Page 1

INSTRUCTION MANUAL

19-001-290B

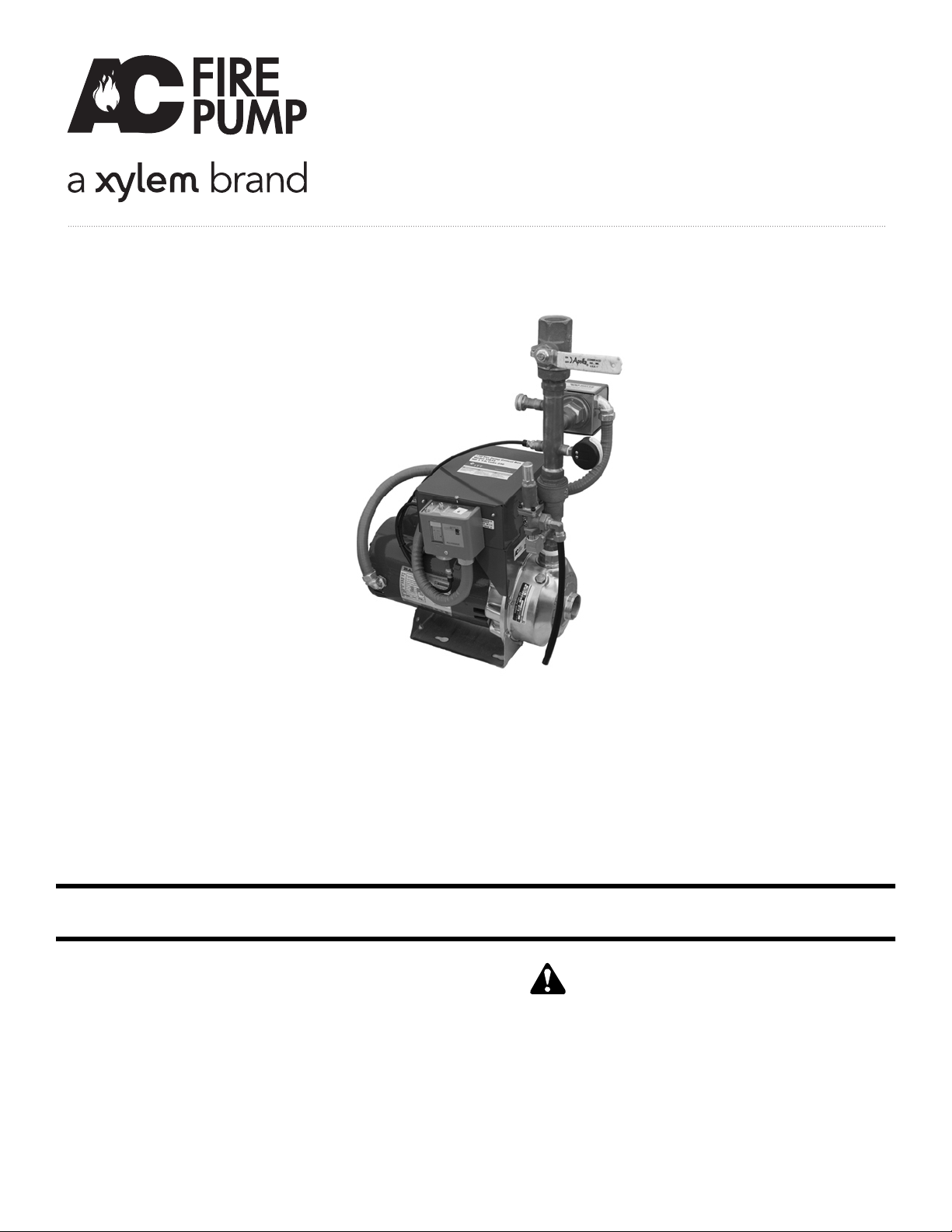

Residential Fire Pump Package

INSTALLER: PLEASE LEAVE THIS MANUAL FOR THE OWNER’S USE.

DESCRIPTION

The assembly consists of a single pump water boosting

system which increases riser pressure by as much as 55 PSI.

