Page 1

A-C FIRE PUMP SYSTEMS

INSTRUCTION MANUAL

AC2516

Series 1580 In-Line Mounted

Centrifugal Fire Pumps

Installation, Operation and Service Instructions

INSTALLER: PLEASE LEAVE THIS MANUAL FOR THE OWNER’S USE.

DESCRIPTION

The Series 1580 Inline Centrifugal Fire Pump is a close

coupled pump which features – high efficiency, rugged

construction, and in-line mounting. These features make

installation, operation and service easy to perform.

OPERATIONAL LIMITS

Unless special provisions have been made for your pump by

A-C Fire Pump Systems, the operational limits for Series

1580 Pumps are as follows:

SEAL OPERATING LIMITS

PACKING

PH Limitations 7-9; Temperature Range 0 to +200°F

For use on open or closed systems which require a large

amount of m akeup water, as well as systems wh ich are

subjected to widely varying chemical conditions and solids

buildup.

MAXIMUM WORKING PRESSURE

Listed on pump nameplate.

Page 2

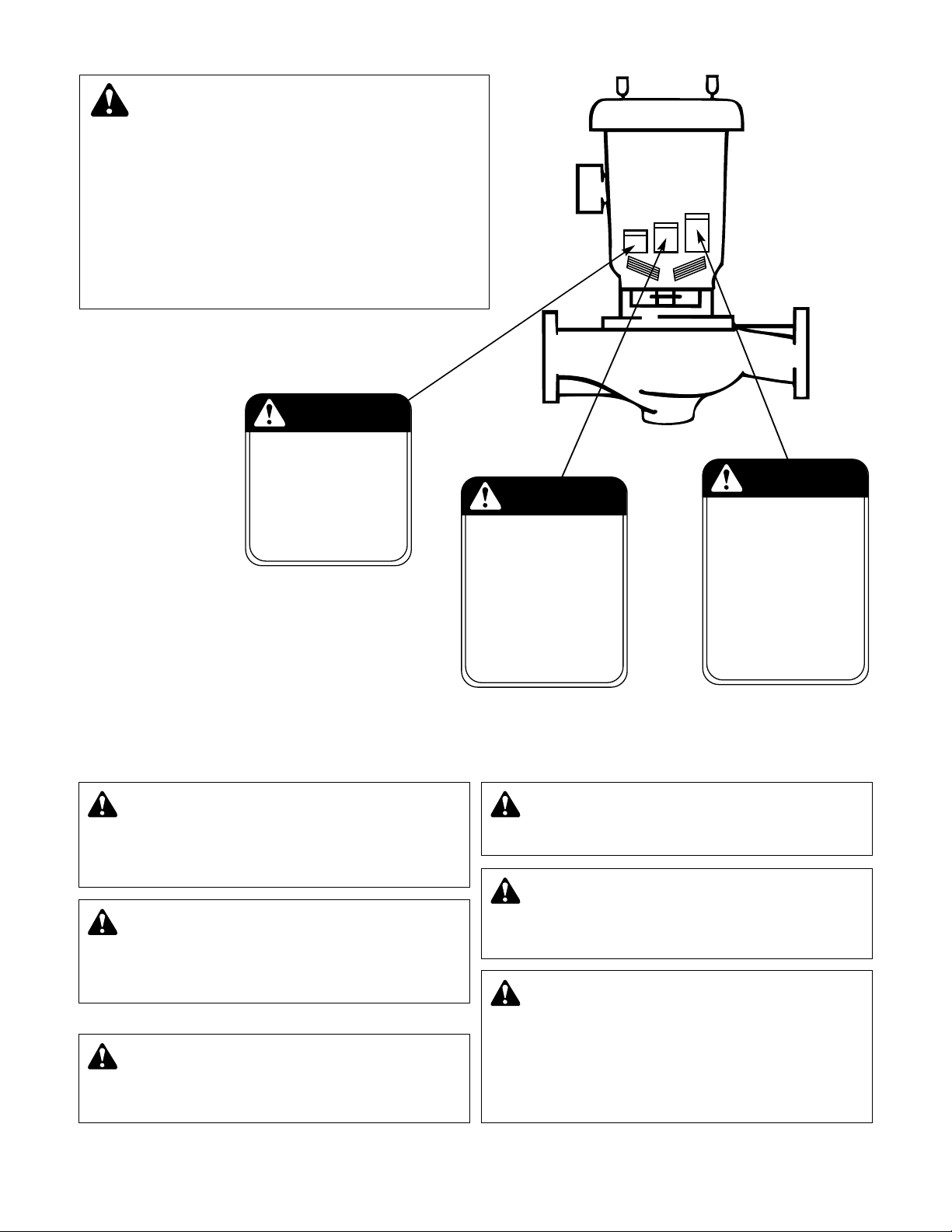

SAFETY

INSTRUCTIONS

This safety alert symbol will be used in this manual and on

the unit safety instruction decals to draw attention to safety

related instructions. When used, the safety alert symbol

means ATTENTION! BECOME ALERT! YOUR SAFETY IS

INVOLVED! FAILURE TO FOLLOW THESE INSTRUCTIONS

MAY RESULT IN A SAFETY HAZARD.

Your Series 1580 Inline Mounted Centrifugal Fire Pump

should have the following safety instructions decals approximately as shown. If the decals are missing or are illegible

contact your local A-C Fire Pump Systems representative

for a replacement.

WARNING

EYEBOLTS OR LIFTING

LUGS IF PROVIDED ARE

FOR LIFTING ONLY THE

COMPONENTS TO WHICH

THEY ARE ATTACHED.

FAILURE TO FOLLOW

INSTRUCTIONS COULD

RESULT IN INJURY

OR DEATH.

P70643

CAUTION

DO NOT RUN PUMP DRY,

SEAL DAMAGE MAY OCCUR.

INSPECT PUMP SEAL

REGULARLY FOR LEAKS,

REPLACE AS REQUIRED.

FOR LUBRICATION

REQUIREMENTS, CONSULT

SERVICE INSTRUCTIONS.

FAILURE TO FOLLOW

INSTRUCTIONS COULD

RESULT IN INJURY OR

PROPERTY DAMAGE.

P70644

