Page 1

Global Water

800-876-1172 • globalw.com

Global Water

Instrumentation, Inc.

11390 Amalgam Way

Gold River, CA 95670

T: 800-876-1172

Int’l: (916) 638-3429, F: (916) 638-3270

PRODUCT NAME: 6308DT MICROCOMPUTER BASED

DO/ Temperature CONTROLLER

- 1 -

Page 2

Global Water

800-876-1172 • globalw.com

Table of Contents

I) Inspection................................................................................................................ 3

II) General Introduction ............................................................................................... 3

III) Mounting Procedure................................................................................................ 3

IV) Using The Global Water Model 6308DT ............................................................... 5

V) Model 6308DT Modes............................................................................................ 9

VI) Controlling The Relays......................................................................................... 15

VII) 4 - 20 mA Output .................................................................................................. 18

VIII) Rs485 Interface Operation .................................................................................... 19

IX) Error Displays And Troubleshooting.................................................................... 19

X) Specifications........................................................................................................ 20

XI) Warranty ............................................................................................................... 21

* Copyright © Global Water Instrumentation, Inc. 2006

- 2 -

Page 3

Global Water

800-876-1172 • globalw.com

I) Inspection

a) Your 6308DT MICROCOMPUTER BASED DO/ TEMPERATURE

CONTROLLER unit was carefully inspected and certified by our Quality

Assurance Team before shipping. If any damage has occurred during shipping,

please notify Global Water Instrumentation, Inc. and file a claim with the carrier

involved.

I) General Introduction

a) The Global Water Model 6308DT (DO and Temperature) System, is a rugged

microprocessor based instrument assembled in a watertight ¼ DIN case, designed

for use in laboratories and process control applications.

The model 6308DT microprocessor allows the user to easily recalibrate the

parameters for the probes. The DO system requires only a single calibration,

regardless of which dissolved oxygen display you use. The microprocessor also

performs a self-diagnostic routine every time you turn on the unit providing you

with basic information about the stability of the instrument.

The system simultaneously displays DO, Temperature, Relay status, and current

output in one LCD graphic screen. The LCD also includes a backlight for badly lit

environments. This system uses a "polygraphic clark" membrane for the DO and a

precise thermistor for temperature, providing you with accurate readings for all

your measurements.

The model 6308DT is equipped with 5 relays (2 active Low and 2 active High

relays for DO and one programmable high or low relay for temperature); all

relays are hysteresis driven and configurable to CENTER or EDGE mode. The

system also has an isolated 4-20mA analog output, offset and span configurable

for the DO display.

The model 6308DT comes with a RS485 interface that can easily let the user log

all data (from multiple models 6308 or 6309) with an IBM© PC/AT compatible

computer.

II) Mounting Procedure

a) Make a cutout on any panel, with a thickness of 1/16 in. (1.5 mm) to 3/8 in.

(9.5mm).

b) Remove the mounting assembly from the controller and insert the controller into

the cutout.

c) Replace the mounting bracket assembly onto the controller and secure the

controller to the mounting panel.

- 3 -

Page 4

Global Water

800-876-1172 • globalw.com

Warning: If the equipment is used in a manner not specified by the

manufacturer, the protection provided by the equipment may be impaired.

d) Cleaning the instrument :

1. Be sure to remove the power before attempting to clean the meter.

2. Use a lint free cloth and clean water or neutral detergent.

3. Wipe the outer surface of the instrument only.

4. Wipe dry the instrument before power again.

- 4 -

Page 5

Global Water

800-876-1172 • globalw.com

III) Using the Global Water Model 6308DT

a) Front Panel

1. The [MODE/-] key.

(a) In Normal mode, this key will change the DO display to DO % or

DO ppm.

(b) In Calibration / Setting mode, this key will move to the next digit of

the current active parameter.

(c) In Calibration/ Setting mode, pressing this key for 2 seconds will

move you back to the previous parameter.

2. The [CAL/VIEW] key.

(a) In Normal mode, the display will go to Calibration / Setting mode if

you press this key for about 2 seconds

(b) During Calibration/Setting mode, this key will switch to the next

available Calibration/Setting page. Pressing this key at the last

Calibration / Setting page will return the user to the Normal mode.

