Page 1

INSTRUCTION MANUAL

19-001-251R3

INSTALLER: PLEASE LEAVE THIS MANUAL FOR THE OWNER’S USE.

Floboy

™

VFD Pumping System

NOTE: This product is not intended for use in potable water applications.

Page 2

Acknowledgements

All materials ©2013 by Flowtronex®, an Xylem company.

Flowtronex® is a registered trademark of Xylem Flowtronex.

All rights reserved. No parts of this work may be reproduced in any form or by any means - graphic,

electronic, or mechanical, including photocopying, recording, taping, or information storage and retrieval

systems - without the written permission of the publisher.

Products that are referred to in this document may be either trademarks and/or registered trademarks of

the respective owners. The publisher and the author make no claim to these trademarks. These include

Microsoft, Windows, Windows NT, ActiveX that are either registered trademarks or trademarks of Microsoft

Corporation in the United States and/or other countries. ©2013 Microsoft Corporation. All rights reserved.

WHILE EVERY PRECAUTION HAS BEEN TAKEN IN THE PREPARATION OF THIS DOCUMENT, THE

PUBLISHER AND THE AUTHOR ASSUME NO RESPONSIBILITY FOR ERRORS OR OMISSIONS, OR

FOR DAMAGES RESULTING FROM THE USE OF INFORMATION CONTAINED IN THIS DOCUMENT

OR FROM THE USE OF PROGRAMS AND SOURCE CODE THAT MAY ACCOMPANY IT. IN NO EVENT

SHALL THE PUBLISHER AND THE AUTHOR BE LIABLE FOR ANY LOSS OF PROFIT OR ANY OTHER

COMMERCIAL DAMAGE CAUSED OR ALLEGED TO HAVE BEEN CAUSED DIRECTLY OR

INDIRECTLY BY THIS DOCUMENT.

Page 3

TABLE OF CONTENTS

ACKNOWLEDGEMENTS II

TABLE OF CONTENTS ·········································· I

TABLE OF FIGURES ············································· II

WARRANTY INFORMATION ··································· 2

SAFETY ······························································· 3

Safety instructions .................................................... 3

Safety Reminders ..................................................... 3

Additional Safety Information ................................... 4

Safety Apparel .......................................................... 4

Coupling Guards ...................................................... 4

Operation .................................................................. 4

Maintenance Safety .................................................. 4

GENERAL DESCRIPTION ······································ 5

Product Description .................................................. 5

Operational Limits .................................................... 5

Nameplate Information ............................................. 5

Station Numbering: ................................................... 6

Example: FBSNV4BF10D46R3ABD ........................ 6

handling .................................................................... 7

Storage ..................................................................... 7

Field Connection Diagrams ...................................... 7

Ground Connections ................................................ 7

RECEIVING ·························································· 8

Preparing to Receive the Pump Station ................... 8

Inspecting the Shipment ........................................... 8

Unpacking and Storing This Equipment ................... 8

INSTALLATION ···················································· 8

Location .................................................................... 8

Foundation ............................................................... 9

Anchoring the Station ............................................... 9

Suction Piping .......................................................... 9

Discharge Piping .................................................... 12

Electrical Connections ............................................ 12

START-UP AND ADJUSTMENTS ···························· 13

Power Check .......................................................... 13

Voltage Variance .................................................... 13

Voltage Imbalance .................................................. 13

Pump Priming ......................................................... 13

Pump Rotation ........................................................ 14

System Pressurization ............................................ 15

Priming Line Adjustment ........................................ 15

Overload Trip Adjustment ....................................... 15

STATION OPERATION ·········································· 16

DOOR SWITCH OPERATION ............................... 16

Individual Pump Switches .............................. 16

OPERATIONAL SETTINGS IN THE HMI .............. 16

Auto-Manual Select ........................................ 16

LDP Override ................................................. 16

Reset Control (F5) .......................................... 16

Resetting Faults ............................................. 16

AUTOMATIC OPERATION .................................... 17

Overview ........................................................ 17

System Charging Mode .................................. 17

NORMAL OPERATION .......................................... 17

MANUAL VFD OPERATION .................................. 18

CONTROLLER BYPASS OPERATION ................. 19

Overview ........................................................ 19

SYSTEM SAFETIES .............................................. 19

Fault Reset ..................................................... 19

Low Discharge Pressure ................................ 19

High Discharge Pressure ............................... 19

Low Inlet Pressure ......................................... 20

Loss of Prime ................................................. 20

INDIVIDUAL PUMP FAULTS ......................... 21

Overload Protection ....................................... 21

High Pump Temperature (Optional) ............... 21

VFD Fault ....................................................... 21

NAVIGATING THE CONTROLS ······························· 21

Overview ................................................................ 21

Pump Status Indicators .......................................... 22

Pressure Setpoint Adjustment ................................ 22

Trends and Alarms ................................................. 23

Totals ..................................................................... 24

Pump Control ......................................................... 24

Start settings .......................................................... 24

Stop Settings .......................................................... 24

Speed Test ............................................................. 25

Safety ..................................................................... 25

Panel Config ........................................................... 25

Sys Config .............................................................. 25

PID Parameters ...................................................... 25

Other Settings ........................................................ 25

MAINTENANCE ···················································· 26

REGULAR MONTHLY MAINTENANCE INTERVALS

............................................................................... 26

Heat exchanger: ............................................. 26

Control panel: ................................................. 26

Motor lubrication: ............................................ 26

Pumps - horizontal: ........................................ 26

Sound and visual checks of whole station: .... 26

Station skid: .................................................... 26

WINTERIZING the PUMP STATION ..................... 27

Winterizing ..................................................... 27

Spring Restart ................................................ 27

TROUBLESHOOTING ············································ 28

LOW DISCHARGE PRESSURE FAULT ............... 28

HIGH DISCHARGE PRESSURE FAULT ............... 29

LOW LEVEL FAULT .............................................. 29

LOW INLET PRESSURE FAULT ........................... 29

LOSS OF PRIME FAULT ....................................... 30

VFD FAULT ............................................................ 30

MOTOR WON’T START ........................................ 31

GLOSSARY OF TERMS ········································· 32

APPENDIX A — FINAL CHECK LIST ························ 35

APPENDIX B — ELECTRICAL WIRING AND

CONTROL SETTINGS FINAL CHECKLIST ················ 36

Page 4

TABLE OF FIGURES

Figure 1: Typical Floboy suction and discharge piping, Boost applications ....................................................... 5

Figure 2: Typical Floboy suction and discharge piping, Lift applications ........................................................... 5

Figure 3: Sample Nameplate ............................................................................................................................. 6

Figure 4: Typical Floboy installation on slab. ..................................................................................................... 9

Figure 5: Anchoring the station to the concrete slab. ......................................................................................... 9

Figure 6: Proper suction lift principles .............................................................................................................. 11

Figure 7: Improper suction lift application ........................................................................................................ 11

Figure 8: Proper installation of pump ............................................................................................................... 12

Figure 9: Confirm rotation by making sure motor is operating in the direction of the motor tag ...................... 15

Figure 10: Floboy controller. ............................................................................................................................ 22

Figure 11: Main Screen .................................................................................................................................... 22

Figure 12: Pump Status Indicators ................................................................................................................... 22

Figure 13: Perssure Setpoint ........................................................................................................................... 22

Figure 14: Setpoint Password Entry Screen .................................................................................................... 22

Figure 15: Entering the password for the setpoint screen ............................................................................... 23

Figure 16: Changing the setpoint ..................................................................................................................... 23

Figure 17: Performance Graph ........................................................................................................................ 23

Figure 18: Alarms Screen ................................................................................................................................ 23

Figure 19: Alarm Description ........................................................................................................................... 23

Figure 20: Menu ............................................................................................................................................... 24

Figure 21: Totals .............................................................................................................................................. 24

Figure 22: Pump Control .................................................................................................................................. 24

Figure 23: Stop Settings .................................................................................................................................. 24

Figure 24: Pump Control, Combo Selection .................................................................................................... 24

Figure 25: Speed Test ..................................................................................................................................... 25

Figure 26: Safety .............................................................................................................................................. 25

Figure 27: Safety, Others ................................................................................................................................. 25

Figure 28: Panel Configuration ........................................................................................................................ 25

Page 5

NOTE: The information contained in this book is intended to assist operating personnel by providing

information about the characteristics of the purchased equipment.