Fig. 1

WARNING

ROTATING COMPONENTS

DISCONNECT AND LOCKOUT

POWER BEFORE SERVICING.

DO NOT OPERATE WITHOUT

ALL GUARDS IN PLACE.

CONSULT INSTALLATION

AND SERVICE INSTRUCTION

SHEET BEFORE OPERATING

OR SERVICING.

FAILURE TO FOLLOW

INSTRUCTIONS COULD

RESULT IN INJURY

OR DEATH.

P70642

ADDITIONAL SAFETY REQUIREMENTS:

ELECTRICAL SAFETY:

WARNING: Electrical Shock Hazard

Electronical connections to be made by a qualified

electrician in accordan ce with all applicable codes,

ordinances, and good practices. Failure to follow these

instructions could result in serious personal injury or death,

and property damage.

WARNING: Electrical Overload Hazard

Three phase motors must have properly sized heaters

to provide overload and under voltage protection. Single

phase motors have built-in overload protectors. Failure to

follow these instructions could result in serious personal

injury or death, and property damage.

THERMAL SAFETY:

WARNING: Extreme Temperature Hazard

If pump, motor, or piping are operating at extremely

high or low temperature, guarding or insulation is required.

Failure to follow these instructions could result in serious

personal injury or death, and property damage.

2

MECHANICAL SAFETY:

WARNING: Unexpected Startup Hazard

Disconnect and lockout power before servicing.

Failure to follow these instructions could result in serious

personal injury or death, and property damage.

WARNING: Excessive System Pressure Hazard

The maximum working pressure of the pump is listed

on the nameplate, do not exceed this pressure. Failure to

follow these instructions could result in serious personal

injury or death, and property damage.

WARNING: Excessive Pressure Hazard

Volumetric Expansion

The heating of water and other fluids causes volumetric

expansion. The associated forces may cause failure of

system components an d release of high temperature

fluids. This will be prevented by installing properly sized

and located compression tanks and pressure relief valves.

