Note that the menus in

your sonde will be shown in English when you receive the instrument and, if this is your language of

choice, no further action is required and you should skip to the next section. If you wish to change the

language of your menus to German or French, use the following instructions.

Follow the step-by-step instructions below to change the language for the menus in your 6-series sonde:

Connect your sonde to the serial port of a PC with access to the Internet using the proper cable as

described in the previous section of this manual.

Make sure that the sonde is powered with either internal batteries or a suitable power supply.

Access the YSI Environmental Software Downloads page at www.ysi.com/edownloads or go to main

page at www.ysi.com and click on Support button in green bar.

Log in, or if a first time user, fill out the registration form and wait for a login password via return E-mail.

Click on the Software folder under the Software Downloads section.

Inside the folder, click on the file 6-Series & 556MPS Code Updater, M-DD-YYYY and save the file to a

temporary directory on your computer.

After the download is complete, run the file that you just downloaded and follow the on-screen

instructions to install the YSI Code Updater on your computer. If you encounter difficulties, contact

YSI Technical Support for advice.

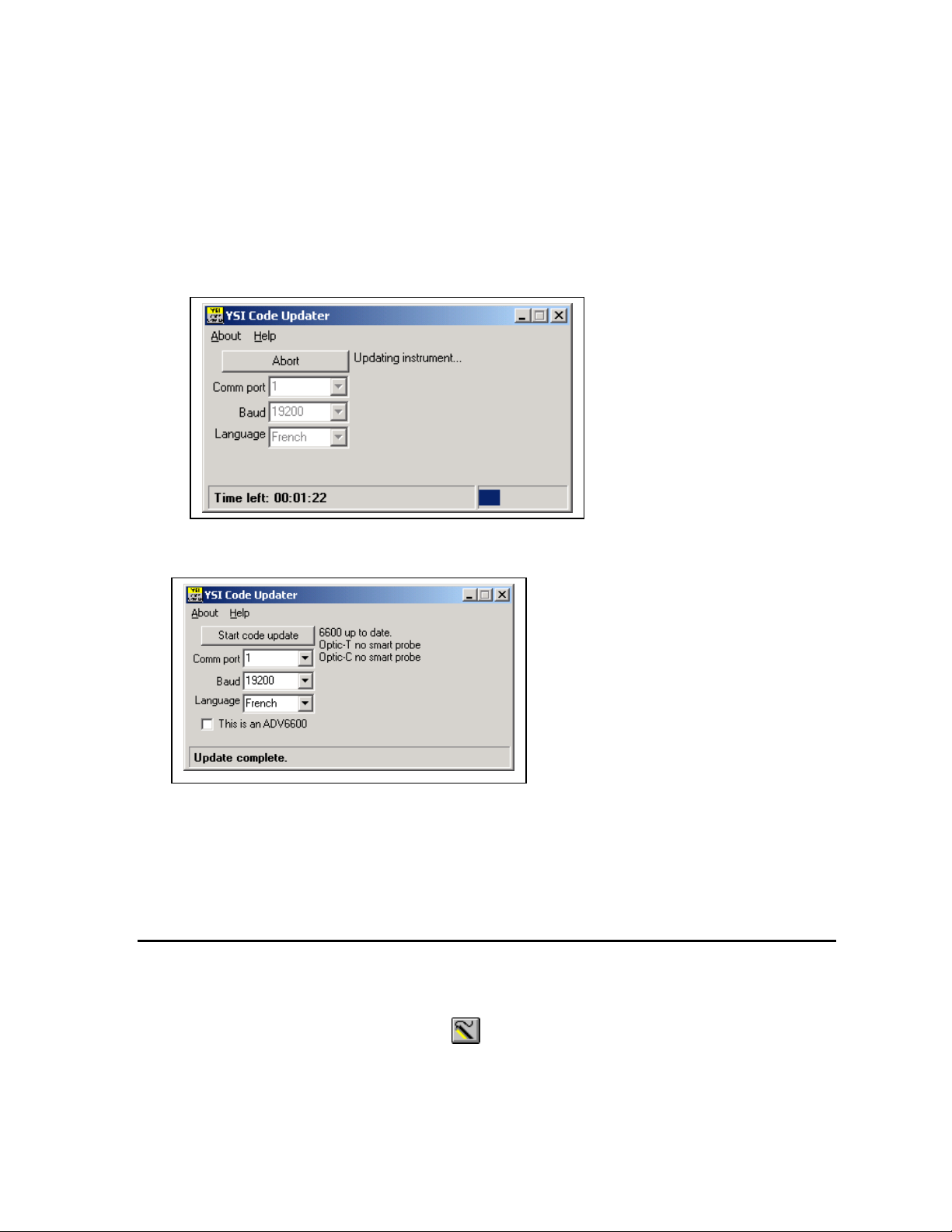

Run the YSI Code Updater software that you just installed on your computer. The following window

will be displayed:

