Page 1

INSTRUCTION MANUAL

U

®

C

MODELS COVERED:

1151AB2 (115V, 4.2A), 1AB2 (230V, 4.2A),

2AB2 (230V, 6.9A)

L

IM156

US

Aquavar ABII Controller

VARIABLE SPEED PUMP CONTROL

INSTALLATION, OPERATION AND TROUBLESHOOTING MANUAL

Page 2

Owner’s Information

Owner’s Information

Table of Contents

Table of Contents

Controller Model Number:

Controller Serial Number:

Pump Model Number:

Pump Serial Number:

Motor Model Number:

Motor SFA:

Tank Serial Number:

Installer:

Installer Telephone Number:

Installation Date:

Wire Lengths (Feet)

Service Entrance to Controller:

Controller to Motor:

Incoming Voltage:

SUBJECT PAGE

1. Safety Instructions ................................................... 3

2. System Components ................................................ 3

3. System Design ......................................................... 4

4. Piping ...................................................................... 5

5. Mounting the Controller ......................................... 5

6. Power Supply and Wiring ........................................ 6

7. Starting the System ............................................... 6-7

8. Diagrams .............................................................. 8-9

9. Troubleshooting ............................................... 10-11

10. Controller Dimensions .......................................... 11

11. Limited Warranty .................................................. 12

NOTICE: RECORD THE MODEL NUMBERS

AND SERIAL NUMBERS FROM THE

PUMP AND CONTROLLER IN THIS

INSTRUCTION MANUAL FOR FUTURE

REFERENCE. GIVE IT TO THE OWNER

OR AFFIX IT TO THE CONTROLLER

WHEN FINISHED WITH THE

INSTALLATION.

NOTE:

• Use Copper wire only.

• Suitable for use on a circuit capable of delivering not more than 5000 RMS

symmetrical amperes. Branch circuit protection provided by fuses.

• Suitable for use in a pollution degree 2 micro-environment.

• Motor overload protection provided at 110% of full load current.

• In order to maintain the environmental rating integrity of the enclosure, all

openings must be closed by equipment rated 3, 3R, 3S, 4, 4X, 6 or 6P.

• Maximum ambient temperature is 50º C.

2

Page 3

Hazardous

voltage

DANGER

Hazardous

Pressure

CAUTION

DANGER

WARNING

CAUTION

CAUTION

1: SAFETY INSTRUCTIONS

WARNING

Hazardous

voltage

Hazardous

Pressure

CAUTION

1: SAFETY INSTRUCTIONS

TO AVOID SERIOUS OR FATAL PERSONAL INJURY

OR MAJOR PROPERTY DAMAGE, READ AND

FOLLOW ALL SAFETY INSTRUCTIONS IN MANUAL

AND ON EQUIPMENT.

THIS MANUAL IS INTENDED TO ASSIST IN THE

INSTALLATION AND OPERATION OF THIS UNIT

AND MUST BE KEPT WITH THE UNIT.

electrical or mechanical part of the system. Failure to

disconnect electrical power before attempting any operation or maintenance can result in electrical shock,

burns or death.

6. When in operation, the motor and pump

could start unexpectedly and cause serious injury.

This is a SAFETY ALERT SYMBOL.

When you see this symbol on the

pump, the controller or in the manual,

look for one of the following signal

words and be alert to the potential for

personal injury or property damage.

Indicates an imminently hazardous

situation which, if not avoided, will

result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, could result

in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, may result

in minor or moderate injury.

Used without a safety alert symbol

indicates a potentially hazardous situation which, if not avoided, could result

in property damage.

NOTE: INDICATES SPECIAL

INSTRUCTIONS WHICH ARE

VERY IMPORTANT AND MUST BE

FOLLOWED.

THOROUGHLY REVIEW ALL INSTRUCTIONS

AND WARNINGS PRIOR TO PERFORMING ANY

WORK ON THIS CONTROLLER.

MAINTAIN ALL SAFETY DECALS.

ALL OPERATING INSTRUCTIONS MUST BE

READ, UNDERSTOOD, AND FOLLOWED BY

THE OPERATING PERSONNEL. GOULDS WATER

TECHNOLOGY ACCEPTS NO LIABILITY FOR

DAMAGES OR OPERATING DISORDERS WHICH

ARE THE RESULT OF NON-COMPLIANCE WITH

THE OPERATING INSTRUCTIONS.

2: SYSTEM COMPONENTS

2: SYSTEM COMPONENTS

Please review the Aquavar ABII components and insure

that you have all the parts and are familiar with their

names. Be sure to inspect all components Goulds Water

Technology supplies for shipping damage.

Aquavar ABII:

1. Pump with Motor

2. Aquavar ABII Controller with Integral Pressure

Sensor Cable

3. Pressure Tank (supplied on some models)

4. Pressure Sensor

5. Mounting Kit

6. Tank Tee with Pipe Plug

7. Pressure Gauge

WARNING

DO NOT power the unit or run the

pump until all electrical and plumbing connections, especially the pressure

sensor connection, are completed. The

pump should not be run dry. All electrical

work must be performed by a qualied

technician. Always follow the National

Electrical Code (NEC), or the Canadian Electrical

Code (CEC) as well as all local, state and provincial

codes. Code questions should be directed to your local

electrical inspector. Failure to follow electrical codes

and OSHA safety standards may result in personal injury or equipment damage. Failure to follow manufacturer's installation instructions may result in electrical

shock, re hazard, personal injury, death, damage to

equipment, unsatisfactory performance and may void

manufacturer's warranty.

