Page 1

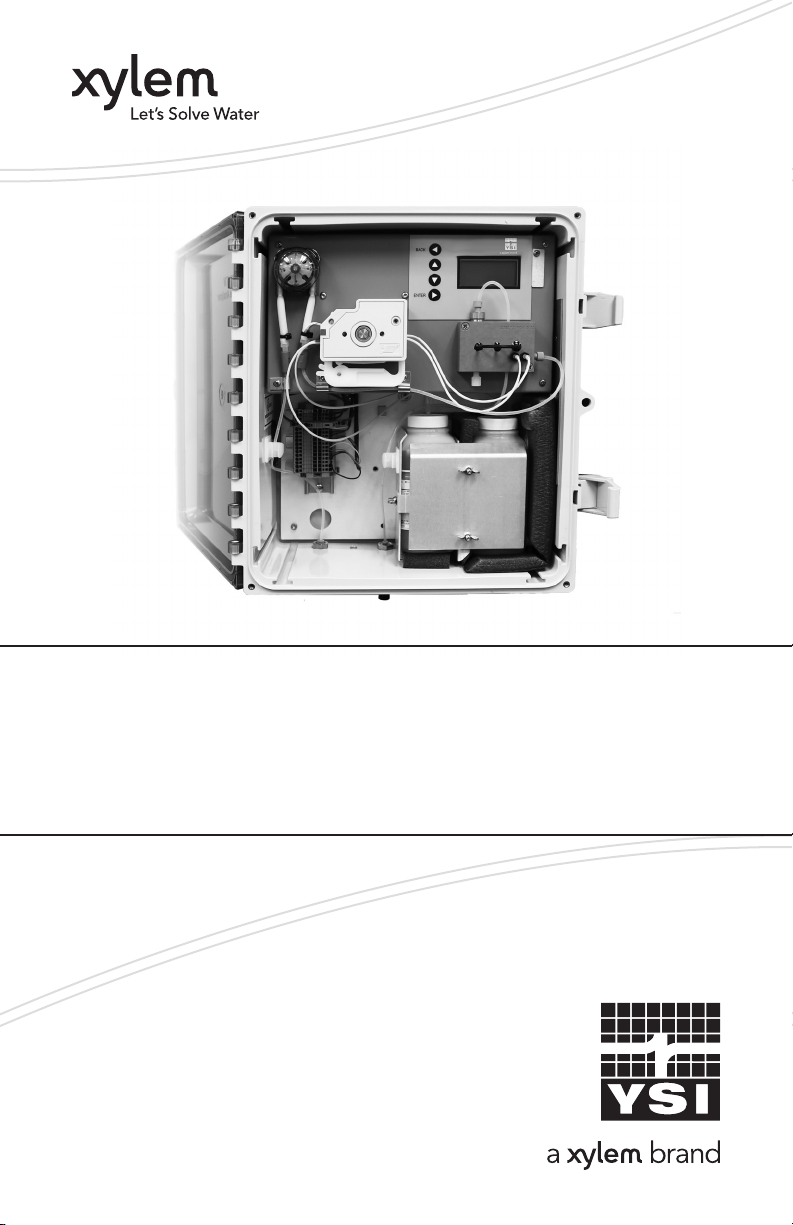

3017M Quick Start Guide

DPD CHLORINE ANALYZER

Quick Start Guide

330028

Page 2

Table of Contents

1 What’s Included?

2 Inspection

3 Materials Required

4 Mounting Instructions

6 Reagent Preparation

7 Sample Inlet Device - Overview, Warnings & Mounting Location

9 Sample Inlet Device - Step-by-Step Installation Procedure

11 Sample Pump Tube Installation

12 Reagent Tube Installation

13 Startup & Operation

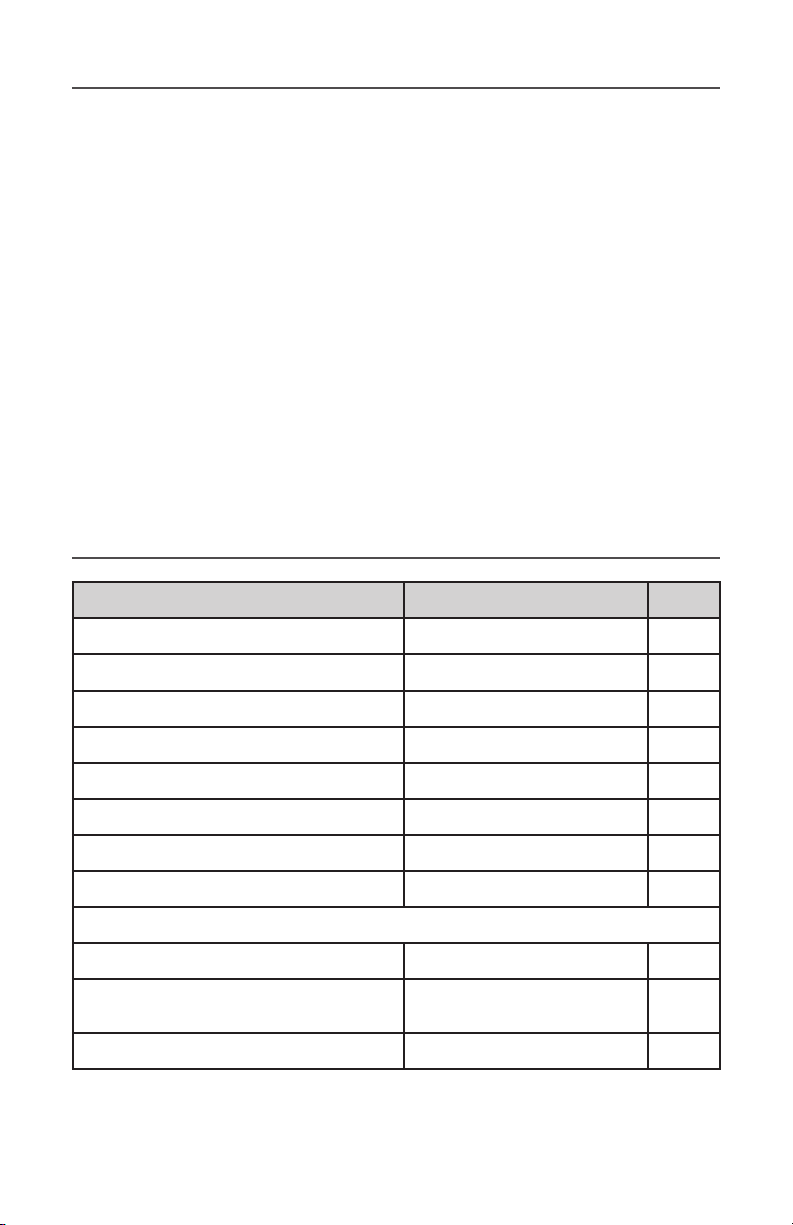

What’s Included?

Item Part # Qty.

3017M Chlorine Analyzer 332266 1

Sample Pump Tube* 332405 1

Reagent Pump Tubes* 332268 2

Silicone Lubricant 331121

Reagent Bottle Cap Assembly* 332270 2

1/2” ID Drain Tube, 6 ft. 327112 1

1/8” OD Sample Inlet Tube, 3 ft. 147901 1

3017M Operators Manual 332100 1

Accessories that may be included:

Sample Inlet Device 327114 1

Kit - Total Chlorine Reagent or

Kit - Free Chlorine Reagent

Reagent Mixing Instructions 330030 1

330006

330007

*Installed on the 3017M

1

1

Page 3

Inspection

Remove the analyzer and Sample Inlet Device from the shipment boxes.

Inspect the shipment for any damage or missing parts. Contact YSI

Customer Support immediately to report any damage or discrepancies

with the shipment. Any questions should be directed to YSI Customer

Support at (800) 765-4974 or (937) 767-7241.

2

5”

1/2” ID Urethane tubing

As close as possible 1m

(3.28 ft) max.