YSI Incorporated Environmental Monitoring Systems Operations Manual 2-25

Page 32

Sondes Section 2

Set the Comm port number to match the port to which you connected the sonde cable and make sure

that the “This is an ADV6600” selection is NOT checked.

NEXT, SELECT THE LANGUAGE (ENGLISH, FRENCH, OR GERMAN) WHICH WILL BE

USED IN YOUR SONDE MENUS.

Then click on the Start Code Update button. An indicator bar will show the progress of the upgrade as

shown below.

When the update is finished (indicated on the PC screen as shown below), close the YSI Code Updater

window (on the PC) by clicking on the "X" in the upper right corner of the window.

Your sonde menus will now appear in the language which you selected prior to running the updater.

If you want to change the language associated with your sonde menu, you MUST rerun the YSI Code

Updater and select the new language via this mechanism.

INTERFACING TO THE SONDE WITH ECOWATCH FOR WINDOWS

When you select Sonde from the EcoWatch for Windows menus, the PC-based software begins direct

communication with the sonde-based software via standard VT100 terminal emulation.

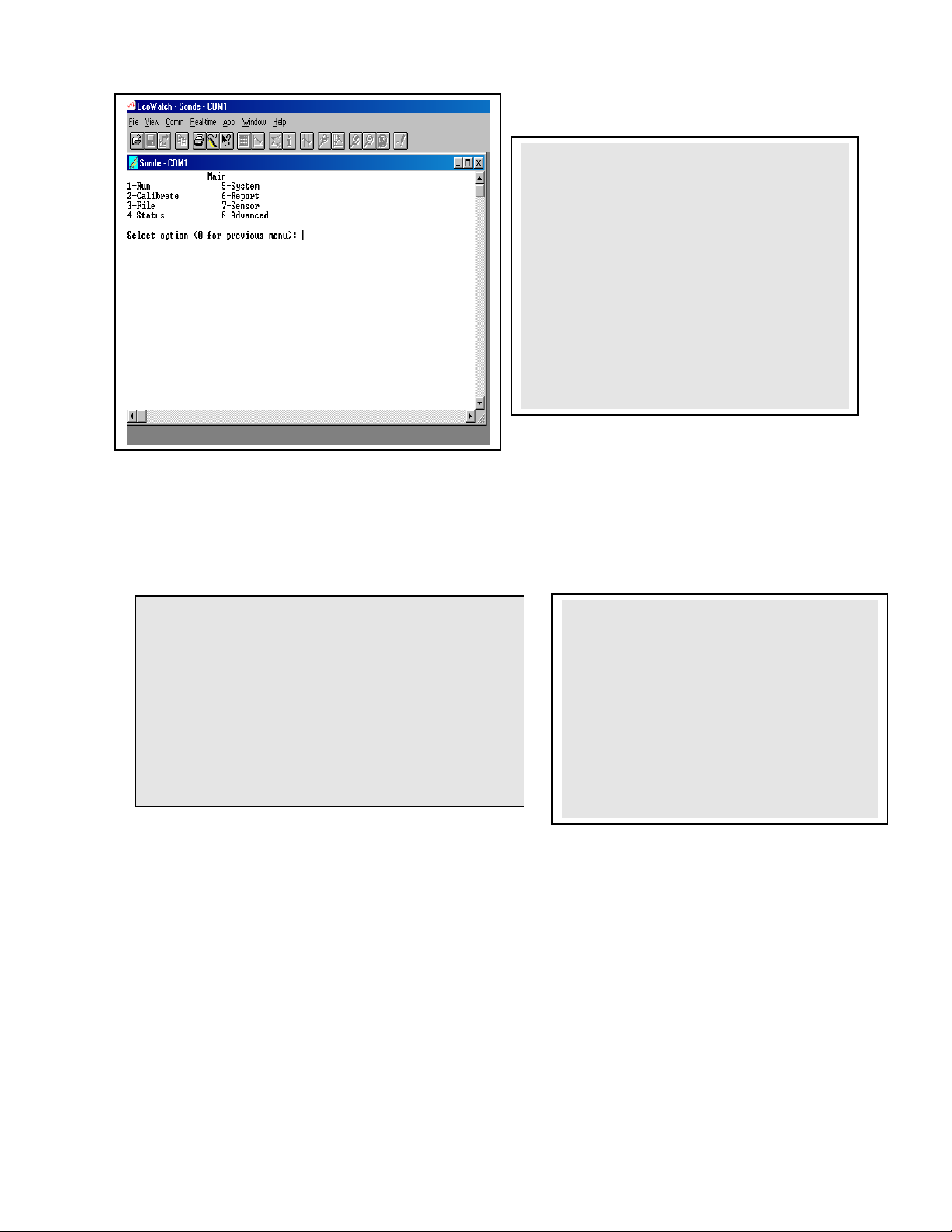

In EcoWatch for Windows, select the sonde icon, . Then select the proper Com port and confirm by

clicking OK. A window similar to that shown below will appear indicating connection to the sonde as

shown in Figure 39. Type “Menu” after the # sign, press Enter, and the sonde Main menu will be

displayed.

YSI Incorporated Environmental Monitoring Systems Operations Manual 2-26

Page 33

Sondes Section 2

------------------Main----------------1-Run 5-System

2-Calibrate 6-Report

3-File 7-Sensor

4-Status 8-Advanced

Select option (0 for previous menu):

Figure 39

If your sonde has previously been used, the Main menu (rather than the # sign) may appear when

communication is established. In this case simply proceed as described below. You will not be required to

type “Menu”.

If you are unable to establish interaction with the sonde, make sure that the cable is properly connected. If

you are using external power, make certain that the YSI 6651 or 6038 power supply or other 12 vdc source

