Page 1

Xerox Wide Format

Applications Guide

X2 Oil Piezo Inkjet

www.xerox.com/iccprofiles

Page 2

Wide Format Oil Inkjet

Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

General Guidance

Choosing Appropriate Materials . . . . . . . . 4

Durability of Graphics

Waterfastness

Printer Compatibility

Use of Approved Supplies

ICC Profiles and Settings

Image Quality

Fire Resistance

Supplies Storage & Handling

X2 Inks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Oil Inkjet Media Range Overview . . . . . . . . . . . . . . . . . . . . . 11

Media Data Sheets

2. 90g/m2 Coated Design Paper

3. 95g/m

4. 125g/m

5. 115g/m

6. 125g/m

7. 160g/m

1. 80 Line Art Paper . . . . . . . 12

2

Hi White Graphic Arts Paper

2

Hi White Graphic Arts Paper

2

Presentation Paper

2

Presentation Paper – 720dpi

2

Heavyweight Presentation Paper

2

8. 120g/m

9. 120g/m

10. 236g/m

11. 150mic White Matt Film

12. 175mic Backlit Film

13. 140mic Pressure Sensitive Vinyl

14. 400g/m

15. 160g/m

16. 250g/m

Outdoor Blue Backed Poster Paper

2

Short Term-Outdoor Blue Backed Paper

2

Reinforced Paper

2

Banner Vinyl

2

Banner Fabric

2

Banner Fabric – Fire Retardant

General Hints & Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Application Ideas

2. Backlit Display

3. Self-adhesive Vinyl

4. Banners

5. GIS, CAD, Engineering & Technical

1. Poster Graphics . . . . . . . . . . . . 29

Lamination Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Glossary of Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

www.xerox.com/iccprofiles.com

2

Page 3

Introduction

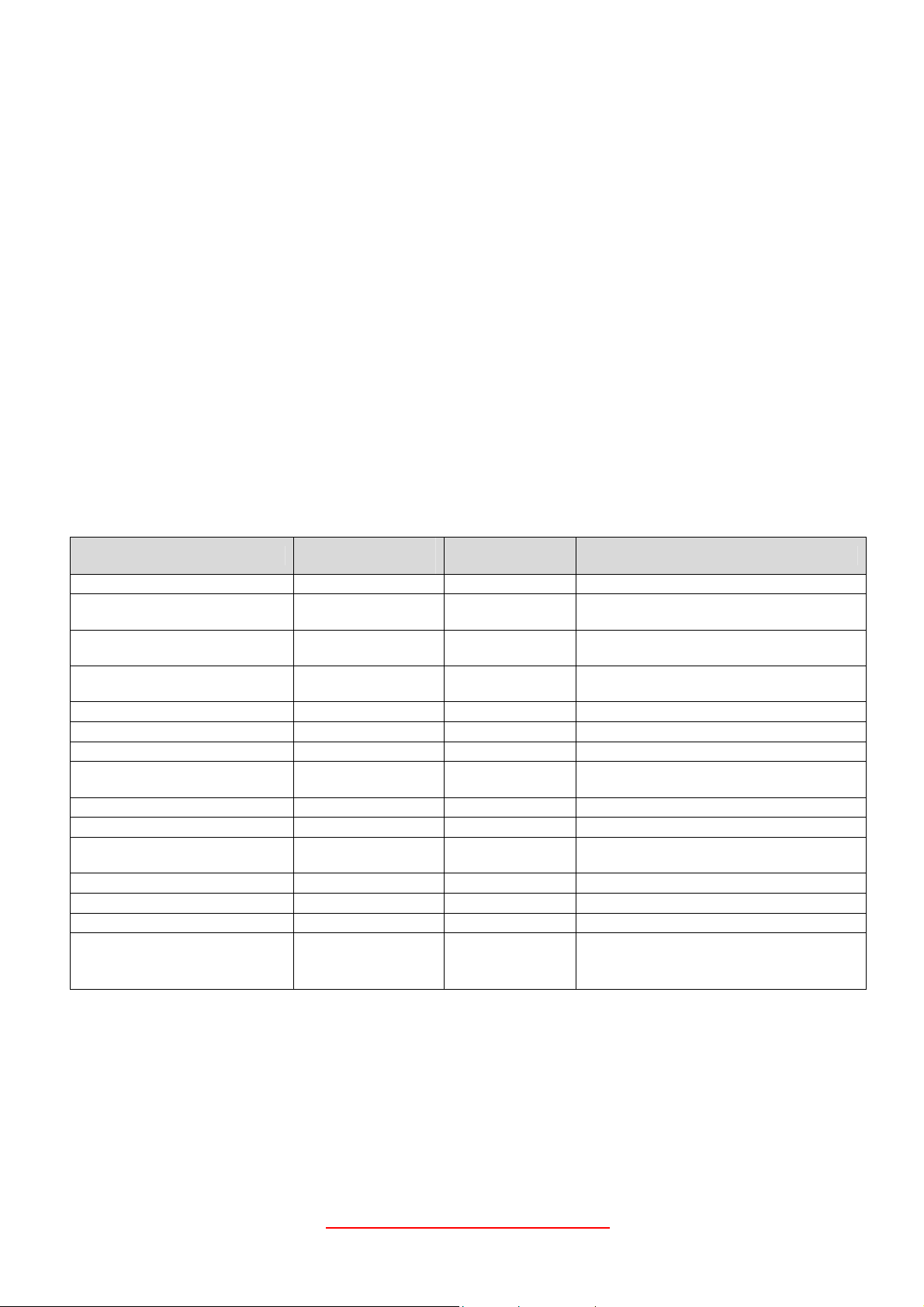

This guide is intended to provide users of Xerox oil inkjet media and Xerox or Seiko oil inkjet printer solutions

with information about media performance and application suitability, and generally to help with selection of

wide format media to ensure that customers expectations are reliably met. This guide is a compilation of

applications for digital prints created on the X2 inkjet prin ters, mostly aimed at the print for pay and graphic

arts market, although a section also addresses the needs of GIS and CAD applications.

The procedures in this guide are general and assume that you are already familiar with the X2 user guide and

general printer / RIP software functions.

Individual media data pages give product specific details and production tips. The Applications Ideas &

Procedures section gives instructions and tips specific to a range of common applications. An overview of

lamination techniques is also included

The Xerox oil inkjet media range is formulated for use on Xerox and non-Xerox printing equipment alike, but is

specific to oil piezo. These media are not suitable for either aqueous or solvent inkjet.

.

www.xerox.com/iccprofiles.

Oil inkjet is the smallest sector of the inkjet market and provides a means of printing for both high-quality,

close-viewed photo-realistic graphics as well as high production volumes. Oil-based i nks give outdoor durabili ty

and colour-fast imaging approaching that of solvent printing systems but without the environmental issues often

associated with solvents. Piezo technology and fast-drying oil inks in the X2 enable print speeds of up to 55

square metres per hour which often makes X2 printing the preferred option for high volume graphics print

production, for such as billboard sets.

Oil inkjet printing requires all media to be coated with an ink receiver with specific properties to hold oil ink in

place and allow it to dry properly. Aqueous and solvent media are rarely suitable for oil and some can prove

spectacularly unsuitable. The properties of oil ink receiver coatings do cause limitations in terms of the print

applications: Clear film and glossy media are not possible for oil printing. Xerox oil inkjet media is formulated

specifically for this technology and designed to extend the capabilities of oil inkjet printing as widel y as possible

across the range of possible applications.

All Xerox Inkjet media are tested and supported for the printing applications described and are backed by the

usual Xerox guarantees. Xerox identifies the media recommended for oil inkjet printing with a green coloured

band on the product label. These media should not be confused with inkjet media for aqueous or solvent

systems as properties and compatibilities are specific.

Further information on Xerox oil inkjet media, as well as other ranges for aqueous and solvent inkjet printing is

available through your usual Xerox supplies contact or via the same enquiries facility on the Xerox website.

©2007 by Xerox. All rights reserved. Edition - August 2007

No part of this manual may be copied or reproduced without prior written permission of Xerox.

X2 and ColorgrafX products mentioned in this publ ication are trademarks of Xerox. All ot her products or services mentio ned

in this document are identified by the trademark of their respective companies or organisations. Xerox disclaims any

responsibility for specifying which marks are owned by which companies or organisation. Xerox reserves the right to make

changes without notice to information contained in this document. Xerox assumes no responsibility for any errors or

consequential damages that may result from use or misrepresentation of any information contained herein.

www.xerox.com/iccprofiles.com

3

Page 4

General Guidance

Choosing Appropriate Materials

Xerox Oil Inkjet Media all vary in coating structure, physical properties (such as base weight and thickness), and

base material type (paper, fabric, films or vinyl). These variances not only need a specific printer set-up to

successfully run each material through the printer, but will cause some differences in achievable image quality

per media type, eg. Fabrics give different image quality to vinyl even if both are printed in the same resolution.

The coating layer or layers on each media type differ because the structure must take account of base

properties (i.e. thickness, absorbency, smoothness, texture), must provide suitable adhesion to both printed

image (ink) and the base material, and the base-coating combination must meet the needs of the application.

Each media is also specified to print within a range of resolutions.

The most common mistake in constructing a graphic is using incorrect materials. The choice of materials

requires critical information about the end-use. Ask the following questions to determine the application

requirements and use the information in this guide to select the materials that will work best.

1. How will the print be viewed?

What is the viewing distance – close-up in an exhibition hall, hanging 10 stor ies up on the side of a

building, or on the side of a moving vehicle?

2. What are the environmental conditions where the print will be displayed?

Indoors or outdoors? Is there a harsh element such as poll ution, water, wind or direct exposure to

sunlight? Are there extreme weather patterns and fluctuations?

3. What is the expected life or durability of the print?

How long will it be displayed? How many times will it be used, stored, or posted?

4. What types of finishing or rigid materials for mounting are needed?

Will it be finished with a laminate or encapsulated? Is a glossy surface best or would glare hinder

viewing? Does the print need to be made into a banner with seams and eyelets?