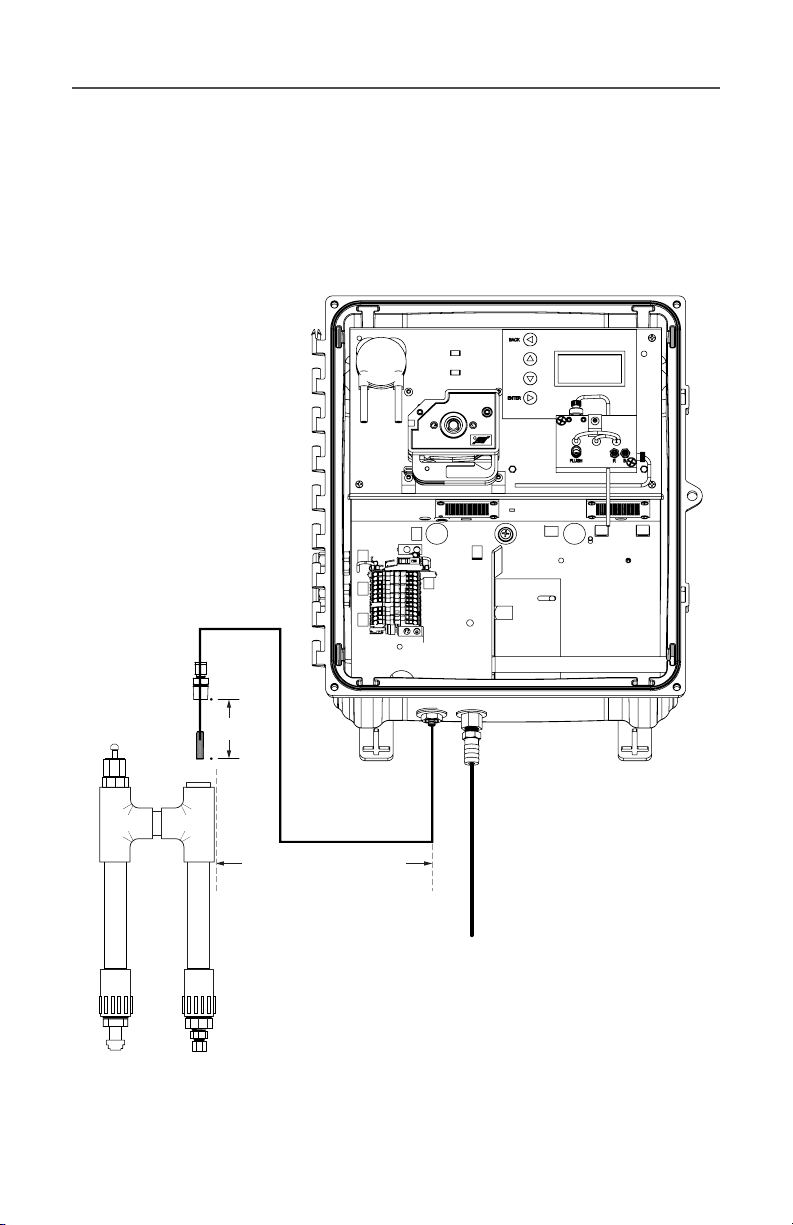

Figure 1: YSI 3017M DPD Chlorine Analyzer and Sample Inlet

Device shown in the recommended installation configuration.

open to atmospheric drain

(item #327112)

