Page 1

INSTRUCTION MANUAL

19-001-200R2

INSTALLER: PLEASE LEAVE THIS MANUAL FOR THE OWNER’S USE.

SILENT STORM

VFD Pumping System

NOTE: This product is not intended for use in potable water applications.

Page 2

ii

Acknowledgements

All materials ©2013 by Xylem Flowtronex, an Xylem company.

Flowtronex© is a registered trademark of Xylem Flowtronex.

All rights reserved. No parts of this work may be reproduced in any form or by any means - graphic,

electronic, or mechanical, including photocopying, recording, taping, or information storage and retrieval

systems - without the written permission of the publisher.

Products that are referred to in this document may be either trademarks and/or registered trademarks of the

respective owners. The publisher and the author make no claim to these trademarks. These include

Microsoft, Windows, Windows NT, ActiveX that are either registered trademarks or trademarks of Microsoft

Corporation in the United States and/or other countries. ©2013 Microsoft Corporation. All rights reserved.

WHILE EVERY PRECAUTION HAS BEEN TAKEN IN THE PREPARATION OF THIS DOCUMENT, THE

PUBLISHER AND THE AUTHOR ASSUME NO RESPONSIBILITY FOR ERRORS OR OMISSIONS, OR

FOR DAMAGES RESULTING FROM THE USE OF INFORMATION CONTAINED IN THIS DOCUMENT OR

FROM THE USE OF PROGRAMS AND SOURCE CODE THAT MAY ACCOMPANY IT. IN NO EVENT

SHALL THE PUBLISHER AND THE AUTHOR BE LIABLE FOR ANY LOSS OF PROFIT OR ANY OTHER

COMMERCIAL DAMAGE CAUSED OR ALLEGED TO HAVE BEEN CAUSED DIRECTLY OR

INDIRECTLY BY THIS DOCUMENT.

Page 3

TABLE OF CONTENTS

ACKNOWLEDGEMENTS ..................................... II

TABLE OF CONTENTS ................................

............... III

WARRANTY INFORMATION ........................................ 2

SAFETY ................................

SAFETY INSTRUCTIONS ................................................. 3

SAFETY REMINDERS ................................

Additional Safety Information ................................

......................................... 3

...................... 3

............. 4

GENERAL DESCRIPTION ............................................ 5

PRODUCT DESCRIPTION ............................................... 5

OPERATIONAL LIMITS ................................

NAMEPLATE INFORMATION ................................

STATION NUMBERING .................................................... 5

HANDLING ................................

STORAGE ......................................................................... 6

FIELD CONNECTION DIAGRAMS ................................

GROUND CONNECTIONS ................................

........................................ 6

.................... 5

........... 5

... 6

............... 7

INSTALLATION ............................................................. 8

LOCATION ........................................................................ 8

FOUNDATION ................................................................... 8

PUMP INSTALLATION ................................

Prior to Installation ................................

Installing Assembled Pump Station ............................ 8

...................... 8

...................... 8

STATION OPERATION ............................................... 11

DOOR SWITCH OPERATION ........................................ 11

System Control Switch .............................................. 11

Individual Pump Switches ......................................... 11

VFD / Bypass Switch ................................

VFD Selector Switch (Optional On Some Stations) –

P 1 / PUMP 2 / PUMP 3 .................................... 11

PUM

Low Discharge/Differential Pressure Switch ............. 11

Wye Strainer or Filter Switch .................................... 12

Lake Screen Switch ................................

Well Pump Switch ................................

Reset Push Button ................................

AUTOMATIC OPERATION ................................

Overview ................................

Line Fill Mode ................................

System Charging Mode ............................................ 13

Normal Operation ................................

................................... 13

................ 11

.................. 12

..................... 12

.................... 12

............. 13

............................ 13

...................... 14

Manual VFD Operation .............................................. 16

VFD Bypass Operation, Manual mod

VFD Bypass Operation, Auto mode ........................... 17

PLC Bypass Operation .............................................. 18

SYSTEM SAFETIES ................................

Automatic Mode of Operation .................................... 19

Manual Mode of Operation ........................................ 19

Low Discharge Pressure ................................

High Discharge Pressure ................................

Low Inlet Pressure ................................

Loss of Prime ................................

Low Level Fault .......................................................... 21

Phase Failure ............................................................. 21

INDIVIDUAL PUMP FAULTS ................................

Overload Protection ................................

High Pump Temperature (Optional) ........................... 22

VFD Fault ................................

e ...................... 16

........................ 19

............ 19

........... 19

..................... 20

............................. 20

........... 21

................... 21

................................... 22

MAINTENANCE .......................................................... 23

REGULAR MAINTENANCE = INVESTMENT .................. 23

REGULAR MONTHLY MAINTENANCE INTERVALS ..... 23

WINTERIZING PUMP STATIONS ................................... 24

Generalized Instruction

Vertical Stations ......................................................... 25

Horizontal Stations ................................

Spring Restart of Pumping Station ............................ 25

s for All Pump Stations ......... 24

..................... 25

TROUBLESHOOTING ................................................ 26

LOW DISCHARGE PRESSURE FAULT .......................... 26

HIGH DISCHARGE PRESSURE FAULT .........................

LOW LEVEL FAULT ................................

LOW INLET PRESSURE FAULT ..................................... 27

LOSS OF PRIME FAULT ................................

PHASE FAULT ................................

VFD FAULT ................................

MOTOR WON’T START ..................................................

......................... 27

................. 28

................................. 28

...................................... 28

27

29

GLOSSARY OF TERMS ............................................. 30

APPENDIX A —

APPENDIX B —

FINAL CHECK LIST ........................ 34

ELECTRICAL WIRING AND

CONTROL SETTINGS FINAL CHECKLIST ............... 35

NOTE: The information contained in this book is intended to assist operating personnel by providing

information about the characteristics of the purchased equipment.

It does not relieve the user of their responsibility of using accepted engineering practices in the installation,

operation, and maintenance of this equipment.

For additional questions, contact:

XYLEM FLOWTRONEX

8:00 AM to 5:00 PM Central time (800) 786-7480 x3

5:00 PM to 8:00 AM Central time

After Hours technician for emergency assistance. (214) 454-5768

support@flowtronex.com

iii

Page 4

2

WARRANTY INFORMATION

Company warrants title to the product(s) and,

except as noted below with respect to items not

of Company’s Manufacturer, also warrants the

product(s) on date on shipment to Purchaser, to

be of the kind and quality described herein, and

free of defects in workmanship and material.

THIS WARRANTY IS EXPRESSLY IN LIEU OF

ALL OTHER WARRANTIES, INCLUDING BUT

NOT LIMITED TO IMPLIED WARRANTIES OF

MECHANTABILITY AND FITNESS, AND

CONSTITUTES THE ONLY WARRANTY OF

COMPANY WITH RESPECT TO THE

PRODUCT(S).

If within one year from date of initial operation, but

nor more than eighteen months from date of

shipment by Company of any item of product(s),

Purchaser discovers that such item was not as

warranted above and promptly notifies Company

in writing thereof, Company shall remedy such

non-conformance by, at Company affected part of

the product(s). Purchaser shall assume all

responsibility and expense for removal,

reinstallation, and freight in connection with the

foregoing remedies. The same obligations and

conditions shall extend to replacement parts

furnished by Company hereunder. Company shall

have the right of disposal of parts replaced by it.

ANY SEPARATELY LISTED ITEM OF THE

PRODUCT(S) WHICH IS NOT MANUFACTURED

BY THE COMPANY IS NOT WARRANTED BY

COMPANY and shall be covered only the express

warrant, if any, of the manufacturer thereof.

THIS STATES PURCHASER’S EXCLUSIVE

REMEDY AGAINST COMPANY AND ITS

SUPPLIERS RELATING TO THE PRODUCT(S),

WHETHER IN CONTRACT OR IN TORT OR

UNDER ANY OTHER LEGAL THEORY, AND

WHETHER ARISING OUT OF WARRANTIES,

REPRESENTATIONS, INSTRUCTIONS,

INSTALLATIONS OR DEFECTS FROM ANY

CAUSE. Company and its suppliers shall have no

obligation as to any product which has been

improperly stored and handled, or which has not

been operated or maintained according to

instructions in Company or supplier furnished

manuals.

Page 5

3

SAFETY

to alert you to potential personal injury

which, if not avoided, will result in death or

Indicates a potentially hazardous situation

which, if not avoided, could result in death or

Indicates a potentially hazardous situation,

if not avoided, may result in minor or

CAUTION

a potentially hazardous situation, which, if not

Read all safety information prior to installation

of the Silent Storm Pumping System.

SAFETY INSTRUCTIONS

SAFETY INSTRUCTION

This is a SAFETY ALERT SYMBOL. It is used

All operating instructions must be

read, understood, and followed by

the operating personnel. Flowtronex

accepts no liability for damages or

operating disorder which are the

result of non compliance with the

operating instructions.

hazards. Obey all safety messages that follow

this symbol to avoid possible injury, death!

