Page 1

1 of 22 Revision Nov 2008

pp

p

Xerox iGen3 90/100/110 Digital Production Press Europe Paper and Specialty Media Guide

April 2010

For your convenience, this guide contains two lists. The Xerox Guaranteed Media List and the non-Xerox Tested Media List.

The Xerox Guaranteed Media List

contains Xerox paper and specialty media that has been extensively tested on the Xerox iGen3 90/100/110

Digital Production Press for image quality and performance. All Xerox paper and specialty media on this list are digitally optimized, designed

and manufactured for optimal performance in Xerox digital printing equipment. Our extensive testing and stringent specifications ensure

that we are able to guarantee the performance and consistency of Xerox paper and specialty media. Xerox paper and specialty media are

tested and qualified by Xerox laboratories to guarantee consistent quality.

The Xerox Custom Media List

Contains custom media that has been tested on the Xerox iGen3 90/100/110 Digital Production Press for image

quality and performance. Custom media on this list are digitally optimized, designed and manufactured for performance in Xerox digital

printing equipment. Customers should validate the Best Practices for Operation are acceptable for their application. When purchasing a

particular media product for the first time, customers are advised to purchase small quantities to insure that expectations are met.

The Non-Xerox Tested Media List

contains non-Xerox branded paper and specialty media. Xerox tested many media products on the Xerox

iGen3 90/100/110 Digital Production Press and based on such testing have published this list of tested media products which may or may

not, at the time of and based upon such testing, meet Xerox performance criteria. No subsequent testing has been done and therefore no

determination can be made as to whether or not such products would currently fail or pass Xerox performance criteria.

General Information

Media observations made in this publication are based on tests conducted using standard images with moderate to heavy image area

coverage. Test machines are maintained within specifications defined by user documentation.

This document will be updated regularly to reflect the most current media test results. Suggested machine adjustments as well as best

practices for operation are included where applicable in order to optimize media performance.

Instructions for programming media, including specific attributes, listed in this document but not yet in the Xerox iGen3 90/100/110 Digital

Production Press stock library can be found in the customer training manual or in the “Define New Stock” section of online help.

When using the Xerox DocuSP Controller, all stocks will be automatically connected to color profiles and calibration. To program a stock with

non-default settings, see the DocuSP 3.7 Customer Documentation or the On-Line Help on the DocuSP Color Server: On-Line Help/Color

Management/Using Color Profiles. When using a Creo DFE, color mapping is done using the Paper Stock Color.

Warranty Disclaimer

Xerox makes no guarantees or warranties, either expressed or implied, concerning the performance, use or replacement of non-Xerox branded media or throughput products. Customers should inquire directly of their paper distributor or

manufacturer for any guarantees they may offer. When purchasing a particular media product for the first time, customers are advised to purchase small quantities to insure their expectations are met. The quality of Xerox supplies is

consistent from ream to ream and is backed by a 100% guarantee. The quality of non-Xerox branded paper may vary from ream to ream or carton to carton, so for optimum performance on Xerox color equipment, use only the best - Xerox

lies. To learn more about the benefits of using Xerox Supplies, please contact your Supplies Representative.

su

2003 Xerox Cor

Xerox, The Document Company, the stylized X, and all Xerox names and product numbers mentioned in this publication are trademarks of Xerox Corporation. Other company trademarks are also acknowledged.

oration. All rights reserved.

Page 2

1 of 22 Revision Nov 2008

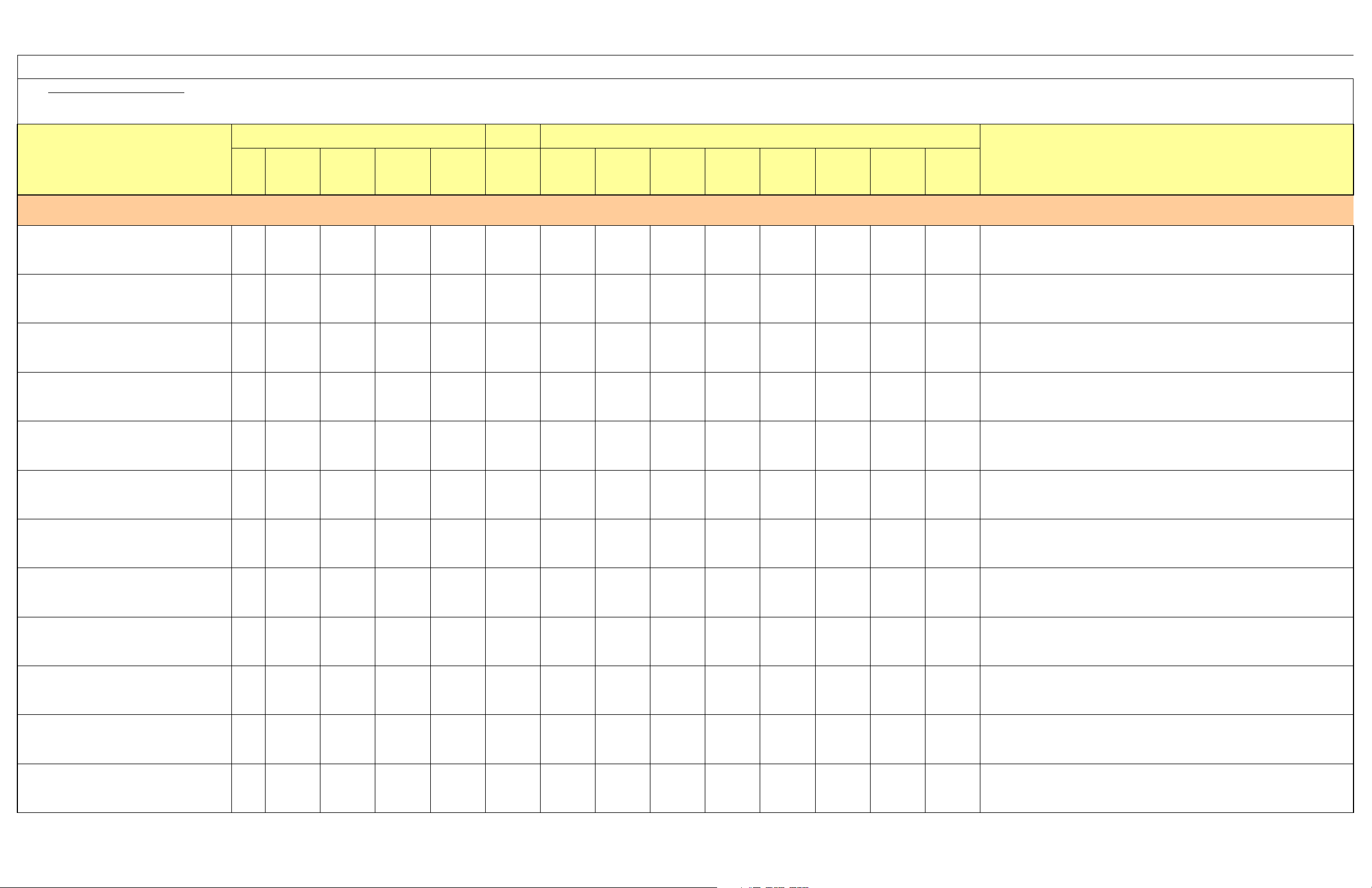

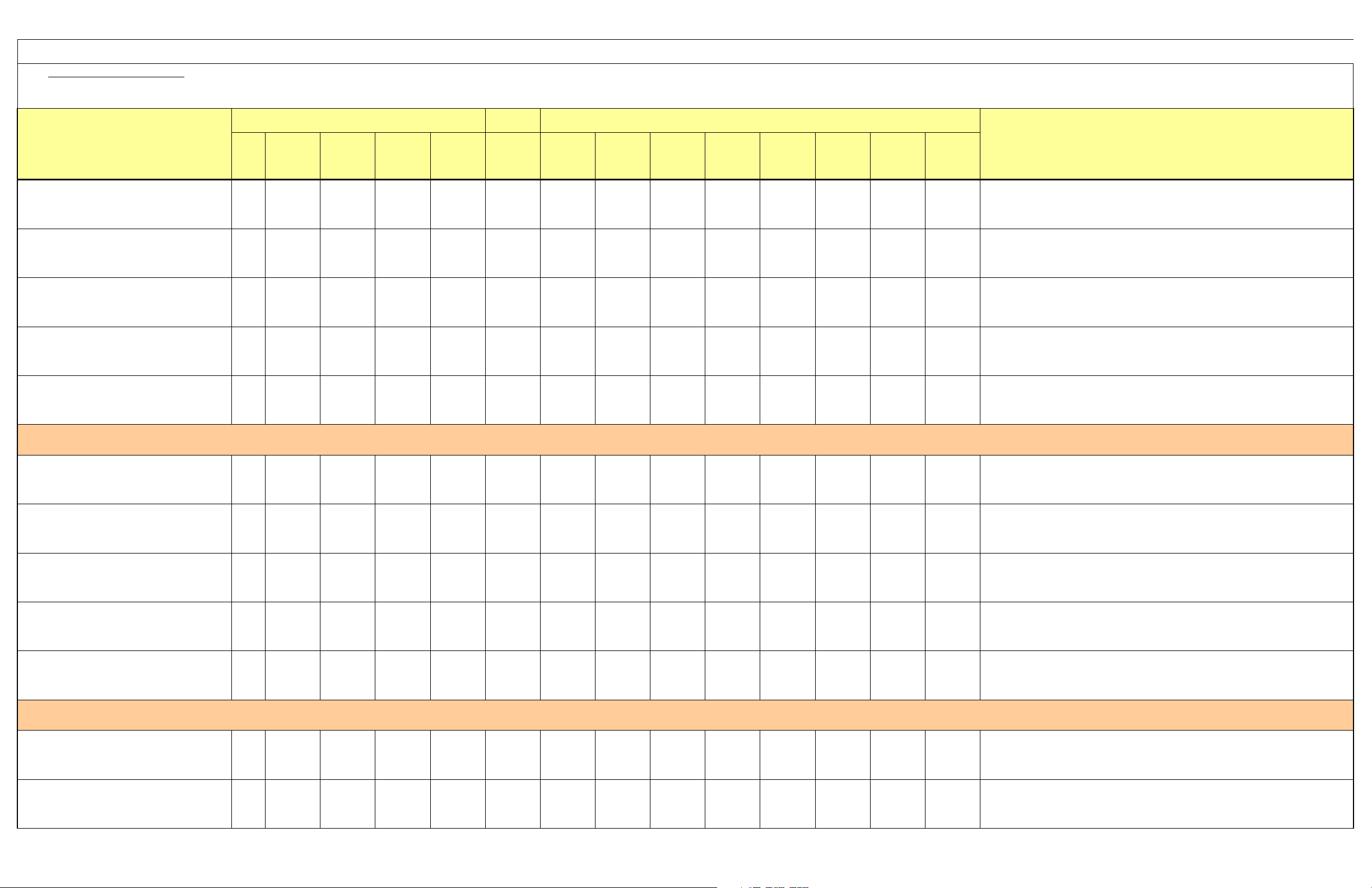

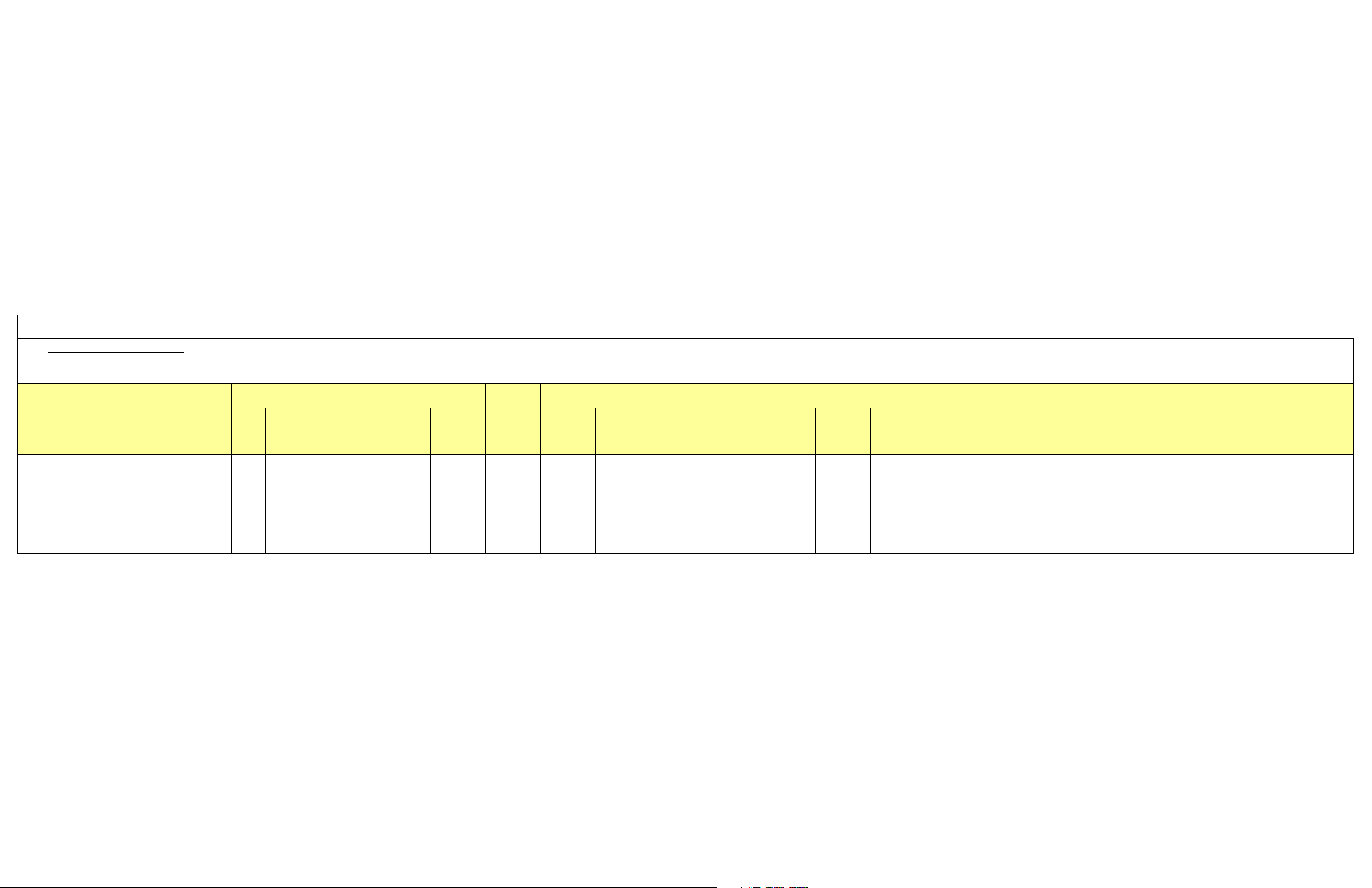

iGen3 Digital Production Press Guaranteed Media List - Europe - April 2010

The Xerox Guaranteed Media List contains Xerox paper and specialty media that has been extensively tested on the Xerox iGen3 90/100/110 Digital Production Press for image quality and performance. All Xerox paper and specialty media on this list are digitally optimized, designed