Page 4

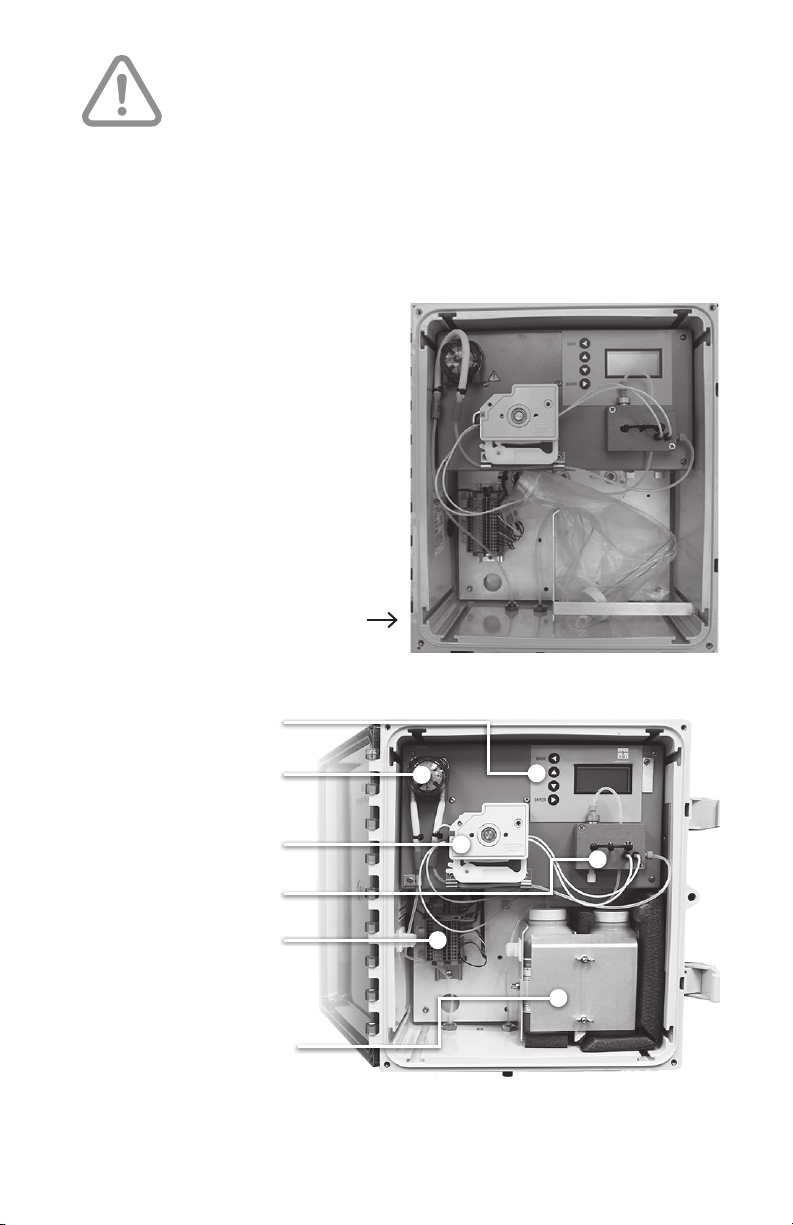

NOTE: Do not apply power to the unit until all of the

following steps have been completed.

The 3017M was shipped from the factory as shown in Figure 2. It will

be necessary to attach the mounting tabs, mount the analyzer, mix the

reagents, position the sample pump tube, tension the reagent pump

tubes and connect the analyzer to the sample.

Materials Required

• #1 Phillips screwdriver

• 1/16” (or smaller)