FAILURE TO FOLLOW THE INSTRUCTIONS

MAY RESULT IN A SAFETY HAZARD.

DANGER

Indicates a potentially hazardous situation

serious injury.

WARNING

serious injury.

CAUTION

which

moderate injury.

When the Pumping System

components reach the end of life

the components should be

disposed of or recycled in

accordance with local laws.

SAFETY REMINDERS

1. This manual is intended to assist in

the installation, operation, and repair

of the system and must be kept with

the system.

2. Installation and maintenance MUST

be performed by properly trained and

qualified personnel.

3. Review all instructions and warnings

prior to performing any work on the

system.

4. Any safety decals MUST be left on

the controller and pump.

5. The system MUST be disconnected

from the main power supply before

attempting any operation or

maintenance on the electrical or

mechanical part of the system.

Failure to disconnect electrical power

before attempting any operation or

maintenance can result in electrical

shock, burns, or death.

Used without the safety alert symbol indicates

avoided, may result in property damage.

Page 6

4

ADDITIONAL SAFETY INFORMATION

This pump has been designed for safe and reliable

operation. A pump is a pressure-containing device

with rotating parts that could be hazardous.

Operators and maintenance personnel must

realize this and follow necessary safety measures.

Proper safety procedures must be followed. Xylem

Flowtronex shall not be liable for damage or

delays caused by a failure to observe the

instructions in this manual.

Safety Apparel:

• Wear insulated work gloves when

handling hot bearings or using bearing

heater.

• Wear heavy work gloves when handling

parts with sharp edges, especially

impellers.

• Wear safety glasses (with side shields) for

eye protection, especially in machine shop

areas.

• Wear steel-toed shoes for foot protection

when handling parts, heavy tools, etc.

• Wear other personal protective equipment

to protect against hazardous/toxic fluids.

Coupling Guards:

• Never operate a pump without a coupling

guard properly installed.

• Never force piping to make a connection

with a pump.

• Use only fasteners of the proper size and

material.

• Ensure there are no missing fasteners.

• Beware of corroded or loose fasteners.

Operation:

• Do not operate below minimum rated flow,

or with suction/discharge valves closed.

• Do not open vent or drain valves, or

remove plugs while system is pressurized.

Maintenance Safety:

• Always lock out power.

• Ensure power is isolated from system and

pressure is relieved before disassembling

pump, removing plugs, or disconnecting

piping.

• Use proper lifting and supporting

equipment to prevent serious injury.

• Observe proper decontamination

procedures.

• Know and follow company safety

regulations.

• Never apply heat to remove impeller.

• Observe all cautions and warnings

highlighted in pump instruction manual.

Page 7

5

GENERAL DESCRIPTION

PRODUCT DESCRIPTION

A Flowtronex Silent Storm Variable Speed

Pumping System is custom built to the

requirements provided by the purchaser. The

Silent Storm pumping system is a modular

variable speed system designed to maintain a

constant discharge pressure while providing a

variable flow rate to match the water demand of

the system. The system minimizes power

consumption by combining a variable speed lead

pump with constant speed lag pumps. The Silent

Storm utilizes a microprocessor-based controller

to efficiently manage pump operation to match a

wide range of pressure boosting applications.

Silent Storm Variable Speed Pumping Systems

are self-contained, pre-assembled and factorytested pumping plants. Silent Storm utilizes state

of the art technology, yet employs a simplistic and

straightforward design that makes installation,

operation, and maintenance an easy task, even for

the most inexperienced of operators.

This manual serves as a guide to understanding

the features of Silent Storm Pumping Systems and

provides a quick and clear reference for answers

to most questions pertaining to its service. Every

attempt has been made to explain all facets of

system operation and maintenance. However,

should you have specific questions not addressed

in this manual, you are encouraged to contact your

nearest Flowtronex Authorized FlowNet

representative, or the factory (800-786-7480

Ext. 3).

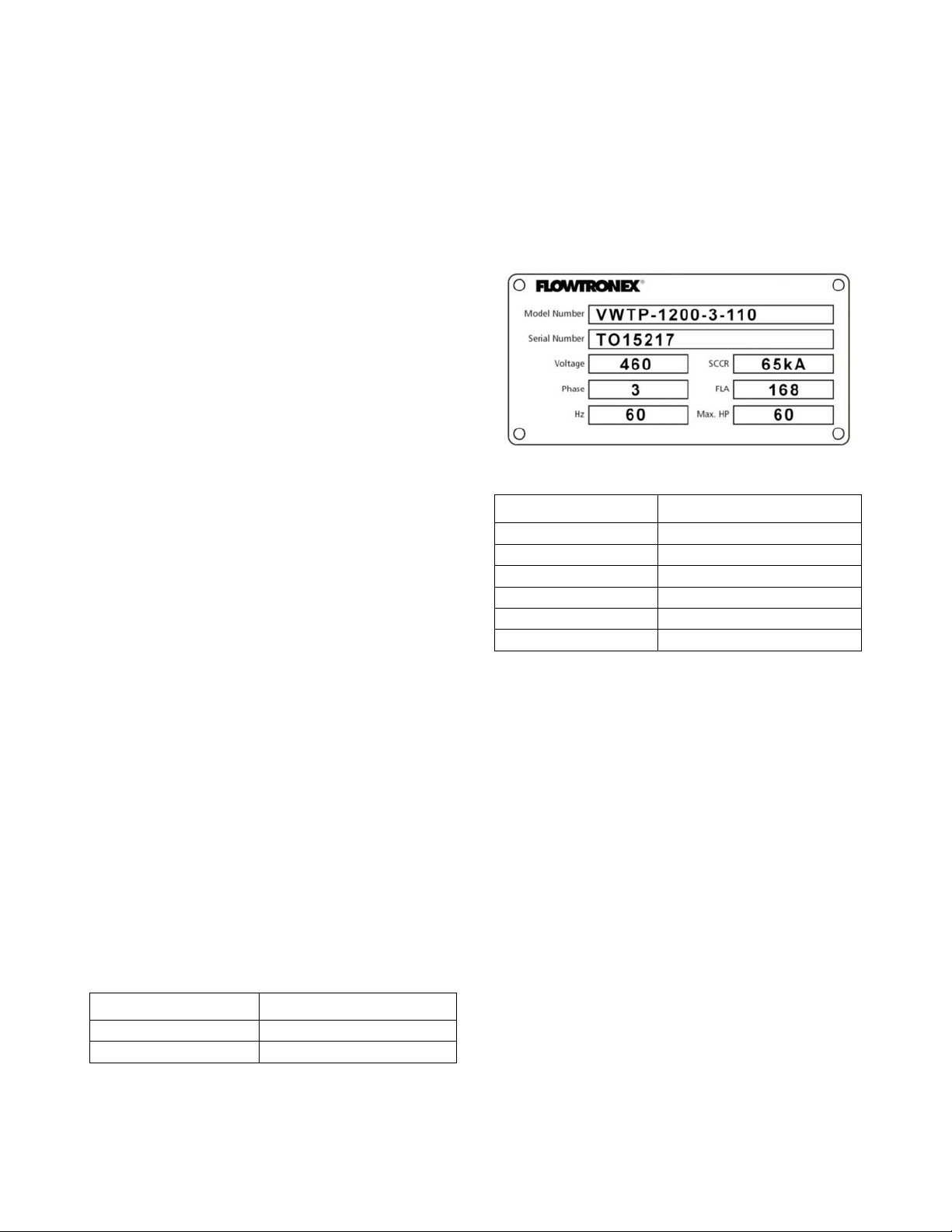

OPERATIONAL LIMITS

See pumping system nameplate information for

pumping system flow capacity, pressure, full load

current and electrical ratings.

Unless special provisions have been made for

your pumping systems, the system pressure rating

is as follows:

