Page 1

INSTRUCTION MANUAL

19-001-300R2

Silent Storm

VFD Pumping System

OMRON Touch Screen Display Manual

Page 2

Acknowledgements

!

!

All materials ©2013 by Xylem Flowtronex.

!

Flowtronex© is a registered trademark of Xylem Flowtronex.

!

All rights reserved. No parts of this work may be reproduced in any form or by any means - graphic, electronic, or

mechanical, including photocopying, recording, taping, or information storage and retrieval systems - without the

written permission of the publisher.

!

Products that are referred to in this document may be either trademarks and/or registered trademarks of the

respective owners. The publisher and the author make no claim to these trademarks. These include Microsoft,

Windows, Windows NT, ActiveX that are either registered trademarks or trademarks of Microsoft Corporation in

the United States and/or other countries. ©2013 Microsoft Corporation. All rights reserved.

!

While every precaution has been taken in the preparation of this document, the publisher and the author assume

no responsibility for errors or omissions, or for damages resulting from the use of information contained in this

document or from the use of programs and source code that may accompany it. In no event shall the publisher

and the author be liable for any loss of profit or any other commercial damage caused or alleged to have been

caused directly or indirectly by this document.

Page 3

Contents

I

© 2013 Flowtronex

!

!

!

!

Table of Contents

!

!

!

!

!

1.0 Basic Navigation

1.1 Main Menu

.........................................................................................................1

.........................................................................................................................

2

1.1.1

System Status

...........................................................................................................

3

1.1.2

Set Clock

...........................................................................................................

7

1.1.3

Alarm Summary

...........................................................................................................

8

1.1.4

Alarm History

...........................................................................................................

9

1.1.5

Station Events

...........................................................................................................

12

1.1.6

Run Data

...........................................................................................................

13

1.1.7

Total Output

...........................................................................................................

18

1.1.8

Start Stop Menu (Combo Menu)

...........................................................................................................

20

1.1.9

Combos

...........................................................................................................

21

1.2 Calculator/Keypad

.........................................................................................................................

24

1.3 Password Protected Screens

........................................................................................................................

25

1.4 Register Access Menus

1.4.1 N Register Menu Key

1.4.2 B Register Menu Key

!

2.0 How Do I?

2.1 Set Clock

2.2 Reset Alarms

!

.........................................................................................................................

25

...........................................................................................................

27

...........................................................................................................

28

!

.........................................................................................................28

.........................................................................................................................

29

!

.........................................................................................................................

29

2.3 Change Combo Parameters

.........................................................................................................................

30

2.4 Define Safety Parameters

!

.........................................................................................................................

34

2.5 Tune my Pump Station using PID

.................................................................................................................

38

2.6 Define Timer Parameters

!

.........................................................................................................................

41

2.7 Define Lockout, Timed Pump, and Well Pump Parameters

.........................................................................

43

2.8 Define My VFD Bypass Parameters

!

.............................................................................................................

48

2.9 Define My Auto Lake Screen Parameters

.....................................................................................................

50

2.10 Define My Lake Fill Parameters

..................................................................................................................

52

2.11 Define My Filter Parameters

!

.......................................................................................................................

54

2.12 Define My Flow Stop Parameters

!

...............................................................................................................

57

2.13 Calibrate my Sensors

2.13.1 Calibrate Pressure

!

.........................................................................................................................

60

...........................................................................................................

67

2.13.1.1 Calibrating the Minimum (0) Pressure

2.13.1.2 Calibrating Maximum Pressure

........................................................................................

69

........................................................................................

70

2.13.2 Calibrate Flow

2.13.2.1 Analog Flowmeter (Krohne)

2.13.2.2 220B Flowmeter

2.13.3 Calibrate VFD Pump RPM

2.13.4 Calibrate Manual Speed Pot

...........................................................................................................

71

........................................................................................

74

........................................................................................

81

...........................................................................................................

85

...........................................................................................................

88

2.13.5 220B Flowmeter with Analog Transmitter

................................................................................................

92

Page 4

II

Omron Touch-Screen Display

© 2013 Flowtronex

!

!

!

!

2.13.5.2 Calibration Procedure with a Signal

Generator

......................................................................................

95

2.13.5.3 Calibration Procedure without a Signal

Generator

.................................................................................

96

2.13.5.4 Calibrating Multiple Zone Pulse Flow Sensors

......................................................................................

98

2.14 Define My Start / Stop Features

.................................................................................................................

98

2.15 Define My Custom Features

.....................................................................................................................

101

2.16 Check My Inputs and Outputs

...................................................................................................................

103

2.16.1 Changing an Input

2.16.2 Changing an Output

...........................................................................................................

106

...........................................................................................................

108

2.17 Define My Miscellaneous Control Features

!

..............................................................................................

109

2.18 Enter New Totalizer (Flow Total) Values

!

..................................................................................................

113

2.19 Set My Interchangeable Pumps

................................................................................................................

115

2.20 Check If False Feedback or Individual Faults are Enabled

.......................................................................

118

2.21 View My Datalogging Parameters

.............................................................................................................

121

2.22 Check My VFD and Jockey Pump Control Settings

..................................................................................

123

2.23 View My Combo Logic

!

.........................................................................................................................

125

2.23.1 Access Combo Table from the Main Menu

............................................................................................

125

2.23.2 Access Combo Menu from the Register Access Menu

.........................................................................

128

2.23.2.1 Pump Logic (Combo Up)

2.23.2.2 Pump Logic (Combo Down)

2.23.2.3 Combo Table

2.23.2.4 Lead Groups

2.23.3 View My I/O Buffers

........................................................................................

130

........................................................................................

133

........................................................................................

135

........................................................................................

137

...........................................................................................................

139

2.24 Define My Station Objects

.........................................................................................................................

141

2.25 Define My Booster Pump Settings

............................................................................................................

144

2.26 Change My Timed Pump Definitions

!

........................................................................................................

147

2.27 Define My Pump Outputs

!

.........................................................................................................................

150

Index

............................................................................................ 153

Page 5

© 2013 Flowtronex

Basic Navigation

1

!

!

!

!

!

1.0 Basic Navigation

!

When power is applied to the pump station, the Flowtronex® PSI splash screen is briefly

displayed.

!

!

Note:

Two important items are displayed on the splash screen:

1) The number to call (1-800-786-7480) if you are experiencing problems

2) the Version number (such as, V8.71L1H.001) of the software.

!

!

!

!

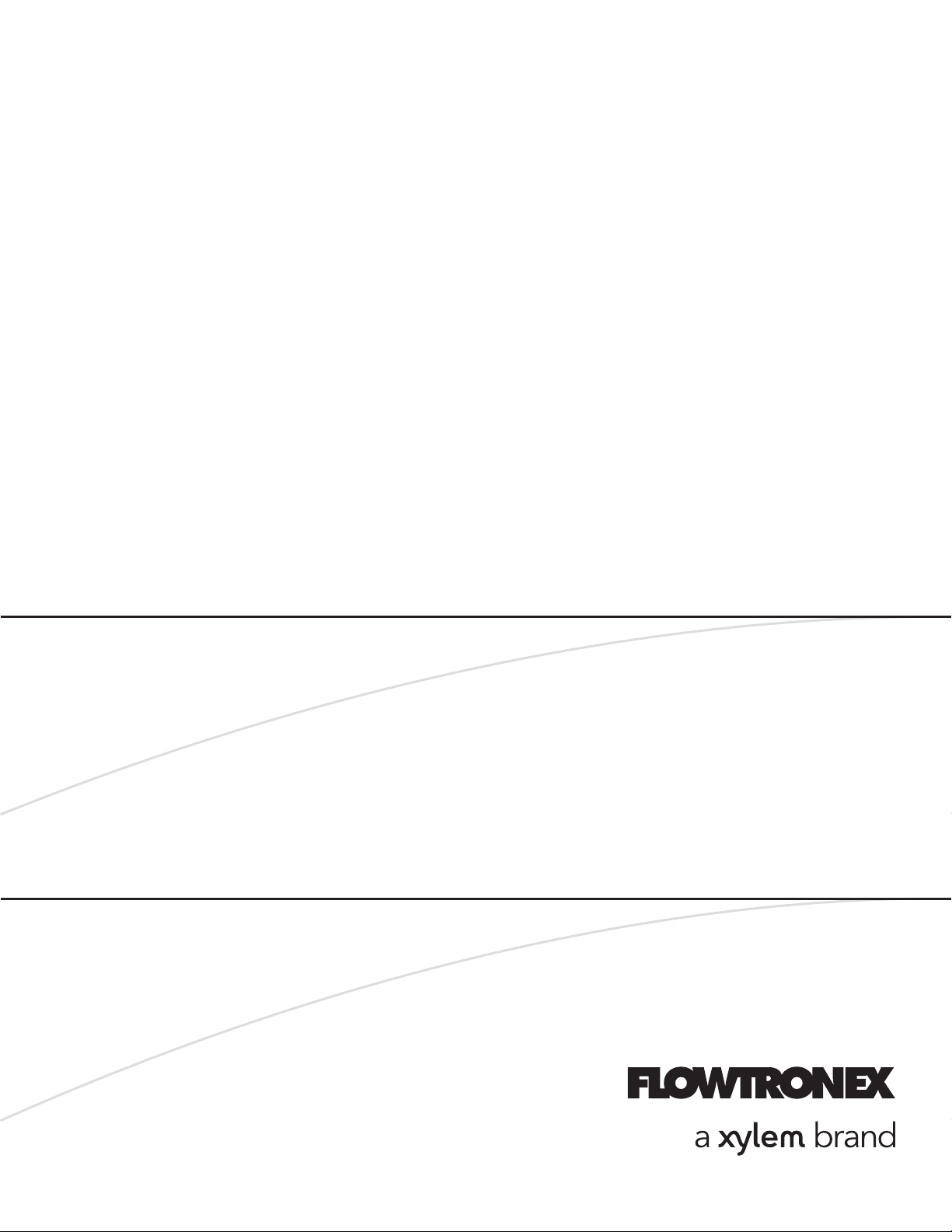

After a brief warm up period, the first Master Control Interface (MCI) status screen is displayed, that

gives an overview of station operation, including Pressure, Main Flow, and Speed (VFD RPM) for the

station.

Page 6

© 2013 Flowtronex

2

Omron Touch-Screen Display

!

!

!

!

!

!

!

This screen also shows several features of the Master Control Interface (MCI) screens.

!

·

Press any touch key, such as Status Mode 1 and Graph, to view or edit parameters.

!

·

Use the up arrow key (▲) and the down (▼) arrow keys to view the next or previous screen

in a series.

!

!

Note:

When there are a series of screens, they are organized like the address list on a cell

phone. It may be faster to go in the opposite direction to reach a particular screen.

For example, if there are five screens in a series, from page 1 it is faster to use the

up arrow key to go to page 5 than it is to move down through four screens.

!

!

·

If available, tap on the Help key to open the help information screens.

!

·

Available on most screens, tap the Main Menu key to go directly to the Main Menu that acts as a

portal to other parts of the MCI application.

!