1. This manual is intended to assist in the installation,

operation and repair of the system and must be kept

with the system.

2. Installation and maintenance MUST be performed by

properly trained and qualied personnel.

3. Review all instructions and warnings prior to performing any work on the system.

4. Any safety decals MUST be left on the controller and

pump.

5. The system MUST be disconnected from

the main power supply before attempting any operation or maintenance on the

3

Page 4

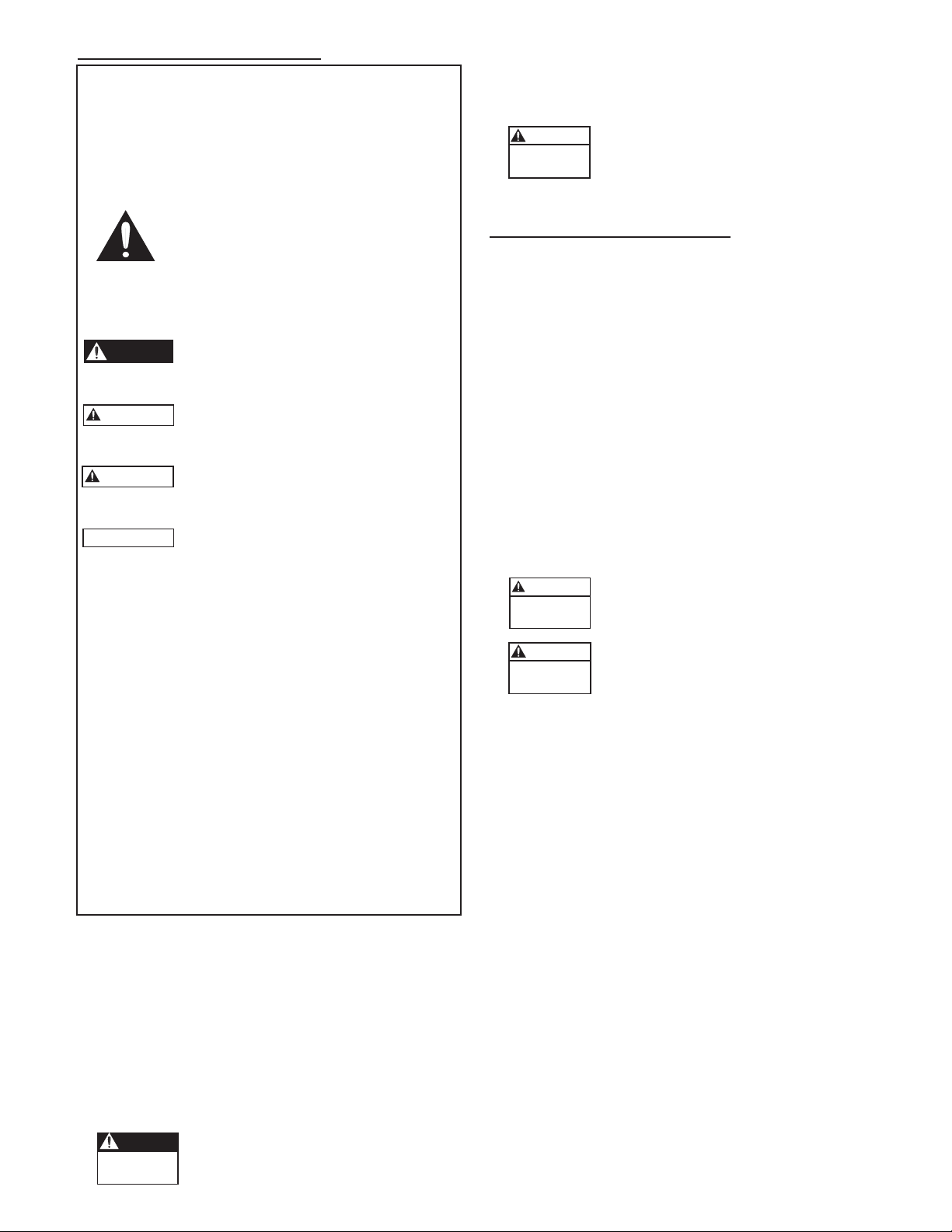

3: SYSTEM DESIGN

3: SYSTEM DESIGN

NOTE: Systems MUST be designed by qualied technicians only and meet all applicable state and local code

requirements.

The following diagrams show a typical system using the Aquavar ABII Constant Pressure System. Connection can be

made directly to a water supply or water can be drawn from a supply tank. Diagram #1 shows a typical set up for a

supply tank.

Home Supply

Aquavar ABII

Controller

Circuit

Breaker

Disconnect

Diagram 1

Aquavar ABII Installation

for Well Pump System

Transducer

Gauge

Tank

Motor/Pump

Relief

Valve

Check Valve

To Drain

Check Valve

Isolation Valves

Unions

Isolation

Valve

Well Supply

Atmospheric

Storage Tank

Diagram #2 shows a set-up for municipal water connection. This allows pump maintenance without main line shut-off.