and manufactured for optimal performance in Xerox digital printing equipment. Our extensive testing and stringent specifications ensure that we are able to guarantee the performance and consistency of Xerox paper and specialty media. Xerox paper and specialty media are tested

and qualified by Xerox laboratories to guarantee consistent quality.

Grammage

Weight (gsm)

Weight of the

paper in grams

per square meter

Sides Coated Coating Type Type Sequence Color

Thickness

(microns)

Best Practices for Operation

Cleanup FinishOther Size

It is imperative to utilize the bolded, abbreviated stock name for

easy migration to future enhancements to the stock library and

Stock Library Name (Full Media Name)

media management tools.

Uncoated Papers

Drilled

Standard cut sizes

A4 A3 SRA3

XeroxColourImpress 80

(Xerox Colour Impressions 80 gsm)

XeroxColotech+GLD90

(Xerox Colotech + Gold 90 gsm)

XeroxColotech+GLD904HD

(Xerox Colotech + GOLD 90 gsm 4 Holed Drilled)

XeroxColotech+ 90

(Xerox Colotech + 90 gsm)

XeroxColotech+ 904HD

(Xerox Colotech + 90 gsm 4 Hole Drilled)

XeroxColourImpress 90

(Xerox Colour Impressions 90 gsm)

XeroxColotech+GLD100

(Xerox Colotech + GOLD 100 gsm)

003R97661 003R97662 80 Uncoated N/A Plain 0 White 91 Yes Regular This media may have a mottled appearance due to poor paper formation (image density and gloss).

003R97988 003R97990 003R97991 90 Uncoated N/A Plain 0 White 101 Yes Regular This media may have a mottled appearance due to poor paper formation (image density and gloss).

Yes 003R97989 90 Uncoated N/A Plain 0 White 101 Yes Regular

003R94641 003R94642 003R95838 90 Uncoated N/A Plain 0 White 97 Yes Regular This media may have a mottled appearance due to poor paper formation (image density and gloss).

Yes 003R97673 90 Uncoated N/A Plain 0 White 97 Yes Regular

003R97663 003R97664 003R97665 90 Uncoated N/A Plain 0 White 98 Yes Regular This media may have a mottled appearance due to poor paper formation (image density and gloss).

003R97993 003R97955 003R97956 100 Uncoated N/A Plain 0 White 110 Yes Regular This media may have a mottled appearance due to poor paper formation (image density and gloss).

If Transfer set point adjustments are required for snow defects, refer to the Snow Sample Artifact Procedure in the

Stack quality and stack height may be affected due to media structure or high area coverage.

This media may have a mottled appearance due to poor paper formation (image density and gloss).

Stack quality and stack height may be affected due to media structure or high area coverage.

latest Customer Maintenance Manual Section 3.

XeroxColotech+GLD1004HD

(Xerox Colotech + Gold 100 gsm 4 Hole Drilled)

XeroxColotech+ 100

(Xerox Colotech + 100 gsm)

XeroxColotech+ 1004HD

(Xerox Colotech + 100 gsm 4 Hole Drilled)

XeroxColotech+ NW 100

(Xerox Colotech + Natural White 100 gsm)

XeroxColourImpress 100

(Xerox Colour Impressions 100 gsm)

Yes 003R97954 100 Uncoated N/A Plain 0 White 110 Yes Regular

003R94646 003R94647 003R95839

Yes 003R97674 100 Uncoated N/A Plain 0 White 110 Yes Regular

003R97102 003R97103 003R97275 100 Uncoated N/A Plain 0 White 109 Yes Regular

003R97666 003R97667 003R97668 100 Uncoated N/A Plain 0 White 110 Yes Regular This media may have a mottled appearance due to poor paper formation (image density and gloss).

003R94648

(A3+)

(305 x 457mm)

100 Uncoated N/A Plain 0 White 110 Yes Regular

If Transfer set point adjustments are required for snow defects, refer to the Snow Sample Artifact Procedure in the

Stack quality and stack height may be affected due to media structure or high area coverage.

If Transfer set point adjustments are required for snow defects, refer to the Snow Sample Artifact Procedure in the

If Transfer set point adjustments are required for snow defects, refer to the Snow Sample Artifact Procedure in the

latest Customer Maintenance Manual Section 3.

latest Customer Maintenance Manual Section 3.

latest Customer Maintenance Manual Section 3.

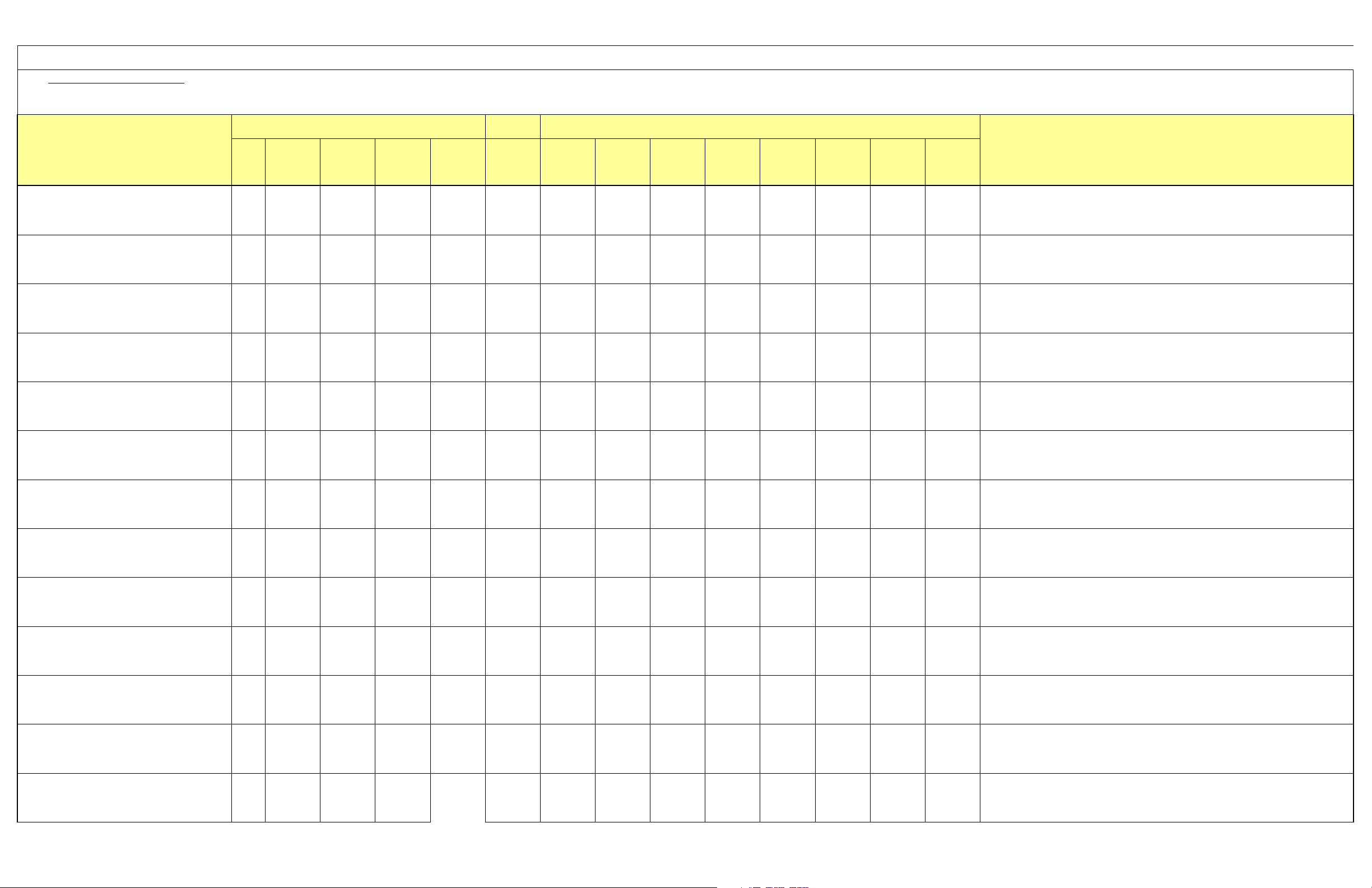

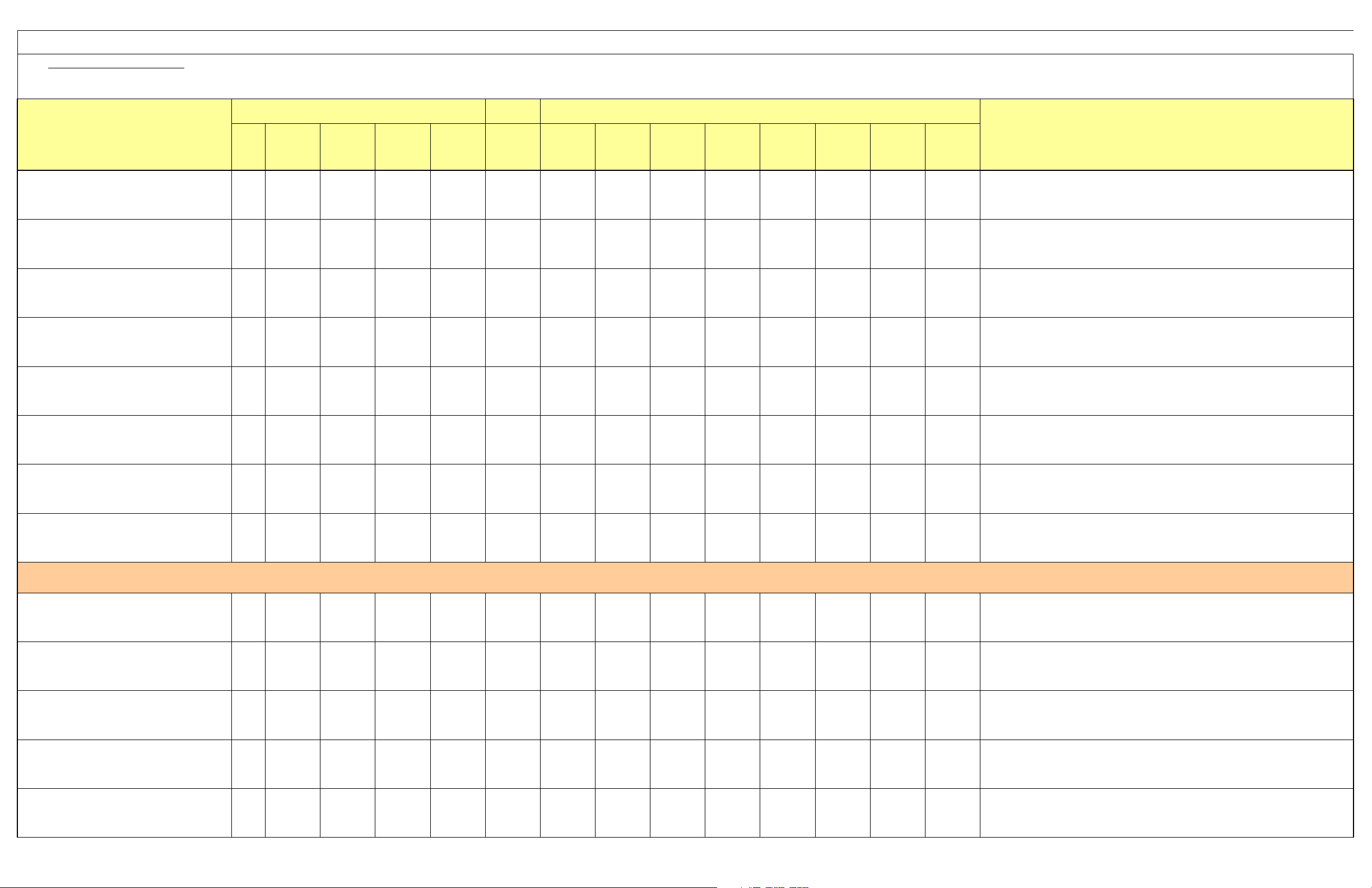

Page 3

2 of 22 Revision Nov 2008

iGen3 Digital Production Press Guaranteed Media List - Europe - April 2010

The Xerox Guaranteed Media List contains Xerox paper and specialty media that has been extensively tested on the Xerox iGen3 90/100/110 Digital Production Press for image quality and performance. All Xerox paper and specialty media on this list are digitally optimized, designed

and manufactured for optimal performance in Xerox digital printing equipment. Our extensive testing and stringent specifications ensure that we are able to guarantee the performance and consistency of Xerox paper and specialty media. Xerox paper and specialty media are tested

and qualified by Xerox laboratories to guarantee consistent quality.