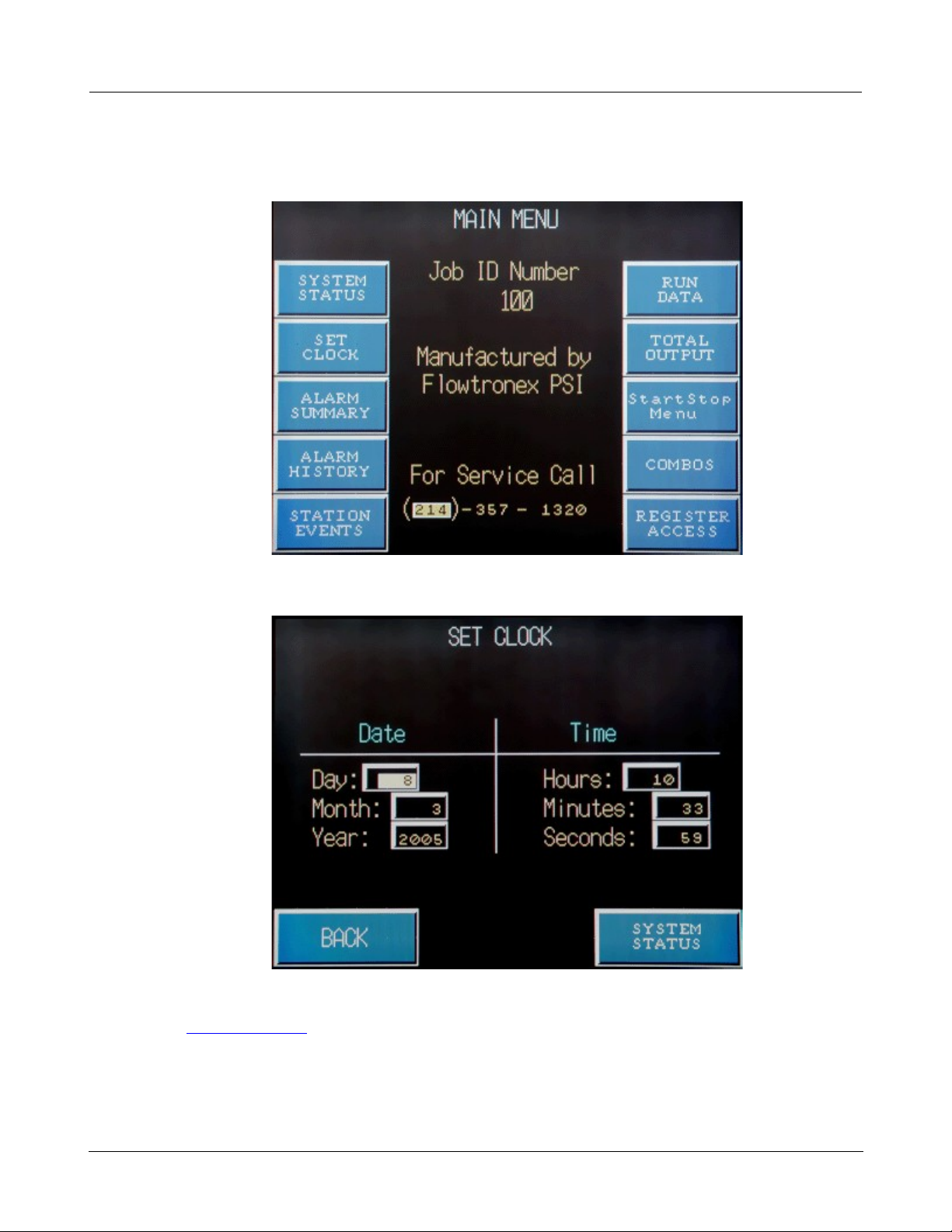

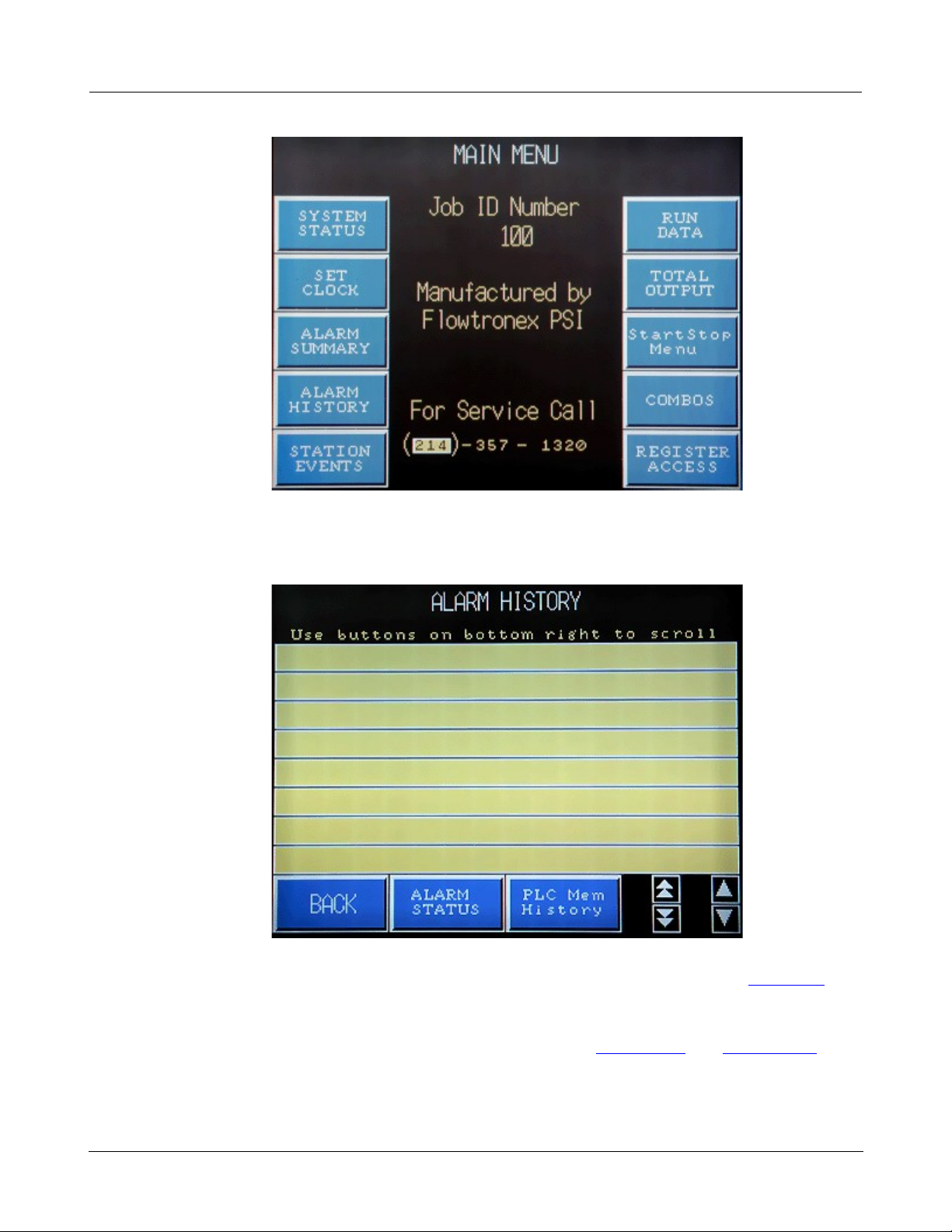

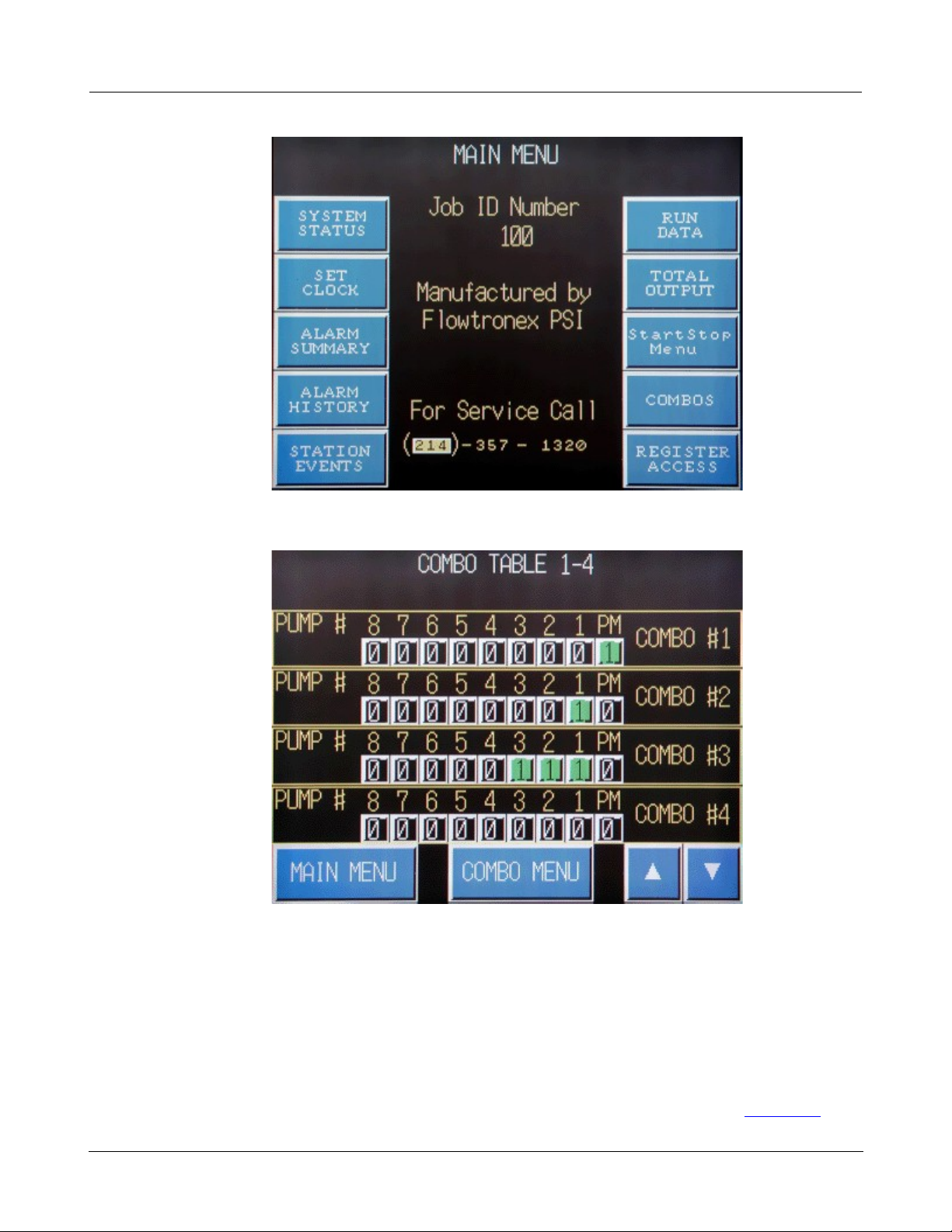

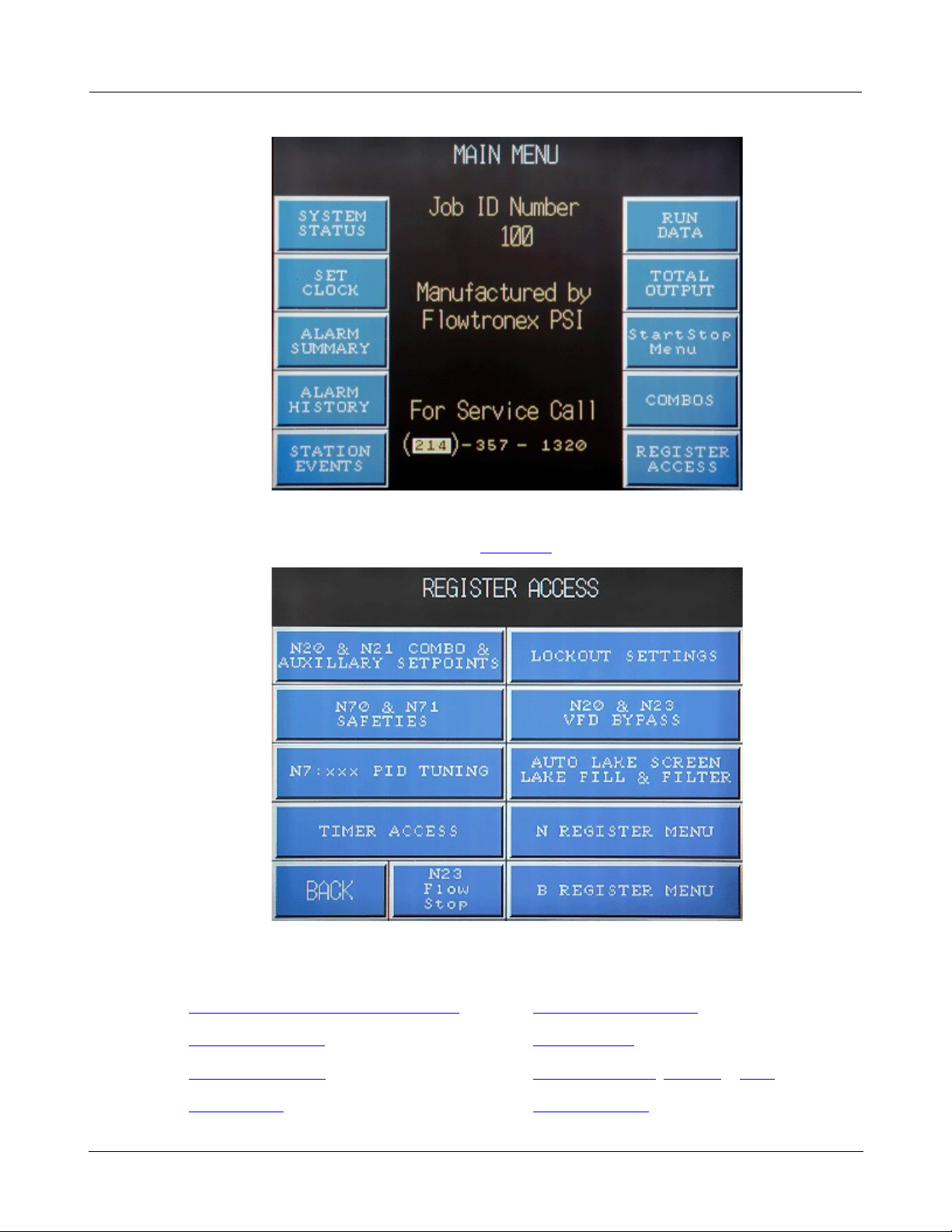

1.1 Main Menu

!

The Main Menu touch screen displays ten touch keys, your station's Job ID Number, and a number to

call for service. The features and characteristics of the different sections and screens are described in

the following sections under Basic Navigation.

Page 7

© 2013 Flowtronex

Basic Navigation

3

!

!

!

!

!

!

!

·

Press one of the ten touch keys to access information screen(s).

!

– System Status

!

– Set Clock

!

– Alarm Summary

!

– Alarm History

!

– Station Events

!

– Run Data

!

– Total Output

!

– Start Stop Menu

!

– Combos

!

– Register

Access

!

!

Note:

Certain functions are password protected and can only be accessed by a certified

Flowtronex® technician. If you press a touch key and the screen doesn't open, then

it is not available to the end user.

!

1.1.1 System Status

!

When the System Status key is pressed on the Main Menu, the first System Status screen is

displayed.

Page 8

© 2013 Flowtronex

4

Omron Touch-Screen Display

!

!

!

!

!

!

!

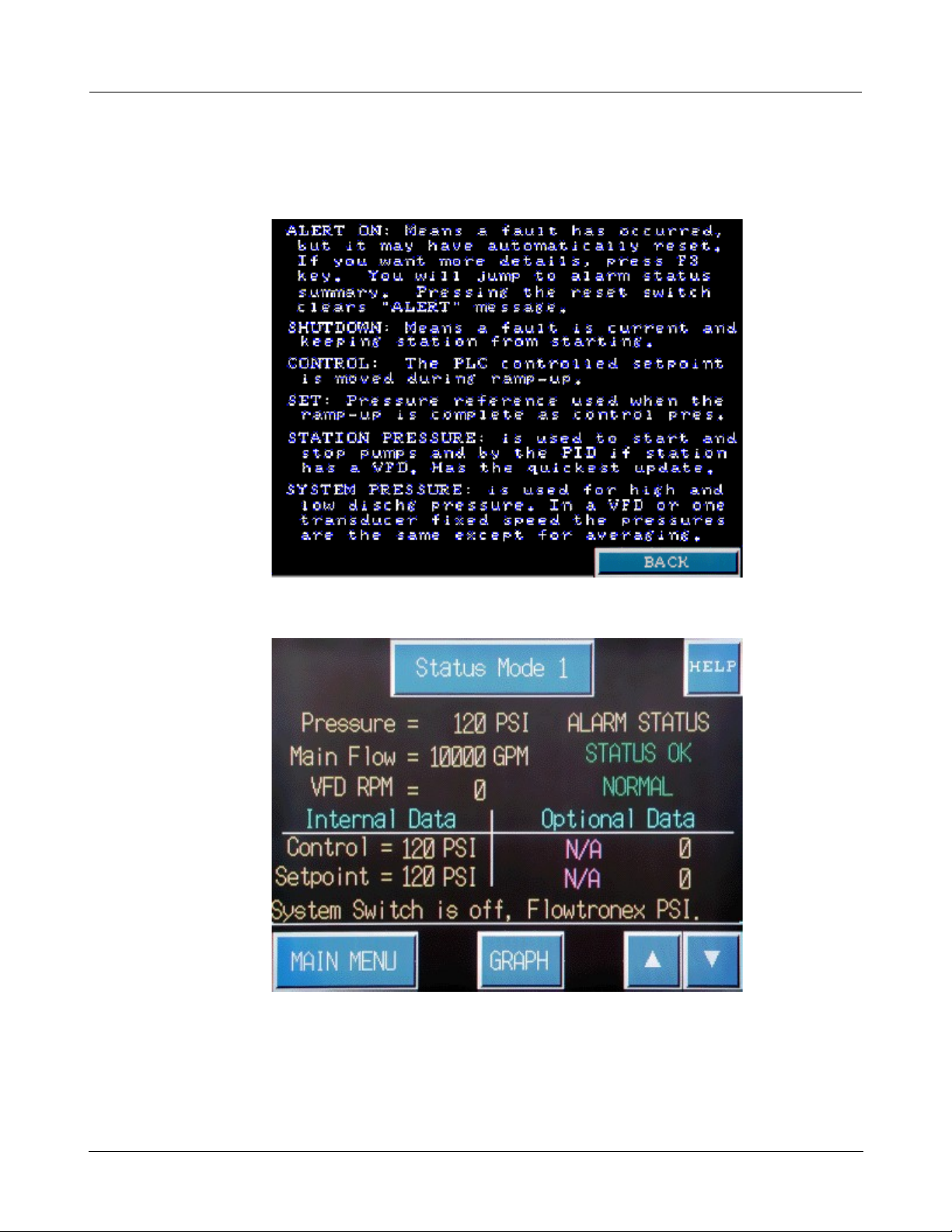

The first system status screen gives an overview of the operational status of the station. Pressure,

Main Flow, and VFD RPM (Speed) are displayed on the top of the screen along with the Alarm or fault

status. In the middle, the Control and Setpoint PSI are displayed along with other Optional Data if

programmed for your station. The final line shows if the enclosure System Switch setting: On, Off, or

Auto.

!

·

Optionally, press the Status Mode 1 key to refresh the screen.

!

·

Optionally, press the Main Menu touch key to return to the Main menu.

!

