Page 1

PHASER™ 5400

LASER PRINTER

Service Quick Reference Guide

Page 2

Page 3

Phaser™ 5400

Laser Printer

Service Quick Reference Guide

Warning

The following servicing instructions are for

use by qualified service personnel only. To

avoid personal injury, do not perform any

servicing other than that contained in

operating instructions unless you are qualified

to do so.

This printing: August 2002

Rev. 1

721P58301

Page 4

Users Safety Summary

Terms in manual: Various terms are used throughout this manual to either provide

additional information on a specific topic or to warn of possible danger that might be

present during a procedure or action. Be aware of all symbols and terms when they are

used, and always read

Note

Caution: A Caution indicates an operating or maintenance procedure,

War ning : A Warning indicates an operating, or maintenance procedure,

Terms on Product:

Note, Caution and Warn in g messages.

: A Note may indicate an operating or maintenance procedure,

practice or condition that is necessary to efficiently accomplish a

task.

A

Note may also provide additional information related to a

specific subject or add a comment on the results achieved through

a previous action.

practice or condition that, if not strictly observed, could result in

damage to, or destruction of, equipment.

practice or condition that, if not strictly observed, could result in

injury or loss of life.

Caution:

Danger:

Power Source:

the supply conductors or between either supply conductor and ground. Use only the

specified power cord and connector. For 220 VAC printers, do not apply more than 250

VAC RMS between the supply conductors or between either supply conductor and

ground. Use only the specified power cord and connector. Refer to a qualified service

technician for changes to the cord or connector.

A personal injury hazard exists that may not be apparent. For

example, a panel may cover the hazardous area.

A personal injury hazard exists in the area where you see the sign.

For 110 VAC printers, do not apply more than 130 VAC RMS between

Warning: If the product loses the ground connection, usage of knobs

and controls (and other conductive parts) can cause an

electrical shock.

Phaser 5400 Laser Printer Service Guide iii

Page 5

Power Supply and Electrical Components:

Before starting any service procedure,

switch off the printer power and unplug the power cord from the wall outlet. If you must

service the printer with power applied, be aware of the potential for electrical shock.

Do not touch any electrical component unless you are instructed to do so by a service

procedure.

S5400-01

Mechanical Components: Manually rotate drive assemblies to inspect sprockets and

gears.

Do not try to manually rotate or manually stop the drive assemblies while any printer motor

is running.

S5400-02

Laser Components

War nin g: This printer generates a laser beam as part of the printing

process. The laser beam is a concentrated narrow beam of

infrared light. The laser beam in this machine is invisible.

Although you cannot see the beam, it can still cause severe

eye damage. Direct eye exposure to the laser beam may

cause eye injury or blindness.

To avoid permanent eye damage, follow these directions:

■ Before starting any service procedure, switch off the printer power and unplug

the power cord from the AC wall outlet.

■ Do not disassemble the Raster Output Scanner Assembly (laser scanner) or any

laser component that displays a Laser Warning Sticker.

■ Use caution when you are working around the Raster Output Scanner Assembly

or when you are performing laser related troubleshooting or repair procedures.

■ Never place a mirror or a reflective tool or object in the laser beam path.

■ Do not disassemble the printer in such a way that the laser beam can exit the

print engine during a print cycle.

iv Phaser 5400 Laser Printer Service Guide

Page 6

Fuser Components

Warning: This printer uses heat and pressure to fuse the toner image

to a sheet of paper. The Fuser Assembly is very hot. Switch

off printer power and wait at least 30 minutes for the Fuser

to cool before you attempt to service the Fuser Assembly or

adjacent components.

Safety Components:

Make sure covers and panels are in place and that all interlock

switches are all functioning correctly after you have completed a printer service call. If

you bypass, or cheat, an interlock switch during a service call, use extreme caution when

working on or around the printer.

Warning Labels: Throughout the printer, warning labels are displayed on potentially

dangerous components. When you service the printer, check to make certain that all

warning labels are in place.

Most importantly, read and obey all posted warning labels.

Warning: Turning the power off using the On/Off switch does not

de-energize the printer. You must remove the power cord to

disconnect the printer from the main power source. Keep the

power cord accessible for removal in case of an emergency.

Safety Instructions:

Read all installation instructions carefully before you plug the

product into a power source.

Care of Product: Disconnect the power plug by pulling the plug, not the cord.

Disconnect the power plug:

■ If the power cord or plug is frayed or otherwise damaged,

■ If any liquid or foreign material is spilled into the case,

■ If the printer is exposed to any excess moisture,

■ If the printer is dropped or damaged,

■ If you suspect that the product needs servicing or repair, or

■ Whenever you clean the product.

Ground the product: Plug the three-wire power cord (with grounding prong) into

grounded AC outlets only. If necessary, contact a licensed electrician to install a properly

grounded outlet.

Phaser 5400 Laser Printer Service Guide v

Page 7

Service Safety Summary

For qualified service personnel only: Refer also to the preceding Users Safety

Summary.

Do not service alone: Do not perform internal service or adjustment of this product

unless another person capable of rendering first aid or resuscitation is present.

Use care when servicing with power: Dangerous voltages may exist at several points in

this product. To avoid personal injury, do not touch exposed connections and components

while power is on.

Disconnect power before removing the power supply shield, soldering or replacing

components.

Do not wear jewelry: Remove jewelry prior to servicing. Rings, necklaces and other

metallic objects could come into contact with dangerous voltages and currents.

Power source: This product is intended to operate from a power source that will not apply

more then 250 VAC rms between the supply conductors or between either supply

conductor and ground. A protective ground connection by way of the grounding

conductor in the power cord is essential for safe operation.

This product is certified under IEC 825 as a Class 1 Laser Product.

CLASS 1 LASER PRODUCT

The Phaser 5400 Laser Printer is certified to comply with Laser Product Performance

Standards set by the U.S. Department of Health and Human Services as a Class 1 Laser

Product. This means that this is a class of laser product that does not emit hazardous laser

radiation; this is possible only because the laser beam is totally enclosed during all modes

of customer operation.

The laser and output of the laser scanner unit produces a beam that, if looked into, could

cause eye damage. Service procedures must be followed exactly as written without

change.

When servicing the machine or laser module, follow the procedures specified in the

manual and there will be no hazards from the laser.

Laser (FDA): Any laser label visible to service must be reproduced in the service manual

with location shown or indicated. Safe working procedures and clear warnings concerning

precautions to avoid possible exposure must also be included.

vi Phaser 5400 Laser Printer Service Guide

Page 8

The Laser contained in the Phaser 5400 Laser Printer meets the following standard: Laser

class 3B, maximum 5 mW, wavelength 780 nm.

