Page 1

INSTRUCTION MANUAL

19-001-350R2

THIS MANUAL IS FOR TECHNICIAN USE ONLY

PACE™ Integrated Pump Controller

Human Machine Interface (HMI)

for the Silent Storm VFD Pumping System

TECHNICIAN GUIDE

Page 2

2

Acknowledgements

All materials ©2013 by Flowtronex, A Xylem company.

Flowtronex© is a registered trademark of Flowtronex a Xylem Company.

All rights reserved. No parts of this work may be reproduced in any form or by any means - graphic,

electronic, or mechanical, including photocopying, recording, taping, or information storage and retrieval

systems - without the written permission of the publisher.

Products that are referred to in this document may be either trademarks and/or registered trademarks of

the respective owners. The publisher and the author make no claim to these trademarks. These include

Microsoft, Windows, Windows NT, ActiveX that are either registered trademarks or trademarks of Microsoft

Corporation in the United States and/or other countries. ©2013 Microsoft Corporation. All rights reserved.

WHILE EVERY PRECAUTION HAS BEEN TAKEN IN THE PREPARATION OF THIS DOCUMENT, THE

PUBLISHER AND THE AUTHOR ASSUME NO RESPONSIBILITY FOR ERRORS OR OMISSIONS, OR

FOR DAMAGES RESULTING FROM THE USE OF INFORMATION CONTAINED IN THIS DOCUMENT

OR FROM THE USE OF PROGRAMS AND SOURCE CODE THAT MAY ACCOMPANY IT. IN NO EVENT

SHALL THE PUBLISHER AND THE AUTHOR BE LIABLE FOR ANY LOSS OF PROFIT OR ANY OTHER

COMMERCIAL DAMAGE CAUSED OR ALLEGED TO HAVE BEEN CAUSED DIRECTLY OR

INDIRECTLY BY THIS DOCUMENT.

Page 3

3

TABLE OF CONTENTS

ACKNOWLEDGEMENTS ......................................... 2

ACKNOWLEDGEMENTS ......................................... 2

INTRODUCTION ....................................................... 6

HMI OVERVIEW ........................................................ 6

TYPICAL PUMPING OPERATION ................... 7

TOUCH-SCREEN PANEL OPERATION .................. 7

ENHANCED KEY PAD ...................................... 8

BASIC SCREEN LAYOUT ........................................ 8

USER TYPES ............................................................ 8

OPERATION MENU .................................................. 9

SYSTEM VIEW & TRENDS .............................. 9

Configure Period Screen ....................................... 9

Configuring the Data Shown on the Screen ........ 10

FLOW TOTALS ............................................... 11

PUMP STATUS ............................................... 11

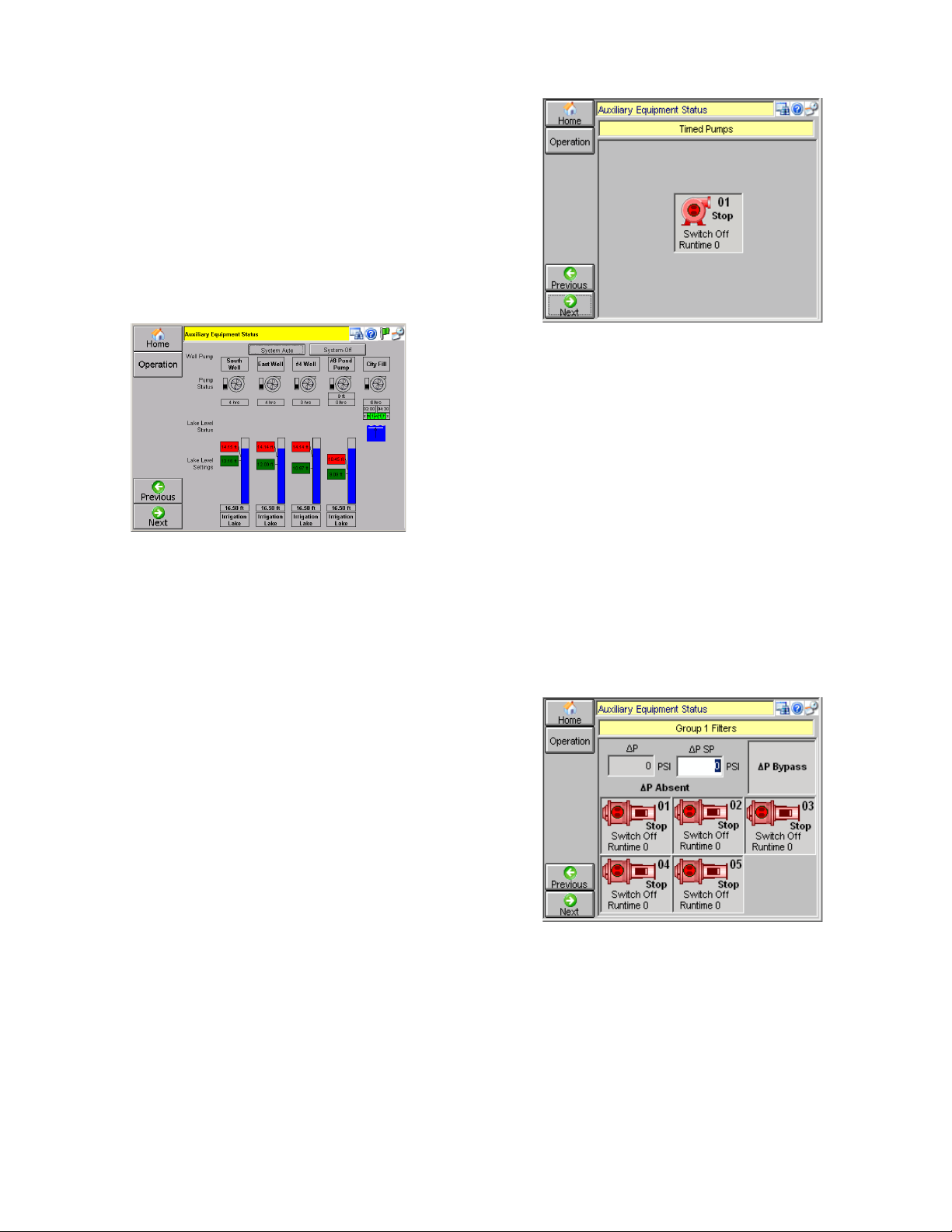

AUXILIARY EQUIPMENT STATUS ................ 12

Booster Pumps: ................................................... 12

Automated Lake (ALS) Monitoring Screen .......... 12

Lake Level Controls Monitoring Screen .............. 12

Lake Level/Transfer/Timed Pump Monitoring Screen:

............................................................................ 13

Timed Pump Monitoring Screen (Non-Integrated

Only) .................................................................... 13

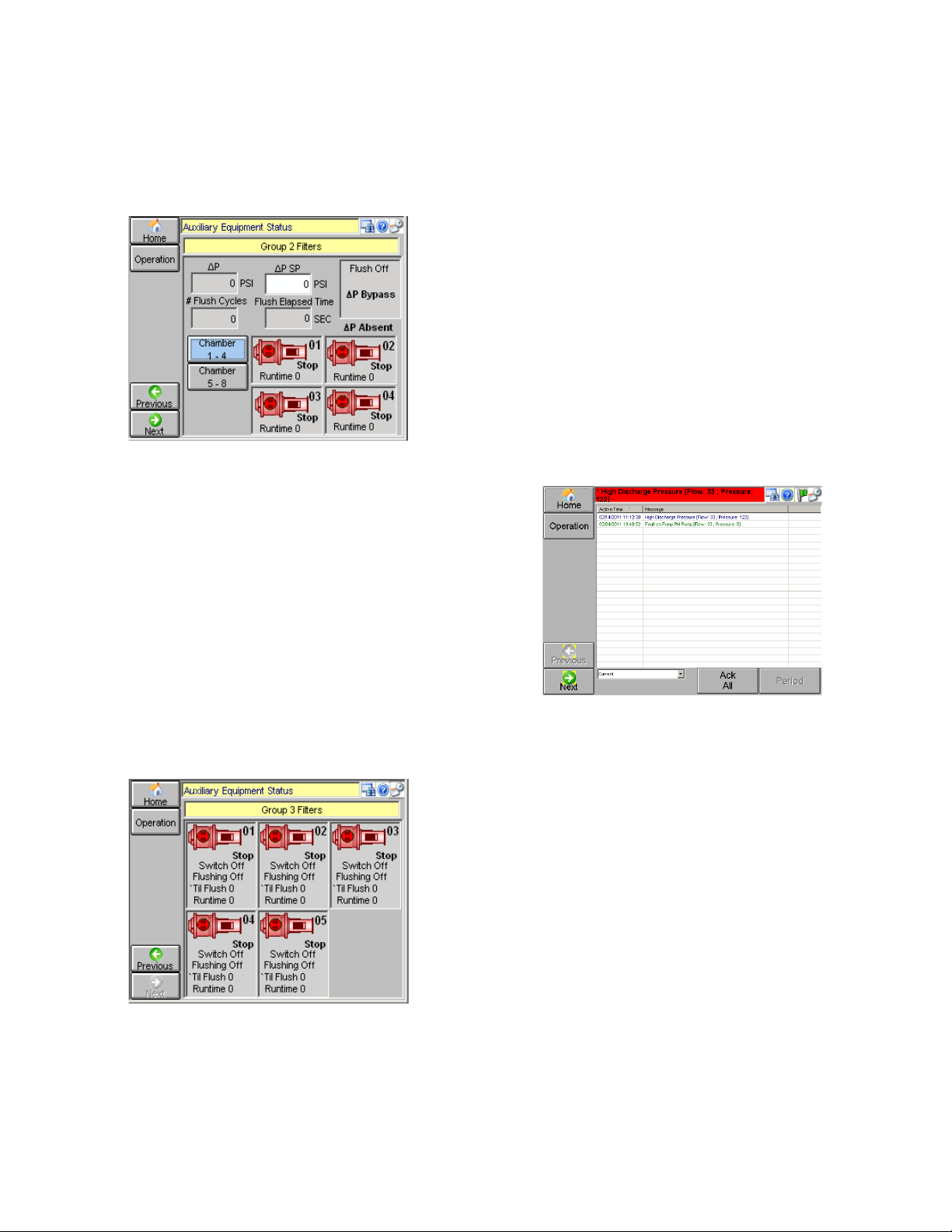

Simple Filters Monitoring Screen ........................ 13

Scanner Filters Monitoring Screen ...................... 13

Solid Separators Monitoring Screen ................... 14

ALARMS .......................................................... 14

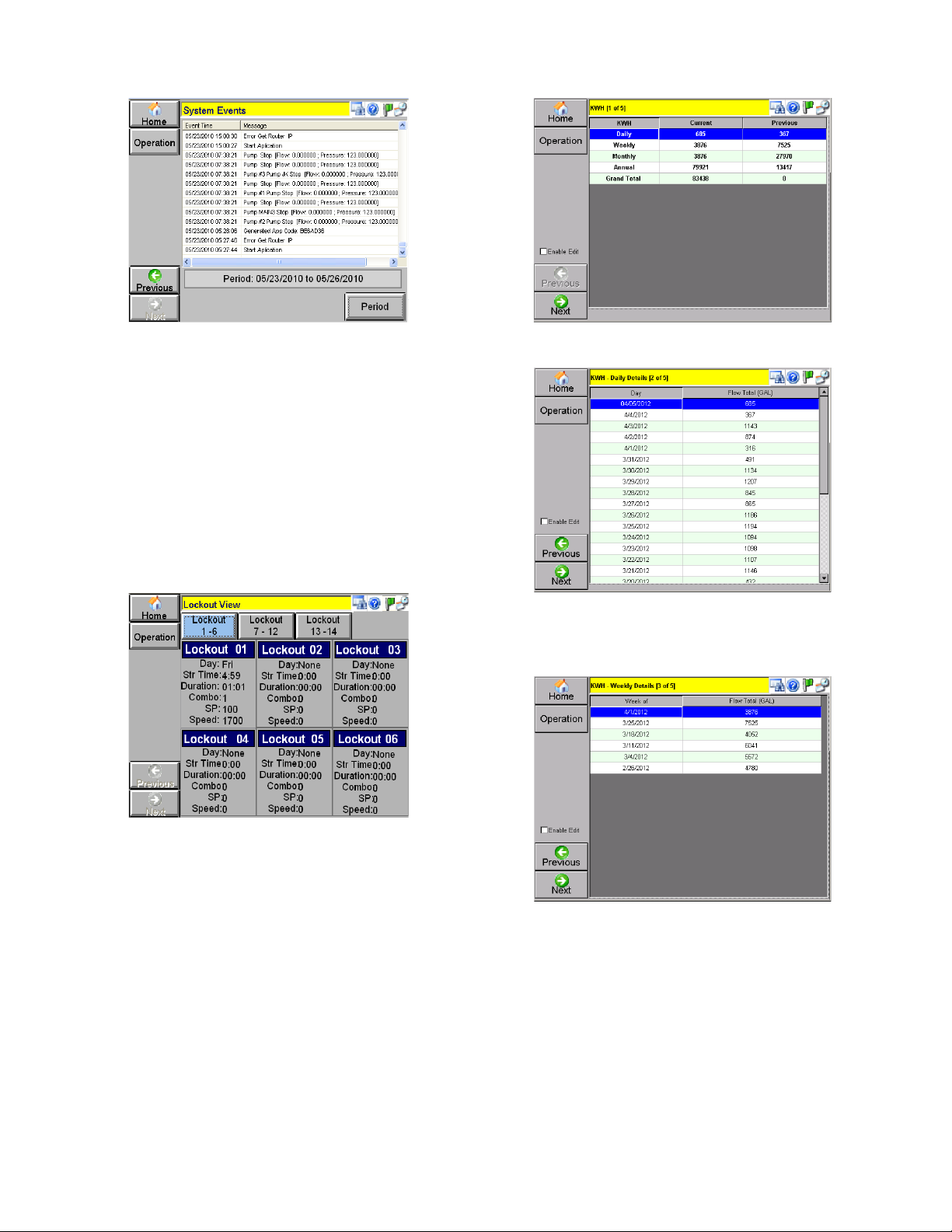

EVENTS .......................................................... 14

LOCKOUT VIEW ............................................. 15

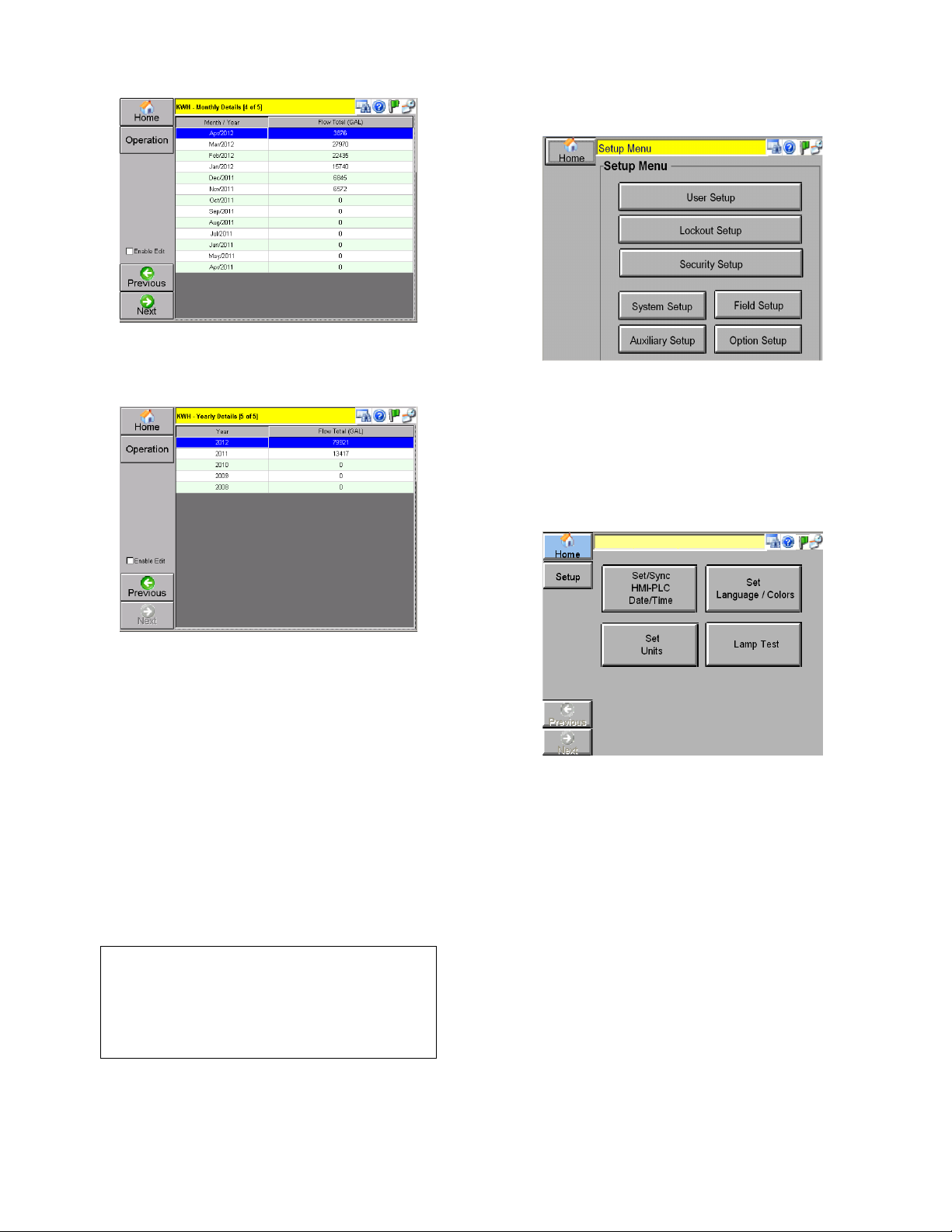

KWH RECORDS ............................................. 15

SETUP MENU ......................................................... 16

USER SETUP ................................................. 16

Set/Sync HMI-PLC Date/Time ............................ 16

Lamp Test ........................................................... 17

LOCKOUT SETUP .......................................... 17

SECURITY SETUP ......................................... 17

SYSTEM SETUP ............................................. 18

Job Information ................................................... 18

Basic Pump Information ...................................... 18

Zone Configuration .............................................. 18

Pump Configuration ............................................ 19

Alarm Setup ........................................................ 19

Combo Options ................................................... 19

FIELD SETUP ................................................. 20

PID Tuning .......................................................... 20

OPA Enable ........................................................ 22

Current dP/dT values are shown to assist in tuning

the dP/dT system. ............................................... 22

Combos ............................................................... 22

Combo Pumps .................................................... 23

AUXILIARY SETUP ......................................... 23

Booster Setup ..................................................... 24

ALS Setup ........................................................... 24

Lake Level Controls Setup .................................. 24

Lake Level Controls Setup (Non-Integrated only)26

Timed Pump Setup (Non-Integrated only) .......... 26

Simple Filters Setup ............................................ 26

Simple Filters Setup ............................................ 26

Scanners Filter Setup ......................................... 27

Options Setup ..................................................... 27

VFD Bypass ........................................................ 27

Analog Scaling .................................................... 27

ActiveX and IP Updates ...................................... 28

WinCE Remote Access ....................................... 28

Alternate SP ........................................................ 28

Database Settings ............................................... 29

SETUP/CONFIGURATION FILE .............................. 30

EXIT APPLICATION ................................................ 31

NETWORKING AND REMOTE ACCESS ................ 31

Remote Software Log In ..................................... 31

WEB REPORTS ....................................................... 31

Log on to Web Reports ....................................... 31

Web Reports Menu ............................................. 32

Trend View .......................................................... 32

Alarms Report ..................................................... 32

Historical Report ................................................. 33

Usage Report ...................................................... 33

Smart Phone and PDA access: .......................... 33

APPENDIX A–GLOSSARY OF TERMS .................. 34

APPENDIX B ─ PANEL SWITCH SETTINGS ......... 37

APPENDIX D–TYPICAL ALARMS CONFIGURATION

.................................................................................. 39

APPENDIX E – DEFAULT IP ADDRESSES FOR

AUXILIARY DEVICES .............................................. 40

APPENDIX F – EMAIL TROUBLESHOOTING ....... 41

DETERMINING THE IP ADDRESS OF THE

SMTP SERVER ............................................... 41

TROUBLESHOOTING GENERAL EMAIL

FAILURES ....................................................... 43

Troubleshooting Email SET Failures .................. 43

Troubleshooting Email Send Failures ................. 44

APPENDIX G: COMPUTER SETUP AND

DETERMINING THE IP ADDRESS OF YOUR PUMP

STATION .................................................................. 46

DETERMINING THE IP ADDRESS: ................ 48

APPENDIX H – GENERAL NETWORKING AND

ROUTER CONFIGURATION DISCUSSION: ........... 50

NOTE: The information contained in this book

is intended to assist operating personnel by

providing information about the characteristics

of the purchased equipment. It does not relieve

the user of their responsibility of using accepted

engineering practices in the installation, operation,

and maintenance of this equipment.

Page 4

4

For additional questions, contact:

XYLEM FLOWTRONEX

8:00 AM to 5:00 PM Central time (800) 786-7480 x3

5:00 PM to 8:00 AM Central time

After Hours technician for emergency assistance:

(214) 454-5768

support@flowtronex.com

TABLE OF FIGURES

Figure 1: Basic Operation ....................................... 7

Figure 2: Connection for USB Keyboard (c). .......... 7

Figure 3: Enhanced Key Pad .................................. 8

Figure 4: Basic Screen Layout ................................ 8

Figure 5: Log in Screen ........................................... 9

Figure 6: Operation Menu ....................................... 9

Figure 7: Trends Screen ......................................... 9

Figure 8: Configure Period .................................... 10

Figure 9: Configure Data ....................................... 10

Figure 10: Technical Overview ............................. 10

Figure 11: Combo Information .............................. 10

Figure 12: Combo Information .............................. 11

Figure 13: Flow Totals, Overview ......................... 11

Figure 14: Flow Totals, Daily Flows ...................... 11

Figure 15: Flow Totals, Weekly Flows .................. 11

Figure 16: Flow Totals Monthly Flows .................. 11

Figure 17: Flow Totals, Yearly Flows .................... 11

Figure 18: Animated Pump Status ........................ 12

Figure 19: Individual Pump Stats .......................... 12

Figure 20: Booster Monitoring Screen .................. 12

Figure 21: ALS Monitoring Screen ........................ 12

Figure 22: Lake Level Controls Monitoring Screen13

Figure 23: Timed Pump Monitoring Screen .......... 13

Figure 24: Simple Filters Monitoring Screen ......... 13

Figure 25: Scanner Filter Monitoring Screen ........ 14

Figure 26: Solid Filter Monitoring Screen .............. 14

Figure 27: Alarms Screen ..................................... 14

Figure 28: Events Screen ..................................... 15

Figure 29: Lockout View Screen ........................... 15

Figure 30: KWH Records, Overview ..................... 15

Figure 31: KWH Records, Daily Usage ................. 15

Figure 32: KWH Records, Weekly Usage ............. 15

Figure 33: KWH Records, Monthly Usage ............ 16

Figure 34: KWH Records, Yearly Usage .............. 16

Figure 35: Setup Menu ......................................... 16

Figure 36: User Setup Menu ................................. 16

Figure 37: Set/Sync HMI-PLC Date/Time ............. 17

Figure 38: Individual Lockout Setup ...................... 17

Figure 39: Parameter Tab in Lockout Setup ........ 17

Figure 40: Security Setup ..................................... 18

Figure 41: Job Information .................................... 18

Figure 42: Basic Pump Information ....................... 18

Figure 43: Zone Configuration .............................. 18

Figure 44: Pump Configuration ............................. 19

Figure 45: Alarm Setup ......................................... 19

Figure 46: Combo Options .................................... 19

Figure 47: PID Settings ......................................... 20

Figure 48: PID Settings ......................................... 20

Figure 49: OPA, Ramp Up and Dp/Dt control ...... 22

Figure 50: Combos ............................................... 23

Figure 51: Combo Pumps .................................... 23

Figure 52: Auxiliary Equipment Setup .................. 24

Figure 53: Booster Setup ..................................... 24

Figure 54: ALS Setup ........................................... 24

Figure 55: Lake Level Controls Setup .................. 25

Figure 56: Level/Timed pump configuration ......... 25

Figure 57: Integrated Timed Pump configuration . 26

Figure 58: Lake Level Controls Setup .................. 26

Figure 59: Timed Pump Setup ............................. 26

Figure 60: Simple Filters Setup ............................ 27

Figure 61: Scanners Filter Setup ......................... 27

Figure 62: Options Setup Menu ........................... 27

Figure 63: VFD Bypass ........................................ 27

Figure 64: Analog Scaling .................................... 28

Figure 65: ActiveX and IP Updates ...................... 28

Figure 66: WinCE Remote Access ....................... 28

Figure 67: Alternate SP ........................................ 28

Figure 68: Pressure SP ........................................ 29

Figure 69: Fertigation SP ..................................... 29

Figure 70: Database Settings ............................... 29

Figure 71: Email Settings ..................................... 30

Figure 72: Setup / Configuration File ................... 31

Figure 73: Exit App Warning ................................ 31

Figure 74: Web Reports Menu ............................. 32

Figure 75: Trends View ........................................ 32

Figure 76: Alarms & Events ................................. 33

Figure 77: Historical Report ................................. 33

Figure 78: Usage Report ...................................... 33

Figure 79: Computer Setup Options .................... 46

Page 5

WARRANTY INFORMATION

Company warrants title to the product(s) and, except as noted below with respect to items not of Company’s

Manufacturer, also warrants the product(s) on date on shipment to Purchaser, to be of the kind and quality

described herein, and free of defects in workmanship and material.

THIS WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES, INCLUDING BUT NOT

LIMITED TO IMPLIED WARRANTIES OF MECHANTABILITY AND FITNESS, AND CONSTITUTES THE

ONLY WARRANTY OF COMPANY WITH RESPECT TO THE PRODUCT(S).