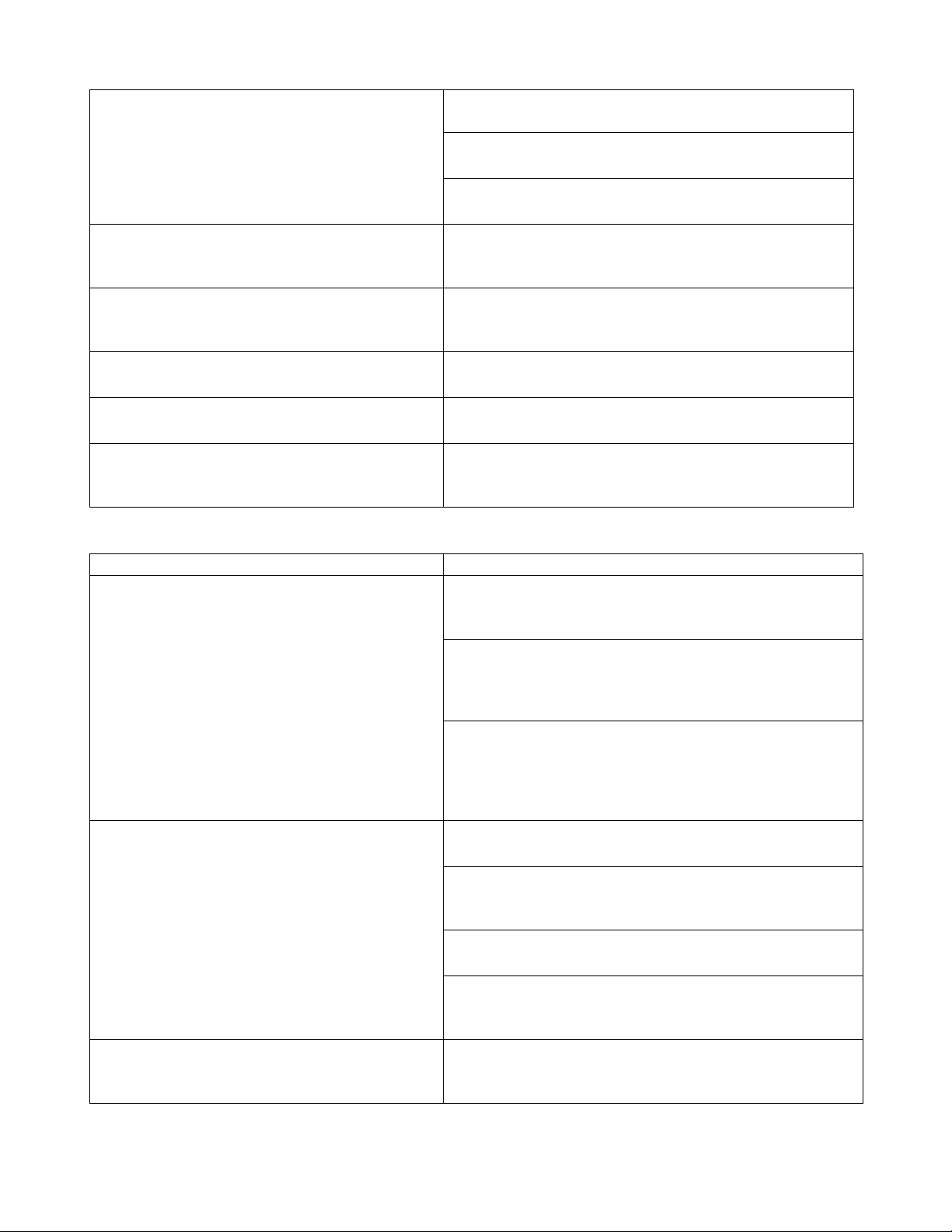

Pump system type

Max discharge pressure

End suction centrifugal

175 psi

Vertical turbine

200 psi

NAMEPLATE INFORMATION

The system nameplate gives identification and

rating information as identified in the figure below.

Figure 1: Sample Nameplate

Field

Explanation

Voltage

Required input voltage

SCCR

Short circuit current rating

Phase

Number of motor phases

FLA

Full load amps

Hz

Required frequency (hertz)

Max. HP

Maximum horsepower

Permanent records for this system are referenced

by the serial number. Include the serial number

with all correspondence and spare parts orders.

STATION NUMBERING

Example: V W T P - 900 - 3 - 120

1. Control Type:

V = VFD

2. Water Source Type:

W = Wet Well

V = Vessel

C = Can

F = Flooded

L = Lift

B = Boost

D = Deep Well

Page 8

6

S = Submerged Sled pump assembly

M = Floating pump assembly

3. Pump Type:

C = Horizontal

S = Submersible

T = Vertical Turbine

M = Multi-stage Horizontal (ex. Goulds

SSV)

E = Submersible Trash Pump (ex. Ebara)

4. System Type:

P = Pump Station

T = Transfer

X = Control Package

5. System Gallons per Minute: If a multi-zone

system, show all zones with a slash ( / )

between each. If it is a control package,

show the total number of pumps to be

controlled.

6. Quantity of Pumps: Include pressure

maintenance pump and current pumps do not include future pumps in model

number.

7. System Pounds per Square Inch: If multizone system, show all zones with a slash

( / ) between each zone. Design must

assume that all zones run at the same

time. Describe in no-uncertain terms the

performance of each zone. If the station

has spacing for future pumps, always

create a model number showing the

current conditions service. Make notes in

your documentation describing the

"current" versus "future" conditions of

service. On boosted systems, model

number should reflect the differential

pressure with notes describing the

incoming pressure.

HANDLING

Qualified personnel should unload and handle the

unit. Prevent damage due to dropping or jolting

when moving the unit. Thoroughly inspect the unit

for damage upon receipt. Immediately notify the

carrier of transportation damage. Ensure that

sensing lines are free of crimps and kinks.

The unit is top heavy due to the position of the

equipment. Do not use component eyebolts to lift

the pump station.

WARNING: Falling Objects Hazard

Eyebolts, if provided, are designed to lift only the

components to which they are attached.

Failure to follow these instructions could result in

serious personal injury, death, and/or property

damage.

STORAGE

During periods of storage, the unit should be

covered to prevent corrosion and contamination

from dirt. Store the unit in a clean, dry location to

prevent condensation and freezing. After storage,

check that it is dry before applying power. Specific

component storage instructions must be followed

in accordance with the respective equipment

manufacturer's recommendations.

CAUTION: Extreme Temperature Hazard

Extreme temperatures are to be avoided. (Below

32ºF and above 110ºF.)

Failure to follow these instructions could result in

serious property damage and/or moderate

personal injury.

FIELD CONNECTION DIAGRAMS

Actual equipment manufacturers/models installed

are system specific. Refer to specific

manufacturers’ Installation, Operation &

Maintenance Manuals for details unique to each

component. The pump instruction manual is

supplied with the system (if applicable).

Review the wiring diagrams and dimensional

drawings prior to unit installation and operation.

NOTE: Electrical supply must match the control

panel nameplate specification. Incorrect voltage

can cause fire, damaging electrical components

and void the warranty.

NOTE: Electrical supply must be installed by a

qualified electrician in accordance with all

applicable codes, ordinances, and good practice.

Page 9

7

GROUND CONNECTIONS

A grounding terminal is provided for a dedicated

ground wire connection. All provisions of the

National Electrical Code and local codes must be

followed.

WARNING: Electrical Shock Hazard

Conduit grounds are not adequate. A separate

ground wire must be attached to the ground lug

provided in the enclosure to avoid potential safety

hazards.

Failure to follow these instructions could result in

serious personal injury, death, or property

damage.

Page 10

8

INSTALLATION

LOCATION

Locate the pumping system in a clean, well

ventilated, and properly drained location. It is

recommended that the location selected facilitates

ease of inspection, maintenance, and service.

Outside installation requires protection from

freezing.

WARNING: Falling Objects Hazard - Heavy

Load, May Drop If Not Lifted Properly.

Do not lift the entire unit by component eyebolts.

Eyebolts on components are used for factory

assembly only and are not intended to lift the

complete package.

Failure to follow these instructions could result in

serious personal injury, death, or property

damage.

FOUNDATION

With proper installation and a suitable foundation,

this unit is built to supply years of service.

Establish a base of concrete weighing a minimum

of 2-1/2 times the weight of the unit. (Check the

shipping tickets or the pumping system drawing for

unit weight.) Tie the concrete pad in with the

finished floor. Use the appropriate anchor bolts to

secure the pumping system to the foundation.

Pump packages with electrical conduit below

surface may require corrosion protection approved

for this condition.

WARNING: Electrical Shock Hazard

Electrical conduit installed below the surface may

require a corrosion resistant protective coating to

prevent conduit corrosion and electrical shock.

Failure to follow these instructions could result in

serious personal injury, death, or property

damage.

Place the unit on its concrete foundation,

supporting it with steel wedges or shims. These

wedges or shims should be put on both sides of

each anchor-bolt and midway between the bolts,

to provide a means of leveling the base.

After the pumping system has been leveled, install

the correct number of anchor bolts and tighten to

secure the system.

PUMP INSTALLATION

In most cases, if the pumps have an overall length

of less than twenty (20) feet, they are shipped

assembled. Only the motor, head shaft, strainer

basket, and discharge connection are shipped

separately. The following instructions describe

installation for assembled pump stations.

Prior to Installation

1. Measure each pump and document on the

set/start report.

2. Confirm wet well probe measurements.

Measure the distance from the bottom of

the wet well to the top of the skid to

ensure that pumps were ordered with the

correct length. Preferred length is 12

inches above the bottom of the wet well.

3. Tighten all bolts and couplings on the

pump before proceeding.

4. Install each pump according to the last

digit on the pump identification tag.