flat-head screwdriver

• 3/8” drive ratchet

• 7/16” socket

• 7/16” wrench

• Scissors

• Rag or paper towels

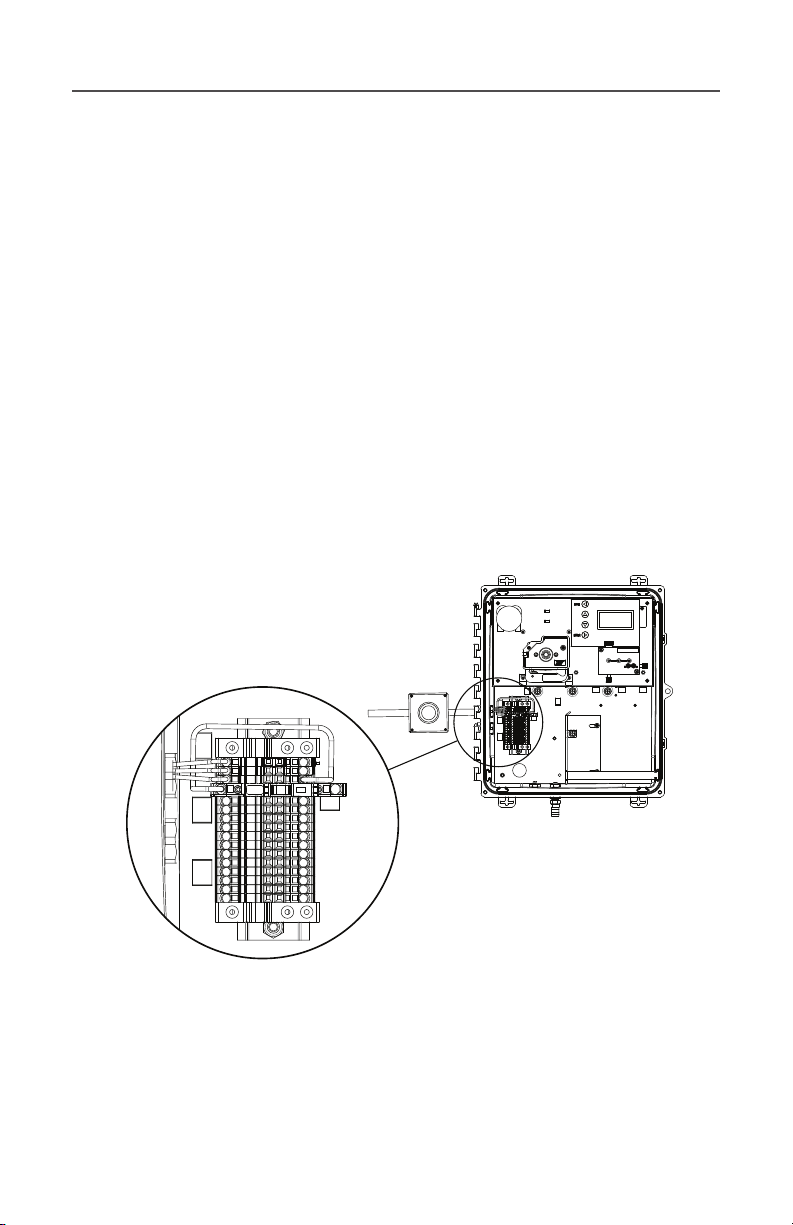

Figure 2: The 3017M Chlorine Analyzer

as it is shipped from the factory

Display & Control

Sample Pump

Reagent Pump

Measuring Cell

I/O Terminal Block

1. Power

2. Communication

3

Reagents

Figure 3: 3017M Chlorine

Analyzer components

Page 5

Mounting Instructions

1. Attach the enclosure’s 4 mounting tabs to the back of the 3017M

using the flat head screws in the hardware kit.

2. Mount the 3017M in the desired location with user supplied

mounting hardware.

3. Install the Sample Inlet Device in its designated location (if

applicable). Below and to the left of the analyzer is an ideal position.

See Figure 1.

4. Power and RS 485/4 to 20 mA connections are made through the

cable glands that are supplied with the analyzer. The cable glands can

be found on the left-hand side of the analyzer.

5. Wire the main power and any other signal or alarm connections.

6. The terminal block connectors are opened by pushing the 1/16”

screwdriver into the small, square opening adjacent to the opening

for the wire. See Figure 4.

External

Power Switch

(recommended)

4

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Figure 4: 3017M terminal block and external power switch

(Wiring reference table on next page)

Page 6

Mounting Instructions, cont’d

Position Connection/Purpose Wire Color

1 AC Earth Green/Green Yellow

2 AC Neutral (Line 2) White/Blue

3 AC Line (Line 1) Black/Brown

4 Fusible Link (0.5A) Brown

5 RS 485-A White

6 RS 485-B Grey

7 RS 485 RTN Purple

8 4-20 mA (-) Blue

9 4-20 mA (+) Green

10 ALARM1 (NC) Yellow

11 ALARM1 (COM) Orange

12 ALARM1 (NO) Red

13 ALARM2 (NC) Brown

14 ALARM2 (COM) Black

15 ALARM2 (NO) Pink

16 SPARE ---

6. Attach the 1/2” ID drain tube to the barbed fitting on the bottom of

the analyzer. Refer to Figure 5.

7. Attach the 1/8” OD tubing to the sample inlet fitting (quick connect)

on the bottom of the analyzer and connect the other end to the

Sample Inlet Device or any other sample spot.

5

Page 7

Mounting Instructions, cont’d

1.736”

(44.08 cm)

2.988”

(75.88 cm)

3.475”

(88.26 cm)

Figure 5: 3017M plumbing connections, bottom view

Reagent Preparation

1. Refer to YSI document 330030 for preparation of the reagents.

2. Install a reagent bottle cap assembly (item #332270) to the reagent

containers.

3. Place the indicator reagent on the right-hand side of the enclosure

(closest to the wall of the enclosure).

4. Place the buffer next to it (left-hand side). Refer to Figure 7.

NOTE: Only high purity, chlorine-free water should be used for the

reagents. Deionized (DI) water, at a minimum, is acceptable.