If within one year from date of initial operation, but nor more than eighteen months from date of shipment by

Company of any item of product(s), Purchaser discovers that such item was not as warranted above and

promptly notifies Company in writing thereof, Company shall remedy such non-conformance by, at Company

affected part of the product(s). Purchaser shall assume all responsibility and expense for removal,

reinstallation, and freight in connection with the foregoing remedies. The same obligations and conditions shal

xtend to replacement parts furnished by Company hereunder. Company shall have the right of disposal of

e

ts replaced by it.

par

ANY

SEPARATELY LISTED ITEM OF THE PRODUCT(S) WHICH IS NOT MANUFACTURED BY THE

COMPANY IS NOT WARRANTED BY COMPANY and shall be covered only the express warrant, if any, of the

manufacturer thereof.

l

THI

S STATES PURCHASER’S EXCLUSIVE REMEDY AGAINST COMPANY AND ITS SUPPLIERS

RELATING TO THE PRODUCT(S), WHETHER IN CONTRACT OR IN TORT OR UNDER ANY OTHER

LEGAL THEORY, AND WHETHER ARISING OUT OF WARRANTIES, REPRESENTATIONS,

INSTRUCTIONS, INSTALLATIONS OR DEFECTS FROM ANY CAUSE. Company and its suppliers shall have

obligation as to any product which has been improperly stored and handled, or which has not been operated

no

maintained according to instructions in Company or supplier furnished manuals.

or

5

Page 6

6

Introduction

This manual assumes that the reader has used and

understands basic Internet browser operation and

has used a Microsoft© Windows Operating System

GUI (Graphical User Interface), such as Windows

2000©, Windows NT©, Windows ME©, or Windows

XP©. This device uses Windows CE-as an

operating system (OS). Windows CE© is a

component-based version of the Windows

operating system designed for embedded devices,

such as PDAs or touch-panel displays.

This manual also assumes the user has some basic

knowledge of pumps and pumping systems.

Note: Button names are shown enclosed in square

brackets, such as [Button], whenever the actual key

or button graphic is not displayed.

The interface is displayed at the pumping station on

the HMI. Users make selections of the options and

enter data using a stylus or hands, and tapping

directly on the HMI’s color, touch-screen panel.

CAUTION: Equipment Damage Hazard

Only use a stylus or clean hands on the HMI

touch-panel device to access screens and

enter data. Use of any other tool, sharp object,

or contact with dirt or chemicals can cause

damage to the screen.

Failure to follow these instructions indicates a

potentially hazardous situation, which, if not

avoided, may result in equipment damage and

void any warranty.

CAUTION: Equipment Damage Hazard

To Clean the equipment:

Disconnect the equipment from any AC outlet,

use a clean damp cloth. Do not use liquid or

spray detergents for cleaning.

Failure to follow these instructions indicates a

potentially hazardous situation, which, if not

avoided, may result in equipment damage and

void any warranty.

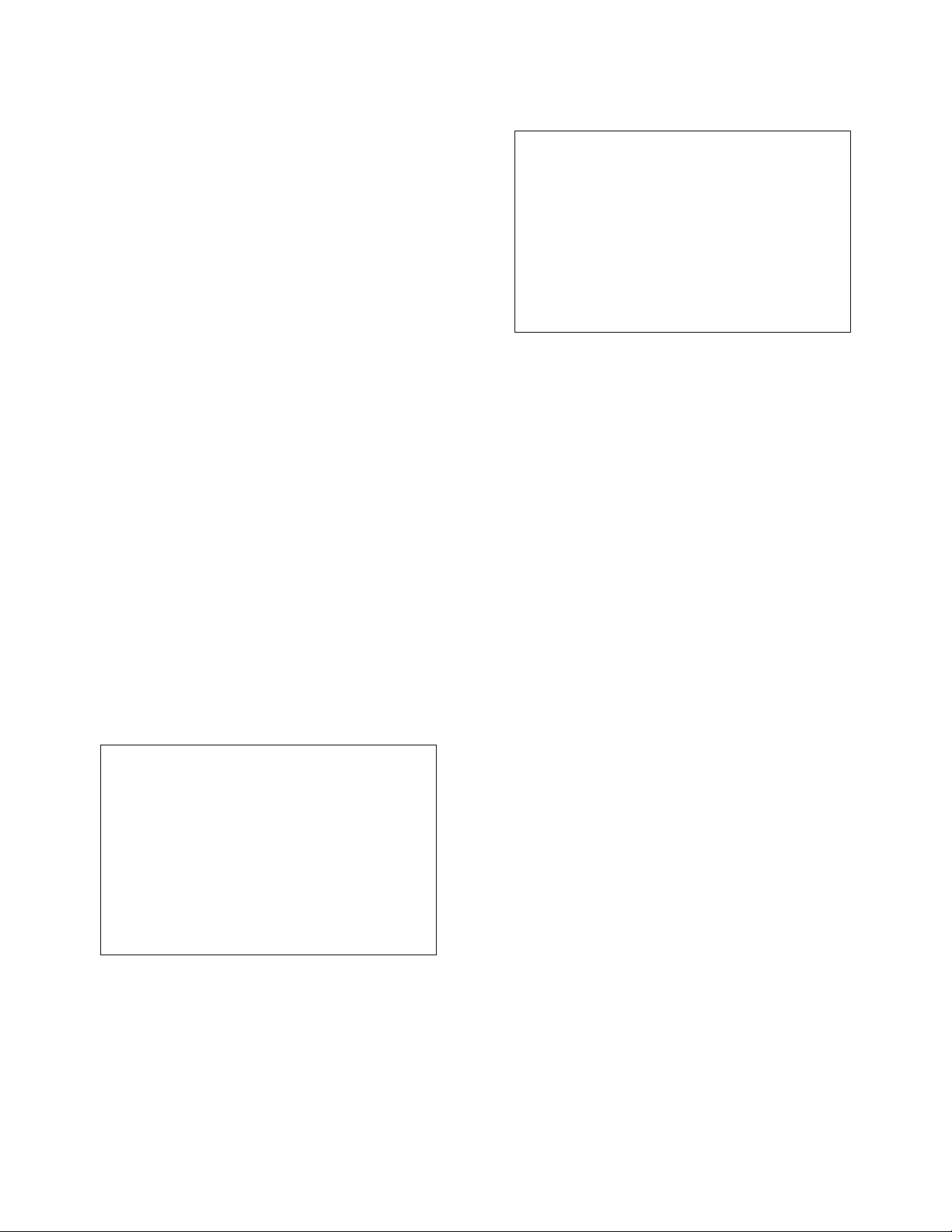

HMI Overview

A web-based version of the application is

operational on the HMI and permits the user to

supervise the pumping station’s operation remotely

at any time from any internet-accessible computer.

The web-based screens are identical to the screens

viewed on the HMI. Web Reports can also be

viewed and printed by users who access the HMI

interface via the internet.

Data and information is exchanged with the

pumping station’s master controller, also called a

Programmable Logic Controller (PLC), located

physically in the NEMA 4 enclosure. The

communication exchanges are made over Ethernet.

A primary PLC is responsible for the real-time

control of the main pumps, while additional PLC(s)

are used to control auxiliary items. The HMI

provides a graphical user interface (GUI) which

permits the pumping station to be monitored, and

allows the controls or variables to be changed when

necessary. All monitoring and control information

can be sent to the pumping station remotely over

the Internet using the web-based version. This

basic communication between the remote user, the

HMI, and the pumping station is illustrated below.

This manual is written for Flownet Technicians and

is an introduction to the Flowtronex PACE HMI

uman Machine Interface). The HMI is a browser-

(H

based system which allows the user to interact with

the settings and reports of the pumping system. This

manual only covers the HMI aspect of the system.

Please see the Silent Storm VFD Pumping System

nstruction Manual for any questions not related to

I

he HMI.

t

The Flowtronex PACE is a modular and scalable

architecture that is used by the HMI (Human

hine Interface) to control a station’s pumps. It

Mac

o handles a variety of changing conditions using a

als

touch

panel display including normal operation,

operation with a v

including lake fi

fertilization injection (fer

operation with timed water features.

ariety of auxiliary equipment

ll controls, boosters, filtration, and/or

tigation) equipment, and

Page 7

7

Figure 1: Basic Operation

TYPICAL PUMPING OPERATION

Several common control variables including flow,

pressure, and level are used for operating an

automatic pumping system. Pump starts and stops

are based on the changes in these control

variables. A VFD (Variable Frequency Drive) is

used to regulate the speed of the lead pump,

replacing the function of a control valve. Pressure

recovery can be made smoothly, resulting in power

and cost savings.

When pressure is used as the key process variable,

the VFD pumping system constantly monitors

pressure to maintain the required demand. Pump

starts and stops are based on the changes in the

system pressure. For example, a pumping system

with one Pressure Maintenance (PM) pump and two

interchangeable main pumps may be grouped into

several different combos (combination of pumps)

that start or stop a specific pump, or a sequence of

pumps, according to defined setpoints.

Each combo has an individual start pressure that

references a setpoint pressure and a start delay

time. At very low demand, the PM pump maintains

the setpoint pressure. Once the demand becomes

greater than the PM pump can handle, the first

combo is activated. The lead pump in this combo is

controlled by the VFD. As demand increases,

additional lag pumps are added, or a different

combination of pumps is activated.

Other configurations are also possible. Consult your

Flownet Technician for proper operation of your

system.

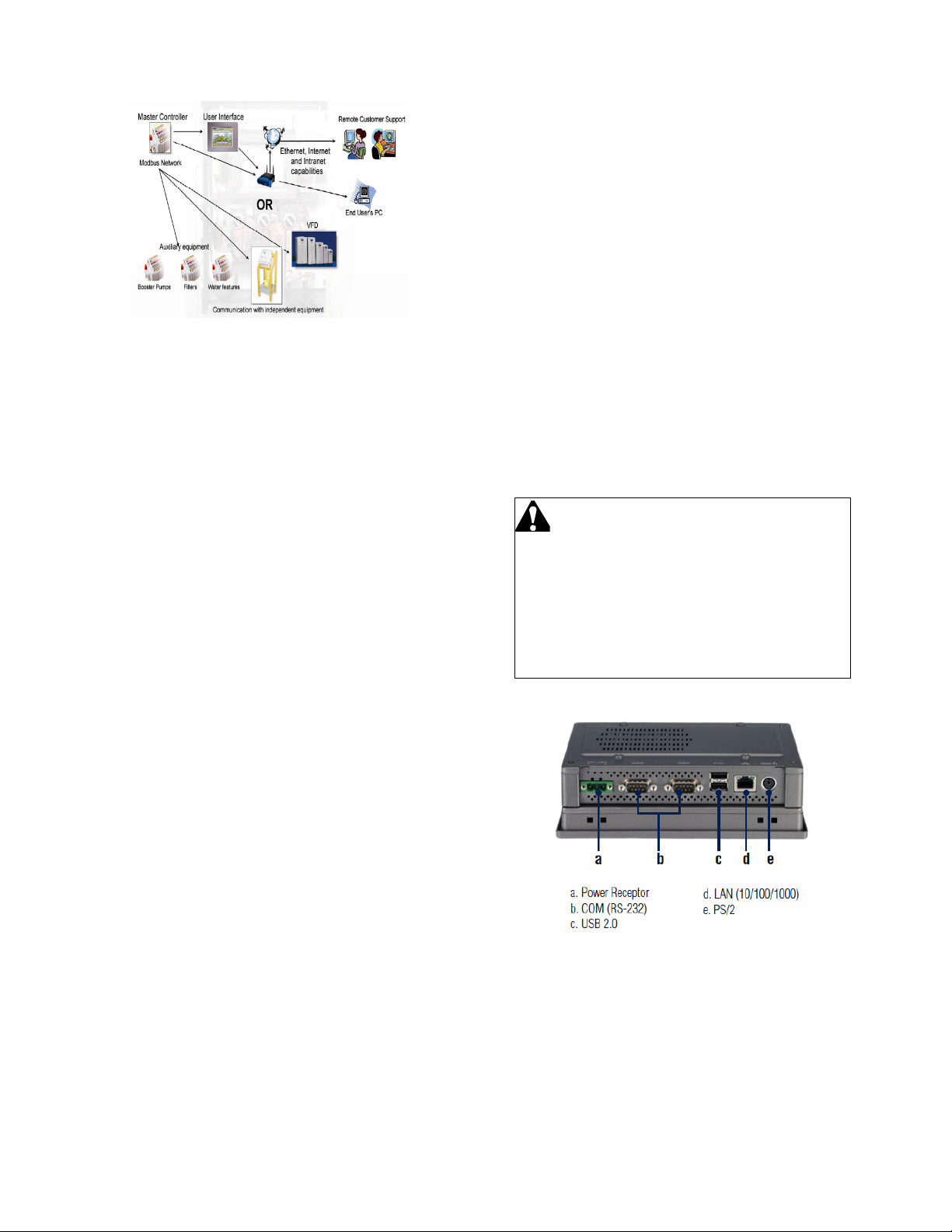

Touch-Screen Panel Operation

This Flowtronex® Pace HMI device manual

describes the operation of the touch-panel display,

located on the enclosure door of the control unit of

the pumping station.

• Use a stylus to tap the buttons or fields

when using the touch-screen panel.

