Xlt H3D-3240 User Manual

XD 9002D

ADKDSWDHD

06/15/2015

XLT Oven & AVI Hood

Technical/Rough-In Specifications

for Gas & Electric Ovens & Hoods

This appliance is for professional use by qualified personnel. This appliance must be installed

by qualified persons in accordance with the regulations in force. This appliance must be installed with

sufficient ventilation to prevent the occurrence of unacceptable concentrations of substances harmful

to health in the room in which it is installed. This appliance needs an unobstructed flow of fresh air for

CAUTION

Electronic copies of the Installation & Operation Manual, Parts & Service Manual, Architectural

Drawings, & a list of International Authorized Distributors are available at: www.xltovens.com

For use with the following XLT Gas & Electric Oven Versions:

Australian (AE) D

Korea (K) D

Standard (S) D

World (W) D

satisfactory combustion & must be installed in a suitably ventilated room in accordance with current

regulations. This appliance should be serviced by qualified personnel at least every 12 months or

sooner if heavy use is expected.

For use with the following AVI Hood Versions:

Standard (S) D

World (W) D

2000887

XLT Ovens

PO Box 9090

Wichita, Kansas 67277

US: 888-443-2751 FAX: 316-943-2769 INTL: 316-943-2751 WEB: www.xltovens.com

2

2

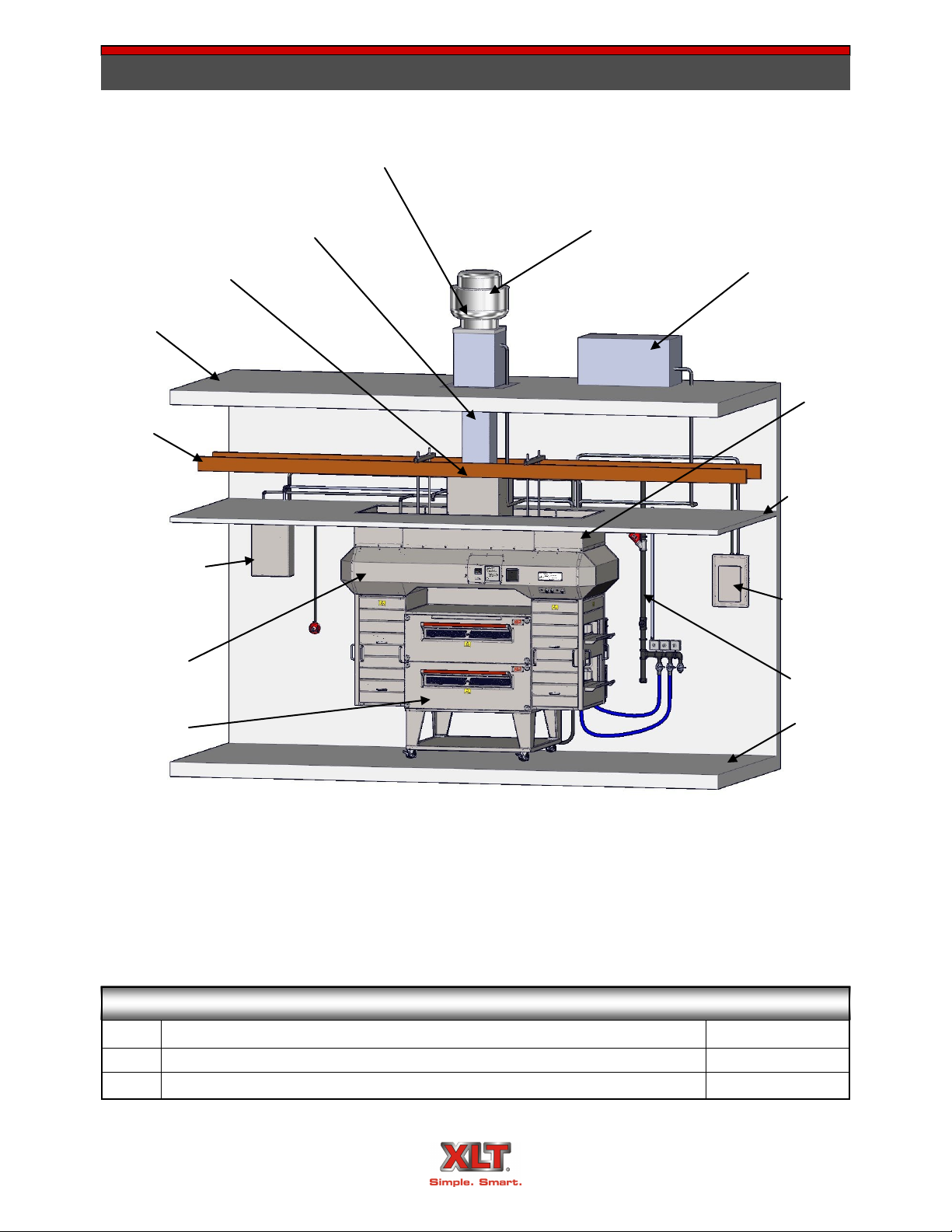

TYPICAL STORE INSTALLATION

Roof Curb

Duct Wrapper

Roof

Roof Joist

Fire

Suppression

Box

AVI Hood

Welded Duct

Exhaust Fan

Roof Top Unit (RTU)

Valance

Ceiling

Service

Panel

Gas

Service

Typical Store Installation

Revision History Table

Revision Comments Date

C Revised (KW/HR) Rating 01/14/2015

D Removed All 3270 and 3870 Single Burner Information 06/15/2015

Technical Support US: 888-443-2751 Technical Support INTL: 316-943-2751

Floor XLT Oven

TABLE OF CONTENTS

Typical Store Installation ............................................................................................................. 2

Warning & Safety Information..................................................................................................... 4

Descriptions .................................................................................................................................. 5

Oven Electrical Requirements ...................................................................................................... 6

Hood Electrical Requirements...................................................................................................... 7

Gas Requirements......................................................................................................................... 8

Fire Suppression ......................................................................................................................... 10

Oven Dimensions ....................................................................................................................... 12

Hood Dimensions ....................................................................................................................... 14

Ventilation Requirements ........................................................................................................... 16