Home Supply Water Main

Check Valve

Aquavar ABII

Isolation Valves

Controller

Circuit

Breaker

Unions

Transducer

Disconnect

Diagram 2

Aquavar ABII Installation

for Municipal Water

System

4

Gauge

Tank

Motor/Pump

Relief

Valve

Check Valve

To Drain

Note: A check

valve or double

check valve may

be required on

the suction side

of the pump.

Consult local

codes.

Page 5

4: PIPING

Hazardous

Pressure

CAUTION

WARNING

Hazardous

voltage

Hazardous

Pressure

CAUTION

Hazardous

Pressure

CAUTION

WARNING

Hazardous

Pressure

CAUTION

4: PIPING

General

NOTE: All plumbing work must be performed by a

qualied technician. Always follow all local, state and

provincial codes.

A proper installation requires a pressure relief valve, a ¼"

female N.P.T. threaded tting (found on tank tee) for the

pressure sensor, and properly sized pipe. Piping should

be no smaller than the pump discharge and/or suction

connections. Piping should be kept as short as possible.

Avoid the use of unnecessary ttings to minimize friction

losses.

Some pump and motor combinations

supplied with this system can create over

200 PSI. Select pipe and ttings accordingly

per your pipe suppliers’ recommendation. Consult local

codes for piping requirements in your area.

All joints must be airtight. Use Teon tape or another

type of pipe sealant to seal threaded connections. Please

be careful when using thread sealant as any excess that

gets inside the pipe may plug the pressure sensor.

Galvanized ttings or pipe should never be connected

directly to the stainless steel discharge head or casing

as galvanic corrosion may occur. Barb type connectors

should always be double clamped.

Pressure Tank, Pressure Relief Valve and

Discharge Piping

The standard Hydro-Pro tanks have a pre-charge of 38

PSI. You may set the tank pre-charge anywhere between

this value and 10 PSI below the system operating

pressure. Use the higher tank pre-charge setting if the

system drifts over 5 PSI at a constant ow rate. Use

only “pre-charged” tanks on this system. Do not use

galvanized tanks. Select an area that is always above 34º

F (1.1º C) in which to install the tank and pressure relief

valve. If this is an area where a water leak or pressure

relief valve blow-off may damage property, connect a

drain line to the pressure relief valve. Run the drain line

from the pressure relief valve to a suitable drain or to

an area where water will not damage property. Use the

supplied tank tee to connect the discharge pipe to the

pressure tank and house plumbing. It is allowable to

pump to multiple locations.

Maximum working pressure of most HydroPro tanks is 125 psi. Check the tank

label or instruction manual to verify data.

Installing the Pump

WARNING: Risk of electric

shock - This pump system has

not been investigated for use

in swimming pool areas.

source as possible. When pumping out of an atmospheric

tank locate the pump below the level of the liquid in the

tank. All piping must be supported independently of the

pump. Be sure that suction and discharge piping are in

line with the suction and discharge of the pump. Install

a check valve between the discharge of the pump and

the pressure sensor and tank. For additional information

refer to Installation, Operation and Maintenance

Instructions supplied with the pump.

Installing the Pressure Sensor

Install the pressure sensor in the tank tee provided with

the unit. The pressure sensor cable supplied with the

controller is 120 inches long. Locate the controller so

there will be enough cable to properly install the pressure

sensor.

Do not install any shut-off valves, lters or

ow/pressure control devices (except for

a check valve) between the pressure sensor and the discharge of the pump as this could create a

hazardous situation.

Use ONLY the pressure sensor provided with the unit.

Install the pressure sensor into one of the ¼" holes on the

tank tee provided in the kit. Install the pressure sensor

vertically to avoid accumulation of debris in the sensor

port. Do not install the tank tee with the ¼" holes facing

down. Align the connector on the end of the pressure

sensor cable with the mating connector on the pressure

sensor and push it on. The tab will lock it in place.

Prevent water from following the cable and entering

sensor connector by creating a “drip loop” in the cable.

5: MOUNTING THE CONTROLLER

5: MOUNTING THE CONTROLLER

General

Mount the controller in a well ventilated, shaded area

using the supplied mounting kit. The controller must be

mounted vertically. Be sure to leave 8 inches of free air

space on every side of the unit. The controller must be

in an area with an ambient between 34º F (1.1º C) and

104º F (40º C). Model 2AB2 will automatically decrease

(derate) the maximum output current of the drive (6.9A)

if the ambient temperature exceeds 104º F

(40º C). The maximum output current of the drive will

be decreased by 0.069A for every degree Fahrenheit

above 104º F, or -1%/º F. The maximum output current

of the drive will be decreased by 0.12A for every degree

Celsius above 40º C, or -1.75%/º C. Model 1AB2

does not require ambient derating and will maintain

a maximum output current of 4.2A in high ambient

temperatures. If installation is more than 3300 feet above

sea level, drive output should also be derated by 2% per

1000 feet above 3300 feet.

NOTE: Do not block the heat sink (ns) and do not

set anything on the units.

Plumb suction and discharge of pump into

piping. Locate the pump as near liquid

5

Page 6

The controller access cover should always

WARNING

Hazardous

voltage

Hazardous

voltage

DANGER

Hazardous

voltage

DANGER

Hazardous

voltage

DANGER

Hazardous

voltage

DANGER

Hazardous

voltage

DANGER

Hazardous

voltage

DANGER

Hazardous

voltage

DANGER

CAUTION

be securely fastened to the control box

due to the dangerous voltage/shock hazard

inside the unit.