• Use the Enhanced Key Pad to enter

text or numbers in blank fields. Tap

and hold the stylus in a blank field to

open the Enhanced Key Pad pop up

screen.

• A USB Keyboard may also be used

instead of the Enhanced Key Pad.

Plug in the USB Keyboard into the

back of the display.

•

Danger: Electric Shock Hazard

Disconnect power before opening any

electrical enclosure. Any procedure requiring

opening an electrical enclosure must be

performed by qualified personnel only.

Failure to follow this guideline could result in

injury or death.

Figure 2: Connection for USB Keyboard (c).

Page 8

8

ENHANCED KEY PAD

Tap and hold the stylus in an editable field

(indicated by a white background) to open the

Enhanced Key Pad.

To use an Enhanced Keypad:

• To clear an entry, tap

to

backspace over entry.

• To close key pad without saving

entries, tap the red

on the key

pad.

• To switch between various alphabetic

and numeric key pads, tap

or

• To submit an entry tap

Figure 3: Enhanced Key Pad

Basic Screen Layout

The application uses a three-part structure for all

screens:

1. The Navigation Bar, located on the far left of

the screen, displays buttons to tap which will

navigate to other key areas of the application. The

content of the navigation bar changes depending on

what type of user is logged in.

2. The Header, located at the top center of the

screen, displays the screen name in the banner,

and (depending on the buttons selected on the

right) the date and time, or the pumping station’s

current flow and pressure readings.

NOTE: A flashing header is indicative of a system

fault.

3. The Main Window, located in the center of the

screen, displays one or more panes of information

about the pumping station. A grayed-out field in this

window is read-only. Other fields (with a few

exceptions) may be edited.

Figure 4: Basic Screen Layout

User Types

There are different types of users recognized by the

system:

Guest: Only operation screens are accessible in

view-only mode. Users are logged in as a Guest by

default.

Supervisor: End-User configurable setup and

operation screens are accessible. Supervisors must

log-in using a password.

Technician: All setup and operation screens are

accessible. Technicians must log-in using a

password. See the Technician Guide for additional

functions.

Note: Some values require you to set the “Enable

Edit” checkbox before you can change the values.

This is a precautionary measure intended to

prevent unwanted and accidental register value

writes. These values are available to technicians

only. Values normally accessed at the Supervisor

level or lower are not affected.

Touch Panel Log In

Tap [Log In] from the Home Screen.

The screen displays the current user type at the top

of the screen.

Page 9

9

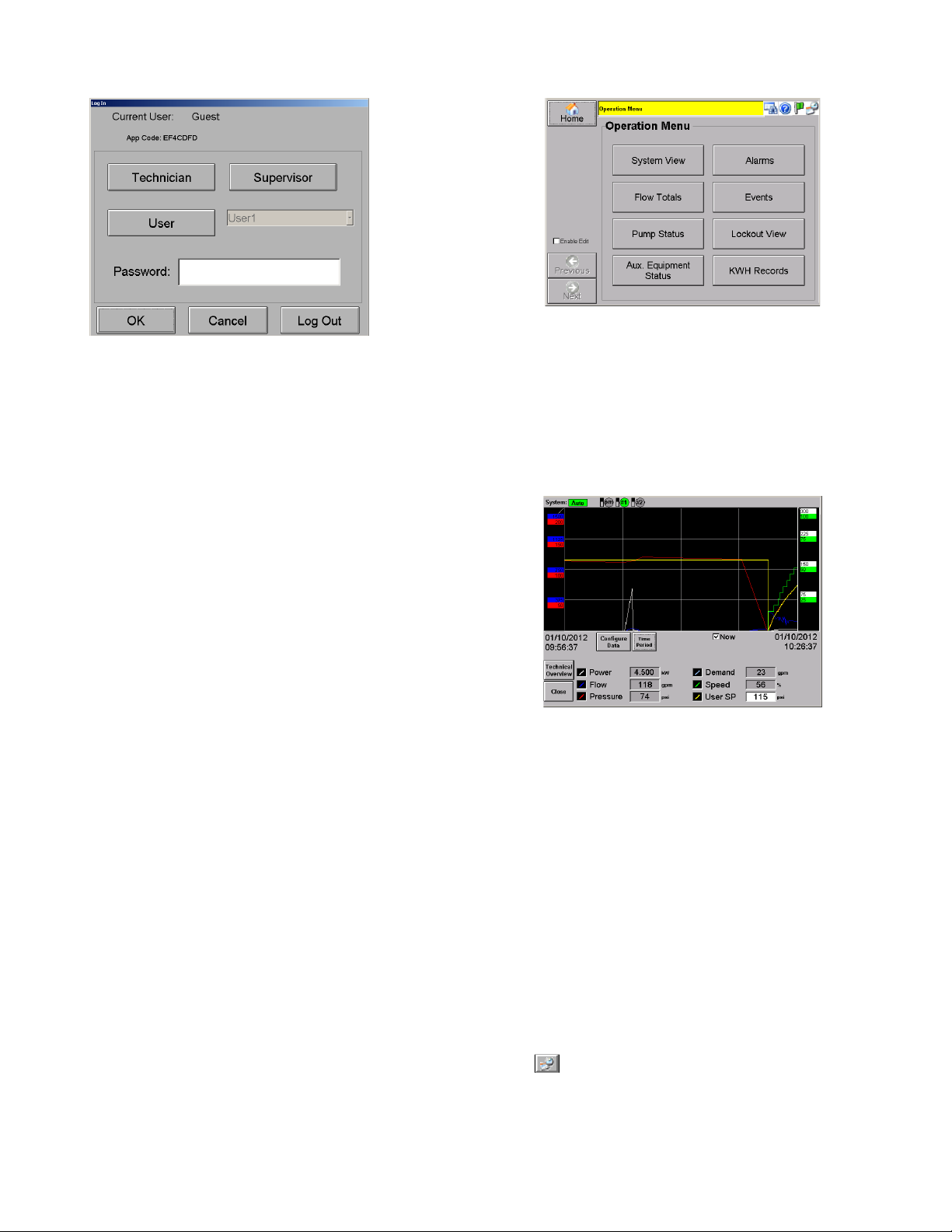

Figure 5: Log in Screen

Default user is a Guest user. No log in is required.

To log in as a Technician, tap [Technician], and

then tap on the empty Password field to enter the

Technician password. Tap [OK] to log in or [Cancel]

to exit without logging in.

To obtain a Technician password, call Flowtronex

customer service and give them the APP code

displayed on the screen. Customer Service will then

give you a password corresponding to that APP

code which will remain active until the last day of

the current month.

After a password has expired, a new APP code

must be generated allowing you to get a new

password. See Security Setup for information on

how to generate an APP code.

NOTE: The web-based screens require an

immediate log-in as either a guest (no username or

password required), a Supervisor (username and

password are required) or a Technician (username

and password are required). The log-in screen will

be displayed first on the web-based application

only.

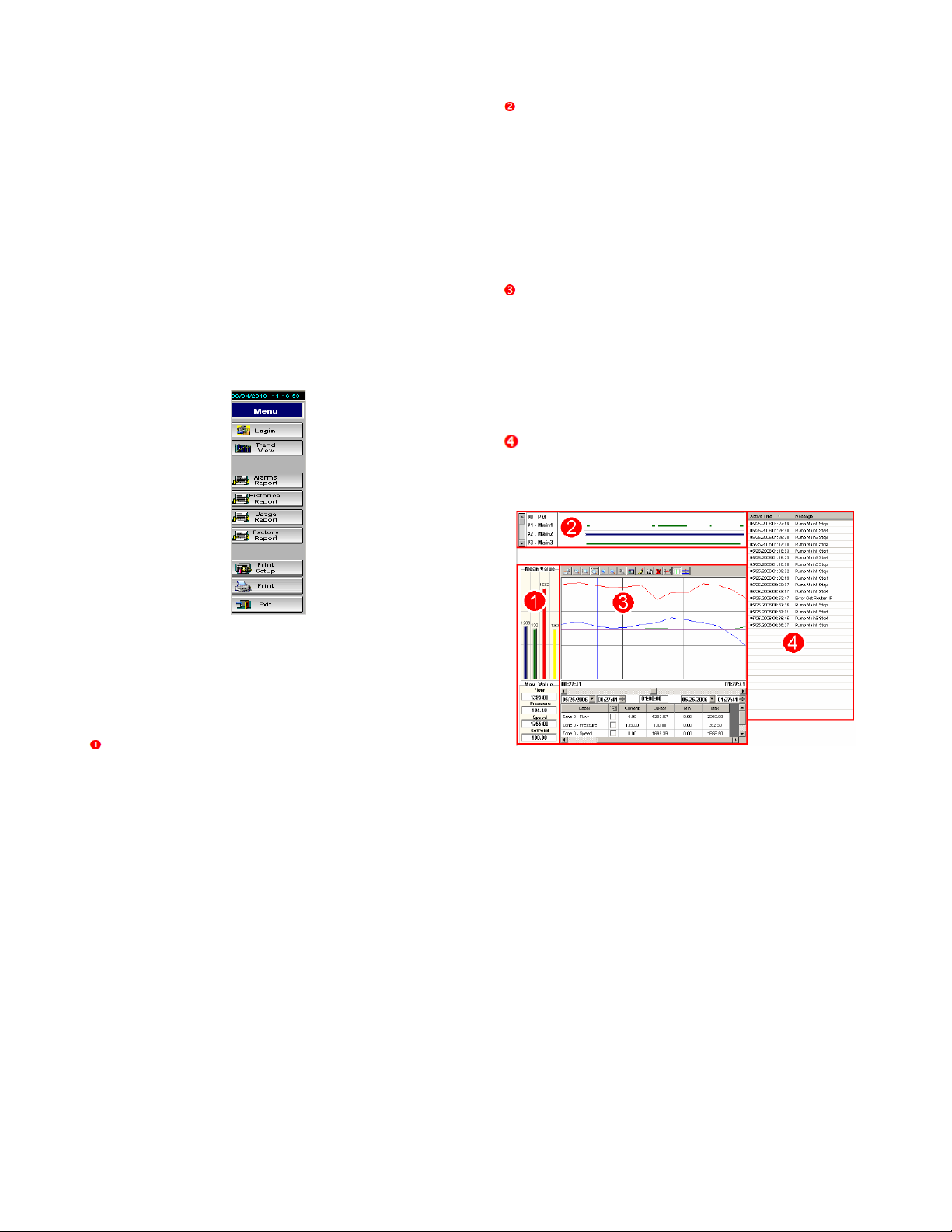

Operation Menu

Tap [Operation] from the Home screen.

The Operation Menu allows you to view the

pumping station’s operational trends (System

View), flow totals, pump and auxiliary equipment

status, alarms, events, lockouts, and power

consumption (KW Data).

Figure 6: Operation Menu

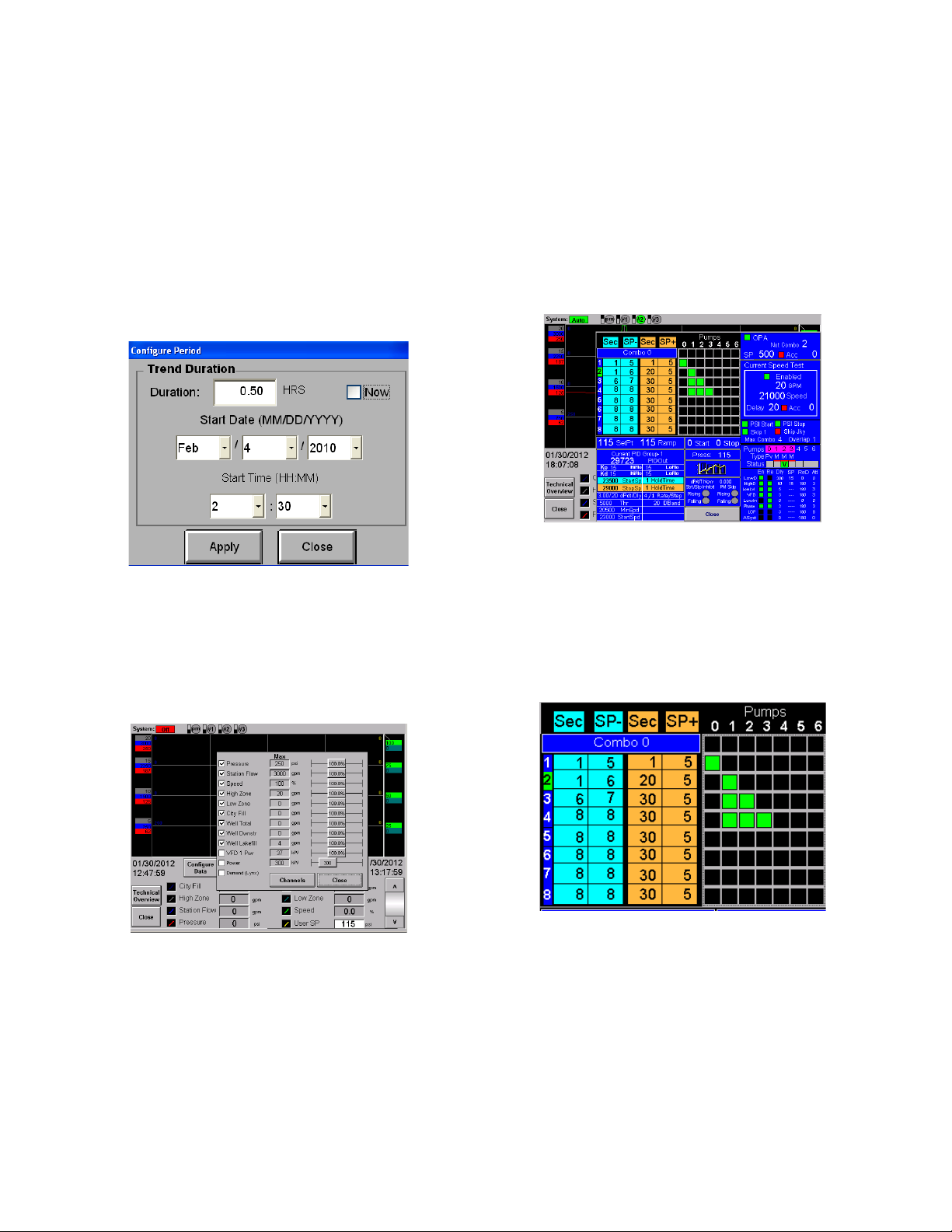

SYSTEM VIEW & TRENDS

Tap [System View] from the Operation menu.