It does not relieve the user of their responsibility of using accepted engineering practices in the installation,

operation, and maintenance of this equipment.

For additional questions, contact:

XYLEM FLOWTRONEX

8:00 AM to 5:00 PM Central time (800) 786-7480 x3

5:00 PM to 8:00 AM Central time

After Hours technician for emergency assistance: (214) 454-5768

support@flowtronex.com

Page 6

2

WARRANTY INFORMATION

Company warrants title to the product(s) and,

except as noted below with respect to items not of

Company’s Manufacturer, also warrants the

product(s) on date on shipment to Purchaser, to

be of the kind and quality described herein, and

free of defects in workmanship and material.

THIS WARRANTY IS EXPRESSLY IN LIEU OF

ALL OTHER WARRANTIES, INCLUDING BUT

NOT LIMITED TO IMPLIED WARRANTIES OF

MECHANTABILITY AND FITNESS, AND

CONSTITUTES THE ONLY WARRANTY OF

COMPANY WITH RESPECT TO THE

PRODUCT(S).

If within one year from date of initial operation, but

nor more than eighteen months from date of

shipment by Company of any item of product(s),

Purchaser discovers that such item was not as

warranted above and promptly notifies Company

in writing thereof, Company shall remedy such

non-conformance by, at Company affected part of

the product(s). Purchaser shall assume all

responsibility and expense for removal,

reinstallation, and freight in connection with the

foregoing remedies. The same obligations and

conditions shall extend to replacement parts

furnished by Company hereunder. Company shall

have the right of disposal of parts replaced by it.

ANY SEPARATELY LISTED ITEM OF THE

PRODUCT(S) WHICH IS NOT MANUFACTURED

BY THE COMPANY IS NOT WARRANTED BY

COMPANY and shall be covered only the express

warrant, if any, of the manufacturer thereof.

THIS STATES PURCHASER’S EXCLUSIVE

REMEDY AGAINST COMPANY AND ITS

SUPPLIERS RELATING TO THE PRODUCT(S),

WHETHER IN CONTRACT OR IN TORT OR

UNDER ANY OTHER LEGAL THEORY, AND

WHETHER ARISING OUT OF WARRANTIES,

REPRESENTATIONS, INSTRUCTIONS,

INSTALLATIONS OR DEFECTS FROM ANY

CAUSE. Company and its suppliers shall have no

obligation as to any product which has been

improperly stored and handled, or which has not

been operated or maintained according to

instructions in Company or supplier furnished

manuals.

Page 7

3

SAFETY

Read all safety information prior to installation

of your pumping system.

SAFETY INSTRUCTIONS

SAFETY INSTRUCTION

This is a SAFETY ALERT SYMBOL. It is used

to alert you to potential personal injury

hazards. Obey all safety messages that follow

this symbol to avoid possible injury or death!

FAILURE TO FOLLOW THE INSTRUCTIONS

MAY RESULT IN A SAFETY HAZARD.

DANGER

Indicates a potentially hazardous situation

which, if not avoided, will result in death or

serious injury.

WARNING

Indicates a potentially hazardous situation

which, if not avoided, could result in death or

serious injury.

CAUTION

Indicates a potentially hazardous situation,

which if not avoided, may result in minor or

moderate injury.

CAUTION

Used without the safety alert symbol indicates

a potentially hazardous situation, which, if not

avoided, may result in property damage.

All operating instructions must be

read, understood, and followed by

the operating personnel.

Flowtronex accepts no liability for

damages or operating disorder

which are the result of non

compliance with the operating

instructions.

When the Pumping System

components reach the end of life

the components should be

disposed of or recycled in

accordance with local laws.

SAFETY REMINDERS

1. This manual is intended to assist in

the installation, operation, and repair

of the system and must be kept with

the system.

2. Installation and maintenance MUST

be performed by properly trained and

qualified personnel.

3. Review all instructions and warnings

prior to performing any work on the

system.

4. Any safety decals MUST be left on

the controller and pump.

5. The system MUST be disconnected

from the main power supply before

attempting any operation or

maintenance on the electrical or

mechanical part of the system.

Failure to disconnect electrical power

before attempting any operation or

maintenance can result in electrical

shock, burns, or death.

Page 8

4

ADDITIONAL SAFETY INFORMATION

This pump has been designed for safe and reliable

operation. A pump is a pressure-containing device

with rotating parts that could be hazardous.

Operators and maintenance personnel must

realize this and follow necessary safety measures.

Proper safety procedures must be followed. Xylem

Flowtronex shall not be liable for damage or

delays caused by a failure to observe the

instructions in this manual.

SAFETY APPAREL:

• Wear insulated work gloves when

handling hot bearings or using bearing

heater.

• Wear heavy work gloves when handling

parts with sharp edges, especially

impellers.

• Wear safety glasses (with side shields) for

eye protection, especially in machine shop

areas.

• Wear steel-toed shoes for foot protection

when handling parts, heavy tools, etc.

• Wear other personal protective equipment

to protect against hazardous/toxic fluids.

COUPLING GUARDS:

• Never operate a pump without a coupling

guard properly installed.

• Never force piping to make a connection

with a pump.

• Use only fasteners of the proper size and

material.

• Ensure there are no missing fasteners.

• Beware of corroded or loose fasteners.

OPERATION:

• Do not operate below minimum rated flow,

or with suction/discharge valves closed.

• Do not open vent or drain valves, or

remove plugs while system is pressurized.

MAINTENANCE SAFETY:

• Always lock out power.

• Ensure power is isolated from system and

pressure is relieved before disassembling

pump, removing plugs, or disconnecting

piping.

• Use proper lifting and supporting

equipment to prevent serious injury.

• Observe proper decontamination

procedures.

• Know and follow company safety

regulations.

• Never apply heat to remove impeller.

• Observe all cautions and warnings

highlighted in pump instruction manual.

Page 9

GENERAL DESCRIPTION

PRODUCT DESCRIPTION

Floboy Pumping Systems are self-contained,

pre-assembled and factory-tested pumping

systems. Floboy utilizes state of the art

technology, yet employs a simplistic and straight

forward design that makes installation, operation

and maintenance an easy task, even for the

most inexperienced of operators.

This manual will serve as a guide to

understanding the features of Floboy Pumping

Systems and provide a quick and clear

reference for answers to most questions

pertaining to its service. Every attempt has been

made to explain all facets of system operation

and maintenance for a variety of applications.

However, should you have specific questions

not explained or illustrated in this manual you

are encouraged to contact your nearest Floboy

Pumping Systems distributor, representative or

the factory.

Floboy utilizes a single main pump (with or

without a pressure maintenance pump) to supply

water to a turf irrigation system or other nonpotable application requiring water at a constant

pressure. Because Floboy is a totally automatic

system, the pump is energized whenever a

demand for water is sensed (pressure start).

Conversely, the pump is de-energized when the

demand no longer exists (pressure stop or flow

stop). In this manner, pressure is maintained in

any system at all times, thereby reducing piping

fatigue and minimizing the introduction of air into

the piping network.