·

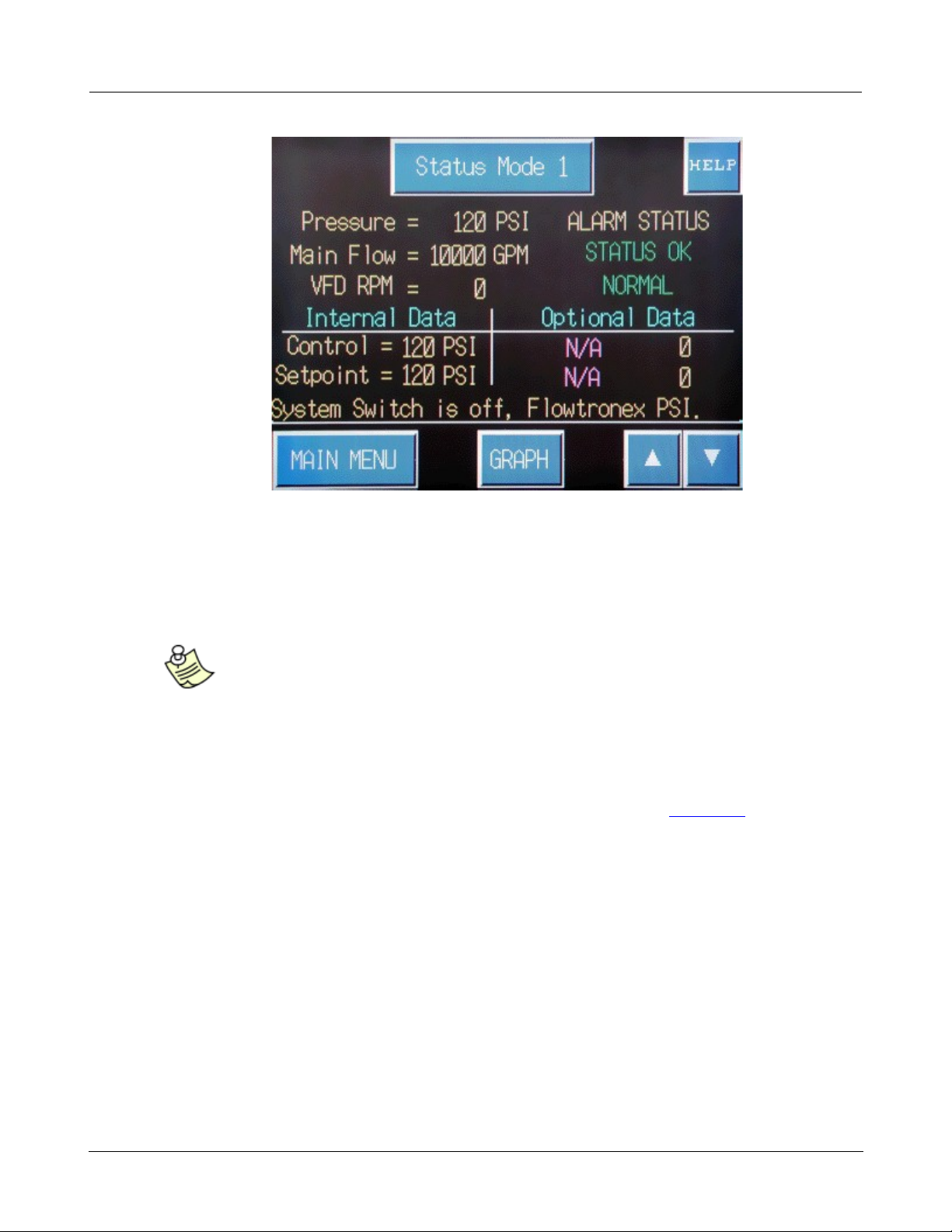

Press the Graph touch key to view the Flow & Pressure graph.

!

!

Page 9

© 2013 Flowtronex

Basic Navigation

5

!

!

!

!

!

·

Press the Back touch key to return to System Status 1 screen.

!

·

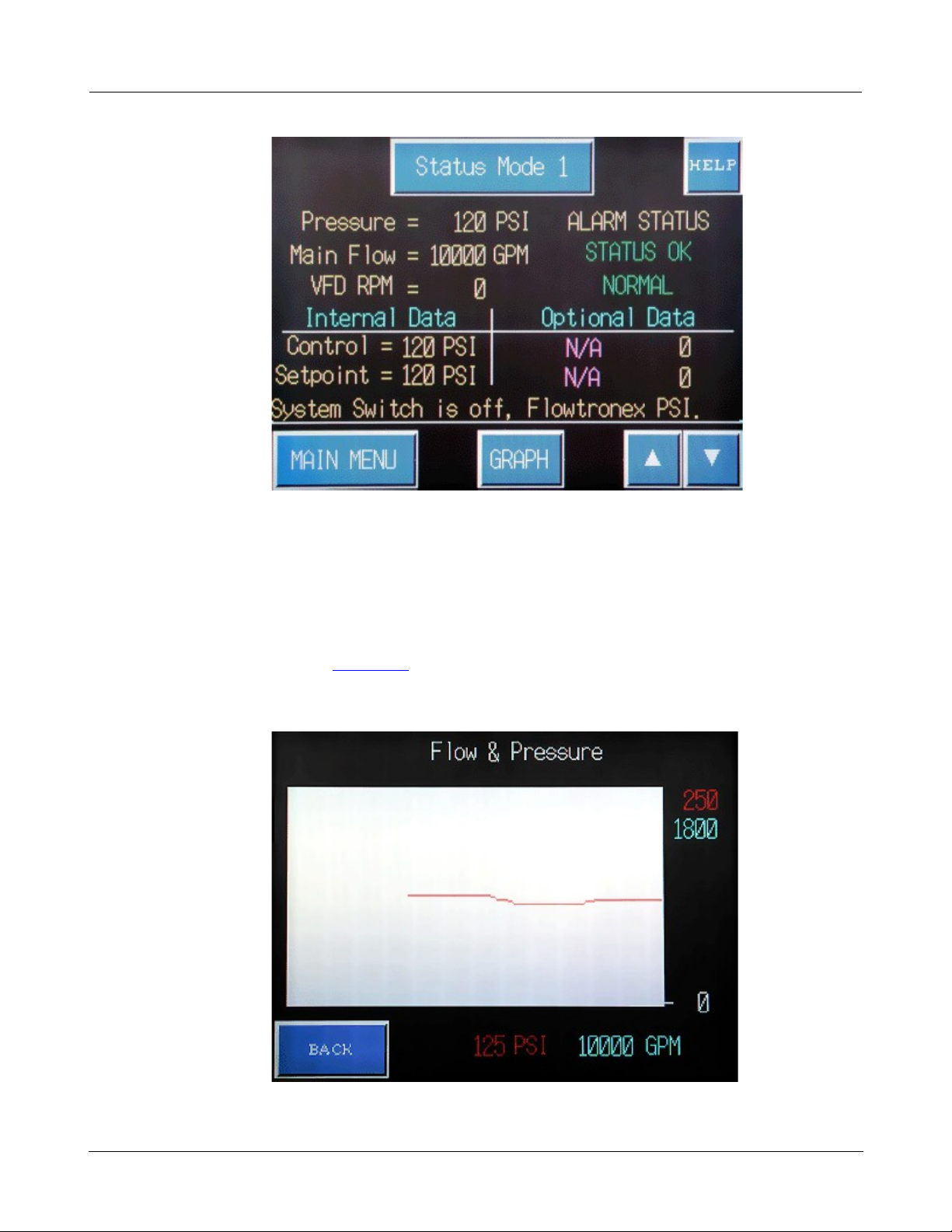

Optionally, press the Help touch key on the System Status screen to view the following information

screen.

!

!

!

·

Press the Back key to return to the first System Status screen.

!

!

!

·

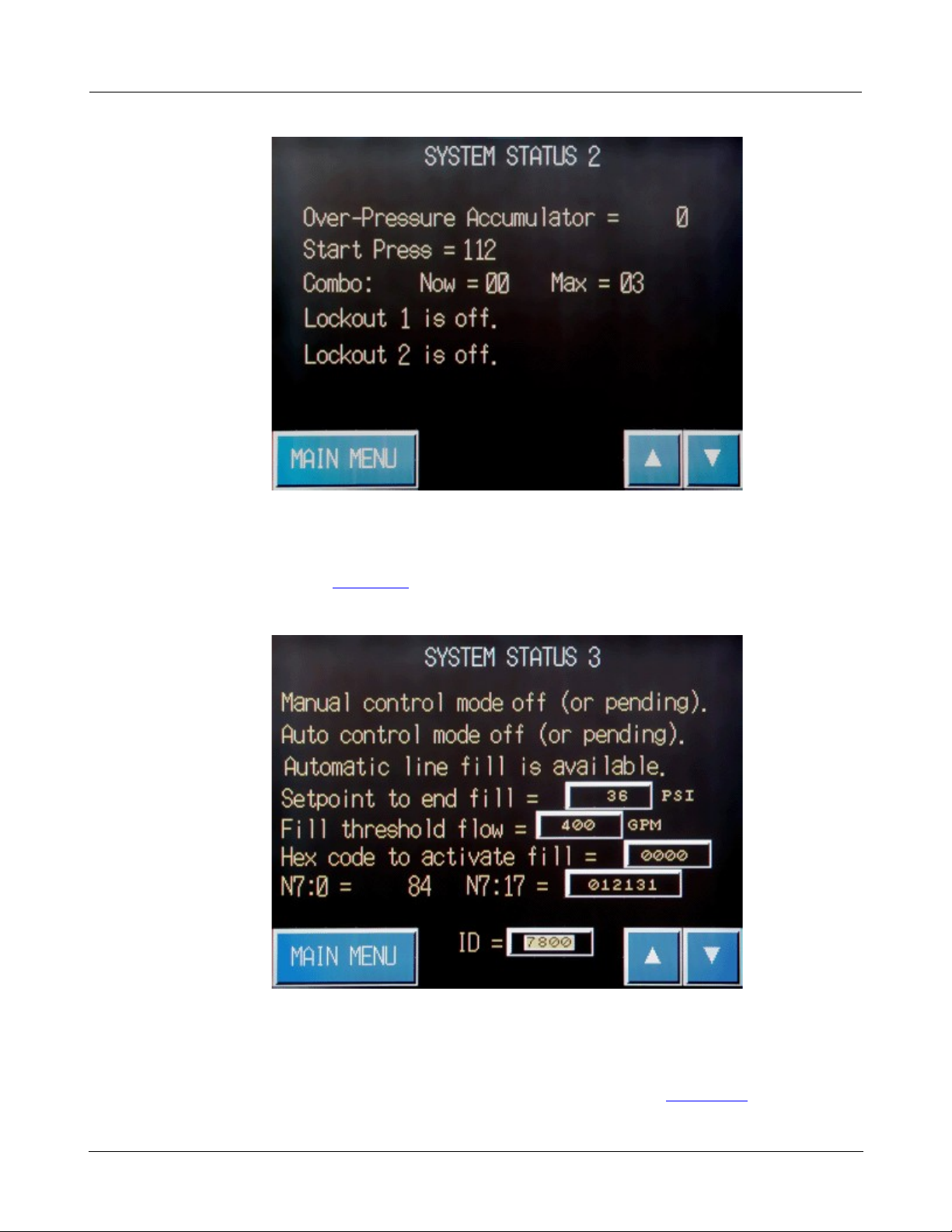

Press the up arrow (▲) or down key (▼) on the first System Status screen to advance to

the second system status screen.

Page 10

© 2013 Flowtronex

6

Omron Touch-Screen Display

!

!

!

!

!

!

!

·

Optionally, press the up arrow (▲) to return to the previous status screen (that is, the System

Status 1 screen).

!

·

Optionally, press the Main Menu touch key to return to the Main menu.

!

·

Press the down arrow (▼) to advance to the System Status 3 screen.

!

!

!

·

Optionally, press the up arrow (▲) to return to the System Status 2 screen

!

·

Optionally, press the down arrow (▼) to display to the first System Status screen.

!

·

Press the Main Menu touch key to return to the Main Menu (See also, Main Menu).

Page 11

© 2013 Flowtronex

Basic Navigation

7

!

!

!

!

1.1.2 Set Clock

!

You can access the Set Clock screen by pressing the Set Clock touch key on the Main Menu.

!

!

!

Use the Set Clock screen to set the time on the PLC.

!

!

!

·

Tap each value for Day, Month, Year, Hours, Minutes, or Seconds to pop open the

calculator/keypad and enter value on the Set Clock screen.

Page 12

© 2013 Flowtronex

8

Omron Touch-Screen Display

!

!

!

!

!

!

!

– Tap the numeric keys, 0 to 9 to enter a value.

!

– Tap the Enter key to have number entered as a value on the displayed screen.

!

– Tap Clr to close popup and return to the displayed screen .

!

·

Optionally, tap the Main Menu key to return to the Main Menu. (See also, Main Menu and Set

Clock in the How Do I? section.)

!

·

Optionally, tap System Status to return to the System Status 1 screen (See also, System Status.)

!

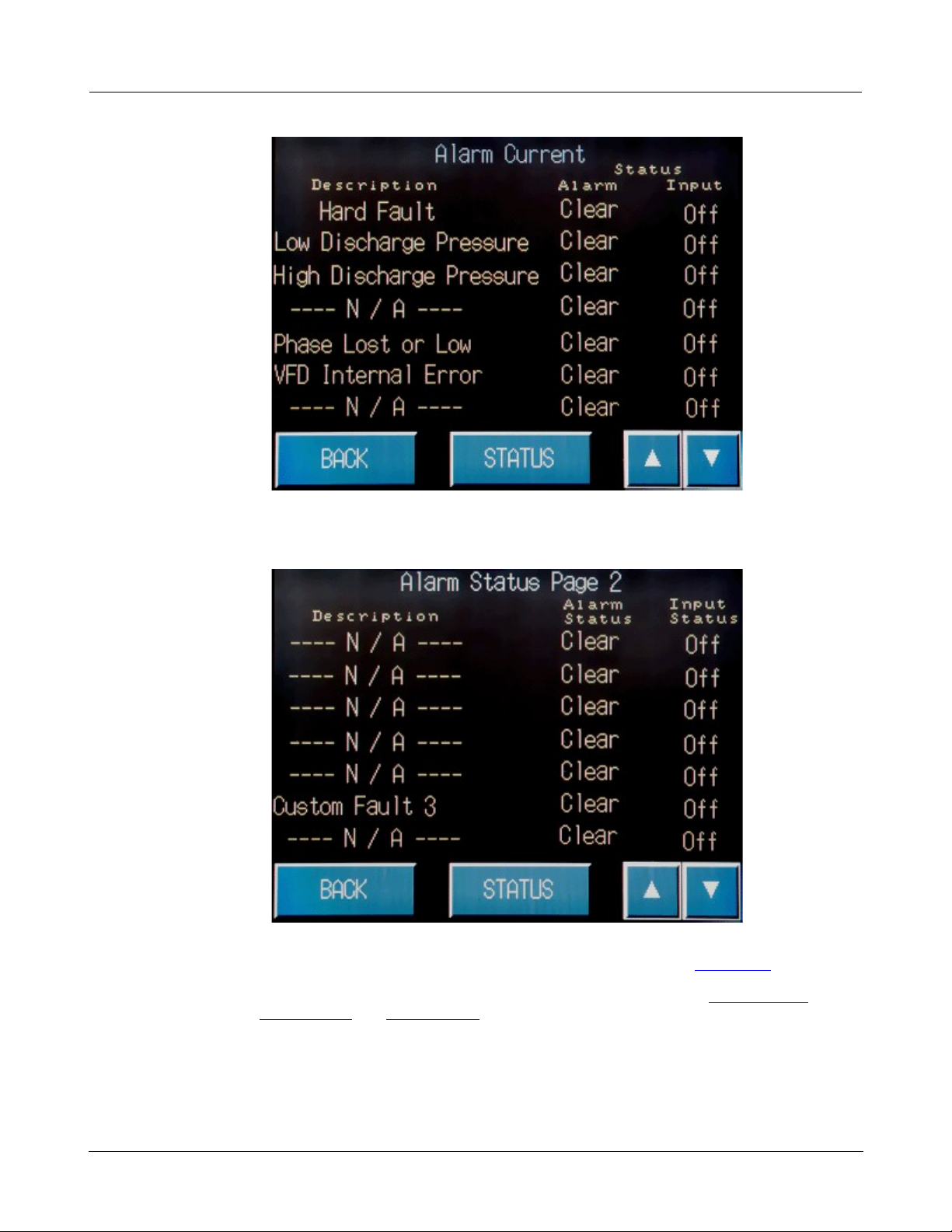

1.1.3 Alarm Summary

!

The alarm summary consists of one screen, Alarm Status, and is accessed by pressing Alarm

Summary from the main menu screen.

!

!

!

·

Tap the Alarm Summary key on the Main Menu to view a list of all current unacknowledged

alarms on the Alarm Current screen.

Page 13

© 2013 Flowtronex

Basic Navigation

9

!

!

!

!

!

!

!

·

Navigate the Alarm Current screen by tapping the down arrow (▼) key to display Alarm

Status page 2.

!

!

!

·

Optionally, tap the Back key to return to the Main Menu screen. (See also, Main Menu.)

!

·

Optionally tap the Status key to display the System Status screen (See also, System Status.)

(See also, Alarm History and Reset Alarms in the How Do I? section.)

!