System View accesses color-coded operational

trends or historical data for several system

variables such as flow, pressure, speed, and

setpoint.

Figure 7: Trends Screen

In the System View screen, a supervisor can

change the setpoint using the User SP field.

You can turn on and off logged channels on the

viewer by tapping the value at the bottom of the

screen.

Power readings may not be available on all

systems. Also on some systems a power reading of

0 will cause the Power display to disappear, and will

reappear when power readings return.

Demand is a function specific to interaction with

Lynx irrigation control systems and will only display

when this data is available from Lynx.

Configure Period Screen

Tap

from the System View menu.

The Configure Period screen allows you to set a

date and duration for viewing system information.

Page 10

10

The trends will be shown for the Duration value,

ending at the current time. When ‘Now’ is checked,

the system defaults to the current date and time.

If ‘Now’ has been checked, ‘Duration’ is the only

editable field.

For viewing historical data, uncheck ‘Now’.

Enter the start date and time, along with duration to

view data for desired time. Tap [Apply] to apply

changes or [Close] to cancel any changes.

NOTE: If ‘Now’ is left unchecked, the system does

not default back to the current date and time.

Figure 8: Configure Period

The trends graph may be enlarged for a better view

by tapping on it.

Configuring the Data Shown on the Screen

In technician mode, you can change the data the

screen shows. Click on “Configure Data”.

Figure 9: Configure Data

Check the box next to the data you want to show.

Not all data is available for all systems. Use the

slider bar on the right to adjust the graph scaling to

a value that makes it most comfortable to read.

100% means the graph scale is the same as the

analog scaling max value. 110% means the graph

scaling is 110% of the analog max scaling for the

channel. The exception here is the KW reading,

which is an absolute number because KW is read

directly, rather than scaled.

Click “Channels” to access the calibration screen

directly from the “Configure Data” screen.

This screen is accessible also from “Setup”>”Options Setup” and is discussed in detail in that

section.

Click “Technical Overview” to access details of

system operation. This is also accessible from the

“Green Flag” button on the header of other screens.

Figure 10: Technical Overview

This screen shows an overview of the configuration

of the station. Most data that is necessary for

tuning is shown, and the settings page for the

information can be accessed by touching the value.

For technicians, the fields available on this screen

should be fairly self-explanatory. However, some

fields can use some clarification:

Figure 11: Combo Information

This field shows, from left to right, the current

combo (highlighted), start time, psi below setpoint,

stop time and psi above setpoint to stop, for each

combo. To the right is a table detailing the pumps

to run in each combo. The example above shows

combo 1 consists of the PM Pump, Combo 2

consists of pump 1 (or any other single pump in the

same group), combo 3 is two main pumps, and

combo 3 is 3 main pumps.

Page 11

11

Figure 12: Combo Information

This shows the Overpressure accumulator settings.

“Not Combo” indicates that OPA will operate at any

combo level above 2. “Factor”

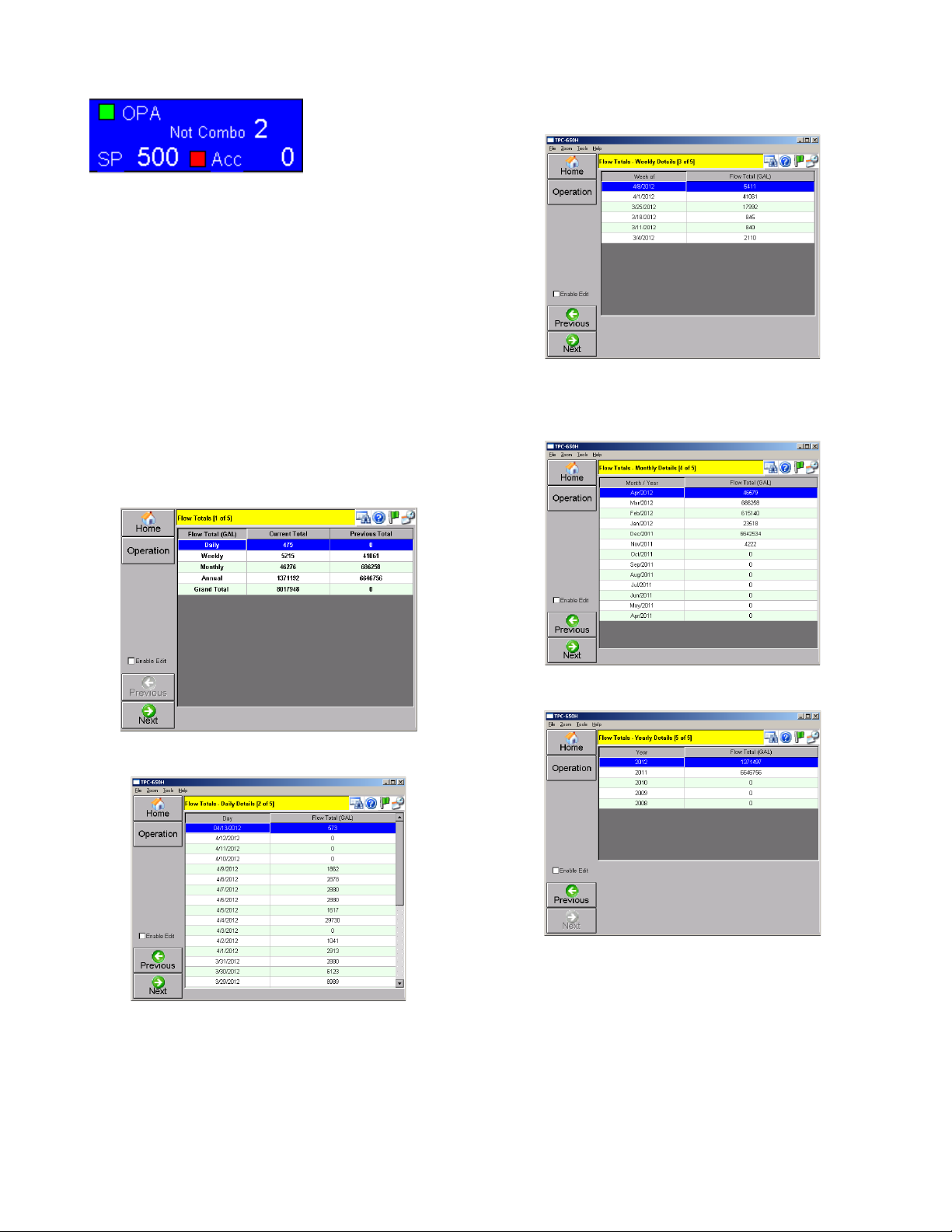

FLOW TOTALS

Tap [Flow Totals] from the Operation menu.

The totalized values (in GAL) for the daily, weekly,

monthly, and yearly flow are displayed in a tabular

format.

Tap [Next] to successively view the totals for each

day, week, month and year. Use the scroll bar to

move up and down or left and right.

Figure 13: Flow Totals, Overview

Figure 14: Flow Totals, Daily Flows

Figure 15: Flow Totals, Weekly Flows

Figure 16: Flow Totals Monthly Flows

Figure 17: Flow Totals, Yearly Flows

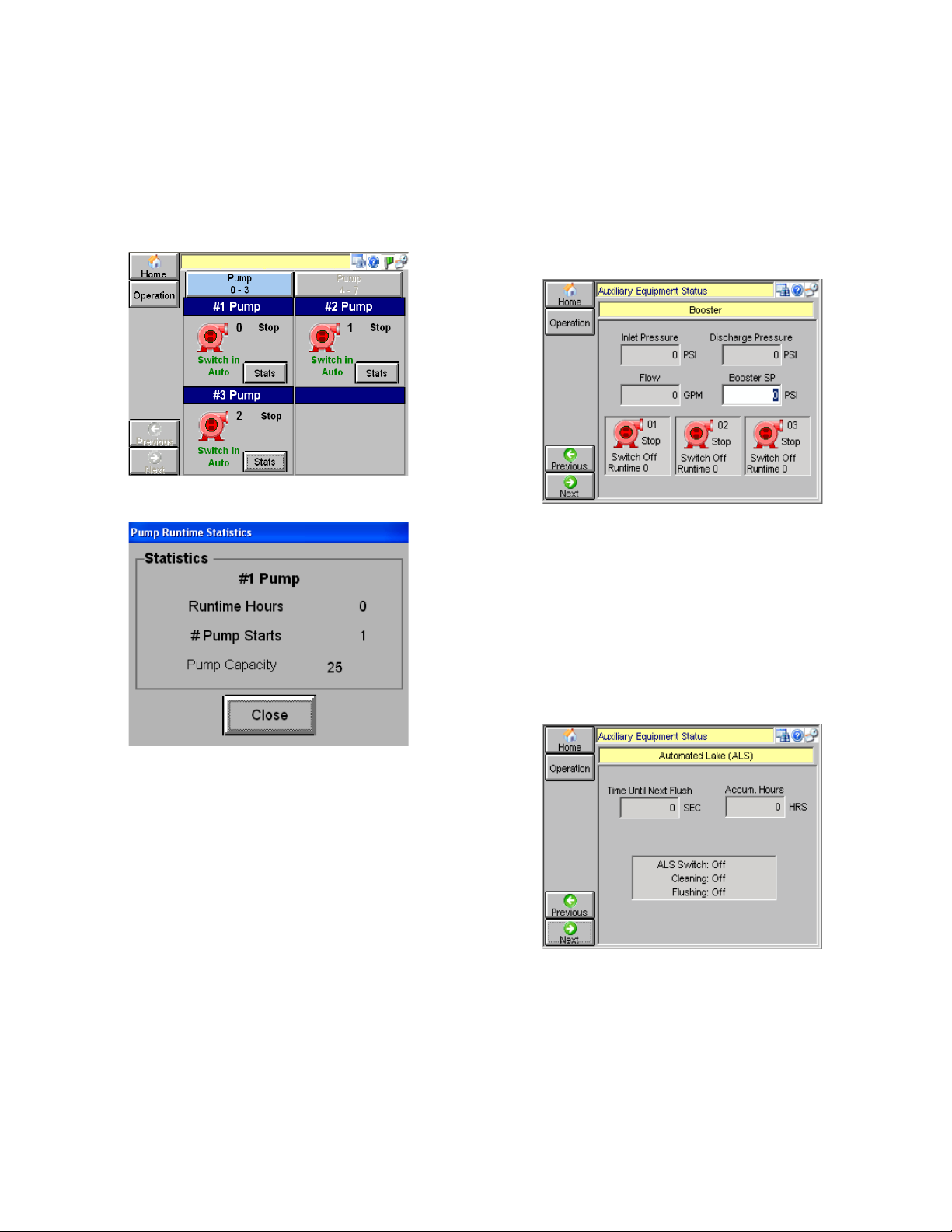

PUMP STATUS

Tap [Pump Status] from the Operation menu.

This screen displays an animated graphical display

of all the pumps in the system (up to eight pumps).

Page 12

12

Red, no animation: Stopped pump

Green, rotating center: Running pump

Yellow, flashing center: Fault condition

Individual pump stats (runtime hours, number of

starts, and pump capacity in GPM) can be viewed

by tapping [Stats] for each pump.

Figure 18: Animated Pump Status

Figure 19: Individual Pump Stats

AUXILIARY EQUIPMENT STATUS

Tap [Aux. Equipment Status] from the Operation

menu.

By tapping [Previous] or [Next], you can navigate

the status screens for each device that has been

set up.

NOTE: The screens described below will only be

displayed if they are applicable to the current

system.

Booster Pumps:

Booster Pumps are typically custom features and

the interface depends greatly on the specific site.

However some basic functionality is provided.

Booster pumps typically require an auxiliary PLC.

Up to three booster pumps may be monitored

simultaneously. All fields are read-only with the

exception of ‘Booster SP’. This pressure (PSI) value

remains same for all installed boosters, and is

generally higher than user defined SP.