Pre-Installation Checklist ........................................................................................................... 17

Exhaust Fan Specifications ........................................................................................................ 18

This document is intended for use by general contractors, architects, sub-contractors and

store owners to provide information during the planning & pre-installation phases of installing

XLT Ovens & AVI Hoods. Please refer to the XLT Installation & Operation Manual for instructions on the assembly and utility hook-up phase of the project.

The process of getting a facility configured to owners’ expectations can be difficult and

frustrating, or it can be accomplished smoothly and on time. The information presented here can

help move the “D” portion of the image below towards “on time” and “under budget”.

3

3

The end goal is to obtain an occupancy permit from the Authority Having Jurisdiction

(AHJ). A thorough understanding of the prevailing local codes can expedite this process and prevent unexpected surprises. Proper planning and execution will allow the successful installation of

new ovens and hood in an existing store overnight with NO downtime.

The purpose of building codes is to provide minimum standards for the protection of life,

limb, property, environment, the safety and welfare of the consumer, general public, and the owners and occupants of structures regulated by codes. Building codes are constantly changing and

they can vary by state, county, city , town, and/or borough. While some states like California,

Florida, Massachusetts, Michigan, and New York have their own set of building codes, most states

have adopted the International Code Council (ICC) series of codes. Always check with your local

building code department in order to learn which codes are being used and how they will affect

you and your construction project. You may want to start by contacting your local inspection department, office of planning and zoning, and/or department of permits.

The information presented here has been proven to satisfy the latest code requirements.

Technical Support US: 888-443-2751 Technical Support INTL: 316-943-2751

4

4

WARNING & SAFETY INFORMATION

The information contained in this manual should be distributed and read by all parties involved in procuring and installing this equipment prior to any work being performed.

To ensure an smooth installation the pre-installation checklist found in the back of this

manual must be reviewed before the XLT equipment is scheduled to arrive.

It is also advisable that a schedule be developed by the general contractor to ensure all activities are completed in the proper sequence and performed by the proper personnel.

XLT will assist in the coordination of disseminating information and scheduling the delivery of equipment. Please contact XLT or your distributor for additional assistance.

XLT wants you to be totally satisfied with every aspect of owning & using your oven &

hood. Your feedback, both positive & negative, is very important to us as it helps us understand

how to improve our products & our company. Our goal is to provide you, our customer, with

equipment that we can be proud to build & you can be proud to own.