The following LASER symbol will be displayed at the start of any procedure where

possible exposure to the laser beam exists.

LUOKAN 1 LASERLAITE

KLASS 1 LASER APPARAT

Phaser 5400 Laser Printer Service Guide vii

Page 9

Federal Communications Commission Compliance

This equipment has been tested and found to comply with the limits set for a Class A

digital device, as stated in Part 15 of the FCC rules. These limits are designed to provide

reasonable protection against harmful interference in a commercial installation. This

equipment generates, uses, and may radiate radio frequency energy. If not installed and

used in accordance with the instructions provided, this equipment may cause disruptive

interference to nearby radio and television communications. Even if the equipment is

installed according to the instructions, there is no guarantee that interference will not

occur in a particular installation. If this equipment does cause disruptive interference to

nearby radio and television reception, switch the equipment off to determine if it is the

true cause of the interference. If the equipment is the cause of the interference, the user

should try to minimize the interference by taking one or more of the following courses of

action:

■ Either re–orient or relocate the radio/television receiving antenna.

■ Increase the separation between the equipment and the radio/television receiver.

■ Connect the equipment to an AC outlet that is not on the same circuit as the

radio/television receiver.

■ If the previous solutions fail to bring results, you should consult either your equipment

dealer or an experienced radio/television technician.

For more information on interference, refer to the Federal Communications Commission’s

booklet “How to Identify and Resolve Radio-TV Interference Problems”. This booklet is

available from the U.S. Government Printing Office, Washington D.C. 20402, Stock No.

004-000-00345-4.

viii Phaser 5400 Laser Printer Service Guide

Page 10

Canadian Notice

This digital apparatus does not exceed the Class A limits for radio noise emissions from

digital apparatus as described in the radio interference regulations of the Canadian

Department of Communications.

Avis Canadien

Cet appareil numerique est conforme aux limites émission de bruits radioélectriques pour

les appareils de classe A stipulés das le réglement sur le brouillage radioéletrique du

Ministére des Communcations du Canada.

European Notice

This equipment was tested and is determined to be compliant with VDE requirements for a

Class A device.

Hinweis

Hiermit wird bescheinigt, dass der Babe Laserdrucker, in bereinstimmung mit den

Betimmunngen der Vfg 104ß 984 funkenstört ist. Der Deutschen Bundespost wurde das

Inverkehrbringen dieses Gertëes angqeigt und die Berechtigung zur berprufung der Serie

auf Einhaltung der Bestimmungen eingeräumt.

Phaser 5400 Laser Printer Service Guide ix

Page 11

Blank Page

x Phaser 5400 Laser Printer Service Guide

Page 12

Table of Contents

Copyright .................................................................................................. ii

Users Safety Summary ........................................................................... iii

Service Safety Summary ......................................................................... vi

List of Figures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xix

List of Tables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxv

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Parts of the Printer ...................................................................................4

Printer Components ...........................................................................4

Printer Options ...................................................................................5

Control Panel .....................................................................................6

Display Screen...................................................................................7

Rear Panel .........................................................................................8

Print Engine Assemblies ..........................................................................9

Paper Path Information ..........................................................................15

Printer Specifications..............................................................................17

RAM and Printer Capabilities...........................................................17

Basic Specifications .........................................................................18

Electrical Specifications ...................................................................18

Mechanical Specifications ...............................................................19

Environmental Specifications...........................................................20

Life Expectancies.............................................................................21

Conforming Regulations and Standards ..........................................21

Printing Speed .................................................................................22

Printing Media Feeding Means ........................................................23

Printing Media ..................................................................................24

Printing Accuracy .............................................................................25

Components to Be Replaced Periodically .......................................26

Options ............................................................................................26

Phaser 5400 Laser Printer Service Guide xi

Page 13

Error Codes and Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Introduction ............................................................................................28

Error messages ...............................................................................28

Measurements .................................................................................29

Service Flowchart ............................................................................29

Repair Analysis Procedure Table...........................................................31

How to Use a Repair Analysis Procedure Table..............................31

How to Follow a Repair Analysis Procedure....................................32

General Notes on Using Repair Analysis Procedures .....................33

Error Codes with Repair Analysis Procedure .........................................35

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Printer Performance Problems Repair Analysis Procedure

(RAP) Table.............................................................................107

Image-Quality Problems Repair Analysis Procedure (RAP) Table ......109

Electrical Interference Repair Analysis Procedure (RAP) Table ..........109

Printer Performance Problems .............................................................110

Image-Quality Troubleshooting ............................................................176

Introduction ....................................................................................176

Image-Quality Defect Definitions ...................................................177

Diagnostics, Test Prints, Service Tests and

NVRAM Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

Entering Diagnostics Mode ..................................................................221

System Controller Board Error (Blink) Codes.......................................222

Recommended Corrective Action ..................................................223

Power On LED Sequence..............................................................223

Diagnostics Menu Map ..................................................................224

System Controller Board Test Prints ....................................................226

Main Menu Test Prints .........................................................................226

Configuration Sheet .......................................................................226

System Controller Board Test Print ...............................................227

Fault History...................................................................................227

Display Faults ................................................................................227

Menu Map......................................................................................227

PS Font List ...................................................................................228

PCL Font List: ................................................................................228

PCL Demo: ....................................................................................228

Print Engine Controller Board Test Print ..............................................229

Analyzing Test Prints ...........................................................................230

Registration ..........................................................................................231

NVRAM Configuration (NVM Config) ...................................................233

xii Phaser 5400 Laser Printer Service Guide

Page 14

Component Tests .................................................................................235

Reset Menu ..........................................................................................239

Maintenance Kit Counter Reset Procedure..........................................240

Maintenance and Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

Scheduled Maintenance.......................................................................241

Recommended Tools ...........................................................................241

Inspect While Servicing ........................................................................241

General Cleaning (if needed) ...............................................................242

FRU Removal / Replacement Procedures (RRPs) . . . . . . . . . . . 245

Contents - Removal and Replacement Procedures .............................245

Introduction...........................................................................................248

Work Notes...........................................................................................248

Preparation...........................................................................................249

Notations in the RRP text .....................................................................249

Adjustment ...........................................................................................249

Repair Procedures ...............................................................................250

RRP 1.1 Left Side Cover ...............................................................250

RRP 1.2 Right Side Cover .............................................................251

RRP 1.3 Top Cover Assembly .......................................................252