is properly working. Recheck the setup of the Com port and other software parameters. Also refer to

Section 6, Troubleshooting.

The sonde software is menu-driven. You select functions by typing their corresponding numbers. You do

not need to press Enter after choosing a selection. Type the 0 or Esc key to return to the previous menu.

Sonde Main Menu

YSI Incorporated Environmental Monitoring Systems Operations Manual 2-27

Page 34

Sondes Section 2

2. Upload

Sonde

SONDE MENU FLOW CHART

2. Unattended sample

1. Conductivity

2. DO %

1. Run

3. File

2. Calibrate

6. Report

7. Sensor

8. Advanced

1. Discrete sample

3. DO mg/L

2. () Time

3. () Temp, C

4. ( ) Temp, F

1. () Date

2. () Cond

3. () DO

4. ( ) ISE1 pH

1. () Temp

4. Others

2. Comm Setup

3. Page Length

4. Instrument ID

5. System

1. Date & Time

5. SDI-12 Address

3. Quick Upload

4. View File

1. Directory

5. Quick View File

6. Delete All Files

7. Test Memory

1. Cal Constants

2. Setup

3. Sensor

4. Data Filter

4. Status

Available Memory

Logging Status

Battery Voltage

Date and Time

MORE

MORE

Figure 40 - Sonde Menu Flow Chart

SYSTEM SETUP

At the Main menu, select System. The System Setup menu will be displayed.

System Setup Menu

1-Date & time

2-Comm setup

3-Page length=25

4-Instrument ID=YSI Sonde

5-Circuit board SN:00003001

6-GLP filename=00003001

7-SDI-12 address=0

Select option (0 for previous menu):

YSI Incorporated Environmental Monitoring Systems Operations Manual 2-28

Page 35

Sondes Section 2

------------------Main----------------1-Run 5-System

2-Calibrate 6-Report

3-File 7-Sensor

4-Status 8-Advanced

Select option (0 for previous menu):

Select 1-Date & time. An asterisk will appear next to each selection to confirm the entry. Press 4 and 5 to

activate the date and time functions. Pay particular attention to the date format that you have chosen when

entering date. You must use the 24-hour clock format for entering time. Option 4- ( ) 4 digit year may be

used so that the date will appear with either a two or four digit year display. If you do not enter the correct

year format (8/30/98 for 2-digit, 8/30/1998 for 4 digit) your entry will be rejected.