5. What is the budget for the job?

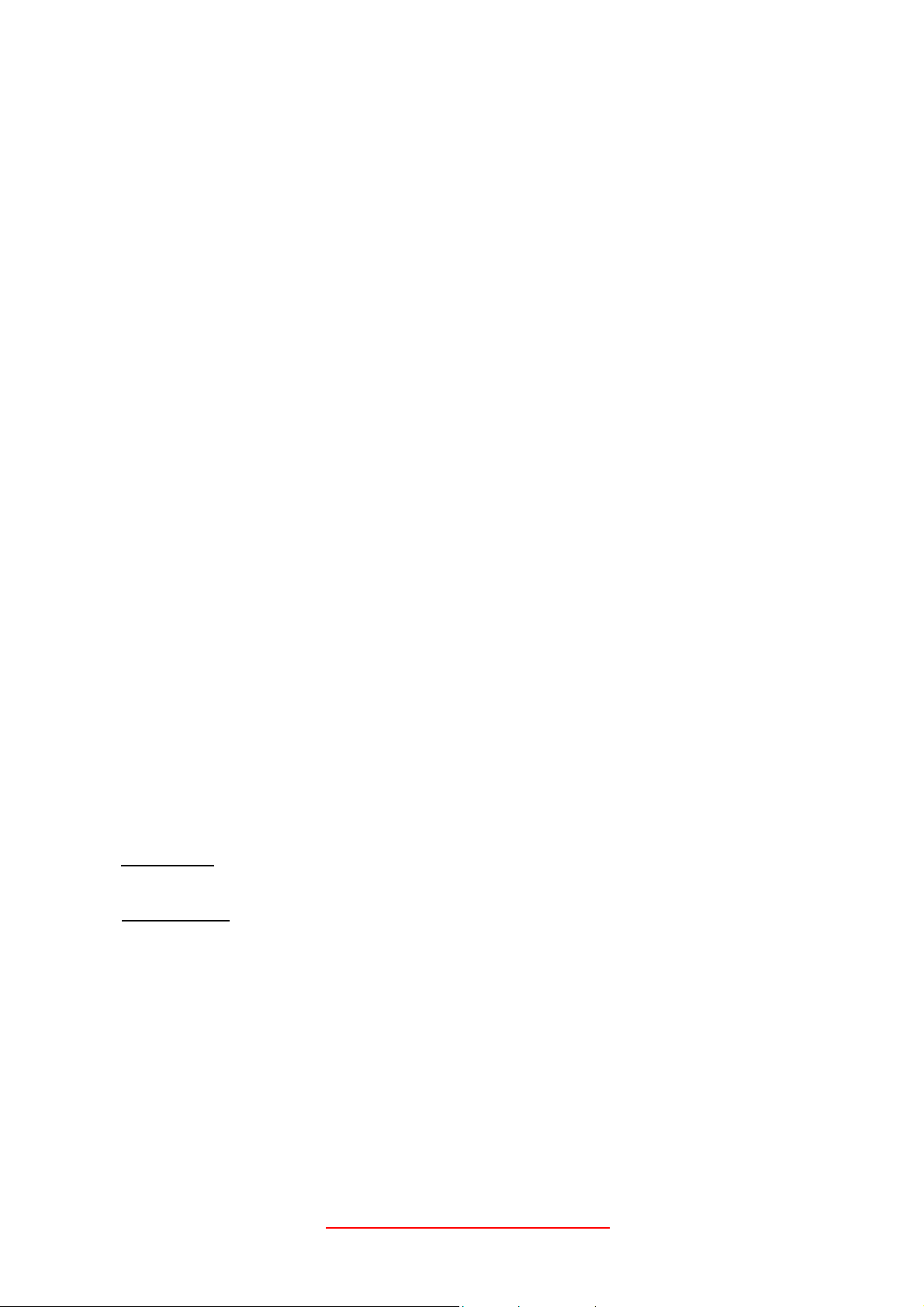

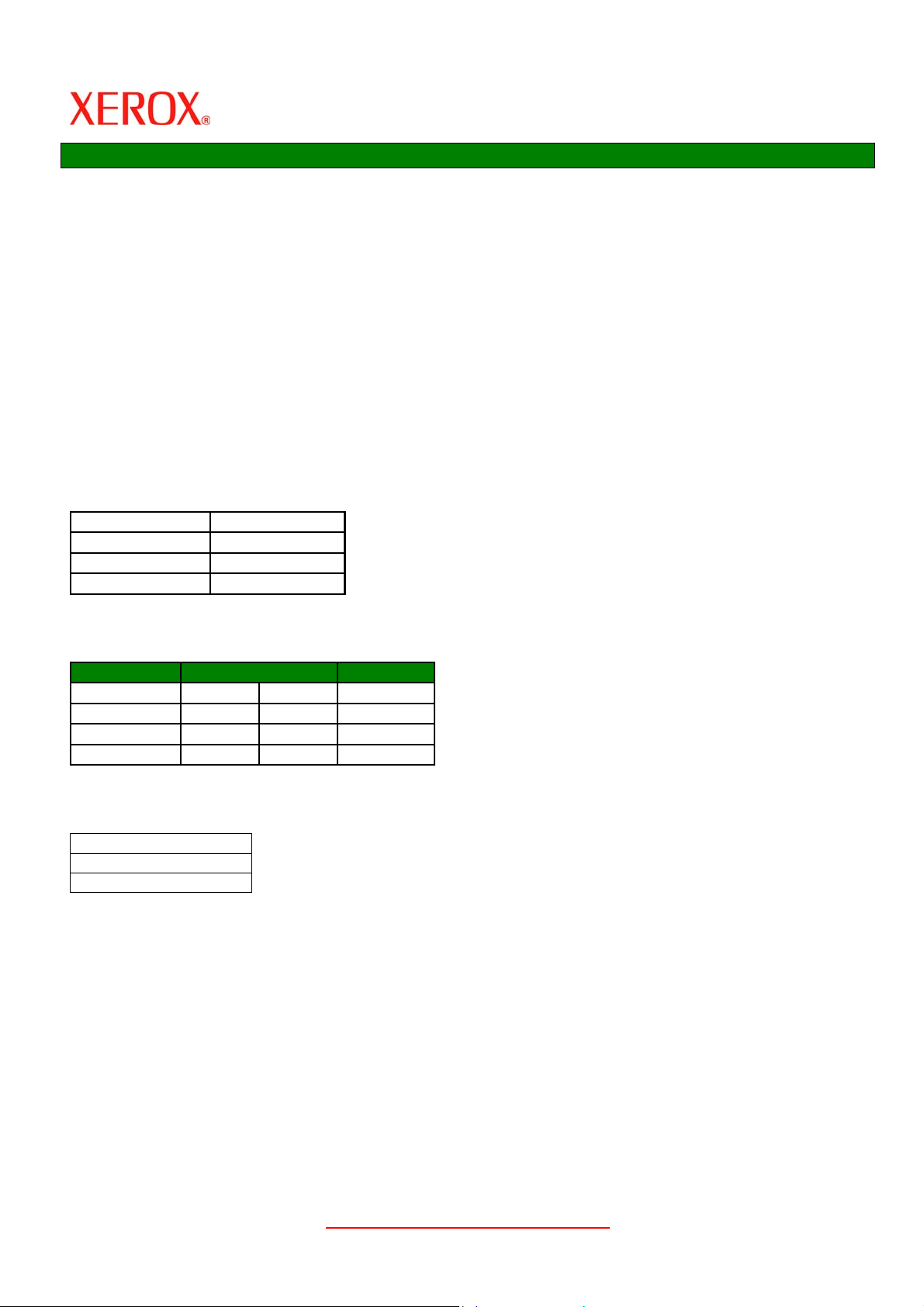

Appropriate Applications for Media

Use the following matrix to quickly determine if

a media type may be su it abl e for an app lication

Poster

Mo unte d P ri nt

Proofs

Check-Plots

Backlit Display

Bill Boa rd

Multi-panel Display

Banner

Wall Gra phics

GIS / CAD

80 g/m2 Line Ar t Paper

90 g/m

95 g/m

125 g/m

120 g/m

125 g/m

115 g/m

160 g/m

236 g/m

White Matt Film

2

Coated Graphi c Design Paper

2

Hi White Graphic Arts Paper

2

Hi White Graphic Arts Paper

2

Outdoor Poster Paper - Blue Backed

2

Presentation Paper, 720 dpi

2

Presentation Paper

2

Heavy Weight Presentation Paper

2

Reinforced Paper

Backlit Film

Banner Fabric

Banner Vinyl

Pressure Sensit ive Vinyl

The solutions presented here have been taken from actual work carried out using X2. Each has been tested in

the field and proven successful for the specified use. While there is no such thing as a typical job, these

methods cover the majority of the applications currently suited to oil inkjet and the X2 printer and are fully

supported by Xerox. Each media data sheet gives a more detailed description of specific media capabilities.

www.xerox.com/iccprofiles.com

4

Page 5

Durability of Graphics

Durability is a function of both ink and media.

Oil-based pigmented inks for X2, Xpress and other oil printers offer prop erties that differ considerably in terms

of UV stability / light-fastness and general resistance to degradation. All are generally suitable for use

outdoors, with or without lamination. Over-laminates and encapsulation will extend the life of most images,

protecting against moisture, mechanical handling, abrasion or UV.

Often a graphic has a life requirement of a few weeks, but signage applications can require the print to survive

without deterioration for several years. The conditions of the environment in which a graphic is to be displayed

should also be taken into consideration.

Ink and media are both critical factors in the life expectancy of oil inkjet prints. The properties of th e media

must support the ink capabilities and must match the needs of the application as part of the total graphics

construction. This guide describes the capabilities for each Xerox oil media printed with X2 inks.

Tests are carried out to simulate different environments. For INDOOR applications, the expected life is

measured under moderate conditions assuming the graphic will be displayed in a normal office environment

with limited exposure to sunlight. The moderate OUTDOOR environment refers to a climate with mild

temperature ranges (4-27˚C), low humidity (10-50%RH) and minimal ambient UV and pollution exposure.

Different environmental factors may affect the application durability. Abuse, wind and moisture will have

cumulative effects on reducing the print life. Any testing and support for conditions outside these

parameters is the responsibility of the print provider.