Failure to follow these instructions could result in serious

personal injury or death, and property damage.

Page 3

PUMP LOCATION

Locate the pump so there is sufficient r

maintenance and service. If the use of a hoist or tackle is

needed, allow ample head room.

WARNING: Falling Object Hazard

Eyebolts or lifting lugs if provided are for lifting only

the components to which they are attached. Failure to follow these instructions could result in serious personal injury

or death, and property damage.

If lifting of the entire pump is required, do so with slings placed

around the pump assembly as shown in Fig. 2A. Or if your

pump configuration looks like Fig. 2B, connect a nylon sling,

wire rope or chain to the brace ribs on the motor adapter.

one sling for each rib. Attach all slings together at least 2 ft,

above the top of the pump.

CAUTION: Some pumps may have the center of

gravity at, or slightly above, the lift point. This may

create a tipping hazard. To avoid this hazard securely bind

the lifting lines to the side of the motor using a strap or

chain wrapped securely around the top of the motor. Unit

should only be lifted vertically. Failure to follow these

instructions could result in serious personal injury or

death, and property damage.

oom for inspection,

Use

Special precautions to avoid sound and vibration transmission

should be taken if the pump is to be located near a noise sen

sitive ar

ea, a sound specialist should be consulted.

If the pump is not on a closed system, it should be placed as

near as possible to the source of the liquid supply, and located

to permit installation with the fewest number of bends or

elbows in the suction pipe.

The installation must be evaluated to determine that the Net

Positive Suction Head Available (NPSHA) meets or exceeds

the Net Positive Head Requir

ed (NPSHR), as stated by the

pump performance curve.

-

Fig. 2A Fig. 2B

24" Min.

Nylon Sling

Chain or

Wire Rope

Securing Strap

Choker Hitch

all Braces

3

Page 4

PIPING

Always install a section of straight pipe between the suction

side of the pump and first elbow or install an A-C Fire

Pump Systems Suction Diffuser. This reduces turbulence of

the suction by straightening out the flow of liquid before it

enters the pump. The length should be equal to five times the

diameter of the pipe.

Be sure to eliminate any pipe-strain on the pump. Support the

suction and discharge pipes independently by use of pipe

hangers or ground supports close to the pump. A support can

be bolted to the underside of the pump body but it must be so

constructed as to allow freedom of movement with the normal

expansion of the piping.

If the pump is to be mounted in vertical piping with the motor

in the horizontal position provide adequate support to prevent

strain on pump parts and piping. It is not recommended that

pump be mounted with the motor vertically downward. Do not

use motor lift rings as a means of suspending the pump.

Line up the piping so that the bolt-holes in the pump flanges

match the bolt-holes in the pipe flanges. DO NOT ATTEMPT

TO SPRING THE SUCTION OR DISCHARGE LINES INTO

POSITION. Bearing wear will result if suction or discharge lines

ar e forced into position. The code for Press ure Piping

(A.S.A.B. 31.1) lists many types of supports available for various applications.

As a rule, ordinary wire or band hangers are not adequate to

maintain

rigid support for the suction and discharge lines.

Where considerable temperature changes are anticipated,

fittings for absorbing expansion should be installed in the

system in such a way as to avoid strain on the pump.

On an open system with suction-lift, use a foot-valve of equal

or greater area than the pump suction piping. Prevent clogging

by using a strainer at the suction inlet next to the foot-valve.

The strainer should have an area three times that of the

suction pipe with a mesh hole diameter of no less than

An A-C Fire Pump Systems Check Valve installed in the discharge line will serve to protect the pump from water hammer,

as an isolation valve for servicing and for throttling.

alignment. It is very important to provide a strong,

1

/4".

NOTES:

1. The pipeline should have isolation valves around the pump

and have a drain valve in the suction pipe.

ROTATION

Pump rotation is clockwise when viewed from back of the

motor. An arrow is provided to show direction of rotation.