Red, no animation: Stopped

Green, rotating center: Running

Yellow, flashing center: Fault condition

Tap [Next] to move to the next status screen.

Figure 20: Booster Monitoring Screen

Automated Lake (ALS) Monitoring Screen

This screen is used to monitor the Automated Lake

Screen. ‘Accum Hours’ is the total accumulated

time ALS has been running for. ‘ALS Switch’

denotes the position of ALS switch on the

enclosure. ‘Cleaning’ and ‘Flushing’ denote

if the respective cycles are on or off.

Tap [Next] to move to the next status screen.

Figure 21: ALS Monitoring Screen

Lake Level Controls Monitoring Screen

A maximum of eight lake level controls can be

monitored/configured on this screen. Supervisor

access or higher is required to configure, but guest

level access can view the settings and status

information.

Page 13

13

The Lake Level Control screen shows the pump

number, whether the pump is currently on or off, if

the enclosure switch is set to on or off, and also

gives a pump’s runtime total in hours. If a well pump

is used, the well level is shown in feet in a read-only

field.

Tap [Next] to move to the next status screen.

Lake Level/Transfer/Timed Pump Monitoring

Screen:

Figure 22: Lake Level Controls Monitoring

Screen

This screen allows you to see the status of the Lake

Level/Timed pump control system at a glance.

Pump status (Off, Run, Fault), switch status

(On/Off), Level settings can be viewed/adjusted

(When logged in as Admin, Technician, or

Supervisor only), pump hours can be monitored,

Start/Duration times for timed pumps can be

monitored, lake levels and/or probe status (as

equipped).

Timed Pump Monitoring Screen (Non-Integrated

Only)

Currently, only one timed pump can be set up and

monitored on the Timed Pumps screen. The screen

is read only, and gives the pump number, status,

and the total run time in hours.

Red, no animation: Stopped

Green, rotating center: Running

Yellow, flashing center: Fault condition

Select [Next] to move to the next status screen.

Figure 23: Timed Pump Monitoring Screen

Simple Filters Monitoring Screen

Simple filters include Wye strainers and other filters

controlled by a simple on-off flush signal. This

screen will monitor all installed filters. ∆P denotes

differential pressure.

Red, no animation: Stopped

Green, rotating center: Running

Yellow, flashing center: Fault condition

A green colored graphic denotes that the filter is

flushing.

Other information displayed includes filter number,

run time (in hours), and whether the enclosure

switch is set to on or off.

Tap [Next] to move to the next status screen.

Figure 24: Simple Filters Monitoring Screen

Scanner Filters Monitoring Screen

The scanner filter monitoring screen shows the

status of a single filter with up to eight chambers.

The inset box shows if the flush cycle is on or off, if

the enclosure filter switch is set to on or off, if ΔP is

bypassed, and if a filter faults, ‘Fault’ blinks as a

notification. Text showing that ΔP is present or

absent is displayed below the box.

Page 14

14

Red, no animation: Stopped

Green, rotating center: Running

Yellow, flashing center: Fault condition

Tap [Next] to move to the next status screen.

Figure 25: Scanner Filter Monitoring Screen

Solid Separators Monitoring Screen

This screen shows the status information for up to

five installed filters. The Solid Separators Status

icon also shows the filter number, the status,

whether the enclosure switch (Switch) is set to on

or off, if the Flushing switch is set to on or off, the

time until the next flush is shown in seconds (‘Til

Flush), and filter Runtime is displayed in hours

(Runtime).

Red, no animation: Stopped

Green, rotating center: Running

Yellow, flashing center: Fault condition

Tap [Next] to move to the next status screen.

Figure 26: Solid Filter Monitoring Screen

ALARMS

Tap [Alarms] from the Operations menu.

The alarms screen shows all current and

unacknowledged alarm events. Use the vertical

scroll bar to view all alarm events if necessary.

The latest alarm flashes in the banner at the top of

the screen till it is acknowledged using [Ack All].

NOTE: Be sure to scroll to the bottom of the alarm

events list before using [Ack All] to ensure that all

alarms have been viewed.

Alarm notifications are color coded.

Red: Active, Unacknowledged Alarm

Green: Active, Acknowledged Alarm

Blue: Inactive, Unacknowledged Alarm

To view alarm events from the past, from the drop

down menu at bottom left, select ‘History’. Tap

[Period], and enter the start and end dates in a pop

up screen. Tap [Apply] to save changes or [Close]

to cancel.

Figure 27: Alarms Screen

EVENTS

Tap [Events] from the Operation menu.

This screen shows system events for current day,

date & time, and a short message about the event.

To view past events, tap [Period] and specify the

start and end date to view the events.

More events may be viewed using the vertical scroll

bar.

Page 15

15

Figure 28: Events Screen

LOCKOUT VIEW

Tap [Lockout View] from the Operations menu.

Lockouts are common when water usage and

power restrictions limit pump usage to a certain

time.

Different lockouts may be viewed using the

numbered tabs at top. The Day selected, the Start

Time, the Duration, the Combo number selected,

the Combo SP (combo setpoint), and the pump

Speed are shown.

Figure 29: Lockout View Screen

KWH RECORDS

Tap [KWH Records] from Operations menu.

The KWH Records are similar to the Totalizers and

record power usage.

NOTE: The data on this screen is available only

when used with Toro™ or Lynx™ irrigation control

systems and/or KW Measurement hardware is

installed.

Figure 30: KWH Records, Overview

Figure 31: KWH Records, Daily Usage

Figure 32: KWH Records, Weekly Usage

Page 16

16

Figure 33: KWH Records, Monthly Usage

Figure 34: KWH Records, Yearly Usage

Note: KHW Metering and records are subject to

calibration and will only monitor the loads

connected to the measurement equipment,

primarily irrigation pumps. The records are intended

as a reference to plan irrigation for maximum

efficiency and are not to be used as a custody

transfer or billing meter.

Setup Menu

Tap [Setup] from the Home screen.

The Setup menu is available for Supervisor use

only.

CAUTION:

Changing the settings in the Setup Menu will

affect the functionality of the system. It is

advisable to record any current settings before

making changes.

Figure 35: Setup Menu

USER SETUP

Tap [User Setup] from the setup menu.

This menu allows a supervisor to set the date/time,

language, colors, and units. A lamp test to check all

lamps on the control panel may also be performed.

Figure 36: User Setup Menu

NOTE: The [Set Language/Colors] and [Set Units]

menu selections are not currently available.

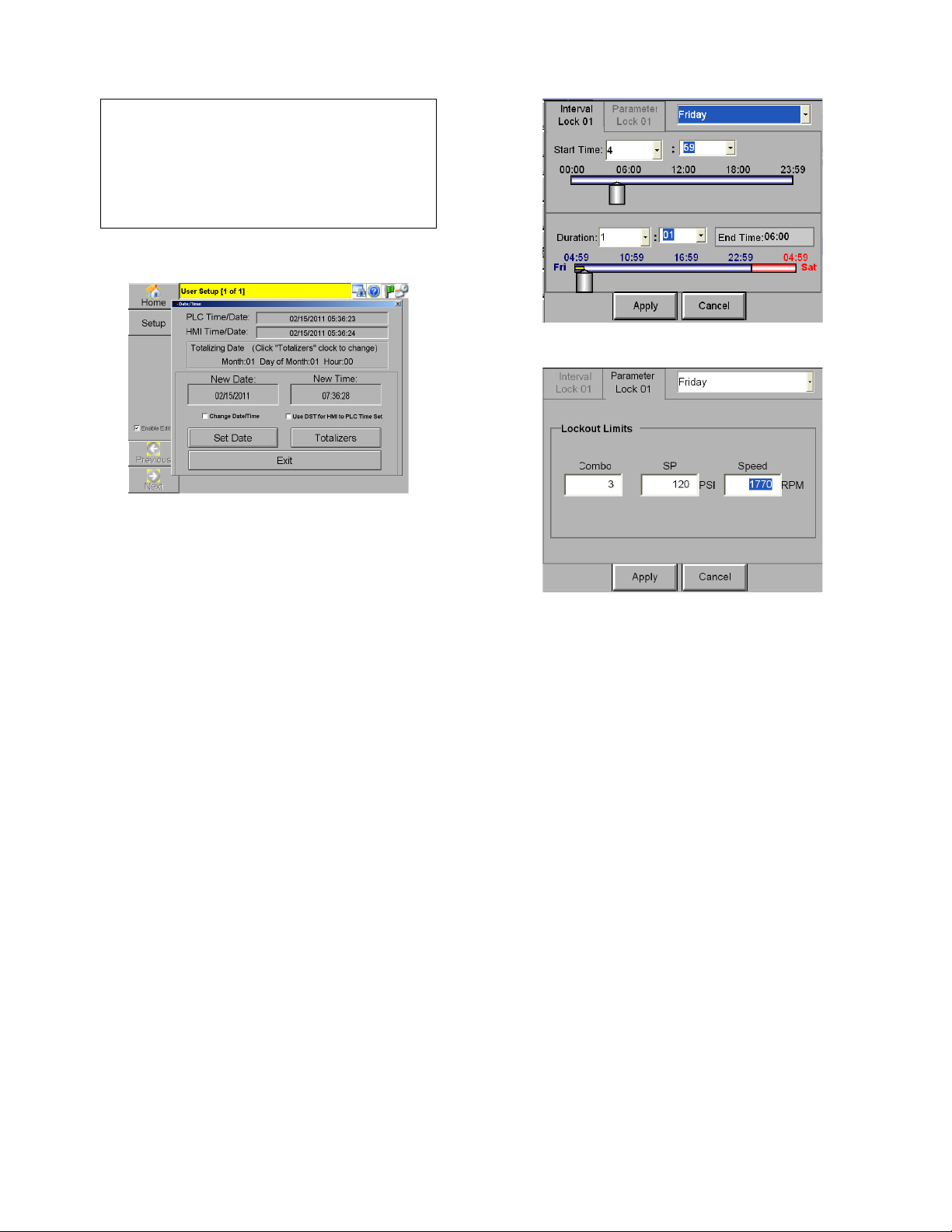

Set/Sync HMI-PLC Date/Time

Tap [Set/Sync HMI-PLC Date/Time] from the User

Setup menu.

This screen allows the date and time to be set, and

synchronized for the PLC and HMI. Tap

[Synchronize] to synchronize HMI & PLC date and

time.

In a new pop up screen, enter the date and time.

Tap [Set Date/Time – Close] to save changes. Tap

[Clear Totalizers] to clear all totalizers.

Note that when the HMI time is set, the HMI will

automatically sync the PLC time once/day.

Page 17

17

CAUTION:

Synchronization should not be done while

using the Internet-based remote client as this

has the potential to negatively affect the time

settings of the system. Syncing should only be

performed locally.

Figure 37: Set/Sync HMI-PLC Date/Time

Lamp Test

Tap [Lamp Test] from the User Setup menu.

Holding this button for 3 seconds causes all lights

on the control panel to light up briefly. Any bulb that

does not light up should be replaced.

LOCKOUT SETUP

Tap [Lockout Setup] from the Setup Menu.

Lockout setup is similar in appearance to the

Lockout View accessible in the Operation menu.

Individual lockouts may be setup by tapping over

each lockout inset. Tapping any inset opens a

configuration window. The day, start time, and

duration may be entered in the interval tab at the

top. In the parameter tab, the combo number,

setpoint, and speed can be entered. Tap [Apply] to

save settings or [Close] to discard any changes.

An individual lockout setup screen is shown below.

Figure 38: Individual Lockout Setup

Figure 39: Parameter Tab in Lockout Setup

The screen shown in Figure 38 sets up a lockout for

Friday beginning at 4:59 AM. The duration is set to

be 1 hour and 1 minute. Thus this lockout will end

at 6:00 AM on Friday. The animated display gives

an indication about time. The Parameter tab

enables a user to define Combo number, maximum

pressure, and maximum speed in RPM.

SECURITY SETUP

Tap [Security Setup] from the Setup Menu.

The Supervisor can change the password assigned

to him/her, and set the number of days after which

the password expires (in the editable field). To

change the password, tap [Change Password] to

change the supervisor password. Enter the new

password in the ‘Password’ and ‘Confirm Password’

field. Tap [Apply] to save changes.

NOTE: Tap [Generate App Code] if your current

Technician password has expired. Use this App

code when calling customer service to obtain a new

password. The [Generate App Code] button is

available to any user without a password.

Page 18

18

Figure 40: Security Setup

SYSTEM SETUP

Tap [System Setup] from the Setup Menu.

A statement will appear warning you that changing

system settings could affect the functionality of the

entire system. You must accept this to proceed.

You can navigate the status screens for each

device that has been set up by tapping [Previous]

or [Next].

NOTE: The screens described below will only be

displayed if they are applicable to the current

system.

Job Information

Enter the job information such as ‘Job Number’,

‘Job Name’, ‘Main PLC IP (usually 192.168.1.10),

and ‘Phone Number’. Notice that the fields ‘HMI

Version’ and ‘PLC Version’ have been grayed out,

and are not editable.

Tap [Next] to move to the next System Setup

screen.

Figure 41: Job Information

Basic Pump Information

The number of pumps can be selected from a drop

down menu. Each pump can be assigned a name in

the editable fields at the bottom of the screen.