-----------Date & time setup----------1-(*)m/d/y 4-( )4 digit year

2-( )d/m/y 5-Date=08/30/98

3-( )y/m/d 6-Time=11:12:30

Select option (0 for previous menu):

Select 4-Instrument ID from the System setup menu to record the instrument ID number (usually the

instrument serial number), and press Enter. A prompt will appear which will allow you to type in the

serial number of your sonde. This will make sure that any data that is collected is associated with a

particular sonde. Note that the selection 5-Circuit Board SN shows the serial number of the PCB that is

resident in your sonde (not the entire system as for Instrument ID). Unlike the Instrument ID, the user

cannot change the Circuit Board SN. The 6-GLP filename and 7-SDI-12 address selections will be

explained in Section 2.9.5

Press Esc or 0 to return to the System setup menu.

Then press Esc or 0 again to return to the Main menu.

YSI Incorporated Environmental Monitoring Systems Operations Manual 2-29

Page 36

Sondes Section 2

------------Sensors enabled-----------1-(*)Time

2-(*)Temperature

3-(*)Conductivity

4-(*)Dissolved Oxy

5-(*)ISE1 pH

6-(*)ISE2 Orp

7-(*)ISE3 NH4+

8-(*)ISE4 NO39-( )ISE5 NONE

A-(*)Optic T Turbidity - 6136

B-(*)Optic C Chlorophyll

Select option (0 for previous menu):

ENABLING SENSORS

To activate the sensors that are in your sonde, select Sensor from the Sonde Main menu.

Note that the exact appearance of this menu will vary depending upon the sensors that are available on your

sonde. Enter the corresponding number to enable the sensors that are installed on your sonde. An asterisk

indicates that the sensor is enabled.

When selecting any of the ISE or Optical ports, a submenu will appear. When this occurs, make a selection

so that the sensor corresponds to the port in which the sensor is physically installed. Only ORP can be

enabled as ISE2. Optic T, Optic C, Optic B, and Optic O generate a submenu on selection. Each optical

port can have one of six probes (6136 Turbidity, 6025 Chlorophyll, 6130 Rhodamine WT, 6131 BGA-PC,

6132 BGA-PE, or 6150 ROX Optical DO) installed as indicated by the submenus.

NOTE CAREFULLY: It is NOT possible to simultaneously activate BOTH the 6562 Rapid Pulse

polarographic dissolved oxygen sensor and the 6150 ROX Optical dissolved oxygen sensor. Activation of

either sensor will automatically deactivate the other selection. Thus, users of 6600V2-2, 6600EDS V2-2,

6820V2-1, and 6920V2-1 sondes CANNOT measure oxygen with both types of sensors.

After all installed sensors have been enabled, press Esc or 0 to return to the Main Menu.

ENABLING PARAMETERS

In order for a specific parameter to be displayed:

1. The sensor must first be enabled as described above.

2. That parameter must be activated in the Report Setup menu described below.

Select Report from the Main menu. A Report Setup menu similar to the one shown below will be

displayed.

YSI Incorporated Environmental Monitoring Systems Operations Manual 2-30

Page 37

Sondes Section 2

--------------Report setup------------1-(*)Date m/d/y E-(*)Orp mV

2-(*)Time hh:mm:ss F-(*)NH4+ N mg/L

3-(*)Temp C G-( )NH4+ N mV

4-(*)SpCond mS/cm H-( )NH3 N mg/L

5-( )Cond I-(*)NO3- N mg/L

6-( )Resist J-( )NO3- N mV

7-( )TDS K-(*)Cl- mg/L

8-( )Sal ppt L-( )Cl- mV

9-(*)DOsat % M-(*)Turbid+ NTU

A-(*)DO mg/L N-(*)Chl ug/L

B-( )DOchrg O-(*)Chl RFU

C-(*)pH P-(*)Battery volts

D-( )pH mV

Select option (0 for previous menu):

Note that the exact appearance of this menu will vary depending upon the sensors that are available and

enabled on your sonde. The asterisks (*) that follow the numbers or letters indicate that the parameter will

appear on all outputs and reports. To turn a parameter on or off, type the number or letter that corresponds

to the parameter.