6: POWER SUPPLY AND WIRING

6: POWER SUPPLY AND WIRING

Power Supply

The 1151AB2 Controller requires a single

phase power supply of 115 volts +/– 15%.

The 1AB2 and 2AB2 Controllers require

a single phase power supply of 230 volts +/– 15%. All

controllers require a dedicated 20 amp two-pole circuit

breaker. A dedicated circuit means no other appliances

use the same circuit! The output power from the motor

controller is three-phase, variable frequency and variable

voltage. Maximum output voltage and frequency are

line input voltage and 60 Hz, respectively. Low supply

voltage will reduce pump performance.

NOTE: Installation and maintenance MUST be performed by properly trained and qualied personnel.

Always follow the National Electric Code or Canadian

Electric Code, as well as all local, state and provincial

codes when wiring the system.

Wire and Conduit

Do not use wire smaller than 14 AWG. Use of

Metal Conduit with Metal Conduit Connectors is

recommended for all electrical connections.

Output Power Connections

Connect the motor leads for 230 volt or

208 volt operation using the nameplate as a

reference. Connect the output power leads

from the controller to the 3 motor leads in the conduit

box on the motor. Connect the ground (green) output

power lead to the ground screw in the conduit box on

the motor. This step is performed in its entirety at the

factory for complete systems. See diagram 4 for details.

NOTE: If the pump has more than 50 feet of wire

from the controller, consult factory for selection of an

output load lter (load reactor).

to properly ground the controller or motor will create an

electrical shock hazard.

NOTE: Do not use GFCI protection with this controller. Nuisance tripping will result.

7: STARTING THE SYSTEM

7: STARTING THE SYSTEM

Status Code Indicator Light is not a voltage

indicator! Always turn off disconnect switch

and circuit breaker before servicing.

Once the controller is powered it will remain electrically charged for 5 minutes after

power is turned off. Wait 5 minutes after

disconnecting power before opening controller access

cover as there is a severe shock hazard.

Setting the Motor Overload Switches

When the unit is powered, the Motor Overload Setting Switches are at a high voltage

potential. DO NOT touch the Motor Over-

load Setting Switches while the power is on.

The Motor Overload Setting Switches adjust the level

of motor overload current protection needed to protect

the motor from damage due to overcurrent conditions.

Turn the circuit breaker and disconnect switch to the off

position, and wait 5 minutes. Remove controller access

cover. On the inside of the access cover is the Motor

Overload Setting table.

shows the switch setting for the desired Motor Overload

Setting. Read the Service Factor Amps off the motor

nameplate. Use the Motor Overload Setting table to

match the Service Factor Amps (SF Amps) of the motor

to the correct switch setting.

the Motor Overload Switches according to the correct

combination on the table. If the Service Factor Amps

of the motor do not match any of the Motor Overload

Settings, use the next lowest switch setting.

for details

.

NOTE: The Motor Overload Setting Switches are

preset at the factory for complete systems.

See Diagram 6 for details.

This table

See Diagram 5 for details.

See Diagram 3

Set

Connecting Input Power

Connect the single-phase power supply

leads and Safety Ground wire from a 20

amp two-pole circuit breaker (in the OFF

position) to one side of a 20-amp two-pole disconnect

switch. Connect the input power leads supplied with

the controller to the other side of the disconnect switch.

Be sure to use Metal Conduit with Metal Conduit

Connectors for electrical connections.

The controller has a high leakage current

to ground. The terminals marked "GND"

in the controller must be connected to the

safety ground from the electrical service entrance. Failure

6

Failure to perform this step will result in

loss of Motor Overload Protection and

will void the Motor Warranty. Nuisance Motor Overload Error tripping or motor damage can occur if these

switches are not set properly.

Setting the Pressure

Turn the circuit breaker and disconnect switch to the off

position, and wait 5 minutes. Remove controller access

cover. Open a faucet in the system and turn the breaker/

disconnect switch to the ON position. The pump will

start and pressure will increase to the factory preset 50

PSI. After the pressure has stabilized, use the Increase/

Decrease Pressure Adjust Pushbuttons on the right-hand

side of the controller to adjust the pressure setting.

Page 7

Push and Hold the Increase or Decrease Pressure Adjust

Hazardous

voltage

DANGER

Hazardous

voltage

DANGER

Pushbutton until the desired pressure setting is reached.

The new pressure setting is automatically saved. Close

the faucet and turn power to controller off. Wait 5

minutes before installing the controller access cover.

NOTE: The maximum allowable pressure setting is

85 psi.

NOTE: It is possible for the pump to maintain

constant pressure with a low ow or a high positive

suction head even if the pump is rotating backwards.

While the pump is running, use an amp probe on one

of the output power leads connected to the motor and

compare the current draw between the two rotation

directions. The lowest current reading indicates the

pump is running in the correct direction.

Setting the Application Switches

When the unit is powered, the Application

Setting Switches are at a high voltage potential. DO NOT touch the Application Setting

Switches while the power is on.

The controller has 6 possible Application Settings.

These settings are used to adjust the Minimum Speed

of the motor and the Ramp Setting, or acceleration and

deceleration ramp. This allows the controller to t a wide

range of applications.