Grammage

Weight (gsm)

Weight of the

paper in grams

per square meter

Sides Coated Coating Type Type Sequence Color

Thickness

(microns)

Best Practices for Operation

Cleanup FinishOther Size

It is imperative to utilize the bolded, abbreviated stock name for

easy migration to future enhancements to the stock library and

Stock Library Name (Full Media Name)

media management tools.

Drilled

Standard cut sizes

A4 A3 SRA3

XeroxColotech+GLD120

(Xerox Colotech + GOLD 120 gsm)

XeroxColotech+ 120

(Xerox Colotech + 120 gsm)

XeroxColourImpress 120

(Xerox Colour Impressions 120 gsm)

XeroxColotech+GLD160

(Xerox Colotech + GOLD 160 gsm)

XeroxColourImpress 160

(Xerox Colour Impressions 160 gsm)

XeroxColotech+ 160

(Xerox Colotech + 160 gsm)

XeroxColotech+ NW 160

(Xerox Colotech + Natural White 160 gsm)

003R97958 003R97959 003R97960

003R94651 003R94652 003R95840

003R98685 003R97669 003R97670 120 Uncoated N/A Plain 0 White 125 Yes Regular This media may have a mottled appearance due to poor paper formation (image density and gloss).

003R97963 003R97964 003R97965 160 Uncoated N/A Plain 0 White 158 Yes Regular This media may have a mottled appearance due to poor paper formation (image density and gloss).

003R98007 003R98008 003R98686 160 Uncoated N/A Plain 0 White 170 Yes Regular This media may have a mottled appearance due to poor paper formation (image density and gloss).

003R94656 003R94657 003R94658 003R95841 160 Uncoated N/A Plain 0 White 170 Yes Regular

003R95956 003R95957 003R97276 160 Uncoated N/A Plain 0 White 157 Yes Regular

003R97961

(iGen3 Max Size)

(364 x 521mm)

003R94653

(A3+)

(305 x 457mm)

120 Uncoated N/A Plain 0 White 125 Yes Regular This media may have a mottled appearance due to poor paper formation (image density and gloss).

120 Uncoated N/A Plain 0 White 129 Yes Regular

If Transfer set point adjustments are required for snow defects, refer to the Snow Sample Artifact Procedure in the

If Transfer set point adjustments are required for snow defects, refer to the Snow Sample Artifact Procedure in the

latest Customer Maintenance Manual Section 3.

latest Customer Maintenance Manual Section 3.

XeroxColotech+GLD200

(Xerox Colotech + GOLD 200 gsm)

XeroxColotech+ 200

(Xerox Colotech + 200 gsm)

XeroxColotech+ NW 200

(Xerox Colotech + Natural White 200 gsm)

XeroxColotech+GLD220

(Xerox Colotech + GOLD 220 gsm)

XeroxColotech+ 220

(Xerox Colotech + 220 gsm)

XeroxColotech+GLD250

(Xerox Colotech + GOLD 250 gsm)

003R97967 003R97968 003R97969 200 Uncoated N/A Plain 0 White 196 Yes Regular This media may have a mottled appearance due to poor paper formation (image density and gloss).

003R94661 003R94662 003R95842

003R95958 003R95959 003R97277 200 Uncoated N/A Plain 0 White 207 Yes Regular

003R97971 003R97972 003R97973 220 Uncoated N/A Plain 0 White 215 Yes Regular This media may have a mottled appearance due to poor paper formation (image density and gloss).

003R94668 003R94669 003R95843

003R97975 003R97976 003R97977 250 Uncoated N/A Plain 0 White 245 Yes Regular This media may have a mottled appearance due to poor paper formation (image density and gloss).

003R94663

(A3+)

(305 x 457mm)

003R94670

(A3+)

(305 x 457mm)

200 Uncoated N/A Plain 0 White 216 Yes Regular

220 Uncoated N/A Plain 0 White 239 Yes Regular

If Transfer set point adjustments are required for snow defects, refer to the Snow Sample Artifact Procedure in the

If Transfer set point adjustments are required for snow defects, refer to the Snow Sample Artifact Procedure in the

latest Customer Maintenance Manual Section 3.

latest Customer Maintenance Manual Section 3.

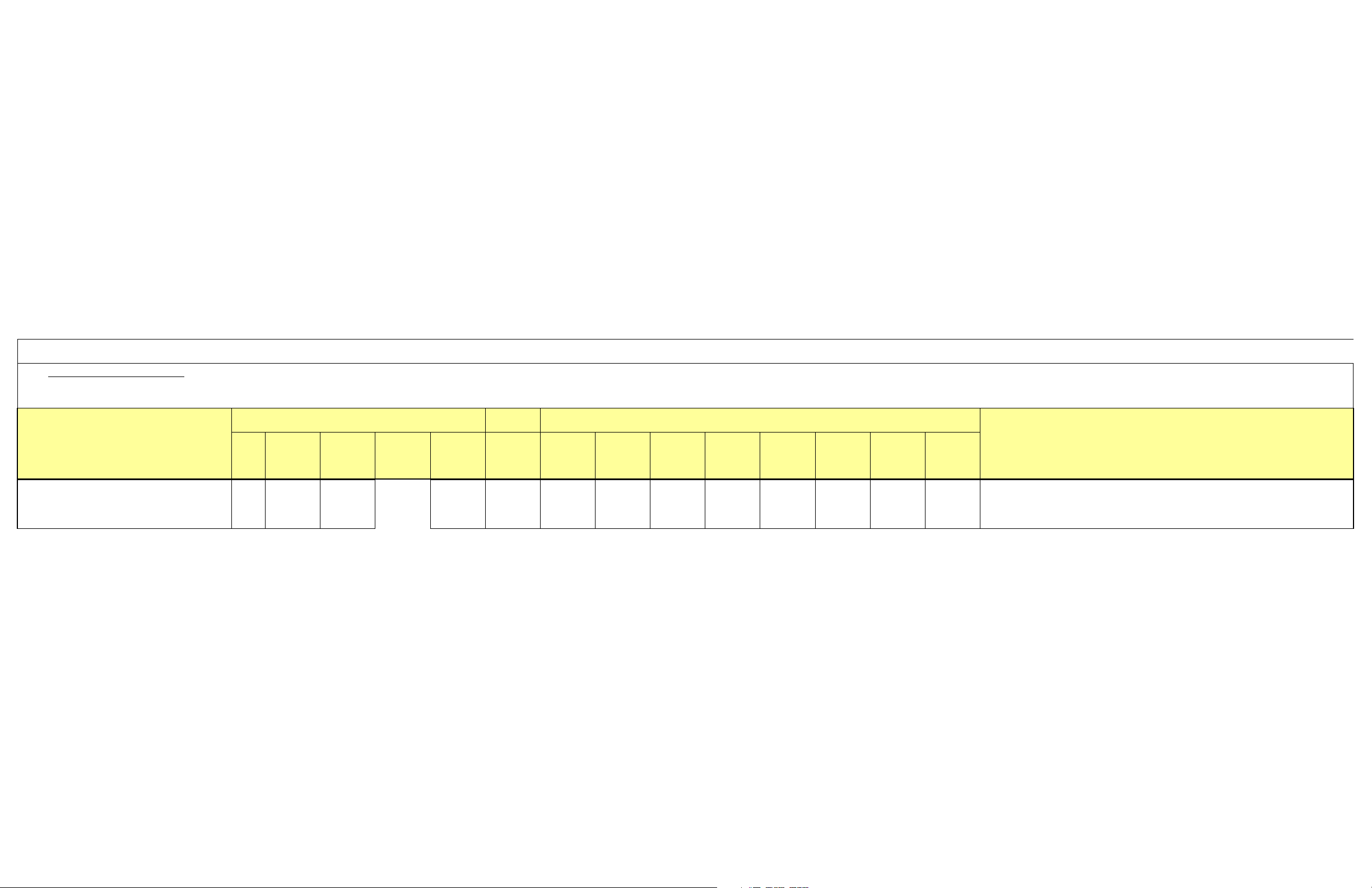

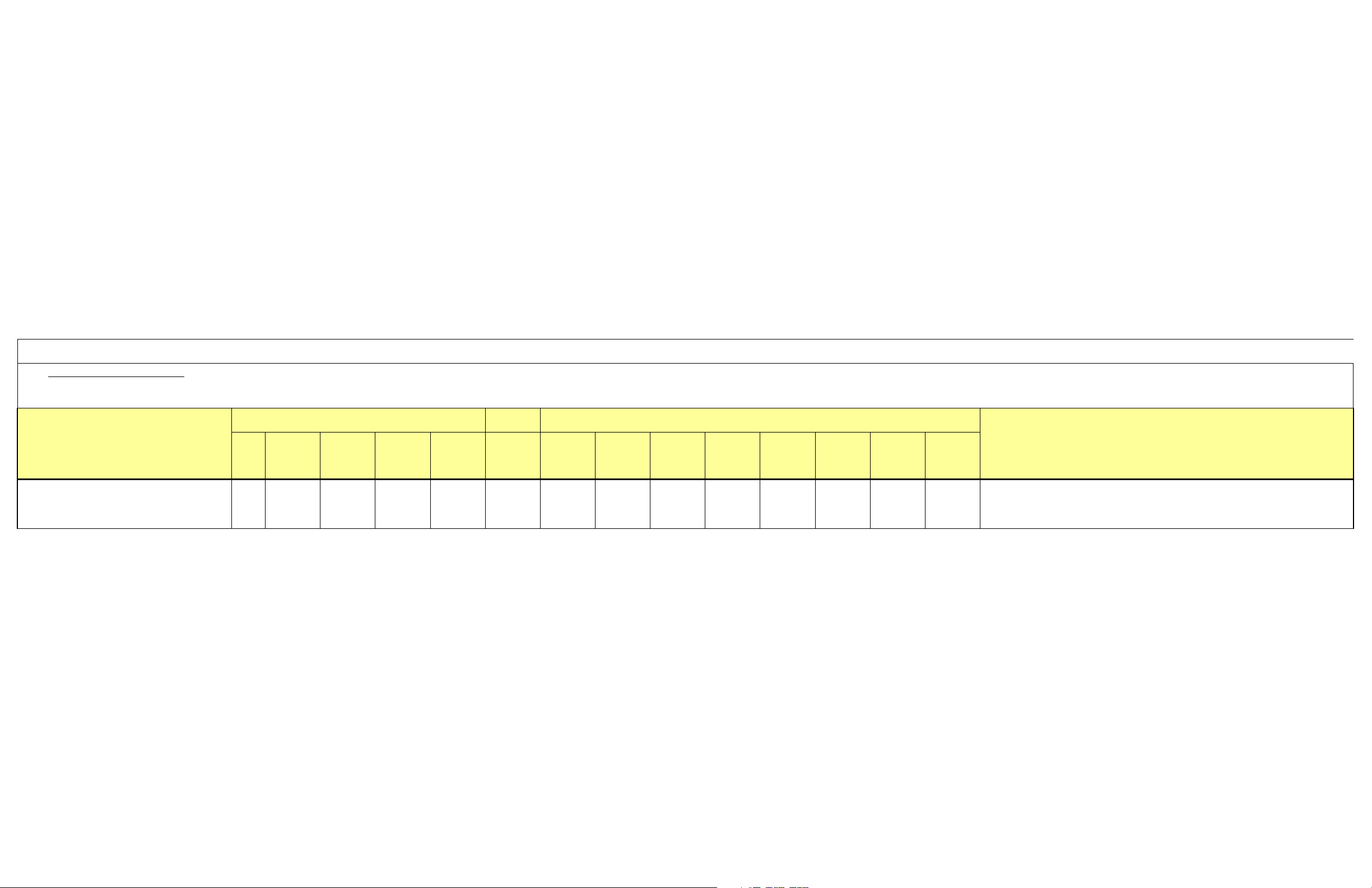

Page 4

3 of 22 Revision Nov 2008

iGen3 Digital Production Press Guaranteed Media List - Europe - April 2010

The Xerox Guaranteed Media List contains Xerox paper and specialty media that has been extensively tested on the Xerox iGen3 90/100/110 Digital Production Press for image quality and performance. All Xerox paper and specialty media on this list are digitally optimized, designed

and manufactured for optimal performance in Xerox digital printing equipment. Our extensive testing and stringent specifications ensure that we are able to guarantee the performance and consistency of Xerox paper and specialty media. Xerox paper and specialty media are tested

and qualified by Xerox laboratories to guarantee consistent quality.