Tap [Next] to move to the next System Setup

screen.

Figure 42: Basic Pump Information

Zone Configuration

The number of flow zones is adjusted here. Up to

7 zones can be selected. This controls how many

flow totalizers are operable. Each flow zone will

keep track of water usage by day, week, month

and year (5 years).

Figure 43: Zone Configuration

The name of the flow zone is set here. Also, the

flow channel that is totalized for each zone is

configured here. These channels match the flow

channels from calibration. In addition to picking a

single channel for a particular zone, multiple

channels can be added together to form a single

flow zone by selcting more than one “Zone” to

totalize. Well pump flows can also be selected for

flow zones and even added to irrigation channels as

required. Flow zones can also be subtracted from

the total by selecting a “Subtract Flows” channel.

This may be required when a meter reads flows

going to more than one zone, and one of these

subsequent zones is metered separately.

Flow filtering is setup here as well. By selecting

“Disable Flow Reading if No Pump Running” for a

channel, that flow reading will be zero’ out when no

pump is running. This is in case the system picks

Page 19

19

up fluctuations that cause the meter to generate

undesirable small flows when the pumps are not

running.

Pump Configuration

Each pump can be selected from a drop down

menu in this screen. Each pump can be assigned a

group, type, and number of VFDs that are going to

be used. Also selections can be made regarding the

pump being a XL, VFD, HPT, HSS, or Only pump

for this VFD.

Enter the minimum run time, Spindown Time, Pump

Capacity, Feedback Delay for each pump.

Tap [Next] to move to the next System Setup

screen.

Figure 44: Pump Configuration

After defining your contactor pump setup, a quick

start-stop on Test mode is recommended to verify

the settings are right. (Check XL or VFD contactors

and VFD relay per pump).

To run a Quick Start-Stop test, perform the

following:

Set all pump switches to OFF

Put the system switch into TEST mode.

For the pump being tested:

Turn ON the pump switch for 3-4 seconds to

verify proper setup.

The pump should run when switched to ON and

stop when switched to OFF.

The pump should not fault – which is indicated

by a flashing pump switch light.

Caution: Pressure surges

Care should be taken to isolate the irrigation

system from pressure surges during this test.

Tap [Next] to move to the next System Setup

screen.

Alarm Setup

This screen allows you to select various alarm

types from the drop down menu, and fill in the

required settings for each alarm.

Figure 45: Alarm Setup

Default settings (standard factory settings) can be

found in Appendix D.

Tap [Next] to move to the next System Setup

screen.

Combo Options

This screen allows you to checkmark various

combo options. ‘PSI Start Enable’ and ‘PSI stop

Enable’ are essential. Without these two, the station

will not start stop based on pressure indications. All

other check-marks are need based.

Figure 46: Combo Options

Logic flow enables you to select which zones are

used for flow shutoff. The zones are added

together to provide the flow to compare to the flow

shutoff setpoints.

This screen also contains the power monitor.

Page 20

20

This is the final System Setup Screen. Tap

[Previous] to move to the prior System Setup

screen or tap [Setup] to return to the menu.

FIELD SETUP

Tap [Field Setup] from the Setup menu.

Figure 47: PID Settings

After the pumping station is configured with initial

values at the factory, field technicians can use the

four Field Setup screens to tune or optimize the

station operation.

You can navigate the status screens for each

device that has been set up by tapping [Previous] or

[Next].

NOTE: The screens described below will only be

displayed if they are applicable to the current

system.

PID Tuning

All fields which have been grayed out are read only.

Figure 48: PID Settings

PID Group:

There are 5 PID sets available for use that are

chosen by which pump(s) are running on VFD.

Pumps using this PID Set:

The decision on which PID set to use is based on

the “best” fit of pumps running on VFD and the

pumps selected here.

Read:

Click “Read” to read the PID values from the PID

group set selected (this is automatically clicked for

you when you enter the screen).

Write:

Click “Write” to save the values to the PID group.

Copying PID data:

The Read/Write buttons are provided to allow the

technician to copy values from one PID group to the

other. To copy, select the PID group to copy from

and click “Read”, then select the PID group to copy

to and press “Write”.

Speed Test:

Speed test is a method to shut down the lead VFD.

When only 1 VFD is running. The PID value is

artificially reduced and the system is monitored for

PID response (pressure drop).

Speed Test shutdown is initiated when flow falls

below “Flow “ for “Delay” seconds.

“Speed” is the speed to which the PID must drop to

pass speed test and shut down the pump.

“Period” is the time between steps for the speed

test routine to lower the PID output, and “Step Size”

is the amout of PID drop per step.

If the speed test routine detects the PID ramping up

during the test, speed test will abort and operation

will return to normal until flow is again below the

“Flow” setpoint for “Delay” seconds.

Proportional and Derivative settings, high and

low flow:

Configuring the proportional and derivitave values is

essentially a trade-off. Both these values have an

impact on the system response. A high proportional

value causes the system to respond faster, thus

reaching the setpoint faster. At the same time, this

faster response means, that the system will easily

overshoot the desired setpoint. This can be

checked by lowering the proportional value, and

increasing the derivative (d-Term) value. The

integral value controls the sampling rate of the PID

loop. The derivative term controls the systems

Page 21

21

response to rapid changes in pressure, regardless

of the value of the pressure. This system uses this

to begin reducing VFD output speed when pressure

is rising quickly, helping to avoid overshoot. The

system can also detect fast pressure drops to begin

increasing VFD output speed before large errors

are detected, increasing the systems

responsiveness.

Good starting values are 25 for Kp and 12 for Kd.

Increase Kp when the system lags too long

changing the speed when pressure is away from

setpoint but relatively steady. Decrease Kp and

increase Kd to reduce overshoot. Decrease Kd

when the system becomes unsteady near setpoint

under steady demand. Generally speaking, only

use enough Kd to reduce overshoot.

Low and high flow settings:

The low flow and high flow settings are used

together to calculate the P and D terms at any given

time. The low flow settings are what the P and D

terms would be if flow were 0. The High Flow

settings are what the P and D terms would be if flow

were greater than or equal to “Max Flow for

Low/High Flow”. The value to use for each

parameter is calculated based on the flow at the

time.

Example: Low Flow Proportional is 10, and High

Flow Proportional is 20, “Max Flow for Low/High

Flow” is 2000. At 1000 gpm, the proportional value

will be calculated to be 15. At 1500 gpm, the

proportional value will be calculated to be 17.5.

Minimum Speed: This is the minimum speed that

the system will operate the VFD under PID control.

This speed should equal the minimum speed that

the pump will flow water at setpoint pressure.

Setting this value too high can cause

overpressurization at low demands, but having this

value too low can cause the PID to hunt since the

speeds below the “true” min speed are ineffective

and cause unnecessary delay in the PID when

operating in these speed ranges. Note that

allowances must be made for varying inlet pressure

and adjustable setpoints. Generally speaking, a low

Min speed is better than a too-high min speed, but

the closer to “true” min speed this is set, the better

the system will operate.

Control Deadband:

This value controls how far from setpoint the

pressure must be before the PID responds. The

units here are in 0.01 psi, so 25=0.25 psi (one

quarter-pound). This smooths the PID response

near setpoint and allows flow waves in the irrigation

to dissipate. However, to large a value here will

cause the system to delay response and could

cause the system to “get behind” in response to a

large change in demand.

Transition Control:

Starting Speed: Starting speed of the Main VFD

when the Main Pump first starts. Should be high

enough to “kick start” the pump since it is starting

under unsupplied demand, but care must be taken

not to force the system to overshoot under low

demand situations. Start the system with demand

just greater than the PM Pumps (or Jockey Pump,

as supplied) capacity and adjust for minimal

overshoot.

Combo Up (After XL Start): This setting controls

the speed the VFD running the main pump will be

forced to when a fixed speed lag pump starts. This

helps prevent overpressuring by reducing the

capacity of the VFD Pump, which is then being

provided by the fixed speed pump after it starts.

Generally set to 1/3 the value between min speed

and 32767. This speed will be held for “Hold Sec”,

which is generally set to 1 (may need to increase

for systems using soft-starters for fixed speed lag

pumps).

Combo Down (After XL Stop): This setting

controls the speed the VFD running the main pump

will be forced to when a fixed speed lag pump

stops. This helps replace the capacity provided by

the fixed speed pump and eliminate pressure dips

when these pumps are shut off. Generally set to

2/3 the value between min speed and 32767. This

speed will be held for “Hold Sec”, which is generally

set to 1.

Speed at 0 psi Startup: This setting controls the

speed the VFD of the Jockey OR main will start if

pressure is very low when the pump starts (see

deadband below). This setting should be adjusted

to be the point the pump just begins to flow water at

0 psi discharge. The actual starting speed will be

calculated between this speed and “Combo Down

(After XL Stop)” speed setting, depending on the

actual pressure at the time of start. A function is

used to calculate the speed between these points.

Threshold Deadband (psi): Determines the

pressure below setpoint to use the Threshold

function for determining starting speed. If set to

“20”, the threshold function is used to calculate

starting speed when pressure is equal to or less

than 20 psi below setpoint.

The VFD 1

st

start factor corresponds to the starting

speed of the first main or Jockey pump starting on

VFD. A high value causes the VFD to start running

at a higher speed, creating more pressure. This

Page 22

22

helps the system to reach the setpoint faster, but at

the same time the system may overshoot the

setpoint very quickly since the PID does not have

enough time to react to the fast occurring changes.

A very low value will make the system take a lot of

time to reach the setpoint.

The values shown in figure 34 below have been

determined from empirical tests, and can be used

as defaults, but each system needs to be tuned, as

pumps and systems are different.

Low Flow (Proportional & Integral) denotes the PID

sensitivity on the first start of the first main.

Tap [Next] to move to the next Field Setup screen.

Figure 49: OPA, Ramp Up and Dp/Dt control

OPA Enable

This is a method used to shut down lag pumps

operating across-the-line in a system that uses both

VFD and XL (across-the-line) pumps. Check this

box to enable.

The overpressure accumulator measures the

overpressure, and calculates a value to addd to the

Overpressure Accumulator depending on this error

on each program scan. The system will shut off a

lag pump when “Trip Preset” is reached.

Min combo: Combo # on which, OPA is not desired

because it is desired that the last pump stop in

speed test.

Ramp Up:

Step (psi): During ramp-up, the # of psi the system

will step up. See “Step (sec)”. Normally set to 1 psi.

Step (sec): During Ramp Up, the time between

ramping the setpoint. Normally set to 4 sec.

dP/dT Control:

Enable (Checkbox): Controls whether the “dP/dT”

pump start/stop control functionality is utilized.

Check to utilize the rate of pressure drop when

starting/stopping pumps.

Start/Stop Inhibit : The rate at which the system

will inhibit pump starts or stops as the pressure rise

or drops during the decision process. Generally

0.5-1.0 is adequate to reduce pump cycling.

PM Skip: Controls how much pressure drop will

cause the system to automatically skip the PM

Pump in the sequence. Fast pressure drop

indicates a large demand has suddenly been

applied to the irrigation system. This is used to

detect the need to skip the small pressure

maintenance pump so that the main pump can

meet this demand as quickly as possible, avoiding

unnecessary pressure dips. Start with values at 1.0

and monitor. To disable this feature but continue to

use the Start/Stop inhibit system above, set this

value to 10 or greater.

dP/dT Inhibit(sec): After the main pump stops,

systems will often experience short pressure dips

that may cause the PM Skip system to restart the

main pump. Set this value to 20 seconds to prevent

the PM Skip process from restarting the main pump

within this period of time.

Current dP/dT values are shown to assist in

tuning the dP/dT system.

Combos

This screen allows you to configure various options

in a combo.

Select the maximum number of combos (up to

eight). For Combo 0, which is the ‘no pump’ combo,

all values except Overlap gray out. A brief

description of all parameters follows.

1. Delay Timer:

Start: number of seconds the station delays before

the start of the specified combo, once ∆P has been

reached

Stop: number of seconds the station delays before

it stops the specified combo, once ∆P has been

exceeded.

2. Normal Differential:

System is not in ‘Bypass’ mode.

Start: Start a specified combo when the difference

between the actual pressure and user defined SP

exceeds this value.

Stop: Stop a specified combo when the difference

between the actual pressure and user defined SP

exceeds this value.

3. Bypass Differential:

System is in VFD Bypass mode. Enabling bypass

for a particular VFD causes all pumps using that

Page 23

23

VFD to go into “Bypass Mode” which means they

will operate as fixed-speed pumps.

Start: Start a specified combo when the difference

between the actual pressure and user defined SP

exceeds this value.

Stop: Stop a specified combo when the difference

between the actual pressure and user defined SP

exceeds this value.

Tap [Next] to move to the next Field Setup screen.

Figure 50: Combos

Combo Pumps

This screen allows you to configure which pump will

be used in which combo.

Tap [Next] to move to the next Field Setup screen.

Figure 51: Combo Pumps

AUXILIARY SETUP

Tap [Auxiliary Setup] from the Setup menu.

These screens allow you to setup and configure

any auxiliary equipment. Check any auxiliary

equipment that needs to be set up.

Each enabled item requires an IP address to

communicate to the PLC using the Modbus

protocol, which can be entered by double clicking

on the IP address field.