For those customers who wish to start and stop

a pump based on a remote signal, as with an

irrigation controller, this function is available as a

selectable option on all models of Floboy. The

system can be controlled using 24V AC/DC

signal outputs from an irrigation controller or

other control devices (relay start).

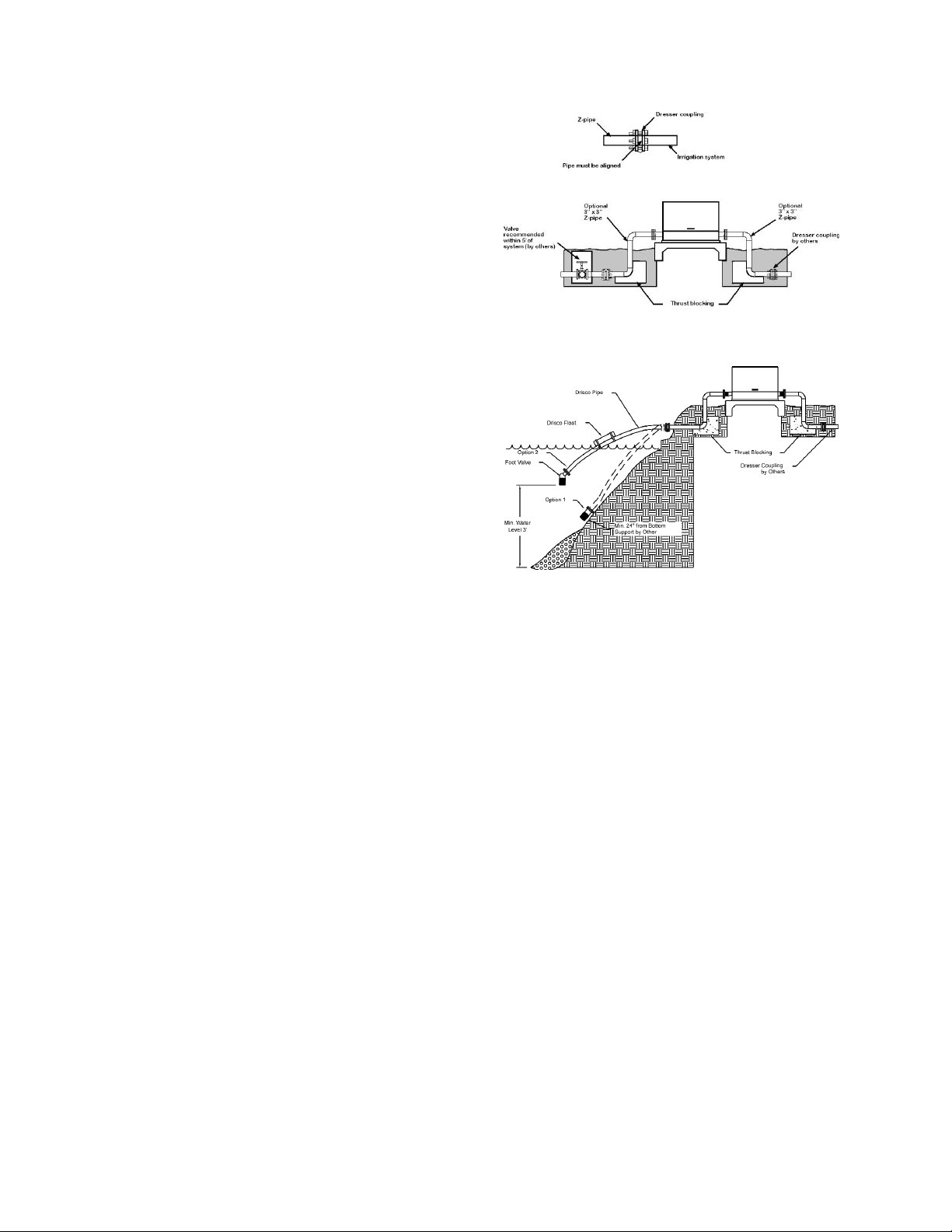

Figure 1: Typical Floboy suction and discharge

piping, Boost applications

Figure 2: Typical Floboy suction and discharge

piping, Lift applications

OPERATIONAL LIMITS

See pumping system nameplate information for

pumping system flow capacity, pressure, full

load current and electrical ratings.

Unless special provisions have been made for

your pumping systems, the system pressure

rating is 175 psi for end suction centrifugal.

NAMEPLATE INFORMATION

The system nameplate gives identification and

rating information as shown below.

Page 10

6

Figure 3: Sample Nameplate

Field

Explanation

Voltage

Required input voltage

SCCR

Short circuit current rating

Phase

Number of motor phases

FLA

Full load amps

Hz

Required frequency (hertz)

Max. HP

Maximum horsepower

Permanent records for this system are

referenced by the serial number. Include the

serial number with all correspondence and spare

parts orders.

STATION NUMBERING:

EXAMPLE: FBSNV4BF10D46R3ABD

08FB=Floboy II

1. Size Code

a. S=Small (52”l x 40”w x 45”h)

b. M=Mid (64”l x 53” w x 55” h’)

2. Lift or Boost

3. Control Type: V = VFD

4. Pump model

5. Horsepower

6. Impeller Code. Specific to type of pump

used.

7. Voltage (46=460, 23=230, 20=208)

8. Start/Stop Control. R=Relay, F=Flow,

P=Pressure. Floboy 2009 models are

field configurable between models,

unlike the previous Floboy systems.

9. Phase: 3=3 Phase, 1=single phase. 3Phase power is generally more efficient

and less expensive per KWH, but may

not be available.

Page 11

7

HANDLING

Qualified personnel should unload and handle

the unit. Prevent damage due to dropping or

jolting when moving the unit. Thoroughly inspect

the unit for damage upon receipt. Immediately

notify the carrier of transportation damage.

Ensure that sensing lines are free of crimps and

kinks.

The unit is top heavy due to the position of the

equipment. Do not use component eyebolts to

lift the pump station.

WARNING: Falling Objects Hazard

Eyebolts, if provided, are designed to lift only

the components to which they are attached.

Failure to follow these instructions could result

in serious personal injury, death, and/or

property damage.

STORAGE

During periods of storage, the unit should be

covered to prevent corrosion and contamination

from dirt. Store the unit in a clean, dry location to

prevent condensation and freezing. After

storage, check that it is dry before applying

power. Specific component storage instructions

must be followed in accordance with the

respective equipment manufacturer's

recommendations.

CAUTION: Extreme Temperature Hazard

Extreme temperatures are to be avoided.

(Below 32ºF and above 110ºF.)

Failure to follow these instructions could result

in serious property damage and/or moderate

personal injury.

FIELD CONNECTION DIAGRAMS

Actual equipment manufacturers/models

installed are system specific. Refer to specific

manufacturers’ Installation, Operation &

Maintenance Manuals for details unique to each

component. The pump instruction manual is

supplied with the system (if applicable).

Review the wiring diagrams and dimensional

drawings prior to unit installation and operation.

Typical wiring diagrams are included in

Appendix D.

NOTE: Electrical supply must match the control

panel nameplate specification. Incorrect voltage

can cause fire, damaging electrical components

and void the warranty.

NOTE: Electrical supply must be installed by a

qualified electrician in accordance with all

applicable codes, ordinances, and good

practice.

GROUND CONNECTIONS

A grounding terminal is provided for a dedicated

ground wire connection. All provisions of the

National Electrical Code and local codes must

be followed.

WARNING: Electrical Shock Hazard

Conduit grounds are not adequate. A separate

ground wire must be attached to the ground lug

provided in the enclosure to avoid potential

safety hazards.

Failure to follow these instructions could result

in serious personal injury or death, or property

damage.