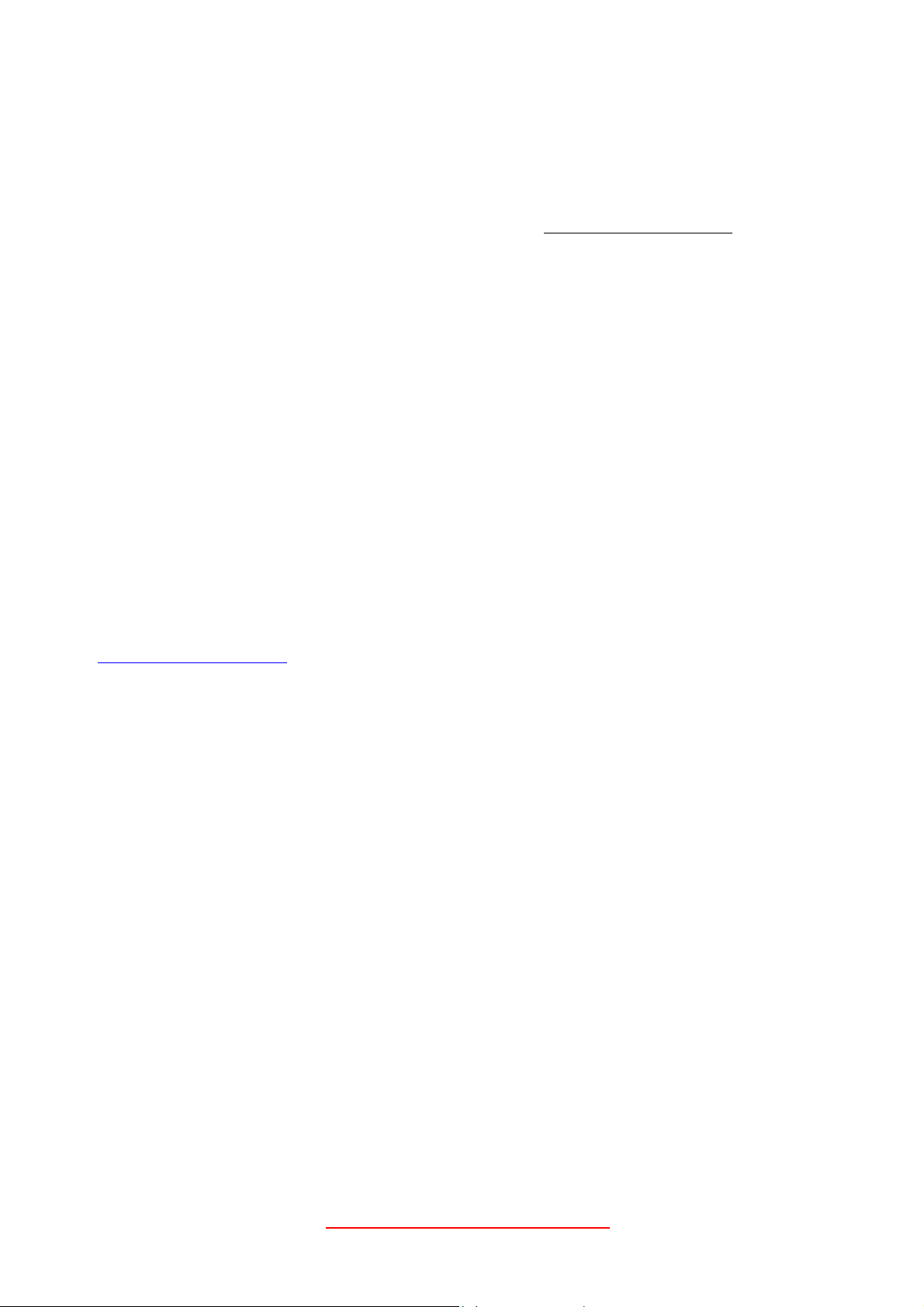

The following table gives a quick reference indication of expected life of imaged media indoors and outdoors.

PRODUCT

80g/m2 Line Art paper No data No data For indoor use only

95g/m2 High White paper 5 years / 18 months 6 months / 2 days

125g/m2 High White paper 5 years / 18 months 6 months / 2 days

115g/m2 Presentation Paper 10 years / 2 years 3 months / not rec.

120g/m2 Blue Back Paper Not recommended 1 year / 6 months No over-laminate required for outdoor pasting

120g/m2 Short Term Blue Back Paper Not recommended 4 months No over-laminate required for outdoor pasting

125g/m2 Presentation paper - 720dpi 15 years / 3 years Not recommended. Laminate with at least a 75 mic thermal laminate

160g/m2 Presentation Paper 5 years / 2 years 1 year / 3 months

236g/m2 Reinforced Paper 10 years / 2 years 1 year / 2 days Can use thermal or pressure sensitive laminates

150 micron White Matt film 2 years / 18 mnths 1 year / 7 months Water resistant without over-lamination.

175 micron Backlit Film 2 years / 1 year Not recommended

Pressure Sensitive Vinyl 5 years / 2 years 1 year / 6 months Use pressure sensitive over-laminates.

160g/m2 Banner Fabric Not Required 2 years / 1 year Laminating will not extend UV life indoors or out.

250g/m2 Fire Retardant Banner Fabric Not applicable 2 years / 1 year Certified M2 and B1 fire retardant

400g/m2 Banner Vinyl Not Required 2 years / 1 year

LAMINATED

(indoor / outdoor)

UN LAMINATED

(indoor / outdoor)

COMMENTS

To protect from moisture / abrasion laminate with at

least a 75 mic thermal laminate

To protect from moisture / abrasion laminate with at

least a 75 mic thermal laminate

To protect from moisture / abrasion laminate with at

least a 75 mic thermal laminate

If protection from moisture / abrasion is required

laminate with at least a 75 mic thermal laminate

Laminated with at least a 75 mic thermal laminate,

assumes installation in a suitable lightbox

No over-laminate required unless subject to moisture

or abrasion. Laminate will not extend UV life indoors

or outdoors.

Expected image life varies for each media type, and according to the type of over-laminate used. The table

above lists durability expectations of each media when laminated with a 75 micron thermal laminate on both

sides of the print (encapsulated with a 4mm sealed edge for outdoor use) unless otherwise specified.

www.xerox.com/iccprofiles.com

5

Page 6

Waterfastness

The term "waterfast" or "water resistant" should not be interpreted to mean "water proof", i.e. a printed image

may be submerged under water, or be held under a running tap without destroying the printed image.

Definition of Waterfast/Water Resistant - these two terms are used interchangeably. It is the abi lity of a

printed image to withstand the effects of water with minimal or acceptable change.

Clarification: Effects of water refers to brief contact with water, such as the result of spilling a glass of water

and immediately blot-drying with a clean, lint-free cloth. It does not include exposure to any other liquid (such

as coffee, tea, alcoholic beverages, milk, seawater, etc.). Minimal or acceptable change r efers to the amount of

ink migration ("running") that occurs when a printed image is exposed to water. Minimal is slight ink migration

from any area of the image, and acceptable would mean no visible ink migration.

Many media are waterfast or water resistant- including white matt film, pressure sensitive vinyls, banner

fabric and banner vinyl. Details on their durability can be found on the media fact sheets or the durability guide.

However most water resistant media are not waterproof and CANNOT be submerged in water or

subjected to running water. Outdoor blue back paper is waterproof when used in its normal billboard

application process. See media fact sheet for detail s. Finishin g guidelines for out door durability e.g. lamination

must be followed when constructing a print for out door use.

Printer Compatibility

All Xerox oil inkjet media are formulated for Xerox X2 equipment but they can also be used in Xpress a nd Seiko

equipment with some differences in output performance. Appropriate print testing should be carried out before

commencing any large-scale production to ensure expectations are fully met. Durability guidelines listed apply

for X2 printed images.

Use of Non-approved Supplies

Xerox authorised inks, media or other supplies are designed and tested to assure optimum

performance from the X2 printer. Non-approved materials may not produce the same quality

product and may cause service problems or damage to the unit. Such damage will void the

warranty and may result in additional service cost.

The X2 printer is sensitive to unique core tolerances, as well as, media curl, which will cause the printer to jam

excessively. Unacceptable core tolerances will cause media slippage and image mis-registration.

Non-Xerox media may not fully be tested in the "corner-to-corner" environmental range, therefore is not

assured to work successfully in the X2. For example, media that is not capable of performing in the high (or

low) end of the humidity and temperature range may cause material "cockle" or head strikes. Although some

media will produce an acceptable level of image quality for some regions, sometimes, the overall quality and

material coating consistency cannot be assured or backed by Xerox.

IMPORTANT NOTE: The use of non-qualified supplies in the Xerox X2 could damage the printer. Such damage

will void the warranty and may incur additional service costs chargeable to the user. They include:

Head Strike which is defined as any contact between the nozzle surface of the writing

heads and the media in the paper path. Head strikes may cause no ill effect to the

writing, however it should be taken as a warning that a Head Crash is about to occur.

Head Crashes occur when the print heads catch the edge of the media as i t begins to

traverse the print area. This is extremely damaging to the print heads and very

expensive to repair. Media that is too thick or curls at the edge can cause head crashes.

If the cause of this damage is due to use of unapproved media, the customer will be charged for parts and

labour for repairs. The labour process requires the damaged head to be replaced and the machi ne recali brated,

resulting in extensive chargeable service and production “down time”.

www.xerox.com/iccprofiles.com

6

Page 7

ICC Profiles & Settings

Although certain generic settings can enable good colour reproduction, the correct printer firmware and software

settings should be used. Overall ink limit, individual ink restrictions and linearisation should be adjusted and set

specifically per printer, ink, RIP software and media used. Limiting and calibrating the amount of ink used

optimises both image quality and drying time, and consequently accelerates the production process. A

specifically created ICC profile should also be used whenever possible to optimise i mage quality and production

of colour. A selection of settings and profiles is available from

Xerox supplies sales contact.

www.xerox.com/iccprofiles or via your usual

Image Quality

The following tips may help you to understand the image quality you should expect from using Xerox media in

your printer, as well as offering hints for ensuring output quality meets application needs:

• LOAD the media properly. It may help to run thicker media in the rear roll position.

• EXPECTATIONS: Image quality varies from one medi a to another. Each media is designed for a set of

application needs. Selecting the right media ensures that image quality expectations are met.

• ENVIRONMENT: Viewing distance and di splay environment must be considered when determining if

output quality is acceptable, e.g. viewing distance of 5m may allow a degree of image imperfection.

• CONSIDER ALTERNATIVES: More than one media type may suit any given application. Ease-of-use,

image quality, and display site all have a bearing on selection. Experiment with alternatives.

• PRINTER SPEED Due to speci fic media characteristics, different print modes or printing speeds are

used. For projects requiring duplicate images in significant quantities, run test images in various modes

to determine the most appropriate speed for your application needs. X2 is designed to provide sellable

output at high speed.

• PANTONE® COLOURS Colour reproduction is a function of the RIP or software connected to the

printer. Xerox provides profiles and settings specific to media, RIP, ink and printer. These profiles are

balanced to perform in a wide range of colour applications. Most RIPs also allow the user to update,

adjust or create colour profiles to meet specific colour requirements. Profiles can be downloaded from

www.xerox.com/iccprofiles for Xerox X2 and both Onyx and Caldera software.

• COCKLE Exceeding the media ink limits can cause cockle. This is undesirable not only in the finished

print but also because it may result in head strikes. A head strike occurs when the print head ru bs a

raised point on the media surface. All Xerox inkjet media is tested to ensure that recommended settings

and profiles will not risk a problem with head strike and will have acceptable finished quality when dried.

• BANDING A certain level of banding may be visible in inkjet print output. This is inherent to inkjet

printing technology. Some possible actions to address banding (not to be confused with gradient

segmentation):

a) Increase Passes - Banding becomes obscured as the number of passes is increased.

b) Set Printing Direction - Unidirectional printing generally gives less banding than bidirectional.

c) Adjust Carriage Speed – Some printers give the operator the ability to slow the carriage speed.

d) Convert Black - Convert single colour black areas to 4 colours (CMYK) in the application software.

e) Rotate - Try rotating the image to reduce the appearance of banding.