Figure 2: Location of Serial Number and

Skid Position

Installing Assembled Pump Station

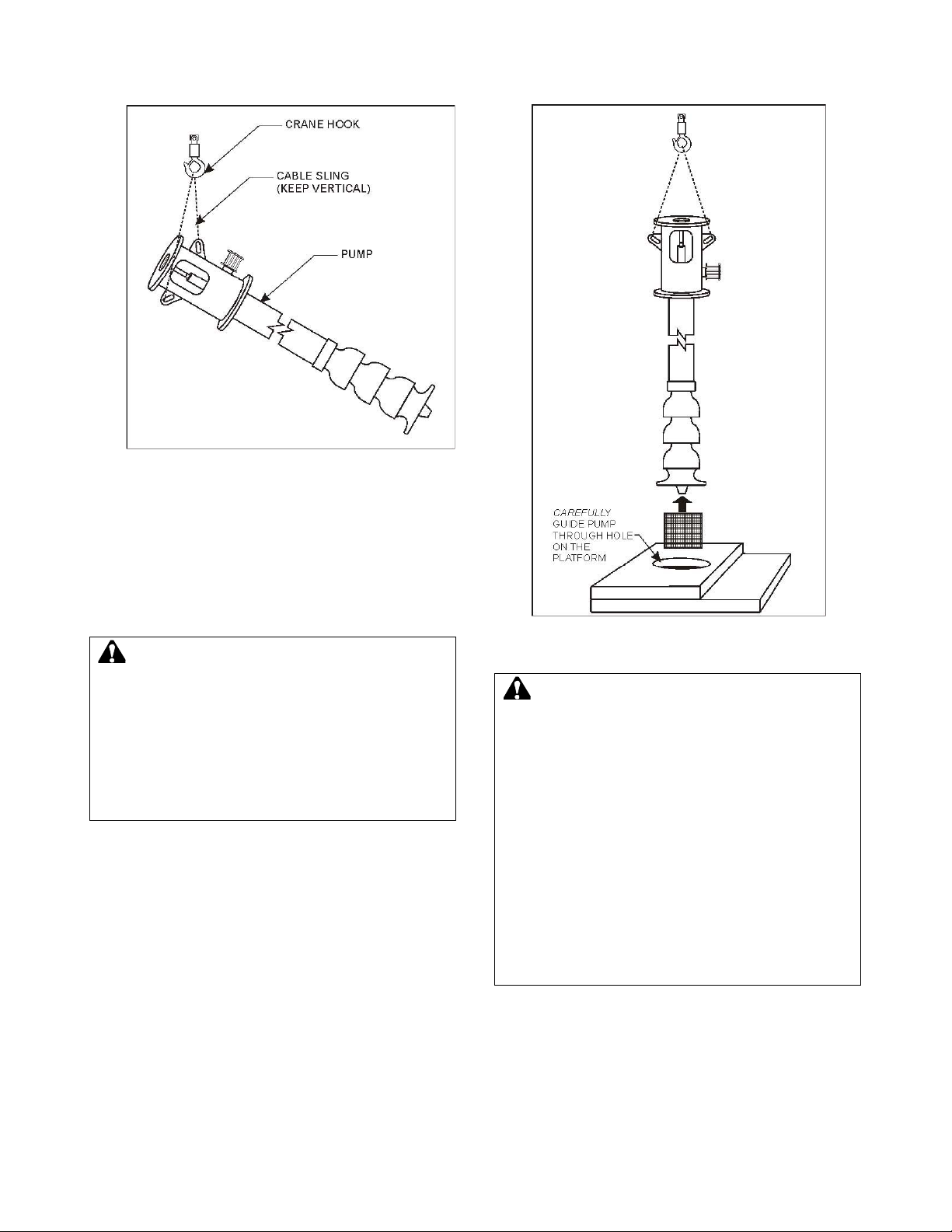

1. To set pump, use a crane or other

adequate lifting device and a cable sling of

adequate length. Attach the cable to the

lifting lugs (lifting eyes) on either side of

the pump.

Page 11

9

Figure 3: Lifting Pump

2. After the cable-sling is attached to the

lifting lugs (lifting eyes) on the pump head,

raise the pump to a vertical position. While

in this position, install the strainer basket

with bolts and clips. Position the pump

over its access hole on the skid.

WARNING: Falling Objects Hazard

DO NOT work under heavy suspended object

unless there is positive support and safeguards

should a hoist or sling fail.

Failure to follow these instructions could result in

serious personal injury, death, or property

damage.

3. Very slowly, lower the pump through its

access, keeping one hand on the pump to

detect any bumping by the pump against

the edge of its hole or the wall of the wet

well. When the pump is properly installed,

it should not touch the side of the wet well.

Premature bearing failure or destruction of

the bowl assembly can result from

improper installation.

Figure 4: Position Head Over Access

Hole on Skid

WARNING: Equipment Damage Hazard

Be prepared to stop lowering the pump

IMMEDIATELY if any bump is felt.

It is possible that the pump bowl could catch on

the edge of the skid and become unhooked from

the cable or other lifting device. Possible serious

bodily injury or damage to the pump could result.

Verify and ensure that the safety latch on the hook

works properly.

Failure to follow these instructions could result in

serious personal injury, death, or property

damage.

4. Push the pump slightly off-center when it

is being lowered in the wet well to avoid

hitting the manifold discharge pipe.

5. Stop lowering the pump when the base of

the head is approximately 1/8 to 1/4 inch

above the platform.

Page 12

10

6. Line up the spool with the pump isolation

valve on the manifold-discharge pipe and

set the pump on the skid. Start threading

the base bolts on the pump head. Slide

the Victaulic clamp gasket so that the

clamp rides in the gloves on both the

isolation valve and the spool. Tighten the

Victaulic clamp. Tighten the base bolts.

7. If the pumps are shipped unassembled,

refer to the Gould Pumps, Model VIT

Installation, Operation, & Maintenance

Instructions.

8. Install the vertical hollow shaft motor to

the top of the pump’s disconnected head.

Refer to the Gould Pumps, Model VIT

Installation, Operation, & Maintenance

Instructions.

WARNING: Falling Objects Hazard

DO NOT work under heavy suspended object

unless there is positive support and safeguards

should a hoist or sling fail.

Failure to follow these instructions could result in

serious personal injury, death, or property

damage.

CAUTION: Motor Rotation Hazard

DO NOT install motor shaft, Gib key, or adjusting

nut until motor rotation has been verified.

Failure to follow these instructions indicates a

potentially hazardous situation, which, if not

avoided, may result in property damage.

Page 13

11

STATION OPERATION

This section covers the sequence of operation for

your station including: Door Switch Operation,

Automatic Operation, and System Safeties.

DOOR SWITCH OPERATION

System Control Switch

Allows operator to select how the station

operates:

OFF Regardless of individual switch

position, pumps do not operate.

AUTO Places the system in

automatic mode.

MANUAL Places the pumps in manual

mode. The operator must start and stop

the individual pumps using each pump’s

switch.

Individual Pump Switches

Allows operator to select which pumps

operate:

NOTE: Pumps have an OFF/ON switch or

a MANUAL/OFF/AUTO switch.

MANUAL These switches start the

individual pumps. However, the system

MANUAL/OFF/AUTO switch must be

placed in the MANUAL position before the

individual pump is turned ON. Otherwise,

each switch must be cycled OFF, then ON

to “arm” the pump for operation.

OFF Selected pump does not operate,

regardless of any other switch position.

AUTO Selected pump operates in

Automatic Mode provided there is not an

individual pump overload trip.

ON Selected pump will operate

immediately if the system switch is set to

MANUAL, and there are no faults. In

AUTO, the pump will come on if there is a

demand for it, and the PLC calls for it.

VFD / Bypass Switch

Enables or disables the VFD:

VFD This switch position enables VFD

operation in either automatic or manual

mode depending on the position of the

system switch. VFD is the normal position

of the switch.

BYPASS This switch position, places the

pump station in either "Automatic VFD

Bypass" or "Manual VFD Bypass" mode of

operation depending on the position of the

MANUAL/OFF/AUTO switch. In this mode,

the pumps will start "across the line."

This mode is intended for use only when

the VFD is not functional. Turn all pump

switches to OFF before placing the

system in BYPASS mode.

VFD Selector Switch (Optional On Some

Stations) – PUMP 1 / PUMP 2 / PUMP 3

This switch determines which pump runs on

the VFD when switch is in the MANUAL mode.

However, if this switch is not present, the first

pump with VFD capability runs as the VFD

pump.

When the switch is in AUTO, the pump

selected to run on the VFD has the lowest

accumulated run time. Only one pump at a

time can run on the VFD (also known as an

inverter). Once a pump is running on the

inverter, this switch is disabled. If another

pump is selected when the inverter is in use,

the newly selected pump does not run.

Low Discharge/Differential Pressure

Switch

This switch allows the operator to enable or

disable either the "Low Discharge Pressure"

shut-down circuit, or the filter differential

pressure circuit. Only one circuit can be

overridden at one time, therefore a three-way

switch is used.

LDP OVERRIDE This position prevents a

low-discharge pressure fault from shutting

down the pump station. Use the LPD

OVERRIDE position during the initial pipe

filling and when restarting the system from

a de-pressurized condition in MANUAL or

AUTO mode.

Page 14

12

ACTIVE PRESSURE OVERRIDE

This activates both the "low discharge

pressure" and "filter differential pressure"

protection systems. Normally, the pump

station should be left in this position during

automatic operation to prevent

overloading the pump motors and avoid

damaging erosion in the event of a major

pipe break.