Page 12

8

RECEIVING

PREPARING TO RECEIVE THE PUMP STATION

Each Floboy Pumping System is shipped on a

wooden pallet and is enclosed in either a

cardboard box or shrink wrap. It will probably

arrive in an enclosed van or semi-trailer which will

require specialized equipment, such as a fork lift,

to off-load. Please remember, it is your

responsibility to provide a safe and secure means

to remove this equipment from the carrier's

vehicle. Once you take possession of the pump

station, the freight carrier is no longer responsible

for damage due to mishandling.

CAUTION

Caution: This equipment is heavy. Do not

attempt to pick it up or move it manually.

Bodily injury may result.

INSPECTING THE SHIPMENT

Inspect the pump station for damaged goods

prior to accepting shipment. Note all damages or

missing components on the "Bill of Lading".

Note: When the pump station arrives, it is your

responsibility to inspect this equipment for

damage or lost goods prior to signing the

carrier's freight bill.

Should you notice shorted or damaged goods, you

must make a notation to that effect on the face of

the "freight bill" and keep a copy so a claim can be

processed with the freight company. If you give

the freight company a clear receipt for goods that

have been damaged or lost in transit you do so at

your own risk and expense.

If you receive the pump station and subsequently

discover damaged equipment or lost goods that

were concealed by the packaging you must

contact the freight company immediately. Do not

proceed with the system's installation until the

freight company has inspected this equipment. A

"Concealed Damage Report" must be made within

15 days of receiving the equipment or any claim of

loss will not be honored.

The factory will assist you in every possible

manner to collect a claim for loss or damage but

be advised that the laws of interstate commerce

make it your responsibility to file, process and

collect all claims directly from the freight company

or its agent.

UNPACKING AND STORING THIS EQUIPMENT

When cutting the packaging with a knife or razor,

take care not to scratch the paint on the metal

enclosure. If the pump station is to be stored for

any period of time, make certain it is left in a

secure location, preferably one which is free of

excessive moisture and freezing conditions.

INSTALLATION

LOCATION

Locate the pumping system in a clean, well

ventilated, and properly drained location. It is

recommended that the location selected facilitates

ease of inspection, maintenance, and service.

Outside installation requires protection from

freezing.

The factory recommends positioning the Floboy

Pumping System on a concrete slab that provides

a permanent and supportive base. The system

should be positioned as close to the intended

source of water as possible. For systems lifting

water from a lake or pond, the pump station

elevation should be close to the water surface

elevation. In most cases the pump site should

never be more than five feet above the minimum

water elevation as long as this elevation is above

the normal flood plane.

Page 13

9

Concrete slabs should be at least 6" thick and be

constructed in a monolithic pour from 3000 psi

concrete and #5 rebar. The slab should be sized

with a minimum of 6" clearance between the edge

of the slab and the edge of the pump station.

Please note that it is the customer's

responsibility to meet all local code and

seismic requirements.

WARNING: Falling Objects Hazard Heavy Load, May Drop If Not Lifted

Properly.

Do not lift the entire unit by component eyebolts.

Eyebolts on components are used for factory

assembly only and are not intended to lift the

complete package.

Failure to follow these instructions could result in

serious personal injury or death, or property

damage.

FOUNDATION

With proper installation and a suitable foundation,

this unit is built to supply years of service.

Establish a base of concrete weighing a minimum

of 2-1/2 times the weight of the unit. (Check the

shipping tickets or the pumping system drawing for

unit weight.) Tie the concrete pad in with the

finished floor. Use the appropriate anchor bolts to

secure the pumping system to the foundation.

Pump packages with electrical conduit below

surface may require corrosion protection approved

for this condition.

WARNING: Electrical Shock Hazard

Electrical conduit installed below the surface may

require a corrosion resistant protective coating to

prevent conduit corrosion and electrical shock.

Failure to follow these instructions could result in

serious personal injury or death, or property

damage.

Place the unit on its concrete foundation,

supporting it with steel wedges or shims. These

wedges or shims should be put on both sides of

each anchor-bolt and midway between the bolts,

to provide a means of leveling the base.

After the pumping system has been leveled, install

the correct number of anchor bolts and tighten to

secure the system.

Figure 4: Typical Floboy installation on slab.

ANCHORING THE STATION

It is always advisable to anchor the station to the

concrete slab or support structure in two or more

locations. Four 1/2" diameter holes have been

provided in the base of the pump station skid for

this purpose. Concrete anchors, such as 3/8" x 4"

Redheads, work well on most concrete structures.

Anchor all four holes. Please note that it's the

customer responsibility to meet any seismic

requirements if applicable.

Figure 5: Anchoring the station to the concrete

slab.

SUCTION PIPING

Suction piping is perhaps the most sensitive and

demanding element of the pump station

installation. Proper suction piping can make the

difference between the pump station operating

properly or not working at all. The following rules

should be observed in the installation of every

suction assembly:

Page 14

10

A. Piping should be sized in accordance with

the architect, engineer or factory's

direction.

B. Piping should be constructed of spring

reinforced suction hose, steel or high

density poly pipe. All joints should be

fusion welded or flanged and pressure

tested to ensure a leak proof connection.

Threaded fittings should be installed with

ample Teflon pipe joint compound and

pressure tested with air using a soap

solution to check for leaks. PVC pipe with

glued or gasketed fittings should never be

used.

C. Piping should be well-supported in order

to eliminate piping strain on the inlet of the

station. Piping strain can be tested simply

by disconnecting the piping connection

closest to the station inlet after the suction

assembly is complete. If the disconnected

piping shows signs of misalignment and

requires force to reconnect, the pump is

experiencing piping strain. Correct this

condition by changing the existing

supports or by adding more supports until

the suction piping connects to the pump

inlet with no misalignment.

D. All piping reducers should be eccentric

with the flat portion of the reducer

positioned on top. Isolation valves should

not be installed in pump suction piping.

Use a minimum number of elbows

(preferably no more than two) in any

suction pipe. These elbows should be 45degrees, if possible. A 90-degree elbow

may be used if positioned properly. The

elbow closest to the pump inlet should

have a section of straight pipe at least six

pipe diameters long between the elbow

and the pump inlet (Example: 4" pipe

requires 4" x 6 = 24" long piece of straight

pipe between the elbow and the pump

inlet).

E. Pump stations that lift water from a lake or

pond must be installed with a foot (check)

valve at the end of the suction pipe. The

valve should never be installed above

ground and should always be equipped

with a properly sized intake screen. The

foot valve shall be constructed of

aluminum and shall contain a rubber

flapper which sets on a machined

aluminum surface to provide a tight seal.

Ample space shall be provided for the

flapper to fold back out of the liquid

stream, keeping friction loss to a

minimum.

F. The foot valve should be positioned at

least 4 pipe diameters below the lowest

possible water level and never lay on the

bottom where silt and sand could be

sucked into the pump. It should always be

mounted in a vertical position.

Note: Never mount a foot valve at an angle

other than vertical since the valve may

experience difficulty in closing securely.

Locate and protect the suction intake from algae

or other floating material with a cleanable screen

or a diversion structure.

Note: Please consult the factory if the pump is

to take its suction from a stream or river that

might experience suspended silt, sand or other

abrasive materials. Special filters or intake

structures may be necessary to protect the

pump from premature wear and failure. The

presence of any abrasive materials will void

the factory warranty.

Page 15

11

Figure 6: Proper suction lift principles

Figure 7: Improper suction lift application

Page 16

12

DISCHARGE PIPING

Like the suction assembly, the discharge piping

requires adherence to certain rules and conditions

in order to minimize future problems. The following

list should be observed when designing and

installing the discharge assembly:

A. Discharge pipe should be constructed of

screwed or welded steel pipe.