Before adjusting the Application Switches, turn the

circuit breaker and disconnect switch to the off position.

Wait 5 minutes. Remove the controller access cover. On

the inside of the access cover is the Application Switch

Setting Table. See Diagram 6 for details. This table shows

the switch setting needed for the desired system response.

See Diagram 3 for details.

Select a Minimum Speed of 10 Hz if the pressure at the

pump’s suction is within 20 PSI of the desired pressure

setting. Select a Minimum Speed of 30Hz if the pressure

at the pump’s suction is more than 20 PSI below the

desired pressure setting, if pumping from a tank or if

drawing a suction lift.

Changing the Ramp Setting changes how fast the

controller can change the speed of the motor. A Slow

Ramp Setting allows the controller to work better in

applications where the average demand for water is low

(less than 3GPM or about 1 faucet). A Fast Ramp Setting

allows the controller to work better in applications

where the demand for water is high because the motor is

allowed to change speed faster.

System Status

The controller is always powered. A Solid Green Status

Code indicates that the pump is in standby mode (pump

not running) or that the line input voltage is low.

Status Code Indicator Light is not a voltage

indicator! Always turn off disconnect switch

and circuit breaker and wait 5 minutes

before servicing.

A Blinking Green Status Code indicates that the pump

is running. A Blinking or Solid Red Light indicates a

problem with the controller. Refer to the access cover

side panel or Diagram 6 for Status Codes. See Section 9

for more details.

NOTE: The Application Switches are preset at the

factory to “0000” or Minimum Speed = 30 Hz, Ramp

Setting = Fast.

Motor Rotation Direction

If the pressure or ow seems low, check motor rotation

direction. Turn the circuit breaker and disconnect

switch to the off position, and wait 5 minutes. Switch

any two leads on the controller output (T1, T2, or T3).

Turn the circuit breaker and disconnect switch to the on

position. Observe pressure and ow. If pressure or ow

still seems low check plumbing.

7

Page 8

Hazardous

voltage

DANGER

Input

1 Phase

GND

L1

L2 (N)

See Manual For

Switch Settings

Applic.

Type

Output

To Motor

1 2 3 4 1 2 3 4

Pressure

Sensor

Input (Wht)

+5V (Red)

Com. (Blk)

T1T2T3

GND

Motor

Overload

Setting

Line output to motor.

Correct motor rotation

determines order of colors.

Pressure

Sensor

9K518

Line input power from

2-pole disconnect or

circuit breaker.