- 5 -

Page 6

3. The [ ] UP key. During Calibration/Setting mode, this key will

increment the current blinking digit of the active parameter.

4. The [ ] DOWN key. During Calibration/Setting mode, this key will

decrement the blinking digit of the active parameter.

5. The [ ] ENTER key. During Calibration/Setting mode, this key will

save the current modified parameter and move to the next parameter on

the page. If the parameter is the last one in the page then it will move to

first parameter on the next available page.

6. The [ ] LIGHT key. This key will turn on or turn off the backlight of

the LCD. The backlight will automatically turn off if there is no key

activity for about two minutes.

7. LCD screen.

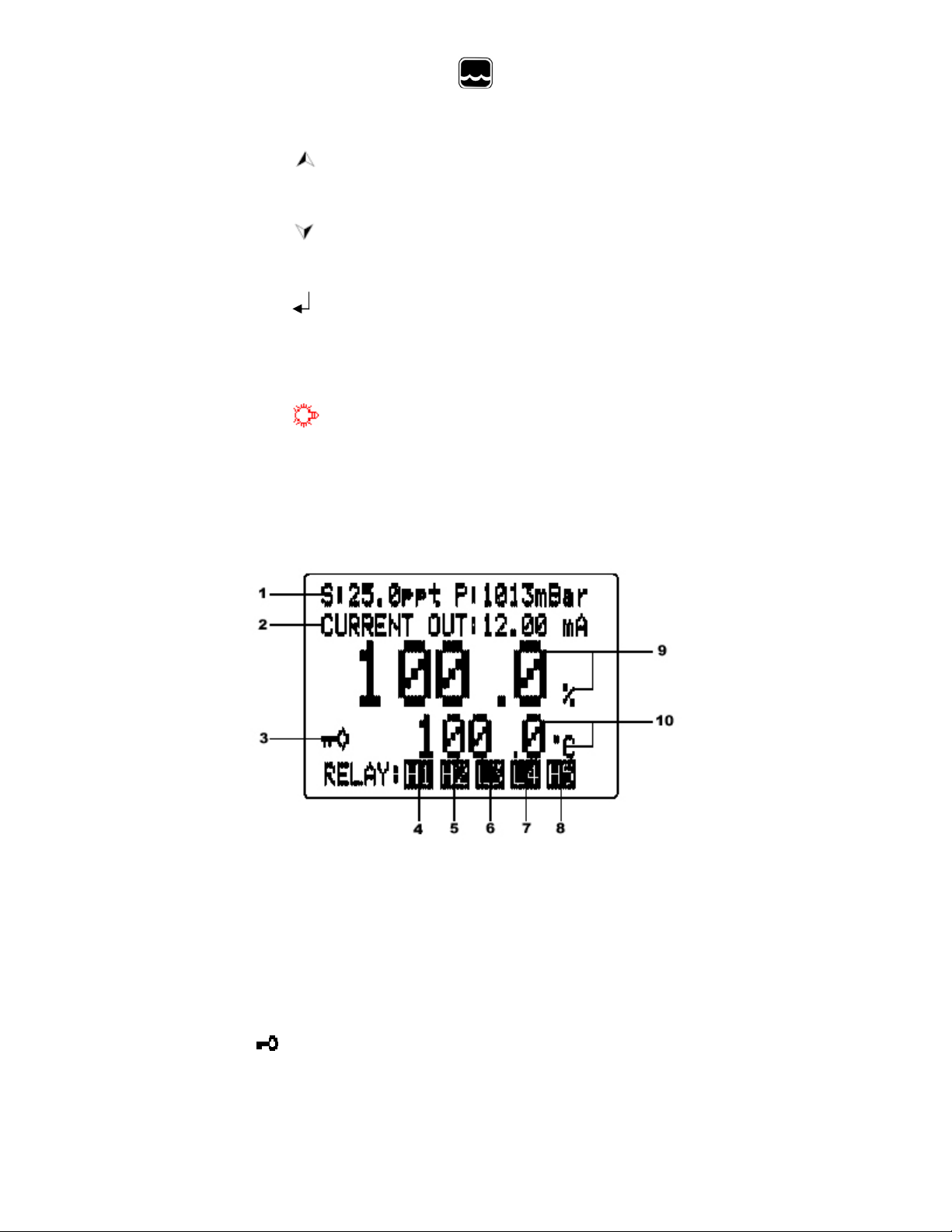

b) NORMAL MODE DISPLAY

Global Water

800-876-1172 • globalw.com

1. S:, P: - Salinity and Pressure settings.

2. CURRENT OUT - this will display the actual reading of the 4-20 mA

output. At POWER-ON, this will show "OFF." for about 3 seconds before

going to main display mode. After exiting the Calibration /Setting pages, a

"FROZEN" message will be displayed for about 3 seconds if the unit is

not password locked.

3. annunciator - This will be displayed if Calibration/Setting pages are

password locked meaning the user cannot change the values unless the

correct 4 digit number has been entered.

- 6 -

Page 7

4. H1 annunciator - this is the status of DO Relay 1. If this is displayed, then

the relay is ON.

5. H2 annunciator - this is the status of DO Relay 2. If this is displayed, then

the relay is ON.

6. L3 annunciator - this is the status of DO Relay 3, if this is displayed the

Relay is ON.

7. L4 annunciator - this is the status of DO Relay 4. If this is displayed, then

the Relay is ON.

8. H5 or L5 annunciator - this is the status of the Temperature Relay 5, if this

is displayed then the Relay is ON. H5 means the relay action is HIGH

while L5 means the relay action LOW.