DIFFERENTIAL PRESSURE OVERRIDE

This switch position allows overriding the

filter differential pressure switch. This

override should be used only temporarily,

and is not intended for prolonged

operation.

Wye Strainer or Filter Switch

If present on the station, this switch controls

the operation of the Wye strainer or filter

solenoid.

OFF Prevents the Wye strainer or filter

from flushing.

MANUAL The Wye strainer or filter

flushes continuously, regardless of other

switch settings. The MANUAL position

may be used for de-pressurization for

maintenance, or when attempting to clean

a seriously dirty screen.

AUTO In this position, the Wye strainer or

filter flushes for 10 to 15 seconds, 60

seconds after the main VSP, or the first

XL (across-the-line) pump, starts.

Afterwards, flushing occurs for 10 to 15

seconds after each hour of continuous

pump operation. This is the normal

position for the switch.

Lake Screen Switch

If present on the station, this switch controls

the operation of the solenoid valve, which

operates the self-rotating lake inlet screen.

OFF Prevents the Lake Screen from

working.

MANUAL Energizes the solenoid

continuously regardless of the status of

the station. This can be used to depressurize the system, or to verify

operation of the screen during

maintenance.

AUTO Causes the Lake Screen solenoid

to open after the main VSP has been

operating at least one minute, the

minimum flow requirement is met, and the

speed test is not trying to stop the VSP.

This is the normal position of this switch.

Well Pump Switch

If present on the station, this switch allows

the operator to control the operation of a well

pump. In most cases, the operation of this

pump is completely independent of the

operation of the pump station. However, the

system is configurable so that the well pump

does not run during the lockout period.

OFF Prevents the well pump from

running.

MANUAL The well pump runs

continuously until the switch is turned

OFF.

AUTO The well pump starts and stops

based on a separate level switch.

Reset Push Button

This button allows the operator to clear

(Reset) any faults within the system once the

cause of the fault has been cleared. It is also

used for the lamp test.

RESETTING FAULTS Faults must be

reset by the reset button, unless the fault

automatically resets as described in the

System Safeties section. Pressing the

reset button clears all fault counters.

These counters prevent certain faults from

automatically resetting indefinitely. If the

fault lamp does not go out after resetting,

the cause of the fault is still present and

must be resolved before normal operation

can continue.

LAMP TEST Pressing this button for five

seconds causes all lamps on the front

panel to illuminate. Replace any lamps

that do not illuminate. For safety reasons,

the lamp test needs to be performed on a

regular basis.

Page 15

13

AUTOMATIC OPERATION

Overview

The primary benefit of Variable Speed

Pumping (VSP) Systems is to ensure surgefree starts and stops while maintaining a

constant down-stream line pressure with no

mechanical pressure-regulating valve. This

minimizes pipeline failures due to surges and,

not incidentally, reduces the utility bill for the

station.

Automatic operation is selected by the system

control switch. In automatic operation, all

pump activity is determined by the PLC. The

position of the individual pump switch lets the

PLC know whether or not it is available to run.

In most cases, all pump switches are in the

ON position. When a pump or a motor is

removed from the system, turn the pump

switch OFF, and the PLC will not try to run

that pump.

The PLC brings one pump on at a time in

order to satisfy the start criteria (usually

setpoint pressure). Some stations are

designed to start and stop the pumps based

on remote start signals, level probe signals, or

other criteria. The standard start and stop

sequence is as follows:

Pressure below setpoint to start

Combo 1

5 PSI

Delay time to start Combo 1

0 SEC

Pressure above setpoint to stop

Combo 1

5 PSI

Delay time to stop Combo 1

5 SEC

Pressure below setpoint to start

Combo 2

10 PSI

Delay time to start Combo 2

0 SEC

Pressure above setpoint to stop

Combo 2+

30 PSI

Delay time to stop Combo 2+

90 SEC

Pressure below setpoint to start

Combo 3+

5 PSI

Delay time to start Combo 3+

10 SEC

NOTE: The criteria for Combo 4 and above

are the same as Combo 3.

The "pressure above setpoint to stop" and

"delay time to stop" parameters only apply to

Combo 1. The values of 30 PSI and 90

seconds were intentionally selected since they

are out of range and will never be used.

There are three (3) main types of auto

operation – line fill, system charging, and

normal operation.

Line Fill Mode

Line Fill Mode is used when downstream

pressure is significantly below setpoint, such

as during the initial startup, or when leaks in

the lines are repaired. Operation is as follows

(performed in order):

System control switch: OFF

All Individual Pump switches: ON

Override/Active switch: LDP Override

(Low Discharge Pressure fault disabled)

VFD Bypass switch: VFD

System control switch: AUTO

As soon as the system control switch is turned

to the AUTO position, the VSP (Variable

Speed Pump) with the lowest run time starts

at a reduced speed. When the VSP starts, the

startup ramp in the program lowers the

setpoint to 2 PSI above the actual

downstream pressure. The VFD adjusts the

speed of the VSP to reach the desired

setpoint. The setpoint ramps up at the rate of

1 PSI every 4 seconds until the normal

setpoint is reached.

This feature prevents the VSP from coming up

to full speed too quickly, and prevents the lag

pump(s) from starting prematurely. This rampup feature allows the system to develop a

controlled and smooth start up from a

completely de-pressurized condition,

minimizing pipe breakage from water hammer.

Once the pressure above setpoint value is

reached, the VSP shuts down. The pump

switches can be left in ON and the system

control switch left in AUTO. The

Override/Active switch should be returned to

the ACTIVE position. The station is now in

system "charging" mode.

System Charging Mode

If there are no heads open, and the pressure

is within the defined range of operation,

pressure may slowly drop due to system

Page 16

14

leakage, or other small demands. A PM pump

is provided to address this issue. Most

stations, but not all, include a PM pump. Door

switches are set as follows (from end of line fill

mode):

System control switch: AUTO

All Individual Pumps switches: ON

Override/Active switch: ACTIVE (Low

Discharge Pressure and differential

pressure faults enabled)

VFD Bypass switch: VFD

NOTE: As downstream pressure drops to

more than 5 PSI below setpoint, the PM pump

starts up. It runs until the system pressure

builds up to 5 PSI above setpoint, and then

shuts off.

Two issues can come into play here. One is

cycle time. This refers to the number of times

an hour that the PM pump starts and stops

(one cycle). If the amount of cycles is

excessive, either the system leaks have to be

repaired, or the start/stop parameters need to

be tuned (normally by dropping the pressure

below setpoint to start, or increasing the

pressure above setpoint to stop). Must-run

times can cause the opposite problem. The

PLC determines the must-run time for each

pump. If this value is set too high, the PM

pump reaches its "pressure above setpoint"

and stops before the must-run time setting

indicates. This can lead to an overpressurization situation. Address this problem

by lowering the must-run time.

WARNING: Excessive Run Time Hazard

Excessive must-run times, stop times, or stop

pressure setting can cause system overpressurization, pipe damage, and potentially

cause personal injury. Consult your service

technician or the factory if you are unsure about

any settings.

Failure to follow these instructions could result in

serious personal injury, death, or property

damage.

Normal Operation

Normal Operation occurs when heads are

turned on, or a demand for water exists. Door

switches are set as follows (from end of line fill

mode):

System control switch: AUTO

Pump 1 switch: ON

Pump 2 switch: ON

Pump 3 switch: ON

PM Pump switch: ON

Override/Active switch: ACTIVE (Low

Discharge Pressure and differential

pressure faults enabled)

VFD Bypass switch: VFD

When the pressure drops 5 PSI below

setpoint, the PM pump starts and continues to

run until the pressure is 5 PSI above the

setpoint. When this pressure is reached, the

PM pump turns OFF. If the pressure continues

to drop to 10 PSI below setpoint, the VSP

starts. Five seconds later, the PM pump turns

OFF. This is the operation sequence for

Combo 1.

When the VSP starts, the startup ramp in the

program lowers the setpoint to 2 PSI above

the actual line pressure. The VFD adjusts the

speed of the VSP to maintain the discharge or

downstream pressure at the setpoint. The

setpoint ramps up at the rate of 1 PSI every 4

seconds until the normal setpoint is reached.

As the setpoint rises, so does the speed of the

VSP. This feature prevents the VSP from

coming up to full speed too quickly and

prevents the lag pump(s) from starting

prematurely. This ramp-up feature allows the

system to develop a controlled and smooth

startup from a completely de-pressurized

condition, minimizing pipe breakage from

water hammer. This is the operation sequence

for Combo 2.

If the VFD reaches full speed driving the main

VSP and the discharge pressure is more than

10 PSI below the setpoint, the demand for

water is greater than the capacity of the VSP.

An XL (across-the-line) pump starts as the lag

pump. This operation sequence occurs during

Combo 3.

When an XL pump starts, and the VFD is

driving another pump, the inverter (VFD)

speed immediately ramps down to the inverter

“speed when lag pump starts” setting. This

permits the XL pump to start with very little

pressure surge, or related water hammer.