1.1.4 Alarm History

!

The Alarm History screen can be accessed either from the Main Menu by tapping the Alarm History

key, or on the Alarm Summary screen by tapping the Alarm History key.

Page 14

© 2013 Flowtronex

10

Omron Touch-Screen Display

!

!

!

!

!

!

!

This screen displays the last alarms or faults in sequence, with the most recent fault listed first. This

screen is useful when you have experienced a system hard fault (the same fault occurred 3 times in a

one hour period).

!

!

!

·

Optionally, press the Main Menu key to return to the Main Menu screen (See also, Main Menu.)

!

·

Optionally, navigate the Alarm History screen and the Alarm Status screen by tapping the single

up (▲) or down arrow (▼) key to scroll one line at a time, or the double up or down arrow to

move to the very first line or last line of the list. (See also, Alarm Status and Reset Alarms in the

How Do I? section.)

!

·

Tap the Alarm Status key to view the Alarm Status screen and view a list of the current

unacknowledged alarms.

Page 15

© 2013 Flowtronex

Basic Navigation

11

!

!

!

!

!

!

!

·

Optionally, press the Back key to return to the Main Menu.

!

·

Tap the Alarm History key to return to the Alarm History screen.

!

·

On the Alarm History screen, press PLC Mem History key to view the Alarm History (PLC

Memory) screen. This screen shows you the status of all faults.

!

!

!

·

Optionally, press the up (▲) or down arrow (▼) to display Alarm Status screen (shown above).

!

·

Optionally, press the Status key to return to the first System Status screen, or press the up (▲)

arrow key .

!

·

Press the Back key to return to the Main Menu screen (See also, Main Menu.)

Page 16

© 2013 Flowtronex

12

Omron Touch-Screen Display

!

!

!

!

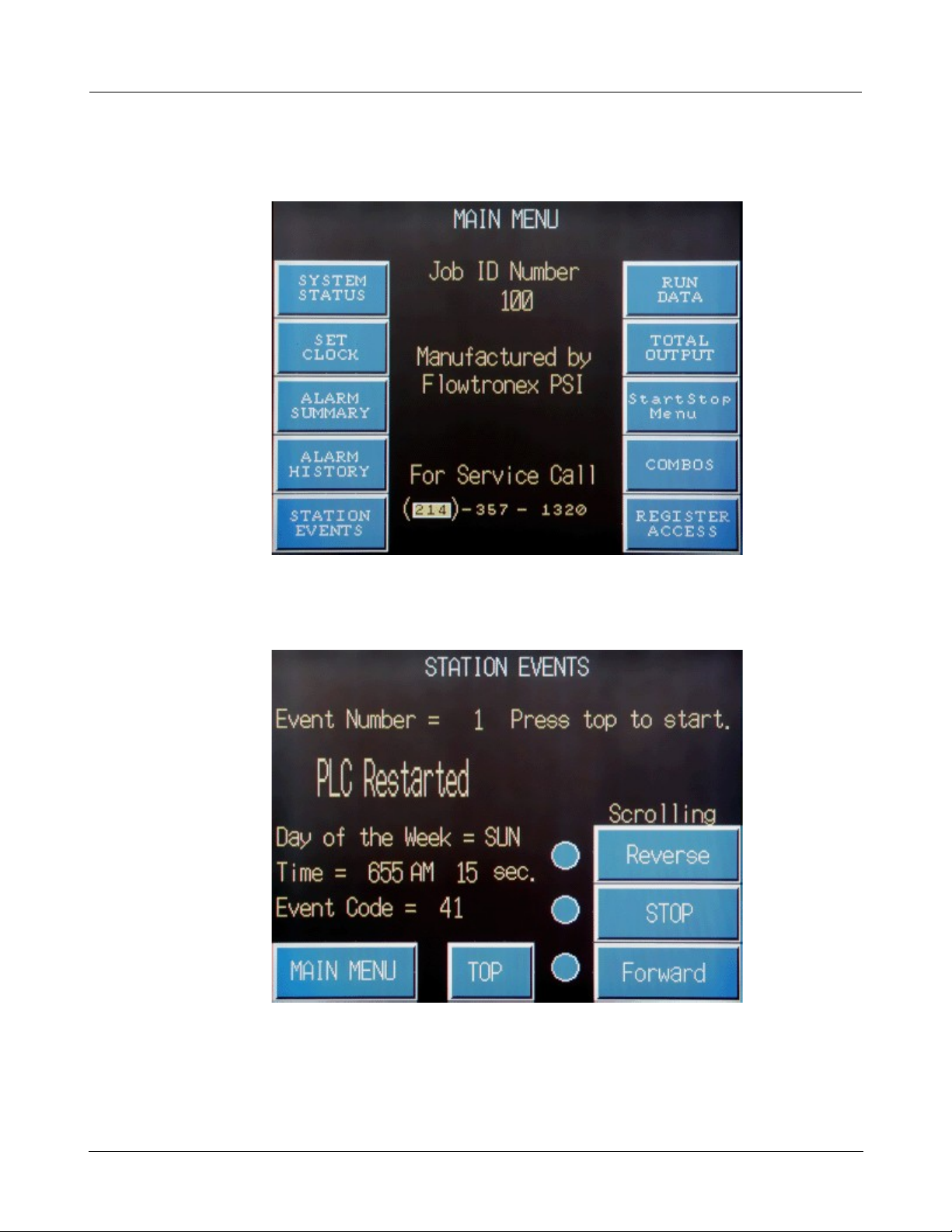

1.1.5 Station Events

!

The Station Events screen can be accessed from the Main Menu by pressing the Station Events key.

!

!

!

This screen is useful for seeing when pumps turned on or off, and can be used for troubleshooting

pump cycle faults. Stations events include such items as PLC Restart, Pressure Maintenance Pump

Stopped or 2nd Main Pump Started.

!

!

!

·

Optionally, press the Top touch key to start the automatic scrolling function that returns you to the

top of the page. As shown above, the Event Number = 1 and the instruction Press top to start is

displayed.

!

·

Optionally, press the Stop touch key to stop scrolling.

Page 17

© 2013 Flowtronex

Basic Navigation

13

!

!

!

!

!

·

Optionally, press the Reverse or Forward key to scrolling in that direction.

!

·

Optionally, press the Main Menu touch key to return to the Main Menu. (See also, Main Menu.)

!

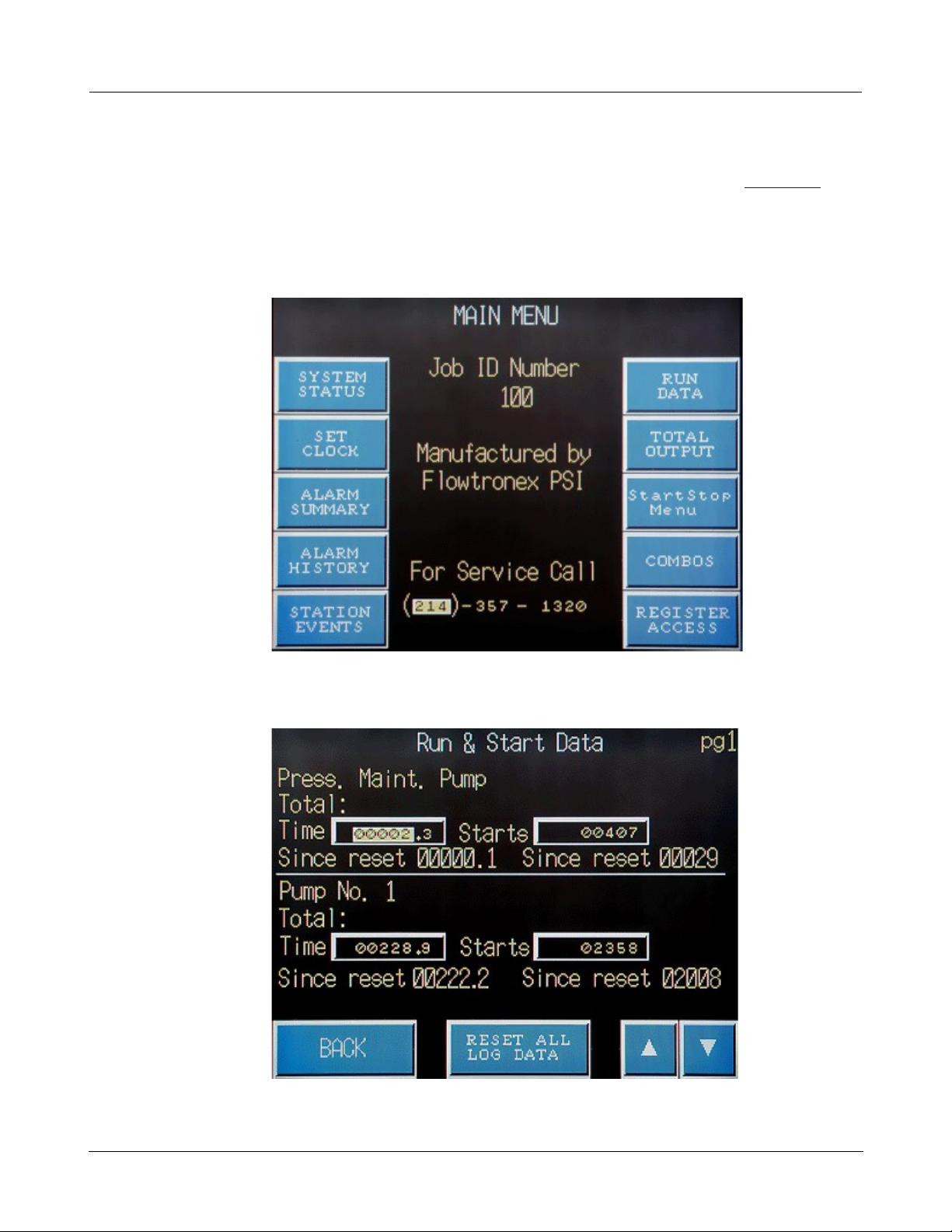

1.1.6 Run Data

!

The seven Run Data screens can be accessed from the Main Menu by pressing the Run Data touch

key.

!

!

!

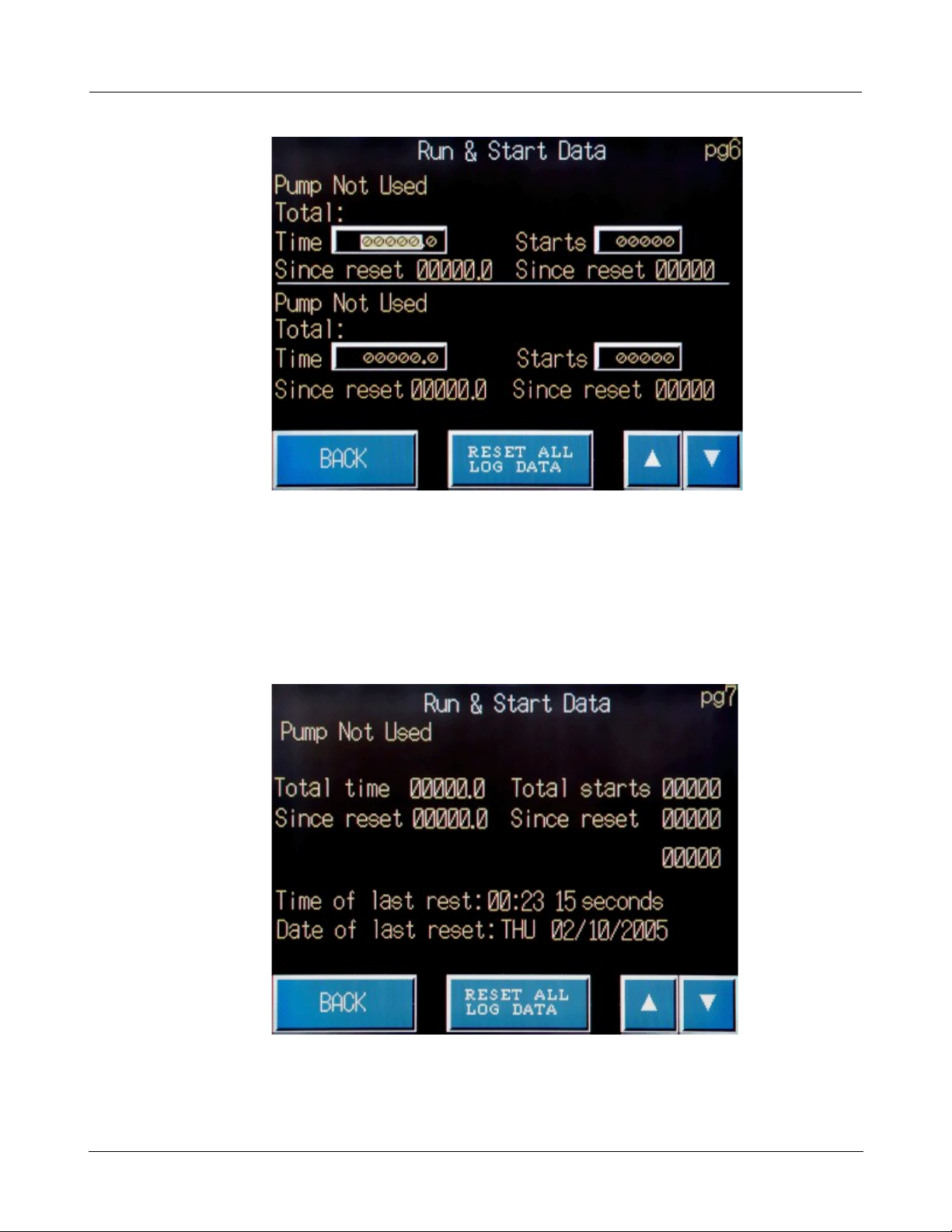

The Run & Start Data screens show you all of your pump hours. You can edit the Time and Starts data

on the Run & Start Data page 1 for the PM (Pressure Maintenance) Pump and Pump No. 1.

!

Page 18

© 2013 Flowtronex

14

Omron Touch-Screen Display

!

!

!

!

!

·

Press the Reset All Log Data touch key to reset the "since reset values for Total Time and Total

Starts". The Total Time and Total Starts displays the cumulative totals.

!

·

Navigate the Run Data screens by tapping the up (▲) and go to Run & Start Data page 7, or

the down arrow (▼) to display the Run Data screen page 2.

!

!

!

You can edit the Time and Starts data on the Run & Start Data page 2 for Pump No. 2. If multiple

pumps are used, Pump No. 3 data is also shown, or else Pump Not Used is displayed.

!

·

Optionally, press Back to return to the Main Menu.

!

·

Optionally, press Reset All Log Data Key to reset the runtime totals.

!

·

Press the up (▲) to display the previous Run & Start Data screen 1, or press the down arrow

(▼)

touch key to display the next Run & Start Data screen 3.

Page 19

© 2013 Flowtronex

Basic Navigation

15

!

!

!

!

!

!

!