RRP 1.4 Front Cover .....................................................................253

RRP 1.5 Lower Left Cover .............................................................254

RRP 1.6 HVPS Cover ....................................................................255

RRP 1.7 Lower Rear Cover ...........................................................256

RRP 1.8 MBF Gear Cover .............................................................257

RRP 1.9 Rear Cover ......................................................................258

RRP 2.1 Multi-sheet Bypass Feeder (MBF) Assembly ..................259

RRP 2.2 MBF Feed Rollers ...........................................................261

RRP 2.3 MBF Tray 1 Turn Roller Clutch Assembly .......................262

RRP 2.4 Tray 1 Turn Roller Assembly...........................................263

RRP 2.5 MBF Retard Holder Assembly.........................................264

RRP 2.6 Tray 1 No Paper Sensor Assembly .................................266

RRP 2.7 MBF No Paper Sensor Assembly ...................................267

RRP 2.8 MBF Feed Solenoid ........................................................269

RRP 2.9 Tray 1 Feed Solenoid ......................................................270

RRP 2.10 Tray 1 Feed Roller ........................................................271

RRP 2.11 Tray 1 Retard Holder Assembly ....................................272

RRP 3.1 Retard Chute Assembly ..................................................273

RRP 3.2 Rear Chute Assembly .....................................................274

RRP 3.3 Lower Turn Roller Assembly ...........................................275

RRP 3.4 Tray 1 Low Paper Sensor ...............................................276

Phaser 5400 Laser Printer Service Guide xiii

Page 15

RRP 3.5 Tray 1 Right Guide Assembly .........................................277

RRP 3.6 Tray 1 Left Guide Assembly............................................279

RRP 3.7 CRUM Board ...................................................................281

RRP 3.8 MBF Assembly Position Sensor ......................................282

RRP 4.1 Paper Transport Assembly..............................................283

RRP 4.2 Registration Actuator.......................................................285

RRP 4.3 Registration Clutch ..........................................................286

RRP 4.4 Registration Sensor.........................................................287

RRP 5.1 Fuser Assembly ..............................................................288

RRP 5.2 Stack Full Sensor ............................................................289

RRP 5.3 Exit Roller Assembly .......................................................291

RRP 5.4 Stack Full Sensor Actuator..............................................294

RRP 6.1 Main Drive Gear Assembly .............................................295

RRP 7.1 Laser Assembly...............................................................297

RRP 7.2 Right Print Cartridge Guide Assembly ............................299

RRP 7.3 Toner Sensor Assembly..................................................301

RRP 7.4 Top Cover Interlock Switch .............................................302

RRP 7.5 Left Print Cartridge Guide Assembly ...............................303

RRP 7.6 Bias Transfer Roller [BTR] Assembly..............................304

RRP 8.1 System Controller PWB ..................................................305

RRP 8.2 High-Voltage Power Supply [HVPS] Board.....................307

RRP 8.3 Duplex Interface Board ...................................................308

RRP 8.4 Main Fan .........................................................................309

RRP 8.5 Print Engine Controller Board .........................................310

RRP 8.6 Low-Voltage Power Supply [LVPS] Assembly ................312

RRP 8.7 LVPS FAN .......................................................................313

RRP 8.8 AC Input Assembly..........................................................314

RRP 8.9 Control Panel +5 VDC Power Supply..............................315

RRP 9.1 Duplex Assembly ............................................................317

RRP 10.1 1000-Sheet High Capacity Stacker [HCS] ....................318

RRP 10.2 HCS Top Cover .............................................................319

RRP 10.3 HCS Rear Cover Assembly...........................................320

RRP 10.4 HCS Front Cover...........................................................321

RRP 10.5 HCS Exit Gate Solenoid................................................322

RRP 10.6 HCS Stack Full Sensor .................................................323

RRP 10.7 HCS Stack Full Sensor Actuator ...................................324

RRP 10.8 HCS Drive Motor Assembly ..........................................325

RRP 10.9 HCS Rear Cover Interlock Switch .................................326

RRP 10.10 HCS Paper Sensor......................................................327

RRP 11.1 500-Sheet Feeder Removal ..........................................328

RRP 11.2 Front Cover ...................................................................329

RRP 11.3 Left Cover......................................................................330

RRP 11.4 Right Cover ...................................................................331

xiv Phaser 5400 Laser Printer Service Guide

Page 16

RRP 11.5 Rear Cover ....................................................................332

RRP 11.6 Drive Assembly .............................................................333

RRP 11.7 Feeder Board ................................................................334

RRP 11.8 Feed Head Assembly....................................................335

RRP 11.9 Feed Rollers ..................................................................336

RRP 11.10 Feed Solenoid .............................................................337

RRP 11.11 Turn Roller Assembly..................................................338

RRP 11.12 Retard Chute Assembly ..............................................339

RRP 11.13 Left Tray Guide ...........................................................340

RRP 11.14 Right Tray Guide .........................................................342

RRP 11.15 Retard Holder Assembly .............................................344

RRP 11.16 Retard Turn Roller Assembly ......................................345

RRP 11.17 Paper Size Sensor ......................................................346

RRP 11.18 Paper Tray Sensor ......................................................347

RRP 11.19 No Paper Sensor.........................................................348

RRP 11.20 No Paper Sensor Actuator ..........................................350

RRP 11.21 Preregistration Sensor ................................................351

RRP 12.1 Removing the 2000-Sheet Feeder ................................352

RRP 12.2 Left Side Cover .............................................................354

RRP 12.3 Upper Rear Cover .........................................................355

RRP 12.4 Lower Rear Cover .........................................................356

RRP 12.5 Right Side Cover ...........................................................357

RRP 12.6 Front Cover ...................................................................358

RRP 12.7 Tray Assembly ..............................................................359

RRP 12.8 2000-Sheet Feeder PWB ..............................................360

RRP 12.9 Tray Lift Motor Assembly ..............................................361

RRP 12.10 A4 Paper Size Sensor.................................................362

RRP 12.11 Casters ........................................................................363

RRP 12.12 Harness Assembly ......................................................364

RRP 12.13 Drive Assembly ...........................................................365

RRP 12.14 Feed, Nudger, and Retard Roller ................................366

RRP 12.15 Paper Height Sensor...................................................367

RRP 12.16 Paper Feed Motor Assembly.......................................368

RRP 12.17 Link Stopper ................................................................369

RRP 12.18 No Paper Sensor.........................................................370

RRP 12.19 No Paper Sensor Actuator ..........................................371

RRP 12.20 Left and Right Wire Cover...........................................372