B. The piping should be constructed in a Z"

configuration with 45 or 90-degree elbows.

The elbow located underground must be

protected against movement by a

concrete thrust block. The concrete form

should be positioned on the station side of

the elbow so that pipe movement is

prohibited in that direction. At least ½ yard

of concrete should encase this elbow and

extend to the virgin soil surrounding the

elbow and pipe. Please note: piping must

be supported properly prior to pouring the

concrete thrust block in order to ensure

piping strain is not present at the pump

discharge. Piping train on the discharge of

the pumps station can be checked in the

same manner as the suction piping strain

described earlier.

C. Connecting the steel pipe to PVC mainline

should be accomplished with a gasketed

transition coupling. Solid connections,

such as flanges or screwed fittings, should

be avoided. Transition couplings are

available at most irrigation supply houses.

Figure 8: Proper installation of pump

station discharge.

ELECTRICAL CONNECTIONS

The pumping system is pre-wired at the factory

and includes all internal wiring necessary to

function. For relay start systems, the customer

must still wire any external controllers and devices

to the relays inside the control panel. The only

electrical connection required in the field is the

main disconnect located in the station control

panel. Electrical cables from the power company's

meter or distribution panel are to be connected to

the top lugs of this main disconnect panel.

DANGER

Electrical wiring poses the danger of

hazardous voltage. Contact with live

electrical connections can cause shock,

burns or even DEATH. All electrical

connections should be made by a qualified

and licensed electrician and then inspected

by local code compliance authorities.

All electrical connections in the control and

disconnect panels are tightened prior to the

pumping system leaving the factory. However,

these connections can become loose during

transit and must be checked before energizing the

pump station. Your electrician should be

requested to perform this task and should be

directed to tighten all high and low voltage

connections, terminal strips and power lugs.

It is important to ground the station properly as

required by code. The electrician installing the

incoming power cables should also provide this

ground connection inside the main disconnect

panel.

CAUTION

In order to ensure the proper operation of the

station's electrical surge control devices it is

important to install proper grounding close to

the station.

The power company's grounding alone may not be

sufficient and additional ground rods may be

needed to ensure adequate protection. The quality

of this ground should be checked by a factory

certified technician or electrician and should not

exceed 20 ohms resistance.

Page 17

13

START-UP AND ADJUSTMENTS

Floboy Pumping Systems are pre-tested in the

factory and all controls are adjusted for the

operating conditions specified. However, there are

certain checks that must be performed prior to

energizing the pump station in order to prevent the

possibility of component damage. These voltage

checks can be performed by a qualified, licensed

electrician.

The required checks, procedures and adjustments

are as follows:

POWER CHECK

DANGER

Electrical wiring poses the danger of

hazardous voltage. Contact with live

electrical connections can cause shock,

burns or even DEATH. All electrical

connections should be made by a qualified

and licensed electrician and then inspected

by local code compliance authorities.

Have a licensed electrician check incoming

voltage to make certain it is in the range specified

and its variance and imbalance are within

acceptable limits. The pump's motor, starter and

wiring are sized for a particular nominal voltage;

either 120, 208, 240 or 480 volts. Voltage is

checked with a calibrated volt meter. On a threephase system (power is supplied with three or four

wires) there will be three fuses in the main

disconnect panel, A, B and C. It is important that

your electrician or technician check the voltage

between each fuse pair, i.e. A to B, B to C and A

to C. These voltage readings should be analyzed

in accordance with the following formulas:

VOLTAGE VARIANCE

1. Average the three voltage readings

2. Subtract the nominal voltage from this average

3. Divide the difference by the nominal voltage to

arrive at a percent variance

4. The maximum acceptable level for voltage

variance is 5%

EXAMPLE:

Assume the actual voltage readings on a nominal

480 volt system are:

A-B = 485 volts, B-C = 492 volts, and A-C = 472

volts

The average voltage is (485+492+472)/3 = 483

volts

The percent voltage variance is (483-480)/480

=.00625 or.625%

VOLTAGE IMBALANCE

1. Average the three voltage readings

2. Find the reading which has the widest deviation

by subtracting the average from each reading

3. Choose the largest difference and divide it by

the average voltage to arrive at a percent

imbalance

4. The maximum acceptable level for voltage

imbalance is 2%

EXAMPLE:

Assume the voltage readings described above

are:

A-B = 485 volts, B-C = 492 volts, and A-C = 472

volts

The average voltage is (485+492+472)/3 = 483

volts

The largest difference is (A/B - Avg.) 485-483 = 2

volts

(B/C - Avg.) 492-483 = 9 volts

(A/C - Avg.) 483-472 = 11 volts

The percent voltage imbalance is: 11/483 =.0228

or 2.28%

In this particular example the voltage variance is

acceptable while the voltage imbalance is not. If

your calculations show either result to be beyond

the acceptable limits noted, you should contact

your power company and have the power

corrected. Failure to do so could result in motor

current imbalance and excessive heat which

reduces the motor's lifetime.

PUMP PRIMING

As noted earlier, priming the pump is the process

of filling the pump's volute case and suction piping

in order to facilitate the pump's ability to move

Page 18

14

water when the motor is energized. For pump

stations whose inlet is supplied with water under

pressure or from an elevated reservoir, the priming

process is not required other than the removal of

trapped air in the suction pipe. A petcock on the

top of the pump volute should be opened to allow

air to escape and the volute to fill with water. Once

the air has completely escaped, close the petcock.

If the pump station sits above its water source

such that a foot valve is required, the pump will

require priming. Remove the cap from the 3/4"

pipe at the station inlet and fill the suction pipe

using a garden hose or bucket. When the pipe

overflows and water is maintained at the top of the

fill pipe for several minutes, the pipe cap can be

re-installed and tightened. You may have to repeat

this filling process two or more times if air is

trapped anywhere in the suction piping. The

presence of air will cause the pump to instantly

lose pressure once the discharge valve is opened.

PUMP ROTATION

CAUTION

Caution: Always ensure that the pump is

primed prior to checking rotation. Failure to do

so can damage the mechanical seal located in

the motor end of the volute case. These seals

are very sensitive and can be destroyed if

allowed to run dry, even for a very brief period

of time.

It is important to note that the pump is designed to

rotate in a given direction. On most pumps the

proper direction of rotation is noted by an arrow

cast or painted on the exterior of the volute casing.

In the absence of this arrow, one can determine

the proper direction of rotation by observing the

pump from the motor end. Rotation should always

be in a clockwise direction when viewing the pump

from this vantage point. Pump rotation can be

checked by momentarily energizing the motor and

observing the shaft between the motor and the

pump.

Three-phase motors can rotate in either direction.

Checking pump rotation by briefly energizing each

motor is accomplished with a two position switch

labeled "Off/On". The switch is located on the

control panel door and it determines the pump's

mode of operation. The procedure for performing

this check is to first turn the main disconnect on

the outside of the station enclosure to the "On"

position. Next, press the manual button on the

front of the controller, then turn the "Off/On" switch

from "Off" to "On". For the VFD Pump, the motor

speed may need to be increased to approximately

10-20% before the motor will turn. Once motor

rotation has been determined, turn the switch back

to "Off". Reverse rotation of centrifugal pumps is

not damaging but performance and efficiency are

poor and long periods of operation will cause

overheating. Running the pump for a minute or

two to determine rotation will not harm the pump.

PM Pump rotation may be more difficult to

determine. Most PM Pump models motor-pump

coupling is not visible, so a performance check is

required to determine proper rotation. With the

pump primed and the station isolation valve closed

and the controller in “Manual”, turn on the PM

Pump switch (Must be cycled off-then-on if the

switch is on when the change to manual is made).