• GHOSTING is when the appearance of one i mage offsets onto subsequent images when printing large

blocks of negative text (blank text inside a colour). This is a feature of oil inkjet systems, not a failure of

any one individual item, i.e. ink or media. The reason for this phenomenon is a difference in the amount

of oil in two areas of the same density. Although the inks are instantly dry to the touch, it takes som e

time for the oil in the inks to completely disperse and stabilise in the media coating. If left exposed to

the air this effect will disappear over time. Several workarounds are possible, depending on the

workflow and application. Please see the suggestions listed in the Application Ideas & Procedures section

for Paper Applications in this guide to determine which method suits you.

www.xerox.com/iccprofiles.com

7

Page 8

Fire Resistance & Flame Retardant Properties

Media for exhibition and display graphics are sometimes required to meet flammability ratings.

The main standards used are the “M” and the “B” ratings ( B1 often considered similar but not higher than M1)

and the US NFPA standards. There is no common international standard at the time of writing.

M1

A material is classified M1 if the tests with the electrical burner (NF P 92-503) results in:

• No inflammation remaining longer than 5 seconds after removing the flame

• No points of ignition with flame propagation higher then 25 cm above the lower edg e of the probe

• No drops of flaming material (test for thermo fusible materials NF P 92-505 to be passed)

If the material pierces without inflammation or with inflammation which subsides within 5 seconds, the

persistency test (NF P 92-504) results in no flame persistency at all and no burning material drops.

M2

A material is classified M2 if it does not fall into category M1 because

• Inflammation persists longer than 5 seconds after removing of the flame

• Destruction of the material deeper than 35 cm from the lower edge of the probe is observed

• No drops of flaming material (test for thermo fusible materials NF P 92-505 to be passed)

If the material pierces without inflammation or with inflammation which subsides within 5 seconds, the

persistency test NF P 92-504 results in flame persisting for no longer than 5 seconds without

propogation and no burning material drops.

ASTM e84 measures the burning behaviour of a material when exposed to heat and fire by observing the

flame spread across the specimen when exposed to an ignition source face down.

NFPA 701 establishes two test procedures to assess the propagation of flame beyond the area exposed to

an ignition source for textiles and films. The tests are appropriate for testing materials that are used as

draperies, curtains or other window treatments, awnings, tents, traps and plastic films used for decorative

or other purposes.

www.xerox.com/iccprofiles.com

8

Page 9

Supplies Storage & Handling

• Ink and media are sensitive to environmental conditions. It is important that supplies are kept in a

controlled area for the best image quality and operations when used in the printer.

• For Standard Inks and Media:

Printing: 18-30˚C non-condensing 30-70% Relative Humidity.

Storage: 5-35˚ 40-60% Relative Humidity

Important: Inks can be permanently damaged if exposed to temperatures outside of this range

for any period of time.

• If medi a are kept in an environment outside of these parameters, they may still be used to print perfectly,

but media should be allowed to normalise in the correct conditions for sufficient time, at least 48 hours prior

to use.

• Always store inkjet media products in their original cartons and also in the original wrapper or bag. The full

packaging is designed to give the best protection to base materials and ink recei ver coatings to maximise

product life.

• In case medi a rolls are separated from their cartons, every roll of Xerox media can be precisely identified

from information printed on the inside of the core.

• Most medi a where sensitised with an ink receiving coating or with other treatments such as adhesive will

have a finite shelf life. Nominally the shelf life expectancy is as described below if kept in original, unopened

packaging, but this largely depends on precise storage conditions.

Media: 2 years

Vinyl: 1 year

Inks: 2 years

• The i mage surface must be kept dry and free of grease, oil, silicones and dirt to achieve best results. It is

recommended that cotton gloves be used when handling inkjet-coated materials to avoid fingerprints.

• Inks can be permanently damaged if exposed to temperatures outside their range for any period of time.

This guide is not as an instruction manual, it is provided as a source of information and advice,

based on practical test experience, and knowledge. While care has been taken to anticipate

problems and outline possible difficulties, it is impossible to cover all situations and the content

and procedures described do not constitute a warranty. It is highly recommended that you test

any application before a job is attempted. The variety of possible applications makes it necessary

for users to take specific steps to ascertain the suitability of materials described here for their

specific purposes.

For further information contact:

Xerox House

Maylands Avenue

Hemel Hempstead

Hertfordshire

HP7 2DE

United Kingdom

Tel +44 (0) 1442 886 019

www.xerox.com/iccprofiles.com

9

Page 10

X2 Inks

X2 graphics inks are pigmented, oil-based, and designed specifically for use with X2 printers and media. These

inks are formulated to be smudge resistant, instant drying and can be laminated i mmediately in most cases.

The colour gamut is based on the SWOP (Standard Web Offset Printing) standards for press-quality, colour

graphics, versatility and easy colour calibration. The inks do not require any special drying time after printing.

6-colour printing adds two tonal inks, Light Cyan and Light Magenta, to the typical suite of 4-col our process

printing (Cyan, Magenta, Yellow, and Black). These colours improve the gradient perce ption between dithered

process colour shifts, or “smoothes out” blended areas of an image by introducing lighter tones of the colours

that construct the blend. For example, skin tones appear more true because the colour of dots creati ng the

image on paper are not as dark from one percentage to the next.

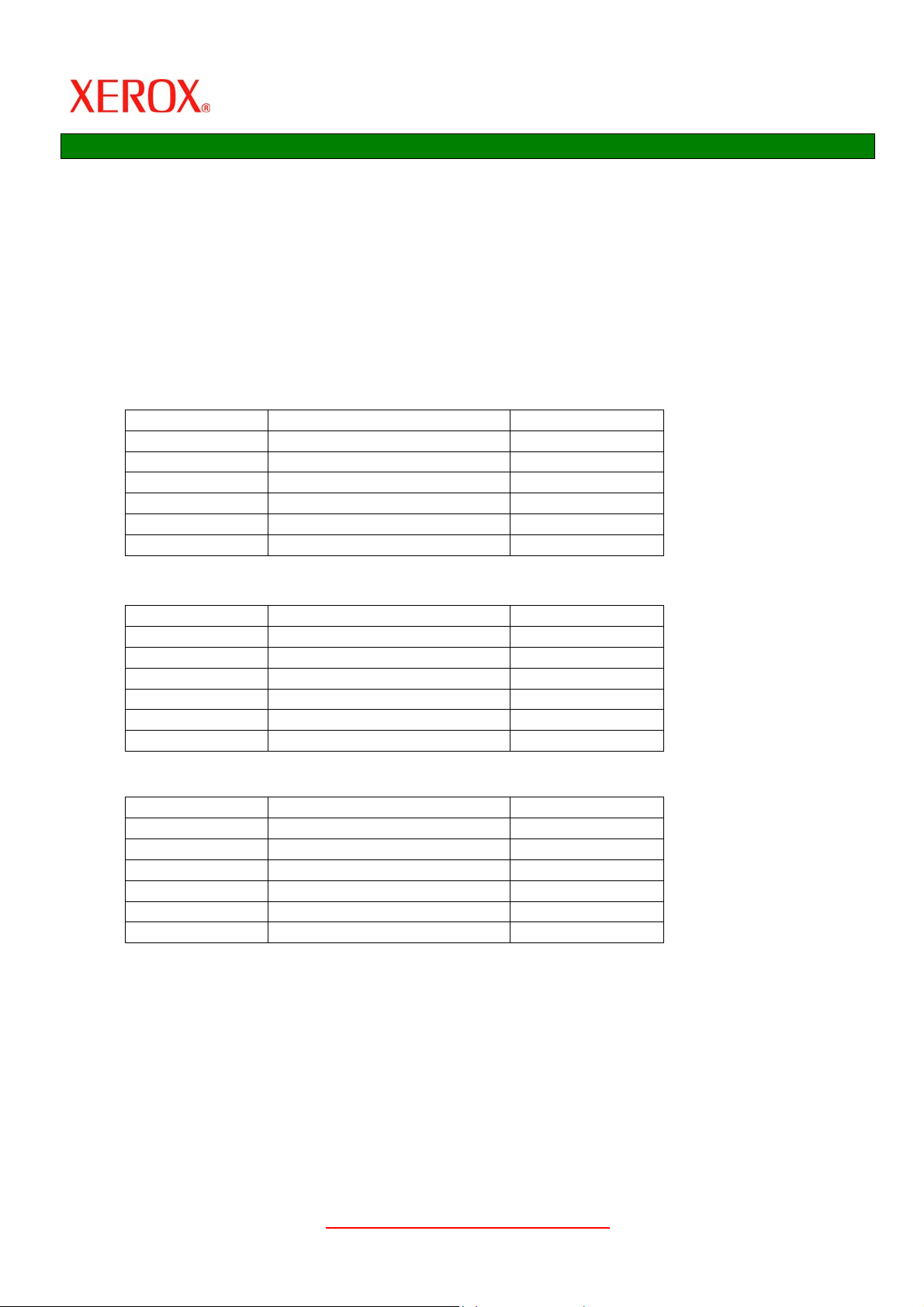

Standard Graphic Arts Inks

Part Number Description Size

026R00711 Graphic Arts Black 500ml

026R00712 Graphic Arts Cyan 500ml

026R00713 Graphic Arts Magenta 500ml

026R00714 Graphic Arts Yellow 500ml

026R00715 Graphic Arts Light Cyan, 500ml

026R00716 Graphic Arts Light Magenta 500ml

Graphic Arts Plus Inks

Part Number Description Size

TBA Graphic Arts Plus Black 750ml

TBA Graphic Arts Plus Cyan 750ml

TBA Graphic Arts Plus Magenta 750ml

TBA Graphic Arts Plus Yellow 750ml

TBA Graphic Arts Plus Light Cyan, 750ml

TBA Graphic Arts Plus Light Magenta 750ml

Production Inks

Part Number Description Size

026R00711 Production Black 500ml

026R00712 Production Cyan 500ml

026R00713 Production Magenta 500ml

026R00714 Production Yellow 500ml

026R00715 Production Light Cyan, 500ml

026R00716 Production Light Magenta 500ml

Critical Operating Instructions

• X2 inks are instantly dry to the touch when printed. All X2 prints can be laminated immediately. Please check

the individual product specification sheet for details on handling and lamination functions.

• Ink yields are ultimately determined by the image being printed. For example, heavy saturated image s will

consume more ink at different ratios than light coverage graphics. The following statement provides a general

assumption to help in determining approximate ink consumption and costs:

• Printing with 75% ink coverage in 360 dpi print mode, one set of inks (3 litres, C,M,Y,K, LC,LM) will yield 469

sq. metres or 5048 sq.ft. The yields are significantly reduced if printing in 720-dpi mode continuously.