9. Dissolved oxygen (% or ppm) display.

10. Temperature display.

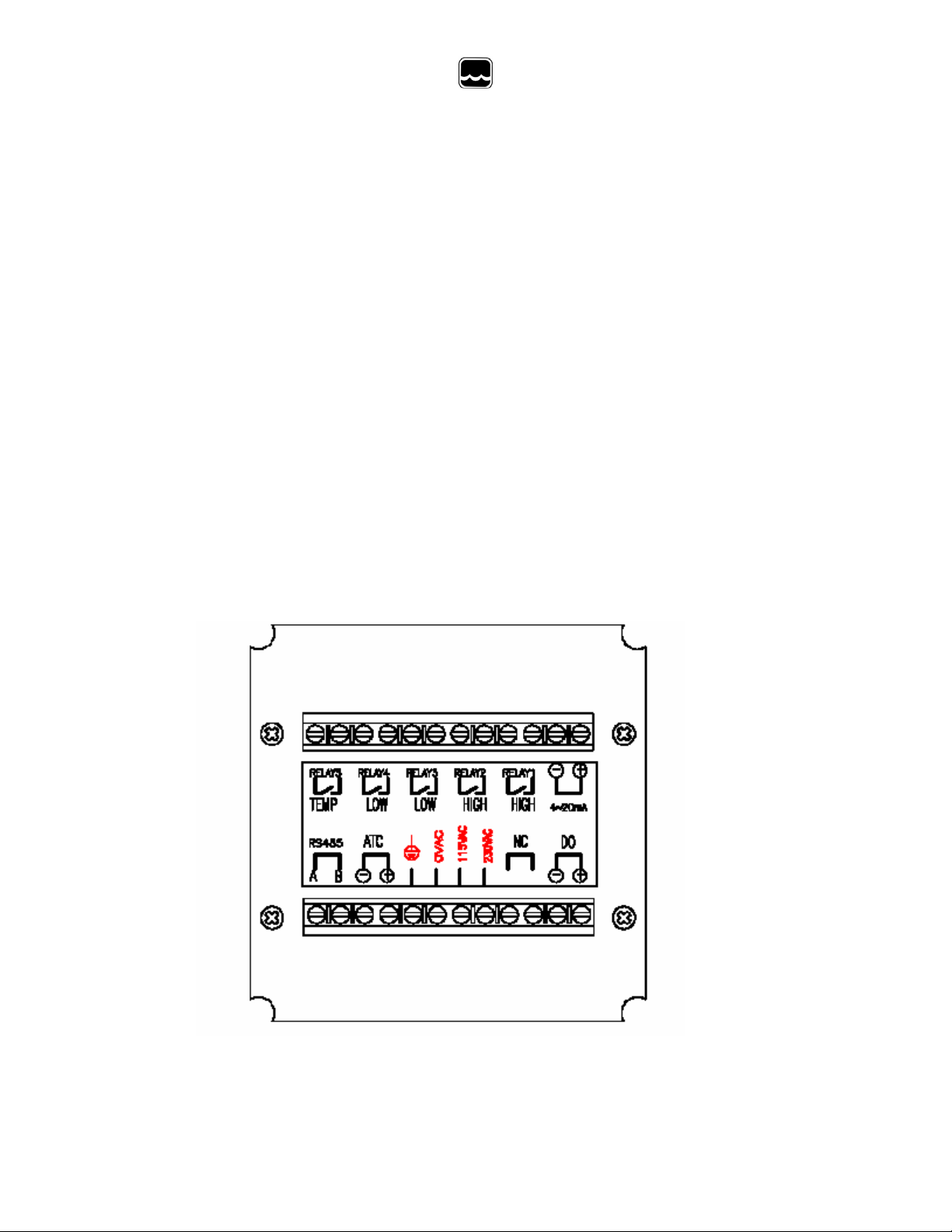

c) REAR CONNECTORS

Global Water

800-876-1172 • globalw.com

Before wiring the probes, relays, analog output, RS485, and power cord be sure

that you are connecting to the right terminal as shown above. Remember that the

unit is ON once the user plugs in the power cord to an AC power supply.

- 7 -

Page 8

1. Connect the AC line to the rear of the instrument. The model 6308PT can

be used with 115VAC or 230VAC 50/60 Hz. Power consumption is

6-watt. Make sure the EARTH connector is connected to the earth

lead of the AC power line.

2. Connect the proper load to the output relays. Make sure that the load

does not exceed the relay rating, 5 Amp at 115VAC and 2.5 Amp at

230 VAC.

3. Set the proper load to the 4-20mA output connector. Make sure that the

load impedance is less than 500 Ohms.

CAUTION: MAKE SURE YOU CONNECT THE AC POWER CORD

TO THE CORRECT AC TERMINALS. CONNECTING

INCORRECTLY MAY DAMAGE THE UNIT PERMANENTLY.

d) Turning ON/OFF the instrument.

By just plugging the unit to a correct AC voltage, the unit will be ready for use.

There is no Power key so unplugging and plugging the unit will turn OFF or turn

ON the unit respectively. After the unit is turned on, it will perform some basic

self- diagnostics and will display "OK" or "BAD." If you received any "BAD"

messages, turn OFF the unit and turn it ON again. (See IX. ERROR DISPLAYS