6

Page 8

Sample Inlet Device - Overview

The Sample Inlet Device (part #327114, see Figure 6) is a simple, easy-

to-use device that serves as the interface between the sample tap and

the 3017M Chlorine Analyzer. The Sample Inlet Device consists of

inlet and outlet ports, a 60-micron filter for filtration of fine particles, if

necessary, and a 20-psig pressure relief valve.

NOTE: The Sample Inlet Device is an optional accessory, and although

it can add great benefits to the 3017M platform, it is not a required

accessory. The following information pertains to the installation of the

Sample Inlet Device, if this doesn’t apply to your installation of the

3017M please skip to page 11.

Sample Inlet Device - Warnings

The selection of a representative sample is important for optimal

performance of the analyzer and analytical results. The sample must be

representative of the condition of the entire process. Erratic reading

will be realized if the sample is drawn from a location that is too close

to the point of chemical injection, if mixing is incomplete, or if the

chemical reaction is incomplete.

Install sample line taps into the side or center of larger process pipes

to minimize the chance of ingestion of sediment or air bubbles. A

tap projecting into the center of a pipe is an ideal location. Opaque

tubing is recommended if the tubing is exposed to sunlight in order to

prevent algae growth.

Sample Inlet Device - Mounting Location

The ideal location for the Sample Inlet Device is below the 3017M

Chlorine Analyzer and as close as practical to the 1/8-inch quickconnect fitting at the bottom of the analyzer. The installation location

of the Sample Inlet Device should not exceed 3.25 ft. (1 m) from

the analyzer. See Figure 1.

7

Page 9

1/4” NPT to 1/8” TUBE

BRASS FITTING

POLY FILTER 60U

SAMPLE INLET

DEVICE ASSEMBLY

INSERT POLY FILTER ON END

OF 1/8” TUBE TO MIDDLE OF

CLEAR INLET TUBE

1/8” X 1X16” ID

TEFLON TUBING

8

1/2” ID URETHANE

TUBING TO DRAIN

1/2” TO 1/4” PVC

REDUCING BUSHING

1/4” TO 1/4” TUBE

BRASS FITTING

1/4” POLY TUBING FROM

FLOW PRESSURE REGULATED

SAMPLE STREAM TAP

Figure 6: YSI 3017M Sample Inlet Device

Page 10

Sample Inlet Device - Step-by-Step Installation Procedure

Mounting - Secure the Sample Inlet Device to the wall,

1

2

panel, or other structure. A Sample Inlet Device mounting

clip is supplied with the Sample Inlet Device kit. Other

mounting options can be applied to the Sample Inlet Device

but are not supplied by the manufacturer.

Plumbing - Push the 1/4-inch OD tubing into the inlet fitting.

A stop will be felt when the tubing is properly seated in the

fitting. Repeat this process for the outlet fitting. Route the

outlet tubing to an atmospheric drain or sump.

Note: In normal flow applications, the inlet to the Sample

Inlet Device can be on either side. In low flow and/or high

particulate applications make sure the inlet is on the same

side as the sample pick-up line.

1. Gently unscrew the 1/8-inch NPT tube fitting at the top

of the Sample Inlet Device. This fitting has a Teflon® twopiece ferrule. Be sure not to lose the front and back ferrule

when taking apart this fitting. Insert the sample pick-up line

into the fitting.

9

2. Attach the 60 micron filter to the end of the sample

pick-up line, if necessary. It is recommended that the 60

micron filter is used in any application that contains or has

the potential to contain any particulate matter within the

sample.

3. Thread the NPT tube fitting into the Sample Inlet

Device. Position the sample pick-up line/filter approximately

mid-way in the Sample Inlet Device. To secure the sample

pick up line in place gently hand tighten (do not overtighten)

the 1/8-inch nut on the NPT tube fitting.

Page 11

Front ferrule

Back ferrule

NPT tube

fitting

3

1/8” nut

Sample inlet assembly

60 micron filter

Testing - Apply sample to the system and check for leaks.

Ensure that the sample from the outlet of the Sample Inlet

Device is flowing freely to the drain.

4

10

Installation of the Sample Inlet Device is complete.

Page 12

Sample Pump Tube Installation

1. Refer to Figure 7.

2. Remove the cover from the sample pump by gently pulling on the

bottom of the pump cover.

3. Position the tube so that the barbed fittings on each end are even.

They will be adjusted in a later step.