• A small amount of ink is left in the bottom of each ink cartridge. There is extra ink in each of the bottles to

compensate for this residue. Do not attempt to pour residue from one bottle into another bottle.

www.xerox.com/iccprofiles.com

10

Page 11

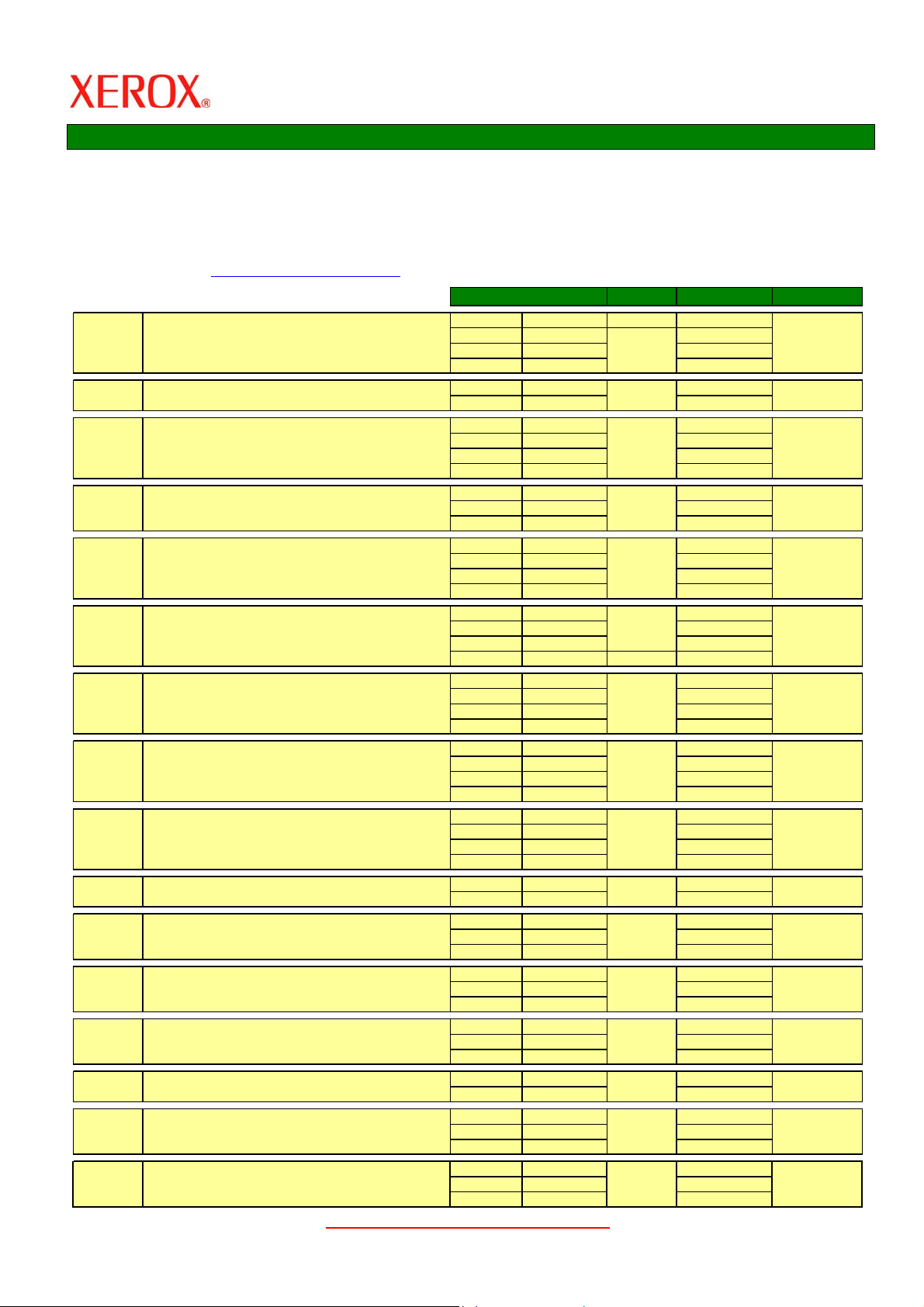

Xerox Oil Inkjet Media Range Overview

The scope of this range is generally from 24” (61cm) to 54” (137cm). Demand for some media types and sizes

varies according to the applications those media types serve. 36”, 42” and 54” roll widths are standard.

Development in inkjet media and coatings is continuous and the range of media available constantly changes to

meet the needs of the market. New media types are regularly introduced and this guide may not include the

full selection available. Whilst Xerox makes every effort to provide and maintain consistent products, media

specifications are subject to change without notice. For specific enquiries or queries please contact Xerox via the

enquiries section in

www.xerox.com/iccprofilesT or contact your Xerox Wide Format representative.

80 g/m

90 g/m

95 g/m

125 g/m

115 g/m

125 g/m

160 g/m

120 g/m

120 g/m

236 g/m

150 mic

175 mic

140 mic

400 g/m

160 g/m

250 g/m

2

Line Ar t Paper

2

Coated Desi gn Paper

2

Hi White Graphic Arts Paper

2

Hi White Graphic Arts Paper

2

Presentation Pap er

2

Presentation Pap er - 720 dpi

2

Heavy Weight Present ation Pa per

2

Outdoor Poster Paper - Blue Backed

2

Short-Term Poster Paper - Blue Backed

2

Reinforced Paper

White Matt Film

Backlit Film

Pressure Sensitive Vinyl

2

Banner Vi nyl

2

Banner Fabric

2

Banner Fabric - Fire Retardant

www.xerox.com/iccprofiles.com

Width

Len gth Code Data Sheet

54" 1370 mm 91 m 023R01365

36" 914 mm 023R01366

A0 841 mm 023R01394

122 m

A1 594 mm 023R01396

A0 841 mm 023R01443

A1 594 mm 023R01444

100 m

54" 1370 mm 023R01424

50" 1270 mm 023R01423

42" 1067 mm 023R01422

100 m

36" 914 mm 023R01425

54" 1370 mm 023R02064

42" 1067 mm 023R02066

76 m

36" 914 mm 023R02067

54" 1370 mm 023R01627

50" 1270 mm 023R01628

42" 1066 mm 023R01629

76 m

36" 914 mm 023R01630

54" 1370 mm 023R01263

50" 1270 mm 023R01264

45.7 m

42" 1066 mm 023R01265

36" 914 mm 65 m 023R01181

54" 1370 mm 023R01437

50" 1270 mm 023R01438

42" 1066 mm 023R01439

61 m

36" 914 mm 023R01440

54" 1370 mm 023R01420

50" 1270 mm 023R01429

42" 1067 mm 023R01614

76 m

36" 914 mm 023R01421

54" 1370 mm 023R02180

50" 1270 mm 023R02181

42" 1067 mm 023R02182

80 m

36" 914 mm 023R02183

54" 1370 mm 023R01296

36" 914 mm 023R01293

23 m

54" 1370 mm 023R01451

42" 1066 mm 023R01455

30 m

36" 914 mm 023R01453

54" 1370 mm 023R02430

42" 1067 mm 023R02429

30 m

36" 914 mm 023R02428

54" 1370 mm 023R02405

42" 1067 mm 023R02404

20 m

36" 914 mm 023R02403

54" 1370 mm 023R01418

36" 914 mm 023R01419

25 m

54" 1370 mm 023R01415

42" 1067 mm 023R01414

25 m

36" 914 mm 023R01416

54" 1370 mm 023R02002

42" 1067 mm 023R02004

25 m

36" 914 mm 023R02005

11

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Page 12

g/

80 g/m2 Line Art Paper 1

Description

An economical, basic 80 g/m2 medium grade, bright white paper with a smooth matt surface, for

use in 360 dpi print mode, but specifically intended for line drawing applications, it meets the line

width specifications for GIS/CAD Engineering applications. Not recommended for printing full

graphic images.

Line Art Paper can be over-laminated with most commonly available thermal and pressure laminates

for added durability.

Applications

Line art, CAD / GIS and engineering drawings, checkplots, charts, graphs, diagrams and similar

images with low levels of ink and area coverage.

Physical Characteristics

95%

115

m

2

Base Weight

Calliper

Opacity

Brightness

80

113 microns

Dimensions

Code Length

023R01365 54” 1372mm 91m

023R01366 36” 914m m 122m

023R01394 A0 841m m 122m

023R01396 A1 594m m 122m

Width

Compatibility

Xerox X2

Xerox Xpress

Seiko IP4XXX

Operating Instructions

• Recommended for indoor use only.

• Use for line drawing and small areas of low saturation covering.

• Laminate with either pressure or thermal laminates if prints are to be exposed to severe

conditions, or if longer durability is required.

o

• For best results store and use within temperatures of 10-30

Store the product in its original carton and bag / wrapper.

• Keep the image surface dry and free of grease, oil, silicones and dirt.

• Ensure that roll ends are protected and that the edge of these media are not damaged. If the

media edges are not flat this can result in damage to the printer.

C and relative humidity of 40-65%.

www.xerox.com/iccprofiles.com

12

Page 13

90g/m2 Coated Design Paper 2

Description

A 90 g/m2 medium grade, bright white paper with an ink receiver coating which meets th e line width

specifications for GIS/CAD and Engineering applications, is ideal for detailed mapping and colour

presentation and will provide good graphic image quality. Available in the full range of ISO sizes

from A0 to A4.

Applications

Good for all high quality technical drawings including highly det ailed images and presentation grade

prints, as well as mapping, signage, corporate graphics and charts, promotional displays, full graphic

posters. Can be used unfinished or laminated for extra durability.

Physical Characteristics

Base Weight

Calliper

Opacity

Brightness

92 g/m

115 microns

2

94%

115

Dimensions

Code Length

023R01443 A0 841mm 100m

023R01444 A1 594mm 100m

Width

Compatibility

Xerox X2

Xerox Xpress

Seiko IP4XXX

Operating Instructions

• Store in a c ool, dry environment, free from direct sunlight, within temperatures of 10-35oC and

non-condensing relative humidity of 30-70%. Store the product in its original carton and

wrapper to protect from dust and moisture.

• Ensure that roll ends are protected and that the edge of these media are not damaged. If the

media edges are not flat this can result in damage to the printer.

• Keep the image surface dry and free of grease, oil, silicones and dirt. It is recommended that

cotton gloves be used for handling to avoid fingerprints.

• The printing environment should be kept near optimal conditions while using this material 21˚C &

50% R.H.). An increase in humidity or temperature can cause printing malfunctions. Head

crashes and carriage jams may occur if used outside of these conditions.

• Shelf life of this material is 2 years if kept in original packaging as specified.

• Folding or creasing prints can result in some loss of image.

• Laminate with thermal laminates if longer durability is required.

www.xerox.com/iccprofiles.com

13

Page 14

g/

95g/m2 Hi White Graphic Arts Paper 3

Description

A 95 g/m2 medium grade, bright white paper for use in 360 dpi print mode. It provides good image

quality and is well suited for general display application s. It also meets the line width specification s

for GIS/CAD Engineering applications.

CAUTION: This material is sensitive to excessive temperature and humidity and can cockle if

subjected to conditions outside of its capability range (e.g. Laminat ing temperature).

Applications

Good for all general graphics, such as posters, courtroom graphics, customer, sales and boardroom

presentations, point of sale graphics, framed images, trade shows, museum signage, in-house

graphics, merchandising materials, mounted prints, exhibit and corporate graphics, promotional

displays, sample prints/check-plots, directional display and map reprodu ctions.