The pump is automatically controlled to run on demand. The

system is to be applied to NFPA 13D systems as required.

This safety alert symbol will be used in this manual and on the

Safety Instruction decal to draw attention to safety related

instructions. When used, the safety alert symbol means

ATTENTION! BECOME ALERT! YOUR SAFETY IS

INVOLVED! FAILURE TO FOLLOW THE INSTRUCTION

MAY RESULT IN A SAFETY HAZARD!

SAFETY

INSTRUCTIONS

Page 2

2

SECTION 1 - GENERAL DESCRIPTION Page

Purpose of Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Storage and Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

SECTION 2 - INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

SECTION 3 - PUTTING THE UNIT INTO SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Adjustments and Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

SECTION 4 - FINAL CHECK LISTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Start Up Check List – Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Start Up Check List – Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

SECTION 5 - TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

APPENDIX A - PROGRAMMABLE CONTROL MODULE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

APPENDIX B - FIELD WIRING DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

APPENDIX C - FIELD PIPING DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Index

NOTE: The information contained in this manual is intended to assist operating personnel by providing information on the characteristics of the purchased equipment.

It does not relieve the user of the responsibility to adhere to local codes and ordinances and the use of accepted practices in

the installation, operation and maintenance of this equipment.

Further information pertaining to the installation, operation, and maintenance of your Residential Fire Pump Package can be

found in the installation Operation and Maintenance manuals for the associated equipment provided:

A. RCW NPE Pump (I.O.M. Part IMPROT)

B. Tank (Model Specific)

Page 3

1.1 The residential fire pumping package will increase the

domestic water pressure at the fixtures from 30 to 55

PSI above that of the city water pressure.

1.2 A pressure switch starts and stops the pump.

1.3

PURPOSE OF MANUAL

1.4 This manual is furnished to acquaint you with some

of the practical ways to install, operate, and maintain

this unit. Read it completely before doing any work

on your unit and keep it handy for future reference.

1.5 Equipment cannot operate well without proper care.

To keep this unit at top efficiency, follow the recommended installation and servicing procedure outlined

in this manual.

1.6

SAFETY INSTRUCTION

1.7 This safely alert symbol will be used in this manual

and on the unit safety instruction to draw attention to

safety related instructions. When used the safety alert

symbol means

ATTENTION BECOME ALERT!

YOUR SAFETY IS INVOLVED! FAILURE TO FOLLOW THIS INSTRUCTION MAY RESULT IN A

SAFETY HAZARD.

1.8 ADDITIONAL SAFETY REQUIREMENTS

1.9 Always use accurate test meters when checking electrical components. Always work with another person

in case of emergency.

1.10

STORAGE

1.11 For long periods of storage, the unit should be

covered to prevent corrosion and contamination from

dirt. It should be STORED in a clean, dry location

between 0 and 170°F. The relative humidity should

not exceed 85%. The unit should be checked periodically to ensure that no condensation has formed.

After storage, again check that it is dry before applying power.

1.12

HANDLING

1.13 Care should be taken to prevent damage due to

dropping or jolting when moving the Residential fire

pump package. Transportation damage should be

brought to the carrier's attention immediately upon

receipt.

1.13.1

Location

1.13.2 Install the residential fire pumping package appropriately for ease of inspection, maintenance and service.

Observe local electrical codes concerning control

panel spacing.

1.14 TEMPERATURE AND VENTILATION

1.15 All electrical equipment is susceptible to failure if

operated in ambient temperatures outside of its rating. The OPERATING temperature range for this unit

is 40 to 105°F. The relative humidity should not

exceed 85% non-condensing. The unit should not be

operated outside these extremes.

1.16

ELECTRICAL CONNECTIONS - A.C. POWER &

SIGNALS INPUT VOLTAGE

1.17 The input voltage tolerance is +10/-10% of nameplate voltage.

1.18

GROUND CONNECTIONS

1.19 A grounding terminal is provided for a dedicated

ground wire connection. All provisions of the National

Electrical Code and local codes must be followed.