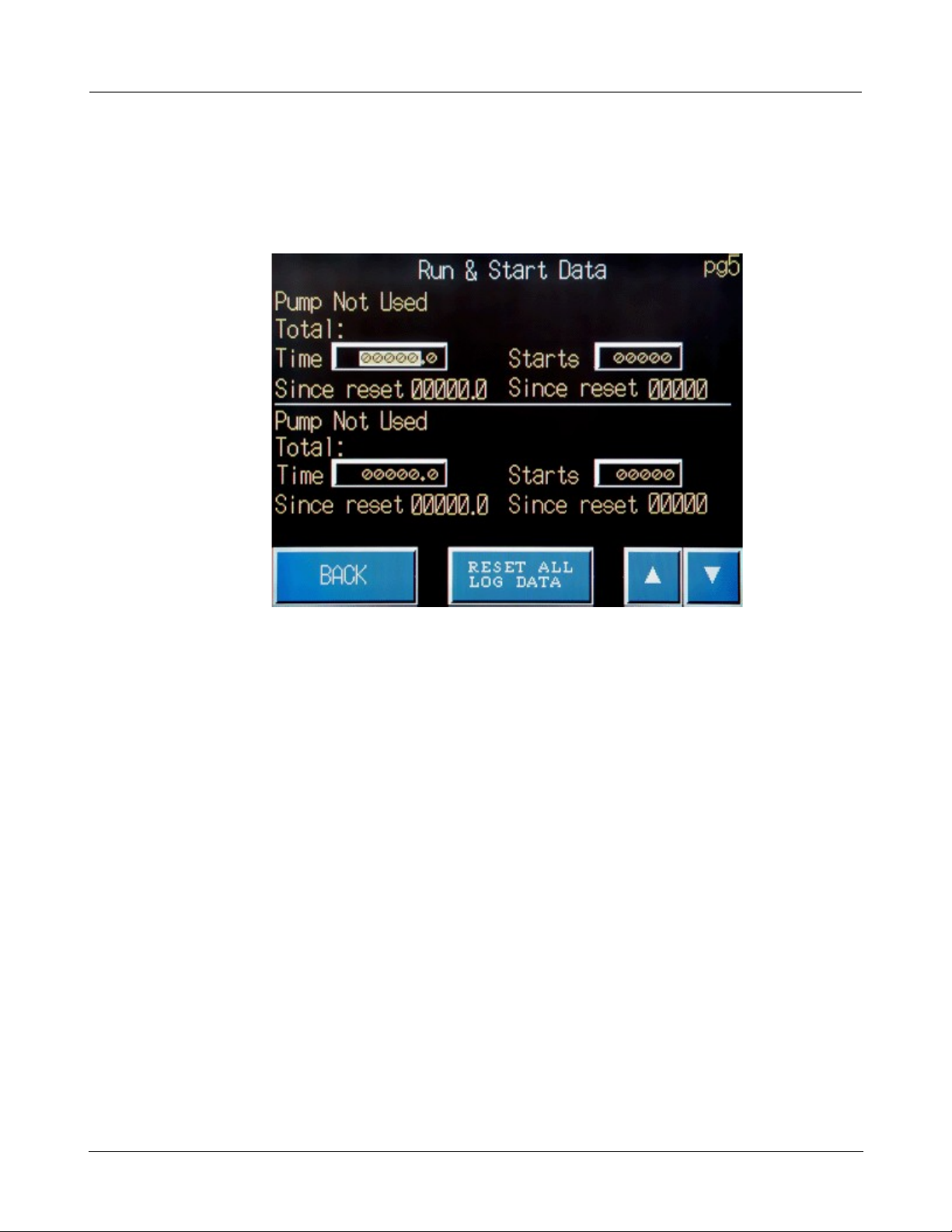

You can edit the Time and Starts data if multiple pumps are used on the Run & Start Data page 3 , or

else Pump Not Used is displayed.

!

·

Optionally, press Back to return to the Main Menu.

!

·

Optionally, press the Reset All Log Data Key to reset the runtime totals.

!

·

Press the up (▲) to display the previous Run & Start Data screen 2, or press the down arrow

(▼)

touch key to display the next Run & Start Data screen 4.

!

!

!

You can edit the Time and Starts data if multiple pumps are used on the Run & Start Data page 4 , or

else Pump Not Used is displayed.

Page 20

© 2013 Flowtronex

16

Omron Touch-Screen Display

!

!

!

!

!

·

Optionally, press Back to return to the Main Menu.

!

·

Optionally, press the Reset All Log Data Key to reset the runtime totals.

!

·

Press the up (▲) to display the previous Run & Start Data screen 3, or press the down arrow

(▼)

touch key to display the next Run & Start Data screen 5.

!

!

!

You can edit the Time and Starts data if multiple pumps are used on the Run & Start Data page 4, or

else Pump Not Used is displayed.

!

·

Optionally, press Back to return to the Main Menu.

!

·

Optionally, press the Reset All Log Data Key to reset the runtime totals.

!

·

Press the up (▲) to display the previous Run & Start Data screen 6, or press the down arrow

(▼)

touch key to display the next Run & Start Data screen 6.

Page 21

© 2013 Flowtronex

Basic Navigation

17

!

!

!

!

!

!

!

You can edit the Time and Starts data if multiple pumps are used on the Run & Start Data page 6, or

else Pump Not Used is displayed.

!

·

Optionally, press Back to return to the Main Menu.

!

·

Optionally, press the Reset All Log Data Key to reset the runtime totals.

!

·

Press the up (▲) to display the previous Run & Start Data screen 5, or press the down arrow

(▼)

touch key to display the next Run & Start Data screen 7.

!

Page 22

© 2013 Flowtronex

18

Omron Touch-Screen Display

!

!

!

!

!

!

Note:

The Reset All Log Data touch key is the same as the Reset touch key. Pressing

either key on any page resets the Since Reset values for Total Time and Total

Starts.

!

!

You can edit the Time and Starts data if multiple pumps are used on the Run & Start Data page 7, or

else Pump Not Used is displayed. The last page (Run & Start Data pg7) also displays the time and

date of the last system reset.

!

·

Optionally, press the Reset All Log Data Key to reset the runtime totals.

!

·

Press Back to return to the Main Menu.

!

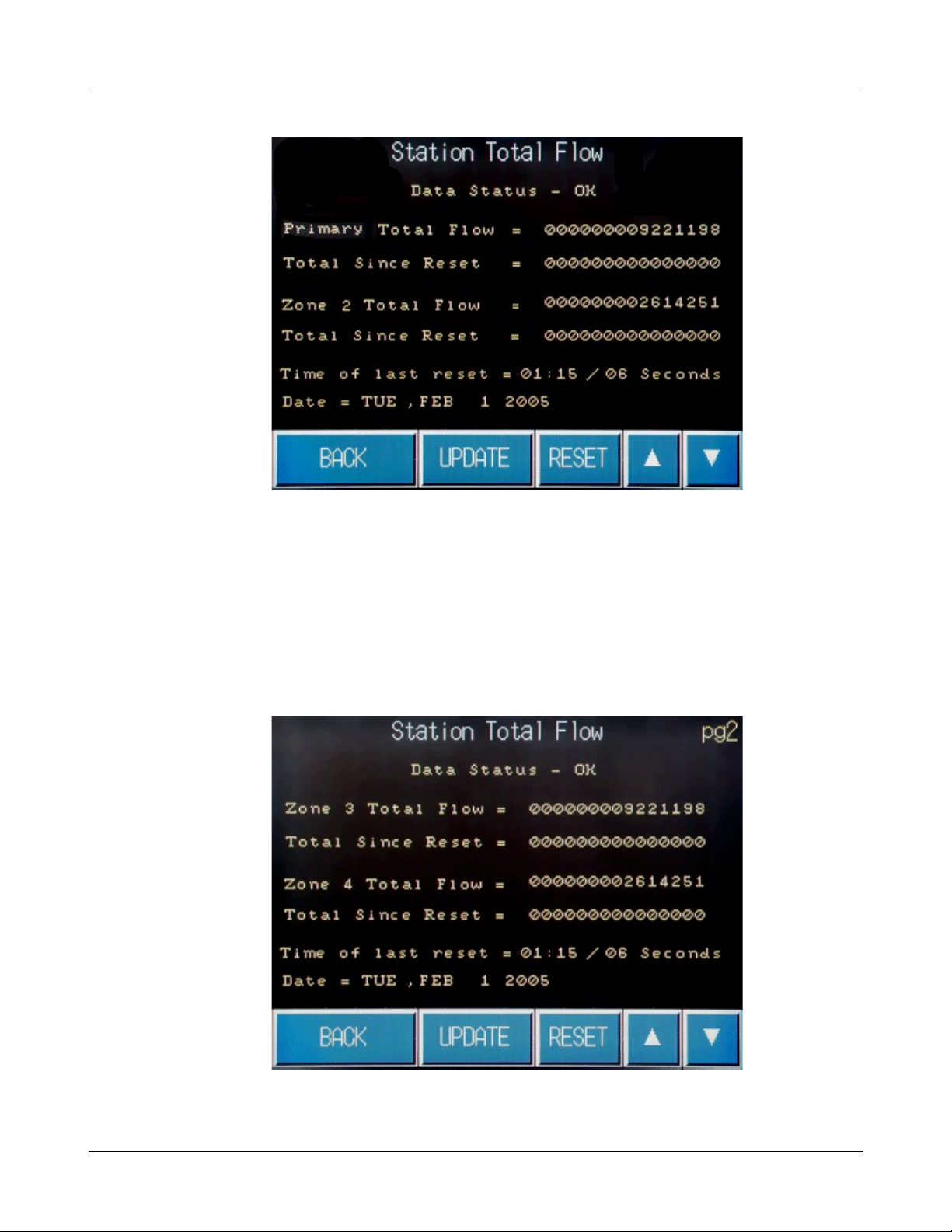

1.1.7 Total Output

!

The Total Output screens can be accessed from the Main Menu.

!

!

!

·

Press the Total Output touch key and display the Station Total Flow screen.

Page 23

© 2013 Flowtronex

Basic Navigation

19

!

!

!

!

!

!

!

The values initially displayed for the flow totals are from the last time that this screen was

accessed

and

updated. This page is also used to view a second flow rate and total if your station is so equipped.

Both pages allow you to view the time and date of the last reset.

!

The Station Total Flow page 1 screen is read-only. Total Flow information shown is fed directly from

the PLC for the Primary Total Flow and Zone 2.

!

·

Press Update touch key to update values from the PLC.

!

·

Press the down arrow (▼) in the bottom right corner of the screen to display to the second Station

Total Flow screens.

!

!

!

The Station Total Flow page 2 screen displays read-only, Total Flow information fed directly from the

Page 24

© 2013 Flowtronex

20

Omron Touch-Screen Display

!

!

!

!

!

PLC for Zone 3 and 4.

!

·

Press Update touch key to update values from the PLC.

!

!

Note:

Always press the Update touch key. This will accomplish two functions. It will grab

the current values from the PLC, and it continuously updates the values while this

screen is open.

!

Be very careful about pressing the Reset touch key, as it resets all four flows (if

your station is so equipped). If you have more than two flows, it is recommended

that you advance to the second page before pressing the Reset touch key.

!

!

·

Optionally, press the Reset touch key to reset the values. (See note above).

!

·

Optionally, press Back to return to the Main Menu.

!

·

Press the up arrow (▲) in the bottom right corner of the screen to return to the first Station Flow

Total

screen.

!

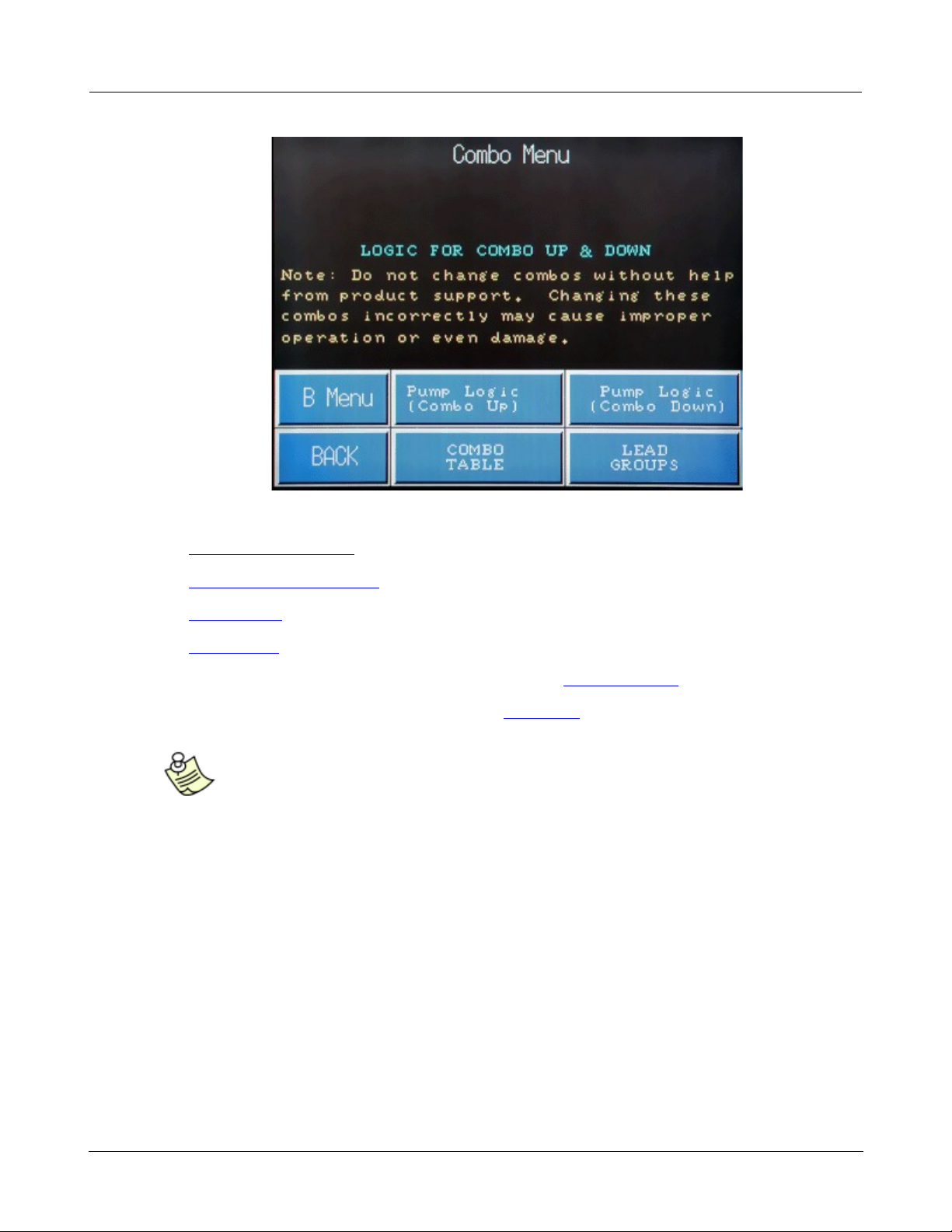

1.1.8 Start Stop Menu (Combo Menu)

!

Access the Combo Menu by pressing the StartStop key on the Main Menu.

!

!

!

·

Tap the StartStop Menu key on the Main Menu to display the Combo Menu Screen.

Page 25

© 2013 Flowtronex

Basic Navigation

21

!

!

!

!

!

!

Tap one of the following keys on the Combo Menu:

!

·

Pump Logic (Combo Up)

!

·

Pump Logic (Combo Down)

!

·

Combo Table

!

·

Lead Groups.

!

·

Optionally, press the B Menu touch key to return to the B Register Menu screen.

!

·

Optionally, press the Back key to return to the Main Menu.

!

!

Note:

Contact Product Support before attempting to changes any combos. Improper

settings can result in damage to your pumping stations or operational failure

!

!