RRP 12.21 Shaft Cover Assembly.................................................373

RRP 12.22 Drive Shaft Assembly ..................................................374

RRP 12.23 Brake Assembly ..........................................................375

RRP 12.24 Left Tray Wires ............................................................376

RRP 12.25 Right Tray Wires .........................................................377

RRP 12.26 Retard Assembly.........................................................378

Phaser 5400 Laser Printer Service Guide xv

Page 17

FRU Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 381

Introduction ..........................................................................................381

Organization of this Section...........................................................381

Using the Parts List........................................................................382

Parts Lists ............................................................................................384

PL 1.1 Covers ................................................................................384

PL 2.1 Paper Tray [A3/Ledger] ......................................................386

PL 2.2 Paper Tray [A4/Letter] ........................................................388

PL 3.1 Paper Feeder .....................................................................390

PL 4.1 Multi-sheet Bypass Feeder (MBF) Assembly .....................392

PL 4.2 Paper Handler ....................................................................394

PL 5.1 Paper Transport .................................................................396

PL 6.1 Rear Cover Assembly With Fuser ......................................398

PL 7.1 Frame & Drives ..................................................................400

PL 8.1 Xerographics ......................................................................402

PL 9.1 Electrical (1 of 2) ................................................................404

PL 9.2 Electrical (2 of 2) ................................................................406

PL 10.1 High Capacity Stacker [HCS] (1 of 2) ...............................408

PL 10.2 High Capacity Stacker [HCS] (2 of 2) ...............................410

PL 11.1 500-Sheet Feeder (1 of 3) ................................................412

PL 11.2 500-Sheet Feeder (2 of 3) ................................................414

PL 11.3 500-Sheet Feeder (3 of 3) ................................................416

PL 12.1 2000-Sheet Feeder (1 of 4) ..............................................418

PL 12.2 2000-Sheet Feeder (2 of 4) ..............................................420

PL 12.3 2000-Sheet Feeder (3 of 4) ..............................................422

PL 12.4 2000-Sheet Feeder (4 of 4) ..............................................424

PL 13.1 Duplex Assembly..............................................................426

Xerox Supplies and Accessories..........................................................428

Plug/Jack Connector Locations. . . . . . . . . . . . . . . . . . . . . . . . . .433

Contents ...............................................................................................433

Plug/Jack (P/J) Locations for the Engine .............................................434

Plug/Jack Location Map 1 - Engine......................................................437

Plug/Jack Location Map 2 - Engine......................................................438

Plug/Jack Location Map 3 - Engine......................................................439

Plug/Jack Location Map 4 - 500-Sheet Feeder ....................................440

Plug/Jack Location Map 5 - Duplex Assembly .....................................442

Plug/Jack Location - 1000-Sheet (High Capacity) Stacker ..................444

Plug/Jack Location - 2000-Sheet Feeder .............................................446

Plug/Jack Location Map 7 - 2000-Sheet Feeder ..................................447

xvi Phaser 5400 Laser Printer Service Guide

Page 18

Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 449

Wiring Diagram Notations ....................................................................449

Organization .........................................................................................450

Master Connection and Wiring Diagram ........................................451

Base Engine Wiring Diagrams.......................................................454

500-Sheet Feeder ..........................................................................465

Duplex Assembly ...........................................................................467

1000-Sheet (High Capacity Stacker) .............................................468

2000-Sheet Feeder ........................................................................469

Phaser 5400 Laser Printer Service Guide xvii

Page 19

Blank Page

xviii Phaser 5400 Laser Printer Service Guide

Page 20

List of Figures

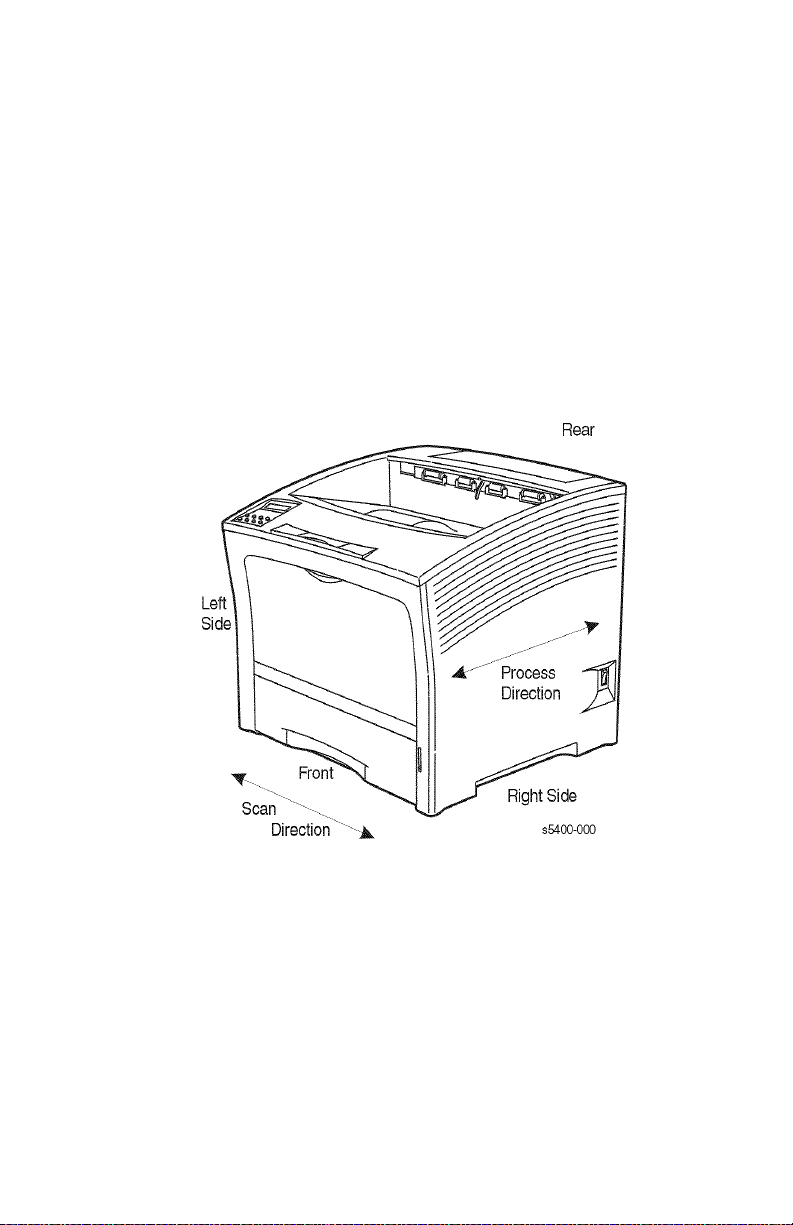

Figure 1 Machine Orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Figure 2 Front View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Figure 3 Rear View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Figure 4 View from Right Front. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Figure 5 View from Left Rear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Figure 6 Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 7 Rear Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 8 Print Engine Assemblies, Sensors and Interlock Locations 1 -