Physical Characteristics

115

m

2

Durability

Indo or La minated 5 ye ars

Indo or Unla minated

Outdoor Laminated

Outdoor Unlaminated

6 months

18 months

2 day s

Base Weight

Calliper

Opacity

Brightness

95

118 microns

94.5%

Dimensions

Code Length

023R01424 54” 1372m m 100m

023R01423 50” 1270mm 100m

023R01422 42” 1067mm 100m

023R01425 36” 914mm 100m

Width

Compatibility

Xerox X2

Xerox Xpress

Seiko IP4XXX

Operating Instructions

• Store in a c ool, dry environment, free from direct sunlight, within temperatures of 10-35oC and

non-condensing relative humidity of 30-70%. Store the product in its original carton and

wrapper to protect from dust and moisture.

• Ensure that roll ends are protected and that the edges of the media are not damaged. If the

media edges are not flat this can result in damage to the printer.

• Keep the image surface dry and free of grease, oil, silicones and dirt. It is recommended that

cotton gloves be used for handling to avoid fingerprints.

• Shelf life of this material is 2 years if kept in original packaging as specified.

• Use within the temperature range 18-30˚C and relative humidity of 40-60%.

• Do not fold or crease prints.

• Laminate only with hot melt laminates if satin or gloss finishes are required, or if protection from

UV, moisture or abrasion is necessary for extra durability.

www.xerox.com/iccprofiles.com

14

Page 15

g/

125g/m2 Hi White Graphic Arts Paper 4

Description

A 125 g/m2 medium grade, bright white paper for use in 360 dpi print mode. It provides good image

quality and is well suited for general display applications . It also meets the line width specifications

for GIS/CAD Engineering applications.

Applications

Good for all general graphics, such as posters, courtroom graphics, sales and boardroom

presentations, point of sale graphics, framed images, trade shows, museum signage, in-house

graphics, merchandising materials, mounted prints, exhibit and corporate graphics, promotional

displays, sample prints/check-plots, directional display and map reproductions.

Physical Characteristics

115

m

2

Durability

Indo or La minated 5 ye ars

Indo or Unla minated

Outdoor Laminated

Outdoor Unlaminated

18 months

18 months

3 day s

Base Weight

Calliper

Opacity

Brightness

125

168 microns

98%

Dimensions

Code Length

023R02064 54” 1372m m 76m

023R02066 42” 1067mm 76m

023R02067 36” 914mm 76m

Width

Compatibility

Xerox X2

Xerox Xpress

Seiko IP4XXX

Operating Instructions

• Store in a c ool, dry environment, free from direct sunlight, within temperatures of 10-35oC and

non-condensing relative humidity of 30-70%. Store the product in its original carton and

wrapper to protect from dust and moisture.

• Ensure that roll ends are protected and that the edges of the media are not damaged. If the

media edges are not flat this can result in damage to the printer.

• Keep the image surface dry and free of grease, oil, silicones and dirt. It is recommended that

cotton gloves be used for handling to avoid fingerprints.

• Shelf life of this material is 2 years if kept in original packaging as specified.

• Use within the temperature range 18-30˚C and relative humidity of 40-60%.

• Do not fold or crease prints.

• Laminate only with hot melt laminates if satin or gloss finishes are required, or if protection from

UV, moisture or abrasion is necessary for extra durability.

www.xerox.com/iccprofiles.com

15

Page 16

g/

115g/m2 Presentation Paper 5

Description

A premium quality, all-purpose paper with a smooth matt print surface and extra features for highvolume 360dpi presentation printing. The front side coating is high-white and has higher ink

capacity to enable stronger colour reproduction. The rear of this paper is coated with a barrier to

prevent ghosting from one image to another. Suitable for thermal laminates. Use for all

presentation applications.

Applications

Good for all presentation graphics such as posters, courtroom graphics, corporate presentations,

point of sale graphics, framed images, trade show graphics, museum signage, in-house graphics,

merchandising materials, mounted prints, exhibit graphics, promotional displays, corporate graphics,

mural panels, media decals, backlit displays, laminated prints, fine art reproductions, photo-realistic

imaging, proofs, directional display and map reproductions.

Physical Characteristics

107

m

2

Durability

Indoor Laminated 5 years

Indoor Unlaminated

Outdoor Laminated

Outdoor Unlaminated

6 months

2 ye a rs

Not r ec ommended

Base Weigh t

Calliper

Opacity

Brightness

115

146 mic ro ns

94%

Dimensions

Code Length

023R01627 54” 1372m m 76m

023R01628 50” 1270mm 76m

023R01629 42” 1067mm 76m

023R01630 36” 914mm 76m

Width

Compatibility

Xerox X2

Xerox Xpress

Seiko IP4XXX

Operating Instructions

• Store in a c ool, dry environment, free from direct sunlight, within temperatures of 10-35oC and

non-condensing relative humidity of 30-70%. Store the product in its original carton and

wrapper to protect from dust and moisture.

• Ensure that roll ends are protected and that the edges of the media are not damaged. If the

media edges are not flat this can result in damage to the printer.

• Keep the image surface dry and free of grease, oil, silicones and dirt. It is recommended that

cotton gloves be used for handling to avoid fingerprints.

• Shelf life of this material is 2 years if kept in original packaging as specified.

• Use within the temperature range 18-30˚C and relative humidity of 40-60%.

• Pr int in 360dpi print mode only.

• Laminate only with hot melt laminates if satin or gloss finishes are required, or if protection from

UV, moisture or abrasion is necessary for extra durability.

• The fine structure of this paper can cause laminated graphics to split if subject to frequent flexing

such as with some pop-up exhibition display systems.

www.xerox.com/iccprofiles.com

16

Page 17

g/

125g/m2 Presentation Paper – 720dpi 6

Description

A premium quality, medium-weight paper, designed for optimum performance in 720 dpi print mode.

It is specially coated to accept the high level of ink saturation and precise dot placement required for

720 dpi imaging. Use for all high quality presentation applications where sharp lines, crisp text and

maximum colour gamut are required. NOTE: For use with Thermal laminates only.

Applications

Good for all highest quality presentation graphics, such as posters, courtroom graphics, customer,

sales or boardroom presentations, point of sale graphics, framed images, trade show graphics,

museum signage, in-house graphics, merchandising materials, mounted prints, exhibit graphics,

promotional displays, corporate graphics, backlit display, fine art reproductions, photo-realistic

imaging and map reproductions.

Physical Characteristics

75

m

2

Durability

Indoor Laminated 15 years

Indoor Unlaminated

Outdoor Laminated

Outdoor Unlaminated

3 months

3 ye a rs

Not r ec ommended

Base Weigh t

Calliper

Opacity

Brightness

125

170 mic ro ns

92%

Dimensions

Code Length

023R01363 54” 1372m m 45.7m

023R01364 50” 1270mm 45.7m

023R01365 42” 1067mm 45.7m

023R01181 36” 914mm 65m

Width

Compatibility

Xerox X2

Xerox Xpress

Seiko IP4XXX

Operating Instructions

• Store in a c ool, dry environment, free from direct sunlight, within temperatures of 10-35oC and

non-condensing relative humidity of 30-70%. Store the product in its original carton and

wrapper to protect from dust and moisture. Shelf life is 2 years if kept in original packaging.

• Ensure that roll ends are protected and that the edges of the media are not damaged. If the

media edges are not flat this can result in damage to the printer.

• Keep the image surface dry and free of grease, oil, silicones and dirt. It is recommended that

cotton gloves be used for handling to avoid fingerprints.

• Use within the temperature range 18-30˚C and relative humidity of 40-60%.

• Pr int in 720 dpi print mode only.

• Laminate only with hot melt laminates if satin or gloss finishes are required, or if protection from

UV, moisture or abrasion is necessary for extra durability.

• Specific set tings are required to obtain acceptable laminate adhesion when using some laminat es

and laminators. Higher temperature settings and slower speed may be necessary. Refer to the

Lamination Procedures section of this guide for specific settings.

• Take extra care when handling 720 dpi prints after lamination to avoid splitting the laminate

adhesion to the paper. Do not tap edges on tables, counters, etc. Roll images loosely (no smaller

then 3” in diameter).

www.xerox.com/iccprofiles.com

17

Page 18

g/

160g/m2 Heavyweight Presentation Paper 7

Description

This heavyweight presentation paper is suitable for heavier in k loading and can be printed in either

360 or 360x720dpi mode. The high ink capacity allows production of bright dense images and a

broad colour gamut. The higher base weight and bulk gives strength and stiffness and therefore

improved handling and better performance without an over-laminate. Nevertheless an overlaminate is recommended to preserve the quality of imaging best suited to this paper. The extra

calliper helps to avoid ghosting for high-speed, high-volume print production.

Applications

Ideal for retail graphics Good for all presentation graphics, such as posters, courtroom graphics,

customer, sales or boardroom presentations, point of sale graphics, framed images, trade show

graphics, museum signage, in-house graphics, merchandising materials, mounted prints, exhibit

graphics, promotional displays, corporate graphics, mural panels, media decals, laminated prints,

fine art reproductions, photo-realistic imaging, proofs, directional display and map reproductions

Physical Characteristics

100

m

2

Durability

Indoor Laminated 5 years

Indoor Unlaminated

Outdoor Laminated

Outdoor Unlaminated

1 ye a r

2 ye a rs

3 months

Base Weigh t

Calliper

Opacity

Brightness

160

200 mic ro ns

97%

Dimensions

Code Length

023R01437 54” 1372m m 61m

023R01438 50” 1270m m 61m

023R01439 42” 1067m m 61m

023R01440 36” 914mm 61m

Width

Compatibility

Xerox X2

Xerox Xpress

Seiko IP4XXX

Operating Instructions

• Store in a c ool, dry environment, free from direct sunlight, within temperatures of 10-35oC and

non-condensing relative humidity of 30-70%. Store the product in its original carton and

wrapper to protect from dust and moisture. Shelf life is 2 years if kept in origin al packaging.

• Ensure that roll ends are protected and that the edges of the media are not damaged. If the

media edges are not flat this can result in damage to the printer.

• Keep the image surface dry and free of grease, oil, silicones and dirt. It is recommended that

cotton gloves be used for handling to avoid fingerprints.

• Use within the temperature range 18-30˚C and relative humidity of 40-60%.

• For use in either 360 dpi or 360x720dpi print modes. Ensure the appropriate colour profile and

resolution setting is used when imaging a file. If an image must be printed in 360x720dpi print

modes, the digital file must be sent to the RIP twice (once using 360dpi settings, and again using

720 dpi settings). The profile settings MUST match the printer setting (i.e. DO NOT print an

image with 720dpi printer settings if the 360dpi colour profile was used, and vice versa.