4. Locate the package of silicone grease and cut a small opening across

one corner of the package.

5. Apply a thin layer of the silicone grease to the section of the tube that

will mount on the roller in the pump. A small bead of approximately

3 mm in diameter should be sufficient. Spread the grease along the

section of the tube that will contact the pump tube rollers. Do not

apply the grease in excess. There is sufficient grease in the startup kit

for multiple pump tube installations. Remove any excess with a rag or

paper towel.

6. Hold the pump tube over the roller, and gently push the roller onto

the drive shaft of the pump motor.

7. Refer to Figure 8.

8. Snap the cover into place so that the roller stays in place.

9. Gently position the sample pump to remove slack on each tube.

11

Figure 7: Sample pump

shown with cover off

Figure 8: Completed pump tube installation

Page 13

Reagent Tube Installation

1. Refer to Figure 9.

2. Tension the reagent pump tubes by depressing the tensioning levers

downward three “clicks”.

3. This completes the installation of the reagent pump tubes.

NOTE: Do not overtighten the reagent pump tubes. This will lead to

permanent failure.

12

Figure 9: Tension lever - complete reagent

pump tube installation

Page 14

Startup and Operation

1. Ensure that the main power and the desired aqueous sample are

available to the instrument.

2. Close the fusible link on the terminal block.

3. The analyzer will power on and initiate a self-test. Once the self-test

is completed, the analyzer will come to SHUTDOWN mode. Power is

not removed from the analyzer.

BACK

Chlorine 3017M

Chlorine 0.00 mg/L

STATUS: SHUTDOWN

MENU

ENTER

4. Using the UP or DOWN button, navigate to the PRIME function and

press ENTER.

5. The sample pump and reagent pump will turn at a higher than normal

speed to fill the sample and reagent lines with liquid.

6. Observe the outlet (waste) line of the measuring cell.

7. If chlorine is present in the water, the water at the outlet of the

measuring cell should turn magenta when the sample and reagents

begin to mix in

the flowcell.

8. When no bubbles are present at the outlet of the measuring cell , the

lines are fully primed with liquid.

9. Using the UP or DOWN button, select STANDBY and ENTER.

10. When you are ready for routine sample analysis, select STARTUP

and ENTER.

13

Page 15

Startup and Operation, cont’d

11. The STARTUP sequence consists of the following steps and will take

several minutes:

1. PRIME: The sample and reagent pumps will turn at a high

speed to prime the lines with liquid.

2. RINSE: The reagent pump will stop, and the sample pump will

continue to turn and rinse the flowcell with sample.

3. AUTOGAIN SET: The zero point, sample without reagent, is

determined.

4. RUN: The sample pump will return to the speed for normal

operation.

5. INJECT REAGENT: The reagent pump will start and run for the

predetermined amount of time.

6. INTEGRATE: The analyzer measures the absorption of light

that corresponds to the concentration of the sample flowing

through the flowcell.

7. CALCULATE VALUE: The concentration of the sample is

calculated against the calibration curve stored on

the analyzer.

8. DISPLAY VALUE: The concentration of the sample is displayed

on the screen.

12. The analyzer should cycle for 15 – 20 minutes (6 – 8 cycles) before

making comparisons with reference methods and adjusting the

analyzer output.

14

Page 16

1) The tissue in plants that brings water upward from the roots;

2) a leading global water technology company.

We’re a global team unified in a common purpose: creating advanced

technology solutions to the world’s water challenges. Developing new

technologies that will improve the way water is used, conserved, and

re-used in the future is central to our work. Our products and services

move, treat, analyze, monitor and return water to the environment, in

public utility, industrial, residential and commercial building services

settings. Xylem also provides a leading portfolio of smart metering,

network technologies and advanced analytics solutions for water,

electric and gas utilities. In more than 150 countries, we have strong,

long-standing relationships with customers who know us for our

powerful combination of leading product brands and applications

expertise with a strong focus on developing comprehensive,

sustainable solutions.

For more information on how Xylem can help you,

go to www.xylem.com

QUICK START GUIDE 330028

YSI, a Xylem brand

1725 Brannum Lane

Yellow Springs, OH 45387

+1.937.767.7241

info@ysi.com

YSI.com

© 2021 Xylem, Inc. 330028 04/21

YSI.com/3017M

Loading...

Loading...