AND TROUBLESHOOTING). If the message persists then you might need to

call your distributor. (See IX. TROUBLESHOOTING).

After the self-diagnostic is complete the temperature will be displayed on the

lower part of the LCD screen and you are ready to make DO calibration or

measurements. Just immerse the probes halfway to the liquid. If possible, do not

allow the probes to touch any solid object in the solution. There should be no air

bubbles around the probes either. Shaking or moving the probes vigorously before

recording any measurement will dislodge any bubbles formed in the probes.

Global Water

800-876-1172 • globalw.com

- 8 -

Page 9

IV) Model 6308DT Modes

a) Main Display Mode

Turning ON the unit will always start in main display mode. This instrument is

designed to provide 3 distinct measurements:

1. Temperature - current temperature of the solution that is always displayed.

2. Dissolved Oxygen % - a measurement of oxygen in percent saturation.

3. Dissolved Oxygen ppm - a measurement of oxygen in ppm.

Temperature and DO (% or ppm) are always simultaneously displayed in the

graphic LCD screen in normal mode. You can select which DO unit to display by

pressing the [MODE/-] key.

b) Calibration/Setting Mode

Pressing the [CAL/VIEW] key for about 2 seconds during main display mode

will bring-up the first page of 6 pages of the Calibration/Setting mode. Pressing

[CAL/VIEW] key will switch to the next page until the last page, where pressing

[CAL/VIEW] again will return the user to main display mode.