• Laminate only with hot melt laminates if satin or gloss finishes are required, or if protection from

UV, moisture or abrasion is necessary for extra durability.

www.xerox.com/iccprofiles.com

18

Page 19

g/

120g/m2 Outdoor Blue Back Poster Paper 8

Description

This matt white water-resistant poster paper is inherently opaque but has a blue back to reinforce

the highest possible opacity to meet the requirements of billboard poster applications as is the case

with traditional screen print papers for this application. It is suitable for a wide range of indoor

graphic applications too, but is primarily designed for outdoor use without lamination. Wet strength

is suitable for soaking as part of the bill posting process. High ink capacity allows bright prints with

excellent colour density and gamut. Tested and approved by the Swiss billboard association APG and

other authorities. Compatible with commonly used adhesives, application practices and Northern

European weathering to meet the needs of billboard advertising specifiers such as Viacom.

Applications

Excellent for all single or multi panelled billboard applications: Bus shelters, subway

advertisements, sporting event signage and promotions, outdoor festival signs and displays, outdoor

markets, construction signs, indoor presentation applications. Also excellent as a low cost backlit

display for such applications as bus shelter advertising.

Physical Characteristics

100

m

2

1 ye a rIndoor Unlaminated

Durability

Out door Unlaminate d 6 mo nths

Base Weigh t

Calliper

Opacity

Brightness

120

155 mic ro ns

98%

Dimensions

Code Length

023R01420 54” 1372m m 76m

023R01429 50” 1270m m 76m

023R01614 42” 1067m m 76m

023R01421 36” 914mm 76m

Width

Compatibility

Xerox X2

Xerox Xpress

Seiko IP4XXX

Operating Instructions

• Store i n a cool, dry environment, out of direct sunlight, within temperatures of 10-35oC and non-condensing

relative humidity of 30-70%. Store rolls in original carton and wrapper to protect from dust and moisture.

Shelf life is 2 years if kept in original packaging as specified.

• Ensure that roll ends are protect ed and that edges of the media are not damaged. If the media edges are

not flat this can result in damage to the printer.

• Use within the temperature range 18-30˚C and relative humidity of 40-60%.

• Wet paper at least 8 hours pri or to pas ti ng. Longer soaki ng has no negati ve impact on the paper ’s stre ngth.

Ensure appropriate microbiological precautions.

• This paper may expand up to 2. 5% when wet. If intended installation requires exact size consider imaging

the design approximately 98% to compensate for possible expansion.

• Let the graphic dry for at least 24 hours prior to soaking and installation.

• This is a same day paste a nd post prod uct. Let soak in water for 1 hour prior to pasting to minimise wrinkles

during installation. Can be soaked in water for up to 48 hours prior to use.

• Do not use anti-freeze during billboard installation as ink adhesion may be lost.

• Recommended Pastes:

Zellura UST

Natural Paste (Fish Paste: K. Blattman, potato starch: AVEBE)

Tylose C 6000, Planatol & Chimcoll (contains biocide, difficult to dissolve)

• Lamination is not required and this paper may not adhere well to some laminate films.

www.xerox.com/iccprofiles.com

19

Page 20

g/

120g/m2 Short-term Outdoor Blue Back Paper 9

Description

This water-resistant poster paper has its opacity reinforced with a blue back to meet the

requirements of billboard poster applications, as is the case with traditiona l screen print papers for

this application. It is suitable for a wide range of indoor graphic applications too, but is primarily

designed for outdoor use without lamination and is suitable for soaking as part of the bill posting

process. Tested with authorities for compatibility with the various adhesives, application practices

and Northern European weathering, meet the requirements of billboard advertising and standard

specifiers such as Viacom for most outdoor campaigns.

Applications

Excellent for all single or multi panelled billboard applicat ions: Bus shelters, subway adv ertisement s,

sporting event signage and promotions, outdoor festival signs and displays, outdoor markets,

construction signs, indoor presentation applications. Also excellent as a low cost backlit display for

such applications as bus shelter advertising.

Physical Characteristics

95

m

2

1 ye a rIndoor Unlaminated

Durability

Out door Unlaminate d 4 mo nths

Base Weigh t

Calliper

Opacity

Brightness

120

150 mic ro ns

97%

Dimensions

Code Length

023R02180 54” 1372m m 80m

023R02181 50” 1270m m 80m

023R02182 42” 1067m m 80m

023R02183 36” 914mm 80m

Width

Compatibility

Xerox X2

Xerox Xpress

Seiko IP4XXX

Operating Instructions

• Store i n a cool, dry environment, out of direct sunlight, within temperatures of 10-35oC and non-condensing

relative humidity of 30-70%. Store rolls in original carton and wrapper to protect from dust and moisture.

Shelf life is 2 years if kept in original packaging as specified.

• Ensure that roll ends are protect ed and that edges of the media are not damaged. If the media edges are

not flat this can result in damage to the printer.

• Use within the temperature range 18-30˚C and relative humidity of 40-60%.

• Wet paper at least 8 hours pri or to pas ti ng. Longer soaki ng has no negati ve impact on the paper ’s stre ngth.

Ensure appropriate microbiological precautions.

• This paper may expand up to 3% when wet. If intended installation requires exact size consider imaging the

design approximately 98% to compensate for possible expansion.

• Let the graphic dry for at least 24 hours prior to soaking and installation.

• This is a same day paste a nd post prod uct. Let soak in water for 1 hour prior to pasting to minimise wrinkles

during installation. Can be soaked in water for up to 48 hours prior to use.

• Do not use anti-freeze during billboard installation as ink adhesion may be lost.

• Recommended Pastes:

- Zellura UST

- Natural Paste (Fish Paste: K. Blattman, potato starch: AVEBE)

- Tylose C 6000, Planatol & Chimcoll (contains biocide, difficult to dissolve)

• Lamination is not required and this paper may not adhere well to some laminate films.

www.xerox.com/iccprofiles.com

20

Page 21

g/

236g/m2 Reinforced Paper 10

Description

A nylon reinforced paper designed for producing vivid, full colour images in 360 dpi mode. The

exceptional durability of this media provides maximum flexibility during post print handling allowing

for edge sewing, taping and grommeting. It provides excellent laminate adhesion with pressure

sensitive as well as thermal laminates. It is an economical paper alternative to using standard

outdoor materials for indoor banner applications.

NOTE: For use with both Thermal and Pressure Sensitive overlaminates. Must be overlaminated on

both sides of a print for long term outdoor use (more than 3 days exposure).

Applications

Excellent for all large format, indoor banner applications including retail, car showrooms,

supermarkets, suspended ceiling displays, office parties, museums, art galleries, entranceways,

office corridors, industrial signage (warnings, hazard, etc.) - vertical or horizontal.

As a laminated paper, this media can be utilised for all presentation applications like trade show

backdrops, mounted prints, window posters, suspended ceiling displays, exhibition graphics,

shopping centre displays and retail signage.

Physical Characteristics

104

m

2

Durability

Indoor Laminated 10 years

Indoor Unlaminated

Outdoor Laminated

Outdoor Unlaminated

1 ye a r

2 ye a rs

2 day s

Base Weigh t

Calliper

Opacity

Brightness

236

280 mic ro ns

97%

Dimensions

Code Length

023R01296 54” 1372m m 23m

023R01293 36” 914mm 23m

Width

Compatibility

Xerox X2

Xerox Xpress

Seiko IP4XXX

Operating Instructions

• Store in a cool, dry environment, free from direct sunlight, within temperatures of 10-35oC and non-

condensing relative humidity of 30-70%. Store the product in its original carton and wrapper to protect

from dust and moisture. Shelf life is 2 years if kept in original packaging.

• Ensure that roll ends are protect ed and that the edges of the media are not damaged. If the media edges

are not flat this can result in damage to the printer.

• Keep the image surface dr y and free of grease, oil, silicones and dirt. It is recommended that cotton gloves

be used for handling to avoid fingerprints.

• Use within the temperature range 18-30˚C and relative humidity of 40-60%.

• For use in 360 dpi print mode only.

• This materi al is suitable for standard finishing procedures for banners: Edges can be sewn and the banner

can be punched for eyelets. To form large displays, panel s should be overlapped 2-3 cm and seamed. A

double stitched hem with a maximum of 5 stitches per inch is recommended.

• Laminate wi th either pressure or thermal laminates if prints are to be exposed to severe conditions, or if

longer durability is required. Heavier weight thermal laminates work best on this paper. Use at least a 125

micron laminate to avoid showing an “orange peel” effect.

www.xerox.com/iccprofiles.com

21

Page 22

g/

150 micron White Matt Film 11

Description

A matt white film designed to produce vivid, full colour direct write digital images in 360 dpi mode.

This tear resistant film provides instant drying with good ink fixation for high-definition, photorealistic images. The matt finish of the base film offers an image surface with minimal light reflection

from white or un-imaged areas, but does not dull the printed image. A true water resistant media for

use as an alternative to paper in “field” projects or when graphics will be exposed to weather or

rough handling. Finished with an over-laminate, this film has the strength, rigidity and dimensional

stability for roll up and pop up displays.

Applications

Good for all presentation graphics, such as posters, courtroom graphics, customer, sales and

corporate presentations, point of sale graphics, framed images, trade show graphics, museum

signage, in-house graphics, merchandising materials, mounted prints, exhibition graphics,

promotional displays and directional display.

Physical Characteristics

95

m

2

Durability

Indoor Laminated 2 years

Indoor Unlaminated

Outdoor Laminated

Outdoor Unlaminated

1 ye a r

18 months

7 months

Base Weigh t

Calliper

Opacity

Brightness

167

145 mic ro ns

94%

Dimensions

Code Length

023R01451 54” 1372m m 30m

023R01455 42" 1067m m 30m

023R01453 36” 914mm 30m

Width

Compatibility

Xerox X2

Xerox Xpress

Seiko IP4XXX

Operating Instructions

• Store in a c ool, dry environment, free from direct sunlight, within temperatures of 10-35oC and

non-condensing relative humidity of 30-70%. Store the product in its original carton and

wrapper to protect from dust and moisture.

• Ensure that roll ends are protected and that the edges of the media are not damaged. If the

media edges are not flat this can result in damage to the printer.

• Keep the image surface dry and free of grease, oil, silicones and dirt. It is recommended that

cotton gloves be used for handling to avoid fingerprints.

• Shelf life of this material is 2 years if kept in original packaging as specified.

• Use within the temperature range 18-30˚C and relative humidity of 40-60%.

• For use in 360 dpi print mode only.

• Laminate with either pressure or thermal laminates if prints are to be exposed to severe

conditions, if longer durability is required, or if a satin or gloss finish is preferred.

www.xerox.com/iccprofiles.com

22

Page 23

g/

175 micron Backlit Film 12

Description

A versatile polyester film specifically coated to provide excellent ima ge quality with rich deep colours

and superior saturation and contrast. This polyester-based material is dimensionally stable with heat

generated in a light box and ideal for all backlit applications, indoors and out. Image Details are

sharp, and image clarity is excellent. Small text will not "break- up" or become fuzz y. Images will not

"wash-out" when viewed under fixture lights, or seem too dark when lights are turned off.