Note also that since a 6136 turbidity probe was selected in the Sensor menu above, the units of turbidity are

presented as “turbid+ NTU”. If a 6026 turbidity probe (which was offered by YSI up until 2002) had

been selected, the units of turbidity would be presented as “turbid NTU”. This designation is designed to

differentiate the data from the two sensor types in later analysis.

For parameters with multiple unit options such as temperature, conductivity, specific conductance,

resistivity and TDS, a submenu will appear as shown below for temperature, allowing selection of desired

units for this parameter.

--------------Select units------------1-(*)NONE

2-( )Temp C

3-( )Temp F

4-( )Temp K

Select option (0 for previous menu): 2

After configuring your display with the desired parameters, press Esc or 0 to return to the Main menu.

YSI Incorporated Environmental Monitoring Systems Operations Manual 2-31

Page 38

Sondes Section 2

----------------Advanced-------------1-Cal constants

2-Setup

3-Sensor

4-Data filter

Select option (0 for previous menu):

-------------Advanced setup----------1-(*)VT100 emulation

2-( )Power up to Menu

3-( )Power up to Run

4-( )Comma radix

5-(*)Auto sleep RS232

6-(*)Auto sleep SDI12

7-( )Multi SDI12

8-( )Full SDI12

Select option (0 for previous menu): 0

CHECKING ADVANCED SETTINGS

Select Advanced from the Main menu. The following menu will be displayed.

Select Setup from the Advanced menu.

Make sure that, other than Auto sleep RS232, all entries are activated or deactivated as shown above.

For sondes which will be used in sampling studies where the user is present and observes readings in realtime, Auto sleep RS232 should usually be “off‟. For sondes that will be used in unattended monitoring

studies, Auto sleep RS232 should usually be “on”. This is described in detail in Section 2.9, Sonde Menu.

When this setup is verified, press Esc or 0 to return to the Advanced menu.

Select 3-Sensor from the Advanced menu and make certain that the entries are identical to those shown

below.

YSI Incorporated Environmental Monitoring Systems Operations Manual 2-32

Page 39

Sondes Section 2

------------Advanced sensor----------1-TDS constant=0.65

2-Latitude=40

3-Altitude Ft=0

4-(*)Fixed probe

5-( )Moving probe

6-DO temp co %/C=1.1

7-DO warm up sec=40

8-( )Wait for DO

9-Wipes=1

A-Wipe int=5

B-SDI12-M/wipe=1

C-Turb temp co %/C=0.3

D-(*)Turb spike filter

E-Chl temp co %/C=0

F-( )Chl spike filter

Select option (0 for previous menu):

------------------Main----------------1-Run 5-System

2-Calibrate 6-Report

3-File 7-Sensor

4-Status 8-Advanced

Select option (0 for previous menu):

If you have a depth sensor installed, you can maintain the default settings of 40 and 0 for 2-Latitude and

3-Altitude, respectively, without affecting your ability to learn the basic calibration and operation of the

sonde. However, if you know the appropriate values for your location, change them. When this setup is

verified, press Esc or 0 to return to the Advanced menu. For more information, see Section 2.9.8,

Advanced.

The display under 3-Sensor may be different from the one shown in the example above, depending on the

sensors that are installed in your unit. For example, if you do not have a chlorophyll probe, the last two

entries (which are relevant only to chlorophyll) will not appear.

When this setup is verified, press Esc or 0 to return to the Advanced menu. For a detailed explanation of

the choices in the Advanced menu, see Section 2.9.8, Advanced. Press Esc or 0 to back up to the Main

menu.

The sonde software is now set up and ready to calibrate and run.

YSI Incorporated Environmental Monitoring Systems Operations Manual 2-33

Page 40

Sondes Section 2

2.6 GETTING READY TO CALIBRATE

2.6.1 INTRODUCTION

HEALTH AND SAFETY

Reagents that are used to calibrate and check this instrument may be hazardous to your health. Take a

moment to review health and safety information in Appendix A of this manual. Some calibration standard

solutions may require special handling.

CONTAINERS NEEDED TO CALIBRATE A SONDE

The calibration cup that comes with your sonde serves as a calibration chamber for all calibrations and

minimizes the volume of calibration reagents required.

Although not recommended except in unusual circumstances, instead of the calibration cup, you may use

laboratory glassware to perform some of the calibrations. If you do not use a calibration cup that is

designed for the sonde, you are cautioned to do the following:

Perform all calibrations with the Probe Guard installed. This protects the probes from possible physical

damage.