Below is a simple flowchart showing the path of the [CAL/VIEW] key:

Global Water

800-876-1172 • globalw.com

- 9 -

Page 10

Global Water

800-876-1172 • globalw.com

You can change any blinking options or digit by pressing the [ ] or [ ] keys.

For options in digit format you need to press the [ MODE/-] key to move to the

next digit. If you are satisfied with the selection you made you need to press the

[ ] ENTER key to save the changes and move to the next option. If you do not

need to change the current blinking option just press the [ ] ENTER key to

move to the next selection.

c) Check Password page

You will only see this page if the unit is password locked. To change any settings

or calibration you need to unlock the system to remove the "PASSWORD

LOCKED" message. You need to enter the correct 4-digit number on the

"ENTER PASSWORD" input. You can still view all the pages of

Calibration/Setting mode if the system is password locked by just pressing the

[CAL/VIEW] key on this page. If the unit is "PASSWORD LOCKED" going to

Calibration/Setting mode will not affect the function of the relays.

- 10 -

Page 11

CAUTION: IF THE UNIT IS NOT LOCKED THEN EVERY TIME THE

USER ENTERS THE CALIBRATION/SETTING MODE THE RELAYS

AND ANALOG OUT WILL BE FROZEN.

d) User Setting page.

You will only see this page if the unit is not password locked. This page is just a

warning, telling you that all relays are frozen, and that you can calibrate and

change the settings.

NOTE: Frozen means all the relays and the analog out will maintain their

last state until the user returns to main display mode.

e) DO Calibration

1. ATC TEMP. - The current temperature of the solution.

2. PRESSURE - user changeable pressure value for DO computations.

3. SALINITY - user changeable salinity value for DO computations.

4. DO ALARM UNIT - this is the unit that the DO RELAY1 to DO

RELAY4 will be based upon. The RELAY1 to RELAY4 values for % and

ppm unit are saved in different memory (eeprom) location.

5. CAL VALUE - this is the DO calibration option. If you move the cursor

Global Water

800-876-1172 • globalw.com

to this line a flashing [ ] icon will appear. Pressing the [ ] ENTER

key will start the DO calibration. The unit of this calibration will depend

on the unit of DO at normal mode. To calibrate the model 6308DT

- 11 -

Page 12

accurately, you will need the following information:

(a) The approximate pressure (in mbar) of the region in which you plan

to take your dissolved oxygen measurements.

(b) The approximate salinity of the water you will be analyzing. Fresh

water has a salinity of approximately zero. Sea water has a salinity

of approximately 35 parts per thousand (ppt).

f) Calibration Procedures

1. Place 5-6 drops of distilled water into the sponge inside the calibration

bottle. Turn the bottle over and allow any excess water to drain out of the

bottle. The wet sponge creates a 100% water saturated-air environment for

the probe, which is ideal for calibration, transport, and storage of the

Model 6308DT probe.

2. Screw in the bottle into probe allowing at least 5 mm space between the

probe and the sponge.

3. Wait around 30 minutes for the dissolved oxygen and temperature

Global Water

800-876-1172 • globalw.com

readings to stabilize. Pressing the [ ] ENTER key will start the

calibration.

4. If you are calibrating in % then the 100% calibration will be displayed. An

error will be displayed if the input is not within the normal DO range. A

[ ] icon will flash, pressing the [ ] ENTER key will start the

calibration. If the input is not within the DO calibration limit then an error

message will be displayed. If all is well then it will save the new

calibration and move to the next page.

5. If you are calibrating in ppm then the current reading in ppm will be

displayed. If you press the [ ] ENTER key, the unit will capture the

current value and then you can change the value by using the [MODE/-],

[ ] UP and [ ] DOWN keys. If you are satisfied with the ppm

value, you need to press the [ ] ENTER key to save the new calibration.

If the DO input is within calibration range then the new calibration will be

saved and move to the next page, otherwise an error message will be

displayed.