Note the system pressure. The pump should have

no trouble generating set point pressure in the

discharge manifold. If pressure does not increase

when the pump is started, first verify that the PM

Pump isolation valves are open, that the station

discharge isolation valve is closed, and the

petcock on the discharge pressure gage is open.

If the pump still fails to produce, verify the PM

Pump discharge pressure reducing valve is not

adjusted all the way out. (If set point pressure is to

be higher than the factory setting, this valve may

need to be reset). If the pump still fails to produce,

change rotation of the pump and retest.

WARNING

Caution: Make certain the power is turned off

at the main disconnect switch prior to

changing any electrical leads.

If the rotation is wrong, it can be corrected by

reversing any two leads on the bottom of the

motor starter or VFD (example: move wire A to the

B location and wire B to the A location). Single

phase motors will require internal rewiring which is

best performed by a Flownet technician, and is

normally only required after motor replacement.

Page 19

15

Figure 9: Confirm rotation by making sure motor is

operating in the direction of the motor tag

SYSTEM PRESSURIZATION

With the system isolation valve on the discharge of

the pump station almost fully closed, turn the

Off/On switch to the "On" position. When the pump

starts, you should notice an immediate increase in

pressure on the manifold pressure gauge. If the

pressure does not rise to at least the operating

pressure of the system, turn the Off/On switch to

"Off" and repeat the priming process described

earlier. Otherwise refer to the "Troubleshooting"

section of this manual or contact the factory for

assistance.

CAUTION

If you open the system isolation valve too

quickly, the pump may instantly lose prime and

will require repeating the priming process.

Leave the station isolation valve in a slightly

cracked state until you are certain water is flowing

into the discharge piping. On irrigation systems it

is a good idea to open several sprinklers at the

remote end of the system. When water begins to

emerge from these heads the system is

reasonably full and the pump station isolation

valve can be gradually opened to its full position.

When starting a centrifugal pump for the first time

it is a good practice to stay close to the pump for

the first few minutes of operation. If you notice

conditions such as smoke from the motor, unusual

odor, loud noises, etc., turn the pump off

immediately and consult the factory. In some

cases the pump may sound like it is pumping

marbles or rocks. This noise may be the sign of

mechanical problems or it may be a hydraulic

phenomenon known as cavitation occurring inside

pump. Cavitation is a condition that may

permanently damage the pump if allowed to

continue. It is usually caused by improper suction

installation or by over demanding the pump. It is

not uncommon to experience cavitation when

filling the discharge piping since empty piping

encourages pump over demand if the station

isolation valve is opened too far or too quickly.

Should you notice this sound, gradually close the

isolation valve until the noise intensity subsides.

Once the system approaches full design pressure,

the cavitation noise should disappear. If throttling

the system isolation valve makes no difference in

the noise intensity, turn the pump off and consult

the factory.

PRIMING LINE ADJUSTMENT

On pumping systems requiring a foot valve in the

suction, a priming line valve is used to apply a

seating pressure to the suction pipe when the

pump is not operational. This valve is set for 30 psi

but can be adjusted if so desired. Turn the valve

adjustment screw clockwise to increase pressure

and counterclockwise to decrease.

OVERLOAD TRIP ADJUSTMENT

Every motor starter assembly uses an electronic

sensor that monitors the motor current. If the

current exceeds a safe limit, considered to be a

point where the motor is overloaded, the sensor

shuts the motor off. The current limit is factory

preset but can be adjusted as noted by the

calibrated scale along side the adjustment screw.

CAUTION

This adjustment should be made by a qualified

technician only. Improper adjustment of this

setting can jeopardize motor lifetime and affect

system warranty.

The overload should never be adjusted above the

motor's full load rating. This rating is stamped on a

motor identification tag fixed to the motor housing.

Make certain the motor full load current rating

corresponds to the correct operating voltage since

multiple voltages and their corresponding current

ratings may be noted on the same tag.

Page 20

16

STATION OPERATION

This section covers the sequence of operation for

your station including: Door Switch Operation,

Automatic Operation, and System Safeties.

DOOR SWITCH OPERATION

Individual Pump Switches

Allows operator to select which pumps

operate:

NOTE: Pumps have an OFF/ON switch.

OFF Selected pump does not operate,

regardless of any other switch position.

ON Selected pump will operate,

provided the system switch is set to AUTO

or MANUAL

OPERATIONAL SETTINGS IN THE HMI

Note: HMI Stands for “Human Machine Interface”

Auto-Manual Select

The Auto-manual Control (circled) resides

on the default screen.

Press the center arrow to move between

auto and manual mode. Pump must be

switched off, then on when changing

mode to manual or pump will not start.

LDP Override

This position prevents a low-discharge pressure

fault from shutting down the pump station. Use the

LPD OVERRIDE “Y” position during the initial pipe

filling and when restarting the system from a depressurized condition in MANUAL or AUTO mode.

Access is gained to this item by pressing the

“Manu” button, accessing the menu then selecting

“Safeties”.

Reset Control (F5)

This control allows the operator to clear (Reset)

any faults within the system once the cause of the

fault has been cleared.

The safety in effect will be shown in the lower

“Status” portion of the screen. You will also be

instructed to press F5 to reset the fault.

Resetting Faults

Faults must be reset by the reset control.

Pressing the reset control clears all fault counters.

If the fault lamp/message does not go out after

resetting, the cause of the fault is still present and

must be resolved before normal operation can

continue.

Page 21

17

AUTOMATIC OPERATION

Overview

The primary benefit of Variable Speed Pumping

(VSP) Systems is to ensure surge-free starts and

stops while maintaining a constant down-stream

line pressure with no mechanical pressureregulating valve. This minimizes pipeline failures

due to surges and, not incidentally, reduces the

utility bill for the station.

Automatic operation is selected by manual-Auto

control on the HMI. In automatic operation, all

pump activity is determined by the controller. The

position of the individual pump switch lets the

controller know whether or not it is available to

run. In most cases, all pump switches are in the

ON position. When a pump or a motor is removed

from the system, turn the pump switch OFF, and

the controller will not try to run that pump.

The controller brings one pump on at a time in

order to satisfy the start criteria (usually set point

pressure). Some stations are designed to start and

stop the pumps based on remote start signals or

flow. The standard start and stop sequence is as

follows:

Pressure below set point to start

Combo 1

-3 PSI

Delay time to start Combo 1

0 SEC

Pressure above set point to stop

Combo 1

5 PSI

Delay time to stop Combo 1

5 SEC

Pressure below set point to start

Combo 2

-5 PSI

Delay time to start Combo 2

3 SEC

System Charging Mode

If there are no heads open, and the pressure is

within the defined range of operation, pressure

may slowly drop due to system leakage, or other

small demands. A PM pump option is available to

address this issue. Not all stations include a PM

pump. System is configured as follows:

System Mode: AUTO

All Individual Pumps switches: ON

LP Override Setting: Off (Low Discharge Pressure

fault enabled)

NOTE: As downstream pressure drops to more

than 5 PSI below set point, the PM pump starts

up. It runs until the system pressure builds up to 5

PSI above set point, and then shuts off.

Two issues can come into play here. One is cycle

time. This refers to the number of times an hour

that the PM pump starts and stops (one cycle). If

the amount of cycles is excessive, either the

system leaks have to be repaired, or the start/stop

parameters need to be tuned (normally by

dropping the pressure below set point to start or

increasing the pressure above set point to stop).

WARNING: Excessive Run Time Hazard

Excessive stop times, or stop pressure setting

can cause system over-pressurization, pipe

damage, and potentially cause personal injury.

Consult your service technician or the factory if

you are unsure about any settings.

Failure to follow these instructions could result in

serious personal injury or death, or property

damage.