Once the lag pump is at full speed, the VSP

ramps back up to try and maintain setpoint

pressure.

Page 17

15

If the demand for water is still greater than the

capacity of these two pumps, then Combo 4

starts. As occurred in the previous Combo, the

inverter (VFD) speed immediately ramps down

to the “speed when lag pump starts” setting.

The second lag pump starts up and goes to

full speed, and the VSP ramps back up to try

and maintain setpoint pressure.

This sequence of events repeats for all

available Combos.

When the flow decreases, the VFD (inverter)

slows down to maintain a constant discharge

pressure. Eventually as the speed decreases,

a setpoint is reached where the VSP is not

pumping any water. The XL pump(s) are

supplying all the water required. If the flow

continues to decrease, the discharge pressure

increases above the setpoint. Slowing the

VFD (inverter) does not reduce the pressure

because the VSP is not currently pumping any

water. Once the pressure reaches 1 or 2 PSI

above the setpoint pressure, the Overpressure

Accumulator starts counting. Once the count

reaches 750, the last XL pump is stopped. If

the pressure is well above the setpoint, or

increasing rapidly, the pump can stop quickly;

in 1 to 2 seconds. If the pressure remains 1 or

2 PSI above setpoint, the pump turns OFF in

approximately 20 seconds. When an XL

pump stops, the inverter (VFD) speed

immediately ramps up to the “speed when lag

pump stops” setting. This prevents the system

pressure from dropping excessively due to the

XL pump shutting off.

Once an XL pump has been stopped, the VSP

waits for the time entered in the "delay time to

start" before the XL pump is permitted by the

program to restart. This feature minimizes

pump cycling and pressure surges. The

generic value for Combo 3 and up is 10

seconds. If the conditions for starting an XL

pump are met after this waiting period,

normally 10 seconds, the pump is restarted.

If the flow continues to decrease, each XL

pump is stopped in the manner described

above, until only the VSP is running. Stopping

the last VSP is accomplished by using "Speed

Test," which uses a stop method different from

stopping an XL pump. Because the inverter

speed keeps lowering as the flow decreases,

the discharge pressure would never get above

the setpoint. In this situation, the VSP would

"idle," pump no water, and would never turn

off. To shut down the VSP, the system

initiates the "Speed Test" whenever the flow is

below a predetermined value for 15 seconds.

The program then lowers the setpoint by 5

PSI. If the VFD speed falls below a

predetermined value and the pressure

remains above the reduced setpoint for 15

seconds, the VSP turns OFF, and the setpoint

returns to normal. Speed Test returns the

station to "System Charging" mode until a new

demand for water is created.

Page 18

16

Manual VFD Operation

Overview

Manual operation is selected by the system

control switch. In manual operation, all pump

activity is controlled by the individual pump

switches. In the case of multiple pumps

available for VFD operation, the VFD select

switch determines which pump(s) run in VFD

mode. However, some stations do not come

equipped with a VFD select switch. In that

case, the first pump that is started is always

the VFD pump. The speed of the VFD pump is

controlled by the speed potentiometer (speed

pot). All other pumps run in XL mode (at full

speed). The Override/Active switch enables or

disables the low-discharge pressure fault.

NOTE: Manual operation is rarely used.

However, it does allow for operation of

individual pumps for testing purposes.

Sequence of Operation (performed in

order)

System control switch: OFF

All Individual Pump switches: OFF

Override/Active switch: LDP Override

(Low Discharge Pressure fault disabled). If

initial system pressure is high enough,

place in Active.

VFD Bypass switch: VFD

VFD Select switch: Pump 1

Speed Potentiometer: Turned 100%

counter-clockwise (0 speed)

System control switch: MANUAL

Pump 1 switch: ON

Speed Potentiometer: Turn clockwise to

increase speed of pump 1

Pump 2 switch: ON (if required)

Speed Potentiometer: Adjust speed as

required to maintain set point pressure.

Pump 3 switch: ON (if required)

Speed Potentiometer: Adjust speed as

required to maintain set point pressure.

NOTE: When done, turn OFF all pump

switches and place system control switch in

OFF. Return Override/Active switch to

ACTIVE. If the station can be run in Automatic

mode, return the system switch to AUTO and

turn ON all pump switches.

VFD Bypass Operation, Manual mode

Overview

This is an abnormal operating mode and

would only be used when the VFD (inverter) is

not operable but there is a need to irrigate. If

the PLC is operable, and PRV (Pressure

Reducing Valve) is in the system and

functioning, we strongly recommend using

Automatic VFD Bypass Mode.

WARNING: Manual VFD Bypass Hazard

This mode of operation should be used as a last

resort if there is no DSR, or it is not functioning

correctly. Constant operator attendance is

recommended when this mode is used. The water

demand must be calculated to match the

individual pump output as closely as possible.

Failure to do so will cause a serious over-pressure

condition.

Failure to follow these instructions could result in

serious personal injury, death, or property

damage.

System Operation (performed in order)

System control switch: OFF

All Individual Pump switches: OFF

Override/Active switch: LDP Override

(Low Discharge Pressure fault disabled). If

initial system pressure is high enough,

place in ACTIVE.

VFD Bypass switch: BYPASS

VFD Select switch: Pump 1

Speed Potentiometer: N/A

System control switch: MANUAL

Pump 1 switch: ON

Allow system pressure to stabilize before

turning on additional pumps.

Pump 2 switch: ON (if required)

Pump 3 switch: ON (if required)

Page 19

17

NOTE: When done, turn OFF all pump

switches and place system control switch in

OFF. Return Override/Active switch to

ACTIVE.

VFD Bypass Operation, Auto mode

Overview

VFD Bypass mode is an EMERGENCY ONLY

mode used when the VFD is inoperative.

Monitor station operation closely when in

bypass mode due to limited pressure control

available. Your station must be equipped with

a PRV (Pressure Reducing Valve) in order to

run VFD Bypass Mode automatically. This

valve now assumes the pressure regulating

function that was performed by the VFD in

normal operation. Ensure that the PRV is

adjusted to maintain your downstream

pressure at no more than 12 PSI above

setpoint pressure. Verify that the PRV is

operating correctly before leaving the station

unattended. Check station regularly to ensure

continued proper operation. If your station is

not equipped with a PRV, do not operate in

automatic VFD bypass mode.

WARNING: VFD Bypass Switch Hazard

This mode of operation should be used as a last

resort if there is no DSR, or it is not functioning

correctly. Constant operator attendance is

recommended when this mode is used. The water

demand must be calculated to match the

individual pump output as closely as possible.

Failure to do so will cause a serious over-pressure

condition.

Failure to follow these instructions could result in

serious personal injury, death, or property

damage.

VFD Bypass mode is selected by the VFD /

Bypass switch. The system control switch

MUST be turned to the OFF position before

selecting VFD bypass mode. Operation is

similar to normal automatic operation but the

start / stop sequences differ greatly. The

registers below regulate this.

NOTE: These are generic values and might

differ from your station.

Pressure below setpoint to start

Combo 1

5 PSI

Delay time to start Combo 1

0 SEC

Pressure above setpoint to stop

Combo 1

5 PSI

Delay time to stop Combo 1

5 SEC

Pressure below setpoint to start

Combo 2

12 PSI

Delay time to start Combo 2

3 SEC

Pressure above setpoint to stop

Combo 2

1 PSI

Delay time to stop Combo 2

60 SEC

Pressure below setpoint to start

Combo 3

15 PSI

Delay time to start Combo 3

10 SEC

Pressure above setpoint to stop

Combo 3

1 PSI

Delay time to stop Combo 3

30 SEC

Flow setpoint to stop Combo 1

0 GPM

Flow setpoint to stop Combo 2

20 GPM

Flow setpoint to stop Combo 3

80% *

Flow setpoint to stop Combo 4

80% **

80% of the previous combo’s maximum

output. * If one main pump puts out 500 gpm,

you would enter 400 gpm here. ** If two main

pumps put out 1000 gpm, you would enter 800

gpm here.

Other significant differences between VFD

Bypass and Automatic VFD Operation are as

follows:

1. The overpressure accumulator is not used

in VFD bypass mode.

2. Flow will dominate stopping main pumps

due to low Combo stop pressure settings.

The PM pump will continue to operate

similarly to VFD mode.

3. VFD Fault and Maximum RPM signals are

ignored.

4. Pump starts are caused by pressure drop

as in VFD mode, but due to operational

differences, the settings are modified from

those used in VFD mode.

Sequence of Operation (performed in

order)

System control switch: OFF

All Individual Pump switches: ON

Page 20

18

Override/Active switch: LDP Override

(Low Discharge Pressure fault disabled). If

initial system pressure is high enough,

place in Active.

VFD Bypass switch: Bypass

VFD Select switch: N/A

Speed Potentiometer: N/A

System control switch: AUTO

When done, place system control switch in

OFF. Return Override/Active switch to

ACTIVE.

The PM pump continues to charge the system

as in Automatic operation. Start and stop

sequence is based on pressure.