1.20

POWER WIRING

1.21 Power wire types and sizes must be selected based

upon conformance with the National Electrical Code

and all local codes and restrictions. In addition, only

copper (Cu) wire rated for at least 75°C may be used

for the power connections. Refer to the input current

as listed on the motor nameplate when sizing wire.

Connect the input power to the screw terminals on

the motor contactor labeled "L1" & "L2". Connect a

ground conductor to the ground lug attached to the

circuit board.

1.21.1

System Pressure Switch

1.21.2 A system pressure switch is connected to the terminals labels "Pressure".

3

Section 1 - General Description

WARNING: Heavy load, may drop if not lifted properly.

Do not lift the entire unit by the motor eyebolts. Lift the

unit with slings placed under the unit base rails.

FAILURE

TO FOLLOW THESE INSTRUCTIONS COULD RESULT

IN SERIOUS PERSONAL INJURY, DEATH, AND/OR

PROPERTY DAMAGE.

WARNING: Electrical Shock Hazard. Inspect all

electrical connections prior to powering the unit.

Wiring connections must be made by a qualified electrician

in accordance with all applicable codes, ordinances, and

good practices.

FAILURE TO FOLLOW THESE INSTRUCTIONS COULD RESULT IN SERIOUS PERSONAL

INJURY, DEATH, AND/OR PROPERTY DAMAGE.

WARNING: Prevent electrical shocks. Disconnect

the power supply before beginning installation.

FAILURE TO FOLLOW THESE INSTRUCTIONS COULD

RESULT IN SERIOUS PERSONAL INJURY, DEATH,

AND/OR PROPERTY DAMAGE.

WARNING: Conduit grounds are not adequate. A

separate ground wire must be attached to the ground

lug provided in the enclosure to avoid potential safety hazards.

FAILURE TO FOLLOW THESE INSTRUCTIONS

COULD RESULT IN SERIOUS PERSONAL INJURY,

DEATH, AND/OR PROPERTY DAMAGE.

Page 4

4

1.21.3

Flow Switch

1.21.4 An optional flow switch is connected to the terminals

labels "Flow Sw".

1.21.5

Local or Remote Alarm Indication

1.21.6 Two relay outputs labeled "Out2" and "Out3" rated

for 7 Amps at 240VAC are supplied. These outputs

are normally open and close to indicate an alarm

condition exists. Out3 closes when the pressure

switch closes and stays closed until system pressure

restores and the preset timer expires. Out2 closes

when the flow switch closes and opens when the

flow switch opens.

1.22

FIELD CONNECTION DIAGRAMS

1.23 Refer to the RCW NPE pump Installation, Operation,

and Maintenance manual for specific details

unique to the pump.

1.24 The following field connection diagrams should be

reviewed prior to unit installation and operation.

Drawing # Description Page

Appendix B Field Wiring Diagram 9

Appendix C Field Piping Diagram 10

2.1 Place the unit preferably on a concrete floor or base.

Level the base in both directions by placing steel

shims between the base and the anchor bolts.

2.2 A well-leveled and secured unit will result in quiet

operation as well as longevity of service.

2.3 See drawing Appendix C for general piping requirements.

2.4 Eccentric increasers can be used in the suction line

when increasing the pipe size. The straight side of

eccentric reducers should be installed on top to eliminate air pockets. Support the suction and discharge

lines independently by the use of pipe hangers or

anchors. Do not attempt to spring the suction and

discharge lines into position.

2.5 The power supply required for the unit is indicted on

the nameplate located inside the control panel. A

dedicated ground wire must be connected to the unit.

Single phase motors have internal overload protection. The disconnecting means and short circuit protection are to be supplied and mounted by others.

2.6 For units installed with an optional tank, the tank

must be installed per the requirements of drawing

Appendix C. Fill the tank per the tank prior to putting

the unit into service.

WARNING: Heavy load, may drop if not lifted properly.

Do not lift the entire unit by the motor eyebolts. Lift

the unit with slings placed under the unit base rails.