Grammage

Weight (gsm)

Weight of the

paper in grams

per square meter

250 Uncoated N/A Plain 0 White 249 Yes Regular

Sides Coated Coating Type Type Sequence Color

Thickness

(microns)

Cleanup FinishOther Size

Best Practices for Operation

If Transfer set point adjustments are required for snow defects, refer to the Snow Sample Artifact Procedure in the

latest Customer Maintenance Manual Section 3.

It is imperative to utilize the bolded, abbreviated stock name for

easy migration to future enhancements to the stock library and

Stock Library Name (Full Media Name)

media management tools.

XeroxColotech+ 250

(Xerox Colotech + 250 gsm)

Drilled

Standard cut sizes

A4 A3 SRA3

003R94671 003R94672 003R95844

003R94673

(A3+)

(305 x 457mm)

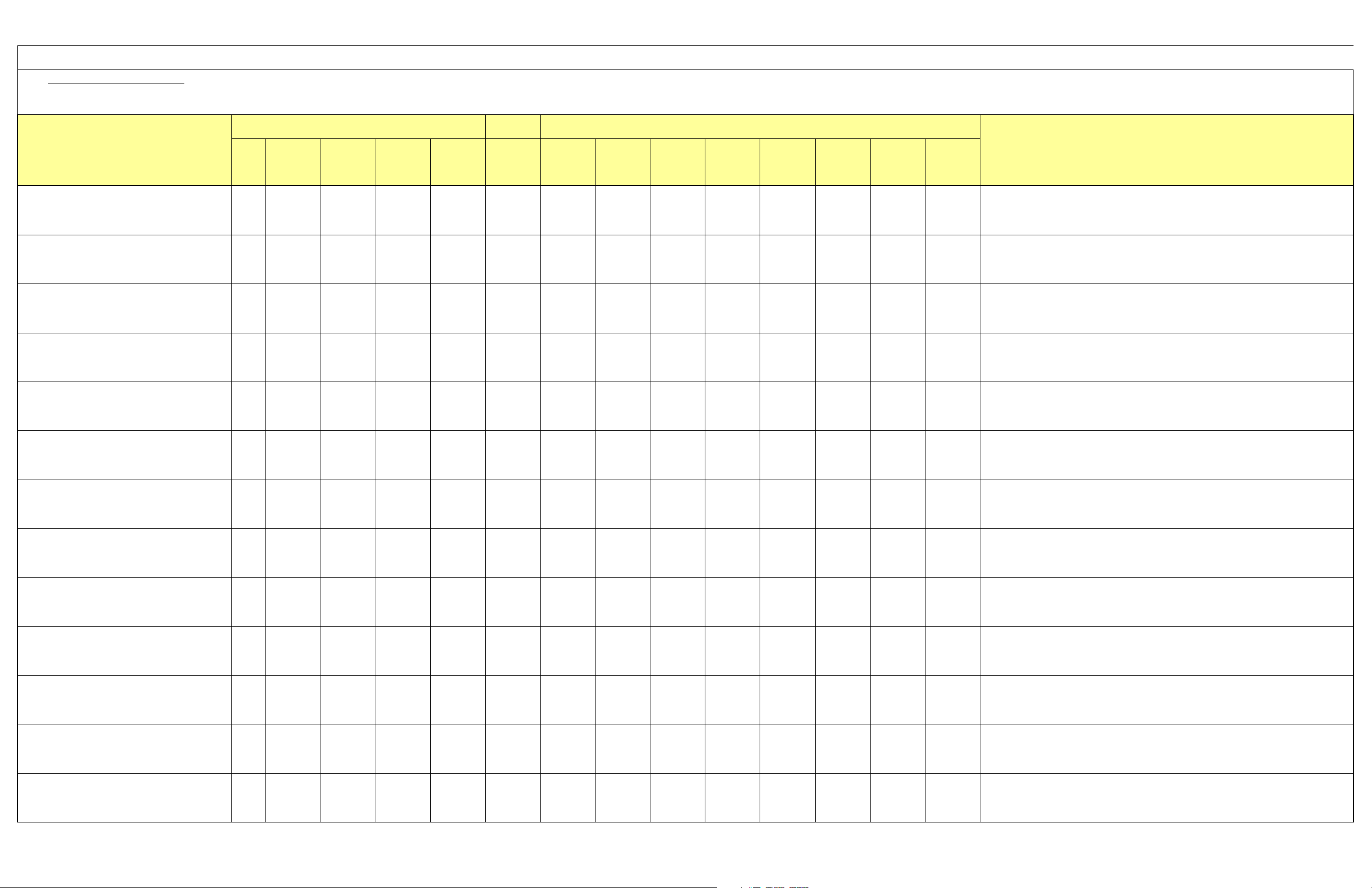

Page 5

4 of 22 Revision Nov 2008

iGen3 Digital Production Press Guaranteed Media List - Europe - April 2010

The Xerox Guaranteed Media List contains Xerox paper and specialty media that has been extensively tested on the Xerox iGen3 90/100/110 Digital Production Press for image quality and performance. All Xerox paper and specialty media on this list are digitally optimized, designed

and manufactured for optimal performance in Xerox digital printing equipment. Our extensive testing and stringent specifications ensure that we are able to guarantee the performance and consistency of Xerox paper and specialty media. Xerox paper and specialty media are tested

and qualified by Xerox laboratories to guarantee consistent quality.

Grammage

Weight (gsm)

Weight of the

paper in grams

per square meter

Sides Coated Coating Type Type Sequence Color

Thickness

(microns)

Best Practices for Operation

Cleanup FinishOther Size

It is imperative to utilize the bolded, abbreviated stock name for

easy migration to future enhancements to the stock library and

Stock Library Name (Full Media Name)

media management tools.

Drilled

Standard cut sizes

A4 A3 SRA3

XeroxColourImpress 250

(Xerox Colour Impressions 250 gsm)

XeroxColotech+GLD280

(Xerox Colotech + GOLD 280 gsm)

XeroxColotech+ 280

(Xerox Colotech + 280 gsm)

XeroxColotech+GLD300

(Xerox Colotech + GOLD 300 gsm)

XeroxColotech+GLD350

(Xerox Colotech + GOLD 350 gsm)

Coated Two Side C2S

XeroxColotech+ G 120

(Xerox Colotech + Gloss Coated 120 gsm)

XeroxColotech+ S 120

(Xerox Colotech + Silk Coated 120 gsm)

003R98687 003R97671 003R97672 250 Uncoated N/A Plain 0 White 250 Yes Regular This media may have a mottled appearance due to poor paper formation (image density and gloss).

003R97979 003R97980 003R97981 280 Uncoated N/A Plain 0 White 270 Yes Regular This media may have a mottled appearance due to poor paper formation (image density and gloss).

003R97097 003R97098 003R97099

003R97983 003R97984 003R97985

003R98625

003R97574 003R97575 003R97576 120

003R97592 003R97593 003R97594 120

003R97660

(iGen3 Max Size)

(364 x 521mm)

003R97986

(iGen3 Max Size)

(364 x 521mm)

003R98626

(iGen3 Max Size)

(364 x 521mm)

280 Uncoated N/A Plain 0 White 291 Yes Regular

300 Uncoated N/A Plain 0 White 300 Yes Regular This media may have a mottled appearance due to poor paper formation (image density and gloss).

350 Uncoated N/A Plain 0 White 350 Yes Regular This media may have a mottled appearance due to poor paper formation (image density and gloss).

Coated Two

Sides

Coated Two

Sides

Gloss Plain 0 White 96 Yes Smooth

Semi-gloss Plain 0 White 115 Yes Smooth

If Transfer set point adjustments are required for snow defects, refer to the Snow Sample Artifact Procedure in the

latest Customer Maintenance Manual Section 3.

XeroxColourImpresG120

(Xerox Colour Impressions Gloss 120 gsm)

XeroxColotech+ G 140

(Xerox Colotech + Gloss Coated 140 gsm)

XeroxColotech+ S 140

(Xerox Colotech + Silk Coated 140 gsm)

Coated Two Side Heavy C2S

XeroxColotech+ G 170

(Xerox Colotech + Gloss Coated 170 gsm)

XeroxColotech+ S 170

(Xerox Colotech + Silk Coated 170 gsm)

003R97886 003R97887

003R97577 003R97578 003R97579 140

003R97595 003R97596 003R97597 140

003R97580 003R97581 003R97582 170

003R97598 003R97599 003R97600 170

003R97888

(iGen3 Max Size)

(364 x 521mm)

120

Coated Two

Sides

Coated Two

Sides

Coated Two

Sides

Coated Two

Sides

Coated Two

Sides

Gloss Plain 0 White 96 Yes Smooth

Gloss Plain 0 White 118 Yes Smooth

Semi-gloss Plain 0 White 135 Yes Smooth

Gloss Plain 0 White 144 Yes Smooth

Semi-gloss Plain 0 White 164 Yes Smooth

Page 6

5 of 22 Revision Nov 2008

iGen3 Digital Production Press Guaranteed Media List - Europe - April 2010

The Xerox Guaranteed Media List contains Xerox paper and specialty media that has been extensively tested on the Xerox iGen3 90/100/110 Digital Production Press for image quality and performance. All Xerox paper and specialty media on this list are digitally optimized, designed

and manufactured for optimal performance in Xerox digital printing equipment. Our extensive testing and stringent specifications ensure that we are able to guarantee the performance and consistency of Xerox paper and specialty media. Xerox paper and specialty media are tested

and qualified by Xerox laboratories to guarantee consistent quality.

Grammage

Weight (gsm)

Weight of the

paper in grams

per square meter

210

Sides Coated Coating Type Type Sequence Color

Coated Two

Sides

Gloss Plain 0 White 181 Yes Smooth

Thickness

(microns)

Best Practices for Operation

Cleanup FinishOther Size

It is imperative to utilize the bolded, abbreviated stock name for

easy migration to future enhancements to the stock library and

Stock Library Name (Full Media Name)

media management tools.

XeroxColotech+ G 210

(Xerox Colotech + Gloss Coated 210 gsm)

Drilled

Standard cut sizes

A4 A3 SRA3

003R97583 003R97584 003R97585

003R11326

(iGen3 Max Size)

(364 x 521mm)

Page 7

6 of 22 Revision Nov 2008

iGen3 Digital Production Press Guaranteed Media List - Europe - April 2010

The Xerox Guaranteed Media List contains Xerox paper and specialty media that has been extensively tested on the Xerox iGen3 90/100/110 Digital Production Press for image quality and performance. All Xerox paper and specialty media on this list are digitally optimized, designed

and manufactured for optimal performance in Xerox digital printing equipment. Our extensive testing and stringent specifications ensure that we are able to guarantee the performance and consistency of Xerox paper and specialty media. Xerox paper and specialty media are tested

and qualified by Xerox laboratories to guarantee consistent quality.

Grammage

Weight (gsm)

Weight of the

paper in grams

per square meter

Sides Coated Coating Type Type Sequence Color

Thickness

(microns)

Best Practices for Operation

Cleanup FinishOther Size

It is imperative to utilize the bolded, abbreviated stock name for

easy migration to future enhancements to the stock library and

Stock Library Name (Full Media Name)

media management tools.

Drilled

Standard cut sizes

A4 A3 SRA3

XeroxColotech+ S 210

(Xerox Colotech + Silk Coated 210 gsm)

XeroxColourImpresG210

(Xerox Colour Impressions Gloss 210 gsm)

XeroxColotech+ G 250

(Xerox Colotech + Gloss Coated 250 gsm)

XeroxColotech+ S 250

(Xerox Colotech + Silk Coated 250 gsm)

XeroxColotech+ G 280

(Xerox Colotech + Gloss Coated 280 gsm)

XeroxColotech+ S 280

(Xerox Colotech+ Silk Coated 280 gsm)

XeroxColotech+ G 350

(Xerox Colotech + Gloss Coated 350 gsm)

003R97601 003R97602 003R97603

003R97889 003R97890

003R97586 003R97587 003R97588 250

003R97604 003R97605 003R97606 250

003R97589 003R97590 003R97591

003R97607 003R97608 003R97609

003R98701 350

003R11350

(iGen3 Max Size)

(364 x 521mm)

003R97891

(iGen3 Max Size)

(364 x 521mm)

003R11327

(iGen3 Max Size)

(364 x 521mm)

003R11351

(iGen3 Max Size)

(364 x 521mm)

210

210

280

280

Coated Two

Sides

Coated Two

Sides

Coated Two

Sides

Coated Two

Sides

Coated Two

Sides

Coated Two

Sides

Coated Two

Sides

Semi-gloss Plain 0 White 203 Yes Smooth

Gloss Plain 0 White 183 Yes Smooth

Gloss Plain 0 White 212 Yes Smooth

Semi-gloss Plain 0 White 242 Yes Smooth

Gloss Plain 0 White 249 Yes Smooth

Semi-gloss Plain 0 White 272 Yes Smooth

Gloss Plain 0 White 309 Yes Smooth

(Xerox Colotech+ Silk Coated 350 gsm)

Specialties- Labels

(Xerox High Speed Laser Labels 1 up)

(Xerox High Speed Laser Labels 8 up)

(Xerox High Speed Laser Labels 10 up)

(Xerox High Speed Laser Labels 16 up)

(Xerox High Speed Laser Labels 24 up)

XeroxColotech+ S 350

XeroxLabelHSLL 1up

XeroxLabelHSLL 8up

XeroxLabelHSLL 10up

XeroxLabelHSLL 16up

XeroxLabelHSLL 24up

003R98700 350

003R96169 140 Uncoated N/A Plain 0 White 164 No Smooth

003R96283 140 Uncoated N/A Plain 0 White 164 No Smooth

003R96284 140 Uncoated N/A Plain 0 White 164 No Smooth

003R96281 140 Uncoated N/A Plain 0 White 164 No Smooth

003R96282 140 Uncoated N/A Plain 0 White 164 No Smooth

Coated Two

Sides

Gloss Plain 0 White 312 Yes Smooth

Imaging over die cuts or label edges may adversely affect fuser roll life.