Use a ring stand and clamp to secure the sonde body to prevent the sonde from falling over. Much

laboratory glassware has convex bottoms.

Insure that all sensors are immersed in calibration solutions. Many of the calibrations factor in

readings from other probes (e.g., temperature probe). The top vent hole of the conductivity sensor must

also be immersed during calibrations.

CALIBRATION TIPS

1. If you use the Calibration Cup for calibration of either the Rapid Pulse

Polarographic or ROX Optical DO sensors in water-saturated air, make

certain to loosen the seal to allow pressure equilibration before calibration.

2. If you choose to calibrate your Rapid Pulse Polarographic or ROX Optical

DO sensor in air-saturated water in a separate vessel, be sure to sparge the

water with an aquarium pump and air-stone for at least 1 hour to assure that

the water is truly saturated with air.

3. The key to successful calibration is to insure that the sensors are completely

submersed when calibration values are entered. Use recommended volumes

when performing calibrations.

4. For maximum accuracy, use a small amount of previously used calibration

solution to pre-rinse the sonde. You may wish to save old calibration

standards for this purpose.

5. Fill a bucket with ambient temperature water to rinse the sonde between

calibration solutions or perform the calibration near a sink where the probes

can be rinsed from the tap.

YSI Incorporated Environmental Monitoring Systems Operations Manual 2-34

Page 41

Sondes Section 2

6. Have several clean, absorbent paper towels or cotton cloths available to dry

the sonde between rinses and calibration solutions. Shake the excess rinse

water off of the sonde, especially when the probe guard is installed. Dry off

the outside of the sonde and probe guard. Making sure that the sonde is dry

reduces carry-over contamination of calibrator solutions and increases the

accuracy of the calibration.

7. Make certain that port plugs are installed in all ports where probes are not

installed. It is extremely important to keep these electrical connectors dry.

USING THE CALIBRATION CUP

Follow these instructions to use the calibration cup for calibration procedures with all of the instruments

except the 600R, 600QS, and 600 OMS V2-1. For these sondes, the over-the-guard bottle that comes with

your sonde, must be used.

Ensure that a gasket is installed in the gasket groove of the calibration cup bottom cap, and that the

bottom cap is securely tightened. Note: Do not over-tighten as this could cause damage to the threaded

portions of the bottom cap and tube.

Remove the probe guard, if it is installed.

Inspect the installed gasket on the sonde for obvious defects and if necessary, replace it with the extra

gasket supplied.

Screw the cup assembly into place on the threaded end of sonde and securely tighten. Note: Do not

over tighten as this could cause damage to the threaded portions of the bottom cap and tube.

Sonde calibration can be accomplished with the sonde upright– i.e. the cable connector end of the

sonde is oriented above the probe end, or inverted where the orientation is reversed. A separate clamp

and stand, such as a ring stand, is required to support the sonde in the inverted position.

When using the Calibration Cup for dissolved oxygen calibration in water-saturated air, make certain

that the vessel is vented to the atmosphere by loosening the bottom cap or cup assembly, depending on

orientation, and that approximately 1/8” of water is present in the cup.

NOTE CAREFULLY: If you are calibrating a 6136 turbidity sensor for use with a 6820V2-1 or 6920V2-1,

you can use either the calibration cup supplied with your sonde or an optional extended length cup for the

calibration. Please see the section below which describes the special calibration recommendations for this

sensor.

YSI Incorporated Environmental Monitoring Systems Operations Manual 2-35

Page 42

Sondes Section 2

Probe to Calibrate

Upright

Inverted

Conductivity

200ml

150ml

pH/ORP

125ml

175ml

ISE

125ml

175ml

All Optical Sensors

50ml

DO NOT CALIBRATE***

Probe to Calibrate

Upright

Inverted

Conductivity

320ml

150ml

pH/ORP

240ml

175ml

ISE

240ml

175ml

All Optical Sensors

225ml

DO NOT CALIBRATE***

Probe to Calibrate

Upright

Inverted

Conductivity

310ml

150ml

pH/ORP

200ml

150ml

ISE

200ml

150ml

All Optical Sensors

225 ml

DO NOT CALIBRATE***

Probe to Calibrate

Upright

Inverted

Conductivity

50ml

50ml

pH/ORP

25ml

50ml

Probe to Calibrate

Upright

Inverted

Conductivity

425ml (650ml)