Tray 1 and MBF Paper Path Components 1 . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 9 FRU Assemblies, Sensors and Interlock Locations 2 . . . . . . . . . . . . . . . . . 10

Figure 10 FRU Assemblies, Sensors and Interlock Locations 3 - Detack Saw,

Registration & Bias Transfer Rollers and Paper Transport Assembly . . . 11

Figure 11 FRU Assemblies, Sensors and Interlock Locations 4 - Fuser Area . . . . . . 12

Figure 12 FRU Assemblies, Sensors and Interlock Locations 5 - Main Drive . . . . . . 13

Figure 13 FRU Assemblies, Sensors and Interlock Locations 6 -

FRU Circuit Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 14 Paper Path Flow. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 15 Paper Path Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 16 Service Flowchart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 17 Fuser Connector P174 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Figure 18 Light Prints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

Figure 19 Blank Prints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

Figure 20 Spots . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

Figure 21 Horizontal (Scan) Deletions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

Figure 22 Vertical (Process) Deletions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

Figure 23 Spot Deletions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

Figure 24 Vertical (Process) Streaks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

Figure 25 Horizontal (Scan) Streaks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

Figure 26 Residual Image . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

Figure 27 Black Prints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

Figure 28 Background . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

Figure 29 Uneven Density . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

Figure 30 Skewed Image . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

Figure 31 Damaged Print . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

Figure 32 Registration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

Figure 33 Skips / Smears . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

Figure 34 Unfused Image . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

Figure 35 Registration Test Pattern . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

Phaser 5400 Laser Printer Service Guide xix

Page 21

Figure 36 Removing the Left Side Cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 250

Figure 37 Right Side Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 251

Figure 38 Top Cover Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 252

Figure 39 Front Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 253

Figure 40 Lower Left Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 254

Figure 41 HVPS Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 255

Figure 42 Lower Rear Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 256

Figure 43 MBF Gear Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 257

Figure 44 Rear Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 258

Figure 45 MBF Paper Handler Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 259

Figure 46 MBF Left Tray Stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 260

Figure 47 MBF Right Tray Stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 260

Figure 48 MBF Feed Roller Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 261

Figure 49 MBF Tray 1 Turn Roller Clutch Assembly . . . . . . . . . . . . . . . . . . . . . . . . 262

Figure 50 Tray 1 Turn Roller Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 263

Figure 51 MBF Pick Up Shaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 264

Figure 52 MBF Tray Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 265

Figure 53 MBF Retard Holder Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 265

Figure 54 Tray 1 No Paper Sensor Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 266

Figure 55 MBF No Paper Sensor Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 267

Figure 56 MBF Tray Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 268

Figure 57 MBF No Paper Sensor Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 268

Figure 58 MBF Feed Solenoid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 269

Figure 59 Tray 1 Feed Solenoid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 270

Figure 60 Tray 1 Feed Roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 271

Figure 61 Tray 1 Retard Holder Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 272

Figure 62 Rear Chute Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 273

Figure 63 Rear Chute Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 274

Figure 64 Lower Turn Roller Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 275

Figure 65 Tray 1 Low Paper Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 276

Figure 66 Paper Level Indicator Arm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 277

Figure 67 Tray 1 Right Guide Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 278

Figure 68 Tray Left Guide Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 279

Figure 69 Removing the CRUM Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 281

Figure 70 MBF Assembly Position Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 282

Figure 71 Paper Transport Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 283

Figure 72 Registration Actuator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 285

Figure 73 Registration Clutch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 286

Figure 74 Registration Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 287

Figure 75 Fuser Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 288

Figure 76 Lower Exit Chute . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 289

Figure 77 Upper Exit Chute . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 290

Figure 78 Stack Full Sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 290

xx Phaser 5400 Laser Printer Service Guide

Page 22

Figure 79 Lower Exit Chute . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 291

Figure 80 Upper Exit Chute . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 292

Figure 81 Upper Exit Roller Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 292

Figure 82 Lower Exit Roller Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 293

Figure 83 Stack Full Sensor Actuator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 294

Figure 84 Shield Cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 295

Figure 85 Gear Drive Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 296

Figure 86 Laser Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 297

Figure 87 Laser Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 298

Figure 88 Right Print Cartridge Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 299

Figure 89 Toner Sensor Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 301

Figure 90 Top Cover Interlock Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 302

Figure 91 Left Print Cartridge Guide Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . 303

Figure 92 Bias Transfer Roller [BTR] Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . 304

Figure 93 Shield Cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 305

Figure 94 System Controller Board Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 306

Figure 95 System Controller Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 306

Figure 96 High-Voltage Power Supply [HVPS] Board . . . . . . . . . . . . . . . . . . . . . . . 307

Figure 97 Duplex Interface Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 308

Figure 98 Main Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 309

Figure 99 Shield Cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 310

Figure 100 Print Engine Controller Board Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . 311

Figure 101 Print Engine Controller Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 311

Figure 102 Low-Voltage Power Supply [LVPS] . . . . . . . . . . . . . . . . . . . . . . . . . . . . 312

Figure 103 LVPS Fan. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 313

Figure 104 AC Input Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 314

Figure 105 Print Engine Controller Board Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . 315

Figure 106 +5 VDC Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 316

Figure 107 Duplex Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 317

Figure 108 High Capacity Stacker [HCS] Assembly. . . . . . . . . . . . . . . . . . . . . . . . . 318

Figure 109 HCS Top Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 319

Figure 110 HCS Rear Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 320

Figure 111 HCS Front Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 321

Figure 112 Exit Gate Solenoid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 322

Figure 113 HCS Stack Full Sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 323

Figure 114 HCS Stack Full Sensor Actuator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 324

Figure 115 HCS Drive Motor Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 325

Figure 116 HCS Rear Cover Interlock Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 326

Figure 117 HCS Paper Sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 327

Figure 118 Feeder Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 328

Figure 119 Front Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 329

Figure 120 Left Cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 330

Figure 121 Right Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 331

Phaser 5400 Laser Printer Service Guide xxi

Page 23

Figure 122 Rear Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 332

Figure 123 Feeder Drive Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 333

Figure 124 Feeder Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 334

Figure 125 Feed Head Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 335

Figure 126 Feed Rollers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 336

Figure 127 Feed Solenoid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 337