Imaging over die cuts or label edges may adversely affect fuser roll life.

Imaging over die cuts or label edges may adversely affect fuser roll life.

Imaging over die cuts or label edges may adversely affect fuser roll life.

Imaging over die cuts or label edges may adversely affect fuser roll life.

Simplex only recommended.

Simplex only recommended.

Simplex only recommended.

Simplex only recommended.

Simplex only recommended.

Page 8

7 of 22 Revision Nov 2008

iGen3 Digital Production Press Guaranteed Media List - Europe - April 2010

The Xerox Guaranteed Media List contains Xerox paper and specialty media that has been extensively tested on the Xerox iGen3 90/100/110 Digital Production Press for image quality and performance. All Xerox paper and specialty media on this list are digitally optimized, designed

and manufactured for optimal performance in Xerox digital printing equipment. Our extensive testing and stringent specifications ensure that we are able to guarantee the performance and consistency of Xerox paper and specialty media. Xerox paper and specialty media are tested

and qualified by Xerox laboratories to guarantee consistent quality.

Grammage

Weight (gsm)

Weight of the

paper in grams

per square meter

Sides Coated Coating Type Type Sequence Color

Thickness

(microns)

Best Practices for Operation

Cleanup FinishOther Size

Imaging over die cuts or label edges may adversely affect fuser roll life.

Simplex only recommended.

It is imperative to utilize the bolded, abbreviated stock name for

easy migration to future enhancements to the stock library and

Stock Library Name (Full Media Name)

media management tools.

(Xerox Labels White with Rounded Corners 1 up)

XeroxLabelWRC 1up

Drilled

Standard cut sizes

A4 A3 SRA3

003R91225 140 Uncoated N/A Plain 0 White 146 No Smooth

Page 9

8 of 22 Revision Nov 2008

iGen3 Digital Production Press Guaranteed Media List - Europe - April 2010

The Xerox Guaranteed Media List contains Xerox paper and specialty media that has been extensively tested on the Xerox iGen3 90/100/110 Digital Production Press for image quality and performance. All Xerox paper and specialty media on this list are digitally optimized, designed

and manufactured for optimal performance in Xerox digital printing equipment. Our extensive testing and stringent specifications ensure that we are able to guarantee the performance and consistency of Xerox paper and specialty media. Xerox paper and specialty media are tested

and qualified by Xerox laboratories to guarantee consistent quality.

Grammage

Weight (gsm)

Weight of the

paper in grams

per square meter

Sides Coated Coating Type Type Sequence Color

Thickness

(microns)

Best Practices for Operation

Cleanup FinishOther Size

It is imperative to utilize the bolded, abbreviated stock name for

easy migration to future enhancements to the stock library and

Stock Library Name (Full Media Name)

media management tools.

Drilled

Standard cut sizes

A4 A3 SRA3

(Xerox Labels White with Rounded Corners 2 up)

(Xerox Labels White with Rounded Corners 6 up)

(Xerox Labels White with Rounded Corners 8 up)

(Xerox Labels White with Rounded Corners 14 up)

(Xerox Labels White with Rounded Corners 15 up)

(Xerox Labels White with Rounded Corners 16 up)

(Xerox Labels White with Rounded Corners 18 up)

XeroxLabelWRC 2up

XeroxLabelWRC 6up

XeroxLabelWRC 8up

XeroxLabelWRC 14up

XeroxLabelWRC 15up

XeroxLabelWRC 16up

XeroxLabelWRC 18up

003R97525 140 Uncoated N/A Plain 0 White 146 No Smooth

003R96288 140 Uncoated N/A Plain 0 White 146 No Smooth

003R91224 140 Uncoated N/A Plain 0 White 146 No Smooth

003R96289 140 Uncoated N/A Plain 0 White 146 No Smooth

003R97259 140 Uncoated N/A Plain 0 White 146 No Smooth

003R96296 140 Uncoated N/A Plain 0 White 146 No Smooth

003R96297 140 Uncoated N/A Plain 0 White 146 No Smooth

Imaging over die cuts or label edges may adversely affect fuser roll life.

Imaging over die cuts or label edges may adversely affect fuser roll life.

Imaging over die cuts or label edges may adversely affect fuser roll life.

Imaging over die cuts or label edges may adversely affect fuser roll life.

Imaging over die cuts or label edges may adversely affect fuser roll life.

Imaging over die cuts or label edges may adversely affect fuser roll life.

Imaging over die cuts or label edges may adversely affect fuser roll life.

Simplex only recommended.

Simplex only recommended.

Simplex only recommended.

Short Edge Feed recommended.

Simplex only recommended.

Short Edge Feed recommended.

Simplex only recommended.

Short Edge Feed recommended.

Simplex only recommended.

Short Edge Feed recommended.

Simplex only recommended.

Short Edge Feed recommended.

(Xerox Labels White with Rounded Corners 21 up)

(Xerox Labels White with Rounded Corners 24 up)

(Xerox Labels White with Rounded Corners 65 up)

XeroxLabelWRC 21up

XeroxLabelWRC 24up

XeroxLabelWRC 65up

XeroxLabelCL 1up

(Xerox Colour Laser Labels 1 up)

XeroxLabelCL 4up

(Xerox Colour Laser Labels 4 up)

XeroxLabelCL 6up

(Xerox Colour Laser Labels 6 up)

003R96298 140 Uncoated N/A Plain 0 White 146 No Smooth

003R97526 140 Uncoated N/A Plain 0 White 146 No Smooth

003R93177 140 Uncoated N/A Plain 0 White 146 No Smooth

003R93872 160 Uncoated N/A Plain 0 White 165 No Regular

003R95813 160 Uncoated N/A Plain 0 White 165 No Regular

003R93873 160 Uncoated N/A Plain 0 White 165 No Regular

Imaging over die cuts or label edges may adversely affect fuser roll life.

Imaging over die cuts or label edges may adversely affect fuser roll life.

Imaging over die cuts or label edges may adversely affect fuser roll life.

Imaging over die cuts or label edges may adversely affect fuser roll life.

Imaging over die cuts or label edges may adversely affect fuser roll life.

Imaging over die cuts or label edges may adversely affect fuser roll life.

Simplex only recommended.

Short Edge Feed recommended.

Simplex only recommended.

Short Edge Feed recommended.

Simplex only recommended.

Short Edge Feed recommended.

Simplex only recommended.

Simplex only recommended.

Simplex only recommended.

Short Edge Feed recommended.

Page 10

9 of 22 Revision Nov 2008

iGen3 Digital Production Press Guaranteed Media List - Europe - April 2010

The Xerox Guaranteed Media List contains Xerox paper and specialty media that has been extensively tested on the Xerox iGen3 90/100/110 Digital Production Press for image quality and performance. All Xerox paper and specialty media on this list are digitally optimized, designed

and manufactured for optimal performance in Xerox digital printing equipment. Our extensive testing and stringent specifications ensure that we are able to guarantee the performance and consistency of Xerox paper and specialty media. Xerox paper and specialty media are tested

and qualified by Xerox laboratories to guarantee consistent quality.

Grammage

Weight (gsm)

Weight of the

paper in grams

per square meter

Sides Coated Coating Type Type Sequence Color

Thickness

(microns)

Best Practices for Operation

Cleanup FinishOther Size

It is imperative to utilize the bolded, abbreviated stock name for

easy migration to future enhancements to the stock library and

Stock Library Name (Full Media Name)

media management tools.

Drilled

Standard cut sizes

A4 A3 SRA3

XeroxLabelCL 8up

(Xerox Colour Laser Labels 8 up)

XeroxLabelCL 14up

(Xerox Colour Laser Labels 14 up)

003R93874 160 Uncoated N/A Plain 0 White 165 No Regular

003R93875 160 Uncoated N/A Plain 0 White 165 No Regular

Imaging over die cuts or label edges may adversely affect fuser roll life.

Imaging over die cuts or label edges may adversely affect fuser roll life.

Simplex only recommended.

Short Edge Feed recommended.

Simplex only recommended.

Short Edge Feed recommended.

Page 11

10 of 22 Revision Nov 2008

iGen3 Digital Production Press Guaranteed Media List - Europe - April 2010

The Xerox Guaranteed Media List contains Xerox paper and specialty media that has been extensively tested on the Xerox iGen3 90/100/110 Digital Production Press for image quality and performance. All Xerox paper and specialty media on this list are digitally optimized, designed

and manufactured for optimal performance in Xerox digital printing equipment. Our extensive testing and stringent specifications ensure that we are able to guarantee the performance and consistency of Xerox paper and specialty media. Xerox paper and specialty media are tested

and qualified by Xerox laboratories to guarantee consistent quality.

Grammage

Weight (gsm)

Weight of the

paper in grams

per square meter

Sides Coated Coating Type Type Sequence Color

Thickness

(microns)

Best Practices for Operation

Cleanup FinishOther Size

It is imperative to utilize the bolded, abbreviated stock name for

easy migration to future enhancements to the stock library and

Stock Library Name (Full Media Name)

media management tools.

Drilled

Standard cut sizes

A4 A3 SRA3

XeroxLabelCL 21up

(Xerox Colour Laser Labels 21 up)

XeroxLabelCL 24up

(Xerox Colour Laser Labels 24 up)

XeroxLabelCL CD

(Xerox Colour Laser Labels CD 2 up)

Specialties- Dividers

(Xerox Colotech + Tabs 5 bank reverse collated white dividers)

(Xerox Colotech + Tabs 10 bank reverse collated white dividers)

XeroxColotechTab R5B W

XeroxColotechTab R10B W

003R95815 160 Uncoated N/A Plain 0 White 165 No Regular

003R97524 160 Uncoated N/A Plain 0 White 165 No Regular

003R97514 160 Uncoated N/A Plain 0 White 165 No Regular

003R97231

(A4+)

(223 x 297mm)

003R97232

(A4+)

(223 x 297mm)

200 Uncoated N/A Precut Tab 5 White 216 No Regular

200 Uncoated N/A Precut Tab 10 White 216 No Regular

Imaging over die cuts or label edges may adversely affect fuser roll life.

Imaging over die cuts or label edges may adversely affect fuser roll life.

Imaging over die cuts or label edges may adversely affect fuser roll life.

If Transfer set point adjustments are required for snow defects, refer to the Snow Sample Artifact Procedure in the

latest Customer Maintenance Manual Section 3.

Please check with your service representative before running. Specific feeder hardware, Tag 016F TAB Media Kit and

Tag 134T RIM 9" Firmware, (included in 1.5 machine configuration) is necessary to run tabs or dividers.

For best performance, do not image within 2 mm of tab edge.

May need to use jogger for uniform stacking.

If Transfer set point adjustments are required for snow defects, refer to the Snow Sample Artifact Procedure in the

latest Customer Maintenance Manual Section 3.

Please check with your service representative before running. Specific feeder hardware, Tag 016F TAB Media Kit and

Tag 134T RIM 9" Firmware, (included in 1.5 machine configuration) is necessary to run tabs or dividers.

For best performance, do not image within 2 mm of tab edge.

May need to use jogger for uniform stacking.

Simplex only recommended.

Short Edge Feed recommended.

Simplex only recommended.

Short Edge Feed recommended.

Simplex only recommended.

(Xerox Dividers Straight Collated 6 Bank White)

(Xerox Dividers Reverse Collated 10 Bank Rainbow)

(Xerox Dividers Reverse Collated 10 Bank White)

(Xerox Dividers Reverse Collated 12 Bank Rainbow)

(Xerox Dividers Reverse Collated 12 Bank White)

(Xerox Dividers Reverse Collated 3 Bank White)

(Xerox Dividers Reverse Collated 4 Bank White)

Xerox Dividers S6B W

XeroxDividers R10B R

XeroxDividers R10B W

XeroxDividers R12B R

XeroxDividers R12B W

XeroxDividers R3B W

XeroxDividers R4B W

003R91013

(A4+)

(223 x 297mm)

003R93988

(A4+)

(223 x 297mm)

003R91001

(A4+)

(223 x 297mm)

003R93987

(A4+)

(223 x 297mm)

003R91002

(A4+)

(223 x 297mm)

003R90871

(A4+)

(223 x 297mm)

003R90872

(A4+)

(223 x 297mm)

160 Uncoated N/A Full Cut Tab 6 White 170 No Regular For best performance, do not image within 2 mm of tab edge.

160 Uncoated N/A Full Cut Tab 10 White 170 No Regular May need to use jogger for uniform stacking.

160 Uncoated N/A Full Cut Tab 10 White 170 No Regular

160 Uncoated N/A Full Cut Tab 12 White 170 No Regular

160 Uncoated N/A Full Cut Tab 12 White 170 No Regular

160 Uncoated N/A Precut Tab 3 White 170 No Regular

160 Uncoated N/A Precut Tab 4 White 170 No Regular

Please check with your service representative before running. Specific feeder hardware, Tag 016F TAB Media Kit and

Tag 134T RIM 9" Firmware, (included in 1.5 machine configuration) is necessary to run tabs or dividers.