GENERAL INSTRUCTIONS

1. Keep the motor properly lubricated.

2. When there is a danger of freezing, drain the pump.

3. Inspect pump regularly for leaky seals or gaskets and loose

or damaged components. Replace or repair as required.

LUBRICATION

Your Series 1580 Inline Fire Pump has been lubricated at the

factory, future lubrication should be in accordance with the

motor manufacturers instructions.

4

Page 5

PRIMING AND STARTING

Shaft

Slinger

Packing Gland

Cover Plate

Cap Screw

Impeller

Washer

Volute Cap

Screw

Flush Line

Impeller Key

Bracket

Gland Bolt

Packing Rings

Lantern Ring

Drip Drain

Cover Plate

Volute Gasket

Impeller

Lock Washer

Impeller

Impeller Cap Screw

Volute

Shaft Sleeve

CAUTION: Seal Damage Hazard

Do not run pump dry, seal damage may occur. Failure

to follow these instructions could result in property damage

and/or moderate personal injury.

Before starting the pump, the pump body must be full of

liquid. Manual priming may be required if the system does not

automatically fill the pump body with liquid. Vent plugs are

provided on the pump body to vent the air. While venting the

air from the pump body

few times by hand.

The pump should be started with the dischar

and the suction valve fully open. After the pump is up to operating speed the discharge valve should be opened slowly.

IMPORTANT: The pump should never be operated with the

suction valve closed or thr

tion. Cavitation will cause the pump performance to fall-off

and also, overtime, can cause impeller and/or casing damage.

, the pump shaft should be rotated a

ottled. This could result in cavita-

FIGURE 5

CROSS SECTION OF SERIES 1580 INLINE MOUNTED CENTRIFUGAL FIRE PUMP

ge valve closed

NOTE: On 6x6x91/2 and 6x6x11 there will be volute and stuff

box wear rings.

5

Page 6

SERVICE INSTRUCTIONS

WARNING: Unexpected Startup Hazard

Disconnect and lock out power before servicing.

Failure to follow these instructions could result in serious

personal injury or death, and property damage.

1. Close valves on suction and discharge sides of pump. (If

no valves have been installed, it will be necessary to drain

the system).

Caution: Extreme Temperature Hazard

Allow pump temperature to reach acceptable level

before proceeding. Open drain valve, do not proceed until

liquid stops coming out of drain valve. If liquid does not

stop flowing from drain valve isolation valves are not sealing and should be repaired before proceeding. After liquid

stops flowing from drain valve, leave drain valve open and

continue. Remove the drain plug located on the bottom of

the pump volute. Do not reinstall plug or close drain valve

until reassembly is completed. Failure to follow these

instructions could result in moderate personal injury or

property damage.

2. Loosen volute capscrews, do not remove them. Using capscrews in the jack screw holes start to remove the pump

assembly from the volute.

WARNING: Excessive System Hazard

Make certain the internal pressure is relieved before

continuing. Failure to follow these instructions could result

in serious personal injury or death, and property damage.

3. Remove seal flushing tube, if used.

Remove the volute capscrews and remove the pump

assembly from the volute.

4. Remove the impeller capscrew, lock washer and washer.

Remove the impeller.

STUFFING BOX CONSTRUCTION

WITH PACKING

1. Remove hex nuts from packing gland and remove coverplate capscrews. Remove coverplate from bracket.

2. Remove packing rings from the stuffing box.

3. Check condition of shaft sleeve and replace if scor

otherwise damaged. Note: Replace gasket between sleeve

and impeller as well if damaged.

4. Insert two packing rings in the stuffing box followed by the

lantern ring and then the remaining two pieces of packing.

Make certain that the packing joints are staggered 90

degrees.

5.

Install, but do not tighten the packing gland.

6. On the 6x6x91/2 and the 6x6x11 pumps the volute and

coverplate have rings. Inspect and replace if necessary.

7. Install coverplate over the pump shaft, tighten capscrews

(per torque chart).

8. Tighten packing gland to compress packing.

9. Install impeller, impeller gasket, impeller washer, lock washer

and capscrew, then tighten (per torque chart).