NORMAL OPERATION

Normal Operation occurs when heads are turned

on, or a demand for water exists. System is

configured as follows:

System control switch: AUTO

PM Pump switch: ON

Pump 1 switch: ON

LP Override setting: “N” (Low Discharge

Pressure fault enabled)

When the pressure drops 5 PSI below set point,

the PM pump starts and continues to run until the

pressure is 5 PSI above the set point. When this

pressure is reached, the PM pump turns OFF. If

the pressure continues to drop to 10 PSI below set

point, the VSP starts and the PM pump turns OFF.

This is the operation sequence for Combo 1.

When the VSP starts, the startup ramp in the

program lowers the set point to 2 PSI above the

actual line pressure. The VFD adjusts the speed of

the VSP to maintain the discharge or downstream

Page 22

18

pressure at the set point. This is the operation

sequence for Combo 2.

When the flow decreases, the VFD slows down to

maintain a constant discharge pressure.

Eventually as the speed decreases, a set point is

reached where the VSP is not pumping any water.

Because the VFD speed keeps dropping as the

flow decreases, the discharge pressure would

never get above the set point. In this situation, the

VSP would "idle," pump no water, and would

never turn off. To shut down the VSP, the system

initiates the "Speed Test" whenever the flow is

below a predetermined value for 15 seconds. The

program then lowers the set point by 5 PSI. If the

VFD speed falls below a predetermined value and

the pressure remains above the reduced set point

for 15 seconds, the VSP turns OFF.

MANUAL VFD OPERATION

Overview

Manual operation is selected by the system mode

control on the HMI. In manual operation, all pump

activity is controlled by the individual pump

switches. The speed of the VFD pump is

controlled by the speed slider on the main screen.

The PM Pump will run in XL mode (at full speed).

The LP Override setting enables or disables the

low-discharge pressure fault.

NOTE: Manual operation is rarely used. However,

it does allow for operation of individual pumps for

testing purposes.

Sequence of Operation (performed in

order)

All Individual Pump switches: OFF

Low Pressure Override setting: “Y” LDP

Override (Low Discharge Pressure fault

disabled). If initial system pressure is high

enough, disable Low Pressure Override

(Set to “N”).

System control mode: MANUAL

Pump 1 switch: ON

Speed Potentiometer: Press up-arrow to

increase speed, or press “Set” to allow

entry of speed directly (in %). Adjust as

required for flow rate / pressure required.

NOTE: When done, turn OFF all pump switches

and place system control switch in OFF. Return

LP Override setting to N. If the station can be run

in Automatic mode, return the system to AUTO

and turn ON all pump switches.

Page 23

19

CONTROLLER BYPASS OPERATION

Overview

This is an abnormal operating mode and would be

used if the controller was not operable and there is

need to irrigate.

WARNING: Controller Bypass Hazard

This mode of operation should be used as a last

resort. Constant operator monitoring is

REQUIRED when this mode is used. No safeties

function in controller bypass, and damage to your

piping or property could occur.

Failure to follow these instructions could result in

serious personal injury or death, or property

damage.

System Operation (performed in order)

All Individual Pump switches: OFF

Using the VFD keypad located below the

pump switches on the door, Set the

following parameters:

1102 - EXT2 (7)

3018 - Not Sel (0)

4011 - Verify set point

4023 - Verify Min Speed

Pump 1 switch: ON

Verify operation before leaving

unattended.

SYSTEM SAFETIES

Overview

The program in the PLC protects the system by

shutting down in either of the “Auto” or “Manual”

Modes of operation if it detects any of the following

problems:

Fault Reset

All faults are cleared by pressing the Reset control

(F5) on the HMI, or by re-arming individual pump

faults by turning the individual pump switch to the

OFF position, and then back ON.

Table 1: Safeties

Low Discharge Pressure

The pressure transducer located in your station

discharge line communicates the downstream

pressure to the controller. The controller monitors

downstream pressure to determine if the pressure

is below the allowable range.

The standard program defines low-discharge

pressure as being 80% of set point pressure. This

setting is in gage pressure, not in reference to set

point. There is a time delay of 300 seconds

(adjustable) before the station faults that is

designed to give the system time to build pressure

beyond this point. The values might vary on your

station.

If the discharge pressure remains below the Low

Pressure set point for longer than 60 seconds, all

pumps are shut down. The red station fault light on

the station comes on, and the display indicates

that a "Low Discharge Pressure Safety" has

occurred.

This fault does not automatically reset. To clear

the fault, press the Reset control on the HMI.

If the pump station is simply unable to keep up

with the demand, shut the station down, and

determine the nature of the problem. Consult the

Troubleshooting section of this manual for

assistance.

High Discharge Pressure

As with the "Low Discharge Pressure" fault, the

controller monitors downstream pressure to

determine if the pressure is out of range, or above

the allowable limit.

The standard controller program defines highdischarge pressure as being 15 PSI above set

point pressure (set in gage pressure without

Alarm or Fault

Low Discharge Pressure

High Discharge Pressure

Low Inlet Pressure (Optional)

Loss of Prime (Optional)

Low Level (Optional)

Individual Pump Faults

VFD Fault

Page 24

20

reference to set point). There is a time delay of

60 seconds, before the station faults that is

designed to give the system time to adjust the

pressure to below this point. These values might

vary on your station.

Based on the values above, if the discharge

pressure remains 15 PSI above the set point for

longer than one minute, the station shuts down.

The red station fault light on the station comes on,

and the display indicates a “high pressure Safety”.

NOTE: At this point, shut the station down, and

determine what the problem is. Consult the

Troubleshooting section of this manual for

assistance.

To clear the fault, press the Reset control (F5).

Low Inlet Pressure

This optional safety is usually used on floodedsuction booster pump applications.

Normally, a pressure switch monitors the inlet

pressure on the "suction" side of the pump. This

switch is located in a box on the lower left side of

the control cabinet. The switch is used in

conjunction with a relay to inform the controller

that it is unsafe to run. Setting the low inlet

pressure condition is accomplished by physically

adjusting the pressure switch. There is a 20

second time delay in the PLC.

Once the inlet pressure drops below the switch

pressure setting, all pumps shut down after a 20

second (adjustable) delay. The red station fault

light comes on, and the display indicates a "Low

inlet Pressure Safety”.

WARNING: Low Inlet Pressure – Station

Shutdown Hazard

At this point, shut the station down, and

determine what the problem is. Consult the

Troubleshooting section of this manual for

assistance.

Failure to follow these instructions could result in

serious personal injury or death, or property

damage.

There are two dials on the pressure switch. The

one on the top is the correct one to adjust. Turn

clockwise to increase the pressure set point,

counter-clockwise to decrease.

CAUTION: Delta Pressure Setting Hazard

Do not adjust the bottom dial. This is a delta

pressure setting, and is not used. This dial must

be adjusted fully counter-clockwise (0 position). If

you are having trouble with your pressure switch,

always verify that this dial is in the 0 (fully

counter-clockwise position) before adjusting the

top dial.

Failure to follow these instructions indicates a

potentially hazardous situation, which, if not

avoided, may result in property damage.

CAUTION: Minimum Pressure Setting Hazard

The pressure setting is based on the minimum

inlet pressure that the pump can safely operate.

Do not lower the pressure switch setting without

consulting the factory.

Failure to follow these instructions could result in

serious personal injury or death, or property

damage.

Loss of Prime

This optional safety is usually used on end-suction

centrifugal pump applications.

A level probe is placed in the suction piping at a

predetermined level. This probe works in

conjunction with a relay to inform the controller

that it is unsafe to run. Fault usually signifies a

malfunctioning foot valve.

After a few seconds, all pumps shut down. The red

station fault light comes on, and the display

indicates a "Loss of Prime fault"

NOTE: At this point, shut the station down, and

determine what the problem is. Consult the

Troubleshooting section of this manual for

assistance.