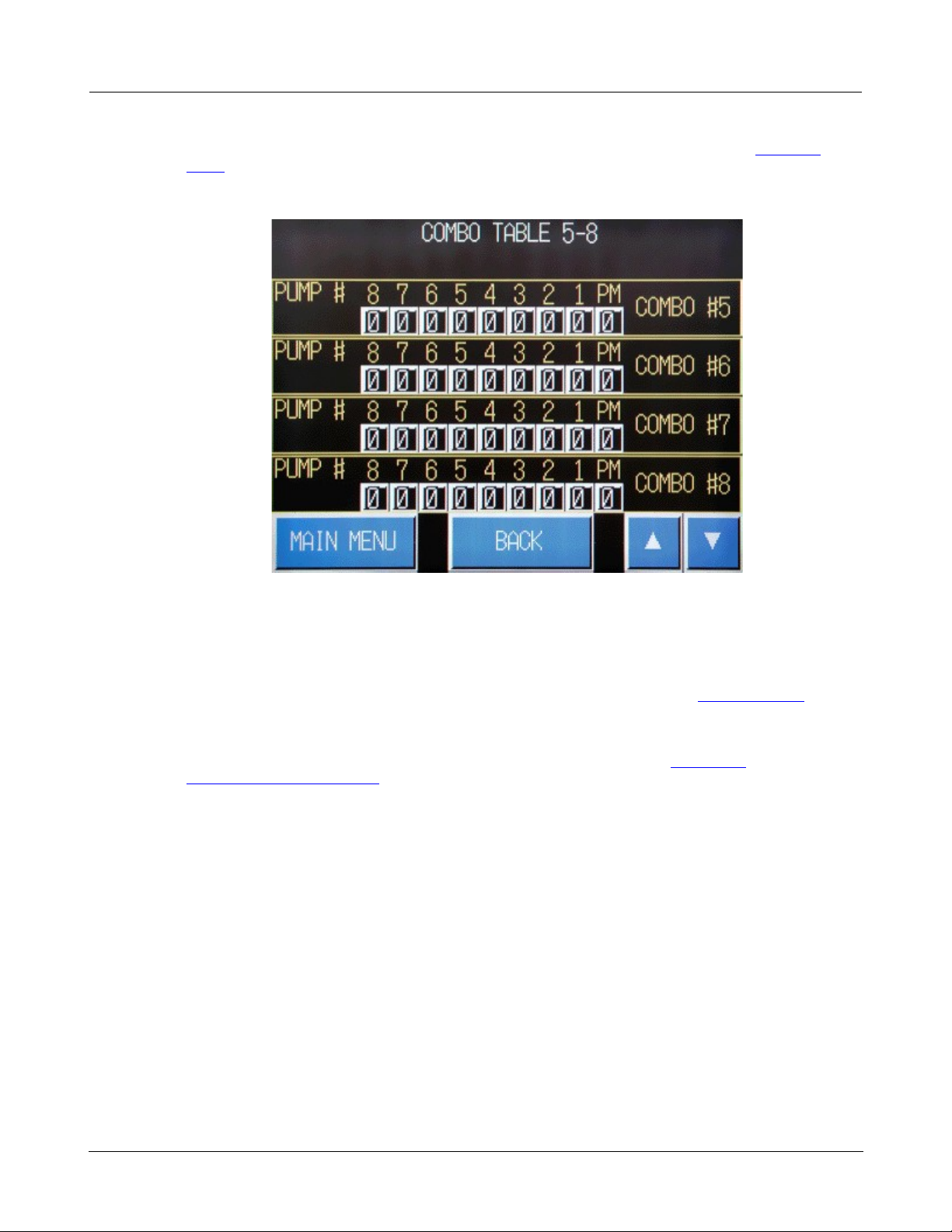

1.1.9 Combos

!

You can display and view the Combo Tables by pressing the Combos key on the Main Menu menu.

The Combo Tables show the pumps assigned to a Combo group (numbered 1 through 8).

Page 26

© 2013 Flowtronex

22

Omron Touch-Screen Display

!

!

!

!

!

!

!

There are two Combo Tables, Combo Table 1-4 and Combo Table 5-8.

!

!

!

The Combo Table is actually a grid with the Combo numbers (Combo #1 to Combo #4) shown on the

right side and the pump numbers (PM and 1-8) shown on the top. The white boxes below the pump

numbers are enabling bits that show if the pump is enabled or disabled. As shown on the screen

above, a one (1) indicates the pump is enabled and a zero (0) shows the pump is not enabled in the

combo group.

For example, Combo #1 above has only the PM pump enabled. In Combo #2, only Pump #2 is

enabled and the PM pump is disabled for this combo. Combo #3 has Pumps #1,# 2, and #3

available and the PM pump is not enabled.

!

·

Optionally, press the Main Menu touch key to return to the Main Menu. (See also, Main Menu.)

Page 27

© 2013 Flowtronex

Basic Navigation

23

!

!

!

!

!

·

Optionally, press the Combo Menu key to view the Combo Menu screen. (See also StartStop

Menu).

!

·

Optionally, press the down (▼) arrow to display Combo Table 5-8 screen.

!

!

!

No pumps are enabled for Combo #5 to #8 shown on the second Combo Table screen.

!

·

To enable a pump, tap on the zero field and a green one is displayed. The number toggles

between a zero (0) and a one (1).

!

·

Optionally, press the Back key to view the Combo Menu screen. (See also StartStop Menu).

!

·

Optionally, press the up (▲) arrows to display Combo Table1-4 screen.

!

·

Press the Main Menu touch key to return to the Main Menu. (See also, Main Menu.) See also

Change Combo Parameters.

Page 28

© 2013 Flowtronex

24

Omron Touch-Screen Display

!

!

!

!

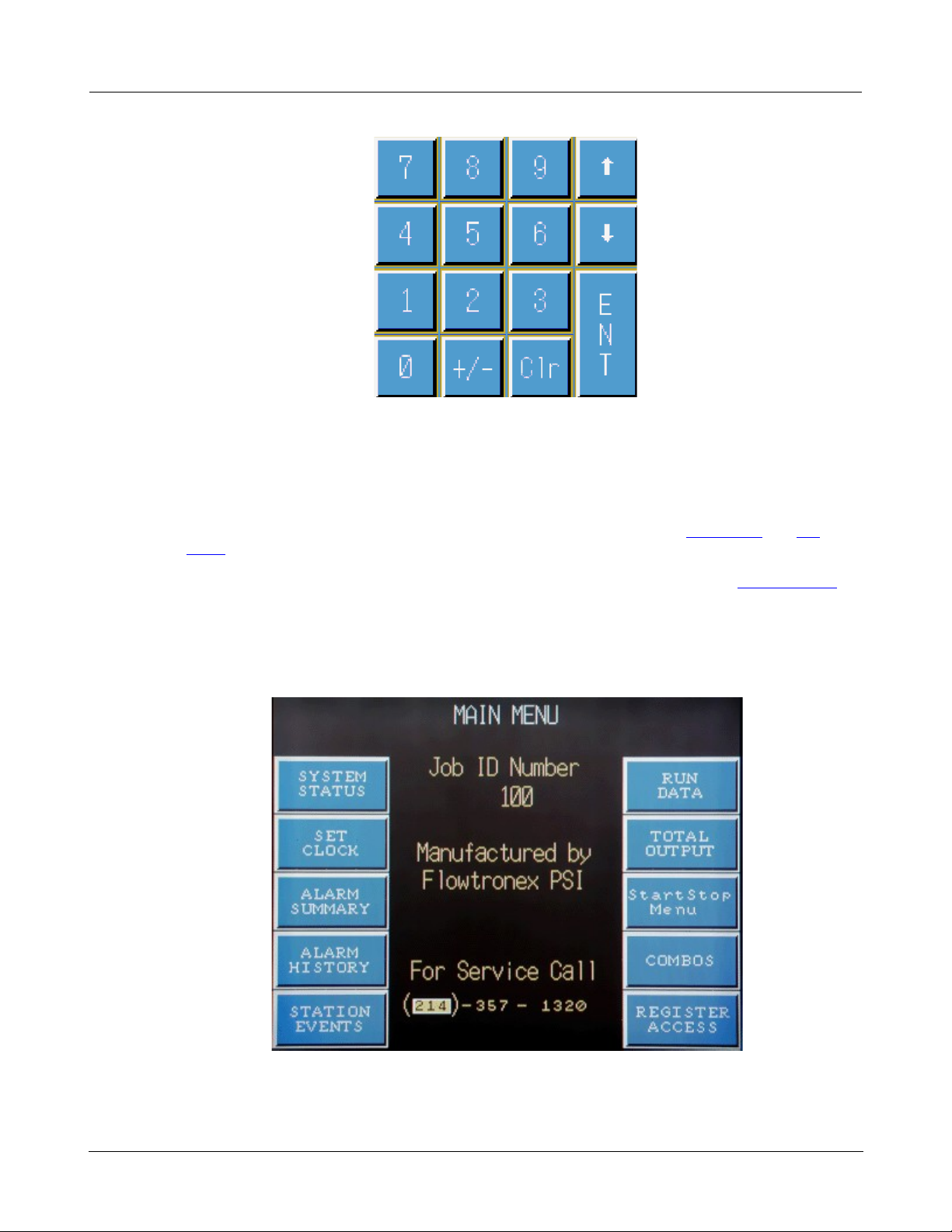

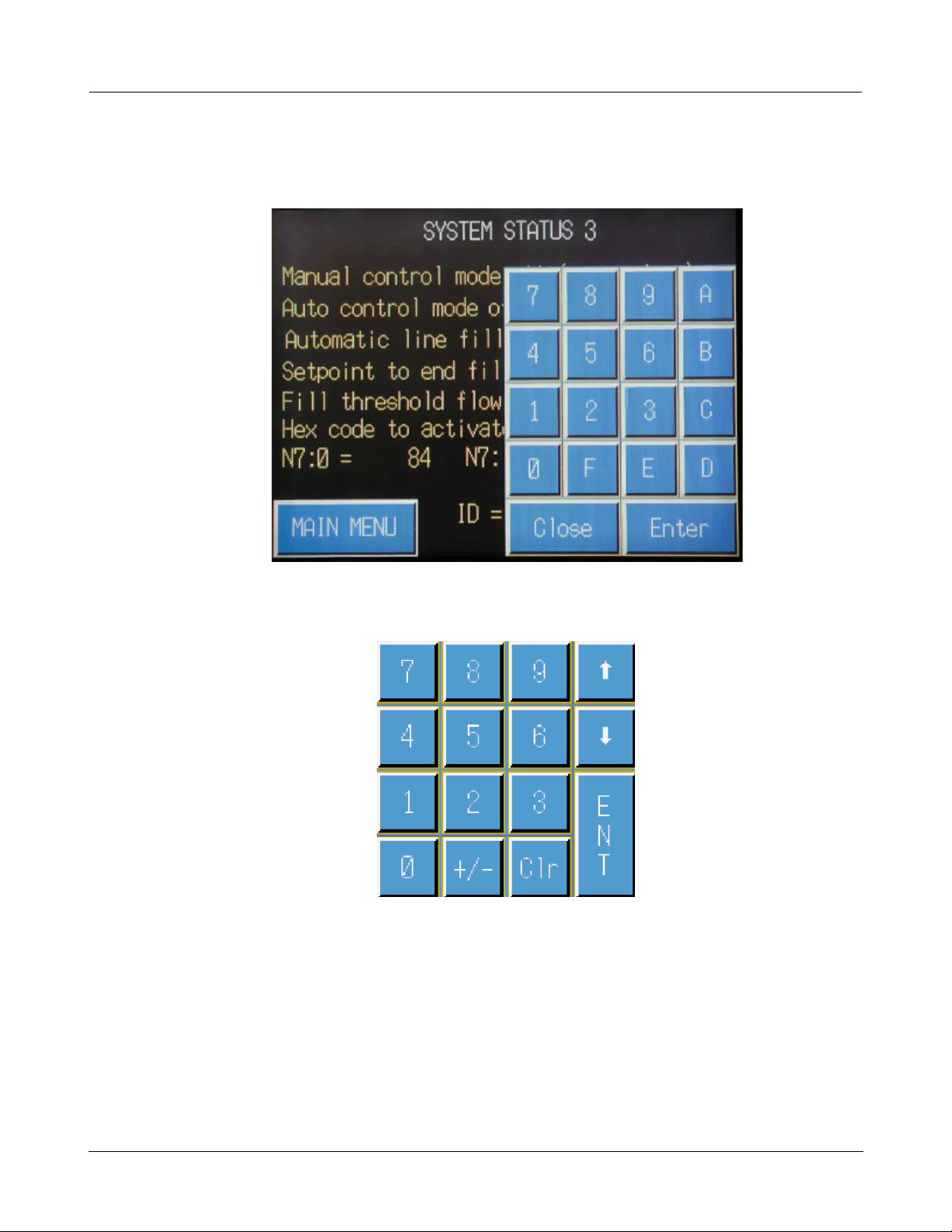

1.2 Calculator/Keypad

!

The calculator/keypad pops over the displayed screen when you tap on an editable value field.

!

!

!

·

Generally, the calculator/keypad, shown below is displayed. When needed, such as when entering

hex numbers, the alphanumeric keypad shown above is displayed.

!

!

!

·

Tap and hold stylus in a blank field to display the appropriate keypad popup screen.

!

– Tap the 0 to 9 (or if displayed, A through F) keys to enter a value.

!

– Tap up arrow

(↑)

or down arrow (↓) to move to the next field for entry.

!

– Tap the ENT or Enter key to have number entered as a value on the displayed screen.

!

– Tap Clr or Close to close popup and return to the displayed screen.

!

– Tap +/- key on the calculator/keypad to toggle the number selected to a positive or negative. If

the selected number is currently positive (such as, 23), tap on the +/- key to make it a negative

Page 29

© 2013 Flowtronex

Basic Navigation

25

!

!

!

!

!

number (such as, –23).

!

1.3 Password Protected Screens

!

The display has certain functions or screens that are password protected and can only be accessed by

a certified Flowtronex® technician (or end users if a passwords is provided). If you press a touch key

and the screen doesn't open, it is not available to the end user. These password-protected screens

are listed below.

!

§ Combos Up/Down

!

§ Combos

!

§ PID Tuning

!

§ Calibration

!

§ Start/Stop Features

!

§ Calibration (analog)

!

§ I/O Control Data

!

§ Totalizers

!

§ N99 Config and ID

!

§ Datalogging Control N104:xx

!

§ B3:xx Mode, Max Speed, and Jockey Cycle

!

§ B40:xx Combos

!

§ B60:xx Pump & Accessory Definitions

!

!

Note:

The end user should call Flowtronex® Product Support (1-800-786-7480) to

determine whether access is required and/or authorized.

!

!

The functionality of these screens is discussed in the "How Do I?" section of this manual (See also,

How Do I?.) This allows the Flowtronex® technician to utilize this manual. Also, if Product Support

determines an End Users needs to access these screens, they can provide users with an access

Password.

!

1.4 Register Access

Menus

!

The Register Access screen is displayed when you press the Register Access touch key on the Main

Menu.

Page 30

© 2013 Flowtronex

26

Omron Touch-Screen Display

!

!

!

!

!

!

!

The different screens and their functions accessed from the Register Access screen are discussed in

the How Do I section of this manual. (See also, How Do I?.)

!

!

!

The Register Access screen displays ten touch keys:

!

!

·

N20 &N21 Combo & Auxiliary Setpoints

·

N20 & N23 VFD Bypass

!

·

N70 & N71 Safeties

·

N23 Flow Stop

!

·

N7 XXX PID Tuning

·

Auto Lake Screen, Lake Fill & Filter

!

·

Timer Access

·

N Register Menu

Page 31

© 2013 Flowtronex

Basic Navigation

27

!

!

!

!

!

!

·

Lockout Settings

·

B Register Menu

!

·

Optionally, press the Main Menu touch key to return to the Main Menu. (See also, Main Menu.)

!

!

Note:

If you press a touch key and the screen doesn't open, it is not available to the end

user. See also, Password Protected Screens.

!

!

1.4.1 N Register Menu Key

!

Press the N Register Menu key on the Register Access Screen to open the N Register screen:

!

!

!

On the N Register Access menu, press one of the following keys:

!

!

·

Calibration

·

I/O Control Data

·

I/O Buffers

N51:xx

!

·

Start/Stop Features

·

More N7 Regs Misc.

Control

·

Datalogging Control N104:

xx

!

·

Custom Features

·

Totalizers

·

Back

!

·

Pulse Flowmeter Data

·

Interchange Groups

!

·

Main Menu

·

N99 Config And ID

!

!

!

Note:

If you press a touch key and the screen doesn't open, it is not available to the end

user. See also, Password Protected Screens.

Page 32

© 2013 Flowtronex

28

Omron Touch-Screen Display

!

!

!

!

1.4.2 B Register Menu Key

!

Press the N Register Menu key on the Register Access Screen to open the N Register screen:

!

!

!

On the B Register Access menu, press one of the following keys:

!

!

·

B3:xx Mode, Max Speed & Jockey Cycle

·

B85:xx Booster Pump Definitions

!

·

B40:xx Combos

·

B90:xx Timed Pump Definitions

!

·

B60:xx Pump & Accessory Definitions

·

B41:xx Pump Outputs

!

·

Main Menu

·

Back

!

!

!

Note:

If you press a touch key and the screen doesn't open, it is not available to the end

user. See also, Password Protected Screens.

!

!

!