Figure 128 Turn Roller Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 338

Figure 129 Retard Chute Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 339

Figure 130 Left Tray Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 340

Figure 131 Paper Level Indicator Actuator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 342

Figure 132 Right Tray Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 343

Figure 133 Retard Holder Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 344

Figure 134 Turn Roller Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 345

Figure 135 Paper Size Sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 346

Figure 136 Paper Tray Sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 347

Figure 137 No Paper Sensor Cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 348

Figure 138 Feed Solenoid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 349

Figure 139 No Paper Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 349

Figure 140 No Paper Sensor Actuator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 350

Figure 141 Sensor Cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 351

Figure 142 Preregistration Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 351

Figure 143 Removing the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 352

Figure 144 Left Side Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 354

Figure 145 Upper Rear Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 355

Figure 146 Lower Rear Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 356

Figure 147 Right Side Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 357

Figure 148 Front Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 358

Figure 149 Tray Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 359

Figure 150 2000-Sheet Feeder Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 360

Figure 151 Tray Lift Motor Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 361

Figure 152 Paper Size Sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 362

Figure 153 Casters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 363

Figure 154 Harness Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 364

Figure 155 Drive Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 365

Figure 156 Pick, Feed and Retard Rollers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 366

Figure 157 Paper Height Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 367

Figure 158 Paper Feed Motor Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 368

Figure 159 Link Stopper. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 369

Figure 160 No Paper Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 370

Figure 161 No Paper Sensor Actuator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 371

Figure 162 Tray Assembly Wire Covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 372

Figure 163 Shaft Cover Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 373

Figure 164 Drive Shaft Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 374

xxii Phaser 5400 Laser Printer Service Guide

Page 24

Figure 165 Brake Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 375

Figure 166 Left Tray Wires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 376

Figure 167 Right Tray Wires. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 377

Figure 168 Feed Gears . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 378

Figure 169 Retard Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 379

Figure 170 Covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 384

Figure 171 Paper Tray (A3/Ledger) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 386

Figure 172 Paper Tray [A4/Letter] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 388

Figure 173 Paper Feeder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 390

Figure 174 Multi-sheet Bypass Feeder (MBF) Assembly . . . . . . . . . . . . . . . . . . . . . 392

Figure 175 Paper Handler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 394

Figure 176 Paper Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 396

Figure 177 Rear Cover Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 398

Figure 178 Frame and Drives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 400

Figure 179 Xerographics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 402

Figure 180 Electrical (1 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 404

Figure 181 Electrical (2 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 406

Figure 182 High Capacity Stacker (1 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 408

Figure 183 High Capacity Stacker (2 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 410

Figure 184 500-Sheet Feeder (1 of 3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 412

Figure 185 500-Sheet Feeder (2 of 3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 414

Figure 186 500-Sheet Feeder (3 of 3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 416

Figure 187 2000-Sheet Feeder (1 of 4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 418

Figure 188 2000-Sheet Feeder (2 of 4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 420

Figure 189 2000-Sheet Feeder (3 of 4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 422

Figure 190 2000-Sheet Feeder (4 of 4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 424

Figure 191 Duplex Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 426

Figure 192 CRC Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 428

Figure 193 P/J Location Map 1 - Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 437

Figure 194 P/J Location Map 2 - Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 438

Figure 195 P/J Location Map 3 - Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 439

Figure 196 P/J Location Map 4 - 500-Sheet Feeder . . . . . . . . . . . . . . . . . . . . . . . . 441

Figure 197 P/J Location Map 5 - Duplex Assembly . . . . . . . . . . . . . . . . . . . . . . . . . 443

Figure 198 P/J Location Map 6 - 1000-Sheet High Capacity Stacker . . . . . . . . . . . 445

Figure 199 P/J Location Map 7 - 2000-Sheet Feeder . . . . . . . . . . . . . . . . . . . . . . . 447

Figure 200 Master Wiring Diagram 1 of 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 451

Figure 201 Master Wiring Diagram 2 of 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 452

Figure 202 Print Engine Controller PWB <–> LVPS <–>

Interlock Switch and Fans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 454

Figure 203 Print Engine Controller PWB <–> Fuser Assembly, Fuser PWB . . . . . . 455

Figure 204 Print Engine Controller PWB-Laser and CRUM PWB . . . . . . . . . . . . . . 456

Figure 205 Print Engine Controller PWB, HVPS and Print Cartridge. . . . . . . . . . . . 457

Phaser 5400 Laser Printer Service Guide xxiii

Page 25

Figure 206 Print Engine Controller PWB <–> Registration Clutch

and Registration Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 458

Figure 207 Print Engine Controller PWB <–> Feed Solenoid, Turn Clutch,

No-Paper Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 459

Figure 208 Print Engine Controller PWB, Low Paper Sensor, MBF Home Switch,

and Tray 1 Paper Size Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 460

Figure 209 Print Engine Controller PWB <–> Main Motor . . . . . . . . . . . . . . . . . . . . 461

Figure 210 Print Engine Controller PWB <–> Toner Sensor . . . . . . . . . . . . . . . . . . 462

Figure 211 Print Engine Controller PWB <–> Duplex Interface PWB <–>

Full Stack Sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 463

Figure 212 Controller and Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 464

Figure 213 500-Sheet Feeder - Tray 2 Wiring Diagram and Signal Information

Between Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 465

Figure 214 500-Sheet Feeder - Tray 3 Wiring Diagram and Signal Information

Between Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 466

Figure 215 Duplex Assembly - Wiring Diagrams and Signal Information

Between Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 467

Figure 216 Master Wiring Diagram, High Capacity Stacker . . . . . . . . . . . . . . . . . . 468

Figure 217 2000-Sheet Feeder - Wiring Diagram and Signal Information

Between Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 469

Figure 218 2000-Sheet Feeder PWB <–> No Paper Sensor. . . . . . . . . . . . . . . . . . 470

Figure 219 2000-Sheet Feeder PWB <–> Low Paper Sensor. . . . . . . . . . . . . . . . . 470

Figure 220 2000-Sheet Feeder PWB <–> Switches . . . . . . . . . . . . . . . . . . . . . . . . 471

xxiv Phaser 5400 Laser Printer Service Guide

Page 26

List of Tables

Table 1 Memory Upgrades. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Table 2 Basic Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Table 3 Electrical Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Table 4 Physical Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Table 5 Printer Clearances. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Table 6 Environmental Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Table 7 Life Expectancies of the Print Engine and Options . . . . . . . . . . . . . . . . . . . 21