GREEN

BLACK

BLACK

GREEN

WHITE

RED

BLACK

BLUE

RED

BLACK

8: DIAGRAMS

WARNING

8: DIAGRAMS

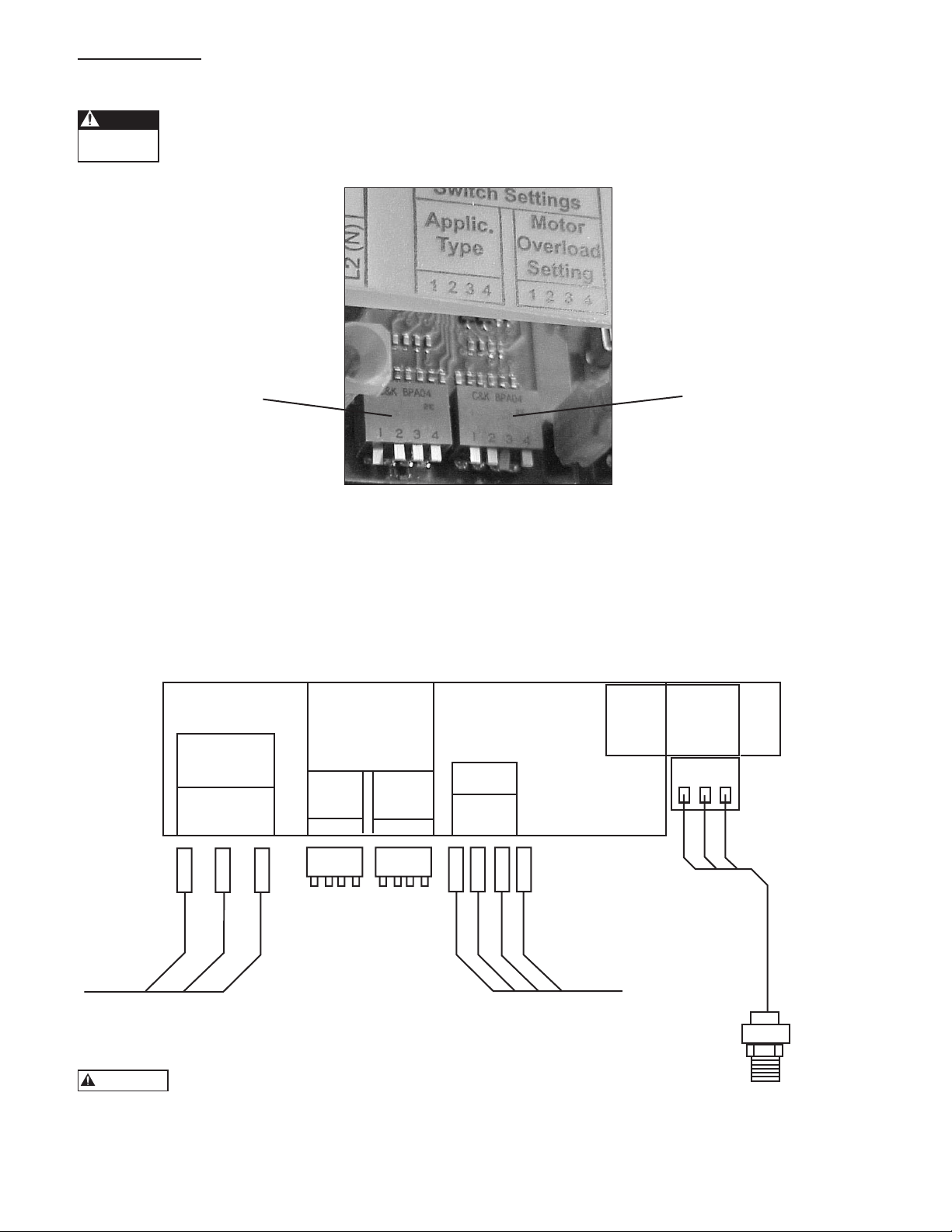

Motor Overload and Application Switch Setting

When the unit is powered, the Motor Overload and Application Setting Switches are at a high voltage

potential. Always turn off the disconnect switch and circuit breaker and wait 5 minutes before touching

the Motor Overload or Application Setting Switches.

Application Switch Setting

See chart that follows for

correct switch settings.

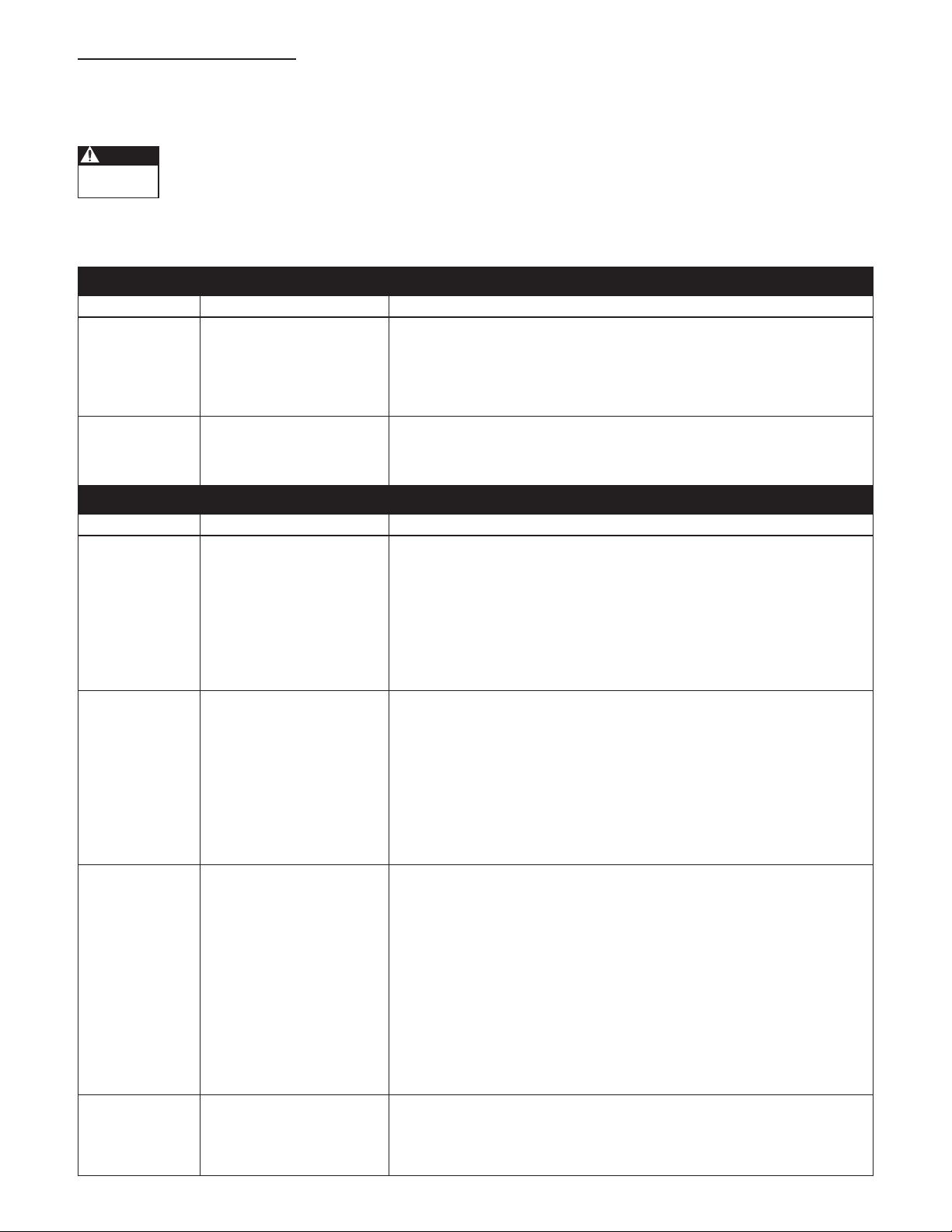

Aquavar ABII Wiring Diagram

Motor Overload Setting Switches

See chart that follows for

correct switch settings.