Applications

Excellent for all displays with some degree of back il lumination, artificial or natural, to boos t display

impact: Lobby signs, parking garage signage, transit shelters, airport fixtures, elevator displays,

retail promotion, shopping centre directories, subway plans, kiosks, window display units, menu

fixtures, retail/supermarket aisle signs, and convenience store signage.

Physical Characteristics

75

m

2

Durability

Indoor Laminated 2 years

Indoor Unlaminated

Outdoor Laminated

Outdoor Unlaminated

Not r ec ommended

1 ye a r

Not r ec ommended

Base Weigh t

Calliper

Opacity

Brightness

200

177 mic ro ns

60%

Dimensions

Code Length

023R02430 54” 1372m m 30m

023R02429 42" 1067m m 30m

023R02428 36” 914mm 30m

Width

Compatibility

Xerox X2

Xerox Xpress

Seiko IP4XXX

Operating Instructions

• Store in a c ool, dry environment, free from direct sunlight, within temperatures of 10-35oC and

non-condensing relative humidity of 30-70%. Store the product in its original carton and

wrapper to protect from dust and moisture. Shelf life is 2 years if kept in origin al packaging.

• Ensure that roll ends are protected and that the edges of the media are not damaged. If the

media edges are not flat this can result in damage to the printer.

• Keep the image surface dry and free of grease, oil, silicones and dirt. It is recommended that

cotton gloves be used for handling to avoid fingerprints.

• Use within the temperature range 18-30˚C and relative humidity of 40-60%.

• For use in either 360 dpi or 360x720dpi print modes. Ensure the appropriate colour profile and

resolution setting is used when imaging a file. If an image must be printed in 360x720dpi print

modes, the digital file must be sent to the RIP twice (once using 360dpi settings, and again using

720 dpi settings). The profile settings MUST match the printer setting (i.e. DO NOT print an

image with 720dpi printer settings if the 360dpi colour profile was used, and vice versa. Print 4colour to achieve maximum colour densities for illuminated display without over-saturating with

ink. Ensure the appropriate colour profile and resolution setting is used.

• For colour critical images, add a blank sheet of white paper to the back of the print and

encapsulate. Ensure that there is at least a 4mm sealed laminate edge around the graphic.

• To enhance the appearance of an image when u sing this media by altering the digital file or to

decrease banding during printing, follow the instructions provided else where in this guide.

• Laminate images immediately, within 4-8 hours of printing, using Thermal laminates only.

www.xerox.com/iccprofiles.com

23

Page 24

g/

140 micron Pressure Sensitive Vinyl 13

Description

This is a general-purpose, calendered self-adhesive white vinyl – pressure sensitive – that will

adhere to a wide variety of smooth substrates with flat or gently curved surfaces using only the

slight pressure of a hand or small tool (such as a squeegee). This PSV has a medium tack adhesive

that enables good adhesion in service but will enable complete removal from substrates without the

use of chemicals or heat. It is designed for use in all indoor, and most outdoor, PSV applications

when properly constructed with an over-laminate.

The in receiver coating gives a bright white imaging surface with a good degree of wat er and scratch

resistance, although lamination is recommended for prints requiring satin, high gloss or other

finishes and/or prints requiring protection from dirt, abrasion or UV, for greater general durability.

This media is suitable for pressure (cold) laminates but not for thermal (hot- melt) laminates.

Applications

For all indoor and some outdoor applications where the printed image is needed to adhere to a

smooth, flat or slightly curved surface: General signage, retail and event promotions, trade show

displays, galleries, museums, hallways, showrooms, market s, retail merchandising and display.

Physical Characteristics

118

m

2

Durability

Indoor Laminated 2 years

Indoor Unlaminated

Outdoor Laminated

Outdoor Unlaminated

6 months

1 ye a r

2 months

Base Weight

Total Calliper

Vinyl Calliper

Opacity

Brightness

290

275 microns

140 microns

98%

Adhesive Clear, removable, acrylic , pressure-sensitive

Release Liner

Coated paper 120g/m

2

Min. Surface / Ambient Air Application Temp. 10° C

Application Surface

Flat or slightly curved

Dimensions

Code Length

023R02405 54” 1372m m 20m

023R02404 42" 1067m m 20m

023R02403 36” 914mm 20m

Width

Compatibility

Xerox X2

Xerox Xpress

Seiko IP4XXX

Operating Instructions

• Store in a c ool, dry environment, free from direct sunlight, within temperatures of 10-35oC and

non-condensing relative humidity of 30-70%. Store the product in its original carton and

wrapper to protect from dust and moisture. Shelf life is 12 months if kept in original packaging.

• Ensure that roll ends are protected and that the edges of the media are not damaged. If the

media edges are not flat this can result in damage to the printer.

• Keep the image surface dry and free of grease, oil, silicones and dirt.

• Print within the temperature range 18-30˚C and relative humidity of 40-60%.

• Clean and prepare substrates following instructions detailed elsewhere in this guide

• Freshly lacquered or painted surfaces should be allowed to dry or cure completely before self-

adhesive vinyl is applied. Test compatibility of surfaces, paints or lacqu ers prior to application.

• Th is media is suitable for pressure (cold) laminates but not thermal (hot-melt) laminates.

www.xerox.com/iccprofiles.com

24

Page 25

g/

400g/m2 Banner Vinyl 14

Description

Vinyl designed for excellent image quality when used in either 360 or 720dpi print mode. This

material is constructed of a tear resistant polyester base fabric embedded between two layers of

white vinyl. It is water resistant, and designed for use in all banner applications indoors and most

outdoor applications except where durability in extreme wind and weather conditions is required. Use

standard finishing procedures for banners. Banner Vinyl gives excellent image permanence and does

not require the use of an over-laminate unless subject to abrasion or extreme moisture.

Applications

Ideal for indoor and outdoor banner applications, e.g., art galleries, retail and event promotions, long

hallways, showrooms, supermarkets, ceiling displays, museums, theatre lobbies, entranceways,

petrol stations, car park advertising, backdrops, signage, and tradeshows.

Physical Characteristics

95

m

2

Durability

Indo or La minated 2 y ears

Indo or Unla minated 2 ye ars

Outdoor Laminated

Outdoor Unlaminated

1 ye a r

1 ye a r

Base Weight

Total Calliper

Opacity

Brightness

400

356 mic ro ns

98%

Tensile strength

Tearing resistance

Temperature stabilit y

Dimensional stability

Fire Rating M2

>1500 N/ 5cm warp, >1400 N/5cm weft

>70 N warp, >70N weft

-10deg C to +60 deg C

<0.5%

Dimensions

Code Length

023R01418 54” 1372m m 25m

023R01419 36” 914mm 25m

Width

Compatibility

Xerox X2

Xerox Xpress

Seiko IP4XXX

Operating Instructions

• Store in a c ool, dry environment, free from direct sunlight, within temperatures of 10-35oC and

non-condensing relative humidity of 30-70%. Store the product in its original carton and

wrapper to protect from dust and moisture. Shelf life is 2 years if kept in origin al packaging.

• Ensure that roll ends are protected and that the edges of the media are not damaged. If the

media edges are not flat this can result in damage to the printer.

• Keep the image surface dry and free of grease, oil, silicones and dirt.

• Use within the temperature range 18-30˚C and relative humidity of 40-60%.

• Avoid ov er-saturating with ink for such as CMY / CMYK black. Reduce individual and overall ink

limits (<220%) to improve drying and production speed. Too much ink may cause light "oilspots" to appear. Working at lower ink limits improves image weather resistance.

• Some banding may be evident close viewed but from the likely viewing distance for banner

graphics it should be invisible. Unidirectional printing can help reduce banding.

• Th is is a heavily coated, extremely thick material. It may be easier to run this media fro m the

back roller and an automatic cutter should not be used during media loading or print production.

• Do not fold images. Use "slip sheets" to prevent image offset from one print to another.

• Over-lamination is not required except for conditions of extreme moisture or abrasion. Use

Pressure Sensitive laminates only.

www.xerox.com/iccprofiles.com

25

Page 26

g/

160g/m2 Banner Fabric 15

Description

Tear resistant, free-flowing polyester fabric designed for optimum image quality in either 360 or 720

dpi print mode, for use indoors or outdoors against a flat surface without lamination. A functional

fabric that can be "finished" to become a vast array of graphics. It has a satin sheen on the backside.

Applications

Ideal for indoor and outdoor banner applications, hanging banners, table fronts, backdrops, window

decorations, ceiling displays, drapes or flags: Trade shows, art galleries, retail and event

promotions, entrance lobbies and corridors, showrooms, supermarkets, shopping centres,

restaurants, ceiling displays, museums, sport arenas, political campaigns …

Physical Characteristics

Base Weight

Total Calliper

160

250 mic ro ns

m

2

Indo or Unla minated 2 ye ars

Durability

Outdoor Unlaminated 1 year

Tensile strength

Tearing resistance

Temperature stabilit y

Dimensional stability

>1500 n/5cm warp, >1400 n/ 5cm weft

>70 N warp, >70N weft

-10deg C to +60 deg C

<0.5%

Dimensions

Code Length

023R01415 54” 1372m m 25m

023R01414 42" 1067m m 25m

023R01416 36” 914mm 25m

Width

Compatibility

Xerox X2

Xerox Xpress

Seiko IP4XXX

Operating Instructions

• Store in a c ool, dry environment, free from direct sunlight, within temperatures of 10-35oC and

non-condensing relative humidity of 30-70%. Store the product in its original carton and

wrapper to protect from dust and moisture. Shelf life is 2 years if kept in origin al packaging.

• Ensure that roll ends are protected and that the edges of the media are not damaged. If the

media edges are not flat this can result in damage to the printer.

• Keep the image surface dry and free of grease, oil, silicones and dirt.

• Use within the temperature range 18-30˚C and relative humidity of 40-60%.

• Fabric is coated over a textured, porous surface. The coating layer on the peaks of the weave

may develop a tendency to "rub-off" if over saturated with ink such as in areas of CMY / CMYK

black. Working at lower ink limits improves image weather resistance.

• An automatic cutter should not be used during media loading or print production.

• Can be handled normally immediately after printing. Use cotton gloves to minimise image rub-

off during installation. Only a small amount of moisture from hands can increase rub-off.

• Do not fold images. Use "slip sheets" to prevent image offset from one print to another.

• Can be stitched with care. Avoid "bunching-up" when sewing. Grommets can be used.

• Over- lamination is not required.

• Outdoors this product should be fixed to a flat structure e.g. building wall. If hung without

protection wind may cause the coating surface to crack, leading to image deterioration.

www.xerox.com/iccprofiles.com

26

Page 27

g/

250g/m2 Banner Fabric – Fire Retardant 16

Description

Tear resistant polyester fabric designed for fine image quality in either 360 or 720 dpi print mode, for

use indoors or outdoors against a flat surface without lamination. This fabric has a fire retardant

coating and is certified M2 flame retardant f or use in fire sensitive indoor spaces. A fun ctional fabric

that can be "finished" to become a vast array of graphics.

Applications