2.0 How Do I?

!

The "How Do I?" section of the manual gives you step-by-step instruction to view and edit the pump

station's system parameters. Certain screens are password protected and can only be accessed by a

certified Flowtronex® technician. In some instances, end users may be given a password to access

and change certain functions under the direction of a technician or Product Support representative.

Follow the directions for changes given by these authorized personnel. Damage or malfunction of your

station could result if information entered is not correct. If you press a touch key and the screen

doesn't open, it is not available to an end user.

Page 33

© 2013 Flowtronex

How Do I?

29

!

!

!

!

2.1 Set Clock

!

You can access the Set Clock screen by pressing the Set Clock touch key on the Main Menu.

!

·

Press the Set Clock touch key on the Main Menu to open the Set Clock screen and set the time

on the PLC.

!

!

!

·

Tap on any of the value fields to open the pop-over calculator/keypad and change the values for

Day and Time. (See also, Calculator/Keypad.).

!

·

Press the System Status key to return to the Main Menu. (See also, System Status.)

!

·

Press the Back key to return to the Main Menu. (See also, Main Menu.)

!

2.2 Reset Alarms

!

Use the Reset button on the enclosure door to reset faults and alarms.

!

!

Note:

The Master Control Interface (MCI) only displays the status of alarms—it does not

clear them.

!

!

Keep in mind, the Low Discharge Pressure switch in the door can be placed in Override, allowing the

pump station to run, build pressure, and remove the Low Discharge Pressure Fault. In the case of a

VFD fault, the fault must be cleared by cycling the power off and on.

!

If a fault or alarm does not reset, the fault is still present. Further troubleshooting and repair must be

performed. Contact Flowtronex® Product Support for further instructions.

Page 34

© 2013 Flowtronex

30

Omron Touch-Screen Display

!

!

!

!

2.3 Change Combo Parameters

!

You can define combo setpoints and parameters by pressing the Register Access touch key on the

Main Menu and opening the Register Access screen.

!

!

!

·

Press the N20 & N21 Combo & Auxiliary Setpoints touch key on the Register Access screen to

open the first of three Combo setpoints screens.

!

!

·

Tap the value field next to any of these registers and the calculator/keypad pops-over the screen.

Enter or edit the value. (See also, Calculator/Keypad.)

!

– Enter the normal mode setpoint in PSI in the N20:0 register. A common setpoint is 120 PSI.

!

– Enter the maximum number of combos (1 to 8) normally used in the N20:1 register.

Page 35

© 2013 Flowtronex

How Do I?

31

!

!

!

!

!

– Enter the setpoint in PSI for Lockout #1 in the N20:3 register. A common setpoint is 120 PSI.

!

– Enter the maximum combo used for Lockout #1 in the N20:4 register.

!

– Enter the setpoint in PSI for Lockout #2 in the N20:5 register. A common setpoint is 120 PSI.

!

– Enter the maximum combo used for Lockout #1 in the N20:6 register.

!

·

Optionally, press the Main Menu touch key to return to the Main Menu. (See also, Main Menu.)

!

·

Optionally, press Back to return to the Register Access key.

!

·

Press the down arrow (▼) in the bottom right corner of the screen to open the next

screen, Combo setpoints page 2.

!

!

!

·

N21:3 defines the pressure below normal setpoint pressure when the first pump (usually the PM

pump, but not always) starts automatically.

!

·

N21:4 defines the time delay before the first pump starts, once the start pressure is reached. This

is normally set to 0.

!

For example, if your normal setpoint pressure is 120 PSI and you enter 10 in N21:3, the first

pump comes on at 110 PSI.

!

·

N21:5 defines the pressure above normal setpoint pressure when the first pump (usually the PM

pump, but not always) stops automatically.

!

For example, if your normal setpoint pressure is 120 PSI and you enter 5 in N21:5, the first

pump retires at 125 PSI.

!

Note:

If this is the first main pump, and it is controlled by a VFD, the value needs to be -2. If station

flow is less than 20 GPM, and the station pressure is at the normal setpoint (125 PSI in this

example), the PLC does a speed test to determine whether to shut the pump down. A speed test

means that the VFD slows down to minimum speed. If the station pressure remains at or above

Page 36

© 2013 Flowtronex

32

Omron Touch-Screen Display

!

!

!

!

!

the value entered in N21:9 (123 PSI in this example), then the pump is retired.

!

·

N21:6 defines the delay time before the first pump stops once the stop pressure is reached. This

is normally set to between 5 and 10 seconds.

!

·

N21:7 defines the pressure below normal setpoint pressure when the second pump (normally the

first main pump, but not always) will start automatically.

!

For example, if your normal setpoint pressure is 120 PSI and you enter 15 in N21:7, the second

pump comes on at 105 PSI.

!

·

N21:8 defines the delay time before the first pump starts, once the start pressure is reached. This

is normally set to 0.

!

·

Tap the value field next to any of these registers and the calculator/keypad pops-over the screen.

Enter or edit the value. (See also, Calculator/Keypad.)

!

·

To define combos 2 and 3+, press the down arrow (▼) in the bottom right corner of the screen

to display Combo setpoints page 3.

!

·

Optionally, press the Main Menu touch key to return to the Main Menu. (See also, Main Menu.)

!

·

Optionally, press Back to return to the Register Access screen.

!

!

!

·

N21:9 defines the pressure above normal setpoint pressure when the second pump (usually the

first main pump, but not always) will stop automatically.

!

For example, if your normal setpoint pressure is 120 PSI and you enter 5 in N21:9, the second

pump retires at 125 PSI.

!

Note:

If this is the first main pump, and it is controlled by a VFD, the value needs to be -2. If station

flow is less than 20 GPM and the station pressure is at the normal setpoint (125 PSI in this

example) the PLC does a speed test to determine whether to shut the pump down. A speed test

means that the VFD slows down to minimum speed. If the station pressure remains at or above

Page 37

© 2013 Flowtronex

How Do I?

33

!

!

!

!

!

the value entered in N21:9 (123 PSI in this example), ,then the pump is retired.

!

Note:

The second (and higher) main pump is normally not controlled by the VFD. Therefore, the value

in N21:13 is usually set to 30 PSI. In the case of multiple VFDs, the value would be -2.

!

·

N21:10 defines the delay time before the second pump stops, once the stop pressure is reached.

This is normally set to 10 seconds.

!

·

N21:11 defines the pressure below normal setpoint pressure when the third pump (normally the

second main pump, but not always) starts automatically.

!

For example, if your normal setpoint pressure is 120 PSI and you enter 15 in N21:11, the second

pump comes on at 105 PSI.

!

·

N21:12 defines the delay time before the third pump starts, once the start pressure is reached.

This is normally set to 0.

!

·

N21:13 defines the pressure above normal setpoint pressure when the third pump (usually the

second main pump, but not always) stops automatically.

!

For example, if your normal setpoint pressure is 120 PSI and you enter 5 in N21:13, the first

pump retires at 125 PSI.

!

Note:

The second (and higher) main pump is normally not controlled by the VFD. Therefore, the value

in N21:13 is usually set to 30 PSI. In the case of multiple VFDs, the value would be -2.

!

·

N21:14 defines the delay time before the third pump stops once the stop pressure is reached. This

is normally set to 90 seconds.

!

·

Tap the value field next to any of these registers and the calculator/keypad pops-over the screen.

Enter or edit the value. (See also, Calculator/Keypad.)

!

!

Note:

Use the values defined for combo 3 when the number of combos exceeds 3.

!

!

!

·

Optionally, press the Main Menu touch key to return to the Main Menu. (See also, Main Menu.)

!

·

Optionally, press Back to return to the Register Access screen.

!

·

Press press the down arrow (▼) in the bottom right corner of the screen to display

Combo setpoints page 4.

!

Three auxiliary setpoints can be used and set up on page 4, Aux Setpoints screen.

Page 38

© 2013 Flowtronex

34

Omron Touch-Screen Display

!

!

!

!

!

!

!

·

Define auxiliary setpoint #1 in the N20:7, Setpoint #2 in the N20:8, and Setpoint #3 in the N20:9.

All setpoint are in PSI.

!

·

Tap the value field next to any of these registers and the calculator/keypad pops-over the screen.

Enter or edit the setpoint value in PSI. (See also, Calculator/Keypad.)

!

·

Press the down arrow (▼) in the bottom right corner of the screen to display Combo

setpoints page 1.

!

·

Press the up arrow (▲) in the bottom right corner of the screen to display Combo setpoints page

3.

!

·

Optionally, press the Main Menu touch key to return to the Main Menu. (See also, Main Menu.)

!

·

Optionally, press Back to return to the Register Access screen.

!

2.4 Define Safety Parameters

!

You can access the Safeties register screens and define your safety parameters, faults, and alarms by

pressing the Register Access touch key on the Main Menu and opening the Register Access screen.

!

!

Note:

Please consult Flowtronex® Product Support before making any changes.

Significant damage to your station could potentially occur if safeties are disabled

by entering invalid values in these registers.

Page 39

© 2013 Flowtronex

How Do I?

35

!

!

!

!

!

!

!

·

Press the N70 & N71 Safeties touch key on the Register Access screen to display the first of three

Safety registers screens.

!

!

!

·

N71:0 defines your Low Pressure Discharge fault. The recommended value to enter is 25 PSI.

!

For example, if your setpoint is 120 PSI and 25 PSI is entered in N71:0, a shutdown on low

pressure is initiated when the station pressure drops to 95 PSI.

!

!

Note:

The recommended value to enter is 25 PSI. This value is rarely changed except for a

booster application.

Page 40

© 2013 Flowtronex

36

Omron Touch-Screen Display

!

!

!

!

!

For example, a pump station supplied by city water has an inlet pressure of 50 PSI. The desired

setpoint pressure is 120 PSI. However, you don't want to start your pumps until there is an actual

demand to avoid pump cycling. Therefore, you would want your pumps to start at approximately

45 PSI. This would require your pressure below normal setpoint pressure to be 75 PSI (120 - 45)

for all of your combos. Please refer to the Change Combo Parameters section of this manual for

the register numbers. Obviously, you cannot have the low discharge pressure set to fault at 95

PSI in this application. It is recommended in this case that N71:0 be set to 90 PSI (120 - 30). This

value would cause the station to fault on low discharge pressure when station pressure dropped

to 30 PSI.

!

!

Note:

Never set the N71:0 register to 0, since this would effectively disable your Low

Discharge Pressure fault.

!

!

·

N70:0 defines the delay time for the Low Discharge Pressure fault. The default value for this

parameter is 300 seconds.

!

For example, by entering 300 seconds in the N70:0 register, the station pressure would have to

remain below the value entered in N71:0 for 5 minutes before the station would shutdown.

!

·

N71:1 is the pressure above setpoint for the High Discharge Pressure fault. The default value is

15 PSI.

!

For example, continuing the 120 PSI setpoint example, if the default value of 15 PSI is entered in

N71:1, the station would shut down on a High Discharge Pressure fault when station pressure

rose to 135 PSI.

!

·

N70:1 is the delay time for a High Discharge Pressure fault. The default value is 60 seconds.

For example, the station pressure would have to remain above the value entered in N71:1 for 1

minute (or 60 seconds) before the station would shutdown.

!

·

N70:2 is the delay time for a Low Water Level fault. The default value is 5 seconds. This is an

option is used when probes are placed at a certain depth in the wet well or lake to prevent

excessive draw down.

!

·

N70:3 is the delay time for a Phase Failure fault. The default value is 1 second.

!

·

N70:4 is the delay time for a VFD fault. The default value is 2 seconds.

!

·

Tap the value field next to any of these registers and the calculator/keypad pops-over the screen.

Enter or edit the value. (See also, Calculator/Keypad.)

!

·

Optionally, press the Main Menu touch key to return to the Main Menu. (See also, Main Menu.)

!

·

Optionally, press Back to return to Register Access screen.

!

·

Press the down arrow (▼) in the bottom right corner of the screen to display the Safety

registers page 2.

Page 41

© 2013 Flowtronex

How Do I?

37

!

!

!

!

!

!

!

The second Safety registers screen is devoted to optional safeties.

!

·

N70:6 is the delay time for a Loss of Prime fault. In this case, a probe is placed in the suction

piping. The default value is 0 seconds.

!

·

N70:7 is the delay time for a Low Inlet Pressure fault. Normally a pressure switch is installed in the

suction piping. The default value is 20 seconds.

!

·

N70:8 is the delay time for a Flow Over-demand fault. The default value is 180 seconds.

!

·

N71:8 is the flow at which a Flow Over-demand fault occurs. The default value is your total station

flow plus 20%.

!

·

N70:9 is the delay time for a Filter Fault. The default value is 0 seconds.

!

·

Optionally, press the Main Menu touch key to return to the Main Menu. (See also, Main Menu.)

!

·

Optionally, press Back to return to the Register Access screen.

!

·

Press the down arrow (▼) in the bottom right corner of the screen to display the Safety

registers page 3.

Page 42

© 2013 Flowtronex

38

Omron Touch-Screen Display

!

!

!

!

!

!

!

Rarely used, the Safety registers page 3 is used for optional safeties.

!

·

N70:11 is the time delay for an Air Temperature fault. This is sometimes used in cold weather

applications to prevent pump station operation when the air temperature approaches freezing. The

default value is 0 seconds.

!

·

N70:13 is the time delay for a Second Level fault. This delay is occasionally used to show a PM or

jockey pump fault. The default value is 5 seconds.

!

·

N70:15 and N70:10 are time delays for Special Faults that are custom programmed faults.

!

·

Tap the value field next to any of these registers and the calculator/keypad pops-over the screen..

(See also, Calculator/Keypad.)

!

·

Optionally, press the Main Menu touch key to return to the Main Menu. (See also, Main Menu.)

!

·

Optionally, press Back to return to the Register Access screen.

!

·

Press the up arrow (▲) in the bottom right corner of the screen to display the Safety

registers page 2.

!

2.5 Tune my Pump Station using PID

!

The PID Tuning screen is not available to an end user. PID Tuning is a critical function and is

performed only by a FlowNet technician, generally during the initial startup of a pump station that use

VFD(s). You can access the PID tuning screens by pressing the Register Access touch key on the

Main Menu and opening the Register Access screen.

Page 43

© 2013 Flowtronex

How Do I?

39

!

!

!

!

!

!

!

·

Press the N7:xxx PID Tuning touch key on the Register Access screen to open the first of two PID

tuning screen.

!

!

!

·

N7:160 is the PID threshold for high-flow coefficients. This is the VFD speed (in counts) when the

PLC switches from the low-flow coefficients to the high-flow coefficients, since some pump

stations perform differently at different flows. The default value is normally 31495. .

!

·

N7:175 is the PID responsiveness value for one register tuning. The default value is 520.

Decreasing the value of this register slows down the responsiveness of the PID loop. Normally,

this should be done if the station is overshooting the setpoint on initial ramp up. Increasing the

value of this register speeds up the responsiveness of the PID loop. This value should also be

changed if the station is taking too long to get to the setpoint. Changes should be made in

increments of no more than 200 with a minimum and maximum values range of 200 and 1100.

Page 44

© 2013 Flowtronex

40

Omron Touch-Screen Display

!

!

!

!

!

Tuning can also be accomplished by tuning the individual low- and high-flow coefficients. This is

especially true if the station performance is significantly different at low and high flows

!

·

N7:161 is the Low-Flow Proportional Coefficient. The default value is 40.

!

·

N7:162 is the Low-Flow Integral Coefficient. The default value is 80. If the station is overshooting

the setpoint on initial ramp up, the responsiveness of the PID loop can be slowed down by

decreasing the value in N7:161, and increasing the value in N7:162. If the station is slow in

reaching the setpoint on initial ramp up, the responsiveness of the PID loop can be sped up by

increasing the value in N7:161, and decreasing the value in N7:162.

!

·

N7:163 is the High-Flow Proportional Coefficient.

!

·

N7:164 is the High-Flow Integral Coefficient.

!

·

N7:165 is the Minimum VFD Speed when ramp-up is complete.

!

·

Tap the value field next to any of these registers and the calculator/keypad pops-over the screen.