Diagram 3

8

Do not connect 230V to a 115V controller. This will

damage the controller and voids the warranty.

Diagram 4

Page 9

8: DIAGRAMS

8: DIAGRAMS (continued)

Typical Motor Nameplate Showing Service Factor Amps (SF AMPS)

Service Factor Amps (SF AMPS)

that are used to set the Motor

Overload Setting Switches.

In this example, use the 4.2 Amp setting indicated on the Motor Overload Setting Table. This setting is used to account

for any voltage uctuation.

Diagram 5

Labels found on the Controller Access Cover:

Motor Overload Setting

WARNING

Disconnect Power And Wait For LED Indicator To Turn

Off Before Touching Motor Overload Setting Switches.

1 = UP 0 = DOWN

DIP Switch Setting Motor Overload Setting (Amps)

1 2 3 4 1AB2 2AB2

1 1 1 1 2.5 4.6

1 1 1 0 2.8 5.2

1 1 0 1 3.3 5.3

1 0 1 1 3.5 5.8

0 1 1 1 3.8 6.5

0 0 0 0 4.2 6.9

Motor Overload Setting Label

Use this label to choose the correct Motor Overload Switch

Setting. This label is found under the controller access cover.

Application Type Switch Setting

WARNING

DIP Switch Setting 1 = UP 0 = DOWN

1 2 3 4 Minimum Speed (Hz) Ramp Setting

1 1 1 1 * 10 Slow

1 1 1 0 * 10 Medium

1 1 0 1 * 10 Fast

1 0 1 1 30 Slow

0 1 1 1 30 Medium

0 0 0 0 30 Fast

*THESE SETTINGS ARE NOT TO BE USED WITH SUBMERSIBLE PUMPS.

Disconnect Power And Wait For LED Indicator To Turn

Off Before Touching Application Setting Switches.

Status Code

to diagnose any

system errors.

Label

Use this label

This label is

found on the

side of the

controller

access cover.

Status Codes*

Green Light Codes

Constant Standby/Low Voltage

Blinking Pump Running

Red Light Codes

Constant Replace Controller

1 Blink No Water/Loss Of Prime

2 Blinks Tank Water-Logged

3 Blinks Pressure Sensor Fault

4 Blinks Pump or Motor Bound

5 Blinks Short Circuit

6 Blinks Ground Fault

7 Blinks High Temperature

8 Blinks Over Voltage (>264V)

9 Blinks Motor Overload

*No Light - No/Very Low Voltage

Application Switch Setting Label

Use this label to choose the correct

Application Switch Setting. This label is

found under the controller access cover.

Diagram 6

9

Page 10

Hazardous

voltage

DANGER

9: TROUBLESHOOTING

9: TROUBLESHOOTING

General

The Aquavar ABII is a self-diagnosing controller. If a problem occurs, observe the Status Code Indicator Light on the

front of the unit. No Status Code Indicator Light means either no or low input voltage (less than 50 V).

Status Code Indicator Light is not a voltage indicator! Always turn off disconnect switch and circuit

breaker and wait 5 minutes before servicing. High voltage may still remain on controller.

Refer to the status code label on the side of the controller access cover to diagnose system errors. See Diagram 6 for details.

USE THE FOLLOWING TABLE TO HELP TROUBLESHOOT PROBLEMS.

GREEN LIGHT CODES

Indicator Code Status Description

Constant Standby/Low Voltage Constant Green Light indicates the pump is off. The system is in

Standby mode when there is no ow in the system and the pressure

setting has been reached. The system is in a Low Voltage condition

when the line input voltage drops below 196VAC for 1AB2 and 2AB2

controllers and 98VAC for 1151AB2 controllers.

Blinking Pump Running Flashing Green Light indicates the pump is running. If pump is not

running, turn off power to controller and wait 5 minutes. Check

output power connections from controller to motor.

RED LIGHT CODES

Constant Controller Error Replace Aquavar ABII Controller

1 Blink No Water/Loss Of Prime This fault is indicated if the system pressure drops 5 PSI or more

below the set pressure and the output current is less than 75% of the

motor overload setting for 10 seconds. The system will automatically

restart in 5 minutes. If 3 faults occur in an hour, the system will not

restart and will need to be manually reset. If the problem reoccurs,

please verify supply capacity, pump capacity, proper setting of the

motor overload switches and that there are no restrictions between

the supply and the pump.

2 Blinks Tank Water-Logged This warning is indicated if there is a drastic drop in system pressure

in a short amount of time. The warning will not impact operation.

The pump will continue to run. This warning can be caused by low air

pressure in the tank or the tank bladder may have failed. This can also

be caused by extreme changes in ow. The error is cleared each time

the pump starts. If the error reoccurs often, check the air pressure in

the tank. Before checking tank air pressure, turn power to control off

to prevent pump from turning on. Relieve system pressure by opening

a faucet.

3 Blinks Pressure Sensor Fault This fault indicates a problem with the pressure sensor feedback.

Verify the connections from the Aquavar ABII Controller to the

pressure sensor. Turn power to controller off and wait 5 minutes.