Table 8 Conforming Regulations and Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Table 9 Printing Speed for the First Sheet Out. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Table 10 Consecutive Printing Speed after the First Sheet Out. . . . . . . . . . . . . . . . 22

Table 11 Supported Media and Media Sizes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Table 13 Paper Weights. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Table 12 Custom Paper Sizes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Table 14 Printing Accuracy. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Table 15 Components to Be Replaced Periodically . . . . . . . . . . . . . . . . . . . . . . . . . 26

Table 16 Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Table 18 Error Code / Repair Analysis Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Table 19 Error Code C3: Insert Tray Troubleshooting Procedure . . . . . . . . . . . . . . 42

Table 20 Paper Size Actuators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Table 21 Error Code C3: Insert Tray 2 (or Tray 3) (500-Sheet Feeder)

Troubleshooting Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Table 22 Paper Size Actuators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Table 23 Error Code C3: 2000-Sheet Feeder Carriage Not In Position Message

Troubleshooting Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Table 24 Add Paper to MBF, Tray 1, 2 or 3 Message

Troubleshooting Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Table 25 Add Paper To 500-Sheet Feeder Troubleshooting Procedure . . . . . . . . . 50

Table 26 Error Code C5: Standard Bin Full Troubleshooting Procedure . . . . . . . . . 52

Table 27 Error Code C5: Stacker Bin Full Troubleshooting Procedure . . . . . . . . . . 55

Table 28 Add Paper to 2000-Sheet Feeder Troubleshooting Procedure . . . . . . . . . 58

Table 29 Error Code E1-1: Paper Jam Tray to Registration

Troubleshooting Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Table 30 Error Code E2-1: Paper Jam Troubleshooting Procedure. . . . . . . . . . . . . 61

Table 31 Paper Jam / Misfeed 500-Sheet Feeder Troubleshooting Procedure . . . . 63

Table 32 Error Code E2-1: Paper Jam / Misfeed 2000-Sheet Feeder

Troubleshooting Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Table 33 Error Code E2-D: Duplex Jam Troubleshooting Procedure . . . . . . . . . . . 67

Phaser 5400 Laser Printer Service Guide xxv

Page 27

Table 34 Error Code E3-1: Paper Jam / Registration To Fuser

Troubleshooting Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Table 35 Error Code E4: Exit Jam Troubleshooting Procedure. . . . . . . . . . . . . . . . . 72

Table 36 Error Code E5: Close Covers Troubleshooting Procedure . . . . . . . . . . . . . 74

Table 37 Insert MBF Troubleshooting Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Table 38 2000-Sheet Feeder Cover Open Troubleshooting Procedure . . . . . . . . . . 78

Table 39 Close Stacker Door Troubleshooting Procedure . . . . . . . . . . . . . . . . . . . . 80

Table 40 Error Code E7: Duplex Jam Troubleshooting Procedure . . . . . . . . . . . . . . 82

Table 41 Error Code E8-1: Stacker Jam Troubleshooting Procedure . . . . . . . . . . . . 84

Table 42 Duplex Unit Fail or Removed Message

Troubleshooting Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Table 43 Error Code E9-2: Stacker Bin Fail Troubleshooting Procedure . . . . . . . . . 88

Table 44 Error Code E9-3: HCF Fail (2000-Sheet Feeder)

Troubleshooting Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Table 45 Error Code J5: Toner Low Troubleshooting Procedure . . . . . . . . . . . . . . . 90

Table 46 Error Code J5: Toner Low Troubleshooting Procedure . . . . . . . . . . . . . . . 91

Table 47 Error Code J6-1: Replace Print Cartridge Troubleshooting Procedure. . . . 92

Table 48 Error Code J8-1: Print Cartridge OEM ID Mismatch

Troubleshooting Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Table 49 Error Code PSE-1 Paper Size Jam Troubleshooting Procedure . . . . . . . . 94

Table 50 Paper Size Actuators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Table 51 Error Code U1: Motor Failure Troubleshooting Procedure . . . . . . . . . . . . . 96

Table 52 Error Code U2: Laser (ROS (Laser Scanner)) Failure

Troubleshooting Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Table 53 Error Code U4: Fuser Failure Troubleshooting Procedure . . . . . . . . . . . . 100

Table 54 Error Code U5: Fan Fail Troubleshooting Procedure . . . . . . . . . . . . . . . . 101

Table 55 0101 - DIMM 1 Troubleshooting Procedure . . . . . . . . . . . . . . . . . . . . . . . 102

Table 56 0102 - DIMM 2 Troubleshooting Procedure . . . . . . . . . . . . . . . . . . . . . . . 103

Table 57 0103 - DIMM 3 Troubleshooting Procedure . . . . . . . . . . . . . . . . . . . . . . . 104

Table 58 Error Code U6: IOT NVM Failure Troubleshooting Procedure . . . . . . . . . 105

Table 59 Print Performance Problems RAP Table . . . . . . . . . . . . . . . . . . . . . . . . . 107

Table 60 Image-Quality Problems RAP Table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Table 61 Electrical Interference RAP Table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Table 62 AC Power Testing Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Table 63 Registration Clutch Troubleshooting Procedure . . . . . . . . . . . . . . . . . . . . 112

Table 64 DC (LVPS) Troubleshooting Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Table 65 LVPS Voltages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Table 66 DC Power Loading Troubleshooting Procedure . . . . . . . . . . . . . . . . . . . . 116

Table 67 LVPS Voltages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Table 68 System Controller Isolation Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Table 69 Low Paper Tray 1/2/3 Troubleshooting Procedure . . . . . . . . . . . . . . . . . . 119

Table 70 Inoperative Printer Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Table 71 Malfunctioning LCD/LED Troubleshooting Procedure . . . . . . . . . . . . . . . 123

Table 72 System Controller Board Voltages at P/J18 . . . . . . . . . . . . . . . . . . . . . . . 125

xxvi Phaser 5400 Laser Printer Service Guide

Page 28

Table 73 Inoperative Keypad Troubleshooting Procedure . . . . . . . . . . . . . . . . . . . 126

Table 74 Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Table 75 Main Motor Assembly Troubleshooting Procedure . . . . . . . . . . . . . . . . . 128

Table 76 Main Motor Harness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Table 77 Laser Assembly Troubleshooting Procedure. . . . . . . . . . . . . . . . . . . . . . 130

Table 78 Fuser Assembly Troubleshooting Procedure . . . . . . . . . . . . . . . . . . . . . 133

Table 79 Registration Sensor Troubleshooting Procedure. . . . . . . . . . . . . . . . . . . 135

Table 80 MBF No Paper Sensor Troubleshooting Procedure . . . . . . . . . . . . . . . . 137