Please check with your service representative before running. Specific feeder hardware, Tag 016F TAB Media Kit and

Tag 134T RIM 9" Firmware, (included in 1.5 machine configuration) is necessary to run tabs or dividers.

Please check with your service representative before running. Specific feeder hardware, Tag 016F TAB Media Kit and

Tag 134T RIM 9" Firmware, (included in 1.5 machine configuration) is necessary to run tabs or dividers.

Please check with your service representative before running. Specific feeder hardware, Tag 016F TAB Media Kit and

Tag 134T RIM 9" Firmware, (included in 1.5 machine configuration) is necessary to run tabs or dividers.

Please check with your service representative before running. Specific feeder hardware, Tag 016F TAB Media Kit and

Tag 134T RIM 9" Firmware, (included in 1.5 machine configuration) is necessary to run tabs or dividers.

May need to use jogger for uniform

May need to use jogger for uniform

May need to use jogger for uniform

May need to use jogger for uniform

May need to use jogger for uniform

Page 12

11 of 22 Revision Nov 2008

iGen3 Digital Production Press Guaranteed Media List - Europe - April 2010

The Xerox Guaranteed Media List contains Xerox paper and specialty media that has been extensively tested on the Xerox iGen3 90/100/110 Digital Production Press for image quality and performance. All Xerox paper and specialty media on this list are digitally optimized, designed

and manufactured for optimal performance in Xerox digital printing equipment. Our extensive testing and stringent specifications ensure that we are able to guarantee the performance and consistency of Xerox paper and specialty media. Xerox paper and specialty media are tested

and qualified by Xerox laboratories to guarantee consistent quality.

Grammage

Weight (gsm)

Weight of the

paper in grams

per square meter

Sides Coated Coating Type Type Sequence Color

Thickness

(microns)

Best Practices for Operation

Cleanup FinishOther Size

It is imperative to utilize the bolded, abbreviated stock name for

easy migration to future enhancements to the stock library and

Stock Library Name (Full Media Name)

media management tools.

Drilled

Standard cut sizes

A4 A3 SRA3

(Xerox Dividers Reverse Collated 5 Bank Rainbow)

(Xerox Dividers Reverse Collated 5 Bank White)

XeroxDividers R5B R

XeroxDividers R5B W

003R90878

(A4+)

(223 x 297mm)

003R90873

(A4+)

(223 x 297mm)

160 Uncoated N/A Precut Tab 5 White 170 No Regular

160 Uncoated N/A Precut Tab 5 White 170 No Regular

Please check with your service representative before running. Specific feeder hardware, Tag 016F TAB Media Kit and

Tag 134T RIM 9" Firmware, (included in 1.5 machine configuration) is necessary to run tabs or dividers.

Please check with your service representative before running. Specific feeder hardware, Tag 016F TAB Media Kit and

Tag 134T RIM 9" Firmware, (included in 1.5 machine configuration) is necessary to run tabs or dividers.

May need to use jogger for uniform

May need to use jogger for uniform

Page 13

12 of 22 Revision Nov 2008

g

iGen3 Digital Production Press Guaranteed Media List - Europe - April 2010

The Xerox Guaranteed Media List contains Xerox paper and specialty media that has been extensively tested on the Xerox iGen3 90/100/110 Digital Production Press for image quality and performance. All Xerox paper and specialty media on this list are digitally optimized, designed

and manufactured for optimal performance in Xerox digital printing equipment. Our extensive testing and stringent specifications ensure that we are able to guarantee the performance and consistency of Xerox paper and specialty media. Xerox paper and specialty media are tested

and qualified by Xerox laboratories to guarantee consistent quality.

Grammage

Weight (gsm)

Weight of the

paper in grams

per square meter

Sides Coated Coating Type Type Sequence Color

Thickness

(microns)

Best Practices for Operation

Cleanup FinishOther Size

It is imperative to utilize the bolded, abbreviated stock name for

easy migration to future enhancements to the stock library and

Stock Library Name (Full Media Name)

media management tools.

Drilled

Standard cut sizes

A4 A3 SRA3

(Xerox Dividers Reverse Collated 6 Bank Rainbow)

(Xerox Dividers Reverse Collated 6 Bank White)

(Xerox Dividers Reverse Collated 8 Bank Rainbow)

(Xerox Dividers Straight Collated 10 Bank Rainbow)

(Xerox Dividers Sraight Collated 10 Bank White)

(Xerox Dividers Straight Collated 12 Bank White)

(Xerox Dividers Straight Collated 5 Bank White)

XeroxDividers R6B R

XeroxDividers R6B W

XeroxDividers R8B R

XeroxDividers S10B R

XeroxDividers S10B W

XeroxDividers S12B W

XeroxDividers S5B W

003R93992

(A4+)

(223 x 297mm)

003R91000

(A4+)

(223 x 297mm)

003R93990

(A4+)

(223 x 297mm)

003R91390

(A4+)

(223 x 297mm)

003R91014

(A4+)

(223 x 297mm)

003R91015

(A4+)

(223 x 297mm)

003R91012

(A4+)

(223 x 297mm)

160 Uncoated N/A Precut Tab 6 White 170 No Regular

160 Uncoated N/A Precut Tab 6 White 170 No Regular

160 Uncoated N/A Precut Tab 8 White 170 No Regular

160 Uncoated N/A Full Cut Tab 10 White 170 No Regular

160 Uncoated N/A Full Cut Tab 10 White 170 No Regular

160 Uncoated N/A Full Cut Tab 12 White 170 No Regular

160 Uncoated N/A Precut Tab 5 White 170 No Regular

Please check with your service representative before running. Specific feeder hardware, Tag 016F TAB Media Kit and

Tag 134T RIM 9" Firmware, (included in 1.5 machine configuration) is necessary to run tabs or dividers.

Please check with your service representative before running. Specific feeder hardware, Tag 016F TAB Media Kit and

Tag 134T RIM 9" Firmware, (included in 1.5 machine configuration) is necessary to run tabs or dividers.

Please check with your service representative before running. Specific feeder hardware, Tag 016F TAB Media Kit and

Tag 134T RIM 9" Firmware, (included in 1.5 machine configuration) is necessary to run tabs or dividers.

Please check with your service representative before running. Specific feeder hardware, Tag 016F TAB Media Kit and

Tag 134T RIM 9" Firmware, (included in 1.5 machine configuration) is necessary to run tabs or dividers.

Please check with your service representative before running. Specific feeder hardware, Tag 016F TAB Media Kit and

Tag 134T RIM 9" Firmware, (included in 1.5 machine configuration) is necessary to run tabs or dividers.

Please check with your service representative before running. Specific feeder hardware, Tag 016F TAB Media Kit and

Tag 134T RIM 9" Firmware, (included in 1.5 machine configuration) is necessary to run tabs or dividers.

Please check with your service representative before running. Specific feeder hardware, Tag 016F TAB Media Kit and

Tag 134T RIM 9" Firmware, (included in 1.5 machine configuration) is necessary to run tabs or dividers.

May need to use jogger for uniform

May need to use jogger for uniform

May need to use jogger for uniform

(Xerox Dividers Straight Collated 6 Bank White)

XeroxDividers S6B W

Specialties- Cards

XeroxDocuCard 1up

(Xerox DocuCard 1 up)

XeroxValuPeel U 1up

(Xerox ValuPeelCard Uncoated 1 up)

XeroxValuPerf U 1up

(Xerox ValuPerfCard Uncoated 1up)

003R97571

(500 sheet box)

003R91013

(A4+)

(223 x 297mm)

160 Uncoated N/A Precut Tab 6 White 170 No Regular

200 Uncoated N/A Plain 0 White 209 No Regular

003R97952 X 216 Uncoated N/A Plain 0 White 194 No Regular

003R97690 X 216 Uncoated N/A Plain 0 White 194 No Regular

Please check with your service representative before running. Specific feeder hardware, Tag 016F TAB Media Kit and

Tag 134T RIM 9" Firmware, (included in 1.5 machine configuration) is necessary to run tabs or dividers.

If Transfer set point adjustments are required for snow defects, refer to the Snow Sample Artifact Procedure in the

Stack quality and stack height may be affected due to media structure or high area coverage.

For feedin

A DocuCard Enabler Kit is available to facilitate feeding and stacking of greater volumes.

without a DocuCard Enabler Kit feed tray load max is 50-100 sheets. Load card inboard for Long Edge Feed

latest Customer Maintenance Manual Section 3.

For uniform image quality do not image within 5 mm of card edge.

Load and stack 50-100 sheets maximum due to media structure.

TAB may need to be cleaned prior to running media.

and trail edge for Short Edge Feed.

For uniform image quality do not image within 5 mm of card edge.

Load and stack 50-100 sheets maximum due to media structure.

It is recommended to not image on back if laminated.

For uniform image quality do not image within 5 mm of card edge.

Load and stack 50-100 sheets maximum due to media structure.

It is recommended to not image on back if laminated.

Page 14

13 of 22 Revision Nov 2008

iGen3 Digital Production Press Guaranteed Media List - Europe - April 2010

The Xerox Guaranteed Media List contains Xerox paper and specialty media that has been extensively tested on the Xerox iGen3 90/100/110 Digital Production Press for image quality and performance. All Xerox paper and specialty media on this list are digitally optimized, designed

and manufactured for optimal performance in Xerox digital printing equipment. Our extensive testing and stringent specifications ensure that we are able to guarantee the performance and consistency of Xerox paper and specialty media. Xerox paper and specialty media are tested

and qualified by Xerox laboratories to guarantee consistent quality.

Grammage

Weight (gsm)

Weight of the

paper in grams

per square meter

Sides Coated Coating Type Type Sequence Color

Thickness

(microns)

Best Practices for Operation

Cleanup FinishOther Size

It is imperative to utilize the bolded, abbreviated stock name for

easy migration to future enhancements to the stock library and

Stock Library Name (Full Media Name)

media management tools.

Drilled

Standard cut sizes

A4 A3 SRA3

XeroxValuPeel C 1up

(Xerox Value Peel Card Coated 1 up)

XeroxValuPerf C 1up

(Xerox ValuPerfCard Coated 1up)

003R97953 X 216 Coated One Side Gloss Plain 0 White 170 No Smooth

003R97677 X 216 Coated One Side Gloss Plain 0 White 170 No Smooth

For uniform image quality do not image within 5 mm of card edge.

Load and stack 50-100 sheets maximum due to media structure.

It is recommended to not image on back if laminated.

TAB may need to be cleaned prior to running media.

For uniform image quality do not image within 5 mm of card edge.

Load and stack 50-100 sheets maximum due to media structure.

It is recommended to not image on back if laminated.

Page 15

14 of 22 Revision Nov 2008

iGen3 Digital Production Press Guaranteed Media List - Europe - April 2010

The Xerox Guaranteed Media List contains Xerox paper and specialty media that has been extensively tested on the Xerox iGen3 90/100/110 Digital Production Press for image quality and performance. All Xerox paper and specialty media on this list are digitally optimized, designed

and manufactured for optimal performance in Xerox digital printing equipment. Our extensive testing and stringent specifications ensure that we are able to guarantee the performance and consistency of Xerox paper and specialty media. Xerox paper and specialty media are tested

and qualified by Xerox laboratories to guarantee consistent quality.

Grammage

Weight (gsm)

Weight of the

paper in grams

per square meter

Sides Coated Coating Type Type Sequence Color

Thickness

(microns)

Best Practices for Operation

Cleanup FinishOther Size

It is imperative to utilize the bolded, abbreviated stock name for

easy migration to future enhancements to the stock library and

Stock Library Name (Full Media Name)

media management tools.

Drilled

Standard cut sizes

A4 A3 SRA3

XeroxDocuGlossC 1up

(Xerox DocuGloss Card 1up)

(Xerox Digital Color Special Advanced Media Business Cards)

XeroxDC BusCards

XeroxDocuMag C

(Xerox DocuMagnet Coated)

XeroxDocuMag U

(Xerox DocuMagnet Uncoated)

Specialties- Synthetic Films

XeroxPremiumNeverTear95

(Xerox Premium NeverTear 95 micron)

003R97678 163 Uncoated N/A Plain 0 White 170 No Regular

003R97512 195 Uncoated N/A Plain 0 White 226 No Regular

003R96071 280

003R96072 280

No 003R98056 003R98057 003R98031 003R98032 125

C1S (Coated

One Side)

C1S (Coated

One Side)

Coated Two

Sides

Gloss Plain 0 White 194 No Smooth

Matte Plain 0 White 170 No Regular

Gloss Plain 0 White 95 Yes Smooth Static build up may affect media runnability and/or stacking.

If Transfer set point adjustments are required for snow defects, refer to the Snow Sample Artifact Procedure in the

Stack quality and stack height may be affected due to media structure or high area coverage.

A DocuCard Enabler Kit is available to facilitate feeding and stacking of greater volumes.