6. DO Control Setting

(a) HI RELAY 1 - The action for this relay is fixed to HIGH. In HI-

action, the relay will turn ON if the DO is greater or equal to

RELAY 1 value, which is modified by the hysteresis value and

- 12 -

Page 13

Global Water

800-876-1172 • globalw.com

hysteresis mode. (See chapter VI. CONTROLLING THE

RELAYS.) Use [

] and [ ] keys to change the blinking digit,

use the [MODE/-] key to select another digit and the [ ] key to

save the new value.

(b) HI RELAY 2 - The action for this relay is fixed to HIGH. In HI-

action, the relay will turn ON if the DO is greater or equal to

RELAY2 value, which is modified by the hysteresis value and

hysteresis mode. (See chapter VI. CONTROLLING THE

RELAYS.) Use [

] and [ ] keys to change the blinking digit,

use the [MODE/-] key to select another digit and the [ ] key to

save the new value.

(c) LO RELAY 3 - The action for this relay is fixed to LOW. In LO-

action the relay will turn ON if the DO is less than or equal to

RELAY3 value, which is modified by the hysteresis value and

hysteresis mode. (See chapter VI. CONTROLLING THE

RELAYS.) Use [ ] and [ ] to change the blinking digit, use the

[MODE/--] key to select another digit and the [ ] key to save the

new value.

(d) LO RELAY 4 - The action for this relay is fixed to LOW. In LO-

action the relay will turn ON if the DO is less than or equal to

RELAY4 value, which is modified by the hysteresis value and

hysteresis mode. (See chapter VI. CONTROLLING THE

RELAYS.) Use [ ] and [ ] keys to change the blinking digit,

use the [MODE/--] key to select another digit and the [ ] key to

save the new value.

(e) HYSTERESIS (mode) - this is the hysteresis mode for DO RELAY 1

to RELAY 4. You can choose "CENTER" or "EDGE" (See chapter

VI. CONTROLLING THE RELAYS.)

(f) HYSTERESIS (value) - this is the actual value of the hysteresis. You

can change this value from 1.0 to 99.9 % or 1.00 to 9.99 ppm.

(See chapter VI. CONTROLLING THE RELAYS .)

7. Current Setting page

(a) 1. 4mA OUT - this value will be used in conjunction with 20 mA to

plot the current output. (See chapter VII. 4-20 mA OUTPUT.)

- 13 -

Page 14

Global Water

800-876-1172 • globalw.com

(b) 2. 20mA OUT - this value will be used in conjunction with the 4 mA

value to plot the output. (See chapter VII. 4-20 mA OUTPUT.)

8. TEMP. CONTROL SETTING

(a) RELAY 5 - the temperature has only one relay to control you need to

set what action it will use, HIGH or LOW action. . (In HIGH-action

the relay will turn ON if the temperature is greater or equal to

RELAY5 value, in LOW-action the relay will turn OFF if the

temperature is less than or equal to RELAY5 value, which is

modified by the hysteresis value and hysteresis mode.) ((See

chapter VI. CONTROLLING THE RELAYS.)

(b) SET POINT- this is the user changeable value for the Temperature

Alarm relay.

- 14 -

Page 15

Global Water

800-876-1172 • globalw.com

(c) HYSTERESIS (mode) - this is the hysteresis mode for

TEMPERATURE alarm. You can choose "CENTER" or "EDGE."

(See chapter VI. CONTROLLING THE RELAYS.)

(d) HYSTERESIS (value) - this is the actual value of the hysteresis. You

can change this value from 0.0 to 19. 9°C. (See chapter VI.

CONTROLLING THE RELAYS.)

(e) RS 485 ID - this is the unique ID/Address for the unit. If you are

connecting multiple model 6308DT or other Global Water models

for logging purposes then this ID/Address must be unique for

each connected unit. This ID/Address is the same address that must

be used by the PC program to communicate with this unit.

(f) LOCK NO - this is your security code if the unit is locked the

value here will not be available. You need to input the correct code

in the PASSWORD CHECK page.

CAUTION: THE USER IS RESPONSIBLE IN

REMEMBERING THEIR PASSWORD NUMBER,

OTHERWISE YOU WOULD NO BE ABLE TO CALIBRATE

OR CHANGE THE SETTINGS.