250ml (250ml)

pH/ORP

300ml (500ml)

250ml (250ml))

ISE

300ml (500ml)

250ml (250ml)

All Optical Sensors

180ml (500ml)

DO NOT CALIBRATE***

Probe to Calibrate

Upright

Inverted

Conductivity

275ml (520ml)

350ml (350ml)

pH/ORP

175ml (400ml)

350ml (350ml)

All Optical Sensors

225ml (420ml)

DO NOT CALIBRATE***

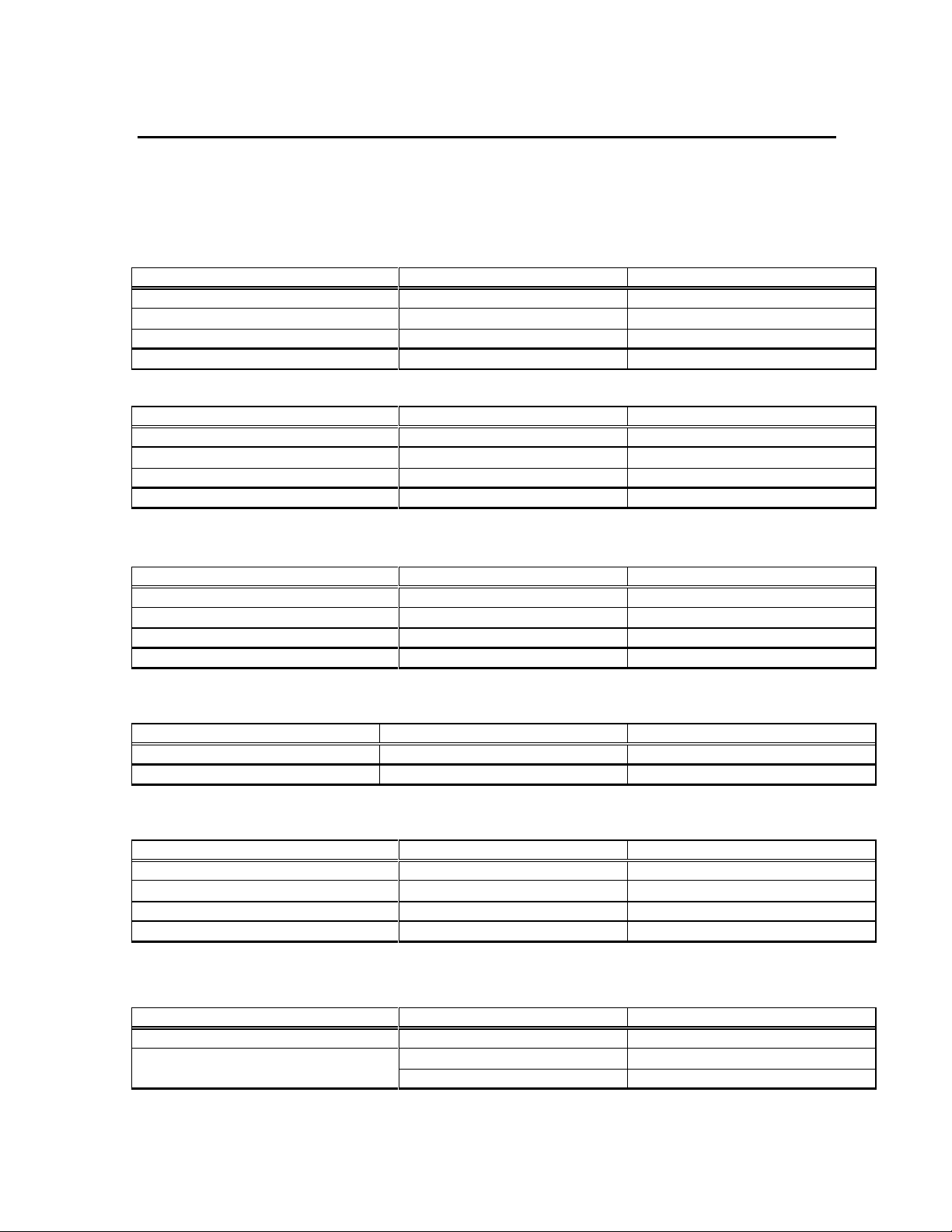

RECOMMENDED VOLUMES OF CALIBRATION REAGENTS

The approximate volumes of the reagents are specified below for both the upright and inverted orientations.