To clear the fault, press the Reset button.

CAUTION: Equipment Damage Hazard

Do not attempt to bypass this safety, as pump

damage will occur.

Page 25

21

INDIVIDUAL PUMP FAULTS

Pump faults are usually caused by the thermal

overload tripping, or circuit fault that causes the

pump NOT to start when requested.

Overload Protection

Overload Protection is standard on all pump

stations. The overload is a safety device that shuts

the motor down when amperage exceeds the set

point of the device.

If the motor amperage exceeds the overload set

point that pump shuts down after a time delay.

This delay time is inversely proportional to the

overload amount. In some instances, an individual

pump can trip without shutting down the entire

system if another pump is available to operate. If

so, the controller will automatically bring the

available pump on line. The controller will indicate

a fault for the specific pump.

WARNING: Overload Hazard

The overloads are located inside the control

panel. All safety procedures must be adhered

to during the any adjustment or resetting

process. Improper procedures or failure to

use proper safety procedures could result in

death or serious injury.

Resetting the overload is accomplished by

pushing in the blue Differential Overloads button

on the right front face of the device, and rotating it

approximately an eighth of a turn clockwise

(applies only to PM Pump).

Adjustment of the overload set point is performed

using the blue dial on the left front face of the

device.

Once the overload has been reset, individual

pump faults require turning the individual pump

switch to the OFF position, and then back ON (rearming).

High Pump Temperature (Optional)

High pump temperature utilizes a temperature

probe inserted into the pump discharge piping.

The probe trips when the water temperature

reaches 120°F, and then immediately shuts down

the pump. “PM Pump High Temp” or “Pump 1

High Temp” will show on the HMI.

The temperature probe automatically resets at

105°F. At that time, the pump can be re-armed,

and pump operation can continue.

NOTE: If the pump continues to shut down for this

issue, shut the station down and determine what

the problem is. Consult the Troubleshooting

section of this manual for assistance.

VFD Fault

The VFD sends a fault signal directly to the

controller. The display shows, "VFD Fault" and the

red station fault light comes on. To determine the

nature of the problem, you must use the VFD

keypad display and review the fault/alarm history.

This procedure is outlined in the VFD section of

this manual. A list of all inverter fault/alarm codes

is found in your VFD manual.

Once you have determined what the VFD

(inverter) fault is, and have cleared it, press the

station Reset button to clear the alarm shutdown

status.

NAVIGATING THE CONTROLS

OVERVIEW

The Floboy controller is a combined touch-screen

interface (HMI) and controller. The device

communicates with the VFD for pressure and flow

readings, inputs (pump switches, safety switches,

etc), and outputs (Fault light, PM Pump contactor,

etc).

All control decisions are made in the controller,

including PID control, pump start/stop decisions

and safeties. Settings for these decision

processes are available in the controller. There

are 6 keys to the right of the controller screen.

These are quick access keys that quickly allow

access to menus and are also provided special

functions in some screens. F5 is the “Reset

Control” and is used to reset system safeties.

Page 26

22

Figure 10: Floboy controller.

The “Menu” key provides access to the slide-out

menu which can be touched directly for navigation

and also serves as a reminder of the function keys

definition in the context of the current screen.

The main screen shows pressure, flow, set point

pressure, VFD speed, pumps status, fault status

and provides access to the “Manual” and

“Automatic” mode selection.

Figure 11: Main Screen

The Flow window will show either a flow rate, if an

optional flow meter was purchased with the

system, or a flow indication, indicating “No” for no

flow, and “Yes” for flow> 0.5 ft/sec.

The lower left corner of the screen will display fault

information and other status indications.

PUMP STATUS INDICATORS show the status of

each pump.

Figure 12: Pump Status Indicators

PRESSURE SET POINT ADJUSTMENT

CAUTION: Equipment Damage Hazard

Be careful not to set the value too low for the

pump you are using, nuisance overloads can

occur. Also, do not set the value too high for your

systems piping or damage may occur.

Touch the numeric value for the set point:

Figure 13: Pressure Set Point

The password screen for set point will come up.

Figure 14: Set Point Password Entry Screen

Touch the button next to the password value.

Enter “1234” for password and press enter.

Page 27

23

Figure 15: Entering the password for the set point

screen

This allows the user to edit the set point.

Touch the button next to the Set point value:

Figure 16: Changing the set point

Change the set point as required. Be careful not

to set the value too low for the pump you are

using, nuisance overloads can occur. Also, do not

set the value too high for your systems piping or

damage may occur.

TRENDS AND ALARMS

Press the Graph button to access the

history/performance graph. Scroll to access

historical data up to 2.3 days of data for pressure,

Flow, Set point and VFD Speed.

Figure 17: Performance Graph

Press the Alarm button to view up to 32 previous

alarms.

Figure 18: Alarms Screen

Alarms are shown as shown in figure 15 below.

Figure 19: Alarm Description

Page 28

24

Pressing the Menu button from the main screen

provides access to the menu system.

Figure 20: Menu

Access to the main functions of the controller is

available from the menus.

Figure 21: Totals

TOTALS: provides access to the Flow totals

(optional flow meter required) and pump hour

meters.

Figure 22: Pump Control

PUMP CONTROL: Allows access to pump start/stop

parameters for station tuning.

START SETTINGS. Select combo and parameters

to set via buttons at top of screen. Pressure is in

reference to set point. Flow rate is used for Flow

Start systems.

Figure 23: Stop Settings

STOP SETTINGS: Pressure is in reference to set

point, flow rate is used when flow stop is

required/configured.

Figure 24: Pump Control, Combo Selection

F3 allows user to change the combo being

adjusted. Note the combo number being adjusted

is shown in the black box on the right-hand side of

the screen.

Page 29

25

Figure 25: Speed Test

SPEED TEST: Delay is how long the controller

waits before initiating speed test (after all other

shutdown parameters are satisfied). Step delay

controls how quickly the VFD speed is reduced, to

detect 0 flow. If VFD speed reaches minimum

speed (set under PID, shown later), then the

controller will shut down the pump. Step size is

the % speed decrease for each step. To “smooth

out” speed test, set Step delay lower and step size

lower. To quicken speed test, set step delay

higher and/or step size higher.

SAFETY:

Figure 26: Safety

The safety functions are controlled in this screen.

Delay controls how long the safety will take to time

out. Set point for Low Pressure and high pressure

are in gage values and not in reference to set

point. Low Pressure override is also found in the

safety menu.

Figure 27: Safety, Others

Inlet water faults are controlled under “Others”.

Short times should be used as these faults can

cause serious damage if the timers are set too

long. 5 seconds is all that is required. High Pump

Temp is also controlled here. The delay is how

long between a high pump temp signal and the

pump is shut down. 5 seconds is all that is

required. The Hold off time controls how long the

pump must run before the HPT is honored. This

prevents exposed inlet piping from causing a HPT

safety on startup due to solar heating of the water

in the pipe.

Figure 28: Panel Configuration

PANEL CONFIG: Used to set screen contrast and

time/date in the controller.

SYS CONFIG (Password required, technician

access only):

PID PARAMETERS, pump configuration and other

factory/technician access parameters are

configured here.

OTHER SETTINGS (Password required, technician

access only): Safeties and other control features

are controlled here.

Page 30

26

MAINTENANCE

Maintenance is an investment that will pay

dividends in the form of improved reliability and

durability. Site maintenance checks are a matter of

day to day, week to week care that is important to

the proper operation of the pumping equipment.

Periodic equipment checks will ensure that the

recommended lubricants, fluids and service parts

are available and planned for. Flowtronex

recommends Preventative Maintenance be

performed quarterly.

DANGER: Personal Injury Hazard