Enter or edit the value. (See also, Calculator/Keypad.)

!

·

Optionally, press the Main Menu touch key to return to the Main Menu. (See also, Main Menu.)

!

·

Optionally, press Back to return to the Register Access screen.

!

·

Press the down arrow (▼) in the bottom right corner of the screen to display the PID

Tuning screen page 3.

!

!

!

·

N7:192 is the VFD Speed in counts when lag pump starts.

!

·

N7:193 is the VFD Speed in counts when lag pump stops.

!

·

N7:155 is the Maximum Inverter Speed in counts during Speed Test.

!

·

N7:55 is the Ramp-up Rate in seconds during system pressure-up.

!

·

N7:156 is the Delay time in seconds until Speed Test begins.

Page 45

© 2013 Flowtronex

How Do I?

41

!

!

!

!

!

·

N7:158 is the Maximum Flow in GPM needed to begin Speed Test.

!

·

To enter or change a value, tap on any value field to open the calculator/keypad. (See,

Calculator/Keypad.)

!

·

Optionally, press the Main Menu touch key to return to the Main Menu. (See also, Main Menu.)

!

·

Optionally, press Back to return to the Register Access menu.

!

·

Press the up arrow (▲) in the bottom right corner of the screen to display the PID Tuning

screen page 1.

!

2.6 Define Timer Parameters

!

You can access the Timer Access register screens and define your time parameters by pressing

the

Register Access touch key on the Main Menu and opening the Register Access screen.

!

!

!

·

Press the Timer Access touch key on the Register Access screen to open the first of two Timer

Access screen. All times shown are in seconds.

Page 46

© 2013 Flowtronex

42

Omron Touch-Screen Display

!

!

!

!

!

!

!

!

Note:

The values on Timer Access page 1 and page 2 are set at the factory and should

not require changing.

!

!

·

Enter a time in seconds in the T4:04 Pre field. Default delay time is 45 seconds for the Pump

anti-cycle fault.

!

·

Enter a time in seconds in the T4:16 Pre field. Default delay time is 15 seconds for the Long start

inhibit fault.

!

·

Enter a time in seconds in the T4:38 Pre field. Default delay time is 3 seconds for the Short start

inhibit fault.

!

·

Enter a time in seconds in the T25:25 Pre field. Default delay time is 15 seconds for the Delay til

lamp test fault.

!

·

Tap the value field next to any of these registers and the calculator/keypad pops-over the screen.

Enter or edit the value. (See also, Calculator/Keypad.)

!

·

Optionally, press the Main Menu touch key to return to the Main Menu. (See also, Main Menu.)

!

·

Optionally, press Back to return to the Register Access screen.

!

·

Press the down arrow (▼) in the bottom right corner of the screen to open the next screen, Timer

Access page 2.

Page 47

© 2013 Flowtronex

How Do I?

43

!

!

!

!

!

!

!

·

Enter a time in seconds in the T4:28 Pre field. Default delay time is 50 seconds for the Time until

dP (Differential Pressure) fault used on the Torpedo and scanner filters.

!

·

Enter a time in seconds in the T4:40 Pre field. Default delay time is 3 seconds for the VFD run

feedback fault.

!

·

Enter a time in seconds in the T25:30 Pre field. Default delay time is 1 seconds for the Combo

overlap during change.

!

·

Tap the value field next to any of these registers and the calculator/keypad pops-over the screen.

Enter or edit the value. (See also, Calculator/Keypad.)

!

·

Press the up arrow (▲) in the bottom right corner of the screen to open the previous

screen, Timer Access page 1.

!

2.7 Define Lockout, Timed Pump, and Well Pump

Parameters

!

You can access the Lockout register screens and define your lockout parameters by pressing the

Register Access touch key on the Main Menu and opening the Register Access screen.

Page 48

© 2013 Flowtronex

44

Omron Touch-Screen Display

!

!

!

!

!

!

!

·

Press the Lockout Settings touch key on the Register Access screen to open the first of four

Lockout Registers screens.

!

!

!

Lockouts are normally used to restrict the number of pumps that can be used within a given time

frame. They can be set up to run at different setpoints then the normal irrigation cycle.

!

·

N20:0 defines the Normal, PSI Setpoint. A common setpoint used is 120 PSI.

!

·

N20:3 defines the Lockout 1, PSI Setpoint. A common setpoint used is 120 PSI.

!

·

N20:5 defines the Lockout 2, PSI Setpoint. A common setpoint used is 120 PSI.

!

·

N20:1 defines the Max(imum) Combos under Normal conditions. Up to eight combos can be set

Page 49

© 2013 Flowtronex

How Do I?

45

!

!

!

!

!

up.

!

·

N20:4 defines the Lockout 1 maximum number of combos.

!

·

N20:6 defines the Lockout 2 maximum number of combos.

!

·

Tap the value field next to any of these registers and the calculator/keypad pops-over the screen..

(See also, Calculator/Keypad.)

!

·

Optionally, press the Main Menu touch key to return to the Main Menu. (See also, Main Menu.)

!

·

Optionally, press Back to return to the Register Access screen.

!

·

Press the down arrow (▼) in the bottom right corner of the screen to open the next

screen, Lockout Registers page 2.

!

!

!

This screen allows you to set the start and stop times of each lockout period. All times are in 24 hour

military times. It also allows you to turn a timed pump on and off. A timed pump is normally a water

feature pump that needs to run at a certain time.

!

·

Enter a time (in HHMM format) in N7:140 that is the Lockout 1 Start Time.

!

·

Enter a time (in HHMM format) in N7:141 that is the Lockout 1 Stop Time.

!

·

Enter a time (in HHMM format) in N7:142 that is the Lockout 2 Start Time.

!

·

Enter a time (in HHMM format) in N7:143 that is the Lockout2 Stop Time.

!

·

Enter a time (in HHMM format) in N7:144 that is the Time Pump Start Time.

!

·

Enter a time (in HHMM format) in N7:145 that is the Time Pump Stop Time.

!

For example, if you wanted to run from 10 PM to 2 AM, you would set Lockout 1 start time to

2200, and Lockout 1 stop time would be set to 0200.

!

·

Tap the value field next to any of these registers and the calculator/keypad pops-over the screen.

Page 50

© 2013 Flowtronex

46

Omron Touch-Screen Display

!

!

!

!

!

Enter or edit the value. (See also,

Calculator/Keypad.)

!

·

Optionally, press the Main Menu touch key to return to the Main Menu. (See also, Main Menu.)

!

·

Optionally, press Back to return to the Register Access screen.

!

·

Press the down arrow (▼) in the bottom right corner of the screen to open the next

screen, Lockout Registers page 3.

!

!

!

This screen allows you to set the day of the week that you want the lockout to occur. It also allows you

to define what days of the week you want the timed pump to run. Bit Sum values are in Hex code.

!

!

Note:

Lockout 1 always overrides Lockout 2 if both are enabled. Start and stop times for

both lockouts can overlap each other, but the definitions for Lockout 1 apply during

that overlapping period.

!

!

·

Optionally, press the Main Menu touch key to return to the Main Menu. (See also, Main Menu.)

!

·

Optionally, press Back to return to the previous screen.

!

·

Press the down arrow (▼) in the bottom right corner of the screen to open the next

screen, Lockout Registers page 4.

Page 51

© 2013 Flowtronex

How Do I?

47

!

!

!

!

!

!

!

Lockout Registers page 4 screen defines whether well pump(s) can be used within normal and lockout

modes of operation. A well pump can be a transfer out (or de-watering) pump, or a transfer in (lake fill)

pump. Please refer to the Lake fill section of this manual to learn how to define the operating

parameters for the well (lake fill) pump(s).

!

·

B64:0 defines the Well Pumps allowed under Normal operation.

!

·

B64:1 defines the Well Pumps allowed under Lockout 1 operation.

!

·

B64:2 defines the Well Pumps allowed under Lockout 2 operation.

!

The other function this screen serves is to allow you to restrict the maximum VFD speed during the

lockout period. The default value should be 100%. This function is rarely used but could come in handy

when electrical usage is restricted. You could set this value to something like 60 - 80 % and limit your

current draw that way.

!

·

N20:11 defines the Maximum VFD Speed allowed under Lockout 1 operation as a percent.

!

·

N20:12 defines the Maximum VFD Speed allowed under Lockout 2 operation as a percent.

!

·

Tap the value field next to any of these registers and the calculator/keypad pops-over the screen.

Enter or edit the value. (See also, Calculator/Keypad.)

!

!

Note:

Caution should be exercised when using this option. If you set the Maximum speed

too low, the pump might not be able to attain the desired setpoint. Shutting

down

on

a low discharge fault is a distinct possibility. It is suggested that you manually

operate the drive at that speed to determine what pressure and flow it will sustain.

!

!

·

Optionally, press the Main Menu touch key to return to the Main Menu. (See also, Main Menu.)

!

·

Optionally, press Back to return to the previous screen.

!

·

Press the up arrow (▲) in the bottom right corner of the screen to open the previous screen,

Page 52

© 2013 Flowtronex

48

Omron Touch-Screen Display

!

!

!

!

!

Lockout Registers page 3.

!

2.8 Define My VFD Bypass Parameters

!

You can access the VFD Bypass screens and define your VFD parameters by pressing the Register

Access touch key on the Main Menu and opening the Register Access screen.

!

!

!

·

Press the N20 & N23 VFD Bypass touch key on the Register Access screen to open the two VFD

Bypass screens. First, a warning screen is displayed to remind you that this is an emergency

operation and to monitor the motor closely during the process.

!

!

!

·

Press the OK touch key to display VFD Bypass page 1 screen.

Page 53

© 2013 Flowtronex

How Do I?

49

!

!

!

!

!

!

!

The values on the VFD Bypass screen page 1 are similar to but not identical to those used for normal

operation. They rarely would require changing. The default values are shown.

!

·

N21:33 is the pressure below setpoint to start combo 1. Default is 005 PSI

!

·

N21:34 is the delay time to start combo 1. Default is 000 Sec.

!

·

N21:35 is the pressure above setpoint to stop combo 1. Default is 005 PSI

!

·

N21:36 is the delay time to stop combo 1. Default is 005 Sec.

!

·

N21:37 is the pressure below setpoint to start combo 2. Default is 012 PSI.

!

·

N21:38 is the delay time to start combo 1. Default is 010 Sec.

!

·

Tap the value field next to any of these registers and the calculator/keypad pops-over the screen.

Enter or edit the value. (See also, Calculator/Keypad.)

!

·

Optionally, press the Main Menu touch key to return to the Main Menu. (See also, Main Menu.)

!

·

Optionally, press Back to return to the Register Access screen.

!

·

Press the down arrow (▼) in the bottom right corner of the screen to open the next screen,

VFD Bypass page 2.

Page 54

© 2013 Flowtronex

50

Omron Touch-Screen Display

!

!

!

!

!

!

!

·

N21:39 is the pressure above setpoint to stop combo 2. Default is 001 PSI.

!

·

N21:40 is the delay time to stop combo 2. Default is 060 Sec.

!

·

N21:41 is the pressure below setpoint to start combo 3+. Default is 015 PSI.

!

·

N21:42 is the delay time to start combo 3+. Default is 010 Sec.

!

·

N21:43 is the pressure above setpoint to stop combo 3+. Default is 001 PSI.

!

·

N21:44 is the delay time to stop combo 3+. Default is 030 Sec.

!

·

Tap the value field next to any of these registers and the calculator/keypad pops-over the screen.

Enter or edit the value. (See also, Calculator/Keypad.)

!

·

Optionally, press the Main Menu touch key to return to the Main Menu. (See also, Main Menu.)

!

·

Optionally, press Back to return to the Register Access screen.

!

·

Press the up arrow (▲) in the bottom right corner of the screen to open the previous screen,

VFD Bypass page 1.

!

2.9 Define My Auto Lake Screen Parameters

!

You can access the Accessories screen and define your Automated Lake Screen (ALS) parameters by

pressing the Register Access touch key on the Main Menu and opening the Register Access screen.

Page 55

© 2013 Flowtronex

How Do I?

51

!

!

!

!

!

!

!

·

Press the Auto Lake Screen Lake Fill & Filter touch key on the Register Access screen to open

the first Accessories screen.

!

!

!

·

N80:0 is the minimum flow (in GPM) to flush. The pump station flow rate that must be met before

the automatic lake screen is allowed to flush. The default value is normally between 45 and 90

GPM.

!

·

N80:1 is the time (in minutes) between Auto Lake Screen (ALS) Strainer flushes. The normal

default value is 30.

!

·

N80:2 is the flush duration in seconds. Normal default value is 10 to 15 seconds.

!

·

Tap the value field next to any of these registers and the calculator/keypad pops-over the screen.

Page 56

© 2013 Flowtronex

52

Omron Touch-Screen Display

!

!

!

!

!

Enter or edit the value. (See also, Calculator/Keypad.)

!

·

Optionally, press the Main Menu touch key to return to the Main Menu. (See also, Main Menu.)

!

·

Optionally, press Back to return to the Register Access screen.

!

·

Press the up (▲) or down arrow (▼) key to display other Accessories parameters screens.

!

2.10 Define My Lake Fill Parameters

!

You can access the Accessories screen and define your Lake Fill parameters by pressing the Register

Access touch key on the Main Menu and opening the Register Access screen.

!

!

!

·

Press the Auto Lake Screen Lake Fill & Filter touch key on the Register Access screen to open

the first Accessories screen.

Page 57

© 2013 Flowtronex

How Do I?

53

!

!

!

!

!

!

!

!

Note:

As shown in this example, the MCI screens loop around, like the telephone list on a

cell phone. It is sometimes easier to move in the opposite direction to reach an item

at the end of the loop.

!

!

·

Pressing the value next to any of these registers, automatically opens the calculator/keypad. Enter

or edit the value. (See also, Calculator/Keypad.)

!

·

Optionally, press the Main Menu touch key to return to the Main Menu. (See also, Main Menu.)

!

·

Optionally, press Back to return to the Register Access screen.

!

·

Press the up arrow (▲) to advance the Accessories page 4 screen.

Page 58

© 2013 Flowtronex

54

Omron Touch-Screen Display

!

!

!

!

!

!

!

·

N80:31 is the delay time until Fill starts. This is normally set to 10 seconds.

!

·

N80:32 is the delay time until Fill stops. This is also normally set to 10 seconds.

!

One other function is defined on this screen—Flow Activated PLC Relays. Depending on the

equipment connected to the relay, such as a fertigation relay, these two outputs can be used to set up

a minimum station flow required for operation.

!

·

N84:0 is the Flow Activated PLC Relay 1. The default is 100 GPM.

!

·

N84:1 is the another Flow Activated PLC Relay 1 that is rarely used. The default is 0 GPM.

!

·

Tap the value field next to any of these registers and the calculator/keypad pops-over the screen.

Enter or edit the value. (See also, Calculator/Keypad.)

!

·

Optionally, press the Main Menu touch key to return to the Main Menu. (See also, Main Menu.)

!

·

Optionally, press Back to return to the Register Access screen.

!

·

Press the up (▲) or down arrow (▼) key to display other Accessories parameters screens.

!

2.11 Define My Filter Parameters

!

You can access the Accessories screen and define your Filter parameters by pressing the Register

Access touch key on the Main Menu and opening the Register Access screen.

Page 59

© 2013 Flowtronex

How Do I?

55

!

!

!

!

!

!

!

·

Press the Auto Lake Screen Lake Fill & Filter touch key on the Register Access screen to open

the first Accessories screen.

!

!

!

!

Note:

As shown in this example, the MCI screens loop around, like the telephone list on a

cell phone. It is sometimes easier to move in the opposite direction to reach an item

at the end of the loop.

!

!

·

Tap the value next to any of these registers to automatically open the pop-over calculator/keypad.

Enter or edit the value. (See also, Calculator/Keypad.)

Page 60

© 2013 Flowtronex

56

Omron Touch-Screen Display

!

!

!

!

!

·

Optionally, press the Main Menu touch key to return to the Main Menu. (See also, Main Menu.)

!

·

Optionally, press Back to return to the previous screen.

!

·