To receive technical support for the oven or hood you purchased, contact XLT anytime day

or night, 365 days per year. Please be prepared to provide the Model & Serial Number.

Installation of all gas appliances & ventilation exhaust hoods should only be performed by a qualified professional who has read & understands these instructions &

is familiar with proper safety precautions. Read this manual thoroughly before in-

WARNING

All electrical connections must be made by a qualified electrician in accordance with NEC,

stalling or servicing this equipment.

OSHA, and all applicable national, state, and local codes.

All plumbing connections must be made by a qualified plumber in accordance with all applica-

ble national, state, and local codes.

All HVAC components must be made by a qualified mechanical contractor in accordance with

national, state, and local codes.

All ovens must have their own separate electrical circuit.

All systems in the AVI Hood must have their own separate electrical circuit.

Each XLT Oven must have it’s own gas shut-off valve.

XLT Ovens reserves the right to make changes in design & specifications, and/or make additions to or improvements to its product without imposing any obligations upon itself to install

them in products previously manufactured.

Technical Support US: 888-443-2751 Technical Support INTL: 316-943-2751

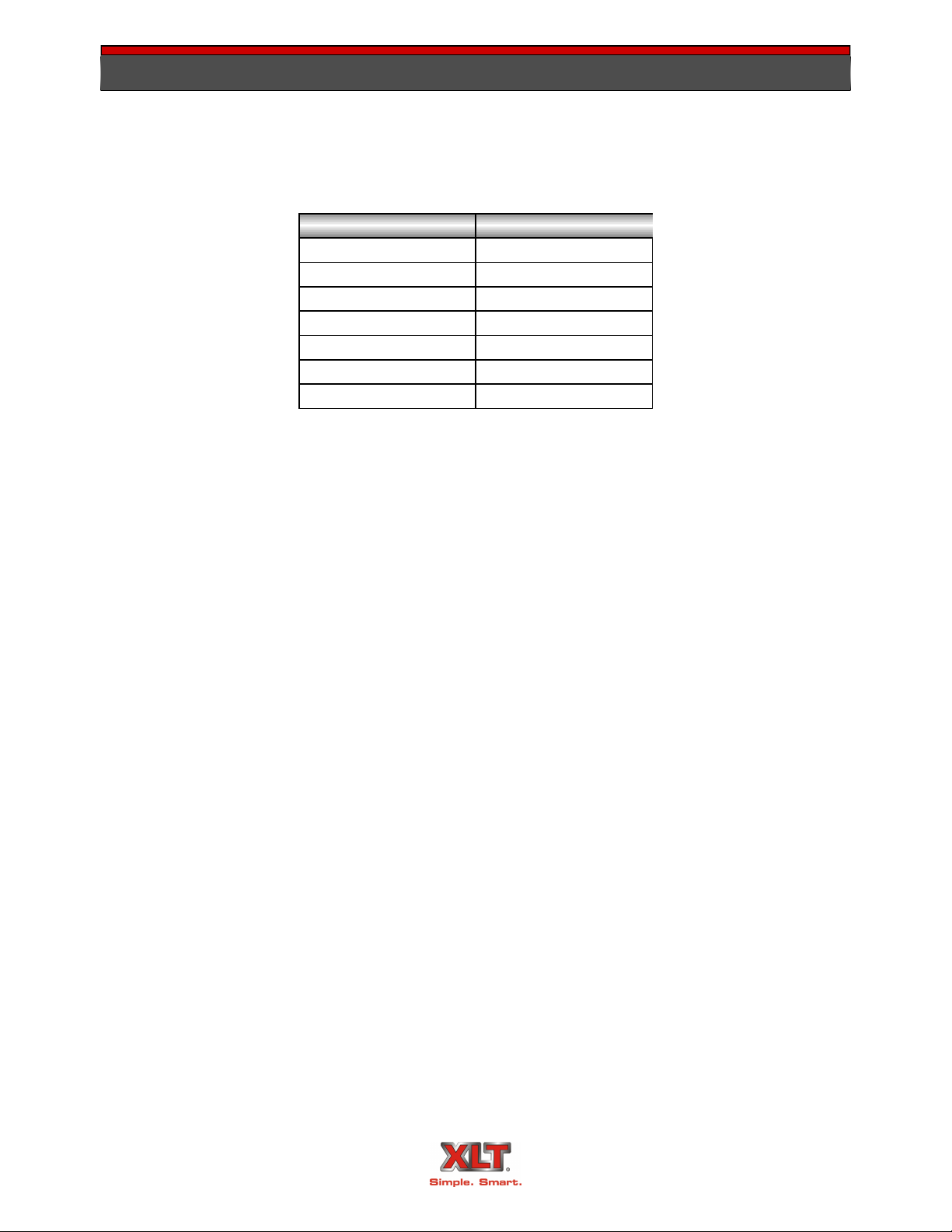