FAILURE TO FOLLOW THESE INSTRUCTIONS COULD

RESULT IN SERIOUS PERSONAL INJURY, DEATH,

AND/OR PROPERTY DAMAGE.

CAUTION: The Residential fire pump package includes

a high pressure relief valve. Make sure the discharge

of the valve is directed to the floor drain before making the

unit operational.

FAILURE TO FOLLOW THESE INSTRUCTIONS COULD RESULT IN PROPERTY DAMAGE

AND/OR MODERATE PERSONAL INJURY.

Section 2 - Installation Instructions

WARNING: Electrical shock hazard. Inspect all elec-

trical connections prior to powering the unit. Wiring

connections must be made by a qualified electrician in

accordance with all applicable codes, ordinances, and

good practices.

FAILURE TO FOLLOW THESE INSTRUCTIONS COULD RESULT IN SERIOUS PERSONAL

INJURY, DEATH, AND/OR PROPERTY DAMAGE.

WARNING: Conduit grounds are not adequate. A

separate ground wire must be attached to the ground

lug provided in the enclosure to avoid potential safety hazards.

FAILURE TO FOLLOW THESE INSTRUCTIONS

COULD RESULT IN SERIOUS PERSONAL INJURY,

DEATH, AND/OR PROPERTY DAMAGE.

CAUTION: Seal damage may occur. Do not run

pumps dry. Fill and vent the pump volute prior to

operation.

FAILURE TO FOLLOW THESE INSTRUCTIONS

COULD RESULT IN PROPERTY DAMAGE AND/OR

MODERATE PERSONAL INJURY.

Page 5

5

3.1 Whenever the riser water pressure falls below the

system pressure switch setting the pump will start

through a power relay.

3.2 When the system pressure rises above the setting of

the system pressure switch the pump will stop (provided the minimum run timer has expired.)

3.3

ADJUSTMENTS AND SETTINGS

3.3.1 System Pressure Switch

3.3.2 Back out the locking screw (see Figure 1) to allow

main adjustment wheel to turn freely.

a) Determine the pressure to be maintained across

the sprinkler system.

b) Adjust main adjustment wheel (see Figure 1) to de-

sired setting for pump to turn ON.

c) Turn main adjustment wheel counterclockwise to

increase or clockwise to decrease pressure. Each

number on main adjust wheel represents an approximate window shift of 1.8 psi for EPS40-2. For

each 1/2 rotation of the adjustment wheel the window changes by approximately 11 psi for EPS40-2.

The LED on Out3 will come ON in the control panel

when pressure switch is activated.

d) The pressure switch has a fixed differential which

doesn't require adjustment for turning OFF the

pump. The approximate differential varies from 3

psi @ 10 psi system pressure to 6 psi @ 100 psi

system pressure.

e) Retest the set point several times to ensure the

accuracy of the setting and to ensure the pump

starts and stops at the correct pressure.

f) Re-seat locking screw.

3.3.6 The minimum run timer is factory set to 5 minutes.

The setting should be verified before the unit is placed

into operation and adjusted if a shorter minimum run

time is desired. Do not adjust the timer with power

applied to the unit. Set the run timer by moving the

small black plastic jumper on the right side of the

PCB to 15 seconds, 30 seconds, 1 min, 2 min, 3 min,

4 min, or 5 min. The system will default to 15 seconds if no jumper is used.

3.3.7

Optional Tank

3.3.8 Refer to the specific IOM that was shipped with the

tank for installation and operating instructions.

3.3.9 Procedure to set Relief valve:

a) Switch ON the pump by opening the test valve

slowly to create a pressure drop.

b) Close the test valve after the pump turns ON.

c) Let the pump run until it reaches the set pressure

and switches OFF.

d) Loosen (counterclockwise) adjusting screw in

relief valve until it releases pressure.

Section 3 - Putting the Unit Into Service

CAUTION: Prevent subsequent damage. A unit

showing symptoms of possible problems (noise,

leaks, vibration, and/or continual operation) must be corrected immediately.

FAILURE TO FOLLOW THESE

INSTRUCTIONS COULD RESULT IN PROPERTY DAMAGE AND/OR MODERATE PERSONAL INJURY.