Table 81 Error Code J3: Laser Safety Switch Open Troubleshooting . . . . . . . . . . 139

Table 82 Tray 1 No Paper Sensor Troubleshooting Procedure . . . . . . . . . . . . . . . 140

Table 83 Size Switch Troubleshooting Procedure . . . . . . . . . . . . . . . . . . . . . . . . . 142

Table 84 Size Switch Voltages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Table 85 Turn Roller Clutch Assembly Troubleshooting Procedure. . . . . . . . . . . . 145

Table 86 Tray 1 Feed Solenoid Troubleshooting Procedure . . . . . . . . . . . . . . . . . 147

Table 87 MBF Feed Solenoid Troubleshooting Procedure . . . . . . . . . . . . . . . . . . 149

Table 88 Toner Sensor Assembly Troubleshooting Procedure . . . . . . . . . . . . . . . 151

Table 89 HVPS Assembly Troubleshooting Procedure . . . . . . . . . . . . . . . . . . . . . 153

Table 90 Electrical Noise Troubleshooting Procedure . . . . . . . . . . . . . . . . . . . . . . 157

Table 91 Low Paper Tray 2 (or Tray 3) / 500-Sheet Feeder

Troubleshooting Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

Table 92 500-Sheet Feeder Feed Solenoid Troubleshooting Procedure. . . . . . . . 161

Table 93 500-Sheet Feeder Motor Troubleshooting Procedure . . . . . . . . . . . . . . . 163

Table 94 500-Sheet Feeder Assembly Not Recognized

Troubleshooting Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

Table 95 Exit Sensor Troubleshooting Procedure . . . . . . . . . . . . . . . . . . . . . . . . . 167

Table 96 Pre-Registration Sensor Troubleshooting Procedure . . . . . . . . . . . . . . . 168

Table 97 HCS Motor Assembly Message Troubleshooting Procedure . . . . . . . . . 170

Table 98 Hard Disk Formatting Troubleshooting Procedure . . . . . . . . . . . . . . . . . 172

Table 99 Erratic Printer Operation Troubleshooting Procedure . . . . . . . . . . . . . . . 173

Table 100 Image-Quality Defect Definitions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

Table 101 Light (Undertoned) Prints Troubleshooting Procedure . . . . . . . . . . . . . 178

Table 102 Blank Prints Troubleshooting Procedure. . . . . . . . . . . . . . . . . . . . . . . . 181

Table 103 Spots Troubleshooting Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

Table 104 Horizontal (Scan) Deletions Troubleshooting Procedure . . . . . . . . . . . 185

Table 105 Vertical (Process) Deletions Troubleshooting Procedure . . . . . . . . . . . 188

Table 106 Spot Deletions Troubleshooting Procedure. . . . . . . . . . . . . . . . . . . . . . 190

Table 107 Vertical (Process) Streaks Troubleshooting Procedure. . . . . . . . . . . . . 192

Table 108 Horizontal (Scan) Streaks Troubleshooting Procedure . . . . . . . . . . . . . 194

Table 109 Residual Image Troubleshooting Procedure . . . . . . . . . . . . . . . . . . . . . 197

Table 110 Black Prints Troubleshooting Procedure . . . . . . . . . . . . . . . . . . . . . . . . 199

Table 111 Background Troubleshooting Procedure. . . . . . . . . . . . . . . . . . . . . . . . 200

Table 112 Uneven Density Troubleshooting Procedure. . . . . . . . . . . . . . . . . . . . . 202

Table 113 Skewed Image Troubleshooting Procedure . . . . . . . . . . . . . . . . . . . . . 204

Phaser 5400 Laser Printer Service Guide xxvii

Page 29

Table 114 Damaged Print Troubleshooting Procedure . . . . . . . . . . . . . . . . . . . . . . 210

Table 115 Registration Troubleshooting Procedure . . . . . . . . . . . . . . . . . . . . . . . . 212

Table 116 Skips / Smears Troubleshooting Procedure . . . . . . . . . . . . . . . . . . . . . . 214

Table 117 Unfused Image Troubleshooting Procedure . . . . . . . . . . . . . . . . . . . . . . 215

Table 118 Resolution Troubleshooting Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . 217

Table 119 System Controller Board Error (Blink) Codes . . . . . . . . . . . . . . . . . . . . . 222

Table 120 System Controller LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

Table 121 Diagnostics Menu Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

Table 122 Test Print Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

Table 123 NVRAM Configuration Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

Table 124 Phaser 5400 Fuser Run Temp Conversion Table . . . . . . . . . . . . . . . . . 234

Table 125 Component Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 235

Table 126 Legend:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 383

Table 127 PL 1.1 Covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 385

Table 128 PL 2.1 Paper Tray [A3/Ledger] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 387

Table 129 PL 2.2 Paper Tray [A4/Letter] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 389

Table 130 PL 3.1 Paper Feeder. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 391

Table 131 PL 4.1 MBF Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 393

Table 132 PL 4.2 Paper Handler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 395

Table 133 PL 5.1 Paper Transport. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 397

Table 134 PL 6.1 Rear Cover Assembly with Fuser . . . . . . . . . . . . . . . . . . . . . . . . 399

Table 135 PL 7.1 Frame and Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 401

Table 136 PL 8.1 Xerographics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 403

Table 137 PL 9.1 Electrical (1 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 405

Table 138 PL 9.2 Electrical (2 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 407

Table 139 PL 10.1 High Capacity Stacker (1 of 2). . . . . . . . . . . . . . . . . . . . . . . . . . 409

Table 140 PL 10.2 High Capacity Stacker (2 of 2). . . . . . . . . . . . . . . . . . . . . . . . . . 411

Table 141 PL 11.1 500-Sheet Feeder (1 of 3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 413

Table 142 PL 11.2 500-Sheet Feeder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 415

Table 143 PL 11.3 500-Sheet Feeder (3 of 3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 417

Table 144 PL 12.1 2000-Sheet Feeder (1 of 4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 419

Table 145 PL 12.2 2000-Sheet Feeder (2 of 4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 421

Table 146 PL 12.3 2000-Sheet Feeder (3 of 4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 423

Table 147 PL 12.4 2000-Sheet Feeder (4 of 4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 425

Table 148 PL 13.1 Duplex . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 427

Table 149 Customer-Replaceable Consumables . . . . . . . . . . . . . . . . . . . . . . . . . . 429

Table 150 Xerox Professional Printing Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 429

Table 151 Xerox Transparency Film . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 429

Table 152 Xerox Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 430

Table 153 Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 430