DESCRIPTIONS

Ovens

Hoods

X3D-1832-xxxxx H3D-1832-xxxxx

X3D-2440-xxxxx H3D-2440-xxxxx

X3D-3240-xxxxx H3D-3240-xxxxx

X3D-3255-xxxxx H3D-3255-xxxxx

X3D-3270-xxxxx-2B H3D-3270-xxxxx-2B

X3D-3855-xxxxx H3D-3855-xxxxx

X3D-3870-xxxxx-2B H3D-3870-xxxxx-2B

This manual covers the following XLT GAS Oven & AVI Hood models:

The first 2 digits of the model number represent the conveyor width & the last two digits

indicate the bake chamber length. The ovens may be used as a single, double, or triple oven stack

configuration. All ovens are available in (NAT) Natural Gas or (LP) Liquid Petroleum gas.

(Electric ovens are also available). The 3270-2B & 3870-2B models have two burners, one on

each side, & have two control boxes. All other models have only a single burner with a single

control box that can be supplied on either end. All models can be configured for a split belt conveyor.

5

5

All installations must conform to local building & mechanical codes.

Utilities must be easily accessible when the ovens are in the installed position. Do not in-

stall utilities directly behind the ovens.

In Australia follow AS/NZS 3000 Wiring and AS5601 Gas Installation.

Additional restrictions apply. Please see the XLT Installation & Operation Manual for more details.

CERTIFICATIONS

For a complete list of Certifications, please see the XLT Installation & Operation Manual.