CAUTION: Relief valve exhaust must be piped to

an adequately sized drain.

FAILURE TO FOLLOW

THESE INSTRUCTIONS COULD RESULT IN PROPERTY

DAMAGE AND/OR MODERATE PERSONAL INJURY.

WARNING: Electrical shock hazard. Disconnect and

lockout power before servicing the unit.

FAILURE TO

FOLLOW THESE INSTRUCTIONS COULD RESULT IN

SERIOUS PERSONAL INJURY, DEATH, AND/OR PROPERTY DAMAGE.

WARNING: Electrical shock hazard. Disconnect and

lockout power before servicing the unit.

FAILURE TO

FOLLOW THESE INSTRUCTIONS COULD RESULT IN

SERIOUS PERSONAL INJURY, DEATH, AND/OR PROPERTY DAMAGE.

FIGURE 1

Page 6

6

A. SYSTEM PIPING AND UNIT

INSTALLATION

____ 1. Is the unit base properly leveled and secured?

____ 2. Is the shut-off valves to the pump suction open?

____ 3. Is the shut-off valve on the discharge line open?

____ 4. Is the shut-off valve on the hose bib closed?

____ 5. Is the piping properly supported to prevent strains

on unit?

____ 6. Is the system, including the pumps, purged of debris

and air?

B. ELECTRICAL WIRING AND

CONTROL SETTINGS

____ 1. Does the feeder line voltage correspond to the unit

voltage? Check the unit nameplate or motor terminal

connection.

____ 2. Are the feeder wires correctly sized for the load?

____ 3. Have all the power terminals in the control panel

been checked for tightness? This is imperative since

stranded wires tend to “flow” and become loose

after initial installation.

____ 4. Is the pressure control correctly set? The pressure

switch needs to be set for proper operation. For

best results, use a continuity meter (across the

switch) to reset the controls. The legend plate on

the control indicates approximate readings only and

therefore should be used with caution.

WARNING: Electrical shock hazard. Inspect all elec-

trical connections prior to powering the unit. Wiring

connections must be made by a qualified electrician in

accordance with all applicable codes, ordinances, and

good practices.

FAILURE TO FOLLOW THESE INSTRUCTIONS COULD RESULT IN SERIOUS PERSONAL

INJURY, DEATH, AND/OR PROPERTY DAMAGE.

WARNING: Electrical shock hazard. Single phase

AC power. Disconnect and lockout power before

servicing the unit.

FAILURE TO FOLLOW THESE

INSTRUCTIONS COULD RESULT IN SERIOUS PERSONAL INJURY, DEATH, AND/OR PROPERTY

DAMAGE.

WARNING: Conduit grounds are not adequate. A

separate ground wire must be attached to the

ground lug provided in the enclosure to avoid potential

safety hazards.

FAILURE TO FOLLOW THESE INSTRUCTIONS COULD RESULT IN SERIOUS PERSONAL

INJURY, DEATH, AND/OR PROPERTY DAMAGE.

CAUTION: Seal damage may occur. Do not run

pumps dry. Fill and vent the pump volute prior to

operation.

FAILURE TO FOLLOW THESE INSTRUCTIONS COULD RESULT IN PROPERTY DAMAGE

AND/OR MODERATE PERSONAL INJURY.

Section 4 - Final Check List

Page 7

5.1 Pump will not operate

1) Check incoming power

2) Check motor overload. Reset if tripped.

3) With contactor pulled in, check voltage of the

motor leads. Voltage should be the same as the

incoming power. If no voltage is present, replace the

contactor. If voltage is present, contact an electrician

to check the leads and motor.

5.2

Pump will not build pressure

1) Suction valve is closed. If closed, open.

2) Discharge valve is closed. If closed, open.

3) Relief valve is open and discharging to drain, Reset

relief valve to correct pressure setting.

4) Hose bib is open. If open, close.

5) Motor not operating at rated RPM. Have motor

checked at local motor repair shop.

6) Internal pump damage. Take pump to authorized

pump repair facility.