For feeding without a DocuCard Enabler Kit feed tray load max is 50-100 sheets.

If Transfer set point adjustments are required for snow defects, refer to the Snow Sample Artifact Procedure in the

For uniform image quality, do not image within 3 mm of card edges (side 1) or within 7 mm of tape edges (side 2).

Stack quality and stack height may be affected due to media structure or high area coverage.

A DocuCard Enabler Kit is available to facilitate feeding and stacking of greater volumes.

If Transfer set point adjustments are required for snow defects, refer to the Snow Sample Artifact Procedure in the

A DocuCard Enabler Kit is available to facilitate feeding and stacking of greater volumes.

latest Customer Maintenance Manual Section 3.

For uniform image quality do not image within 5 mm of card edge.

Load and stack 50-100 sheets maximum due to media structure.

TAB may need to be cleaned prior to running media.

latest Customer Maintenance Manual Section 3.

For uniform image quality do not image within 5 mm of card edge.

For uniform image quality do not image within 5 mm of card edge.

Simplex only recommended

latest Customer Maintenance Manual Section 3.

Simplex only recommended

(Xerox Premium Never Tear 120 micron)

Specialties- Other

(Xerox One Step Transfer Paper)

(Xerox Laser Window GraphiX Clear)

(Xerox Laser Window GraphiX Opaque)

XeroxPremiumNeverTear120

XeroxDuraPaper X250

(Xerox DuraPapaer X250)

Xerox UltraMagnet

(Xerox Ultra Magnet)

XeroxTransferPaper

XeroxLasWinGraphiX C

XeroxLasWinGraphiX O

No 003R98058 003R98059 003R98035 003R98036 155

003R97513 200 Uncoated N/A Plain 0 White 255 No Regular

003R98060 350 Coated One Side Gloss Plain White 194 No Smooth

003R97949 003R97951 118 Coated One Side Gloss Custom 0 White 143 No Smooth

003R97494 003R98675 003R98676 003R98677 200 Coated One Side Gloss Transparency Clear 114 No Smooth

003R97511 003R97539 003R98678 003R98679 200 Coated One Side Gloss Transparency Clear 114 No Smooth

Coated Two

Sides

Gloss Plain 0 White 120 Yes Smooth Static build up may affect media runnability and/or stacking.

If image permanence adjustment is required, refer to ADJ 1-Pressure Roll Contact Arc Adjustment procedure in the

It is recommended that this media be run to stacker top tray.

Static build up may affect media runnability and/or stacking.

To enable running Service must set NVM 6876 (LE Late tat TAR sensor Jam Offset) to maximum value.

To enable running toggle NVM 12509 (Lower Tray Multifeed Detected FLTByp).

Static build up may affect media runnability and/or stacking.

For uniform image quality, do not image within 3 mm of die cut on back of decal.

Static build up may affect media runnability and/or stacking.

For uniform image quality, do not image within 3 mm of die cut on back of decal.

Static build up may affect media runnability and/or stacking.

latest Customer Maintenance Manual.

Simplex only recommended

Feed from a lower tray only.

Output to top tray or bypass tray, if enabled.

For best print quality print 15 mm from edges of the sheet.

Lead edge to Trail edge skew.

Simplex only recommended

Simplex only recommended

Simplex only recommended

Page 16

15 of 22 Revision Nov 2008

iGen3 Digital Production Press Guaranteed Media List - Europe - April 2010

The Xerox Guaranteed Media List contains Xerox paper and specialty media that has been extensively tested on the Xerox iGen3 90/100/110 Digital Production Press for image quality and performance. All Xerox paper and specialty media on this list are digitally optimized, designed

and manufactured for optimal performance in Xerox digital printing equipment. Our extensive testing and stringent specifications ensure that we are able to guarantee the performance and consistency of Xerox paper and specialty media. Xerox paper and specialty media are tested

and qualified by Xerox laboratories to guarantee consistent quality.

Grammage

Weight (gsm)

Weight of the

paper in grams

per square meter

Sides Coated Coating Type Type Sequence Color

Thickness

(microns)

Best Practices for Operation

Cleanup FinishOther Size

It is imperative to utilize the bolded, abbreviated stock name for

easy migration to future enhancements to the stock library and

Stock Library Name (Full Media Name)

media management tools.

Drilled

Standard cut sizes

A4 A3 SRA3

(Xerox Universal Paper Backed Transparency)

XeroxPBTrans

XeroxTransWh 150 gsm

(Xerox Translucent White 150 gsm)

XeroxDocuPac M

(Xerox DocuPac Folders Matte)

003R98199 200 Coated One Side Gloss Transparency Clear 187 No Smooth

007R96576 150

003R97353 180

Coated Two

Sides

Coated Two

Sides

Matte Plain White 160 No Smooth

Matte Custom 0 White 223 No Smooth For uniform image quality, do not image within 10 mm of raised score or 2 mm of dimpled score

This media may have a mottled appearance due to paper formation (image density and gloss).

Stack quality and stack height may be affected due to media structure or high area coverage.

Static build up may affect media runnability and/or stacking.

Deliver to stacker FACE DOWN to avoid stacking issues.

Simplex only recommended

Page 17

16 of 22 Revision Nov 2008

iGen3 Digital Production Press Guaranteed Media List - Europe - April 2010

The Xerox Guaranteed Media List contains Xerox paper and specialty media that has been extensively tested on the Xerox iGen3 90/100/110 Digital Production Press for image quality and performance. All Xerox paper and specialty media on this list are digitally optimized, designed

and manufactured for optimal performance in Xerox digital printing equipment. Our extensive testing and stringent specifications ensure that we are able to guarantee the performance and consistency of Xerox paper and specialty media. Xerox paper and specialty media are tested

and qualified by Xerox laboratories to guarantee consistent quality.

Grammage

Weight (gsm)

Weight of the

paper in grams

per square meter

Sides Coated Coating Type Type Sequence Color

Thickness

(microns)

Best Practices for Operation

Cleanup FinishOther Size

It is imperative to utilize the bolded, abbreviated stock name for

easy migration to future enhancements to the stock library and

Stock Library Name (Full Media Name)

media management tools.

Specialties- Carbonless

Drilled

Standard cut sizes

A4 A3 SRA3

(Xerox Carbonless, 2 part, Straight PreCollated, White and Pink)

(Xerox Carbonless, 2 part, Straight PreCollated, White and Yellow)

(Xerox Carbonless, 3 part, Reverse PreCollated, Pink, Yelllow and

(Xerox Carbonless, 3 Part, Straight PreCollated, White, Yellow and

(Xerox Carbonless, 4 part, Reverse PreCollated, Green, Pink, Yellow

(Xerox Carbonless, 4 part, Straight PreCollated, White, Yellow,Pink

(Xerox Carbonless, Coated Back, Singles, White)

(Xerox Carbonless, Coated Front and Back, Singles, White)

(Xerox Carbonless, Coated Front and Back, Singles , Yellow)

(Xerox Carbonless, Coated Front, Single, Pink)

(Xerox Carbonless, Coated Front, Singles, White)

(Xerox Carbonless, Coated Front, Singles, Yellow)

XeroxCarb2SWP

XeroxCarb2SWY

XeroxCarb3RPYW

White)

XeroxCarb3SWYP

Pink)

XeroxCarb4RGPYW

and White)

XeroxCarb4SWYPB

and Blue)

XeroxCarbCBSingleW

XeroxCarbCFBSingleW

XeroxCarbCFBSingleY

XeroxCarbCFSingleP

XeroxCarbCFSingleW

XeroxCarbCFsingleY

003R99107 80 Uncoated N/A Ordered 2 White 110 Yes Regular

003R99105 80 Uncoated N/A Ordered 2 White 110 Yes Regular

003R99109 80 Uncoated N/A Ordered 3 White 110 No Regular

003R99108 80 Uncoated N/A Ordered 3 White 110 No Regular

003R99112 80 Uncoated N/A Ordered 4 White 110 No Regular

003R99111 80 Uncoated N/A Ordered 4 White 110 No Regular

003R99069 80 Uncoated N/A Plain White 110 No Regular

003R99070 80 Uncoated N/A Plain White 110 No Regular

003R99071 80 Uncoated N/A Plain Yellow 112 No Regular

003R99077 80 Uncoated N/A Plain Pink 107 No Regular

003R99075 80 Uncoated N/A Plain White 110 No Regular

003R99076 80 Uncoated N/A Plain Yellow 112 No Regular

This media may have a mottled appearance due to paper formation (image density and gloss).

Optimization of decurler settings may be needed for best stacking and runnability.

This media may have a mottled appearance due to paper formation (image density and gloss).

Optimization of decurler settings may be needed for best stacking and runnability.

This media may have a mottled appearance due to paper formation (image density and gloss).

Optimization of decurler settings may be needed for best stacking and runnability.

This media may have a mottled appearance due to paper formation (image density and gloss).

Optimization of decurler settings may be needed for best stacking and runnability.

This media may have a mottled appearance due to paper formation (image density and gloss).

Optimization of decurler settings may be needed for best stacking and runnability.

This media may have a mottled appearance due to paper formation (image density and gloss).

Optimization of decurler settings may be needed for best stacking and runnability.

This media may have a mottled appearance due to paper formation (image density and gloss).

Optimization of decurler settings may be needed for best stacking and runnability.

This media may have a mottled appearance due to paper formation (image density and gloss).

Optimization of decurler settings may be needed for best stacking and runnability.

This media may have a mottled appearance due to paper formation (image density and gloss).

Optimization of decurler settings may be needed for best stacking and runnability.

This media may have a mottled appearance due to paper formation (image density and gloss).

Optimization of decurler settings may be needed for best stacking and runnability.

This media may have a mottled appearance due to paper formation (image density and gloss).

Optimization of decurler settings may be needed for best stacking and runnability.

This media may have a mottled appearance due to paper formation (image density and gloss).

Optimization of decurler settings may be needed for best stacking and runnability.

Fuser Fluid II is recommended for duplex applications.

Reverse PreCollated product run face up to stacker is recommended.

Fuser Fluid II is recommended for duplex applications.

Reverse PreCollated product run face up to stacker is recommended.

Fuser Fluid II is recommended for duplex applications.

Reverse PreCollated product run face up to stacker is recommended.

Fuser Fluid II is recommended for duplex applications.

Reverse PreCollated product run face up to stacker is recommended.

Fuser Fluid II is recommended for duplex applications.

Reverse PreCollated product run face up to stacker is recommended.

Fuser Fluid II is recommended for duplex applications.

Reverse PreCollated product run face up to stacker is recommended.

Fuser Fluid II is recommended for duplex applications.

Fuser Fluid II is recommended for duplex applications.

Fuser Fluid II is recommended for duplex applications.

Fuser Fluid II is recommended for duplex applications.

Fuser Fluid II is recommended for duplex applications.

Fuser Fluid II is recommended for duplex applications.

Page 18

1 of 20 Revision Nov 2008

g

g

g

g

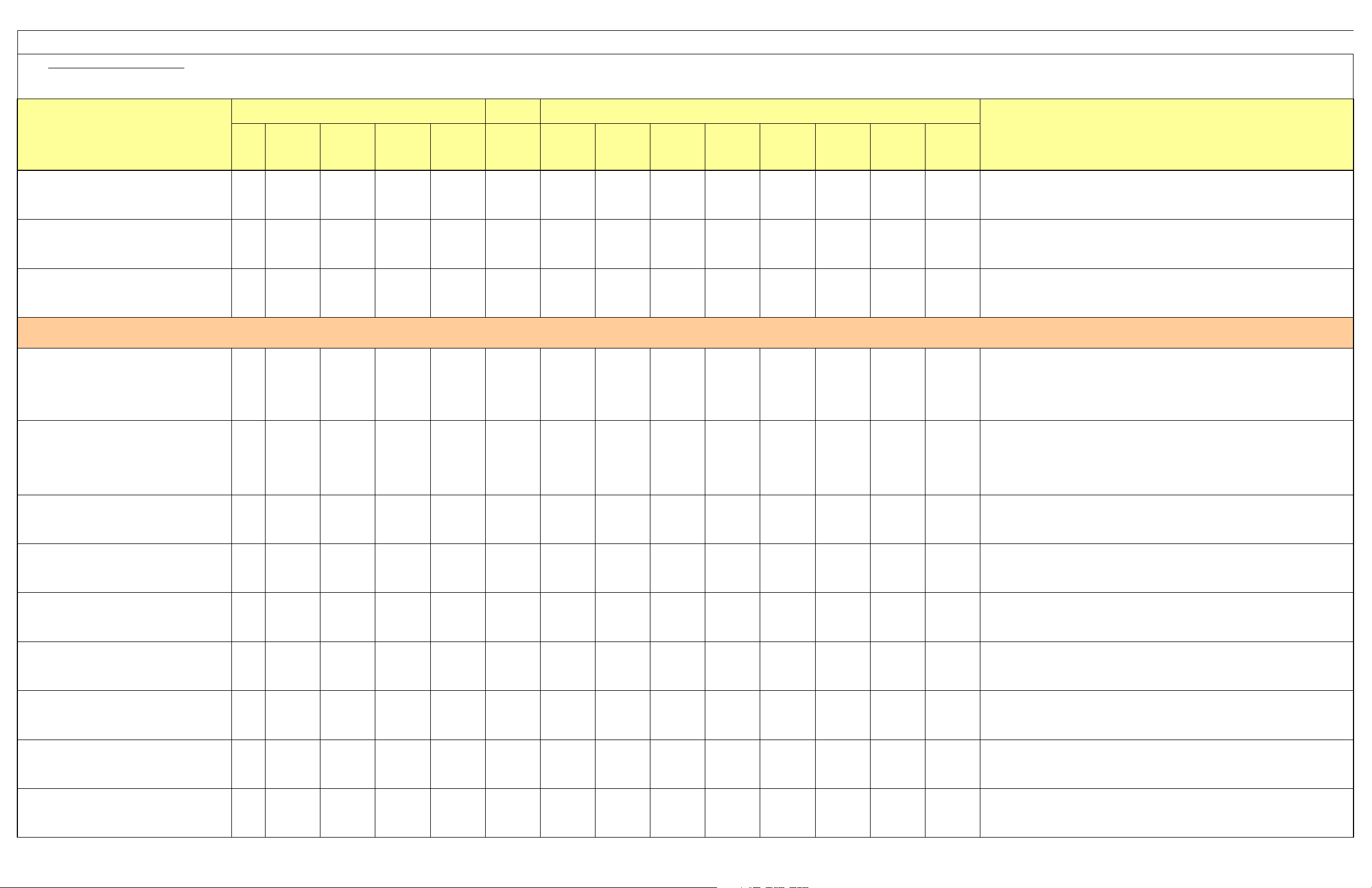

iGen3 Digital Production Press Custom Media List - Europe - April 2010

It is imperative to utilize the bolded, abbreviated stock name for easy

migration to future enhancements to the stock library and media

Stock Library Name (Full Media Name)

management tools.