Technical Support US: 888-443-2751 Technical Support INTL: 316-943-2751

6

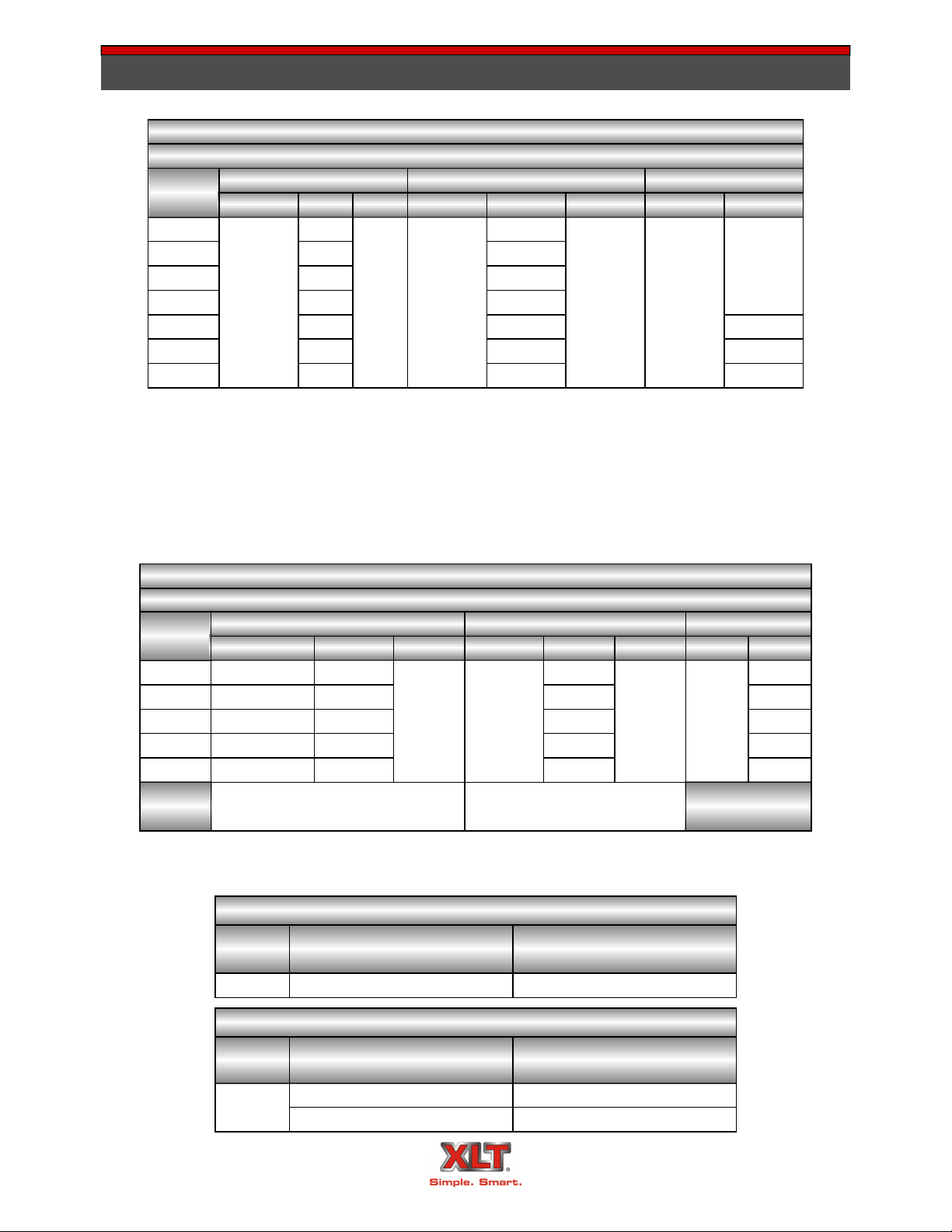

Volts AC Amps Hertz Volts AC Amps Hertz Phase KW

1832 208/240 44/38 24 16

2440 208/240/480 75/65/33 41 27

3240 208/240/480 75/65/33 41 27

3255 208/240/480 88/77/38 48 32

3855 208/240/480 88/77/38 48 32

Electric Oven Electrical Requirements

Per EACH Oven

Oven

Model

STANDARD

WORLD

ALL

60

380503

4 Wire Service - L1, L2, L3

5 Wire Service - L1, L2, L3

N +2 Grounds (per oven)

+1 Ground (per oven)

Volts AC Amps Hertz Volts AC Amps Hertz Volts AC Watts

1832 6 3

2440 6 3

3240 6 3

3255 6 3

3270-2B

12 6 1320

3855 6 3 660

3870-2B 12 6 1320

Gas Oven Electrical Requirements

Per EACH Oven

50/60

Oven

Model

Australia & World

Standard

120 VAC

1Φ

50/60

220/230/

240 VAC

1Φ

Korea

220 VAC

1Φ

660

All

Conveyor Belt Times

Oven

Models

MINIMUM

MAXIMUM

1:30

17:00

Oven Operating Temperature Range

Oven

Models

MINIMUM

MAXIMUM

400° F

590° F

All

205° C

310° C

6

OVEN ELECTRICAL REQUIREMENTS

FOR EACH GAS OVEN:

A separate 20 amp circuit breaker must be provided for each oven deck.

Electrical connections must be accessible when the ovens are in the installed position.

Electrical connections must meet all local code requirements.

A DISCONNECT MUST BE INSTALLED IN ACCORDANCE TO LOCAL BUILDING CODES:

Technical Support US: 888-443-2751 Technical Support INTL: 316-943-2751

7

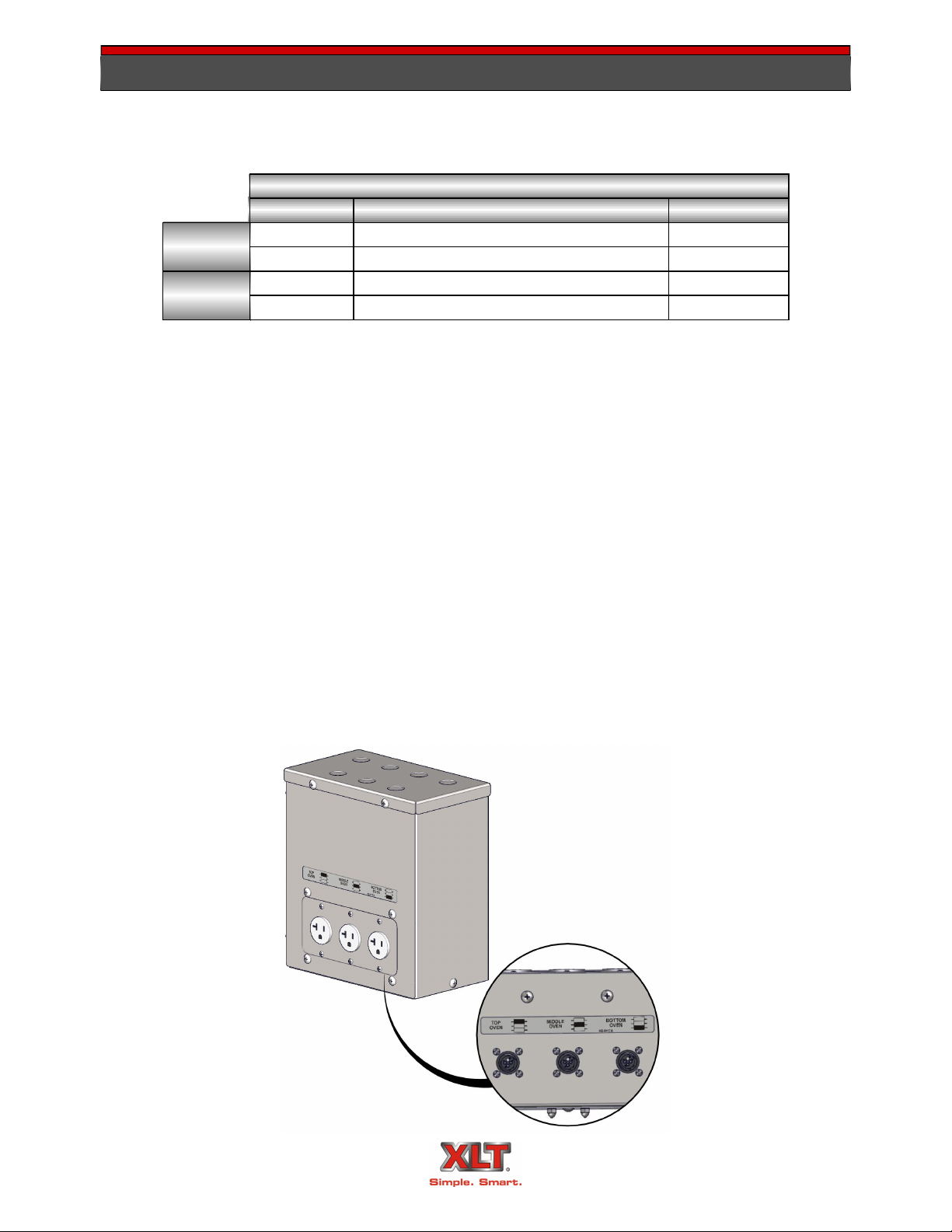

# of Circuits Rating Purpose

1 208/240 VAC, 1 Phase, 60 Hz, 6 Amp VFD Controller

up to 3 120 VAC, 1 Phase, 60 Hz, 20 Amp Ovens

1 230 VAC, 1 Phase, 50 Hz, 6 Amp VFD Controller

up to 3 230 VAC, 1 Phase, 50 Hz, 10 Amp Ovens

AVI Hood Electric Utility Specifications

World

Standard

HOOD ELECTRICAL REQUIREMENTS

7

Inputs into VFD Box

Outputs from Junction Box

The AVI Hood system provides:

One (1) switching outputs for HVAC damper and/or dedicated unit. (Optional 2-3 add-on)

One (1) 230 VAC, 10 Amp, variable frequency, three phase power output for the ventilation

exhaust fan.

Up to Three (3) receptacles for ovens. (Gas Only)

One (1) 120 VAC fire alarm signal for Standard hoods, or one (1) 24 VAC fire alarm signal for

World Hoods

For Oven & Hood installations with the VFD option, all electrical connections are made in

the junction box located on the right rear corner of the upper portion of the hood. Power for the

exhaust fan is provided from the VFD controller. Optional fire suppression & MUA damper relay

connections may also be made in the junction box.

For Oven & Hood installations without the VFD option only the lighting and oven receptacle connections are made in the junction box. Ovens without a AVI hood are plugged into the receptacles on the wall.

Technical Support US: 888-443-2751 Technical Support INTL: 316-943-2751

Loading...

Loading...