Default IP addresses can be found in Appendix E.

Note: Pace 5.0+ supports integrated auximilary

equipment. Setting the IP address of the auxiliary

equipment to the same as the main PLC enables

the integrated auxiliary device.

Page 24

24

You can navigate the status screens for each

device that has been set up by tapping [Previous] or

[Next].

NOTE: The screens described below will only be

displayed if they are applicable to the current

system.

Figure 52: Auxiliary Equipment Setup

Note: Timed Pump operation is included in Lake

Level control operation if using and integrated

controller (included in main PLC).

Booster Setup

The terms in this menu are described below:

Stop Pressure: If pressure rises above this value,

system stops.

Low Inlet Pressure: If inlet pressure falls below

this value, a Low Inlet fault is activated.

Low Dschrg Pressure: If pressure falls below this

value, a Low Discharge fault is activated.

High Dschrg Pressure: If pressure rises above this

value, a High Discharge fault is activated.

Pressure SP: User defined pressure maintained for

the booster.

Tap [Pump Config] to enter configurations for each

of the booster pumps in a popover screen. Up to 3

pumps may be configured.

Tap [Time Delay] to enter time delays in a popover

screen.

Tap [Next] to move to the next Auxiliary Setup

screen.

Figure 53: Booster Setup

ALS Setup

In this screen, Flush Times and Flow Rates may be

edited.

Time until Flush (sec): Time period between

flushes.

Duration of Flush (sec): Time duration for the

flush.

Flow Start Cleaning (GPM): Flow rate when flush

starts.

Flow Stop Cleaning (GPM): Flow rate when flush

stops.

Tap [Next] to move to the next Auxiliary Setup

screen

Figure 54: ALS Setup

Lake Level Controls Setup

This screen allows you to configure all aspects of

Lake fill, transfer pump and timed pump operation

when using an integrated lake level control system.

Page 25

25

Figure 55: Lake Level Controls Setup

Up to 8 Well/Transfer/Timed pumps can be

controlled when using the integrated system. Set

the IP address of the lake Level Controls auxiliary

equipment to match the main PLC to enable the

integrated controls (Note: The IO mapping must be

configured for the Lakefill/Transfer/Timed pumps to

use the integrated system, consult the factory when

adding equipment to 5.0+ Pace systems).

The master Auto button must be enabled for any of

the level/timed pumps to run. Press “System Off” to

disable all Level/Timed pumps. (Pump station

operation is not affected).

Touch the pump name to configure the pump.

Figure 56: Level/Timed pump configuration

Set the pump name by touching the Name field for

the pump you are configuring. This is the “Source”.

Each pump can be configured to run individually or

as part of a pump group. For each pump to run

standalone based on it’s own level control, select

each pump to be in a separate group. To use the

run-time of the pumps to “Lead Select” a group of

well pumps, put them in the same group. When the

first pumps level (or level/time combination) calls for

the pump to run, all pumps in the group will be

evaluated to determine which will run, based on run

hours and switch settings.

Timed pump can be configured with or without level

control. A timed pump will be enabled to run on the

days specified, after the start time and for the

duration specified. If also level controlled, then the

pump will be allowed to run during the “enabled”

period when the level in the controlled lake calls for

the pump to run. If no level control is also

configured, the pump will run after the start time

and for the duration specified. Setting up the timed

operation will be described in detail below.

Start and Stop delays apply to level control and are

used to de-bounce, or account for wave action on

the probes or transducer signal.

Selecting a transducer tells the system to use the

transducer signal for level control rather than level

probes/floats.

Well/Txfr allows you to set up the pump as Well or

Transfer (Well pumps “Pump up” while Transfer

pumps “Pump Down”, though this distinction only

truly matters when using the transducer for level

control, both modes require a signal-on to run when

using probes for control).

Fbk selects whether the pump will provide a

feedback (pump running confirmation) to the PLC.

If selected, a pump fault will be reported if the pump

does not provide this feedback signal when called

to run. If not selected, the PLC will assume the

pump is running any time it is called for.

Fault Enables select whether to enable faults for the

well/transfer/timed pumps. LL enables Low Level

Safety, HPT enables the High Pump Temp safety,

and Seal enables the Seal Failure safety. HPT and

Seal are typically for submersible sump-type

pumps while Low Level safety is typically used for

turbine or submersible turbine type pumps.

Configuring Timed Pumps:

Touch the pump image of any pump configured for

timed operation to open the Run Time configuration

screen.

Timed pump control consists of a Day to Enable,

Start time and Duration. The start day, time and

duration are taken together to determine if the

pump is in an allowable period to run. If the current

time is greater than the time period defined by Start

time and day, and less than start time and day, plus

duration, then the pump will be allowed to run.

Note that this means it is possible for a pump to run

Page 26

26

on a day that is not selected if the previous days

duration setting extends past midnight.

Figure 57: Integrated Timed Pump configuration

For example, assume the pump is configured as

shown above. If the current time is Monday-Friday,

between 2:00 AM and 6:30 AM, the city fill valve will

be open if the probes for #8 Pond call for it. Any

other time the controls will ignore the probes and

the valve will remain closed.

If the setting were configured for 10:00 PM and the

duration was set for 4:00 hors, the pump could run

starting at 10:00 PM Monday-Friday, and would be

allowed to run until 2:00 AM the following morning

(even Saturday morning) but would not start

Saturday or Sunday evening (and would thus not

run Monday morning from midnight to 2:00 AM).

Lake Level Controls Setup (Non-Integrated only)

This screen allows you to enter the delay times for

the pump to start and stop after a specified level

has been reached. Time to Fault (sec) is the time

delay for system to issue a fault after a fault occurs.

Tap [Lvl Setup] to enter the start and stop levels

(feet) for up to 5 pumps in a popover screen.

Specify the type of pump using the radio buttons.

A well pump starts when the well water level falls

below the start level, and stops when the water

level is above the start level.

A transfer pump starts when the water level in the

tank is above the start level, and stops when the

level falls below the stop level.

Tap [Next] to move to the next Auxiliary Setup

screen.

Figure 58: Lake Level Controls Setup

Timed Pump Setup (Non-Integrated only)

This screen allows you to enable the timed pump

setup. If the ‘Feedback Enable’ box is checked, the

pump will send feedback to the PLC.

Enable the checkboxes for each day that a pump

needs to be timed. For each day enabled, enter the

start time and duration in a pop up screen.

Tap [Next] to move to the next Auxiliary Setup

screen.

Figure 59: Timed Pump Setup

Simple Filters Setup

This screen allows you to setup the simple or Wye

filters.

∆P Present (sec) is the time between flushes when

differential pressure is on, or when the analog

differential pressure is less than the differential

setpoint. Check the ‘Wye’ checkbox to enable a

Wye filter, (which doesn’t use ∆P) and enter values

in editable fields.

Simple Filters Setup

This screen allows you to setup the simple or Wye

filters.

Page 27

27

∆P Present (sec) is the time between flushes when

differential pressure is on, or when the analog

differential pressure is less than the differential

setpoint. Check the ‘Wye’ checkbox to enable a

Wye filter, (which doesn’t use ∆P) and enter values

in editable fields.

Tap [Next] to move to the next Auxiliary Setup

screen.

Figure 60: Simple Filters Setup

Scanners Filter Setup

The Scanners Filter setup screen is similar to

Simple Filters setup, but it does not have the Wye

filter option.

Select the filter from the drop down menu and enter

values in the editable fields as needed.

Tap [Next] to move to the next Auxiliary Setup

screen.

Figure 61: Scanners Filter Setup

Options Setup

Tap [Options Setup] from the Setup Menu.

NOTE: After the pumping station is configured with

initial values at the factory, this menu allows you to

configure additional options.

Tap over any field to access the desired setup

options.

Figure 62: Options Setup Menu

VFD Bypass

Tap [VFD Bypass] from the Options Setup Menu.

This screen allows you to enable or disable bypass

for desired VFDs using the radio buttons.

Tap [Close] to return to the Options Setup Menu.

Figure 63: VFD Bypass

Analog Scaling

Tap [Analog Scaling] from the Options Setup Menu.

This screen allows you to scale raw values into

engineering units for up to 4 analog signal inputs

and outputs.

For each signal such as Pressure, the analog input

values are shown on the left while the analog output

values are shown on the right.

Use the scroll bar to scroll left and right. Enter

values in all editable fields.

Tap [Edit Analog I/O Names] to change any of the

names of the variables displayed (Flow, Pressure,

etc). This can also be used when adding on

functionality to the system. There are a few ‘spare’

Page 28

28

I/O names available and those can be edited to

match the new variable for scaling.

Tap [Close] to return to the Options Setup Menu.

Figure 64: Analog Scaling

ActiveX and IP Updates

Tap [ActiveX and IP Updates] from the Options

Setup Menu.

By default both ISSymbol URL and Agent URL are

automatically populated.

View Current Configuration: View the entire URL

in a popover screen.

Set Configuration: Set and save new web

configurations.

Email: Get notifications via email.

Tap [Close] to return to the Options Setup Menu.

Figure 65: ActiveX and IP Updates

WinCE Remote Access

Tap [WinCE Remote Access] from the Options

Setup Menu.

This screen allows you to communicate with a

remote server using Telnet. This feature is intended

for advanced custom jobs.

CAUTION:

Before using this feature or changing any

settings on this screen, please call customer

service.

Tap [Close] to return to the Options Setup Menu.

Figure 66: WinCE Remote Access

Alternate SP

Tap [Alternate SP] from the Options Setup Menu.

Enter and store different alternate setpoints in the

pop up screen for Pressure SP and also alternate

setpoints for Fertigation SP.

Tap [Close] to return to the Options Setup Menu.

Figure 67: Alternate SP

Page 29

29

Figure 68: Pressure SP

Figure 69: Fertigation SP

Database Settings

This feature helps make changes to database

settings. The database is used to send and receive

information from the irrigation control system. The

“Gateway” software should be installed on the

irrigation computer and network connections

confirmed before enabling the remote database

connection.

The defaults will include:

Data Server: 192.168.1.15

Database:

For Windows “7” connected systems:

C:\Program Files (x86)\Flowtronex\FlxStationDataII.MDB

For Windows XP and earlier systems:

C:\Program Files\Flowtronex\FlxStationDataII.MDB

Enable Remote: Checked.

Note:

The database should only be enabled after

installing the “Gateway” software on the

irrigation PC. While the system will operate

correctly, unnecessary events and exceptions

are generated which can load the HMI

processor and take up valuable event-table

space.

Figure 70: Database Settings

After enabling the database connection, the HMI

must be restarted with the Gateway software

running on the host irrigation computer. This can be

accomplished through cycling power or by shutting

down and restarting the application.

Email Settings

This page allows you to set up email addresses

where Alarm and shutdown messages will be sent.

These emails will notify the user if the station has

shut down or experienced a problem that the site

personnel should be aware of. This way the user

will be notified immediately in case of a pump

station problem. If a fault occurs, an email will be

sent to him.

The email settings can be configured to send

emails to multiple individuals or email addresses.

The vast majority of cell phone providers also allow

email messages to be sent to cell phones as text

messages. A list of known formats is provided

below.

Enable: Check this box to enable email alarms

from the Pace controls.

Use Authentication: Check this box if your email

service requires POP3 authentication.

Note: The IP address of the POP3 server must be

the same as the IP address of the SMTP server.

This is usually the case (both servers usually reside

behind the same firewall/router).

To: Enter the email address to send the alarm

messages to. Multiple email addresses can be

Page 30

30

entered by separating the email addresses with a

semicolon.

Examples: Me@gmail.com; TheBoss@test.com;

SecondGuy@test.com; 555555555@verizon.net.

The following list shows email address formats for

various cell carriers. Sending an email to these

addresses will generate an SMS text message to

the cellular phone.

T-Mobile: phonenumber@tmomail.net

Virgin Mobile: phonenumber@vmobl.com

Cingular: phonenumber@cingularme.com

Sprint: phonenumber@messaging.sprintpcs.com

Verizon: phonenumber@vtext.com

Nextel: phonenumber@messaging.nextel.com

US Cellular: phonenumber@email.uscc.net

SunCom: phonenumber@tms.suncom.com

Powertel: phonenumber@ptel.net

AT&T: phonenumber@txt.att.net

Alltel: phonenumber@message.alltel.com

Metro PCS: phonenumber@MyMetroPcs.com

Where “phonenumber” is the 10 digit phone number

of the user.

SMTP: Enter the IP address of the SMTP server

you will be using. Windows CE devices require the

IP address rather than the server name.

See “Determining the IP address of the SMTP

server” in Appendix F for these instructions.

From: Enter the complete email address used for

this service. Most email servers will ignore your

email request if the “From” address does not match

the account.

Example: mypumpstation@runbox.com

User: For most email service providers, enter the

first part of the email address without the domain

name. Note that some providers require the full

email address as your user name.

Example: mypumpstation

Password: The password to your email account.

Example: flowtronex

After configuring your email settings, test the setup.

Tap [Set] to load the information into the email

generator. Then tap [Send]. A test email will be

immediately sent to the address(es) provided.

If the colored box remains green after hitting Send, the

configurations are working correctly. If the box turns

red there has been an error. The number after “Status”