Once a demand for water exists, the PLC

starts the main pump with the lowest run time

as an XL (across- the-line) pump, based on

the “pressure below setpoint." If the flow

capacity of the main pump exceeds the

demand for water, pressure increases until the

PRV opens and discharges the excess flow

back into the water source. As demand for

water increases, the PRV closes. If the PRV is

completely closed, and the “pressure below

setpoint" drops low enough, the PLC brings on

the next Combo as required (all in XL mode).

The lead pump remains at full speed while the

next pump also comes up to full speed. If the

cumulative flow capacity of the main pumps in

operation exceeds the demand for water, the

PRV opens and discharges the excess flow

back into the water source. This process is

repeated for all available Combos.

Combo shutdown based on flow is made

possible by the way flow is read. The location

of the flow meter measures only the flow that

is actually being used. The flow out of the

PRV discharge that is returned into the water

source does not count as "measured flow."

The result is as demand for water decreases,

pressure continues to rise. The PRV opens as

required to maintain pressure. As more flow is

going out the PRV discharge, less flow is

actually being used. When the flow reading

drops below the “flow setpoint to stop” value,

the pumps shut down in the reverse order that

they started. Based on the demand for water,

this process continues until all main pumps

have shut down, and the station returns to

"System Charging" mode.

PLC Bypass Operation

Overview

This is an abnormal operating mode and

would be used if the PLC was not operable

and there is need to irrigate.

WARNING: PLC Bypass Hazard

This mode of operation should be used as a last

resort if there is no DSR, or it is not functioning

correctly. Constant operator attendance is

recommended when this mode is used. The water

demand must be calculated to match the

individual pump output as closely as possible.

Failure to do so will cause a serious over-pressure

condition. The high pressure discharge safety

does not function in PLC bypass, and damage to

your piping could occur. The only safeties that

function in PLC bypass are low discharge

pressure and phase fault.

Failure to follow these instructions could result in

serious personal injury, death, or property

damage.

System Operation (performed in order)

System control switch: OFF

All Individual Pump switches: OFF

Override: LDP Override (Low Discharge

Pressure fault disabled). If initial system

pressure is high enough, place in Active

VFD Bypass switch: NA

VFD Select switch: NA

Speed Potentiometer: N/A

PLC Bypass switch: BYPASS

System control switch: MANUAL

Pump 1 switch: ON

Allow system pressure to stabilize before

turning on additional pumps.

Pump 2 switch: ON (if required)

Pump 3 switch: ON (if required)

NOTE: When done, turn OFF all pump

switches and place system control switch

in OFF. Return Override/Active switch to

ACTIVE.

Page 21

19

SYSTEM SAFETIES

Overview

The program in the PLC protects the system

by shutting down in either of the “Auto” or

“Manual” Modes of operation if it detects any

of the following problems:

Alarm or Fault

Automatic Restart?

Low Discharge

Pressure

No Automatic Restart

High Discharge

Pressure

Automatic Restart

Low Inlet Pressure

(Optional)

Automatic Restart

Loss of Prime

(Optional)

Automatic Restart

Low Level (Optional)

Automatic Restart

Station Phase

Pressure (Optional)

No Automatic Restart

Individual Pump

Faults

No Automatic Restart

VFD Fault

Automatic Restart

Table 1: Automatic Restart After Alarm

or Fault

Automatic Mode of Operation

"High Discharge Pressure," “Station Phase

Failure," "Low Inlet Pressure," "Low Level,"

"Loss of Prime," and "VFD Fault" allow the

system to restart automatically when the fault

clears in the automatic mode of operation. The

PLC allows three (3) automatic restarts (which

can be caused by any combination of these

faults) in a one-hour period. At the fourth

occurrence in a one-hour period, the station

shuts down (hard fault). "Low Discharge

Pressure" and "Individual Pump Faults," do

not allow the system to restart automatically

when the fault clears. These faults must be

cleared and manually reset before station

operation can resume. Individual pump faults

require turning the pertinent individual pump

switch to the OFF position, and then back ON

(called, re-arming). In some instances, an

individual pump can trip an alarm without

shutting down the entire system, provided

another pump is available to operate.

Manual Mode of Operation

All faults are cleared by pressing the Reset

button, or by re-arming individual pump faults.

Low Discharge Pressure

The pressure transducer located in your

station discharge line communicates the

downstream pressure to the PLC. The PLC

monitors downstream pressure to determine if

the pressure is below the allowable range.

The standard PLC program defines lowdischarge pressure as being 25 PSI below

setpoint pressure. There is a time delay of 300

seconds (five minutes) before the station

faults that is designed to give the system time

to build pressure beyond this point. The

values might vary on your station.

Based on the values above, if the discharge

pressure remains 25 PSI below the setpoint

for longer than five minutes, all pumps are

shut down. The red station fault light on the

control panel door comes on, and the display

indicates that a "Low Discharge Pressure

fault" has occurred.

This fault does not automatically reset. To

clear the fault, press the Reset button. The

station runs for another five minutes before

determining whether the low discharge

pressure condition still exists.

NOTE: If you are attempting to run in

automatic line fill mode, place the

Override/Active switch in OVERRIDE. Return

switch to the ACTIVE position once the

pressure is high enough to do so.

If the pump station is simply unable to keep up

with the demand, shut the station down, and

determine the nature of the problem. Consult

the Troubleshooting section of this manual for

assistance.

High Discharge Pressure

As with the "Low Discharge Pressure" fault,

the PLC monitors downstream pressure to

determine if the pressure is out of range, or

above the allowable limit.

The standard PLC program defines highdischarge pressure as being 15 PSI above

setpoint pressure. There is a time delay of

60 seconds, or one minute, before the station

faults that is designed to give the system time

to adjust the pressure to below this point.

These values might vary on your station.

Based on the values above, if the discharge

pressure remains 15 PSI above the setpoint

for longer than one minute, the station shuts

Page 22

20

down. Once the high pressure condition

clears, the station automatically resets, and

automatic operation resumes. The PLC allows

three (3) automatic restarts in a one-hour

period. At the fourth occurrence in a one-hour

period, the station shuts down (hard fault).

The red station fault light on the control panel

door comes on, and the display indicates an

"Alarm Shutdown Alert." Go to "Alarms," and

the display should show that a "High

Discharge Pressure fault" has occurred.

NOTE: At this point, shut the station down,

and determine what the problem is. Consult

the Troubleshooting section of this manual for

assistance.

To clear the fault, press the Reset button.

Low Inlet Pressure

This optional safety is usually used on

flooded-suction booster pump applications.

Normally, a pressure switch monitors the inlet

pressure on the "suction" side of the pump.

This switch is located in a box on the lower left

side of the control cabinet. The switch is used

in conjunction with a relay to inform the PLC

that it is unsafe to run. Setting the low inlet

pressure condition is accomplished by

physically adjusting the pressure switch.

There is a 20 second time delay in the PLC.

Once the inlet pressure drops below the

switch pressure setting, all pumps shut down

after a 20 second delay. Once the low inlet

pressure condition clears, the station

automatically resets and automatic operation

resumes. The PLC allows three (3) automatic

restarts in a one-hour period. At the fourth

occurrence in a one-hour period, the station

shuts down (hard fault). The red station fault

light on the control panel door comes on, and

the display indicates an "Alarm Shutdown

Alert." Go to "Alarms," and the display should

show that a "Low Inlet Pressure fault" has

occurred.

WARNING: Low Inlet Pressure – Station

Shutdown Hazard

At this point, shut the station down, and determine

what the problem is. Consult the Troubleshooting

section of this manual for assistance.

Failure to follow these instructions could result in

serious personal injury, death, or property

damage.

There are two dials on the pressure switch.

The one on the top is the correct adjustment.

Turn clockwise to increase the pressure

setpoint, counter-clockwise to decrease.

CAUTION: Delta Pressure Setting Hazard

Do not adjust the bottom dial. This is a delta

pressure setting, and is not used. This dial must

be adjusted fully counter-clockwise (0 position). If

you are having trouble with your pressure switch,

always verify that this dial is in the 0 (fully counterclockwise position) before adjusting the top dial.

Failure to follow these instructions indicates a

potentially hazardous situation, which, if not

avoided, may result in property damage.

WARNING: Minimum Pressure Setting

Hazard

The pressure setting is based on the minimum

pressure that the pump can safely operate. Do not

lower the pressure switch setting without

consulting the factory

.

Failure to follow these instructions could result in

serious personal injury, death, or property

damage.

Loss of Prime

This optional safety is usually used on endsuction centrifugal pump applications.

A level probe is placed in the suction piping at

a predetermined level. This probe works in

conjunction with a relay to inform the PLC that

it is unsafe to run. Fault usually signifies a

malfunctioning foot valve.

After a second or two, all pumps shut down. If

the loss of prime condition clears, the station

automatically resets, and automatic operation

resumes. The PLC allows three (3) automatic

restarts in a one-hour period. At the fourth

occurrence in a one-hour period, the station

shuts down (hard fault). The red station fault

light on the control panel door comes on, and

the display indicates an "Alarm Shutdown

Alert." Go to "Alarms" and the display should

show that a "Loss of Prime fault" has

occurred.