10. Install new volute gasket then install pump assembly into

volute. Tighten volute capscrews (per torque chart). Install

seal flushing tube. Install drain plug, close drain valve.

11. Open isolation valves, inspect pump for leaks, if not leaking

return pump to service. (See note for packing adjustment.)

ed or

NOTE:

Before starting pump, back off packing gland nuts or screws

until glands are loose. Re-tighten with fingers until glands are

just snug against the first packing ring. After pump is running

at first start, water may run freely from packing. This is normal

and should be allowed to continue for a period of time before

further tightening of the glands. Take up gland bolts uniformly,

one flat at a time.

An adequate leakage rate is not one single valve for all pumps

and installations, but is the amount required to provide adequate cooling and lubrication. The required leakage will be

largely influenced by operating pressure, fluid temperature,

shaft speed, etc.

For fluid temperatures in the range of 32° to 190°F, average

leakage rates of 60 to 80 drops per minute are recommended.

However, each individual pump and installation will have

unique operating conditions that will result in broadly variable

leakage rate requirements.

At fluid operating temperatures near the upper limit of 190°F,

the maximum temperature rise of the leakage is particularly

important. A packed pump should never operate with steam

forming at the gland. This necessarily limits the temperature

rise to a maximum of about 20°F. If the formation of steam

persists at higher leakage rates, cooling water must be provided

by means of an external supply, or a heat exchanger used to

cool the by-pass flush.

6

Page 7

CAPSCREW TORQUE (FOOT-POUND)

CAPSCREW HEAD

TYPE MARKING

1

/4

5

/16

CAPSCREW DIAMETER

3

/8

7

/16

1

/2

5

/8

3

/4

7

/8 1

SAE Grade 2 6 13 25 38 60 120 190 210 300

Brass

Stainless Steel or 4 10 17

27 42 83 130 200 300

SAE Grade 5 10 20 35 60 90 180 325 525 800

SAE Grade 8 13 28

DEALER SERVICING

If trouble occurs that cannot be rectified contact your local

A-C Fire Pump Systems representative. He will need the following information in order to give you assistance.

1. Complete nameplate data of pump and motor.

RECOMMENDED SPARE PARTS

The pumps covered by this manual have been designed and

built with certain replaceable wearing parts. The recommended

inventory of spare parts depends upon the installation and the

importance of continued operation.

For normal service, with repairs to be made in the field, the fol

lowing parts are r

Parts should be order

sible since circumstances beyond the control of the company

ecommended for stock.

1 set of packing rings (complete)

1 shaft sleeve

2 sets of wearing rings (if provided)

1 set of gaskets

1 lantern ring

ed as far in advance of their use as pos-

46 75 115 225 370 590 895

2. Suction and discharge pipe pressure gauge readings.

3. Ampere draw of the motor.

4. A sketch of the pump hook-up and piping.

RECOMMENDED SPARE PARTS

may reduce existing stock. Not all parts ar

be manufactured for each or

der.

To facilitate rapid handling of your order for spare parts, be

sure to include the following information:

-

1. Serial number of the pump.

2. Quantity of each part.

3. Name of part.

4. Material desired. (Parts will be furnished in original

materials unless specified as a material change. All material

substitutions should be discussed with the factory.)

e stocked and must

7

Page 8

TUV

DIN ISO 9001

ISO 9001

Certified

© COPYRIGHT 1970, 2000

PRINTED IN U.S.A. 4-00

USA

Bell & Gossett

8200 N. Austin Avenue

Morton Grove, IL 60053

Phone: (847) 966-3700

Facsimile: (847) 966-9052

http://www.bellgossett.com

INTL.

Bell & Gossett / Export Dept.

8200 N. Austin Avenue

Morton Grove, IL 60053

Phone: (847) 966-3700

Facsimile: (847) 966-8366

http://www.bellgossett.com

CANADA

Fluid Products Canada

55 Royal Road

Guelph, Ontario,

N1H 1T1, Canada

Phone: (519) 821-1900

Loading...

Loading...