V) Controlling the Relays

a) Isolation Voltage

The maximum isolation voltage of the relay output contacts is 1500 VDC. The

voltage differential between the relay output contacts and the load should not

exceed 1500 VDC.

b) Output Load

The current through the relay output contacts should not exceed 5 Amp at 115

VAC and 2.5 Amp at 230 VAC in order not to cause permanent damage to the

relay contacts. This rating is specified for resistive loads only.

c) Relay action, relay set point, hysteresis mode & hysteresis value

Relay

Action

HIGH CENTER S.P.+ ½(H.V.) S.P. -½ (H.V.)

HIGH EDGE S.P. S.P. - (H.V)

LOW CENTER S.P.-½ (H.V.) S.P.+½ (H.V.)

LOW EDGE S.P S.P.+(H.V.)

S.P. = Relay Set point

H.V. = Hysteresis value (Dead Band)

Hysteresis mode Effective RELAY-

ON Set point

Effective RELAY-

OFF Set point

- 15 -

Page 16

Global Water

800-876-1172 • globalw.com

If the relay action is set to HIGH and the hysteresis mode is CENTER,

the relay will turn ON at [(RELAY SETPOINT) + (0.5 * hysteresis value)],

and will turn OFF at [(RELAY SET POINT) - (0.5 * hysteresis value)].

If the relay action is set to HIGH and the hysteresis mode is EDGE, the relay will

turn ON at (RELAY SET POINT), and will turn OFF at [(RELAY SET POINT) (hysteresis value)].

If the relay action is set to LOW and the hysteresis mode is CENTER, the

relay will turn OFF at [(RELAY SET POINT ) + (0.5 * hysteresis value)], and

will turn ON at [(RELAY SET POINT) - (0.5 * hysteresis value)].

If the relay action is set to LOW and the hysteresis mode is EDGE, the relay will

turn ON at (RELAY SET POINT), and will turn OFF at [RELAY SET POINT+

(hysteresis value)].

- 16 -

Page 17

d) DO Relays

Global Water

800-876-1172 • globalw.com

There are four independent Alarm channels for DO display. The hysteresis mode

(center or edge) and hysteresis value will be used by four DO relays. The actions of

the DO relays are dependent on set point, relay action type (HIGH or LOW),

hysteresis mode (Center or Edge), hysteresis value, and the current DO display. (See

figure above.)

e) Temperature Relay

1. One relay channel is available for temperature display which has

independent set point , action (see figure 1) setting ( HIGH or LOW ),

hysteresis mode (center or edge) and hysteresis value. The action of the

Temperature relay is dependent on set point, relay action type (HIGH or

LOW), hysteresis mode (Center or Edge), hysteresis value, and the

current Temperature display. (See figure above).

- 17 -

Page 18

VI) 4 - 20 mA Output

a) Isolation Voltage

The maximum isolation voltage of the 4-20 mA output is 500 VDC. The voltage

differential between the 4-20 mA output and the load should not exceed 500

VDC.

b) Output Load

The maximum load is 500Ω. Output current inaccuracies may occur for load

impedance in excess 500Ω.

c) DO Linear Output

Global Water

800-876-1172 • globalw.com

1. The analog output will produce a linear analog output if the user selects

this option. The analog output will be dependent on the DO_4 mA setting,

DO_20 mA setting, and the current DO display. The DO LINEAR

analog output is based on the following equation:

mA(DO) = 4mA+(16mA)*(D(DO) - DO(4)) /(DO(20) - DO(4))

Where :

mA(DO) = analog output

D(DO) = current DO display

DO(4) = DO user setting for 4 mA

DO(20) = DO user setting for 20 mA.

Note :

• The range for 4mA and 20mA settings is 0.0 to 500.0% or 0.00 to

60.00 mg/L.

• The absolute difference of the 4mA and 20 mA settings must be

greater or equal to 1.0% or 0.10 mg/L or else the analog output will

be disabled.

- 18 -

Page 19

Global Water

800-876-1172 • globalw.com

VII) Rs485 Interface Operation

a) Introduction

1. This section assumes you are familiar with the basics of data

communication, the RS485 interface, a rudimentary knowledge, and a

copy of the more popular Windows® $ 9X computer languages capable of

using a PC RS485 card or RS232-RS485 converter (third party vendor)

module. A simple program must be written in order to send your

command and receive data from the meter.