Note that the volume values are only estimates. The actual amount of calibrator solution required will

depend on how many and what type of other probes are installed in you sonde bulkhead.

Table 1A 6820V2-1 and 6920V2-1 Sondes with Standard Calibration Cup*

Table 1B 6820V2-1 and 6920V2-1 Sondes with Optional Extended Calibration Cup*

Table 2 6820V2-2 and 6920V2-2 Sondes with Extended Calibration Cup*

Table 3 600XL and 600XLM Sondes

Table 4 6600V2-2 Sonde with Short Calibration Cup and Long Cup in Parentheses*

Table 5 6600EDSV2-2 Sonde with Short Calibration Cup and Long Cup in Parentheses*

YSI Incorporated Environmental Monitoring Systems Operations Manual 2-36

Page 43

Sondes Section 2

Probe to Calibrate

Upright

Inverted

Conductivity

525ml

150ml

pH/ORP

500ml

150ml

All Optical Sensors

425ml

DO NOT CALIBRATE***

Probe to Calibrate

Upright

Inverted

Conductivity

375ml

N/A

Turbidity, Chlorophyll, Rhodamine WT

350ml

N/A

Probe to Calibrate

Upright

Inverted

Conductivity

350ml

N/A

pH/ORP

120ml

N/A

Table 6 6600V2-4 Sonde with Standard Long Calibration Cup****

Table 7 600 OMS V2-1 Sonde* *

Table 8 600R and 600QS Sondes

* See section below for special instructions dealing with calibration of 6136 turbidity sensor.

** See section below for special instructions dealing with calibration of the conductivity sensor for the 600

OMS V2-1.

*** Optical Sensors CANNOT be calibrated with the sonde in the Upside-Down position because of

interference from the meniscus of the calibration standard.

**** An extended length calibration cup is supplied with the 6600V2-4, 6600V2-2, and 6600EDSV2-2 to

facilitate calibration of the 6136 turbidity sensor. This cup requires the use of larger volumes of other

calibration solutions. Users may choose to purchase the shorter calibration cup sleeve for calibration of

sensors other than the 6136 to reduce the volumes of calibrant. The shorter cal cup sleeve is YSI Item

Number 066267 and can be obtained by contacting YSI Technical Support.

CALIBRATION OF THE 6136 TURBIDITY SENSOR

The 6136 can be calibrated using either the calibration cup supplied with the sonde or with an extended length

calibration cup which can be purchased as an option for the 6820V2-1 and 6920V2-1. An extended cup is

supplied as a standard item with the 6820V2-2, 6920V2-2, 6600V2-4, 6600V2-2, and 6600EDSV2-2 sondes.

If you choose to calibrate with the short calibration cup, you also MUST first make certain that the vessel is

equipped with a BLACK bottom. In addition, you should engage only ONE THREAD when screwing the

calibration cup onto the sonde in order to keep the turbidity probe face as far as possible from the calibration

cup bottom to avoid interference. Even with these techniques, there will still be a small interference from the

bottom of the calibration cup that will cause your field turbidity readings to be approximately 0.5 NTU lower

than the actual reading. This small error is usually only evident when the sonde is deployed in very clear water

where the readings might appear as slightly negative values, e.g., a turbidity of 0.1 NTU would appear as –0.4

NTU.

Use of the extended length cup will require the use of significantly more standard solutions for 6820V2-1/

6920V2-1 sondes (additional 180 mL) if calibration is done in the upright position. To minimize

calibration solution volumes for sensors other than turbidity, users may wish to purchase the shorter

calibration cup sleeve which is supplied as standard with the 6820V2-1 and 6920V2-1. The shorter cal cup

sleeve for any 6600 is Item Number 066267, and the shorter cal cup sleeve for any 6820/6920 is Item

Number 069286. These can be ordered from YSI Technical Support.

YSI Incorporated Environmental Monitoring Systems Operations Manual 2-37

Page 44

Sondes Section 2

---------------Calibrate-------------1-Conductivity 6-ISE3 NH4+

2-Dissolved Oxy 7-ISE4 NO3-

3-Pressure-Abs 8-Optic T-Turbidity-6026