NOTE: At this point, shut the station down,

and determine what the problem is. Consult

the Troubleshooting section of this manual for

assistance.

To clear the fault, press the Reset button.

Page 23

21

WARNING: Equipment Damage Hazard

Do not attempt to bypass this safety, as pump

damage will occur.

Failure to follow these instructions could result in

property damage and/or moderate personal injury.

Low Level Fault

This safety is used in Vertical Turbine pump

applications to signal when the wet well level

is too low to permit safe operation of the

pumps. Used in conjunction with a relay, three

(3) level probes are placed in the wet well.

From bottom to top, these are the "reference"

(ground) probe, the "low" probe, and the

"reset" probe. If the wet well level drops below

the "low" probe, the relay sends a signal to the

PLC telling it to shut down pump operation.

The fault cannot be cleared until the reset

probe is under water.

After a five (5) second time delay, all pumps

shut down. Once the low level condition

clears, the station automatically resets and

automatic operation resumes. The PLC allows

three (3) automatic restarts in a one-hour

period. At the fourth occurrence in a one-hour

period, the station shuts down (hard fault).

The red station fault light on the control panel

door comes on, and the display indicates an

"Alarm Shutdown Alert." Go to "Alarms," and

the display should show that a "Low Level

fault" has occurred.

NOTE: At this point, shut the station down,

and determine what the problem is. Consult

the Troubleshooting section of this manual for

assistance.

To clear the fault, press the Reset button.

Phase Failure

This safety utilizes a phase monitor to analyze

incoming voltage and determines whether all

voltage parameters are acceptable and the

phase sequence is correct.

The LED on the phase monitor is lit if there is

no fault. If there is a problem, the LED is off.

After approximately one (1) second, all pumps

are shut down. Once the phase failure

condition clears, the station automatically

resets, and automatic operation resumes. The

PLC allows three (3) automatic restarts in a

one-hour period. At the fourth occurrence in a

one-hour period, the station shuts down (hard

fault). The red station fault light on the control

panel door comes on, and the display

indicates an "Alarm Shutdown Alert." Go to

"Alarms," and the display should show that a

"Phase Failure fault" has occurred.

NOTE: At this point, shut the station down,

and determine what the problem is. Consult

the Troubleshooting section of this manual for

assistance.

WARNING: Electrical Shock Hazard

As this is an electrical problem, adhere to all

safety procedures during troubleshooting. To clear

the fault, press the reset button.

Failure to follow these instructions could result in

property damage and/or moderate personal injury.

INDIVIDUAL PUMP FAULTS

There are three faults that are considered

Individual Pump Faults. These are overload

protection, high pump temperature (optional), and

individual pump phase fault (optional).

Overload Protection

Overload Protection is standard on all pump

stations. The overload is a safety device that

shuts the motor down when amperage

exceeds the setpoint of the device.

If the motor amperage exceeds the overload

setpoint that pump shuts. In some instances,

an individual pump can trip without shutting

down the entire system if another pump is

available to operate. If so, the PLC will

automatically bring the available pump on line.

The green light above the pump switch flashes

for the pump that was shut down. Go to

"Alarms," and the display should show that an

"Individual Pump fault" has occurred. The PLC

does not differentiate between the different

individual pump faults.

WARNING: Overload Hazard

The overloads are located inside the control

panel. All safety procedures must be adhered to

during the any adjustment or resetting process.

Failure to follow these instructions could result in

property damage and/or moderate personal injury.

Page 24

22

Resetting the overload is accomplished by

pushing in the blue Differential Overloads

button on the right front face of the device,

and rotating it approximately an eighth of a

turn clockwise.

Adjustment of the overload setpoint is

performed using the blue dial on the left front

face of the device.

Once the overload has been reset, individual

pump faults require turning the individual

pump switch to the OFF position, and then

back ON (re-arming).

High Pump Temperature (Optional)

High pump temperature utilizes a temperature

probe inserted into the pump discharge piping.

The probe trips when the water temperature

reaches 120°F, and then immediately shuts

down the pump. The green light above the

pump switch flashes, indicating which pump

has shut down. Go to "Alarms," and the

display should show that an "Individual Pump

fault" has occurred.

The temperature probe automatically resets at

105°F. At that time, the pump can be rearmed,

and pump operation can continue.

NOTE: If the pump continues to shut down for

this issue, shut the station down and

determine what the problem is. Consult the

Troubleshooting section of this manual for

assistance.

VFD Fault

The VFD sends a fault signal (120 VAC)

directly to the PLC. The display shows,

"Inverter Fault." This is normally a VFD fault.

To determine the nature of the problem, you

must use the VFD keypad display and review

the fault/alarm history. This procedure is

outlined in the VFD section of this manual. A

list of all inverter fault/alarm codes is found in

your VFD manual.

In some instances, the display shows,

"Inverter Relay Fault." In this case the PLC

failed to get a VFD run signal back from the

drive. This could be a problem external to the

VFD. Consult the Troubleshooting section of

this manual for more details.

After a two (2) second time delay, the VFD

pump shuts down. The lag pump(s) continues

to run. The PLC allows three (3) automatic

restarts in a one-hour period. At the fourth

occurrence in a one-hour period, the station

shuts down (hard fault). The red station fault

light on the control panel door comes on, and

the display indicates an "Alarm Shutdown

Alert." Go to "Alarms," and the display should

show either an "Inverter fault" or an "Inverter

Relay fault" has occurred. The fault does not

have to be cleared in order to allow auto

restart.

Once you have determined what the VFD

(inverter) fault is, and have cleared it, press

the station Reset button to clear the alarm

shutdown status.

Page 25

23

MAINTENANCE

REGULAR MAINTENANCE = INVESTMENT

Maintenance is an investment that will pay

dividends in the form of improved reliability and

durability. Site maintenance checks are a matter of

day to day, week to week care that is important to

the proper operation of the pumping equipment.

Periodic equipment checks will ensure that the

recommended lubricants, fluids and service parts

are available and planned for. Flowtronex

recommends Preventative Maintenance be

performed quarterly.

DANGER: Personal Injury Hazard

Performing maintenance work on your pump

station can be dangerous. You face the risk of

electrical shock or related injuries, and must be

trained in the danger of electricity. If you have any

doubt, have a qualified technician do the work.

Contact the factory for the closest authorized

FlowNet service office to you.

Failure to follow these instructions will result in

death or serious injury.

REGULAR MONTHLY MAINTENANCE

INTERVALS

1. Heat exchanger:

a. Verify that the flow through the heat

exchanger is a solid streamline out of

the exhaust line into the wet well. Too

little flow reduces cooling capacity.

2. Control panel:

a. Using the operator interface, verify that

all the buttons operate properly. Also

review the station operation, fault

history, and data log for station

operation.

b. Verify that all surge devices are

visually sound. Check the surge device

for the station (mounted on the back of

the control panel). Black soot on or

around the device indicates that it has

taken a surge and needs to be

replaced.

3. Motor lubrication:

a. If your motor has an oil bath thrust

bearing, you need to ensure that it is

filled to the recommended fill line on

the sight glass (that is, filled to the

minimum line).

b. If it is a grease filled bearing, ensure

that grease is not all over the inside of

the motor and down in the bottom of

the motor. This could be a sign of overfilling. Refer to the motor

manufacturer's lubrication instructions.

4. Pumps - vertical turbine:

a. Verify that the area surrounding the

pump shaft has no silt built up around

the head. If there is silt build up, fix it

immediately.

CAUTION: Equipment Damage Hazard

Silt buildup is a sign of problems with the wet well

and/or intake screen.

Failure to follow these instructions indicates a

potentially hazardous situation, which, if not

avoided, may result in property damage.

5. Pumps - horizontal:

a. For a horizontal pump, verify that the

mechanical seal is not leaking between

the pump and the motor.

6. Exercise the DSR using the following

procedure. With system switch and all pump

switches in the off position, close the pump

station discharge isolation valve. Place the

system switch in manual and start a VFD

pump. Slowly ramp up the VFD speed. The

DSR should open and relieve system pressure

when it exceeds set point pressure by

approximately 12-15 psi. Adjust DSR as

required to meet this requirement. Repeat test

at least once to ensure repeatability.

7. Sound and visual checks of whole station:

a. Just listen. Do you hear any odd

sounds rubbing or grinding or maybe

Page 26

24

even electrical arcing or that something

is in a bind? This can indicate a

serious problem.

b. There is going to be some harmonic

vibration with the pumps and motor.

We are looking for excessive vibration

or noise. Can you see a bend in the

pump shaft? Do the motor and shaft

shake violently? This needs servicing

immediately. Do not operate pump if

vibration is excessive.

c. Confirm that the building cooling and

ventilation systems are operating and

clear of all obstructions. Maximum

operating range for equipment is 40°C

(104°F). Verify that water, grease, oil,

hardware, etc. are not leaking or loose

on the pump station.