A sample source program in Visual Basic® $ 6.0 is included in the

accompanying disk.

b) Preparing The Meter

1. This meter comes equipped with a 2-wire RS485 interface. Just connect

each terminal to the respective RS485 terminal on your PC. (If the DEMO

program is not working, try reversing the connections of the terminals.)

After you have connected correctly the meter (or multiple meters with

unique ID number) and turned on both the meter(s) and the computer,

you are now ready to program a simple routine to read data from the

instrument.

Read the file "6308DT.TXT" in the accompanying disk to jump-start you

in using the meter with your RS485 enabled PC.

VIII) Error Displays And Troubleshooting

LCD

display

"UNDR" a. >50.0 °C

"OVER"

EEPROM:

BAD

ROM :

BAD

ATC display DISPLAY unit Possible cause(s) [Action(s)]

a.% or ppm -DO

b. "OVER"

b. % or ppm -DO

cal

"UNDR" % or ppm-DO Temperature < -10.0°C.

During power-on Unit has failed its EEPROM test.

During power-on Unit has failed its ROM test.

a. Temperature > 50.0°C.

[Bring solution to a lower

temperature.]

[Bring buffer/solution to a

higher temperature.]

[Turn instrument OFF and back

to ON again.]

[Return for service. (See IX.

TROUBLESHOOTING)]

[Turn instrument OFF and back

to ON again.]

- 19 -

Page 20

Global Water

800-876-1172 • globalw.com

[Return for service. (See IX.

TROUBLESHOOTING)

RAM :

BAD

Other issues

a) Call us for tech support: 800-876-1172 or 916-638-3429 (many problems can be

solved over the phone). Fax: 916-638-3270 or Email: globalw@globalw.com.

Be prepared to describe the problem you are experiencing including specific

details of the application and installation and any additional pertinent information.

b) In the event that the equipment needs to be returned to the factory for any reason,

please call to obtain an RMA# (Return Material authorization). Do not return

items without an RMA# displayed on the outside of the package.

Clean and decontaminate the 630DT if necessary.

Include a written statement describing the problems.

Send the package with shipping prepaid to our factory address. Insure your

shipment, as the warranty does not cover damage incurred during transit.

c) When calling for tech support, please have the following information ready;

1. Model #.

2. Unit serial number.

3. P.O.# the equipment was purchased on.

4. Our sales number or the invoice number.

5. Repair instructions and/or specific problems relating to the product.

IX) Specifications

a) DO

Display Range Accuracy Resolution

Dissolved O2 %

0 to 500.0% ±0.2 % of span

air-sat

Dissolved O2 %

(ppm)

Depends on

DO%

During power-on Unit has failed its RAM test.

[Turn instrument OFF and back

to ON again.]

[Return for service. (See IX.

TROUBLESHOOTING)]

0.1%

(meter only)

±0.2 % of span

0.01ppm

(meter only)

- 20 -

Page 21

Global Water

800-876-1172 • globalw.com

b) Temperature

Range Resolution Accuracy

-10.0 to 120.0 °C 0.1 °C ±0.1 °C

c) DO

Salinity compensation 0.0 to 40.0 ppt (manual)

Pressure compensation 640 to 1100 mBar (manual)

Temperature compensation -10.0 to 50.0 °C (automatic)

d) Temperature

Temperature sensor Thermistor, 2252. at 25°C

X) Warranty

a) Global Water Instrumentation, Inc. warrants that its products are free from defects

in material and workmanship under normal use and service for a period of one

year from date of shipment from factory. Global Water’s obligations under this

warranty are limited to, at Global Water’s option: (I) replacing or (II) repairing;

any products determined to be defective. In no case shall Global Water’s liability

exceed the products original purchase price. This warranty does not apply to any

equipment that has been repaired or altered, except by Global Water

Instrumentation, Inc., or which has been subject to misuse, negligence, or

accident. It is expressly agreed that this warranty will be in lieu of all warranties

of fitness and in lieu of the warranty of merchantability.

b) The warranty begins on the date of your invoice.

- 21 -

Loading...

Loading...