5.3

Pump will not start automatically

1) No power. Restore if there is no power.

2) System pressure switch is not adjusted properly.

Refer to section 3.

7

Section 5 - Troubleshooting

DANGER: Troubleshooting live control panels ex-

poses personnel to hazardous voltages. Electrical

troubleshooting must only be done by a qualified electrician.

FAILURE TO FOLLOW THESE INSTRUCTIONS

COULD RESULT IN SERIOUS PERSONAL INJURY,

DEATH, AND/OR PROPERTY DAMAGE.

WARNING: Electrical shock hazard. Inspect all elec-

trical connections prior to powering the unit. Wiring

connections must be made by a qualified electrician in

accordance with all applicable codes, ordinances, and

good practices.

FAILURE TO FOLLOW THESE INSTRUCTIONS COULD RESULT IN SERIOUS PERSONAL

INJURY, DEATH, AND/OR PROPERTY DAMAGE.

Page 8

8

1.1 The control system allows for intelligent pump control

while improving system reliability. Timers and relays

used in a conventional controller are integrated into a

single sequence controller. The working program is

stored on a non-volatile EEPROM chip that is an integral part of the unit. This means there is no danger of

ever losing a program due to power losses.

1.2. OK LED is on when the processor is running. If this

LED is not lit, check power connections. If power is

applied to the unit and LED is still not lit, replace unit.

1.3. The Aux in LED is reserved for future use.

1.4. The Flow Sw. LED is lit when the flow switch is

closed.

1.5. The Pressure LED is lit when the pressure switch is

closed.

1.6. The Out3 LED is lit when Output 3 is closed. Output

3 is closed when the pressure switch is closed, or

when the pressure switch is open and the run timer is

active.

1.7. The Out2 LED is lit when Output 2 is closed. Output

2 is closed when the flow switch is closed.

1.8. The Contactor LED is lit when the Contactor output is

closed. The Contactor output closes when the pressure switch is closed, or when the pressure switch is

open and the run timer is active.

2.0 CHANGING THE MINIMUM RUN TIME

2.1 Adjustable Settings

2.2 The run timer is adjustable to 15 seconds, 30 seconds, 1 minute, 2 minutes, 3 minutes, 4 minutes, and

5 minutes. On the right hand side of the PCB near

the OK LED is a small black plastic jumper which sets

the run time. Shorting the pins at the top of the connector will set the run time to 5 minutes. Shorting the

next set of pins down will set the timer to 4 minutes.

Shorting the bottom set of pins sets the timer to 15

seconds. Each setting is labeled on the PCB. If no

jumper is used, the timer defaults to 15 seconds.

Appendix A - Programmable Control Module

WARNING: Electrical shock hazard. Inspect all elec-

trical connections prior to powering the unit. Wiring

connections must be made by a qualified electrician in

accordance with all applicable codes, ordinances, and

good practices.

FAILURE TO FOLLOW THESE INSTRUCTIONS COULD RESULT IN SERIOUS PERSONAL

INJURY, DEATH, AND/OR PROPERTY DAMAGE.

WARNING: Electrical shock hazard. Disconnect and

lockout power before servicing the unit.

FAILURE

TO FOLLOW THESE INSTRUCTIONS COULD RESULT

IN SERIOUS PERSONAL INJURY, DEATH, AND/OR

PROPERTY DAMAGE.

Page 9

9

Appendix B - Field Wiring Diagram

Voltage HP Amps M1-M2 GND Conduit Size

230 1-1/2 10 #14 #12 1/2"

230 3 17 #10 #10 1/2"

230 5 28 #8 #8 1/2"

Page 10

Appendix C - Field Piping Diagram

Xylem Inc.

10661 Newkirk Street

Dallas, TX 75220

Phone: (469) 221-1200

Fax: (214) 357-5861

www.xyleminc.com/brands/acfirepump

A-C Fire Pump is a trademark of Xylem Inc. or one of its subsidiaries.

© 2012 Xylem Inc. 19-001-290B August 2012

Loading...

Loading...