Remove controller access panel. Be sure sensor cable is wired as

shown in Diagram 4. If cable is wired correctly, check the voltage on

the Input (White) pressure sensor terminal connection in the

Aquavar ABII controller. Using a DC voltmeter, connect the positive

lead to the Input (White) pressure sensor terminal connection, connect

the negative lead to the Com. (Black) pressure sensor terminal

connection. Turn power to controller on. The DC voltage measured

should be in the valid range of 0.5 Vdc to 4.5 Vdc (+/- 0.2 Vdc). If the

voltage is outside this range, replace pressure sensor.

4 Blinks Pump or Motor Bound This fault can be caused by mechanical binding from debris in pump

or from an electrical failure in the motor. Verify the error by turning

power to controller off for 1 minute and then on. Pump must be

checked if error persists.

10

Page 11

(135.36)

5.33

(259.08)

10.20

(237.06)

9.33

(12.07)

.48

(157.90)

6.22

(135.36)

5.33

(135.36)

5.33

(259.08)

10.20

(237.06)

9.33

(12.07)

.48

(157.90)

6.22

(114.30)

4.50

(57.15)

2.25

(81.28)

3.20

(16.51)

.65

9: TROUBLESHOOTING

9: TROUBLESHOOTING (continued)

RED LIGHT CODES

Indicator Code Status Description

5 Blinks Short Circuit Check wiring for shorting phase to phase and phase to ground. Turn

power to controller off and wait 5 minutes. Remove controller

access panel. Disconnect motor leads marked T1, T2, and T3. Measure

resistance between all motor leads using an ohmmeter. NOTE: Motor

winding resistance is typically 2 to 10 OHMS depending on motor.

6 Blinks Ground Fault Check wiring for shorting phase to ground. Turn power to controller

off and wait 5 minutes. Remove controller access panel. Disconnect

motor leads T1, T2, T3, and Ground from controller. Measure

resistance between all motor leads and ground using a Megohmmeter.

Connect one Megohmmeter lead to any one of the motor leads and

the other to ground lead. Set Megohmmeter to 500V DC output.

Resistance readings less than 500,000 ohms or 0.5 Megohms indicate

a damaged motor.

7 Blinks High Temperature This fault is caused by a high temperature inside of the controller. The

controller will shut off when the temperature inside the controller

reaches 158º F (70º C). The controller will turn back on when the

temperature inside the controller reaches 150º F (65.5º C). Avoid

installing the controller where ambient temperatures exceed 104º F

(40º C). Avoid installing the controller where it is exposed to direct

sunlight.

8 Blinks Over Voltage Measure input voltage using an AC voltmeter. Connect the positive

and negative leads to L1 and L2 on the Aquavar ABII controller. Verify

line input voltage is not greater than 264 VAC for 1AB2 and 2AB2

controllers and 132VAC for 1151AB2.

9 Blinks Motor Overload This fault is indicated when the current supplied to the motor exceeds

the Motor Overload Setting on the Aquavar ABII controller. Refer to

Section 7, Setting the Motor Overload DIP Switches for details. If

switches are set according to Section 7, check motor.

10: CONTROLLER DIMENSIONS

10: CONTROLLER DIMENSIONS

(8.38)

.33

(242.04)

9.53

(232.56)

9.16

(57.15)

2.25

(114.30)

4.50

(81.28)

3.20

(16.51)

.65

Liquid

Tight

(135.36)

5.33

(12.07)

.48

(237.06)

9.33

(99.06)

3.90

(157.90)

6.22

(259.08)

10.20

1

∨2”

11

Page 12

GOULDS WATER TECHNOLOGY LIMITED WARRANTY

This warranty applies to all water systems pumps manufactured by Goulds Water Technology.

Any part or parts found to be defective within the warranty period shall be replaced at no charge to the dealer during the warranty period. The warranty period shall exist for a

period of twenty-four (24) months from date of installation or thirty (30) months from date of manufacture, whichever period is shorter.

A dealer who believes that a warranty claim exists must contact the authorized Goulds Water Technology distributor from whom the pump was purchased and furnish complete

details regarding the claim. The distributor is authorized to adjust any warranty claims utilizing the Goulds Water Technology Customer Service Department.

The warranty excludes:

(a) Labor, transportation and related costs incurred by the dealer;

(b) Reinstallation costs of repaired equipment;

(c) Reinstallation costs of replacement equipment;

(d) Consequential damages of any kind; and,

(e) Reimbursement for loss caused by interruption of service.

For purposes of this warranty, the following terms have these definitions:

(1) “Distributor” means any individual, partnership, corporation, association, or other legal relationship that stands between Goulds Water Technology and the dealer in purchases,

consignments or contracts for sale of the subject pumps.

(2) “Dealer” means any individual, partnership, corporation, association, or other legal relationship which engages in the business of selling or leasing pumps to customers.

(3) “Customer” means any entity who buys or leases the subject pumps from a dealer. The “customer” may mean an individual, partnership, corporation, limited liability company,

association or other legal entity which may engage in any type of business.

THIS WARRANTY EXTENDS TO THE DEALER ONLY.

Xylem, Inc.

2881 East Bayard Street Ext., Suite A

Seneca Falls, NY 13148

Phone: (800) 453-6777

Fax: (888) 322-5877

www.xyleminc.com/brands/gouldswatertechnology

Goulds is a registered trademark of Goulds Pumps, Inc. and is used under license.

Aquavar ABII is a trademark of Xylem Inc. or one of its subsidiaries.

© 2011 Xylem Inc. IM156 Revision Number 4 September 2011

Loading...

Loading...