Uncoated

XeroxXmail60

(Xerox Xmail 60 gsm)

Recycled Uncoated

XeroxColotechRecycled90

(Xerox Colotech Recycled 90 gsm)

XeroxColotechRecycled100

(Xerox Colotech Recycled 100 gsm)

XeroxColotechRecycled120

(Xerox Colotech Recycled 120 gsm)

Textured Uncoated

The Xerox CUSTOM Media List

contains custom media that has been tested on the Xerox iGen3 100/110 Digital Production Press for image quality and performance.

Custom media on this list are digitally optimized, designed and manufactured for performance in Xerox digital printing equipment.

Best Practices for Operation are outlined below.

Customers should validate the Best Practices for Operation are acceptable for their application.

*Any alterations to the product's basic design, including sheet size, must be tested and approved by the Xerox Media & Compatibles Technology Center.*

When purchasing a particular media product for the first time, customers are advised to purchase small quantities to insure that expectations are met.

CUSTOM media may be ordered through the Xerox Supply Account Manager.

Base Size Tested

A4 A3 short grain SRA3 FinishType

Other Size

XX

003R98801 003R98802

003R98804 003R98805

003R98807 003R98808

Grammage

Weight (gsm)

Weight of the

paper in grams

per square meter

60 Uncoated N/A Plain White 86 No Regular

90 Uncoated N/A Plain White 90 No Regular

100 Uncoated N/A Plain White 100 No Regular

120 Uncoated N/A Plain White 120 No Regular

Thickness

(microns)

CleanupCoating Type Sides Coated Sequence Color

Due to the nature of the raw material used, print output can be more wavy than virgin fibre paper and some sheets may have inclusions which

Due to the nature of the raw material, print output can be more wavy than virgin fibre paper and some sheets may have inclusions which may

Due to the nature of the raw material, print output can be more wavy than virgin fibre paper and some sheets may have inclusions which may

Best Practices for Operation

Stack quality and stack height may be affected due to media structure or high area coverage.

High area coverage with multilayer colors may be stressful on the fusing system.

Simplex only recommended

may affect print quality.

affect print quality.

affect print quality.

XeroxHammerEmboss250

(Xerox Hammer Embossed 250 gsm)

XeroxLineEmbossed250

(Xerox line Embossed 250 gsm)

XeroxLinenEmbossed250

(Xerox Embossed Linen 250 gsm)

XeroxTextileEmboss250

(Xerox Textile Embossed 250 gsm)

Synthetics

XeroxPremNeverTear195

(Xerox Premium NeverTear 195 micron)

XeroxPremNeverTear270

(Xerox Premium Never Tear 270 gsm)

007R96574 250 250 Uncoated N/A Plain White 310 No Rough

007R96572 250 250 Uncoated N/A Plain White 330 No Rough

003R97691 250 250 Uncoated N/A Plain White 300 No Rough

007R96573 250 250 Uncoated N/A Plain White 300 No Rough

003R98041 003R98042 003R98043 003R98044 260

003R98045 003R98046 003R98047 003R98048 300

Coated Two

Sides

Coated Two

Sides

Gloss Plain White 195 No Smooth

Gloss Plain White 270 No Smooth

If Transfer set point adjustments are required for snow defects, refer to the Snow Sample Artifact Procedure in the latest Customer

For additional image quality tips please contact the media hotline.

eneric starting point for this weight and type of media. Adjustments may need to be made to achieve optimum transfer and or toner

This is a

If Transfer set point adjustments are required for snow defects, refer to the Snow Sample Artifact Procedure in the latest Customer

For additional image quality tips please contact the media hotline.

This is a

eneric starting point for this weight and type of media. Adjustments may need to be made to achieve optimum transfer and or toner

If Transfer set point adjustments are required for snow defects, refer to the Snow Sample Artifact Procedure in the latest Customer

For additional image quality tips please contact the media hotline.

This is a

eneric starting point for this weight and type of media. Adjustments may need to be made to achieve optimum transfer and or toner

If Transfer set point adjustments are required for snow defects, refer to the Snow Sample Artifact Procedure in the latest Customer

For additional image quality tips please contact the media hotline.

This is a

eneric starting point for this weight and type of media. Adjustments may need to be made to achieve optimum transfer and or toner

Static build up may affect media runnability and/or stacking.

Some side to side color difference may be seen if auto duplexing.

Static build up may affect media runnability and/or stacking.

Some side to side color difference may be seen if auto duplexing.

Maintenance Manual Section 3.

ATA mode may help image quality.

adhesion for individual media.

Maintenance Manual Section 3.

ATA mode may help image quality.

adhesion for individual media.

Maintenance Manual Section 3.

ATA mode may help image quality.

adhesion for individual media.

Maintenance Manual Section 3.

ATA mode may help image quality.

adhesion for individual media.

Some skew may be seen if auto duplexing.

Feed from a lower tray.

High static may impact inline finishing.

Some skew may be seen if auto duplexing.

Feed from a lower tray.

High static may impact inline finishing.

Static build up may affect media runnability and/or stacking.

XeroxPremNeverTear350

(Xerox Premium NeverTear 350 gsm)

003R98049 003R98050 003R98051 003R98052 350

Coated Two

Sides

Gloss Plain White 350 No Smooth

Some side to side color difference may be seen if auto duplexing.

Some skew may be seen if auto duplexing.

Feed from a lower tray.

High static may impact inline finishing.

Page 19

2 of 20 Revision Nov 2008

iGen3 Digital Production Press Custom Media List - Europe - April 2010

It is imperative to utilize the bolded, abbreviated stock name for easy

migration to future enhancements to the stock library and media

Stock Library Name (Full Media Name)

management tools.

XeroxPremNeverTear145

(Xerox Premium NeverTear 145 microns)

XeroxPNeverTearBlue130

(Xerox Premium NeverTear Blue 130 microns)

XeroxPNeverTearGrn130

(Xerox Premium NeverTear Green 130 microns)

The Xerox CUSTOM Media List

contains custom media that has been tested on the Xerox iGen3 100/110 Digital Production Press for image quality and performance.

Custom media on this list are digitally optimized, designed and manufactured for performance in Xerox digital printing equipment.

Best Practices for Operation are outlined below.

Customers should validate the Best Practices for Operation are acceptable for their application.

*Any alterations to the product's basic design, including sheet size, must be tested and approved by the Xerox Media & Compatibles Technology Center.*

When purchasing a particular media product for the first time, customers are advised to purchase small quantities to insure that expectations are met.

CUSTOM media may be ordered through the Xerox Supply Account Manager.

Base Size Tested

A4 A3 short grain SRA3 FinishType CleanupCoating Type Sides Coated Sequence Color

Other Size

003R98037 003R98038 003R98039 003R98040 195

XXXX200200Coated Two Sides Gloss Plain White 130 No Smooth

XXXX200200Coated Two Sides Gloss Plain White 130 No Smooth

Grammage

Weight (gsm)

Weight of the

paper in grams

per square meter

Coated Two

Sides

Thickness

(microns)

Gloss Plain White 145 No Smooth

Best Practices for Operation

Static build up may affect media runnability and/or stacking.

Some side to side color difference may be seen if auto duplexing.

Some skew may be seen if auto duplexing.

Feed from a lower tray.

High static may impact inline finishing.

Static build up may affect media runnability and/or stacking.

Some side to side color difference may be seen if auto duplexing.

Some skew may be seen if auto duplexing.

Feed from a lower tray.

High static may impact inline finishing.

Static build up may affect media runnability and/or stacking.

Some side to side color difference may be seen if auto duplexing.

Some skew may be seen if auto duplexing.

Feed from a lower tray.

High static may impact inline finishing.

XeroxPNeverTearPink130

(Xerox Premium NeverTear Pink 130 microns)

XeroxPNeverTearYell130

(Xerox Premium NeverTear Yellow 130 micron)

Specialties

(Xerox Business Reply Envelopes 1 up)

(Xerox Universal Paper Backed Transparency SRA3)

(Xerox Crystal Clear Self Adhesive Label)

XeroxBRE 1up

XeroxPBtrans SRA3

XeroxDuraPaperLabel

(Xerox DuraPaper label)

XeroxCrysClearLabel

XXXX200200Coated Two Sides Gloss Plain White 130 No Smooth

XXXX200200Coated Two Sides Gloss Plain White 130 No Smooth

X 150 Uncoated N/A Plain 0 White 160 No Regular

003R98201 200

003R97344 003R98645 003R98688 200 200

003R97244 003R97347 300 300

Coated Two

Sides

Gloss Transparency Clear 187 No Smooth

Coated Two

Sides

Coated Two

Sides

Gloss Plain White 250 No Smooth

Gloss Plain White 254 No Smooth

Static build up may affect media runnability and/or stacking.

Some side to side color difference may be seen if auto duplexing.

Some skew may be seen if auto duplexing.

Feed from a lower tray.

High static may impact inline finishing.

Static build up may affect media runnability and/or stacking.

Some side to side color difference may be seen if auto duplexing.

Some skew may be seen if auto duplexing.

Feed from a lower tray.

High static may impact inline finishing.

This media may have a mottled appearance due to poor paper formation (image density and gloss).

Stack quality and stack height may be affected due to media structure or high area coverage.

This media may have a mottled appearance due to paper formation (image density and gloss).

High area coverage with multilayer colors may be stressful on the fusing system.

Load Business Reply Envelopes perforated side up.

Static build up may affect media runnability and/or stacking.

For uniform image quality, do not image within 3 mm of label edges.

It is recommended that this media be run to stacker top tray.

High static may impact inline finishing.

Load and stack 2

Simplex only recommended

Output to top tray only. 80 sheets.

Do not invert.

Simplex only recommended

Simplex only recommended

Output to top tray only. 80 sheets.

XeroxGlossWhiteLabel

(Xerox Glossy white Self Adhesive Label)

003R97245 003R97348 300 300

Coated Two

Sides

Gloss Plain White 254 No Smooth

It is recommended that this media be run to stacker top tray.

High area coverage with multilayer colors may be stressful on the fusing system.

Simplex only recommended

Output to top tray only. 80 sheets.

High static may impact inline finishing.

Page 20

3 of 20 Revision Nov 2008

iGen3 Digital Production Press Custom Media List - Europe - April 2010

It is imperative to utilize the bolded, abbreviated stock name for easy

migration to future enhancements to the stock library and media

Stock Library Name (Full Media Name)

management tools.

XeroxDuraDocPap703670PE

(Xerox DuraDocument Paper 703670PE)

XeroxDuraDocPap503650PT

(Xerox DuraDocument Paper 503650PT)

XeroxDuraDocPap504950PE

(Xerox DuraDocument Paper 504950PE)

The Xerox CUSTOM Media List

contains custom media that has been tested on the Xerox iGen3 100/110 Digital Production Press for image quality and performance.

Custom media on this list are digitally optimized, designed and manufactured for performance in Xerox digital printing equipment.

Best Practices for Operation are outlined below.

Customers should validate the Best Practices for Operation are acceptable for their application.

*Any alterations to the product's basic design, including sheet size, must be tested and approved by the Xerox Media & Compatibles Technology Center.*

When purchasing a particular media product for the first time, customers are advised to purchase small quantities to insure that expectations are met.

CUSTOM media may be ordered through the Xerox Supply Account Manager.

Base Size Tested

A4 A3 short grain SRA3 FinishType CleanupCoating Type Sides Coated Sequence Color

X 170 170 Uncoated N/A Custom White 203 No Regular

X 170 170 Uncoated N/A Custom White 203 No Regular

007R96123 170 170 Uncoated N/A Custom White 203 No Regular

Other Size

Grammage

Weight (gsm)

Weight of the

paper in grams

per square meter

Thickness

(microns)

This is a generic starting point for this weight and type of media. Adjustments may need to be made to achieve